Page 1

RATCHET STRAP (MODEL NO. HG00921A)

LUGGAGE STRAP SET

(MODEL NO. HG00921B)

RATCHET STRAPS WITH qUICK-RELEASE

fASTENING

RATCHET STRAP / LUGGAGE

STRAP SET / RATCHET STRAPS

WITH qUICK-RELEASE

fASTENING

Operation and Safety Notes

NAPENJALNI TRAK Z RAGLJO/

KOMPLET JERMENOV

ZA ZATEGOVANJE IN

POVEZOVANJE/ POVEZOVALNA

TRAKOVA S HITRIM ZAPIRALOM

Navodila za upravljanje in varnostna opozorila

UPÍNACÍ POPRUH S

ROHATKOU / SÚPRAVA

NAPÍNACÍCH A

UPÍNACÍCH POPRUHOV

/ NAPÍNACIE POPRUHy S

RýCHLOUZáVEROM

Pokyny pre obsluhu a bezpečnostné pokyny

(MODEL NO. HG00921C)

RACSNIS RÖGZÍTŐHEVEDER/

RÖGZÍTŐHEVEDER

KÉSZLET/ GyORSZáRAS

RÖGZÍTŐHEVEDER

Kezelési és biztonsági utalások

UPÍNACÍ PáS S RáČNOU /

SADA NAPÍNACÍCH A

UPÍNACÍCH PáSŮ / UPÍNACÍ

POPRUHy S RyCHLOUZáVěREM

Pokyny pro obsluhu a bezpečnostní pokyny

SPANNGURT MIT RATSCHE /

SPANN- UND ZURRGURTSET / SPANNGURTE

MITSCHNELLVERSCHLUSS

Bedienungs- und Sicherheitshinweise

IAN 285009

Page 2

GB Operation and Safety Notes Page 5

HU Kezelési és biztonsági utalások Oldal 14

SI Navodila za upravljanje in varnostna opozorila Stran 23

CZ Pokyny pro obsluhu a bezpečnostní pokyny Strana 32

SK Pokyny pre obsluhu a bezpečnostné pokyny Strana 40

DE / AT / CH Bedienungs- und Sicherheitshinweise Seite 49

Page 3

HG00921A

HG00921B

HG00921C

Page 4

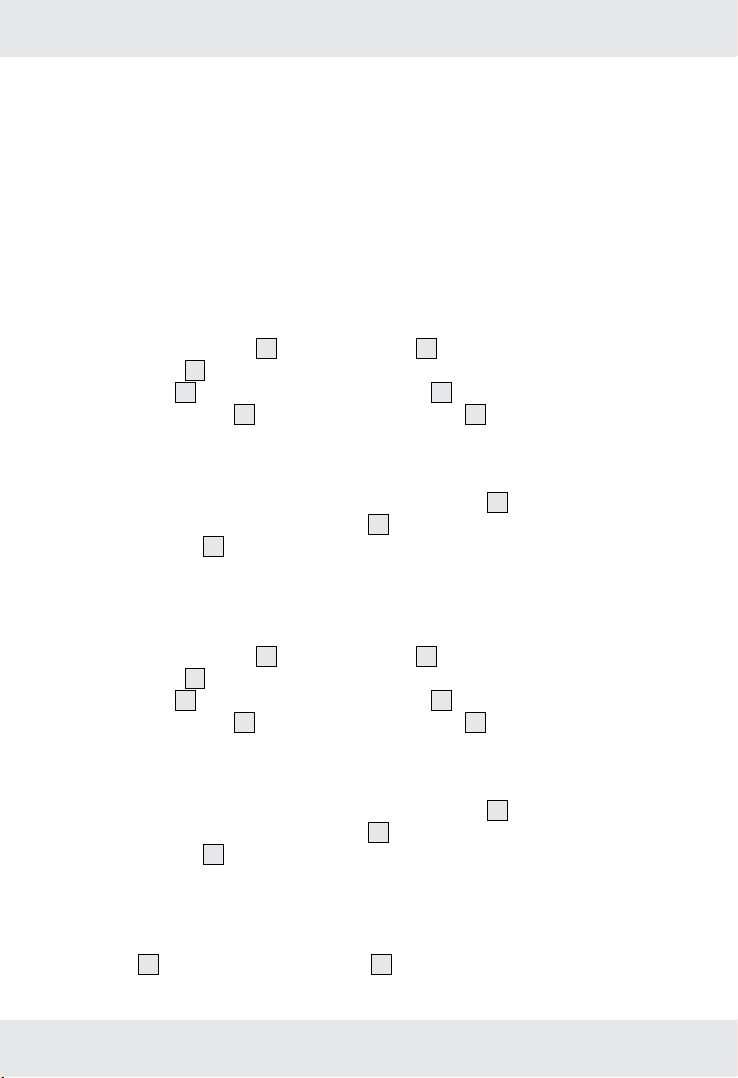

I

II

Page 5

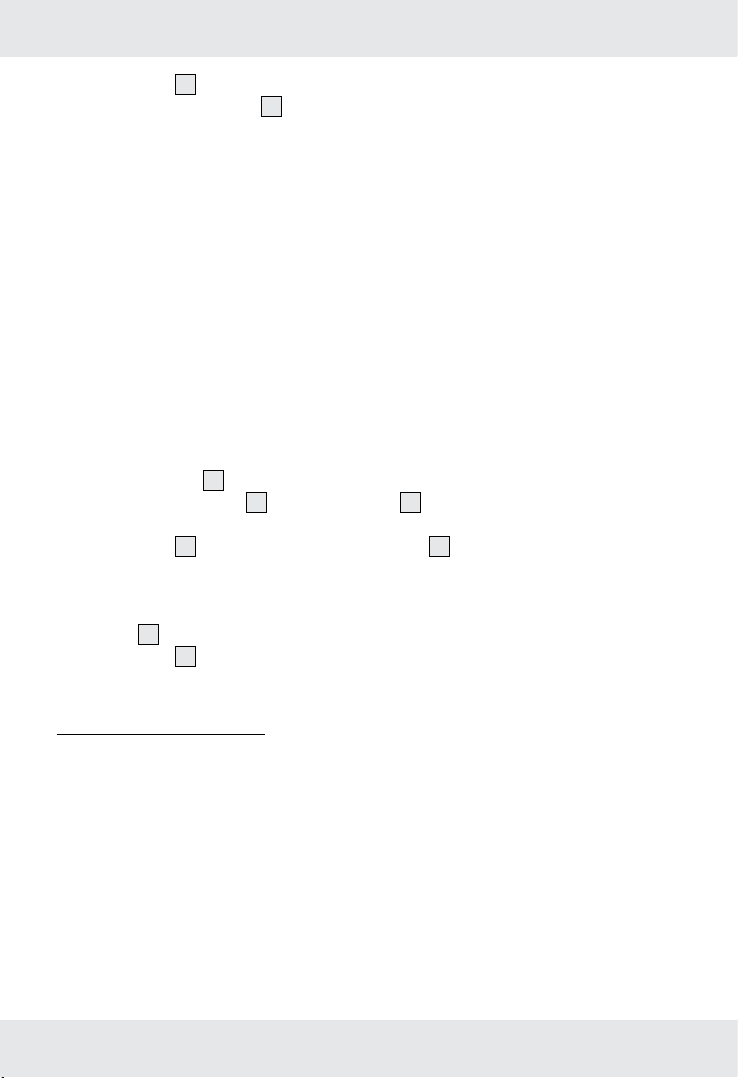

A

1

4

2

3

B

1

123

Page 6

C

5

6

Page 7

Introduction .......................................................................................................... Page 6

Intended use ............................................................................................................... Page 6

Technical data ............................................................................................................ Page 6

Scope of Delivery ......................................................................................................Page 7

Safety instructions .......................................................................................... Page 7

General Safety Instructions .......................................................................................Page 7

Safety instructions for lashing straps ......................................................................... Page 7

Practical information regarding the use

and care of lashing straps ....................................................................... Page 9

Use ............................................................................................................................... Page 10

Attaching the lashing strap ........................................................................................ Page 10

Releasing the lashing strap ........................................................................................ Page 11

Cleaning and care ........................................................................................... Page 12

Disposal ................................................................................................................... Page 12

Warranty ................................................................................................................ Page 12

5 GB

Page 8

Ratchet strap (HG00921A)

Luggage strap set (HG00921B)

Ratchet straps with quick-release fastening (HG00921C)

Q

Introduction

The instructions for use are to be considered as part of the product. They contain

important information concerning safety, use and disposal. Before using the product,

please familiarise yourself with all of the safety information and instructions for

use. The product must only be used as described and for the stated fields of application. If

you pass the product on to third parties, please give them all of the documentation as well.

Q

Intended use

The product is designed to lash, attach and secure loads. The lashing straps serve to “press“

the load down to the loading surface of a vehicle or to connect it directly with the vehicle.

They are not designed to lift or carry loads. The permissible load must not be exceeded.

Any use other than previously mentioned or any product modification is prohibited and can

lead to injuries and / or product damage. The manufacturer is not liable for any damages

caused by any use other than for the intended purpose. The product is not intended for

commercial use.

Q

Technical data

HG00921A

Length: approx. 5m (L

Permissible load (LC): 350 daN / Looped: 700 daN / S

Material: Polyester (PES)

)

G

25daN

HF

HG00921B

Length: LGF (length – fixed end): 0.26 m

LGL (length – adjustable end): 4.7 m

Permissible load (LC): 350 daN (3500 N = Newton / 350 kg (m / s

Material: Polyester (PES)

HG00921C

Length: approx. 2.5 m

Permissable load (LC): 100 daN (1000 N = Newton / 100 kg (m / s

Looped: 200 daN

Material: Polyester (PES)

6 GB

2

)) / SHF 25daN

2

)) /

Page 9

Q

Scope of Delivery

Check the delivery for completeness and condition of the product immediately after

opening and ensure all parts are included.

1 x Ratchet strap, approx. 5 m (HG00921A)

1 x Lashing strap with ratchet tensioner and S hook, approx. 0.26 m (HG00921B)

1 x Lashing strap with S-hook, approx. 4.7 m (HG00921B)

2 Lashing straps with clamping lock, approx. 2.5 m (HG00921C)

1 x Directions for use

Q

Safety instructions

Keep all the safety advice and instructions in a safe place for future

reference!

General Safety Instructions

J

of life due to strangulation. Children often underestimate this danger. Always keep

children away from this product. This product is not a toy.

J Do not use the product if you see it is damaged in any way.

J Check that all parts have been assembled correctly. Improper assembly may result in injury.

WARNING!

INFANTS AND CHILDREN! Never leave children unattended with the

packaging material. The packaging poses a risk of suffocation and danger

DANGER TO LIFE AND RISK OF ACCIDENTS FOR

Safety instructions for lashing straps

J Always check the lashing strap for damage before using it. On no account use the

lashing strap if the strap is damaged.

J Carefully check dirty straps or straps that have been contaminated with corrosive or other

materials that may damage them. You may have to ask the manufacturer to check them.

J Have the lashing straps and all components checked by an expert at least once a year.

In accordance with the conditions of use and the operational circumstances, further

checks by a professional may be necessary from time to time.

J On no account use the lashing strap if:

- there are broken threads or cuts in the thread, especially if the edges have been

nicked or there are other alarming cases of damage

- the labelling is missing or is no longer legible

- there is damage to the connections, or deformation due to exposure to heat (friction,

7 GB

Page 10

radiation)

- there is damage due to the effect of corrosive substances.

J On no account use the ratchets if:

- there are incipient tears, breakages or considerable cases of or damage from corrosion

- there is widening > 5 % (5 % in the hook mouth or general deformation)

- there is visibly permanent deformation of load-bearing parts

J Repairs to the lashing straps may only be carried out if the information regarding the

manufacturer, material and maximum permissible tensile load is clearly designated on

the label. They may only be carried out by the manufacturer or a person specified by

him. Following repair, the manufacturer or the person designated by the manufacturer

must ensure that the maximum permissible tensile load of the lashing straps as originally

specified on the label is maintained.

J Never exceed the permissible tensile load of the lashing strap as stated on the label.

(see also “Technical data”).

J Choose the most suitable lashing strap in accordance with the intended load that needs

to be lashed down, the tensile load and loading surface (see label).

CAUTION! DANGER OF ACCIDENT! When lashing using additional fittings and

lashing devices, make sure that they are suitable for the lashing strap.

J Check that the vehicle parts you wish to strap the load to are sturdy enough.

CAUTION! In addition to the accelerating forces, wind may cause lateral forces to arise

during the journey.

J Never pull the lashing strap over rough surfaces or sharp edges if they are not furnished

with suitable protection.

J Make sure that the lashing straps are not twisted and that the load is distributed across

their entire width.

J Do not place any objects onto the lashing strap if this may damage it.

J Keep lashing strap away from hot surfaces.

J Evenly distribute the lashing straps on the load to be secured.

J Never use the lashing straps to lift loads.

J Make sure you do not put any load on the tip of the S hook unless it is a hook that is

designed for such a purpose. To avoid detachment of a lashing hook without a lock in

a lashing point on the loading surface, suspend from the inside outwards.

J Never attach S hooks and ratchets to edges.

J Never extend the ratchet handle to achieve greater tensioning forces if this is not

expressly allowed by an instruction.

CAUTION! DANGER OF ACCIDENT! Always choose suitable lashing straps, lashing

points and lashing methods. The size, shape and weight of the cargo as well as the

intended mode of use, the transport environment and the type of cargo determine the

correct choice.

J To ensure the load is secured properly, the webbing needs to be wrapped around the

ratchet at least 1.5 times.

J Tighten the webbing manually as far as possible so that the belt does not need to be

8 GB

Page 11

wrapped more than 3 times around the ratchet to tighten the load.

J Do not exceed the roof load indicated by the vehicle manufacturer.

CAUTION! DANGER OF ACCIDENT! When lashing down, pay attention to the

required preload force. At least 2 lashing straps are required. For reasons of stability,

at least two lashing straps of the same kind must be used for lashing down and two

pairs of lashing straps of the same kind used for diagonal lashing.

CAUTION! DANGER OF ACCIDENT! During transportation, regularly check that

the cargo is correctly lashed and tighten the lashing strap if necessary.

Q

Practical information regarding the use

and care of lashing straps

1. In selecting and using lashing equipment, you must consider the required lashing force,

the mode of use and the type of cargo to be lashed. The size, shape and weight of

the cargo as well as the intended mode of use, the transport environment and the type

of cargo determine the correct choice. For stability reasons, at least two lashing straps

must be used for lashing down and two pairs of lashing straps used for diagonal lashing.

2. Due to different characteristics and because of different changes in length under load,

only identical lashing device combinations (e.g. lashing chains and lashing strap made

of synthetic fibres) may be used in parallel for lashing the same load. When using

additional fittings and lashing devices, make sure that they fit the lashing strap.

3.

During use, flat hooks must engage over the entire width of the bearing surface of the hook.

4. Opening the lashing: Before opening, make sure that the cargo is stable even without

being secured and does not endanger unloading personnel by falling down. If necessary,

attach blocking devices to the cargo that has been planned for further transport

beforehand in order to prevent the load falling or tipping over. This also applies if

one uses tensioning elements that make safe removal possible.

5. Before starting to unload, you must loosen the lashing until the load is free.

6. During loading and unloading attention has to be paid to proximity of any low

overhead power lines.

7. The materials from which lashing straps are made have selective resistance to chemical

attacks. Seek the advice of the manufacturer or supplier if exposure to chemicals is

anticipated. It should be noted that the effects of chemicals may increase with rising

temperatures. The resistance of synthetic fibres to chemical reactions is summarised

below:

- Polyester is affected less by mineral acids but is attacked by alkaline solutions.

- Harmless acid solutions or alkalis can become so concentrated through evaporation

that they cause damage. Contaminated lashing straps should immediately be taken

out of use, rinsed in cold water and dried in the open air.

8. This lashing straps are suitable for the following temperature ranges:

– –40 °C to +120 °C for Polyester (PES);

These temperature ranges may alter depending on the chemical environment. In this

9 GB

Page 12

event, you must seek the advice of the manufacturer or supplier. A change in the

environmental temperature during transport may affect the forces in the webbing.

Check the lashing force after entering warm regions.

9. Lashing straps must be taken out of use or returned to the manufacturer for repair if

they show any signs of damage. The following points are considered to be signs of

damage:

- for webbing (that must be taken out of use): tears, cuts, nicks and breaks in load-

bearing fibres and stitches; deformations resulting from exposure to heat.

- with end fittings and tensioning devices: deformations, cracks, pronounced signs of

wear, signs of corrosion. Only lashing straps bearing identification labels shall be

repaired. If there is any accidental contact with chemical products, the lashing strap

must be removed from service and the manufacturer or supplier consulted.

10. Care should be taken that the lashing strap is not damaged by the sharp edges of

the load on which it is used. Regular visual inspection before and after each use is

recommended.

11. Only legibly marked and labelled lashing straps may be used.

12. Lashing straps must not be overloaded: The maximum hand force of 250 N (25 daN

on the label; 1 daN ≈ 1 kg) may be applied with only one hand. Mechanical aids

such as bars or levers etc. may not be used unless they are part of the tensioning

device. (HG00921A, HG00921B)

13. Lashing straps may not be used when knotted.

14. Damage to labels must be prevented by keeping them away from sharp edges of

the load and, if possible, from the load.

15. Webbing must be protected against friction, abrasion and damage from loads with

sharp edges by using protective sleeves and / or corner protectors.

Q

Use

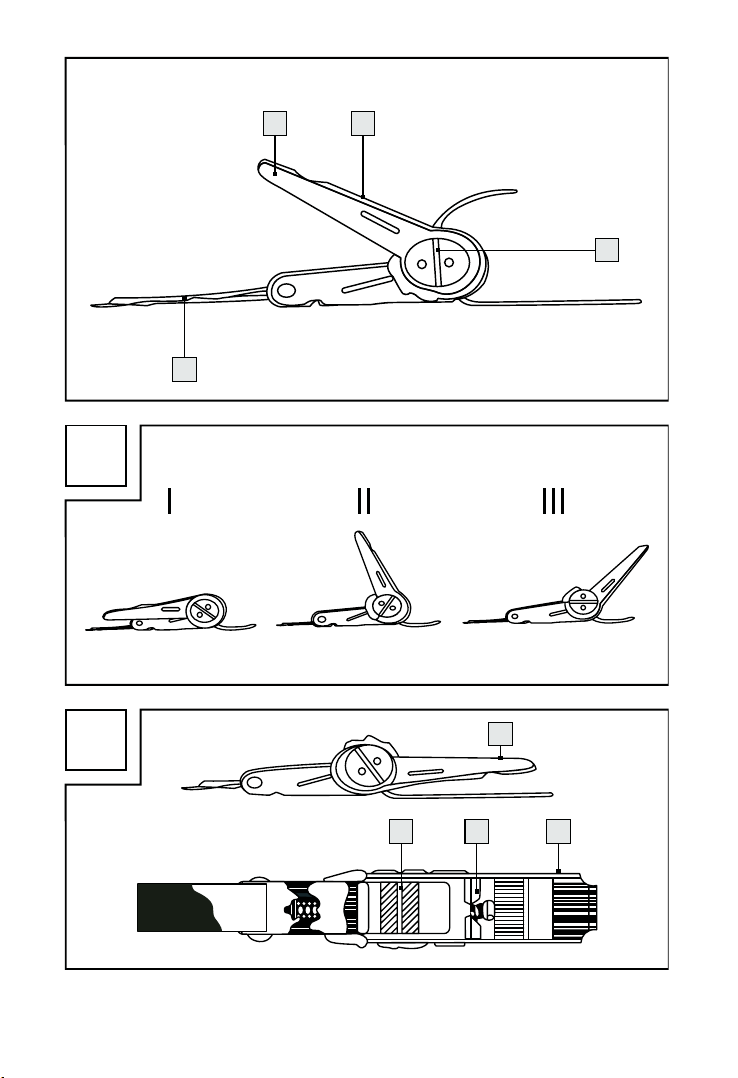

Lashing down (HG00921A, HG00921B, HG00921C):

With lashing straps stretched over it, the load is pressed down onto the loading area

(see Fig. I).

Diagonal lashing (HG00921B):

The load is secured by 4 lashing straps and directly connected to the vehicle (see Fig. II).

Q

Attaching the lashing strap

The selected lashing equipment must be strong and long enough for the intended purpose

and have the correct length for the type of lashing. Responsible users plan cargo security in

advance: they plan the attachment and removal of the lashing devices before the start of

the journey. With longer trips, partial unloading must be considered. Calculate the number

of lashing devices according to EN 12195-1. Only lashing systems labelled for lashing down

10 GB

Page 13

with STF (standard tension force) may be used for friction lashing.

HG00921A:

j Place the lashing strap around the load

j Open the ratchet handle

webbing

can be inserted into it (see Fig. A III).

4

j Insert the webbing

the slotted shaft

3

j Tighten the lashing strap by moving the handle

and place the slotted shaft 3 into the position so that the

1

into the slotted shaft 3 of the ratchet. Carefully pull it through

4

until the webbing 4 lies snug against the load.

of the ratchet backwards and

1

forwards (see Fig. A I - III). Tighten the lashing strap until you have obtained the tension

you wish to have.

Note: Make sure that webbing

times around the slotted shaft

j Bring the ratchet handle

4

is wound at least 1.5 times to a maximum of 3

.

3

into the basic position (see Fig. A I). The load is now

1

secure.

HG00921B:

j Use the S hook to securely attach the lashing strap to the load.

j Open the ratchet handle

webbing

4

can be inserted into it (see Fig. A III).

j Insert the webbing

the slotted shaft

3

until the webbing 4 lies snug against the load.

and place the slotted shaft 3 into the position so that the

1

4

into the slotted shaft 3 of the ratchet. Carefully pull it through

j Tighten the lashing strap by moving the handle of the ratchet backwards and forwards (see

Fig. A I - III). Tighten the lashing strap until you have obtained the tension you wish to have.

Note: Make sure that webbing

times around the slotted shaft

j Bring the ratchet handle

1

4

is wound at least 1.5 times to a maximum of 3

.

3

into the basic position (see Fig. A I). The load is now secure.

HG00921C:

j Loop the lashing strap around the load.

j Press the clamping lock

down and pass the webbing 6 through the clamping lock

5

from below (see Fig. C).

j Carefully pull the webbing

want. Then release the clamping lock

Q

Releasing the lashing strap

through the clamping lock until you get the tension you

6

.

5

CAUTION! Check before releasing the strap that the load is stable. Make sure that

the load is stable even without the lashing strap and that it cannot fall down.

CAUTION! RISK OF INJURY! Make sure that nobody is near the load when you

release the lashing strap. Falling parts could cause injuries.

CAUTION! RISK OF INJURY! When opening the lashing equipment, the preload

11 GB

Page 14

force is released at a stroke. That is why you should open the lashing strap with the utmost

caution.

Note: Before starting to unload, make sure that the lashing equipment is released so that

the load can be lifted freely.

HG00921A & HG00921B:

j Open the ratchet handle

j Press the ratchet lock

1

into the maximum position (see Fig. A III).

2

and open the ratchet handle 1 until the end stop

(see Fig. B).

j Pull the webbing

4

completely out of the slotted shaft 3 .

j Release the S hook and thus the lashing strap from the load.

HG00921C:

j Press the clamp

j Pull the webbing

Q

Cleaning and care

5

down (see Fig. C).

out of the clamping lock completely.

6

Note: Regular care will maintain the quality and functionality of the lashing strap.

j Clean the lashing strap with lukewarm water and pH-neutral cleaning agents. Avoid

corrosive detergents.

j The ratchet tensioner should be regularly cleaned and then lightly greased. When greasing

it, make sure that parts that come into contact with the webbing are not greased.

j Store the lashing strap in a dry, well-ventilated cool place.

j Avoid contact with chemicals, acids and alkalis as they may damage the lashing strap.

Q

Disposal

The packaging is made entirely of recyclable materials, which you may dispose

of at local recycling facilities.

Contact your local refuse disposal authority for more details of how to dispose of your wornout product.

Q

Warranty

The product has been manufactured to strict quality guidelines and meticulously examined

before delivery. In the event of product defects you have legal rights against the retailer of

this product. Your legal rights are not limited in any way by our warranty detailed below.

The warranty for this product is 3 years from the date of purchase. Should this product

show any fault in materials or manufacture within 3 years from the date of purchase, we

will repair or replace it – at our choice – free of charge to you.

12 GB

Page 15

The warranty period begins on the date of purchase. Please keep the original sales receipt

in a safe location. This document is required as your proof of purchase. This warranty

becomes void if the product has been damaged, or used or maintained improperly.

The warranty applies to defects in material or manufacture. This warranty does not cover

product parts subject to normal wear, thus possibly considered consumables (e.g. batteries)

or for damage to fragile parts, e.g. switches, rechargeable batteries or glass parts.

13 GB

Page 16

Bevezető .............................................................................................................. Oldal 15

Rendeltetésszerű használat ....................................................................................Oldal 15

Műszaki adatok ......................................................................................................Oldal 15

A szállítmány tartalma ............................................................................................ Oldal 16

Biztonsági tudnivalók .............................................................................. Oldal 16

Általános biztonsági tudnivalók ............................................................................. Oldal 16

A rögzítő hevederre vonatkozó biztonsági tudnivalók ......................................... Oldal 16

A rögzítő heveder használatára és

ápolására vonatkozó tudnivalók .................................................. Oldal 18

Kezelés .................................................................................................................. Oldal 19

A rögzítő heveder felhelyezése .............................................................................. Oldal 20

A rögzítő heveder kioldása .................................................................................... Oldal 21

Tisztítás és ápolás ........................................................................................ Oldal 21

Mentesítés .......................................................................................................... Oldal 21

Garancia .............................................................................................................. Oldal 22

14 HU

Page 17

Racsnis rögzítőheveder (HG00921A)

Rögzítőheveder készlet (HG00921B)

Gyorszáras rögzítőheveder (HG00921C)

Q

Bevezető

Gratulálunk új termékének vásárlása alkalmából. Ezzel egy magas minőségű

termék mellett döntött. Az első üzembevétel előtt ismerkedjen meg a készülékkel.

Ehhez figyelmesen olvassa el a következő Használati utasítást és a biztonsági

tudnivalókat. A terméket csak a leírtak szerint és a megadott felhasználási területeken

alkalmazza. Őrizze meg ezt az utasítást. A termék harmadik félnek történő továbbadása

esetén mellékelje a termék a teljes dokumentációját is.

Q

Rendeltetésszerű használat

A termék rakományok leszorítására, rögzítésére és biztosítására készült. A rögzítő hevederek

arra valók, hogy egy jármű rakományát a rakodó felületre rászorítsák, vagy közvetlenül a

járművel összekössék. Nem valók terhek megemelésére vagy hordozására. A megengedett

terhelést nem szabad túllépni. Az előbb leírtaktól eltérő alkalmazások, vagy a termék

megváltoztatása nem megengedett és sérülésekhez és / vagy a termék megkárosításához

vezethetnek. A rendeltetésétől eltérő alkalmazásokból származó károkért a gyártó nem áll

jót. A termék nem ipari használatra készült.

Q

Műszaki adatok

HG00921A

Hossza: kb. 5 m (L

Megengedett terhelés (LC): 350 daN / Hurokba kötve: 700 daN / S

Anyaga: poliészter (PES)

)

G

25daN

HF

HG00921B

Méretek: LGF (rögzített rész hossza): 0,26 m

LGL (szabad rész hossza): 4,7 m

Megengedett terhelés (LC) : 350 daN (3500 N = Newton / 350 kg (m / s

S

25daN

HF

Anyaga: poliészter (PES)

HG00921C

Długość L

: ok. 2,5 m

G

Siła maks. (LC): 100 daN (1000 N = Newton / 100 kg (m / s

Hurokba kötve: 200 daN

Materiał: Poliester (PES)

2

)) /

2

)) /

15 HU

Page 18

Q

A szállítmány tartalma

A kicsomagolás után azonnal ellenőrizze a csomagolás tartalmát, annak teljességét,

valamint a termék és az elemek kifogástalan állapotát.

1 x Racsnis rögzítőheveder, kb. 5 m (HG00921A)

1 x rögzítő heveder racsnis feszítővel és S-kampóval, kb. 0,26 m (HG00921B)

1 x rögzítő heveder S-kampóval, kb. 4,7 m (HG00921B)

2 x heveder feszítő csattal, kb. 2,5 m (HG00921C)

1 x használati utasítás

Q

Biztonsági tudnivalók

ŐriZZe MeG valaMennyi BiZtonsÁGi tudnivalÓt És utasÍtÁst a JÖvŐ

idŐ sZÁMÁra!

Általános biztonsági tudnivalók

J

veszély és a termék által stranguáció miatti életveszély áll fenn. A gyerekek gyakran lebecsülik

a veszélyeket. Tartsa a gyerekeket a terméktől mindig távol. A termék nem játékszer.

J Ne használja a terméket, ha azon károsodásokat fedez fel.

J Vizsgálja meg, hogy mindegyik részt szabályszerűen szerelték e össze. Szakszerűtlen

szerelés esetén sérülésveszély áll fenn.

FIGYELMEZTETÉS!

ÉS GYEREKEK SZÁMÁRA! Sohase hagyja a gyerekeket felügyelet nélkül

a csomagolóanyagokkal és a termékkel. A csomagolóanyagok által fulladás-

ÉLET- ÉS BALESETVESZÉLY KISGYEREKEK

A rögzítő hevederre vonatkozó biztonsági tudnivalók

J Vizsgálja meg minden egyes használat előtt a rögzítő hevedert esetleges sérülések

szempontjából. A heveder sérülései esetén a rögzítő hevedert semmiképpen se használja.

J Vizsgálja meg gondosan azokat a rögzítő hevedereket, amelyekre agresszív vagy más

a használatát veszélyeztető anyagok tapadtak, vagy azt megszennyezték. Esetleg

vizsgéltassa meg azokat a gyártóval.

J Vizsgáltassa meg a rögzítő hevedert és annak valamennyi alkotó részét évente legalább

egyszer egy szakemberrel. A használati feltételektől és az üzemelési adottságokktól

függően további szakember általi vizsgálatokra is szükség lehet.

J Sohase használja a rögzítő hevedert:

- ha a hevederben szálak elszakadtak vagy benne elvágott szálak vannak, különösen

ha a szélek vannak bevágva, vagy más aggasztó sérüléseknél

16 HU

Page 19

- hiányzó vagy már nem olvasható megjelölések esetén

- csatlakozások megkárosodása, hő hatása (surlódások, hősugarak) miatti deformációk

esetén

- agresszív anyagok hatása által bekövetkezett károsodásoknál.

J Semmiképpen se alkalmazza a racsnis feszítőt:

- repedések, törések vagy jelentős korróziós jelenségek ill. károsodások esetén

- > 5 % tágulások (5 % a kampónyílásban vagy általános deformálódások) esetén

- a teherviselő részek felismerhető deformálódásánál

J A rögzítő hevederek javítását csak akkor szabad elvégezni, ha a gyártó, az anyag és

a megengedett húzási terhelés megjelölései a címkén egyértelműen megállapíthatók. A

javításokat csak a gyártó, vagy az általa megbízott személyek végezhetik el. Azoknak

biztosítaniok kell, hogy a javítás után újra használható rögzítő heveder az eredetileg a

címkén megadott maximális feszítő erőt elérte.

J Sohase terhelje meg a rögzítő hevedert a címkén megadott megengedett feszítő erő

felett (lásd a „Műszaki adatokat“).

J Válassza ki a rögzítés módja, feszítő erő és rakodó felület szerint a megfelelő rögzítő

hevedert (lásd az megjelölő címkét).

m

VIGYÁZAT! BALESETVESZÉLY! Válassza ki mindig a megfelelő rögzítő hevedereket, rögzítési

pontokat és rögzítési módokat. A helyes kiválasztást a rakomány alakja, és súlya határozza meg,

de a szándékolt alkalmazási mód, a szállítás környezete és a rakomány jellege is.

J Bizonyosodjon meg arról, hogy a járműnek az a része, amelyhez a rakományt rögzíteni

kell elég szilárd e.

m VIGYÁZAT! A szállítás közbeni gyorsulási erők mellett oldalirányú, a szél által okozott

erők is felléphetnek.

J Sohase húzza át a rögzítő hevedert érdes felületeken vagy éles széleken, ha azok

nincsenek megfelelően védve.

J Ügyeljen arra, hogy a rögzítő hevederek legyenek elcsavarodva és a terhelést teljes

szélességükben hordozzák.

J Ne helyezzen tárgyakat a rögzítő hevederre, ha azok által megkárosodhat.

J Tartsa a rögzítő hevedert forró felületektől távol.

J Helyezze a rögzítő hevedert egyenletesen a biztosítandó rakományra.

J Sohase használja a rögzítő hevedert ütköző részként.

J Ügyeljen arra, hogy az S-kampók hegye ne legyen megterhelve: hacsak nem egy

olyan kampóról van szó, amely erre a különleges célra alkalmas. Akassza a rögzítő

kampót mindig belülről kifelé, hogy a rakodó felület egyik rögzítési pontján a biztosítás

nélküli kiakadást elkerülhesse.

J Sohase helyezze az S-kampót és a racsnis feszítőt szélekre.

J Sohase hosszabbítsa meg, magasabb feszítő erők elérésére a racsnis feszítő karját,

vagy csak akkor, ha azt egy megfelelő használati utasítás határozottan engedélyezi.

m VIGYÁZAT! BALESETVESZÉLY! A rögzítésnél kiegészítő fémeszközök és rögzítő

szerkezetek alkalmazása esetén ügyeljen arra, hogy azok a rögzítő hevederhez találjanak.

J A rakomány biztonságos rögzítéséhez a racsnis feszítőre minimum 1,5-szer kell a

17 HU

Page 20

hevedert rátekerni.

J Feszítse meg előre kézzel a racsnis feszítőt annyira, hogy a racsnis feszítőre a hevedert ne

kelljen több mint 3-szorosan feltekerni ahhoz, hogy a rakomány jól rögzítve legyen.

J Tetőterhelésnél semmiképpen se lépje túl a gyártó megadásait.

m VIGYÁZAT! BALESETVESZÉLY! A lerögzítésnél vegye figyelembe a szükséges

előfeszítő erőt. Minimum 2 rögzítő hevederre van szükség. Stabilitási okok miatt a

lerögzítéshez minimum két azonos rögzítő hevederre és az átlós irányú rögzítéshez két

pár azonos rögzítő hevederre van szükség.

m VIGYÁZAT! BALESETVESZÉLY! Ellenőrizze útközben rendszeresen a rakomány

szabályszerű rögzítését és esetleg húzza után a rögzítő hevedert.

Q

A rögzítő heveder használatára és ápolására vonatkozó

tudnivalók

1. A rögzítő hevederek kiválasztásánál és használatánál figyelembe kell venni a

szükséges leszorító erőt, valamint a használat módját és a rögzítendő rakomány

jellegét. A helyes kiválasztást a rakomány méretei, alakja, és súlya határozza meg,

de a szándékolt alkalmazási mód, a szállítás környezete és a rakomány jellege is. A

lerögzítéshez minimum két azonos rögzítő hevederre és az átlós irányú rögzítéshez

két pár azonos rögzítő hevederre van szükség.

2. A külömböző viselkedési módok és a terhelés alatti külömböző hosszúságváltozások

miatt ugyananak a rakománynak a rögzítésére külömböző rögzítő eszközöket (pld.

rögzítő láncokat és műanyagrostokból készült rögzítő hevedereket) használni nem

szabad. A rögzítésnél kiegészítő fémrészek és rögzítő szerkezetek alkalmazása esetén

ügyeljen arra, hogy azok a rögzítő hevederhez találjanak.

3.

Használat közben a lapos kampónak a teljes szélességében kell a kampóalapra felfeküdni.

4. A rögzítés felnyitása: A felnyitás előtt meg kell arról bizonyosodni, hogy a rakomány

biztosítás nélkül is a rakodási felületen biztosan álljon és a lerakót egy esetleges leesés

nem veszélyezteti. Ha szükséges, a rakomány leesésének és / vagy felborulásának a

megakadályozására máris felhasználhatók a további szállításhoz szükséges

fémeszközök. Ez akkor is érvényes, ha olyan rögzítő elemeket alkalmaz amelyek

biztonságos eltávolítást tesznek lehetővé.

5. A lerakodás előtt a rögzítést annyira kell feloldani, hogy a rakomány szabadon álljon.

6. A rakodás és lerakodás alatt ügyelni kell az esetleges mélyre lenyúló felső vezetékekre.

7. A nyersanyagok amelyekből a rögzítő hevederek készülnek, a vegyi behatásokkal

szemben külömböző ellenállóképességekkel rendelkeznek. Ha a rögzítő heveder

vegyi hatásoknak van kitéve, a gyártó vagy a forgalmazó erre vonatkozó utasításait

figyelembe kell venni. Eközben figyelembe kell venni, hogy a vegyi hatások kihatása

növekvő hőmérsékleteknél megnövekszik. A műszálak vegyi hatásokkal szembeni

ellenállóképességét a következőkben foglaltuk össze:

- A poliésztert az ásványi savak kevésbbé támadják meg. Az alkáli oldatok viszont

megkárosíthatják.

18 HU

Page 21

- Ártalmatlan sav- vagy lúg-oldatok párolgások által annyira töménnyé válhatnak,

hogy károkat okozhatnak. A szennyezett rögzítő hevedereket azonnal helyezze

üzemen kivül, mossa át hideg vizben és szárítsa meg a levegőn.

8. Ezek a rögzítő hevederek a következő hőmérsékleti tartományokban való használatra

alkalmasak:

- poliészter számára (PES)–40 °C-tól +120 °C-ig.

Ezek a hőmérsékleti tartományok a vegyi környezettől függően megváltozhatnak.

Ebben az esetben be kell szerezni a gyártó vagy a forgalmazó javaslatait. A

környezeti hőmérséklet változásai befolyásolhatják a heveder rögzítő hatását.

Melegebb területekre való érkezés esetén vizsgálja meg a heveder szorító erejét.

9. A rögzítő hevedereket üzemen kívül kell helyezni, vagy helyreállítás céljából vissza kell

küldeni a gyártóhoz, ha rajta károsodások jelei mutatkoznak. A következő pontokban

felsoroltakat lehet károsodások jeleinek minősíteni:

- a hevedereken (amelyeket üzemen kívül helyeztek): szakadások, vágások, teherviselő

rostok bemetszése és törése és hő hatására keletkezett varratok,ill. alakváltozások;

- a végek vasalt részein és a rögzítő elemeken előállt deformálodások, repedések,

erős kopási és korróziós jelek. Csak olyan rögzítő hevedereket szabad helyreállítani,

amelyek azonosítási cimkékkel rendelkeznek. Ha a rögzítő heveder véletlenül

vegyszerekkel érintkezik, helyezze azt üzemen kívül, és forduljon tanácsért a

gyártóhoz vagy a forgalmazóhoz.

10. Ügyeljen arra, hogy a rögzítő hevedert a rögzített rakomány szélei ne károsítsák

meg. A használat előtt és után rendszeres szemléléses vizsgálat elvégzését ajánljuk.

11. Csak olvasható megjelölésekkel rendelkező és cimkével ellátott rögzítő hevedereket

használjon.

12. A rögzítő hevedereket nem szabad túlterhelni: A maximális 250 N-os kézi erőt

(25 daN a cimkén; 1 daN ≈ 1 kgs) csak egy kézzel szabad alkalmazni. Mechanikai

segédeszközöket mint pld. rudakat vagy emelőkarokat stb. használni nem szabad,

vagy csak akkor, ha azok a feszítő elem részei. (HG00921A, HG00921B)

13. Bogozott rögzítő hevedereket használni nem szabad.

14. Gátolja meg a cimkék sérülését úgy, hogy azt a rakomány széleitől, és ha lehet, a

rakománytól távol tartja.

15. Óvja a hevedereket súrlódástól és dörzsöléstől, valamint éles szélekkel rendelkező

rakományoktól, védőburkolatok és / vagy élvédők használatával.

Q

Kezelés

Leszorítás (HG00921A, HG00921B, HG00921C):

A rakományt felülről rögzítő hevederekkel a rakodó felületre préselik (lásd a I ábrát).

Átlós rögzítés (HG00921B):

A rakományt 4 rögzítő hevederrel biztosítják és közvetlenül a járműhöz kötik (lásd a II ábrát).

19 HU

Page 22

Q

A rögzítő heveder felhelyezése

A kiválasztott rögzítő heveder az alkalmazás céljának megfelelően erősnek és megfelelően

hosszúnak kell lennie, hogy a hosszúsága a rögzítés módjának megfeleljen. A rögzítési

eljárásnál mindig jó ha figyelembe veszi hogy: A rögzítő hevederek felhelyezését és

eltávolítását az utazás előtt kell eltervezni. Egy hosszabb út alkalmával esetleges részleges

lerakodásokat is figyelembe kell venni. A szükséges rögzítő hevederek számát az EN 12195-1

szerint kell kiszámítani. Csak olyan rögzítési rendszereket szabad alkalmazni, amelyeket a

címkén megadott a lerögzítéshez szükséges STF-re (normál feszítő erő) készítettek.

HG00921A:

j Helyezze a rögzítő hevedert a rakomány köré.

j Nyissa fel a racsnis feszítő-kart

hevedert

j Fűzze be a hevedert

4

be tudja fűzni (lásd az A III ábrát).

4

át a hornyos tengelyen

j

Feszítse meg a rögzítő hevedert úgy, hogy a racsnis feszítő karját ide-oda mozgatja

1

és állítsa be úgy a hornyos tengelyt 3, hogy a

a racsnis feszítő hornyos tengelyébe 3. Húzza azt óvatosan

3

addig, amíg a heveder 4 a rakományon szorosan fekszik.

(lásd az A I-III ábrát). Feszítse a rögzítő hevedert addig, amíg a kívánt ráfeszülést elérte.

Utalás: Ügyeljen arra, hogy a heveder 4 legalább 1,5-szeresen és maximálisan

3-szorosan legyen a hornyos tengelyre

j Állítsa a racsnis feszítő karját

1

3

rátekerve.

az alaphelyzetébe (lásd az A I ábrát). A rakomány

most biztosítva van.

HG00921B:

j Rögzítse a rögzítő hevedert az S-kampóknál fogva biztosan a rakományra.

j Nyissa fel a racsnis feszítő-kart

hevedert

j Fűzze be a hevedert

4

be tudja fűzni (lásd az A III ábrát).

4

át a hornyos tengelyen

j

Feszítse meg a rögzítő hevedert úgy, hogy a racsnis feszítő karját ide-oda mozgatja

1

és állítsa be úgy a hornyos tengelyt 3, hogy a

a racsnis feszítő hornyos tengelyébe 3. Húzza azt óvatosan

3

addig, amíg a heveder 4 a rakományon szorosan fekszik.

(lásd az A I-III ábrát). Feszítse a rögzítő hevedert addig, amíg a kívánt ráfeszülést elérte.

Utalás: Ügyeljen arra, hogy a heveder 4 legalább 1,5-szeresen és maximálisan

3-szorosan legyen a hornyos tengelyre

j Állítsa a racsnis feszítő karját

1

3

rátekerve.

az alaphelyzetébe (lásd az A I ábrát). A rakomány

most biztosítva van.

HG00921C:

j Hurkolja a rögzítő hevedert a rakomány köré.

j Nyomja a csat nyelvét

5

lefelé és vezesse át a hevedert 6 alulról át a feszítő csaton

(lásd az C ábrát).

j Húzza át óvatosan a hevedert

engedje el a csat nyelvét

20 HU

6

a szorító csaton, amíg a kívánt feszítést elérte. Utána

5

.

Page 23

Q

A rögzítő heveder kioldása

m

VIGYÁZAT! A kioldás előtt bizonyosodjon meg róla, hogy a rakomány biztosan áll e.

Ügyeljen arra, hogy a rakomány rögzítő heveder nélkül is biztosan álljon és ne eshessen le.

m

VIGYÁZAT! SÉRÜLÉSVESZÉLY! Ügyeljen arra, hogy amikor a rögzítő hevedert leoldja,

a rakomány közelében személyek ne tarozkódjanak. Leeső részek sérüléseket okozhatnak.

m VIGYÁZAT! SÉRÜLÉSVESZÉLY! A rögzítés kioldásánál a feszítő erő egy csapásra

felszabadul. Ezért a rögzítő hevedert nagyon óvatosan nyissa fel.

Utalás: A lerakodás előtt ügyeljen arra, hogy a rögzítés annyira ki legyen oldva, hogy a

rakomány szabadon álljon.

HG00921A & HG00921B:

j Állítsa a racsnis feszítő karját

j Nyomja meg a racsni biztosítót

1

a legszélsőbb helyzetébe (lásd az A III ábrát).

2

és billentse át ütközésig a racsnis feszítő karját 1

(lásd a B ábrát).

j Húzza ki egészen a hevedert

4

a hornyos tengelyből 3.

j Oldja le az S-kampót és ezáltal a rögzítő hevedert a rakományról.

HG00921C:

j Nyomja a csat nyelvét

j Húzza ki a hevedert

Q

Tisztítás és ápolás

5

lefelé (lásd az C ábrát).

6

teljesen a csatból.

Utalás: A rendszeres ápolás biztosítéka a rögzítő heveder minőségének és

funkcionalitásának a megőrzésére.

j Tisztítsa a rögzítő hevedert langyos vizzel és ph-semleges mosószerrel. Kerülje az

agresszív tisztítószereket.

j A racsnis feszítőt rendszeresen kell tisztítani és a végén enyhén kenőzsírral bekenni. A

kenés alkalmával ügyeljen arra, hogy azokat a részeket, amelyek a hevederrel

kapcsolatba kerülnek, ne kenje be.

j Tárolja a feszítő hevedert egy száraz, jól szellőző, hűvös helyiségben.

j Kerülje el annak a vegyszerekkel, savakkal, lúgokkal való kapcsolatba kerülését, mivel

azok a rögzítő hevedert megkárosíthatják.

Q

Mentesítés

A csomagolás környezetbarát anyagokból áll, amelyeket a helyi újraértékesítési

helyeken mentesíthet.

A kiszolgált termék leselejtezési lehetőségeiről tájékozódjon a községi vagy a városi

21 HU

Page 24

önkormányzatnál.

Q

Garancia

A terméket szigorú minőségi előírások betartásával gondosan gyártottuk, és szállítás előtt

lelkiismeretesen ellenőriztük. Ha a terméken hiányosságot tapasztal, akkor a termék

eladójával szemben törvényes jogok illetik meg Önt. Ezeket a törvényes jogokat a

következőkben ismertetett garancia vállalásunk nem korlátozza.

A termékre 3 év garanciát adunk a vásárlás dátumától számítva. A garanciális idő a

vásárlás dátumával kezdődik. Kérjük, jól őrizze meg a pénztári blokkot. Ez a bizonylat

szükséges a vásárlás tényének az igazolásához.

Ha a termék vásárlásától számított 3 éven belül anyag- vagy gyártási hiba merül fel, akkor

a választásunk szerint a terméket ingyen megjavítjuk vagy kicseréljük. A garancia

megszűnik, ha a terméket megrongálták, nem szakszerűen kezelték vagy tartották karban.

A garancia az anyag- vagy gyártáshibákra vonatkozik. A garancia nem terjed ki azokra a

termékrészekre, melyek normál kopásnak vannak kitéve és ezért fogyóeszköznek

tekinthetők (pl. elemek), vagy a törékeny részekre sérülésére, pl. kapcsolók, akkuk, vagy

üvegből készült részek.

22 HU

Page 25

Uvod ............................................................................................................................ St ran 24

Namen uporabe ......................................................................................................... Stran 24

Tehnični podatki .......................................................................................................... Stran 24

Obseg dobave ............................................................................................................ Stran 25

Varnostna opozorila ..................................................................................... Stran 25

Splošna varnostna navodila ....................................................................................... Stran 25

Varnostna opozorila za privezovalne trakove ...........................................................Stran 25

Praktična navodila za uporabo

in nego privezovalnih trakov ................................................................ Stran 27

Uporaba ................................................................................................................... Stran 28

Nameščanje privezovalnega traku ............................................................................ Stran 28

Odstranjevanje privezovalnega traku ........................................................................ Stran 29

Čiščenje in nega ................................................................................................. S tran 30

Odstranjevanje .................................................................................................. Stran 30

Garancijski list .................................................................................................... Stran 31

23 SI

Page 26

Napenjalni trak z ragljo (HG00921A)

Komplet jermenov za zategovanje in povezovanje (HG00921B)

Povezovalna trakova s hitrim zapiralom (HG00921C)

Q

Uvod

Iskrene čestitke ob nakupu vašega novega izdelka. Odločili ste se za kakovosten

izdelek. Pred prvo uporabo se seznanite z izdelkom. V ta namen pozorno preberite

naslednja navodila za uporabo in varnostne napotke. Izdelek uporabljajte samo

tako, kot je opisano in samo za navedena področja uporabe. To navodilo shranite. V primeru

izročitve izdelka tretjim, jim predajte tudi vso dokumentacijo.

Q

Namen uporabe

Ta izdelek je predviden za privezovanje, pritrjevanje in varovanje tovora. Privezovalni trakovi

služijo za „pritiskanje“ tovora ob tovorno površino vozila ali direktno povezovanje z vozilom.

Niso namenjeni za dvigovanje ali nošenje tovora. Dopustne sile se ne sme prekoračiti.

Kakršnakoli drugačna uporaba, od zgoraj opisane, ali spreminjanje izdelka ni dovoljeno in

lahko vodi do povzročitve poškodb in / ali škode na izdelku. Za škodo, nastalo pri

nestrokovni uporabi, proizvajalec ne prevzame jamstva. Izdelek ni namenjen za

profesionalno uporabo.

Q

Tehnični podatki

HG00921A

Dolžina: pribl. 5 m (L

Dopustna sila (LC): 350daN / V zanki: 700 daN / S

Material: Poliester (PES)

)

G

25daN

HF

HG00921B

Dolžina: LGF (dolžina fiksnega konca): 0,26 m

LGL (dolžina premičnega konca): 4,7 m

Dopustna sila (LC): 350 daN (3500 N = Newton / 350 kg (m / s

2

)) / SHF 25daN

Material: Poliester (PES)

HG00921C

Méretek L

: kb. 2,5 m

G

Megengedett terhelés (LC) : 100 daN (1000 N = Newton / 100 kg (m / s

V zanki: 200 daN

Anyaga: poliészter (PES)

24 SI

2

)) /

Page 27

Q

Obseg dobave

Takoj ko odvijete embalažo, preverite popolnost in nepoškodovanost izdelka ter vseh delov.

1 x Napenjalni Trak Z Ragljo, pribl. 5 m (HG00921A)

1 x Privezovalni trak z ragljo in z S-kavljem, pribl. 0,26 m (HG00921B)

1 x Privezovalni trak z S-kavljem, pribl. 4,7 m (HG00921B)

2 x Privezovalni trak z vpenjalno sponko, pribl. 2,5 m (HG00921C)

1 x Navodilo za uporabo

Q

Varnostna opozorila

varnostna navodila in opoZorila shranite Za prihodnJo uporaBo!

Splošna varnostna navodila

J

embalažnega materiala in življenjska nevarnost zaradi strangulacije. Otroci pogosto

podcenjujejo nevarnosti. Otrokom nikoli ne dovolite zadrževanja v bližini izdelka. Ta

izdelek ni igrača.

J Izdelka ne uporabljajte, če kaže znake poškodb.

J Preverite, če so vsi deli pravilno montirani. Pri nepravilni montaži obstaja nevarnost poškodb.

OPOZORILO!

NESREČ ZA MALČKE IN OTROKE! Otrok z embalažnim materialom in

izdelkom nikoli ne pustite nenadzorovanih. Obstaja nevarnost zadušitve zaradi

ŽIVLJENJSKA NEVARNOST IN NEVARNOST

Varnostna opozorila za privezovalne trakove

J Pred vsako uporabo privezovalni trak prekontrolirajte, ali kaže znake poškodb.

Privezovalnega traku na noben način ne uporabljajte, če opazite poškodbe traku.

J Privezovalne trakove, ki so umazani z agresivnimi ali drugimi snovmi, ki bi lahko ogrožale

uporabo, skrbno prekontrolirajte. Eventualno jih dajte prekontrolirati proizvajalcu.

J Privezovalne trakove in vse konstrukcijske dele dajte vsaj enkrat na leto v kontrolo

strokovnjaku. Odvisno od pogojev uporabe in delovnim danostim so lahko vmes

potrebne dodatne kontrole s strani strokovnjaka.

J Privezovalnega traku na noben način ne uporabljajte pri:

-

raztrganih ali prerezanih nitih, še posebno pri zarezanih robovih ali drugih spornih poškodbah

- manjkajoči ali nečitljivi oznaki

- poškodbah spojev, spremembi oblike zaradi vpliva toplote (drgnjenje, sevanje)

- škodi, ki je posledica vpliva agresivnih snovi.

J Ragelj na noben način ne uporabljajte pri:

25 SI

Page 28

- razpokah, prelomih ali znatnim pojavom korozije oz škodi zaradi korozije

- razširitvi > 5 % (5 % v zevu kavlja ali splošnih spremembah oblike)

- opazno nepopravljivih spremembah oblike na nosilnih delih

J Popravila na privezovalnih trakovih se sme opravljati samo takrat, kadar se da oznako

proizvajalca, material in najvišjo dopustno natezno silo z etikete jasno razbrati. Popravila

sme izvajati samo proizvajalec ali od njega pooblaščeno osebje. Le-to mora zagotoviti,

da privezovalni trakovi po popravilu, ko so zopet pripravljeni na uporabo, dosežejo

najvišjo dopustno natezno silo, ki je bila prvotno navedena na etiketi.

J Privezovalnega traku nikoli ne obremenjujte preko dopustne natezne sile, navedene na

etiketi (glejte tudi „Tehnični podatki“).

J Skladno s predvideno vrsto privezovanja, natezno silo in tovorno površino izberite

ustrezni privezovalni trak (glejte označevalno etiketo).

m POZOR! NEVARNOST NESREČ! Izberite ustrezne privezovalne trakove, privezovalne

točke in privezovalne metode. Pravilno izbiro določajo velikost, oblika in teža tovora,

pa tudi nameravana vrsta uporabe, transportni pogoji in vrsta tovora.

J Prepričajte se, da so deli vozila, na katere nameravate pritrditi tovor, dovolj stabilni.

m POZOR! Poleg sil pospeška se lahko med vožnjo pojavijo tudi stranske sile zaradi vetra.

J Privezovalnega traku nikoli ne vlecite preko grobih površin ali ostrih robov, če le-ti niso

ustrezno zaščiteni.

J Pazite na to, da privezovalni trakovi niso zaviti in nosijo s celotno širino.

J Na privezovalni trak ne postavljajte predmetov, če bi le-ti privezovalni trak lahko

poškodovali.

J Privezovalni trak držite stran od vročih površin.

J Privezovalne trakove enakomerno razporedite na tovoru, ki ga želite zavarovati.

J Privezovalnih trakov nikoli ne uporabljajte kot sredstev za zadrževanje.

J Pazite na to, da S-kavlji niso obremenjeni na konici: če ne gre za kavelj, ki je primeren za

ta poseben namen uporabe. Kavelj vedno pritrdite od znotraj navzven, da preprečite

snemanje brez varovala na neki privezovalni točki na tovorni površini.

J S-kavljev in ragelj nikoli ne polagajte na robove.

J Ročaja raglje nikoli ne podaljšujte, da bi dosegli večji napon, če to ni izrecno

dovoljeno z ustreznim navodilom za uporabo.

m POZOR! NEVARNOST NESREČ! Pri uporabi dodatnih delov okovja in privezovalnih

priprav za pritrjevanje je treba paziti na to, da se le-ti ujemajo s privezovalnim pasom.

J Za varno pritrditev tovora mora biti na raglji najmanj 1,5 navitja traku.

J Trak z roko že vnaprej tako napnite, da na raglji za napenjanje tovora niso potrebni

več kot 3 navoji traku.

J Pri tovoru na strehi nikakor ne prekoračite podatkov proizvajalca.

m POZOR! NEVARNOST NESREČ! Pri privezovanju upoštevajte potrebno silo

prednapenjanja. Potrebna sta najmanj 2 privezovalna trakova. Zaradi stabilnosti je

treba za privezovanje uporabljati najmanj dva enaka privezovalna trakova in dva para

enakih privezovalnih trakov za diagonalno privezovanje.

m POZOR! NEVARNOST NESREČ! Med vožnjo redno kontrolirajte, ali je tovor še

26 SI

Page 29

vedno pravilno pritrjen in privezovalni trak po potrebi naknadno zategnite.

Q

Praktična navodila za uporabo in nego privezovalnih

trakov

1. Pri izbiri in uporabi privezovalnih trakov je treba upoštevati potrebno vlečno silo kot

tudi vrsto uporabe in vrsto tovora, ki ga nameravamo pritrditi. Pravilno izbiro določajo

velikost, oblika in teža tovora, pa tudi nameravana vrsta uporabe, transportni pogoji

in vrsta tovora. Zaradi stabilnosti je treba za privezovanje uporabljati najmanj dva

privezovalna trakova in dva para privezovalnih trakov za diagonalno privezovanje.

2.

Zaradi različnih načinov obnašanja in spreminjanja dolžine pod obremenitvijo se za isti

tovor ne sme uporabljati različnih privezovalnih sredstev (npr. privezovalnih verig in

privezovalnih trakov iz kemijskih vlaken). Pri uporabi dodatnih delov okovja in privezovalnih

priprav za pritrjevanje je treba paziti na to, da se le-ti ujemajo s privezovalnim trakom.

3. Med uporabo morajo ploščati kavlji s celotno širino ležati na tleh kavlja.

4. Odpiranje priveza: Pred odpiranjem se je treba prepričati, da tovor tudi brez varovanja

še varno stoji in razkladalca ne ogroža s padcem na tla. Če je potrebno, je treba

sredstva za zadrževanje za nadaljnji transport že predhodno pritrditi na tovor, da se

prepreči padanje in / ali prevračanje tovora. To velja tudi takrat, kadar se uporablja

napenjalne elemente, ki omogočajo varno odstranjevanje.

5. Pred začetkom raztovarjanja je treba privezovalne priprave toliko sprostiti, da tovor

prosto stoji.

6. Med natovarjanjem in raztovarjanjem je treba paziti na vse nizko viseče nadzemne

vode v bližini.

7. Materiali, iz katerih so izdelani privezovalni trakovi, razpolagajo z različno odpornostjo

proti kemičnim vplivom. Upoštevati je treba navodila proizvajalca ali dobavitelja, če

bodo privezovalni trakovi verjetno izpostavljeni kemikalijam. Pri tem je treba upoštevati,

da se posledice kemičnih vplivov pri naraščajočih temperaturah povečajo. Odpornost

umetnih vlaken proti kemičnim vplivom je povzeta v nadaljevanju:

- Poliester mineralne kisline malo načenjajo. Alkalne raztopine ga lahko poškodujejo.

- Nenevarne raztopine kislin ali lužin se lahko zaradi izhlapevanja tako skoncentrirajo,

da povzročijo škodo. Onesnažene privezovalne trakove je treba takoj vzeti iz uporabe,

sprati v hladni vodi in posušiti na zraku.

8. Ti privezovalni trakovi so primerni za uporabo v naslednjih temperaturnih območjih:

- –40 °C do +120 °C za Poliester (PES);

Ta temperaturna območja se lahko odvisno od kemičnega okolja spremenijo. V tem

primeru je treba pridobiti priporočila proizvajalca ali dobavitelja. Spreminjanje

temperature okolice med transportom lahko vpliva na moč traku. Vlečno silo je treba

po vstopu v topla območja prekontrolirati.

9. Privezovalne trakove je treba vzeti iz uporabe ali poslati nazaj proizvajalcu v popravilo,

če kažejo znake poškodb. Naslednje točke je treba obravnavati kot znake poškodb:

- pri trakovih (ki jih je treba vzeti iz uporabe): razpoke, prerezi, vrezi in prelomi vlaken

27 SI

Page 30

in šivov, ki nosijo tovor, spremembe oblike zaradi vpliva toplote;

- pri končnih delih okovja in napenjalnih elementih: spremembe oblike, razpoke, močni

znaki obrabe in korozije. Popravljati se sme samo privezovalne trakove, ki imajo etiketo

za identifikacijo. Če pride do naključnega stika s kemikalijami, je treba privezovalni

trak vzeti iz uporabe in vprašati proizvajalca ali dobavitelja o nadaljnjem ravnanju.

10. Paziti je treba na to, da se privezovalni trak na robovih tovora, na katerem je pritrjen,

ne poškoduje. Priporočeni so redni kontrolni pregledi pred vsako uporabo.

11. Uporabljati se sme samo privezovalne trakove, ki so označeni s čitljivimi etiketami.

12. Privezovalnih trakov se ne sme preobremenjevati: Maksimalno ročno silo 250 N

(25 daN na etiketi; 1 daN ≈ 1 kg) se sme izvajati samo z eno roko. Ne sme se

uporabljati mehanskih pomagal kot so palice ali vzvodi itn., razen v primeru, če so

le-te del napenjalnega elementa. (HG00921A, HG00921B)

13. Zavozlanih privezovalnih trakov se ne sme uporabljati.

14. Poškodbe etikete je treba preprečiti tako, da se etikete drži, če je to mogoče, stran

od robov tovora in stran od tovora.

15. Trakove je treba z uporabo zaščitnih prevlek in / ali ščitnikov za robove zaščititi pred

drgnjenjem in obrabo ter pred poškodbami zaradi tovora z ostrimi robovi.

Q

Uporaba

Privezovanje ob podlago (HG00921A, HG00921B, HG00921C):

Privezovalne trakove se napne preko tovora in tovor pritisne ob tovorno površino (glejte sl. I).

Diagonalno privezovanje (HG00921B):

Tovor se zavaruje s 4 privezovalnimi trakovi in pritrdi direktno na vozilo (glejte sl. II).

Q

Nameščanje privezovalnega traku

Izbrani privezovalni trak mora biti za namen uporabe tako dovolj močan kot tudi dovolj dolg

in imeti pravo dolžino glede na vrsto privezovanja. Vedno se je treba ozirati na dobro prakso

privezovanja: Nameščanje in odstranjevanje privezovalnih trakov je treba načrtovati pred

začetkom vožnje. Med daljšo vožnjo je treba upoštevati delno raztovarjanje. Število

privezovalnih trakov je treba izračunati skladno z EN 12195-1. Za privezovanje ob

podlago se sme uporabljati samo takšne privezovalne sisteme, ki so na etiketi označeni s

STF (normalna napenjalna sila) za privezovanje ob podlago.

HG00921A:

j Privezovalni trak s pomočjo S-kavlja varno pritrdite na tovor.

j Odprite ročaj raglje

4

traku

j Trak

(glejte sl. A III).

4

vdenite v gred z ozko odprtino 3 raglje. Previdno ga potegnite skozi gred z

ozko odprtino

28 SI

1

in gred z ozko odprtino 3 postavite v položaj za vdevanje

3

, dokler se trak 4 tesno ne prilega tovoru.

Page 31

j Privezovalni trak napnite, tako da ročaj raglje premikate sem in tja (glejte sl. A I-III).

Privezovalni trak napenjajte toliko časa, dokler ne dosežete želenega napona.

Opozorilo: Upoštevajte, da morajo biti na na gredi z ozko odprtino

1,5 in največ 3 navitja traku

j Ročaj raglje

1

postavite v osnovni položaj (glejte sl. A I). Tovor je zdaj zavarovan.

4

.

3

najmanj

HG00921B:

j Privezovalni trak s pomočjo S-kavlja varno pritrdite na tovor.

j Odprite ročaj raglje

4

traku

j Trak

(glejte sl. A III).

4

vdenite v gred z ozko odprtino 3 raglje. Previdno ga potegnite skozi gred z

ozko odprtino

1

in gred z ozko odprtino 3 postavite v položaj za vdevanje

3

, dokler se trak 4 tesno ne prilega tovoru.

j Privezovalni trak napnite, tako da ročaj raglje premikate sem in tja (glejte sl. A I-III).

Privezovalni trak napenjajte toliko časa, dokler ne dosežete želenega napona.

Opozorilo: Upoštevajte, da morajo biti na na gredi z ozko odprtino

1,5 in največ 3 navitja traku

j Ročaj raglje

1

postavite v osnovni položaj (glejte sl. A I). Tovor je zdaj zavarovan.

4

.

3

najmanj

HG00921C:

j Privezovalni trak ovijte okrog tovora.

j Sponko

5

pritisnite navzdol in trak 6 od spodaj speljite skozi vpenjalno sponko

(glejte sl. C).

j Trak

Q

6

previdno potegnite skozi vpenjalno sponko, dokler ne dosežete želenega

napona. Sponko

5

spustite.

Odstranjevanje privezovalnega traku

m POZOR! Pred odstranjevanjem se prepričajte, da je tovor varno stoji. Pazite na to, da

tovor tudi brez privezovalnega traku varno stoji in ne more pasti na tla.

m

POZOR! NEVARNOST POŠKODB! Pazite na to, da se v bližini tovora ne nahajajo

osebe, če bi se privezovalni trak odvezal. Na tla padajoči deli lahko povzročijo poškodbe.

m POZOR! NEVARNOST POŠKODB! Pri odpiranju privezovalne opreme se

prednapetostna sila naenkrat sprosti. Zato privezovalni trak odprite skrajno previdno.

Opozorilo: Pred začetkom raztovarjanja pazite na to, da je privez tako daleč odvezan,

da tovor prosto stoji.

HG00921A & HG00921B:

j Ročaj raglje

j Pritisnite varovalo raglje

j Trak

1

postavite v najbolj skrajni položaj (glejte sl. A III).

2

in ročaj raglje 1 odprite do konca (glejte sl. B).

4

v celoti potegnite ven iz gredi z ozko odprtino 3.

j S tovora snemite S-kavelj in s tem odstranite privezovalni trak.

29 SI

Page 32

HG00921C:

j Sponko

j Trak

Q

Čiščenje in nega

5

pritisnite navzdol (glejte sl. C).

6

v celoti potegnite ven iz vpenjalne sponke.

Opozorilo: Redna nega zagotavlja kvaliteto in delovanje privezovalnega traku.

j Privezovalni trak čistite z mlačno vodo in ph-nevtralnim pralnim sredstvom. Izogibajte se

uporabi agresivnih čistil.

j Napenjalno ragljo je treba redno čistiti in nato rahlo namazati. Pri podmazovanju pazite

na to, da se delov, ki pridejo v stik s trakom, ne maže.

j Napenjalni trak skladiščite na suhem, dobro zračenem in hladnem mestu.

j Preprečite stik s kemikalijami, kislinami in lužinami, ker le-te lahko poškodujejo

privezovalni trak.

Q

Odstranjevanje

Embalaža je sestavljena iz ekoloških materialov, ki jih lahko odlagate na

lokalnim lokacijah za recikliranjem.

O možnostih odstranjevanja izrabljenih električnih naprav vprašajte na vaši občinski ali

mestni upravi.

30 SI

Page 33

Pooblaščeni serviser:

OWIM GmbH & Co. KG

Stiftsbergstraβe 1

DE-74167 Neckarsulm

NEMČIJA

Servisna telefonska številka: 00386 (0) 80 28 60

Garancijski list

1. S tem garancijskim listom jamčimo OWIM GmbH & Co. KG da bo izdelek v garan-

cijskem roku ob normalni in pravilni uporabi brezhibno deloval in se zavezujemo, da

bomo ob izpolnjenih spodaj navedenih pogojih odpravili morebitne pomanjkljivosti in

okvare zaradi napak v materialu ali izdelavi oz. po svoji presoji izdelek zamenjali ali

vrnili kupnino.

2. Garancija je veljavna na ozemlju Republike Slovenije.

3. Garancijski rok za proizvod je 3 leta od dneva izročitve blaga. Dan izročitve blaga je

enak dnevom prodaje, ki je razviden iz računa.

4. Kupec je dolžan okvaro javiti pooblaščenemu servisu oz. se informirati o nadaljnjih

postopkih na zgoraj navedeni telefonski številki. Svetujemo vam, da pred tem natančno

preberete navodila o sestavi in uporabi izdelka.

5. Kupec je dolžan pooblaščenemu servisu predložiti garancijski list in račun, kot potrdilo

in dokazilo o nakupu.

6. V primeru, da proizvod popravlja nepooblaščeni servis ali oseba, kupec ne more

uveljavljati zahtevkov iz te garancije.

7. Vzroki za okvaro oz. nedelovanje izdelka morajo biti lastnosti stvari same, in ne vzroki,

ki so zunaj proizvajalčeve oz. prodajalčeve sfere. Kupec ne more uveljavljati zahtevkov

iz te garancije, če se ni držal priloženih navodil za sestavo in uporabo izdelka ali, če je

izdelek kakorkoli spremenjen ali nepravilno vzdrževan.

8. Jamčimo servisiranje in rezervne dele za minimalno dobo, ki je zahtevana s strani

zakonodaje.

9. Obrabni deli oz. potrošni material so izvzeti iz garancije.

10. Vsi potrebni podatki za uveljavljanje garancije se nahajajo na dveh ločenih

dokumentih (garancijski list, račun).

11. Ta garancija proizvajalca ne izključuje pravic potrošnika, ki izhajajo iz odgovor-

nosti prodajalca za napake na blagu.

Prodajalec:

Lidl Slovenija d.o.o.k.d., Pod lipami 1, SI-1218 Komenda

31 SI

Page 34

Úvod ........................................................................................................................ Strana 33

Použití ke stanovenému účelu ................................................................................. Strana 33

Technické údaje .......................................................................................................Strana 33

Rozsah dodávky ...................................................................................................... Strana 34

Bezpečnostní pokyny ............................................................................... Strana 34

Všeobecné bezpečnostní pokyny ..........................................................................Strana 34

Bezpečnostní pokyny pro zajišťovací pásy ............................................................Strana 34

Praktické pokyny kpoužití a

ošetřování zajišťovacích popruhů ................................................. Strana 36

Obsluha ................................................................................................................ Strana 37

Přiložení zajišťovacího popruhu ............................................................................. Strana 37

Uvolnění zajišťovacího popruhu .............................................................................Strana 38

Čistění a ošetřování .................................................................................... Strana 39

Likvidace ............................................................................................................. Strana 39

Záruka ................................................................................................................... Strana 39

32 CZ

Page 35

Upínací pás s ráčnou (HG00921A)

Sada napínacích a upínacích pásů (HG00921B)

Upínací popruhy s rychlouzávěrem (HG00921C)

Q

Úvod

Blahopřejeme Vám ke koupi nového výrobku. Rozhodli jste se pro kvalitní

výrobek. Před prvním uvedením do provozu se seznamte s výrobkem. K tomu si

pozorně přečtěte následující návod k obsluze a bezpečnostní pokyny. Používejte

výrobek jen popsaným způsobem a pouze pro uvedené oblasti použití. Uschovejte si,

prosím, tento návod. Všechny podklady vydejte při předání výrobku i třetí osobě.

Q

Použití ke stanovenému účelu

Výrobek je stanoven k připevnění, upevnění a zajištění nákladu. Zajišťovací pásy slouží k

tomu, aby úložnou plochu vozidla „přitlačily“ nebo přímo s vozidlem svázaly. Nejsou určeny

ke zvedání nebo nošení břemen. Nesmí se překročit přípustná síla. Kterékoliv jiné použití než

předtím popsané použití nebo změna na výrobku nejsou přípustné a mohou vést kporaněním

a / nebo poškozením výrobku. Za škody vzniklé z použití k nestanovenému účelu nepřevezme

výrobce ručení. Výrobek se nehodí pro průmyslové použití.

Q

Technické údaje

HG00921A

Délka: cca. 5 m (LG)

Přípustná síla (LC): 350 daN / Ve smyčce: 700 daN (dekanewtonů) / S

Materiál: polyester (PES)

25daN

HF

HG00921B

Délka: LGF (délka pevný konec): 0,26 m

LGL (délka volný konec): 4,7 m

Přípustná síla (LC): 350 daN ( 3500 N = newton / 350 kg ( m / s

Materiál: polyester (PES)

HG00921C

Délka L

: cca. 2,5 m

G

Přípustná síla (LC): 100 daN (1000 N = newton / 100 kg (m / s

Ve smyčce: 200 daN (dekanewtonů)

Materiál: polyester (PES)

2

)) / SHF 25daN

2

)) /

33 CZ

Page 36

Q

Rozsah dodávky

Bezprostředně po rozbalení zkontrolujte úplnost dodávky a bezvadný stav výrobku a všech

jeho částí.

1 x Upínací pás s ráčnou, cca. 5 m (HG00921A)

1 x zajišťovací popruh snapínací řehtačkou a s hákem S, cca. 0,26 m (HG00921B)

1 x zajišťovací popruh s hákem S, cca. 4,7 m (HG00921B)

2 x připevňovací popruh se svěracím zámkem, cca. 2,5 m (HG00921C)

1 x návod k obsluze

Q

Bezpečnostní pokyny

uschoveJte BeZpeČnostnÍ poKyny a nÁvody pro Budoucnost!

Všeobecné bezpečnostní pokyny

J

života strangulací. Děti často podcení nebezpečí. Chraňte výrobek před dětmi. Výrobek

není hračkou.

J Výrobek už více nepoužívejte, vykazuje-li poškození.

J Zkontrolujte, jsou-li všechny díly odborně namontovány. Při neodborné montáži existuje

nebezpečí poranění.

VÝSTRAHA!

MALÉ DĚTI A DĚTI!

a výrobkem. Existuje nebezpečí udušení obalovým materiálem a ohrožení

NEBEZPEČÍ OHROŽENÍ ŽIVOTA A ÚRAZU PRO

Nikdy nenechejte děti bez dozoru sobalovým materiálem

Bezpečnostní pokyny pro zajišťovací pásy

J Před každým použitím přezkoušejte zajišťovací popruh vzhledem kpravděpodobným

poškozením. Nikdy nepoužívejte zajišťovací popruh při poškození pásu.

J Přezkoušejte pečlivě zajišťovací popruhy, jsou-li na nich přilnuté agresivní nebo jinak použití

ohrožující látky nebo jsou-li znečištěny. Nechejte je případně přezkoušet výrobcem.

J Nechejte zajišťovací popruhy a všechny konstrukční díly aspoň jednou za rok přezkoušet

odborníkem. Podle podmínek použití a provozních vlastností mohou být čas od času

žádoucí další zkoušky odborníkem.

J Nikdy nepoužívejte zajišťovací popruh při:

- lomech nebo řezech příze, zejména při zářezech na hranách nebo jiných povážlivých

poraněních

- chybějící nebo už více nečitelné značce

- poškození spojení, deformaci působením tepla (tření, záření)

34 CZ

Page 37

- poškozeních působením agresivních látek.

J Nikdy nepoužívejte řehtačky při:

- trhlinách, lomech nebo značných jevech koroze, popř. poškození

- rozšíření > 5 % (5 % v rozevření háku nebo všeobecných deformacích)

- rozpoznatelné trvalé deformace na nosných dílech

J

Opravy na zajišťovacích popruzích se smí provést jen tehdy, lze-li jednoznačně zjistit značku

výrobce, surovinu a přípustnou nejvyšší sílu vtahu na etiketě. Smějí je vykonat jen výrobce

nebo jím pověřené osoby. Tyto musí zajistit, aby po opravě znovu kpoužití připravené

zajišťovací popruhy dosáhly nejvyšší přípustnou sílu vtahu původně danou na etiketě.

J Zajišťovací popruh nikdy nezatěžujte povolenou silou v tahu uvedenou na etiketě (viz

také „Technické údaje“).

J Zvolte podle plánovaného druhu připevnění, síly v tahu, povrchu nákladu vhodný

zajišťovací popruh (viz značku na etiketě).

m POZOR! NEBEZPEČÍ ÚRAZU! Zvolte vždy vhodné zajišťovací popruhy, zajišťovací

body a zajišťovací metodu. Velikost, tvar a hmotnost nákladu určují správný výběr, ale i

zamýšlený způsob použití, okolí přepravy a druh nákladu.

J Ujistěte se, že jsou díly vozidla, na nichž se má náklad upevnit, dostatečně stabilní.

m POZOR! Ksilám zrychlení během jízdy se mohou navíc vyskytnout boční síly vzhledem

květru.

J Nikdy netahejte zajišťovací popruh před drsné povrchy nebo ostré hrany, nejsou-li tyto

opatřeny vhodnou ochranou.

J Dbejte na to, aby nebyly zajišťovací popruhy zkroucené a nesly po celé šířce.

J Na zajišťovací popruh nestavte předměty, může-li se jimi poškodit.

J Zajišťovací popruh chraňte před horkými povrchy.

J Zajišťovací popruhy rozložte pravidelně na břemeno, které se má zajistit.

J Nikdy nepoužívejte zajišťovací popruhy jako prostředek kdorazu.

J Dbejte na to, aby nebyl hák Szatížen na špičce: pokud se nejedná o hák, který se hodí

k tomuto zvláštnímu účelu. Zavěste zajišťovací háky vždy zevnitř směrem ven, aby se

zabránilo vyvěšení bez zajištění vzajišťovacím bodě na úložné ploše.

J Nikdy nepřiložte háky Sa řehtačky na hrany.

J Nikdy neprodlužte rukojeť řehtačky, aby se dosáhlo větších napínacích sil, není-li to

výslovně podle příslušného návodu k obsluze povoleno.

m POZOR! NEBEZPEČÍ ÚRAZU! Dbejte při použití přídavných dílů kování a

zajišťovacích zařízení na to, aby se kzajišťovacímu popruhu hodily.

J K bezpečnému upevnění nákladu se musí na řehtačku umístit aspoň 1,5 vinutí pásu

popruhu.

J Přednapněte pás popruhu rukou už tak daleko, aby se kupnutí nákladu nemusela více

než 3 vinutí pásu umístit na řehtačku.

J Při střešní zátěži nikdy nepřekročte údaje výrobce.

m POZOR! NEBEZPEČÍ ÚRAZU! Při připevnění dolů dbejte na požadovanou

předpjatou sílu. Jsou zapotřebí aspoň 2 zajišťovací popruhy. Zdůvodů stability se musí

použít aspoň dva stejné zajišťovací popruhy připevnit dolů a dva páry stejných

35 CZ

Page 38

diagonálních zajišťovacích popruhů.

m POZOR! NEBEZPEČÍ ÚRAZU! Během jízdy pravidelně zkontrolujte, je-li náklad

ještě náležitě připevněn a případně zajišťovací popruh dodatečně napněte.

Q

Praktické pokyny kpoužití a

ošetřování zajišťovacích popruhů

1. Při volbě a použití zajišťovacích popruhů se musí vzít zřetel na požadovanou sílu vtahu,

jakož i na způsob použití a druh zajišťovaného nákladu. Velikost, tvar a hmotnost

nákladu určují správný výběr, ale i zamýšlený způsob použití, okolí přepravy a druh

nákladu. Zdůvodů stability se musí použít aspoň dva stejné zajišťovací popruhy

kzajištění stlačením a dva páry zajišťovacích popruhů při diagonálním zajištění.

2. Kvůli různému chování a kvůli změně délky při zátěži se nesmí různé zajišťovací

prostředky (např. zajišťovací řetězy a zajišťovací popruhy z chemických vláken)

používat k zajištění téhož břemene. Při použití přídavných dílů kování a zajišťovacích

zařízení se musí dbát na to, aby se kzajišťovacímu popruhu hodily.

3. Během použití se musí ploché háky položit scelou šířkou vzákladu háku.

4. Otevření zajištění: Před otevřením by se mělo ujistit, že náklad i bez zabezpečení

bezpečně stojí a neohrožuje vykládající osobu spadnutím dolů. Je-li třeba, musí se už

pro další přepravu plánované prostředky k dorazu na náklad umístit, aby se zabránilo

spadnutí dolů a / nebo překlopení nákladu. To se přihodí i tehdy, použijí-li se napínací

prvky, které umožňují bezpečné odstranění.

5.

Před zahájením vykládání musí být zajištění tak dalece uvolněna, aby stálo břemeno volně.

6. Během nakládání a vykládání se musí dbát na blízkost všech nízko zavěšených

venkovních vedení.

7. Suroviny, znichž jsou zajišťovací popruhy vyrobeny, disponují různou odolností proti

chemickým působením. Je třeba dbát na pokyny dodavatele, jsou-li zajišťovací popruhy

pravděpodobně vystaveny chemikáliím. Přitom je třeba mít na paměti, že se působení

chemických vlivů při vzrůstajících teplotách zvýší. Odolnost umělohmotných vláken

vůči chemickým působením je shrnuto vnásledujícím:

- Polyester je málo agresivně napaden minerálními kyselinami. Alkalická ředidla jej

mohou poškodit.

- Nevinné roztoky kyselin a louhů se mohou difúzním odpařováním koncentrovat tak,

že vyvolají škody. Znečištěné zajišťovací popruhy je zapotřebí okamžitě uvést mimo

provoz, opláchnout je ve studené vodě a na vzduchu osušit.

8. Tyto zajišťovací popruhy se hodí pro použití vnásledujících teplotních rozsazích:

- –40 °C až +120 °C pro polyester (PES);

Tyto teplotní rozsahy se mohou podle chemického okolí měnit. Vtomto případě

doporučujeme se řídit doporučeními výrobce nebo dodavatele. Změna teploty okolí

během přepravy může ovlivnit sílu vzajišťovacím popruhu. Sílu vtahu je třeba

přezkoušet po vstupu do teplých oblastí.

9. Zajišťovací popruhy se musí vzít zprovozu nebo poslat zpět výrobci kopravě,

36 CZ

Page 39

vykazují-li známky poškození. Následující body lze považovat za známky poškození.

- u pásů popruhů (které se mají vzít zprovozu): trhliny, řezy, zápichy a lomy ve

vláknech a švech nosících zátěž, deformace působením tepla;

- u koncových dílů kování a napínacích prvků: deformace, trhliny, zjevné známky

opotřebení a koroze. Opravit se smějí jen zajišťovací popruhy, které vykazují etikety

kjejich identifikaci. Dojde-li knáhodnému kontaktu schemikáliemi, musí se zajišťovací

popruh vzít zprovozu a informovat výrobce nebo dodavatel.

10. Je třeba dbát na to, aby se zajišťovací popruh nepoškodil hranami nákladu, na nichž

je umístěn. Doporučuje se pravidelná vizuální kontrola před každým použit a po něm.

11. Je třeba použít čitelně označené a etiketami opatřené zajišťovací popruhy.

12. Zajišťovací popruhy se nesmí přetížit. Maximální ruční síla 250 N (25 daN na etiketě;

1 daN ≈ 1 kg) se smí vyvinout jednou rukou. Nesmí se použít mechanické pomocné

prostředky, jako jsou tyče nebo páky atd., ledažeby tyto byly částí napínacího prvku.

(HG00921A, HG00921B)

13. Nesmí se použít zauzlené zajišťovací popruhy.

14. Poškozením na etiketách je třeba zabránit tím, že se chrání před hranami nákladu a

pokud je možné, před nákladem.

15. Pásy popruhů je třeba chránit před třením a oděrem, jakož i před poškozeními náklady

sostrými hranami použitím ochranných povlaků a / nebo chráničů hran.

Q

Obsluha

Zajištění stlačením (HG00921A, HG00921B, HG00921C):

Náklad se stlačí zajišťovacími popruhy s přepnutím na úložnou plochu (viz obr. I).

Diagonální zajištění (HG00921B):

Náklad se zajistí 4 zajišťujícími popruhy a přímo sváže s vozidlem (viz. II).

Q

Přiložení zajišťovacího popruhu

Zvolený zajišťovací popruh musí být pro účel použití jak silný, tak i dostatečně dlouhý a

vzhledem kzajišťovanému způsobu vykazovat správnou délku. Je třeba vždy dbát na dobrou

praxi zajištění. Umístění a odstranění zajišťovacích popruhů je třeba plánovat před začátkem

jízdy. Během delší jízdy je třeba přihlédnout kdílčím vykládáním. Počet zajišťovacích popruhů

je třeba počítat podle EN 12195-1. Smějí se používat k zajištění stlačením jen takové

zajišťovací popruhy, které jsou dimenzovány k zajištění stlačením s STF (běžná napínací

síla) na etiketě.

HG00921A:

j Oviňte zajišťovací pás kolem nákladu.

j Otevřete rukojeť řehtačky

pás popruhu

4