Page 1

PDS 200 A

BENCH GRINDER

Operation and Safety Notes

6

Page 2

Before reading, unfold both pages containing illustrations and familiarise yourself with all functions of the

device.

GB / IE / CY Operation and Safety Notes Page 5

Page 3

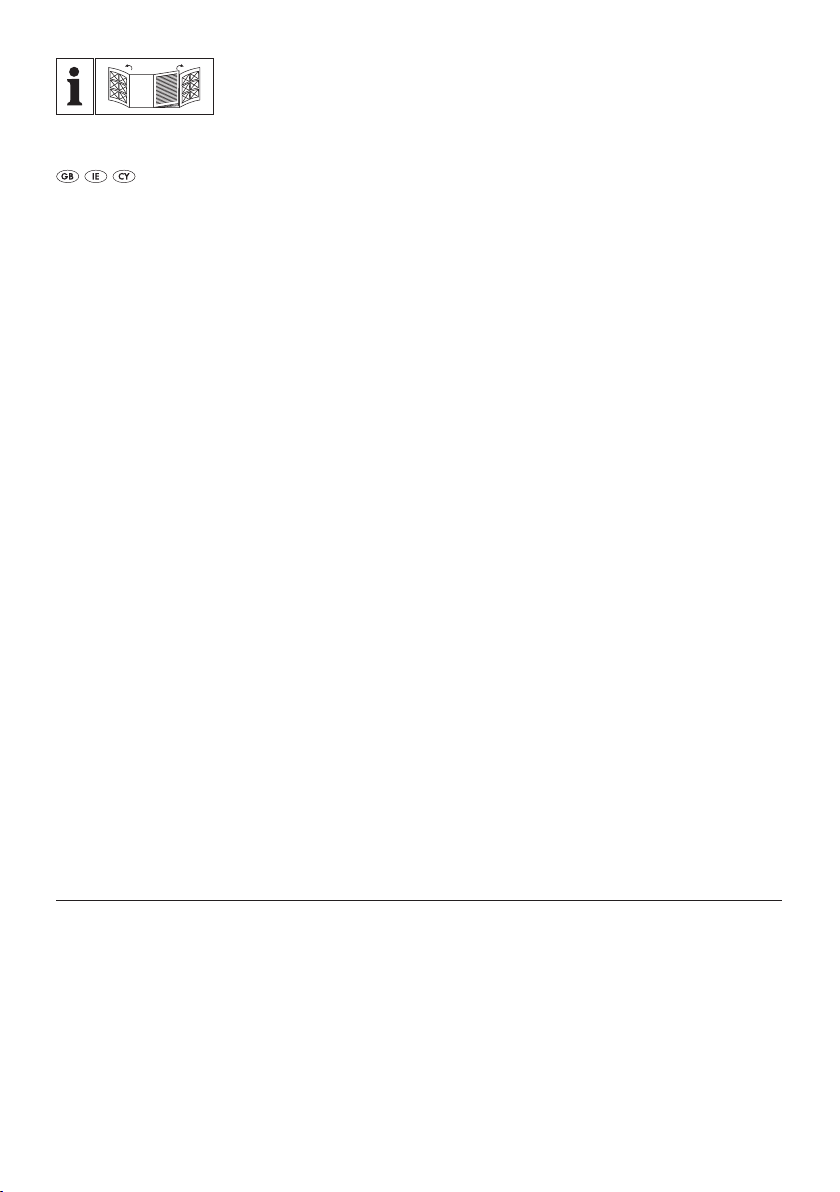

14

A B

13

1

2

3

4

5

6

7

8

9

11 10

12

C D

E F

Page 4

G H

2

7

14

2

I K

2 2

L

N

5

6 5 6

7

33

M

O

7

Page 5

Table of contents

Introduction

Proper use ......................................................................................................................Page 6

Features and equipment ...............................................................................................Page 6

Included items ...............................................................................................................Page 6

Technical information ....................................................................................................Page 7

General safety advice

Working safely ..............................................................................................................Page 7

Safety advice relating specifically to bench grinders .................................................Page 8

Before use

Assembly........................................................................................................................Page 9

Positioning the workpiece / tool rests and eye guard mounts ....................................Page 10

Preparing for first use

Switching on and off .....................................................................................................Page 10

Grinding a workpiece ...................................................................................................Page 10

Replacing a grinding wheel .........................................................................................Page 10

Original accessories / Attachments ..............................................................................Page 11

Maintenance and cleaning .........................................................................Page 11

Service .........................................................................................................................Page 11

Warranty ...................................................................................................................Page 11

Disposal ......................................................................................................................Page 12

Declaration of Conformity / Manufacturer..................................Page 12

5 GB/IE/CY

Page 6

Introduction

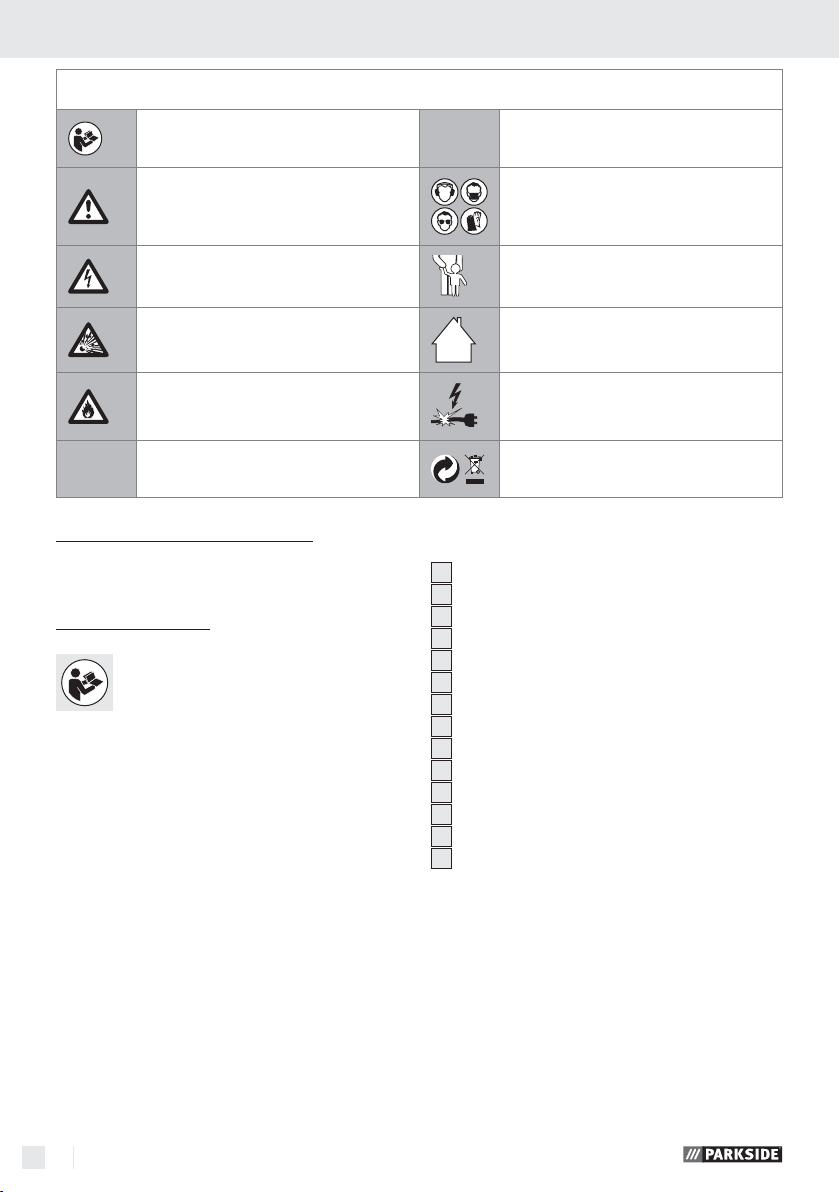

The following pictograms are used in these operating instructions / on the device:

Read instruction manual!

Observe caution and safety notes!

Caution – electric shock!

Danger to life!

Risk of explosion! For indoor use only!

Risk of fire!

V

Volt (AC)

~

Bench grinder PDS 200 A

For grinding and sharpening metal tools

Introduction

Please make sure you familiarise your-

self fully with the way the device works

before you use it for the first time and

that you understand how to handle electrical power

tools correctly. To help you do this please read the

accompanying operating instructions. Keep these

instructions in a safe place. If you pass the device

on to anyone else, please ensure that you also pass

on all the documentation.

W

Features and equipment

1

2

3

4

5

6

7

8

9

10

11

12

13

14

Watts (effective power)

Wear hearing protection, dust

protection mask, protective glasses

and protective gloves.

Keep children away from electrical

power tools!

Risk of loss of life by electric shock from

damaged mains lead or mains plug!

Dispose packaging and appliance in

an environmentally-friendly way!

Magnifying glass

Eye guard mount

Eye guard

Grinding wheel

Workpiece / tool rest

Adjuster screw for workpiece / tool rest

Wheel guard cover

Mounting holes

ON / OFF switch

Machine-side flange

Left-hand thread

Outside flange

Nut

Fastening screw

Proper use

The double grinding machine is intended for grinding and sharpening metal tools such as drills, chisels

etc. and metal items. The device is not intended for

commercial use. Any other use or modification to

the device shall be considered as improper use

and could give rise to considerable dangers.

The manufacturer will not accept liability for loss or

damage arising from improper use.

6 GB/IE/CY

Included items

Check that all the items and accessories

are present immediately after unpacking

the device:

1 Bench grinder PDS 200 A with

- 2 x eye guard mounts / eye guards

- 2 x workpiece / tool rests / adjuster screws

1 Operating instructions

Page 7

Introduction / General safety advice

Technical information

Rated voltage: 230 V ~ 50 Hz

Nom. power input: 200 W

No load speed: n

2.950 min

0

-1

Grinding wheel diameter: 150 mm

Grinding wheel width: 20 mm

Grinding wheel bore: 20 mm

Circumferential speed max.: 23.2 m / s

Weight including

removable parts: 7.5 kg

Noise data:

Refers to A-weighted sound level.

Sound pressure level: 75.30 dB (A)

Sound level: 85.00 dB (A)

Values determined in accordance with EN 61029.

General safety advice

CAUTION! In order to protect yourself from

the danger of electric shock, injury or fire when

using electrical power tools, please observe

the following basic safety precautions. Read all

these requirements before you use the electrical

power tool, and keep the safety advice in a

safe place.

Working safely

1. Keep your working area clean and

tidy.

A disorderly working area can lead to accidents.

2. Be aware of the effects of the environment.

Do not leave electrical power tools out in the

rain.

Do not use electrical power tools in moist or

wet surroundings.

Ensure that your working area is well lit.

Do not use electrical power tools in

areas where there is risk of fire or

explosion.

3.

Protect yourself from electric

shock.

Avoid touching earthed objects such as pipes,

heating radiators, ovens or refrigerators with

parts of your body.

4. Keep other people at a safe distance.

Do not allow other people, in partic-

ular children, to touch the electrical

power tool or the mains lead.

Keep them away from your working area.

5. Store currently unused electrical

power tools in a safe place.

When not being used electrical power tools

should be stored in dry conditions in a high or

enclosed place, out of reach of children.

6. Do not overload your electrical pow-

er tool.

By keeping within the specified working range

of the tool you will work more safely and

achieve a better result.

7. Use the right electrical power tool for

the task.

Do not use low-output devices for heavy tasks.

Do not use an electrical power tool for purposes

for which it was not intended. For example, do

not use a hand operated circular saw for trimming tree branches or cutting logs.

8. Wear suitable clothing.

Do not wear loose-fitting clothing or jewellery.

They could become caught on moving parts.

We recommend that you wear anti-slip foot-

wear when working outdoors.

If you have long hair, wear a hair net.

9.

Use personal protective

equipment.

Wear protective glasses.

Wear a dust mask if your work generates

dust.

10. Attaching the vacuum dust extraction

device.

Where there are connection points provided

for vacuum dust extraction please ensure that

the connections are made and used properly.

11.

Do not use the mains lead for

purposes for which it was

not intended.

7 GB/IE/CY

Page 8

General safety advice

Do not use the mains lead to pull the plug out

of the mains socket. Protect the mains lead

from heat, oil and sharp edges.

12. Securely support the workpiece.

Use clamps or a vice to grip the workpiece

firmly. This is much safer than holding it with

your hand.

13. Avoid placing your body in an

unnatural position.

Keep proper footing and balance at all times.

14. Look after your tools carefully.

Keep cutting tools sharp and clean. This way

you will work more safely and achieve better

results.

Follow the advice on tool lubrication and con-

sumables replacement.

Check the condition of the mains lead on your

electrical power tool regularly and have any

damage repaired by a competent specialist.

Check the condition of extension leads regu-

larly and replace them if they are damaged.

Keep handles and hand grips clean, dry and

free of oil and grease.

15. Pull the mains plug out of the mains

socket.

Do this if the electrical power tool is not being

used, before carrying out maintenance tasks

on the electrical power tool and whenever you

are changing inserted tools, e.g. saw blades,

drills or router bits.

16. Make sure that no spanners, keys

etc. are left attached.

Check before switching on that all spanners,

keys and setting tools have been removed.

17. Avoid unintentionally starting up the

device.

Check that the switch is set to OFF on the de-

vice when the mains plug is inserted into the

mains socket.

18. Using an extension lead for working

outdoors.

When working outside, always use an approved

and appropriately labelled extension lead.

19. Remain alert.

Watch what you are doing. Proceed with cau-

tion. Do not use electrical power tools if you

cannot concentrate.

8 GB/IE/CY

20. Check the electrical power tool for

damage.

Before the electrical power tool is used, care-

fully check the safety equipment and any

slightly damaged parts to see that they are still

working properly.

Check that all moving parts on the tool are

working properly, can move freely and are not

damaged. All parts must be correctly attached

and fulfil all the requirements necessary to allow

the electrical power tool to operate properly.

Damaged safety equipment and components

must be properly repaired or replaced at a

competent electrical equipment repair centre

unless otherwise indicated in the operating instructions.

Damaged switches must be replaced at a

Customer Service Centre.

Never use an electrical power tool that cannot

be switched on and off properly.

21. CAUTION!

The use of inserted tools and accessories other

than those recommended by the manufacturer

could lead to you being injured.

22. Have your electrical power tool

repaired at an electrical equipment

repair specialist.

This electrical power tool complies with the

relevant safety regulations. Repairs may only

be carried out by a specialist electrical repair

centre using original spare parts, otherwise

injury could occur to the user.

Safety advice relating spe-

cifically to bench grinders

Do not touch the mains lead if it becomes damaged

or cut through while you are using the device.

Pull the plug out of the mains socket immediately

and have the device repaired by a suitably

qualified person or at your service centre.

Do not operate the device if it is damp and do

not use it in a damp environment.

If you use the device outdoors, always connect

it through a residual current device (RCD) with

a maximum trip current of 30 mA.

Page 9

General safety advice / Before use

If using an extension lead, always use one that

is approved for outdoor use.

If a dangerous situation arises, pull the mains

plug immediately out of the mains socket.

Always work with the mains lead leading

away from the rear of the device.

DANGER OF FIRE FROM FLY-

ING SPARKS! Grinding metal cre-

ates flying sparks. For this reason,

always make sure that nobody is placed in any

danger and that there are no inflammable materials near the working area.

WARNING!

with harmful / noxious dusts represents a risk to

the health of the person operating the device

and to anyone near the work area.

NOXIOUS FUMES! Working

Wear protective glasses, hearing

protection, dust protection mask and

protective gloves.

DANGER OF BURNS! The workpiece gets

hot during grinding. Never touch the part you

are grinding. Allow the workpiece to cool sufficiently first. When grinding for longer periods,

stop grinding from time to time and allow the

workpiece to cool before continuing. Do not

operate the device for continuous periods exceeding 30 minutes.

The double grinding machine is intended for

dry grinding of the surfaces of metal objects.

The device may only be used for dry grinding.

Do not grind materials containing asbestos.

Asbestos is a known carcinogen.

Do not use damaged grinding wheels

4

.

Only use grinding wheels with details that cor-

respond with those given on the device rating

plate. The circumferential speed should be

equal to or greater than the value given on the

device rating plate.

2

Adjust the eye guard mounts

and the eye guards

on the grinding wheels can be evened out.

Keep the gap as small as possible.

3

(spark deflectors)

periodically so that wear

Avoid contact with the moving grinding wheel.

Never leave the device working unattended.

Never use the device for a purpose for which it

was not intended.

Before you insert the mains plug into the sock-

et, always check that the device is switched off.

Always switch the device on before bringing

the workpiece into contact with the grinding

wheel. After grinding, lift off the workpiece

before switching the device off.

Hold the workpiece firmly with both hands at

all times when working.

Always keep proper footing and balance.

After you have finished grinding metal, allow

the grinding wheel(s) to come to a standstill.

When taking a break from your work, before

carrying out any tasks on the device itself and

when you are not using the device, always pull

the mains plug out of the mains socket.

Handle the device carefully and treat it with re-

spect. Always keep the device clean, dry and

free of oil or grease.

Remain alert at all times! Always watch what

you are doing and proceed with caution. Do

not use the device if you cannot concentrate or

you are feeling unwell.

Store grinding wheels in such a way that they

are not subject to mechanical loads or damaging environmental influences.

Before use

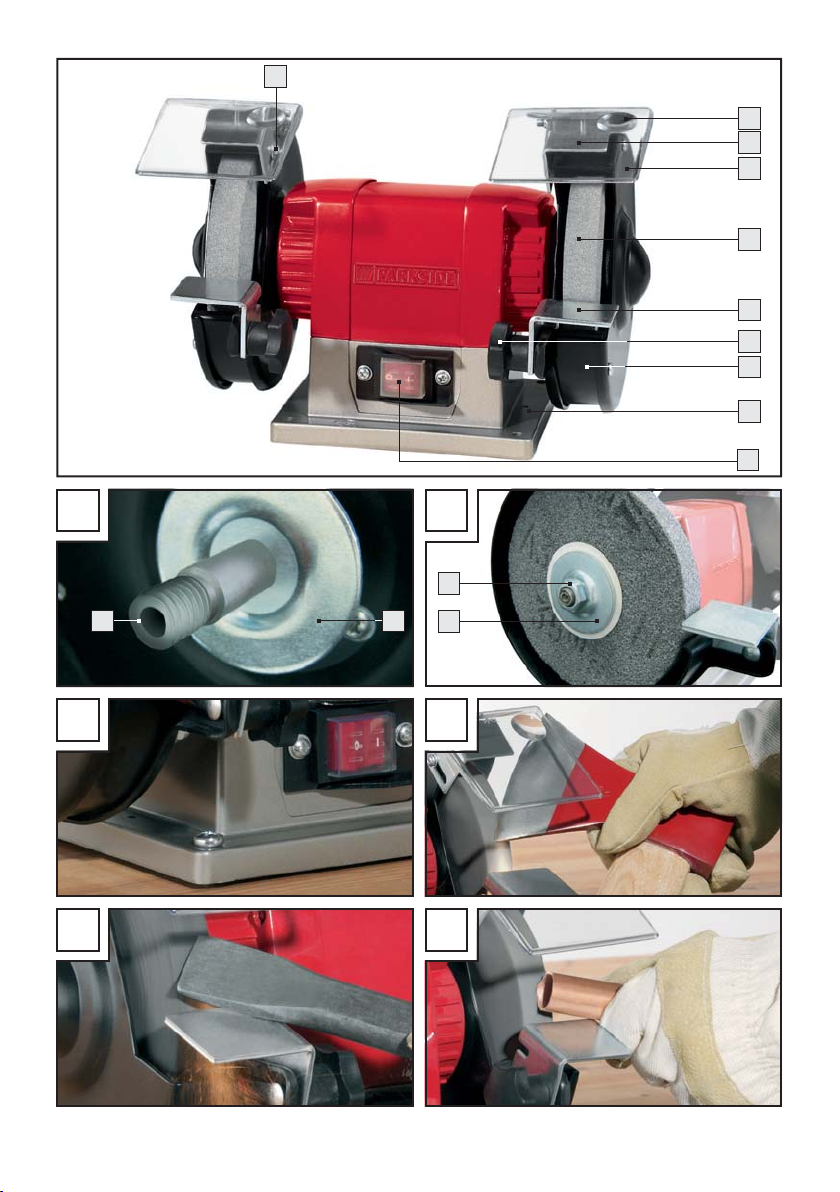

Assembly

Before using the device for the first time make

sure that you have fitted all its parts.

1) Attach the two eye guard mounts

side of the wheel guard covers

on the left and right sides. Use the illustrated

fixings in the arrangement shown (see Figs. G, H).

2) Attach the eye guards

2

mounts

sides. Use the illustrated fixings in the arrangement shown (see Figs. I, K).

Note: The illustrations show the left side.

3) Attach the two workpiece / tool rests

inside of the wheel guard covers

on the left and right sides. Use the illustrated

fixings in the arrangement shown (see Figs. L, M).

Note: The illustrations show the left side.

, one each on the left and right

3

to the eye guard

2

to the in-

7

, one each

5

7

, one each

to the

Mount the double grinding machine on a firm,

level surface, if at all possible on a fixed support, e.g. working surface, workbench. Use the

9 GB/IE/CY

Page 10

Before use / Preparing for first use

four mounting holes 8 and suitable fixings

(not supplied). Refer to Figure C.

Positioning the workpiece / tool

rests and eye guard mounts

To ensure safe working, the workpiece / tool rests 5,

the eye guards

must be correctly positioned.

Check and correct the settings at frequent intervals

to ensure even wear on the grinding wheels

Adjusting the workpiece / tool rests:

1) To adjust the setting, first loosen the adjuster

screw

2) Bring the workpiece / tool rest

the grinding wheel

the grinding wheel

tool rest

3) Retighten the adjuster screw

using your hand that the grinding wheel

movement is true and free.

Adjusting the eye guard mounts:

1) To adjust the setting, first loosen the fastening

screw

2) Bring the eye guard mount

grinding wheel

grinding wheel

must be no more than 2 mm.

3) Retighten the fastening screw

using your hand that the grinding wheel

movement is true and free. A worn out grinding

wheel

when the specified gap cannot be achieved even

after readjusting the positions of the workpiece /

tool rest

Preparing for first use

Switching on and off

3

and the eye guard mounts 2

6

.

5

close up to

4

, the distance between

4

and the workpiece /

5

must be no more than 2 mm.

14

.

4

, the distance between the

4

and the eye guard mount 2

4

needs to be replaced. This is necessary

5

and / or the eye guard mount 2.

6

and check

2

close up to the

14

and check

4

4

4

Switching off:

Press the ON / OFF switch

9

into the “0“

position to switch the device off.

Grinding a workpiece

NOTE: Use the fine grinding wheel for precise

grinding tasks (grade “A80M”).

NOTE: Use the coarse grinding wheel for rough

grinding tasks (grade “A36M”).

.

Switch on the machine as described above.

To grind metal tools or metal items, place the

workpiece on the workpiece / tool rest

slowly bring it up to the grinding wheel

Press the workpiece carefully against the grind-

ing wheel

the device. When grinding always use the

circumferential end face (not the sides) of the

grinding wheel only (See Figures D, E, F).

Replacing a grinding wheel

WARNING!

carrying out any tasks on the device itself and

when you are not using the device, always pull the

mains plug out of the mains socket.

4

. Pressing too hard can overload

RISK OF INJURY! Before

Do not use damaged grinding wheels.

Only use grinding wheels with details that cor-

respond with those given on the device rating

plate. The circumferential speed should be

equal to or greater than the value given on the

device rating plate.

Only grinding wheels with markings indicating

the manufacturer, the type of adhesive, dimensions and permitted circumferential speed are

to be used. If you install new grinding wheels

carry out a ringing test before use. Grinding

wheels in good condition give a clear ringing

noise when struck lightly with a plastic hammer.

5

and

4

.

Switching on:

Press the ON / OFF switch

9

into the “1“

position to switch the device on and run it

at a constant speed.

10 GB/IE/CY

1) Take off the outer part of the wheel guard cov-

7

er

by unscrewing the 3 threaded fixings

(see Figs. N, O).

Page 11

Preparing for first use / Maintenance and cleaning / Service / Warranty

2) Release the nut 13 and then remove the outside flange

3) Now replace the grinding wheel and reassemble all the components in the reverse order.

Take note that the left-hand side of the double

grinding machine has a left-hand thread

the right-hand side has a right-hand thread. This

ensures that the nuts

off in the direction of rotation of the spindle.

12

.

11

and

13

can only be screwed

Use only the supplied flanges to mount the

grinding wheels.

Note: The grinding wheels are fitted with

a ½“ adapter so that they can be used

with grinding wheels purchased later

with either a ½“, or a 20 mm bore.

Grinding wheels are available in various

grit grades and hardnesses. The central fix-

ing holes in grinding wheels must not be redrilled.

Original accessories /

Attachments

Use only the accessories and attachments de-

tailed in the operating instructions. The use of

inserted tools or accessories other than those

recommended in the operating instructions

could lead to you suffering an injury.

Maintenance and cleaning

Service

WARNING!

repaired at the service centre or by

qualified specialist personnel using

original manufacturer parts only. This

will ensure that your device remains safe to use.

WARNING!

to be replaced, always have the

replacement carried out by the manufacturer or its service centre. This will

ensure that your device remains safe to use.

Warranty

This appliance is guaranteed for 3 years

from the date of purchase. It has been carefully produced and meti-culously checked

before delivery. Please keep your receipt

as proof of purchase. Contact your service

centre by telephone in case of questions

pertaining to the warranty. Your goods

can

be transmitted free of cost only in this

manner. This warranty applies only to the

initial

purchaser and is non-transferable.

The warranty covers only material or manufacturing faults, not normal wear or damage to fragile

parts such as switches or rechargeable batteries.

The appliance is intended solely for private, not

commercial, use.

Have your device

If the plug or lead needs

WARNING!

carrying out any tasks on the device itself and when

you are not using the device, always pull the mains

plug out of the mains socket.

The device is largely maintenance-free.

RISK OF INJURY! Before

Clean the device frequently. For best results,

clean the double grinding machine immediately after you have finished using it.

Do not allow any liquids to enter the device.

Use a dry cloth to clean the device.

Do not under any circumstances use petrol or

strong solvents.

Store the device in a dry room.

If this product has been subjected to improper or

inappropriate handling, abuse, or interventions not

carried out by one of our authorised sales and

service outlets, the warranty will be considered void.

This warranty does not affect your statutory rights.

GB

DES UK LTD

Tel.: 0871 5000 700 (£ 0,10 / minute)

e-mail: support.uk@kompernass.com

11 GB/IE/CY

Page 12

Warranty / Disposal / Declaration of Conformity / Manufacturer

IE

Kompernaß Service Ireland

Tel.: 1850 930 412 (0,082 €/Min.)

* Standard call rates apply.

Mobile operators may vary.

e-mail: support.ie@kompernass.com

Disposal

The packaging is wholly composed of

environmentally-friendly materials that

can be disposed of at a local recycling

centre.

Do not dispose of electrical

power tools with the household

rubbish!

In accordance with European Directive 2002 / 96 / E

(covering waste electrical and electronic equipment)

and its transposition into national legislation, worn

out electrical power tools must be collected separately

and taken for environmentally compatible recycling.

Contact your local refuse disposal authority for

more details of how to dispose of your worn out

electrical devices.

Declaration of Conformity /

Manufacturer

We, Kompernaß GmbH, Burgstr. 21,

D-44867 Bochum, Germany, declare that this

product complies with the following EU directives:

Machinery Directive

(98 / 37 / EC)

EU Low Voltage Directive

(2006 / 95 / EC)

Electromagnetic Compatibility

(2004 / 108 / EC)

Type / Device description:

Parkside Bench grinder PDS 200 A

Bochum, 31.10.2009

C

Hans Kompernaß

- Managing Director -

12 GB/IE/CY

We reserve the right to make technical modifications in the course of further development.

Page 13

IAN 37837

KOMPERNASS GMBH

Burgstraße 21

D-44867 Bochum

© by ORFGEN Marketing

Last Information Update: 10 / 2009

Ident.-No.: PDS 200 A102009-6

6

Loading...

Loading...