Parkside PSHL 2 A2 Operation And Safety Notes Translation Of The Original Instructions

AUTOMATIC WELDING HELMET PSHL 2 A2

PDF

ONLINE

www.lidl-service.com

GB IE NI

AUTOMATIC WELDING HELMET

Operation and Safety Notes

Translation of the original instructions

DE

AT CH

AUTOMATIK-SCHWEIßHELM

Montage-, Bedienungs- und Sicherheitshinweise

Originalbetriebsanleitung

IAN 310884

DK

AUTOMATISK SVEJSEHJELM

Brugs- og sikkerhedsanvisninger

Oversættelse af den originale driftsvejledning

NI

IEGB

DK

GB

Before reading, unfold the page containing the illustrations and familiarise yourself with all

functions of the device.

DK

Før du læser, vend siden med billeder frem og bliv bekendt med alle apparatets funktioner.

DEIEATNICH

Klappen Sie vor dem Lesen die Seite mit den Abbildungen aus und machen Sie sich anschließend mit allen Funktionen des Gerätes vertraut.

GB / IE / NI Operation and Safety Notes Page 5

DK Brugs- og sikkerhedsanvisninger Side 19

DE / AT / CH Montage-, Bedienungs-, und Sicherheitshinweise Seite 33

E

16

16

17

Table of contents

List of pictograms used ..................................................................................Page 6

Introduction .........................................................................................................Page 6

Intended use ...........................................................................................................Page 6

Parts Description ....................................................................................................Page 6

Technical Data ........................................................................................................Page 7

Scope of delivery ...................................................................................................Page 7

Safety instructions ............................................................................................Page 7

Initial use ..............................................................................................................Page 11

Cleaning and Maintenance ..........................................................................Page 13

Storage ..................................................................................................................Page 13

Environmental instructions and disposal information ....................Page 13

Troubleshooting .................................................................................................Page 13

Warranty and service information ..........................................................Page 14

Warranty terms .......................................................................................................Page 14

Extent of warranty ..................................................................................................Page 14

Processing of warranty claims ................................................................................Page 14

Service ...................................................................................................................Page 15

Label meanings .................................................................................................Page 15

EU Declaration of Conformity .....................................................................Page 16

GB/IE/NI 5

List of pictograms used / Introduction

List of pictograms used

Read instructions for use!

Do not dispose of electrical

equipment in household waste!

Attention: The welding helmet

does not provide any eye, ear

or face protection!

Made from recycling material

Automatic Welding Helmet

PSHL 2 A2

Introduction

Congratulations!

You have chosen a high-quality

product from our company. Familiarise

yourself with the product before using it for

the first time. In addition, please carefully

refer to the instructions for use and the safety

instructions below.

Caution!

Attention, potential dangers!

Important notice!

Warning: arc rays can injure

the eye's retinas!

wheel and is also adjustable for flying sparks

during grinding work. Only use the product

as described and for its indicated purpose.

Keep these instructions in a safe place.

When passing this product on to others,

please also include all the documents. Any

use other than the intended is prohibited and

potentially dangerous. Damages resulting

from noncompliance or misuse are not

covered by the

in the manufacturer‘s

warranty and are not included

liability. This device

has been designed for household use and

may not be used for commercial or industrial

purposes.

KEEP OUT OF THE REACH OF

CHILDREN!

Intended use

This welding helmet protects the eyes and

face from sparks, splashes and UV rays while

welding and automatically adapts to the

lighting conditions. It ensures an immediate,

sensor-controlled darkening upon arc ignition

as well as automatic illumination at the end

of the welding procedure (including a short

delay to protect against afterglow). This

welding helmet provides a freely adjustable

DIN protection level with a lateral adjustment

6 GB/IE/NI

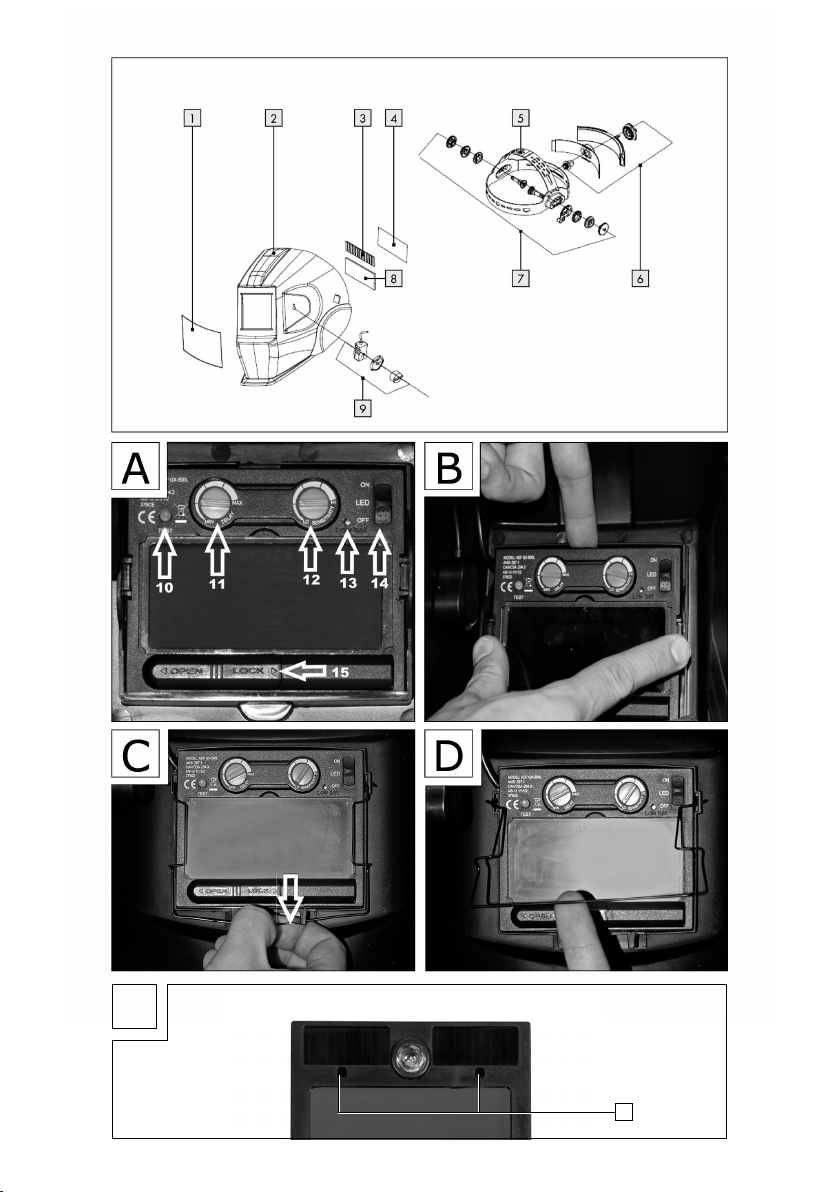

Parts Description

1

Viewing pane

2

Helmet casing

3

Solar cell

4

Rear pane

5

Headband

6

Rear control dial headband

7

Lateral control dial headband

8

UV filter

9

Darkening regulator

10

Test button

11

Delay setting

12

Sensitivity setting

13

Low battery display

Introduction/ Safety instructions

14

LED Lighting switch

15

Battery compartment

Bracket

16

17

arc sensor

Technical Data

Filter cartridge size: 110 x 90 x 10 mm

Field of vision: 9.2 x 4.2 cm

Bright state: DIN 4

Dark state: DIN 9–DIN 13

Switching times

Bright to dark: 0.23~0.72 ms

Dark to bright: 0.15~0.45 s

Switch on / off: Fully automatic

Energy supply: Solar cell

UV / IR protection: DIN 16

Operating temperature: -5 °C to +55 °C

Storage temperature: -20 °C to + 70 °C

Welding procedure: MMA, MIG, MAG,

TIG, plasma cutting

and plasma welding

Maximum service life: approx. 6 years

Scope of delivery

1 Auto-Darkening Welding Helmet

1 Set of instructions for use

Safety instructions

Please carefully read the

instructions for use and follow

the specified notices. Familiarise

yourself with the equipment, its

proper use and the safety notices

using these instructions for use.

All technical data about this

welding helmet is on the label,

please learn about this product‘s

technical facts.

The product is not suitable for

laser welding.

The product is only approved for

use within a temperature range

of between -5 °C to 55 °C.

The product is not fire-resistant.

Welding helmet and ADF filter

must not be exposed to any

heat or moisture.

Do not remove the ADF filter

from the welding helmet and

never open the housing of the

ADF filter without authorisation

from the manufacturer.

Prior to each use, check

whether the Welding/

Grinding setting was selected

correctly.

The cover lens must be installed

on the outer side of the ADF

filter. Otherwise, the ADF filter

can get damaged.

Do not carry out any

modifications/replacements on

the welding helmet and ADF

filter without consent.

If the filter does not darken

automatically whilst welding

please stop the operation

immediately and contact the

dealers without delay.

Do not use any alcohol, fuel or

diluting agents to clean the ADF

filter. Do not place the ADF filter

in water.

GB/IE/NI 7

Safety instructions

The response time of the ADF

liquid crystal slows down if the

ambient temperature is lower,

however this does not have

an impact on the protective

functions.

Please replace the housing of

the ADF filter immediately if it is

damaged or scratched because

this can impair visibility and the

protective performance.

Please replace the viewing

pane immediately if it is broken

or scratched. Do not use any

hard objects to replace the

viewing pane of the filter.

Regularly clean the surfaces

of the ADF filter, sensor and

solar cells.

The welding helmet cannot

withstand any damages that

are caused by a heavy blow,

explosion or abrasive liquids.

The useful life depends on many

different individual factors such

as usage, cleaning, storage

and maintenance. Regular

inspections and replacement

in the case of damage are

recommended.

The material used to manufac-

ture the product will age over

time. This can result in breakages on the welding helmet, for

example. As a result of these

damages, the welding helmet

is no longer able to provide

effective protection. In this case,

the user should replace the

welding helmet immediately.

This product cannot be used

for overhead welding work

and cutting operations. If this

product is use for overhead

welding or cutting, the molten

metal drops could burn through

the ADF filter and result in

injuries to the user.

If the filter is faulty, the user must

stop using the welding helmet

immediately. Slag splashes can

damage the surface of the filter

and cause injury to the user’s

skin or cause other serious

accidents.

This product is temperature

resistant and hardly inflammable

but in case of direct contact

with naked flames or in case of

access to an object with a high

temperature, the helmet may

begin to burn or melt. Please

store and only use the welding

helmet in the manner described

in order to reduce such risks.

The ADF filter is an electronic

product that is not waterproof.

Please ensure it is kept dry and

clean and not stored in a damp

environment.

8 GB/IE/NI

Safety instructions

Improper use could result in in-

jury to the user and cause other

types of diseases.

Please examine the filter prior

to each use. As soon as the

function and appearance seem

defective, they must no longer

be used.

The use of the welding helmet

is prohibited if the filter flickers

or if the level of darkening no

longer corresponds to the

standard value or there are

other abnormal working

conditions.

Please do not expose this

product to unnecessary solar

radiation.

Please only use original spare

parts. The use of non-original

parts can cause problems with

regard to the protective function, serviceability and degree

of product protection.

Exceeding the service life

(insufficient protection) – please

check the protective glasses

prior to each use for damage

and durability.

Using eye protection without

the filter effect against radiation

(damages the eyes) – prior to

each use check whether the

eye protection exhibits the

necessary scale number.

Using the product against

splashes (insufficient protection) –

always check whether the

correct protective effect is

present.

Using the product against large

dust particles (injury, accident).

The eye protection equipment

must only be used for the work

described in the operating

instructions.

Any deviation from

the instructions in the operating

instructions can result in injuries

or accidents.

Using damaged products

(insufficient protection) –

prior to each use check the

protective glasses for damage

and durability.

Improper use of the eye protec-

tion (injury, accident). The eye

protection device must only be

used for the work described

in the operating instructions.

Any deviation from the instructions can result in injuries or

accidents.

This device may be used by

children aged 16 years and up,

as well as by persons with

reduced physical, sensory or

mental capacities, or lacking

experience and / or knowledge,

so long as they are supervised

or instructed in the safe use

GB/IE/NI 9

Safety instructions

of the device and understand

the associated risks. Do not

allow children to play with the

product. Cleaning and user

main tenance should not be

performed by children without

supervision.

The welding helmet with auto-

matic darkening is not suitable

for laser and gas welding.

Never place the welding

helmet on hot surfaces.

Never open the welding

helmet. Never carry out repairs

on or modifications to the

welding helmet. These may

only be carried out by trained

experts.

Please ensure that you have set

the automatic darkening before

each welding procedure.

The safety visor should not be

opened. It protects the filter

from dirt and damage.

If the filter does not

automatically darken, then

immediately end the welding

procedure and contact the

manufacturer.

Only use the welding helmet

in temperatures between -5 °C

and +55 °C. The filter‘s reaction time will slow down if this

temperature has not been

reached or is exceeded.

Clean the filter, the surface of

the helmet and the solar cells

regularly.

Replace the protective visor if

scratches or damages appear.

The welding helmet does not

provide protection against

impact.

Frequent use, cleaning or

storage can mean that the

service life is less than 6 years.

Replace the welding helmet

immediately if the viewing

panel gets scratched or the

viewing panel is visibly

damaged in any other way.

ATTENTION! Materials

that come into contact with the

wearer‘s skin may cause allergic

reactions in people with sensitive

skin.

ATTENTION! Eye protection

can represent a hazard for the

wearer if it is worn over normal

corrective glasses due to the

impact from high-speed particles.

ATTENTION! If protection

against high-speed particles at

extreme temperatures is required,

the eye protection chosen must be

labelled with the letter T directly

after the letter for the impact

10 GB/IE/NI

Safety instructions / Initial use

intensity, i. e. FT, BT or AT. If the

letter for the impact intensity is not

followed by the letter T, the eye

protection may only be used

against high-speed particles at

room temperature.

Initial use

Note: Only use the welding helmet with the

rear pane mounted

Note: Keep the UV filter‘s sensors

and clear.

After opening the package, immediately

check to ensure that the package contents

are complete and undamaged. Contact your

dealer immediately if the package contents is

incomplete or has any defects. Do not use the

device if it is defective

Check that the welding helmet and the

protective screen are intact before each use.

If the protective screen has scratches, cracks

or irregularities, it must be replaced before

use, as serious injuries may occur otherwise.

Remove the protective film from the inside

and the outside of the visor.

Adjust the welding helmet with the help of

the headband

dial headband

welding helmet to the respective head

size and the lateral control dial headband

7

in order to lock the welding helmet.

When adjusting, ensure that your head is

placed as far into the helmet as possible

and that it sits as close as possible to your

face.

Set the appropriate darkening shade

before the welding procedure (see the

following table). The darkening shade

may be manually adjusted from 9 to 13

by twisting the darkening regulator

the outside of the helmet.

4

.

5

. Turn the rear control

6

in order to adjust the

8

clean

9

on

ATTENTION! The darkening regulator

9

has the setting position “grind“. If the

darkening regulator

9

is set to this position

the automatic darkening is deactivated.

Only use this setting when you do not wish

to use the welding helmet for welding. The

automatic darkening is then no longer active.

Check the light density before each use.

Test procedure: Bring the viewing panel

closer to an external light source with a

value of more than 40 W and examine

whether or not the screen darkens or

illuminates. To do so, turn the darkening

control

9

clockwise from "Grind" to

the next position. This sets the filter to

auto-darkening mode. If you turn the

darkening control

9

anticlockwise back

to "Grind", the filter's auto-darkening

feature is once again deactivated.

To replace the UV filter/solar cell, press

the locking lugs on both sides outwards

(Fig. B). Then lift the filter with your finger

to the upper edge.

the filter at the notch at the top of

Then use a finger to lift

the filter.

Then remove the darkening control

9

from the exterior of the welding helmet by

simply pulling it away, and unscrew the

nut that is located beneath it. Once you

have removed the nut from the thread,

you can completely remove the filter from

the welding helmet. (Variant: Black)

To replace the UV filter/solar cell, pull the

bracket

16

at the bottom edge of the filter

over the two protruding locking pins and

outwards (see figure C). Flip the bracket

upwards (see figure D). With your thumbs

centred underneath the filter, lift the filter

and pull it down to remove it.

Then remove the darkening control

9

from the exterior of the welding helmet by

simply pulling it away, and unscrew the nut

that is located beneath it. Once you have

removed the nut from the thread, you

can completely remove the filter from the

welding helmet.

You can use the test button

(Variant: With flames)

10

to check

whether the welding helmet's darkening

GB/IE/NI 11

Initial use

feature is working properly.

You can adjust the delay setting

11

to

configure whether or not the autodarkening feature should be switched

off immediately after stopping welding

work, depending on the type of welding

work. At the lowest setting, auto-darkening

is switched off immediately. Turn the

rotary switch clockwise towards the

highest setting to prolong the time the

auto-darkening feature remains active

after welding work. This feature is very

useful for handling afterglow.

You can use the sensitivity setting

12

to

adjust the light sensitivity of the sensor.

With low incident light, the control can be

adjusted to the highest setting to ensure

that the auto-darkening feature is activat

ed even for a weak light source. Even

with this additional feature, you can also

adjust the light sensitivity of the sensor to

suit your own personal requirements.

The lowlight sensor switches the LED lamp

on in dark environments and off in brightly

lit environments. This helps to illuminate

the object being welded in dark working

conditions. The LED lamp can be switched

on and off using the lamp control

14

. If

the battery charge level is too low, you

can replace the batteries. To do so, slide

the left side of the battery compartment

15

to the left (see figure A). A low battery

charge level is indicated with a red

warning light on the display 13.

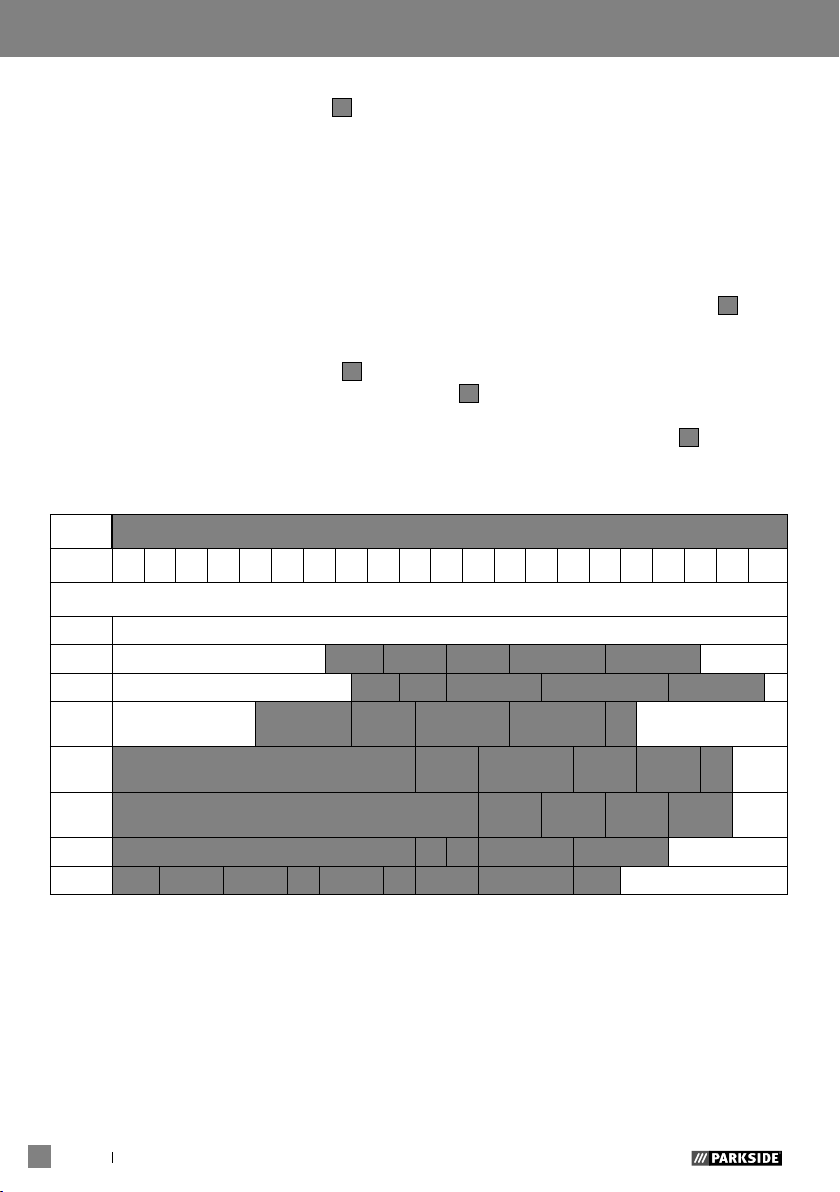

Table for setting the darkening shades

Arc current (ampere)

1,5 6 10 15 30 40 60 70 100 125 150 175 200 225 250 300 350 400 450 500 600

Grind

SMAW 8 9 10 11 12 13 14

MAG 8 9 10 11 12 13 14

TIG /

GTAW

MIG

(schwer)

MIG

(leicht)

PAC 9 10 11 12 13

PAW 4 5 6 7 8 9 10 11 12

8 9 10 11 12 13

Grinding function - automatic dimming not active

9 10 11 12 13 14

10 11 12 13 14

-

SMAW: welding with coated

electrodes

MIG (heavy): MIG welding heavy metals

MIG (light): MIG welding light metals

and alloys

TIG / GTAW: welding with inert gases

MAG: welding with metal active

gass

12 GB/IE/NI

PAC: plasma cutting

PAW: plasma welding

Grind:

Grinding function: Automatic

dimming not active. Only use the

setting if you do not use welding

helmet for welding.

Cleaning and ... / Storage / Environmental instructions ... / Troubleshooting

Cleaning and Maintenance

Environmental instructions

and disposal information

Do not use any harsh cleaning agents to

clean the helmet casing

Never bring the UV filter

with water.

Clean the product with a soft, dry

cloth, with a cloth dampened with pure

alcohol or with a cloth dampened with

disinfectant.

Storage

Keep the device in a dry place and out of

the reach of children.

2

.

8

into contact

Don‘t waste, recycle!

The device, accessories and packaging

should be recycled in an environmentally

friendly manner.

Do not throw the auto-darkening welding

helmet into household rubbish, fire or water.

If possible, non-operational equipment should

be recycled. Contact your local retailer for

information.

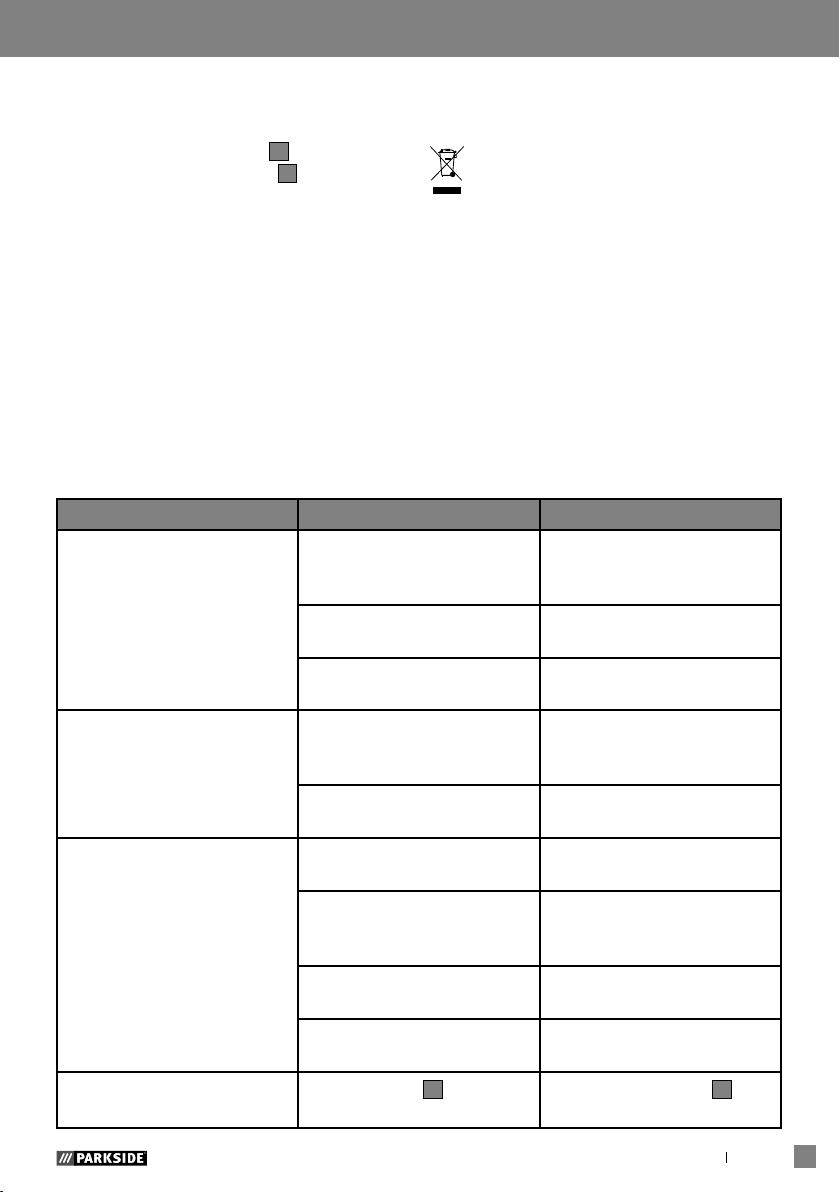

Troubleshooting

Error Cause Solution

The filter does not darken in

a normal way or flickers.

The reaction is slow. The ambient temperature is

The visibility is poor. The protector / the protective

The welding helmet slips.

The protector does not

darken in a normal way or

flickers.

The arc sensor is not clear. Clean the arc sensor's

The welding current is

too low.

too low / high.

The sensitivity is too low. Set the sensitivity to a

screen is dirty.

The protective film on the

protective screen was not

removed.

The ambient light is not

sufficient.

The wrong darkening shade

has been set.

The headband

put on incorrectly.

5

has been

Clean the protector or

replace it.

surface.

Set the sensitivity to the

maximum degree.

Only use the welding

helmet in temperatures

between -5 °C and +55 °C.

higher setting.

Clean the protector and the

protective screen.

Remove the protective film.

Apply more light to your

work surroundings.

Reset the darkening shade.

Put on the headband 5

again tighter.

GB/IE/NI 13

Warranty and service information

Warranty and service

information

Creative Marketing & Consulting

GmbH warranty

Dear customer, the warranty for this device

is 3 years from the date of purchase. In the

event of product defects, you have legal

rights against the retailer of this product.

Your statutory rights are not limited in any

way by our warranty detailed below.

Warranty terms

The warranty period begins on the date of

purchase. Please keep the original receipt in

a safe place. This document is required as

your proof of purchase. Should this device

show any fault in materials or manufacture

within 3 years from the date of purchase, it

will be repaired or replaced – at our choice

– by us free of charge. This warranty is

conditional on the defective device and the

receipt of purchase being presented within

the 3 year warranty period, and that there is

a brief written description of the nature of the

defect and of the date it arose.

If the defect is covered by our warranty,

you will receive the product which has been

repaired or a new product. A repair or

exchange of the device does not begin a

new warranty period.

Extent of warranty

This warranty becomes void if the device

has been damaged or improperly used or

maintained.

All instructions provided in the instructions

for use must be followed strictly to constitute

proper use of the product. Purposes and

practices which the operating instructions

warn of or advise against must be avoided

without fail.

This product is intended for private,

non-commercial use only. Any incorrect or

improper use of the device, use of force and

changes not performed by our authorized

service branch will void the warranty.

Processing of warranty

claims

Please follow the instructions below to ensure

your claim is processed quickly:

When inquiring about your product please

have your receipt and product number

(e.g. IAN) ready as your proof of purchase.

The product number can be found on the type

plate, an engraving, the cover page of your

instructions (bottom left) or the decal at the

back or bottom. In the event of malfunctions

or other defects, please first contact the ser

vice department below by phone or e-mail.

A product recorded as defective, along with

the proof of purchase (sales receipt) and

a description of the defect and when it

occurred, can then be returned free of charge

to you to the service address provided.

-

The appliance has been manufactured to

strict quality guidelines and meticulously

examined before delivery.

The warranty applies to defects in material or

manufacture. This warranty does not apply

to product parts subject to normal wear and

tear and which can therefore be considered

as wear items, or to damage to fragile parts,

e.g. switches, storage batteries or glass parts.

14 GB/IE/NI

Note:

On www.lidl-service.com you can

download this as well as many other

manuals, product videos and software.

Warranty and service information / Label meanings

Service

Only use original accessory parts:

Black variant

(PSHL 2 A2, Item no.:2169):

• Viewing pane (CMC 1B CE):

110.8 mm x 90 mm x 1.0 mm

• Rear lens (CMC 1F CE):

98.6 mm x 46 mm x 0.8 mm

Variant with flames

(PSHL 2 A2, Item no.:2170):

• Viewing pane (CMC 1B CE):

109.6 mm x 86 mm x 1.0 mm

• Rear lens (CMC 1F CE):

98.6 mm x 46 mm x 0.8 mm

How to contact us:

GB/IE/NI

Name: C.M.C. Creative Marketing

& Consulting GmbH

Website: www.cmc-creative.de

E-mail: service.gb@cmc-creative.de

Phone: 0-808-189-0652

Registered office: Germany

IAN 310884

Please note that the following address is not

a service address. Please first contact the

service point named above.

Address:

C.M.C. Creative Marketing & Consulting

GmbH

Katharina-Loth-Str. 15

DE-66386 St. Ingbert

DEUTSCHLAND

Ordering spare parts:

www.lidl.com/contact-us

Label meanings

Safety viewing panels approved

according to DIN EN 166

(CXXXXCMC, CXXXXCMC):

• Viewing pane: CMC 1 B CE

CMC = manufacturer code

1 = optical class

B = mechanical strength

(medium-energy impact at 120 m/s)

CE = CE symbol)

• Rear pane: CMC 1 F CE

CMC = manufacturer code

1 = optical class

F = mechanical strength

(low-energy impact at 45 m/s)

CE = CE symbol)

ADF approved according to

DIN EN 379:

1/1/1/2/379 CE (CXXXXCMC)

Legend:

4 = bright state

9–13 = dark state

CMC = manufacturer code

number 1 = optical class

number 2 = scattered light grade

number 3 = homo-geneity class

number 4 = angle dependency class

379 = test standard

CE = CE symbol

Welding helmet case:

CMC EN 175 F CE

(CXXXXCMC, CXXXXCMC)

Manufacturer identification: CMC

Number of the standard: EN 175

Area(s) of application (if required): S, F, B

Mass in grams (if required)

IP rating for welding helmet, order no.:

2169/2170: F

CE = CE symbol

4/9-13 CMC

:

GB/IE/NI 15

Loading...

Loading...