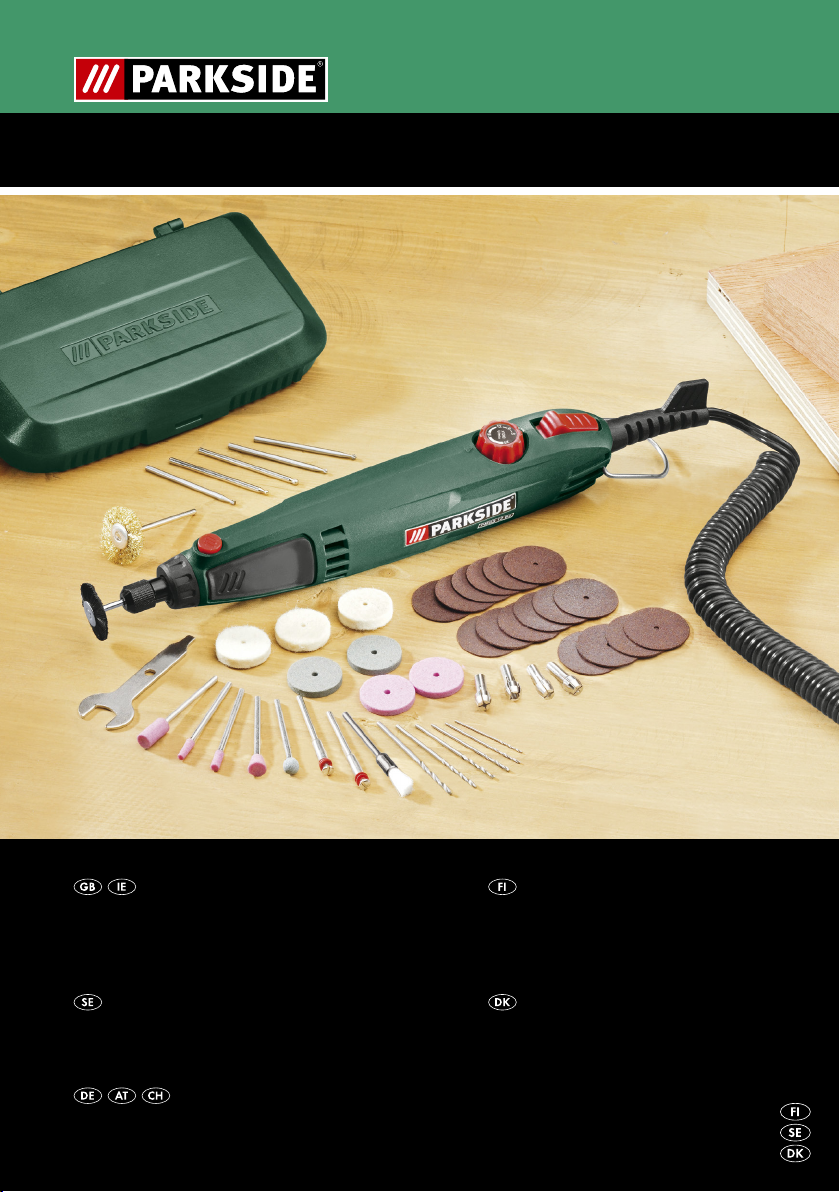

MODELLING AND ENGRAVING SET PMGS 12 B2

MODELLING AND

ENGRAVING SET

Operation and Safety Notes

Translation of original operation manual

MODELLBYGGE- OCH GRAVERINGSSET

Bruksanvisning och säkerhetsanvisningar

Översättning av bruksanvisning i original

MODELLBAU- UND GRAVIERSET

Bedienungs- und Sicherheitshinweise

Originalbetriebsanleitung

PIENOISMALLIRAKENNUS-

JA KAIVERRUSSARJA

Käyttö- ja turvaohjeet

Alkuperäisen käyttöohjeen käännös

MODELBY GNINGS- OG

GRAVERINGSSÆT

Brugs- og sikkerhedsanvisninger

Oversættelse af den originale driftsvejledning

Before reading, unfold the page containing the illustrations and familiarise yourself with all functions of the

device.

Käännä ennen lukemista kuvallinen sivu esiin ja tutustu seuraavaksi laitteen kaikkiin toimintoihin.

Vik ut bildsidan och ha den till hands när du läser igenom anvisningarna och gör dig bekant med

apparatens / maskinens funktioner.

Før du læser, vend siden med billeder frem og bliv bekendt med alle apparatets funktioner.

Klappen Sie vor dem Lesen die Seite mit den Abbildungen aus und machen Sie sich anschließend mit allen

Funktionen des Gerätes vertraut.

GB / IE Operation and Safety Notes Page 5

FI Käyttö- ja turvaohjeet Sivu 17

SE Bruksanvisning och säkerhetsanvisningar Sidan 29

DK Brugs- og sikkerhedsanvisninger Side 41

DE / AT / CH Bedienungs- und Sicherheitshinweise Seite 53

321

5

8

2

„AUS (OFF)“

„EIN (ON)“

76

45

a

8 9

11

b

10

23

22

21

20

19

18

C

8 10

e

F

12

13

14

15

16

17

4

D

G

Table of contents

Introduction

Proper use ......................................................................................................................Page 6

Features and equipment ...............................................................................................Page 6

Included items ...............................................................................................................Page 7

Technical information ....................................................................................................Page 7

General safety advice for electrical power tools ..................Page 7

1.

Workplace safety .....................................................................................................Page 8

2.

Electrical safety .........................................................................................................Page 8

3. Personal safety ..........................................................................................................Page 8

4.

Careful handling and use of electrical power tools ...............................................Page 9

Safety advice for all uses ..............................................................................................Page 9

Safety advice relating to kickback ...............................................................................Page 10

Special safety advice relating to grinding and disc-cutting ........................................Page 11

Further special safety advice for disc-cutting ...............................................................Page 11

Special safety advice for abrading using sandpaper ................................................Page 12

Special safety advice for polishing ..............................................................................Page 12

Special safety advice for working with wire brushes ..................................................Page 12

Device-specific safety instructions for small drill PMGS 12 B2 and

mains adapter-PMGS 12 B2-1 ....................................................................................Page 12

Operation

Inserting or replacing a tool / collet .............................................................................Page 13

Switching on and off / Setting the speed range ..........................................................Page 13

Advice on working with materials / Tools / Speed ranges .........................................Page 14

Tips and tricks ................................................................................................................Page 14

Maintenance and cleaning .........................................................................Page 15

Service .........................................................................................................................Page 15

Warranty ...................................................................................................................Page 15

Disposal ......................................................................................................................Page 15

Conformity Declaration / Manufacturer ..........................................Page 16

5 GB/IE

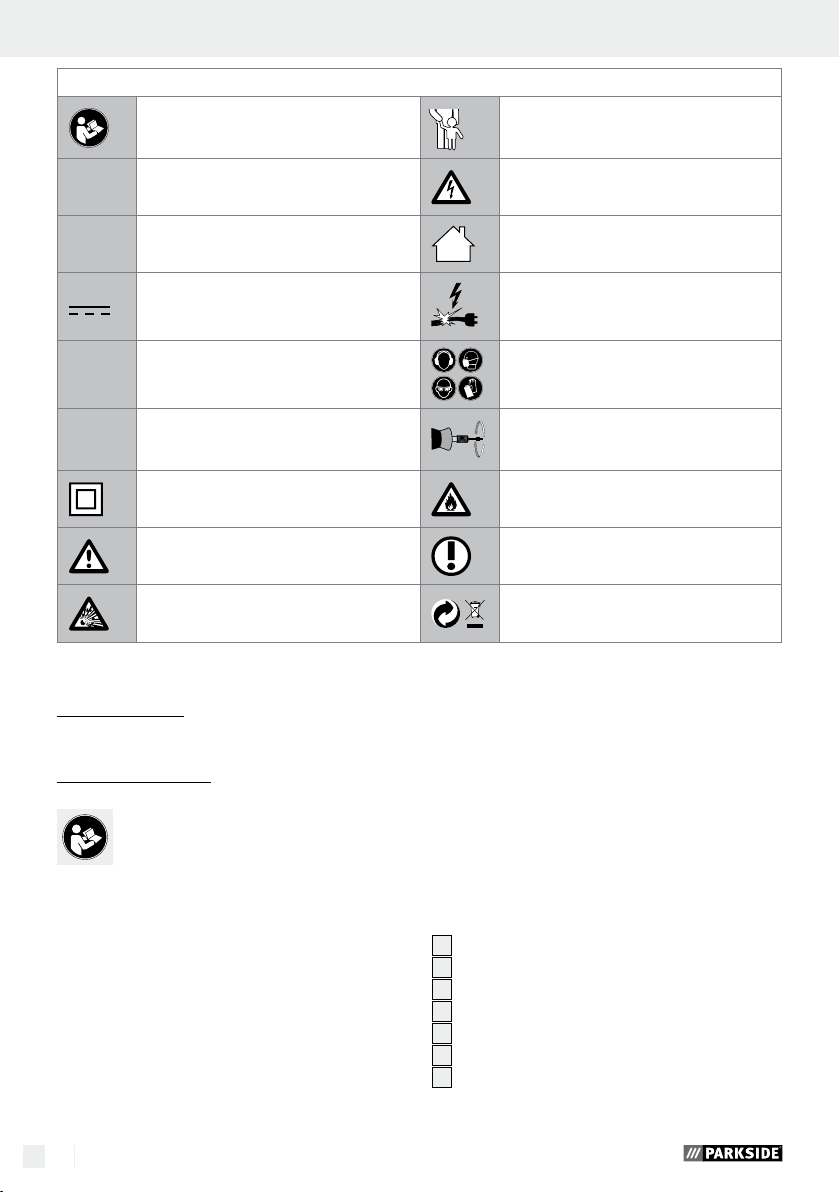

The following pictograms are used in these operating instructions / on the device:

Read instruction manual!

V

W

n

mA

A / Ah

Volt (AC)

~

Watts (Effective power) For indoor use only!

Direct current

(Type of current and voltage)

Design no-load speed

0

Milliamps / Amps / Amp-hours

Safety class II Risk of fire!

Observe caution and safety notes! Proper procedure and handling.

Risk of explosion!!

Modelling and engraving set

PMGS 12 B2

Q

Introduction

Please make sure you familiarise yourself

fully with the way the device works before

you use it for the first time and that you

understand how to handle electrical power tools

correctly. To help you do this please read the accompanying operating instructions. Keep these instructions

in a safe place. If you pass the device on to anyone

else, please ensure that you also pass on all the

documentation.

Q

Proper use

The small drill is to be used for drilling, milling, engraving, polishing, cleaning up, grinding, separating

6 GB/IE

Keep children away from electrical

power tools!

Caution – electric shock!

Danger to life!

Risk of loss of life by electric shock

from damaged mains lead or mains

plug!

Wear hearing protection, dust

protection mask, protective glasses

and protective gloves.

Avoid contact with rapidly

rotating tools!

Dispose packaging and appliance in

an environmentally-friendly way!

and sawing of wood, metal, plastic, ceramic or stone

in dry rooms. Any other use or modification to the

drill / grinder shall be considered as improper use

and could give rise to considerable dangers. The

manufacturer will not accept liability for loss or

damage arising from improper use. Not intended

for commercial use.

Q

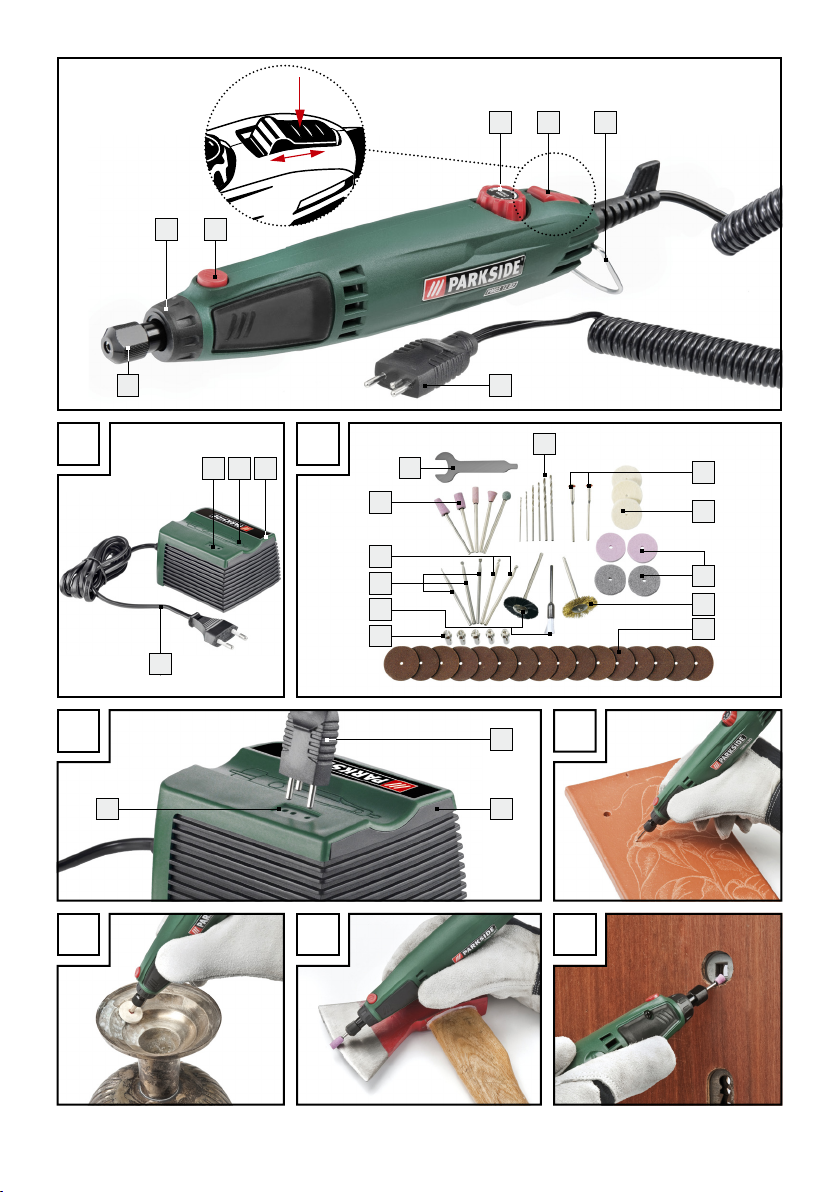

Features and equipment

Small drill:

1

Rotational speed control

2

ON / OFF switch

3

Metal stirrup hanger

4

Plug for mains adapter

5

Clamping nut

6

Spigot nut

7

Spindle lock

Introduction / General safety advice for electrical power tools

Mains adapter (see Fig. A):

8

Plug-in device for plug

9

Tray

10

Mains adapter

11

Power cable (with mains plug)

4

Accessories (see Fig. B):

12

6 HSS drills

13

2 Mandrels for mounting tools

14

3 Polishing wheels

15

4 Grinding wheels

16

1 Metal brush

17

16 Cutting wheels

18

5 Collets

19

2 Plastic brushes

20

3 Milling bits

21

2 Engraving bits

22

5 Grinding bits

23

1 Combination tool

Q

Included items

1 Small drill

1 Mains adapter

1 Plastic case

1 Accessory kit (50-piece)

1 Operating instructions

Q

Technical information

Small drill PMGS 12 B2:

Nominal voltage: 12 V

Nominal output: 22 W

Idle-running speed: n

5000–20000 min

0

-1

Max. drill bit diameter: ø 3.2 mm

Certified acc. to:

EN60745-1; EN60745-2-1

EN60745-2-3

Noise and vibration data:

Measured values for noise are determined in accordance with EN 60745. The A-weighted noise level

of the electrical power tool are typically:

Sound pressure level: 54.70 dB(A)

Sound power level: 65.70 dB(A)

Uncertainty K: 3 dB

Evaluated acceleration, typical:

Hand / arm vibration: 1.868 m / s

Uncertainty K = 1.5 m / s

2

2

The vibration level given in these

instructions has been measured in accordance with

a standardised measurement procedure specified

in EN 60745 and can be used to compare devices.

Different uses of the device give rise to different

vibration levels and in many cases they may exceed

the values given in these instructions. It is easy to

underestimate the vibration load if the electrical power tool is used regularly in particular circumstances.

Note: If you wish to make an accurate assessment

of the vibration loads experienced during a particular

period of working, you should also take into account

the intervening periods of time when the device is

switched off or is running but is not actually in use.

This can result in a much lower vibration load over

the whole of the period of working.

Mains adapter PMGS 12 B2-1:

INPUT:

Rated voltage: 230 V∼ 50 Hz

OUTPUT:

Nominal voltage: 12 V

Nominal current: 1 A

Protection class: II /

Certified acc. to: EN61558

General safety advice for

electrical power tools

Read all the safety advice

and instructions! Failure to observe the safety

advice and instructions may result in electric shock,

fire and / or serious injury.

Keep all the safety advice and instructions

in a safe place for future reference!

The term “electrical tool” used in the safety advice

refers to electrical tools powered by mains electricity

(by means of a mains lead) and electrical tools

7 GB/IE

powered by rechargeable batteries (without a

mains lead).

1. Workplace safety

a) Keep your working area clean and

well lit. Untidy or poorly lit working areas

can lead to accidents.

b)

inflammable liquids, gases or dusts.

c)

Distractions can cause you to lose control of

Do not work with the device

in potentially explosive environments in which there are

Electrical power tools create sparks, which can

ignite dusts or fumes.

Keep children and other

people away while you are

operating the electrical tool.

the device.

2. Electrical safety

a)

The mains plug on the device must match

the mains socket. The plug must not

be modified in any way. Do not use

an adapter plug with devices fitted

with a protective earth. Unmodified

plugs and matching sockets reduce the risk of

electric shock.

b) Avoid touching earthed surfaces such

as pipes, radiators, ovens and refrigerators with any part of your body.

There is an increased risk of electric shock if

your body is earthed

c) Keep the device away from rain or

moisture. Water entering an electrical device

increases the risk of electric shock.

d)

device, to hang up the device or to pull

8 GB/IE

Do not use the mains lead for

any purpose for which it was

not intended, e.g. to carry the

the mains plug out of the mains socket.

Keep the mains lead away from heat,

oil, sharp edges or moving parts of the

device. Damaged or tangled mains leads

increase the risk of electric shock.

.

e) When working outdoors with an

electrical power tool always use extension cables that are also approved

for use outdoors. The use of an extension

cable suitable for outdoor use reduces the risk

of electric shock.

f) Use a residual current device (RCD)

for protection if operating the electrical power tool in a moist environment

is unavoidable. The use of an RCD reduces

the risk of electric shock.

3. Personal safety

a) Remain alert at all times, watch what

you are doing and always proceed

with caution. Do not use the device if

you are tired or under the influence of

drugs, alcohol or medication. One mo

of carelessness when using the device can lead

to serious injury.

b)

personal protective equipment such as dust

c) Avoid unintentional operation of the

d) Remove any setting tools or spanners

e) Avoid placing your body in an unnat-

f) Wear suitable clothing. Do not wear

Wear personal protective

equipment and always wear

safety glasses. The wearing of

masks, non-slip safety shoes, safety helmets or

ear protectors, appropriate to the type of electrical power tool used and work undertaken,

reduces the risk of injury.

device. Check that the electrical power

tool is switched off before you connect

it to the mains, pick it up or carry it.

Accidents can happen if you carry the device

with your finger on the ON / OFF switch or with

the device switched on.

before you switch the device on. A tool

or spanner left attached to a rotating part of a

device can lead to injury.

ural position. Keep proper footing

and balance at all times. By doing this

you will be in a better position to control the

device in unforeseen circumstances.

loose clothing or jewellery. Keep your

ment

General safety advice for electrical power tools

hair, clothing and gloves clear of moving parts. Loose clothing, jewellery or long

hair can become trapped in moving parts.

g) If vacuum dust extraction and collection

devices are fitted do not forget to

that they are properly connected and

correctly used. The use of these devices

reduces the hazard presented by dust.

4.

Careful handling and use

check

of electrical power tools

a) Do not overload the device. Always

use an electrical power tool that is

intended for the task you are undertaking. By using the right electrical power

tool for the job you will work more safely and

achieve a better result.

b) Do not use an electrical power tool if

its switch is defective. An electrical power

tool that can no longer be switched on and off

is dangerous and must be repaired.

c) Pull the mains plug from the socket

before you make any adjustments to

the device, change accessories or when

the device is put away. This precaution is

intended to prevent you from unintentionally

starting the device.

d) When not in use always ensure that

electrical power tools are kept out of

reach of children. Do not let anyone use

the device if he or she is not familiar

with it or has not read the instructions

and advice. Electrical power tools are dan-

gerous when they are used by inexperienced

people.

e) Look after the device carefully. Check

that moving parts are working properly and move freely. Check for any

parts that are broken or damaged

enough to detrimentally affect the

functioning of the device. Have damaged parts repaired before you use

the device. Many accidents have their origins

in poorly maintained electrical power tools.

f) Keep cutting tools clean and sharp.

Carefully maintained cutting tools with sharp

cutting edges are less likely to jam and are

easier to control.

g) Use the electrical power tool, accesso-

ries, inserted tools etc. in accordance

with these instructions and advice, and

the stipulations drawn up for this particular type of device. In doing this, take

into account the working conditions

and the task in hand. The use of electrical

power tools for purposes other than those intended can lead to dangerous situations.

Q

Safety advice for all uses

General safety advice for grinding,

sanding (with sandpaper), wire brushing,

polishing and disc-cutting:

a) This electrical power tool is intended

for use as a grinding, sanding, wirebrushing, and disc-cutting machine.

Observe all the safety advice, instructions, information in figures and all

other information you received with

this device. If you do not observe the following

advice it could lead to electric shock, fire and /

or serious injury.

b) Normative statement / advice for this tool is not

applicable.

c) Do not use any accessory not specifi-

cally intended by the manufacturer

for this electrical power tool. Although

an accessory may fit on your electrical power

tool, this does not on its own guarantee that it

can be safely used.

d) The maximum permitted speed of an

attachment must be at least as high as

the maximum speed indicated for the

electrical power tool. An accessory rotating

faster than its permitted speed could disintegrate

or fly off.

e) The external diameter and the thickness

of the attachment must be compatible

with the dimensions of your electrical

power tool. Attachments that are not dimen-

sionally compatible cannot be adequately

guarded or controlled.

9 GB/IE

f) Grinding discs, flanges, grinding

wheels or other accessories must fit

exactly on to the spindle of your electrical power tool. Attachments that do not

exactly fit on the spindle turn unevenly, vibrate

severely and could lead to loss of control.

g) Do not use damaged attachments.

Before every use check attachments

such as grinding discs for loose fragments and cracks, grinding wheels for

cracks, deterioration or excessive

wear and wire brushes for loose or

broken wires. If the electrical power

tool or attachment is dropped, inspect

for damage or change the attachment

for an undamaged one. When you

have inspected and inserted the attachment, position yourself and bystanders away from the plane of the

rotating attachment and run the device

at maximum speed for one minute.

Damaged attachments will usually break apart

during this test.

h)

Wear personal protective

equipment. Use a full face visor, safety goggles or safety

glasses, depending on the application.

Wear a dust mask, hearing protectors,

safety gloves or special apron capable

of stopping particles of the grinding

medium or workpiece, as appropriate

for the task. Eyes must be protected from

the flying debris which can arise from some

operations. Dust or breathing masks must be

capable of filtering out the dust generated by

the application. Prolonged exposure to loud

noise can lead to hearing loss.

i) Keep bystanders at a safe distance

from your work area. Anyone entering

the work area must wear personal

protective equipment. Fragments of the

workpiece or of a broken attachment could fly

off and cause injury beyond the immediate

working area.

j) Hold the device by the insulated han-

dle surfaces when you are undertaking work where there is the danger

of the attachment striking hidden

10 GB/IE

electricity cables or the device’s mains

lead. Contact with a live wire could cause

metal parts of the device to become live and

lead to electric shock.

k) Keep the mains lead away from rotat-

ing attachments. If you lose control of the

device the mains lead may become severed or

trapped and your hand or arm may be pulled

into the rotating attachment.

l) Never lay the electrical power tool

down until after the attachment has

come to a complete standstill. The rotat-

ing attachment may snag when it comes into

contact with the surface and cause you to lose

control of the device.

m) Do not have the electrical power tool

running while you are carrying it. Your

clothing could become trapped by unintentional contact with the rotating attachment and the

tool could be pulled into your body.

n) Clean the ventilation slots on your

electrical power tool regularly. The motor’s fan draws dust into the housing. A build-up

of metal dust could give rise to an electrical

hazard.

o)

Never use the electrical

power tool near inflammable

materials. Sparks could ignite

these materials.

p) Do not use attachments that require

the use of coolants. The use of water or

other liquid coolants could result in electric shock.

Q

Safety advice

relating to kickback

Kickback is the sudden reaction to a pinched or

snagged rotating attachment, such as a grinding

disc, grinding pad, wire brush etc. Pinching or

snagging results in the rotating attachment coming

to an abrupt stop. This causes the electrical power

tool (if not controlled) to move in the opposite direction to the direction of rotation of the attachment

at the point of constraint.

If, for example, a grinding disc is pinched or snags

in a workpiece, this can cause the edge of the

General safety advice for electrical power tools

grinding disc to penetrate the workpiece, become

trapped there and either free itself or kickback. The

grinding disc moves towards or away from the operator, depending on the direction of movement of

the disc at the point of constraint. The grinding disc

could also break.

Kickback occurs as a result of incorrect use or misuse of the electrical power tool. It can be prevented

by taking the appropriate precautions as described

below.

a) Maintain a firm grip on the electrical

power tool and position your body

and arms to allow you to resist kickback forces. Always use the auxiliary

handle, if provided, to exercise the

greatest possible control over kickback forces or reaction torques as the

device builds up to full speed. By taking

suitable precautions the operator can control

kickback and reaction forces.

b) Do not place your hands near a rotat-

ing attachment. If kickback occurs the attachment could move over your hand.

c) Avoid positioning your body in the

area into which the electrical power

tool would move in the event of a

kickback. A kickback moves the electrical

power tool in the opposite direction to the direction of movement of the grinding disc at the

point of constraint.

d) Work particularly carefully in the

area of corners, sharp edges etc. to

avoid the attachment bouncing or

snagging on the workpiece. Corners,

sharp edges or bouncing have a tendency to

snag the rotating attachment. This causes loss

of control or kickback.

e) Do not use saw-chain woodcarving

discs or toothed discs. Such attachments

create frequent kickback and loss of control of

the electrical power tool.

Q

Special safety advice relating

to grinding and disc-cutting

a) Always use the guard designed for

the type of abrasive consumable you

are using. Always use abrasive consumables

approved for use with your electrical power

tool. Abrasive consumables not approved for

use with your electrical power tool cannot be

adequately guarded and are unsafe.

b) To ensure the highest level of opera-

tional safety, the disc guard cover must

be attached to the electrical power tool

and set in such a way that the smallest

possible area of the abrasive consumable is exposed to the operator. The disc

guard cover is there to protect the operator from

pieces breaking off and accidental contact with

the abrasive consumable.

c) Abrasive consumables must be used

only for their recommended purposes, For example: never grind with the

side face of a cutting disc. Cutting discs

are intended for removing material using the

edge of the disc. Sideways forces on these

abrasive consumables can cause them to break.

d) Always use an undamaged mounting

flange of the correct size and shape

for your selected grinding disc. Suitable

flanges support the grinding disc and reduce the

chance of it breaking. Flanges for cutting discs

different from the flanges for other abrasive discs.

e) Never use worn down abrasive con-

sumables intended for larger electrical

power tools. Abrasive consumables intended

for larger electrical power tools are not designed

for the faster rotational speeds of these smaller

electrical power tools and could break.

Q

Further special safety

are

advice for disc-cutting

a) Avoid snagging the cutting disc and

do not use too much contact pressure.

Do not attempt to make excessively

deep cuts. Overloading the cutting disc in-

creases the load and the tendency of the disc

11 GB/IE

to twist or snag in the cut, making kickback or

disc breakage more likely.

b) Avoid the area in front of or behind

the rotating cutting disc. If the cutting disc

is moving away from you at the point of constraint in the workpiece, then, in the event of

a kickback, the electrical power tool and the

rotating disc may be thrown towards you.

c) If the cutting disc jams or you stop

work for a while, switch the device

off and hold it until the disc comes to

a complete stop. Never attempt to

pull the still rotating cutting disc out of

the cut as this could cause kickback.

Determine and rectify the reason for the jamming.

d) Do not switch on the device if the cut-

ting disc is in the workpiece. Allow

the cutting disc to reach full speed before carefully continuing with the cut.

Otherwise the disc could snag, jump out of the

workpiece or cause a kickback.

e) Support boards or workpieces whilst

cutting to reduce the risk of kickback

caused by a jammed cutting disc. Large

workpieces may bend under their own weight.

The workpiece must be supported to both sides

of the cutting disc and particularly near the

cutting disc and at the workpiece edge.

f) B

e particularly careful when pocket

cutting in existing walls or other areas

where you cannot see what you are cutt

ing into. The cutting disc plunged into the surface

could cut through gas or water pipes, electricity

cables or other objects and cause kickback.

Q

Special safety advice for

abrading using sandpaper

Do not use over-sized sanding sheets.

Follow the manufacturer’s recommendations for sanding sheet size. Sanding

sheets that project beyond the backing pad

could cause injury in addition to jamming,

tearing of the sheet or kickback.

Q

Special safety

advice for polishing

Do not use the polishing bonnet if it

has any loose parts, in particular the

fastening cords. Tuck the fastening cords

away or trim them. Loose fastening cords rotating with the attachment could catch your fingers

or become trapped in the workpiece.

Q

Special safety advice for

working with wire brushes

a) Bear in mind that wire brushes lose

pieces of wire during normal use. Do

not overload the wires by applying too

much pressure. Flying pieces of wire can very

easily penetrate thin clothing and / or skin.

b) U

se a guard, if recommended, but m

sure that the wire brush does not come

into contact with the guard. The diameters

of disc brushes and cup brushes can increase

due to contact pressure and centripetal forces.

Device-specific safety

instructions for small drill

PMGS 12 B2 and mains

adapter-PMGS 12 B2-1

protective equipment: safety glasses

CAUTION! The tool continues to rotate

Securely support the

Never support your-

When you use the drill /

grinder wear the following

and protective gloves.

after it has been switched off!

Avoid contact with rapidly rotating

drill / grinder components.

workpiece. Use clamps or a vice to grip the

workpiece firmly. This is much safer than holding

it in your hand.

self by placing your hands near or in

front of the device or the workpiece

surface. A slip can result in injury.

ake

12 GB/IE

General safety advice for electrical power tools / Operation

Avoid contact with moving sanding or

grinding tools.

DANGER OF FIRE FROM FLYING

SPARKS! Abrading metal creates

flying sparks. For this reason, always

make sure that nobody is placed in any danger

and that there are no inflammable materials

near the working area.

DUST HAZARD! Any

harmful / noxious dusts generated from machining represent a risk to the health of the person

operating the device and to anyone near the

work area.

Wear a dust mask!

NOXIOUS FUMES!

Ensure that there is adequate ventilation when

machining surfaces containing plastic or covered with paint, varnish etc.

Do not soak the materials or the sur-

face you are about to work on with

liquids containing solvents.

Avoid abrading paints containing lead

or other substances hazardous to

health.

Do not machine materials containing

asbestos. Asbestos is a known carcinogen.

Do not machine moist materials or

damp surfaces.

NOTE! Do not allow the tool to come to a

standstill by overloading it!

Switch the device off

and allow it to come to a standstill before you put it down.

Always keep the de

vice

clean, dry and free of oil or grease.

Children or persons who lack the knowledge or

experience to use the device or whose physical,

sensory or intellectual capacities are limited

must never be allowed to use the device without

supervision or instruction by a person responsible

for their safety. Children must never be allowed

to play with the device.

Q

Operation

Never use the device for a purpose

for which it was not intended or with

non-original parts / accessories. The use

of tools or accessories other than those recommended in the operating instructions could lead

to you suffering an injury.

Q

Inserting or replacing

a tool / collet

Press the spindle lock 7 and keep it pressed.

Rotate the clamping nut 5 until the lock

engages.

Loosen the clamping nut 5 with the combina-

23

tion key

.

If a tool is already inserted, remove it.

First insert the tool you wish to use though the

clamping nut

collet

5

before you insert it into the

18

suitable for the tool shaft.

Press the spindle lock 7 and keep it pressed.

Insert the collet 18 into the threaded insert and

tighten the clamping nut

the combination key

5

on the thread using

23

.

Using the Insertion tool with mandrel

NOTE: Use the screwdriver end of the combi-

nation key

the mandrels

23

to release or tighten the screw of

13

.

Insert the mandrel 13 into the electrical tool as

described.

With the aid of the combination wrench 23,

unscrew the screw from the mandrel

Place the insertion tool you wish to have onto

the screw between the two washers.

With the aid of the combination wrench 23,

tighten the screw on the mandrel

Q

Switching on and off /

13

Setting the speed range

13

:

13

.

.

Switching on / Setting the speed range:

Connect the plug 4 to the power supply unit 10

by inserting it into the plug-in device

8

provided

for such purposes (see Fig. C).

13 GB/IE

Connect the device to the power supply by

inserting the mains plug into the socket.

Press down the ON / OFF switch 2 and then

move it in direction of the rotational speed con-

1

trol

. Then set the rotational speed control to

a position between “5” and “20”.

Switching off:

Set the rotational speed control 1 to position

“5”. Press down the ON / OFF switch

2

and

then move it in direction of the cable.

Q

Advice on working with

materials / Tools / Speed ranges

Use the highest speed when working on steel

or iron with the milling bits

Use a short trial on a test piece to determine the

optimum rotational speed range for working on

zinc, zinc alloy, aluminium, copper and lead.

Use the low speed range for working on plastics

and low-melting point materials.

Use high speeds on wood.

Use the medium speed range for cleaning,

polishing and buffing.

The following information shall be considered as

recommendatory only. Learn by practical experience

which tools and settings are the best for the materials you work with.

Setting the appropriate speed:

Numeral on the

rotational speed

control

1

5

8

12

16

20

20

.

Material to be

worked on

Plastics and low melting

point materials

Stone, Ceramics

Softwood, metal

Hardwood

Steel

Examples of appropriate tool selection

Function:

Function Accessory Application

Drilling

HSS drill

Milling Milling bits

20

Drilling wood

12

Various tasks, e.g.

hollowing out,

gouging, shaping,

grooving or slotting

Engraving Engraving

bits

21

Making marks,

craft projects

(see Fig. D)

Polishing,

derusting

CAUTION!

Use only the

lightest contact pressure

of the tool on

Metal brush

16

Polishing

wheel

14

Derusting

Working on various metals and

plastics, in particular noble metals

like gold or silver

(see Fig. E)

the workpiece.

Cleaning Plastic brush

19

E.g. cleaning complex plastic housings or the area

around a door lock

Grinding Grinding

wheels

grinding bits

22

Grinding work on

stone, wood; fine

,

15

work on hard materials such as ceram

or alloyed steel

(see Figs. F, G)

Cutting and

sawing

Q

Tips and tricks

Cutting discs

17

Cutting metal,

plastic or wood

If you use press too hard you run the risk of breaking the tool or damaging the workpiece. You will

achieve the best results by operating the tool at a

constant rotational speed and using a low contact

pressure on the workpiece.

ic

14 GB/IE

Maintenance and cleaning / Service / Warranty / Disposal

Q

Maintenance and cleaning

The device is maintenance-free.

Clean all the dirt off the drill / grinder. Use a

dry cloth for cleaning.

and repaired parts. Any damage and defects extant

on purchase must be reported immediately after

unpacking the appliance, at the latest, two days after

the purchase date. Repairs made after the expiration

of the warranty period are subject to payment.

Q

Service

Have your device

repaired at the service centre or by

qualified specialist personnel using

original manufacturer parts only. This

will ensure that your device remains safe to use.

If the plug or lead

needs to be replaced, always have

the replacement carried out by the

manufacturer or its service centre. This

will ensure that your device remains safe to use.

Q

Warranty

The warranty for this appliance is for 3

years from the date of purchase. The appliance has been manufactured with care

and meticulously examined before delivery. Please retain your receipt as proof

of purchase. In the event of a warranty

claim, please make contact by telephone

with our Service Department. Only in this

way can a post-free despatch for your

goods be assured.

The warranty covers only claims for material and

maufacturing defects, but not for transport damage,

for wearing parts or for damage to fragile components, e.g. buttons or batteries. This product is for private use only and is not intended for commercial use.

The warranty is void in the case of abusive and improper handling, use of force and internal tampering

not carried out by our authorized service branch.

statutory rights are not restricted in any way by this

warranty.

Your

GB

Service Great Britain

Tel.: 0871 5000 720

(0,10 GBP/Min.)

e-mail: kompernass@lidl.co.uk

IAN 66445

IE

Service Ireland

Tel: 1890 930 034

(0,08 EUR/Min. (peak)

0,06 EUR/Min. (off peak))

e-mail: kompernass@lidl.ie

IAN 66445

Q

Disposal

The packaging is wholly composed of

environmentally-friendly materials that can

be disposed of at a local recycling centre.

Do not dispose of electric tools

in the household waste!

In accordance with European Directive 2002 / 96 / EC

about waste electrical and electronic equipment

and its transposition into national legislation, worn

out electric tools must be collected separately and

taken for environmentally compatible recycling.

Please contact your municipal or city council to ask

about how to dispose of old electrical tools.

The warranty period will not be extended by repairs

made unter warranty. This applies also to replaced

15 GB/IE

Conformity Declaration / Manufacturer Sisällysluettelo

Q

Conformity Declaration /

Manufacturer

We, Kompernaß GmbH, the person responsible for

documents: Mr Semi Uguzlu, Burgstr. 21, D-44867

Bochum, Germany, hereby declare that this product

complies with the following standards, normative

documents and EU directives:

Machinery Directive

(2006 / 42 / EC)

EU Low Voltage Directive

(2006 / 95 / EC)

Electromagnetic compatibility

(2004 / 108 / EC)

Applicable harmonized standards

EN 60745-1:2009, EN 60745-2-1:2010

EN 60745-2-3:2007+A11

EN 55014-1:2006+A1

EN 55014-2:1997+A1+A2

EN 61558-1:1997+A1+A11, EN 61558-2-6:1997

EN 61000-3-2:2006+A1+A2

EN 61000-3-3:2008

Type / Device description:

Modelling and engraving set PMGS 12 B2

Date of manufacture (DOM): 09–2011

Serial number: IAN 66445

Bochum, 30.09.2011

Semi Uguzlu

- Quality Manager -

We reserve the right to make technical modifications

in the course of further development.

16 GB/IE

Sisällysluettelo

Aluksi

Määräystenmukainen käyttö .........................................................................................Sivu 18

Varusteet ......................................................................................................................... Sivu 18

Toimituslaajuus ............................................................................................................... Sivu 19

Tekniset tiedot ................................................................................................................. Sivu 19

Sähkötyökaluja koskevat yleiset turvaohjeet .......................... Sivu 19

1.

Työpaikkaturvallisuus ................................................................................................. Sivu 20

2.

Sähköturvallisuus .......................................................................................................Sivu 20

3. Henkilöiden turvallisuus .............................................................................................Sivu 20

4.

Sähkötyökalujen huolellinen käsittely ja käyttö ....................................................... Sivu 21

Kaikkien käyttöjen turvallisuusohjeet .............................................................................Sivu 21

Jos kone iskee takaisin - turvallisuusohjeet käyttäjälle ................................................. Sivu 22

Erityisiä turvallisuusohjeita hiontaan ja katkaisutöihin..................................................Sivu 23

Erityisiä katkaisuhiontaa koskevia turvallisuusohjeita ..................................................Sivu 23

Eritysturvallisuusohjeet hiekkapaperilla hiontaan .........................................................Sivu 24

Erityiset turvallisuusohjeet kiillotustöihin ........................................................................ Sivu 24

Erityiset turvallisuusohjeet teräsharjoilla työskentelyyn ................................................ Sivu 24

Pienoisporakoneen PMGS 12 B2 ja verkkolaitteen PMGS 12 B2-1

laitekohtaiset turvaohjeet ............................................................................................... Sivu 24

Käyttöönotto

Työkalun / kiinnitysholkin kiinnittäminen / vaihtaminen ................................................ Sivu 25

Päälle- ja poiskytkeminen / Pyörimisnopeusalueen asettaminen ................................. Sivu 25

Ohje materiaalin työstöön / Työkalu / Pyörimisnopeusalue ........................................Sivu 25

Vihjeitä ja niksejä ........................................................................................................... Sivu 26

Huolto ja puhdistus ............................................................................................Sivu 26

Huolto............................................................................................................................Sivu 26

Takuu ............................................................................................................................. Sivu 26

Hävittäminen .......................................................................................................... Sivu 27

Vaatimustenmukaisuusvakuutus / Valmistaja ...........................Sivu 27

17 FI

Aluksi

Tässä käyttöohjeessa / laitteessa käytetään seuraavia kuvakkeita:

Lue käyttöohje! Pidä lapset loitolla sähkötyökalusta!

V

W

n

mA

A / Ah

Voltti (Vaihtojännite) Varo sähköiskua! Hengenvaara!

~

Watti (Vaikutusteho)

Tasavirta

(Virta- ja jännitelaji)

Mittaus-tyhjäkäyntikierrosluku

0

Milliampeeria / ampeeria /

ampeerituntia

Suojausluokka II Palonvaara!

Huomioi varoitus- ja turvaohjeet! Näin käyttäydyt oikein!

Räjähdysvaara!

Pienoismallirakennus- ja

Kaiverrussarja PMGS 12 B2

Q

Aluksi

T

utustu ennen käyttöönottoa laitteeseen, se

käyttöohjeisiin ja sähkölaitteita koskeviin

yleisiin turvallisuusohjeisiin. Lue tämä käyttö-

opas huolella. Säilytä käyttöopas huolellisesti. Saatat

myöhemmin tarvita sen tietoja. Jos luovut laitteesta,

anna uudelle omistajalle myös kaikki laitteen asiakirjat.

Q

Määräystenmukainen käyttö

Tarkoitettu käytettäväksi

ainoastaan sisätiloissa!

Viallisen verkkojohdon tai pistokkeen

käyttöön liittyvän sähköiskun aiheuttama

hengenvaara!

Käytä aina laitteella työskennellessäsi

suojalaseja, kuulo- ja hengityssuojaimia

sekä asianmukaisia työkäsineitä.

Vältä kosketusta nopeasti pyöriviin

työkaluihin!

Hävitä pakkaus ja laite ympäristöystävällisesti!

ystenmukaisena ja sisältää huomattavia onnettomuusvaaroja. Määräystenvastaisesta käytöstä syntyneistä

vahingoista valmistaja ei ota mitään vastuuta.

Q

Varusteet

n

Pienoisporakone:

1

Kierrosluvun säätö

2

PÄÄLLE- / POISKYTKIN

3

Metallisanka

4

Verkkolaitteen pistotulppa

5

Kiinnitysmutteri

6

Hattumutteri

7

Karan lukitus

Pienporakonetta voidaan käyttää puun, metallin, muovin, keramiikan tai kiven poraamiseen, jyrsimiseen,

kaivertamiseen, siistimiseen, hiomiseen, katkaisemiseen ja sahaamiseen kuivissa tiloissa. Jokaista muuta

käyttöä tai laitteen muutamista pidetään ei-määrä-

18 FI

Verkkolaite (katso kuva A):

8

Pistorasia pistotulpalle

9

Syvennys

10

Verkkolaite

11

Virtajohto (ja pistotulppa)

4

Aluksi / Sähkötyökaluja koskevat yleiset turvaohjeet

Tarvikkeet (katso kuva B):

12

6 HSS-poranterää

13

2 Kiristystuurnaa työkalun kiinnitykseen

14

3 Kiillotuslaikkaa

15

4 Hiomalaikkaa

16

1 Metalliharja

17

16 Erotuslaikkaa

18

5 Kiristyspihtiä

19

2 Muoviharjaa

20

3 Jyrsintäterää

21

2 Kaiverrusterää

22

5 Hiontaterää

23

1 Monitoimiavaimen

Q

Toimituslaajuus

1 Pienoisporakone

1 Verkkolaite

1 Muovilaukku

1 Tarvikesarja (50 osaa)

1 Käyttöohje

Q

Tekniset tiedot

Pienoisporakone PMGS 12 B2:

Nimellisjännite: 12 V

Nimellisteho: 22 W

Joutokäynnin kierrosluku: n

5000–20000 min

0

Poran maks.: ø 3,2 mm

Tarkastettu (mukaisesti): EN60745-1;

EN60745-2-1

EN60745-2-3

Melu- ja tärinätiedot:

Melun mittausarvo laskettu EN 60745 standardin

mukaisesti. Sähkötyökalun A-mitattu melutaso on

tyypillisesti:

Äänenpainetaso: 54,70 dB(A)

Äänitehotaso: 65,70 dB(A)

Epävarmuus K: 3 dB

Arvioitu kiihtyvyys, tyypillisesti:

Käteen ja käsivarteen kohdistuva värinä: 1,868 m / s

Epävarmuus K = 1,5 m / s

2

Näissä ohjeissa ilmoitettu

värähtelytaso on määritetty normissa EN 60745

standardoidulla mittausmenetelmällä ja sitä voidaan

käyttää laitevertailussa.

Värähtelytaso muuttuu sähkötyökalun käytön mukaan

ja se saattaa monesti ylittää tässä ohjeessa mainitun

arvon. Värähtelyrasitusta saatetaan aliarvioida, jos

sähkötyökalua säännöllisesti käytetään tällä tavalla.

Huomio: Liikekuormituksen arvioimiseksi tietyn

työajan kestäessä on huomioitava myös ajat, jolloin

laite on sammutettuna, tai ajat, jolloin laite on käynnissä, mutta ei työkäytössä. Tämä saattaa vähentää

merkittävästi liikerasitusta kokonaistyöskentelyajan

kestäessä.

Verkkolaite PMGS 12 B2-1:

SISÄÄNMENO / Input:

Nimellisjännite: 230 V∼ 50 Hz

ULOSTULO / Output:

Nimellisjännite: 12 V

Nimellisvirta: 1A

Kotelointiluokka: II /

Tarkastettu (mukaisesti): EN61558

-1

Sähkötyökaluja koskevat

yleiset turvaohjeet

Lue kaikki turva- ja muut

ohjeet! Turva- ja muiden ohjeiden laiminlyönti voi

aiheuttaa sähköiskun, tulipalon ja / tai vakavia loukkaantumisia.

Säilytä kaikki turva- ja muut ohjeet tulevaa

tarvetta varten!

Turvallisuusohjeissa käytetty käsite ”sähkötyökalu“

koskee verkkokäyttöisiä sähkötyökoneita (verkkojohdolla) ja akkukäyttösisiä sähkötyökoneita (ilman

johtoa).

2

19 FI

Sähkötyökaluja koskevat yleiset turvaohjeet

1. Työpaikkaturvallisuus

a) Pidä työskentelypaikka puhtaana ja

hyvin valaistuna. Epäjärjestys ja huono

valaistus voivat johtaa tapaturmiin.

b)

syttyviä nesteitä, kaasuja tai jossa

c)

ole sallittua. Voit helposti menettää kontrollin

Älä käytä laitetta räjähdys-

vaarallisessa ympäristössä,

jossa säilytetään helposti

kehittyy pölyä. Sähkötyökalut kehittävät

kipinöintiä, joka voi sytyttää pölyn tai höyryn.

Lapsien ja asiattomien henki-

löiden läsnäolo työpaikalla

laitteen ollessa käynnissä ei

laitteeseen.

2. Sähköturvallisuus

a) Laitteen pistokkeen pitää sopia pisto-

rasiaan. Pistoketta ei saa muuttaa

millään tavalla. Älä käytä adapteria

yhdessä suojamaadoitettujen laitteiden

kanssa. Alkuperäinen pistoke ja sopivat pis-

torasia vähentävät sähköiskuvaaraa.

b) Vältä kosketusta maadoitettuihin pin-

toihin, kuten putkiin, lämpöpattereihin,

liesiin sekä jääkaappeihin. Vaarana on

saada sähköisku, jos kehosi on maadoitettu.

c)

Älä pidä laitetta sateessa tai muussa

kosteudessa. Veden pääsy laitteeseen lisää

sähköisku vaaraa.

d) Älä kanna laitetta riiputta-

malla sitä kaapelista ja vedä

kaapeli irti pistorasiasta

pitämällä kiinni pistokkeesta. Älä jätä

kaapelia kuumaan paikkaan, älä

päästä siihen öljyä, varo teräviä reunoja sekä laitteen pyöriviä osia. Vialliset

tai kietoutuneet kaapelit lisäävät riskiä saada

sähköisku.

e) Jos työskentelet ulkotiloissa, käytä

silloin jatkokaapelia, jonka käyttö on

sallittu myös ulkotilaan. Ulkotilaan sovel-

tuva kaapeli vähentää riskiä saada sähköisku.

f) Jos sähkötyökalua joudutaan käyttä-

mään kosteassa ympäristössä, on

20 FI

käytettävä vikavirtakytkintä. Vikavirta-

kytkimen käyttö pienentää sähköiskun vaaraa.

3. Henkilöiden turvallisuus

a) Ole aina tarkkaavainen, tarkista aina,

mitä teet ja toimi järkevästi sähkölaitteilla työskennellessäsi. Älä käytä

laitetta, jos olet väsynyt, käyttänyt

huumeita, alkoholia tai lääkkeitä.

Epätarkkaavaisuus laitetta käytettäessä voi

aiheuttaa vaikeita loukkaantumisia.

b)

teiden käyttö, kuten pölynaamari, turvakengät,

c) Varo käynnistämästä laitetta vahin-

d) Poista kaikki työkalut ja ruuviavaimet

e)

f) Käytä sopivaa vaatetusta. Älä käytä

g) Jos laitteeseen asennetaan pölynimu-

Käytä henkilökohtaisia tur-

vavarusteita ja suojalaseja

aina. Henkilökohtaisten turvavarus-

kypärä tai kuulosuoja, vähentävät loukkaantumisriskiä.

gossa. Varmista, että sähkötyökalu

on kytketty pois päältä, ennen kuin

liität sen pistorasiaan, nostat sen tai

kannat sitä. Tapaturmat ovat mahdollisia, jos

sormesi on laitetta kantaessasi virtakytkimellä

tai laite on kytketty päälle.

paikalta ennen kuin kytket laitteen.

Pyörivässä laiteosassa oleva työkalu tai avain

voi johtaa tapaturmaan.

Vältä työskentelemästä epätavallises

asennossa. Asetu tukevaan asentoon

ja pysyttele koko ajan tasapainossa.

Pystyt silloin hallitsemaan laitteen erityisesti

yllättävissä tilanteissa.

löysiä vaatteita äläkä pidä koruja.

Hiukset, vaatteet ja käsineet on pidettävä etäällä liikkuvista osista. Löysät

vaatteet, korut ja avonaiset hiukset voivat jäädä

kiinni liikkuviin osiin.

ri- ja lastunkeruulaite, varmistu sitä

ennen, että osat on liitetty ja niitä käytetään oikein. Näiden laitteiden liittäminen

vähentää pölystä aiheutuvia vaaroja.

sa

Loading...

Loading...