Page 1

Motor Control Module (MCM)

for the 4848 Reactor Controller

Meter Installation in 4848 Reactor Controller

1. Unplug the power cord of the 4848 controller. Re-

move the (2) screws located on the top/front cover at

the rear corners of the controller. Gently lift the cover

forward, which is hinged at the bottom, taking care

not to apply tension on any internal wiring.

2. If applicable, remove and discard the black hole plug

on the sloped front panel above the "RPM" text. This

can be done by pinching the clasps on the back of the

plug from the inside of the front plate.

599M

Installation Instructions

PLUG

CLASP

3. Insert the MCM (2084E) through the panel cutout,

from outside in, making sure the rubber gasket is

on the outside of the controller front panel. (If wires

are preinstalled, remove the terminal connector by

releasing the tabs on the sides of the module and

gently pulling the terminal connector off. Reference

photos below.) Slide the white mounting bracket

onto the module with the mounting screws pointing

towards the front panel. Slide the mounting bracket

forward until it touches the controller panel. The

clasps on the mounting bracket should align with the

groves on the module. Gently tighten the screws until the module is held into place. (If removed, reattach

the terminal connector.)

2100E Black Hole Plug

Terminal Connector Removal

Page 2

MCM Installation

Meter Installation in 4848 Reactor Controller (Continued)

Meter Installation Diagram

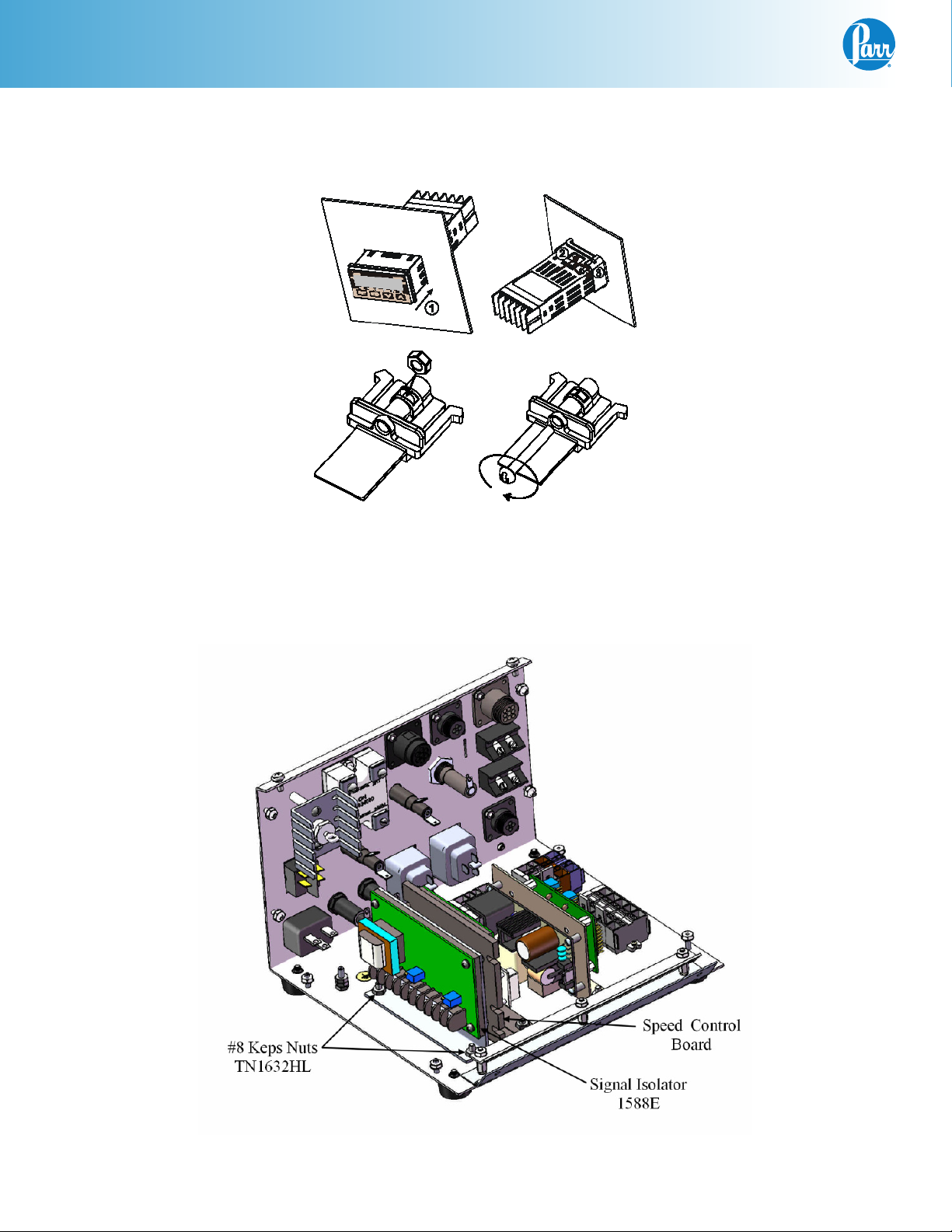

4. Mount the 1588E Signal Isolator, orient as shown, using the (2) TN1632HL keps nuts supplied.

4848 Inside View

2

Parr Instrument Company

Page 3

MCM Installation

Wiring Installation in 4848 Reactor Controller

1. If applicable, remove the black hole plug on the back of the controller labeled RPM INPUT. This can

be done by pinching the clasps on the back of the plug from inside the back panel.

2. Insert the 4-pin receptacle (494E), on the A2106E harness, into the RPM input hole from the inside

out. Slide the ring terminal, from the A2106E green wire, onto one of the mounting studs. Mount the

receptacle using the (2) #4 keps nuts provided.

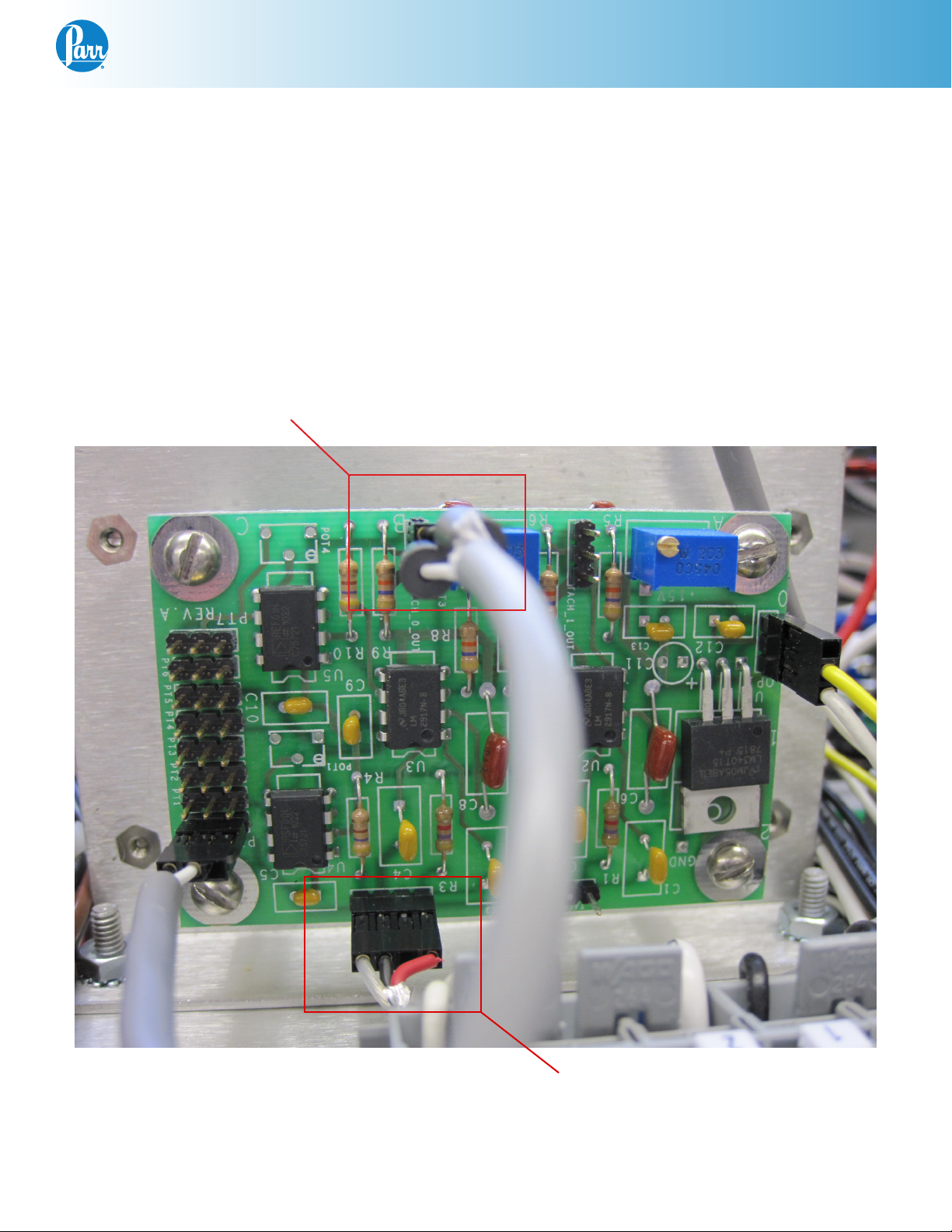

3. Locate the A1695E excitation board as shown.

TACH OUT

A1695E Excitation Board

TACH IN

www.parrinst.com

3

Page 4

MCM Installation

Wiring Installation in 4848 Reactor Controller (Continued)

4. Attach the 4-pin edge connector from the

A2106E to the “Tach In” (slot A). Align the empty

spot on the edge connector to the empty pin on

the “Tach In” of the A1695E excitation board.

Reference the A1695E Picture on page 3.

5. Find the 2 wire cable, black and white wires with

one end stripped and the other end has a 3 pin

edge connector as shown, and plug the 3-pin

edge connector to the “Tach Out” (slot A). The

Orientation of the black wire does not matter;

the connection can be plugged in either way.

6. The stripped end of the 2 wire cable attaches

to the 2084E meter. Take care not to apply too

much torque which could cause the wire to

eventually break. The meter’s pins are labeled

1-12, as shown. The black wire from the A2106E

harness attaches to pin 6, and the white wire attaches to pin 4. (This may already be connected

for your convenience.)

TACH OUT

TACH IN

7. Find the 2 wire cable with white and black wires

that has both ends stripped, and attach one end

to the 2084E meter. White wire #3 to terminal

#11 and black wire #4 to terminal #12. (This may

already be connected for your convenience.)

The other end of the white wire #3 attaches to

terminal block position #4 and the black wire #4

attaches to terminal block position #3.

Note: The terminal block position can be opened

up using a small flat head screw driver to release

the tension from the spring inside the block so you

can press the wire against the spring.

7 8 9 10 11 12

1 2 3 4 5 6

2084E Pin Out

Wago Terminal Block

4

Parr Instrument Company

(Pin 5 is blank)

Page 5

MCM Installation

Wiring Installation in 4848 Reactor Controller (Continued)

8. Find the remaining black wire #2 from the kit and attach one end to pin 1 on the 2084E meter. Take

care not to apply too much torque which could cause the wire to break. (This may already be connected for your convenience.) The other end attaches to terminal block position #5.

9. Find the remaining white wire #1 from the kit and attach one end to pin 2 on the 2084E meter. Take

care not to apply too much torque which could cause the wire to break. (This may already be connected for your convenience.) The other end attaches to terminal block position #2.

10. Find the black wire #5 (with one end stripped and one end has a snap spade terminal connector)

and attach the stripped end to the 2084E meter terminal #9. (This may already be connected for your

convenience.) The snap spade end attaches to the 1588E signal isolator terminal #5.

11. Find the red wire #6 (with one end stripped and the other end having a snap spade terminal attached) and attach the snap spade connector to terminal #6 on the 1588E signal isolator. Attach the

stripped end to terminal #10 on the 2084E Meter.

12. Find the black wire #7 (one end has a snap spade terminal the other has a female quick disconnect

terminal) and attach the snap spade connector to terminal #9 on the 1588E signal isolator. The female quick disconnect attaches to terminal F- on the speed control board.

13. Find the red wire #8 and attach the snap spade connector to terminal #10 on the 1588E signal isolator. Attach the female quick disconnect to the top position on the local/remote switch.

14. Disconnect the orange wire #10 at the speed control board terminal P2 and attach to the bottom position on the remote/local switch.

15. Find the orange wire #9 and attach one end to terminal P2 on the speed control board. The other end

attaches to the middle position on the local/remote switch.

16. Find the black wire #11 (with one end stripped and the other end has a snap spade terminal attached) and attach the snap spade connector to terminal #4 on the 1588E signal isolator. Attach the

stripped end to terminal block #1.

17. Find the white wire #12 (with one end stripped and the other end has a snap spade terminal attached) and attach the snap spade connector to terminal #1 on the 1588E signal isolator. Attach the

stripped end to terminal block #2.

C

D

E

A

B

Snap Spade

A

E

D

C

Quick Disconnect Terminals

www.parrinst.com

5

Page 6

MCM Installation

Wiring Installation in 4848 Reactor Controller (Continued)

Pin Outs:

2084E Color: Attaches to:

Pin 1 Black Terminal Block 5

Pin 2 White Terminal Block 2

Pin 3

Pin 4 White A1695E Excit Board

Pin 5

Pin 6 Black A1695E Excit Board

Pin 7

Pin 8

Pin 9 Black 1588E Terminal 5

Pin 10 Red 1558E Terminal 6

Pin 11 White Terminal Block 4

Pin 12 Black Terminal Block 3

1588E Color: Attaches to:

Pin 1 White Terminal Block 2

Pin 2 Jumper

Pin 3 Jumper

Pin 4 Black Terminal Block 2

Pin 5 Black 2084E Terminal 9

Pin 6 Red 2084E Terminal 10

Pin 7

Pin 8

Pin 9 Black Speed Control F-

Pin 10 Orange

Pin 1 on 115V

Pin 3 on 230V

Pin 4 on 115V

Pin 2 on 230V

Local/Remote Switch

Top Position

Final Steps:

Close the controller and replace the two screws on the top plate. Plug the 4848 controller back in, and turn it on.

The RPM display should read zero when the motor is not turning.

It is useful to check that the settings on the display are set correctly. Check these against the defaults listed in the

back of these instructions.

Motor Control Module (MCM) Wiring Schematic

FROM A2106E RPM INPUT HARNESS

TO TERMINAL

BLOCK

2065E

REF

115V

JUMPER SETTING

1

N

2

3

4

L

IN

1588E

SIGNAL

ISOLATER

OUT

12

11

- 5

+ 6

10

1

N

2

3

4

1

2

3

9

4

1588E

SIGNAL

ISOLATER

L

230V

JUMPER SETTING

N

1588E

SIGNAL

ISOLATER

L

IN

OUT

IN

OUT

- 5

5 OUT

+ 6

6

7

9

8

10

- 5

+ 6

REF

9

10

1 - WHITE

2 - BLACK

3 - WHITE

4 - BLACK

BLACK

RED

2

N

1

L

4 +

6 11 +

12 9 -

5

10 +

6

7

F -

P1

CONTROL BOARD

P3

9

P2

8

T

9

M

B

10

10

2084E

IN

RPM DPM

RS485

A1250EEE OR

A1220EEE

DC SPEED

REF

REMOTE

LOCAL

ADJUSTABLE

POTENTIOMETER

6

Parr Instrument Company

REF

Page 7

MCM Installation

Factory Default Settings

MCM Module

Keys command:

1. Press “SET” to select

2. Press return key move to next operation mode

3. Up/Down arrow keys to adjust value or select type

Main Screen: SP = 0

Press return key and release

Operation Mode Select type/value Comment

r-S Run Run/Stop

SP 0 Decimal point position

LoC OFF Lock mode (lock all keys or only up/down arrow able to use)

Out1 - (read-only) Motor output %

Press and hold down “SET” for 5-sec

Operation Mode Select type/value Comment

InPt v5

tP-H 2206 Upper-limit range

tP-L 0 Lower-limit temperature range

CTRL PID Control mode (ON/OFF, MANUAL, PID and PID PROG)

S-HC Heat Heat/Cool control

ALA1 0 Alarm mode

SALA OFF System alarm

CoSH ON Communication write function that able to use set point from software

C-S1 RTU Format type

C-no 2 Communication address

bPS 9600 Communication baud rate

Len 8 Data length setting

PrtY Even Parity bit setting

StoP 1 Stop bit setting

Input type

(v5 = 0-5V, v10 = 0-10V, nA0 = 0-20mA, nA4 = 4-20mA, nV =0-50mV)

Press “SET” and release

Operation Mode Select type/value Comment

At OFF Auto Tuning ON/OFF

PID0 0 The 0th PID Parameter

SV 0 The 0th SV

P0 170 Proportional control

C0 1 Integral control

D0 0 Derivative control

CoF0 0 Integral value

HtPd .5 Heat/Cool cycle control

tPoF 0 Inaccuracy adjustment

www.parrinst.com

7

Page 8

599M R02 Revision 11/08/13

Loading...

Loading...