Page 1

Operating & Maintenance Instruction Manual 490M

Description

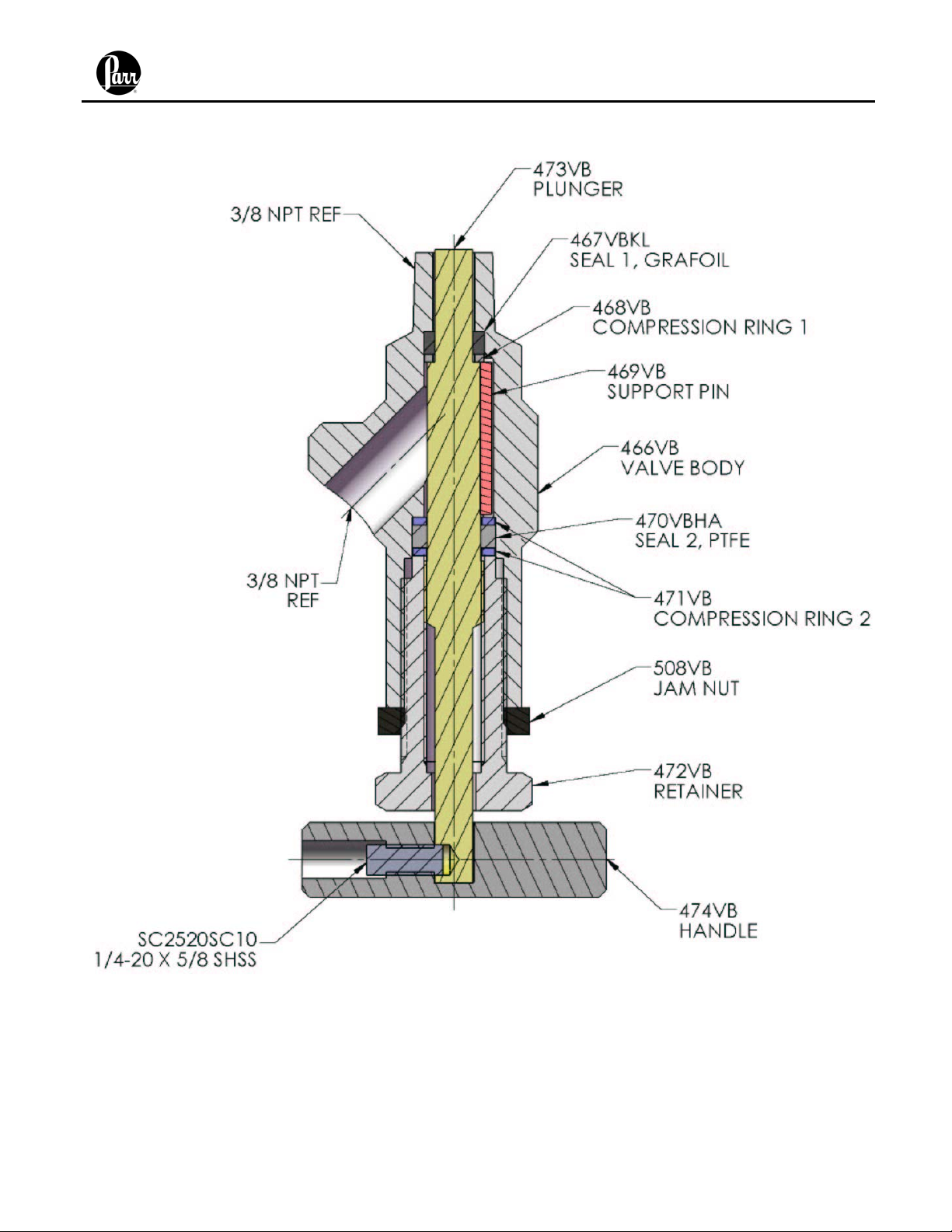

The Parr Instrument Company bottom drain valve is a rising stem, process sampling valve. In the closed position,

the stem of the valve is flush with the inside bottom of the vessel so that there is a minimum of dead space

between the bottom of the vessel and the shut off point of the valve. In the fully open position, the stem is retracted

completely to open a clear passage from the vessel. When the valve is re-closed, any material in this passage will

be pushed back into the reactor by the rising stem. As the plunger moves to the closing end of the stroke, a seal is

established as the plunger contacts the compression ring and compre sses the seal.

Installation and Operation

These valves are designed to be installed in the bottom of Parr cylinders that are machined specifically for

installation with a minimum of dead space. Pipe thread sealant tape should be applied to the valve body threads

and then installed turning clockwise into the cylinder. The valve should be tightened sufficiently to seal the pipe

threads and bring the stem of the valve approximately even with the inside bottom of the cylinder.

The valve is opened by turning the handle counterclockwise. The more turns open; the valve will provide a larger

passage for product flow.

The valve is closed by turning the handle clockwise until the plunger meets the compression ring and compresses

the seal.

Typical torque values on the valve handle required to seal the valves are as follows:

A465VB 10 – 15 ft/lbs

A465VB2 10 – 15 ft/lbs

A485VB 5 – 10 ft/lbs

A485VB2 5 – 10 ft/lbs

A560VB 15 – 20 ft/lbs

Significantly more torque should not be required to seal the valves. If the valve is leaking, it is a good indication

that the seal is worn or has been damaged. The valve should be disassembled, inspected, cleaned as re quired

and seals replaced.

Disassembly of the Bottom Drain Valves

1. Retract the plunger to the fully open position by turning the handle counterclockwise.

2. Loosen the jam nut from the valve body by turning it counterclockwise in relation to the valve body.

3. Loosen the retainer by turning it counterclockwise in relation to the valve body until its threads are clear of the

valve body.

4. Pull the plunger, handle, and retainer out of the valve body together.

5. Remove the lower compression rings and seal. Inspect these parts for wear and replace if necessary.

6. Remove the support pin from the valve body.

7. Remove the upper compression ring and seal. Inspect these parts for wear and replace if necessary.

Bottom Drain Valves

Models A465VB, A465VB2, A485VB, A485VB2 & A560VB

- 1 -

Page 2

Bottom Drain Valves Models A465VB, A465VB2, A485VB & A560VB

Assembly of Bottom Drain Valves

1. Before assembly, all parts of the valve should be clean and in good condition.

Note: Assembly of the valve is easier if it is removed from service and oriented so that the threads going into the

cylinder face downwards.

2. Install a PTFE upper seal into the cavity in the valve body. The plunger may be used to help with the

installation.

3. Install a small compression ring behind the PTFE upper seal.

4. Install the pin into the groove. The pin will rest on the upper compression ring.

5. Install one larger compression ring followed by a PTFE upper seal, and then the final compression ring is

installed into the proper recesses in the valve body.

6. Apply generous amounts of lubrication using a high temperature thread lubricant. See the “Lubrication of the

Bottom Drain Valves” section in this manual. Apply lubrication to the following threads:

The outer threads of the plunger.

The inner threads of the retainer.

The inner threads of the valve body where the retainer will go.

The outer threads of the retainer.

7. Install the jam nut as far as it will go onto the threads of the retainer.

8. Screw the plunger about half of the way into the retainer.

9. Guide the retainer and plunger combination into the valve body until the threads of the retainer engage with

the valve body.

10. Continue tightening the retainer until it is hand tight.

11. Install the handle onto the plunger with the pin and set screw.

12. Rotate the handle clockwise until the plunger extends as high as it will go.

13. Loosen the plunger by turning the handle counterclockwise one complete turn.

14. Tighten the retainer into valve body to the following torque:

A465VB 20 ft/lbs

A465VB2 20 ft/lbs

A485VB 15 ft/lbs

A485VB2 15 ft/lbs

A560VB 20 ft/lbs

15. Tighten the jam nut on the retainer until it comes into contact with the valve body.

16. Tighten the valve handle clockwise until the plunger is in the fully engaged position.

Lubrication of the Bottom Drain Valves

Lubrication of the threads should be done with a nickel based high temperature thread lubricant. Lubricate all inner

and outer straight threads on the valve body, retainer and plunger.

The frequency of lubrication depends on the amount of use the valve receives. If the valve sits for a long period of

time (one or more months), it should be lubricated before use. If the valve is used daily, then lubrication may be

required once a week.

Applications that include operating temperatures of 250°C and above will require more frequent lubrication of the

valve threads.

Operating Instruction Manual

- 2 -

Page 3

Bottom Drain Valves Models A465VB, A465VB2, A485VB & A560VB

A465VB

Operating Instruction Manual

* Available in other alloys

- 3 -

Page 4

Bottom Drain Valves Models A465VB, A465VB2, A485VB & A560VB

A465VB2

Operating Instruction Manual

* Available in other alloys

- 4 -

Page 5

Bottom Drain Valves Models A465VB, A465VB2, A485VB & A560VB

A485VB

Operating Instruction Manual

* Available in other alloys

- 5 -

Page 6

Bottom Drain Valves Models A465VB, A465VB2, A485VB & A560VB

A485VB2

Operating Instruction Manual

* Available in other alloys

- 6 -

Page 7

Bottom Drain Valves Models A465VB, A465VB2, A485VB & A560VB

A560VB

Operating Instruction Manual

* Available in other alloys

- 7 -

Page 8

PARR INSTRUMENT COMPANY

211 Fifty-Third Street

Moline, Illinois 61265 USA

309/762-7716 800/872-7720

Fax 309/762-9453

http://www.parrinst.com

• E-Mail: parr@parrinst.com

Revision 01/24/08

Loading...

Loading...