Page 1

Parr Magnetic Drives

Operating Instruction Manual

234M

Page 2

Parr Magnetic Drives

Preface 3

Description 3

Related Instructions 3

Light Duty A1120HC/A2140HC/A2150HC Series 3

Heavy Duty Drives A1180HC/A1750HC/A2160HC/A2170HC

Series 3

Extra Heavy Duty Drives A1180HC2/A1750HC2/ A2160HC2/

A2170HC2 Series 3

Characteristics 3

Servicing the Magnetic Drive 4

The O-Ring Seal 5

Servicing the Outer Drive 5

Disassemble the Outer Drive 5

Reassemble the Outer Drive 5

Removing and Installing Mag netic Drives with Flat Gasket

Seals 6

Removing and Installing Mag netic Drives with Olive Seals 6

Servicing the Cooling Sleeve 6

Older Models 6

Installing the Stirrer Shaft on a Footless Magnetic Drive 6

Gasket Material Designations 7

Specifications 8

Magnetic Drives With Lower Foot Bearing 8

Magnetic Drives Without Lower Foot Bearing (Footless) 9

Drawings and Parts Lists 10

A1120HC6 Magnetic Drive 10

A1180HC Magnetic Drive 11

A1180HC5 Magnetic Drive 11

A1750HC Magnetic Drive 12

A1750HC2 Magnetic Drive 12

A2140HC/A2140HC2 Magnetic Drive 13

A2150HC Magnetic Drive 13

A2160HC Magnetic Drive 14

A2160HC4 Magnetic Drive 14

A2170HC Magnetic Drive 15

A2170HC2 Magnetic Drive 15

Customer Service

Questions concerning the installation or operation

of this instrument can be answered by the Parr

Customer Service Department:

Accessories 7

Drive Maintenance Tools 7

Spanner Wrenches 7

1-309-762-7716 • 1-800-872-7720

Fax: 1-309-762-9453

E-mail: parr@parrinst.com

http://www.parrinst.com

2

Parr Instrument Company

Page 3

Parr Magnetic Drives

Preface

Description

The principle operation of Parr magnetic drives provides for attaching the stirrer shaft to an inner set of

magnets. This inner assembly is then surrounded by

the drive housing that seals to the reac tor head allowing pressurization without leakage. A second set of

magnets is then mounted around the sealed hous ing.

The outer magnetic assembly is then coupled to a

motor drive system to provide rotation. The coupling

force be tween the two sets of magnets permits the

shaft to turn at the rpm selected for the motor.

Parr magnetic drives are available in three torque ratings: 16 in-lb, 60 in-lb, and 120 in-lb (1.8 Nm, 6.6 Nm, and

13.2 Nm). The drives are also available with two types

of shafts; one that requires a lower support bushing and

one that is “footless.” The Model number assigned to

each drive depends upon the above selection as well as

the type of connec tion used to mount the drive into the

re actor head and the type of upper cap used for connection to the overarm and motor drive system.

normally ade quate to carry the usual stirring loads developed in a Parr “Mini” reactor and the one and two

liter bench top and floor stand models with general

purpose stir rers. The outer magnetic drive housing

measures 2¼” O. D. x 3½” high.

Heavy Duty Drives A1180HC/A1750HC/ A2160HC/A2170HC Series

This is a 6-pole model with 60 inch pounds of coupling

torque to handle most of the stirring loads arising in

Parr one and two liter, and one, two, and 5 gallon floor

stand reactors with heavy duty stirrers. The drive housing meas ures 3½” O. D. x 4½ high.

Extra Heavy Duty Drives A1180HC2/ A1750HC2/ A2160HC2/A2170HC2 Series

This is the largest of the three Parr drives. It consists of

two, 6-pole mag nets assemblies mounted end-to end

to provide 120 inch-pounds of coupling torque for use

as an alternative drive for large Parr reactors when a

strong drive is required to handle very high viscosity

loads. The drive housing measures 3½” O.D. x 6½” high.

Related Instructions

The following Parr publications are available to

further your understanding of this equipment and its

component parts:

No. Description

201M Limited Warranty

Parr Magnetic Drive Service Instructional Video

Go to http://youtu.be/zjBw5l_yBHw to view a video

supplement to aid users with performing routine mainte-

nance on Parr Instrument Company’s Magnetic Drives.

Light Duty A1120HC/A2140HC/A2150HC Series

This is the smallest of the three drives. It is a 4-pole

model with 16 inch-pounds coupling torque. This is

Conversion from a smaller to a larger drive or to a

“footless” drive may require modification to the standard over/arm and motor configuration. It may require

a different head.

Note: Unless otherwise indicated, the instructions

given here apply to all of the above units.

Characteristics

Parr magnetic drives require minimal attention or

maintenance. The spe cially designed neodymiumironboron permanent magnets used in these drives have

excellent temperature sta bility and can be relied upon

to operate for long periods with little or no flux degradation. When properly installed, the outer rotor should

spin freely and the inner (driven) unit should follow

without slippage, providing a high torque stirring

action. The magnets in both inner and outer rotors are

epoxy bonded to their iron cores.

Care must be taken to prevent these components from

being heated above 100 °C, which would destroy the

bond ing of the magnet assemblies. To pre vent overheating, each magnetic drive has an attached cooling

sleeve through which a steady flow of cold water

should be fed during all vessel operations at temperatures above 100 ºC. Tubing connections for flowing

water connections are provided on each sleeve, and

a 10 foot length of tub ing is furnished to connect to a

water source.

www.parrinst.com

3

Page 4

Parr Magnetic Drives

Servicing the Magnetic Drive

All non-wetted rotating parts in Parr magnetic drives

are permanently lubricated and do not require servicing during normal operation. During operation, inspect

the magnetic drive for unusual noise or leakage. If

problems are encountered with these items take corrective action. The magnetic drive has internal bearings

and thrust washers which require replacement over

time due to physical wear. Excessive lateral or axial

play in the stirrer shaft is an indication of worn bearings or thrust washers. Labored rotation or excessive

debris inside the reactor cylinder also indicates a need

for maintenance. It’s difficult to recommend a timebased preventative maintenance interval for the drive

due to the wide spectrum of operating conditions encountered. The experience of the laboratory should be

used to guide the need for preventative maintenance.

It is advisable to check the drive from time to time for

evidence of leakage into the confined space between

the inner and outer rotors. This can be done without

removing the drive from the vessel head and does

not require complete disassembly. While performing

maintenance or rebuilding the drive, the PTFE o-ring

that seals the top plug should always be renewed if the

plug is removed. To inspect the drive:

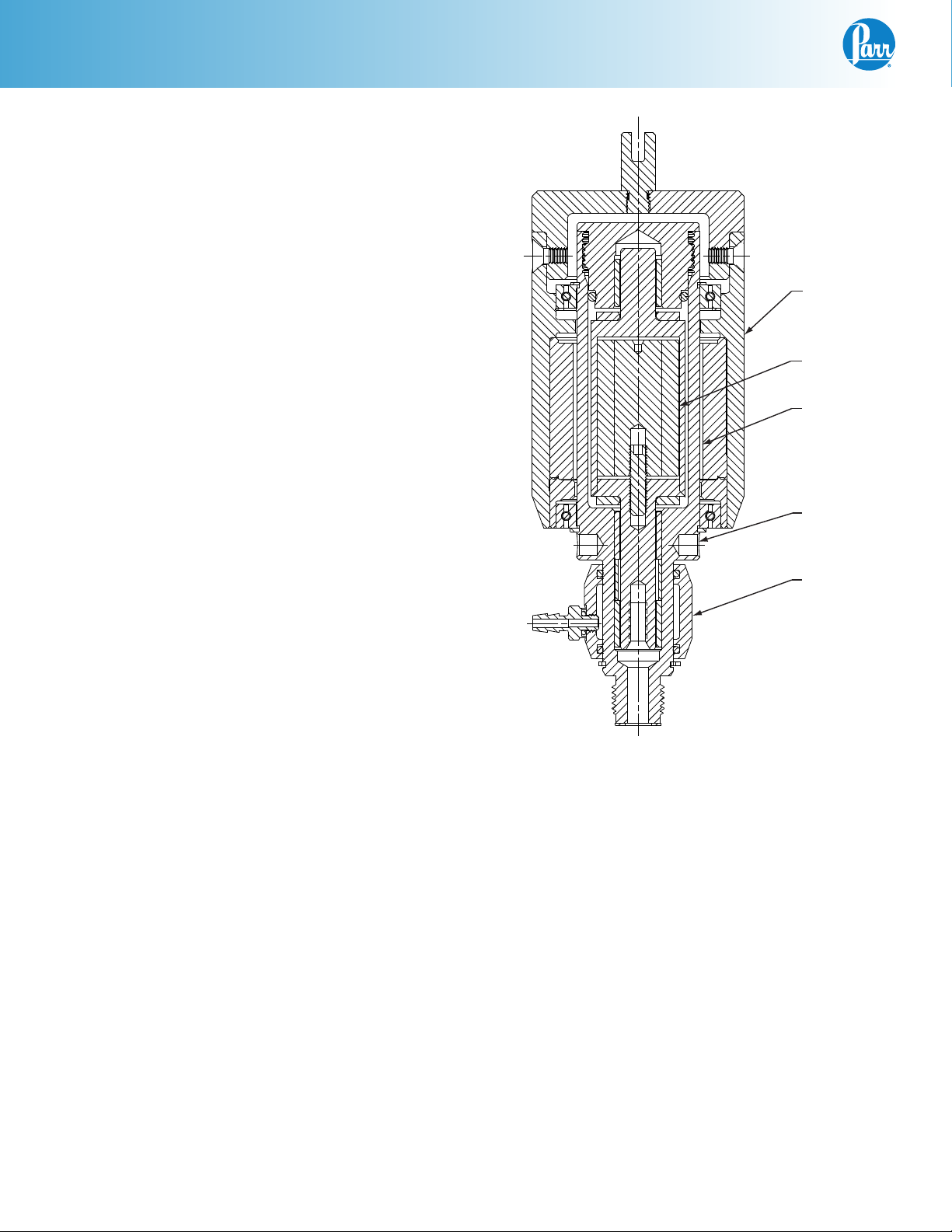

Outer Driving

Magnetic

Assembly

Inner Magnetic

Rotor

Non-Rotating

Inner Housing

Holes for

Pin Spanner

Wrench

Cooling

Sleeve

1. Remove the four socket head screws located near

the top of the outer housing and remove the top

cover from the housing. This will expose the plug

which aligns the inner rotor and carries the principle O-ring seal.

2. Unscrew the plug, using a 264AC5 face spanner inserted into the two holes at the top of the plug while

holding the rotor firmly with a 264AC3 or 264AC4

pin spanner inserted into one of the holes at the bottom of the assembly above the cooling sleeve. With

the plug removed, the sleeve bushing and thrust

washer at the top of the rotor will be exposed.

3. Check for any evidence of leakage past the O-ring

seal. If vapors from the reactor have produced

solid deposits in or around the rotor housing, the

deposits will have to be removed to keep them

from destroying the slide bushings or jamming the

rotor. If cleaning is not re quired, replace the plug

and close the drive.

4. If cleaning is required, the inner ro tor can be

removed without removing the entire drive from

the bomb head. To remove: Remove propeller from

shaft. For vessels with a one piece shaft, the shaft

can be used to push the rotor out of the stirrer

housing. For vessels with a lower coupled shaft assembly, the shaft will need to be disconnected from

Parr Magnetic Drive

the upper shaft. In the larger magnetic drives, the

rotor can be removed by attaching a threaded (5/16

– 24) rod to the top of the inner rotor and pulling up

from the top of the housing.

The inner rotor is a laser-welded, sealed unit which

should require no mainte nance, but it can be damaged

by over heating as mentioned earlier. With the rotor

removed, it may be advisable to re place the three sleeve

bushings which guide the inner rotor. Two of these, plus

a spacer, are located deep in the mag netic drive housing.

The third sleeve bushing is held in the top plug. Although

these bushings can be pulled out with a wire hook or

scribe, removal is much easier using a specially designed bush ing removal tool (See Page 8). Simply screw

the threaded end of the removal tool into the bushing

until it is firmly en gaged, then pull out the bushing. The

spacer between the two bushings should slide out freely.

Remove the bottom bushing in the same manner.

4

Parr Instrument Company

Page 5

Parr Magnetic Drives

When replacing the bushings in the magnetic drive

housing, slide the parts into place carefully and be sure

to separate the two lower bushings with a spacer. A

specially designed bushing insertion tool is available

for this operation (See Page 8). Using the insertion tool,

slide a bushing onto the end of the tool with the longest

shank, then insert the tool with the bushing into the

opening in the rotor chamber and push it down until the

shoulder on the tool strikes the bottom of the chamber.

This will position the bushing properly. Then drop the

spacer into the opening and use the short end of the

installation tool to insert the upper sleeve bushing,

again pushing the tool downward until it strikes the

bottom of the plug. When properly installed, the top of

the upper bushing should be flush with the bottom of

the rotor chamber.

After cleaning the rotor and the chamber, install the

inner rotor as follows:

1. Set the lower thrust washer into posi tion so that it

will be available to cushion the rotor if it should accidentally slam into the bottom of the chamber.

2. Lower the rotor into the chamber slowly, but be

prepared to resist the strong pull of the outer

magnets during this operation. Use the same rod

employed when removing the rotor to resist the

strong pull during assembly.

3. Replace the upper sleeve bushing and the O-ring

in the top plug; insert the upper thrust washer; lubricate the threads with 424HC2 anti-seize lubricant

(careful not to get any on the O-ring) and screw the

top plug into place. Then replace the top cover and

secure it with the four socket head screws.

The O-Ring Seal

The O-ring, which seals the top plug in Parr magnetic

drives, is made of PTFE. If solvent attack becomes a

problem, the O-ring may have to be replaced with an

O-ring made of another material.

Servicing the Outer Drive

The outer drive is supported by two high quality sealed

ball bearings which do not require lubrication. Any oil

leak or noise from the bearing will indicate that the

seal or the bearing has failed and the bearing must be

replaced.

Disassemble the Outer Drive

1. Remove the four socket head screws located near

the top of the outer housing; then lift the cover

from the housing to expose the upper snap ring.

Peel the snap ring out of its groove with a small

screwdriver; slide it upward and remove it.

2. Take a firm grip on the outer drive housing and

pull it upward to separate the outer assembly from

the magnetic drive housing. The lower bearing may

not come out with the housing. If not, remove at

this time.

Reassemble the Outer Drive

1. Slide the lower spiral snap ring back into its

groove; then slide the lower ball bearing onto the

inner hous ing. The inner magnets should hold the

bearing at the middle of the housing.

2. Slide the outer drive assembly over the rotor,

thereby pushing the lower bearing down against

the lower spiral snap ring. Hold both parts firmly

during this step so that the magnets do not slam

the outer drive into place.

3. Insert the upper wave spring into its groove in

the outer drive housing and slide the ball bearing

into place against the wave spring, then anchor

the bearing by pushing the retaining snap ring

downward until it snaps into its groove above the

bearing. During this step sufficient pressure must

be applied against the snap ring and force the

wave spring downward and allow the snap ring to

drop bearing to force the wave spring down ward

and allow the snap ring to drop into its groove. This

can be done with a pair of screw drivers, using

alternating pressure on the snap ring. This must be

done carefully to be sure that the screw drivers do

not slip and damage the seals in the bearings. To

simplify the opera tion, Parr offers a magnetic drive

assem bly tool (Part No. 2086HC) consisting of a

properly sized cup which can be pushed downward

against the snap ring to force it into its groove.

There are cups on the 2086HC assembly tool to fit

both the small and larger Parr magnetic drives.

4. Replace the top cover and secure it with the four

socket head screws.

www.parrinst.com

5

Page 6

Parr Magnetic Drives

Removing and Installing Mag netic Drives with

Flat Gasket Seals

These magnetic drive assemblies can be removed

from the vessel head using the appropriate pin spanner wrench fur nished with the apparatus (See Table on

Page 8). First, unscrew the stirrer shaft from the inner

rotor, then insert the pin spanner into one of the holes

below the outer jacket and unscrew the drive as sembly

while holding the vessel head firmly. The cooling

sleeve can be held stationary when unscrewing the

drive from the head. The drive is sealed into the head

with a gasket which usually will remain in the head

when the drive is removed.

If the gasket appears to be in good condi tion, it can be

reused. If it is question able, replace with a new one.

Apply a lib eral coating of anti-seize lubricant to the

mounting threads of the drive body before screwing

the drive into the head. Tighten the drive firmly with

the pin spanner and screw the stirrer shaft into the

inner rotor to complete the assembly.

Removing and Installing Mag netic Drives with

Olive Seals

To remove these magnetic drive assemblies, unscrew

the stirrer shaft, then hold the bomb head firmly and

use the 739HC (1-5/16”) wrench furnished with the

appara tus to remove the drive by unscrewing the

gland nut located below the cooling sleeve. The cooling sleeve can be held stationary during this operation

to clear the nearby fittings as the drive is re moved.

These drives are sealed into the head by compression

from the gland nut onto a tapered 663HC olive. There

is no gasket in this gland. Remove and clean the olive

whenever the gland is removed.

Servicing the Cooling Sleeve

The cooling sleeves used on Parr mag netic drives have

two O-rings which seal the sleeve onto the stem of the

drive housing. These O-rings will have to be replaced

after long service or after ex cessive heating with no

water flowing through the sleeve . To replace the O-rings

it will be necessary to remove the drive assembly from

the head as de scribed above. After removing the drive,

rotate and pull off the cooling sleeve after removing the

clip ring, if present. The O-rings can now be removed

from the sleeve, but be careful not to scratch or damage

the O-ring grooves. Clean any accumulated lime deposits from the sleeve and insert new O-rings into the

grooves; then moisten the O-rings and slide the cooling

sleeve into place on the drive stem. The drive can now

be rein stalled in the head as described above.

Older Models

All series 4520 and 4530, one and two liter reactors built

before November, 1985 were equipped with A1120HC2

and A1120HC3 magnetic drives respectively. These

older models are similar to the present A1120HC style

except they have different mounting threads and different shaft lengths for attachment to the for mer 229HC

style head. All instructions given here for the current

A1120HC drive apply to these older models as well.

Installing the Stirrer Shaft on a Footless Magnetic Drive

Normally the stirrer shaft is simply screwed into the

inner magnetic rotor housing from the underside the

stirrer housing. There is no interference in magnetic

drive Series A1120HC, A1180HC or A1750HC to cause a

problem.

To install these drives, coat both sealing faces on the

663HC olive with anti-seize lubricant and set the olive

squarely in the head. Lubricate the threads on the

stem of the magnetic drive and screw the 664HC gland

nut onto the stem as far as it will go; then back it off

one-quarter turn. Lubricate the threads on the gland

nut and screw the drive assembly into the head, being

careful to maintain the one-quarter turn relationship

between the stem and the nut. Tighten the nut firmly

to complete the connection. Screw the stirrer shaft into

the drive from the underside of the head and check the

assembly by spinning the drive by hand. The stirrer

should turn freely without binding.

6

Parr Instrument Company

In the Series A2140/50HC, A2160HC and A2170HC

footless magnetic drives it is pos sible to trap the thrust

washer between the shoulder machined on the shaft

and the inner magnetic rotor housing. If this happens

there will be a large amount of run out in the shaft or

the shaft will be too long for the cylinder. This can be

prevented by first removing the outer magnetic drive

housing and the plug. Then use the shaft to push up

from the bottom the inner magnetic rotor housing and

installing the thrust washer on the stirrer shaft below

the machined shoulder so there is no interference from

the thrust washer. Screw the stirrer shaft and the inner

magnetic rotor housing parts together and reassemble

the rest of the magnetic drive.

Page 7

Gasket Material Designations

Parr Magnetic Drives

Common Trade Name Type of Material

ASTM

Designations

Nitrile, buna-N Butadiene / acryloelastomer NBR JB

Viton®

Kalrez®

Chemraz®

Parofluor®

1

2

3

4

Fluoroelastomer FKM JV

Perfluoroelastomer FFKM JK

Ethylene/ Propylene Ethylene propylene Copolymer elastomer EP JE

Teflon ®

Grafoil®

1. Viton® is a registered trademark of DuPont

2. Kalrez® is a registered trademark of DuPont

3. Chemraz® is a registered trademark of Green, Tweede & Co. Ltd.

4. Parofluor® is a registered trademark of Parker Hannifin Corporation

5. Teflon ® is a registered trademark of DuPont

6. Grafoil® is a registered trademark of UCAR Carbon, Inc.

5

6

Tetrafluoroethylene polymer PTFE HA

Flexible graphite FG KL

Parr

Suffix

Accessories

Drive Maintenance Tools

A1120HC, A2140HC and A2150HC Series

Part No. Description

1947HC Bushing Installation Tool

1948HC Bushing Removal Tool

A1180HC and A1750HC Series

Part No. Description

1950HC Bushing Installation Tool

1951HC Bushing Removal Tool

A2160HC and A2170HC Series

Part No. Description

2177HC Bushing Installation Tool

2178HC Bushing Removal Tool

All Magnetic Drives

Spanner Wrenches

A1180HC, A1750HC, A2160HC and A2170HC Series

Part No. Description

264AC3 Pin Spanner Wrench, 2”

A1120HC, A2140HC, and A2150HC Series

Part No. Description

264AC4 Pin Spanner Wrench, 1½”,

All Magnetic Drives

Part No. Description

264AC5 Face Spanner Wrench, Adj.,

Part No. Description

2086HC Bearing Installation Tool

www.parrinst.com

7

Page 8

Parr Magnetic Drives

Specifications

Magnetic Drives With Lower Foot Bearing

Part No. Upper Shaft Size Torque Head Series No. Seal Overarm Connection

A1120HC 3/16 16 IN LB 1370HC

818HC

2240HC

1458HC

1836HC

2300HC

A1120HC2 3/16 16 IN LB 229HC Gasket Rubber Sleeve/Spline Coupling

A1120HC5 5/16 16 IN LB 1352HC

1807HC

A1120HC6 3/16 16 IN LB 1370HC

2240HC

2300HC

2301HC

2252HC

2201HC

2902HC

2432HC

2772HC

2774HC

2776HC

3340HC

A1120HC9 3/16 16 IN LB 2635HC

2915HC3/HC4

A1120HC8 5/16 16 IN LB 2510HC Olive Universal Coupling

A1180HC/

A1180HC2

A1180HC4 5/16 60 IN LB 2259HC

A1750HC/

A1750HC2

5/16 60 IN LB/

120 IN LB

5/16 60 IN LB/

120 IN LB

657HC

755HC

1421HC

2248HC

2260HC

1811HC

1807HC

1352HC

2690HC

2758HC

2258HC

2271HC

2270HC

2510HC

2690HC

2700HC

2758HC

755HC

2248HC

657HC

2260HC

1811HC

1421HC

1807HC

1352HC

1557HC

2758HC

2957HC

Gasket Rubber Sleeve/Spline Coupling

Olive Rubber Sleeve/Spline Coupling

Gasket Universal Coupling

Gasket Pulley

Olive Rubber Sleeve/Spline Coupling

Olive Universal Coupling

Olive Chamfered Coupler

8

Parr Instrument Company

Page 9

Parr Magnetic Drives

Magnetic Drives Without Lower Foot Bearing (Footless)

Part No. Upper Shaft Size Torque Head Series No. Seal Overarm Connection

A2140HC 3/8 16 IN LB 818HC39

818HCHC40

1370HC25

2300HC6

1836HC6

A2140HC2 3/8 16 IN LB 2201HC5

2201HC6

2201HC7

2201HC8

1370HC25

2252HC26

2252HC25

2300HC5

2300HC6

2301HC5

2301HC6

A2150HC 3/8 16 IN LB 1807HC Olive Rubber Sleeve/Spline Coupling

A2150HC2 3/8 16 IN LB 2510HC Olive Universal Coupling

A2160HC/

A2160HC2

5/8 60 IN LB/

120 IN LB

657HC98

2271HC2

2758HC

2758HC25

2758HC26

A2160HC3 5/8 60 IN LB 2700HC2

2690HC4

2758HC

2758HC25

2758HC26

A2170HC/

A2170HC2

5/8 60 IN LB/

120 IN LB

1557HC5

1557HC14

1557HC15

2957HC5

2957HC13

3187HC5

3187HC14

2758HC

2758HC25

2758HC26

Gasket Rubber Sleeve/Spline Coupling

Gasket Universal Coupling

Gasket Rubber Sleeve/Spline Coupling

Gasket Universal Coupling

Gasket Chamfered Coupler

2185HC when

A1120HC6/HC8

A2140HC2

A2150HC2

or

2295HC when

A1180HC4/HC5

A2160HC3/HC4

Drive Adapters for Magnetic Drives

2437HC when

A1120HC/HC2/HC5

A2140HC

A2150HC

or

2457HC when

A1180HC/HC2

A2160HC/HC2

2634HC

when

A1120HC9

www.parrinst.com

1748HC w/

1747HC2

cover, short

when

A1180HC3

A1750HC2

A2170HC2

or

1748HC w/

1747HC

cover, tall

when

A1750HC

A2170HC

9

Page 10

Parr Magnetic Drives

Drawings and Parts Lists

1133HC TYP

(3) PLACES

2.25 REF

2185HC

1142HC3

*1136HC2

SA1632FS06

NOTES:

1) (*) DENOTES PARTS WHICH ARE OF CORRESPONDING MATERIAL

IN ASSEMBLIES CONSTRUCTED OF SPECIAL MATERIAL

2) SHAFTS ARE NOT INCLUDED AS PART OF A1120HC6

3) FOR USE WITH JP0025TBO6 TUBING

TYP (4) PLACES

1137HC

1138HC

(2) PLACES

A1120HC6 Magnetic Drive

6.29 REF

1132HC TYP

IMPRINT AREA

AND

DIRECTION

(2) PLACES

1144HC

A1147HC

CH5211A*PYT CH9311

*1134HC

1138HC2

*1135HC

1.30 REF

SHAFT ENGAGEMENT

825HC

827HC TYP

(2) PLACES

2683HC

2714HC TYP

(2) PLACES

48HC

A2685HC

COOLING

SLEEVE

ASSY

(SEE NOTE 3)

Lower Housing

A1120HC2 Magnetic Drive Assembly

All upper parts are the same as shown for A1120HC Series

except the drive adapter

A1120HC5 & A1120HC8 Magnetic Drive Assembly

All upper parts are the same as shown for A1120HC Series

except the drive adapter

Lower Housing

Parts for A1120HC Series Magnetic Drives

357HC O-ring, FKM 1132HC Thrust washer 1139HC Bearing

48HCFG Gasket, gold plated 1133HC Bushing 1142HC3 Jacket cover

48HC Gasket, silver 1134HC Spacer 1144HC Wave spring

48HCKL Gasket, graphite 1135HC Stirrer housing A1147HC Outer magnetic housing assy

663HC Olive 1135HC2 Stirrer housing 1462HC Backup washer

825HC Snap ring, external 1135HC3 Stirrer housing 1463HC Gasket, PTFE

827HC O-ring, NBR 1136HC2 Plug 2185HC Drive adapter

2714HC Hose barb 1137HCHA O-ring, PTFE 2437HC Drive adapter (Hub)

A2685HC Cooling sleeve assy 1138HC Snap ring, external SA1632FS06 Set screw

A1125HC Rotor assembly 1138HC2 Snap ring, spiral

10

Parr Instrument Company

Page 11

Parr Magnetic Drives

A1188HC2

1179HC

WAVE SPRING

(3) 1166HC

BUSHING

1169HC2*

PLUG

2457HC

DRIVE ADAPTER

3.50 REF

1178HC2

COVER

1172HC

SNAP RING

*-NOTE:

PARTS MARKED RESPECTIVELY ARE OF

CORRESPONDING MATERIAL IN ASSEMBLIES

CONSTRUCTED OF SPECIAL MATERIAL

2X 1165HC

1179HC

* 1169HC2

A1180HC Magnetic Drive

A1185HC*

1168HC*

HOUSING

ROTOR ASSY

(2) 1165HC

THRUST WASHER

AND

DIRECTION

IMPRINT AREA

1171HC_

O-RING

(4) SA1632FS08

(8-32 X 1/2 FL HD SOC SCR)

A1188HC

MAGNETIC

HOUSING ASSY

(2) 1170HC

BEARING

8.30 REF

9.36 REF

A1180HC5 Magnetic Drive

AND

DIRECTION

IMPRINT AREA

1172HC2

SNAP RING

1167HC* (2) 716HC REF

SPACER

79HW2

PLUG REF

* A1604HC

QD CONNECTOR

694HC

COOLING SLEEVE

REF

(2) 715HC

O-RING REF

A740HC

COOLING SLEEVE

ASSEMBLY

REF

1172HC2

* 1167HC

* 1603HC

A740HC

COOLING

SLEEVE

ASSEMBLY

REF

3X 1166HC

2457HC

3.50 REF

1178HC2

1172HC

1171HC__

4X SA1632FS08

(8-32 X 1/2 FHSS)

10.28

REF

11.34 REF

*-NOTE:

PARTS MARKED RESPECTIVELY ARE OF

CORRESPONDING MATERIAL IN ASSEMBLIES

CONSTRUCTED OF SPECIAL MATERIAL

2X 1170HC

Parts for A1180HC and A1180HC2 Series Magnetic Drives

79HW2 Plug 1168HC Rotor housing, 60 in/lb A1185HC Rotor assembly, 60 in/lb

663HC Olive 1169HC2 Plug A1188HC Outer magnetic housing assy, 60 in/lb

715HC O-ring, NBR 1170HC Bearing A1188HC2 Outer magnetic housing assy, 120 in/lb

716HC Quick disconnect 1171HCHA O-ring, PTFE 1603HC Rotor housing, 120 in/lb

A740HC Cooling sleeve assy 1172HC Snap ring, external A1604HC Rotor assembly, 120 in/lb

1165HC Thrust washer 1172HC2 Snap ring, spiral 2295HC Drive adapter

1166HC Bushing 1178HC2 Jacket cover 2457HC Drive adapter (Hub)

1167HC Spacer 1179HC Wave spring SA1632FS08 Set screw

www.parrinst.com

11

Page 12

Parr Magnetic Drives

3.50 REF

(3) 1166HC

1748HC

REF

*-NOTE:

PARTS MARKED ARE OF

CORRESPONDING MATERIAL IN ASSEMBLIES

CONSTRUCTED OF SPECIAL MATERIAL

1169HC2*

1747HC

COVER

1172HC

SNAP RING

THRUST WASHER

1179HC

BUSHING

PLUG

A1750HC Magnetic Drive

(2) 1165HC

WAVE

SPRING

(4) SA1632FS08

(8-32 X 1/2 FL HD SOC SCR)

AND

DIRECTION

IMPRINT AREA

1171HC_

O-RING

11.83 REF

A1188HC

MAGNETIC

HOUSING

ASSEMBLY

A1185HC*

ROTOR ASSEMBLY

8.30 REF

1172HC2

SNAP RING

(2) 1170HC

BEARING

1167HC*

SPACER

1168HC*

HOUSING

(2) 715HC

79HW2

O-RING REF

PLUG REF

A740HC

COOLING SLEEVE

REF

(2) 716HC REF

QD CONNECTOR

694HC

COOLING SLEEVE

REF

A740HC

COOLING

SLEEVE

REF

A1750HC2 Magnetic Drive

1747HC2

3.50 REF

*1169HC2

1748HC

(2) 1165HC

1171HC_

(4) SA1632FS08

(8-32 X 1/2 FHSC)

(2) 1170HC

1172HC

1179HC

AND

IMPRINT AREA

DIRECTION

11.87 REF

*A1604HC

10.28 REF

A1188HC2

1172HC2

*1603HC

*1167HC

(3) 1166HC

*-NOTE:

PARTS MARKED RESPECTIVELY ARE OF

CORRESPONDING MATERIAL IN ASSEMBLIES

CONSTRUCTED OF SPECIAL MATERIAL

Parts for A1750HC and A1750HC2 Series Magnetic Drives

79HW2 Plug 1167HC Spacer 1747HC Jacket cover, long

663HC Olive 1168HC Rotor housing 1747HC2 Jacket cover, short

715HC O-ring, NBR 1169HC2 Plug A1185HC Rotor assembly, 60 in/lb

716HC Quick disconnect 1170HC Bearing A1188HC Outer magnetic housing assy, 60 in/lb

A740HC Cooling sleeve assy 1171HCHA O-ring, PTFE A1188HC2 Outer magnetic housing assy, 120 in/lb

1165HC Thrust washer 1172HC Snap ring, external 1603HC Rotor housing

1166HC Bushing 1172HC2 Snap ring, spiral A1604HC Rotor assembly, 120 in/lb

1179HC Wave spring SA1632FS08 Set screw

12

Parr Instrument Company

Page 13

Parr Magnetic Drives

1132HC TYP

(2) PLACES

1137HC_

1133HC TYP

1142HC3

2.25 REF

2185HC

*1136HC2

NOTES:

1) (*) DENOTES PARTS WHICH ARE OF CORRESPONDING

MATERIAL IN ASSEMBLIES CONSTRUCTED OF SPECIAL MATERIAL

2) SHAFT NOT INCLUDED AS PART OF A2140HC2

3) FOR USE WITH JP0025TB06 TUBING

(3) PLACES

SA1632FS06 TYP

(4) PLACES

1138HC

A2140HC/A2140HC2 Magnetic Drive

7.86

1144HC

1139HC TYP

(2) PLACE3S

AND

DIRECTION

IMPRINT AREA

A1147HC

1138HC2

*1134HC

*A2145HC

A2150HC Magnetic Drive

8.86

*2144HC

825HC

827HC TYP

(2) PLACES

2683HC

2714HC TYP

(2) PLACES

2142HC SERIES

GASKET REF

*2141HC SERIES SHAFT

Ø.375 REF

NOT SHOWN

(SEE NOTE 2)

A2685HC

COOLING SLEEVE ASSY

(SEE NOTE 3)

A1147HC

7.80

1138HC2

*1134HC

*2144HC2

825HC

827HC TYP

(2) PLACES

2683HC

2714HC TYP

(2) PLACES

*2141HC SERIES SHAFT

Ø.375 REF

NOT SHOWN

(SEE NOTE 3)

A2685HC

COOLING SLEEVE ASSY

(SEE NOTE 3)

1132HC TYP

(2) PLACES

1137HC_

1133HC TYP

(3) PLACES

2437HC

1142HC3

*1136HC2

SA1632FS06

TYP (4) PLACES

1138HC

2.25

REF

NOTES:

1) (*) DENOTES PARTS WHICH ARE OF CORRESPONDING

MATERIAL IN ASSEMBLIES CONSTRUCTED OF SPECIAL MATERIAL

2) SHAFT IS NOT INCLUDED AS PART OF A2150HC

3) FOR USE WITH JP0025TB06

AND

IMPRINT AREA

1144HC

1139HC TYP

(2) PLACES

DIRECTION

*A2145HC

Parts for A2140HC and A2150HC Series Magnetic Drives

2142HCFG Gasket, gold plated 2714HC Hose barb 1138HC Snap ring, external

2142HC Gasket, silver A2685HC Cooling sleeve assy 1138HC2 Snap ring, spiral

2142HC2KL Gasket, flex graphite A2145HC Rotor assembly T316 1139HC Torque tube bearing

663HC3 Olive 1132HC Thrust washer 1142HC3 Jacket cover

664HC Gland nut 1133HC Bushing 1144HC Wave spring

825HC Snap ring, external 1134HC Spacer A1147HC Magnetic housing assy

827HC O-ring, NBR 2144HC Housing 2185HC Drive adapter

2683HC Cooling sleeve 1136HC2 Plug 2437HC Drive adapter (Hub)

1137HCHA O-ring, PTFE SA1632FS06 Set screw

663HC3

OLIVE REF

www.parrinst.com

13

Page 14

Parr Magnetic Drives

12.37 REF

* 2166HC2

PLUG

2457HC

DRIVE ADAPTER

REF3.50

A1188HC

MAGNETIC

HOUSING

ASSEMBLY

1179HC

WAVE SPRING

A2160HC Magnetic Drive

* A2165HC ROTOR ASSEMBLY

1172HC2 SNAP RING

AND

DIRECTION

IMPRINT AREA

COOLING SLEEVE ASS'Y

(3) 2162HC BUSHINGS

A740HC

REF

}

(2) 715HC O-RING REF

(2) 716HC QD CONNECTORS REF

694HC COOLING SLEEVE REF

* 2135HC SERIES SHAFT

.625 REF

NOT SHOWN

3.50 REF

* 2166HC2

PLUG

2295HC

DRIVE ADAPTER

1178HC2

COVER

1172HC

SNAP RING

1178HC2

COVER

1172HC

SNAP RING

1179HC

WAVE SPRING

(2) 2161HC

THRUST WASHERS

1171HC

O-RING

(4) SA1632FS08

(8-32 X 1/2 FHSS)

(2) 2161HC

THRUST WASHERS

1171HC_

O-RING

(4) SA1632FS08

(8-32 X 1/2 FHSS)

10.89 REF

(2) 1170HC BEARINGS

*-NOTE:

PARTS MARKED RESPECTIVELY ARE OF

CORRESPONDING MATERIAL IN ASSEMBLIES

CONSTRUCTED OF SPECIAL MATERIAL

9.83 REF

A2160HC4 Magnetic Drive

A1188HC2

MAGNETIC HOUSING

ASSEMBLY

11.75 REF

* A2165HC2

MOTOR ASSEMBLY

1172HC2

SNAP RING

(2) 1170HC

BEARINGS

AND

DIRECTION

IMPRINT AREA

79HW2 PLUG REF

* 2163HC SPACER

A740HC

COOLING SLEEVE ASS'Y

REF

(3) 2162HC

BUSHINGS

79HW2 PLUG REF

2163HC

SPACER

*-NOTE:

PARTS MARKED REPECTIVELY ARE OF

CORRESPONDING MATERIAL IN ASSEMBLIES

CONSTRUCTED OF SPECIAL MATERIAL

* 2164HC HOUSING

(2) 716HC QD CONNECTORS REF

694HC COOLING SLEEVE REF

(2) 715HC O-RING REF

2136HC SERIES

GASKET

REF

* 2135HC SERIES SHAFT

Ø.625 REF

NOT SHOWN

2136HC SERIES

GASKET

REF

2164HC2

HOUSING

Parts for A2160HC Series Magnetic Drives

79HW2 Plug A1188HC Magnetic housing assy, 60 in/lb 2164HC Rotor housing, 60 in/lb

715HC O-ring, NBR A1188HC2 Magnetic housing assy, 120 in/lb 2164HC2 Rotor housing, 120 in/lb

716HC Quick disconnect 2136HCFG Gasket, gold plated A2165HC Rotor assembly, 60 in/lb

A740HC Cooling sleeve assy 2136HC Gasket, silver A2165HC2 Rotor assembly, 120 in/lb

1171HCHA O-ring, PTFE 2136HC2HA Gasket, PTFE 2166HC2 Plug

1172HC Snap ring, external 2136HC2KL Gasket, flex graphite 2295HC Drive adapter (Hub)

1172HC2 Snap ring, spiral 1170HC Torque tube bearing 2457HC Drive adapter

1178HC2 Jacket cover (thrd) 1178HC2 Jacket cover SA1632FS08 Set screw

1179HC Wave spring

14

Parr Instrument Company

Page 15

3.50 REF

A740HC

13.34 REF

1748HC

DRIVE KEY

REF

MAGNETIC HOUSING ASSEMBLY

A1188HC

1179HC

WAVE SPRING

* 2166HC2

PLUG

1747HC

COVER

1172HC

SNAP RING

A2170HC Magnetic Drive

AND

IMPRINT AREA

(2) 2161HC

THRUST WASHERS

1171HC_

O-RING

(4) SA1632FS08

(8-32 X 1/2 FHSS)

DIRECTION

1172HC2 SNAP RING

(3) 2162HC BUSHINGS

(2) 1170HC BEARINGS

A2165HC ROTOR ASSEMBLY

A740HC

COOLING SLEEVE ASS'Y

REF

79HW2 PLUG REF

2163HC SPACER

Parr Magnetic Drives

(2) 716HC QD CONNECTORS REF

694HC COOLING SLEEVE REF

(2) 715HC O-RING REF

* 2135HC SERIES SHAFT

Ø.625 REF

NOT SHOWN

2136HC SERIES

GASKET

REF

* 2164HC

HOUSING

3.50 REF

*-NOTE:

PARTS MARKED RESPECTIVELY ARE OF

CORRESPONDING MATERIAL IN ASSEMBLIES

CONSTRUCTED OF SPECIAL MATERIAL

1179HC

WAVE SPRING

* 2166HC2

PLUG

1747HC2

COVER

1748HC

DRIVE KEY

REF

1172HC

SNAP RING

A2170HC2 Magnetic Drive

IMPRINT AREA

(2) 2161HC

THRUST WASHERS

1171HC_

O-RING

(4) SA1632FS08

(8-32 X 1/2 FHSS)

AND

9.83 REF

13.37 REF

A1188HC2

MAGNETIC HOUSING

ASSEMBLY

DIRECTION

* A2165HC2 ROTOR ASSEMBLY

1172HC2 SNAP RING

(3) 2162HC BUSHINGS

(2) 1170HC BEARINGS

*-NOTE:

PARTS MARKED RESPECTIVELY ARE OF

CORRESPONDING MATERIAL IN ASSEMBLIES

11.75 REF

CONSTRUCTED OF SPECIAL MATERIAL

COOLING SLEEVE ASS'Y

REF

(2) 716HC OD CONNECTORS REF

694HC COOLING SLEEVE REF

(2) 715HC O-RING REF

79HW2 PLUG REF

* 2163HC SPACER

* 2135HC SERIES SHAFT

Ø.625 REF

NOT SHOWN

2136HC SERIES

GASKET

REF

* 2164HC2 HOUSING

Parts for A2170HC Series Magnetic Drives

79HW2 Plug 1747HC2 Jacket cover, short 2162HC Bushing

715HC O-ring, NBR A1188HC Magnetic housing assy, 60 in/lb 2163HC Spacing

716HC Quick disconnect A1188HC2 Magnetic housing assy, 120 in/lb 2164HC Rotor housing, 60 in/lb

A740HC Cooling sleeve assy 2136HCFG Gasket, gold plated 2164HC2 Rotor housing, 120 in/lb

1171HCHA O-ring, PTFE 2136HC Gasket, silver A2165HC Rotor assy, 60 in/lb

1172HC Snap ring, external 2136HC2HA Gasket, PTFE A2165HC2 Rotor assy, 120 in/lb

1172HC2 Snap ring, spiral 2136HC2KL Gasket, flex graphite 2166HC2 Plug

1179HC Wave spring 2161HC Thrust washer SA1632FS08 Set screw

1747HC Jacket cover, long

www.parrinst.com

15

Page 16

234M R06 10/24/14

Loading...

Loading...