Parkside PKO 500 A1 Operation And Safety Notes

IAN 292195

COMPRESSOR PKO 500 A1

GB

NI

NIIE

COMPRESSOR PKO 500 A1

Operation and Safety Notes

Translation of original operation manual

GB

KOMPRESSOR PKO 500 A1

Drifts- og sikkerhedsinstruktioner

Oversættelse af den originale driftsvejledning

DK

DK

IE

AT

KOMPRESSOR PKO 500 A1

Bedienungs- und Sicherheitshinweise

Originalbetriebsanleitung

DE

GB / IE / NI Operation and Safety Notes Page 07

DK Drifts- og sikkerhedsinstruktioner Side 15

DE / AT Bedienungs- und Sicherheitshinweise Seite 52

Before reading, unfold the page containing the illustrations and familiarise yourself with all functions of the device.

GB IE NI

Klappen Sie vor dem Lesen die Seite mit den Abbildungen aus und machen Sie sich anschließend mit allen Funktionen des Gerätes vertraut.

DE AT

Før du læser, vend siden med billeder frem og bliv bekendt med alle apparatets funktioner.

DK

1

3

1

2

8

10

13

11

14

I

H

9

3

7

19

18

34 5 67

12

5

9

24

22

25

14

13

4

11

23

21

21

24

23 24

9

24

22

25

24

11

21

23

13

12

2

16 17

ON

OFF

10 11

7

12

8 9

B

A

D E C

15

G

max

min

18

16

20

6

1

26

1

27

26

15

13

C

D

F

GB IE NI

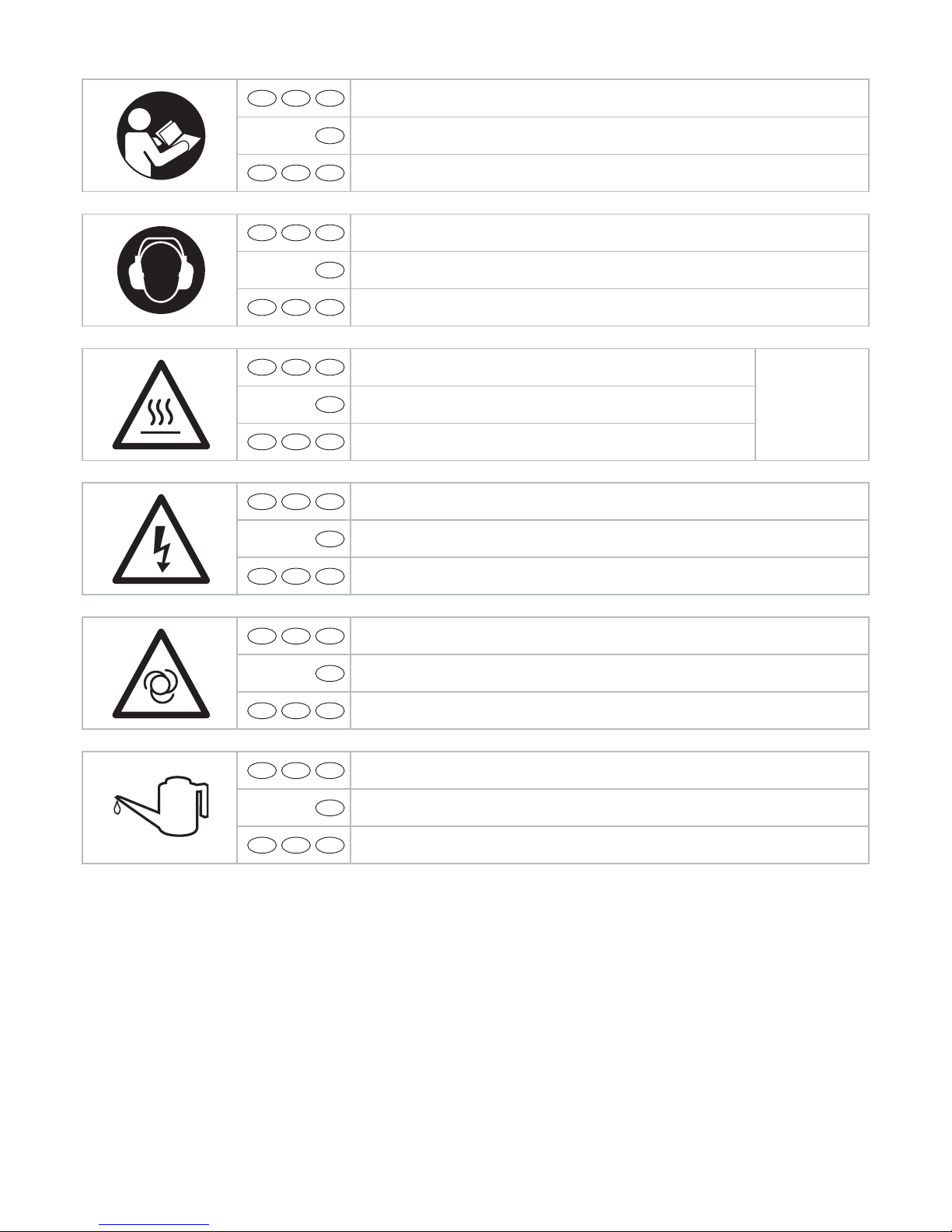

Read and follow the operating and safety instructions before you start working with this power

tool.

DK

Læs betjeningsvejledningen før du tager dette elektriske værktøj i brug.

DE AT CH

Vor Inbetriebnahme Bedienungsanleitung und Sicherheitshinweise lesen und beachten!

GB IE NI

Beware of electrical voltage!

DK

Advarsel mod elektrisk spænding!

DE AT CH

Warnung vor elektrischer Spannung!

GB IE NI

Warning! The equipment is remote-controlled and may start-up without warning.

DK

Advarsel! Enheden er fjernstyret og kan gå i gang uden varsel.

DE AT CH

Warnung! Die Einheit ist ferngesteuert und darf ohne Warnung anlaufen

GB IE NI

Caution! Before using for the first time, check the oil level and replace the oil sealing plug!

DK

Vigtigt! Kontroller oliestanden, og skift olieproppen ud inden ibrugtagning første gang!

DE AT CH

Achtung! Vor Erstinbetriebnahme Ölstand überprüfen und Ölverschlussstopfen austauschen!

GB IE NI

Wear ear-muffs. The impact of noise can cause damage to hearing.

DK

Brug høreværn. Støjudviklingen fra maskinen kan forårsage høretab.

DE AT CH

Tragen Sie einen Gehörschutz. Die Einwirkung von Lärm kann Gehörverlust bewirken.

GB IE NI

Beware of hot parts!

(G Fig.12)

DK

Advarsel mod varme dele!

DE AT CH

Warnung vor heißen Teilen!

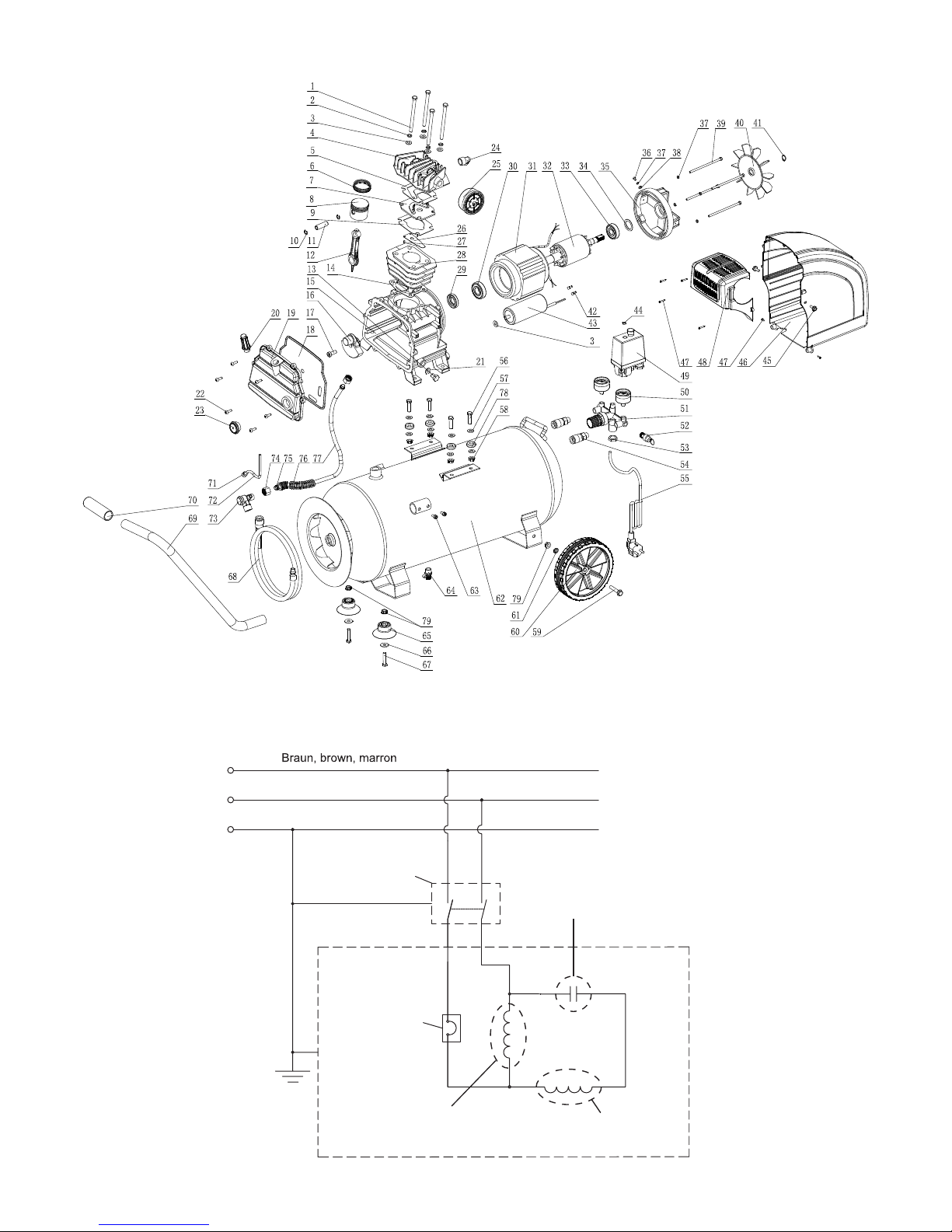

Blau, blue, bleu

Grün/Gelb, green/yellow,

verdure/jaune

L

N

Motorbetriebskondensator,

running capacitor,

condensateur de fonctionnement

Hauptwicklung,

main winding,

enroulement principal

Hilfswicklung,

auxiliary winding,

enroulement auxiliaire

Thermoschutzschalter,

thermal protector,

protection thermique

Masse,

ground,

masse

Pressure switch,

Interruptor de

presión

G

7

GB/IE/NI

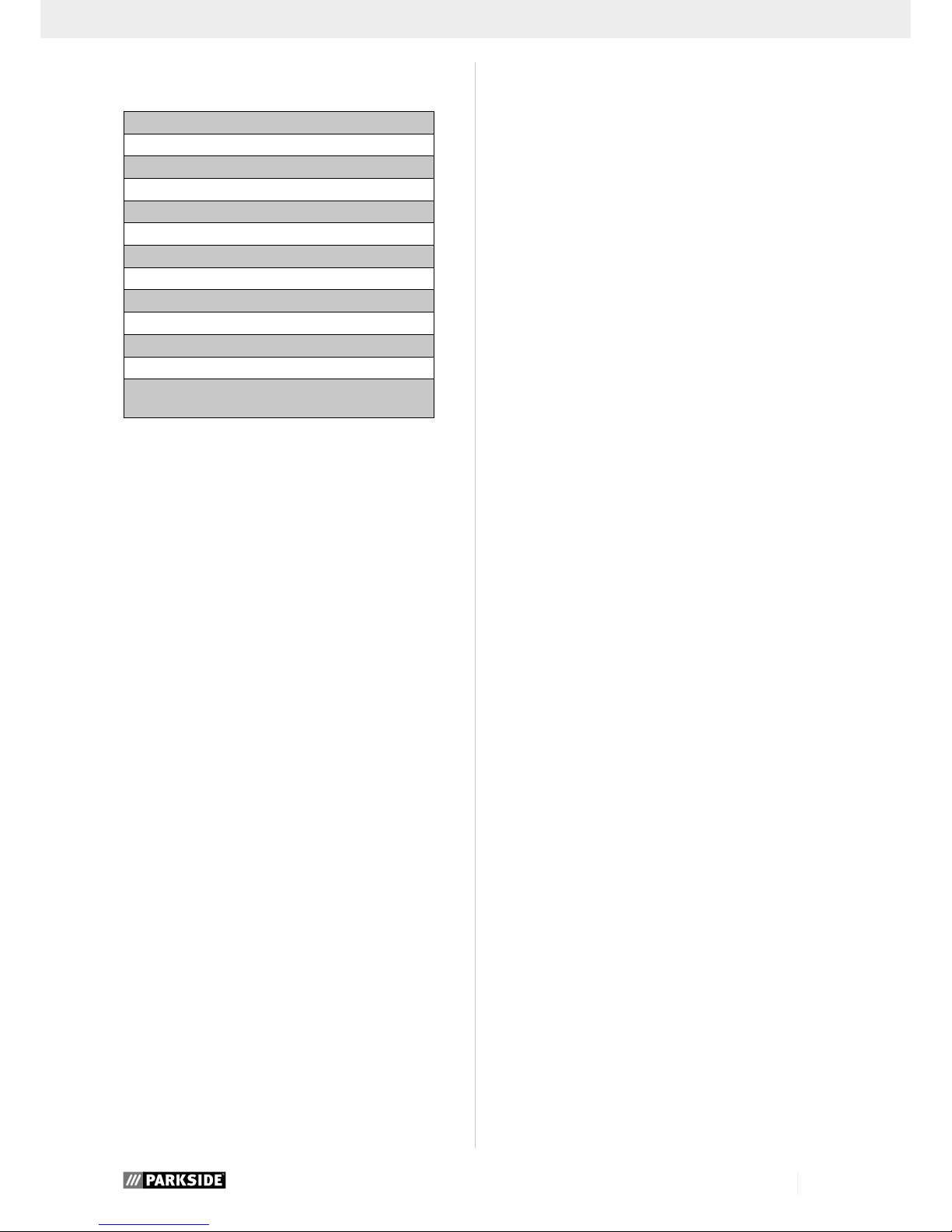

Table of contents: Page:

1. Introduction 8

2. Device description 8

3. Scope of delivery 8

4. Intended use 9

5. Safety information 9

6. Technical data 11

7. Before starting the equipment 11

8. Attachment and operation 11

9. Electrical connection 12

10. Cleaning, maintenance and storage 12

11. Disposal and recycling 13

12. Transport 13

13. Troubleshooting 13

14. Warranty certificate 14

15. Declaration of conformity 33

8

GB/IE/NI

1. Introduction

MANUFACTURER:

scheppach

Fabrikation von Holzbearbeitungsmaschine GmbH

Günzburger Straße 69

D-89335 Ichenhausen

DEAR CUSTOMER,

we hope your new tool brings you much enjoyment and

success.

NOTE:

According to the applicable product liability laws, the

manufacturer of the device does not assume liability for

damages to the product or damages caused by the product

that occurs due to:

• Improper handling,

• Non-compliance of the operating instructions,

• Repairs by third parties, not by authorized service tech-

nicians,

• Installation and replacement of non-original spare

parts,

• Application other than specified,

• A breakdown of the electrical system that occurs due to

the non-compliance of the electric regulations and local

regulations.

We recommend:

Read through the complete text in the operating instructions before installing and commissioning the device. The

operating instructions are intended to help the user to

become familiar with the machine and take advantage of

its application possibilities in accordance with the recommendations. The operating instructions contain important

information on how to operate the machine safely, professionally and economically, how to avoid danger, costly

repairs, reduce downtimes and how to increase reliability

and service life of the machine.

In addition to the safety regulations in the operating instructions, you have to meet the applicable regulations that apply for the operation of the machine in your country. Keep

the operating instructions package with the machine at all

times and store it in a plastic cover to protect it from dirt

and moisture. Read the instruction manual each time before

operating the machine and carefully follow its information.

The machine can only be operated by persons who were instructed concerning the operation of the machine and who

are informed about the associated dangers. The minimum

age requirement must be complied with.

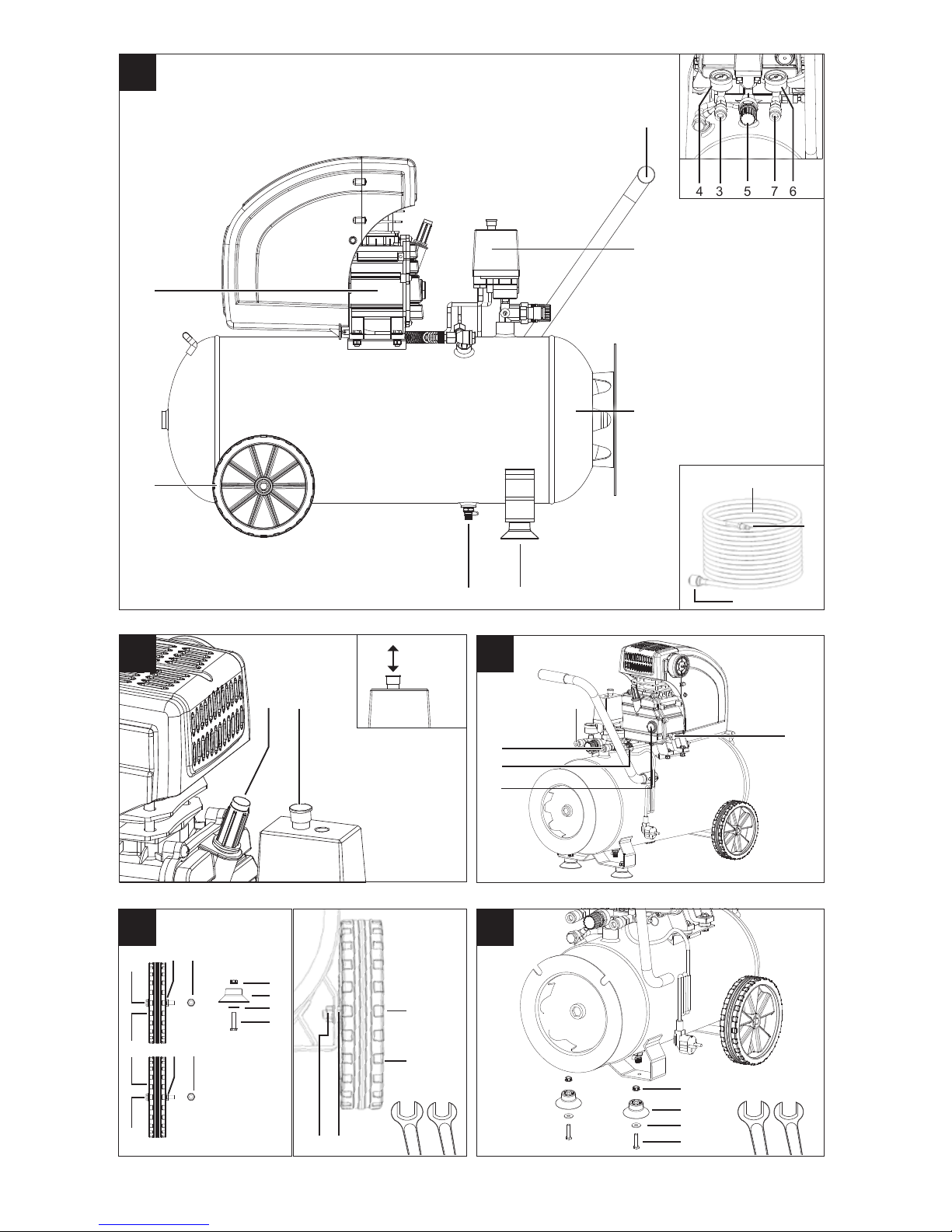

2. Device description (Fig. 1-13)

1. Transport handle

2. Pressure switch

3. Quick-lock coupling (regulated compressed air)

4. Pressure gauge (for reading the preset vessel pressure)

5. Pressure regulator

6. Pressure gauge (for reading the vessel pressure)

7. Quick-lock coupling (unregulated compressed air)

8. Pressure vessel

9. Supporting foot

10. Drain plug for condensation water

11. Wheel

12. Oil drain plug

13. Compressor pump

14. Compressed air hose

15. Air filter

16. Oil sealing plug

17. ON/OFF switch

18. Oil – level window

19. Safety valve

20. Oil filler opening

21. Flange screw

22. Washer

23. Nut

24. Flange nut

25. Screw

26. Allen Screw

27. Allen Key 5 mm

3. Scope of delivery

1x Transport handle

1x Air filter

2x Supporting foot

2x Wheel

1x Oil sealing plug

1x Compressed air hose

1x Allen Key 5 mm

1x Translation of Original Operating Manual

• Open the packaging and remove the device carefully.

• Remove the packaging material as well as the packag-

ing and transport bracing (if available).

• Check that the delivery is complete.

• Check the device and accessory parts for transport

damage.

• If possible, store the packaging until the warranty pe-

riod has expired.

ATTENTION

The device and packaging materials are not toys! Children must not be allowed to play with plastic bags,

film and small parts! There is a risk of swallowing and

suffocation!

9

GB/IE/NI

4. Intended use

The compressor is designed to generate compressed air for

compressed-air driven tools which can be driven with an air

volume of up to approx. 260 l/min (e.g. tire inflator, blowout pistol and paint spray gun). Due to the limited air output

it is not possible to use the compressor to drive tools with

very high air consumption (for example orbital sanders, die

grinders and hammer screwdrivers).

The equipment is to be used only for its prescribed purpose.

Any other use is deemed to be a case of misuse. The user

/ operator and not the manufacturer will be liable for any

damage or injuries of any kind caused as a result of this.

Please note that our equipment has not been designed for

use in commercial, trade or industrial applications. Our

warranty will be voided if the equipment is used in commercial, trade or industrial businesses or for equivalent

purposes.

5. Safety information

m Attention! The following basic safety measures must be

observed when using electric tools for protection against

electric shock, and the risk of injury and fire. Read all these

notices before using the electric tool and keep the safety

instructions for later reference.

m Attention! The following basic safety actions must be

taken when using this compressor in order to protect the user from electric shocks and the risk of injury and fi re. Read

and follow these instructions before using the equipment.

Safe work

1 Keep the work area orderly

– Disorder in the work area can lead to accidents.

2 Take environmental influences into account

– Do not expose electric tools to rain.

– Do not use electric tools in a damp or wet environ-

ment. There is a risk of electric shock!

– Make sure that the work area is well-illuminated.

– Do not use electric tools where there is a risk of

fire or explosion.

3 Protect yourself from electric shock

– Avoid physical contact with earthed parts (e.g.

pipes, radiators, electric ranges, cooling units).

4 Keep children away

– Do not allow other persons to touch the equipment

or cable, keep them away from your work area.

5 Securely store unused electric tools

– Unused electric tools should be stored in a dry,

elevated or closed location out of the reach of

children.

6 Do not overload your electric tool

– They work better and more safely in the specified

output range.

7 Wear suitable clothing

– Do not wear wide clothing or jewellery, which can

become entangled in moving parts.

– Rubber gloves and non-slip shoes are recom-

mended when working outdoors.

– Tie long hair back in a hair net.

8 Do not use the cable for purposes for which it is not

intended

– Do not use the cable to pull the plug out of the

outlet. Protect the cable from heat, oil and sharp

edges.

9 Take care of your tools

– Keep your compressor clean in order to work well

and safely.

– Follow the maintenance instructions.

– Check the connection cable of the electric tool

regularly and have it replaced by a recognised

specialist when damaged.

– Check extension cables regularly and replace

them when damaged.

10 Pull the plug out of the outlet

– During non-use of the electric tool or prior to

maintenance and when replacing tools such as

saw blades, bits, milling heads.

11 Avoid inadvertent starting

– Make sure that the switch is switched off when

plugging the plug into an outlet.

12 Use extension cables for outdoors

– Only use approved and appropriately identified

extension cables for use outdoors.

– Only use cable reels in the unrolled state.

13 Remain attentive

– Pay attention to what you are doing. Remain

sensible when working. Do not use the electric tool

when you are distracted.

14 Check the electric tool for potential damage

– Protective devices and other parts must be care-

fully inspected to ensure that they are fault-free

and function as intended prior to continued use of

the electric tool.

– Check whether the moving parts function fault-

lessly and do not jam or whether parts are damaged. All parts must be correctly mounted and

all conditions must be fulfilled to ensure fault-free

operation of the electric tool.

– Damaged protective devices and parts must be

properly repaired or replaced by a recognised

workshop, insofar as nothing different is specified

in the operating manual.

– Damaged switches must be replaced at a cus-

tomer service workshop.

– Do not use any faulty or damaged connection

cables.

– Do not use any electric tool on which the switch

cannot be switched on and off.

15 Have your electric tool repaired by a qualified

electrician

– This electric tool conforms to the applicable safety

regulations. Repairs may only be performed by an

electrician using original spare parts. Otherwise

accidents can occur.

10

GB/IE/NI

16 Important!

– For your own safety you must only use the acces-

sories and additional units listed in the operating

instructions or recommended or specified by the

manufacturer. The use of mounted tools or accessories other than those recommended in the

operating instructions or catalogue may place

your personal safety at risk.

17 Noise

– Wear ear muffs when you use the compressor.

18 Replacing the power cable

– To prevent hazards, leave the replacement of

damaged power cables strictly to the manufacturer or a qualified electrician. There is a risk of

electric shock!

19 Inflating tires

– Directly after inflating tires, check the pressure

with a suitable pressure gauge, for example at

your filling station.

20 Roadworthy compressors for building site operations

– Make sure that all lines and fittings are suitable for

the maximum permissible operating pressure of

the compressor.

21 Place of installation

– Set up the compressor on an even surface.

22 Supply hoses at pressures above 7 bar should be

equipped with a safety cable (e.g. a wire rope).

ADDITIONAL SAFETY INSTRUCTIONS

Safety instructions for working with compressed air

and blasting guns

• The compressor pump and lines can become very hot

during operation. Touching these parts will burn you.

• The air which is sucked in by the compressor must be

kept free of impurities that could cause fires or explosions in the compressor pump.

• When releasing the hose coupling, hold the hose cou-

pling piece with your hand. This way, you can protect

yourself against injury from the rebounding hose.

• Wear safety goggles when working with the blow-out

pistol. Foreign bodies or blown off parts can easily

cause injuries.

• Do not blow at people with the blow-out pistol and do

not clean clothes while being worn. Risk of injury!

Safety information for paint spraying

• Do not process any paints or solvents with a flash point

below 55° C. There is a risk of explosion!

• Do not heat up paints or solvents. There is a risk of ex-

plosion!

• If hazardous liquids are processed, wear protective fil-

ter units (face guards). Also, adhere to the safety information provided by the manufacturers of such liquids.

• The details and designations of the Ordinance on Haz-

ardous Substances, which are displayed on the outer

packaging of the processed material, must be observed.

• Additional protective measures are to be undertaken if

necessary, particularly the wearing of suitable clothing

and masks.

• Do not smoke during the spraying process and/or in the

work area. There is a risk of explosion! Paint vapors are

easily combustible.

• Never set up or operate the equipment in the vicinity of

a fire place, open lights or sparking machines.

• Do not store or eat food and drink in the work area.

Paint vapors are harmful to your health.

• The work area must exceed 30 m

3

and sufficient ventilation must be ensured during spraying and drying.

Do not spray against the wind. Always adhere to the

regulations of the local police authority when spraying

combustible or hazardous materials.

• Do not process media such as white spirit, butyl alcohol

and methylene chloride with the PVC pressure hose.

These media will destroy the pressure hose.

Operating pressure vessels

• You must keep your pressure vessel in good working

order, operate the vessel correctly, monitor the vessel,

carry out necessary maintenance and repair work immediately and meet the relevant safety precautions.

• The supervisory authority may enforce essential control

measures in individual cases.

• A pressure vessel is not allowed to be used if it has

faults or deficiencies that can endanger workers or third

parties.

• Check the pressure vessel for signs of rust and dam-

age each time before using. Do not use the compressor

with a damaged or rusty pressure vessel. If you discover

any damage, then please contact the customer service

workshop.

Do not lose these safety instructions

Residual risk

Observe the specified maintenance and safety instructions

in the instruction manual.

Always be attentive at work and keep third persons at a safe

distance from your workplace.

Even with proper use of the device, a certain residual risk

remains, which can not be excluded. The following potential hazards can be derived from the type and design of

the device:

unintentional commissioning of the product.

Hearing loss if no suitable hearing protection is worn.

Wear safety glasses to prevent your eyes and face from

dust and dirt particles.

Inhalation of whirled-up dust and dirt particles.

11

GB/IE/NI

6. Technical data

Mains connection 220 - 240 V ~ 50Hz

Motor rating W

1800

Operating mode

S1

Compressor speed

2850 min

-1

Pressure vessel capacity (in liters)

approx. 50

Operating pressure

approx. 10 bar

Theoretical intake capacity (l/min)

approx. 260

Sound power level L

WA

97 dB(A)

Uncertainty K

WA

2,22 dB

Protection type

IP20

Weight of the unit in kg

approx. 34

Oil (15W 40) l

approx. 0,4

Max. altitude

(above mean sea level)

1000 m

The noise emission values were measured in accordance

with EN ISO 3744:1995.

Wear hearing protection.

The effects of noise can cause a loss of hearing.

7. Before starting the equipment

Before you connect the equipment to the mains supply

make sure that the data on the rating plate are identical to

the mains data.

• Check the equipment for damage which may have oc-

curred in transit. Report any damage immediately to

the transport company which was used to deliver the

compressor.

• Install the compressor near the point of consumption.

• Avoid long air lines and supply lines (extension cables).

• Make sure that the intake air is dry and dustfree.

• Do not install the compressor in a damp or wet room.

• The compressor may only be used in suitable rooms

(with good ventilation and an ambient temperature from

+5 °C to 40 °C). There must be no dust, acids, vapors,

explosive gases or inflammable gases in the room.

• The compressor is designed to be used in dry rooms. It

is prohibited to use the compressor in areas where work

is conducted with sprayed water.

• The oil level in the compressor pump has to be checked

before putting the equipment into operation.

8. Attachment and operation

m Important!

You must fully assemble the appliance before using it

for the first time!

You will require the following tools for assembly and installation: Open-ended wrench size 12, 13 and 14 mm (not

included)

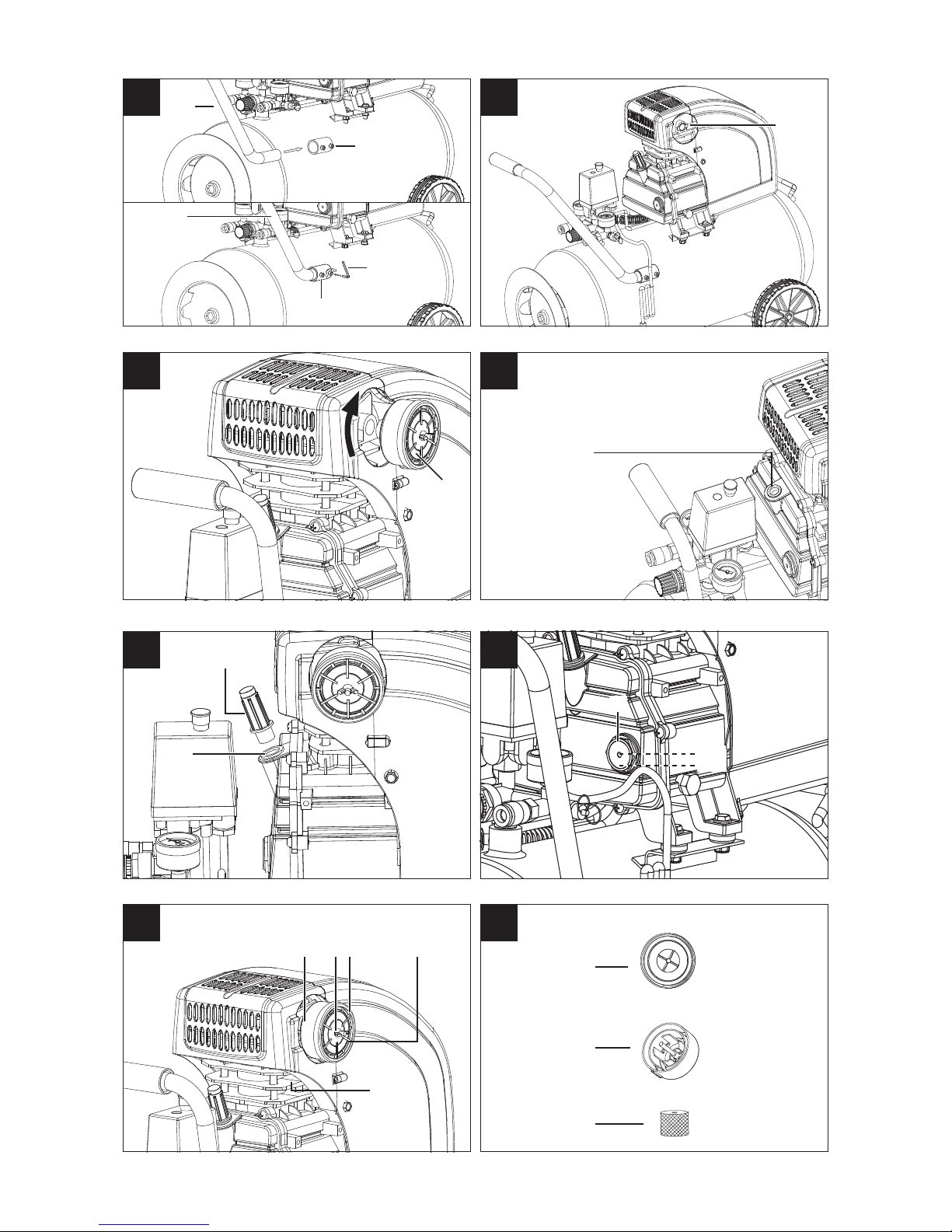

8.1 Fitting the wheels (Fig. 4)

• Fit the supplied wheels as shown.

8.2 Fitting the supporting feet (Fig. 4,5)

• Fit the supplied supporting foot as shown.

8.3 Fitting the Transport handle(Fig. 6)

• Fit the supplied Transport handle as shown.

8.4 Fitting the air filter (Fig. 7,8)

• Remove the transportation stop (B) and screw the air fil-

ter (15) to the equipment.

8.5 Changing the transportation cover (A) (Fig. 9,10)

• Remove the transportation cover from the oil filter open-

ing (20) and insert the supplied oil sealing plug (16)

into the oil filler opening.

8.6 Mains connection

• The compressor is equipped with a mains cable with

shock-proof plug. This can be connected to any 220 240 V~ 50 Hz shock-proof socket.

• Before you use the machine, make sure that the mains

voltage is the same as the operating voltage (see the

rating plate).

• Long supply cables, extensions, cable reels etc. cause a

drop in voltage and can impede motor start-up.

• At low temperatures below +5°C, sluggishness may

make starting difficult or impossible.

8.7 ON/OFF switch (Fig. 2)

• Pull the ON/OFF switch (17) upwards to switch on the

compressor. To switch off the compressor, press the

ON/OFF switch down.

8.8 Setting the pressure (Fig. 1,3)

• Use the pressure regulator (5) to set the pressure on the

pressure gauge (4).

• The set pressure can be drawn from the quick lock cou-

pling (3).

• The vessel pressure can be read off the pressure gauge

(6).

• The vessel pressure is drawn from the quick lock cou-

pling (7).

8.9 Setting the pressure switch (Fig. 1)

• The pressure switch (2) is set at the factory.

Cut-in pressure approx. 8 bar

Cut-out pressure approx. 10 bar.

8.10 Fitting the compressed air hose (Fig. 1, 3)

• Use the compressed air hose (14) if you intend to carry

out work at a greater distance from the compressor. To

do so, connect the nipple (H) on the compressed air

hose to one of the quick release couplings (3, 7). Then

attach the compressed air tool to the quick-release coupling (I) on the compressed air hose.

Loading...

Loading...