Philips MG2.1E AA Schematic

1

Colour Television Chassis

MG2.1E

AA

mg21frtp.eps

290798

ServiceManual

Content

1. Technical specifications 2

2. Connection facilities, chassis overview 3

3. Safety instructions, maintenance, 5

warnings and Notes

4. Mechanical instructions 7

5. Service modes, DST, error messages, 9

protections, faultfinding and repair tips including:

Errorcodes-table 15

Protection-structure (overview and detailed) 17

Fault find tree 22

6. Block diagrams 29

Block diagram 29

(Supply, Deflection, CRT)

Block diagram 30

(Video, Audio, Control)

Survey of testpoints 31

Oscillograms 32

Wiring diagram 33

Overview I2C -ICs 33

Supply lines overview 34

7. Electrical Diagrams and PWB lay-outs

Diagram PWB

Power Supply (Diagram A1) 35 36,37

Line Deflection (Diagram A2) 38 36,37

Frame Deflection / Frame Rotation (Diagram A3) 39 36,37

Audio Amplifier (Diagram A4) 40 36,37

Mains switch Panel (Diagram E) 41 41

CRT / Scavem Panel (Diagram F) 42 43

Tuner, IF, I/O, Video processing (Diagram K1) 46 44,45

Input / Output (Diagram K2) 47 44,45

Sound processing (Diagram K3) 48 44,45

Audio Dolby (Diagram K4) 49 44,45

Secam Correction (Diagram U) 49 49

Featurebox 6 (Eco) (Diagram K5) 50 44,45

Video control & Geometry (Diagram K6) 51 44,45

Teletext & Control (Diagram K7) 52 44,45

Side I/O Panel (Diagram O) 53 53

Top Control Panel (Diagram P) 54 54

DC Shift (Diagram G) 54 54

Diversity tables 55

8. Electrical alignments 57

9. Circuit Descriptions: not available (see Training

Manual) 63

10. Directions for use 64

11. List of abbreviations 75

12. Spare parts list 77

Published by CO 9871 TV Service DepartmentPrinted in The NetherlandsCopyright reserved 1998 Philips Consumer Electronics B.V. Eindhoven, The Netherlands. All rights reserved. No part of this publication may be reproduced, stored in a retrieval system or transmitted, in any form or by any means, electronic, mechanical, photocopying, or otherwisewithout the prior permision of Philips.Subject to modification5 4822 727 21622

©

Copyright reserved 1998 Philips Consumer Electronics B.V. Eindhoven, The

Netherlands. All rights reserved. No part of this publication may be reproduced,

stored ina retrievalsystem ortransmitted, in any form or by any means, electronic, mechanical, photocopying, or otherwise without the prior permision of Philips.

Published by CO 9871 TV Service Department Printed in The Netherlands Subject to modification 5 4822 727 21622

2 MG2.1E

1 Technical specifications

Mains voltage : 220V - 240V (±10%);

Aerial input impedance : coaxial 75 Ω

Minimal aerial voltage : 30µV (VHF), 40µV

Maximum aerial voltage : 180 mV

Programmes : 0-99

VCR programmes : 0, 90-99

1 Technical specifications

50-60Hz (± 5%)

(UHF)

2 Specification connections

3MG2.1E

2 Specification connections

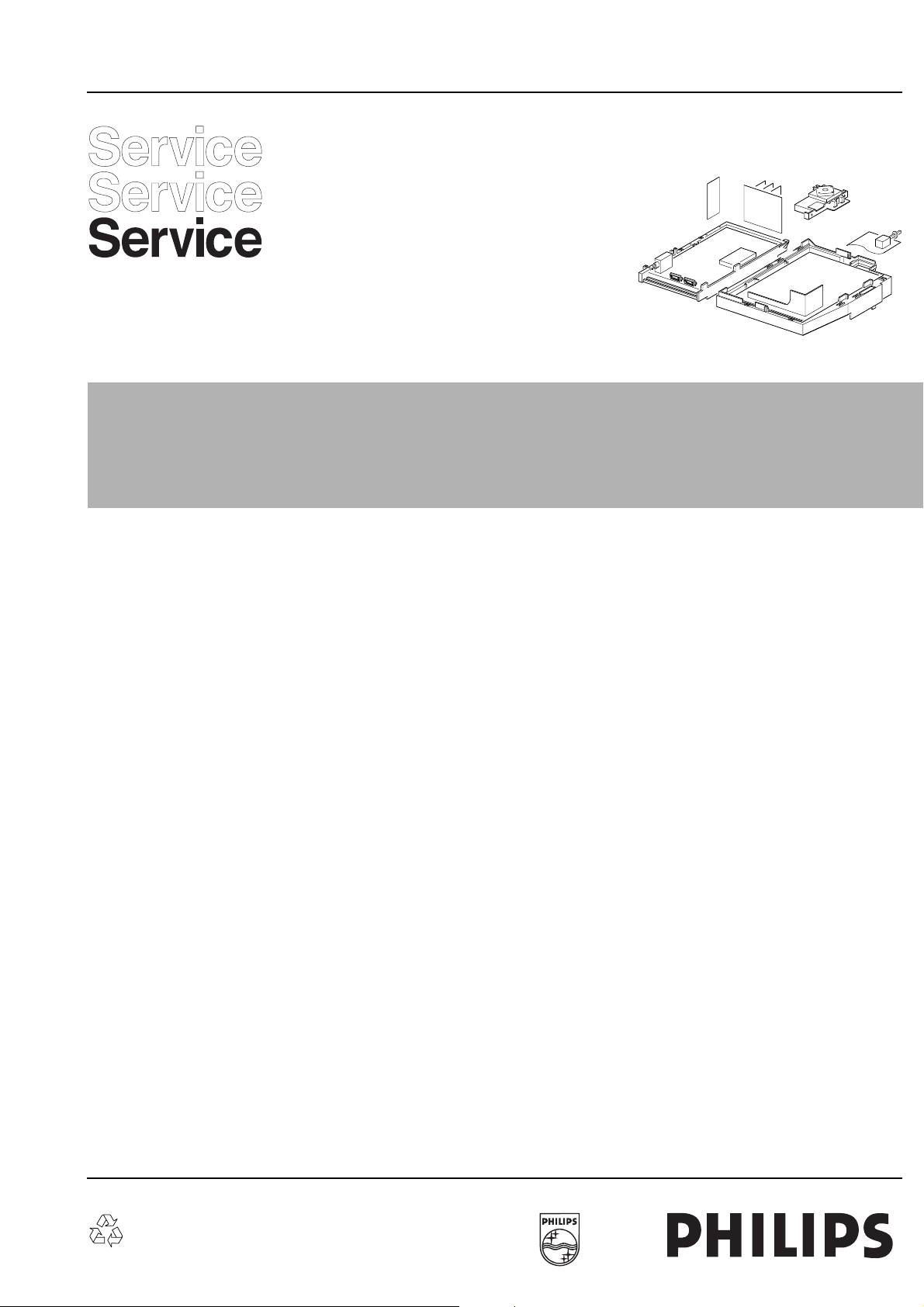

2.1 Front connections

TOP CONTROL FL7/FL8

STYLING

SK 1

'IR-

RECEIVER'

'IR-SERVICE-LED'

AUTO TV

SENSOR

(OPTIONAL)

BICOLOUR

STANDBY LED

CL 86532057_top.AI

Figure 2-1

2.1.1 Audio/Video

- Video 1Vpp/75Ω jq

- Audio L(0.5Vrms ≥10kΩ) jq

- Audio R(0.5Vrms ≥10kΩ) jq

- Headpho

ne (32-600Ω≥10mW) ot

2.1.2 SVHS

1- v

2- v

3- Y (1Vpp; 75Ω) j

4- C (0.3 Vpp;75Ω) j

AUDIO R

AUDIO L

VIDEO

SVHS

310798

5- Blue v

6- Audio L (0.5Vrms ≥10kΩ) j

7- Blue (0.7Vpp/75Ω) j

8- CVBS-

status 0-1.3V:INT

4.5-7V:EXT 16:9

3.5

9.5-12V:EXT 4:3 j

9- Green v

1011- Green (0.7Vpp/75Ω) j

1213- Red v

14- RGB-

status v

15- Red (0.7Vpp/75Ω) j

16- RGB-

status 0-0.4V:INT

1-3V:EXT/75Ω

17- CVBS v

18- CVBS v

19- CVBS (1Vpp/75Ω) k

20- CVBS (1Vpp/75Ω) j

21- Earth

socket

2.2.2 External 2 (in/out): SVHS+RGB+CVBS (intended for VCR.)

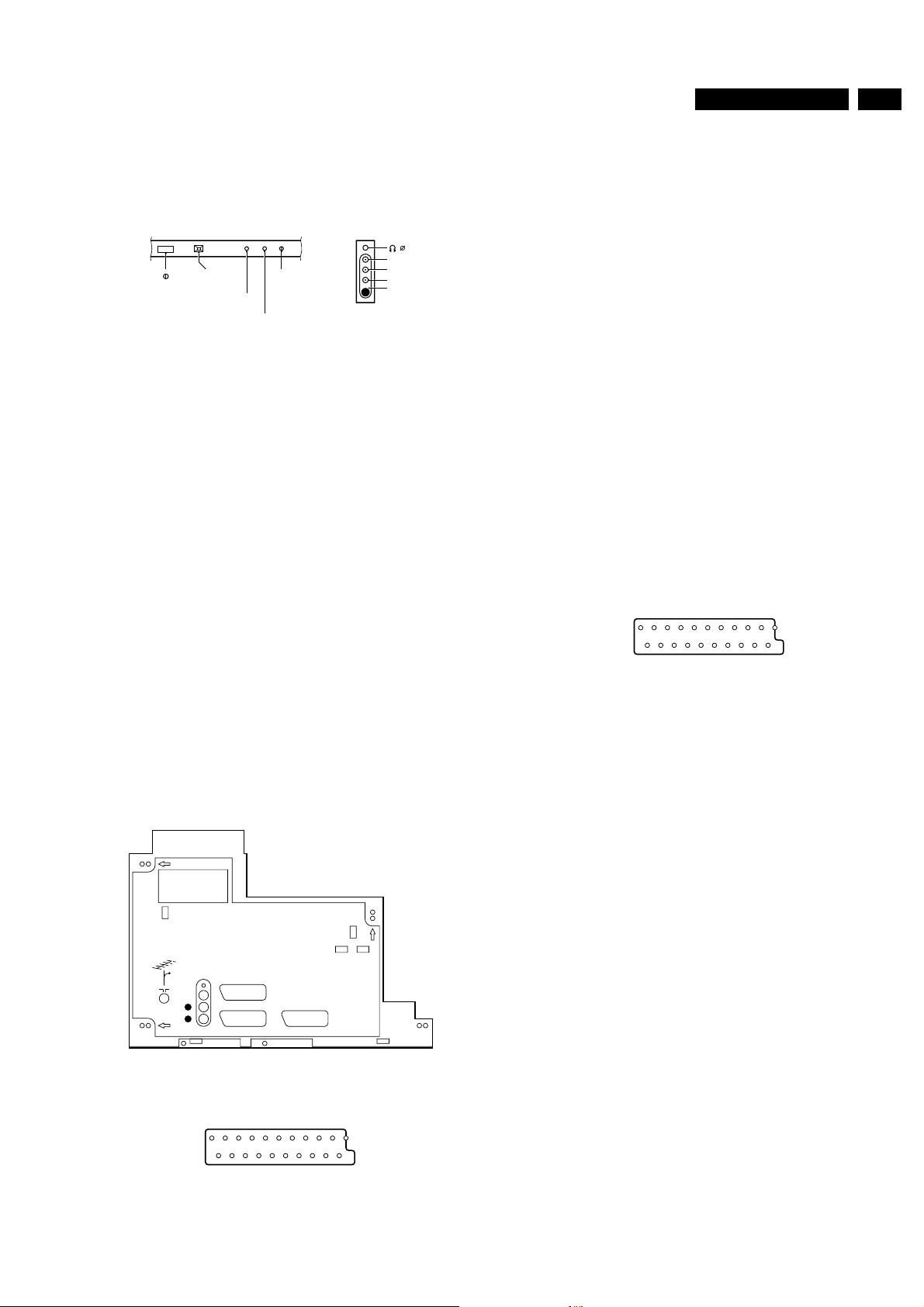

2.2 Rear connections

See figure 2.2

2.2.1 External 1(in/out): RGB+CVBS

EXTERNAL 3 (OPTIONAL)

L

R

AUDIO EXTERNAL 1

EXTERNAL 2

CL 86532057_rear.AI

Figure 2-2

1- Audio R (0.5Vrms ≤1kΩ) k

2- Audio R (0.5Vrms ≥10kΩ) j

3- Audio L (0.5Vrms ≤1kΩ) k

4- Audio v

310798

1- Audio R (0.5Vrms ≤1kΩ) k

2- Audio R (0.5Vrms ≥10kΩ) j

3- Audio L (0.5Vrms ≤1kΩ) k

4- Audio v

5- Blue v

6- Audio L (0.5Vrms ≥10kΩ) j

7- Blue /

Chroma

out (0.7Vpp/75Ω) j

8- CVBS-

status 0-1.3V:INT

4.5-7V:EXT 16:9

9.5-12V:EXT 4:3 j

9- Green v

10- Easy link

11- Green (0.7Vpp/75Ω) j

1213- Red v

14- RGB-

status v

15- Red /

chromain (0.7Vpp/75Ω) j

16- RGB-

status (0-0.4V:INT

1-3V:EXT/75Ω)

17- CVBS v

18- CVBS v

19- Y/CVBS (1Vpp/75Ω) k

20- Y/CVBS (1Vpp/75Ω) j

21- Earth

socket

4 MG2.1E

2 Specification connections

2.2.3 External 3 (in): CVBS+Audio (optional)

12- Audio R (0.5Vrms >10kΩ) j

34- Audio v

56- Audio L (0.5Vrms>10kΩ) j

78- CVBS-

status 0-1.3V:INT

CRT/SCAVEM PANEL

F

SIDE I/O PANEL

O

SHIELDING

SMALL SIGNAL PANEL

K

4.5-7V:EXT 16:9

9.5-12V:EXT 4:3 j

91011121314151617- CVBS v

18- CVBS v

1920- CVBS (1Vpp/75Ω) j

21- Earth

socket

TOP CONTROL PANEL

MAINSWITCH PANEL

P

E

Figure 2-3

LARGE SIGNAL PANEL

CL 86532057_002.eps

A

170798

3 Safety instructions, Maintenance instruction,

5MG2.1E

3 Safety instructions, Maintenance instruction, Warnings and Notes

3.1 Safety instructions for repairs

1. Safety regulations require that during a repair:

– the set should be connected to the mains via an

isolating transformer;

– safety components, indicated by the symbol ∆, should

be replaced by components identical to the original

ones;

– when replacing the CRT, safety goggles must be worn.

2. Safety regulations require that after a repair the set must

be returned in its original condition. In particular attention

should be paid to the following points. h

– As a strict precaution, we advise you to resolder the

solder joints through which the horizontal deflection

current is flowing, in particular: ('general repair

instruction')

• all pins of the line output transformer (LOT);

• fly-back capacitor(s);

• S-correction capacitor(s);

• line output transistor;

• pins of the connector with wires to the deflection

coil;

• other components through which the deflection

current flows.

– Note:

– This resoldering is advised to prevent bad

connections due to metal fatigue in solder joints

and is therefore only necessary for television sets

older than 2 years.

– The wire trees and EHT cable should be routed

correctly and fixed with the mounted cable clamps.

– The insulation of the mains lead should be checked for

external damage.

– The mains lead strain relief should be checked for its

function in order to avoid touching the CRT, hot

components or heat sinks.

– The electrical DC resistance between the mains plug

and the secondary side should be checked (only for

sets which have a mains isolated power supply). This

check can be done as follows:

• unplug the mains cord and connect a wirebetween

the two pins of the mains plug;

• set the mains switch to the on position (keep the

mains cord unplugged!);

• measure the resistance value between the pins of

the mains plug and the metal shielding of the tuner

or the aerial connection on the set. The reading

should be between 4.5 MΩ and 12 MΩ;

• switch off the TV and remove thewire between the

two pins of the mains plug.

– The cabinet should be checked for defects to avoid

touching of any inner parts by the customer.

3.2 Maintenance instruction

It is recommended to have a maintenance inspection carried

out by a qualified service employee. The interval depends on

the usage conditions:

– When the set is used under normal circumstances, for

example in a living room, the recommended interval is 3 to

5 years.

– When the set is used in circumstances with higher dust,

grease or moisture levels, for example in a kitchen, the

recommended interval is 1 year.

– The maintenanceinspection contains the followingactions:

• Execute the above mentioned 'general repair

instruction'.

• Clean the power supply and deflection circuitry on the

chassis.

• Clean the picture tube panel and the neck of the picture

tube.

3.3 Warnings

1. In order to prevent damage to ICs and transistors, all highvoltage flashovers must be avoided. In order to prevent

damage to the picture tube, the method shown in Fig. 3.1

should be used to discharge the picture tube. Use a highvoltageprobe and a multimeter (positionDC-V). Discharge

until the meter reading is 0V (after approx. 30s).

2. ESD All ICs and many other semiconductors are

susceptible to electrostatic discharges (ESD). Careless

handling during repair can reduce life drastically. When

repairing, make sure that you are connected withthe same

potential as the mass of the set by a wristband with

resistance. Keep components and tools also at this same

potential.

– Available ESD protection equipment:

– anti-static table mat (large 1200x650x1.25mm) 4822

466 10953

– anti-static table mat (small 600x650x1.25mm) 4822

466 10958

– anti-static wristband 4822 395 10223

– connection box (3 press stud connections, 1 M ohm)

4822 320 11307

– extension cable (2 m, 2 M ohm; to connect wristband

to connection box) 4822 320 11305

– connecting cable (3 m, 2 M ohm; to connect table mat

to connection box) 4822 320 11306

– earth cable (1 M ohm;to connect any productto mat or

connection box) 4822 320 11308

– complete kit ESD3 (combining all 6 prior products -

small table mat) 4822 310 10671

– wristband tester 4822 344 13999

3. Togetherwith the deflection unit and anymultipole unit, the

flat square picture tubes used from an integrated unit. The

deflection and the multipole units are set optimally at the

factory.Adjustmentofthisunit during repair is therefore not

recommended.

4. Be careful during measurements in the high-voltage

section and on the picture tube.

5. Never replace modules or other components while the unit

is switched on.

6. When making settings, use plastic rather than metal tools.

This will prevent any short circuits and the danger of a

circuit becoming unstable.

7. Wearsafety goggles during replacement ofthe picture tube

6 MG2.1E

a

3 Safety instructions, Maintenance instruction,

3.4 Notes

1. The direct voltages and oscillograms should be measured

with regard to the tuner earth , or hot earth as this is called

(see fig. 3.3)

2. The direct voltages and oscillograms shown in the

diagrams are indicative and should be measured in the

Service Default Mode (see chapter 8) with a colour bar

signal and stereo sound (L:3 kHz, R:1 kHz unless stated

otherwise) and picture carrier at 475.25 MHz.

3. Wherenecessary, the oscillograms and directvoltages are

measured with and without aerial signal. Voltages in the

power supply section are measured both for normal

operation and in standby . These values are indicated by

means of the appropriate symbols (see fig. 3.3).

4. The picture tube PWB has printed spark gaps. Each spark

gap is connected between an electrode of the picture tube

and the Aquadag coating.

5. The semiconductors indicated in the circuit diagram and in

the parts lists are completely interchangeable per position

with the semiconductors in the unit, irrespective of the type

indication on these semiconductors.

6. Manufactured under license from Dolby Laboratories

Licensing Corporation.

7. DOLBY, the double D symbol and PRO LOGIC are

trademarks of Dolby Laboratories Licensing Corporation.

V

tuner earth

tuner aarde

la masse du tuner

Tuner-Erde

massa del tuner

tierra del sintonizador

with aerial signal

met antenne signaal

avec signal d'antenne

mit Antennensignal

con segnale d'antenna

con la señal de antena

normal condition

normaal bedrijf

fonctionnement normal

normaler Betrieb

funzionamento normale

funcionamiento normal

Figure 3-1

massa calda

zonder antenne signaal

CL 26532098/042

140792

hot earth

hete aarde

la terre directe

heißen Erde

tierra caliente

without aerial signal

sans signal d'antenne

.ohne Antennensignal

senza segnale d'antenn

sin la señal de antena

stand by

stand by

position de veille

in Bereitschaft

modo di attesa

posición de espera

Figure 3-2

4 Mechanical instructions

4 Mechanical instructions

4.1 Removing the rear cover

AA

A

A

A

A

A A AA'

or

A

Figure 4-1

1. Remove the fixation screws (A) of the rear cover, notice

also the screw for the side-I/O,see figure 4.1. The screw A

is only valid for the 3-scart configuration.

2. Remove the rear cover.

4.2 Service positions

There are two predefined service positions:

1. Service position for the top side (component-side)

2. Service position for the bottom side (only valid for LSP)

(copper-side)

or oror

A

CL 86532042_001.AI

160798

7MG2.1E

Side I/O assembly

SSP - bracket

LSP - topbracket

A

2

2

LSP - bracket

1

1

Bottom tray

CL 86532042_002.AI

240798

Figure 4-3

1. Remove 1 screw in case of a 2-scart I/O coverplate and 2

screws in case of a 3-scart I/O coverplate (see figure 4.2).

2. Remove the I/O coverplate by releasing the snapat the left

side.PulltheI/Ocover plate to the left and then backwards.

The I/O-bracket hinges at the right side. It can be removed

now.

3. Pull backwards (about 8 cm) the bracket with the SSP and

the LSP. These brackets are not fixed to each other, but

can be repositioned backwards, as if they were one

bracket.

4. Hook the brackets in the first row of fixation-holes of the

bottom tray; see figure 4.3. In other words re-position the

fixation from (1) to (2).

4.2.2 Service position bottom side (only for LSP)

4.2.1 Service position top side

Figure 4-2

CL 86532042_003.ai

090698

Figure 4-4

CL 86532042_005.ai

090698

8 MG2.1E

1

4 Mechanical instructions

2. Press the board upwards and remove the board from the

bracket.

4.6 Removing the top control board

Top control board

2

Figure 4-5

1. Referring to previous Service position one must remove

the SSP and LSP from bottom tray by pulling back these

two panels.

2. Disconnect the SSP from the LSP bracket.

3. The two panels must be shifted some 25 cm to the right.

When doing this the side-assembly canbe taken out of the

hinge (see figure 4.4), and placed on the bottom tray.

4. Either the LSP-topbracket must be removed first, or the

cabling from SSP to LSP (0310 and O311) must be rerouted outside the LSP-topbracket to get room to position

these panels.

5. TurntheLSP 90 degrees anti clock wise and placethe LSP

in the hole of the bottom tray. If needed a screw can

reinforce the stability of this position (see figure 4.5) (see

(2)).

6. The left front hook of the SSP panel can be fixed in a

fixation-hole, that was used in previous service-position for

the right front hook of the SSP. See described movementaction (1). (There is no right fixation hole.)

4.2.3 (Service position bottom side SSP)

1. (See figure 4.3). Remove the two fixation screws of the

LSP-topbracket (one on the left handside, one on the right

hand side).

2. Disconnect wirings from cable-clamps of LSP-topbracket.

3. In case the line transformer is changed by a bigger type a

part of the LSP-topbracket can be removed by breaking it.

CL 86532042_004.AI

240798

CL 86532042_006.ai

160798

Figure 4-6

1. See figure 4.6. Pull 2 clamps to the outer side.

2. Topcontrolboardcan be pushed down now, while it hinges

still in the front.

3. Now the board can be pulled backwards.

4. (If by accident the hinge in front is damaged or one of the

clampsisbroken, the top control board can also befixed by

2 screws.)

4.7 Removing the side I/O board

1. The complete Side I/O-assembly can be lifted out of the

hinges and placed on the bottom tray of the set (see fig

4.4).

2. The board can easily be removed out of the bracket by

releasing the fixation clamps.

4.8 Removing the mains switch/LED board

1. Release the two fixation clamps.

2. Pull the board backwards.

4.3 Removing the LSP-top bracket

1. (See figure 4.3). Remove the two fixation screws of the

LSP-topbracket (one on the left handside, one on the right

hand side).

2. Disconnect wirings from cable-clamps of LSP-topbracket.

3. In case the line transformer is changed by a bigger type a

part of the LSP-topbracket can be removed by breaking it.

4.4 Removing the SSP from SSP-bracket

1. Release the three fixation clamps on the right hand side of

the bracket.

2. Press the board upwards and remove the board from the

bracket.

4.5 Removing the LSP from LSP-bracket

1. Release the two fixation clamps on the right hand side of

the bracket.

(4)

(6)

(5)

(5)

(4)

86532093_002.AI

051198

Figure 4-7

4.9 Mounting the rear cover

Before mounting the rear cover, check whether the mains cord

is mounted correctly in the guiding brackets.

5 Service modes, error codes and protections

5 Service modes, error codes and protections

In this chapter the following paragraphs are included:

5.1 Test points

5.2 Service modes and Dealer Service Tool and ComPair

(including fault finding tips related to CSM-mode)

5.3 Error codes

5.4 Protections

Fault find tree

5.1 Test points

– Tuning frequency 475.25 MHz.

– TV-system for BGLM sets set to BG, for BGLL'I sets to LL'.

– All picture settings at 50% (brightness, colour, contrast,

HUE).

– All sound settings at 50% except volume at 25% (so bass,

treble, balance at 50%, volume at 25%).

– All service-unfriendly modes are disabled (like sleep timer,

child lock, blue mute).

Entering the SDM can be done in 2 ways:

9MG2.1E

The MG2.1E chassis is equipped with test points in the service

printing. These test points are referring to the functional blocks:

• P1-P2-P3, etc.: Test points for the power supply.

• L1-L2-L3, etc.: Test points for the line drive and line output

circuitry.

• F1K-F2K-F3K, etc on Small Signal Panel: Test points for

the frame drive.

• F1F-F2F-F3F, etc. on CRT/Scavem Panel: Test points for

the CRT-panel circuitry.

• F1-F2-F3, etc. on Large SmallSignalPanel: Test points for

the frame output circuitry.

• S1-S2-S3, etc: Test points for the synchronisation

circuitry.

• V1-V2-V3, etc: Test points for the video processing

circuitry.

• I1-I2-I3, etc: Test points for the Tuner/IF part.

• A1-A2-A3, etc. on Small Signal Panel: Test points for the

audio processing circuitry.

• A1-A2-A3, etc. on Large Signal Panel: Test points for the

audio amplifiers.

• C1-C2-C3, etc: Test points for the control circuitry.

• T1-T2-T3, etc: Testpoints for the teletext circuitry.

• SC1-SC2-SC3, etc: Test points for the Scavem circuitry.

The numbering is done in a for diagnostics logical sequence;

always start diagnosing within a functional block in the

sequence of the relevant test points for that functional block.

5.2 Service modes, Dealer Service Tool and ComPair

For easy installation and diagnosis the dealer remote control

RC7150 is introduced. The RC7150can be used for allnew TV

sets, including all set of the MG2.1E chassis. The RC7150 is

also called Dealer Service Tool or DST. The ordering number

of the DST (RC7150) is 4822 218 21232.

5.2.1 Installation features for the dealer

The dealer can use the RC7150 for programming the TV-set

with presets. 10 Different program tables can be programmed

into the DST via a TV-set (downloading from the GFL, MD2 or

MG2.1 to the DST; see GFL, MD2 and MG2.1 service

manuals) or by the DST-I (DST interface; ordering code 4822

218 21277).

For explanation of the installation features of the DST, the

directions for use of the DST (4822 727 20073) are

recommended (for the MG2.1E chassis, download code 4

should be used).

5.2.2 Diagnose features for the servicer

The MG2.1E sets can be put in the two service modes via the

DST RC7150. These are the Service Default Mode (SDM) and

the Service Alignment Mode (SAM). The SDM and SAM can

also be entered by shortcircuiting the relevant pins onthe SSP.

Service Default Mode (SDM)

Specification of the SDM:

– By the "DEFAULT" key on the DST while the set is in the

normal operation mode.

– By short-circuiting for a moment the two pins (pin 2 and 3

of connector 0356) on the component side of the SSP with

the indication "SDM" (activation can be performed in all

modes except when the set has a problem with the mainprocessor).

Note: If the SDM is entered via the pins, all the protections are

de-activated.

Exiting the SDM can only be done via the STANDBY

command.By switching off-on the set with themains switchthe

MG2.1E will come up again in the SDM.

Service Alignment Mode (SAM)

Specification of the SAM:

– Software alignments (see chapter 8).

– Option settings (see chapter 8).

– Error buffer reading and erasing. The most recent error

code is displayed on the left side.

– Operation counter.

– Software version.

Entering the SAM can be done in 2 ways:

– By the > button on the DST while the set is in the normal

operation mode (or SDM). Enter the password '3-1-4-0'

and press OK.

– By short-circuiting for a moment the two pins (pin 1 and 2

of connector 0356) on the component side of the SSP with

the indication "SAM" (activation can be performed in all

modes except when the set has a problem with the

microprocessor).

Note: If the SAM is entered via the pins, all protections are deactivated.

Exiting the SAM can be done via the MENU command or via

switching off-on the set with the mains switch.

Customer Service Mode (CSM)

All MG2.1E sets are equipped with the 'Customer Service

Mode' (CSM). This 'Customer Service Mode' is a special

service mode which can be activated and deactivated by the

customer upon request of the service technician/dealer during

a telephone conversation in order to identify the status of the

set. This CSM is a 'read only' mode, therefore modifications in

this mode are not possible.

Switching-on of the Customer Service Mode

The Customer Service Mode will switch-on after pressing

simultaneously the "MUTE" knob on the remote control

handset and the "MENU" button on the TV for at least 4

seconds. This activation only works if there is no menu on the

screen.

Switching-off the Customer Service Mode

The Customer Service Mode will switch-off after pressing any

key of the remote control handset (with exception of the

10 MG2.1E

5 Service modes, error codes and protections

"cursor-up" and "cursor-down" keys), or the buttons on the TV

or by switching off the TV set with the mains switch.

Detailed explanation of the Customer service Mode

After switching on the Customer Service Menu the following

screen will appear:

CUSTOMER SERVICE MENU 1

1 SW Version

2 Code 1

3 Code 2

4 LS Volume

5 LS Brightness

6 LS Contrast

7 LS Colour

8 LS Headphone

9 Sharpness

10 Dolby

11 Surround mode

............

... ... ... ... ...

... ... ... ... ...

..

..

..

..

..

.

.....

............

86532061_004.AI

230798

Figure 5-1 Customer Service Menu 1

Line 1: Software version; the build in software version

(AAAABCX.Y)

– AAAA= MG21(chassis name)

– B = E (Europe)

– C = 1 (language cluster)

– X = main version number

– Y = sub version number

Details on the software version can be found in the chapter

"Software Survey" of the publication "Product Survey - Colour

Television".

Line 2: Code 1; gives the last 5 errors of the error buffer. As

soon as the built-in diagnose software has detected an error

the buffer is adapted.

Line 3: Code 2; gives the first 5 errors of the error buffer. As

soon as the built-in diagnose software has detected an error

the buffer is adapted.

control handset after pressing the red button for picture menu

and selecting "contrast".

Line 7: LS Colour; gives the Last Status of the colour

saturation, as set by the customer. The value can vary from 0

(colour is minimum) to 63 (colour is maximum). Colour values

can be changed via "cursor left" and "cursor right" keys on the

remote control handset after pressing the redbutton for picture

menu and selecting "colour".

Line 8: LS Headphone; gives the Last Status of the headphone

volume, as set by the customer. The value can vary from 0

(volume is minimum) to 24 (volume is maximum). Headphone

volume values can be changed via the "cursor left"and "cursor

right" keys on the remote control handset after pressing the

green button for sound menu and selecting "headphone".

Line 9: Sharpness; gives the sharpness value. The value can

vary from 0 (sharpness is minimum) to 7 (sharpness is

maximum). In case of bad antenna signals a too high value of

the sharpness can result in a noisy picture. Sharpness values

can be changed via the "cursor left" and "cursor right" keys on

the remote control handset after pressing the red button for

picture menu and selecting "sharpness".

Line 10: Dolby; indicates whether the received transmitter

transmits Dolby sound (present) or not (not present). Attention:

The presence of Dolby can only be tested by the software on

the Dolby Signalling bit. If a Dolby transmission is therefore

received without a Dolby Signalling bit, then this indicator will

show "not present" even though such a Dolby transmission is

received.

Line 11: Surround Mode; indicates the by the customer

selected surround mode. In case the set is a Non-Dolby set

there will be displayed "0". If it is a Dolby-set then is displayed:

"Pro Logic", "Dolby 3 Stereo", "Hall" or "Off". For Dolby-set

surroundmodecanbe changed via the "cursor left" and "cursor

right" keys on the remote control handset after pressing the

green button for sound menu and selecting "Surround

settings".

By means of the "cursor-down" knob on the remote control

handset the Customer Service Menu 2 will appear. By means

of the "cursor-up" knob on the remote control handset the

Customer Service Menu 1 will appear again.

The last occurred error is displayed on the leftmost position of

code2. Each error code is displayedasa 3 digit number. When

less than 10 errors occur, the rest of the line(s) is(are) empty.

In case of no errors the text "No Errors" is displayed. See

paragraph 5.3 of this chapter for a description of the error

codes.

Line 4: LS Volume; gives the Last Status of the volume as set

by the customer for this selected transmitter. The value can

vary from 0 (volume is minimum) to 24 (volume is maximum).

Volume values can be changed via the volume key on the

remote control handset.

Line 5: LS Brightness; gives the Last Status of the brightness

as set by the customer for this selected transmitter. The value

can vary from 0 (brightness is minimum) to 63 (brightness is

maximum). Brightness values can be changed via the "cursor

left" and "cursor right" keys on theremote control handset after

pressing the red button for picture menu and selecting

"brightness".

Line 6: LS Contrast; gives the Last Statusof the contrast as set

by the customer. The value can vary from 0 (contrast is

minimum) to 63 (contrast is maximum). Contrast valuescan be

changed via "cursor left" and "cursor right" keys on the remote

Customer Service Menu 2 represents following information:

CUSTOMER SERVICE MENU 2

12 Rear Volume

13 Centre Volume

14 DNR

15 Noise Figure

16 Digital option

17 Colour System

18 TV System

19 Audio System

20 Tuned bit

21 Speaker config.

22 DVD

.

.

...

.

......

.....

.....

.....

.....

............

............

86532061_005.AI

230798

Figure 5-2 Customer Service Menu 2

Line 12: Rear Volume; gives the volume value of the surround

sound loudspeakers. This value can vary from 0 (minimum

volume) to 63 (maximum volume). Rear volume can be

changed via the "cursor left" and "cursor right" keys on the

remote control handset after pressing the green button for

5 Service modes, error codes and protections

11MG2.1E

soundmenu,selecting "Surround settings" and selecting "Rear

volume". This feature is only available when surround mode is

in "Dolby Pro Logic" or "Hall".

Line 13: Centre Volume; gives the volume value of the centre

loudspeakers. This value can varyfrom 0 (minimum volume) to

63 (maximum volume). Centre volume can bechanged via the

"cursor left" and "cursor right" keys on the remote control

handset after pressing the green button for sound menu,

selecting 'Dolby Pro Logic' and selecting "centre volume". This

feature is only available when surround mode is in "Dolby Pro

Logic" or "Dolby 3 Stereo".

Line 14: DNR (Dynamic Noise Reduction); gives the setting of

the DNR for the selected transmitter. The following selections

are possible:

• "off", "min", "med" or "max"

• "off" or "automatic" (MG2.1E with "Automatic Noise

Reduction").

The DNR can be changed via the "DNR" key on the remote

control handset.

Line 15: Noise Figure; gives the selected noise ratio for this

selected transmitter. This value can vary from 0 (good signal)

to127(averagesignal)and to 255 (bad signal). This only works

in case the DNR selection is "off/automatic".

Line 16: Digital Option; gives the selected digital mode,

"100Hz", Digital Scan" or "Natural Motion". Digital option can

be changed via the "cursor left" and "cursor right" keys on the

remote control handset after pressing the redbutton for picture

menu and selecting "digital options".

Line 17: Colour System; gives information about the colour

system of the selected transmitter.

– Black and white: No colour carrier received

– PAL: PAL signal received

– SECAM: SECAM signal received

– NTSC: NTSC signal received

Line 18: TV System; gives information about the video system

of the selected transmitter.

– BG: BG signal received

– DK: DK signal received

– I: PAL I signal received

– L: SECAM L signals received

– M38.9: NTSC M signal received with video carrier on 38.9

MHz

– MN: NTSC M signal received

Line 19: Audio System; gives information about the audio

system of the selected transmitter.

– Sound Muted: No sound

– Dolby Pro Logic: Dolby Pro Logic sound received

– Mono: Mono sound received

– Stereo: Stereo sound received

– Dual I: Language I received

– Dual II: Language II received

– Digital Mono: Digital mono sound is received

– Digital Stereo: Digital stereo sound is received

– Digital Dual I: Digital language I is received

– Digital Dual II: Digital language II is received

Line20: Tuned Bit; gives information about the tuning method

ofthe stored preset. Ifthe value is "Yes" thepreset is stored via

manual entry of the frequency when a transmitter was not

present on that frequency. In that case the TV will attempt to

perform a micro-search every time the preset number is

selected. Once the micro-search has been successful the

Tuned Bit will be set to "No".

Line 21: Speaker configuration; gives the configuration setting

for the speakers. In case the set is a Non-Dolby set there will

be displayed "0". If it is a Dolby-set then is displayed: "Full

internal", "L/R external", "Surround external" or "Full external".

For the Dolby-set the speaker configuration can be changed

via the "cursor left" and "cursor right" keys on the remote

control handset after opening the installation menu and

selecting "set-up". The installation menu can be opened by

pressing "timer" and "enlarge" at the same time. This feature is

only available when the set has virtual Dolby.

Line 22: DVD; gives theconfiguration setting for DVD. Thiscan

be "Present" or "Not Present". If "Present" is selected the

startingpointisatopqualitysignalandanumber of settings are

therefore changed automatically. DVD can be changed via the

"cursor left" and "cursor right" keys on the remote control

handset after opening the installation menu and selecting "setup". The installation menu can be opened by pressing "timer"

and "enlarge" at the same time.

Problems and solving tips

The procedures to change the value or the status of the

different settings is described in the paragraph 'Detailed

explanation of the Customer Service Mode'.

Picture problems

Worse picture quality in case of DVD pictures Check line 22

"DVD". In case line 22 gives the indication "Not Present"

change the setting into "Present".

Snowy/noisy picture

1. Check line 15 "Noise Figure". In case the value is 127 or

higher and the value is also high on other programs check

the aerial cable/aerial system.

2. Check lines 9 "Sharpness", 14 "DNR" and 15 "Noise

Figure". In case the value of line 9 is 3 or 4 and the value

of line 15 is high (127 or higher), lower the value of line 9

"sharpness" and switch DNR (line 14) to "automatic", "on"

or to a higher value.

Picture too dark

1. Press "Smart Picture" button on the Remote Control

handset. In case picture improves, raise the brightness

value or raise the contrast value. The new value(s) are

automatically stored for all TV channels.

2. After switching on the Customer Service Mode the picture

is OK. Raise the brightness value or raise the contrast

value. The new value(s) are automatically stored for all TV

channels.

3. Check lines 6 "LS Brightness" and 7 "LS Contrast". The

value of line 6is low (<10) or the value of line 7 islow ((10).

Raise the brightness value or raise the contrast value.

Picture too bright

1. Press "Smart Picture" button on the Remote Control

handset. In case picture improves, reduce the brightness

value or reduce the contrast value. The new value(s) are

automatically stored for all TV channels.

2. After switching on the Customer Service Mode the picture

is OK. Reduce the brightness value or reduce the contrast

value. The new value(s) are automatically stored for all TV

channels.

3. Check lines 6 "LS Brightness" and 7 "LS Contrast". The

value of line 6 is high (>40) or the value of line 7 is high

((50). Reduce the brightness value or raise the contrast

value.

12 MG2.1E

5 Service modes, error codes and protections

Fading picture

Digital scan effect. Check line 14 "DNR". The status of "DNR"

is 'med' or 'max'. Reduce "DNR" to 'min' or switch off the digital

scan.

White line around picture elements and text

1. Press "Smart Picture" button on the Remote Control

handset. In case picture improves, reduce the sharpness

value. The newvalue(s) are automatically storedfor all TV

channels.

2. After switching on the Customer Service Mode the picture

is OK. Reduce the sharpness value. The new value(s) are

automatically stored for all TV channels.

3. Check line 8 "Sharpness". Reduce the sharpness value.

The new value(s) are automatically stored for all TV

channels

Nopicture. Check line 20 "Tuned bit".In case the value is 'Yes',

install the required program again. Open the installation menu

bypressing "timer" and "enlarge" atthe same time and perform

manual installation.

Blue picture. No proper signal is received. Check the aerial

cable/aerial system.

Blue picture and/or unstable picture. A scrambled or decoded

signal is received.

Colours not correct/unstable picture. Check lines 17 "Colour

System" and 18 "TV System". In case line 17 is 'SECAM' and

line18is'BG',theinstalledsystem for this preset is 'USA', while

'France' is required. Install the required program again. Open

the installation menu by pressing "timer" and "enlarge" at the

same time and perform manual installation. Select 'System;

France'.

Unstable picture. Check lines 17 "Colour System" and 18 "TV

System". In case line 17 is 'SECAM' and line 18 is 'M 38,9', the

installed system for this preset is 'West Europe', while 'France'

is required. Install the required program again. Open the

installationmenu by pressing "timer" and"enlarge" at the same

time and perform manual installation. Select 'System; France'.

Menu text not sharp enough.

1. Press "Smart Picture" button on the Remote Control

handset. In case picture improves, reduce the contrast

value. The new value(s) are automatically stored for all TV

channels.

2. After switching on the Customer Service Mode the picture

is OK. Reduce the contrast value. The new value(s) are

automatically stored for all TV channels.

3. Check line 7 "LS Contrast". The value of line 7 is high

(>50). Reduce the contrast value.

Sound problems

No sound from left and right speaker.

Black and white picture. Check line 5 "LS colour". In case the

value is low ((10) raise the value of colour. The new value(s)

are automatically stored for all TV channels.

No colours/colour lines around picture elements.

1. Check lines 17 "Colour System" and 18 "TV System". In

case line 17 is 'PAL' and line 18 is 'M 38,9', the installed

system for this preset is 'USA', while 'West Europe' is

required. Install the required program again. Open the

installation menu by pressing "timer" and "enlarge" at the

same time and perform manual installation. Select

'System; West Europe'.

2. In case line 17 is 'PAL' and line 18 is 'L', the installed

system for this preset is 'France', while 'West Europe' is

required. Install the required program again. Open the

installation menu by pressing "timer" and "enlarge" at the

same time and perform manual installation. Select

'System; West Europe'.

No colours/noise in picture

1. Check lines 17 "Colour System" and 18 "TV System". In

case line 17 is 'Black and White' and line 18 is 'BG', the

installed system for this preset is 'West Europe', while

'USA' is required. Install the required program again. Open

the installation menu by pressing "timer" and "enlarge" at

the same time and perform manual installation. Select

'System; USA'.

2. In case line 17 is 'Black and White' and line 18 is 'L', the

installed system for this preset is 'France', while 'USA' is

required. Install the required program again. Open the

installation menu by pressing "timer" and "enlarge" at the

same time and perform manual installation. Select

'System; USA'

Colours not correct. Check lines 17 "Colour System" and 18

"TV System". In case line 17 is 'PAL' and line 18 is 'L', the

installed system for this preset is 'France', while 'West Europe'

is required. Install the required program again. Open the

installationmenu by pressing "timer" and"enlarge" at the same

time and perform manual installation. Select 'System; West

Europe'.

1. Press "Smart Sound" button on the Remote Control

handset. In case sound improves, raise the volume value.

The new value(s) are automatically stored for all TV

channels.

2. After switching on the Customer Service Mode the volume

is OK. Raise the volume value. The new value(s) are

automatically stored for all TV channels.

3. Check line 4 "LS Volume". The value is low. Raise the

value of "Volume". The new value(s) are automatically

stored for all TV channels.

Sound too loud for left and right speaker.

1. Press "Smart Sound" button on the Remote Control

handset. In case sound improves, reduce the volume

value. The new value(s) are automatically stored for all TV

channels.

2. After switching on the Customer Service Mode the volume

is OK. Reduce the volume value. The new value(s) are

automatically stored for all TV channels.

3. Check line 4 "LS Volume". The value is high. Reduce the

value of "LS Volume". The new value(s) are automatically

stored for all TV channels.

No sound from "centre" speaker. Check line 12 "Centre

Volume". The value is low. Raise the value of the "Centre

Volume"

Sound too loud from "centre" speaker. Check line 12 "Centre

Volume". The value is high. Reduce the value of the "Centre

Volume"

Diagnose Mode (only active during transmission of error

codes and diagnose 99)

This mode is activated by the DIAGNOSE command on the

DST for reading the error codes and erasing the error buffer by

the DST even when the set is in protection and so there is no

picture (assuming that the power supply and the control part

are working). For activation see paragraph 5.3. The diagnose

Mode is only a temporarily mode (the set will go back to the

previous mode), and can not be switched on permanently.

5 Service modes, error codes and protections

13MG2.1E

Note: The diagnose mode can not be entered if the SAM is

activated.

Compair

ComPair (Computer Aided Repair) is a service tool for Philips

Consumer Electronics products. ComPair is a further

developmenton the DST service remote control allowingfaster

and more accurate diagnostics. ComPair has three big

advantages:

• ComPair helps you to quickly get an understanding how to

repairthe MG2.1E in short time byguiding youstepby step

through the repair procedures.

• ComPair allows very detailed diagnostics (on I2Clevel)and

is therefore capable of accurately indicating problem

areas. You do not have to know anything about I2C

commands yourself; ComPair takes care of this.

• ComPair speeds up the repair time since it can

automatically communicate with the MG2.1E (when the

micro processor is working) and all repair information is

directly available. When ComPair is installed together with

the SearchMan MG2.1E electronic manual, schematics

and PCBs are only a mouse-click away.

ComPair consists of a Windows based fault finding program

and an interface box between PC and the (defective) product.

The ComPair interface box is connected to the PC via a serial

or RS232 cable. In case of the MG2.1E chassis, the ComPair

interface box and the television communicate with each other

via bi-directional infrared signal.

Automatic information gathering

Step-by-step start up. Under normal circumstances, a fault in

the power supply or an error during start-up will switch the

television to protection-mode. ComPair can take over the

initialisation of the television. In this way it is possible to

distinguish which part of the start-up routine (hence which

circuitry) is causing the problem.

Reading out the error buffer, ComPair can automatically read

out the contents of the entire error buffer.

Diagnosis on I2C level. ComPair can access the I2C bus of the

television without a physical connection. ComPair can send

and receive infrared commands to the micro controller of the

television. These commands are translated by the controller to

I2C commands and vice versa. In this way it is possible for

ComPairto communicate (read and write) to devices onthe I2C

busses of the MG2.1E.

Manual information gathering

Automatic diagnosis is only possible if the micro controller of

the television is working correctly and only to a certain extend.

When this is not the case, ComPair will guide you through the

fault finding tree by asking you questions and showing you

examples. You can answer by clicking on a link (e.g. text or an

oscillogram) that will bring you to the next step in the

faultfinding process.

A question could be: Do you see snow? (Click on the correct

answer)

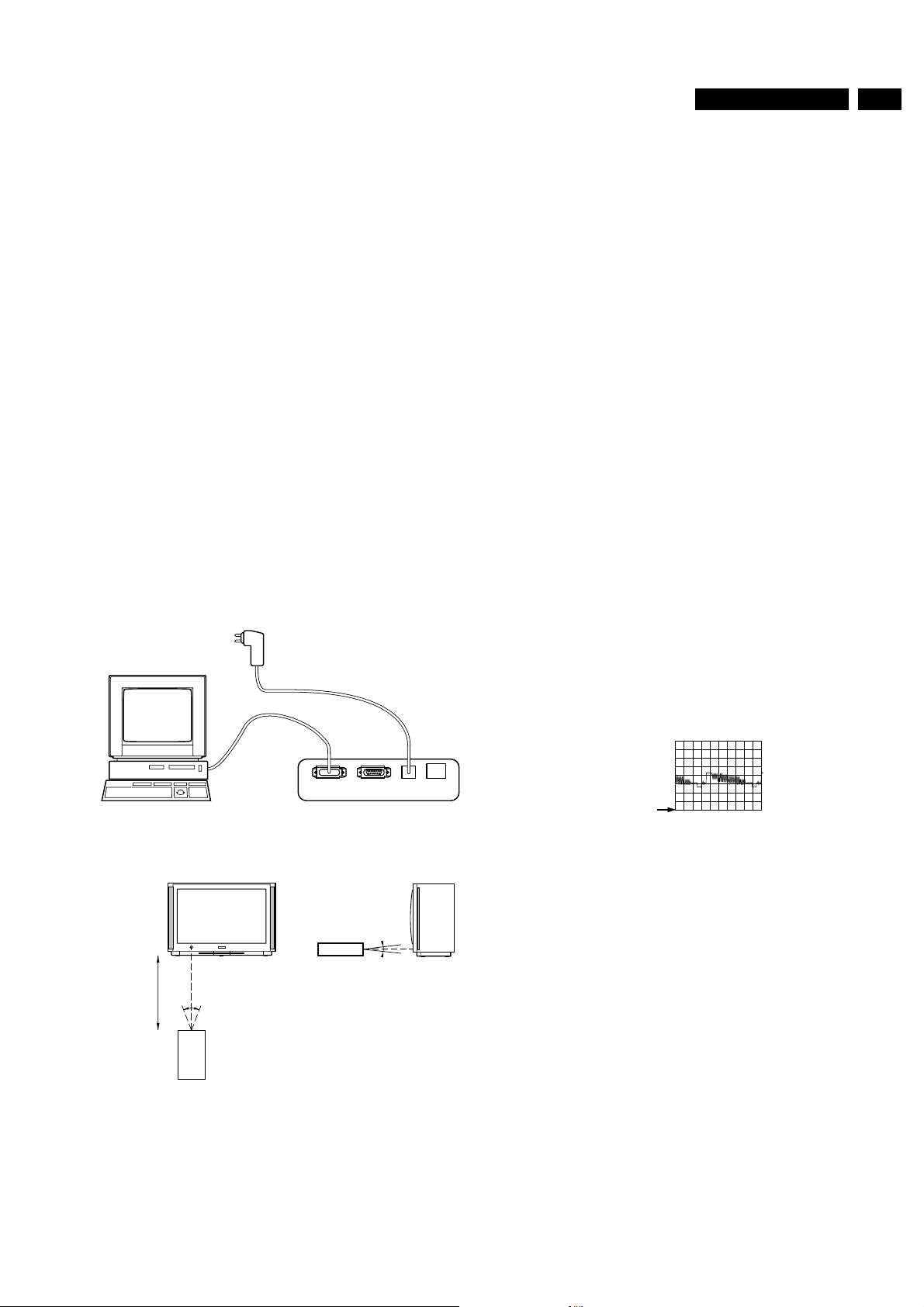

PC VCR I2CPower

9V DC

86532027_003.EPS

Figure 5-3

o

10

0.3-0.6m

20

o

86532027_002.EPS

Figure 5-4

The ComPair fault finding program is able to determine the

problem of the defective television. ComPair can gather

diagnostic information in 2 ways:

1. Communication to the television (automatic)

2. Asking questions to you (manually)

ComPair combines this information with the repair information

in its database to find out how to repair the MG2.1E.

050898

050898

YES / NO

An example can be: Measure testpoint I7 and click on the

correct oscillogram you see on the oscilloscope

I7 B7502

1V / div DC

10µs / div

Figure 5-5

By a combination of automatic diagnostics and an interactive

question/answer procedure, ComPair will enable you to find

most problems in a fast and effective way.

Additional features

Beside fault finding, ComPair provides some additional

features like:

• Uploading/downloading of presets

• Managing of preset lists

• Emulation of the Dealer Service Tool

SearchMan (electronic service manual)

When ComPair is installed in combination with SearchMan, all

schematics and PCBs will be directly available whileyou repair

a television if you click on a PCB or schematic link.

Example: Measure the DC voltage on C2568 (PCB/schematic)

on the small signal level.

Clicking on PCB will automatically pop-up a picture of the PCB

with the location of C2568 marked. Clicking on schematic will

14 MG2.1E

5 Service modes, error codes and protections

automatically pop-up the schematic with the location of C2568

marked.

Stepwise Startup /Shutdown feature of set can be used via

Compair

Stepwise startup explanation

Via ComPair the stepwise startup (see also chapter 4) can be

realised. This is very helpful when a protection is activated.

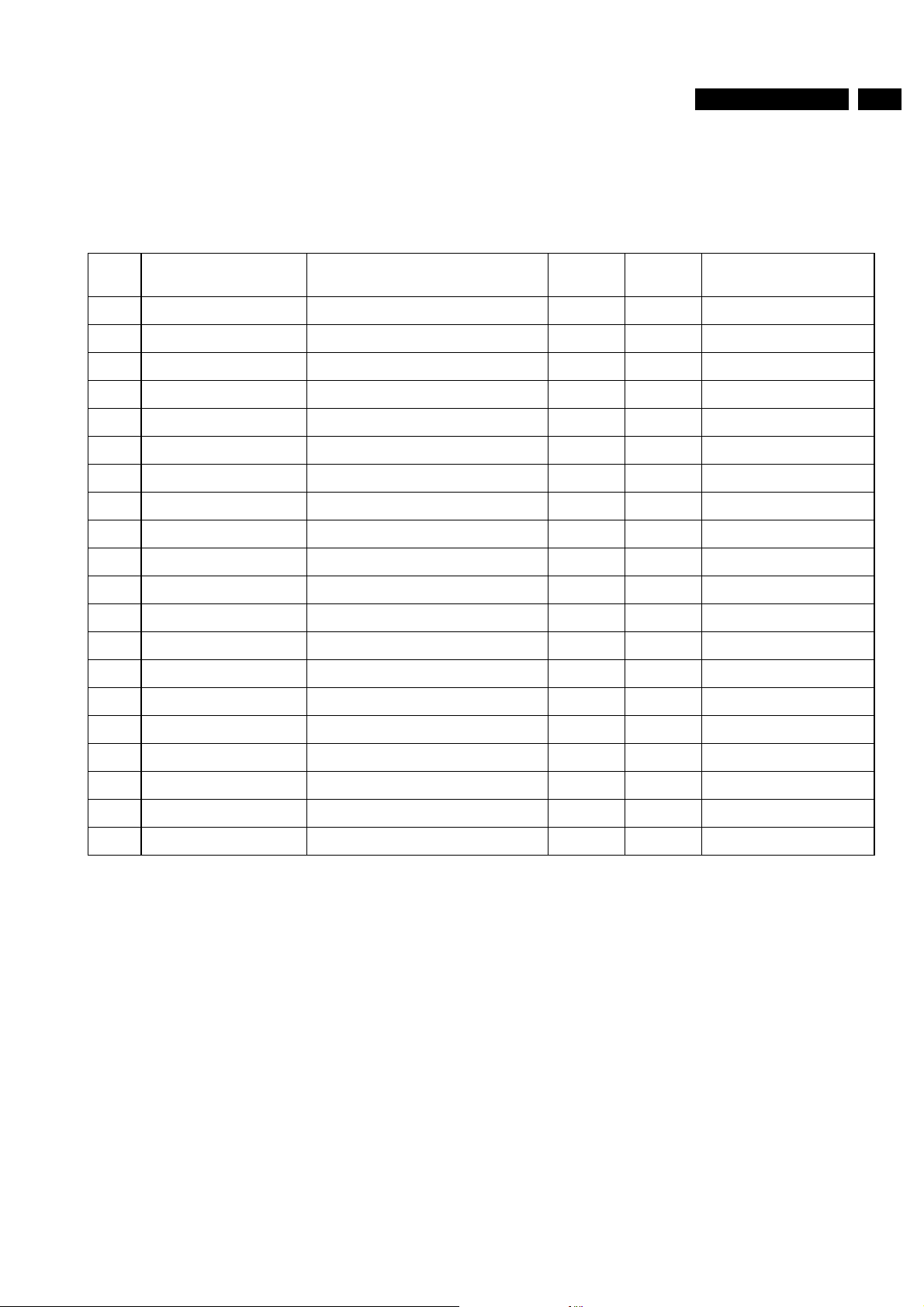

State Description mode Display leds Errorcode possible

0 Low Power Standby/uC in Stby Red on None

1 High Power Standby/set in Stby Red 0.5Hz None

2 Supply on. Protections 5V2, 8V6, DC-Prot activated. Orange/Green 0.25 Hz 67,68,76

3 ICs initialized. (Sound) Protection 3V3 activated Orange/Green 0.5 Hz plus 77

4 EHT startup. No blackcurrent stabilisation. Protections VFB,

HFB, LDP, BC-prot activated (blanked picture)

5 TV operates, unblanked picture Orange/Green 10 Hz

Stepwise shutdown explanation

In the stepwise shutdown mode, state 2 is skipped. (ICs can

not be de-initialised).

State Description mode Display leds (Note *) Prot. de-activated

Orange/Green 2 Hz plus 70,71,73,74

5 TV operates, unblanked picture Orange/Green 10 Hz 4 No blackcurrent stabilisation (no picture) Orange/Green 2 Hz 3 ICs stay initialised. (Sound) All protections are off Orange/Green 0.5 Hz 74,73,71,70

1 High Power Standby/set in Stby Red 0.5Hz 77,76,68,67

0 Low Power Standby/uC in Stby Red on -

Note: When set is in stepwise-mode and due to stepping-up a

protection is activated, the set really will go into protection

(blinking red led). The set will not leave the stepwise-mode

however. By stepping up the set can be activated again, until

state X, where protection was activated. At state (X-1)

diagnostic measurements can be performed.

5.3 Error codes

5.3.1 Reading error codes from the error buffer

The error buffer can be read in 2 ways:

1. On the screen via the Service Alignment Mode (SAM). In

case picture is OK, the error buffer can be read the easiest

via the SAM. In the main menu of the SAM the last 10

different error codes occurred are displayed. The most

recent detected error code is displayed on the left side, so

e.g.: 0 0 0 0 0means no error codes present in the buffer

3 0 0 0 0means one error code present in the buffer; error

code 3 2 3 0 0 0 means two error codes present in the

buffer; error code 2 is the most recent, error code 3 is

detected before 2

2. On the display of the DST. If anerror has been detected by

the MG2.1E chassis, the set might go into protection.

Without the presence ofa picture the errorscan be read by

the DST, as long as the main-processor is still active

(green LED continuous and red LED blinking fast (5Hz); in

case of red LED is blinking slow (1,25Hz) there is a mainprocessor problem). To transmit the errors from the TV to

the DST:

5.3.2 Clearing the error buffer

1. Press the "DIAGNOSE" key (in all modes except the

SAM)

2. Press "1" to view the last error detected.

3. Hold the DST 5 to 10 cm from in front of the stand-by

LED of the set (the IR-sending LED of MG2.1E is

located near the stand-by LED).

4. Press the "OK" key.

Theerroris represented by a 2 digit number. The 2 digitson the

DST are displayed sequentially, with a pause before it is

repeated. The digit after the pause is the 1st digit. If thedisplay

reads 4 - 7, the error code is 47. To read other error codes,

press "DIAGNOSE" and one of the other digit keys. Note:

– If the DST cannot communicate to the MG2.1E in a proper

way, ERROR 2 is shown in the display of the DST. Trying

again by changing the DST position a little bit might often

help.

– If the error buffer of MG2.1E is empty, no errors are

displayed by the DST; the display remains blank.

The error buffer can be cleared in 2 ways:

1. Inthe SAM by selecting the itemRESET ERROR BUFFER

in the main menu.

2. Bythe "DIAGNOSE 99" command ofthe DST (in all modes

except the SAM). Press the DIAGNOSE key on the DST,

followed by 9 and 9 and then >.

Note: When error buffer is full (10 codes), no new error can be

stored anymore. However of every error raised is monitored

5 Service modes, error codes and protections

15MG2.1E

how long it exists in the error buffer. When for any reason a

false raised error exists in the buffer, it will be deleted after 50

hours. If this error still is actual after 50 hours, it will be raised

again. In this way is safeguarded that history of error codes is

stored. Sometimes it is an option to first write down the error

buffer content, reset the buffer, and look again which error

codes are generated by the set.

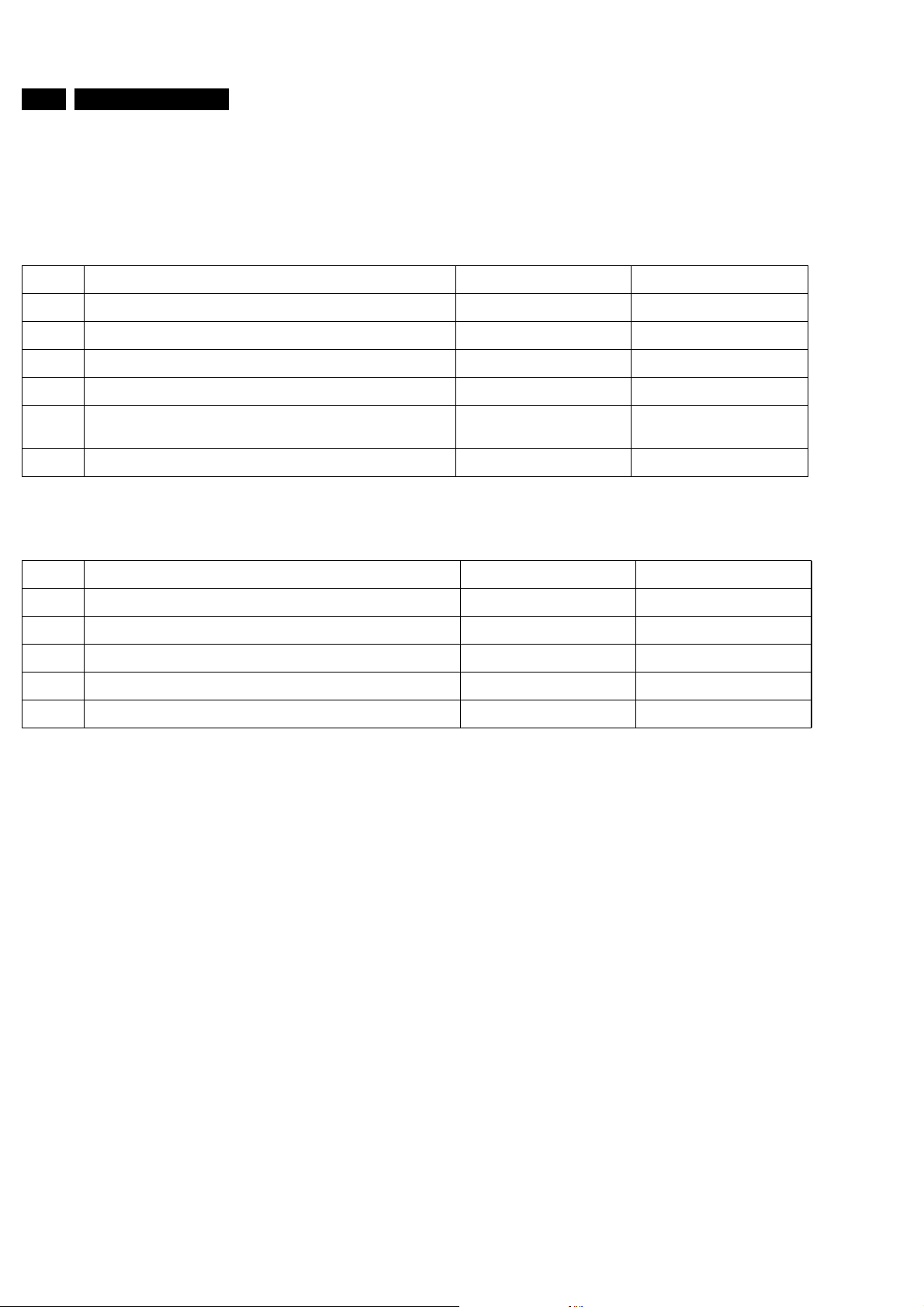

5.3.3 Error code table

Table 5-1 Error messages

Error Device Description Defective

item

1 ST24E16 Non volatile memory IC7008 K7 Control

2 ST24E32 or M24C32 Non volatile memory IC7008 K7

3 SAA5800 OTC2.5 microprocessor/TXT IC7003 K7

5 UV1316 Tuner U1102 K1 Tuner

15 TDA9320H HIP I/O-video processing IC7501 K1 Chroma IF IO

20 TDA9330H HOP video control/deflection processor IC7300 K6 Video Controller

25 MSP3410D ITT sound processor I 7751 K3 Audio module

26 SAA7712H SEDSP dolby processor IC7770 K4

50 SAA4978H Picnic IC7609 K5 Feature Box

51 SAA4990H Prozonic IC7608 K5

Diagram Defective module indication

65 Slow I2C bus blocked fig 5.7 Slow I2C bus blocked

66 Fast I2C bus blocked fig 5.7 Fast I2C bus blocked

67 Supply 5V 5V2 fig 5.6 +5 V Supply

68 Supply 8V 8V6 fig 5.8 +8V Supply

70 V fail protection VFB fig 5.9 A3/A2/K6 Vertical Flyback

71 H fail protection HFB fig 5.9 A2/K6 Horizontal Flyback

73 Line Deflection protection LDP IC7484 A2/K6 Line Deflection

74 Beam Current Protection BC-PROT TS7351 K6/K7 Beam Current

76 DC Sound protection DC-PROT TS7762 A4/A1 Sound Output

77 Feature box protection FBX-PROT fig 5.6 K4 +3V3 (FBX) Supply

Remark:If on the DST the text "ERROR 2" is displayed, this

means that the communication from the TV to the DST has

failed.

5.4 Protections

5.4.1 General

The MG2.1E "Protection Diagram" shows the structure of the

protection system. See protection diagram (fig 5.6).

will increase, which results in a quick slow-down of the FFS

supply.

Twoservice-modes. To get a quick diagnoses the MG2.1E has

two service-modes implemented:

• The service default mode. Start-up of the set in a

predefined way.

• The service alignment mode. In this mode items of the set

can be adjusted via a menu and with the help of test

patterns.

One micro-processor. The MG2.1E has only one microprocessor (OTC) and it remains active during Standby. This

because power of the microprocessor and the attached

memory chip set is coming from the 3V3 supply, which is

derived from the 5V Standby-circuitry. So in both power-on as

in Standby-mode the microprocessor is connected to this

power supply. The micro processor controls the Standby-line

for switching on and off the main supply. In the standby-mode

or in the protection-mode the Standby-line will open the

contacts of relay 1002 via T7000 and T7001, this results in

switching off the mains input to the main supply (FFS). In the

mean time via T7550 the intensity of LED of the opto-coupler

Both modes can be entered via the service connector on the

SSP (connector 0356) or via the DST (dealer service tool) or

via ComPair. The service alignment mode can not be entered

in Standby, the set has to be in normal operation.

Protection levels. If a fault situation is detected an error code

will be generated and if necessary the set will be put in the

protection-mode. The protection-mode is indicated by blinking

of the red LED. In some error cases the micro processor does

not put the set in the protection-mode. The error codes of the

error buffer can be read via the service-menu (SAM) or via the

service send-LED and the DST/ ComPair . The DST diagnose

functionalitywill force the setinto the Service-standby, which is

16 MG2.1E

5 Service modes, error codes and protections

alike the usual Standby, however the micro-processor has to

remain in normal operation completely.

The protections of the MG2.1E can be divided in 4 groups ;

• Protection from I2C-busses (Fast and Slow) or I2C-IC

errors (device errors).

• Protection from the inputs on the OTC.

• Protections from the status register of the HOP

(communicated via I2C-bus).

• DC-protection (sound amplifiers) monitored on OTC.

5.4.2 Protection from the I2C bus (fig. 5.7)

Innormal operation some registers of theI2Ccontrolled ICs will

be refreshed every 200 msec. During this sequence three I2Cbusses and the I2C -ICs as well will be checked. The I2C

protection will take place if the SDA andSCL are whether short

circuited to ground or to each other. An I2C error can also

occur, if the power supply of the IC is missing.

5.4.3 Protection from the inputs on the OTC (fig.5.8)

If a protection is detected at an input of the OTC, all protection

inputs of the OTC will be scanned every 200 msec. for 5 times.

If the protection on one of the inputs is still activated after 1

sec., then the set will be put in the protection-mode. Before the

scanning is started a so-called ESD-refresh will be carried out

first, because the interrupt on one of the inputs may be caused

either by a FLASH or by ESD. As a FLASH or ESD can harm

the settings of some ICs, the HOP-HIP-ITT-EDRIC-TEA6417TEA6422-LTP-PICNIC and Tuner are initialised again to

ensure the normal picture and sound conditions of the set.

• 8V6 and 5V2 protection (see detailed figure 5.8). The

presence of the 8V6 and 5V2 is sensed by the OTC. If the

8V6 and 5V2 is not present, then an error code is stored in

the error buffer and the set is put in the protection-mode.

• BC protection (Beam Current). (See detailed figure 5.8).

The beam current is measured by a circuit on the SSP. If

the beam current exceeds a certain reference level, then

via D6350 and T7351 the BC-input of the OTC is set to

high. The error code isstored in the errorbuffer and the set

is put in the protection-mode.

• DC-protection. (Fig. 5.10) This is an urgent protection, the

circuitry is located at the LSP. The output of the protection

circuit will slow-down the FFS power supply immediately

via the opto-coupler and via the Standby-relay the supply

will be switched into Standby-mode at once. To be able to

store the error code in the error buffer the protection

signals are also wired to the OTC. The protection is

activated in case of :

– Unbalance of +Vs and -Vs

– Unbalance of +7V7 and -7V7

– DC output present on one of the audio amplifiers

• VFB: Vertical Flyback (See detailed figure 5.9). The HOP

will blank the screen , if the vertical flyback signals are not

present at the VFB-guard input .The relevant status bit will

be set in the register of the HOP. The error code is stored

in the error buffer, in this case protection is not necessary.

• LDP-protection (Line Deflection Protection) (See detailed

figure 5.8). Two protection circuits are connected to the

LDP-input of the HOP :

1. Flash detection. From the EHT-info, via D6341 and

T7341 a flash will stop the H-drive and line output

stage immediately. The FLS-bit inthe status register of

the HOP is set to 'high'. As the duration of a flash is

very short the FLS-bit will be reset to 'low' again after

the flash refresh, so via a slow start the set will be

started again.

2. LDP detection. The EW-protection, coming from the

line-output is also connected to the same input as

above. The current through the EW-stage is measured

by R3483 and R3484 on the LSP. The voltage across

these precision resistors will increase in case of a

failure at the line output stage. If the voltage becomes

higher than 1 V, then the output of IC7484 will become

'high' and remains 'high' via D6485 and R3490. Via

D6344 the H-drive will be stopped. The FLS-bit will be

set to 'high' and remains 'high' by means of the

software filtering even after a flash refresh. The OTC

will put the set in Standby-mode. The error code is

stored in the error buffer and the set gets into the

protection mode.

5.5 Fault find trees

See fault find trees at the end of this chapter. (figures 5.11-

5.17)

5.4.4 Protections from the status register of the HOP (fig. 5.9)

Every 200 msec. the status register of the HOP is read by the

OTC via I2C. If a protection signal is detected on one of the

inputs of the HOP, then the relevant error bit in the HOP

register is set to 'high'. If the error bit is still 'high' after 1 sec.,

the OTC will store the error code in the error buffer and

depending on the relevancy of the errorbit the set will either go

into the protection-mode or not.

• HFB: Horizontal Flyback (See detailed figure 5.9). If the

horizontal flyback is not present, then this is detected via

the HOP. One status bit is set to 'high'. The error code is

stored in the error buffer and the set will go into the

protection mode

Loading...

Loading...