Panasonic DMR-E50 DVD Schematic

ORDER NO.DSD0302003C8

DVD Video Recorder

DMR-E50EB

DMR-E50EG

DMR-E50GCS

Colour

(S).......................Silver Type

SPECIFICATIONS

Power supply: AC220-240 V, 50 Hz (For

Power consumption: 29 W

Recording system: DVD video recording

Recordable discs: 12 cm 4.7 GB DVD-RAM

Specifications

E50EB/ EG)

AC220-240 V, 50/ 60 Hz

(For E50GCS)

standards (DVD-RAM),

DVD video standards (DVDR)

12 cm 9.4 GB DVD-RAM

8 cm 2.8 GB DVD-RAM

12 cm 4.7 GB DVD-R

(for General Ver. 2.0)

www.electronicsrepair.net

Recording time: Maximum 360 min.

(with 4.7 GB disc)

XP: Approx. 60 minutes

SP: Approx. 120 minutes

LP: Approx. 240 minutes

EP: Approx. 360 minutes

Region Number: Region No.2 (E50EB/ EG)

Region No.3 (E50GCS)

Playable discs: 12 cm 4.7 GB DVD-RAM

12 cm 9.4 GB DVD-RAM

8 cm 2.8 GB DVD-RAM

12 cm 4.7 GB DVD-R

(for General Ver. 2.0)

DVD-Video

CD-Audio (CD-DA)

Video CD

CD-R/RW

(CD-DA,Video CD MP3

formatted discs)

Audio

Recording system: Dolby Digital, 2ch

Audio In: AV1/ AV2 (21 pin) AV3/AV4

(pin jack)

Input Level: Standard: 0.5 Vrms

Full scale: 2 Vrms at 1k Hz

Input Impedance: more than 10k ohm

Audio Out: AV1/ AV2 (21 pin) Audio Out

(pin jack)

Output Level: Standard: 0.5 Vrms

Full scale: 2 Vrms at 1k Hz

Output Impedance:less than 1k ohm

Digital Audio Out: Optical terminal (PCM,

Dolby Digital, DTS, MPEG)

Television System

Tuner System: PAL I 75 ohm (For E50EB)

PAL I 75 ohm terminated

(For E50EB)

PAL B/ G/ H 75 ohm

terminated

(For E50EG/ GCS)

Channel Coverage:

DMR-E50EB only UHF: CH 21-68

DMR-E50EG only VHF: CH E2-E12, A-H2 (For

Italy)

UHF: CH 21-69

CH S01-S05 (S1-S3)

CATV

S1-S20 (M1-U10)

:

S21-S41 [8MHz,

RASTER]

DMR-E50GCS only VHF: CH E2-E12

UHF: CH 21-69

CH S01-S05

CATV

CH M1-M10

:

CH U1-U10

CH S21-S41

RF Converter

Output:

UHF:

CH21-68, 71 ± 3dB

75 ohm

(For the E50EB)

Not provided

(For the E50EG/ GCS)

Video

Video System: PAL colour signal, 625 lines,

50 fields

NTSC colour signal, 525

lines, 60 fields

Recording system: MPEG2 (Hybrid VBR)

Video in: AV1/AV2 (21 pin), AV3/AV4

(pin jack)

1Vp-p 75 ohm, terminated

S-Video in: AV2 (21 pin), AV3 /AV4 (S

terminal)

1Vp-p 75 ohm, terminated

RGB In: AV2 (21 pin), 0.7Vp-p (PAL)

75 ohm, terminated

Video Out: AV1/AV2 (21 pin), Video Out

(pin jack)

1Vp-p 75 ohm, terminated

S-Video Out: AV1 (21 pin), S-Video Out(S

terminal)

1Vp-p 75 ohm, terminated

RGB Out: AV1 (21 pin) 0.7Vp-p (PAL)

75 ohm, terminated

Dimensions(W)x(H)x(D)

Approx. 430x79x283 mm

:

Mass: Approx. 3.8 Kg

Operating

5 °C-40°C

Temperature:

Operating Humidity

range:

10 %-80 % RH (no

condensation)

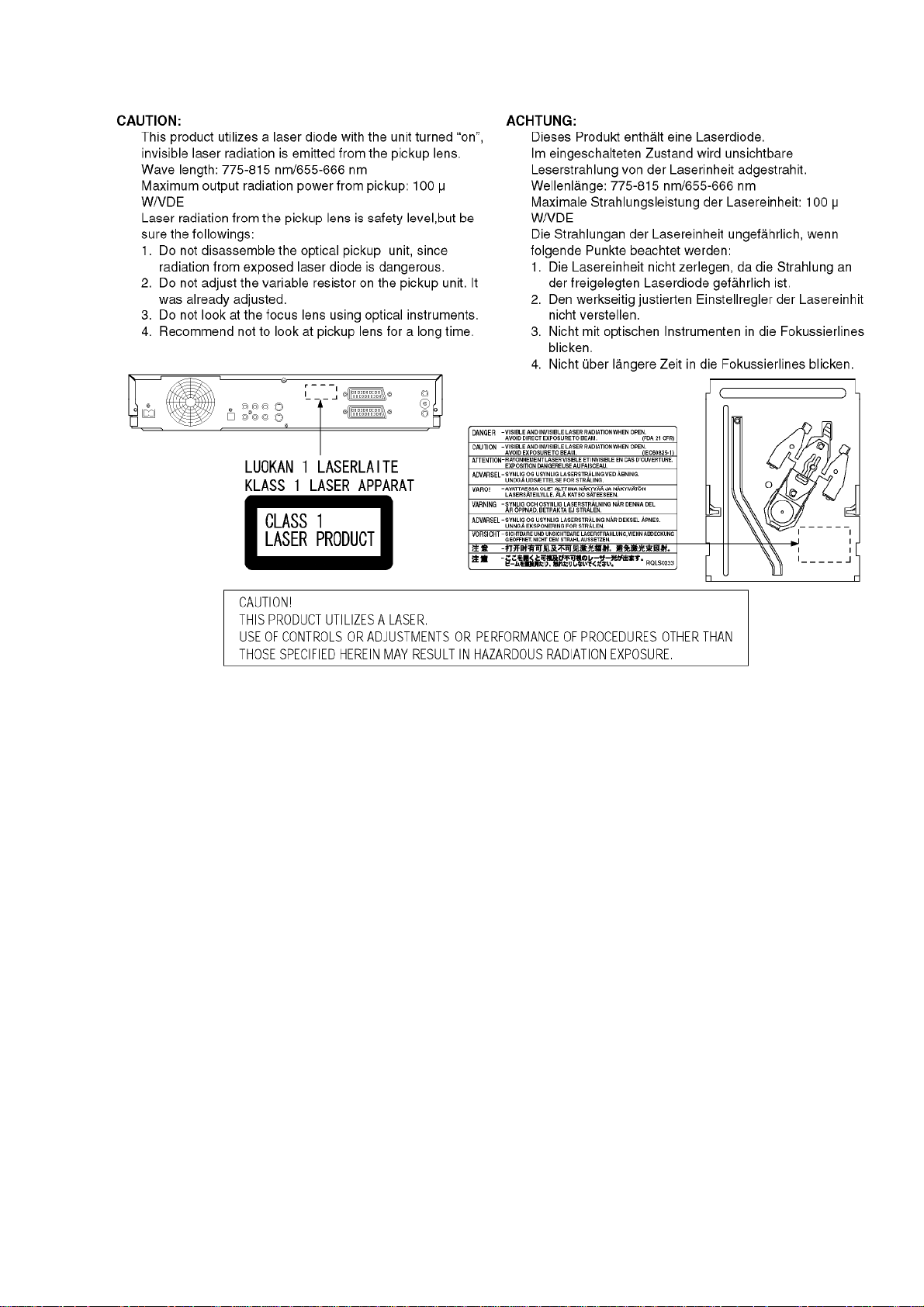

LEASER Specification

Class 1 LASER Product

Wave Length: 775-815nm, 655-666nm

Laser Power: No hazardous radiation is

emitted with the safety

protection

Notes:

Mass and dimensions shown are approximate.

Specifications are subject to change without notice.

Notes:

The part of DVD RAM Drive (VXY1772) is listed

separately.

Please refer to ORDER NO. RAM0301002C0.

1

1. SAFETY PRECAUTIONS

1.1. GENERAL GUIDELINES

1. When servicing, observe the original lead dress. If a short circuit is found, replace

all parts which have been overheated or damaged by the short circuit.

2. After servicing, see to it that all the protective devices such as insulation barriers,

insulation papers shields are properly installed.

3. After servicing, make the following leakage current checks to prevent the customer

from being exposed to shock hazards.

1.1.1. LEAKAGE CURRENT COLD CHECK

1. Unplug the AC cord and connect a jumper between the two prongs on the plug.

2. Measure the resistance value, with an ohmmeter, between the jumpered AC plug

and each exposed metallic cabinet part on the equipment such as screwheads,

connectors, control shafts, etc. When the exposed metallic part has a return path to

thechassis, the reading should be between 1M

When the exposed metal does not have a return path to the chassis, the reading

and 5.2M .

must be

.

Figure 1

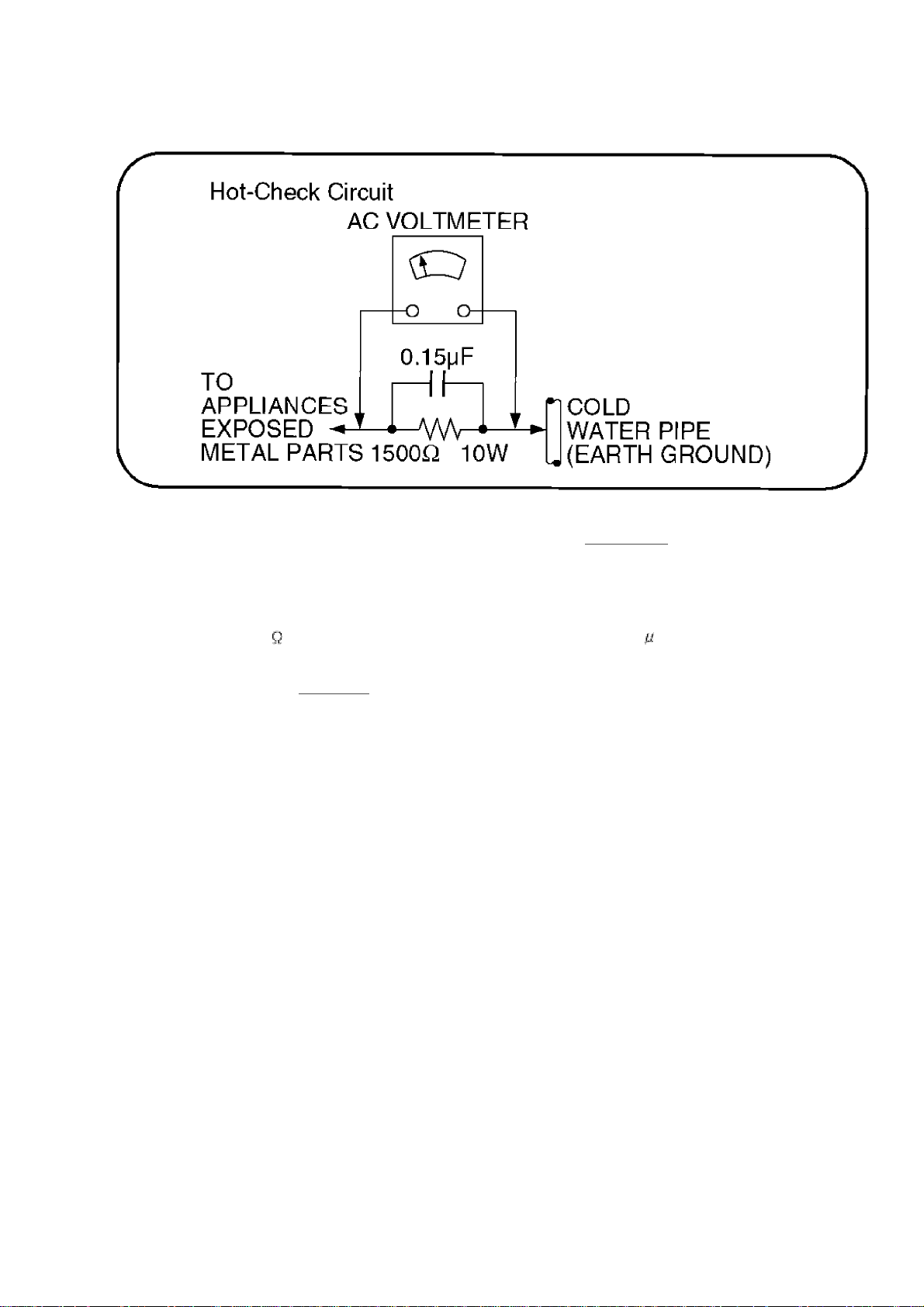

1.1.2. LEAKAGE CURRENT HOT CHECK (See Figure 1 .)

1. Plug the AC cord directly into the AC outlet. Do not use an isolation transformer for

this check.

2. Connect a 1.5k

each exposed metallic part on the set and a good earth ground such as a water

pipe, as shown in

3. Use an AC voltmeter, with 1000 ohms/volt or more sensitivity, to measure the

potential across the resistor.

4. Check each exposed metallic part, and measure the voltage at each point.

5. Reverse the AC plug in the AC outlet and repeat each of the above measurements.

6. The potential at any point should not exceed 0.75 volts RMS. A leakage current

tester (Simpson Model 229 or equivalent) may be used to make the hot checks,

leakage current mu3st not exceed 1/2 milliamp. In case a measurement is outsideof

the limits specified, there is a possibility of a shock hazard, and the equipment

should be repaired and rechecked before it is returned to the customer.

, 10 watts resistor, in parallel with a 0.15 F capacitors, between

Figure 1 .

2. PREVENTION OF ELECTRO STATIC DISCHARGE

(ESD) TO ELECTROSTATICALLY SENSITIVE (ES)

DEVICES

Some semiconductor (solid state) devices can be damaged easily by static electricity.

Such components commonly are called Electrostatically Sensitive (ES) Devices.

Examples of typical ES devices are integrated circuits and some field-effect

transistorsand semiconductor "chip" components. The following techniques should

be used to help reduce the incidence of component damage caused by electro static

discharge (ESD).

1. Immediately before handling any semiconductor component or semiconductorequipped assembly, drain off any ESD on your body by touching a known earth

ground. Alternatively, obtain and wear a commercially available discharging ESD

wrist strap, whichshould be removed for potential shock reasons prior to applying

power to the unit under test.

2. After removing an electrical assembly equipped with ES devices, place the

assembly on a conductive surface such as alminum foil, to prevent electrostatic

charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4. Use only an anti-static solder removal device. Some solder removal devices not

classified as "anti-static (ESD protected)" can generate electrical charge sufficient

to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges

sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective package until

immediately before you are ready to install it. ( Most replacement ES devices are

packaged with leads electrically shorted together by conductive foam, alminum foil

or comparableconductive material).

7. Immediately before removing the protective material from the leads of a replacement

ES device, touch the protective material to the chassis or circuit assembly into

which the device will be installed.

Caution

Be sure no power is applied to the chassis or circuit, and observe all other safety

precautions.

8. Minimize bodily motions when handling unpackaged replacement ES devices.

(Otherwise hamless motion such as the brushing together of your clothes fabric or

the lifting of your foot from a carpeted floor can generate static electricity (ESD)

sufficient todamage an ES device).

3. Precaution of Laser Diode

4. How to replace the Lithium Battery

REPLACEMENT PROCEDURE

1. Remove the Top cover and DVD-RAM drive unit with Main P.C.B. by referring the

Disassembling Procedure.

2. Unsolder the Lithium Batteries: B7501 and then replace it into new one.

( As shown in 16.2. The Main P.C.B. )

NOTE:

The lithium battery is a critical component. ( Type No.: CR2354-1GUF Manufactured by

Panasonic. )

It must never be subjected to excessive heat or discharge.

It must therefore only be fitted in equipment designed specifically for its use.

Replacement batteries must be of the same type and manufacture.

They must be fitted in the same manner and location as the original battery, with the

correct polarity contacts observed.

Do not attempt to re-charge the old battery or re-use it for any other purpose.

It should be disposed of in waste products destined for burial rather than incineration.

5. Handling the Lead-free Solder

5.1. About lead free solder (PbF)

Distinction of PbF P.C.B.:

P.C.B.s (manufactured) using lead free solder will have a PbF stamp on the P.C.B.

Caution:

- Pb free solder has a higher melting point than standard solder; Typically the melting

point is 50 - 70°F (30 - 40°C) higher. Please use a high temperature soldering iron. In

case of the soldering iron with temperature control,please set it to 700 ± 20°F (370 ±

10°C).

- Pb free solder will tend to splash when heated too high (about 1100°F/600°C).

- When soldering or unsoldering, please completely remove all of the solder on the

pins or solder area, and be sure to heat the soldering points with the Pb free solder

until it melts enough.

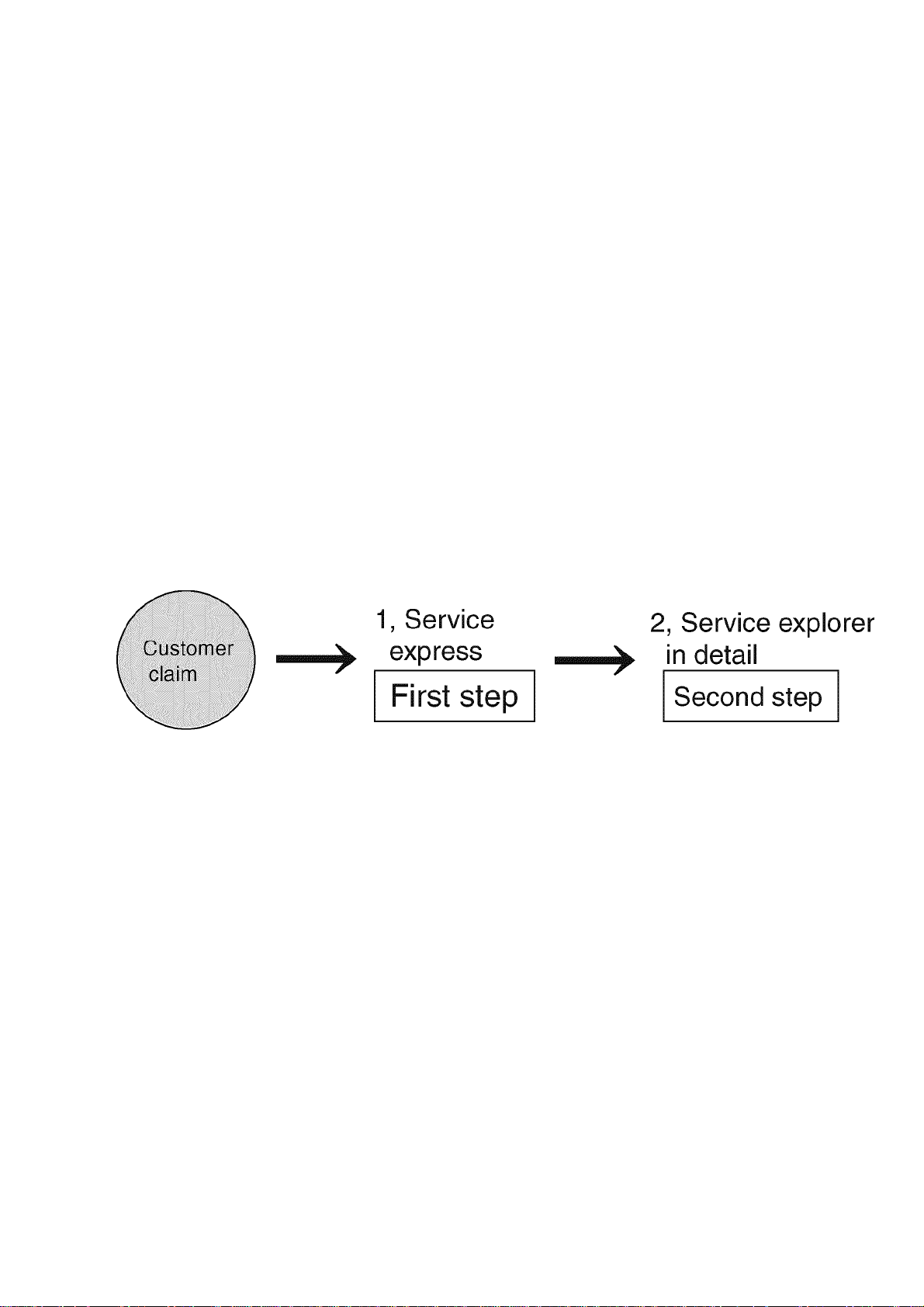

6. Service Explorer

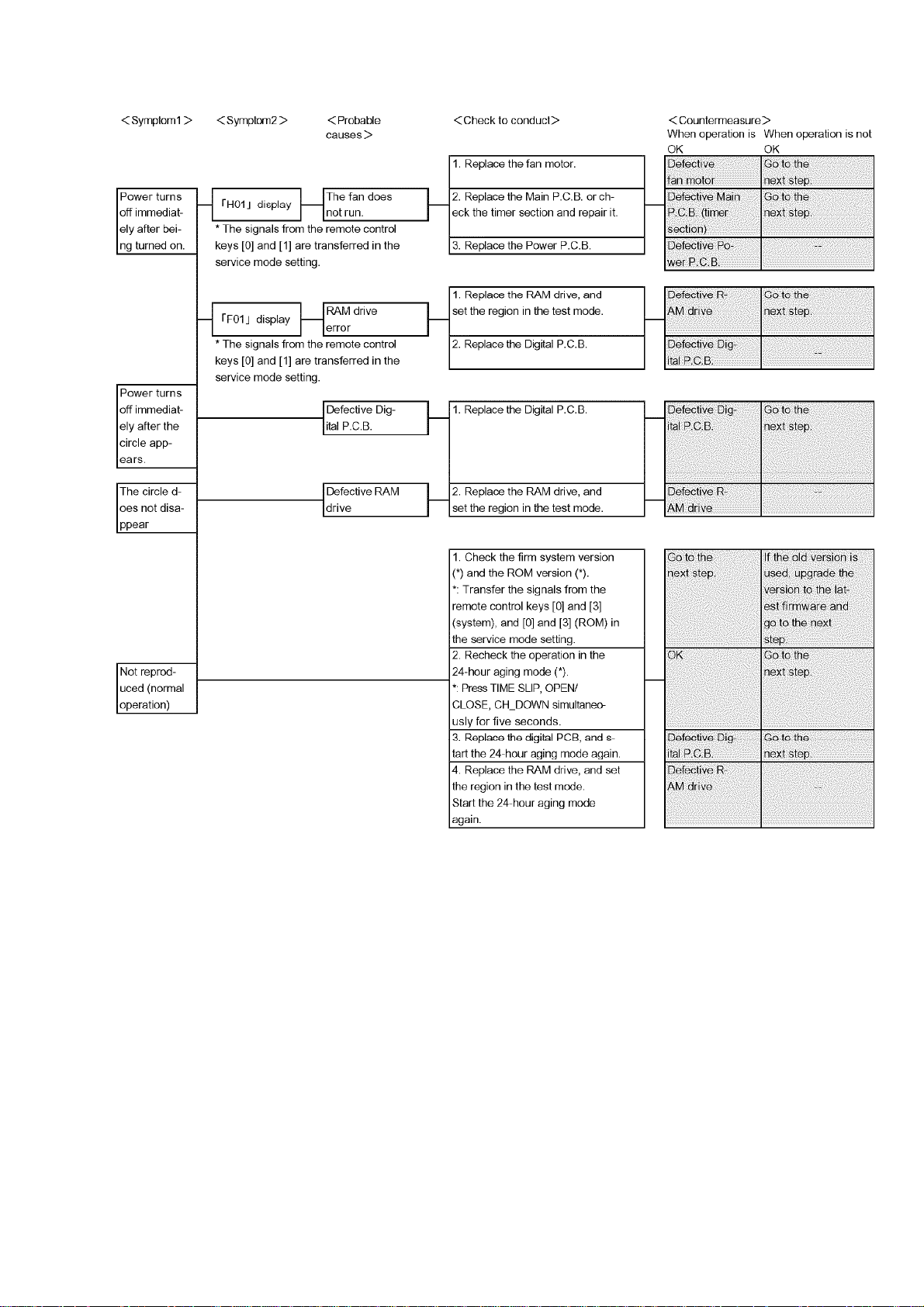

The Service Explorer provides information about all possible causes based on the

symptoms and gives step by step instructions making parts. It consists of two parts,

based on applications: the first is the “Service Explorer Express” andthe second is

“Service Explorer in Detail”.

1. For details about the service / test modesetting mentioned in the description, refer

to the “List of various modes”.

- Service mode setting: While the power is off, press TIME SLIP, STOP, and

OPEN / CLOSE simultaneously for five seconds.

- Process mode 1 setting: While the power is off, press SKIP(R), TIME SLIP, and

OPEN / CLOSE simultaneously for five seconds.

2. For disassembly and replacement procedures, refer to the “Assembling and

Disassemling”.

6.1. Service Explorer Express

The following steps allow you to check each block separately (Digital P.C.B., RAM

drive, Main / Power Supply / Front P.C.B.).

Items needed: RAM drive, Digital P.C.B., Digital extension cable, Remote control.

Conditions: Nothing special.

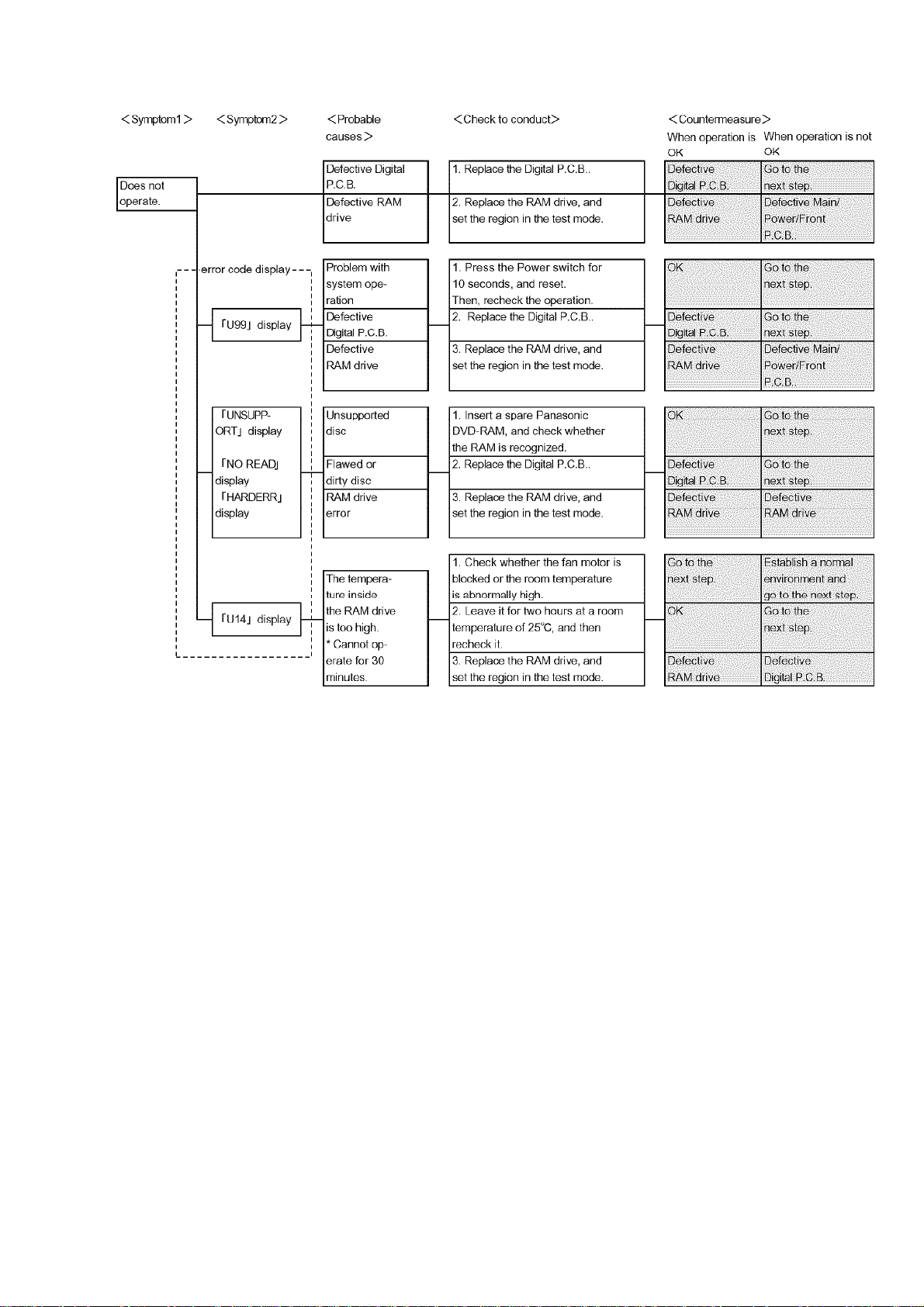

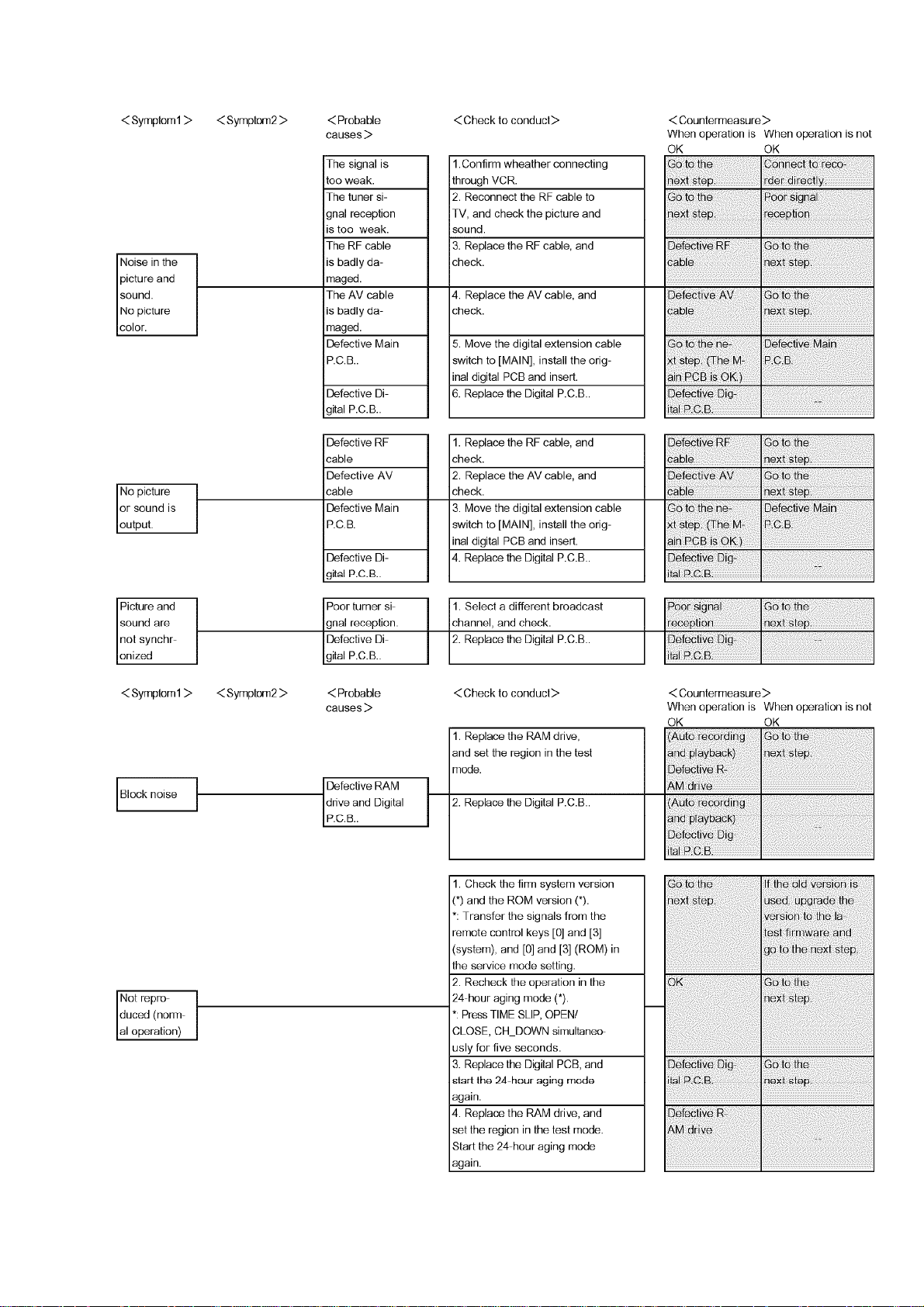

6.2. Service Explorer in Detail

6.2.1. Does not operate

items needed: RAM drive, digital P.C.B., remote control.

Conditions: Nothing special.

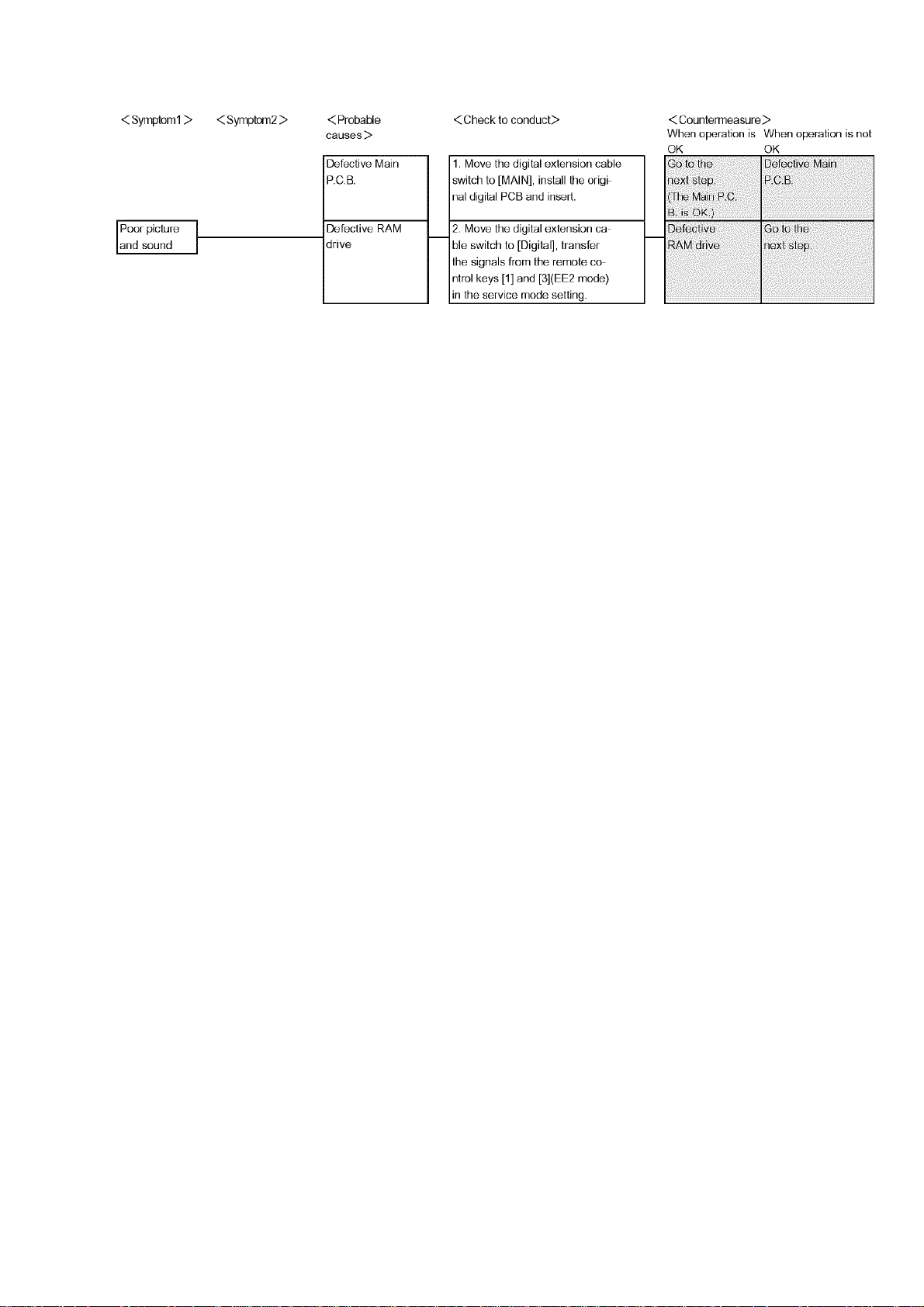

6.2.2. Poor Pictures

Items needed: RAM drive, Digital P.C.B., RF cable, AV cable.

Conditions: Check with TU IN-AV OUT(EE). When recording or playback is partially

needed, follow the instructions.

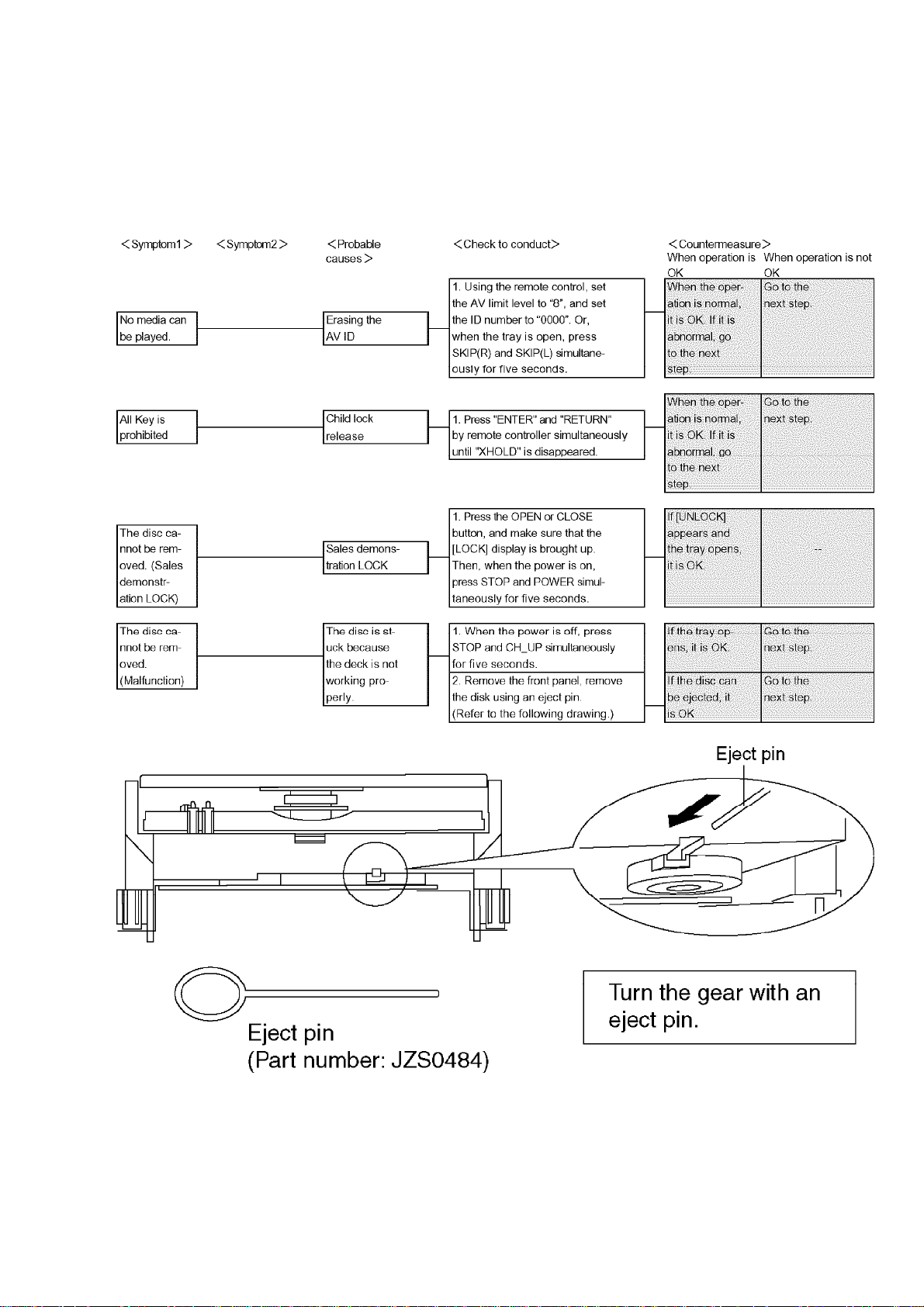

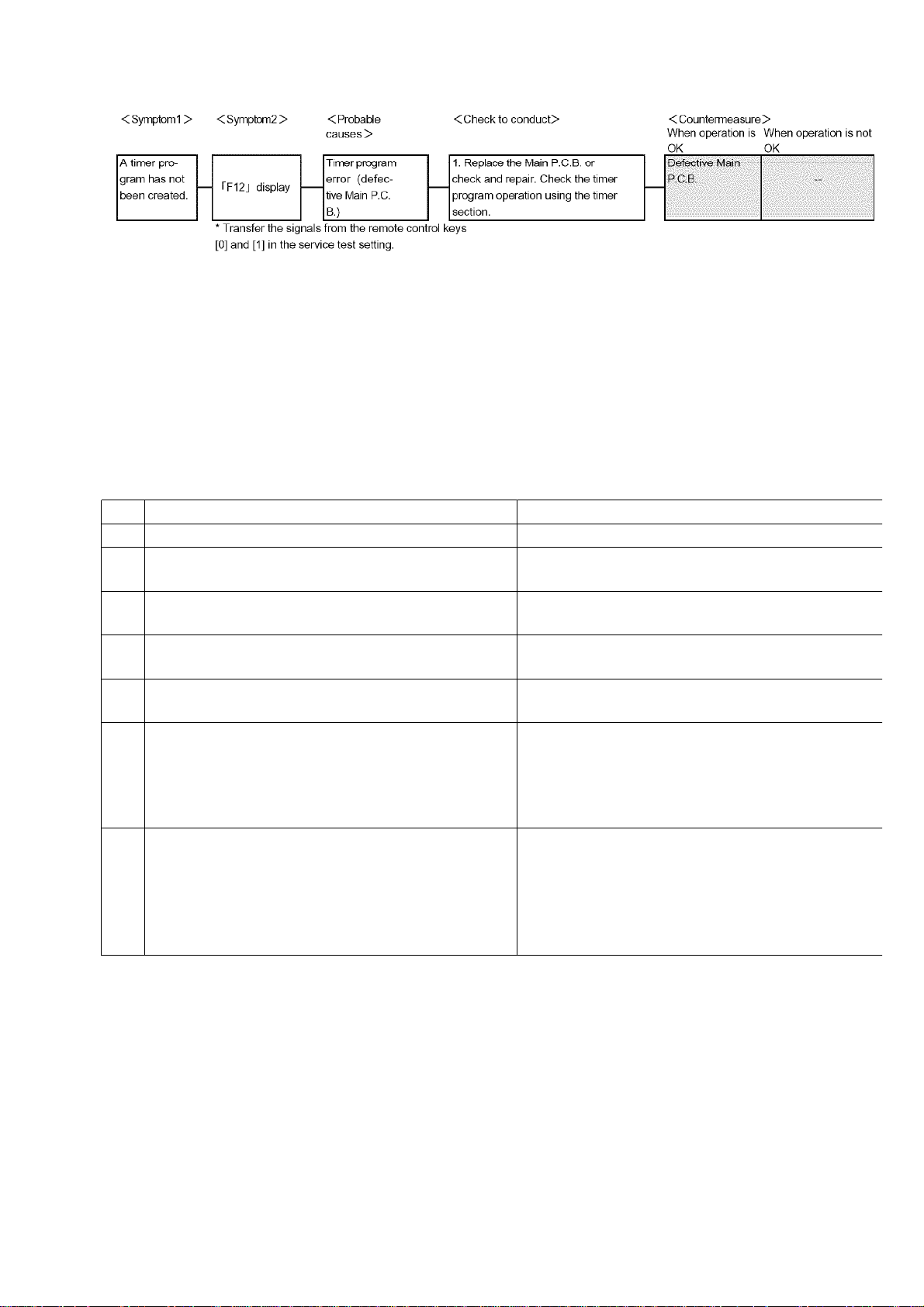

6.2.3. Other

Items needed: Digital P.C.B., HDD.

Conditions: Nothing special.

7. Standard Inspection Specifications after Making

Repairs

7.1. Standard Inspection Specification

After making repairs, we recommend performing the following inspection, to check

normal operation.

No. Procedure Item to Check

1 Turn on the power. The Panasonic RAM disc should be recognized.

2 Enter the EE (TU IN / AV IN - AV OUT) mode. No abnormality should be seen in the picture,

sound or operation.

3 Perform auto recording and playback for one

minute using the RAM disc.

4 If a problem is caused by a VCD, DVD-R, DVD-

Video, Audio -CD, or MP3, playback the test disc.

5 After checking and making repairs, upgrade the

firmware to the latest version.

6 Transfer [9][9] in the service mode setting, and

initialize the service settings (return various

settings and error information to their default

values. The laser time is not included in this

initialization).

7 To replace the RAM drive, reset all the information

(including the laser time) in the process mode 1

setting.

*The laser time is the total time that DVDs or CDs

have been played or recorded.It is recorded on

the Digital P.C.B..

No abnormality should be seen in the picture,

sound or operation.

No abnormality should be seen in the picture,

sound or operation.

Make sure that [FIRM_SUCCESS] appears in the

FL displays.

Make sure that [FACT INIT] appears in the FL

display.

After checking it, turn the power off.

Maku sure that [TEST L1] appears in the FL

display.

After checking it, turn the power off.

Use the following checklist to establish the judgement criteria for the picture and

sound.

Item Contents Item Contents Check

Picture

Block noise Distorted sound

Crosscut noise noise (static, background noise,

Dot noise The sound level is too low.

Picture disruption The sound level is too high.

Not bright enough The sound level changes.

Too bright

Flickering color

Color fading

Sound

etc.)

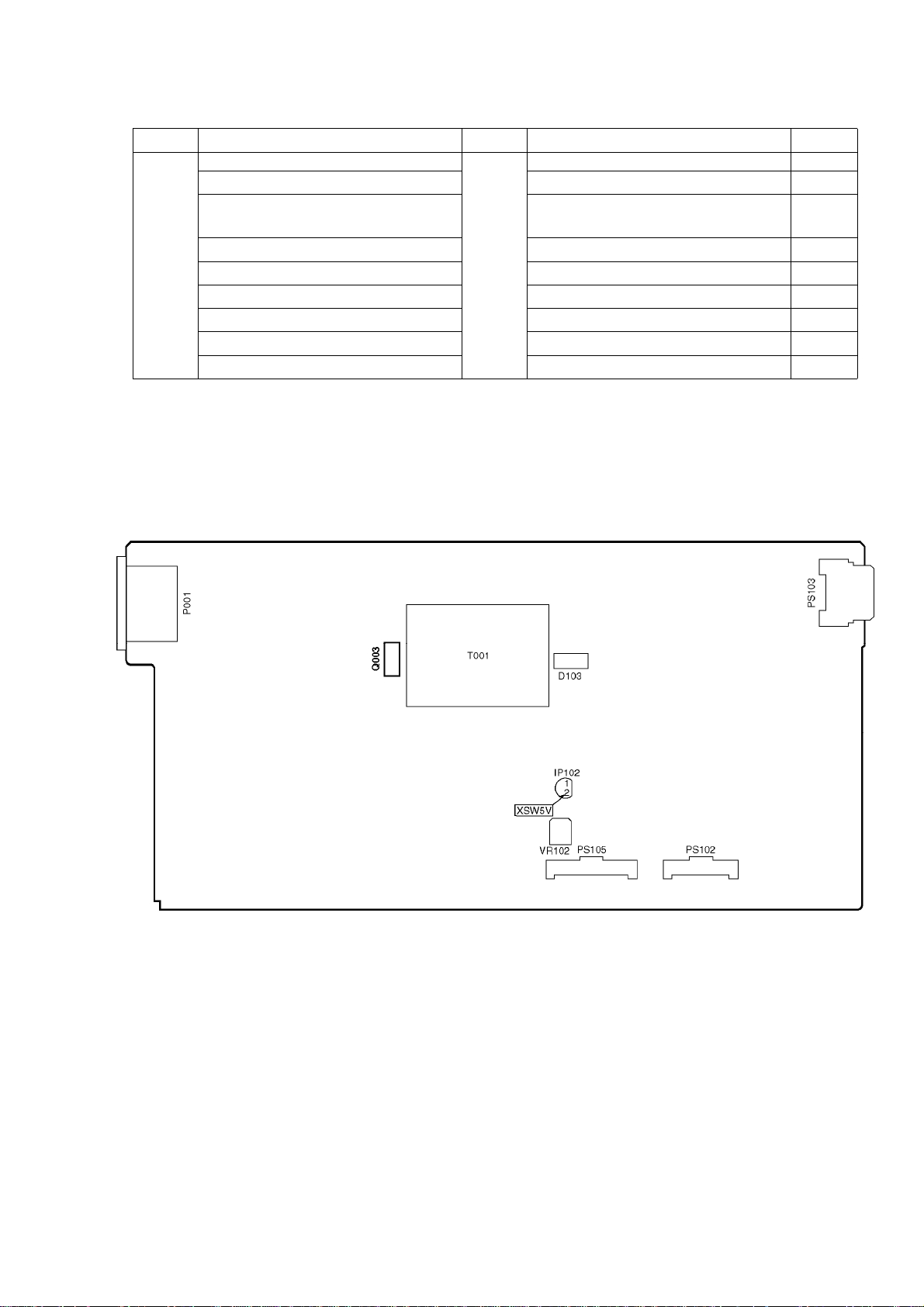

7.2. Power Supply +5V Adjustment Procedure

1. When the T001, Q003 and D103 is replaced, adjust the “XSW5V” measuring point

(IP102-2) in the VR102 to the value between 5.12 - 5.15V.

8. Assembling and Disassembling

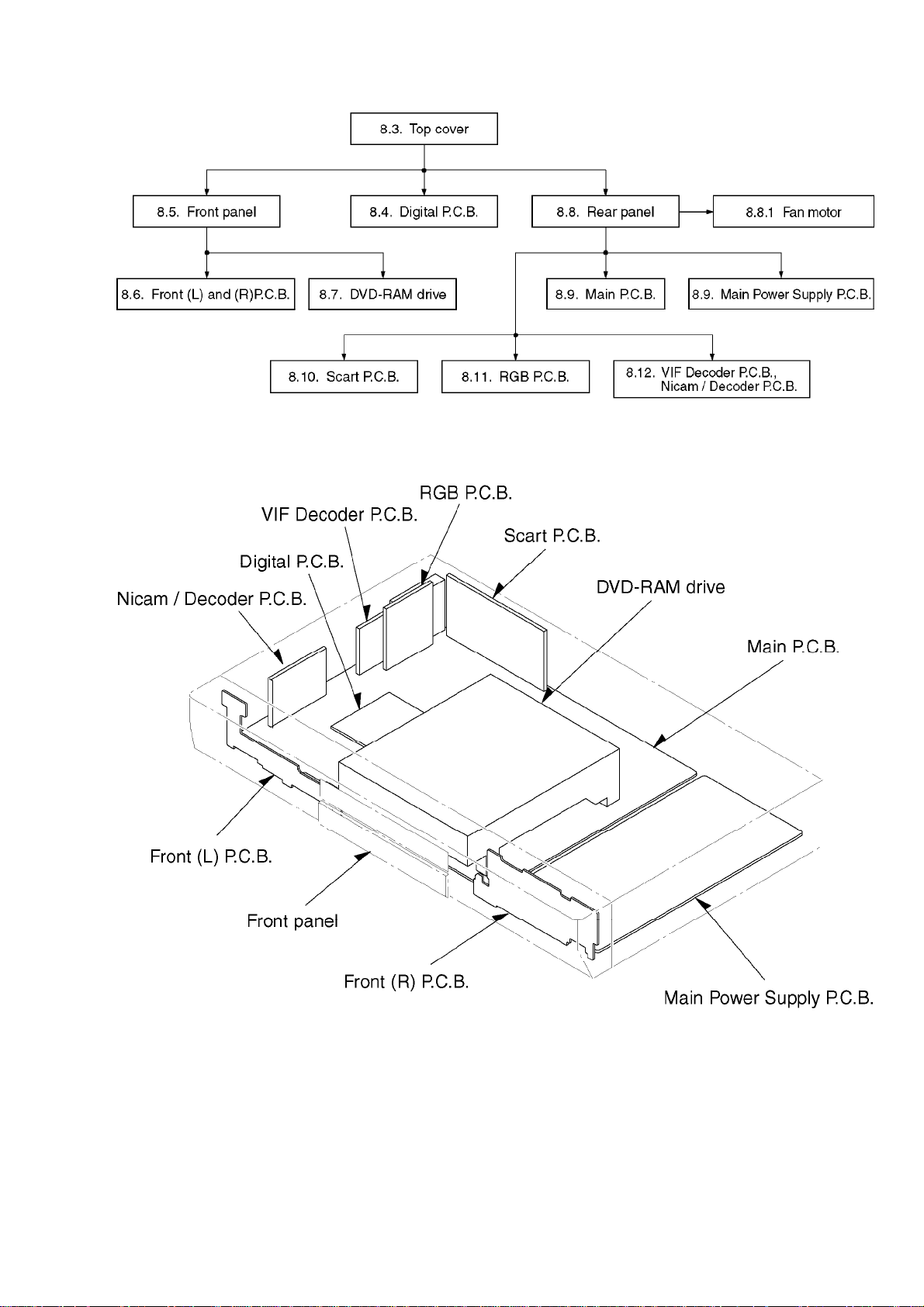

8.1. Disassembly flow chart

The following chart is the procedure for disassembling the casing and inside parts for

internal inspection when carrying out the servicing.

To assemble the unit, reverse the steps shown in the chart below.

8.2. P.C.B. Positions

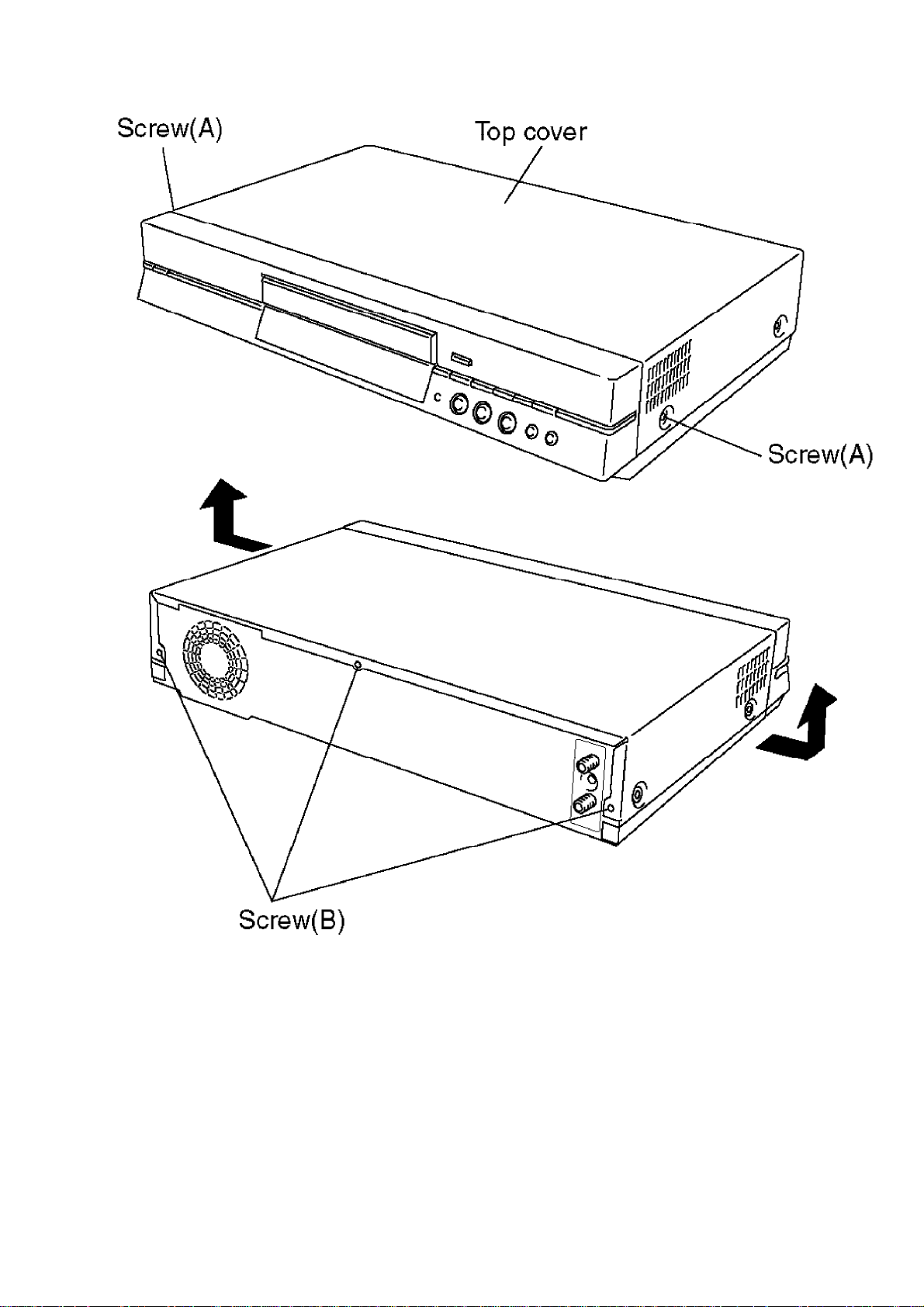

8.3. The Top Cover

1. Remove the 2 screws (A) and 3 screws (B).

2. Open the both ends at the front side of the Top cover a bit and lift the Top cover in

the direction of the arrows.

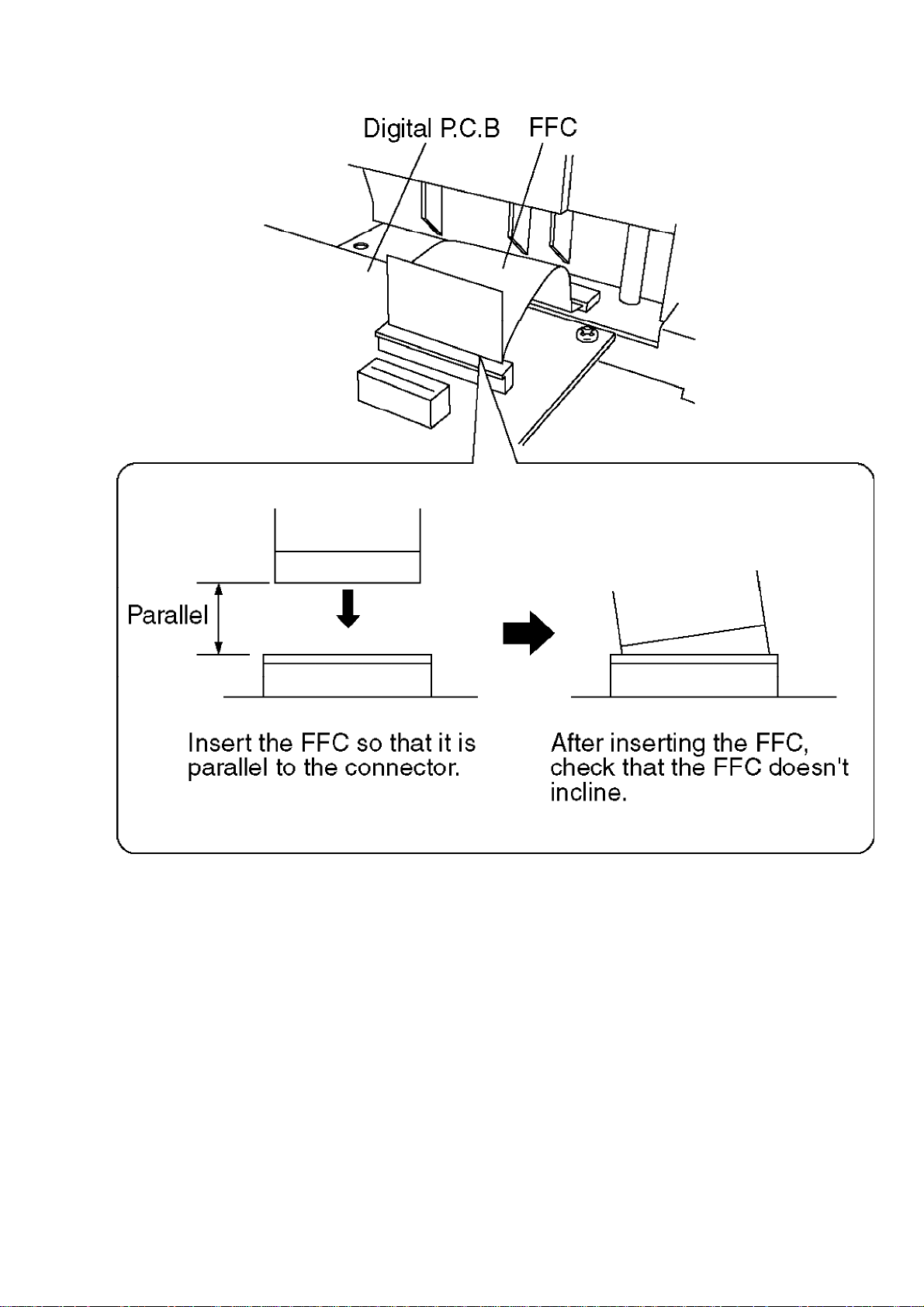

8.4. The Digital P.C.B.

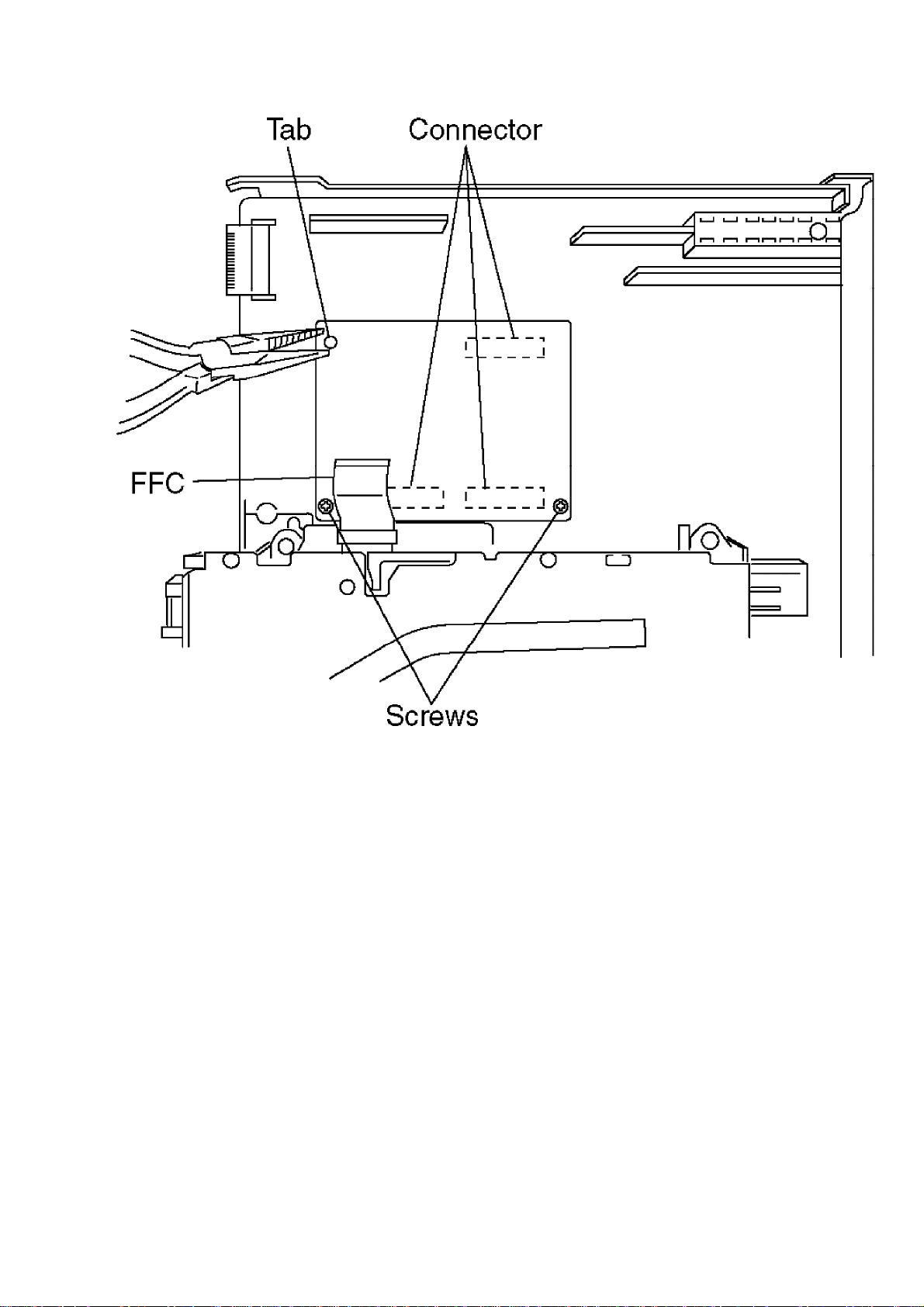

1. Remove the FFC.

CAUTION:

When replacing Digital P.C.B., pay attention as below.

2. Remove the 2 screws.

3. Pinch the tab with the pliers to pull out the 3 Connectors and Digital P.C.B.

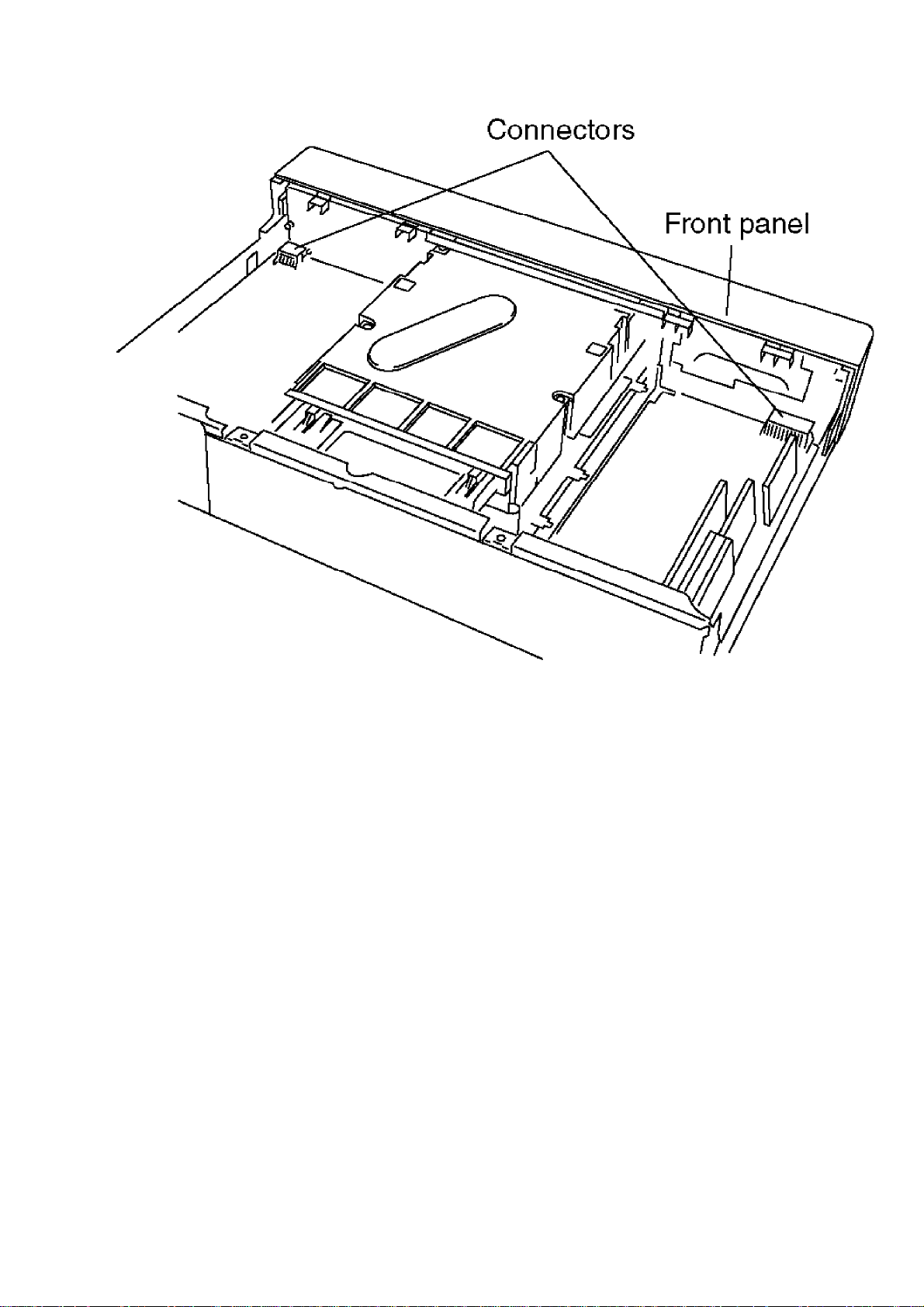

8.5. The Front panel

1. Remove the 2 connectors.

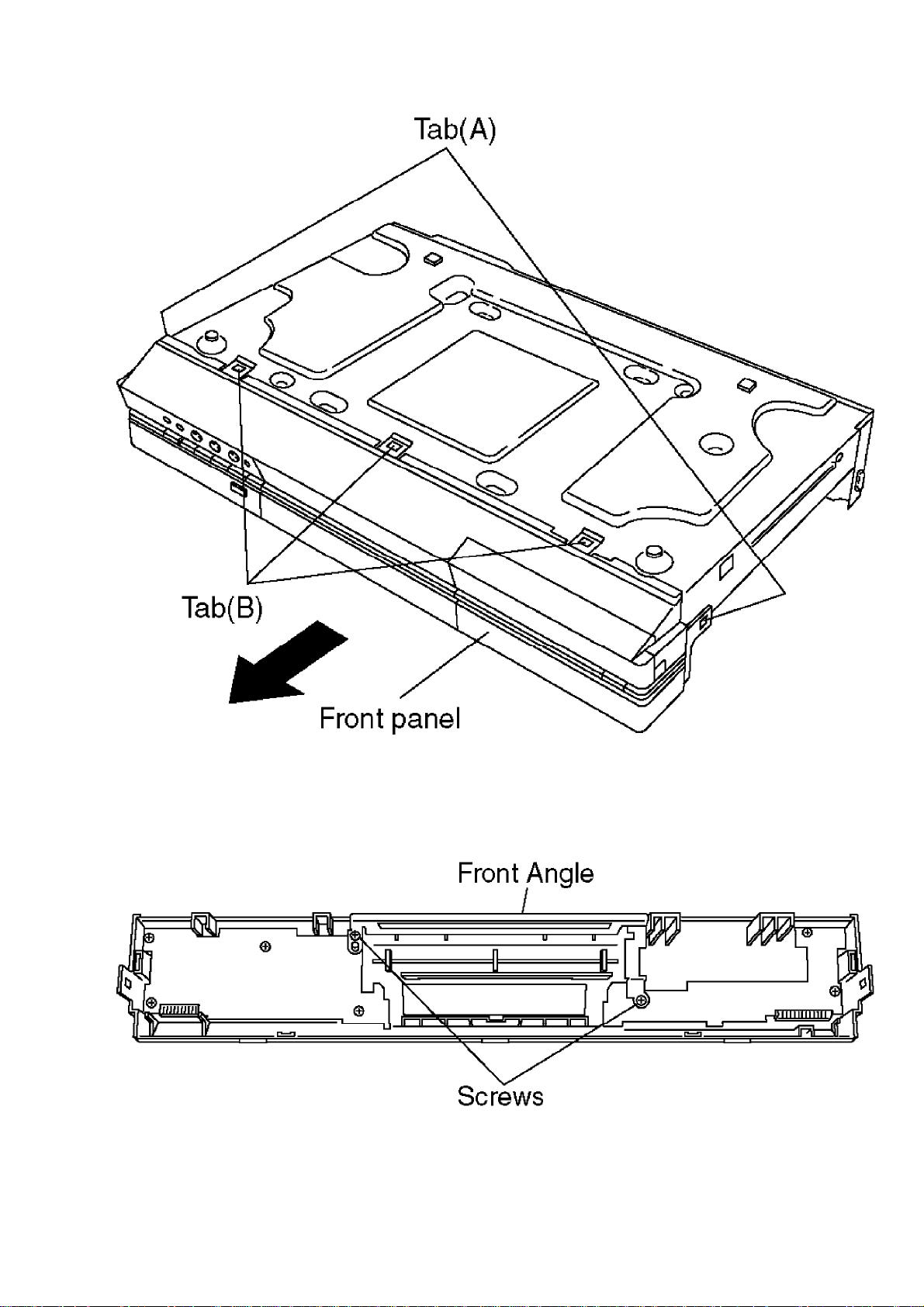

2. Remove the 2 tab (A) and 3 tab (B) in this order. (The tab (A) and the tab (B) should

be removed at the same time, respectively.)

3. Move the front panel to your side slowly and remove it.

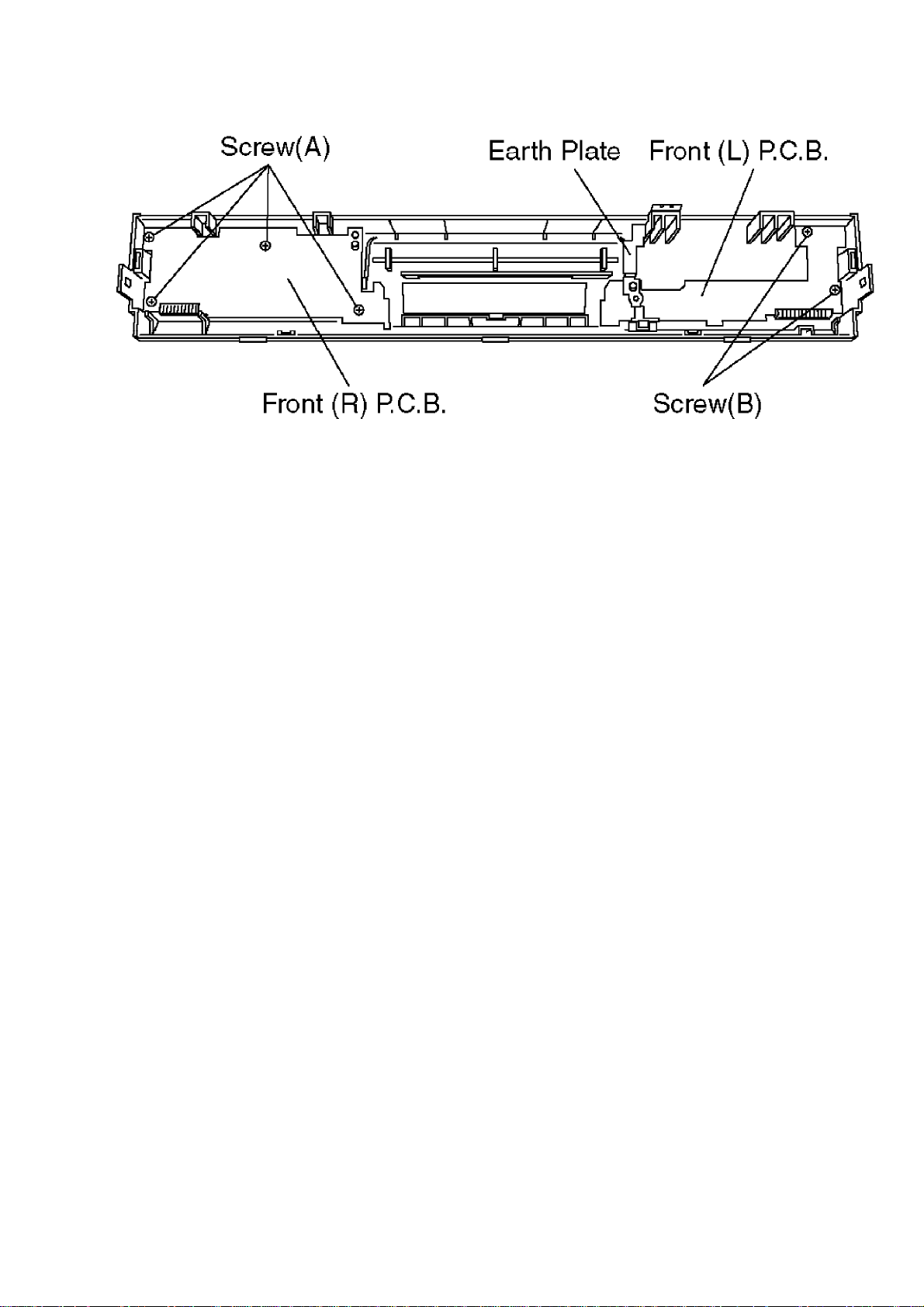

8.6. The Front (L) and (R) P.C.B.

1. Remove the 2 screws and remove the Front Angle.

2. Remove the 4 screws (A) and remove the Front (R) P.C.B.

3. Remove the 2 screws (B) with Earth plate and remove the Front (L) P.C.B.

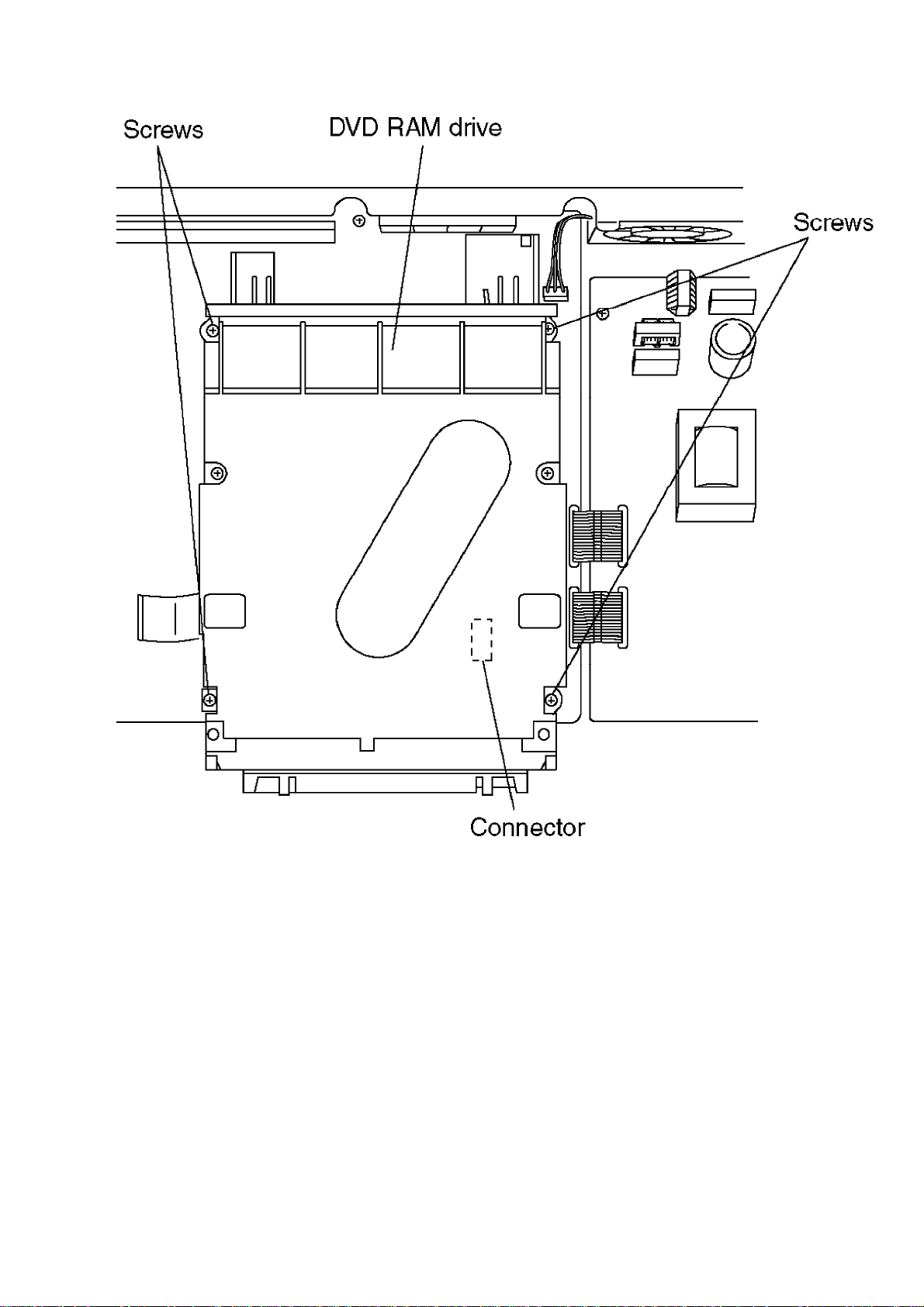

8.7. The DVD-RAM Drive

1. Remove the 4 screws.

2. Pull out the DVD-RAM Drive vertically and remove the connector.

8.8. The Rear panel

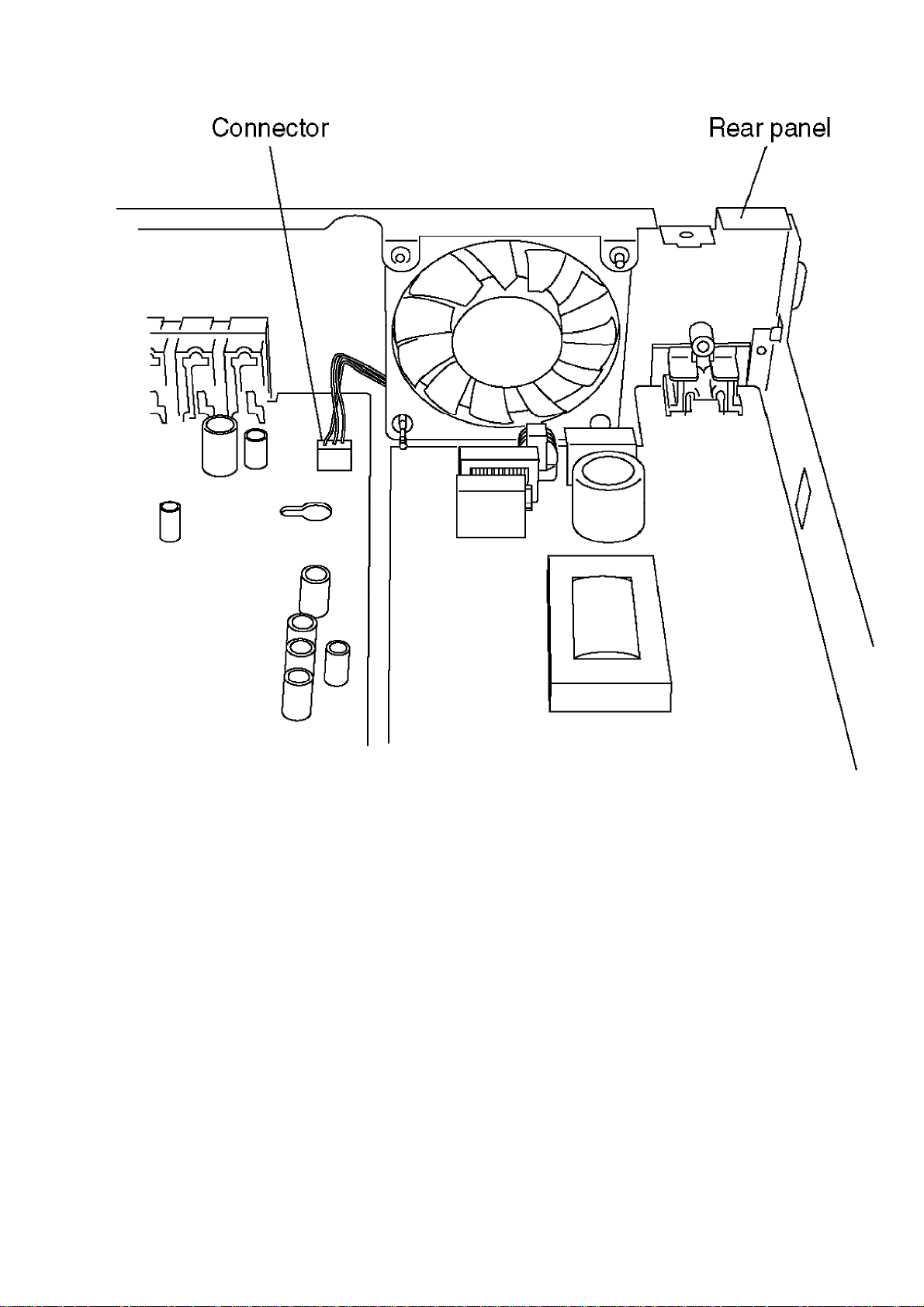

1. Remove the Fan Motor connector.

2. Remove the 8 screws (A) and a screw (B).

3. Remove the 2 tabs and remove the Rear panel.

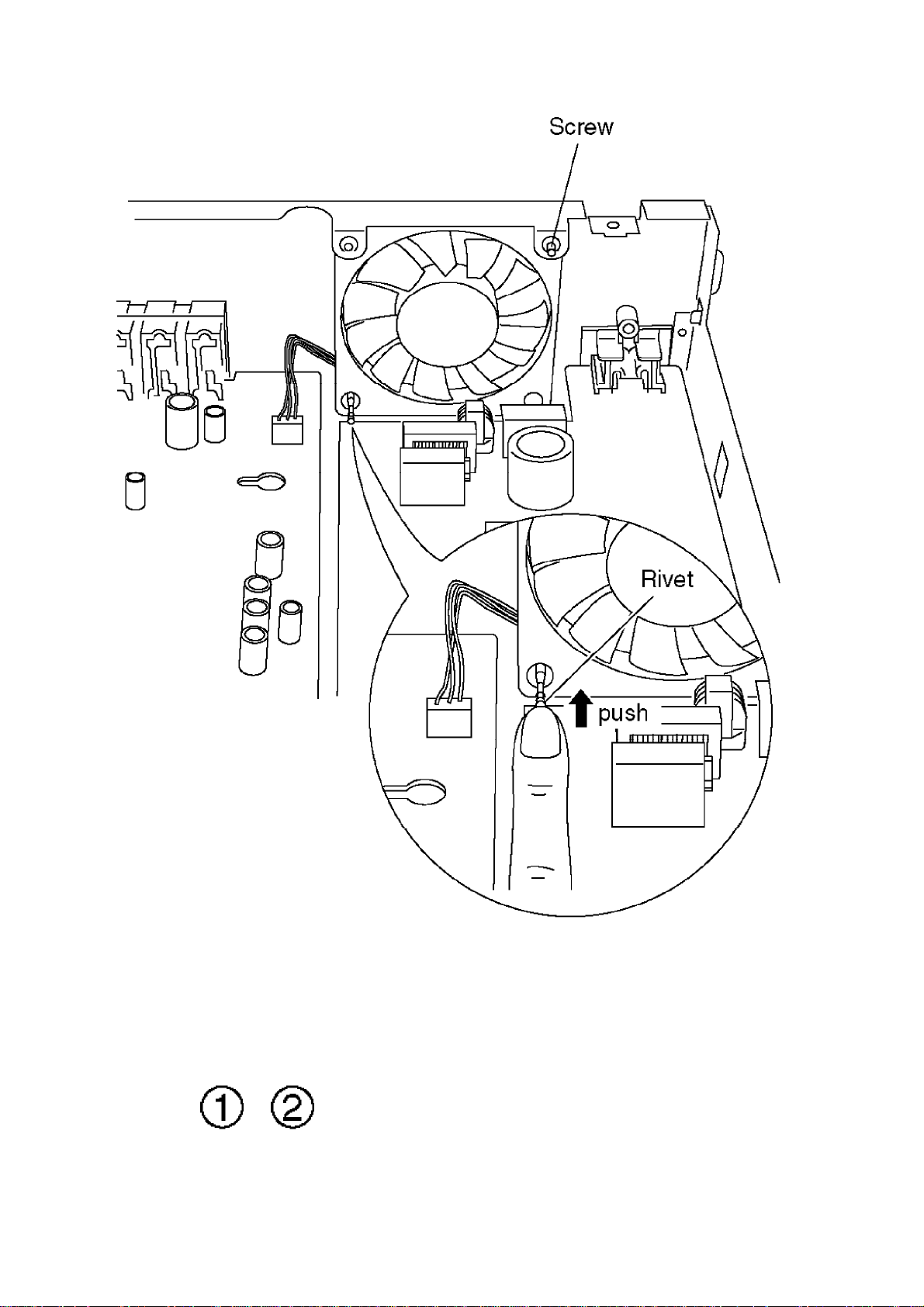

8.8.1. In case of removing Fan motor from Rear panel

1. Remove a screw.

2. Push tip of rivet to remove it.

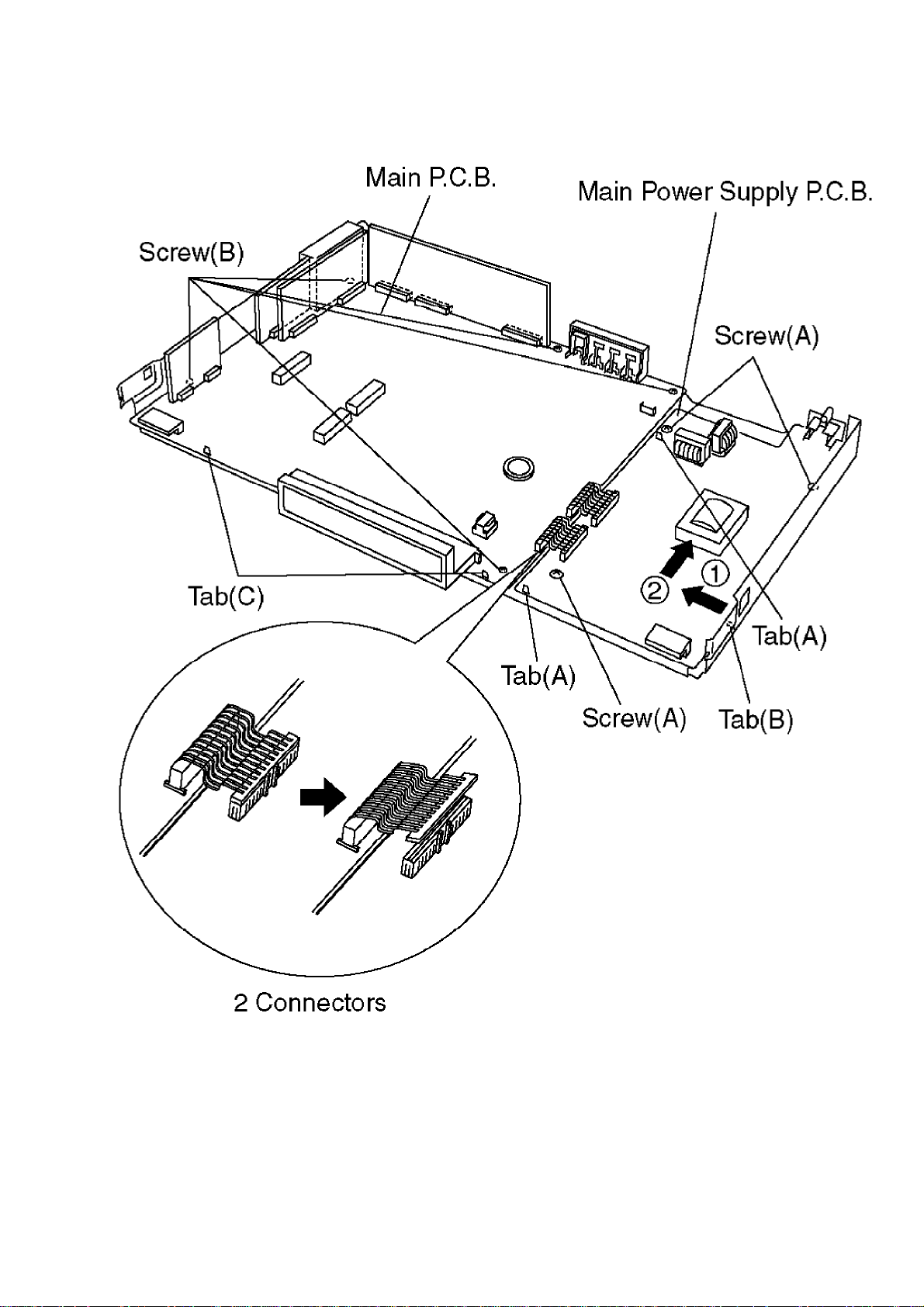

8.9. The Main Power Supply P.C.B. and Main P.C.B.

1. Remove the 2 connectors.

2. Remove the 3 screws (A) and 2 tab (A).

3. Remove the Main Power Supply P.C.B and tab (B), pull out it in the direction of the

arrow.

4. Remove the 5 screws (B) and 2 tab (C).

to .

5. Remove the Main P.C.B.

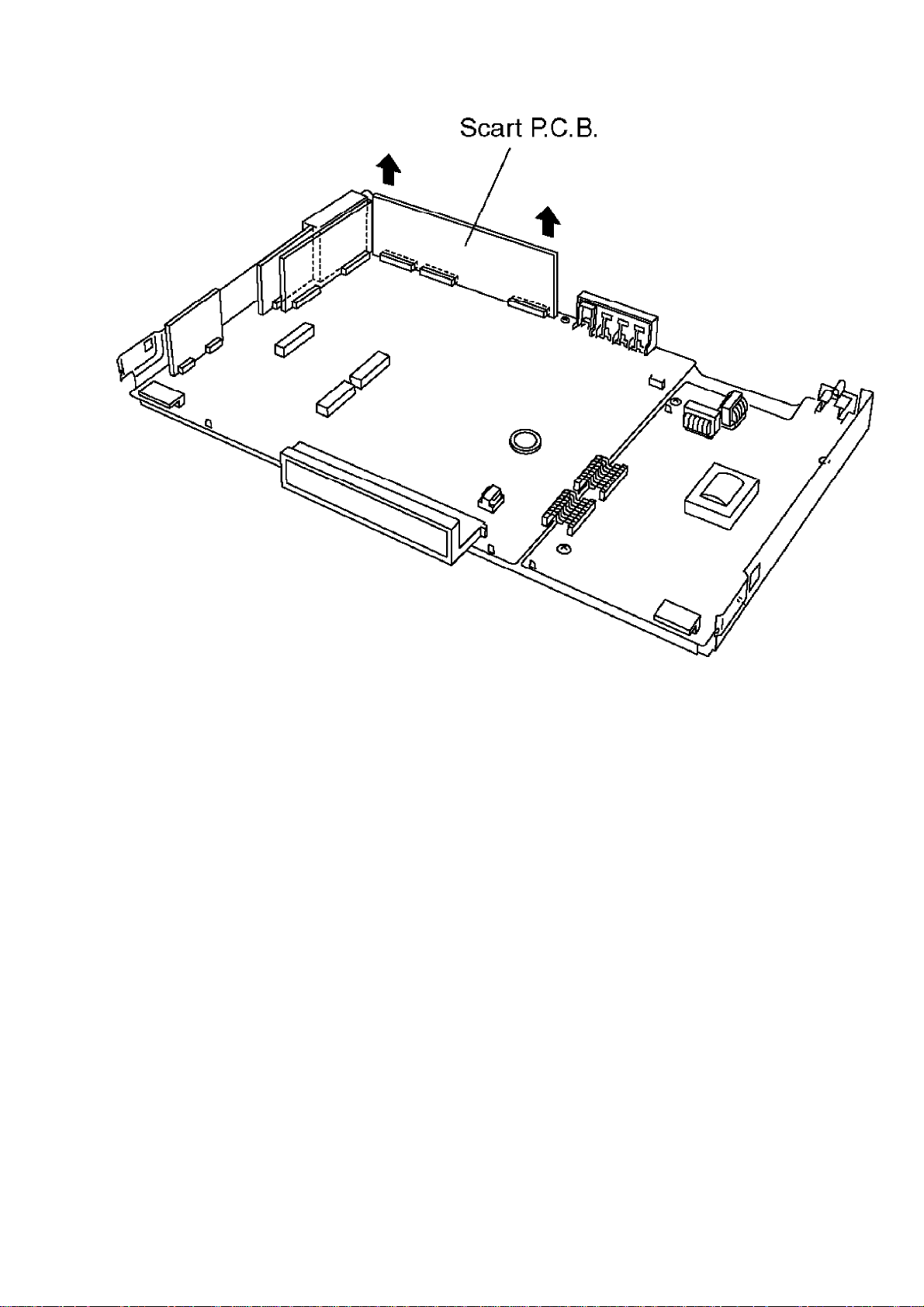

8.10. The Scart P.C.B.

1. Pull out the Scart P.C.B.

8.11. The RGB P.C.B.

1. Pull out the RGB P.C.B.

Loading...

Loading...