Pfaff 1246, 1245 User Manual

1245

1246

Instruction

manual

2962-17

Betriebsanleitung

841

engi.

10.97

_______

This

chapter

Instruction

,,Specifications”.

manual

is

valid

for

all

models

and

subclasses

listedinthe

The

part,

reprintng,

only

is

copying

permitted

source.

PFAFF

G.M.

Aktiengesellschaft

-

67653

-

67655

3020

Kaiserslautem

1

54

Kaiserslautern

Postfach

D

Königstr.

D

Editing/Illustrations

Verlag-TO

D-77901

Lahr

translation

or

with

our

of

previous

Instruction

PFAF

permission

and

Manuals,

with

written

whether

reference

in

whole

the

to

in

or

Contents

Chapter

Index

Page

-

1

1

.01

.02

1

1

.03

.04

1

.05

1

.05.01

1

1

.05.02

1.06

2

3

3.01

3.02

3.03

3.04

3.05

3.06

Safety

Directives

General

Safety

notes

symbols

Important

Operating

Operating

Specialist

personnel

Danger

Proper

use

Specifications

PFAFF1245

Possible

Max.

models

number

PFAFF1246

Possible

Max.

models

number

on

for

points

specialist

and

personnel

and

of

stitches/min

1

and

of

stitches/mm

1

safety

the

user

personnel

subclasses

subclasses

1-1

1

1

1

1

1

1

1

1-4

2

3

3-1

3

3

3-3

3

3-4

-

1

1

-

-

2

2

-

3

3

-

3

-

1

-

1

-

1

-

2

-

3

-

4

5

5.01

5.02

5.03

5.04

6

7

7.01

7.02

7.03

7.04

7.05

7.06

7.07

7.08

Disposal

Transport,

Transport

Transport

Disposal

of

Storage

Explanation

Controls

switch

On/off

Pedals

(on

Pedal

(on

the

on

Key

for

Lever

regulator

Feed

regulator

Feed

Adjustment

the

of

packaging

the

to

within

the

of

machines

machines

machine

lifting

nut

machine

customer

customer’s

the

packaging

symbols

the

with

with

head

presser

the

reverse

/

machines

on

the

for

storage

and

subclass

automatic

(for

sewing

top-feed

premises

machines

foot

with

-91

0/01>

presser-foot

with

backtacking

stroke

lifter

(subclass

backtacking

mechanism

-910/98)

mechanism

-91

1/97

-91

1/97)

-

4

-

5

-

5

-

5

-

5

-

5

-

6

7-1

7

77

7

7

7

7

7

1

1

1

1

1

1

1

1

-

1

1

-

-

2

2

-

3

-

3

-

4

-

FAFF

Index

8

8.01

8.01.01

8.01.02

8.0103

8.01.04

8.01

8.01

8.0107

8.02

8.03

9

9.01

9.02

9.03

9.04

9.05

9.06

9.07

05

.06

Contents

commissioning

Mounting

and

Mounting

table-top

Adjusting

Adjusting

Mounting

Mounting

Mounting

Mounting

Mounting

the

V-belt

the

upper

the

lower

the

tilt-over

spool

the

sewing

the

Commissioning

machine

Switching

the

Preparation

needle

Inserting

Inserting

Winding

the

the

the

needle

bobbin

Removing/Threading

bobbin

Inserting

Threading

Adjusting

Threading

Adjusting

the

the

the

the

the

needle

needle

needle

needle

tension

V-belt

V-belt

safeguard

holder

machine

the

in

in

thread,

case

height

lamp

on/off

the

the

the

thread

thread

thread

thread

guard

guard

PFAFF

PFAFF

adjusting

bobbin

Adjusting

/

/

tension

I

tension

the

1245

1246

case

machine

thread

the

bobbin

the

in

the

the

in

PFAFF

PFAFF

tension

thread

1245

1246

tension

.

Chapter

-

Page

8-1

8-1

-

8

8

-

8-2

8

-

-

8

-

8

-4

8

-

8

8

9

9

9-2

9

9

9-3

9-

9

1

2

3

3

4

5

5

-

1

-

1

-

2

-

3

-

5

-

6

10

10.01

10.02

10.03

10.04

10.05

0.06

1

10.07

10.08

11

11

11

01

.02

and

Care

Servicing

Cleaning

General

lubrication

Lubricating

Lubricating

Lubricating

Checking

Emptying

Adjustment

gauges

Tools,

on

Notes

maintenance

maintenance

and

hook

the

head

the

the

top-feed

air

pressure

the

Cleaning

/

and

adjusting

the

other

intervals

excentric

drive

container

water

accessories

for

air

the

of

adjusting

filter

1

10-

1

-

10

10-1

10

2

-

10

-3

-

4

10

10-4

10-5

10-5

11-1

-

1

11

1

-

11

PFAFF

Index

11

.03

1.04

1

.04.01

11

.04.02

11

.04,03

11

.04,04

11

.04,05

1

‘1

.04.06

11

.04.07

11

.04.08

11

.04.09

11

11.04.10

.04.11

1

1

11,04,12

.0413

11

11.04,14

11.04.15

11.04.16

11.04.17

Contents

Abbreviations

Adjusting

Positioning

Positioning

Height

the

the

the

of

the

Pre-adjusting

Centering

Lifting

Driving

the

motion

motion

Hook-to-needle

Top-feed

Lifting

stroke

motion

Bobbin-case

Safetyclutch

Bobbin

thread

check

check

winder

Needle

Thread

Thread

Presser-foot

basic

feed

feed

bottom

needle

the

needle

of

the

of

the

clearance,

of

the

opener

tension

spring

spring

pressure

machine

across

dog

in

dog

feed-dog

height

the

in

bottom

bottom

feed

top

release

PFAFF

on

the

needle

feed-dog

and

needle

direction

the

direction

hole

top

rise,

with

1246

of

feeds

needle

of

sewing

thread

sewing

height

trimmer

and

needle

-900/56

guard

Chapter

,

Page

11-1

11

-

11-2

11-3

1

-

1

1

1

-

11-6

-

11

-

11

11-9

11-11

11-12

11-13

11-14

11-15

11-16

11-17

11-18

11-19

2

4

5

7

8

.05

11

.05.01

11

11.05.02

11

.05.03

11.05.04

11.05.05

11

.05.06

.05.07

11

.05.08

11

11

.05.09

11.05.10

11.05.11

11.05.12

11.05.13

11.05.14

.05.15

11

11.05.16

Adjusting

the

Pre-adjusting

Tripping

lever

PawI

Engaging

Release

Engaging

Linkage

Final

solenoid

trip

lever

rod

adjustment

Catch

Connecting

Thread-catcher

Knife

Thread

catcher

Bobbin-thread

Tension

release

Positioner

thread

the

rod

control

of

(for

height

reverse

clamp

bar

trimmer

control

the

PFAFF

position

spring

cam

-900/56

1246

cam

only)

11-20

11-20

11-21

11-22

11-23

11-24

11-25

11-26

11-27

11-28

11-29

11-30

11-31

11-32

11-34

11-36

11-38

PFAFF

Safety

Safety

1.01

1.02

Directives

machine

This

conformity

addition

In

regulations

other

mental

The

other

protection

regionally

supervisory

General

machine

This

•

completely

Notes

All

•

before

danger

The

•

machine

This

•

operated

adhered

be

When

•

bobbin),

maintenance

the

off

Everyday

•

Repairs

•

appropriately

or

When

•

removed

function

and

•

Work

Workisnot

•

Exceptions

•

Modifications

of

all

Only

•

expressly

have

us

products

shall

We

constructed

is

manufacturer’s

and

this

to

and

valid

notes

may

read

Safety

on

operating

and

may

without

to.

exchanging

when

work,

On/Off

maintenance

special

and

servicing

from

checks

electrical

on

permitted

to

relevant

the

parts

spare

point

not

been

can

notbeliable

Instruction

requirements

legal

regulations!

regulations

organisations

safety

on

be

only

understood

and

Instruction

and

machine!

the

instructions

safety

onlybeused

safety

its

sewing

threading

switch

trained

or

the

this

and

out

lead

the

machine

the

by

or

work

maintenance

personnel!

carrying

compressed

carried

equipment

on

onlytobe

are

alterations

safety

have

which

any

that

tested

negative

to

for

in

accordance

declarations.

Manual,

operated

tools

parts

regulations!

and

any

observe

social

the

of

to

are

the

for

devices.

(e.g.

machine,

is

removing

onlytobe

is

work

repairs

out

air

by

out

may

and

found

the

to

been

replacement

approved

changes

damage

with

the

also

-including

insurance

strictly

adequately

of

machine

the

purpose

safety

presser

leaving

when

separated

be

plug

the

carried

only

may

pneumatic

on

The

carried

be

in

the

parts

us.

by

the

in

which

adhered

by

be

by

Instruction

Manuals

on

the

All

needle,

to

supply!

appropriately

only

equipment

machine

approved

European

generally

all

thoseofthe

society

to!

trained

Manual!

motor

the

itself

which

for

regulations

foot,

the

from

the

from

by

out

carried

be

devices,

exceptions

only

trained

out

are

which

regulations

only

may

are

us

accessories

or

installation

The

structural

caused

be

may

regulations

accepted,

country

for

occupational

operators

manufacturer

aretobe

it

is

intended

relevant

needle

machine

power

the

mains!

appropriately

by

out

the

to

personnel!

appropriately

by

connected

50110.

EN

carried

be

used

be

to

which

and/or

characteristics

by

contained

statutory

all

and

only

and

aretobe

followed!

and

its

operation

to

feed

plate,

unattended

supply

trained

qualified

machine

this

are

trained

the

to

under

out

repairs!

for

not

are

of

use

the

of

non-original

in

the

and

environ

valid

accidents

having

after

read

not

may

are

or

dog

during

and

switching

by

personnel!

service

is

adjustments

power

staff

to

be

personnel!

supply!

observance

We

supplied

such

any

machine.

parts.

or

be

to

by

PFAFF

Safety

1.03

1.04

Safety

\

•

I

Important

This

•

operating

The

•

The

•

the

is

It

•

Itisthe

•

removed

Itisthe

•

work

symbols

Danger!

Points

Dangerofinjury

points

Instruction

personnel

Instruction

operating

machine

duty

the

obligation

deactivated.

or

obligation

the

on

be

to

for

Manual

Manual

specialist

and

regarding

and

the

of

of

of

machine.

observed.

for

the

isacomponent

all

times.

at

must

safe

operator

operator

the

operator

the

operating

user

read

be

personnel

work

only

to

to

to

and

part

before

is

methods.

operate

ensure

ensure

specialist

of

operating

be

to

the

that

that

personnel!

the

machine

instructed

machine

none

only

authorized

the

of

and

machine

as

to

perfect

in

safety

the

must

for

the

safety

running

mechanisms

persons

available

be

the

equipment

operate

first

order.

time.

are

and

the

to

of

Further

information

can

be

obtained

agent.

PFAFF

your

at

‘FAFF

1-2

Safety

t05

.05.01

1

1

.05.02

Operating

Operating

Operating

machine

operating

The

always

•

never

•

machine!

wear

not

•

ensure

also

•

always

•

safety!

Specialist

Specialist

electronics

adjustment

and

personnel

personnel

well

as

as

personnel

observe

any

use

loose-fitting

that

immediately

personnel

personnel

mechanics.

and

the

of

specialist

persons

are

taking

is

Notes

the

working

authorized

only

report

persons

are

machine.

care

obliged

on

methods

clothing

to

They

personnel

responsible

faults

of

observe

to

Safety

which

jewellery

or

persons

user

the

with

a

responsible

are

for

arising

the

in

the

could

such

operate

any

specialist

equpping,

the

in

sewing

the

following

Instruction

the

limit

chains

as

the

changes

education

the

for

area.

points

Manual!

of

level

or

machine.

the

in

machine

in

the

lubrication,

operating

and

safety

rings!

fields

maintenance,

and

must:

in

which

of

using

electrics,

cleaningofthe

the

its

limit

may

repair

and

specialist

The

always

•

switch

•

cannot

never

•

contained

when

•

the

replace

•

maintenance

personnel

observe

the

off

switched

be

workonparts

only

servicing

compressed

protective

the

the

On/Off

in

the

or

air

work!

obliged

is

Notes

switch

again

on

which

regulations

carrying

supply!

coverings

observe

to

Safety

on

before

unintentionally!

connected

still

are

EN

repairs

out

only

The

and

the

Instruction

the

in

carrying

50110.

pneumatic

on

exceptions

the

close

following

adjustments

out

the

to

to

electrical

Manual!

power

devices,

this

points

are

control

and

repairs

or

supply!

remove

function

box

must:

and

Exceptions

machine

the

checks.

all

after

ensure

are

repairs

that

from

or

it

1-3

PFAFI

Safety

1.06

A

I,”

A

I,”

A

/f\

Danger

A

working

machine

Never

Never

machine

injury!

On

the

area

while

into

reach

objects

leave

settings!

mechanically

has

motor

1

metre

of

operation

is

in

it

sewing

the

on

Objects

activated

cometoa

is

area

table

the

can

clutch

standstifll

be

to

so

become

kept

that

while

in

or

motors

Danger

bothinfrontofand

free

it

is

always

sewing!

needle

the

trapped

without

of

or

injury!

easily

Danger

plate

be

actuating

an

accessible.

of

area

slung

injury

while

away!

behind

by

adjusting

lock,

the

the

Danger

wait

needle!

the

of

until

‘FAFF

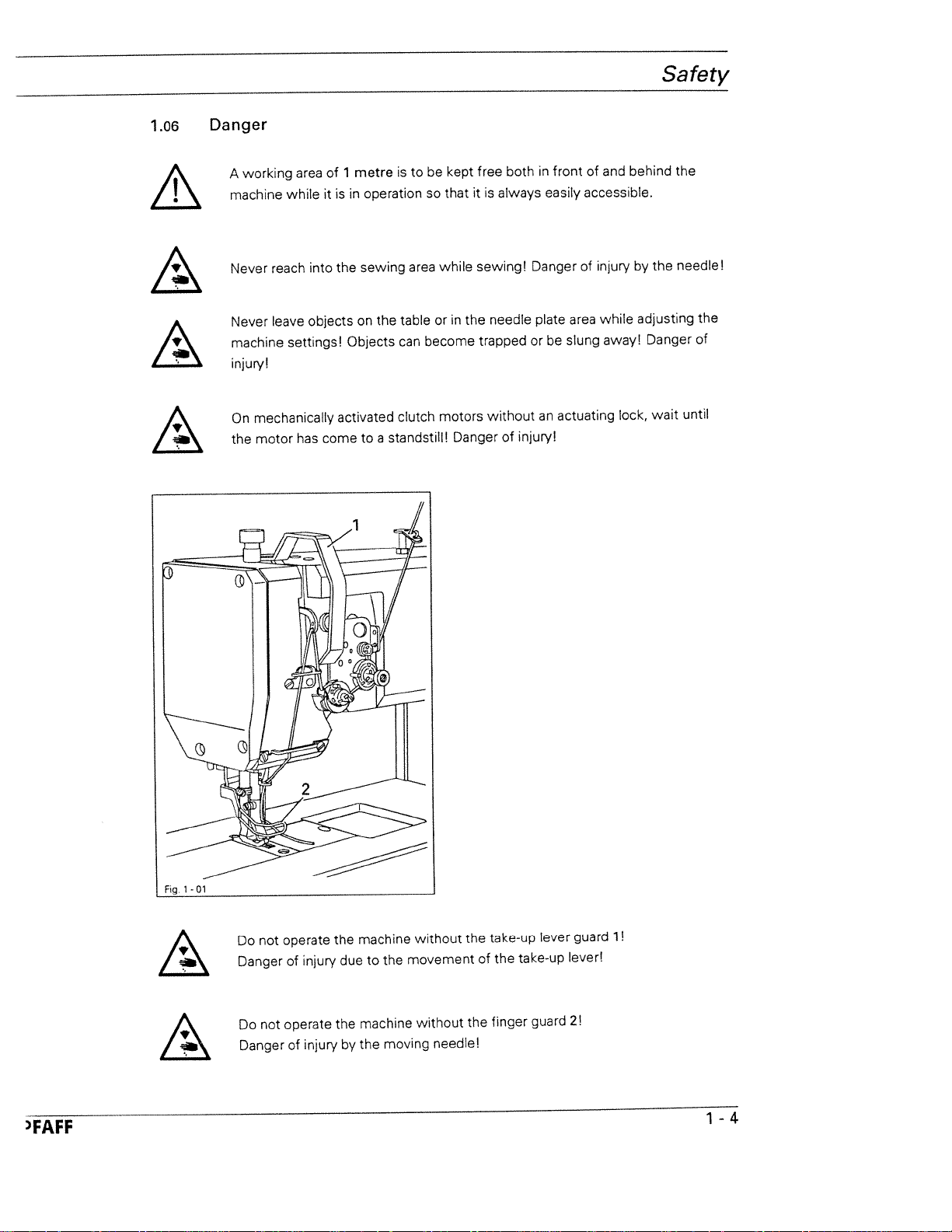

Fig.

A

1

-01

1!

guard

the

lever

take-up

guard

lever!

2!

take-up

needle!

the

the

of

finger

movement

the

moving

without

without

machine

injury

injury

the

due

the

by

to

machine

the

operate

not

V

Do

Danger

not

Do

Danger

of

operate

of

1-4

Safety

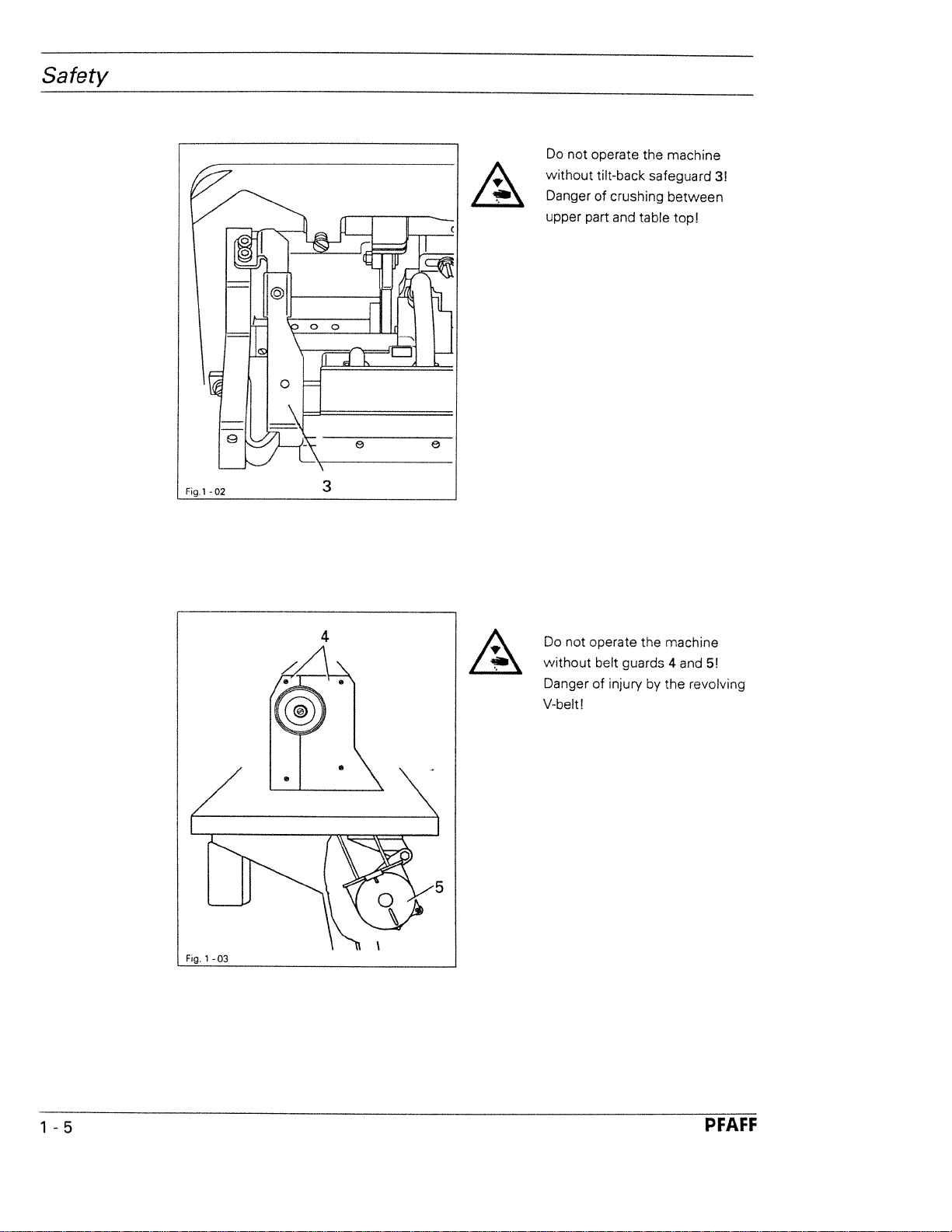

Do

not

without

Danger

upper

operate

tilt-back

of

crushing

part

and

the

machine

safeguard

between

table

top!

3!

1-03

4

A

I—”

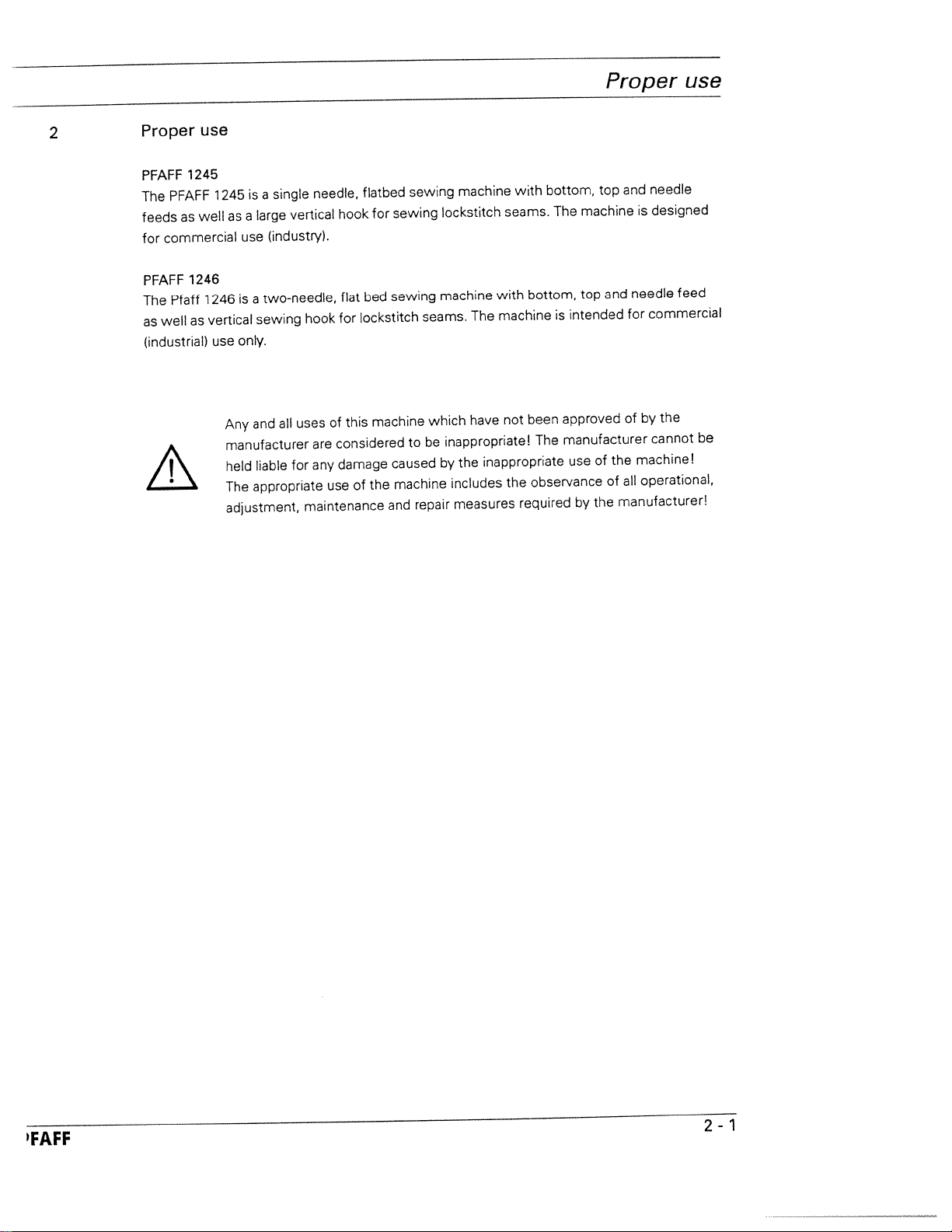

not

Do

without

Danger

V-belt!

operate

belt

of

injury

the

guards

by

machine

and

4

revolving

the

5!

1-5

PFAFF

Proper

use

2

Proper

PFAFF

The

feeds

for

PFAFF

The

as

(industrial)

use

1245

PFAFF

well

as

commercial

1246

1246

Pfaff

vertical

well

as

use

is

1245

a

large

a

as

use

two-needle,

is

a

sewing

only.

and

Any

manufacturer

liable

held

appropriate

The

adjustment,

needle,

single

vertical

(industry).

hook

uses

all

are

any

for

maintenance

flatbed

hook

bed

flat

lockstitch

for

this

of

considered

damage

of

use

sewing

for

sewing

machine

caused

machine

the

and

sewing

seams.

which

to

be

repair

machine

by

machine

with

The

have

inappropriate

the

seams.

machine

not

the

lockstitch

inappropriate!

includes

measures

with

bottom,

bottom,

been

The

observance

required

top

The

machine

and

top

intended

is

approved

manufacturer

of

use

the

by

needle

and

designed

is

needle

commercial

for

the

of

by

cannot

machine!

the

operational,

all

of

manufacturer!

feed

be

‘FAFF

2-1

Specifications

3

3.01

Specifications•

PFAFF

Stitch

Needle

Needle

ModeIC’

Max.

Model

Max.

Model

Model

Handwheel

Max.

Dimensions

Length

Width

Height

Clearance

Clearance

Fabric

Net

Power

Power

Fuse

Working

Air

Working

Emission

1245

type:

system

thickness

thread

C:

stitch

N

N8

speed

clearance

weight

supply

consumption

protection

air

consumption

noise

n=2300spm

measurement

Noise

thickness

length:

eff.

of

width

height

(machine

pressure

workplace

at

in

1/100

dia.:

machine:

(presser

level:

mm:

(synthetic

foot

head):

accordance

in

A):

raised)

with

DIN

-

635-48-A-i

45

190-

240

50

V

16

1

x

301

(!ockstitch)

110-140

6.0

8.0

chapter

see

approx.

approx.

570

177mm

approx.4lOmm

265

115

approx.

1

Hz,

60

/

max.

delayed

A,

work

I

—0.8

/

82d8(A)

134-35

20/3

mm

mm

mm

80

3.03

mm

mm

mm

mm

14

40

phase

600

action

6

cycle

kg

VA

bar

3.02

3-1

Subiect

•

A

comparable

Or

Possible

C

Model

Additional

Subclass

Subclass

Subclass

alteration

to

thicknesses

models

equipment:

-900/56

-910/

1

-91

/

of

and

thread

other

subclasses

types

processing

For

medium-heavy

Automatic

materials

Thread

presser-foot

Bartacker

trimmer

lifter

PFA

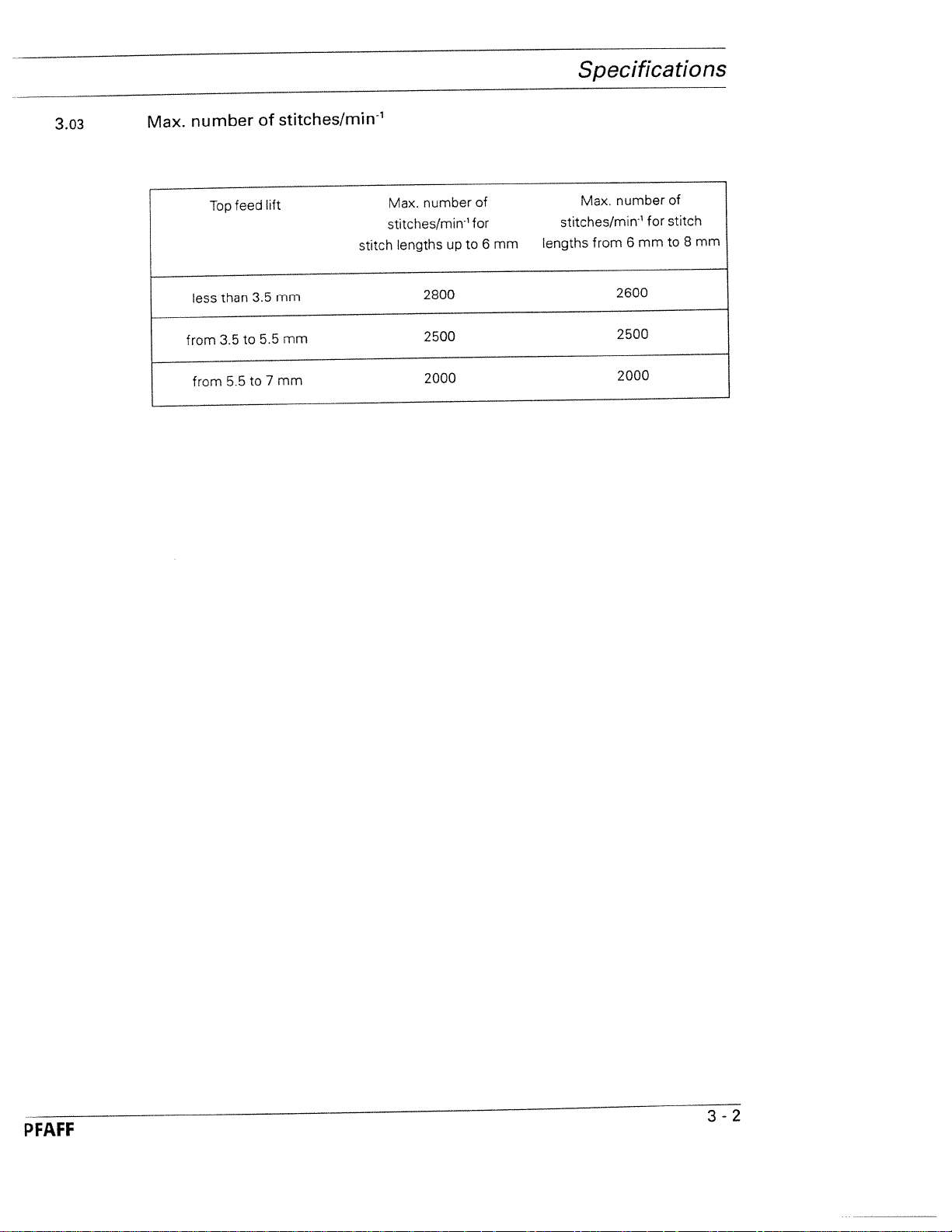

3.03

Max.

number

of

stitches/min

1

Specifications

less

from

from

Top

3.5

than

5.5

feed

to

3.5

to

5.5

lift

7

mm

mm

mm

Max.

stitches/min’

stitch

number

lengths

2800

2500

2000

up

number

of

for

mm

to

6

Max.

stitches/mirr

1

lengths

from

2600

2500

2000

of

stitch

for

mm

8

mm

to

6

PFAFF

3-2

Specifications

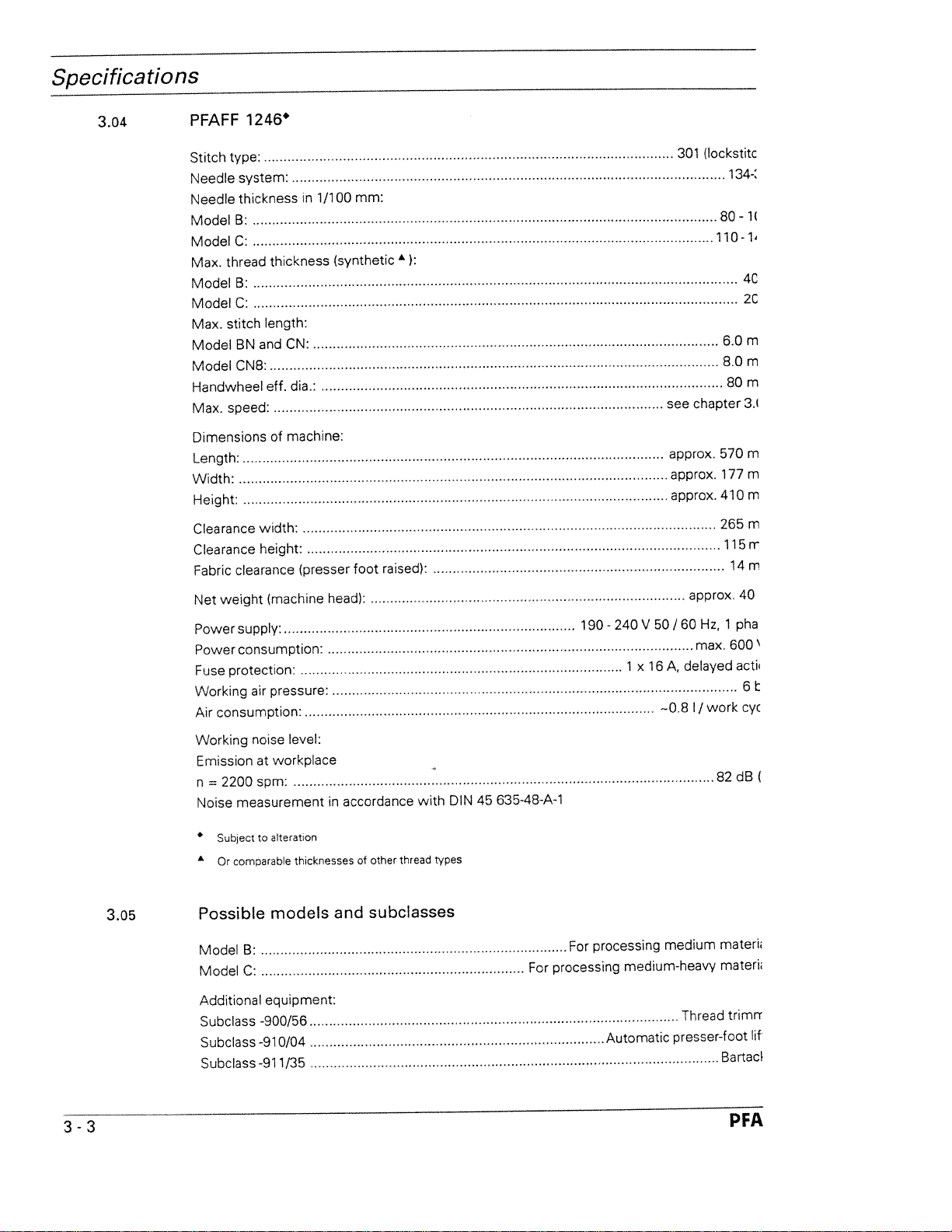

3o4

PFAFF

type

Stitch

Needle

Needle

ModeIB

ModelC

Max.

Model

Model

Max.

Model

Model

Handwheel

Max.

Width

system:

thickness

thread

B

C

stitch

BN

CN8

speed

Dimensions

Length

Height

Clearance

Clearance

clearance

Fabric

weight

Net

Power

supply

consumption

Power

protection

Fuse

Working

consumption

Air

1246

length:

and

eff.

width:

height

(machine

air

in

thickness

CN

dia

machine:

of

(presser

pressure

mm:

00

1/1

(synthetic’):

foot

head)

raised>

190

-

240

V

1

x

301

see

approx.

approx.

approx.410m

approx.

60

50/

16

delayed

A,

—0.8

(lockstitc

80-1<

110-1

6.0

8.0

chapter

570

177

265

115

Hz,

max.

work

I

/

134-:

80

14

40

1

pha

600’

acti

4C

2C

m

m

m

3.(

m

m

rn

rr

m

6

cyc

t

3-3

3o5

Working

Emission

=

2200

n

measurement

Noise

Subject

•

Or

comparable

“

Possible

Model

Model

Additional

Subclass

Subclass

Subclass

noise

at

spm:

alteration

to

models

B

C

equipment:

-900/56

-910/04

-911/35

level:

workplace

thicknesses

accordance

in

of

and

with

thread

other

subc’asses

types

DIN

635-48-A-i

45

For

processing

For

processing

medium-heavy

Automatic

medium

Thread

presser-foot

dB

82

materi

materi

trimrr

Bartac)

PFA

hf

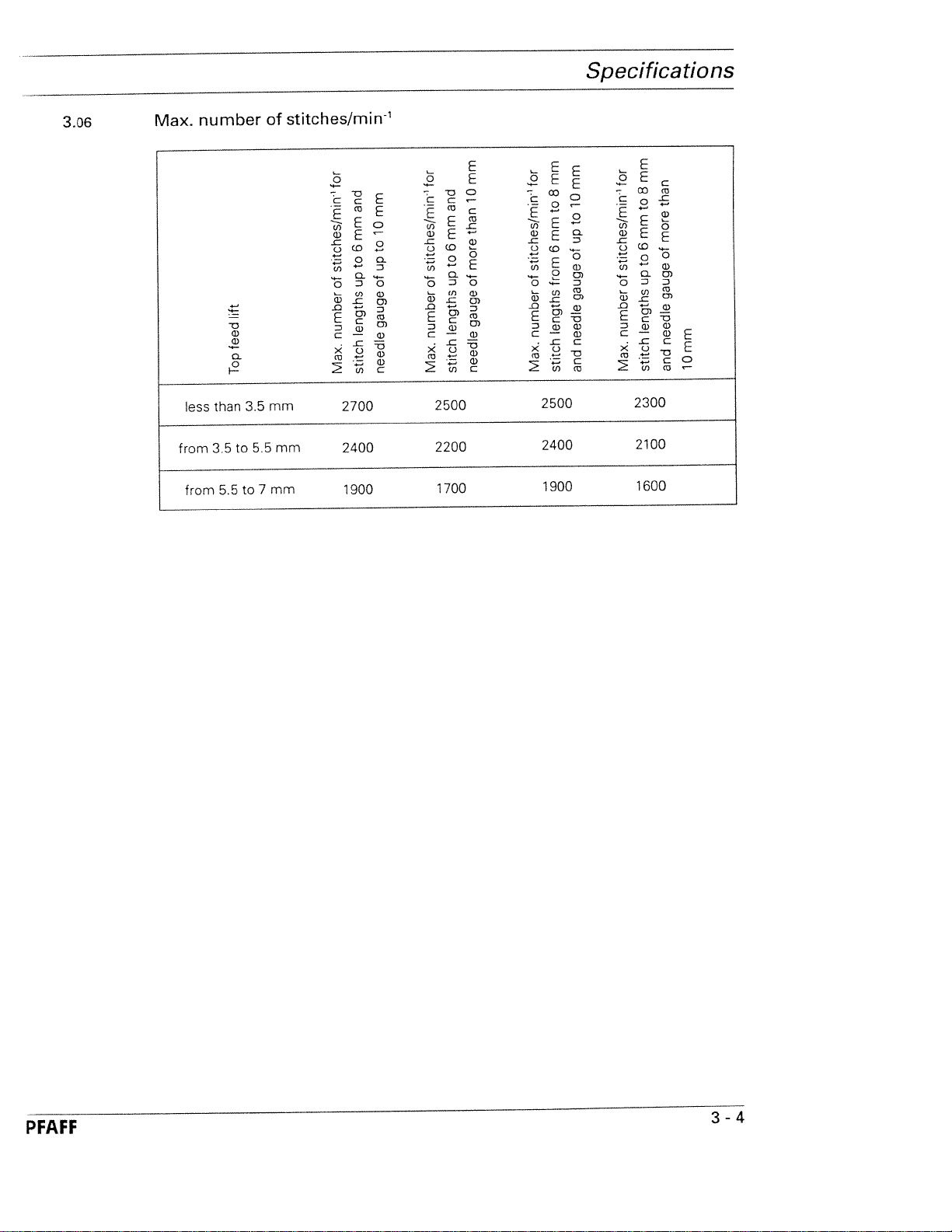

CD

(I)

C,

-4-.

Cl)

0

CD

C

x

for

and

mm

10

mm

6

to

to

up

stitches/mm

up

of

of

mm

for

10

and

than

mm

6

to

more

stitches/mm

up

of

of

mm

for

mm

8

10

to

to

mm

up

6

of

stitches/mm’

1

from

of

gauge

lift

feed

Top

b-i

D

—

S”

3

()

3

-

0,

—

0

(71

3

3

lengths

number

Max,

stitch

N)

a

a

N)

(0

a

gauge

needle

a

a

a

lengths

number

stitch

Max.

a

N)

(71

N)

N)

a

—

a

gauge

needle

a

a

a

lengths

number

Max.

stitch

01

N)

4

a

N)

(0

o

needle

and

a

a

a

mm

for

8

than

to

mm

more

6

of

to

stitches/mm’

1

up

of

gauge

lengths

number

needle

Max.

and

stitch

a

a

N)

N)

—

a

a

-

a

a

01

mm

10

n1

c)

Disposal

of

the

machine

care

of

on

is

to

is

of

in

waste

machine

machines

the

consists

be

disposed

regulations.

to

be

accordance

waste

taken

is

the

are

steel,

plastics

of

ofinaccordance

necessary

If

that

parts

with

the

responsibility

aluminium,

copper.

and

with

specialist

a

soiled

with

locally

valid

of

the

brass

the

is

lubricants

pollution

customer.

various

and

locally

tobecommissioned.

are

control

plastics.

valid

separately

regulations

I

machine

4

Disposal

The

•

The

•

The

The

•

environmental

of

proper disposal

materials

electrical

machine

used

equipment

waste

protection

Special

disposed

4-1

PFAFI

Transport

storage

5

Transport

packaging

and

packaging

and

storage

5.01

5.02

5.03

5.04

Transport

the

Within

Machines

transported.

Transport

manufacturer

The

taken

to

be

Disposal

packaging

The

disposal

Storage

machine

The

protected

longer

For

protected

be

Federal

for

the

of

from

storage

to

export

within

transport

to

the

of

of

packaging

can

against

the

Republic

are

carries

packaging

the

be

dust

the

customer’s

of

packaged

customer’s

the

liability

no

machine

the

machine

is

the

for

stored

moisture.

and

individual

corrosion

premises

Germany,

crate

in

a

for

an

in

to

parts

of

months

6

of

consists

responsibility

up

e.g.bya

machine

the

or

premises

transport

upright

wood,

of

machine,

the

of

film

wrapped

within

position

paper,

customer.

the

in

not

if

oil.

is

delivered

dependingonhow

the

only.

cardboard

use.

especially

without

customer’s

and

this

During

the

premises.

VCE

time

moving

packaging.

are

they

The

fibre.

it

should

parts,

Care

proper

be

should

is

FAFF

1

5

Explanation

6

the

of

Explanation

following

the

in

information

symbols

The

symbols

of

section

accentuated

are

have

used

Note,

symbols

the

of

the

information

Instruction

this

symbols.

by

following

Manual,

meanings:

certain

tasks

important

or

pieces

of

Cleaning,

Lubrication,

Servicing,

to

(only

be

care

greasing

repairing,

carried

adjustment,

by

out

specialist

maintenance

personnel>

6-1

PFAI

Controls

7

7.01

Controls

On/off

0

N

N

N

7O1

Fi

switch

;-

®\

•

the

Turn

the

on/off

machine

on.

also

machine

switch

is

on,

switch

The

found

be

motors.

used,

same.

the

the

the

on

on

1

light

in

on

When

switch

off

and

and

off.

the

in

illustration

the

machines

other

may

switching

by

When

switch

with

motors

not

the

is

can

Quick

are

look

FAFF

7.02

Pedals

+2

7-02

Fg.

(on

machines

with

subclas

-1

-910/01)

0

+1

With

0

+1

1

-

+2

the

=

=

=

on/off

Machine

Sew

thread

Trim

trimmer)

Raise

switch

stop

(on

presserfoot

on

machines

with

thread

7-1

Controls

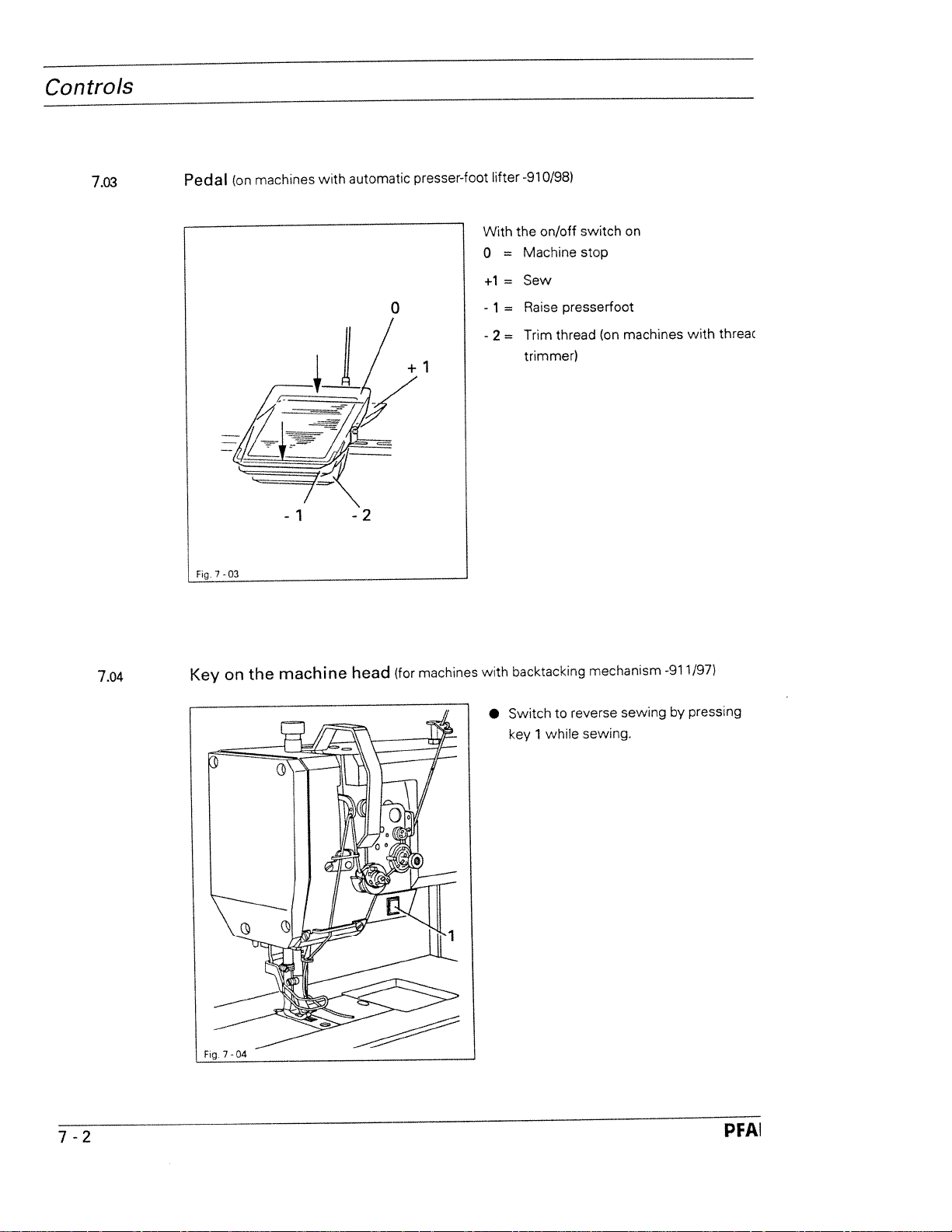

7.03

Pedal

(on

machines

with

automatic

0

presser-foot

1

lifter

With

0

+1

-

1

2

-

the

=

=

=

=

-910/98)

on/off

Machine

Sew

Raise

Trim

thread

trimmer)

switch

stop

presserfoot

(on

on

machines

with

threac

7.04

Fiq

Key

7-03

on

the

-1

machine

-2

head

(for

machines

with

•

backtacking

to

Switch

while

1

key

mechanism

reverse

sewing.

sewing

-91

by

1/97)

pressing

7-2

Fig

7-04

PFAI

Controls

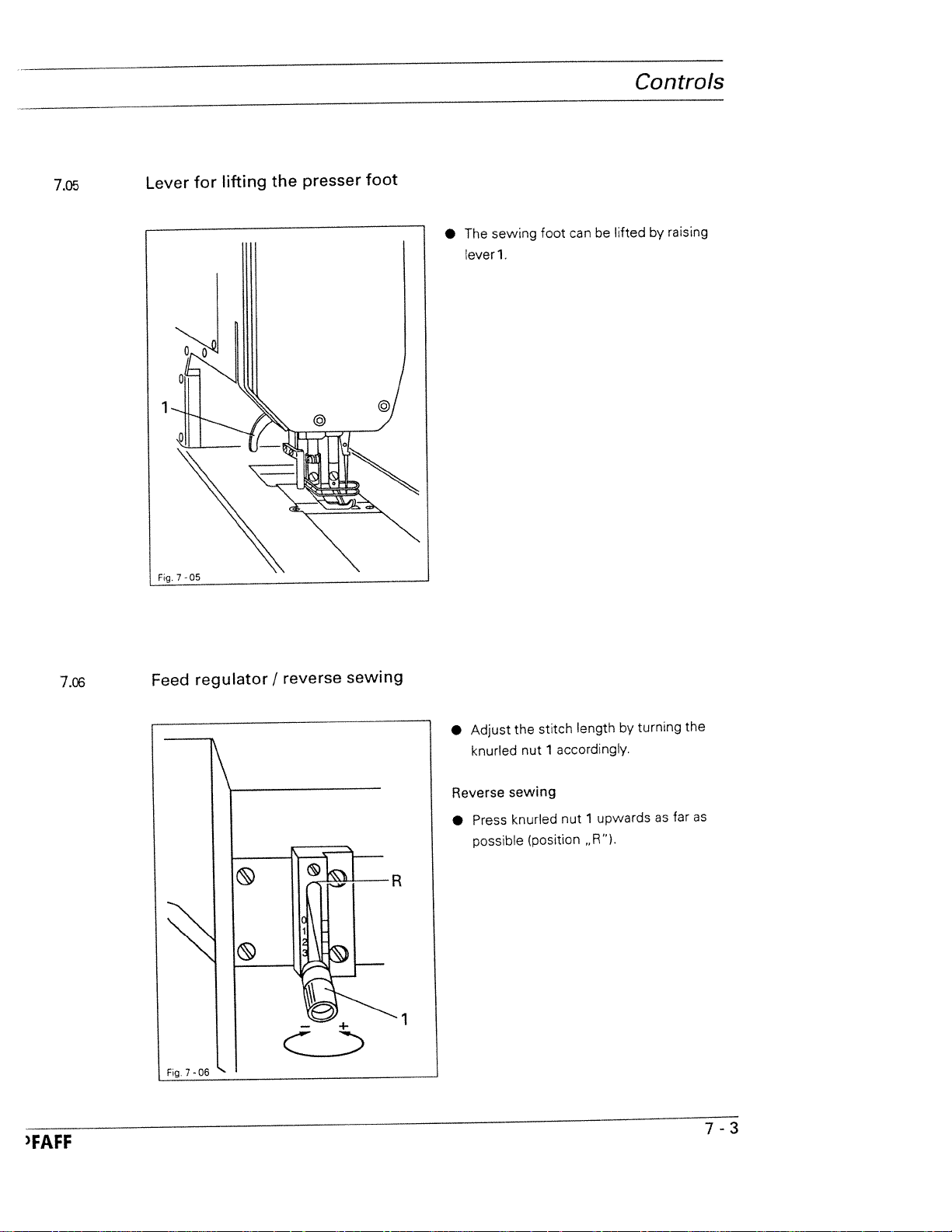

7.05

Lever

1

Fig.

presser

lifting

for

05

7

the

foot

can

be

lifted

The

•

sewing

even.

foot

raising

by

7.06

Feed

regulator

reverse

/

sewing

Adjust

•

knurled

Reverse

Press

•

possible

the

nut

sewing

knurled

lposition

length

stitch

1

accordingly.

nut

upwards

1

WI.

by

turning

as

far

the

as

FAFF

7-3

Controls

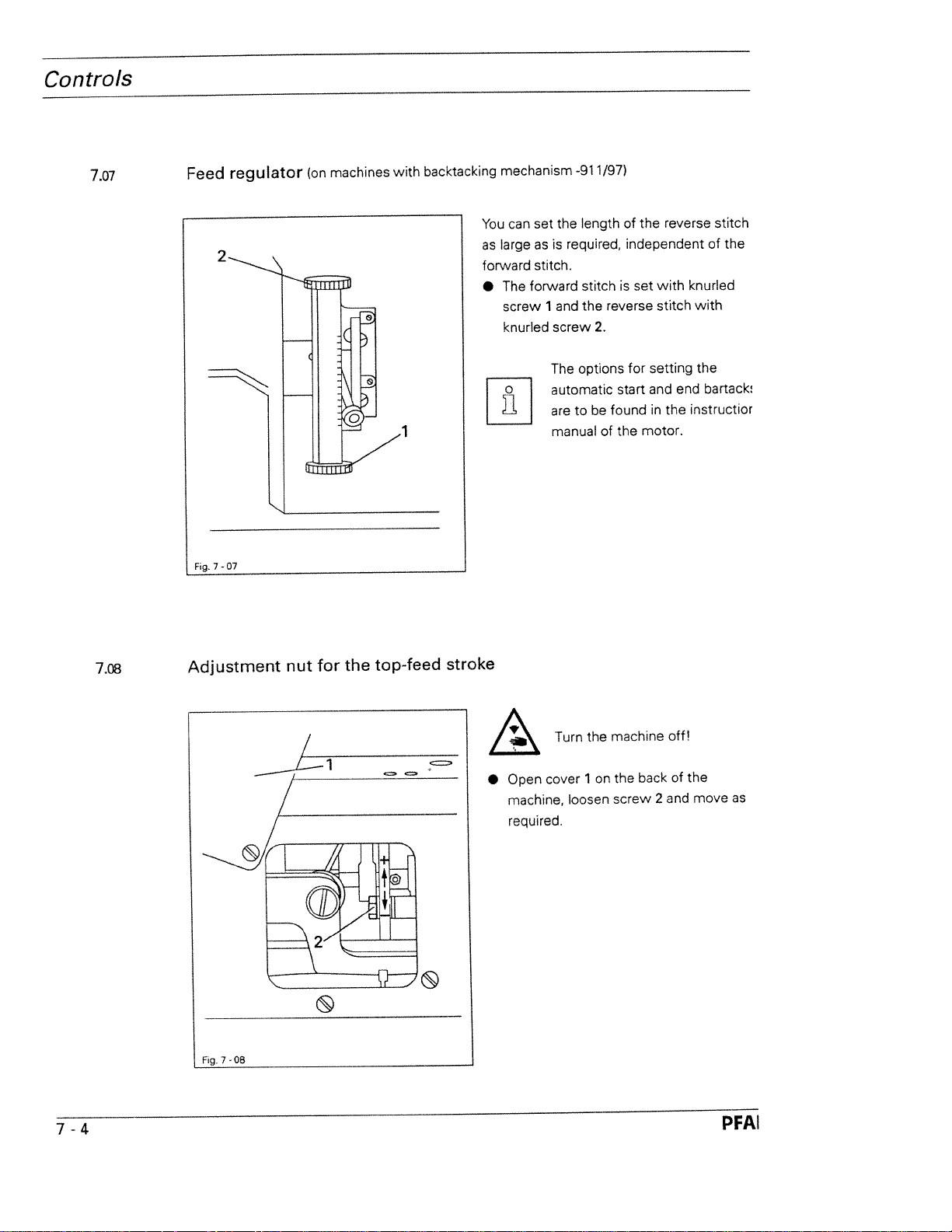

7.07

Feed

Fig.

regulator

2.

7

O7

(on

machines

with

.1

backtacking

mechanism

can

You

large

as

forward

The

•

screw

knurled

set

the

is

as

stitch.

forward

1

and

screw

The

automatic

are

manual

-91

1/97)

length

required,

stitch

the

2.

options

be

to

of

the

of

independent

set

is

reverse

for

start

found

motor.

the

reverse

with

stitch

setting

and

in

the

knurled

with

the

bartack

end

instructior

stitch

of

the

7.08

Adjustment

Fig.708

nut

for

the

top-feed

stroke

•

cover

Open

machine,

required.

Turn

loosen

the

1

machine

the

on

screw

back

off!

the

of

as

move

and

2

7-4

PFAI

the

Mounting

commissioning

8

Mounting

and

and

commissioning

machine

the

machine

8.01

8.oi.oi

A

Mounting

necessary

The

location

stable

A

o

L

Adjusting

The

All

the

If

and

and

electricity

specifications),

(see

horizontal

and

Due

following

the

machine

relevant

machine

table

the

motor,

the

reasons

to

table-top

must

safety

top

and

surface

description

a

is

only

regulations

delivered

is

which

while

even

compressed

well

as

packaging,

of

height

be

you

as

of

mounted

aretobe

without

intend

sewing.

air

sufficient

the

how

and

a

table,

use

to

supplies

table

adjust

to

commissioned

observed!

it

must

can

hold

be

must

illumination

lowered

is

top

height

the

by

ensured

be

the

weight

available

the

at

for

the

of

qualified

that

of

the

at

machine’s

transport.

table

personnel!

the

machine

the

machine’s

location.

The

top.

frame

‘FAFF

Fig.

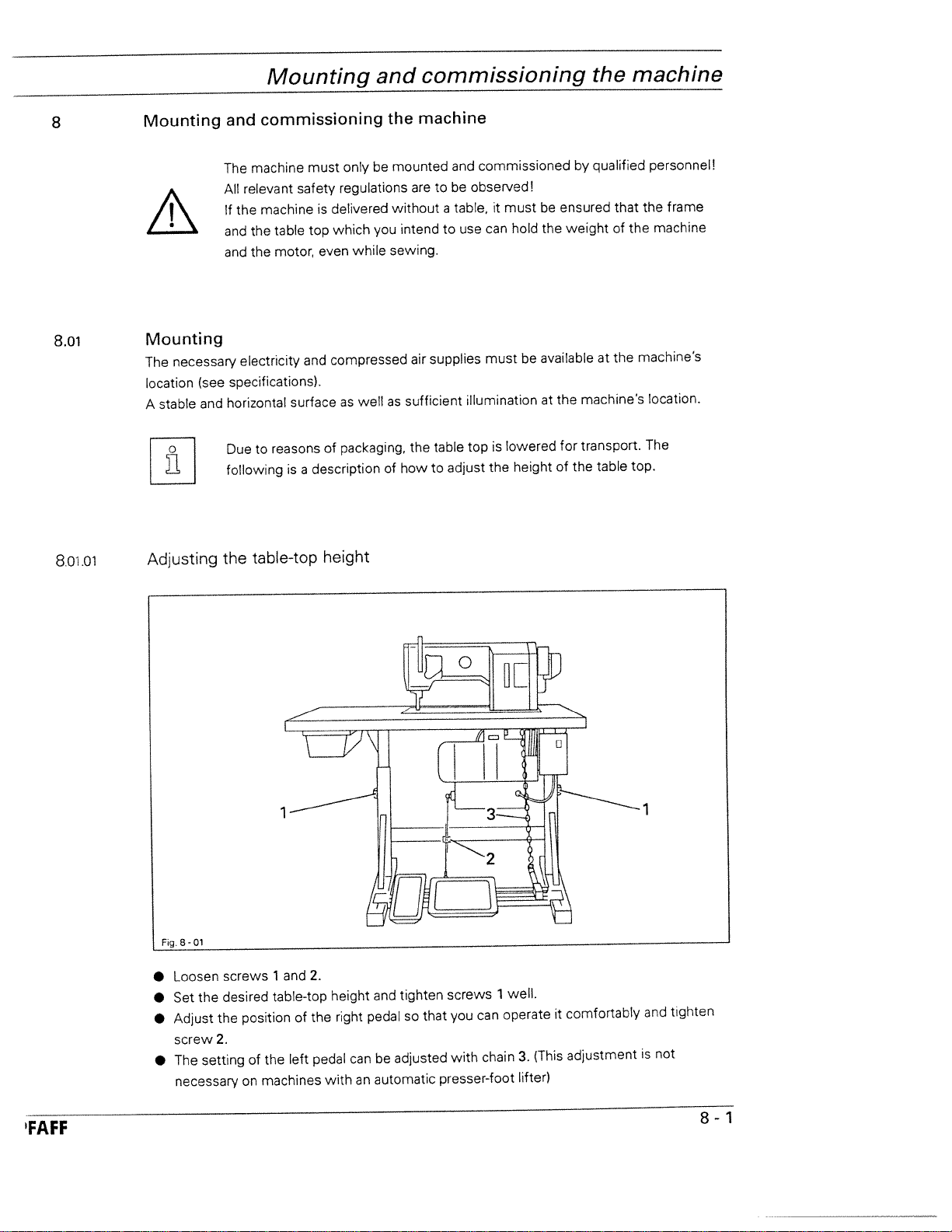

Loosen

•

Set

•

Adjust

•

screw

The

•

necessary

8-01

the

the

2.

setting

screws

desired

position

of

on

and

1

table-top

of

left

the

machines

2.

the

pedal

with

height

right

can

and

pedal

be

automatic

an

tighten

that

so

adjusted

screws

can

you

chain

with

presser-foot

well.

1

operate

3.

lifter)

it

(This

comfortably

adjustment

and

is

tighten

not

8-1

Mounting

commissioning

and

the

machine

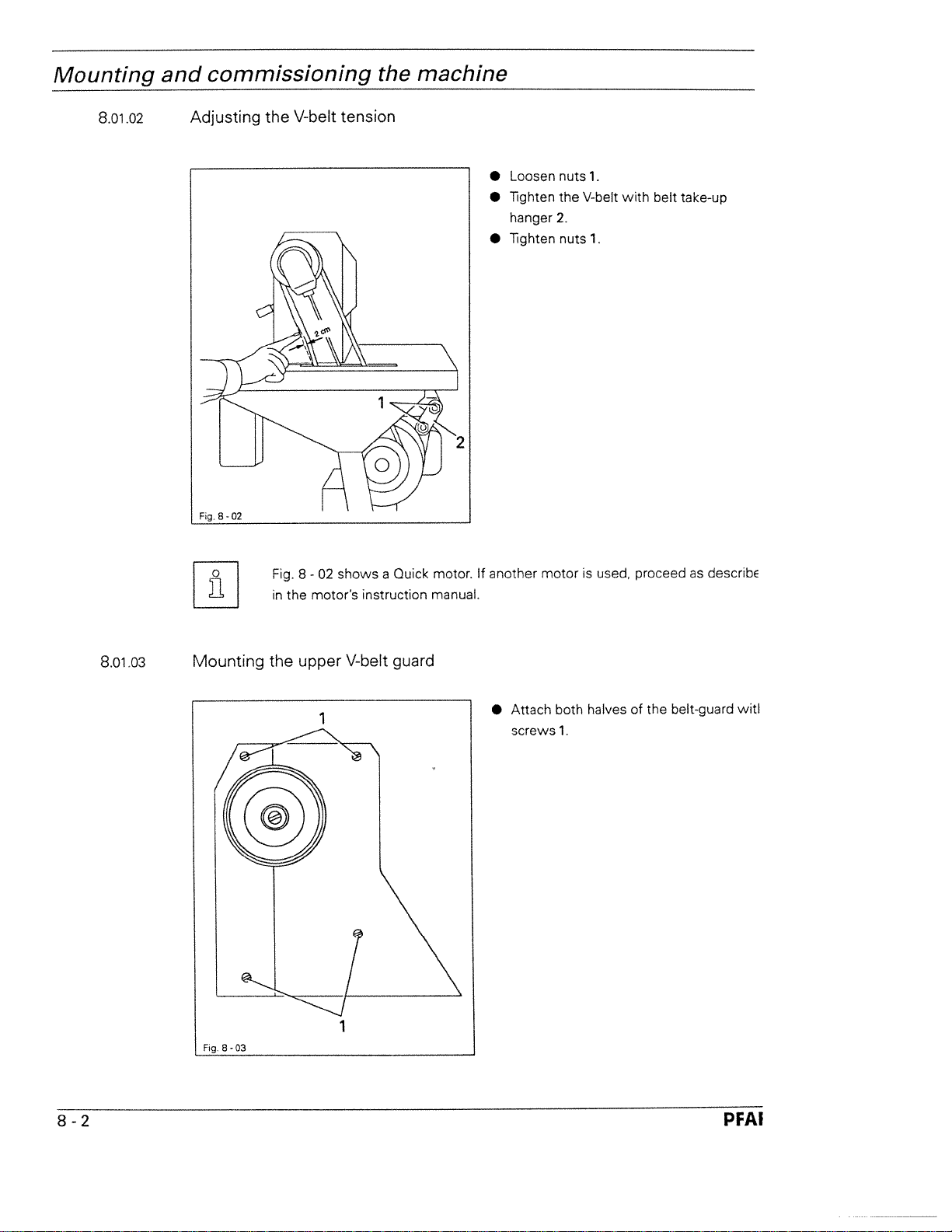

8.01.02

Adjusting

Fig.802

the

V-belt

tension

•

•

•

Loosen

Tighten

hanger

Tighten

nuts

the

2.

nuts

1.

V-belt

1.

with

belt

take-up

8.01.03

Mounting

Fig.

in

the

8-02

the

upper

shows

motor’s

instruction

V-belt

Quick

a

guard

motor.

manual.

another

If

•

Attach

screws

is

motor

both halves

1,

used,

proceed

of

the

describE

as

belt-guard

witl

8-2

Fig

8-03

PFAI

Loading...

Loading...