Parkside PSHL 2 B1 Assembly Manual

AUTOMATIC WELDING HELMET PSHL 2 B1

GB

CY

AUTOMATIC WELDING HELMET

Assembly, operating and safety instructions

Translation of the original instructions

HR

AUTOMATSKA MASKA

ZA ZAVARIVANJE

Upute za posluživanje i za Vašu sigurnost

Prijevod originalnih uputa za uporabu

RS

AUTOMATSKA MASKA

ZA ZAVARIVANJE

Prevod originalnog uputstva za upotrebu

BG

АВТОМАТИЧЕН ЗАВАРЪЧЕН

ШЛЕМ

Указания за монтаж, работа и безопасност

Превод на оригиналното ръководство за

експлоатация

IAN 314800

RO

MASCĂ DE SUDURĂ,

AUTOMATĂ

Indicații de montare, operare și siguranță

Traducerea instrucţiunilor de utilizare originale

DE AT CH

AUTOMATIK - SCHWEISSHELM

Bedienungs- und Sicherheitshinweise

Originalbetriebsanleitung

HR

RO

RS

BG

GB

CY

Before reading, unfold the page containing the illustrations and familiarise yourself with all

functions of the device.

HR

Prije nego što pročitate tekst, otvorite stranicu sa slikama i upoznajte se na osnovu toga sa

svim funkcijama uređaja.

RS

Pre čitanja rasklopite obe strane sa slikama te se upoznajte sa svim funkcijama uređaja.

RO

Desfaceți înainte să citiți pagina cu ilustrații și apoi familiarizați-vă cu toate funcțiile

aparatului.

BG

Преди да прочетете отворете страницата с фигурите и след това се запознайте с

всички функции на уреда.

DE AT CH

Klappen Sie vor dem Lesen die beiden Seiten mit den Abbildungen aus und machen Sie sich

anschließend mit allen Funktionen des Gerätes vertraut.

GB / CY Operation and Safety Notes Page 5

HR Upute za montažu, uporabu i sigurnost Stranica 21

RS Prevod originalnog uputstva za upotrebu Strana 37

RO Indicații de montare, operare și siguranță Pagina 55

BG Указания за монтаж, работа и безопасност Страница 71

DE / AT / CH Montage-, Bedienungs- und Sicherheitshinweise Seite 91

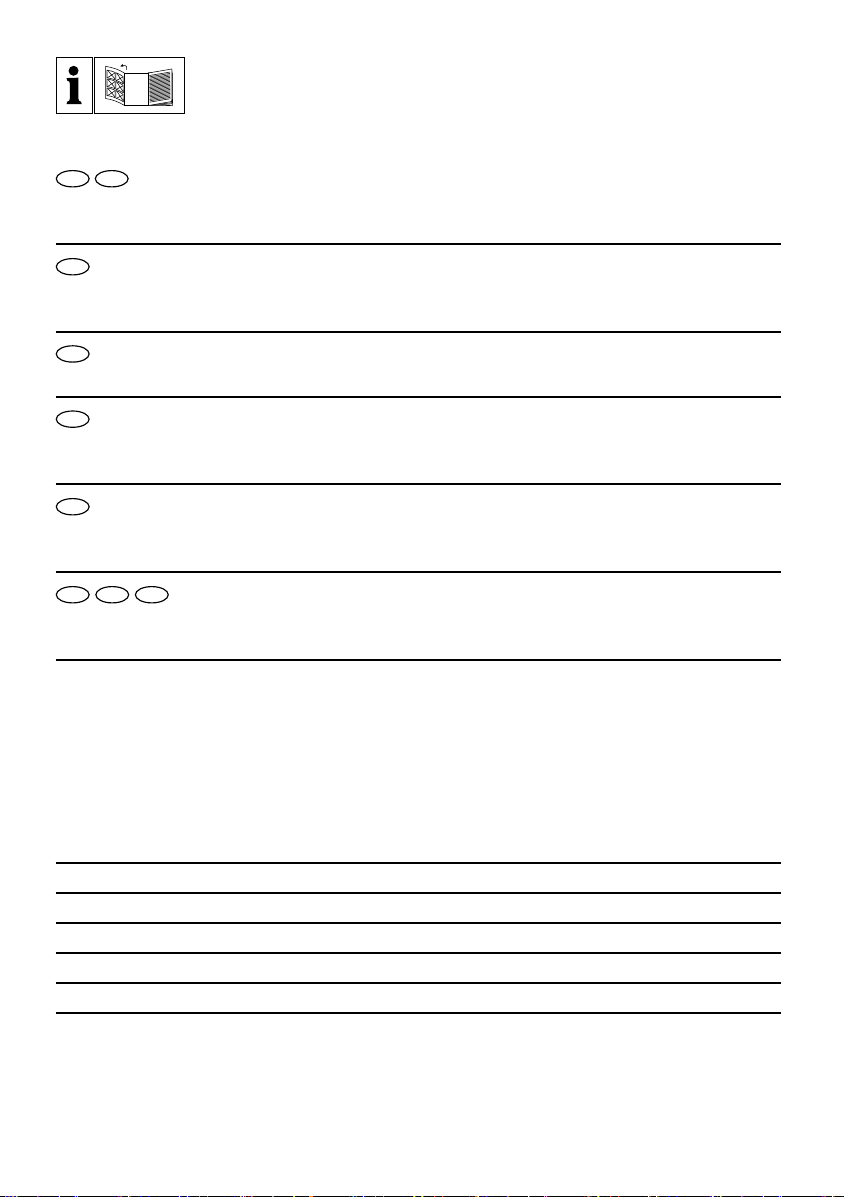

A

1 2 53

4

9 7

8

B C

6

11 12 13 14 15

10

16 16

D

2.

1.

E

3

18

17

Table of contents

List of pictograms used ..................................................................................Page 6

Introduction .........................................................................................................Page 6

Intended use ...........................................................................................................Page 6

Parts Description ....................................................................................................Page 6

Technical Data ........................................................................................................ Page 7

Scope of delivery ...................................................................................................Page 7

Safety instructions ............................................................................................Page 7

Initial use ..............................................................................................................Page 11

Troubleshooting ................................................................................................. Page 14

Cleaning and Maintenance ..........................................................................Page 14

Storage ..................................................................................................................Page 14

Environmental instructions and disposal information ....................Page 14

Warranty and service information ..........................................................Page 15

Warranty terms ....................................................................................................... Page 15

Extent of warranty ..................................................................................................Page 15

Processing of warranty claims ................................................................................Page 15

Service ...................................................................................................................Page 16

Label meanings .................................................................................................Page 16

EU Declaration of Conformity .....................................................................Page 17

5GB/CY

List of pictograms used / Introduction

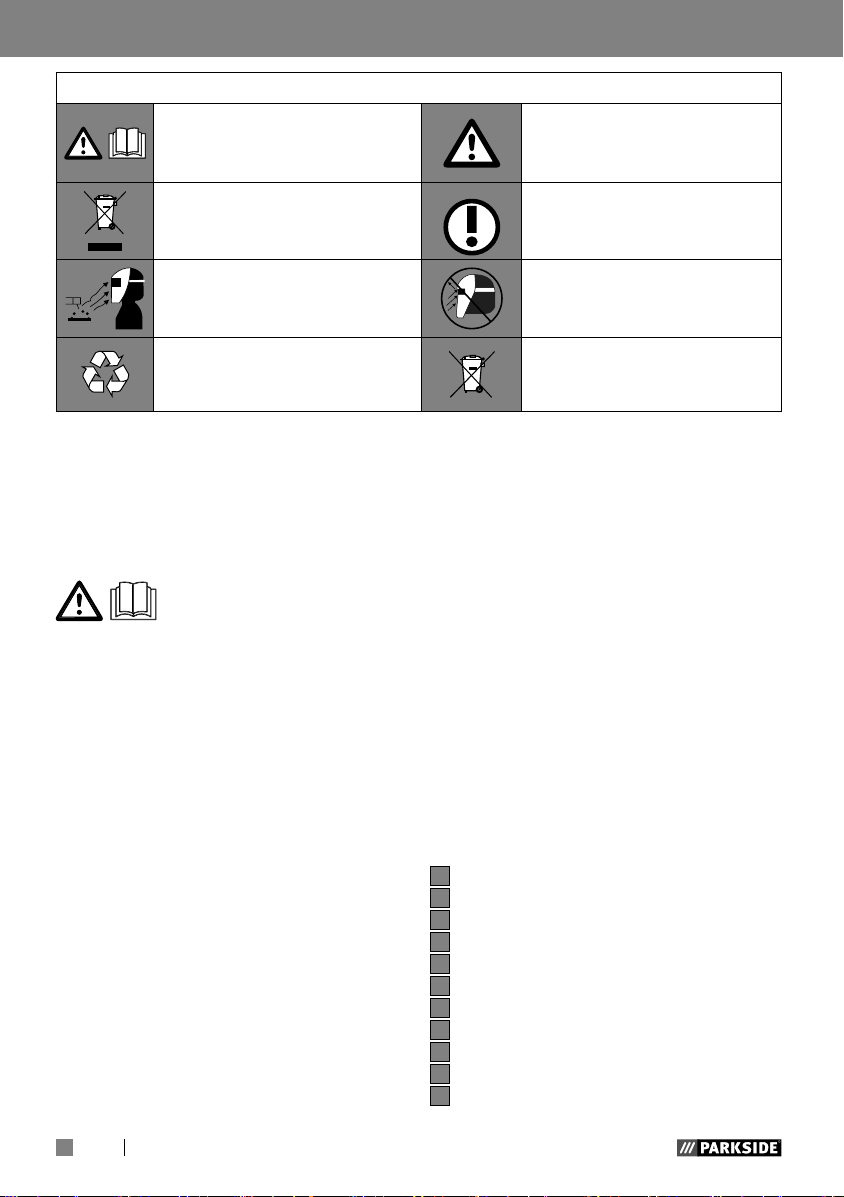

List of pictograms used

Caution!

Read instructions for use!

Do not dispose of electrical

equipment in household waste!

Attention: The welding helmet

does not provide any eye, ear

or face protection!

Made from recycling material

Automatic Welding Helmet

PSHL 2 B1

Introduction

Congratulations!

You have chosen a high-quality product from our company. Familiarise

yourself with the product before using it for

the first time. In addition, please carefully

refer to the instructions for use and the safety

instructions below.

KEEP OUT OF THE REACH OF

CHILDREN!

Attention, potential dangers!

Important notice!

Warning: arc rays can injure

the eye's retinas!

Dispose of batteries in an environmentally friendly manner!

adjustment wheel and is also adjustable for

flying sparks during grinding work. Only use

the product as described and for its indicated purpose. Keep these instructions in a safe

place.

When passing this product on to others,

please also include all the documents. Any

use other than the intended is prohibited and

potentially dangerous. Damages resulting

from noncompliance or misuse are not covered by the warranty and are not included

in the manufacturer‘s liability. This device

has been designed for household use and

may not be used for commercial or industrial

purposes.

Intended use

This welding helmet protects the eyes and

face from sparks, splashes and UV rays

while welding and automatically adapts to

the lighting conditions. It ensures an immediate, sensor-controlled darkening upon arc

ignition as well as automatic illumination at

the end of the welding procedure (including

a short delay to protect against afterglow).

This welding helmet provides a freely adjustable DIN protection level with a lateral

6 GB/CY

Parts Description

1

Viewing pane

2

Helmet casing

3

Solar cell

4

Rear pane

5

Headband

6

Rear control dial headband

7

Lateral control dial headband

8

UV filter

9

Darkening regulator

10

Low battery display

11

Test button

Introduction/ Safety instructions

12

Sensitivity setting

13

Delay setting

14

LED Lighting switch

15

Battery compartment

16

Bracket

17

Arc sensor

18

LED

19

Battery

Technical Data

Filter cartridge size: 110 x 90 x 9 mm

Field of vision: 9.2 x 4.2 cm

Bright state: DIN 4

Dark state: DIN 9–DIN 13

Switching times

Bright to dark: 0.23~0.72 ms

Dark to bright: 0.1~2 s

Switch on / off: Fully automatic

Energy supply: Solar cell

UV / IR protection: DIN 16

Operating temperature: -5 °C to +55 °C

Storage temperature: -20 °C to + 70 °C

Welding procedure: MMA, MIG, MAG,

TIG, plasma cutting

and plasma welding

Maximum service life: approx. 6 years

Scope of delivery

1 Auto-Darkening Welding Helmet

1 Set of instructions for use

Safety instructions

Please carefully read the

instructions for use and follow

the specified notices. Familiarise

yourself with the equipment, its

proper use and the safety notices

using these instructions for use.

All technical data about this

welding helmet is on the label,

please learn about this product‘s

technical facts.

The product is not suitable for

laser welding.

The product is only approved

for use within a temperature

range of between -5 °C to 55

°C.

The product is not fire-resistant.

Welding helmet and ADF filter

must not be exposed to any

heat or moisture.

Do not remove the ADF filter

from the welding helmet and

never open the housing of the

ADF filter without authorisation

from the manufacturer.

Prior to each use, check wheth-

er the Welding/Grinding setting was selected correctly.

The cover lens must be in-

stalled on the outer side of the

ADF filter. Otherwise, the ADF

filter can get damaged.

Do not carry out any

modifications/replacements on

the welding helmet and ADF

filter without consent.

If the filter does not darken

automatically whilst welding please stop the operation

immediately and contact the

dealers without delay.

7GB/CY

Safety instructions

Do not use any alcohol, fuel

or diluting agents to clean the

ADF filter. Do not place the

ADF filter in water.

The response time of the ADF

liquid crystal slows down if the

ambient temperature is lower,

however this does not have an

impact on the protective functions.

Please replace the housing

of the ADF filter immediately

if it is damaged or scratched

because this can impair visibility and the protective performance.

Please replace the viewing

pane immediately if it is broken or scratched. Do not use

any hard objects to replace

the viewing pane of the filter.

Regularly clean the surfaces

of the ADF filter, sensor and

solar cells.

The welding helmet cannot

withstand any damages that

are caused by a heavy blow,

explosion or abrasive liquids.

The useful life depends on

many different individual factors such as usage, cleaning,

storage and maintenance.

Regular inspections and replacement in the case of damage are recommended.

The material used to manufac-

ture the product will age over

time. This can result in breakages on the welding helmet,

for example. As a result of

these damages, the welding

helmet is no longer able to

provide effective protection.

In this case, the user should

replace the welding helmet immediately.

This product cannot be used

for overhead welding work

and cutting operations. If

this product is use for overhead welding or cutting, the

molten metal drops could burn

through the ADF filter and result in injuries to the user.

If the filter is faulty, the user

must stop using the welding helmet immediately. Slag

splashes can damage the surface of the filter and cause injury to the user’s skin or cause

other serious accidents.

This product is temperature re-

sistant and hardly inflammable

but in case of direct contact

with naked flames or in case

of access to an object with a

high temperature, the helmet

may begin to burn or melt.

Please store and only use the

welding helmet in the manner

described in order to reduce

such risks.

8 GB/CY

Safety instructions

The ADF filter is an electronic

product that is not waterproof.

Please ensure it is kept dry

and clean and not stored in a

damp environment.

Improper use could result in

injury to the user and cause

other types of diseases.

Please examine the filter prior

to each use. As soon as the

function and appearance seem

defective, they must no longer

be used.

The use of the welding helmet

is prohibited if the filter flickers

or if the level of darkening no

longer corresponds to the

standard value or there are

other abnormal working conditions.

Please do not expose this

product to unnecessary solar

radiation.

Please only use original spare

parts. The use of non-original

parts can cause problems with

regard to the protective function, serviceability and degree

of product protection.

Exceeding the service life

(insufficient protection) –

please check the protective

glasses prior to each use for

damage and durability.

Using eye protection without

the filter effect against radia-

tion (damages the eyes) – prior to each use check whether

the eye protection exhibits the

necessary scale number.

Using the product against

splashes (insufficient protection) – always check whether

the correct protective effect is

present.

Using the product against

large dust particles (injury,

accident). The eye protection

equipment must only be used

for the work described in the

operating instructions. Any deviation from the instructions in

the operating instructions can

result in injuries or accidents.

Using damaged products

(insufficient protection) –

prior to each use check the

protective glasses for damage

and durability.

Improper use of the eye protec-

tion (injury, accident). The eye

protection device must only be

used for the work described in

the operating instructions. Any

deviation from the instructions

can result in injuries or accidents.

This device may be used by

children aged 16 years and

up, as well as by persons with

reduced physical, sensory or

mental capacities, or lacking

9GB/CY

Safety instructions

experience and / or knowledge, so long as they are supervised or instructed in the

safe use of the device and understand the associated risks.

Do not allow children to play

with the product. Cleaning

and user main tenance should

not be performed by children

without supervision.

The welding helmet with auto-

matic darkening is not suitable

for laser and gas welding.

Never place the welding

helmet on hot surfaces.

Never open the welding

helmet. Never carry out repairs on or modifications to

the welding helmet. These may

only be carried out by trained

experts.

Please ensure that you have

set the automatic darkening

before each welding procedure.

The safety visor should not be

opened. It protects the filter

from dirt and damage.

If the filter does not automati-

cally darken, then immediately end the welding procedure

and contact the manufacturer.

Only use the welding helmet

in temperatures between -5 °C

and +55 °C. The filter‘s reaction time will slow down if this

temperature has not been

reached or is exceeded.

Clean the filter, the surface of

the helmet and the solar cells

regularly.

Replace the protective visor if

scratches or damages appear.

The welding helmet does not

provide protection against impact.

Frequent use, cleaning or stor-

age can mean that the service

life is less than 6 years. Replace the welding helmet immediately if the viewing panel

gets scratched or the viewing

panel is visibly damaged in

any other way.

ATTENTION! Materials

that come into contact with the

wearer‘s skin may cause allergic

reactions in people with sensitive

skin.

ATTENTION! Eye protection

can represent a hazard for the

wearer if it is worn over normal

corrective glasses due to the impact from high-speed particles.

ATTENTION! If protection

against high-speed particles at

extreme temperatures is required,

the eye protection chosen must

be labelled with the letter T direct-

10 GB/CY

Safety instructions / Initial use

ly after the letter for the impact

intensity, i. e. FT, BT or AT. If the

letter for the impact intensity is

not followed by the letter T, the

eye protection may only be used

against high-speed particles at

room temperature.

Initial use

Note: Only use the welding helmet with the

rear pane mounted

Note: Keep the UV filter‘s sensors

and clear.

After opening the package, immediately

check to ensure that the package contents

are complete and undamaged. Contact your

dealer immediately if the package contents

is incomplete or has any defects. Do not use

the device if it is defective

Check that the welding helmet and the

protective screen are intact before each use.

If the protective screen has scratches, cracks

or irregularities, it must be replaced before

use, as serious injuries may occur otherwise.

4

.

8

clean

Adjust the welding helmet with the help

of the headband

dial headband

welding helmet to the respective head

size and the lateral control dial head-

7

band

helmet. When adjusting, ensure that your

head is placed as far into the helmet as

possible and that it sits as close as

possible to your face.

Set the appropriate darkening shade

before the welding procedure (see the

following table). The darkening shade

may be manually adjusted from 9 to 13

by twisting the darkening regulator

the outside of the helmet.

ATTENTION! The darkening regulator

9

has the setting position “grind“. If the

darkening regulator

the automatic darkening is deactivated.

Only use this setting when you do not wish

to use the welding helmet for welding.

The automatic darkening is then no longer

active.

Check the light density before each use.

in order to lock the welding

5

. Turn the rear control

6

in order to adjust the

9

is set to this position

9

on

Remove the protective film from the in-

side and the outside of the visor.

11GB/CY

Initial use

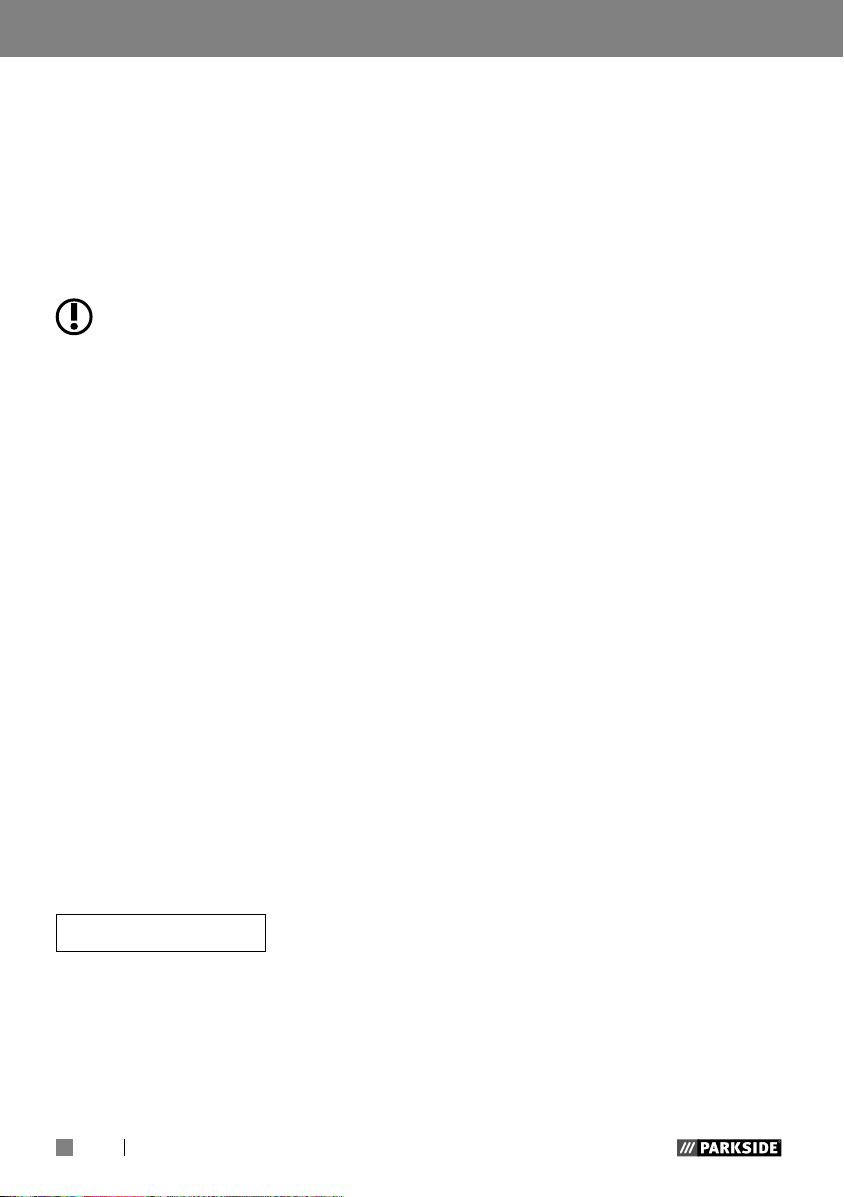

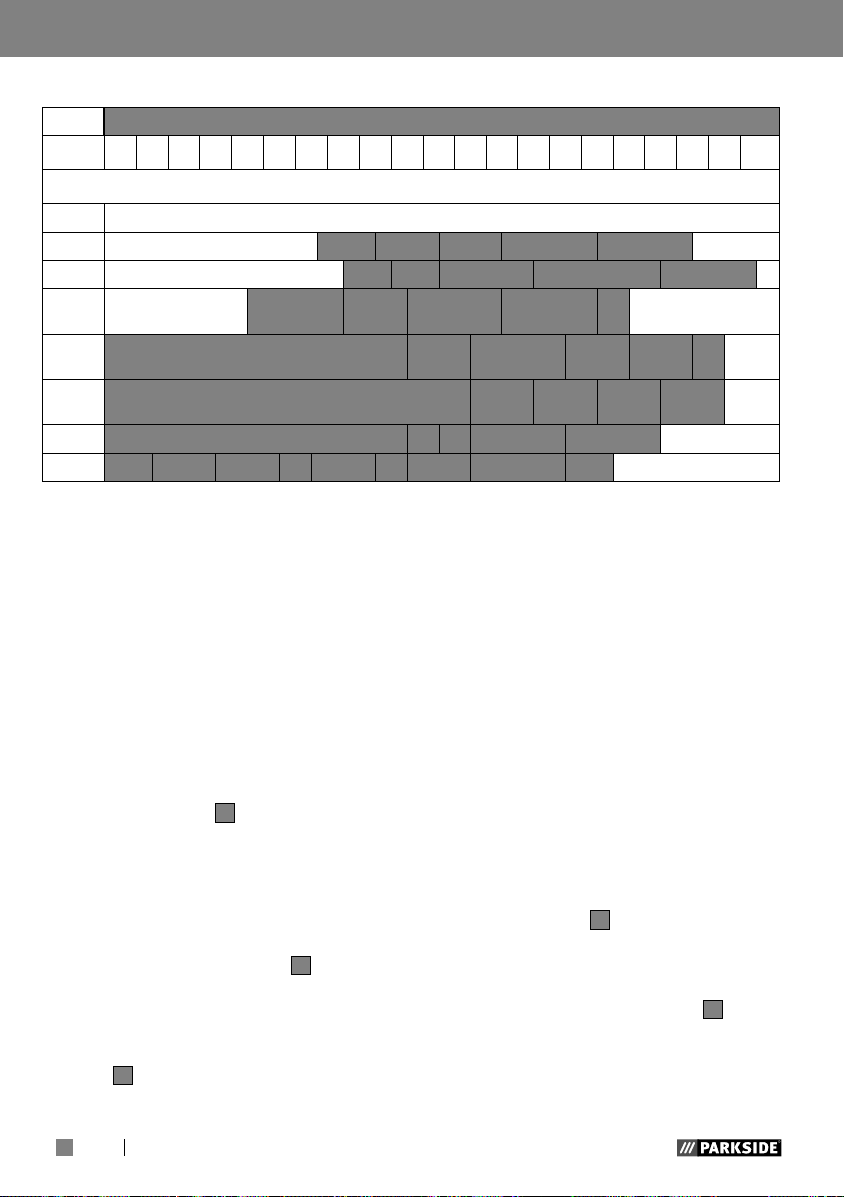

Table for setting the darkening shades

Arc current (ampere)

1,5 6 10 15 30 40 60 70 100 125 150 175 200 225 250 300 350 400 450 500 600

Grind

SMAW 8 9 10 11 12 13 14

MAG 8 9 10 11 12 13 14

TIG /

GTAW

MIG

(heavy)

MIG

(light)

PAC 9 10 11 12 13

PAW 4 5 6 7 8 9 10 11 12

8 9 10 11 12 13

SMAW: welding with coated

electrodes

MIG (heavy): MIG welding heavy metals

MIG (light): MIG welding light metals

and alloys

TIG / GTAW: welding with inert gases

Grinding function - automatic dimming not active

9 10 11 12 13 14

10 11 12 13 14

PAC: plasma cutting

PAW: plasma welding

Grind: Grinding function: Automatic dim-

ming not active. Only use the setting

if you do not use welding helmet for

welding.

MAG: welding with metal active

gass

Test procedure

You can use the test button

11

to check

whether the welding helmet's darkening

feature is working properly.

Bring the viewing panel closer to an ex-

ternal light source with a value of more

than 40 W and examine whether or

not the screen darkens or illuminates.

To do so, turn the darkening control

clockwise from "Grind" to the next position. This sets the filter to auto-darkening

mode.

If you turn the darkening control

9

an-

Change UV filter

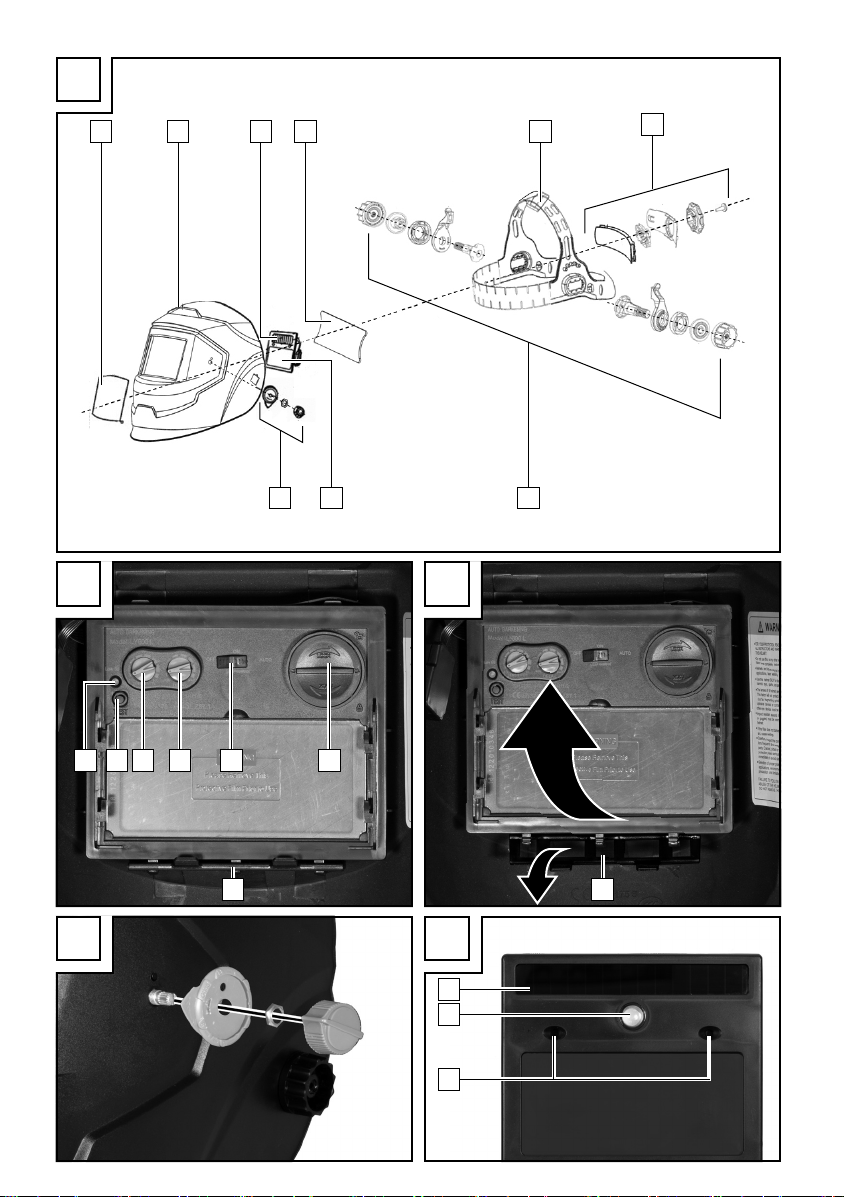

Press the clip

Then remove the darkening control

9

Once you have removed the nut from the

16

downwards to change

the UV filter / solar cell. (see fig. C).

Subsequently you can remove the filter

(see fig. C).

9

from the exterior of the welding helmet by

simply pulling it away, and unscrew the

nut that is located beneath it (see fig. D).

thread, you can completely remove the filter from the welding helmet. (see fig. D)

ticlockwise back to "Grind", the filter's

auto-darkening feature is once again

deactivated.

12 GB/CY

Initial use

Delay setting

You can adjust the delay setting

13

to

configure whether or not the autodarkening feature should be switched

off immediately after stopping welding

work, depending on the type of welding

work. At the lowest setting, auto-darkening

is switched off immediately. Turn the

rotary switch clockwise towards the

highest setting to prolong the time the

auto-darkening feature remains active

after welding work. This feature is very

useful for handling afterglow.

Sensitivity setting

You can use the sensitivity setting

12

to

adjust the light sensitivity of the sensor.

With low incident light, the control can

be adjusted to the highest setting to ensure that the auto-darkening feature is

activated even for a weak light source.

Even with this additional feature, you

can also adjust the light sensitivity of the

sensor to suit your own personal requirements.

LED light with lowlight sensor

The LEDs

are controlled with the LED light switches

18

integrated in the welding helmet

14

. The LED 18 can be manually switched on

by pressing the LED light switch

14

(middle

position “ON”).

The welding helmet as a lowlight sensor. This

is activated by switching the LED light switch

14

to the right position “Auto”. The lowlight

sensor automatically switches the LED lamp

on in dark environments and off in brightly

lit environments. This helps to illuminate the

object being welded in dark working conditions. The LED light switch

14

should always

be switched of (left position “OFF”) at the

end of work and when storing the welding

helmet.

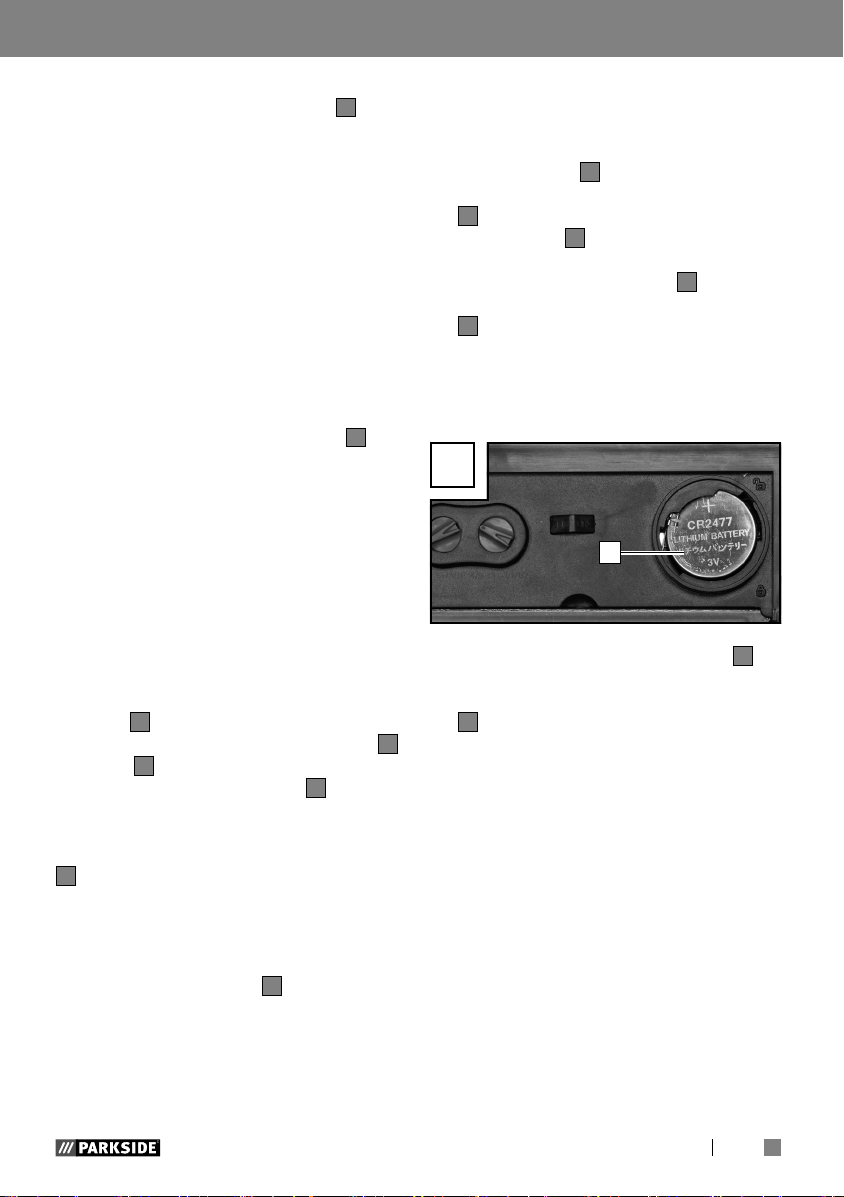

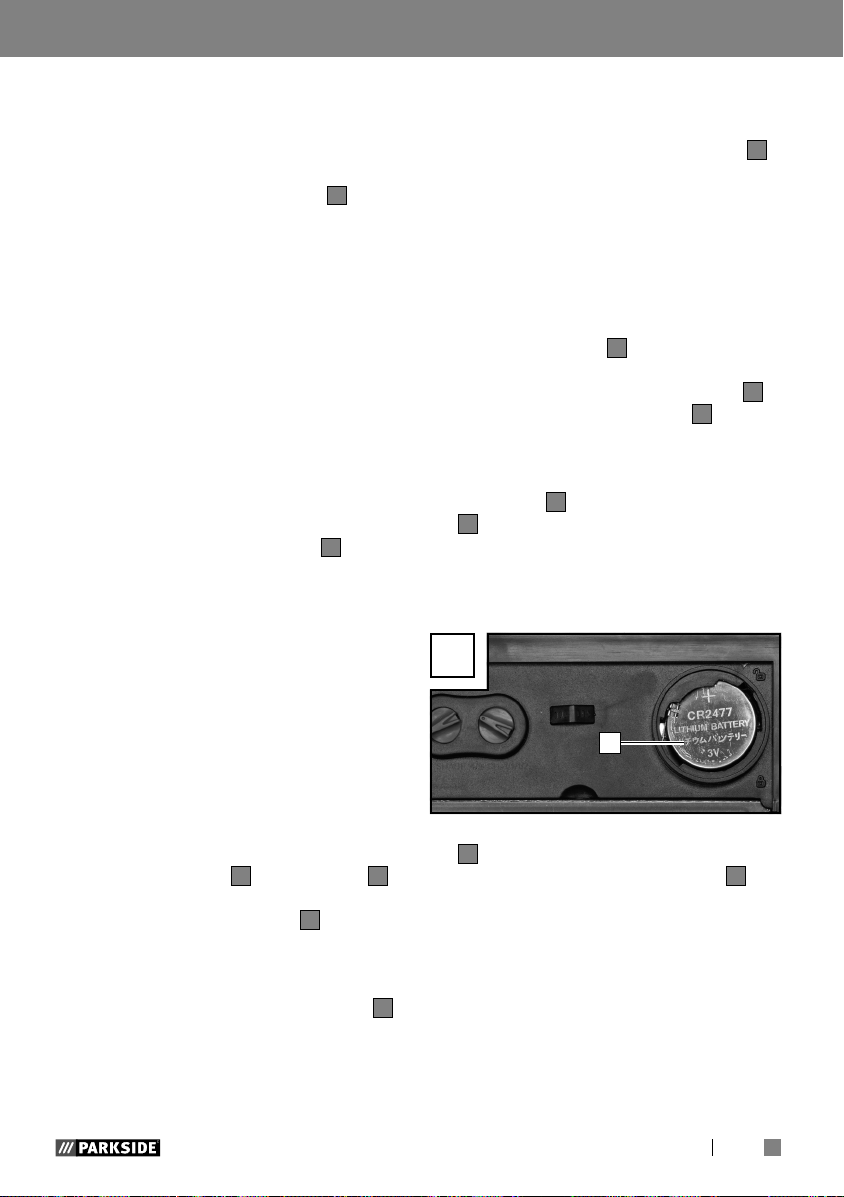

Battery replacement

If the battery charge level is too low you can

replace the batteries. A low battery charge

level is indicated with a red warning light on

the Battery display

In order to open the battery compartment

15

, you must turn the cover of the battery

compartment

10

.

15

counter-clockwise (see

image B).

You can remove the battery

19

, once you

have removed the battery compartment

15

.

Observe the correct polarity when insert-

ing the new battery. The positive pole

marking “+” must face upwards (see following Figure F).

F

19

Then, close the battery compartment

close the battery compartment, you must

turn the position the battery compartment

15

and turn it clockwise.

15

. To

13GB/CY

Troubleshooting / Cleaning and ... / Storage / Environmental instructions ...

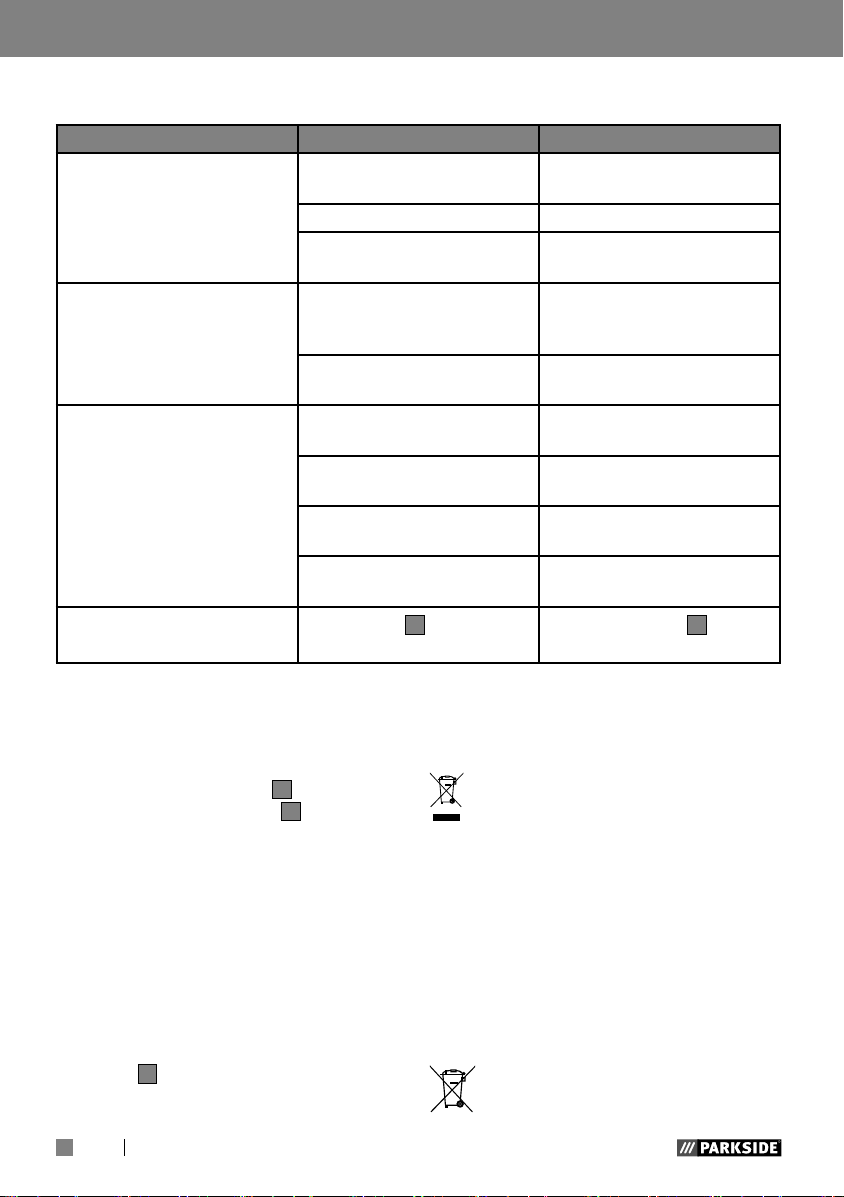

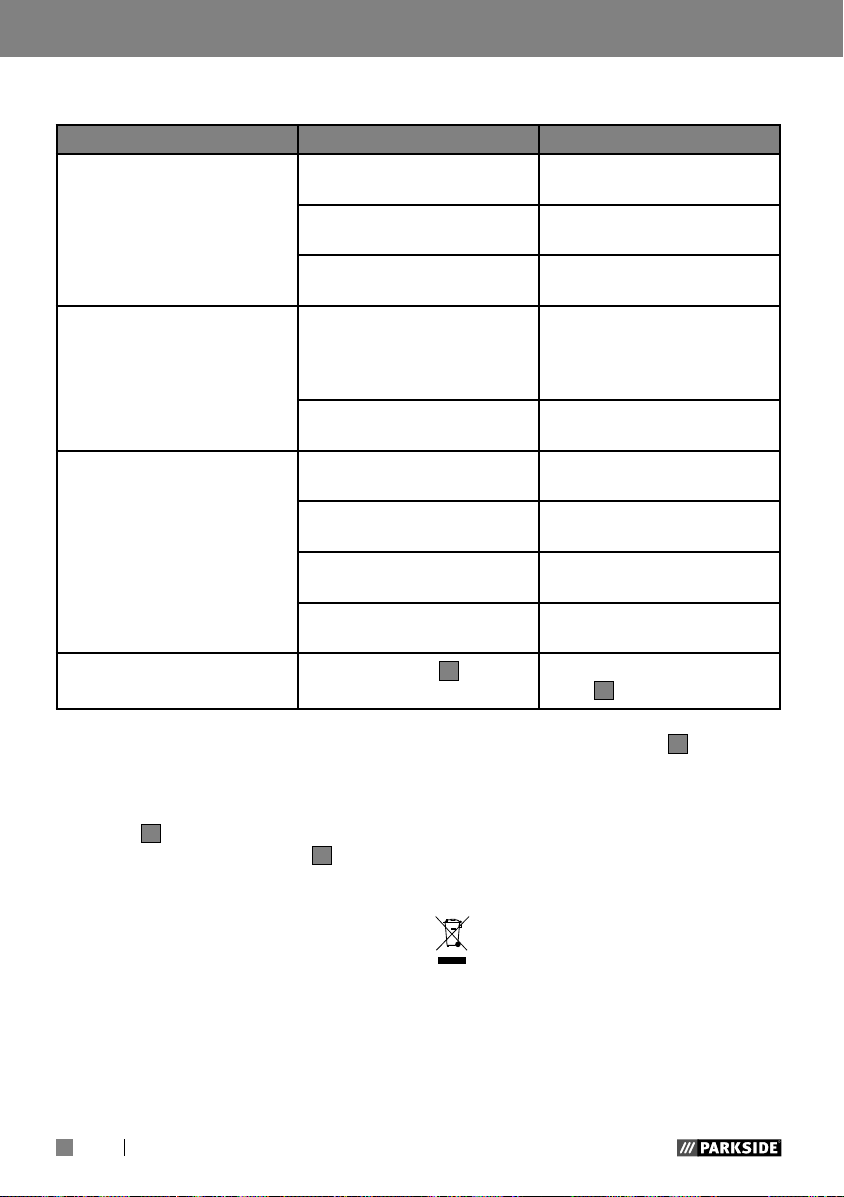

Troubleshooting

Error Cause Solution

The filter does not darken in a

normal way or flickers.

The reaction is slow. The ambient temperature is too

The visibility is poor. The protector / the protective

The welding helmet slips.

The protector does not darken in a

normal way or flickers.

The arc sensor is not clear. Clean the arc sensor's surface.

The welding current is

too low.

low / high.

The sensitivity is too low. Set the sensitivity to a

screen is dirty.

The protective film on the protec-

tive screen was not removed.

The ambient light is not sufficient. Apply more light to your work

The wrong darkening shade has

been set.

5

The headband

on incorrectly.

has been put

Clean the protector or replace it.

Set the sensitivity to the

maximum degree.

Only use the welding

helmet in temperatures

between -5 °C and +55 °C.

higher setting.

Clean the protector and the

protective screen.

Remove the protective film.

surroundings.

Reset the darkening shade.

Put on the headband

tighter.

5

again

Cleaning and Maintenance

Do not use any harsh cleaning agents to

clean the helmet casing

Never bring the UV filter

with water.

Clean the product with a soft and dry or

moistened cloth or clean it with a cloth

moistened with disinfectant.

2

.

8

into contact

Storage

Keep the device in a dry place and out

of the reach of children.

During storage, make sure the LED light

14

switch

is switched off [left position

“OFF”].

14 GB/CY

Environmental instructions

and disposal information

Don‘t waste, recycle!

The device, accessories and packaging

should be recycled in an environmentally

friendly manner.

Do not throw the auto-darkening welding helmet into household rubbish, fire or water. If

possible, non-operational equipment should

be recycled. Contact your local retailer for

information.

As the consumer you are legally

obliged (by the German Battery

... / Warranty and service information

Ordinance) to return any and all used

batteries. Batteries containing harmful

substances are labelled with the adjacent

symbol, which indicates the prohibition on

disposal in household waste. The abbreviations for the relevant heavy metals are: Cd =

cadmium, Hg = mercury, Pb = lead.

Take used batteries to a waste management

company in your city or community, or return

them to your dealer. This satisfies your legal

obligations while also making an important

contribution to protecting the environment.

Warranty and service

information

Creative Marketing & Consulting

GmbH warranty

Dear customer, the warranty for this device

is 3 years from the date of purchase. In the

event of product defects, you have legal

rights against the retailer of this product.

Your statutory rights are not limited in any

way by our warranty detailed below.

Warranty terms

The warranty period begins on the date of

purchase. Please keep the original receipt in

a safe place. This document is required as

your proof of purchase. Should this device

show any fault in materials or manufacture

within 3 years from the date of purchase, it

will be repaired or replaced – at our choice

– by us free of charge. This warranty is

conditional on the defective device and the

receipt of purchase being presented within

the 3 year warranty period, and that there

is a brief written description of the nature of

the defect and of the date it arose.

If the defect is covered by our warranty,

you will receive the product which has been

repaired or a new product. A repair or

exchange of the device does not begin a

new warranty period.

Extent of warranty

The appliance has been manufactured to

strict quality guidelines and meticulously

examined before delivery.

The warranty applies to defects in material

or manufacture. This warranty does not

apply to product parts subject to normal

wear and tear and which can therefore be

considered as wear items, or to damage to

fragile parts, e.g. switches, storage batteries

or glass parts.

This warranty becomes void if the device

has been damaged or improperly used or

maintained.

All instructions provided in the instructions

for use must be followed strictly to constitute

proper use of the product. Purposes and

practices which the operating instructions

warn of or advise against must be avoided

without fail.

This product is intended for private,

non-commercial use only. Any incorrect or

improper use of the device, use of force and

changes not performed by our authorized

service branch will void the warranty.

Processing of warranty

claims

Please follow the instructions below to ensure

your claim is processed quickly:

When inquiring about your product please

have your receipt and product number

(e.g. IAN) ready as your proof of purchase.

The product number can be found on the

type plate, an engraving, the cover page of

your instructions (bottom left) or the decal at

the back or bottom. In the event of malfunctions or other defects, please first contact

15GB/CY

... / Label meanings

the service department below by phone or

e-mail.

A product recorded as defective, along with

the proof of purchase (sales receipt) and

a description of the defect and when it

occurred, can then be returned free of

charge to you to the service address provided.

Note:

On www.lidl-service.com you can

download this as well as many other

manuals, product videos and software.

Service

Only use original accessory parts:

Black variant / Variant with flames

(PSHL 2 B1, Item no.:2182/2183):

• Viewing pane (CMC 1F CE):

118 mm x 95 mm x 1.0 mm

• Rear lens (CMC 1F CE):

103.8 mm x 47.3 mm x 1.0 mm

How to contact us:

GB/CY

Name: C.M.C. Creative Marketing

& Consulting GmbH

Website: www.cmc-creative.de

E-mail: service.gb@cmc-creative.

de

Phone: 0-808-189-0652

Registered office: Germany

IAN 314800

Please note that the following address is not

a service address. Please first contact the

service point named above.

Address:

C.M.C. Creative Marketing & Consulting

GmbH

Katharina-Loth-Str. 15

DE-66386 St. Ingbert

DEUTSCHLAND

Ordering spare parts:

www.lidl.com/contact-us

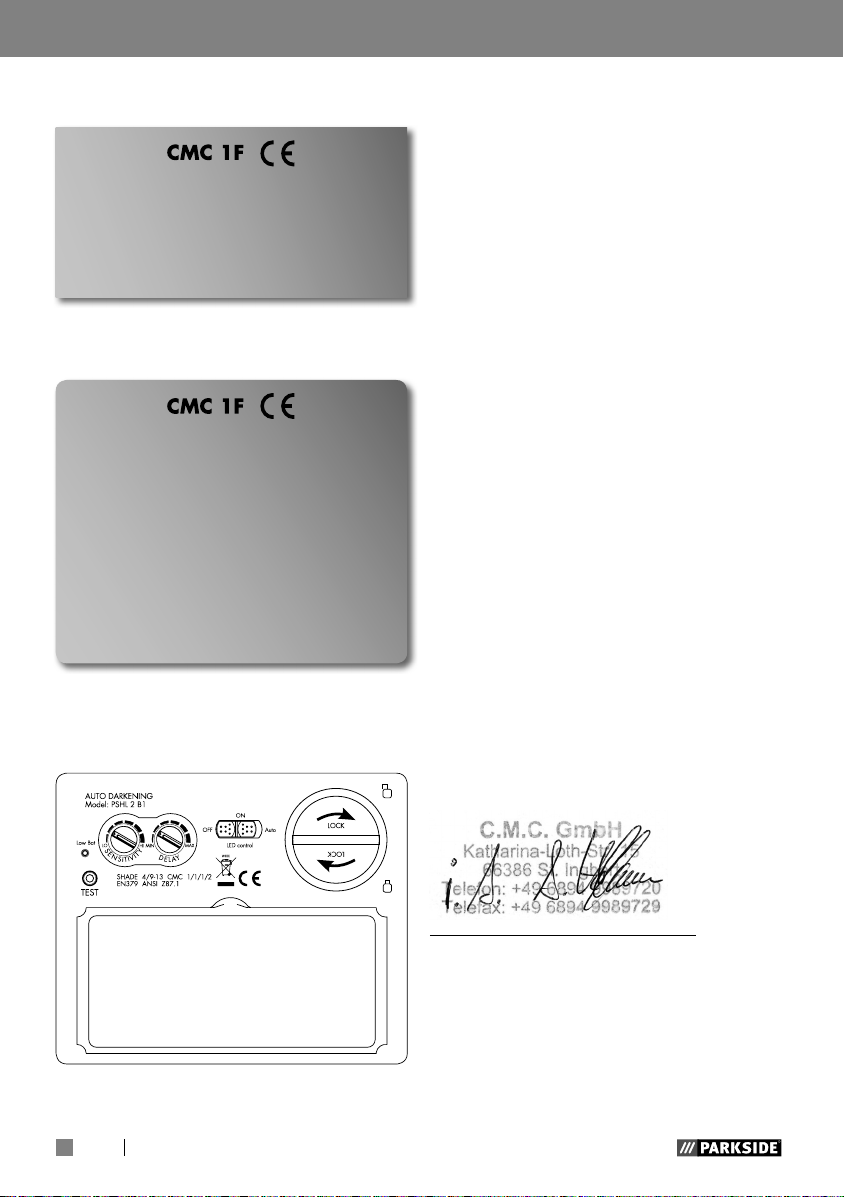

Label meanings

Safety viewing panels approved

according to DIN EN 166

(CXXXXCMC, CXXXXCMC):

• Viewing pane: CMC 1 F CE

CMC = manufacturer code

1 = optical class

F = mechanical strength

(low-energy impact at 45 m/s)

CE = CE symbol)

• Rear pane: CMC 1 F CE

CMC = manufacturer code

1 = optical class

F = mechanical strength

(low-energy impact at 45 m/s)

CE = CE symbol)

ADF approved according to

DIN EN 379: 4/9-13 CMC

1/1/1/2/379 CE (CXXXXCMC)

Legend:

4 = bright state

9–13 = dark state

CMC = manufacturer code

number 1 = optical class

number 2 = scattered light grade

number 3 = homo-geneity class

number 4 = angle dependency class

379 = test standard

CE = CE symbol

16 GB/CY

Label meanings / EU Declaration of Conformity

Welding helmet case:

CMC EN 175 F CE

(CXXXXCMC, CXXXXCMC):

Manufacturer identification: CMC

Number of the standard: EN 175

Area(s) of application (if required): S, F, B

Mass in grams (if required)

IP rating for welding helmet, order no.:

2182/2183: F

CE = CE symbol

Description

of scope

of application

Mechanical strength

Mechanical strength

Mechanical strength

Symbol

S

F

B

Protec-

tion type

increased

strength

Low

energy

impact

Medium

energy

impact

If the symbols F, B and S are not

obtained for the viewing panel as well as the

supporting body, the entire eye protection

device is to be conferred with a lower

rating.

Certification body:

DIN CERTCO Gesellschaft für

Konformitätsbewertung mbH

Alboinstrasse 56

12103 Berlin

Notified body number 0196

EU Declaration of Conformity

1. PSA (product, type, batch or serial number):

Automatic welding helmet

IAN: 314800

Serial number:

2182 (black variant) /

2183 (variant with flames)

Year of manufacture: 2019/25

Model: PSHL 2 B1

2. Name and address of the manufacturer

and his/her representative, if required:

C.M.C. Creative Marketing &

Consulting GmbH

Documentation Officer:

Alexander Hoffmann

Katharina-Loth-Str. 15

66386 St. Ingbert

GERMANY

3. The manufacturer is solely responsible for

the creation of the declaration of conformity.

C.M.C. Creative Marketing &

Consulting GmbH

4. The object of the declaration (identification of the PPE that enables traceability;

if necessary, it can contain a sufficient

sharp image if it is necessary for the

identification of the PPE):

Welder visor PSHL 2 B1,

item no. 2182, welder visor PSHL 2

B1, item no. 2183

17GB/CY

EU Declaration of Conformity

Viewing pane without filter effect

PSHL 2 B1, item no. 2182, 2183

Viewing pane without filter effect

PSHL 2 B1, item no. 2182, 2183

Automatic welder protective filter

with manually adjustable protection level PSHL 2 B1, item no. 2182,

2183

under number 4 corresponds to the

relevant harmonisation legislation of the

union:

Electromagnetic Compatibility

2014 / 30 / EU

RoHS directive

2011 / 65 / EU

Personal Protective Equipment Ordinance

(EU) / 2016/425

6. Indication of the relevant harmonised

standards used or other technical specifications in relation to which conformity is

declared, including the date of the standards

or other technical specifications:

EN 166:2001

EN 175:1997

EN 379:2009.

7. The notified certification body DIN CERTCO

Gesellschaft für Konformitätsbewertung

mbH, Alboinstrasse 56, 12103 Berlin,

Notified body number 0196, carried out the

EC type

examination and issued the EC type examination certificate CXXXXCMC/R0, CXXXXCMC/R0, CXXXXCMC/R0, CXXXXCMC/R0,

CXXXXCMC/R0.

St. Ingbert, 11.01.19

5. The object of the declaration described

18 GB/CY

On behalf of M. Sc. Alexander Hoffmann

– Quality Assurance –

19GB/CY

20 GB/CY

Popis sadržaja

Značenje korištenih simbola ........................................................................ Stranica 22

Uvod ................................................................................................................................. Stranica 22

Namjenska uporaba ..................................................................................................... Stranica 22

Opis dijelova................................................................................................................... Stranica 22

Tehnički podaci .............................................................................................................. Stranica 23

Opseg isporuke ............................................................................................................. Stranica 23

Sigurnosne upute .................................................................................................. Stranica 23

Stavljanje u pogon ................................................................................................ Stranica 27

Čišćenje i održavanje ......................................................................................... Stranica 30

Skladištenje ............................................................................................................... Stranica 30

Upute za okoliš i napomene za zbrinjavanje ................................... Stranica 30

Uklanjanje smetnji ................................................................................................ Stranica 30

Napomene za jamstvo i servisne postupke ...................................... Stranica 31

Uvjeti jamstva................................................................................................................. Stranica 31

Opseg jamstva ............................................................................................................... Stranica 31

Postupak u slučaju koji je pokriven jamstvom ......................................................... Stranica 32

Servis .............................................................................................................................. Stranica 32

Značenje oznaka .................................................................................................... Stranica 32

EU izjava o sukladnosti .................................................................................... Stranica 33

21HR

Značenje korištenih simbola / Uvod

Značenje korištenih simbola

Oprez!

Pročitajte upute za rad!

Pažnja, moguće opasnosti!

Ne zbrinjavajte električne uređaje preko kućnog otpada!

Pažnja: kacige za zavarivanje

ne nude zaštitu za oči,

uši i lice!

Izrađen od recikliranog

materijala

OPREZ

UPOZORENJE: Mogućnost strujnog udara !

Ne otvarati kućište proizvoda !

Automatska maska za

zavarivanje PSHL 2 B1

Uvod

Čestitamo! Time ste se

odlučili za jedan vrlo kvalitetan uređaj iz naše kuće. Prije prvog

korištenja upoznajte se s proizvodom.

Stoga pažljivo pročitajte slijedeće upute za

korištenje i sigurnost.

NE DOZVOLITE DA DOĐE U DJEČJE

RUKE!

Namjenska uporaba

Važna napomena!

Pažnja: zrake svjetlosnog luka

mogu ozlijediti mrežnicu očiju!

Odložite baterije na ekološki

prihvatljiv način!

zavarivanje (uključujući kratko vrijeme

zavlačenja za zaštitu od zaostalog žarenja).

Kaciga za zavarivanje ima kontinuirano

podesive DIN-stupnjeve zaštite pomoću

bočnog kotačića i može se namjestiti na

leteće iskre kod brušenja. Koristite proizvod

samo kako je opisano i u navedene svrhe.

Brižno čuvajte ove upute. Ako proizvod

dajete nekoj drugoj osobi, predajte joj i

sve upute. Svaka primjena koja odstupa

od navedenog korištenja je zabranjena i

potencijalo je opasna. Štete koje nastaju

zbog nepoštivanja uputa ili zloupotrebe

nisu pokrivene jamstvom i ne spadaju u

opseg odgovornosti koje snosi proizvođač.

Uređaj je dizajniran za kućnu upotrebu i

ne smije se koristiti u komercijalne svrhe ili

industrijski.

Ova kaciga za zavarivanje štiti za vrijema

zavarivanja oči i lice od iskra, štrcanja i

UV zračenja i automatski se prilagođava

uvjetima svjetla. Ona pruža neposredno,

senzorski kontrolirano zatamnjenje kod

paljenja svjetlosnog luka i automatsko

vraćanje svjetla na normalu na završetku

22 HR

Opis dijelova

1

prednje staklo

2

kućište kacige

3

solarna ćelija

4

unutarnje staklo

Uvod / Sigurnosne upute

5

traka za glavu

6

stražnji rotirajući prekidač na traci za

glavu

7

bočni rotirajući prekidač na traci za glavu

8

UV-ltar

9

regulator zatamnjenja

10

testna tipka

11

namještanje odgađanja

12

namještanje senzibilnosti

13

prikaz niske razine napunjenosti baterije

14

prekidač za LED rasvjetu

15

pretinac za baterije

16

luk

17

senzor električnog luka

18

LED

19

baterija

Tehnički podaci

Dimenzije kazete ltra 110 x 90 x 9 mm

Vidno polje: 9,2 x 4,2 cm

Svjetlo stanje: DIN 4

Tamno stanje: DIN 9–DIN 13

Vrijeme preklapanja

Svjetlo prema tamnom: 0,23~0,72 ms

Tamno prema svjetlomu: 0,1~2 s

Uključivanje / isključivanje: potpuno

automatski

Dovod energije: solarna ćelija

UV- / IR-zaštita: DIN 16

Radna temperatura: -5 °C do + 55 °C

Temperatura skladištenja: -20 °C do + 70

°C

Procesi zavarivanja: MMA, MIG,

MAG, TIG,

rezanje plazmom

i zavarivanje

plazmom

Maksimalni rok trajanja: cca. 6 godina

Opseg isporuke

1 automatska maska za zavarivanje

1 upute za korištenje

Sigurnosne upute

Molimo, pažljivo pročitajte upute

za korištenje i pridržavajte se

opisanih uputa. Pomoću ovih

uputa za korištenje upoznajte se

s uređajem, njegovom pravilnom

uporabom i sigurnosnim napomenama. Na tipskoj pločici stoje

svi tehnički podaci ove kacige za

zavarivanje, molimo, informirajte

se o tehničkim osobinama ovog

proizvoda.

Proizvod nije prikladan za

lasersko zavarivanje.

Proizvod je odobren samo za

uporabu u rasponu temperature od -5 °C do + 55 °C.

Proizvod nije otporan na va-

tru.

Ne izlažite masku za zavari-

vanje i samozatamnjujući ltar

toplini ili vlazi.

Nemojte uklanjati samozatam-

njujući ltar iz maske za zavarivanje i nikad ne otvarajte kućište samozatamnjujućeg ltra

bez dopuštenja proizvođača.

Prije svake uporabe provjerite

je li ispravno odabrana postavka Zavarivanje/brušenje.

Prednji podložni disk mora biti

postavljen na vanjskoj strani

samozatamnjujućeg ltra.

U suprotnom se samozatam-

23HR

Sigurnosne upute

njujući ltar može oštetiti.

Nemojte ništa mijenjati/zamje-

njivati na maski za zavarivanje i samozatamnjujućem ltru

bez odobrenja.

Odmah prestanite s radom

i smjesta se obratite prodavaču ako se tijekom zavarivanja

ltar automatski ne zatamni.

Samozatamnjujući ltar ne-

mojte čistiti alkoholom, benzinom ili razrjeđivačem. Samozatamnjujući ltar nemojte

stavljati u vodu.

Vrijeme reakcije samozata-

mnjujućeg tekućeg kristala

usporava se kada je temperatura okoline niža, ali ne utječe

na zaštitne funkcije.

Odmah zamijenite kućište sa-

mozatamnjujućeg ltra ako je

oštećen ili izgreben jer će

to znatno umanjiti vidljivost

i zaštitu.

Odmah zamijenite stakla ako

su slomljena ili izgrebana.

Nemojte upotrebljavati tvrde

predmete za zamjenu stakla

ltra.

Redovito čistite površine

samo zatamnjujućeg ltra,

senzora i solarnih ćelija.

Maska za zavarivanje ne pod-

nosi oštećenja uzrokovana

snažnim udarcem, eksplozijom ili korozivnim tekućinama.

Vrijeme uporabe ovisi o mno-

gim pojedinačno različitim

čimbenicima kao što su uporaba, čišćenje, skladištenje i

održavanje. Preporučuju se

redovita provjera i zamjena

u slučaju oštećenja.

S vremenom će materijal od

kojeg je proizvod izrađen stariti. Zato na maski za zavarivanje može doći do pucanja.

Zbog takvih oštećenja maska

za zavarivanje ne može

pružiti učinkovitu zaštitu.

U tom slučaju korisnik odmah

treba zamijeniti masku

za zavarivanje.

Ovaj se proizvod ne smije

upotrebljavati za zavarivanje

i rezanje na visini iznad glave.

Ako se ovaj proizvod upotrijebi za zavarivanje ili rezanje na

visini iznad glave, kapljice rastaljenih metala mogu izgorjeti

kroz samozatamnjujući ltar i

ozlijediti korisnika.

Ako je ltar neispravan, ko-

risnik mora odmah prestati

raditi s maskom za zavarivanje. Prskanje nečistoća može

oštetiti površinu ltra i ozlijediti

korisnikovu kožu ili uzrokovati

druge ozbiljne nesreće.

Ovaj je proizvod otporan na

temperaturu i teško zapaljiv,

ali u slučaju izravnog dodira

24 HR

Sigurnosne upute

s otvorenim plamenom ili pristupom objektu visoke temperature, maska za zavarivanje može početi goriti ili taliti

se. Spremate i upotrebljavajte

masku za zavarivanje samo

kako je opisano da bi se smanjili takvi rizici.

Samozatamnjujući ltar elek-

tronički je proizvod koji nije

vodootporan. Pazite da ostane suh i čist i nemojte ga skladištiti u vlažnu okolinu.

Nepravilna upotreba može re-

zultirati ozljedom korisnika

i uzrokovati druge vrste bolesti.

Prije svake upotrebe provjeri-

te ltar. Ako izgleda da nešto

nije u redu s radom i izgledom, ne smijete ga nastaviti

upotrebljavati.

Ako ltar treperi ili stupanj

zatamnjenja više ne zadovoljava standardnu vrijednost

ili postoje drugi neuobičajeni

radni uvjeti, masku za zavarivanje više ne smijete upotrebljavati.

Nemojte nepotrebno izlagati

ovaj proizvod suncu.

Upotrebljavajte samo

originalne dodatne proizvode.

Upotreba neoriginalnih dijelova pribora može uzrokovati probleme u smislu zaštitne

funkcije, iskoristivosti i stupnja

zaštite proizvoda.

Prekoračeni vijek trajanja (ne-

dovoljna zaštita) – Prije svake

upotrebe provjerite jesu li zaštitne naočale oštećene

i dokad vrijede.

Upotreba zaštite za oči bez

učinka ltra protiv optičkog

zračenja (oštećenje očiju) –

Prije svake upotrebe provjerite ima li zaštita za oči potrebni

broj ljestvice.

Upotreba proizvoda protiv pr-

skanja (nedovoljna zaštita) –

Uvijek provjerite ima li ispravno zaštitno djelovanje.

Upotreba proizvoda protiv

velikih čestica prašine

(ozljeda, nesreća). Uređaj za

zaštitu za oči smije se upotrebljavati samo za rad opisan

u uputama za uporabu. Svako

odstupanje od uputa iz rukovanje može uzrokovati ozljede

ili nesreće.

Upotreba oštećenih proizvo-

da (nedovoljna zaštita) – Prije

svake upotrebe provjerite jesu

li zaštitne naočale oštećene

i dokad vrijede.

nepravilna upotreba zašti-

te za oči (ozljeda, nesreća).

Uređaj za zaštitu za oči smije

se upotrebljavati isključivo za

rad opisan u instrukcijama za

uporabu. Svako odstupanje

25HR

Sigurnosne upute

od uputa može uzrokovati ozljede i nesreće.

Ovaj uređaj mogu koristiti dje-

ca od 16 godina i starija djeca, kao i osobe s umenjenom

psihičkom, senzoričkom

i mentalnom sposobnošću ili

s umanjenim iskustvom ako

su pod nadzorom ili ako su

upoznati sa sigurnom uporabom uređaja i razumiju opasnosti koje proizlaze iz upotrebe. Djeca se ne smiju igrati

uređajem. Čišćenje i održavanje ne smiju vršiti djeca bez

nadzora.

Kaciga za zavarivanje sa

automatskim zatamnjenjem

nije pogodna za lasersko i autogeno zavarivanje.

Nemojte položiti kacigu za

zavarivanje nikada na vruću

površinu.

Kacigu za zavarivanje ni

u kojem slučaju ne otvarajte.

Nemojte popravljati niti promijeniti kacigu za zavarivanje.

To smiju izvesti samo educirane stručne osobe.

Obratite pozornost na to,

da ste prije svake operacije

zavarivanja namjestili automatsko zatamnjenje.

Sigurnosni vizir se ne smije

otvoriti. On štiti ltar od prljavštine i oštećenja.

Ako ltar automatski ne pota-

mni, prekinite odmah postupak zavarivanja i kontaktirajte

proizvođača.

Koristite kacigu za zavariva-

nje samo kod temperatura između -5 °C i +55 °C. Vrijeme

reakcije ltera će se usporiti, ako je temperatura ispod /

iznad te temperature.

Redovito čistite ltar, površinu

kacige i solarne ćelije.

Zamijenite zaštitni vizir, ako

ima ogrebotine ili ako je oštećen.

Kaciga za zavarivanje ne štiti

od udarca.

Uporaba, čišćenje i skladište-

nje mogu umanjiti rok trajanja

od 6 godina. Izgrebanu ili na

drugi način vidljivo oštećenu

masku za gledanje tj. kacigu

za zavarivanje treba odmah

zamijeniti.

Pažnja! Materijali koji dola-

ze u kontakt s kožom nositelja,

mogu kod osjetljivih osoba izazvati alergijske reakcije.

Pažnja! Uređaji za zaštitu

očiju mogu za nosioca predstav

ljati opasnost od čestica velike

brzine zbog prenašanja udarca,

ako se nose iznad standardnih

naočala za korigiranje vida.

26 HR

Sigurnosne upute / Stavljanje u pogon

Pažnja! Ako je potrebna

zaštita od brzih čestica kod

ekstremnnih temperatura, mora

odabrani uređaj za zaštitu očiju

biti označen sa slovom T odmah

nakon slova za intenzitet udara, tj FT, BT ili AT. Ako slovu za

intenzitet udarca ne slijedi odmah slovo T, onda se uređaj za

zaštitu očiju može koristiti samo

na sobnoj temperaturi od čestice

velike brzine.

Stavljanje u pogon

Napomena: koristite kacigu za zavarivanje

samo sa ugrađenim unutarnjim staklom

Napomena: držite senzore

čiste i jasne.

Odmah nakon otvaranja pakiranja

provjerite je li sadržaj potpun i neoštećen.

Odmah se obratite prodajnom predstavniku

ako je isporuka nepotpuna ili ima nedostatke. Nemojte upotrebljavati uređaj ako je

neispravan.

17

UV-ltra 8

4

.

bočne rotirajuće prekidače trake za

7

glavu

zavarivanje.

podešavanja, da kaciga za zavarivanje

sjedi što je moguće dublje na glavi i što je

moguće bliže vašem licu.

Namjestite prije procesa zavarivanja

odgovarajući stupanj zatamnjenja (vidi

slijedeći tablicu). Stupanj zatamnjenja

se može ručno namjestiti od 9 do 13,

tako da okrečete na regulatoru zatamnjenja

Pažnja! Regulator zatamnjenja 9 ima

namješteni položaj „Grind“. Ako je regulator

zatamnjenja

automatsko zatamnjivanje je deaktivirano.

Koristite to podešavanje samo, ako kacigu

za zavarivanje ne želite koristiti za varenje.

Automatsko zatamnjivanje tada nije aktivno.

Pr ije svakog korištenja provjerite propu-

snost svjetla.

da biste zaključali kacigu za

Obratite pozornost kod

9

na vanjskoj strani kacige.

9

namješten na taj položaj,

Provjerite prije svakog puštanja u pogon, dali su kaciga za zavarivanje i zaštitna

stakla ispravni. Ako zaštitno staklo ima

ogrebotine, pukotine ili kvržice, mora se

obavezno zamijeniti prije uporabe, jer inače

može doći do teških ozljeda.

Uklonite zaštitnu foliju s unutarnje i vanj-

ske strane vizira.

Kacigu za zavarivanje postavite s

pomoću trake za glavu

stražnji rotirajući prekidač trake za glavu

6

da biste prilagodili kacigu za zavari-

vanje na odgovarajuću veličinu glave i

5

. Okrećite

27HR

Stavljanje u pogon

Tablica za podešavanje stupnjeva zatamnjenja

Struja svjetlosnog luka (ampera)

1,5 6 10 15 30 40 60 70 100 125 150 175 200 225 250 300 350 400 450 500 600

Grind

SMAW 8 9 10 11 12 13 14

MAG 8 9 10 11 12 13 14

TIG /

GTAW

MIG

(teško)

MIG

(lahko)

PAC 9 10 11 12 13

PAW 4 5 6 7 8 9 10 11 12

SMAW: zavarivanje s obučenom

MIG (teško): MIG zavarivanje teških

MIG (lahko): MIG zavarivanje laganih

TIG / GTAW: zavarivanje s inertnim pli-

Funkcija brušenja - automatsko zatamnjenje nije aktivno

8 9 10 11 12 13

9 10 11 12 13 14

10 11 12 13 14

PAC: rezanje plazmom

elektrodom

PAW: zavarivanje plazmom

Grind: Funkcija brušenja: Automatsko

metala

zatamnjenje nije aktivno. Postavkom se koristite samo ako kacigu

metala i legura

za zavarivanje ne upotrebljavate za

zavarivanje.

nom

MAG: zavarivanje s matal aktivnim

plinom

Provedba testnog postupka

Testnom tipkom

11

možete kontrolirati

automatsko zamračivanje ltra se pono-

vo deaktivira.

funkcionira li funkcija zatamnjenja kacige za zavarivanje.

Provođenje test procesa: približavajte

se s vizualnim staklom eksternom izvoru

svjetla s više od 40 W i provjerite da li

se staklo zatamnjuje ili dali je svjetlo. Za

to regulator zamračivanja

9

okrenite

u smjeru okretanja kazaljke na satu sa

„Grind“ na sljedeći stupanj.

Na taj način zamračivanje ltra nastupa

automatski. Ako regulator zamračiva-

9

nja

ponovo vratite natrag u smjeru

okretanja kazaljke na satu na „Grind“,

Zamjena UV ltra

Da biste zamijenili UV ltar/solarnu će-

liju, pritisnite luk

16

prema dolje. (vidjeti

sliku C). Zatim možete izvaditi ltar (vidjeti sliku C).

Zatim jednostavnim povlačenjem uklo-

nite regulator za zamračivanje

9

na

vanjskoj strani kacige za zavarivanje,

a potom otpustite maticu koja se nalazi

ispod (vidjeti sliku D).

Nakon što ste maknuli maticu s navoja

28 HR

Stavljanje u pogon

možete potpuno odvojiti ltar od kacige

za zavarivanje (vidjeti sliku D).

Postavljanje odgode

Preko namještanja odgađanja

13

sno o procesu zavarivanja možete

varirati, da li se automatsko zamračivanje treba ili ne treba isključiti direktno

nakon završetka procesa zavarivanja.

Automatsko zamračivanje se automatski isključuje na min. stupanj. Što više

prekidač okrećete u smjeru okretanja

kazaljke na satu tj. u smjeru maks. stupnja, to će zamračivanje nakon procesa

zavarivanja duže postojati. Ova funkcija

je veoma smislena prilikom naknadnog

bljeska.

Postavljanje senzibilnosti

S namještanjem senzibilnosti

12

regulirati svjetlosnu osjetljivost senzora.

U slučaju malog upada svjetla, regulator

je moguće namjestiti na maks. stupanj,

da bi automatsko zamračivanje također

nastupilo pri slabom izvoru svjetla. Također, kod ove dodatne funkcije, ovisno o

vlastitim potrebama, možete namjestiti

svjetlosnu osjetljivost senzora.

, ovi-

možete

u slučaju tamne okolice služi osvjetljivanju

predmeta koji se zavaruju. Nakon završetka

rada i za spremanje kacige za zavarivanje

prekidač LED lampice za osvjetljavanje

14

uvijek treba biti isključen (lijeva postavka

„OFF“).

Zamjena baterija

Preko pretinca za baterije možete izmijeniti

baterije sa slabom napunjenosti. Obavijest

o slaboj napunjenosti baterije dobivate

preko prikaza baterije

10

uz pomoć crvene

upozoravajuće lampice.

Da biste otvorili pretinac za baterije

poklopac pretinca za baterije

15

morate

15

,

okrenuti u smjeru suprotnom od kazaljke

na satu (vidjeti sliku B).

Nakon što ste uklonili poklopac pretinca

za baterije

19

.

15

, možete izvaditi baterije

Pri umetanju nove baterije, morate uzeti

u obzir polaritet. Oznaka pola plus „+“

mora pokazivati prema gore (vidjeti sljedeću sliku F).

F

19

LED svjetla sa senzorom za

prigušivanje

LED lampicom integriranom u kacigu za

zavarivanje [18] upravlja prekidač LED lampice za osvjetljavanje

14

. LED lampica 18

može se ručno uključiti tako da se prekidač

LED lampice za osvjetljavanje

14

uključi

(srednja postavka „ON“).

Kaciga za zavarivanje raspolaže senzorom

za prigušivanje. To se aktivira tako da se

prekidač LED lampice za osvjetljavanje

14

prebaci na desnu postavku „Auto“. Zatim

senzor prigušivanja u slučaju tamne okolice

automatski uključuje LED lampicu, a u slučaju svijetle okolice ponovo je isključuje. To

Zatim opet zatvorite poklopac pretinca

15

. Da biste zatvorili pretinac za baterije, poklopac pretinca za baterije

morate umetnuti i okrenuti u smjeru kazaljke na satu.

15

29HR

Uklanjanje smetnji / Čišćenje i održavanje / Skladištenje / Upute za ...

Uklanjanje smetnji

Greška Uzrok Rješenje

Filtar se ne zatamnjuje

redovito odnosno treperi.

Reakcija je usporena.

Vidljivost je loša.

Kaciga za zavarivanje klizi.

Protektor je zaprljan ili

defektan.

Senzor za svjetlosni luk nije

jasan.

Struja varenja je premala.

Temperatura okoline je

preniska / previsoka.

Osjetljivost je premala.

Protektor / zaštitno staklo je

zaprljano.

Zaštitna folija nije uklonjena

sa zaštitnog stakala.

Svjetlo okoline nije dovolj-

no.

Namješten je krivi stupanja

zatamnjenja.

5

Traka za glavu

namještena.

je krivo

Očistite protektor ili ga

zamijenite.

Očistite površinu senzora

svjetlosnog luka.

Ostavite osjetljivost na

maks. stupanj.

Koristite kacigu za

zavarivanje samo kod

temperatura između

-5 °C i +55 °C.

Postavite osjetljivost na

više.

Očistite protektor i zaštitno

staklo.

Uklonite zaštitnu foliju.

Namjestite više svjetla

u vašoj radnoj okolini.

Namjestite ponovo stupanj

zatamnjenja.

Namjestite traku za glavu

5

ponovo i uže.

Čišćenje i održavanje

Za čišćenje nemojte koristiti nagrizaju-

ća sredstava, kako ne bi oštetili kućište

kacige

Ne dovodite nikada UV-ltar

takt s vodom.

Proizvod očistite mekom i suhom kr-

pom, navlaženom krpom ili krpom navlaženom sredstvom za dezinfekciju.

2

.

8

u kon-

Skladištenje

Spremite uređaj na suho mjesto i izvan

dohvata djece.

Pritom pripazite da je prekidač LED

30 HR

lampice za osvjetljavanje

skladištenja isključen (lijeva postavka

„OFF“).

14

tijekom

Upute za okoliš i napo-

mene za zbrinjavanje

Recikliranje sirovina umjesto

otpada

Uređaj, oprema i ambalaža se trebaju

ekološki reciklirati.

Ne bacajte automatsku kacigu za zavarivanje ukućni otpad, vatru ili vodu. Ako

Loading...

Loading...