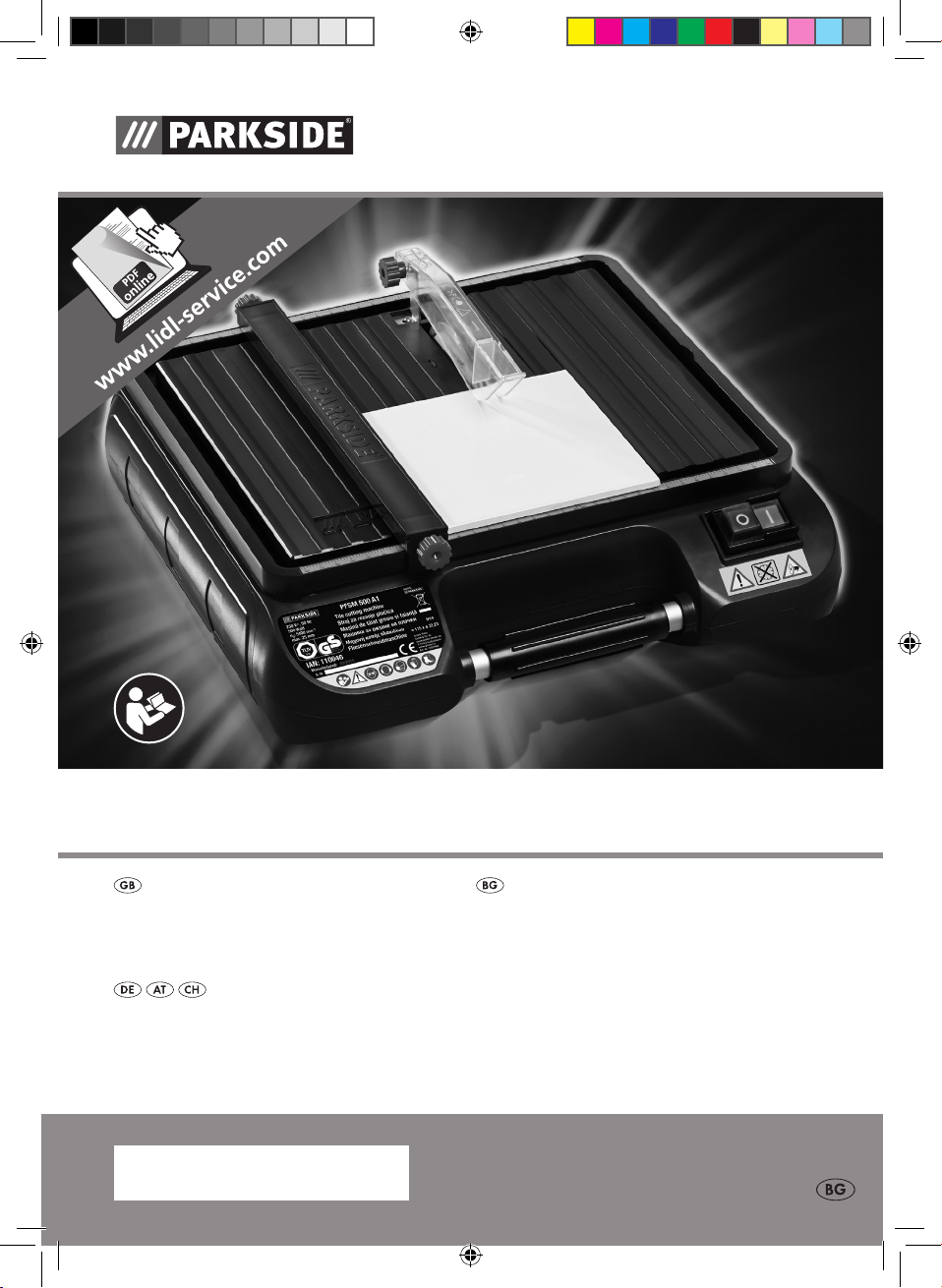

Parkside PFSM 500 A1 Translation Of The Original Instructions

TILE CUTTING MACHINE PFSM 500 A1

TILE CUTTING MACHINE

Translation of the original instructions

МАШИНА ЗА РЯЗАНЕ НА ПЛОЧКИ

Превод на оригиналното ръководство за

експлоатация

FLIESENSCHNEIDMASCHINE

Originalbetriebsanleitung

IAN 110046

110046_par_Fliesenschneidemaschine_cover_BG.indd 2 29.05.15 13:21

Before reading, unfold the page containing the illustrations and familiarise yourself with all

functions of the device.

Преди да прочетете отворете страницата с фигурите и след това се запознайте с всички

функции на уреда.

Klappen Sie vor dem Lesen die Seite mit den Abbildungen aus und machen Sie sich anschließend

mit allen Funktionen des Gerätes vertraut.

GB Translation of the original instructions Page

BG Превод на оригиналното ръководство за експлоатация Страница

DE / AT / CH Originalbetriebsanleitung Seite

110046_par_Fliesenschneidemaschine_cover_BG.indd 3 29.05.15 13:21

4

16

30

1

11

10

2

3

789

4

5

6

12

GB

Content

Introduction .................................4

Intended use ................................ 4

General description ...................... 5

Scope of delivery ............................. 5

Function description..........................5

Summary ........................................ 5

Technical specications ................. 5

Safety Instructions........................6

Symbols and icons ........................... 6

General safety instructions ................ 6

Further Safety Instructions .................. 8

Residual risks ................................... 9

Assembly ..................................... 9

Mounting the cutting disc .................. 9

Attaching the protective cover .......... 10

Mounting the parallel stop ............... 10

Setting up ..................................... 10

Checking the closure ...................... 11

Operation .................................. 11

Switching on and off ...................... 11

Performing a parallel cut ................. 11

Performing an angle cut .................. 12

Performing a mitre cut (jolly cut) ....... 12

Cleaning and maintenance ......... 12

Cleaning ....................................... 13

Storage ......................................13

Waste disposal and environ-

mental protection ....................... 13

Replacement parts/accessories ... 13

Guarantee .................................14

Repair Service ............................ 15

Service-Center ............................ 15

Importer .................................... 15

Translation of the original

EC declaration of conformity ......43

Exploded Drawing ..................... 49

Introduction

Congratulations on the purchase of your

new device. With it, you have chosen a

high quality product.

During production, this equipment has

been checked for quality and subjected to

a nal inspection. The functionality of your

equipment is therefore guaranteed.

The operating instructions constitute

part of this product. They contain

important information on safety, use

and disposal. Before using the product, familiarise yourself with all of

the operating and safety instructions.

Use the product only as described

and for the applications specied.

Keep this manual safely and in the

event that the product is passed on,

hand over all documents to the third

party.

Intended use

The tile cutting machine is designed for

small and medium-sized tiles (glazed,

ceramic or similar). Wood and metal must

not be cut with it. This machine is intended

to be used together with water.

The equipment is designed for use by

adults. Young people under the age of 16

are permitted to use the equipment only

under supervision. The manufacturer shall

not be liable for damages caused by use

other than for the intended purpose or by

incorrect operation.

4

GB

General description

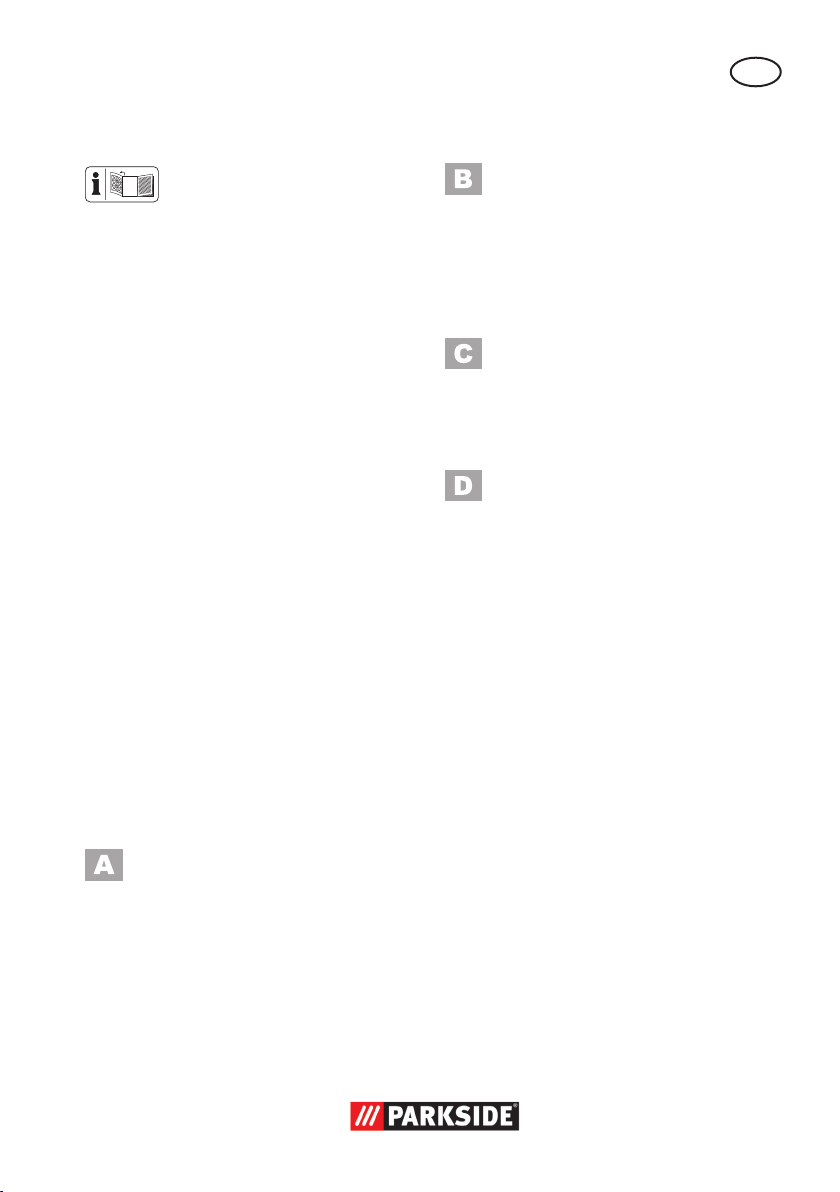

The illustrations can be found

on the front and rear fold-out

pages.

Scope of delivery

Unpack the equipment and check that it is

complete. Dispose of the packaging material correctly.

• Appliance

• Full-rim diamond cutting disc

• Protective cover

• Parallel stop

• Angle stop

• Wrench

• Mounting material

• Translation of the original instructions

for usel

Function description

The tile cutting machine is equipped with a

full-rim diamond cutting disc and a workta-

ble. It is suitable for cutting tiles. The use of

water is essential.

For the function of the operating parts,

please refer to the descriptions below.

Summary

1 Wrench of nut

2 Wrench of shaft

3 Protective cover

4 Work surface, foldable

5 On switch

6 Off switch

7 Carry handle

8 Measuring scale

9 Parallel stop

10 Mains cable

11 Angle stop

12 Power cord holder

13 Shaft

14 Mounting ange

15 Full-rim diamond cutting disc

16 Pressure disc

17 Shaft nut

18 Protective cover of the cutting

disc

19 Nut

20 Protective cover

21 Screw with star grip

22 Retaining bracket

23 Screw

24 Closure

25 Drain hole

Technical specications

Nominal input voltage ......230 V~, 50 Hz

Power consumption ..................... 500 W

Measurement idling speed n0... 5400 min

Safety class .......................................... I

Mechanical rating .......................... IP 44

Weight .......................... approx. 4.7 kg

Depth of cut 90° ..................max. 25 mm

Depth of cut 45° ..................max. 16 mm

Sound pressure level

(LpA) ....................... 94 dB(A); KpA=3 dB

Sound power level (LwA)

measured .............104 dB(A); KwA=3 dB

guaranteed .........................107 dB(A)

Cutting disc:

Idling speed n

................................... max.13200 min

Disc speed ....................... max. 80 m/s*

Outer diameter ................... Ø 115 mm

Bore hole .......................... Ø 22,2 mm

* The grinding disc must keep a rotational

speed of 80 m/s.

0

-1

-1

5

GB

Noise and vibration values have been

determined according to the standards and

regulations mentioned in the declaration of

conformity.

Technical and optical changes may be

undertaken in the course of further development without notice. All dimensions, references and information in this instruction

manual are therefore not guaranteed. Legal

claims made on the basis of the instruction

manual can therefore not be considered as

valid.

Safety Instructions

Symbols and icons

Symbols on the device:

Read the instruction manual

Warning!

Wear eye protection

Wear ear protection

Wear breathing protection

Wear cut-resistant gloves

Wear anti-slip safety shoes

Risk of injury from the rotating tool!

Keep hands away

Use only diamond cutting discs with

an enclosed rim

Do not dispose of electrical equip-

ment in household waste

Other symbols on the

cutting disc:

Never use faulty grinding discs

Symbols in the manual:

Warning symbols with in-

formation on damage and

injury prevention.

Instruction symbols (the instruction is

explained at the place of the exclamation mark) with information on

preventing damage.

Help symbols with information on

improving tool handling.

General safety instructions

Safe operation:

• Keep work area clear. Cluttered

areas and benches invite injuries.

• Consider work area environ-

ment.

- Do not expose tools to rain. Do not

use tools in damp or wet locations.

Water entering a power tool will increase the risk of electric shock.

- Keep work area well lit.

- Do not use tools in the presence of

ammable liquids or gases.

Power tools create sparks which may

ignite the dust or fumes.

• Guard against electric shock.

Avoid body contact with earthed or

grounded surfaces (e.g. pipes, radiators, ranges, refrigerators).

• Keep other persons away.

Do not let persons, especially children,

not involved in the work touch the tool

or the extension cord and keep them

away from the work area.

6

GB

• Store idle tools. When not in use,

tools should be stored in a dry lockedup place, out of reach of children.

• Do not force the tool. It will do

the job better and safer at the rate for

which it was intended.

• Use the right tool.

- Do not force small tools to do the job

of a heavy duty tool.

- Do not use tools for purposes not

intended; for example do not use circular saws to cut tree limbs or logs.

Use of the power tool for operations dif-

ferent from those intended could result in

a hazardous situation.

• Dress properly.

- Do not wear loose clothing or jewellery, they can be caught in moving

parts.

- Anti-slip footwear is recommended

when working outdoors.

- Wear protective hair covering to contain long hair.

• Use protective equipment.

- Use safety glasses.

- Use face or dust mask if working operations create dust.

• Connect dust extraction equip-

ment. If the tool is provided for the

connection of dust extraction and collecting equipment, ensure these are

connected and properly used.

• Do not abuse the cord. Never

yank the cord do disconnect it from the

socket. Keep the cord away from heat,

oil and sham edges.

• Secure work. Where possible use

clamps or a vice to hold the work. It is

safer than using your hand.

• Do not overreach. Keep proper

footing and balance at all times.

This enables better control of the power

tool in unexpected situations.

• Maintain tools with care.

Many accidents are caused by poorly

maintained power tools.

- Keep cutting tools sharp and clean

for better and safer performance.

- Follow instruction for lubricating and

changing accessories.

- Inspect tool cords periodically and if

damaged have them repaired by an

authorized service facility.

- Inspect extension cords periodically

and replace if damaged.

- Keep handles dry, clean and free

from oil and grease.

• Disconnect tools. When not in use,

before servicing and when changing

accessories disconnect tools from the

power supply.

Such preventive safety measures reduce

the risk of starting the power tool accidentaIly.

• Remove adjusting keys and

wrenches. Form the habit of checking to see that keys and adjusting

wrenches are removed from the tool

before turning it on. A wrench or a key

left attached to a rotating part of the

power tool may result in personal injury.

• Avoid unintentional starting.

Ensure switch is in “off” position when

plugging in.

• Use outdoor extension leads.

When the tool is used outdoors, use

only extension cords intended for outdoor use and so marked.

• Stay alert, watch what you are

doing and use common sense

when operating a power tool.

Do not use a power tool while you are

tired or under the inuence of drugs,

alcohol or medication. A moment of

inattention white operating power tools

may result in serious personal injury.

7

GB

• Check damaged parts.

This will ensure that the safety of the

power tool is maintained.

- Before further use of tool, it should be

carefully checked to determine that it

will operate properly and perform its

intended function.

- Check for alignment of moving parts,

binding of moving parts, breakage of

parts, mounting and any other conditions that may affect its operation.

- A guard or other part that is damaged should be properly repaired or

replaced by an authorized service

centre unless otherwise indicated in

this instruction manual.

- Have defective switches replaced by

an authorized service centre.

- Do not use the tool if the switch does

not turn it on and off.

There is a risk of injury.

• Warning.

The use of any accessory or attach-

ment other than one recommended in

this instruction manual may present a

risk of personal injury.

• Have your tool repaired by a

qualied person. This electric tool

complies with the relevant safety rules.

Repairs should only be carried out by

qualied persons using original spare

parts, otherwise this may result in considerable danger to the user.

Further Safety Instructions

• Connect the device only to a power

point with a residual current protective

device (RCD) with a measured residual

current of not more than 30 mA.

• Keep the mains cable and extension

cable away from the grinding disc.

In the event that it is damaged or sev-

ered, immediately disconnect the plug

from the socket.

Do not touch the cable before it has

been disconnected from the mains.

Risk of electric shock.

• The replacement of the plug or the connection line must always be executed

by the manufacturer of the electric tool

or his/her customer service in order to

avoid any hazards.

• Only switch the device on once it is

safely xed to the worktop.

• For your own safety only use accessories and attachments which were

stated in the operating instructions or

recommended or specied by the tool

manufacturer.

• Only use grinding tools recommended

by the manufacturer. Do not use any

saw blades. Ensure that the dimensions

match those of the device.

• Only use grinding discs where the

printed rotational speed is at least as

high as what has been specied on the

name plate of the device.

• Carry out a visual inspection of the

grinding disc before use. Do not use

any damaged or deformed grinding

discs. Replace any damaged or worn

grinding discs.

• Never operate the device without

spark protection or protective hoods.

Periodically readjust the spark protec-

tion in order to offset the wear and

tear of the grinding disc (distance max.

2 mm).

• Replace the grinding disc if the spark

protection and the workpiece support

can no longer be readjusted to a distance of max. 2 mm at the latest.

• Make sure that the sparks produced

by grinding do not present a danger,

e.g. reach people or ignite ammable

substances.

8

GB

• Always wear safety goggles, safety

gloves, respiratory protection and ear

protection when grinding, brushing

and separating.

• Never keep the ngers between the

grinding disc and spark protection

or in close proximity to the protective

hoods. There is a risk of crushing.

• The rotating parts of the device cannot

be covered due to functional reasons.

Therefore, proceed cautiously and hold

the workpiece rmly in order to avoid

slipping which could cause your hands

to come into contact with the grinding

disc.

• The workpiece gets hot during grinding. Do not touch the machined area,

allow it to cool down. There is a risk

of burning. Do not use coolants or the

like.

• If you are tired or have consumed alcohol or tablets, do not work with the

device. Always have a break on time.

• Switch the device off and remove the

mains plug

- to loosen a blocked insertion tool,

- if the connection line is damaged or

entangled,

- in case of unusual sounds.

• Do not use circular saw blades, chain

saw blades or diamond cutting discs

with a serrated edge.

Residual risks

Even if properly operating and handling

this electric tool, some residual risks will

remain. Due to its construction and build,

this electric tool may present the following

hazards:

a) Lung damage, if suitable respiratory

protection is not worn.

b) Hearing damage, if suitable ear protec-

tion is not worn.

c) Damages to health due to

- touching the area of the grinding tool

which was not covered;

- the ejection of pieces from workpiece

or damaged grinding discs.

d) Damage to your health caused by

swinging your hands and arms when

operating the appliance for longer periods of time or if the unit is not held or

maintained properly.

Warning! During operation, this

electric tool generates an electro-

magnetic eld which, under certain

circumstances, may impair the functionality of active or passive medical

implants. To reduce the risk of serious or lethal injuries, we recommend

that persons with medical implants

consult their doctor and the manufacturer of their medical implant before

operating the machine.

Assembly

Caution! Risk of injury!

- Ensure that you have sufcient

space in which to work, and that

you do not endanger other people.

- All covers and protective devices

must be assembled properly before commissioning.

- Disconnect the mains plug before

changing the setting on the device.

Mounting the cutting disc

1. Unfold the work surface ( 4).

2. Pull the folding work surface ( 4) out

of the holder and place the holder to

one side.

9

GB

3. Remove the protective cover of the

cutting disc (18). In order to do this,

pull the protective cover of the cutting

disc (18) towards the back and tilt it

to one side. You can remove the protective cover of the cutting disc (18)

by pulling it upwards out of the water

tank.

4. Release the shaft nut (17).

5. Remove the nut (17) and the pressure

disc (16) from the shaft (13). The

mounting ange (14) remains on the

shaft (13).

6. Place the full-rim diamond cutting disc

(15) on the shaft (13). Please note the

direction of rotation. This is marked on

the full-rim diamond cutting disc (15)

and on the protective cover (3).

7. Push the pressure disc (16) with the

straight side against the full-rim diamond cutting disc (15).

8. Turn the shaft nut (17) using wrenches

(1) and (2) to block the shaft (13). First

attach wrench (1) and then wrench

(2).

9. Attach the protective cover of the cutting disc (18) again. Insert the protective cover of the cutting disc (18) into

the oor guide of the water tank. Press

the protective cover of the cutting disc

(18) on the left and push the protective cover back as far as it will go.

10. Reinsert the folding work

surface ( 4).

A cutting disc whose maximum

speed is lower than the nominal speed of the machine must

not be used.

Attaching the protective cover

1. Remove the screw (23) from the device.

2. Place the angle bracket (22) in line

behind the full-rim diamond cutting

disc (15) through the mounting hole.

3. Use the screw (23) to attach the retaining bracket (22) to the device.

4. Align the angle bracket (22) with the

full-rim diamond cutting disc (15).

5. Push the protective cover (20) on to

the retaining bracket (22).

6. Screw the protective cover (20) on to

the retaining bracket (22). For this, use

the screw with the star grip (21) and

the nut (19).

The protective cover (3) can-

not be rigidly xed in place. It

simply lies on top of the work

surface.

Mounting the parallel stop

1. Insert the parallel stop (9) into the

guide mechanism of the device at one

end.

2. Pull the guide clamp of the parallel

stop (9) in order to be able to insert

the guide mechanism on the opposite

side.

3. Attach the two screws with a star grip

to both ends of the parallel stop (9) in

order to be able to clamp the parallel

stop into place.

4. Clamp the parallel stop (9) rmly in

place with the two screws with a star

grip.

Setting up

• The device must only be used on a at

and stable surface.

• The carrying handle is used exclusively

for transporting the device. The device

can be moved from place to place, but

must not be carried during operation.

10

GB

• The device is intended to be used with

water.

Checking the closure

1. Unfold the work surface (4).

2. Check that the closure (24) is rmly

xed in the drain hole (25).

Fill water into the tank of the device. The

lling level is marked on the protective co-

ver of the cutting disc.

Operation

Caution! Risk of injury!

- Always disconnect the plug from

the mains socket before working.

- Only use grinding discs and

accessories recommended by the

manufacturer. Using other attachment tools and other accessories

can represent a risk of injury for

you.

- Never operate the device without protective equipment.

Keep your hands away from

the grinding disc when the

device is in operation. Injury

hazard!

Never operate the device

without water.

that it is securely supported

on the work surface.

Switching on and off

Ensure that the mains voltage

matches the specications on the

rating plate.

Connect the equipment to the mains.

1. To switch on, press the “I” On switch

and the device starts up ( 5).

2. To switch off, press the “0” off switch

and the device switches off ( 6).

After switching on the device, wait until the

device has reached its max. speed. Only

then must you start with the grinding.

The disc will continue to

run after the equipment is

switched off. There is a risk

of injury.

Test run:

Before starting work and after each

change of grinding disc, carry out a test

run of at least 60 seconds with no load.

Switch off the equipment immediately if the

disc runs lumpy, substantial vibrations occur, or abnormal noises are generated.

Performing a parallel cut

The workpiece must not be

too small. Otherwise, your

ngers and hands will be

placed in extreme danger

due to the close proximity of

the cutting disc. The workpiece must not be too large

either. It must be ensured

1. Adjust the parallel stop (9) to the desired distance from the full-rim diamond

cutting disc (15).

2. The desired width can be read off on

the measuring scale (8).

3. Fix the parallel stop (9) rmly in place

with the two star grips.

4. Place the workpiece on the work sur-

11

GB

face and against the parallel stop (9).

5. Turn the device on.

6. Push the workpiece evenly and not too

fast across the work surface through

the full-rim diamond cutting disc (15).

7. Always ensure that is a sufcient distance between your ngers and hands

and the full-rim diamond cutting disc

(15).

Performing an angle cut

1. Push the angle stop (11) on to the parallel stop (9).

2. Adjust the desired working angle on

the angle stop (11).

3. The angle can be read off on the scale.

4. Fix the angle stop (11) in place with

the winged screw.

5. Ensure that the parallel stop (9) is

xed in place, as required.

6. Place the workpiece on the work surface and against the angle stop (11).

7. Turn the device on.

8. Push the workpiece evenly and not too

fast across the work surface through

the full-rim diamond cutting disc (15).

9. Always ensure that is a sufcient distance between your ngers and hands

and the full-rim diamond cutting disc

(15).

3. The work surface (4) can be xed in

place at 22.5° and 45°.

4. Place the workpiece on the folding

work surface.

5. Turn the device on.

6. Push the workpiece evenly and not too

fast across the folding work surface

through the full-rim diamond cutting

disc (15).

7. Always ensure that is a sufcient distance between your ngers and hands

and the full-rim diamond cutting disc

(15).

A jolly cut may only be car-

ried out near the edge of the

workpiece.

Cleaning and

maintenance

Disconnect the plug before adjust-

ment, maintenance or repair.

Have any work not described

in these instructions carried

out by a specialist workshop.

Use only original components.

Allow the equipment to cool

before carrying out any maintenance and cleaning work.

There is a risk of burns.

Note the reduced depth in the

case of a mitre cut.

Performing a mitre cut (jolly cut)

1. Place the folding work surface (4) in

position.

2. Fix the folding work surface (4) rmly

in place with the two set-up aids.

12

Before each use, check the equipment

for obvious defects such as loose, worn

or damaged components and check that

screws or other parts are sitting correctly.

In particular, check the grinding disc. Replace damaged parts.

GB

Cleaning

Do not use cleaning agents or sol-

vents. Chemical substances may

attack plastic parts of the equipment.

Never clean the equipment under

running water.

• Clean the equipment thoroughly after

each use.

• Clean the surface of the equipment

with a brush or cloth.

Storage

• Store the appliance in a dry place well

out of reach of children.

• Grinding discs must be stored dry and

upright and are not to be stacked.

Waste disposal and environmental protection

Be environmentally friendly. Return the

tool, accessories and packaging to a recy-

cling centre when you have nished with

them.

Machines are not to be place with

domestic waste.

Hand over the device at an utilization loca-

tion. The plastic and metal parts employed

can be separated out into pure materials

and recycling can be implemented. Ask

your Service Center about this. Defective

units returned to us will be disposed of for

free.

Replacement parts/accessories

Spare parts and accessories can be obtained at www.grizzly-service.eu

If you do not have internet access, please contact the Service Centre via telephone

(see “Service-Center” page 15). Please have the order number mentioned below ready.

SET1 Mounting ange, Pressure disc, Shaft nut 91104211

SET2 Angle stop 91104212

SET3 Work surface, foldable 91104213

SET4 Parallel stop 91104214

SET5 Protective cover 91104215

SET6 Closure 91104216

32 Full-rim diamond cutting disc 91104210

13

GB

Guarantee

Dear Customer, this equipment is provided

with a 3-year guarantee from the date of

purchase. In case of defects, you have statutory rights against the seller of the prod-

uct. These statutory rights are not restricted

by our guarantee presented below.

Terms of Guarantee

The term of the guarantee begins on the

date of purchase. Please retain the original

receipt. This document is required as proof

of purchase.

If a material or manufacturing defect occurs

within three years of the date of purchase

of this product, we will repair or replace –

at our choice – the product for you free of

charge. This guarantee requires the defective equipment and proof of purchase to be

presented within the three-year period with

a brief written description of what constitutes the defect and when it occurred.

If the defect is covered by our guarantee, you

will receive either the repaired product or a

new product. No new guarantee period begins on repair or replacement of the product.

Guarantee Period and Statutory

Claims for Defects

The guarantee period is not extended by

the guarantee service. This also applies for

replaced or repaired parts. Any damages

and defects already present at the time of

purchase must be reported immediately after unpacking. Repairs arising after expiry

of the guarantee period are chargeable.

Guarantee Cover

The equipment has been carefully produced

in accordance with strict quality guidelines

and conscientiously checked prior to delivery.

The guarantee applies for all material and

manufacturing defects. This guarantee

does not extend to cover product parts

that are subject to normal wear and may

therefore be considered as wearing parts

(e.g. grinding discs, carbon brushes, stopper, protective screen) or to cover damage

to breakable parts (e.g. switches, batteries,

or parts made of glass).

This guarantee shall be invalid if the product has been damaged, used incorrectly or

not maintained. Precise adherence to all of

the instructions specied in the operating

manual is required for proper use of the

product. Intended uses and actions against

which the operating manual advises or

warns must be categorically avoided.

The product is designed only for private and

not commercial use. The guarantee will be

invalidated in case of misuse or improper handling, use of force, or interventions not undertaken by our authorised service branch.

Processing in Case of Guarantee

To ensure quick handling of you issue,

please follow the following directions:

• Please have the receipt and identication number (IAN 110046) ready as

proof of purchase for all enquiries.

• Please nd the item number on the rating plate.

• Should functional errors or other defects occur, please initially contact the

service department specied below by

telephone or by e-mail. You will then

receive further information on the processing of your complaint.

• After consultation with our customer

service, a product recorded as defective

can be sent postage paid to the service

address communicated to you, with the

proof of purchase (receipt) and speci-

cation of what constitutes the defect

and when it occurred. In order to avoid

acceptance problems and additional

costs, please be sure to use only the ad-

14

GB

dress communicated to you. Ensure that

the consignment is not sent carriage

forward or by bulky goods, express or

other special freight. Please send the

equipment inc. all accessories supplied

at the time of purchase and ensure adequate, safe transport packaging.

Repair Service

For a charge, repairs not covered by the

guarantee can be carried out by our ser-

vice branch, which will be happy to issue

a cost estimate for you. We can handle

only equipment that has been sent with adequate packaging and postage.

Attention: Please send your equipment to

our service branch in clean condition and

with an indication of the defect.

Equipment sent carriage forward or by

bulky goods, express or other special

freight will not be accepted.

We will dispose of your defective devices

free of charge when you send them to us.

Service-Center

Service Great Britain

Tel.: 0871 5000 720

(£ 0.10/Min.)

E-Mail: grizzly@lidl.co.uk

IAN 110046

Importer

Please note that the following address is

not a service address. Please initially con-

tact the service centre specied above.

Grizzly Tools GmbH & Co. KG

Stockstädter Straße 20

63762 Großostheim

Germany

www.grizzly-service.eu

15

BG

Съдържание

Увод ..................................................... 16

Предназначение ................................ 16

Общо описание ................................. 17

Обем на доставката ....................... 17

Описание на функцията................. 17

Преглед ........................................... 17

Технически данни ............................. 17

Инструкции за безопасност ............ 18

Символи .......................................... 18

Общи инструкции за безопасност ...18

Допълнителни инструкции за безо-

пасност ............................................ 21

Сkpити oлacнocти ........................... 22

Монтаж ................................................ 22

Монтаж на режещия диск .............. 23

Монтаж на предпазния капак ....... 23

Монтаж на успоредния

ограничител ................................... 23

Разполагане .................................... 24

Проверка на запушалката ............. 24

Обслужване ....................................... 24

Включване и изключване ............... 24

Извършване на успореден срез .... 25

Извършване на ъглов срез ............ 25

Извършване на кос срез

(тип „Jolly“) ...................................... 25

Техническа поддръжка u

Почистване ........................................ 26

Почистване ..................................... 26

Съхранение ........................................ 26

Изхвърляне/защита на околната

среда ................................................... 26

Резервни части/Принадлежности .. 27

Гаранция ............................................. 28

Ремонтен сервиз ............................... 29

Service-Center .................................... 29

Вносител ............................................ 29

Превод на оригиналната CE-

декларация за съответствие .......... 45

Технически чертеж ............................ 49

Увод

Сърдечно Ви честитим закупуването на

Вашия нов уред. По такъв начин Вие сте

избрали един висококачествен продукт.

По време на производството уредът е

проверяван за качество и е подложен на

крайна проверка. Така функционалната

пригодност на Вашия уред е гарантирана.

Ръководството за експлоатация

е неразделна част от продукта.

То съдържа важни указания за

безопасността, употребата и

изхвърлянето. Преди употребата на продукта се запознайте с

всички указания за обслужване

и инструкции за безопасност.

Използвайте продукта само съгласно описанието и за посочените области на употреба. Пазете

упътването добре и когато предавате продукта на трети лица, предавайте заедно с него и всички

документи.

Предназначение

Машината за рязане на плочки е предназначена за малки и средно големи

плочки (кахли, керамика или подобни).

Не е позволено рязане на дърво и метал. Машината работи с вода.

Уредът е предназначен за употреба от

домашни майстори. Той не е създаден

за промишлена непрекъсната употреба.

Уредът е предназначен за употреба от

възрастни. Младежи над 16-годишна

възраст могат да използват уреда само

под контрол. Операторът или ползвателят носи отговорност за злополуки или

щети на други хора или тяхната собственост.

16

Loading...

Loading...