Omron SIGMA LINEAR MOTORS DATASHEET

SGLG@, SGLF@, SGLT@

Sigma linear motors

Direct drive linear servo motors for faster

machine cycles

• Direct control of the motors using XtraDrive and

Sigma-II drives

• Improved machine performance

• Easy of operation & high reliability

• Designed for high force density in compact

packages

• Exhibit exceptional force linearity even at near peak

force regions

• Extremely energy efficient, due to its optimized

magnetic circuitry design and high-density windings

• Can reach speeds as high as 5 meters per second.

• Coreless and iron core types available

Ratings

• 230 VAC Single-phase 12.5 to 560 N (1200 N Peak)

• 400 VAC Three-phase 80 to 2250 N (7500 N Peak)

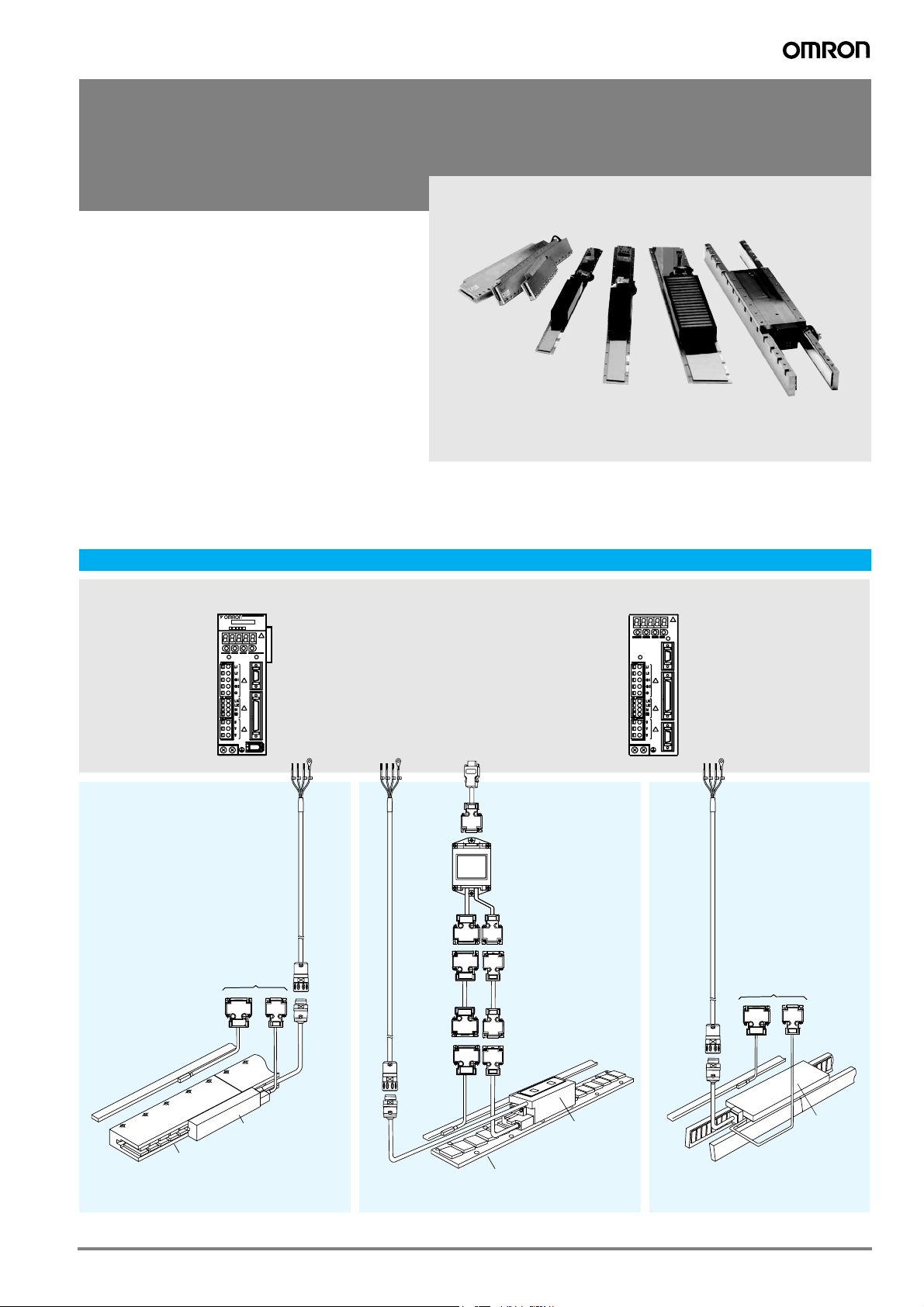

System configuration

(Refer to servo drive chapter)

SGDH-

Ver.

CHARGE POWER

CN3

CN1

CN2

(To serial converter unit)

Linear

scale

Linear scale

SERVOPACK

200V

Servo Drive with option

boards for

flexible system

configuration

Sigma-II

Servo Drive

Power

cable

Hall

sensor

Power

Power

cable

Linear scale

cable

(extension)

Linear

scale

Drive options

Serial

converter

cable

Serial converter

unit

Hall sensor

cable

(extension)

Power

cable

Hall

sensor

POWER

Intelligent

CN3

CHARGE

Servo Drive

CN1

XtraDrive

CN2

Power

cable

Power

(To serial converter unit)

Hall

sensor

Linear

scale

SGLG_ Linear

Servo Motor

Magnetic way

SGLGM

Linear coil

SGLGW

Power

SGLF_ Linear

Servo Motor

Magnetic way

SGLFM

Linear coil

SGLFW

Magnetic way

SGLTM

Linear coil

SGLTW

SGLT_ Linear

Servo Motor

195Sigma linear motors

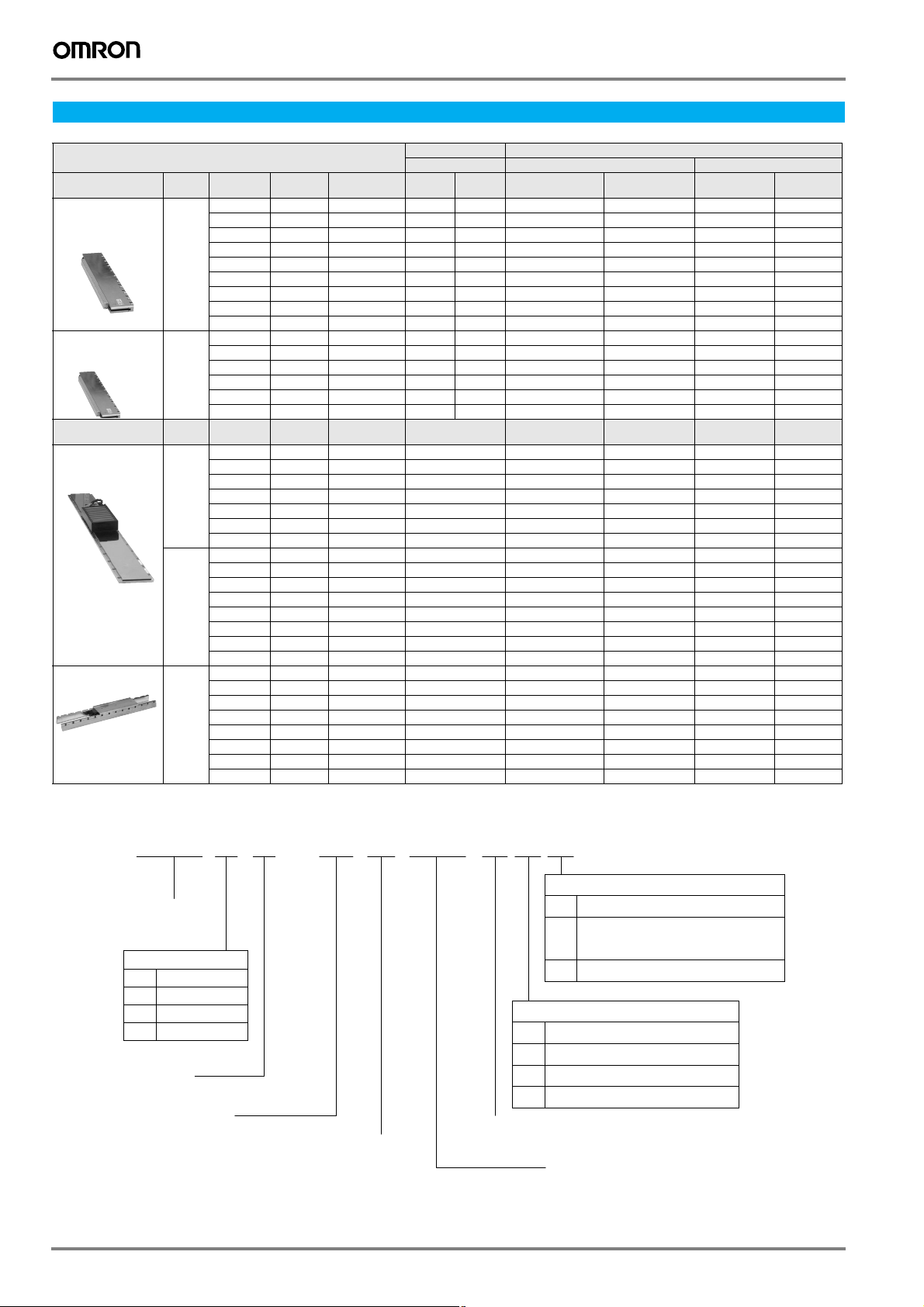

Servo Motor / Servo Drive Combination

Sigma series linear servo motor Serial converter Servo drive

Type Voltage Rated

SGLGW coreless

standard-force

magnetic ways

SGLGW coreless

high-force

magnetic ways

Type Voltage Rated

SGLFW

linear motors

SGLTW

linear motors

230 V 12.5 N 40 N 30A050 [B / C] 158 250 SGDH-A5AE-OY - XD-P5-MN01 -

230 V 57 N 230 N 40A140 [B / C] 059 255 SGDH-02AE-OY - XD-02-MN01 -

230 V 25 N 86 N 20A090A 017 SGDH-02AE-OY - XD-02-MN01

400 V 80 N 220 N 35D120A 211 - SGDH-05DE-OY - XD-05-TN

400 V 300 N 600 N 35D170H 193 - SGDH-10DE-OY - XD-10-TN

25 N 80 N 30A080 [B / C] 156 251 SGDH-01AE-OY - XD-01-MN01 47 N 140 N 40A140 [B / C] 001 252 SGDH-01AE-OY - XD-01-MN01 70 N 220 N 60A140 [B / C] 004 258 SGDH-02AE-OY - XD-02-MN01 93 N 280 N 40A253 [B / C] 002 253 SGDH-02AE-OY - XD-02-MN01 140 N 420 N 40A365 [B / C] 003 254 SGDH-04AE-OY - XD-04-MN01 140 N 440 N 60A253 [B / C] 005 259 SGDH-04AE-OY - XD-04-MN01 210 N 660 N 60A365 [B / C] 006 260 SGDH-08AE-S-OY - XD-08-MN 325 N 1300 N 90A200 [A / C] 101 264 SGDH-15AE-S-OY - XD-15-MN -

114 N 460N 40A253 [B / C] 060 256 SGDH-04AE-OY - XD-04-MN01 171 N 690 N 40A365 [B / C] 061 257 SGDH-08AE-S-OY - XD-08-MN 85 N 360N 60A140 [B / C] 062 261 SGDH-02AE-OY - XD-02-MN01 170 N 720 N 60A253 [B / C] 063 262 SGDH-08AE-S-OY - XD-08-MN 255 N 1080 N 60A365 [B / C] 047 263 SGDH-15AE-S-OY - XD-15-MN -

40 N 125 N 20A120A 018 SGDH-02AE-OY - XD-02-MN01

80 N 220 N 35A120A 019 SGDH-02AE-OY - XD-02-MN01

160 N 440 N 35A230A 020 SGDH-08AE-S-OY - XD-08-MN01

280 N 600 N 50A200B 181 SGDH-08AE-S-OY - XD-08-MN

560 N 1200 N 50A380B 182 SGDH-15AE-S-OY - XD-15-MN

560 N 1200 N 1ZA200B 183 SGDH-15AE-S-OY XD-15-MN

160 N 440 N 35D230A 212 - SGDH-05DE-OY - XD-05-TN

280 N 600 N 50D200B 189 - SGDH-10DE-OY - XD-10-TN

560 N 1200 N 50D380B 190 - SGDH-15DE-OY - XD-15-TN

560 N 1200 N 1ZD200B 191 - SGDH-15DE-OY - XD-15-TN

1120 N 2400 N 1ZD380B 192 - SGDH-30DE-OY - XD-30-TN

1500 N 3600 N 1ED380B 333 - SGDH-20DE-OY - XD-20-TN

2250 N 5400 N 1ED560B 334 - SGDH-30DE-OY - XD-30-TN

600 N 1200 N 35D320H 194 - SGDH-20DE-OY - XD-20-TN

450 N 900 N 50D170H 195 - SGDH-10DE-OY - XD-10-TN

900 N 1800 N 50D320H 196 - SGDH-20DE-OY - XD-20-TN

670 N 2600 N 40D400B 197 - SGDH-30DE-OY - XD-30-TN

1000 N 4000 N 40D600B 198 - SGDH-50DE-OY - XD-50-TN

1300 N 5000 N 80D400B 199 - SGDH-50DE-OY - XD-50-TN

2000 N 7500 N 80D600B 200 - SGDH-75DE-OY - -

Peak force Model code for

force

Peak force Model code 230 V

force

JZDP-@008-[code] Sigma-II series XtraDrive

Rev A, B

code for

Rev C

230 V

(1-phase)

(1-phase)

400 V

(3-phase)

400 V

(3-phase)

230 V

(1-phase)

230 V

(1-phase)

400 V

(3-phase)

400 V

(3-phase)

Motor coil

Linear Σ series

Linear servo motor

W : Coil assembly

Servo motor model

Code

Specifications

G

Coreless

F-type iron core

F

T-type iron core

T

Magnet height

㧙

WFSGL

35 D 120 A P

D

Cable connector for main circuit cable

Code

MS connector or connector made

−

by Tyco Electronics AMP K.K.

Connector made by Interconnectron

D

Specifications

Options

Code

P

C

H

With hall sensor and forced cooling

Specifications

With hall sensor (standard)

Forced cooling

Design revision order

Voltage

A㧦200 VAC

A,B,C

Length of coil assembly

D㧦400 VAC

196 AC servo systems

Magnetic way

SGL

FM

35 324 A C

Linear Σ series

Linear servo motor

Model

Code

Specifications

G

Coreless

F

F-type iron core

T

T-type iron core

M : Magnetic way

Magnet width

Length of magnetic way

Serial converter unit

D008JZDP – – 001

Design revision order

A,B,C

Serial converter unit model

Symbol

A008

D008

Note: * When using a linear scale made by Heidenhain an extension

cable is required

Appearance

Applicable

linear scale

Made by

Renishaw

or

(Heidenhain *)

Hall sensor

Yes

Code

C

With magnet cover

-Y

With base and magnet cover For SGLTM type

Mounting type 1

-M

Mounting type 1 & high thrust force

T-

Mounting type 2

T-M

Mounting type 2 & high thrust force

Design revision order

A,B,C

Servo motor model

30A050B

30A080B

40A140B

40A253B

SGLGW-

(coreless)

When a

standardforce

magnetic

way is used.

SGLGW +

SGLGM-

-M

(coreless)

When a

high-force

magnetic

way is used.

SGLFW-

(Iron core,

F-type)

40A365B

60A140B

60A253B

60A365B

90A200A

90A370A

90A535A

40A140B

40A253B

40A365B

60A140B

60A253B

60A365B

20A090A

20A120A

35A120A

35A230A

50A200B

50A380B

1ZA200B

1ZA380B

35D120A

35D230A

50D200B

50D380B

1ZD200B

1ZD380B

1ED380B

1ED560B

Options

Specifications Remarks

For iron-core types

- SGLFM

- SGLTM

For SGLGM type

Applicable linear servo motor

Symbol

158

156

001

002

003

004

005

006

101

102

103

059

060

061

062

063

047

017

018

019

020

181

182

183

184

211

212

189

190

191

192

333

334

Model

30A050C

30A080C

40A140C

40A253C

40A365C

60A140C

60A253C

60A365C

90A200C

90A370C

90A535C

40A140C

40A253C

40A365C

60A140C

60A253C

60A365C

Symbol

250

251

252

253

254

258

259

260

264

265

266

255

256

257

261

262

263

Servo motor model

SGLTW-

(Iron core,

T-type)

20A170A

20A320A

20A460A

35A170A

35A320A

35A460A

35A170H

35A320H

50A170H

50A320H

40A400B

40A600B

80A400B

80A600B

35D170H

35D320H

50D170H

50D320H

40D400B

40D600B

80D400B

80D600B

Symbol

011

012

013

014

015

016

105

106

108

109

185

186

187

188

193

194

195

196

197

198

199

200

Sigma linear motors 197

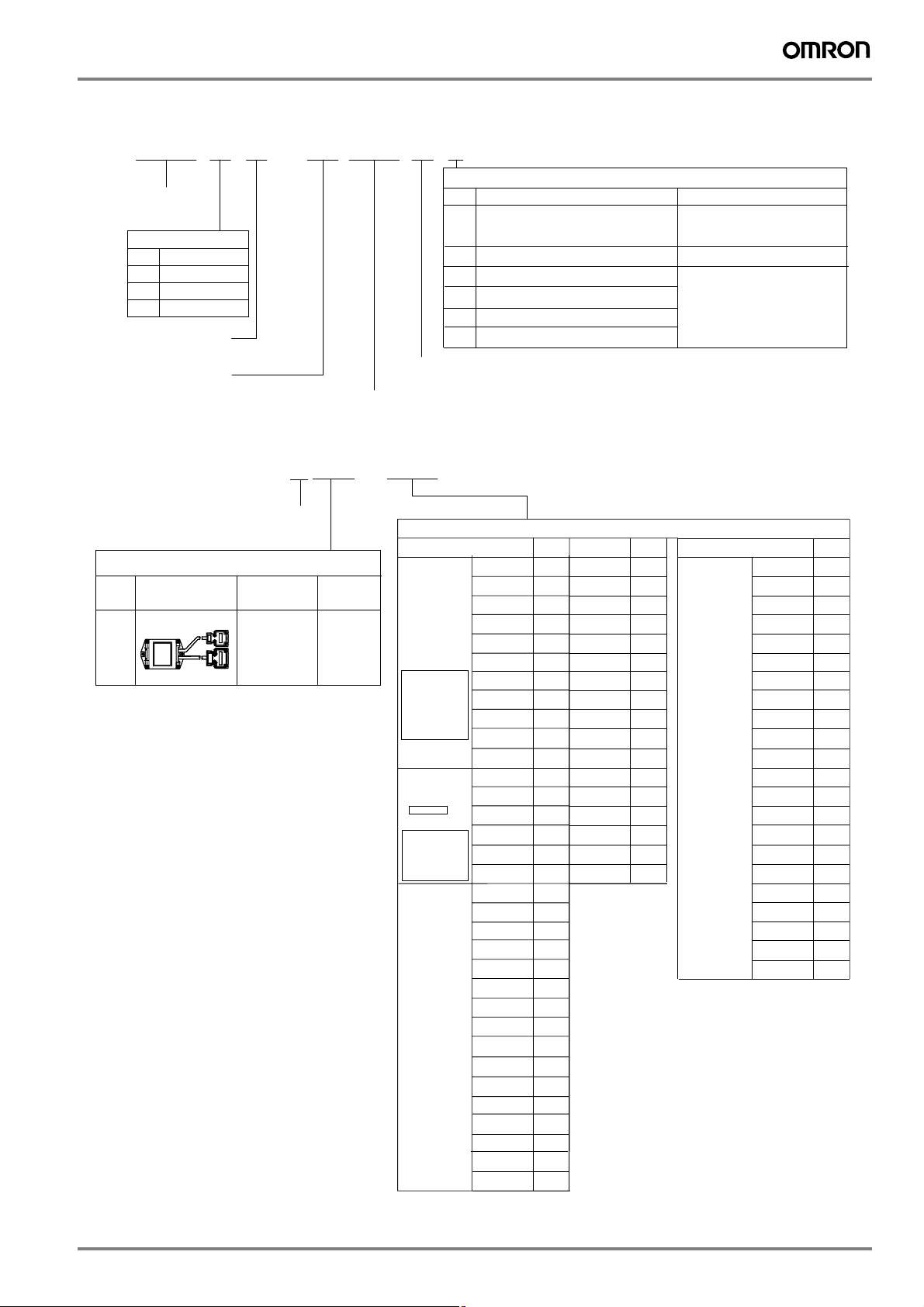

Servo motor specifications

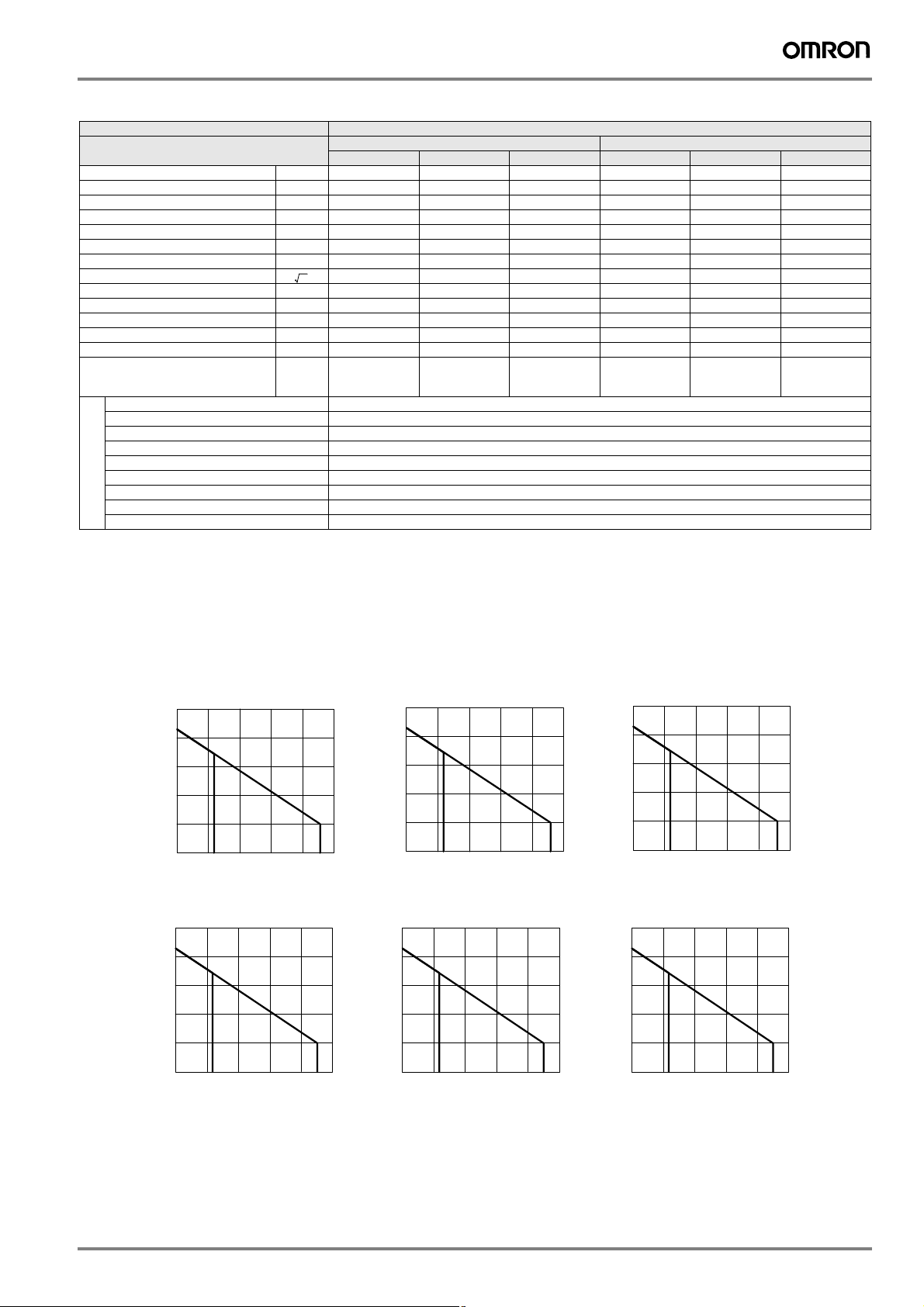

Coreless SGLGW/SGLGM - (with standard-force magnetic ways)

Voltage 230 V

Linear servo motor

model SGLGW-

Rated force

Rated current

Instantaneous peak force

Instantaneous peak current

∗

∗

∗

∗

N 12.5 25 47 93 140 70 140 210 325

Arms 0,51 0,79 0.8 1.6 2.4 1,16 2,2 3,3 4.4

N 40 80 140 280 420 220 440 660 1300

Arms 1.62 2.53 2.4 4.9 7.3 3.5 7.0 10.5 17.6

Coil assembly weight kg 0.14 0.19 0.40 0.66 0.93 0.48 0.82 1.16 2.2

Force constant N / A

rms 26.4 33.9 61.5 61.5 61.5 66.6 66.6 66.6 78

BEMF constant V /(m / s) 8.8 11.3 20.5 20.5 20.5 22.2 22.2 22.2 26.0

Motor constant 3.7 5.6 7.8 11.0 13.5 11.1 15.7 19.2 26.0

Electrical time constant ms 0.2 0.4 0.4 0.4 0.4 0.5 0.5 0.5 1.4

N /

w

Mechanical time constant ms 7.30 4.78 5.59 4.96 4.77 3.41 3.08 2.98 3.18

Thermal resistance (with heat sink) K / W 5,19 3,11 1,67 0,87 0,58 1,56 0,77 0,51 0,39

Thermal resistance (without heat sink) K / W - - 3,02 1,80 1,23 2,59 1,48 1,15 1.09

Magnetic attraction N 000000000

Heat sink size mm 200 x

Time rating Continuous

Insulation class Class B

Ambient temperature 0 to +40 °C

Ambient humidity 20 to 80% (non-condensing)

Insulation resistance 500 VDC, 10 MΩ min.

Excitation Permanent magnet

Dielectric strength 1500 VAC for 1 minute

Basic specifications

Protection methods Self-cooled, air-cooling

Allowable winding temperature 130 °C

30A 40A 60A 90A

050C 080C 140C 253C 365C 140C 253C 365C 200C

300 x

12

300 x

400 x

12

400 x

500 x

12

200 x

300 x

12

300 x

400 x

12

400 x

500 x

12

800 x

900 x

12

Note: 1. The items marked with an * and “force and speed characteristics” are the values at a motor winding temperature of 100 °C during oper-

ation in combination with a servo drive. The others are at 20 °C (68°F).

2. The above specifications show the values under the cooling condition when a heat sink (aluminium board) listed in the following table is

mounted on the coil assembly.

Force-speed characteristics - (with standard-force magnetic ways)

A: Continuous duty zone

B: Intermittent duty zone

SGLGW-30A050C

6.0

5.0

Motor

4.0

speed

3.0

(m/s)

A

2.0

1.0

0

0 10203040

SGLGW-40A253C

6.0

5.0

Motor

4.0

speed

(m/s)

A

3.0

2.0

1.0

0

0 100 200 300 400

SGLGW-60A253C

6.0

5.0

Motor

4.0

speed

(m/s)

A

3.0

2.0

1.0

0

0 200 400 600

Force (N)

Force (N)

Force (N)

SGLGW-30A080C

6.0

5.0

Motor

4.0

speed

3.0

B

(m/s)

50

A

2.0

1.0

0

0 20406080

Force (N)

Motor

speed

B

(m/s)

100

SGLGW-40A365C

6.0

5.0

Motor

4.0

speed

(m/s)

B

A

3.0

2.0

1.0

0

0 150 300 450 600

B

Force (N)

Motor

speed

(m/s)

SGLGW-60A365C

6.0

5.0

Motor

4.0

speed

(m/s)

B

A

3.0

2.0

1.0

0

0 300 600 900

B

Force (N)

Motor

speed

(m/s)

SGLGW-40A140C

6.0

5.0

4.0

A

3.0

2.0

1.0

0

0 50 100 150 200

B

Force (N)

SGLGW-60A140C

6.0

5.0

4.0

A

3.0

2.0

1.0

0

0 100 200 300

B

Force (N)

SGLGW-90A200C

6.0

5.0

4.0

A

3.0

2.0

1.0

0

0 300 600 900 1200 1500

Force (N)

B

198 AC servo systems

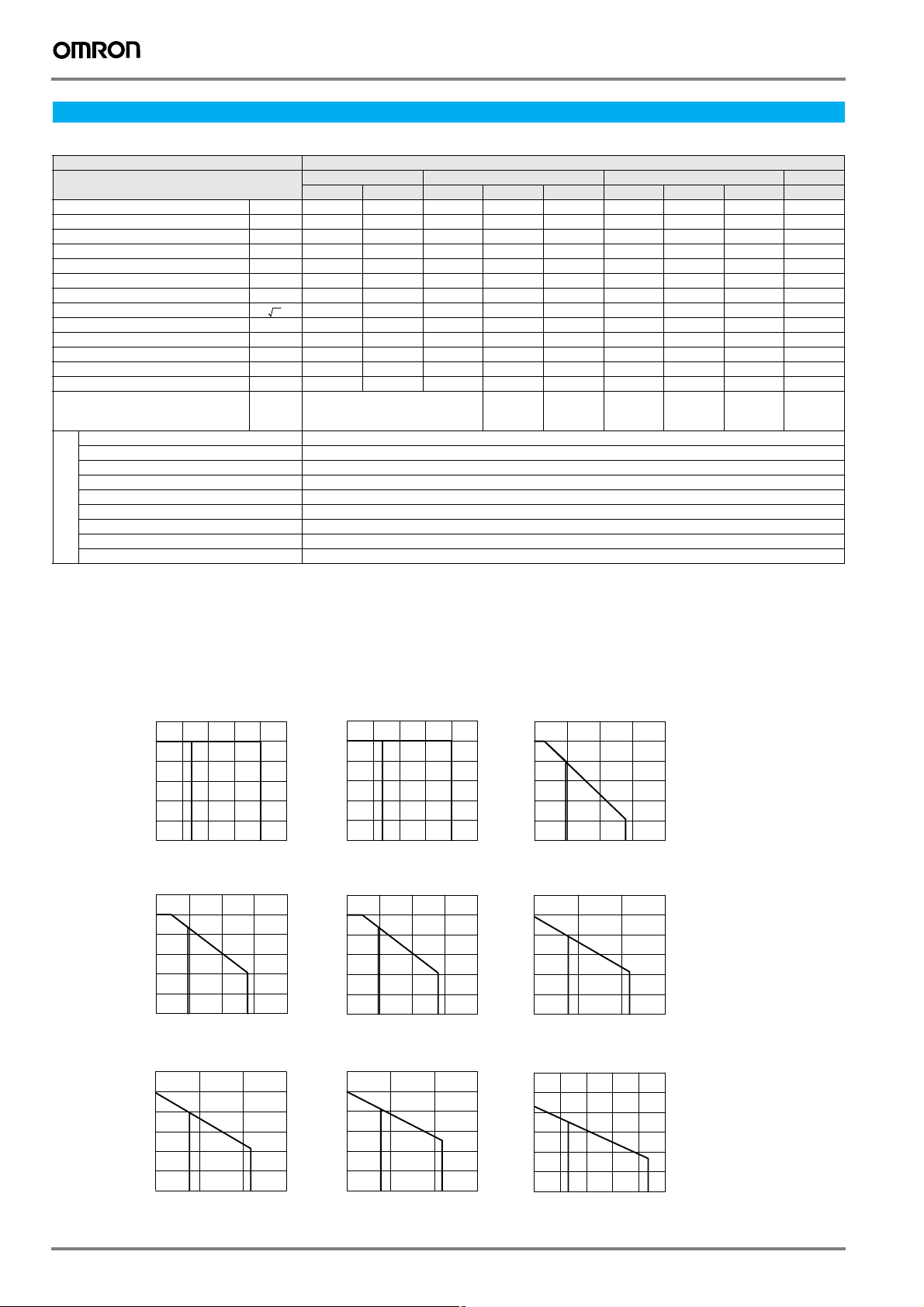

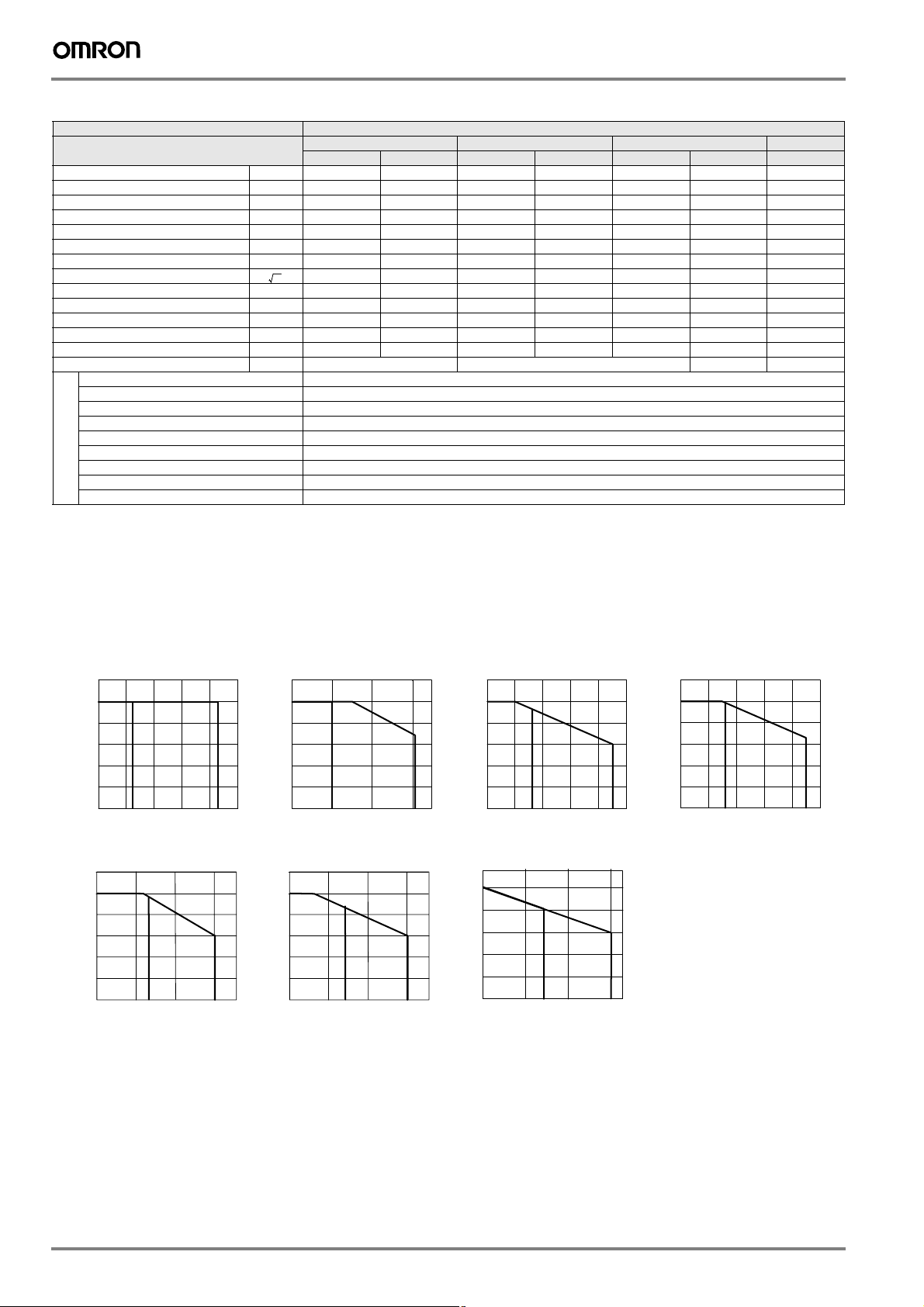

Coreless SGLGW/SGLGM - (with high-force magnetic ways)

Voltage 230 V

Linear servo motor

model SGLGW-

Rated force

Rated current

Instantaneous peak force

Instantaneous peak current

Coil assembly weight kg 0.40 0.66 0.93 0.48 0.82 1.16

Force constant N / A

BEMF constant V /(m / s) 25.3 25.3 25.3 25.8 25.8 25.8

Motor constant 9.6 13.6 16.7 12.9 18.2 22.3

Electrical time constant ms 0.4 0.4 0.4 0.5 0.5 0.5

Mechanical time constant ms 3.69 3.24 3.12 2.52 2.29 2.21

Thermal resistance (with heat sink) K / W 1.67 0.87 0.58 1.56 0.77 0.51

Thermal resistance (without heat sink) K / W 3.02 1.80 1.23 2.59 1.48 1.15

Magnetic attraction N 0 0 0 0 0 0

Heat sink size mm 200 x

Basic specifications

∗

∗

∗

∗

N 57 114 171 85 170 255

Arms 0.81.62.41.22.23.3

N 230 460 690 360 720 1080

Arms 3.2 6.5 9.7 5.0 10.0 14.9

rms 76.0 76.0 76.0 77.4 77.4 77.4

N /

w

Time rating Continuous

Insulation class Class B

Ambient temperature 0 to +40 °C

Ambient humidity 20 to 80% (non-condensing)

Insulation resistance 500 VDC, 10 MΩ min.

Excitation Permanent magnet

Dielectric strength 1500 VAC for 1 minute

Protection methods Self-cooled, air-cooling

Allowable winding temperature 130 °C

140C 253C 365C 140C 253C 365C

300 x

12

40A 60A

300 x

400 x

12

400 x

500 x

12

200 x

300 x

12

300 x

400 x

400 x

500 x

12

12

Note: 1. The items marked with an * and “force and speed characteristics” are the values at a motor winding temperature of 100 °C during oper-

ation in combination with a servo drive. The others are at 20 °C (68°F).

2. The above specifications show the values under the cooling condition when a heat sink (aluminium board) listed in the following table is

mounted on the coil assembly.

Force-speed characteristics - (with high-force magnetic ways)

A: Continuous duty zone

B: Intermittent duty zone

SGLGW-40A365C

5

4

3

2

A

1

0

0 150 450300 600 750

B

Force (N)

SGLGW-60A365C

5

4

3

2

A

1

0

0 240 720480 960 1200

B

Force (N)

Motor

speed

(m/s)

Motor

speed

(m/s)

SGLGW-40A140C

5

4

3

2

A

1

0

0 50 150100 200 250

B

Force (N)

SGLGW-60A140C

5

4

3

2

A

1

0

0 80 240160 320 400

B

Force (N)

Motor

speed

(m/s)

Motor

speed

(m/s)

SGLGW-40A253C

5

4

3

2

A

1

0

0 100 300200 400 500

B

Force (N)

SGLGW-60A253C

5

4

3

2

A

1

0

0 160 480320 640 800

B

Force (N)

Motor

speed

(m/s)

Motor

speed

(m/s)

Sigma linear motors 199

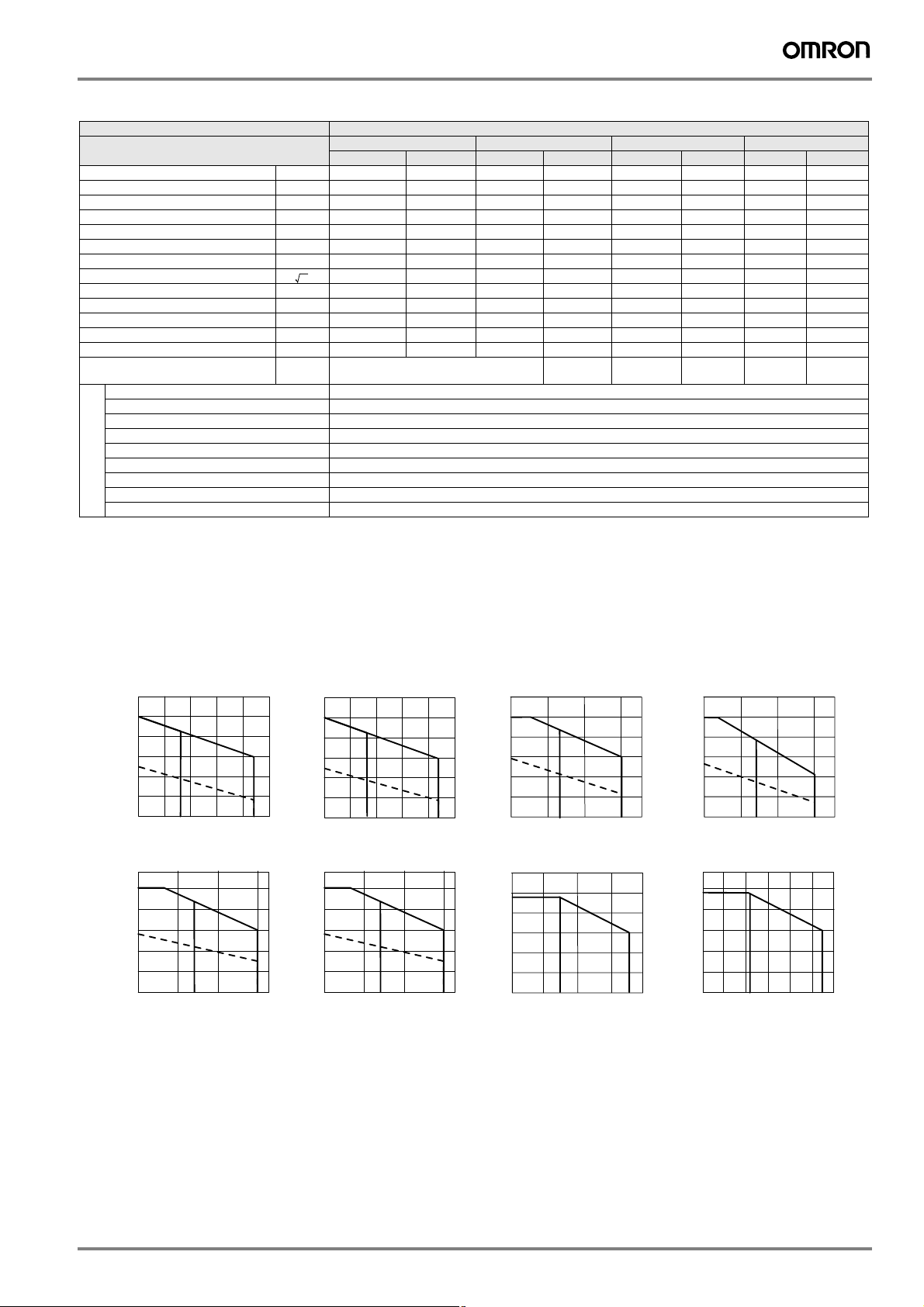

Iron-core SGLFW/SGLFM (200 V)

Voltage 230 V

Linear servo motor

model SGLFW-

Rated force

Rated current

Instantaneous peak force

Instantaneous peak current

∗

∗

∗

∗

N 25 40 80 160 280 560 560

Arms 0.7 0.8 1.4 2.8 5.0 10.0 8.7

N 86 125 220 440 600 1200 1200

Arms 3.0 2.9 4.4 8.8 12.4 25.0 21.6

Coil assembly weight kg 0.7 0.9 1.3 2.3 3.5 6.9 6.4

Force constant N / A

rms 36.0 54.0 62.4 62.4 60.2 60.2 69.0

BEMF constant V /(m / s) 12.0 18.0 20.8 20.8 20.1 20.1 23.0

Motor constant 7.9 9.8 14.4 20.4 34.3 48.5 52.4

Electrical time constant ms 3.2 3.3 3.6 3.6 15.9 15.8 18.3

N /

w

Mechanical time constant ms 11.0 9.3 6.2 5.5 3.0 2.9 2.3

Thermal resistance (with heat sink) K / W 4.35 3.19 1.57 0.96 0.82 0.32 0.6

Thermal resistance (without heat sink) K / W 7.69 5.02 4.10 1.94 1.48 0.74 0.92

Magnetic attraction N 314 462 809 1586 1650 3260 3300

Heat sink size mm 125 x 125 x 13 254 x 254 x 25 400 x 500 x 40 254 x 254 x 25

Time rating Continuous

Insulation class Class B

Ambient temperature 0 to +40 °C

Ambient humidity 20 to 80% (non-condensing)

Insulation resistance 500 VDC, 10 MΩ min.

Excitation Permanent magnet

Dielectric strength 1500 VAC for 1 minute

Basic specifications

Protection methods Self-cooled

Allowable winding temperature 130 °C

20A 35A 50A 1ZA

090A 120A 120A 230A 200B 380B 200B

Note: 1. The items marked with an * and “force and speed characteristics” are the values at a motor winding temperature of 100 °C during oper-

ation in combination with a servo drive. The others are at 20 °C (68°F).

2. The above specifications show the values under the cooling condition when a heat sink (aluminium board) listed in the following table is

mounted on the coil assembly.

Force-speed characteristics (200 V)

A: Continuous duty zone

B: Intermittent duty zone

SGLFW-20A090A

6

5

Motor

4

speed

3

(m/s)

A B

2

1

0

0 20 40 60 80 100

Force (N)

SGLFW-50A200B

6

5

Motor

4

speed

3

(m/s)

2

1

0

0 400200 600

Force (N)

Motor

speed

(m/s)

Motor

speed

BA

(m/s)

SGLFW-20A120A SGLFW-35A120A SGLFW-35A230A

6

5

4

3

A

2

1

0

0 40 80 120 140

B

Force (N)

SGLFW-50A380B

6

5

4

3

2

1

0

0 800400 1200

Force (N)

BA

6

5

Motor

4

speed

(m/s)

3

A

2

1

0

0 50 100 150 200 250

Force (N)

SGLFW-1ZA200B

6

5

4

Motor

speed

3

(m/s)

2

1

0

0 800400 1200

Force (N)

B

BA

6

5

Motor

4

speed

3

(m/s)

A

2

1

0

0 100 200 300 400 500

B

Force (N)

200 AC servo systems

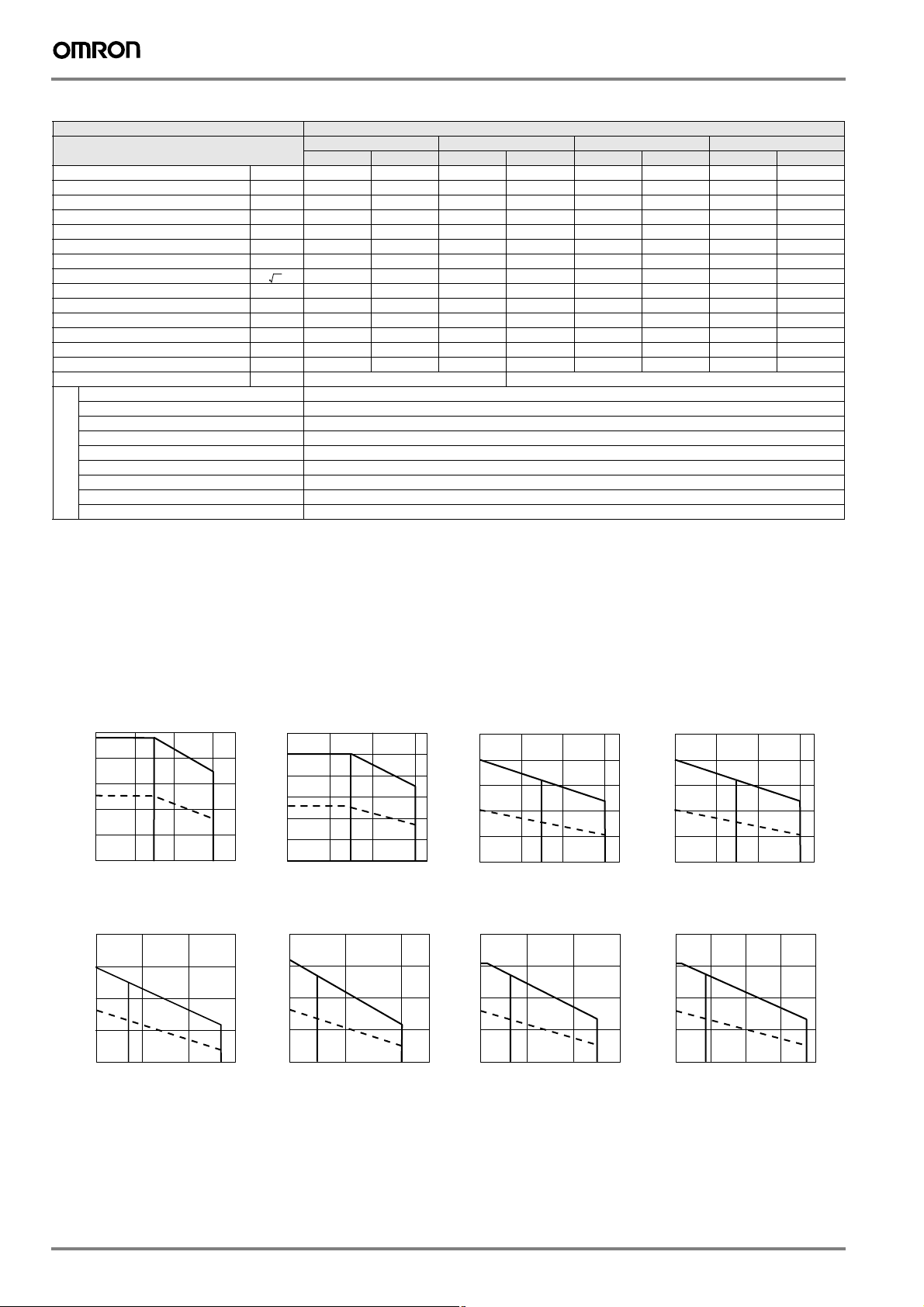

Iron-core SGLFW/SGLFM (400 V)

Voltage 400 V

Linear servo motor

model SGLFW-

Rated force

Rated current

Instantaneous peak force

Instantaneous peak current

∗

∗

∗

∗

N 80 160 280 560 560 1120 1500 2250

Arms 0.7 1.4 2.3 4.5 4.9 9.8 6.4 9.6

N 220 440 600 1200 1200 2400 3600 5400

Arms 2.3 4.6 5.6 11.0 12.3 24.6 18.1 27.2

Coil assembly weight kg 1.3 2.3 3.5 6.9 6.4 11.5 22 33

Force constant N / A

rms 120.2 120.2 134.7 134.7 122.6 122.6 250 250

BEMF constant V /(m / s) 40.1 40.1 44.9 44.9 40.9 40.9 83.2 83.2

Motor constant 13.8 19.5 33.4 47.2 51.0 72.1 95.4 117

Electrical time constant ms 3.5 3.5 15.0 15.0 17.4 17.2 19.7 19.6

N /

w

Mechanical time constant ms 5.5 5.5 3.2 3.2 2.5 2.2 1.8 1.8

Thermal resistance (with heat sink) K / W 1.57 0.96 0.82 0.32 0.6 0.28 0.21 0.13

Thermal resistance (without heat sink) K / W 4.1 1.94 1.48 0.74 0.92 0.55 0.50 0.35

Magnetic attraction N 810 1590 1650 3260 3300 6520 9780 14600

Heat sink size mm 254 x 254 x 25 400 x 500

Time rating Continuous

Insulation class Class B

Ambient temperature 0 to +40 °C

Ambient humidity 20 to 80% (non-condensing)

Insulation resistance 500 VDC, 10 MΩ min.

Excitation Permanent magnet

Dielectric strength 1500 VAC for 1 minute

Basic specifications

Protection methods Self-cooled

Allowable winding temperature 130 °C

35D 50D 1ZD 1ED

120A 230A 200B 380B 200B 380B 380B 560B

x 40

254 x 254

x 25

400 x 500

x 40

609 x 762

x 50

762 x 1270

x 64

Note: 1. The items marked with an * and “force and speed characteristics” are the values at a motor winding temperature of 100 °C during oper-

ation in combination with a servo drive. The others are at 20 °C (68°F).

2. The above specifications show the values under the cooling condition when a heat sink (aluminium board) listed in the following table is

mounted on the coil assembly.

Force-speed characteristics (400 V)

A: Continuous duty zone

B: Intermittent duty zone

SGLFW-35D120A

6

5

Motor

4

speed

3

(m/s)

2

1

0

0 15050 100 200

SGLFW-1ZD200B

6

5

4

Motor

speed

3

(m/s)

2

1

0

0 800400 1200

A

Force (N)

Force (N)

SGLFW-35D230A

6

5

Motor

4

speed

(m/s)

BA

250

B

3

2

1

0

0 100 200 300 400 500

6

5

4

Motor

speed

3

(m/s)

2

1

0

0

Force (N)

SGLFW-1ZD380B

A

Force (N)

BA

B

1600800 2400

Motor

speed

(m/s)

Motor

speed

(m/s)

SGLFW-50D200B

6

5

4

3

A

2

1

0

0 400200 600

Force (N)

SGLFW-1ED380B

3.0

2.5

2.0

1.5

A

1.0

0.5

0

1000

0

2000

Force (N)

Motor

speed

4000

(m/s)

Motor

speed

(m/s)

B

B

3000

SGLFW-50D380B

6

5

4

3

2

1

0

3.0

2.5

2.0

1.5

1.0

0.5

0

A

0 800400 1200

Force (N)

SGLFW-1ED560B

A

0

30002000 5000

Force (N)

B

B

600040001000

Note: The dotted line indicates characteristics when the linear servo motor for 400 VAC is used with an input power supply for 200 VAC. In this

case, the serial converter should be changed. Contact your OMRON Yaskawa representatives.

Sigma linear motors 201

Iron-core SGLTW/SGLTM (400 V)

Voltage 400 V

Linear servo motor

model SGLTW-

Rated force

Rated current

Instantaneous peak force

Instantaneous peak current

∗

∗

∗

∗

N 300 600 450 900 670 1000 1300 2000

Arms 3.2 6.5 3.2 6.3 3.7 5.5 7.2 11.1

N 600 1200 900 1800 2600 4000 5000 7500

Arms 7.5 15.1 7.3 14.6 20.7 30.6 37.6 56.4

Coil assembly weight kg 4.7 8.8 6 11 15 23 25 36

Force constant N / A

rms 99.6 99.6 153.3 153.3 196.1 196.1 194.4 194.4

BEMF constant V /(m / s) 33.2 33.2 51.1 51.1 65.4 65.4 64.8 64.8

Motor constant 36.3 51.4 48.9 69.1 59.6 73 85.9 105.2

Electrical time constant ms 14.3 14.3 15.6 15.6 14.4 14.4 15.4 15.4

N /

w

Mechanical time constant ms 3.5 3.5 2.5 2.5 4.2 4.2 3.2 3.2

Thermal resistance (with heat sink) K / W 0.76 0.4 0.61 0.3 0.24 0.2 0.22 0.18

Thermal resistance (without heat sink) K / W 1.26 0.83 0.97 0.8 0.57 0.4 0.47 0.33

Magnetic attraction

Magnetic attraction

∗1

∗2

N 00000000

N 1400 2780 2000 3980 3950 5890 7650 11400

Heat sink size mm 400 x 500 x 40 609 x 762 x 50

Time rating Continuous

Insulation class Class B

Ambient temperature 0 to +40 °C

Ambient humidity 20 to 80% (non-condensing)

Insulation resistance 500 VDC, 10 MW min.

Excitation Permanent magnet

Dielectric strength 1500 VAC for 1 minute

Basic specifications

Protection methods Self-cooled

Allowable winding temperature 130 °C

*1. The unbalanced magnetic gap resulting from the coil assembly installation condition causes a magnetic attraction on the coil assembly.

*2. The value indicates the magnetic attraction generated on one side of the magnetic way.

Note: 1. The items marked with an * and “force and speed characteristics” are the values at a motor winding temperature of 100 °C during oper-

ation in combination with a servo drive. The others are at 20 °C (68 °F).

2. The above specifications show the values under the cooling condition when a heat sink (aluminium board) listed in the following table is

mounted on the coil assembly.

35D 50D 40D 80D

170H 320H 170H 320H 400B 600B 400B 600B

Force-speed characteristics (400 V)

A: Continuous duty zone

B: Intermittent duty zone

SGLTW-35D170H SGLTW-35D320H

5

4

Motor

3

speed

(m/s)

2

1

0

0 400200 600

BA

Force (N)

6

5

Motor

4

speed

(m/s)

3

2

1

0

0 800400 1200

Force (N)

Motor

speed

BA

(m/s)

SGLTW-40D400B SGLTW-40D600B

Motor

speed

(m/s)

4

3

A

2

1

0

0 40002000

Motor

speed

(m/s)

B

4

3

Motor

speed

(m/s)

A

2

1

0

0 20001000 3000

Force (N) Force (N)

B

Note: The dotted line indicates characteristics when the linear servo motor for 400 VAC is used with an input power supply for 200 VAC. In this

case, the serial converter should be changed. Contact your OMRON Yaskawa representatives.

SGLTW-50D170H SGLTW-50D320H

5

4

3

2

1

0

0 600300 900

Force (N) Force (N)

BA

5

4

Motor

3

speed

(m/s)

2

1

0

0 1200600 1800

SGLTW-80D400B SGLTW-80D600B

4

3

A

2

1

0

0 4000 60002000

B

Force (N) Force (N)

Motor

speed

(m/s)

4

3

2

1

0

0 4000 6000 80002000

A

BA

B

202 AC servo systems

Loading...

Loading...