Panasonic EYFLA, EYFMA, EY9810FLA49 Operation Manual

Operating Instructions

Instructions d’utilisation

Manual de instrucciones

Cordless Mechanical Pulse Driver / Cordless Mechanical Pulse Wrench

Visseuse à impulsions mécaniques sans fil / Clé de serrage à impulsions mécaniques sans fil

Atornillador de impulso mecánico inalámbrico / Llave de impulso mecánico inalámbrica

Model No : EYFLA4A / EYFLA4AR

EYFLA5A / EYFLA5AR

EYFLA5P / EYFLA5PR

EYFLA5Q / EYFLA5QR

EYFLA6J / EYFLA6JR

EYFLA6P / EYFLA6PR

EYFLA7A / EYFLA7AR

EYFLA8A / EYFLA8AR

EYFLA8C / EYFLA8CR

EYFLA8P / EYFLA8PR

EYFLA9C / EYFLA9CR

EYFLA9P / EYFLA9PR

EYFMA1J / EYFMA1JR

EYFMA1P / EYFMA1PR

EYFMA2C / EYFMA2CR

EYFMA2P / EYFMA2PR

EYFLA4A EYFLA9C

IMPORTANT

This manual contains safety information. Read manual completely before first using this product and save this

manual for future use.

IMPORTANT

Ce mode d’emploi contient des informations sur la sécurité. Lisez-le en entier avant d’utiliser le produit et

conservez-le pour référence.

IMPORTANTE

Este manual contiene información de seguridad. Lea completamente este manual antes de utilizar por primera

vez este producto, y guárdelo para poder consultarlo en el futuro.

Index / Index / Indice

CD

English: Page 10

Français: Page 30

Español: Página 53

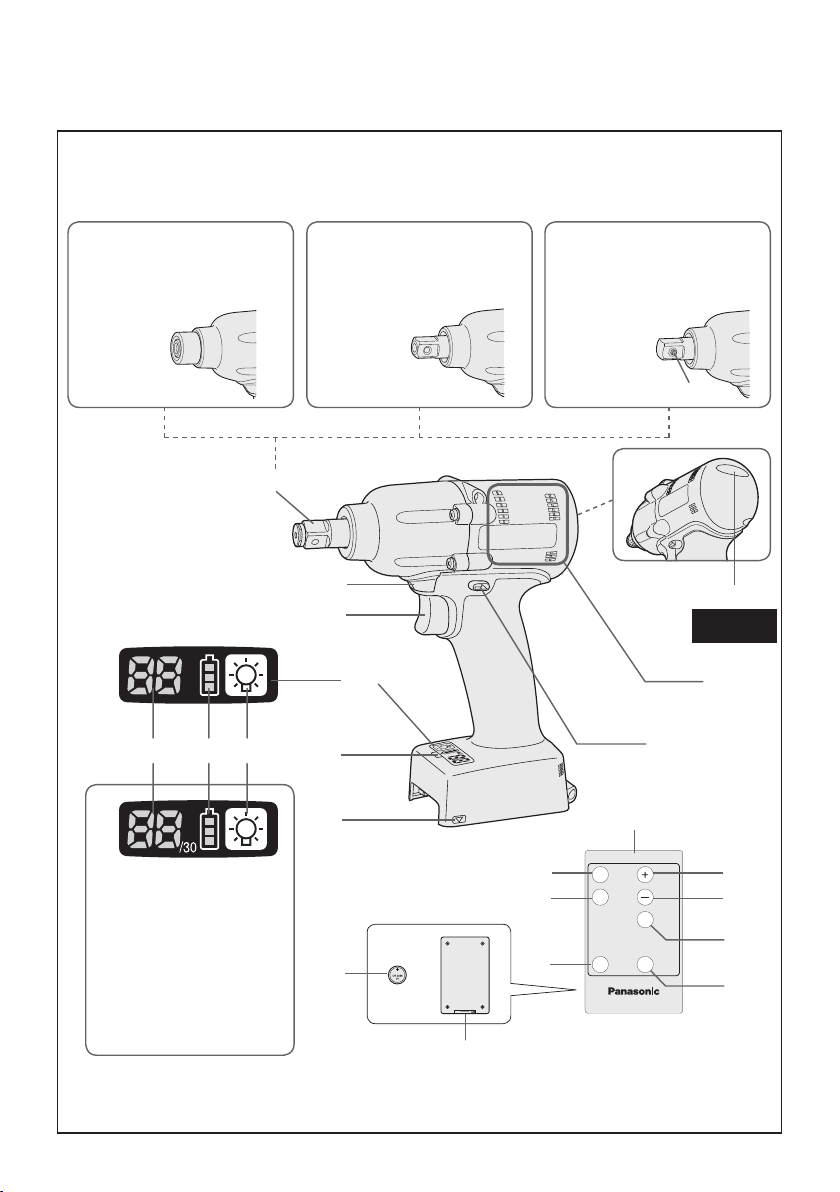

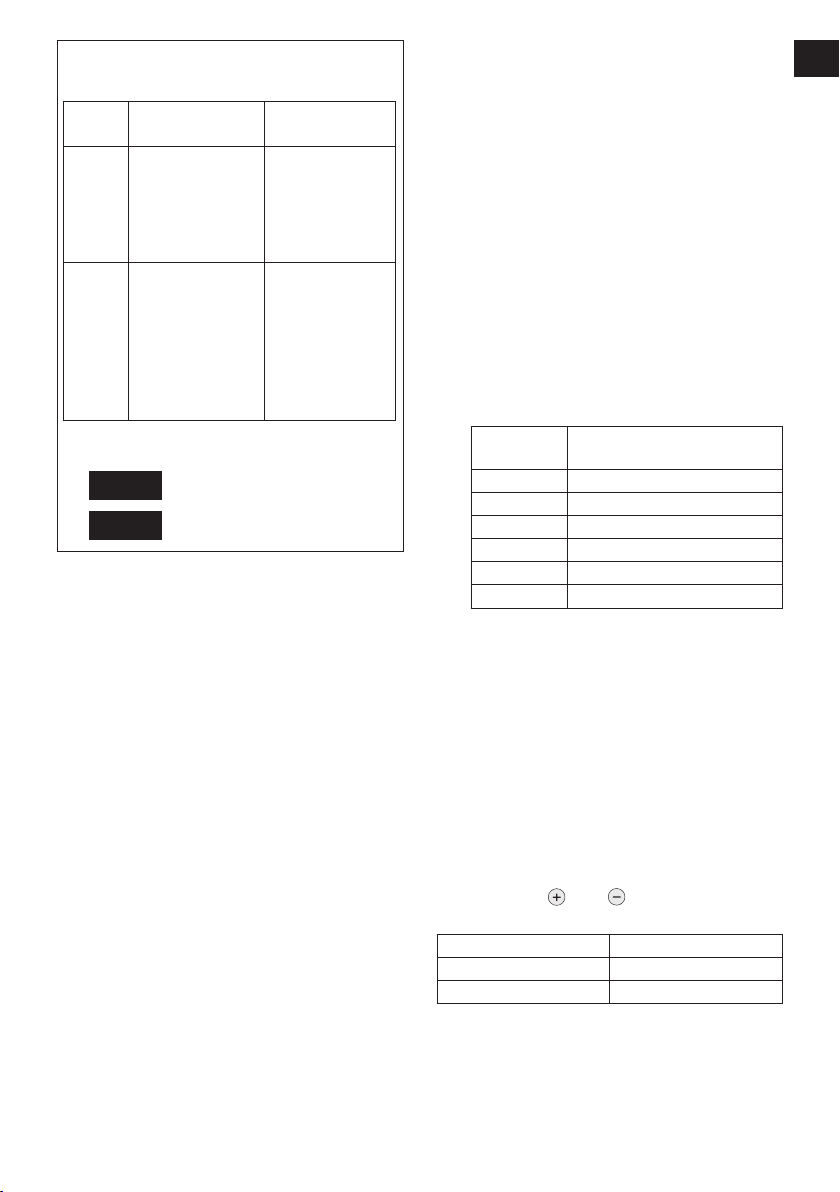

FUNCTIONAL DESCRIPTION

DESCRIPTION DES FONCTIONS

DESCRIPCIÓN FUNCIONAL

EYFLA4A / EYFLA4AR

EYFLA5A / EYFLA5AR

EYFLA7A / EYFLA7AR

EYFLA8A / EYFLA8AR

EYFLA5Q / EYFLA5QR

EYFLA6J / EYFLA6JR

EYFMA1J / EYFMA1JR

EYFLA5P / EYFLA5PR

EYFLA6P / EYFLA6PR

EYFLA9P / EYFLA9PR

EYFMA1P / EYFMA1PR

EYFMA2P / EYFMA2PR

(A)-1

(A)-2 (A)-3

(A)

EYFLA8C / EYFLA8CR

EYFLA9C / EYFLA9CR

EYFMA2C / EYFMA2CR

(I)

(H)

(G)

(J)(K)(L)

(F)

(E)

Other than

EYFLA7 / EYFLA8

EYFLA9 / EYFMA2

Autre que

EYFLA7 / EYFLA8

EYFLA9 / EYFMA2

Diferente de

EYFLA7 / EYFLA8

EYFLA9 / EYFMA2

Remote control and battery are not included.

La télécommande et la batterie ne sont pas incluses.

El control remoto y la batería no están incluídos.

(V)

(U)

(T)

(S)

(R)

(D)

(M)

A

B

EYFA31

EYFA31

(W)

(B)

[Fig.17]

(C)

(N)

(O)

(P)

(Q)

-

2 -

Square drive (retainer ring and pin)

Entraînement carré (anneau de retenue et goupille)

(A)

Excitador cuadrado (anillo retenedor y pasador)

6.35 mm (1/4”) hex quick connect chuck

Mandrin de connexion rapide hexagonal de 6,35 mm (1/4”)

(A-1)

Mandril de conexión rápida hexagonal de 6,35 mm (1/4”)

Square drive (pin type)

Entraînement carré (type à goujon)

(A-2)

Excitador cuadrado (tipo pasador)

Square drive (pin-detent type)

Entraînement carré (type à goupille d’arrêt)

(A-3)

Excitador cuadrado (tipo pasador retenedor)

Tightening conrmation lamp

Témoin de conrmation de serrage

(B)

Lámpara de conrmación de apriete

Vent holes

(C)

Trous d'aération

Agujeros de ventilación

Forward/Reverse lever

Levier d’inversion marche avant/marche arrière

(D)

Palanca de avance/marcha atrás

Alignment marks

(E)

Marques d’alignement

Marcas de alineación

Remote control receiver

Récepteur de la télécommande

(F)

Receptor de control remoto

Control panel

Panneau de commande

(G)

Panel de control

Variable speed control trigger

Gâchette de commande de vitesse

(H)

Disparador del control de velocidad variable

LED light

Lumière DEL

(I)

Luz indicadora

LED light on/off button

Bouton Marche/Arrêt de la lumière DEL

(J)

Botón ON/OFF de luz LED

Battery indication lamp

Témoin indicateur de la batterie

(K)

Lámpara de indicadora de la batería

Display

Afchage

(L)

Visor

Remote control

(M)

Télécommande

Control remoto

+ button

(N)

Bouton +

Botón +

− button

(O)

Bouton −

Botón −

OK button

(P)

Bouton OK

Botón OK (correcto)

D button

(Q)

Bouton D

Botón D

C button

(R)

Bouton C

Botón C

B button

(S)

Bouton B

Botón B

A button

(T)

Bouton A

Botón A

Holder

(U)

Support

Retenedor

Battery

(V)

Batterie

Batería

Pin-detent

(W)

Goupille d'arrêt

Pasador retenedor

-

3 -

Illustrations / Illustrations / Ilustraciones

[Fig.1]

rubber ring

anneau en

caoutchouc

anillo de cauch

[Fig.2]

[Fig.3]

o

pin

goupille

pasador

[Fig.6]

groove

rainure

ranura

Proper socket attachment

Fixation correcte de la douille

Montaje de cubo apropiado

[Fig.7]

[Fig.8]

[Fig.9]

[Fig.4]

[Fig.5]

-

[Fig.10]

Alignment

marks

Marques

d’alignement

Marcas de

alineación

[Fig.11]

Button

Bouton

Botón

4 -

[Fig.12]

[Fig.16]

[Fig.13]

[Fig.14]

Vertically

Verticalement

Verticalmente

Forward

Rotation en

sens normal

Avance

Verrouillage de commutateur

[Fig.17]

[Fig.18]

Reverse

Rotation en

sens inverse

Marcha

atrás

Switch lock

Bloqueo del interruptor

EYFLA9 / EYFMA2

Approx. 50 cm

Environ 50 cm

Aprox. 50 cm

[Fig.15]

Approx. 60°

Environ 60°

Aprox. 60°

-

5 -

(2) (1)

EYFLA9 / EYFMA2

(2) (1)

[Fig.19]

CD

[Fig.20]

[Fig.21]

Display

Afchage

Visor

Battery indication lamp

Témoin indicateur de la batterie

Lámpara de indicadora de la batería

EYFLA9 / EYFMA2

[Fig.22]

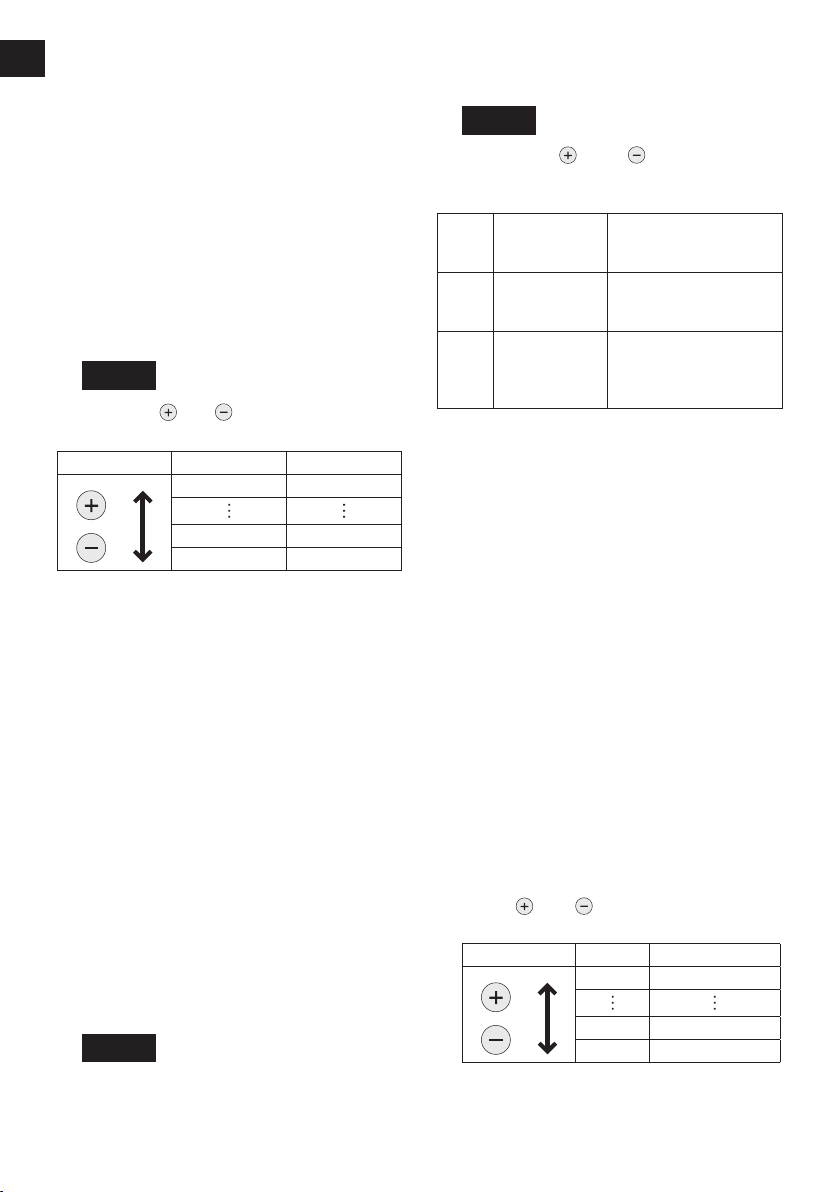

Tightening torque

Couple de serrage

Par de torsión de apriete

Niveau de réglage du couple de serrage

A

(1)

B

(2)

EYFA31

EYFLA9 / EYFMA2

EYFMA1(M14)

EYFMA1(M12)

EYFMA1(M10)

EYFLA5(M6)

EYFLA4(M6)

Torque setting level

Nivel de ajuste de par de torsión

EYFLA6(M10)

EYFLA6(M8)

EYFLA5(M8)

EYFLA4(M8)

-

6 -

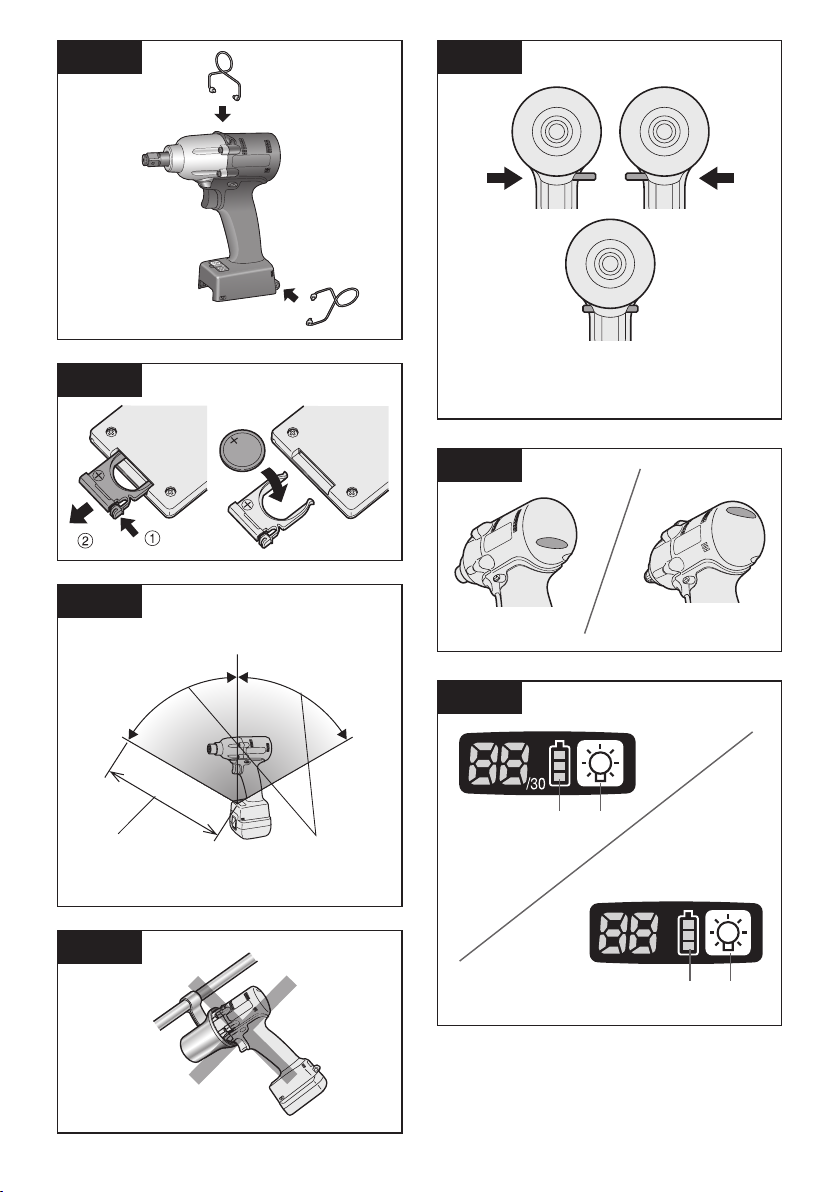

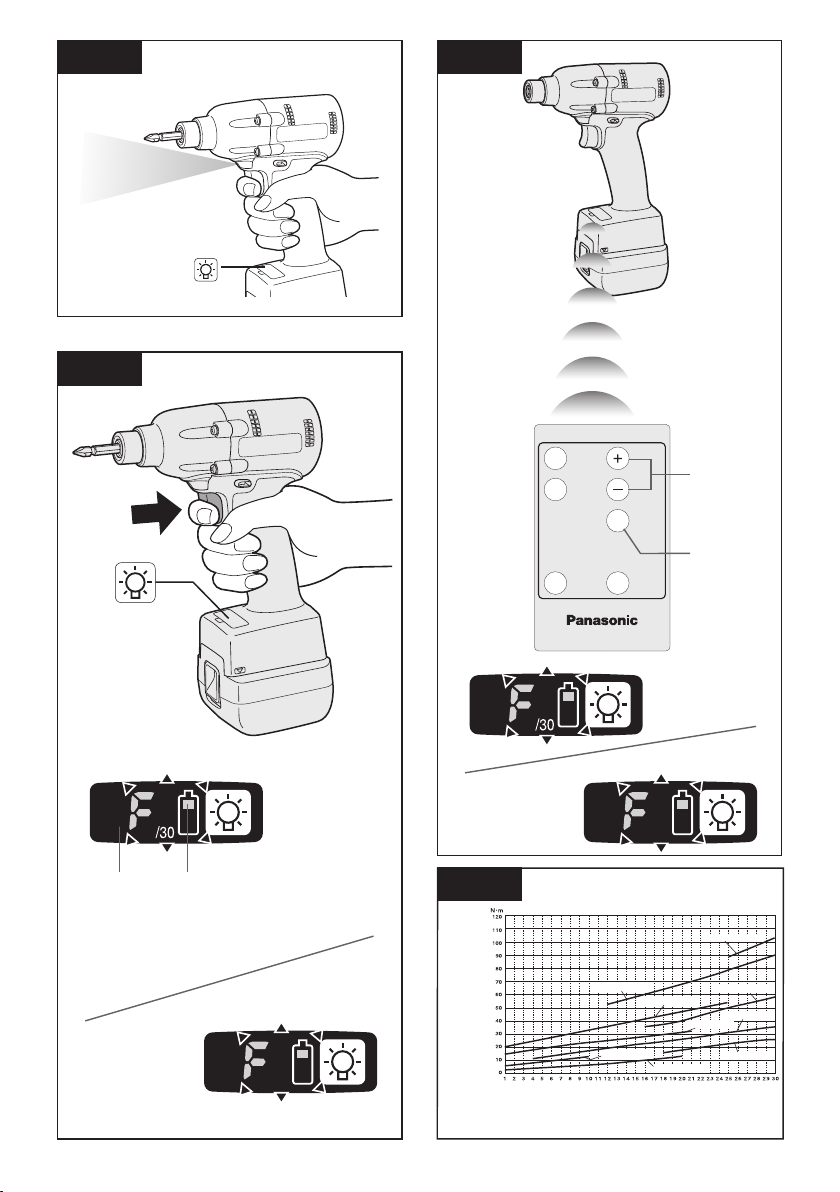

[Fig.23]

[Fig.24]

Tightening torque

Couple de serrage

Par de torsión de apriete

Niveau de réglage du couple de serrage

[Fig.26]

Torque setting

Réglage du couple

de serrage

Ajuste de par de

torsión

Torque setting level

Nivel de ajuste de par de torsión

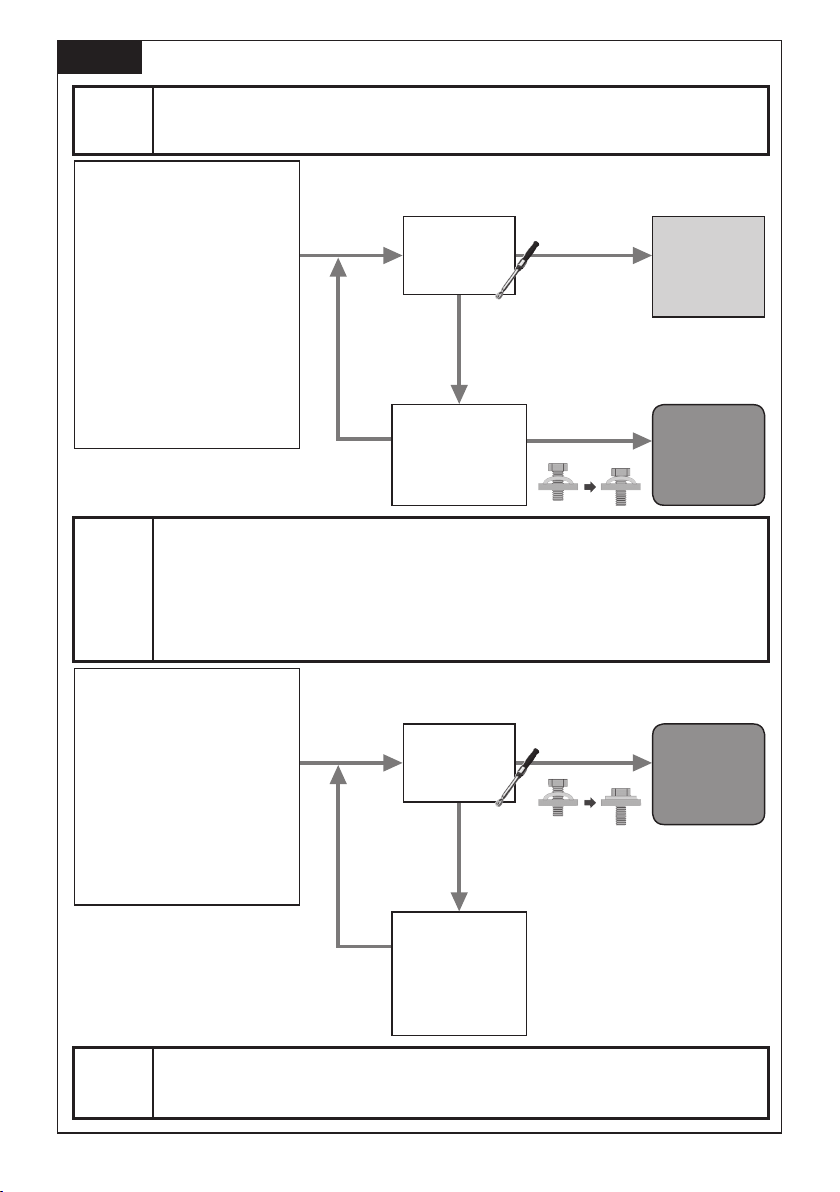

Torque

Couple de serrage

Par de torsión

L7

(1)

A

B

[Fig.25]

EYFLA9 / EYFMA2

Tightening completed

Serrage terminé (s’arrête automatiquement)

Apriete terminado (Se detiene automáticamente)

(Stops automatically)

(2)

(3)

Snug point

detection level

Niveau de

détection du

point de

préserrage

Nivel de

detección del

punto de apriete

exacto

L6

L5

L4

L3

Load generated halfway

Charge générée à mi-chemin

L2

Carga generada a la mitad

L1

Load generated halfway

Charge générée à mi-chemin

Carga generada a la mitad

-

7 -

Snug point

Point de

préserrage

Punto de

apriete exacto

Impact Monitoring

Mode

Mode de surveillance

de l’impact

Modo de monitoreo

de impacto

Tightening time

Durée du serrage

Tiempo de apriete

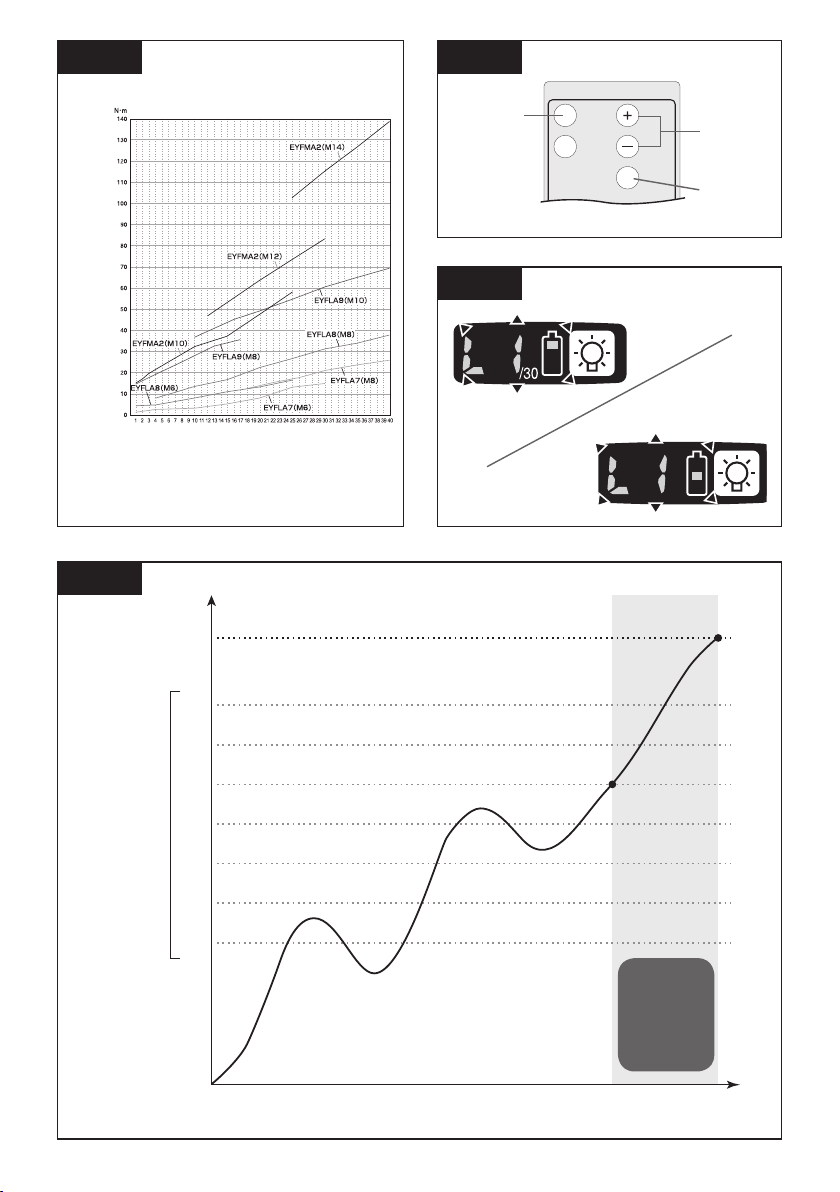

[Fig.27]

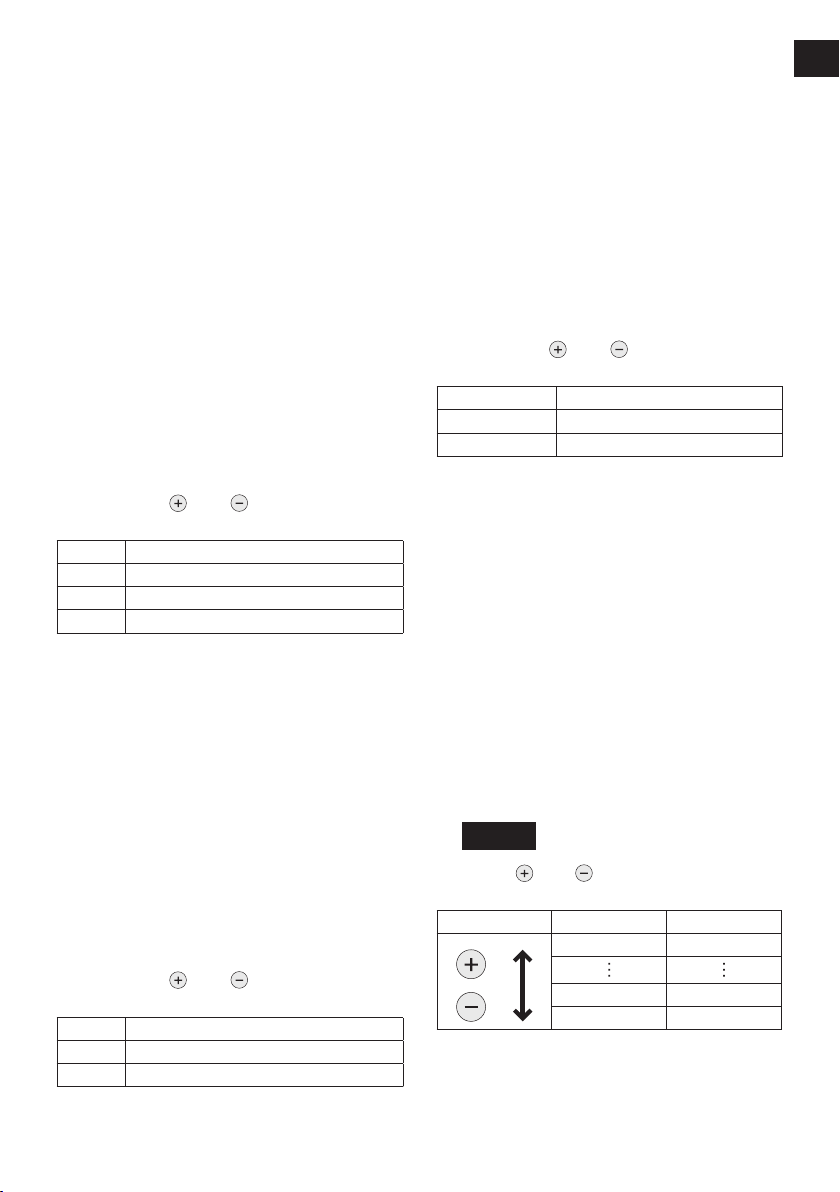

How to set / Comment régler ? / Cómo ajustar

[Step 1]

Étape 1

[

[Paso 1]

Select Torque Setting Stage (1-40)

]

Sélectionnez l’étape de réglage du couple de serrage (1-40)

Seleccione Etapa de ajuste de par de torsión (1-40)

Torque Setting Stage:

Select referring to index chart

[Fig. 23]

Snug Tight Detection setting: L1

Étape de réglage du couple de

serrage :

Sélectionnez se référer au

tableau d’annexe [Fig. 23]

Réglages de la détection de

préserrage serré : L1

Etapa de ajuste de par de torsión:

Seleccione consultando el

cuadro de índice [Fig. 23]

Ajuste de detección de punto de

apriete exacto: L1

[Step 2]

Étape 2

[

[Paso 2]

Torque Setting Stage:

* Select referring to index chart

Snug Tight Detection setting:

Change from L1 to L2

Étape de réglage du couple de

serrage :

* Sélectionnez se référer au

tableau d’annexe

Réglages de la détection de préserrage

serré : Modification de L1 à L2

Etapa de ajuste de par de torsión:

* Seleccione consultando el

cuadro de índice

Ajuste de detección de punto de

apriete exacto: Cambie de L1 a L2

* Please reset Torque Setting Stage if it’s

increased in Step1.

* Veuillez réinitialiser l’étape de réglage

du couple de serrage si elle a été

augmentée à l’étape 1.

* Vuelva a ajustar la Etapa de ajuste de par

de torsión si se aumentó en el Paso 1.

Select Flush Detection Level (L1-L7 / Use only when final torque can’t be increased by Torque

Setting Stage change)

* Increase Flush Detection Level one by one. There is a risk of over torque when Flush Detection Level is increased.

Sélectionnez le niveau de détection de l’encastrement (L1-L7 / à utiliser uniquement quand le couple de

]

serrage final ne peut pas être augmenté par la modification de l’étape de réglage du couple de serrage)

* Augmente le niveau de détection d’encastrement un par un. Il existe un risque de trop fort couple de serrage lorsque le

niveau de détection d’encastrement est augmenté.

Seleccione Nivel de detección de nivel (L1-L7 / Use sólo cuando el par de torsión final se puede

aumentar mediante el cambio de la Etapa de ajuste de par de torsión)

*

Aumente el nivel de detección de nivel uno a uno. Existe la posibilidad de que se apriete demasiado cuando se aumenta el nivel de detección de nivel.

Trial fastening

Essai de

fixation

Apriete de

prueba

Trial fastening

Essai de

fixation

Apriete de

prueba

Final torque meets target torque

Le couple de serrage final correspond au couple de serrage prévu

Par de torsión final cumple con el par de apriete objetivo

Check torque

Vérifiez le couple

de serrage

Verifique par

de torsión

Even though changing Torque Setting

Not OK

Pas OK

No OK

Modifiez l’étape de réglage

du couple de serrage

ajuste de par de torsión

Vérifiez le couple

Not OK

Pas OK

No OK

Modifiez les réglages de la

détection de préserrage serré

detección de punto de

Stage, final torque can’t be increased.

(Fastener doesn’t seat correctly)

Malgré la modification de l’étape de réglage du couple de serrage,

le couple de serrage final ne peut pas être augmenté.

(L’attache n’est pas fixée correctement)

A pesar de cambiar la Etapa de ajuste de par de torsión, el par de

torsión final no se puede aumentar.

(Seguro no se asienta correctamente)

Change Torque

Setting Stage

Cambie Etapa de

Final torque is above lower tolerance limit

Le couple de serrage final dépasse la limite inférieure de tolérance

Par de torsión final está encima del límite de tolerancia inferior

Check torque

de serrage

Verifique par

de torsión

Final torque can’t be increased.

(Fastener doesn’t seat correctly)

Le couple de serrage final ne peut pas être augmenté.

(L’attache n’est pas fixée correctement)

El par de torsión final no se puede aumentar.

(Seguro no se asienta correctamente)

Change Snug Tight

Detection setting

L2→L3~L7

L2→L3~L7

Cambie el ajuste de

apriete exacto

L2→L3~L7

OK / OK / OK

Not OK

OK / OK / OK

Flush!

Setting

complete

Réglage

terminé

Ajuste

completo

Move to Step 2

Passez à l’étape 2

Vaya al Paso 2

Move to Step 3

Passez à l’étape 3

Vaya al Paso 3

[Step 3]

Étape 3

[

[Paso 3]

Fine-tune Torque Setting Stage to meet target torque and complete setting

]

Affinez l’étape de réglage du couple de serrage afin d’atteindre le couple de serrage prévu et de terminer les réglages

Haga el ajuste fino de Etapa de ajuste de par de torsión para cumplir con el par de torsión objetivo y completar el ajuste.

-

8 -

[Fig.28]

EYFLA9 / EYFMA2

[Fig.32]

[Fig.29]

EYFLA4AR, EYFLA5AR, EYFLA5PR,

EYFLA5QR, EYFLA6JR, EYFLA6PR,

EYFLA7AR, EYFLA8AR, EYFLA8CR,

EYFLA8PR, EYFLA9CR, EYFLA9PR

EYFMA1JR, EYFMA1PR, EYFMA2CR,

EYFMA2PR

[Fig.30]

[Fig.33]

EYFLA9 / EYFMA2

[Fig.34]

EYFLA9 / EYFMA2

[Fig.31]

-

9 -

[Fig.35]

6)

EN EN

I

.

GENERAL SAFETY

RULES

If operating a power tool in a damp

location is unavoidable, use a residual

current device (RCD) protected supply.

Use of RCD reduces the risk of electrical

shock.

WARNING! Read all instructions

Failure to follow all instructions listed

below may result in electric shock, fire

and/or serious injury. The term “power

tool” in all of the warnings listed below

refers to your mains operated (corded)

power tool and battery operated

(cordless) power tool.

SAVE THESE INSTRUCTIONS

Work Area Safety

1) Keep work area clean and well lit.

Cluttered or dark areas invite accidents.

2)

Do not operate power tools in explosive

atmospheres, such as in the presence

of flammable liquids, gases or dust.

Power tools create sparks which may

ignite the dust or fumes.

3) Keep children and bystanders away

while operating a power tool.

Distractions can cause you to lose control.

Electrical Safety

1) Power tool plugs must match the

outlet. Never modify the plug in any

way. Do not use any adapter plugs

with earthed (grounded) power tools.

Unmodified plugs and matching outlets

will reduce risk of electric shock.

2) Avoid body contact with earthed or

grounded surfaces such as pipes,

radiators, ranges and refrigerators.

There is an increased risk of electric shock

if your body is earthed or grounded.

3) Do not expose power tools to rain or

wet conditions.

Water entering a power tool will increase

the risk of electric shock.

4) Do not abuse the cord. Never use

the cord for carrying, pulling or

unplugging the power tool. Keep

cord away from heat, oil, sharp edges

or moving parts.

Damaged or entangled cords increase

the risk of electric shock.

5)

When operating a power tool outdoors,

use an extension cord suitable for

outdoor use.

Use of a cord suitable for outdoor use

reduces the risk of electric shock.

Personal Safety

1)

Stay alert, watch what you are doing

and use common sense when operating

a power tool. Do not use a power tool

while you are tired or under the influence

of drugs, alcohol or medication.

A moment of inattention while operating

power tools may result in personal injury.

2) Use safety equipment. Always wear

eye protection.

Safety equipment such as dust mask,

non-skid safety shoes, hard hat, or

hearing protection used for appropriate

conditions will reduce personal injuries.

3) Avoid accidental starting. Ensure the

switch is in the off position before

plugging in.

Carrying power tools with your finger on

the switch or plugging in the power tools

that have the switch on invites accidents.

4) Remove any adjusting key or wrench

before turning the power tool on.

A wrench or a key left attached to a

rotating part of the power tool may result

in personal injury.

5) Do not overreach. Keep proper

footing and balance at all times.

This enables better control of the power

tool in unexpected situations.

6) Dress properly. Do not wear loose

clothing or jewellery. Keep your

hair, clothing and gloves away from

moving parts.

Loose clothes, jewellery or long hair can

be caught in moving parts.

7) If devices are provided for the

connection of dust extraction and

collection facilities, ensure these are

connected and properly used.

Use of these devices can reduce dust

related hazards.

Power Tool Use and Care

1)

Do not force the power tool. Use the

correct power tool for your application.

The correct power tool will do the job

better and safer at the rate for which it

was designed.

-

10 -

2) Do not use the power tool if the

switch does not turn it on and off.

Any power tool that cannot be controlled

with the switch is dangerous and must

be repaired.

3) Disconnect the plug from the power

source and/or the battery pack from

the power tool before making any

adjustments, changing accessories,

or storing power tools.

Such preventive safety measures

reduce the risk of starting the power tool

accidentally.

4)

Store idle power tools out of the reach

of children and do not allow persons

unfamiliar with the power tool or these

instructions to operate the power tool.

Power tools are dangerous in the hands

of untrained users.

5) Maintain power tools. Check for

misalignment or binding of moving

parts, breakage of parts and any other

condition that may affect the power

tools operation. If damaged, have the

power tool repaired before use.

Many accidents are caused by poorly

maintained power tools.

6) Keep cutting tools sharp and clean.

Properly maintained cutting tools with

sharp cutting edges are less likely to

bind and are easier to control.

7) Use the power tool, accessories

and tool bits etc. in accordance with

these instructions and in the manner

intended for the particular type of

power tool, taking into account the

working conditions and the work to

be performed.

Use of the power tool for operations

different from those intended could

result in a hazardous situation.

8) Hold power tool by insulated gripping

surfaces, when performing an

operation where the fastener may

contact hidden wiring.

Fasteners contacting a “live” wire may

make exposed metal parts of the power

tool “live” and could give the operator an

electric shock.

Battery Tool Use and Care

1) Ensure the switch is in the off position

before inserting battery pack.

Inserting battery pack into power tools

that have the switch on invites accidents.

2) Recharge only with the charger

specified by the manufacturer.

A charger that is suitable for one type

of battery pack may create a risk of fire

when used with another battery pack.

3) Use power tools only with specifically

designated battery packs.

Use of any other battery packs may

create a risk of injury and fire.

4)

When battery pack is not in use, keep it

away from other metal objects like paper

clips, coins, keys, nails, screws, or other

small metal objects that can make a

connection from one terminal to another.

Shorting the battery terminals together

may cause burns, or a fire.

5) Under abusive conditions, liquid may

be ejected from battery; avoid contact.

If contact accidentally occurs, flush

with water. If liquid contacts eyes,

additionally seek medical help.

Liquid ejected from the battery may

cause irritation or burns.

Service

1) Have your power tool serviced by a

qualified repair person using only

identical replacement parts.

This will ensure that the safety of power

tool is maintained.

II

. INTENDED USE

This tool is a Cordless Mechanical Pulse Driver /

Wrench and can be used to tighten bolts, nuts,

and screws. Additionally, it provides a torque

control function that automatically stops tool

operation when a preset load is reached to deliver consistent tightening torque.

Additionally, a separately available Assembly

Qualier can provide wireless monitoring to

determine whether tightening has been completed properly.

IMPROPER USE

The use of the tool other than INTENDED USE

is dangerous and must be avoided.

The tool must not be used for the purposes

such as the following;

• to mix paint or building materials,

• polishing, grinding, sharpening, engraving.

-

11 -

RESIDUAL RISK

EN EN

Some residual risks remains even with proper

use of the tool such as the following;

• contact with the rotating bit

• contact with the sharp edges of material or

something.

III

.

ADDITIONAL SAFETY

RULES

1) If the bit becomes jammed, immedi-

ately turn the trigger switch off to prevent an overload, which can damage the battery pack or motor. Use

reverse motion to loosen jammed

bits.

2) Do NOT operate the Forward/

Reverse lever when the trigger switch

is on. The battery will discharge rapidly and damage to the unit may

occur.

3) During charging, the charger may

become slightly warm. This is normal.

Do NOT charge the battery for a long

period.

4) Do not strain the tool by holding the

speed control trigger halfway (speed

control mode) so that the motor

stops.

5) To prevent injury during use, hold

the tool steady at all times and avoid

waving it around.

6) Make certain that there are no hidden

gas or water pipes, or electrical wires

in the area where you will be working. Coming into contact with hidden

pipes or wires could result in electric

shock, or water or gas leaks.

7) Make sure to hold the object you are

working on steady.

8) Check for damaged parts.

• Check thoroughly for damage to

the protective cover and other parts

before operating.

• Check to make sure the tool and all

of its functions are working properly.

• Check the adjustment of all movable parts, and check all fixed parts

to make sure they are fitted properly

and free of damage. Check all parts

of the tool for abnormal function.

9) When attempting to repair the protective cover or other parts, please follow

the instructions in the user manual. In

cases where there are no instructions

in the manual, please take it back to

the store to have it repaired.

10) If the tool gets exceptionally hot during use, please take it in for service

and repair.

11) To avoid potential injury, keep face

and hands away from the drill bit and

any shavings.

12) Do not wear gloves when operating

the tool, as they may get caught by

the drill, leading to injury.

13) Battery terminals, screw shavings,

and tool accessories such as drill

bits will be very hot immediately after

operation. Do not touch them as

there is a risk of burning yourself.

-

12 -

WARNING

• Do not use other than the Panasonic battery packs that are designed for use with

this rechargeable tool.

• Panasonic is not responsible for any damage or accident caused by the use of

recycled or counterfeit battery pack.

• Do not dispose of the battery pack in a

fire, or expose it to excessive heat.

• Do not allow metal objects to touch the

battery pack terminals.

• Do not carry or store the battery pack

in the same container as nails or similar

metal objects.

• Do not charge the battery pack in a

high-temperature location, such as next

to a fire or in direct sunlight. Otherwise,

the battery may overheat, catch fire, or

explode.

• After removing the battery pack from the

tool or the charger, always reattach the

pack cover. Otherwise, the battery contacts could be shorted, leading to a risk

of fire.

• When the Battery Pack Has Deteriorated,

Replace It with a New One. Continued

use of a damaged battery pack may result

in heat generation, ignition or battery rupture.

• To prevent leakage, overheating, smoke

generation, fire, and rupturing from occurring, follow these instructions when handling our rechargeable power tools (tool

main body/battery pack/charger).

- Do not allow material cuttings or dust to

fall onto the battery pack.

- When storing, remove any material cuttings and dust from the battery pack,

and place the battery pack separately

from metal objects (screws, nails, etc.)

when storing in the tool case.

• Do not handle the rechargeable power

tools in the following way.

(There is a hazard of smoke generation,

fire, and rupturing)

- Use or leave in places exposed to rain

or moisture

- Use submerging in water

Symbol Meaning

V

n

0

Revolutions or reciprocations

-1

… min

Ah

IV

. ASSEMBLY

Electrical capacity of battery

injury, user must read and

understand instruction manual.

Do not incinerate or heat bat-

tery pack. Do not charge or

use under conditions of high

temperature. Do not expose to

Do not disassemble or modify.

Do not expose to rain or water.

Volts

Direct current

No load speed

per minutes

pack

To reduce the risk of

high temperatures.

CAUTION:

Make sure that the socket, extension or

any attachment used with the tool to hold

fasteners is designed specifically for power

tools (Impacting tools).

Using the tool with attachments designed

for hand tools may break the attachments

and cause possible danger.

Also, Make sure that there is nothing

wrong on the attachment before operating.

NOTE:

• If a worn or deformed socket is used,

the square drive (retainer ring and pin)

may not enter the socket properly.

•

When attaching or removing a bit,

disconnect battery pack from tool or

place the switch in the center position

(switch lock).

•

Keep the temperature of the tool

above the freezing point (0°C/32°F)

when attaching sockets to or removing

them from the square drive on the

tool. Do not use excessive force when

attaching or removing sockets.

-

13 -

Attaching or Removing Bit

EN EN

NOTE:

•

When attaching or removing a bit,

disconnect battery pack from tool or

place the switch in the center position

(switch lock).

1. Hold the collar of quick connect chuck

and pull it out from the tool.

2. Insert the bit into the chuck. Release

the collar.

3. The collar will return to its original

position when it is released.

Pull the bit to make sure it does not come out.

4.

5. To remove the bit, pull out the collar in

the same way.

CAUTION:

• If the collar does not return to its

original position or the bit comes out

when pulled on, the bit has not been

properly attached. Make sure the bit

is properly attached before use.

EYFLA4A/EYFLA5A/EYFLA7A/EYFLA8A

EYFLA4AR/EYFLA5AR/EYFLA7AR/EYFLA8AR

12 mm

(15/32")

9 mm – 9.5 mm

(23/64" – 3/8")

6.35 mm

(1/4")

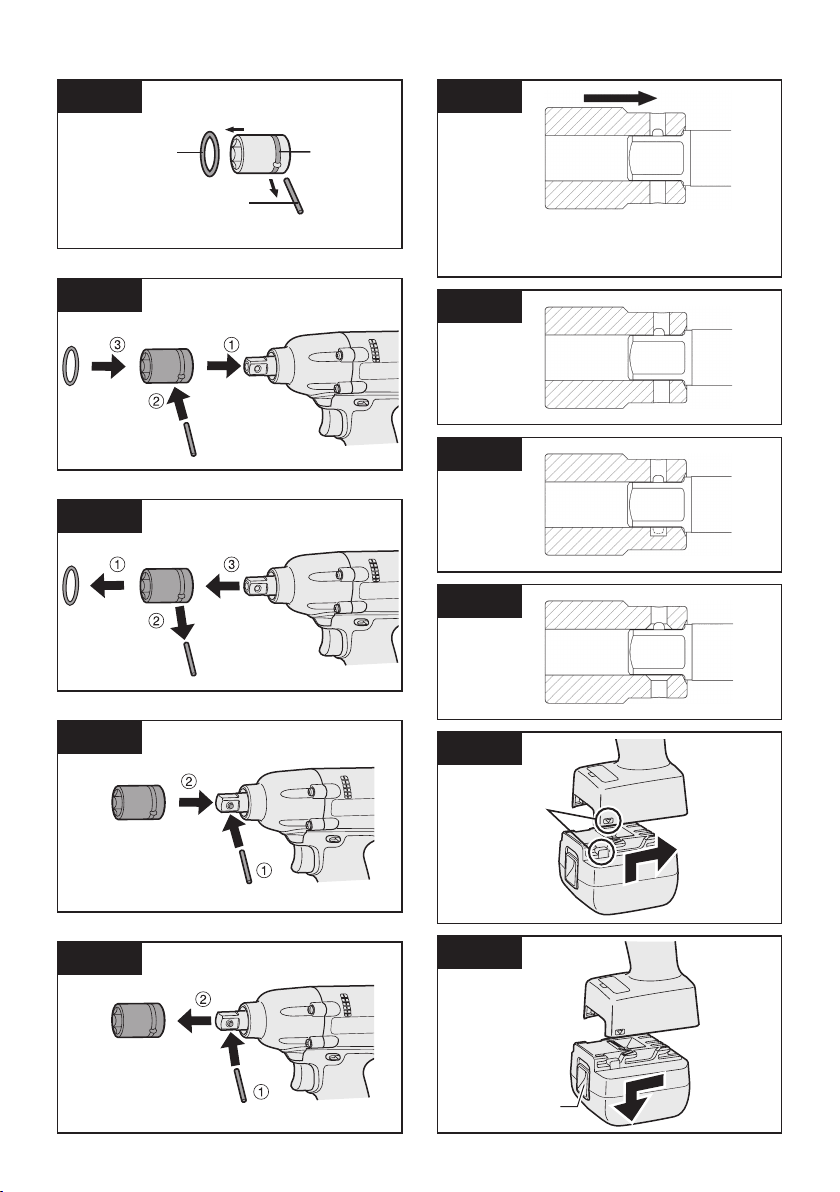

Attaching Socket (Pin type)

Remove the socket’s rubber ring and pin.

[Fig.1]

1 Attach the socket to the tool.

2 Insert the pin. (Taking care to align the

pin holes on the socket and tool.)

3 Attach the rubber ring by sliding it into

place over the groove.

[Fig.2]

3 Remove the socket from the tool.

[Fig.3]

Attaching Socket (Pin-detent)

1 Depress the pin-detent on the square

drive.

2 Attach the socket to square drive.

3 Make sure the socket is securely

attached to the square drive.

[Fig.4]

Removing Socket (Pin-detent)

1 Insert a small rod into the hole on the

socket.

Depress the pin-detent, then detach the

2

socket.

[Fig.5]

CAUTION:

• When attaching a socket to the driver,

verify that the socket and pin-detent do

not interfere with one another.

[Fig.6]

• Some sockets may not function well with

the driver due to their shape. Avoid use

of sockets such as the following:

1

Sockets shaped so that the pindetent makes contact with the side

of the socket’s pin hole when the

socket is attached to the driver.

The pin-detent will be subjected to

excessive force, possibly damaging it.

[Fig.7]

2 Sockets with a pin hole on one

side only

You may be unable to remove the

socket if it is attached in the wrong

orientation.

[Fig.8]

NOTE:

Be sure to attach the rubber ring to

prevent the pin from falling out.

Removing Socket (Pin type)

1 Remove the rubber ring.

2 Remove the pin.

-

14 -

3 Sockets whose pin holes have

beveled edges

The socket will not be held in

place with sufficient force, so that

it may come off during use.

[Fig.9]

Attaching or Removing

Bat tery Pack

1. To connect the battery pack:

Align the highlighted marker points

and attach battery pack.

• Slide the battery pack until it locks

into position.

[Fig.10]

2. To remove the battery pack:

Push down the button and slide the

battery pack forward.

[Fig.11]

Attaching the tool hanger

[Fig.12]

V.

OPERATION

WARNING

Do not inhale any smoke emitted from the

tool or battery pack as it may be harmful.

Before Using the Remote

Control (Available as an

optional accessory)

Insert the battery

[Fig.13]

1. Pull out the battery holder.

1 Push in on the fastener as indicated

by the arrow.

2 Pull out the holder.

2. Insert the battery and push the holder

back in.

NOTE:

• If the tool does not respond to the

wireless remote control even when

the remote control is operated close

to the tool, the battery (CR2025) is

dead. Replace it with a fresh battery.

• The included battery is provided for

sample use and may not last as long

as commercially available batteries.

Wireless remote control range

[Fig.14]

The remote control should be operated

within approximately 50 cm and approximately 60° vertically and horizontally of

the perpendicular relative to the infrared

receiver on the tool.

• Under the following circumstances, you

may not be able to operate the tool,

even within this range.

- If there is an object between the remote

control’s transmitter and the tool’s receiver.

- Use outdoors or in other environments

where the remote control receiver is

expos ed to a strong light source, or

when the remote control transmitter or

receiver is dirty may cause the tool to

fail to respond, even when the remote

control is used within the operating

range.

[Main Unit]

CAUTION:

If a tool holder is used with the Panasonic

EYF series assembly tools, make sure

the tool’s trigger switch doesn’t hit the tool

holder. It may run the tool accidentally and

result in battery failure by unexpected battery

discharge.

[Fig.15]

CAUTION:

When storing or carrying the tool, set the

Forward/Reverse lever to the center position

(switch lock).

NOTE:

Exercise caution to ensure no objects

come into contact with the tool’s trigger

switch.

If an object comes into contact with

the tool’s trigger switch, even while the

Forward/Reverse lever is in the center

position (locked), a small amount of electric

current may continue flowing, which may

cause an excessive discharge from the

battery pack and subsequent battery pack

failure.

-

15 -

Switch and Forward/Reverse

EN EN

Lever Operation

[Fig.16]

1. Push the lever for forward or reverse

rotation. Check the direction of the

lever before using.

2. Depress the trigger switch slightly to

start the tool slowly.

3. Speed will increase by pressing the

trigger. The tool stops working immediately by releasing the trigger.

4. When done with an application, lock

the switch by centering the lever.

NOTE:

The more the speed control trigger is pulled,

the higher the speed becomes.

CAUTION:

When operating the tool by pulling the trigger, there may be a momentary lag before

rotation starts. This does not signal a malfunction.

* This lag occurs as the tool’s circuitry

starts up when the trigger is pulled for the

first time after installing a battery pack

or after the tool has not been used for

at least 1 minute (or at least 5 minutes

when the LED is on). Rotation will start

without any lag during second and subsequent operations.

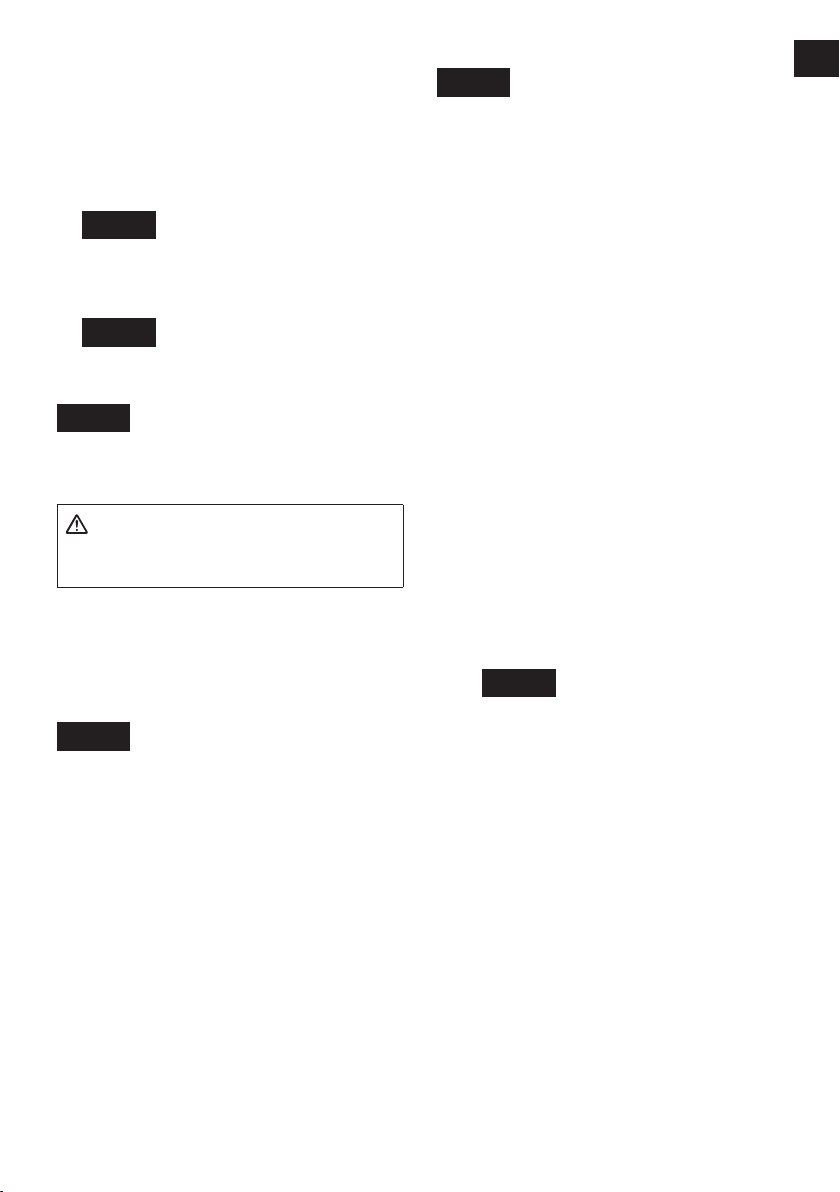

Tightening confirmation lamp

The tightening confirmation lamp can

be used to check whether the torque

control function was activated.

[Fig.17]

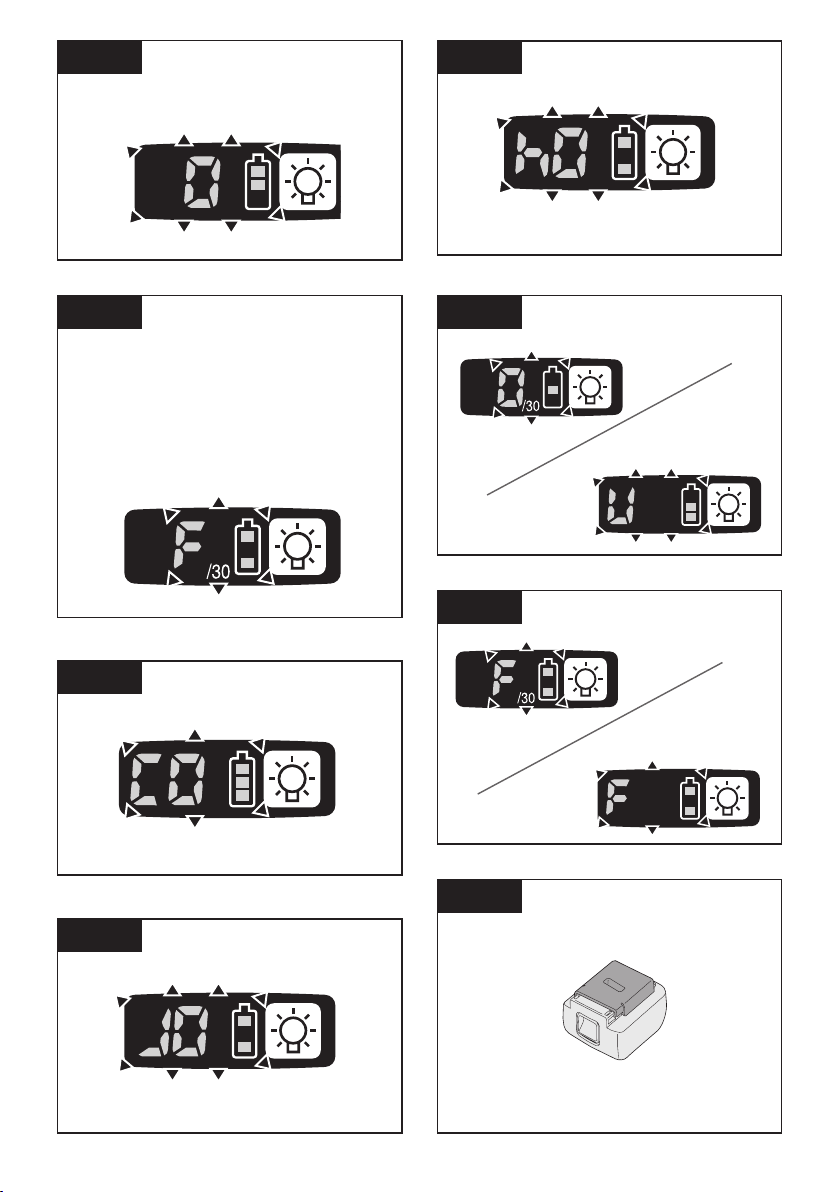

Tool status Lamp display

Tightening complete

(with torque control

function operation)

• Tightening not complete

Tightening complete with

•

retightening within 1 second

The automatic stop

function has been

activated.

Green

(For approx. 2

seconds)

Red

(For approx. 2

seconds)

Red

(For approx. 5

minutes)

CAUTION:

• When the tool stops automatically

after the switch is released during

impact-mode tightening and then

reengaged within 1 second, the red

lamp will light up to indicate the risk

of excessive torque application as a

result of retightening.

NOTE

• The tightening confirmation lamp

will not turn on under the following

conditions:

• When the torque clutch is set to “F”

• During reverse rotation operation

• The lamp turns off when the tool is

in operation.

Control Panel

[Fig.18]

(1) LED light

[Fig.18 (1), 19]

Before the use of LED light, always pull the

power switch once.

Press

The light illuminates with very low current, and

it does not adversely affect the performance

of the tool during use or its battery capacity.

Caution: DO NOT STARE INTO BEAM.

Use of controls or adjustments or performance of procedures other than those

specied herein may result in hazardous

radiation exposure.

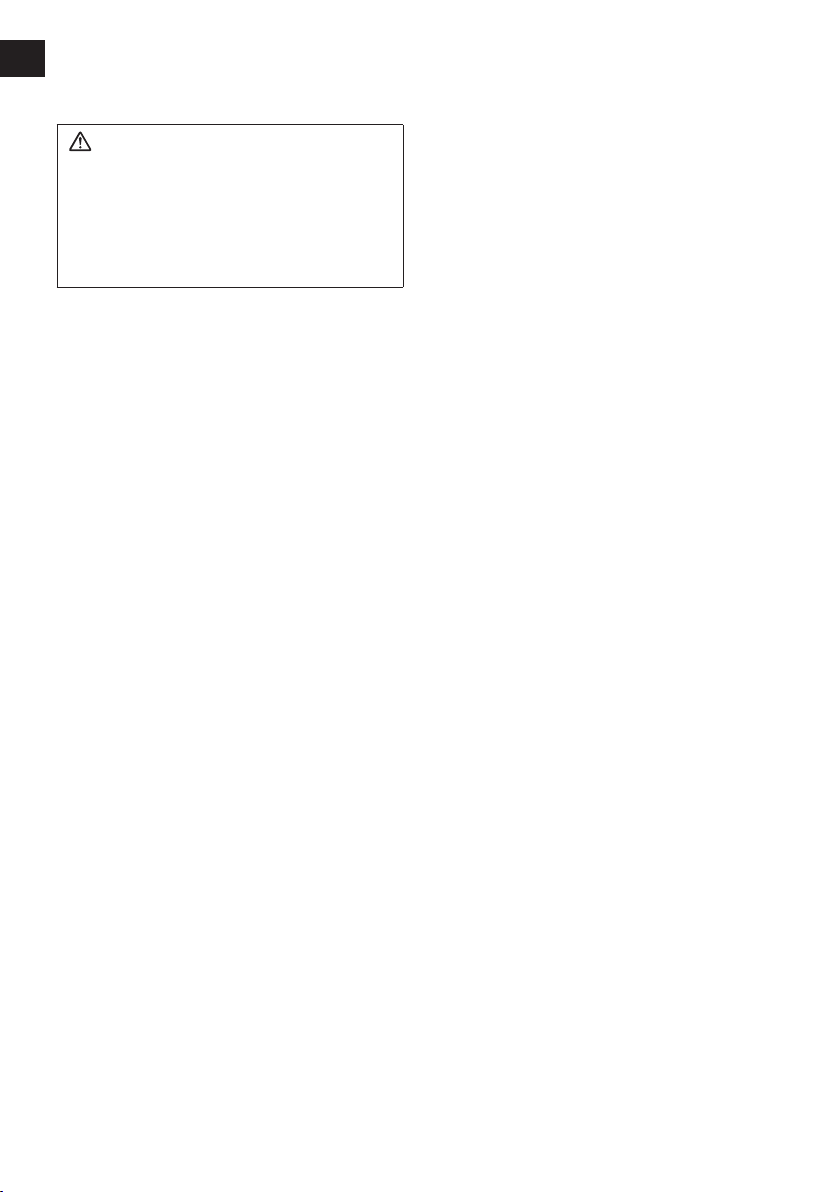

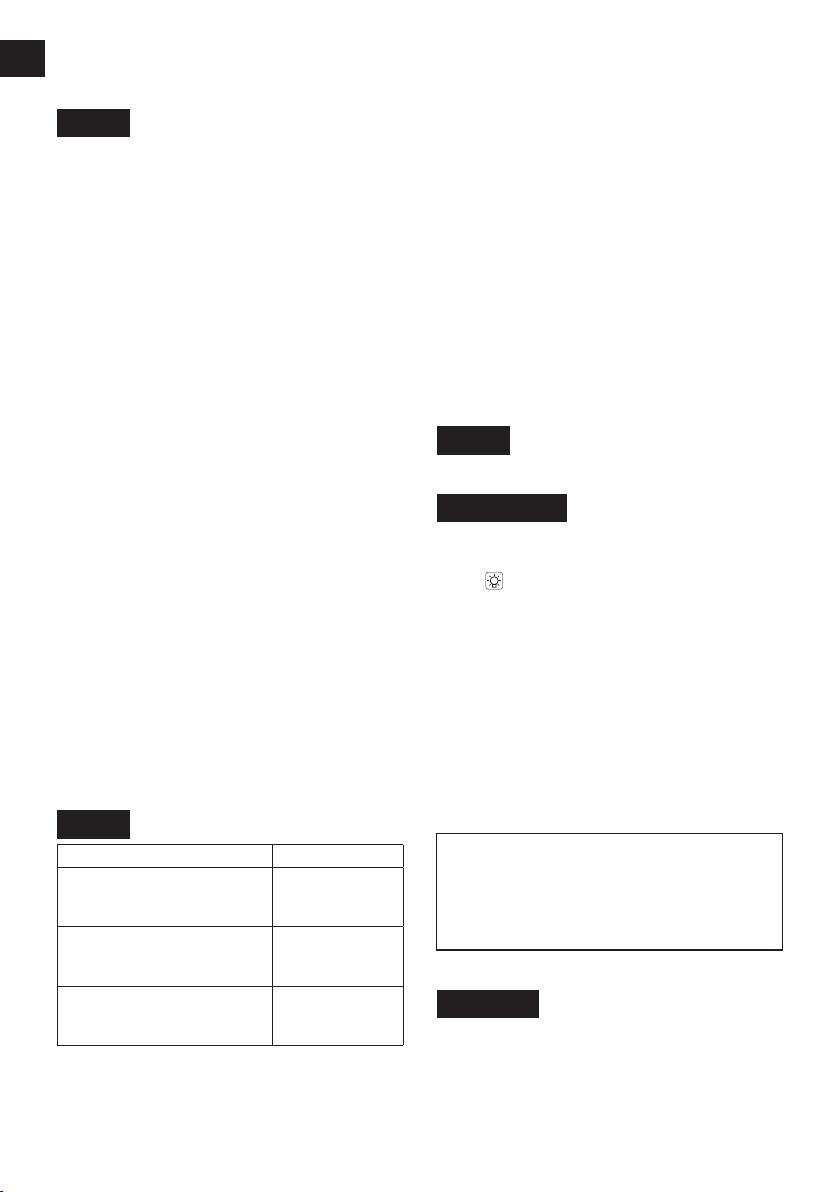

(2) The battery indication lamp

[Fig.18 (2)]

• Use the battery indication lamp to check

the LED light on button.

CAUTION:

•

The built-in LED light is designed to illuminate the small work area temporarily.

• Do not use it as a substitute for a

regular flashlight, since it does not

have enough brightness.

• LED light turns off when the tool

has not been used for 5 minutes.

how much power is left in the battery.

-

16 -

• Battery life varies slightly with ambient

temperature and battery characteristics.

The lamp is designed to provide a rough

indication of remaining battery life.

Indicator Battery status

Fully charged

Approx. 40% or less

remaining

Flashing Approx. 20% or

less remaining (indicates

need to recharge battery)

The battery pack will need

Flashing

Flashing

to be charged soon.

No charge

The battery pack needs to

be charged.

(The tool’s automatic

power-off function will

activate at this stage.)

Automatic power-off function

• The automatic power-off function is

designed to prevent a loss of tightening torque due to reduced battery voltage. Once it has been activated, the tool

will not operate until the battery pack has

been charged (or replaced with a fresh

unit), even if the trigger is depressed.

Indicator

Flashing

NOTE:

• All 3 bars on the battery indication

lamp will flash when the automatic

power-off function is activated.

• When the battery indication lamp

begins flashing, the battery pack

should be charged (or replaced with

a fresh unit) immediately.

• Be sure to fully charge the battery

pack in question after activation of

the automatic power-off function.

Failure to do so may prevent the

automatic power-off function from

being properly deactivated.

-

(3) The torque control function

• The torque control function calculates

the load from the motor’s rotational

angle during the hammer impact and

determines that the bolt has been properly seated when a preset load value

is exceeded. Driving is then automatically stopped after a preset number of

impacts have been delivered to the bolt.

CAUTION:

• Always check the tool’s tightening

torque before use. Improper tool

operation may result in excessive or

inadequate tightening.

• Always operate the tool with the

switch fully engaged. The torque

control function will not operate

when the switch is not sufficiently

engaged, preventing the tool from

stopping automatically.

• In work where a heavy load comes

to bear during tightening, the load

may be interpreted as the seating

of the bolt, preventing the bolt from

being completely tightened.

• Repeated tightening of the same

bolt may break the bolt or deform

the material into which the bolt is

being driven as a result of excessive tightening.

• The tightening torque value and precision vary with factors such as the

material into which the bolt is being

driven and the condition of the socket

being used. Adjust the torque as necessary for the work being performed.

Bolt tightening torque varies due to

the factors described below.

1) Bolt

• Bolt diameter: Tightening torque generally increases with bolt diameter.

• Torque coefficient (indicated by the

bolt manufacturer), grade, length, etc.

2) Other

• Bit and socket condition: Material,

amount of play, etc.

• Use of a universal joint or socket adapter

• User: Manner in which the tool is

applied to the bolt, strength with

which the tool is held, manner in

which the tool’s switch is engaged

• Condition of object being tightened:

Material, seating surface finish

17 -

Setting the tool to configuration

3…28

1F30 229

3…38

1F40 239

EN EN

mode

1. Turn off the control panel.

• If the control panel is on, remove

and then reinsert the battery pack.

2. Engage the switch while pushing the

button and then release both the

button and the switch.

• After all the LED lamps have turned

off, the control panel will flash and

change to configuration mode.

[Fig.20]

NOTE:

• Tools ship from the factory set to “F”

mode (torque control function off).

• The control panel will turn off if the

tool is not operated for a period of 5

minutes.

Configuring the torque clutch setting

[Fig.21]

1. Press the and buttons to select

the clutch setting that is appropriate

• You can select from 40 torque clutch

settings (1 to 40).

• Use figures from the Tightening

Torque Chart to guide your selection

of torque clutch setting. (See the following tightening torque chart)

2. Press the OK button to accept the

selected torque clutch setting.

• The control panel will stop flashing

and light up.

CAUTION:

•

You must press the OK button in order

for the selected setting to take effect.

• Be sure to verify the new value after

changing the setting.

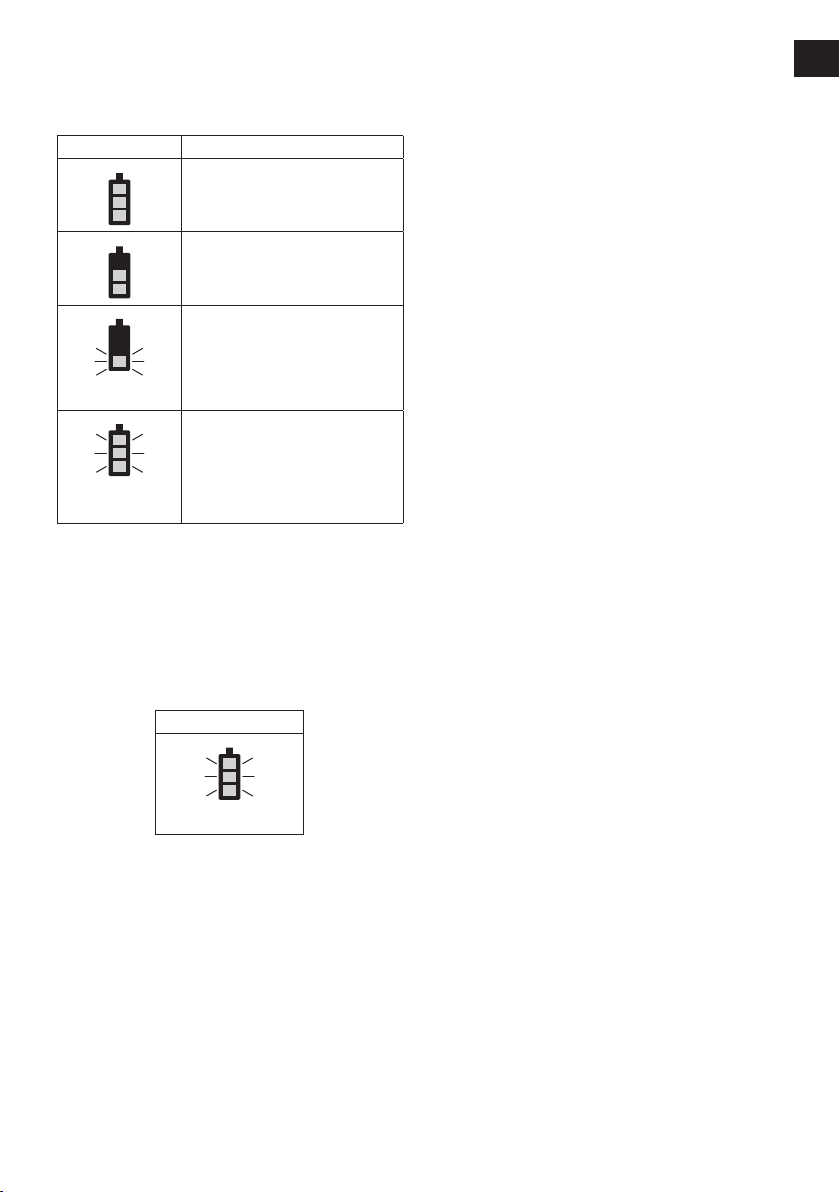

Tightening Torque Chart (for Reference

Use)

e values illustrated on this chart were

Th

measured under the conditions described

below and are provided for reference purposes. Actual tightening torque varies with

ambient conditions (the particular bolt being

tightened, hardware being used, method of

holding the bolt in place, etc.).

[EYFLA4, EYFLA5, EYFLA6, EYFMA1]

[Fig.22]

for the work being performed.

[EYFLA4, EYFLA5, EYFLA6, EYFMA1]

As the button

is pressed

As the button

is pressed

[EYFLA7, EYFLA8, EYFLA9, EYFMA2]

[Fig.23]

• “F” indicates that the torque control

function is off.

• You can select from 30 torque clutch

settings (1 to 30).

[EYFLA7, EYFLA8, EYFLA9, EYFMA2]

As the button

is pressed

• “F” indicates that the torque control

As the button

is pressed

function is off.

Measurement conditions

• Temperature: Room temperature

(20°C/68°F)

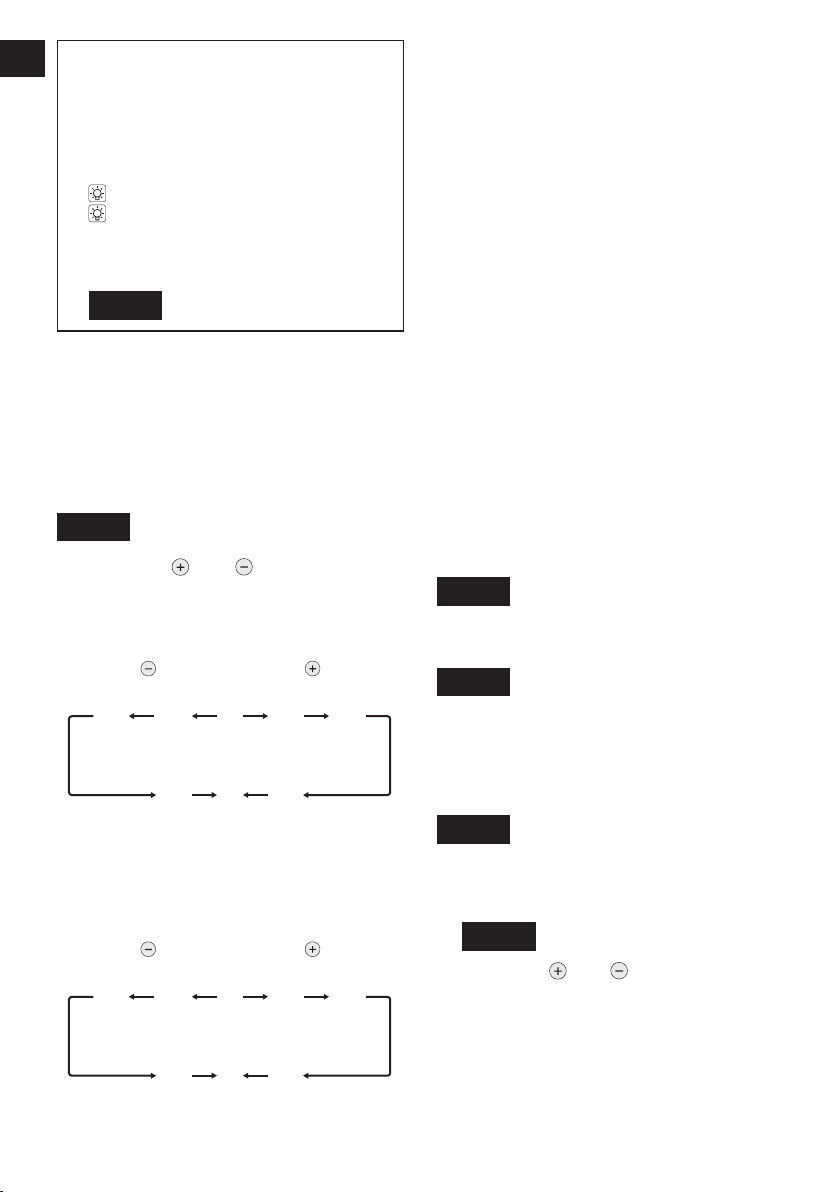

Setting the snug point detection level

[Fig.24]

1. Press the A button.

• The snug point detection level setting

value will be displayed.

[Fig.25]

2. Press the and buttons to set the

best snug point detection level for the

work you’re performing.

3. Press the OK button to accept the

number of torque stages and the

snug point detection level.

The tool’s panel will flash and then light

up continuously.

-

18 -

Snug point detection level guidelines

[EYFLA4, EYFLA5, EYFLA6, EYFMA1]

Display

L1

L2

Snug point

detection level

Low

(Use for work

characterized by

low loads before

the snug point is

reached.)

High

(Use for work

characterized by

high loads before

the snug point is

reached.)

Applications

(reference)

• Tightening

bolts in

materials that

are easily

cracked or

deformed, etc.

• Tightening

bolts in

materials with

misaligned

holes, etc.

• Tightening

self-tapping

screws, etc.

[EYFLA7, EYFLA8, EYFLA9, EYFMA2]

[Fig.26]

[Fig.27]

CAUTION:

• The setting will not be changed until you

press the OK button.

• After changing the setting, be sure to check

the new setting value. (See “Checking Tool

Settings.”)

[

EYFLA4, EYFLA5, EYFLA6, EYFMA1

• Set the snug point detection level from

“L1.” Setting the snug point detection

level from “L2” may result in cracking or

deformation of the target material.

• If the tool stops before the snug point at

snug point detection level “L1,” set the

snug point detection level to “L2.”

• Changing the snug point detection level

from “L1” to “L2” may increase the torque.

Set the number of torque stages again

after making this change.

[EYFLA7, EYFLA8, EYFLA9, EYFMA2]

• Set the snug point detection level from

“L1.” Setting the snug point detection

level from “L7” may result in cracking or

deformation of the target material.

• If the tool stops before the snug point at

snug point detection level “L1,” set the

snug point detection level to “L7.”

• Changing the snug point detection

level from “L1” to “L7” may increase the

torque. Set the number of torque stages again after making this change.

IMPORTANT INFORMATION:

• Pressing the A button toggles the display between the snug point detection level setting value and the number of torque stages setting value.

• The tool ships with the snug point

detection level set to “L1.”

• When the number of torque stages

has been set as shown below, the

snug point detection level cannot be

switched from “L1” to “L2 ~ L7.”

Model

EYFLA4 1 to 8

EYFLA5 1 to 3

EYFLA7 1 to 40

EYFLA8 1 to 40

EYFLA9 1 to 40

EYFMA2 1 to 40

Number of torque stages

setting

Cross thread reduction function

[EYFLA7, EYFLA8, EYFLA9, EYFMA2]

The tool runs in reverse approximately 360° before running forward to assist

]

in the alignment of the threads to help

reduce cross threads.

1. Set the tool to setting configuration

mode. (See page 18.)

2. Press the D button once.

The cross thread reduction function setting

value will be displayed.

3. Press the and buttons to change

the setting to ON or OFF.

Display Function

R0 OFF

R1 ON

4. Press the OK button to accept the

new setting.

-

19 -

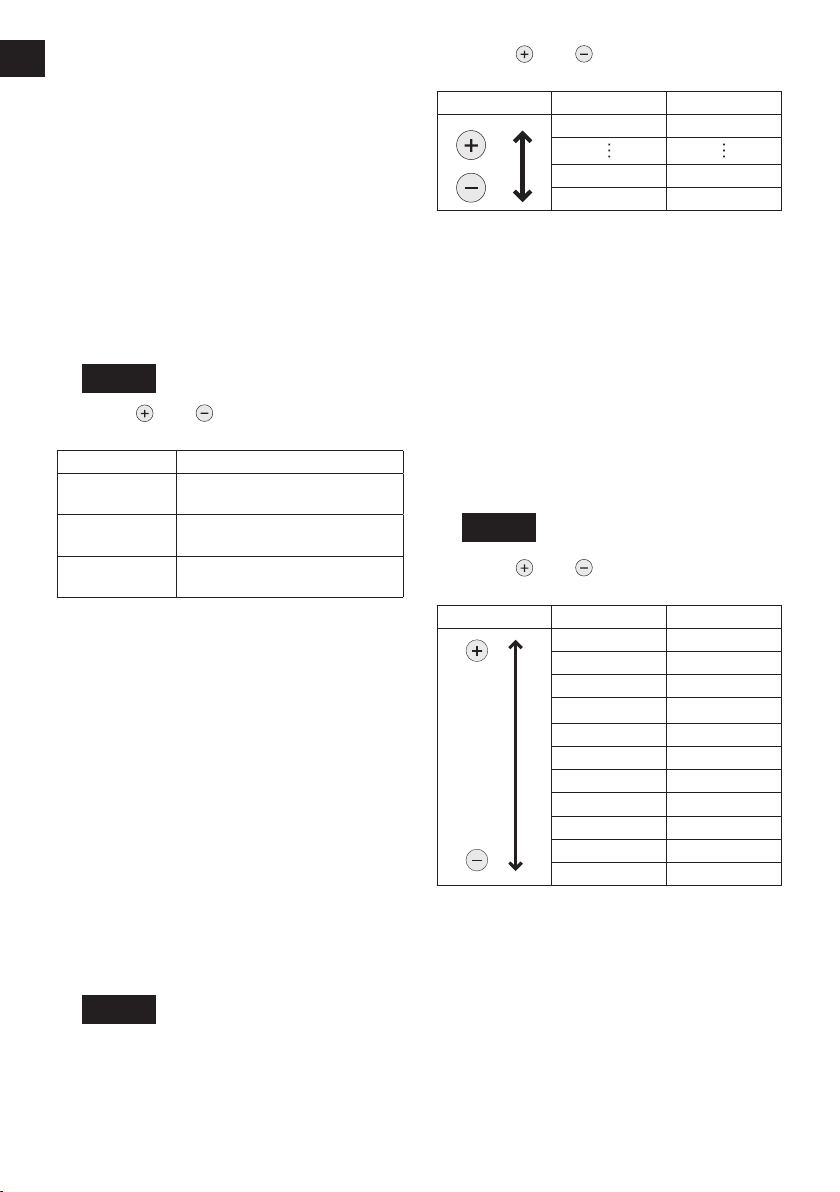

Rundown error detecting function

EN EN

(EYFLA7, EYFLA8, EYFLA9,

EYFMA2)

The rundown error detecting function

causes a red indicator to flash if work

ends more quickly than a set time, for

example due to retightening of a previously tightened fastener or binding of the

screw’s thread.

1. Set the tool to setting configuration

mode. (See page 18.)

2. Press the B button twice.

The rundown error detecting function setting value will be displayed.

[Fig.28]

3.

Press the and buttons to change the

time as desired.

Buttons Display Seconds

30 3

1 0.1

0 OFF

4. Press the OK button to accept the

selected setting.

When the cross thread reduction function

is ON, the set time will be counted after

the tool operates in reverse for approximately 360°.

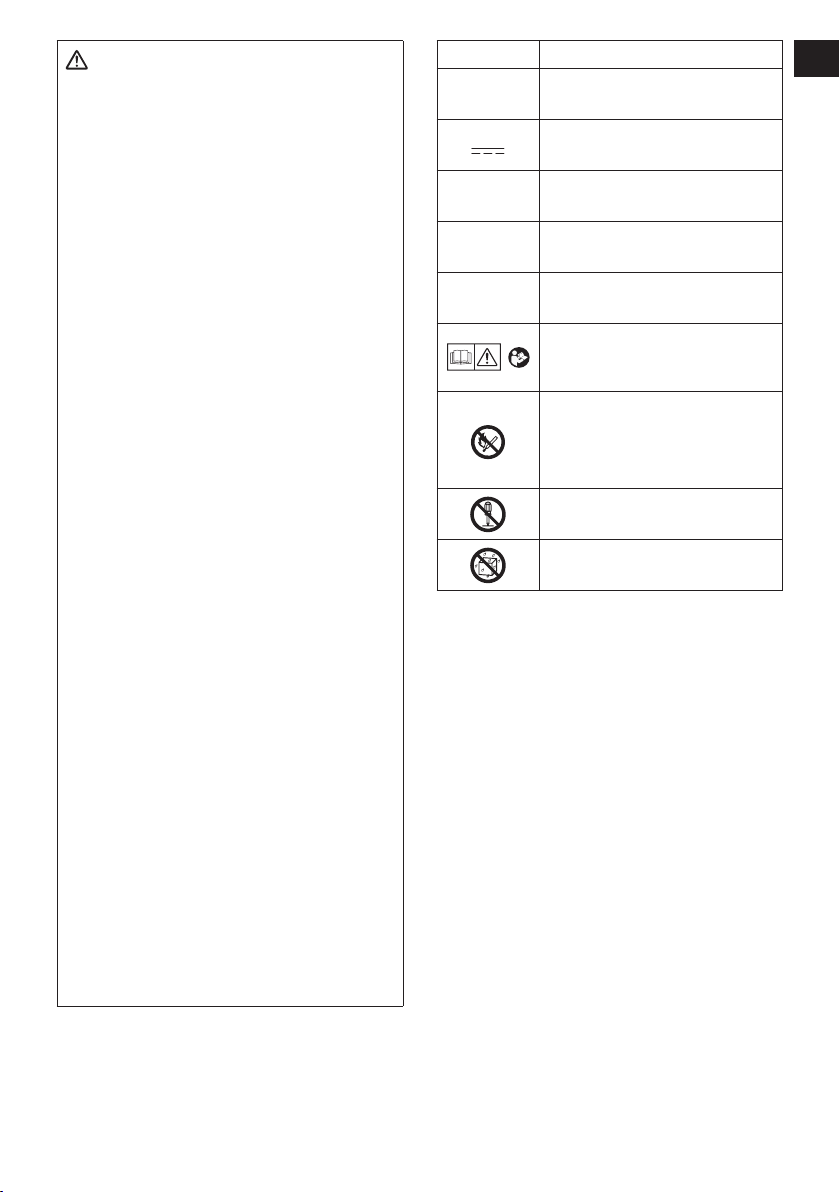

Radio signal range limitation

function on/off setting (EYFLA4AR,

EYFLA5AR, EYFLA5PR, EYFLA5QR,

EYFLA6JR, EYFLA6PR, EYFLA7AR,

EYFLA8AR, EYFLA8CR, EYFLA8PR,

EYFLA9CR, EYFLA9PR, EYFMA1JR,

EYFMA1PR, EYFMA2CR, EYFMA2PR

1. Set the tool to configuration mode.

(See page 18.)

2. Press the C button.

The control panel will begin flashing.

•

Display: The letter “F” ashes on and off.

Battery indication lamp: The upper and lower

bars of the battery ash on and off.

[Fig.29]

3. Press the C button again.

• Radio signal range limitation function

ON/OFF setting value will be displayed.

[Fig.30]

4. Press the and buttons to set

radio signal range limitation function

ON/OFF.

Display

Radio signal

range limitation

function mode

C0 OFF

C1 ON

Status

Tool is operational in the absence of communications with

the Assembly Qualier.

Tool is not operational

in the absence of com

munications with the As-

sembly Qualier.

5. Press the OK button to accept the

new setting.

Factory settings

• Radio signal range limitation function

setting: C0 (OFF)

NOTE:

• For more information about how to register

the tool and Assembly Qualifier, see the

Assembly Qualifier instruction manual.

Tightening time reminder

(EYFLA7, EYFLA8, EYFLA9,

EYFMA2)

The tool is locked when it reaches the set

tightening time, and the main unit stops

operation. This feature is convenient for

regular inspection of the tool performance.

1. Set the tool to setting configuration

mode. (See page 18.)

2. Press the C button twice.

)

The setting value will be displayed.

3. Press and buttons as required to

change the time.

Operation Display Tightening time

99 99 hours

1 1 hour

0 OFF

-

4. Press the OK button to accept the new

setting.

-

20 -

NOTE:

• When the remaining time prior to the

tightening time is less than 1 hour, the

display will alternate between the “set

value” and “-1”.

If the current tightening time remains

unchanged and the inspection duration

is extended, the new set value must be

greater than the current one.

When it reaches the set time, the

display alternates between the set

value and 0.

Buzzer setting

(EYFLA7, EYFLA8, EYFLA9,

EYFMA2)

You can select from three buzzer modes.

1. Set the tool to setting configuration

mode. (See page 18.)

2. Press the A button twice.

The current setting value will be displayed.

3. Press the and buttons to set the

desired value.

Display Function

b0 No buzzer

b1

Buzzer accompanying green indicator

b2 Buzzer accompanying red indicator

4. Press the OK button to accept the new

setting.

NOTE:

The tool ships with the buzzer mode set to

b0 by default.

LED light setting

(EYFLA7, EYFLA8, EYFLA9,

EYFMA2)

You can select from two LED light modes.

1. Set the tool to setting configuration

mode. (See page 18.)

2. Press the B button once.

The current setting value will be displayed.

3. Press the and buttons to set the

desired value.

Display Function

d1 Linked to LED light button

d2 Linked to trigger switch operation

4. Press the OK button to accept the new

setting.

NOTE:

The tool ships with the LED light mode set

to d1 by default.

Speed control function

(EYFLA7, EYFLA8, EYFLA9,

EYFMA2)

The speed (RPM) can be changed with the

amount of depression of the trigger.

1. Set the tool to setting configuration

mode. (See page 18.)

2. Press the B button three times.

The setting value will be displayed.

3. Press the and buttons to set the

desired value.

Operation Function

P0 Speed control ON

P1 Speed control OFF

4.

Press the OK button to accept the new

setting.

Setting the undetect time

(EYFLA7, EYFLA8, EYFLA9,

EYFMA2)

To set the time to undetect the function of

“snug point detection level” from the start

tightening, do as follows.

1. Set the tool to the configuration mode.

(See page 18.)

2. Press button A three times.

•

The current set value is displayed, and the

main unit panel starts flashing.

Display: J0 ashing.

Battery capacity indicator: The upper and

lower bars ash.

[Fig.31]

3. Press and buttons as required to

change the time.

Operation Display Seconds

30 3

1 0.1

J0 OFF

4. Press the OK button to accept the new

setting.

-

21 -

Setting the impact speed

EN EN

corresponding to the length

of the socket used

(EYFLA9, EYFMA2)

To set the stable impact speed based on the

length of the socket used, do as follows:

1. Set the tool to the configuration mode.

(See page 18.)

2. Press button D three times.

• The current set value is displayed, and

the main unit panel starts flashing.

Display: h0 ashing.

Battery capacity indicator: The upper

and lower bars ash.

[Fig.32]

3. Press and buttons as required to

change the value.

Display Impact Speed Standard

h0

h1

h2

4. Press the OK button to accept the new

setting.

Setting use interval

Use interval is set to prevent the screwdriver

from continuing its operation when the

tool is automatically stopped due to the

implementation of the torque correction

feature. This setting is valid even when the

switch is off.

1. Set the tool to the configuration mode.

(See page 18.)

[EYFLA4, EYFLA5, EYFLA6, EYFMA1]

2. Press button B.

• The main unit panel starts flashing.

Display: 0 flashing intermittently.

Battery capacity indicator: The middle

bar flashes intermittently.

[Fig.33]

Standard socket

(high speed)

Up to 150 mm socket

(medium speed)

Up to 250 mm socket

(low speed)

3. Press and buttons as required to

set the time.

Operation Display Seconds

30 3

1 0.1

0 OFF

4. Press OK to confirm the settings.

• The control panel stops flashing and lights

up to display the torque clutch settings.

NOTE:

Check the new value after you change the

settings.

[EYFLA7, EYFLA8, EYFLA9, EYFMA2]

2. Press button D twice.

• The current set value is displayed, and

the main unit panel starts flashing.

Display: U flashing.

Battery capacity indicator: The upper and

lower bars flash.

[Fig.33]

3. Press and as required to change

the time.

Operation Display Seconds

U9 3

U8 2.5

U7 2

U6 1.5

U5 1.2

U4 1

U3 0.7

U2 0.5

U1 0.3

U0 0.1

U OFF

4. Press the OK button to accept the new

setting.

• The control panel stops flashing and lights

up to display the torque clutch settings.

NOTE:

Check the new value after you change the

settings.

-

22 -

Initializing all settings

Factory settings

• Torque clutch setting: “F” (torque control

function off)

• Interval setting: U or 0 (OFF)

[EYFLA9, EYFMA2]

• Snug point detection level → L1

• Cross thread reduction function → R0

• Rundown error detecting function → 0

• Tightening time reminder → 0

• Radio signal range limitation function

→ C0

• Buzzer setting → b0

• LED light setting → d1

• Speed control setting → P0

• Undetect time setting → J0

• Impact speed setting corresponding to

the length of the socket used → h0

• This section explains how to revert all tool

settings to their default values at the time of

shipment from the factory.

• The error display will be turned off.

1. Set the tool to the setting configuration

mode.

(See page 18.)

2. Press the C button.

The control panel will begin flashing.

Display: The letter “F” flashes on and off.

Battery indication lamp: The upper and

lower bars of the battery flash on and off.

[Fig.34]

3. Press the OK button to accept the

selected setting.

The control panel will stop flashing and

light up.

Checking Tool Settings

(EYFLA4, EYFLA5, EYFLA6,

EYFMA1)

• This section describes how to have the

tool display current settings for approximately 3 seconds when the tool is

stopped.

• You cannot check tool settings when

the control panel is turned off. First,

engage the switch briefly to reactivate

the display.

Checking the torque clutch setting

Press the A button.

• Control panel display

Display: The torque set lights up.

Battery indication lamp: The upper bar of

the battery flashes on and off.

Checking the interval

Press the B button.

• Control panel display

Display: The interval set lights up.

Battery indication lamp: The middle bar of

the battery flashes on and off.

Checking tool circuits

Press the D button.

• Control panel display

Display: The torque set display lights up.

Battery indication lamp: The middle and

lower bars of the battery flash on and off.

Display Tool circuit

H6 EYFLA4

H7 EYFLA5

H8 EYFLA6

H9 EYFMA1

NOTE:

If you engage the switch while a setting

is being displayed, the control panel will

revert to the torque clutch setting display.

CAUTION:

The torque set display is not intended to

be used to identify the type of drive component parts (hammer, etc.) used in a particular tool.

Checking Tool Settings

(EYFLA7, EYFLA8, EYFLA9,

EYFMA2)

• This section describes how to have the

The current set value will display for

another 2 seconds after the tool stops

operation.

• The set status cannot be checked when

the tool panel is off. You can press the

trigger switch once to turn on the panel.

-

23 -

Loading...

Loading...