Parkside PHKS 1300 A1 CIRCULAR SAW Operation And Safety Notes

CIRCULAR SAW PHKS 1300 A1

HÅNDRUNDSAV

Brugs- og sikkerhedsanvisninger

Oversættelse af den originale driftsvejledning

CIRCULAR SAW

Operation and Safety Notes

Translation of original operation manual

3

HANDCIRKELSÅG

Bruksanvisning och säkerhetsanvisningar

Översättning av bruksanvisning i original

KÄSIPYÖRÖSAHA

Käyttö- ja turvaohjeet

Alkuperäisen käyttöohjeen käännös

HANDKREISSÄGE

Bedienungs- und Sicherheitshinweise

Originalbetriebsanleitung

GB / IE Operation and Safety Notes Page 5

FI Käyttö- ja turvaohjeet Sivu 17

SE Bruksanvisning och säkerhetsanvisningar Sidan 29

DK Brugs- og sikkerhedsanvisninger Side 41

DE / AT / CH Bedienungs- und Sicherheitshinweise Seite 53

Before reading, unfold both pages containing illustrations and familiarise yourself with all functions of the

device.

Käännä ennen lukemista molemmat kuvalliset sivut esiin ja tutustu seuraavaksi laitteen kaikkiin toimintoihin.

Vik ut båda bildsidorna och ha den till hands när du läser igenom anvisningarna och gör dig bekant med

apparatens / maskinens funktioner.

Før du læser, vend begge sidene med billeder frem og bliv bekendt med alle apparatets funktioner.

Klappen Sie vor dem Lesen die beiden Seiten mit den Abbildungen aus und machen Sie sich anschließend

mit allen Funktionen des Gerätes vertraut.

1

1

6

11

2

3

12

12a

12b

9

13

14

15

4

5

8

9

9

10

7

7

7 a

17

18

16

max. 5 mm

max. 5 mm

A

C

E

G

D

F

B

11

12

19

212223246

2526

18

10

20

16

5 GB/IE

Table of contents

Introduction

Proper use ......................................................................................................................Page 6

Features and equipment ...............................................................................................Page 6

Included items ...............................................................................................................Page 7

Technical information ....................................................................................................Page 7

General safety advice for electrical power tools

1. Workplace safety .....................................................................................................Page 7

2.

Electrical safety .........................................................................................................Page 8

3. Personal safety ..........................................................................................................Page 8

4.

Careful handling and use of electrical power tools ...............................................Page 9

Safety advice relating specifically to this device .........................................................Page 9

Preparing for use

Switching on and off .....................................................................................................Page 12

Setting the cutting angle ...............................................................................................Page 13

Setting the cutting depth ...............................................................................................Page 13

Setting the guide fence .................................................................................................Page 13

Switching the laser on and off ......................................................................................Page 13

Working with the circular saw .....................................................................................Page 13

Setting the speed ...........................................................................................................Page 13

Connecting the vacuum sawdust extraction device ....................................................Page 14

Changing a saw blade .................................................................................................Page 14

Installing and setting the riving knife ............................................................................Page 14

Tips and tricks ................................................................................................................Page 14

Maintenance and cleaning ........................................................................Page 15

Service .........................................................................................................................Page 15

Warranty ...................................................................................................................Page 15

Disposal ......................................................................................................................Page 15

Declaration of Conformity / Manufacturer....................................Page 16

6 GB/IE

Introduction

Circular saw PHKS 1300 A1

Introduction

Please make sure you familiarise your-

self fully with the way the device works

before you use it for the first time and

that you understand how to handle electrical power tools correctly. To help you do this please read

the accompanying operating instructions. Keep

these instructions in a safe place. If you pass the

device on to anyone else, please ensure that you

also pass on all the documentation.

Proper use

For sawing longitudinal, cross and mitre cuts in firmly supported solid wood, plywood, plastic and

lightweight construction materials. Please note that

the blade pre-installed in the saw as supplied is intended for use with wood only. Any other use or

modification to the device shall be considered as

improper use and could give rise to considerable

dangers. Not suitable for commercial use.

Features and equipment

1

Rotation speed setting wheel

2

Safety lock-out

3

ON / OFF switch

4

Spindle lock

5

Cutting depth setting clamp

6

Allen key

7

Automatic blade guard

7 a

Release lever for the automatic blade guard

8

Base plate

9

Cutting angle setting clamp

10

Battery compartment cover

11

Laser ON / OFF switch

12

Laser

12 a

Laser outlet aperture

12 b

Cutting angle scale

13

Wing screw for guide fence

14

Guide fence slot

15

Guide fence

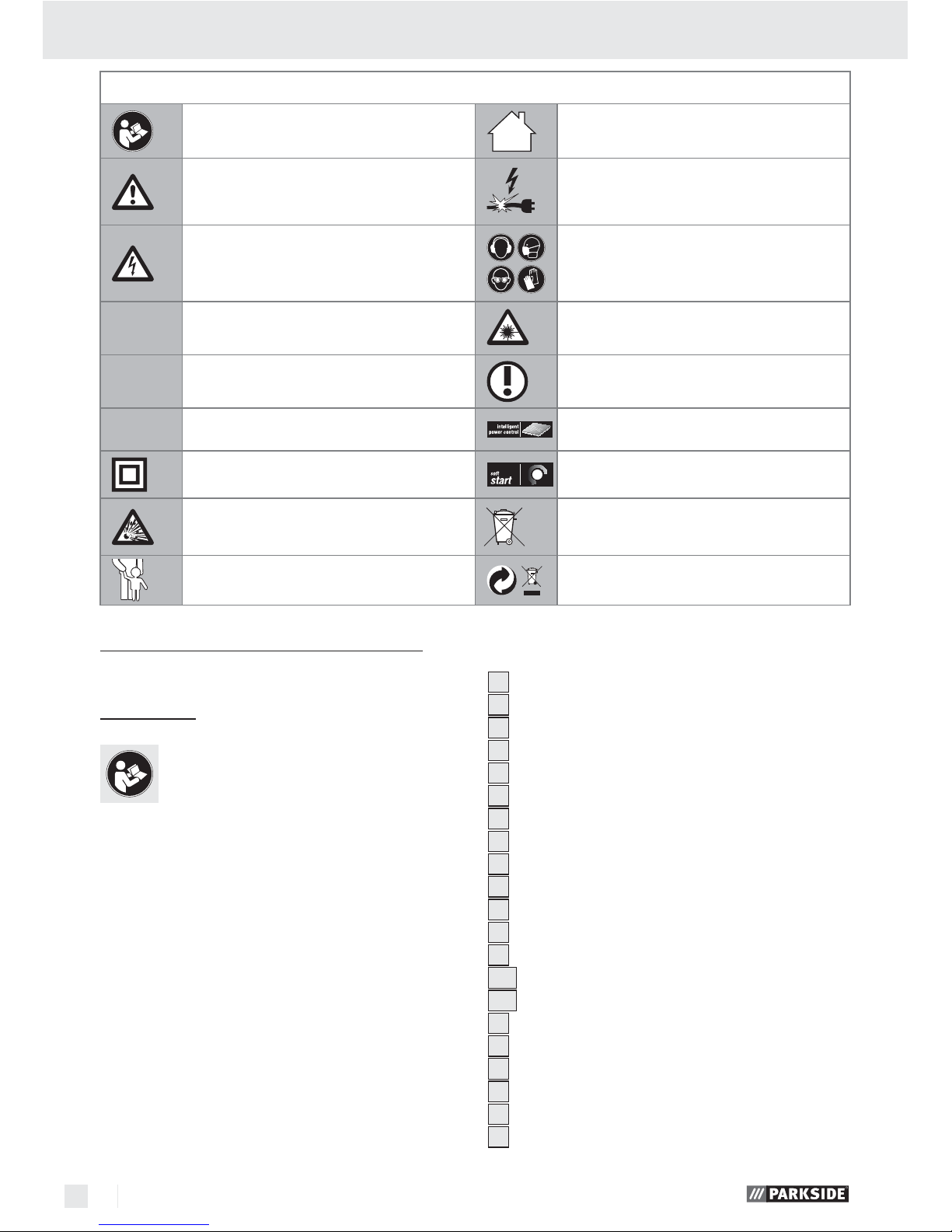

The following pictograms are used in these operating instructions / on the device:

Read instruction manual! For indoor use only!

Observe caution and safety notes!

Risk of loss of life by electric shock from

damaged mains lead or mains plug!

Caution – electric shock!

Danger to life!

Wear hearing protection, dust

protection mask, protective glasses

and protective gloves.

V

~

Volt (AC)

Caution, laser! Do not expose yourself

to laser radiation.

n

0

Design no-load speed Proper procedure and handling.

W

Watts (Effective power) Automatic power delivery system

Safety class II Electronic soft start

Risk of explosion!

Do not dispose of rechargeable batteries

with your household refuse!

Keep children away from

electrical power tools!

Dispose packaging and appliance in

an environmentally-friendly way!

7 GB/IE

Introduction / General safety advice for electrical power tools

16

Riving knife

17

Sawdust removal connector

18

Adapter for vacuum sawdust removal

19

Cutting depth scale

20

Auxiliary handle

21

Drive spindle

22

Mounting flange

23

Clamping flange

24

Clamping screw with plain washer

25

Riving knife mounting

26

Mounting screws

Included items

1 Circular saw

1 Guide fence

1 Adapter for vacuum sawdust removal

1 Allen key

1 Operating instructions

Technical information

Rated power: 1300 W

Rated voltage: 230 V~, 50 Hz

No-load rotational speed: n

0

2200 – 5200 min

-1

Saw blade: 190 x 30 x 1.8

(2.6 mm tooth thickness)

Cutting depth: 66 mm

Protection class: II /

Noise and vibration data:

Measured values for noise are determined in accordance with EN 60745. The A-weighted noise

level of the electrical power tool are typically:

Sound pressure level: 96 dB(A)

Sound power level: 107 dB(A)

Uncertainty K: 3 dB

Wear ear protection!

Evaluated acceleration, typical:

Hand / arm vibration a

h

= 3,447 m / s

2

Uncertainty K = 1,5 m / s

2

WARNING! The vibration level given in these

instructions has been measured in accordance with

a standardised measurement procedure specified in

EN 60745 and can be used to compare devices.

Different uses of the device give rise to different vibration levels and in many cases they may exceed the

values given in these instructions. It is easy to underestimate the vibration load if the electrical power

tool is used regularly in particular circumstances.

Note: If you wish to make an accurate assessment

of the vibration loads experienced during a particular

period of working, you should also take into account

the intervening periods of time when the device is

switched off or is running but is not actually in use.

This can result in a much lower vibration load over

the whole of the period of working.

General safety advice for

electrical power tools

WARNING!

Read all the safety advice

and instructions! Failure to observe the safety

advice and instructions may result in electric shock,

fire and / or serious injury.

Keep all the safety advice and instructions

in a safe place for future reference!

The term “electrical tool” used in the safety advice

refers to electrical tools powered by mains electricity (by means of a mains lead) and electrical tools

powered by rechargeable batteries (without a

mains lead).

1. Workplace safety

a) Keep your working area clean and

well lit. Untidy or poorly lit working areas

can lead to accidents.

b)

Do not work with the device

in potentially explosive environments in which there are

inflammable liquids, gases or dusts.

Electrical power tools create sparks, which can

ignite dusts or fumes.

8 GB/IE

General safety advice for electrical power tools

c) Keep children and other

people away while you are

operating the electrical tool.

Distractions can cause you to lose control of

the device.

2. Electrical safety

a)

The mains plug on the device must match

the mains socket. The plug must not

be modified in any way. Do not use

an adapter plug with devices fitted

with a protective earth. Unmodified

plugs and matching sockets reduce the risk of

electric shock.

b) Avoid touching earthed surfaces such

as pipes, radiators, ovens and refrigerators with any part of your body.

There is an increased risk of electric shock if

your body is earthed

.

c) Keep the device away from rain or

moisture. Water entering an electrical device

increases the risk of electric shock.

d)

Do not use the mains lead for

any purpose for which it was

not intended, e.g. to carry the

device, to hang up the device or to pull

the mains plug out of the mains socket.

Keep the mains lead away from heat,

oil, sharp edges or moving parts of the

device. Damaged or tangled mains leads

increase the risk of electric shock.

e) When working outdoors with an

electrical power tool always use extension cables that are also approved

for use outdoors. The use of an extension

cable suitable for outdoor use reduces the risk

of electric shock.

f) Use a residual current device (RCD)

for protection if operating the electrical power tool in a moist environment

is unavoidable. The use of an RCD reduces

the risk of electric shock.

3. Personal safety

a) Remain alert at all times, watch what

you are doing and always proceed

with caution. Do not use the device if

you are tired or under the influence of

drugs, alcohol or medication. One mo

ment

of carelessness when using the device can lead

to serious injury.

b)

Wear personal protective

equipment and always wear

safety glasses. The wearing of

personal protective equipment such as dust

masks, non-slip safety shoes, safety helmets or

ear protectors, appropriate to the type of electrical power tool used and work undertaken,

reduces the risk of injury.

c) Avoid unintentional operation of the

device. Check that the electrical power

tool is switched off before you connect

it to the mains, pick it up or carry it.

Accidents can happen if you carry the device

with your finger on the ON / OFF switch or with

the device switched on.

d) Remove any setting tools or spanners

before you switch the device on. A tool

or spanner left attached to a rotating part of a

device can lead to injury.

e) Avoid placing your body in an unnat-

ural position. Keep proper footing

and balance at all times. By doing this

you will be in a better position to control the

device in unforeseen circumstances.

f) Wear suitable clothing. Do not wear

loose clothing or jewellery. Keep your

hair, clothing and gloves clear of moving parts. Loose clothing, jewellery or long

hair can become trapped in moving parts.

g) If vacuum dust extraction and collection

devices are fitted do not forget to

check

that they are properly connected and

correctly used. The use of these devices

reduces the hazard presented by dust.

9 GB/IE

General safety advice for electrical power tools

4. Careful handling and use

of electrical power tools

a) Do not overload the device. Always

use an electrical power tool that is

intended for the task you are undertaking. By using the right electrical power

tool for the job you will work more safely and

achieve a better result.

b)

Do not use an electrical power tool if

its switch is defective. An electrical power

tool that can no longer be switched on and off

is dangerous and must be repaired.

c) Pull the mains plug from the socket

before you make any adjustments to

the device, change accessories or when

the device is put away. This precaution is

intended to prevent you from unintentionally

starting the device.

d) When not in use always ensure that

electrical power tools are kept out of

reach of children. Do not let anyone use

t

he device if he or she is not familiar wit

h

it or has not read the instructions and

advice. Electrical power tools are dangerous

when they are used by inexperienced people.

e) Look after the device carefully. Check

that moving parts are working properly and move freely. Check for any

parts that are broken or damaged

enough to detrimentally affect the

functioning of the device. Have damaged parts repaired before you use

the device. Many accidents have their origins

in poorly maintained electrical power tools.

f) Keep cutting tools clean and sharp.

Carefully maintained cutting tools with sharp

cutting edges are less likely to jam and are

easier to control.

g) Use the electrical power tool, accesso-

ries, inserted tools etc. in accordance

with these instructions and advice, and

the stipulations drawn up for this particular type of device. In doing this, take

into account the working conditions

and the task in hand. The use of electrical

power tools for purposes other than those intended can lead to dangerous situations.

Safety advice relating

specifically to this device

Ensure that the device is always used in accord-

ance with the advice in these operating instructions and only by persons over 16 years of age.

Note: Do not use grinding discs. Failure to observe

this advice may result in injury or damage.

To avoid danger to life

from electric shock:

Frequently check the condition of the

device, mains lead and plug. Do not

use the device if these kinds of parts

are damaged. Never open up the device. A

damaged device, mains lead or plug presents a serious danger to life from electric shock. Always

have any repairs carried out or replacement parts

fitted at the service centre or by an electrical

equipment repair specialist.

Do not operate the device if it is damp and do

not use it in a damp environment.

If you use the device outdoors, always connect

it through a residual current device (RCD) with

a maximum trip current of 30 mA. If using an

extension lead, always use one that is approved

for outdoor use.

Note: Always keep the mains lead away from the

working area of the machine and lead away the

mains lead from the rear.

CAUTION! To avoid

the risk of injury:

a) Keep your hands away from the area

around the saw and clear of the saw

blade. Hold the auxiliary handle or the

motor housing with your free hand. If

you have both hands on the saw they cannot

be injured by the saw blade.

b) Do not grip the underside of the work-

piece. The blade guard cannot protect you

from the saw blade under the workpiece.

10 GB/IE

c) Set the cutting depth to match the thick-

ness of the workpiece. Less than a full tooth

height should be visible below the workpiece.

d) Never hold the workpiece in your hand

or steady it with your leg whilst saw

ing.

Keep the workpiece steady on a stable

supporting surface. It is important to see that

the workpiece is firmly held in place to minimise

any danger of it making contact with your body,

jamming of the saw blade or loss of control.

e) Hold the device by the insulated handle

surfaces when you are undertaking

work where there is the danger of the

cutting tool striking hidden electricity

cables or the device‘s mains lead. Con-

tact with a live wire means that the metal parts

of the device may also become live and this

can result in an electric shock.

f) When cutting longitudinally always use

a guide fence or a straight edge guide.

This will improve the accuracy of your cut and

reduce the risk of the blade jamming.

g) Always use a saw blade of the correct

size and with the appropriate central

fixing hole bore. Saw blades that do not

correspond with the attachment components

on the saw will not run true and could lead to

loss of control.

h) Never use a damaged or incorrect

saw blade washer or screw. The saw

blade washer and screw have been specially

designed to give your saw optimum performance

and safety in use.

To avoid the device kicking back:

Kickback occurs as a result of incorrect use or misuse of the saw. It can be prevented by taking the

appropriate precautions as described below.

a) Hold the saw with both hands and

bring your arms into a position in

which you will be able to withstand

any kickback forces. Always stand to

the side of the saw blade and never

bring your body in line with the saw

blade. When kickback occurs, the circular

saw may jump backwards but the operator

can control the kickback forces by adopting

suitable precautions.

b) If the saw blade jams or sawing stops

for another reason, release the ON /

OFF switch and hold the saw in the

workpiece without moving it until the

saw blade comes to a complete stand

still. Never try to remove the saw from

the tool or to pull it backwards as long

as the saw blade is still moving otherwise this could cause a recoil action.

Find the reason for the saw blade jamming

and take the appropriate action to rectify it.

c) If you wish to restart a saw that has

been inserted into the workpiece, centre the saw blade in the saw gap and

check that the saw teeth do not catch

on the workpiece. If the saw blade jams, it

may move itself out of the workpiece or cause

a kickback when the saw is restarted.

d) Support boards whilst cutting to reduce

the risk of kickback caused by a

jammed saw blade. Large boards may

bend under their own weight. Boards must be

supported on both sides as well as near the

saw gap and at the edges.

e) Do not use blunt or damaged saw

blades. Saw blades with blunt or misaligned

teeth are in effect too wide for the designed saw

gap and this gives rise to increased friction,

jamming and kickback.

f) Make sure that the cutting depth and

angle setting fastenings are tightened

before sawing starts. If these settings

move during sawing, this can lead to the saw

blade jamming and kickback.

g) Be particularly careful when carrying

out

a plunge cut in an obscured area, e.g.

in an existing wall. The plunging blade

could

jam in a hidden object and cause kickback.

Causes of kickback:

a) A kickback is a sudden reaction to a saw blade

becoming hooked, jammed or misaligned. This

causes an out of control circular saw to raise

itself and move out of the workpiece and towards

the operator.

b) If the sawblade becomes hooked or trapped in

a narrowing saw gap, it is suddenly prevented

General safety advice for electrical power tools

11 GB/IE

from rotating and the force of the motor throws

the device back in the direction of the operator.

c) If the sawblade distorts or becomes misaligned

in the saw cut, the teeth at the rear edge of the

sawblade may hook themselves into the workpiece surface causing the sawblade to move

out of the saw gap and the circular saw to jump

backwards in the direction of the operator.

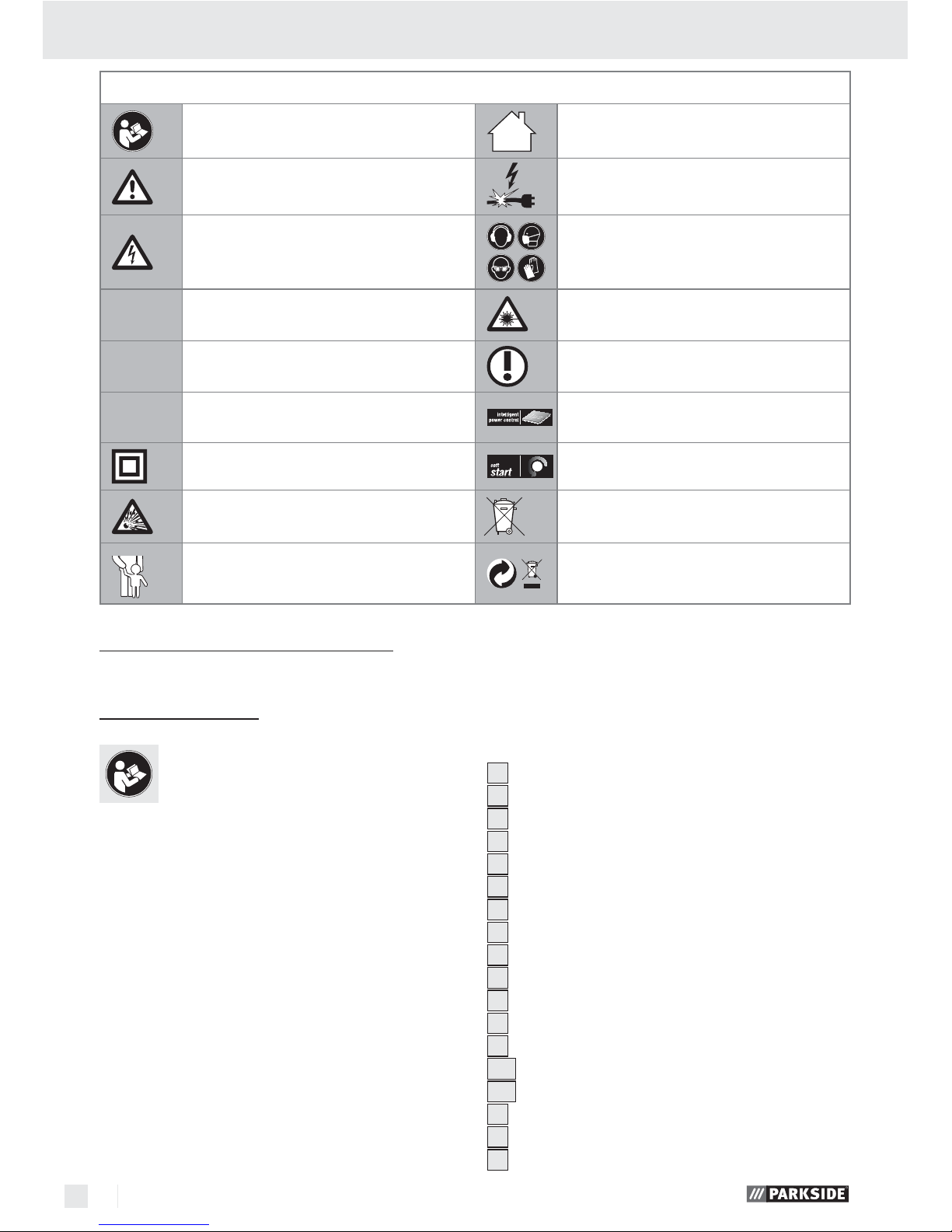

Special safety advice for circular saws

and automatic blade guards

a) Before you use the saw, always check

that the automatic blade guard

7

closes properly. Do not use the saw if the

bottom compartment of the blade

guard

does not move freely or close immediately. Never jam or tie the automatic

blade guard in the open position. The

bottom part of automatic blade guard may become bent if the saw falls on to the floor. Open

the blade guard with the release lever and make

sure that it moves freely and does not touch the

saw blade or other parts at all cutting angles

and depths.

b) Check that the spring on the automatic

blade guard functions properly. If the

automatic blade guard or spring does

not function properly, have the device

serviced before you use it. Damaged

parts,

sticky deposits or accumulations of splinters can

delay the operation of the bottom blade guard.

c) Open the automatic blade guard by

hand only for certain cuts such as

plunge

or angle cuts. Open the automatic

blade

guard with the release lever

7 a

and

let it go again as soon as the saw blade

penetrates the workpiece. The automatic

blade guard must be allowed to operate automatically for all saw cuts.

d) Do not put the saw down on a work

bench or the floor without the automatic blade guard covering the saw

blade. If unprotected, a rotating saw blade

moves the saw against the cutting direction and

saws whatever is in its way. Always be aware

that the saw blade takes some time to stop.

Special safety advice for circular saws

and riving knives

a) Use the riving knife matched to the in-

stalled saw blade. The riving knife must be

thicker than the body of the blade but thinner

than the width of the teeth.

b) Adjust the riving knife as described in

the operating instructions. If its thickness,

position or alignment is incorrect, this can lead

to the riving knife not effectively preventing

kickback.

c) Always use the riving knife, except

for plunge cuts. After completing plunge

cutting, put the riving knife back in place. The

riving knife interferes with plunge cuts and can

result in kickback.

d) For the riving knife to work properly,

it must be within the saw gap. The riving knife is ineffective in preventing kickback

for short cuts.

e) Do not operate the saw if the riving

knife is bent out-of-true. Even a slight defect

can cause the blade guard to close too slowly.

WARNING! Protecting yourself

from laser radiation:

LASER RADIATION

DO NOT STARE INTO BEAM

CLASS 2 LASER PRODUCT

P max.: < 1 mW ·

: 650 nm

EN 60825-1: 2007

Do not look directly into the laser beam or into

the opening from which it is emitted.

General safety advice for electrical power tools

12 GB/IE

WARNING!

Looking at the laser output

aperture

12 a

with optical instruments (e.g.

magnifying glass, magnifying lens, etc.) could

result in eye damage.

Never direct the laser beam on to reflective

surfaces or at people or animals. Even a brief

look into a laser beam can damage your eyes.

Changing batteries:

Open the battery compartment cover

10

using

a suitable cross-head screwdriver (see Fig. G).

Remove the used batteries.

Observing the correct polarity, insert two new

1.5 V alkaline batteries type LR44 (e.g. GPA 76)

and screw the battery compartment cover

10

tightly in place again.

CAUTION! The use of operating or adjustment

devices or other methods of working other than

those indicated in this document may lead to

exposure to hazardous radiation.

Working safely:

If a dangerous situation arises, pull the mains

plug immediately out of the mains socket.

Never use the device for a purpose for which it

was not intended.

Always keep the device clean, dry and free of

oil or grease.

If the saw is used whilst fixed in place on a saw ta-

ble then the saw table must have a restart cut-out.

Make sure the device is switched on before

placing it against the workpiece.

Always work away from your body.

Do not saw materials containing asbestos.

The course of the cut must have no obstructions

above or below it.

The saw blade must not project more than

3 mm out of the workpiece.

When you are sawing, always make sure that you

do not cut through any nails, screws or the like.

Do not work with the device in the overhead

position.

Protect the saw blade from sharp blows or im-

pacts and prevent it from becoming tilted.

When you switch off the saw, allow the blade

to slow down naturally - do not assist this process in any way.

Cracked or distorted blades are not to be used.

HSS (High Speed Steel) saw blades are not to

be used.

Before carrying out any work on the saw, e.g.

setting the base plate etc. always pull the

mains plug out of the mains socket.

Never remove sawdust or splinters whilst the

saw is running.

Have a suitable, tested vacuum removal device

attached to the saw when working with woods

or materials that create dusts that may be hazardous to health.

Always use the safety devices integrated into

the circular saw, e.g. the safety lock-out

2

and automatic blade guard

7

.

Ensure that all moving parts of the saw blade

protection system function properly and all the

assemblies and components involved in covering the saw blade are in perfect working order.

Do not lock on the ON / OFF switch

3

in

hand-guided operation.

Preparing for use

The PHKS 1300 A1 circular saw has Intelligent

Power Control.

This automatic power

delivery system ensures

that for a particular

speed range the power output remains constant when

working on harder and more resistant materials.

Switching on and off

Switching on:

Press the safety lock-out

2

to the left or right

and keep it pressed.

Press the ON / OFF switch

3

. Once the saw

is running you can release the safety lock-out

2

again.

The circular saw is fitted with an

electronic soft start system. The

motor starts with a delay.

General safety advice for electrical power tools / Preparing for use

13 GB/IE

Preparing for use

Switching off:

Release the ON / OFF switch

3

.

Setting the cutting angle

You can set the cutting angle accurately with the

help of the cutting angle scale

12 b

.

Release the wing screws / locking bolts of the

cutting angle preselector

9

on both sides, set

the desired angle on the cutting angle scale

12 b

and retighten the wing screws / locking bolts.

Setting the cutting depth

Note: If possible we recommend that the cutting

depth is set approximately 3 mm greater than the

material thickness. This should help to ensure you

achieve a clean cut.

Release the wing screw on the cutting depth

setting clamp

5

, set the required cutting depth

on the scale

19

and retighten the wing screw.

Setting the guide fence

Release the wing screw 13 of the base plate 8

and insert the guide fence

15

into the slot 14.

Retighten the wing screw

13

.

Switching the laser on and off

Switching on:

Move the laser ON / OFF switch

11

to setting “I”.

Switching off:

Move the laser ON / OFF switch 11 to setting “0”.

Note: If the batteries are exhausted replace them

with two 1.5 V alkaline batteries LR44 (e.g. GPA 76).

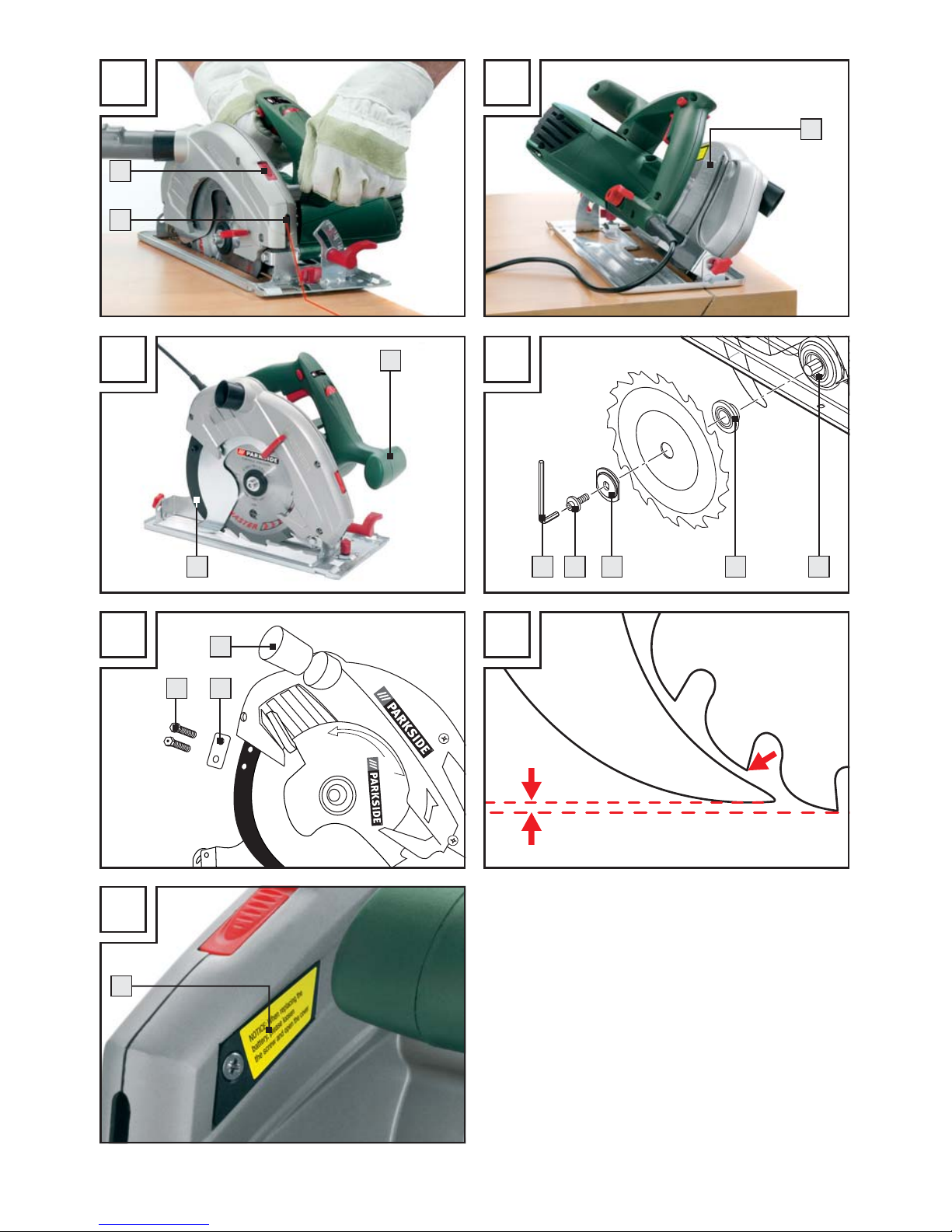

Working with the circular saw

1. Switch on the device as described in the section

about “Switching on and off” and then place it

first with the front edge of the base plate

8

against the material.

2. Align the device using the guide fence

15

or

with reference to marked-out line or by using

the laser.

3. Hold the machine with both hands by the

handles (see Fig. A) and saw the material

with moderate pressure.

Setting the speed

Turn the wheel

1

to the desired speed setting

(arrow marking )

(1 = lowest speed / 6 = highest speed):

Use the general settings suggested in the following

table (information offered without liability) or adjust

the speed setting on the setting wheel

1

to the

material being cut.

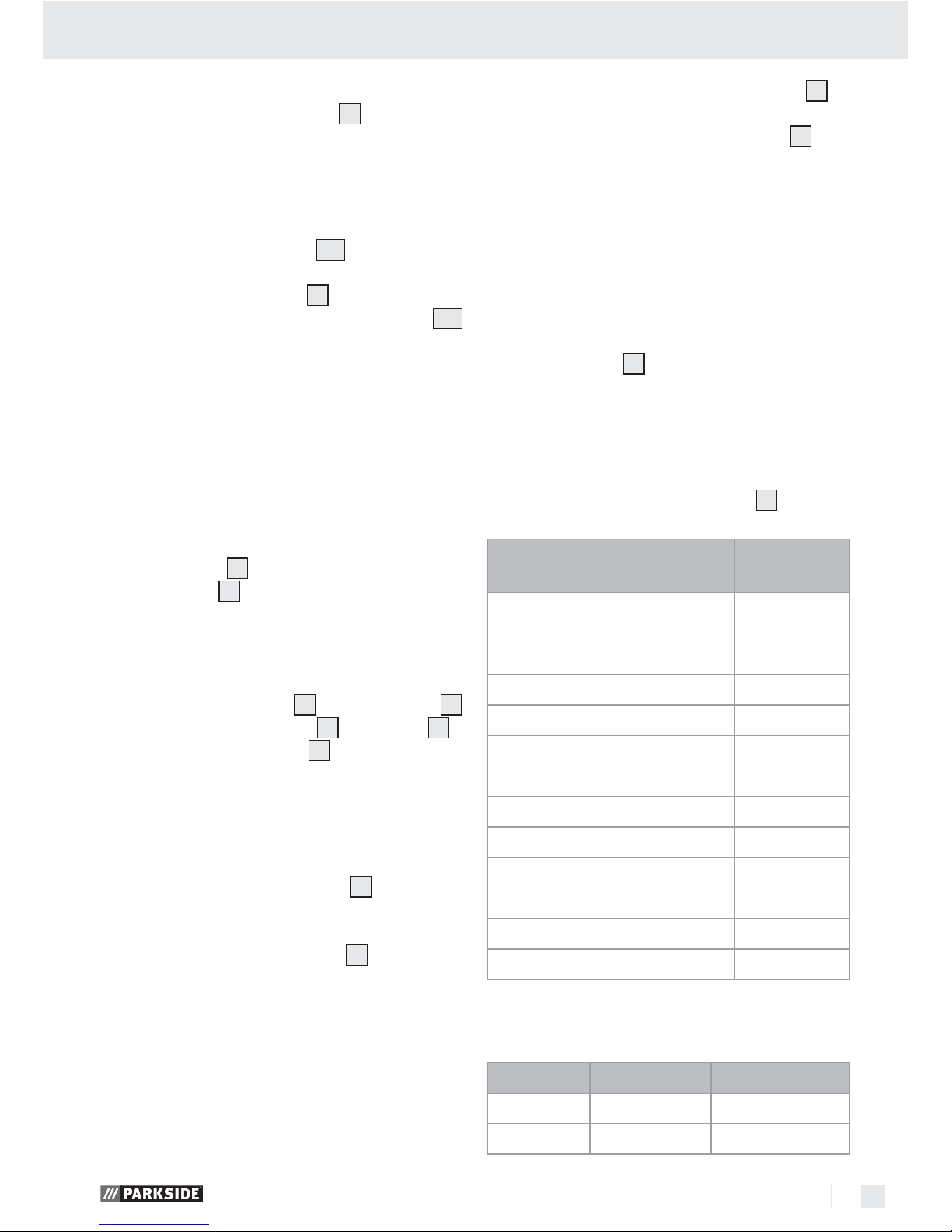

Material Speed

setting

Hard- and softwood (solid wood)

cut longitudinally and transversely

6

Plywood, hard fibre board 6

Chipboard 6

Blockboard, laminated wood 6

Coated and veneered board 6

PVC board 3-5

Acrylic glass panels, Plexiglas 2-4

Aluminium board 4-6

Aluminium profiles 4-6

Plasterboard 1-2

Mineral wool board 1-2

Cement-bound chipboard 1-2

The circumferential speeds at minimum and maximum

rotational speeds are approx.:

Setting Rpm Metres/ sec

1 2200 21.8

6 5200 51.7

14 GB/IE

Preparing for use

Make sure that the cutting speed resulting from the

effects of different saw blades, materials and the

force you apply to advance the saw is always less

than the circumferential speed (CS) under no load.

Connecting the vacuum

sawdust extraction device

Insert the adapter for vacuum sawdust removal

18

into the sawdust removal connector 17.

Connect a vacuum device approved for the

extraction of sawdust and splinters (see Fig. A).

Changing a saw blade

WARNING!

Press the spindle lock only after

the mains plug has been pulled out of the socket!

1. Then remove the guide fence

15

by releasing

the wing screw

13

.

2. Set the cutting depth (by means of the wing

screw for cutting depth setting clamp

5

) to

the minimum position, 0 mm.

3. Swing back the retractable blade guard

7

with the help of the retracting lever

7 a

and put

the device down.

4. Press the spindle lock button

4

(until it engages)

and release the clamping screw

24

using the

Allen key

6

. Now remove the clamping screw

with integral washer head

24

and the clamp-

ing flange

23

(see Fig. D).

5. Detach the saw blade.

6. The installation of a sawblade is done in the

reverse order.

7. Press the spindle lock button

4

(until it engages)

and tighten the clamping screw

24

using the

Allen key.

WARNING!

The arrow on the saw blade

must agree with the arrow showing the direction of

rotation (running direction shown on the device).

Ensure that the saw blade is suitable for the

saw spindle speed.

Installing and setting

the riving knife

WARNING!

The distance between the riving

knife

16

and the saw blade must not be greater

than 5 mm. If the riving knife has been removed e.g.

for a plunge cut, this distance must be observed

again when the riving knife is reinstalled (see Fig. F).

Removing the riving knife (see Fig. E):

1. Release the wing screws of the cutting depth

setting clamp

5

and swing the circular saw

up until it meets the stop; this exposes the riving

knife mounting

25

.

2. Screw out the mounting screws

26

and remove

the riving knife

16

.

WARNING!

After completion of the plunge

cut the riving knife

16

must be reinstalled before

the circular saw is used for any other sawing tasks.

Setting the riving knife (see Fig. F):

Set the distance between the riving knife

16

and

the tips of the saw blade teeth to a maximum of

5 mm, and the distance between the tip of the riving

blade and the lowest point of the saw blade to a

maximum of 5 mm.

The distances to be set are illustrated in Fig. F.

Tips and tricks

Use the cutting angle scale according to the

cutting angle

12 b

: rectangular cut = 0° mark,

45° cut = 45° mark.

Breaking out of the cut edges of delicate sur-

faces, e.g. coated chipboard or doors, can be

avoided by applying masking tape in advance

along the cutting line. This has the additional

advantage that masking tape shows up the cutting line better than a smooth surface. An even

more effective way of stopping the cut edges

from being broken out is to clamp a thin piece

of wood along the cutting line, which is then

also sawn through.

15 GB/IE

Maintenance and cleaning / Service / Warranty / Disposal

Maintenance and cleaning

WARNING!

DANGER OF INJURY!

Always pull the mains plug out of the socket before

doing any work on the device.

Clean the device after you have finished using it.

Use a cloth to clean the outside of the device -

never use petrol, solvents or cleaners.

Service

WARNING!

Have your device

repaired at the service centre or by

qualified specialist personnel using

original manufacturer parts only. This

will ensure that your device remains safe to use.

WARNING!

If the plug or lead

needs to be replaced, always have

the replacement carried out by the

manufacturer or its service centre. This

will ensure that your device remains safe to use.

Warranty

The warranty for this appliance is for 3

years from the date of purchase. The appliance has been manufactured with care

and meticulously examined before delivery. Please retain your receipt as proof

of purchase. In the event of a warranty

claim, please make contact by telephone

with our Service Department. Only in this

way can a post-free despatch for your

goods be assured.

The warranty covers only claims for material and

maufacturing defects, but not for transport damage, f

or

wearing parts or for damage to fragile components,

e.g. buttons or batteries. This product is for private

use only and is not intended for commercial use.

The warranty is void in the case of abusive and improper handling, use of force and internal tampering not carried out by our authorized service branch.

Your statutory rights are not restricted in any way

by this warranty.

The warranty period will not be extended by repairs

made unter warranty. This applies also to replaced

and repaired parts. Any damage and defects extant

on purchase must be reported immediately after

unpacking the appliance, at the latest, two days after

the purchase date. Repairs made after the expiration

of the warranty period are subject to payment.

GB

DES UK LTD

Tel.: 0871 5000 700 (£ 0.10 / minute)

e-mail: support.uk@kompernass.com

IE

Kompernass Service Ireland

Tel: 1850 930 412 (0,082 EUR/Min.)

Standard call rates apply.

Mobile operators may vary.

e-mail: support.ie@kompernass.com

Disposal

The packaging is wholly composed of

environmentally-friendly materials that

can be disposed of at a local recycling

centre.

Do not dispose of electrical

power tools with the household

rubbish!

In accordance with European Directive 2002 / 96 / EC

(covering waste electrical and electronic equipment)

and its transposition into national legislation, worn

out electrical power tools must be collected separately and taken for environmentally compatible recycling.

Contact your local refuse disposal authority for

more details of how to dispose of your worn out

electrical devices.

Do not dispose of rechargeable

batteries with your household

refuse!

16 GB/IE

Disposal / Declaration of Conformity / Manufacturer

Disposal of batteries

Batteries must be recycled in accordance with

Directive 2006 / 66 / EC and must not be disposed

of with household refuse. Battery users are obliged

by law to take all rechargeable and single-use batteries to a collection point operated by a public

authority or a retailer.

Declaration of Conformity /

Manufacturer

We, Kompernaß GmbH, the person responsible for

documents: Mr Felix Becker, Burgstr. 21, D-44867

Bochum, Germany, hereby declare that this product

complies with the following standards, normative

documents and EU directives:

Machinery Directive

(2006 / 42 / EC)

EU Low Voltage Directive

(2006 / 95 / EC)

Electromagnetic Compatibility

(2004 / 108 / EC)

Applicable harmonized standards

EN 60745-1: 2006, EN 60745-1: 2009

EN 60745-2-5:2007, EN 60745-2-5/A11:2009

EN 55014-1: 2006, EN 55014-2/A2: 2001

EN 61000-3-2: 2006, EN 61000-3-3: 2008

IEC 60745-1: 2006, IEC 60745-2-5: 2006

Type / Device description:

Circular saw PHKS 1300 A1

Date of manufacture (DOM): 07 - 2010

Serial number: IAN 54379

Bochum, 31.07.2010

Hans Kompernaß

- Managing Director -

We reserve the right to make technical modifications in the course of further development.

17 FI

Aluksi

Määräystenmukainen käyttö ........................................................................................ Sivu 18

Varusteet ........................................................................................................................ Sivu 18

Toimitus sisältää ............................................................................................................ Sivu 19

Tekniset tiedot ................................................................................................................ Sivu 19

Sähkötyökaluja koskevat yleiset turvaohjeet

1. Työpaikkaturvallisuus ................................................................................................ Sivu 19

2.

Sähköturvallisuus ...................................................................................................... Sivu 20

3. Henkilöiden turvallisuus ............................................................................................ Sivu 20

4.

Sähkötyökalujen huolellinen käsittely ja käyttö ...................................................... Sivu 20

Laitetta koskevat turvallisuusohjeet ............................................................................... Sivu 21

Käyttöönotto

Kytkentä ja poiskytkentä ............................................................................................... Sivu 24

Sahauskulman säätö ..................................................................................................... Sivu 24

Sahaussyvyyden säätö ................................................................................................. Sivu 24

Rinnakkaisohjaimen säätö ............................................................................................ Sivu 24

Laserin kytkentä / poiskytkentä ..................................................................................... Sivu 24

Käsipyörösähän käsittely .............................................................................................. Sivu 24

Käyntinopeuden säätö.................................................................................................. Sivu 25

Lastuimurin liitäntä ......................................................................................................... Sivu 25

Sahanterän vaihto ......................................................................................................... Sivu 25

Halkaisukiila purkaminen ja säätö ...............................................................................Sivu 25

Vinkit ja konstit ............................................................................................................... Sivu 26

Huolto ja puhdistus ........................................................................................... Sivu 26

Huolto........................................................................................................................... Sivu 26

Takuu ............................................................................................................................ Sivu 26

Hävittäminen ......................................................................................................... Sivu 26

Vaatimustenmukaisuusvakuutus / Valmistaja .......................... Sivu 27

Sisällysluettelo

18 FI

Aluksi

Käsipyörösaha PHKS 1300 A1

Aluksi

Tutustu ennen käyttöönottoa laitteeseen,

sen käyttöohjeisiin ja sähkölaitteita kos-

keviin yleisiin turvallisuusohjeisiin. Lue

tämä käyttöopas huolella. Säilytä käyttöopas huolellisesti. Saatat myöhemmin tarvita sen tietoja. Jos

luovut laitteesta, anna uudelle omistajalle myös

kaikki laitteen asiakirjat.

Määräystenmukainen käyttö

Tukevalla alustalla täyspuun, lastulevyjen sekä kevytrakenneaineksien sahaukseen. Ota huomioon,

että laitteeseen kiinnitetty sahanterä on tarkoitettu

vain puun sahaukseen. Laitteen käyttö muuhun tarkoitukseen tai muutoksien teko siihen katsomtaan

määräystenvastaiseksi ja on vaarallista.

Ei kaupalliseen käyttöön.

Varusteet

1

Käyntinopeuden säädin

2

Käynnistyksen esto

3

Virtakytkin KYTKIN / KATKAISIN

4

Karalukitus

5

Sahaussyvyyden valinta

6

Kuusiokoloavain

7

Teränsuoja

7 a

Suojakotelon takaisinvetovipu

8

Peruslaatta

9

Sahauskulman valinta

10

Paristotilan kansi

11

KYTKIN / KATKAISIN laserlisäke

12

Laser

12 a

Laserlähtö

12 b

Sahauskulma-asteikko

13

Rinnakkaisohjaimen siipiruuvi

14

Rinnakkaisohjaimen paikka

15

Rinnakkaisohjain

16

Halkaisukiila

17

Lastunpoisto

18

Pölyimuriadapteri

Tässä käyttöohjeessa / laitteessa käytetään seuraavia kuvakkeita:

Lue käyttöohje!

Tarkoitettu käytettäväksi ainoastaan

sisätiloissa!

Huomioi varoitus- ja turvaohjeet!

Viallisen verkkojohdon tai pistokkeen

käyttöön liittyvän sähköiskun aiheuttama hengenvaara!

Varo sähköiskua! Hengenvaara!

Pidä ja kuulonsuojainta, hengitys- /

pölysuojanaamaria, suojalaseja ja

suojakäsineitä.

V

~

Voltti (Vaihtojännite)

Huomio, Laser! Älä asetu alttiiksi

lasersäteelle.

n

0

Mittaus-tyhjäkäyntikierrosluku Näin käyttäydyt oikein!

W

Watti (Vaikutusteho) Automaattinen voimansyöttö

Suojausluokka II Elektroninen pehmeä käynnistys

Räjähdysvaara!

Älä hävitä akkuja tavallisen

kotitalousjätteen mukana!

Pidä lapset loitolla sähkötyökalusta!

Hävitä pakkaus ja laite

ympäristöystävällisesti!

19 FI

Aluksi / Sähkötyökaluja koskevat yleiset turvaohjeet

19

Sahaussyvyysasteikko

20

Lisäkahva

21

Käyttökara

22

Kiinnityslaippa

23

Kiristyslaippa

24

Kiristysruuvi ja aluslevy

25

Halkaisukiilan kiinnitys

26

Kiinnitysruuvit

Toimitus sisältää

1 Käsipyörösaha

1 Rinnakkaisvaste

1 Pölyimurin adapteri

1 Sisäkuusiokoloavain

1 Käyttöohje

Tekniset tiedot

Nimellisvirranotto: 1300 W

Nimellisjännite: 230 V~, 50 Hz

Tyhjäkäyntikierrosluku: n

0

2200 - 5200 min

-1

Sahanterä: 190 x 30 x 1,8 (2,6 mm

hampaiden vahvuus)

Sahaussyvyys: 66 mm

Suojausluokka: II /

Melu- ja tärinätiedot:

Melun mittausarvo laskettu EN 60745 standardin

mukaisesti. Sähkötyökalun A-mitattu melutaso on

tyypillisesti:

Äänenpainetaso: 96 dB(A)

Äänitehotaso: 107 dB(A)

Epävarmuus K: 3 dB

Käytä kuulosuojaimia!

Arvioitu kiihtyvyys, tyypillisesti:

Käteen ja käsivarteen

kohdistuva värinä a

h

= 3,447 m / s

2

Epävarmuus K = 1,5 m / s

2

VAROLTUS!

Näissä ohjeissa ilmoitettu

värähtelytaso on määritetty normissa EN 60745

standardoidulla mittausmenetelmällä ja sitä voidaan

käyttää laitevertailussa.

Värähtelytaso muuttuu sähkötyökalun käytön mukaan ja se saattaa monesti

ylittää tässä ohjeessa mainitun arvon. Värähtelyrasitusta saatetaan aliarvioida, jos sähkötyökalua

säännöllisesti käytetään tällä tavalla.

Huomio: Liikekuormituksen arvioimiseksi tietyn

työajan kestäessä on huomioitava myös ajat, jolloin

laite on sammutettuna, tai ajat, jolloin laite on käynnissä, mutta ei työkäytössä. Tämä saattaa vähentää

merkittävästi liikerasitusta kokonaistyöskentelyajan

kestäessä.

Sähkötyökaluja koskevat

yleiset turvaohjeet

VAROLTUS!

Lue kaikki turva- ja muut

ohjeet! Turva- ja muiden ohjeiden laiminlyönti voi

aiheuttaa sähköiskun, tulipalon ja / tai vakavia loukkaantumisia.

Säilytä kaikki turva- ja muut ohjeet tulevaa

tarvetta varten!

Turvallisuusohjeissa käytetty käsite „sähkötyökalu“

koskee verkkokäyttöisiä sähkötyökoneita (verkkojohdolla) ja akkukäyttösisiä sähkötyökoneita (ilman

johtoa).

1. Työpaikkaturvallisuus

a) Pidä työskentelypaikka puhtaana ja

hyvin valaistuna. Epäjärjestys ja huono

valaistus voivat johtaa tapaturmiin.

b)

Älä käytä laitetta räjähdys-

vaarallisessa ympäristössä,

jossa säilytetään helposti

syttyviä nesteitä, kaasuja tai jossa

kehittyy pölyä. Sähkötyökalut kehittävät

kipinöintiä, joka voi sytyttää pölyn tai höyryn.

c)

Lapsien ja asiattomien henki-

löiden läsnäolo työpaikalla

laitteen ollessa käynnissä ei

ole sallittua. Voit helposti menettää kontrollin

laitteeseen.

20 FI

Sähkötyökaluja koskevat yleiset turvaohjeet

2. Sähköturvallisuus

a) Laitteen pistokkeen pitää sopia pisto-

rasiaan. Pistoketta ei saa muuttaa

millään tavalla. Älä käytä adapteria

yhdessä suojamaadoitettujen laitteiden

kanssa. Alkuperäinen pistoke ja sopivat pis-

torasia vähentävät sähköiskuvaaraa.

b) Vältä kosketusta maadoitettuihin pin-

toihin, kuten putkiin, lämpöpattereihin,

liesiin sekä jääkaappeihin. Vaarana on

saada sähköisku, jos kehosi on maadoitettu.

c)

Älä pidä laitetta sateessa tai muussa

kosteudessa. Veden pääsy laitteeseen lisää

sähköisku vaaraa.

d)

Älä kanna laitetta riiputta-

malla sitä kaapelista ja vedä

kaapeli irti pistorasiasta

pitämällä kiinni pistokkeesta. Älä jätä

kaapelia kuumaan paikkaan, älä päästä

s

iihen öljyä, varo teräviä reunoja sekä

laitteen pyöriviä osia. Vialliset tai kietou

tu-

neet kaapelit lisäävät riskiä saada sähköisku.

e) Jos työskentelet ulkotiloissa, käytä

silloin jatkokaapelia, jonka käyttö on

sallittu myös ulkotilaan. Ulkotilaan sovel-

tuva kaapeli vähentää riskiä saada sähköisku.

f) Jos sähkötyökalua joudutaan käyttä-

mään kosteassa ympäristössä, on

käytettävä vikavirtakytkintä. Vikavirta-

kytkimen käyttö pienentää sähköiskun vaaraa.

3. Henkilöiden turvallisuus

a) Ole aina tarkkaavainen, tarkista aina,

mitä teet ja toimi järkevästi sähkölaitteilla työskennellessäsi. Älä käytä

laitetta, jos olet väsynyt, käyttänyt

huumeita, alkoholia tai lääkkeitä.

Epätarkkaavaisuus laitetta käytettäessä voi

aiheuttaa vaikeita loukkaantumisia.

b)

Käytä henkilökohtaisia tur-

vavarusteita ja suojalaseja

aina. Henkilökohtaisten turvavarus-

teiden käyttö, kuten pölynaamari, turvakengät,

kypärä tai kuulosuoja, vähentävät loukkaantumisriskiä.

c) Varo käynnistämästä laitetta vahin-

gossa. Varmista, että sähkötyökalu on

kytketty pois päältä, ennen kuin liität

sen pistorasiaan, nostat sen tai kannat

sitä. Tapaturmat ovat mahdollisia, jos sormesi

on laitetta kantaessasi virtakytkimellä tai laite

on kytketty päälle.

d) Poista kaikki työkalut ja ruuviavaimet

paikalta ennen kuin kytket laitteen.

Pyörivässä laiteosassa oleva työkalu tai avain

voi johtaa tapaturmaan.

e) V

ältä työskentelemästä epätavallisess

a

asennossa. Asetu tukevaan asentoon

ja pysyttele koko ajan tasapainossa.

Pystyt silloin hallitsemaan laitteen erityisesti

yllättävissä tilanteissa.

f) Käytä sopivaa vaatetusta. Älä käytä

löysiä vaatteita äläkä pidä koruja.

Hiukset, vaatteet ja käsineet on pidettävä etäällä liikkuvista osista. Löysät

vaatteet, korut ja avonaiset hiukset voivat jäädä

kiinni liikkuviin osiin.

g) Jos laitteeseen asennetaan pölynimu-

ri- ja lastunkeruulaite, varmistu sitä

ennen, että osat on liitetty ja niitä käytetään oikein. Näiden laitteiden liittäminen

vähentää pölystä aiheutuvia vaaroja.

4. Sähkötyökalujen huolellinen

käsittely ja käyttö

a) Ä

lä ylirasita laitetta. Käytä työssäsi tätä

työtä varten tarkoitettua sähkötyökalua. Sopivan sähkötyökalun kanssa työskentelet

paremmin ja varmemmin sen tehoalueella.

b) Älä käytä mitään sähkötyökalua,

jonka käynnistyskytkin on viallinen.

Sähkötyökalu, jota ei voi enää kytkeä päälle

tai päältä, on vaarallinen ja se on korjattava.

c) Irrota pistotulppa pistorasiasta, ennen

kuin säädät laitetta, vaihdat sen varusteita tai laitat sen varastoon. Nämä

varotoimenpiteet estävät sen, että laite käynnistyy

vahingossa.

d)

Säilytä sähkötyökaluja silloin, kun nii-

tä ei käytetä, lasten ulottumattomissa.

Älä anna henkilöiden käyttää laitetta,

Loading...

Loading...