Page 1

Page 2

17

13

2$

PFAFF

1016

hy

19

PFAFF

hohhy

106

Page 3

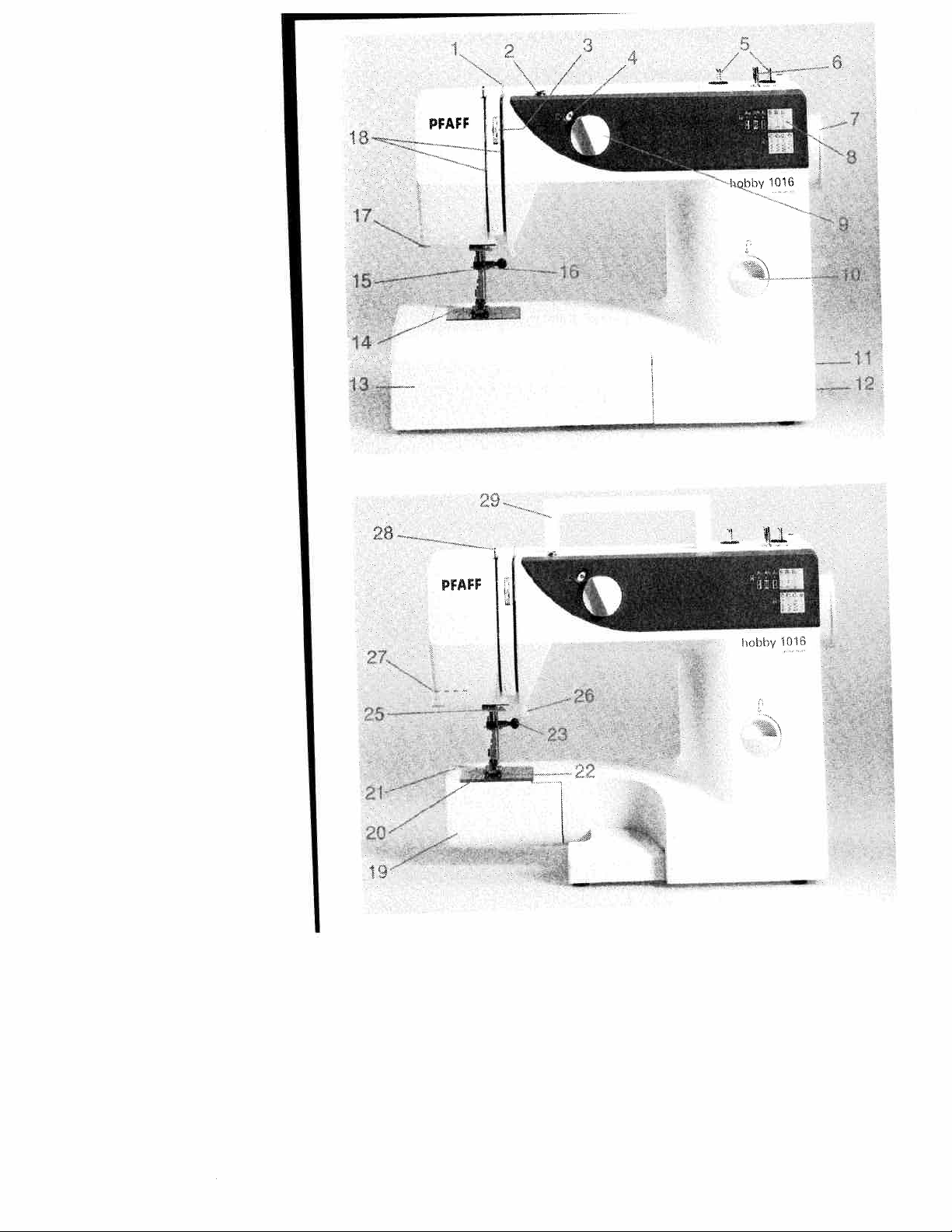

Parts

of

the

sewing

machine

hobby

1016

Thread

1

Bobbin

2

Needle

3

Adjustment

4

Spool

5

Bobbin

6

Handwheel

7

Stitch

8

Pattern

9

Reverse

10

Connection

11

Master

12

Detachable

13

Needle

14

Thread

15

Thread

16

Thread

17

Threading

18

Hook

19

Presser

20

Free-arm

21

Feed

22

Needle

23

Thread

25

Presser

26

Sewing

27

Take-up

28

29

guide

winder

thread

holder

winder

pattern

adjustment

switch

plate

cover

dog

Carrying

field

key

guide

guide

cutter

slot

foot

holder

guide

bar

lamp

lever

handle

tension

tension

chart

bushing

support

work

(enclosing

holder

with

lifter

(max.

with

button

sewing

with

fixing

15

presser

with

presser

screw

W)

foot

accessory

hook)

foot

box

Page 4

P’ease

standing

fold

of

this

this

open

page

instruction

simplify

to

manual

when

the

reading

under

it.

ndex

on

pages

5

—

4

Page 5

Sewing

for

fun

Congratulations!

Pfaff

made

hours

features

Furthermore,

which

instruction

Thg,

by

of

will

sewing

Your

please

carefully.

way

best

make

and

have

you

If

dealer,

advice.

or

wish

We

own

very

sewing

the

make

manual

take

is

It

find

to

full

any

who

you

fashion

very

mach

will

You

which

pleasure.

latest

has

sewing

the

out

use

further

be

numerous

The

is

of

happy

ideas.

it

certainly

many

bought

have

sure

is

Your

design

in

much

simple

as

is

follow.

to

to

time

time

what

just

features.

its

all

questions,

to

enjoyable

bring

to

new

practical

easier

Before

read

well

your

assist

hours

quality

a

sewmg

and

to

these

spent,

machine

just

you

product

countless

you

machThe

technology.

features

you.

for

operate

start

you

instructions

and

your

ask

with

creatmg

is

can

help

as

sew

the

Pfaff

your

this

do

Page 6

IMPORTANT

States

For

This

use

to:

United

the

machine

sewing

electric

an

Read

instructions

all

DANGER

sewing

The

1

appliance

Always

2.

Do

3.

Do

4.

place

WAR

Do

1.

by

Only

2.

Only

Never

3.

properly,

the

adjustment.

Never

4.

the

Never

5.

Do

6.

Do

7.

administered.

To

8

Never

9.

blocked.

Do

10.

Keep

11

needle.

Always

12.

Do

13.

14.

15.

16.

unplug

reach

not

place

not

in

NNG

allow

not

near

or

use

use

operate

nearest

operate

sewing

drop

not

not

disconnect

operate

not

fingers

not

Do

not

Switch

threading

Always

when

from

or

this

attachments

itithas

use

operate

unplug

use

use

pull

the

unplug

making

appliance,

To

machine

the

before

for

store

or

into

drop

be

to

children.

sewing

this

authorized

the

machine

insert

or

of

out

where

turn

on

by

away

the

bent

or

push

sewing

needle,

any

SAFETY

only

designed

is

the

before

the

reduce

should

electric

replacing

machine

sewing

a

sewing

a

water

reduce

To

as

used

machine

recommended

sewing

dropped

been

dealer

sewing

foot

and

anything

doors.

aerosol

controls

all

surface

soft

a

on

pulling

all

from

needle

proper

needles.

blunt

or

fabric

machine

changing

machine

sewing

other

user

and

following

using

risk

never

outlet

sewing

machine

other

or

risk

the

toy.

a

for

machine

or

or

machine

control

into

(spray)

to

cord.

moving

plate.

while

off

needle,

servicing

NSTRUCTONS

manufactured

basic

sewing

this

electric

of

left

be

immediately

light

has

that

where

liquid.

burns,

of

care

Great

its

intended

the

by

ifithas

damaged,

center

service

any

with

free

opening.

any

products

off

0

(

as

such

unplug.

To

parts

The

use

Only

stitching.

when

(0”)

threading

the

from

adjustments

unattended

from

)

position

bed

a

Special

wrong

It

making

electric

for

precautions

safety

machine.

shock:

using

after

Replace

bulb.

into

fallen

it

can

fire,

electric

necessary

is

purpose

manufacturer

damaged

a

dropped

or

for

examination

openings

air

accumulation

the

being

are

then

couch

or

the

hold

care

plate

needles

deflect

may

any

bobbin,

outlet

HOUSEHOLD

plugged

when

before

and

with

bulb

Unplug

water.

pulled

be

or

fall

shock,

when

described

as

contained

as

or

cord

water.

into

blocked.

used

remove

where

the

not

plug,

required

is

can

cause

recommended

needle,

the

adjustments

changing

or

removing

when

mentioned

should

this

plug,

repair

of

where

or

plug

the

the

in

in.

cleaning.

same

or

sewing

Return

Keep

lint

air

cord.

around

by

causing

in

presser

the

only.

use

always

Always

type

immediately.

tub

a

into

to

injury

machine

manual.

this

in

this

in

not

ifitis

the

electrical

ventilation

and

dust

oxygen

socket

from

openings

the

to

needle

manufacturer.

the

if

needle

the

foot,

covers,

instruction

When

adhered

be

unplug

rated

sink.

or

persons:

manual

working

appliance

mechanical

or

openings

loose

being

is

may

sewing

break.

break.

to

area,

etc.

lubricating,

manual,

you

this

Watts.

5

Do

used

is

cloth

be

machine

such

not

to

of

as

or

Please

KEEP

observe

also

THESE

notes

safety

general

the

NSTRUCTONS

3.

Page

on

N

A

SAFE

PLACE

Page 7

Notes

machines

The

requirements.

user

The

1.

with

regard

of

the

sewing

When

2.

nance

parts

machine

the

ging

maximum

The

3.

sewing

authorized

An

4.

adjust

machine

The

5.

cording

plate.

tion

not

Do

6

machine,

the

not

7.

Do

there

•

its’

it

•

is

when

cur

warm

To

unplug

8.

plug

the

main

If

the

9

pose

accepted

be

avoid

To

10.

open

side

This

fled

service

sure

11

Be

The

12.

supply

10%

+1-

1-

4

When

13.

outer

the

cally

85°C.

to

therefore

damage.

According

14.

magnetic

accepted

sed,

ged

on

meet

must

to

and

needle

during

area

leaving

or

work

or

accessories,

from

cord

lead

is

lamp

tension

the

the

to

insert

the

use

visible

is

functioning

i.e.

wet,

cold

a

room.

lead

close

out

plug

appliance

incorrectly

or

for

risk

the

machine

the

machine

the

solely

is

staff.

use

to

machine

with

a

and

%.

properly,

used

components

controlled

Constant

not

to

compatibility,

for

the

should

should

or

safety

relevant

the

exercise

up-and-down

the

constantly

work.

machine,

the

changing

when

always

main

the

from

permissible

watts.

15

mechanic

PFAFF

the

of

put

be

must

indications

any

oblects

machine

damage

disturbed,

is

condensation

machine

from

cord

wall.

the

to

wall

of

the

used

is

operated,

possible

any

electric

of

There

the

that

responsibility

the

PFAFF

only

designated

is

nominal

frequency

rated

a

the

control

foot

use

permitted

laws

the

mains

any

mains

changes

for

safety

adequate

observe

during

disconnect

by

power

wall

the

wattage

drive,

belt

operation

into

the

on

openings

into

if:

which

installed

is

socket,

wall

not

Do

socket

the

for

no

damage.

shock,

no

are

user

original

for

voltage

temperature

non-electroni

a

of

can

low

a

at

order

in

concerning

liability

no

interruptions

line

power

made

be

domestic

caution

movement

the

mainte-

mechanical

wrong

can

of

a

of

unplug-

outlet,

for

only

specifica-

can

pull

the

by

liability

do

parts

repair.

our

parts

mains

of

reach

speed

avoid

to

electro

can

be

it.

to

the

must

oc-

in

a

grasp

the

cord.

pur-

not

in

quail-

of

up

is

be

cau

chan

the

ac-

on

can

sewing

Environment

The

recommended

25°C)

(-

machine

not

appliances

machine

such

dampness,

heat-producing

or

cals

ventilation

For

used

on

Treatment

Always

tecting

Cleaning

Housing:

cleaning

For

lint-free

soft

cloth

a

Please

not

Do

such

ducts

micals

temperature

a

liquids.

an

avoid

it

cloth.

note!

use

for

Ambient

(40°C)

Humidity:

13°F

The

should

tronic

personal

This

mechanical

pervised

in

severe

tricity,

to

20%

+140°F

to

insensitive

is

used

be

computers,

is

a

appliance,

in

the

use

that

way

purposes

unobstructed,

damage

against

the

To

alcohol,

with

any

insecticides

petrol

as

cleaning

machines

environment

(10°C)

50°F

80%

Storage

(60°C).

to

in

direct

the

radios,

as

such

hitting

housing

remove

high

home.

it

direct

the

radio

quality

It

not

is

oblects,

to

(gas)

transmitters,

is

a

It

subjected

sunlight,

the

solid,

the

dropping.

or

use

any

or

housing.

is:

to

temperature

interference,

vicinity

televisions,

electronic-

machine

be

should

static

corrosive

machine

level

machine

clean.

a

dry,

stubborn

chemical

or

low-viscosity

104°F

of

etc.

for

operated

to:

dust,

elec

chemi

must

surface.

by

dirt,

pro

but

elec

su

pro-

-

it

be

soft

use

che

Page 8

Index

A

Accessories

Accessory

B

tape

Bias

Bobbin

case

thread

Bobbin

Buttonholes

Buttons

C

Changing

Changing

Cleaning

Control

Cording

panel

needles

and

compartment

binder

tension

needle

the

sewing

the

oiling

and

foot

lamp

hobby

12-13

26-27

—

Sewingforfun

41

9

44

13

24

18

51

50

19

45

F

Feed

dog,

foot

Felling

control

Foot

arm

Free

G

Gathering

General

H

Handwheel.

Hemming

removing

Hook,

K

Knit-edge

lowering

with

sewing

releasing

with

foot

the

aids

the

straight

twin

stitch

needle

18

45

8

9

30

22

10

28

50

46

D

Darning

Detachable

Drawing

E

guide

Edge

stitch

Elastic

Electrical

work

bobbin

the

up

connection

support

thread

31

9

16

22

25

8

L

Lace-work

buttonhole

Linen

buttonhole

Linen

M

Maintenance

switch

Master

with

gimp

thread

35

27

27

49

8

Page 9

hobby

Sewing

—

for

fun

N

Needle

Needle

Needle

O

the

Oiling

Optional

p

Patchwork

Practical

Presser

o

and

Quilt

R

Repairing

Reverse

Richelieu

Roll

hemming

Ruffler

charts

removing

plate,

thread

machine

accessories

quilt

sewing

lifter

bar

patchwork

tears

sewing

tension

foot

47-48

51

22

39-40

50

21

15

46

31

20

38

34

44

Setting

Sewing

Sewing

Sewing

Sewing

utility

feet

feet

lamp

patches

on

Sewing

Shell

Smocking

Special

Spool

Stitch

Straight

T

Thread

Thread

Threading

Threading

Topstitching

Traditional

problems

edging

accessories

placement

chart

stitch

cutter

tension

the

embroidery

Troubleshooting

needle

Twin

W

Winding

the

stitches

(normal

(special

needle

bobbin

accessories)

accessories)

their

and

chart

thread

techniques

solutions

20

42

43

51

31

52

36

29

43

10

6

23

16

12

14-15

14

22

37

52

28

10-11

S

Safety

Serging

notes

with

the

zigzag

stitch

23

z

stitch

Zigzag

2

Zippers

23

32-33

Page 10

hobby

—

Sewing

for

fun

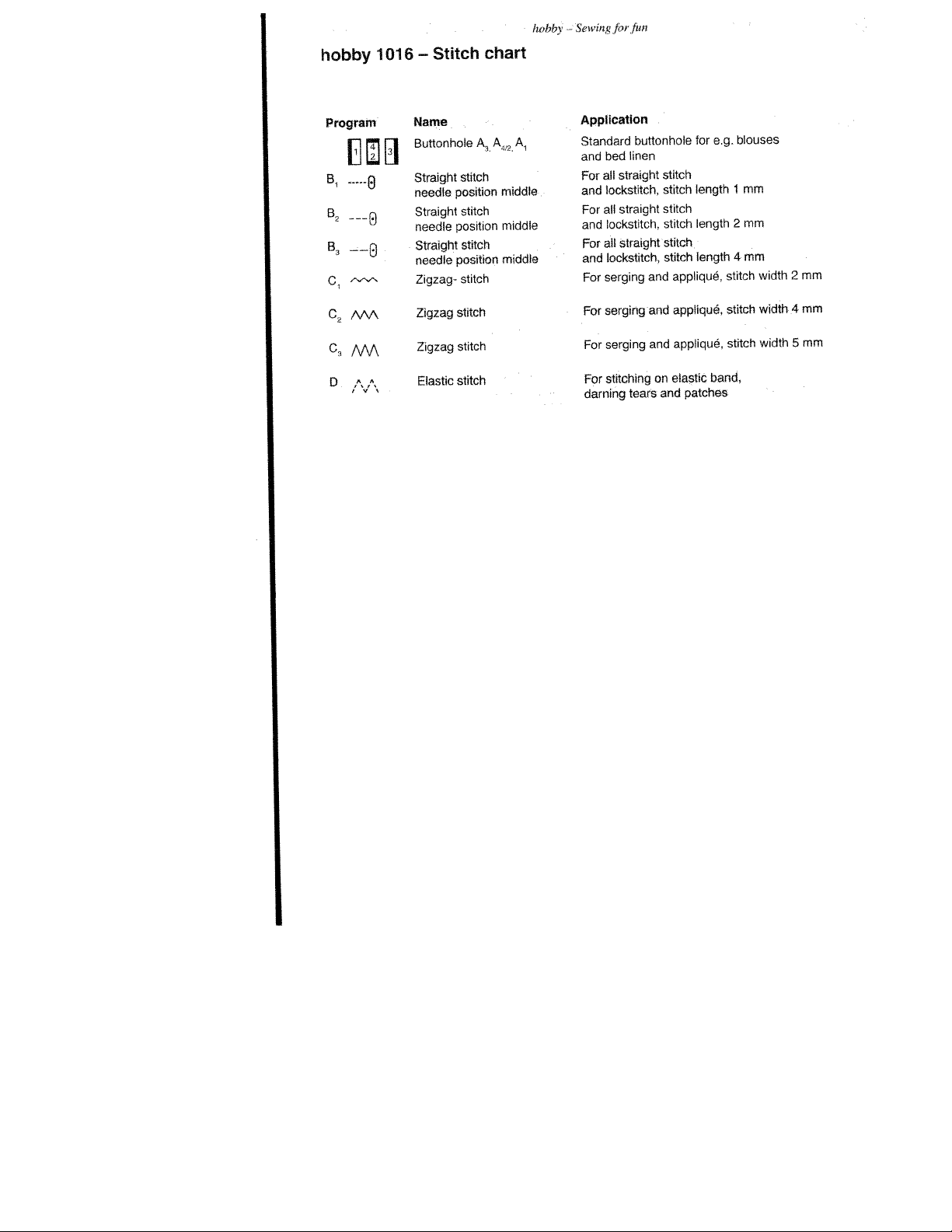

hobby

Program

B

83

9

-“-“--“

C,

C

C

3

D

1

2

,.

,.

1016—

Name

Buttonhole

3

Straight

needle

Straight

needle

Straight

needle

Zigzag-

Zigzag

Stitch

Zigzag

Elastic

A

3

stitch

position

stitch

position

stitch

position

stitch

stitch

stitch

stitch

chart

A

42

middle

middle

middle

Application

for

blouses

length

length

length

appliqué,

appliqué,

appliqué,

elastic

patches

e.g.

stitch

stitch

band,

1

2

4

stitch

mm

mm

mm

width

width

width

mm

2

4

mm

mm

5

A

1

Standard

and

For

and

For

and

For

and

For

For

For

For

darning

buttonhole

linen

bed

straight

all

lockstitch,

straight

all

lockstitch,

straight

all

lockstitch,

serging

serging

serging

stitching

tears

stitch

stitch

stitch

stitch

stitch

stitch

and

and

and

on

and

Page 11

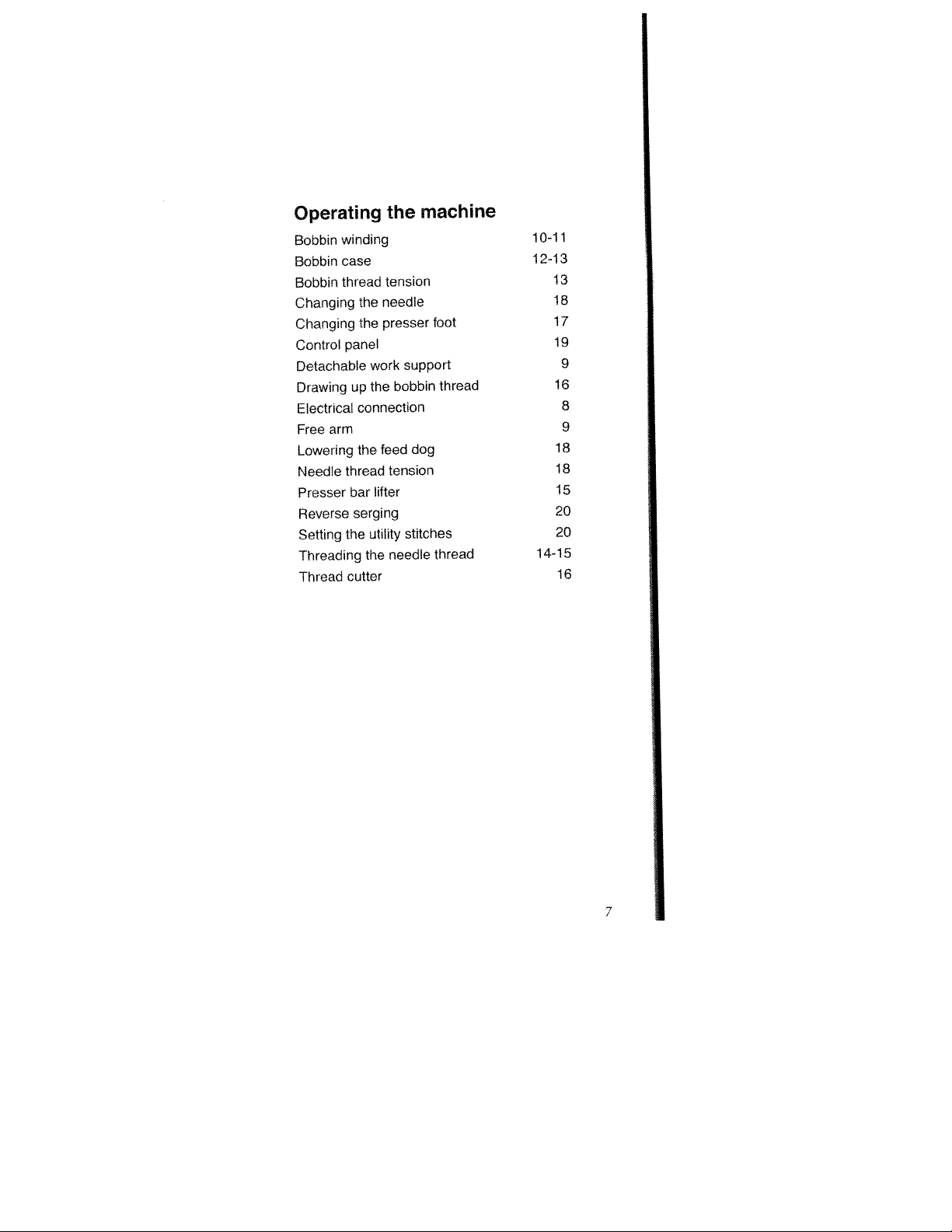

Operating

Bobbin

winding

case

Bobbin

Bobbin

Changing

Changing

Control

thread

Detachable

Drawing

Electrical

arm

Free

Lowering

Needle

Presser

Reverse

Setting

Threading

Thread

panel

up

thread

bar

serging

the

cutter

the

tension

needle

the

presser

the

support

work

bobbin

the

connection

feed

the

tension

lifter

stitches

utility

needle

the

machine

foot

thread

dog

thread

10-11

12-13

13

18

17

19

9

16

8

9

18

18

15

20

20

14-15

16

Page 12

pFFF

Operating

machine

the

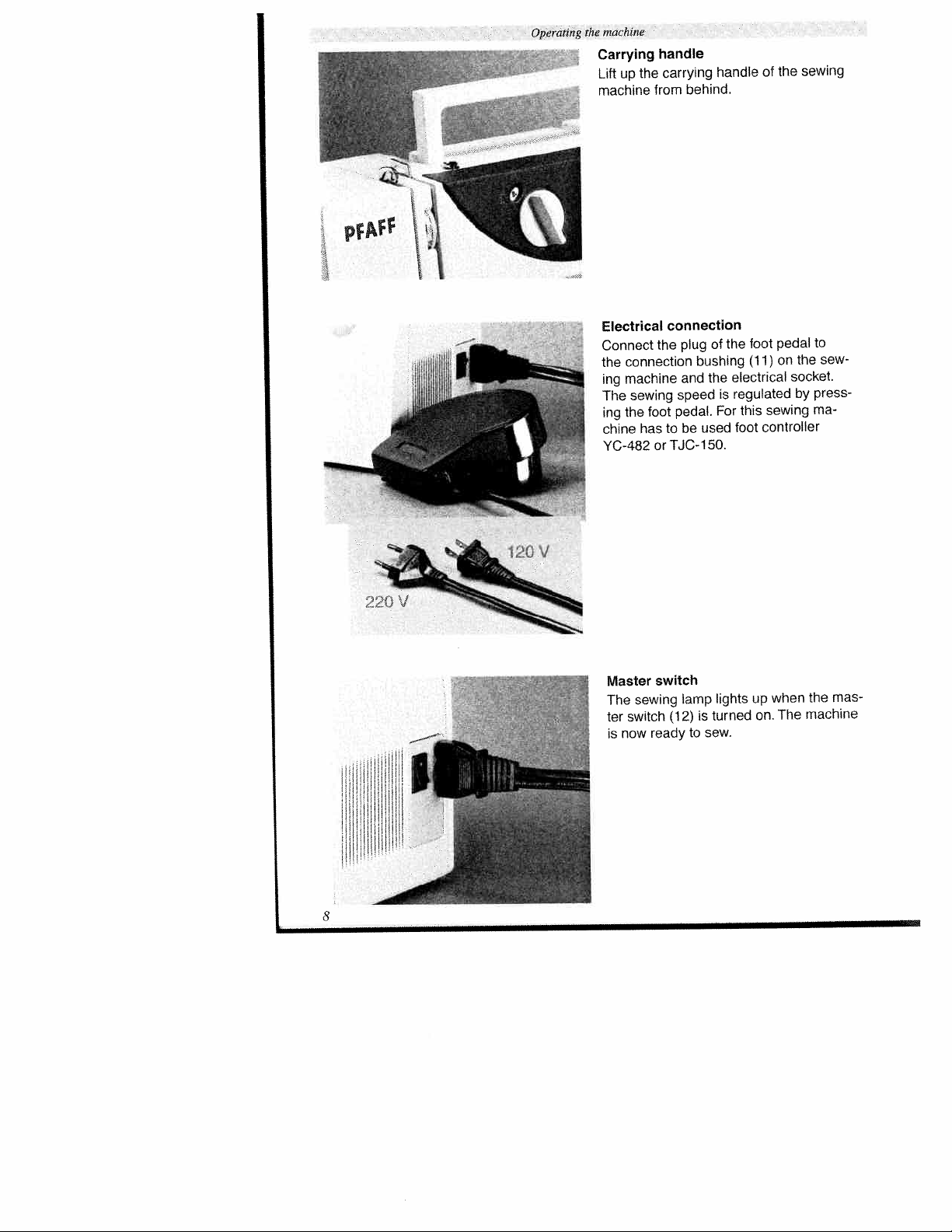

Carrying

Lift

machine

up

the

handle

carrying

from

behind.

handle

sewing

the

of

220

Electrical

Connect

the

ing

The

ing

chine

YC-482

connection

the

connection

machine

sewing

pedal.

foot

the

to

has

TJC-1

or

plug

bushing

and

speed

be

of

the

used

50.

the

electrical

regulated

is

this

For

foot

pedal

foot

on

(11)

sewing

controller

to

the

socket.

press

by

ma

sew

V

sewing

switch

now

switch

(12)

ready

lamp

to

is

sew.

lights

turned

up

on.

when

The

mas

the

machine

Master

The

ter

is

8

Page 13

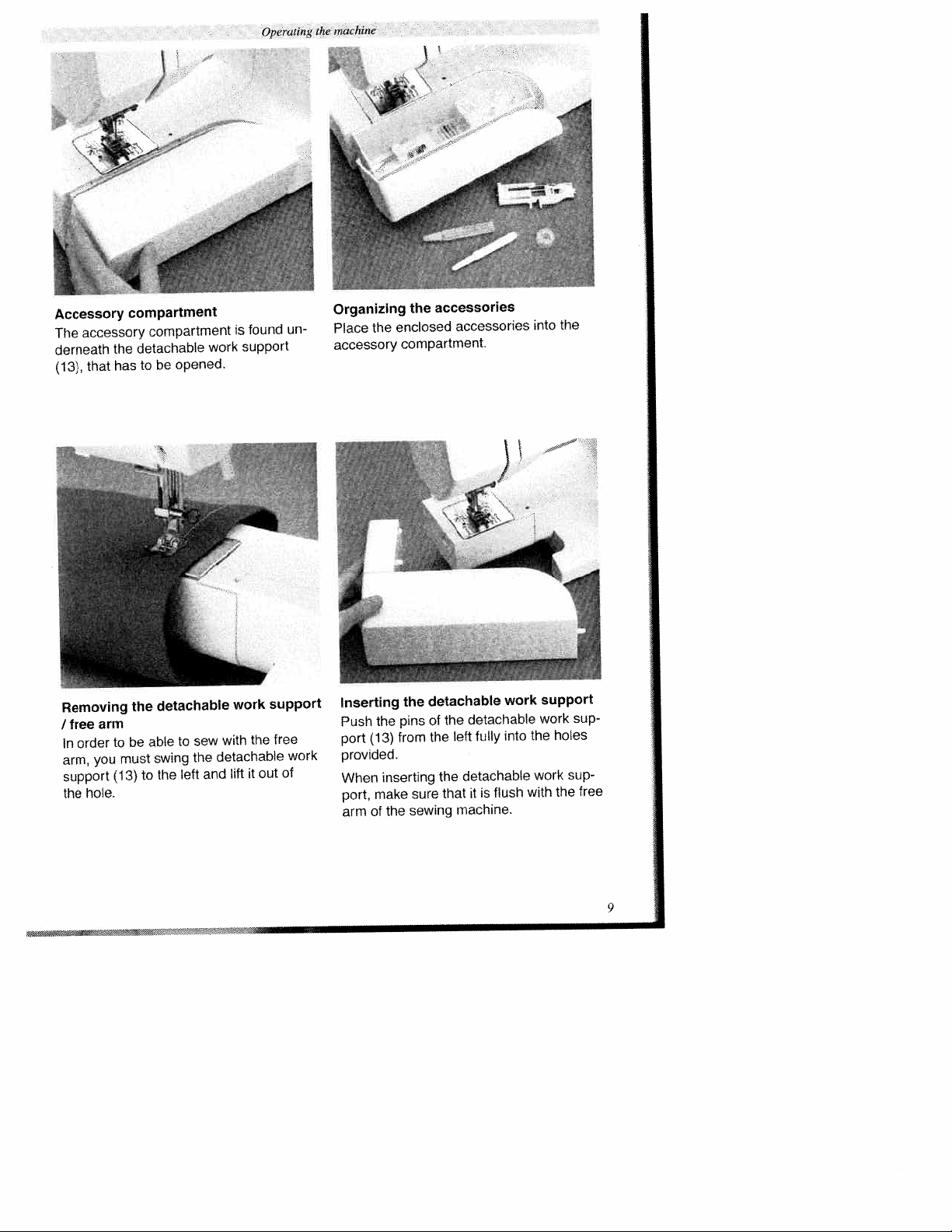

Accessory

accessory

The

derneath

that

(13),

)

compartment

compartment

detachable

the

be

to

has

opened.

work

found

is

support

Operating

un-

machine

the

Organizing

Place

accessory

the

enclosed

the

compartment.

accessories

accessories

into

the

Removing

arm

free

I

order

In

you

arm,

support

hole.

the

to

must

(13>

the

be

able

to

detachable

sew

to

the

swing

left

the

work

with

detachable

lift

and

the

it

support

tree

out

work

of

Inserting

the

Push

(13)

port

provided.

When

make

port,

of

arm

the

pins

from

inserting

sure

sewing

the

detachable

detachable

the

of

fully

left

the

detachable

the

it

that

machine.

is

work

into

flush

support

work

the

work

with

holes

sup

the

sup

free

9

Page 14

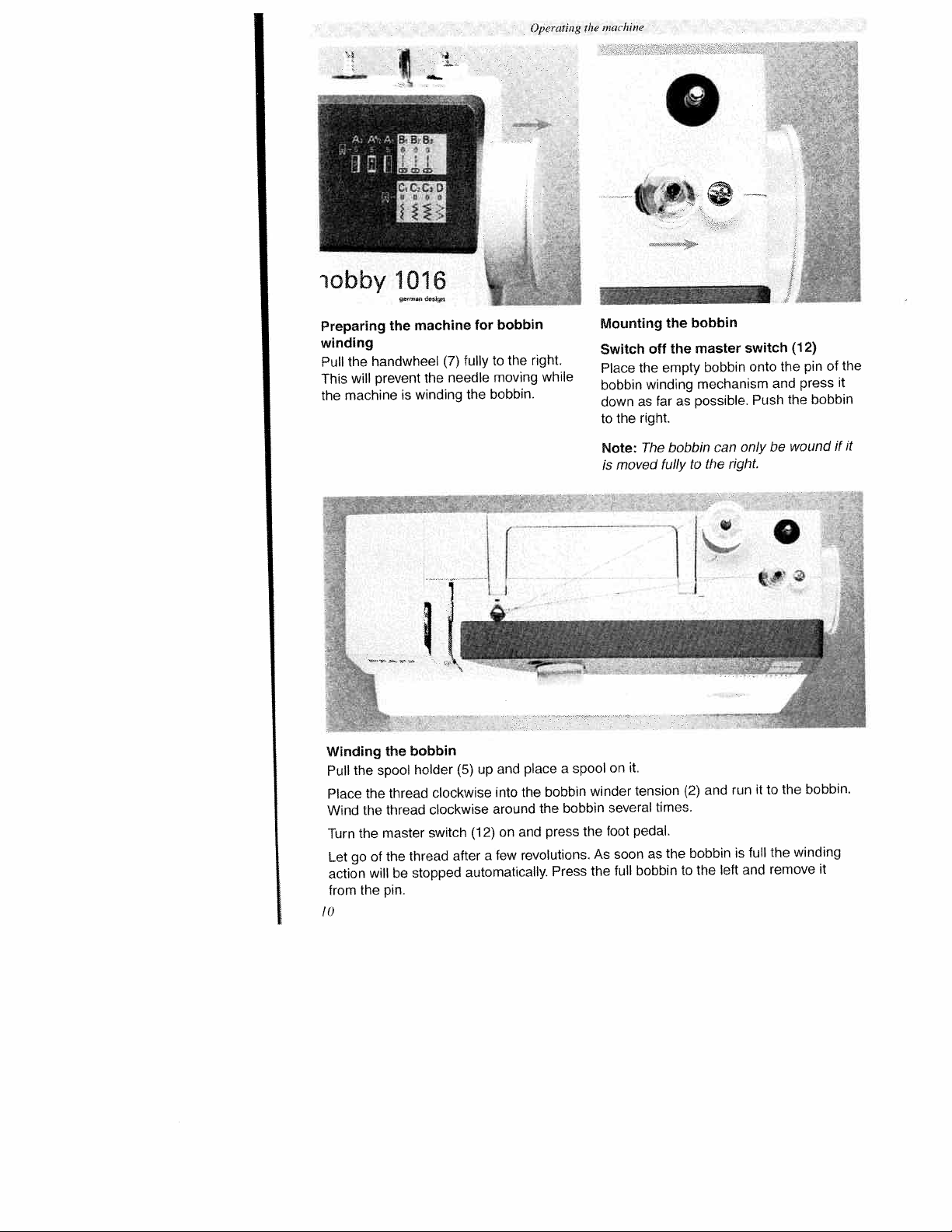

iobbylOl6

handwheel

the

prevent

will

machine

the

is

Preparing

winding

Pull

This

the

machine

(7)

needle

the

winding

for

fully

the

bobbin

the

to

moving

bobbin.

Operating

a

right.

while

rncwhine

the

Mounting

Switch

Place

bobbin

down

to

Note:

is

the

as

right.

the

moved

off

winding

The

bobbin

the

master

the

bobbin

empty

mechanism

faraspossible.

can

bobbin

right.

the

to

fully

switch

onto

Push

only

(12)

the

and

the

wound/fit

be

pin

press

bobbin

the

of

it

C

C

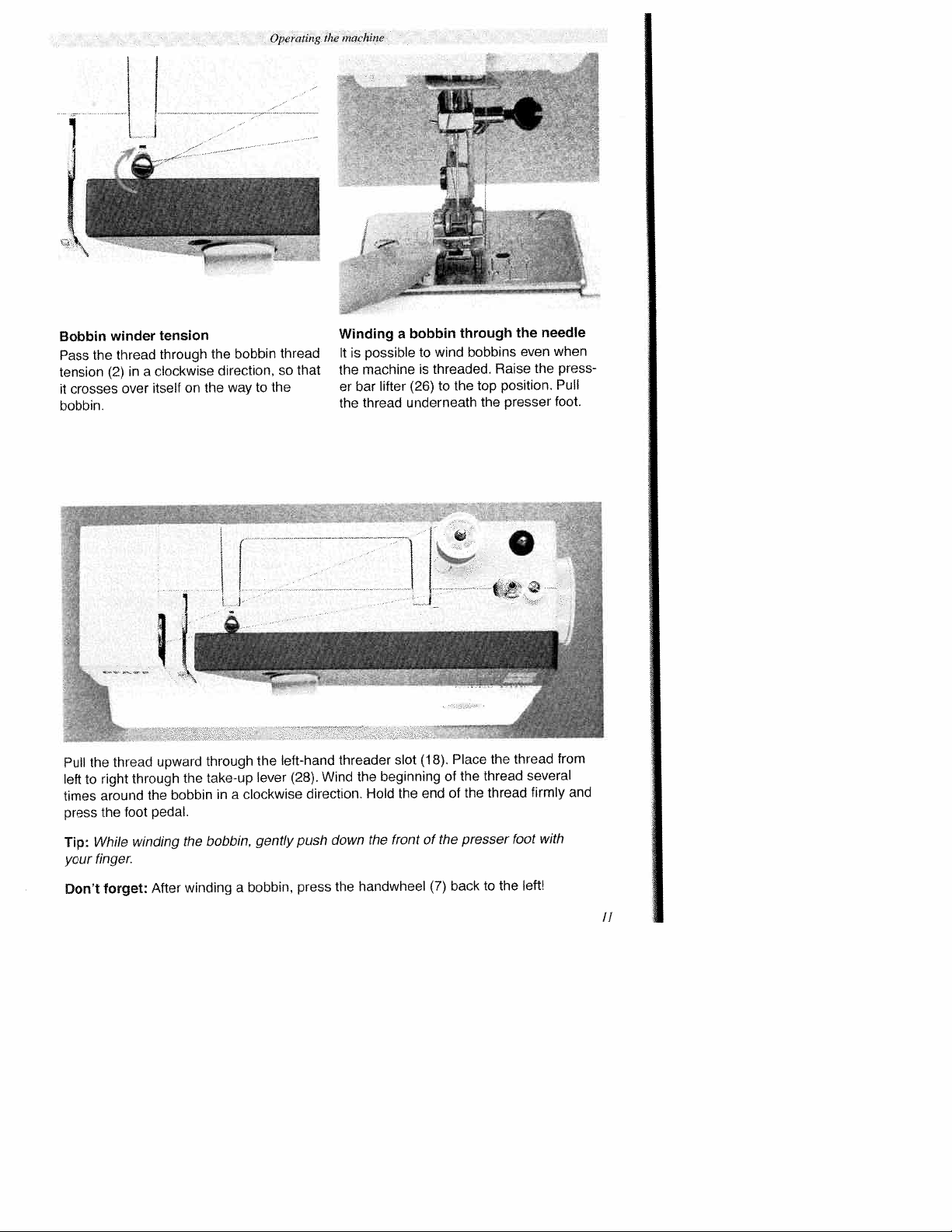

Winding

Pull

Place

Wind

Turn

Let

go

action

from

10

the

the

the

the

the

of

will

the

spool

thread

thread

master

the

be

pin.

bobbin

holder

clockwise

clockwise

switch

thread

stopped

and

(5)

up

into

around

on

(12)

few

after

a

automatically.

place

a

bobbin

the

bobbin

the

press

and

revolutions.

Press

spool

winder

the

As

the

on

it.

several

foot

soon

full

IH°

tension

pedal.

bobbin

times.

as

(2)

the

to

and

bobbin

the

left

run

is

full

and

to

it

the

remove

the

winding

bobbin.

it

Page 15

Bobbin

Pass

tension

it

crosses

bobbin.

the

winder

thread

in

(2)

over

tension

through

clockwise

a

itself

on

the

direction,

way

the

#i

bobbin

to

Operating

thread

that

so

the

the

I

machine

Winding

possible

It

is

machine

the

bar

er

the

thread

a

lifter

bobbin

wind

to

threaded.

is

the

to

(26)

underneath

through

bobbins

top

the

the

even

Raise

position.

presser

needle

the

when

press

Pull

foot.

Pull

left

times

press

Tip:

your

Don’t

the

to

While

finger.

thread

right

around

foot

the

forget:

upward

through

the

pedal.

winding

After

1

(L

the

bobbin

the

winding

i

through

take-up

in

a

bobbin,

a

I

the

lever

clockwise

gently

bobbin,

left-hand

(28).

direction.

push

press

threader

Wind

down

the

slot

beginning

the

the

Hold

front

the

handwheel

1

(18).

end

of

(7)

of

the

Place

the

of

presser

back

the

the

thread

thread

the

to

thread

several

firmly

foot

left!

from

and

with

II

Page 16

Operafi,1g

the

,ncu’hjne

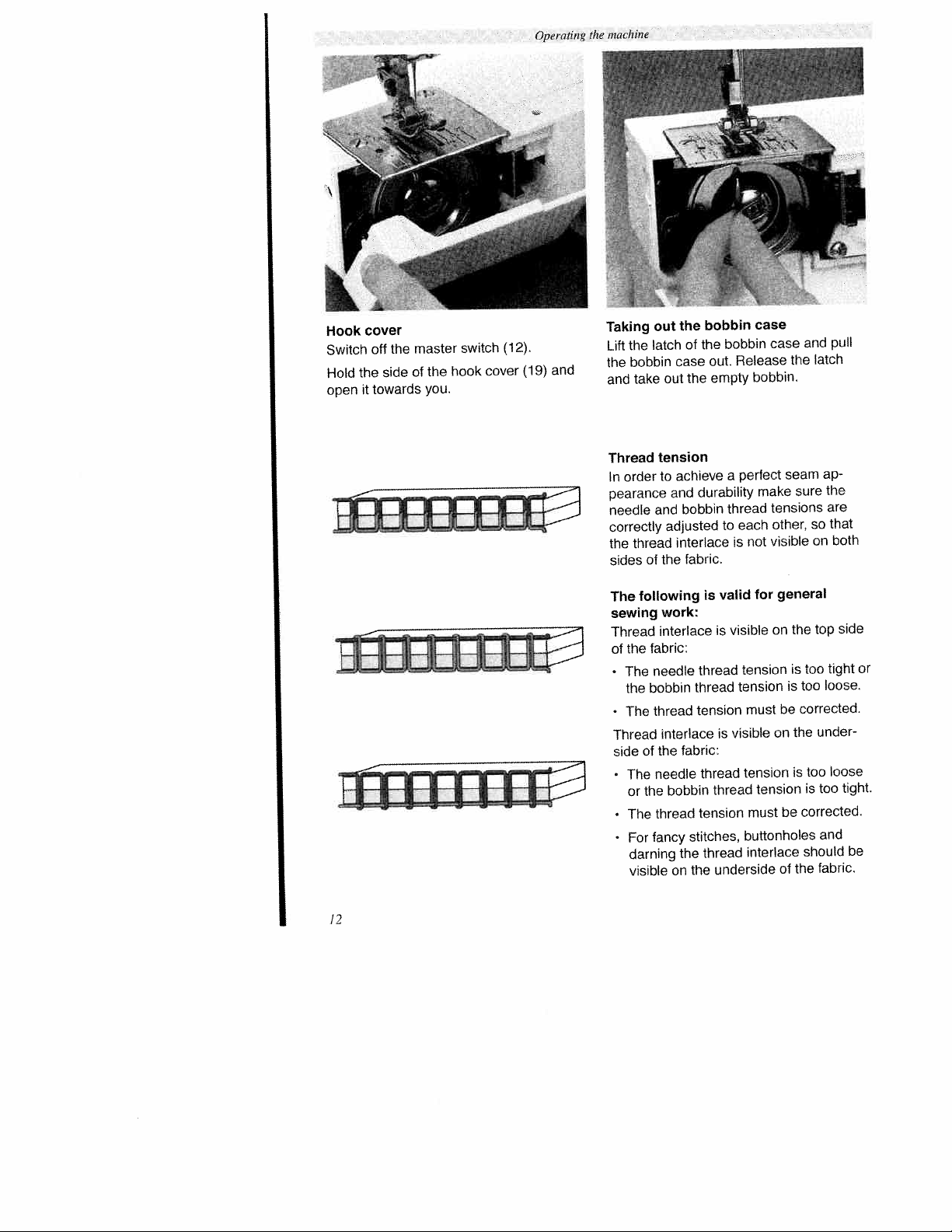

Hook

Switch

Hold

open

cover

off

the

it

towards

the

side

master

the

of

you.

switch

hook

cover

(12).

(19)

and

Taking

Lift

the

the

bobbin

take

and

Thread

order

In

pearance

needle

correctly

thread

the

sides

following

The

sewing

Thread

the

of

The

•

the

The

•

Thread

side

The

•

or

The

•

For

darning

visible

out

latch

out

tension

to

and

the

of

work:

interlace

fabric:

needle

bobbin

thread

interlace

the

of

needle

the

thread

fancy

the

of

case

the

achieve

durability

and

bobbin

adjusted

interlace

fabric.

thread

thread

tension

fabric:

thread

bobbin

tension

stitches,

the

the

on

bobbin

bobbin

the

out.

empty

a

thread

to

valid

is

is

is

thread

thread

underside

case

Release

bobbin.

perfect

make

each

not

is

for

visible

tension

tension

must

visible

tension

tension

must

buttonholes

interlace

and

case

the

seam

sure

tensions

other,

visible

general

the

on

is

too

too

is

corrected.

be

the

on

is

corrected.

be

should

the

of

latch

so

on

top

under

too

is

fabric.

pull

ap

the

are

that

both

tight

loose.

loose

too

and

side

or

tight.

be

12

Page 17

Operating

the

machine

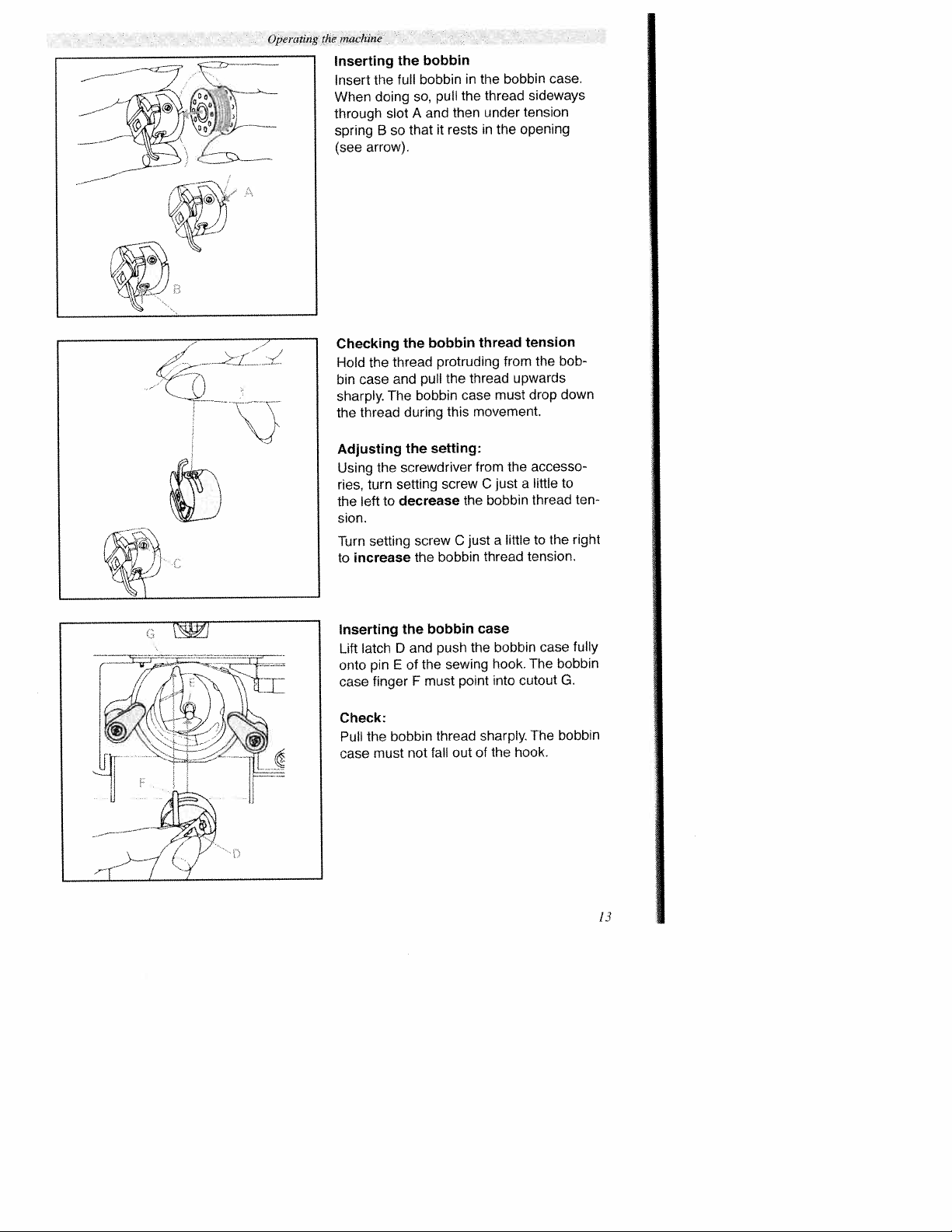

Inserting

Insert

When

through

springBso

(see

Checking

Hold

bin

case

sharply.

thread

the

Adjusting

Using

ries,

left

the

sion.

Turn

to

increase

the

doing

slot

arrow).

thread

the

and

The

the

turn

to

setting

bobbin

the

bobbininthe

full

pull

so,

A

and

it

that

bobbin

the

protruding

pull

the

bobbin

this

during

setting:

the

screwdriver

screw

setting

decrease

screw

bobbin

the

the

then

rests

thread

case

movement.

from

the

C

just

thread

under

in

the

thread

must

just

C

bobbin

a

thread

bobbin

sideways

tension

opening

tension

from

upwards

drop

the

a

little

tension.

case.

bob

the

down

accesso

little

to

thread

the

to

ten

right

Inserting

latch

Lift

pin

onto

finger

case

Check:

the

Pull

must

case

the

D

and

E

of

F

bobbin

not

bobbin

push

the

must

thread

fall

the

sewing

point

out

case

bobbin

hook.

into

sharply.

of

the

The

cutout

The

hook.

case

fully

bobbin

G.

bobbin

13

Page 18

Operating

machine

the

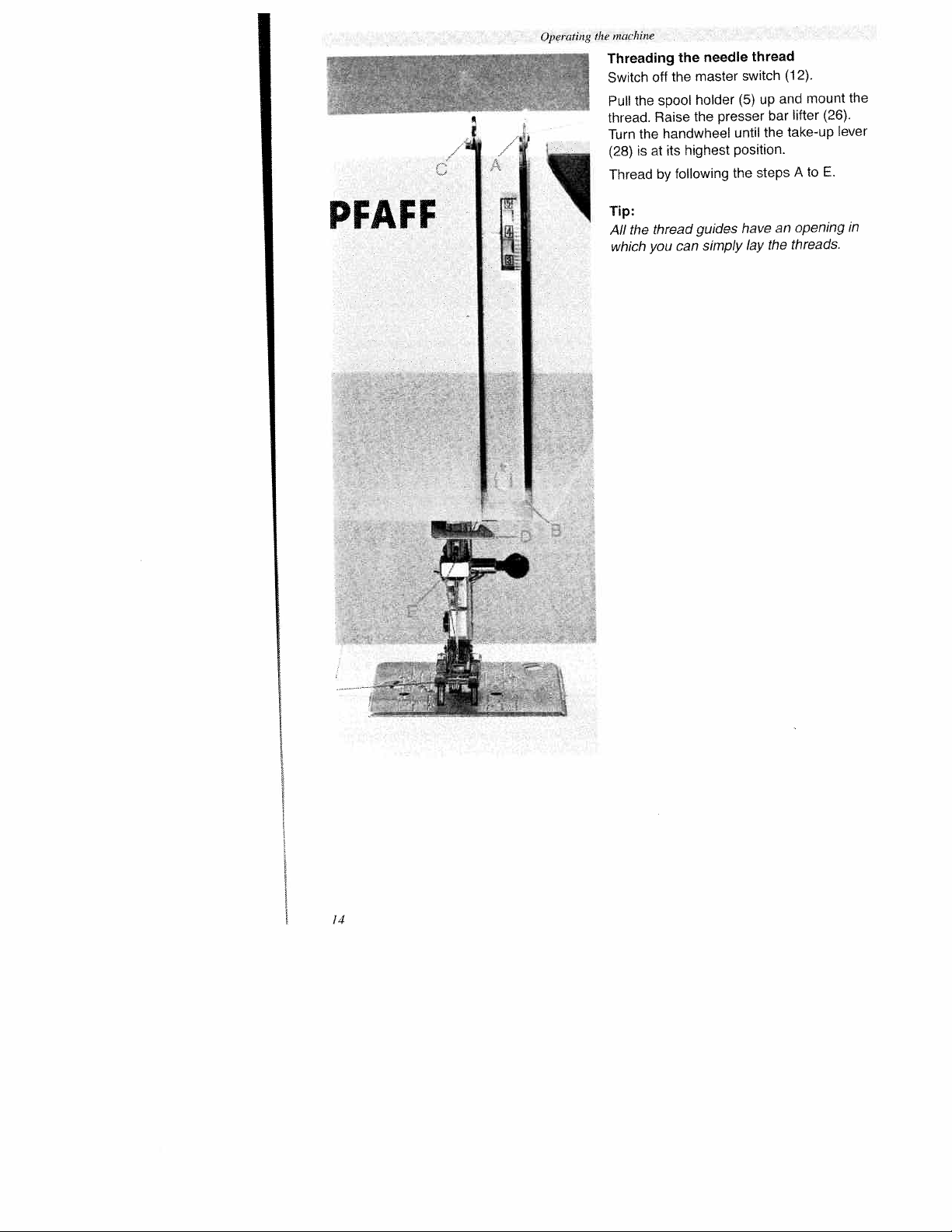

Threading

Switch

Pull

thread.

Turn

(28)

Thread

the

the

is

off

at

the

the

spool

the

Raise

handwheel

highest

its

following

by

needle

master

holder

presser

thread

switch

up

(5)

bar

the

until

position.

steps

the

2).

(1

and

lifter

take-up

A

mount

(26).

E.

to

the

lever

PFAFF

Tip:

the

All

which

J

thread

you

can

guides

simply

have

lay

an

the

opening

threads.

in

14

Page 19

Operating

machine

the

Threading

Thread

of

the

Presser

The

with

the

needle

bar

presser

presser

the

the

needle

from

lifter

foot

needle

thread

the

is

bar

front

raised

lifter

through

the

to

and

(26).

the

back.

lowered

eye

I’;

Page 20

1

_____

Operating

bQ’d

‘

nachine

the

Drawing

Raise

thread

you

tion

loop.

bobbin

the

until

and

Pull

up

presser

and

the

the

the

thread

the

turn

needle

bobbin

needle

bobbin

foot.

handwheel

the

thread

Hold

at

is

thread

thread

the

highest

its

has

to

needle

towards

formed

draw

posi

up

a

the

thread

the

under

hook

the

cover

presser

(19)

and

foot

to

pull

the

the

left.

I

Bobbin

Close

thread

I

-

I

L

/

the

the

cutter

thread

thread

from

cutter

the

back

(17).

front

the

to

Thread

Pull

over

]6

Page 21

Operatin.g

machhie

the

Removing

Switch

Raise

Press

the

disengages

(20).

rear

the

the

off

the

needle

front

of

the

the

master

presser

from

presser

to

the

of

the

switch

highest

its

presser

foot

presser

foot

(12).

foot

down

foot

position.

up

until

holder

and

it

c_4t

I

4

Attaching

the

Place

holder

foot

lifter

bar

engage

foot

Check:

Please

erly

attached

lifter.

the

presser

(20)

(26)

check

is

in

that

by

presser

the

foot

that

so

lowered,

presser

the

raising

foot

under

when

the

presser

the

the

the

pins

foot

presser

presser

presser

of

holder.

foot

is

the

prop

bar

17

Page 22

PFAFF

J

Operaüng

machine

the

Changing

Switch

remove:

To

the

set

fixing

the

downwards.

insert:

To

must

foot

far

as

tighten

Setting

Set

thread

the

tension

The

For

tween

the

the

off

Lower

needle

screw

The

the

to

face

insert

and

will

it

as

fixing

the

neecile

the

required

the

tension

dial.

normal

embroidery

setting

and

2

needle

master

to

its

(23)

flat

rear.

the

go.

screw

amount

(3)

and

3.

switch

presser

the

highest

and

A

side

Lower

needle,

the

Hold

(23)

thread

using

for

sewing

buttonhole

pull

of

pushing

needle

of

the

(12).

foot

point.

needle

the

needle

the

presser

the

firmly.

tension

needle

the

markings

4-5.

is

sewing

and

Loosen

up

it

and

on

be

18

I44IiiR

I

Lowering

certain

For

buttons,

on

lowered.

and

(19)

right-hand

and

wards

dog,

feed

into

the

feed

the

sewing

the

do

To

move

position

then

push

left-hand

feed

this,

the

to

down

dog

work,

dog

open

metallic

(B)

right.

the

the

position

such

(22)

the

by

slide

as

has

hook

slide

pushing

engage

To

and

(A).

sewing

to

cover

the

to

it

lock

be

down

the

it

Page 23

Operating

the

machine

—

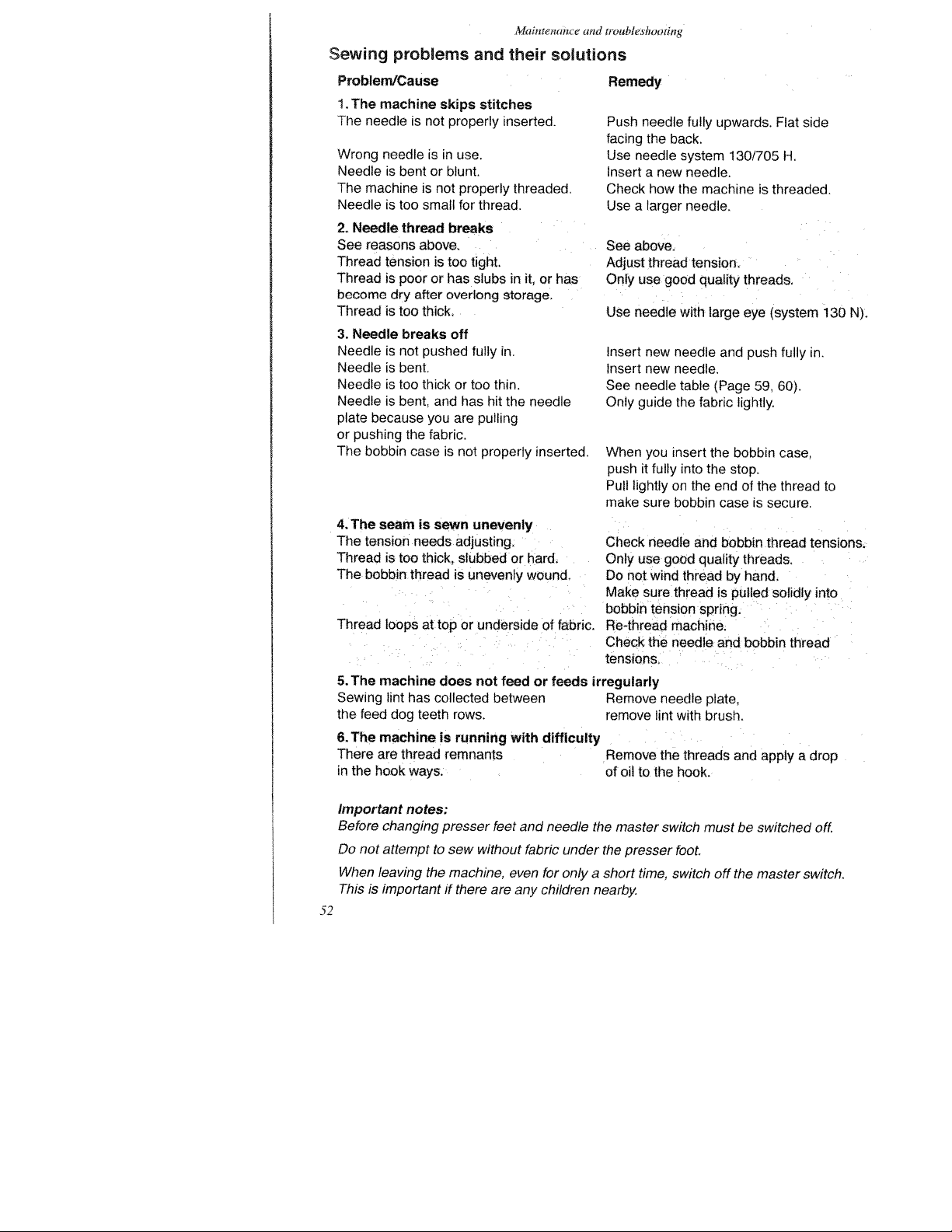

Control

the

All

control

stitch

panel

sewing

panel

pattern

programs

sewing

your

of

adjustment

and

button

relevant

the

machine.

(9)

on

The

the

recommendations

foot

various

left.

programs

hobby

are

are

1016

depicted

selected

using

on

the

the

‘9

Page 24

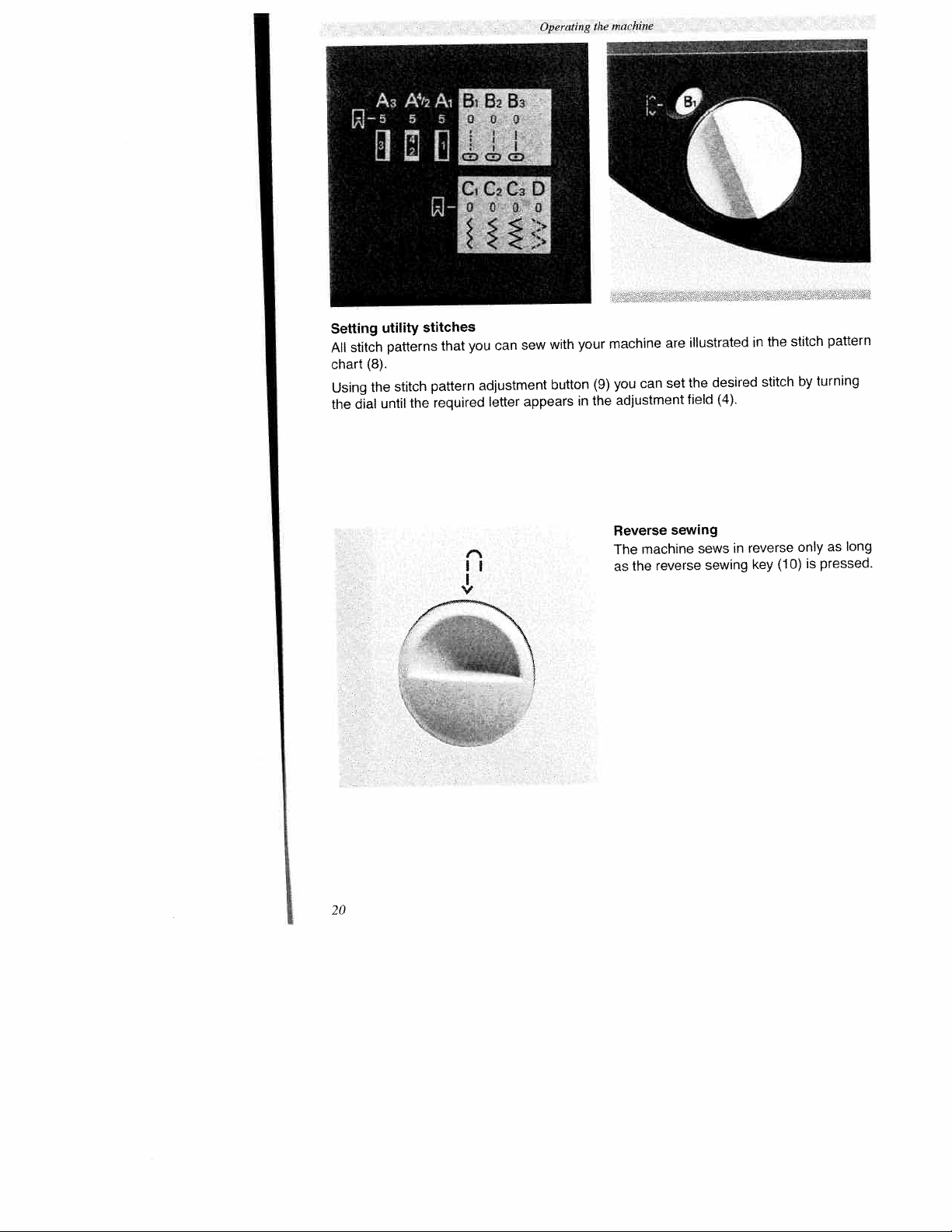

Setting

stitch

All

chart

Using

dial

the

(8).

the

utitity

patterns

stitch

until

stitches

the

that

pattern

required

can

you

adjustment

letter

Operating

sew

appears

with

button

your

in

the

machine

machine

you

(9)

adjustment

the

can

are

set

illustrated

the

desired

(4).

field

in

stitch

the

stitch

by

pattern

turning

20

Reverse

machine

The

the

as

sewing

reverse

sews

sewing

in

reverse

(10)

key

only

is

long

as

pressed.

Page 25

Utility

and

Buttonholes

Darning

Elastic

Gathering

General

Hemming

Lace

Non-elastic

Roll

Sewing

Shell

Smocking

Zippers

stitches

practical

stitch

sewing

work

hemming

on

edging

with

stitches

buttons

aids

the

sewing

twin

needle

26-27

31

25

30

22

28

35

32

23

34

24

36

29

33

2?

Page 26

P

FA

F

F

j

Utility

stitches

wid

4

pruc&aI

Needle

order

In

needle

the

sions

other.

in

is

Check

stitch.

tween

If

the

the

fabric.

If

the

loose,

side

The

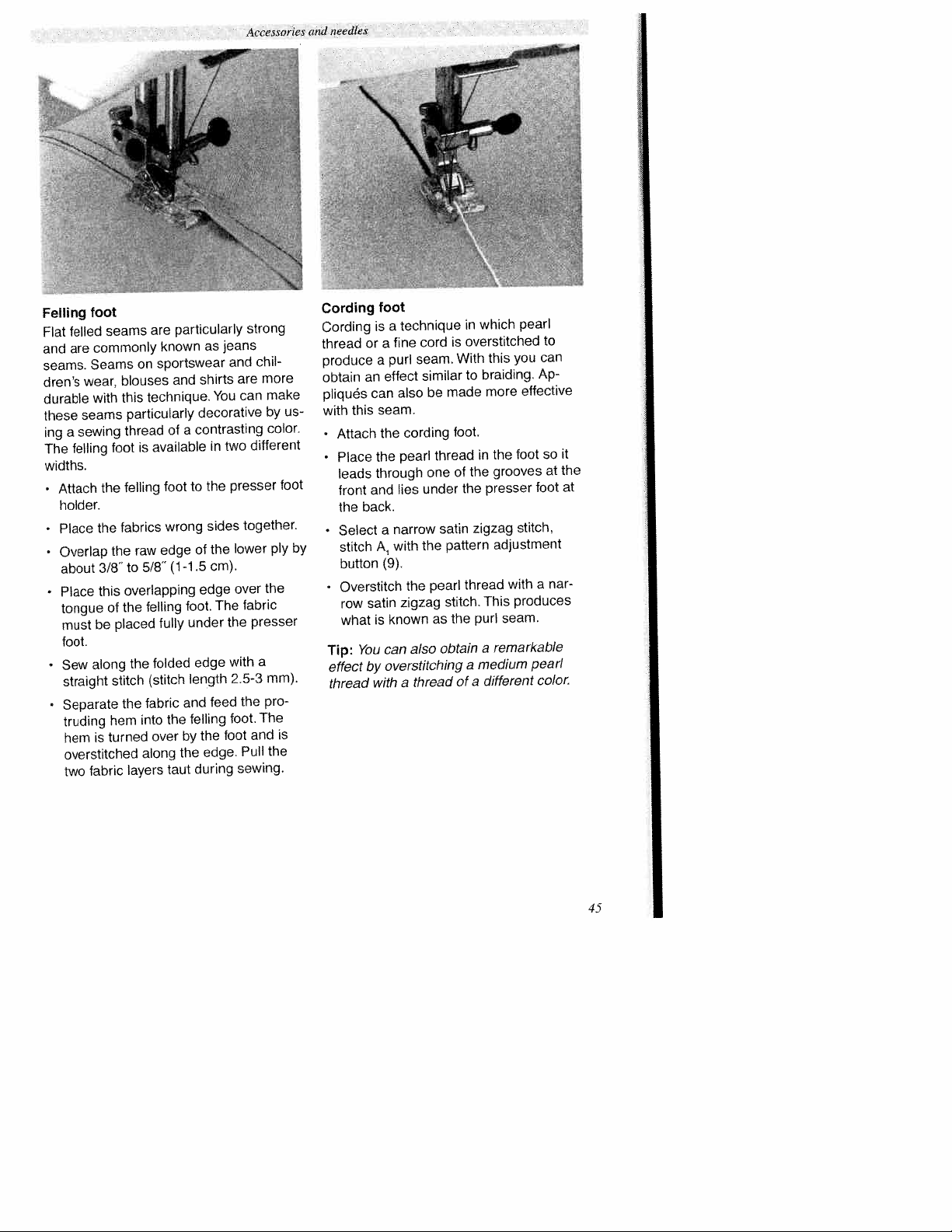

sion

sewing

thread

achieve

to

thread

must

normal

The

the

range

tension

the

thread

The

two

the

needle

interlace

needle

interlace

the

the

of

adjustment

described

is

tension

correctly

be

from

layers

thread

will

thread

fabric.

perfectly

a

and

setting

4to5.

using

interlace

of

tension

on

be

tension

will

the

of

page

on

bobbin

adjusted

for

wide

a

fabric.

top

the

on

be

bobbin

15.

utility

must

is

is

sewn

thread

to

zigzag

be

too

side

set

the

thread

seam,

ten

each

stitches

be-

tight,

the

of

too

reverse

ten.

Topstitching

broad

using

guarantees

to

inserted

is

with

aid

ensure

ofathick

piece

a

sewing

accessories)

(special

For

mend

cessory

parallel

guide

cured

Feed

To

ning

ing

thickness

the

with

topstitching

edge

the

edge

the

into

fixing

screw

thick

for

of

toot

seam,

fabric

the

work

to

feeding

support

precise

as

the

edge

work

guide.

topstitching

fabric.

the

of

C

hole

F

seams

at

recommend

we

which

under

we

This

is

it.

guide

and

the

the

the

recom

ac

which

The

is

begin

same

back

is

edge

se

plac

of

22

Page 27

Utility

titches

and

practical

4

r.

sewing

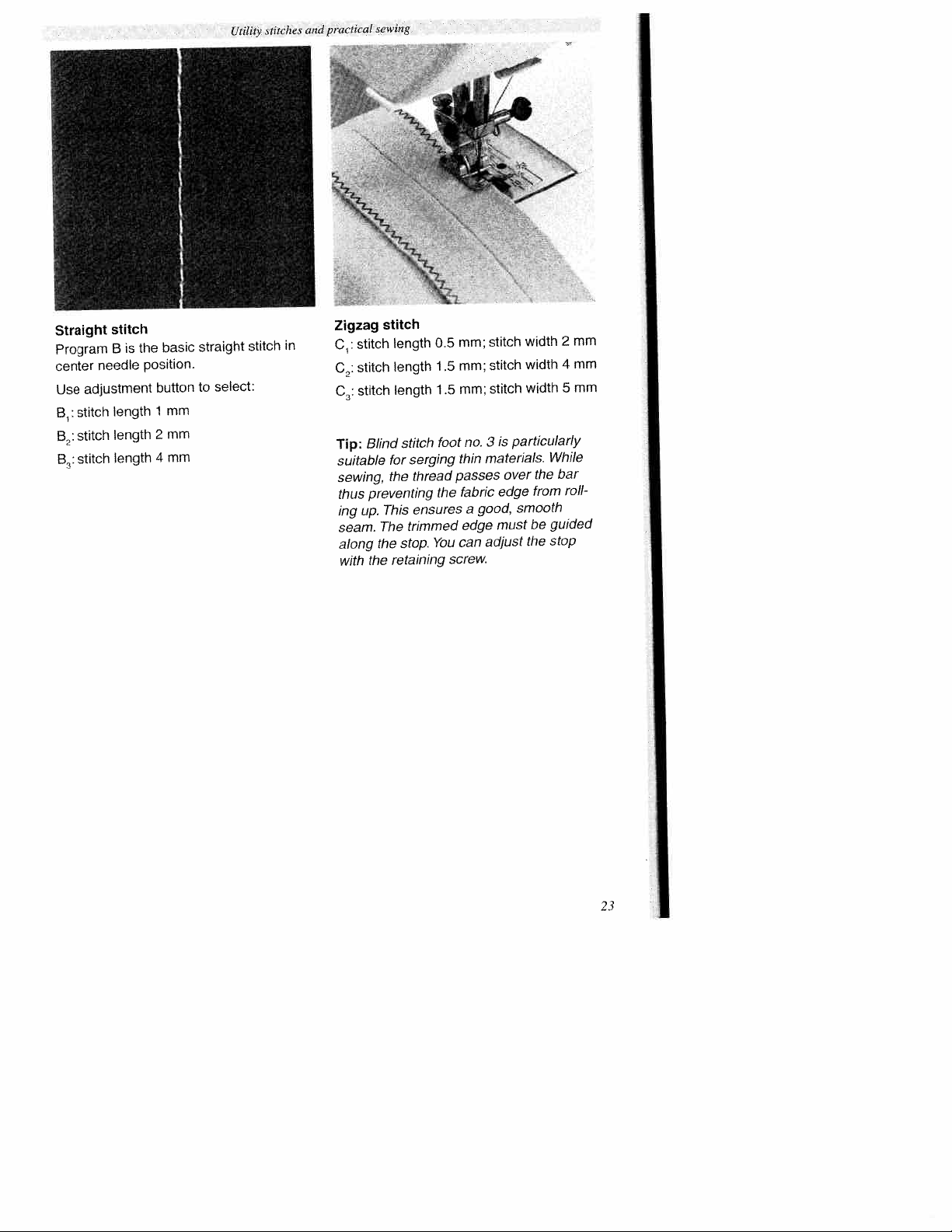

Straight

Program

center

adjustment

Use

stitch

B:

stitch

B2:

stitch

B:

stitch

B

needle

length

length

length

the

is

basic

position.

button

mm

1

mm

2

mm

4

straight

select:

to

stitch

stitch

stitch

stitch

Blind

suitable

sewing,

preventing

thus

ing

up.

seam.

along

the

with

stitch

length

length

length

stitch

for

the

This

The

the

stop.

retaining

0.5

1.5

1.5

foot

serging

thread

the

ensures

trimmed

You

mm;

mm;

mm;

no.

thin

passes

fabric

a

edge

can

screw.

stitch

stitch

stitch

particularly

is

3

materials.

over

edge

good,

must

adjust

width

width

width

the

from

smooth

be

the

mm

2

4

5

While

bar

roll

guided

stop

mm

mm

Zigzag

in

C:

02:

03:

Tip:

23

Page 28

practtctd

wtd

stitches

Utility

fi

sewing

Sewing

For

sewing

must

lowered

be

Select

02,

button

on

be

by

buttons

on

removed

(ci.

the

4

turning

(9).

buttons,

and

page

zigzag

mm

the

the

the

20).

stitch

presser

feed

dog

stitch

stitch,

adjustment

foot

must

Sewing

Attach

•

Place

•

button

hand

•

Remove

and

Wrap

•

and

on

the

match

a

and

column

the

the

knot

buttons

presser

sew

the

button

shank

it.

between

as

on

match

apart.

with

foot.

described

this

and

with

a

page.

the

thread

the

pull

sewing

holes

in

the

shank

in

the

fabric

thread

the

left

24

Page 29

4

Utility

stiteiws

prarticai

and

Elastic

Stitch

Because

used

underwear;

bands:

•

•

•

•

•

sewing

stitch

D

for

and

replacing

If

to

close

needed,

If

mm

4

Divide

mark.

and

if

you

dle

matching

the

Stretch

matching

Overlap

the

with

skirts

On

elastic

the

with

its

of

sewing

skirt,

cuffs.

its

long

fabric

pin

the

marks

the

elastic

and

is

sewn

elastic

high

on

elastic,

edge.

gather

straight

and

You

the

marks.

elastic

ends

pants

elasticity,

elastic

trouser

the

stitch

elastic

may

elastic

to

as

slightly

stitch.

onto

stitch.

band,

and

off

cut

fabric

into

it

find

to

fit

the

sew.

you

(trousers)

prepared

the

this

dress

old

edge

(c.f.

easier

the

fabric,

and

stitch

e.g.

waist

elastic

with

page

quarters

to

fabric

secure

the

edge

is

on

the

30).

han

at

25

Page 30

Utility

stitches

and

practical

sewing

Buttonholes

Sewing

not

buttonholes

have

buttonhole

Generally,

additionally

the

that

so

(from

Avalon

dissolves

that

poorly

can

it

efficiently

Embroidery

fabric

a

Using

test

a

sew

Note:

every

Before

will

it

as

red

The

is

It

Tip:

project.

your

rotated.

be

to

foot.

buttonholes

stabilize

fabric

Madeira)

in

be

the

by

and

marker

buttonhole

buttonhole

i.e.

go,

markings

important

is

some

does

water.

used

machine

darning

red

the

give

to

very

To

are

not

very

is

On

either

threads

pin,

or

first.

you

arrow

you

always

easy

make

sewn

materials

gather

good

materials

on

or

buttonholes

and

mark

must

isatthe

means

a

sew

all

with

sewing

lined,

onto

such

when

for

such

underneath

particularly

are

the

slide

of

test

a

hobby

the

of

buttonholes

doubled

silk,

as

sewn.

being

purpose.

this

velvet

as

the

much

are

starting

runner

the

red

first

determining

buttonhole

organza

fabric.

good

points

line.

models

even

fabric,

This

and

easier

of

the

of

The

the

on

easier

However,

and

isaspecial

thick

The

to

sewing

for

the

buttonholes

buttonhole

markings

red

length

same

the

because

recommend

we

it

with

rayon

type

fabrics

wool

material

sew.

attractive

foot

buttonhole.

of

the

fabric/stabilizer

is

the

is

thus

and

are

fabric

necessary

backing

stabilizer

of

feed

that

fed

seams.

always

forward

cm

0.5

does

the

paper

more

as

apart.

as

to

far

26

Page 31

Utility

stitches

mu!

practical

sewing

Program

Sewing

foot

hole

Linen

Attach

•

foot

Position

•

and

A

1

the

Select

•

for

stays

Select

-

buttonhole

and

Select

*

bartack

fabric

Select

•

few

a

fabric

Cut

pair

a

/A

412

A

3

buttonholes

buttonhole

the

forward

the

sew

desired

setting

bartack.

the

position

in

setting

the

in

setting

stitches

stays

straight

tying

stays

open

scissors

of

A

1

/

buttonhole

far

as

pattern

first

the

length.

and

A

112

Make

while

and

A

3

in

seam

length.

same

A

42

while

position.

in

stitch

stitches.

off

position.

in

buttonhole

the

the

with

foot

will

it

as

adjustment

buttonhole

sew

sure

doing

sew

reverse

the

and

again

making

setting

Make

slitting

a

or

and

go.

4-6

the

the

with

button

slide

dial

seam

stitches

fabric

this.

second

direction

sew

sure

and

B

1

sure

the

knife.

a

aid

the

at

few

the

sew

the

in

of

buttonhole

Linen

especially

sew

To

sportswear,

on

e.g.

thread.

gimp

a

elastic

On

particularly

tonhole

the

Lay

•

trusion

derneath

front.

Clamp

•

protrusion

of

Slide

•

wards

tonhole

column.

the

Pull

•

buttonhole

iwri

materials

important

stretching.

from

gimp

and

A

the

threads

the

buttonhole

the

possible

as

as

loop

with

durable

we

the

thread

pass

presser

B.

described

the

of

trim

and

gimp

buttonholes,

recommend

gimp

prevent

to

the

over

thread

the

towards

foot

left

the

to

runner

sew

and

in

the

thread

gimp

thread

the

.

thread

thread

the

rear

ends

and

far

as

the

left

using

but

pro

right

for

but

hand

into

ends.

is

un

the

the

Tip:

tack

a

pin

In

by

into

order

cutting

the

prevent

to

open

bartack.

damaging

buttonhole,

the

the

bar-

insert

27

Page 32

L’iihtv

stir

euH

ttci1

pru

u,id

s

he

•

Hemming

Topstitching

normal

and

needle.

Professional

cycling

and

easily

and

needle

twin

ensure

Please

for

needle

fold

First

desired

Topstitch

the

Cut

to

close

difficult

On

Tip:

wear

knit

topstitching

before

the

with

work

stretch

hems

shorts

the

with

available

is

that

stretch

iron

and

the

for

hem

the

protruding

seam.

the

advisable

it

is

Il

twin

be

can

materials

T-shirts,

on

can

twin

you

fabrics!

the

hem.

from

hem

materials

it.

needle

carried

sewn

be

needle.

various

in

use

width

the

edge

such

baste

to

—I—

with

knitwear

the

of

face

out

the

quickly

The

widths.

jersey

fabric

side.

fabric

ribbed

as

the

on

twin

hem

..—.

_,*•_,*.

*

/

I

Threading

Place

•

Pass

•

thread

the

Lay

•

guides

threads

the

needles.

left

I

spool

a

both

guides

threads

(15)

the

i

I

.

•.*

i*•

needle

twin

pins.

spool

the

of

each

on

thread

right

the

one

and

of

page

and

of

through

14).

the

thread

the

threads

the

of

(cf.

behind

(16)

and

each

into

28

Page 33

Utility

stifehet

and

practical

Smocking

light

Fine,

silk

and

smocking

tiful

elastic

with

ditional

the

with

thread

bobbin

must

case

however,

the

sion,

Sew

•

gather.

of

Mark

fabric

Each

•

presser

When

•

another,

its

sequent

will

Knot

end

sewing

fabrics

are

bobbin

elastic

much

is

thread,

the

tighter

test

a

the

and

additional

sewing

original

irregular.

be

the

the

of

effect

especially

work.

thread

case

thread.

stronger

the

set

be

higher

the

seam

line

first

sew

width

foot’s

several

must

you

length

seams.

threads

seam

elastic

with

as

such

suitable

For

should

you

and

As

tension

loose.

very

the

gathering

determine

to

on

along

seam

from

stretch

when

Otherwise

the

at

the

on

batiste,

smocking

wind

the

the

than

the

of

Dont

bobbin

face

the

it.

be

can

the

seams

the

sewing

beginning

reverse

threads

rayon

for

use

by

it

elastic

normal

bobbin

thread

effect.

the

side

sewn

first

next

fabric

gather

the

beau

work

an

hand

forget

level

row.

to

the

side.

ad

of

at

sub

and

ten

the

a

one

to

29

Page 34

Utilily

stirche.s

atid

practical

Gathering

program

With

and

skirts

4

mm.

effect

gathers.

of

Mark

•

the

threads

yond

Each

•

one

Gather

the

amount

the

Secure

thread

sewing

with

valances

ensure

To

should

you

first

the

and

fabric

to

ends

the

subsequent

presser

the

bobbin

of

thread.

the

ends.

the

you

B

3

line

sew

extend

foot

piece

thread.

gather

gathers

straight

can

withastitch

consistent

a

two

sew

the

on

along

approx.

the

fabric.

of

seam

width

fabric

of

You

how

by

by

stitch

gather

gathering

three

or

side

face

Allow

it.

10-20

be

can

the

from

pulling

by

determine

much

knotting

sleeves,

length

rows

of

the

cm

sewn

last.

the

you

the

of

be

pull

30

Page 35

Utility

titches

and

practical

Darning

Darning

suitable

Sew

•

til

that

it

sewing

with

for

over

well

is

the

with

repairing

the

rows

elastic

the

elastic

the

damaged

covered.

overlap.

stitch

stitch

damaged

area

Take

is

care

D

especially

areas.

rows

in

ensure

to

un

WW*

Repairing

tears,

On

useful

is

reverse

the

fabric

laid

ensures

a

Lay

•

material.

than

Sew

•

ance

Trim

•

the

to

Sewing

cover

To

sew

to

area.

aged

Baste

•

damaged

fabric.

Sew

•

stitch.

tic

Trim

-

seam

To

Tip:

patch,

the

in

is

the

pivot

tears

frayed

to

lay

reinforces

you

piece

damaged

the

over

with

underlaid

the

seam.

on

larger

new

a

the

over

the

from

simplify

turn

fabric.

fabric.

edges

piece

a

of

side

perfect

a

fabric

of

must

It

damaged

the

size

the

patches

holes

piece

new

area

fabric

the

damaged

the

turning

handwheel

the

Raise

the

the

always

area.

of

piece

well,

of

piece

the

of

area

reverse

small

or

fabric

of

The

fabric.

workpiece

repair.

underneath

a

be

area

tear.

the

fabric

of

is

it

onto

fabric

fabric

of

side

face

with

edges

back

side

corners

the

until

presser

the

holes

under

under

and

the

larger

little

accord

in

back

necessary

the

the

onto

the

of

the

the

to

fabric.

the

of

of

needle

the

foot

it

dam

elas

the

and

3’

Page 36

Sewing

are

There

skirts

For

zipper.

tered

(trousers),

types

ferent

stores:

retail

outerwear

and

ommend.

as

such

plastic

finish

softer

in

different

we

a

metal

jeans.

zipper

zippers

recommend

men’s

For

lapped

zippers

of

invisible,

to

zippers

For

will

your

to

ways

zipper

are

metal,

name

other

all

work

completed

A

to

inserting

or

ladies’

a

few.

for

well

Utility

in

sew

works

available

plastic,

We

heavier

materials

create

and

garment.

p

titche

zippers.

cen

a

pants

best.

in

jeans

rec

fabrics

all

For

it

pers

to

sew

teeth

the

The

per.

(optional

ry)

can

foot

the

in

left

the

pending

sewing

types

important

is

close

of

zipper

accesso

engaged

be

holder

right,

or

on

of

the

the

zip

to

foot

zip

to

de

method

insertion.

of

practical

and

Dif

a

a

Inserting

(concealed

•

Attach

sory)

Baste

•

position

that

presser

Sew

•

needle

foot

er

You

•

to

the

cross-wise

32

to

or

the

in

can

end

centered

on

zipper

the

the

pin

under

it

teeth

foot.

of

half

in

the

close

and

now

of

seam.

both

right

the

run

the

material.

sew

the

zippers

sides)

foot

side.

zipper

the

along

zipper,

the

the

zipper

(optional

place

in

presser

the

leaving

Raise

zipper.

rest

and

of

foot

side

the

the

stitch

acces

and

so

of

the

press

seam

the

the

•

•

Sew

the

lel,

seam

Stop

and

Raise

zipper.

You

seam.

the

same

as

shortly

leave

the

will

second

the

the

presser

now

half

distance

half.

first

before

needle

able

be

the

foot

the

of

from

end

the

in

and

complete

to

zipper

center

the

of

the

material.

open

paral

seam

the

the

Page 37

Trouser

Press

•

1I8

seam

Baste

•

edge

Engage

•

set

Stitch

•

teeth.

zippers

the

mm)

(4

allowance.

the

that

so

the

needle

the

close

front

left

narrower

zipper

the

zipper

to

to

the

1?

seam

under

teeth

foot

the

edge

Utility

-.

allowance

the

than

the

still

are

the

on

required

the

of

stitches

over

actual

overlapping

visible.

right

and

position.

zipper

and

practical

sewing

Shortly

the

open

seam.

the

Close

•

evenly

along

Stitch

•

To

Tip:

achieve

ommend

accessories).

before

zipper

zipper

onto

using

the

the

the

accurate

the

end

and

and

other

basted

edge

of

finish

baste

zipper

seam.

seams

guide

the

sewing

the

seam,

overlap

half.

we

(special

the

rec

33

Page 38

Utility

stitches

and

practical

hemming

Roll

the

With

you

ries)

scarves,

the

edges

edges

the

neat

Double-fold

•

(about

Place

•

hemmer

B,

Leave

•

presser

the

Lower

•

ing,

the

run

presser

sewing

roll

can

or

ruffles

beforehand.

from

durable

and

11872

the

and

to

secure.

the

foot

hemmer

the

guide

hemmer.

underneath

foot.

hemmer

finish

fraying

the

mm

folded

sew

needle

and

foot

presser

fabric

the

Ensure

(special

the

without

edge

fabric

per

fabric

a

in

insert

scroll.

foot

the

edge

having

Hemming

produces

and

finish.

edge

fold).

edge

straight

few

fabric,

the

the

and

evenly

edge

fabric

the

side

right

accesso

of

blouses,

under

fabric

while

of

iron

to

prevents

a

the

stitches

the

raise

into

sew

into

does

the

not

34

Tip:

the

zigzag

On

roll

silk,

hem

stitch.

viscose

particularly

is

and

chiffon

attractive

fabrics,

with

a

Page 39

Utility

stitches

practical

and

Lace-work

A

Lace

beautiful

achieved

clothes

serts.

Baste

•

fabric.

Stitch

lace

Carefully

•

at

wards

Overstitch

•

small

Cut

•

of

Lace

Tablecloths,

be

mings.

•

•

•

sewing

inserts

heirloom

christening

on

other

and

to

lace

the

close

very

straight

using

the

slit

Press

center.

the

garment.

the

both

stitch.

zigzag

excess

the

away

project.

your

with

edges

napkins

beautifully

enhanced

Serge/clean-finish

lace

the

Stitch

the

till

up

fabric

corners

the

over

Fold

diagonally.

Continue

until

effect

garments

face

the

both

to

stitch.

fabric

these

edges

fabric

corners

and

the

the

onto

corner.

first

edges

all

can

wear,

edges

behind

the

of

clothing

with

fabric

face

and

are

be

children’s

lace

with

side

the

edges

lace

on

lace

edges.

side

stitch

stitched.

of

the

of

can

trim

in

the

the

lace

to

with

back

of

them

a

all

the

35

Page 40

edging

Shell

shell

The

fabrics

soft

frequently

It

is

undergarments.

on

tension

thread

will

edge

Serge

allowance.

seam

sure

Make

•

presser

provides

This

edging

edge

such

pull

the

foot

effect.

is

used

is

in.

fabric

that

at

very

as

set,

half

a

silk

The

edge

the

more

effective

and

an

as

tighter

the

fabric

of

Utility

for

rayon

edge

the

farther

iron

and

runs

foot

the

prominent

stitches

thin,

fabric.

finish

bobbin

the

over

under

width.

shell

shell

the

the

and

practical

Tip:

thread

the

trast

cotton

ent

sewing

If

you

at

shell

the

at

thread

colored

add

the

edging

same

light

a

edge

you

colored

you

and

time.

can

fabric

pearl

strengthen

can

obtain

Instead

place

also

underneath.

a

cotton

pretty

of

pearl

differ

a

con

36

Page 41

Traditional

techniques

Patchwork

Richelieu

quilt

embroidery

39

40

38

37

Page 42

T,,dirionc,1

T

j

e1nb,y)derv

I

Iechniquev

Richelieu

very

This

embroidery

Transfer

the

of

Place

lizer

and

lizer.

Attach

•

make

To

•

sew

straight

mm).

Carefully

•

areas

mately

not

maintain

the

sewing.

Embroider

•

stitch

When

•

tear

stabilizer

areas

machine.

under

tightly

all

cut

areas

away

sewing

•

•

artistic

is

your

fabric

layers

two

foot

the

the

of

stitch

cut

that

1/8”

away

the

zigzag.

satin

all

and

water.

in

form

easy

pattern

using

area

the

hoop

number

embroidery

contours

(stitch

away

form

will

mm)

(2

the

shape

while

contours

the

stitching

large

dissolve

bar

of

create

to

onto

fabric

a

water-soluble

of

be

to

fabric

the

your

to

0

twice

length

fabric

the

cutouts

the

from

stabilizer

and

is

of

areas

remaining

eyelet

and

your

with

right

the

marker.

stabi

embroidered

stabi

and

machine,

stable,

more

using

approx.

the

from

approxi

stitching.

helps

it

—

stability

with

of

satin

a

completed,

water-soluble

small

side

the

1

Do

38

Page 43

rraditional

ernbividery

Patchwork

Quilting

nique.

ican

material

popular

thusiasts.

Patchwork

sively

have

ideas

A

of

pieces

continually

top

the

ting

the

uniform

techniques

The

settlers

by

the

a

always

quilt

material,

of

layer

middle

and

quilt.

quilt

traditional

is

a

method

developed

remnants

artistic

quilts

hand.

possibility

reality

Lots

material

changing

the

of

layer

connected

quilt

The

piece

that

has

hobby

used

Nowadays,

to

much

in

a

consists

geometrically

of

are

patterns

This

quilt.

polyester

of

to

backing

fabric.

of

hand

the

to

become

many

for

be

to

make

shorter

three

of

joined

is

the

sewing

wives

make

sewing

sewn

however,

your

together

to

tacked

or

back

usually

is

of

use

very

a

exclu

creative

time.

layers

shaped

form

onto

cotton

layer

tech

Amer

of

en

you

in

the

bat

of

one

3v

Page 44

Traditional

embroidery

And

When

simply

cushions,

projects.

iechniques

this

out

Cut

ing

templates

yourself.

mm)

should

templates.

Spread

in

accordance

small

squares

together.

together

sewn

quilt.

of

the

The

seam

not

ally

towards

the

Baste

batting

three

these

then

sewn

stitches.

small

more

and

machine,

Quilting

away

3

mm

number

foot

(see

the

bind

is

what

piecesofyour

the

you

A

seam

already

these

pieces

with

which

These

and

allowances

serged

darker

the

completed

backing.

and

layers

together

However,

practical

with

i.e.

usually

is

from

or

the

0

page

quilting

the

edges

wearable

do

you

have

allowance

be

the

squares

will

are

and

fabric

of

by

with

the

stitched

the

quilt

46).

finished

is

or

art

quilt

bought

included

in

out

pattern

can

you

will

form

of

quilts

always

side.

top

quilt

traditional

In

material

hand

it

the

straight