Page 1

SafetyStock Technical Guide

Functional Overview and Implementation Instructions

© 2008 Omnicell, Inc. SafetyStock Technical Guide/67-3025 Rev C

Page 2

This guide is CONFIDENTIAL and designed only for Omnicell Technical personnel and/or designated

representatives.

This guide and accompanying software and/or hardware described in it are protected under copyright laws and may

not be copied, wholly or in part, without the express written consent of Omnicell, Inc. The same proprietary and

copyright notices must be attached to any permitted copies as were attached to the original works.

Omnicell, Inc.

1201 Charleston Road

Mountain View, CA 94043

(650) 251-6100

www.omnicell.com

OMNICELL, ANESTHESIA TT, DECISIONCENTER, FLEXBIN, MEDGUARD, OMNIBUYER, OMNICENTER,

OMNIEVOLVE, OMNIFLOORSTOCK, OMNIGATE, OMNILINKRX, OMNIRX, OMNISCANNER,

OMNISUPPLIER, OMNITRACK, ONSITE, OPEN TOUCH, OPTIFLEX, OPTIFLEX MOBILETRACK,

PHARMACYCENTRAL, POINT-TO-POINT MEDICATION SAFETY, PROSERV1, SAFETYMED, SAFETYPAK,

SAFETYSTOCK, SECUREVAULT, SEE & TOUCH, SINGLEPOINTE, SURE-MED, TOUCH & GO,

VCOMMANDER, VDIRECTOR, VMANAGER, VSUITE, WORKFLOWRX, and the OMNICELL design mark are

trademarks or registered trademarks of Omnicell, Inc. in the United States and internationally.

©1999 - 2008 All rights reserved.

SafetyStock Technical Guide/67-3025 Rev C © 2008 Omnicell, Inc.

Page 3

SafetyStock

SafetyStock™ is a bar code confirmation system that promotes patient safety by minimizing the

opportunity for stocking and dispensing errors. SafetyStock users scan bar codes to confirm the

identity of medication and supply products for restock, selected issues, and returns to the Color

Touch cabinet.

Technical Overview

SafetyStock is an Omnicell option. It requires the purchase of an Option Key. Restock, Issue and

Bin Bar Code Confirmation functions will not work until SafetyStock is properly enabled. Other

related features and enhancements, such as Automatic Stock-out, function independently of

SafetyStock and do not require an Option Key

medication restocking and issuing functions, however, can also be used for supply items.

Existing cabinet functionality directs both the pharmacy technician and the nurse to the correct

location during restock and issue transactions. SafetyStock provides an additional layer of safety,

using bar code scanning to ensure that medication items are restocked correctly and, if so

configured, that the correct medication is issued from the cabinet.

SafetyStock is also designed for facilities using Omnicell WorkflowRx. In such cases, SafetyStock

uses the Restock Labels generated by WorkflowRx, and is able to receive restock information from

and send restock confirmations to WorkflowRx. For non-WorkflowRx accounts, Pick and Restock

labels and reports are generated at the OmniScanner Shelf Label Bar Code. In either case, an

approved model of SATO printer is required (see System Requirements/Compatibility).

SafetyStock bar code confirmation involves three primary elements:

Labeling and scanning for restock confirmation

Labeling and scanning for issue and return confirmation (optional)

Labeling and scanning for bin location confirmation (optional)

In addition, the following restock options and enhancements are introduced with this feature:

Selective Restock

Allows users to manually generate a restock at the OmniCenter for select items, outside of the

normal restock process.

Automatic stock-out restock generation

Automatically generates a restock for specified items that reach a zero quantity, within a

configurable time period prior to normal restock.

Customizable default printer settings

Provide the ability to specify different default printers for various functions, such as restock

reports and label printing.

Restock tab user interface changes

Feature separates screens for restock by route, by cabinet, by item (Selective Restock), and for

reprints, along with numerous other UI enhancements.

1-1

. The SafetyStock feature is primarily used for

© 2008 Omnicell, Inc. SafetyStock Technical Guide/67-3025 Rev C

Page 4

1-2 SafetyStock

Hardware Installation

Addition of Restock Configuration section to Administration tab, Setup Admin Type.

New Restock Configuration screens allow users to set defaults for various restock functions,

such as default printer settings.

System Requirements/Compatibility

OmniCenter and Color Touch cabinets running Omnicell 8100 software or higher. Blue

Screen and Sure-Med DOS cabinets are not supported.

A supported Symbol bar code scanner at the OmniCenter.

A supported Symbol bar code scanner at each cabinet.

One scanner per software host, maximum distance equal to three cells, side-by-side.

A SATO printer to generate restock labels.

A valid Omnicell Option Key (encrypted with the allowable number of cabinets).

Hardware Installation

This section covers the hardware installation of the SafetyStock scanner (for various cabinet

types). Installation can be performed at the customer facility by a qualified Omnicell

representative.

Important:

(5.5.1.x) or higher.

SafetyStock is only supported on Color Touch cabinets running Omnicell 8100 software

Overview

Hardware installation procedures vary by product. Each type uses a different kit:

OmniRX, Half-Cell, or OmniRX TT [kit #20-6032]

Implant Tracking [kit #12-6006]

OmniSupplier [kit #20-6033]

OmniCenter or OCRA (OmniCenter Remote Access) machines [kit #20-6031]

SecureVault [kit #20-6039]

OmniRx, Half Cell, or OmniRx TT

The following instructions apply to SafetyStock scanner for OmniRx, Half Cell, or the OmniRX

TT using kit #20-6032.

Required Tools

T-10 Torx driver

ESD wristband

Cam lock key #2036

SafetyStock Technical Guide/67-3025 Rev C © 2008 Omnicell, Inc.

Page 5

SafetyStock 1-3

#70-6048

#53-1109

#70-6049

#53-3081

#65-1057

#82-6071

#88-0022

#88-6026

#42-1303

Scanner Document

#60-3003

Strain Relief

#91-2052

AUX Cut out Bracke t

#53-7156

Hardware Installation

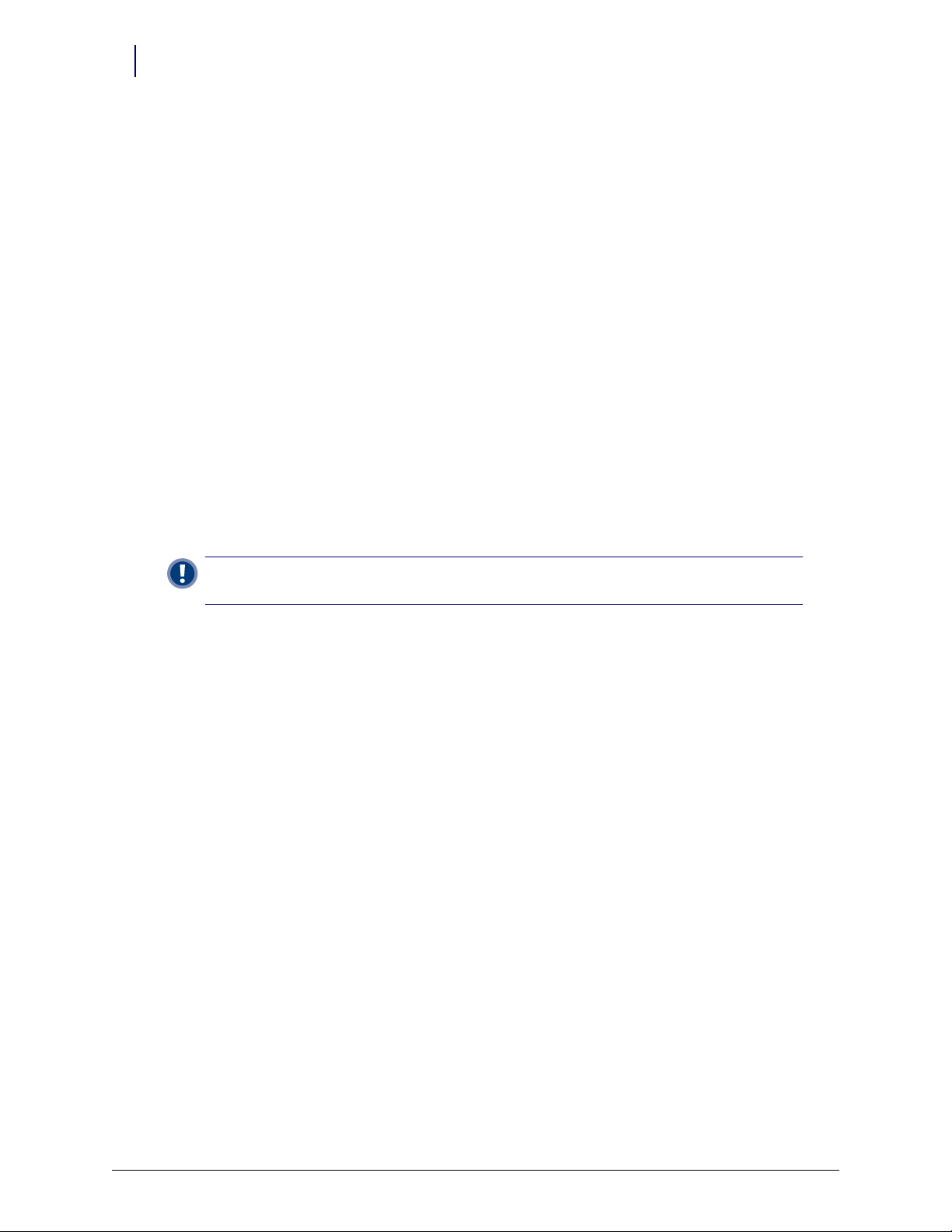

Required Kit/Parts

The following figures display the contents of the scanner kit (#20-6032). See “Parts/Kit List” on

page A-1 for more kit details.

Figure 1-1. Kit #12-1266

Figure 1-2. Parts from kits #14-1244, #20-6032

Cabinet Preparation

1. Log on to the Administration menu.

2. Press Exit To Shell.

© 2008 Omnicell, Inc. SafetyStock Technical Guide/67-3025 Rev C

Page 6

1-4 SafetyStock

Hardware Installation

3. Press OK on the confirmation window.

4. Select the Shutdown On Exit option in the Exit the Shell section.

5. Press Exit The Shell.

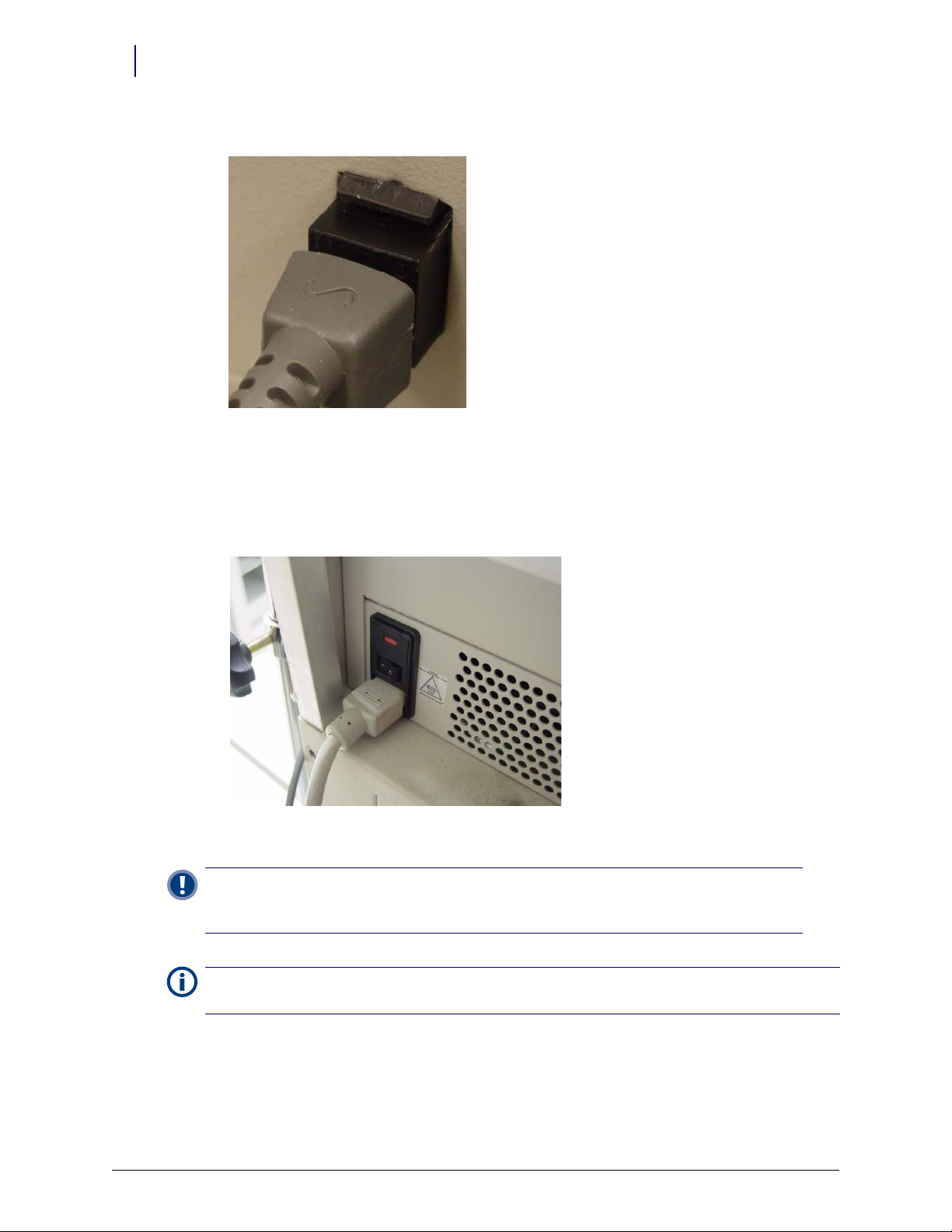

6. Power down the cabinet and disconnect the power cord.

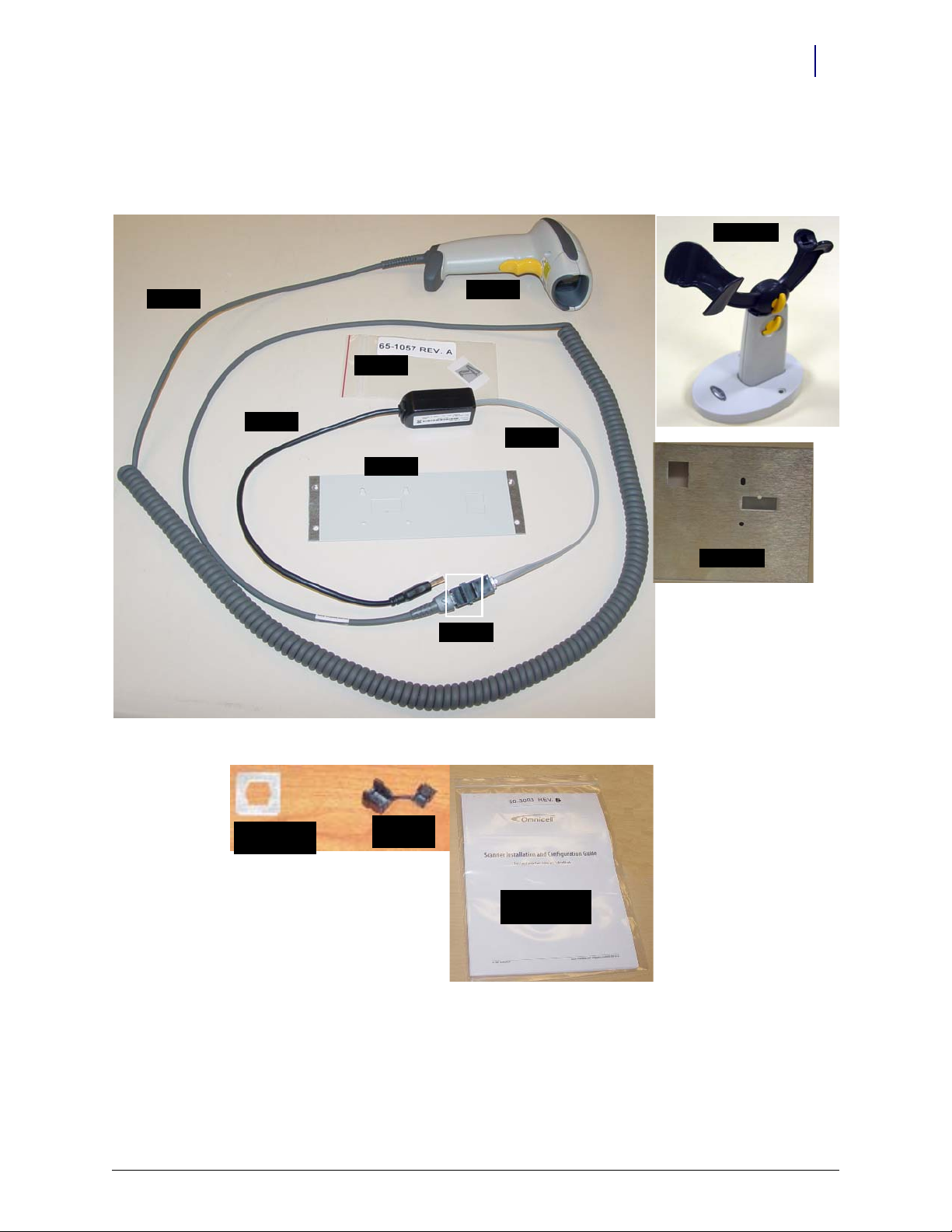

7. Unlock the cabinet top in the back using cam lock key #2036 (#92-1008).

Figure 1-3. Unlocking the cabinet top

8. Lift the cabinet top from the back on its hinge. The top is not removed.

9. Prop up the cabinet top with a stand. A switch panel extrusion can be used.

Caution: The cabinet lid is heavy and must be propped up securely. If it came down on its own, it could

cause injury.

Figure 1-4. Accessing the electronics sled

Caution: Put on an ESD wristband and secure it to a ground before working in the electronics sled.

SafetyStock Technical Guide/67-3025 Rev C © 2008 Omnicell, Inc.

Page 7

SafetyStock 1-5

#42-1303

#82-6071

#88-6026

Hardware Installation

Cable Connections

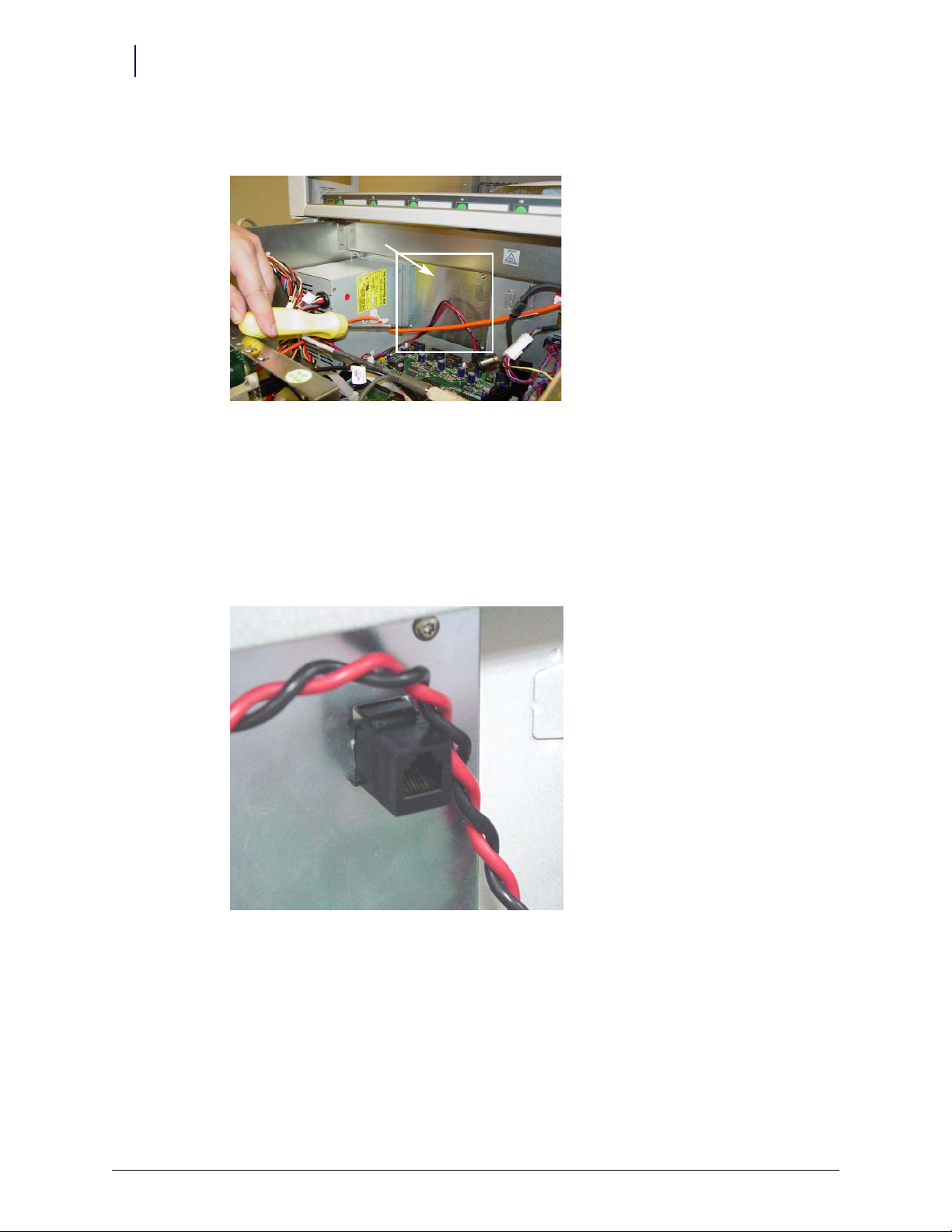

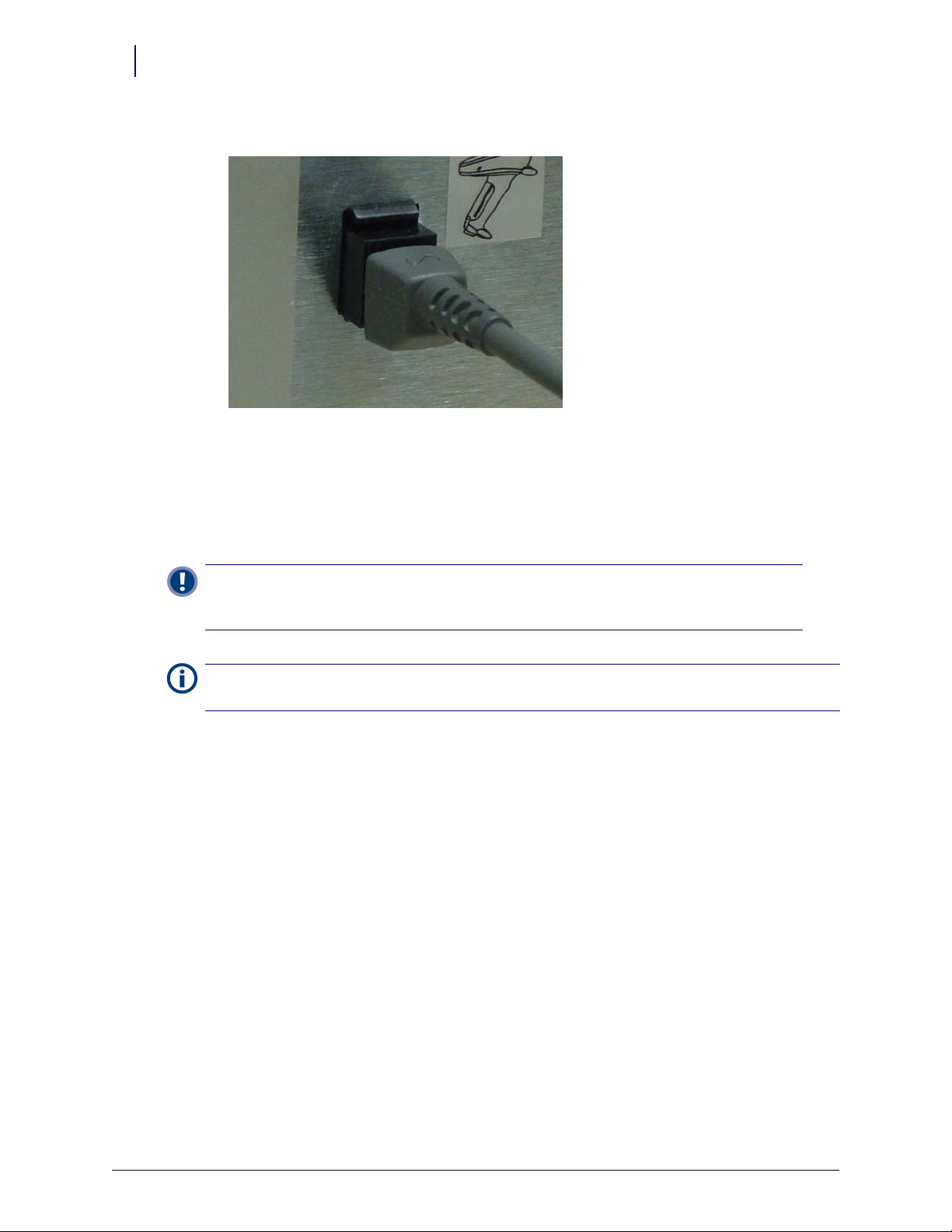

1. Disconnect the RJ-12 coupler from the #12-1266 Bar Code Scanner Manufacturing Assembly

Kit. The adapter cable (#42-1303) remains connected to the Synapse adapter and the USB

cable (#88-0022). The scanner cable (#88-6026) remains connected to the scanner (#70-6048).

Figure 1-5. RJ-12 coupler from kit

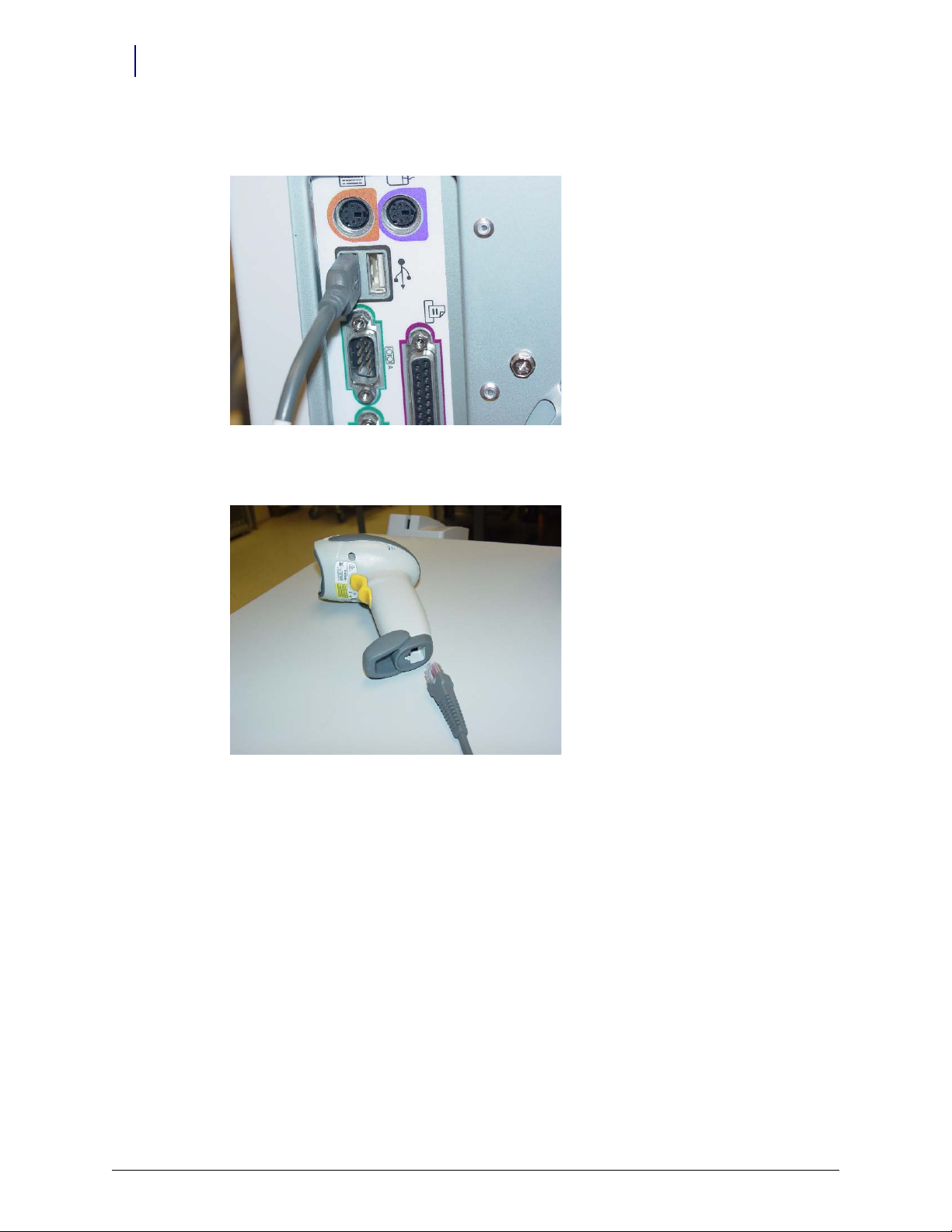

2. Connect the USB Synapse cable (#88-0022) from the kit into the mother board.

Note: It may be necessary to move any existing USB cables to the lower USB port for ease of installment.

Figure 1-6. Connecting the USB cable to the motherboard

© 2008 Omnicell, Inc. SafetyStock Technical Guide/67-3025 Rev C

Page 8

1-6 SafetyStock

Hardware Installation

A number situations are possible concerning the coupler on the OmniRx. See the following

table for the procedure that goes with the given situation. For all other cabinet types, go to Step

6.

Cutout big enough for

Rear plate bracket present Aux Port Available

No Yes Yes Step 3

No Yes No Step 4

No No N/A Step 5

Yes N/A N/ A Ste p 6

RJ-12 Connector Next Step

Table 1-1. OmniRx situations and related steps

Important: Always use the kit’s plate to replace the rear plate bracket on the OmniRx (step 6) if it exists. This

will avoid extra work later or sacrificing an Aux port for a future peripheral addition. Existing back plate

brackets may not have a cutout for a remote antenna in case the OmniTT were to be made wireless later.

Available cutouts in the back of the sled may need to be punched out if there is no Aux port in place and no

back plate bracket. These cutouts may be large enough for the RJ-12 coupler (step 3). If not, a strain relief is

used to secure the cable to the sled (step 4) with the cable connected to the coupler outside the sled. Care is

needed to ensure the cable is not easily disconnected.

Step 5 is used where there is no back plate bracket and no open Aux ports/cutouts. The scanner and Aux port

share the same sled opening with cables connected to their couplers outside the sled. This method allows the

addition of the scanner without sacrificing the use of the peripheral. Care is needed to ensure cables are not

easily disconnected.

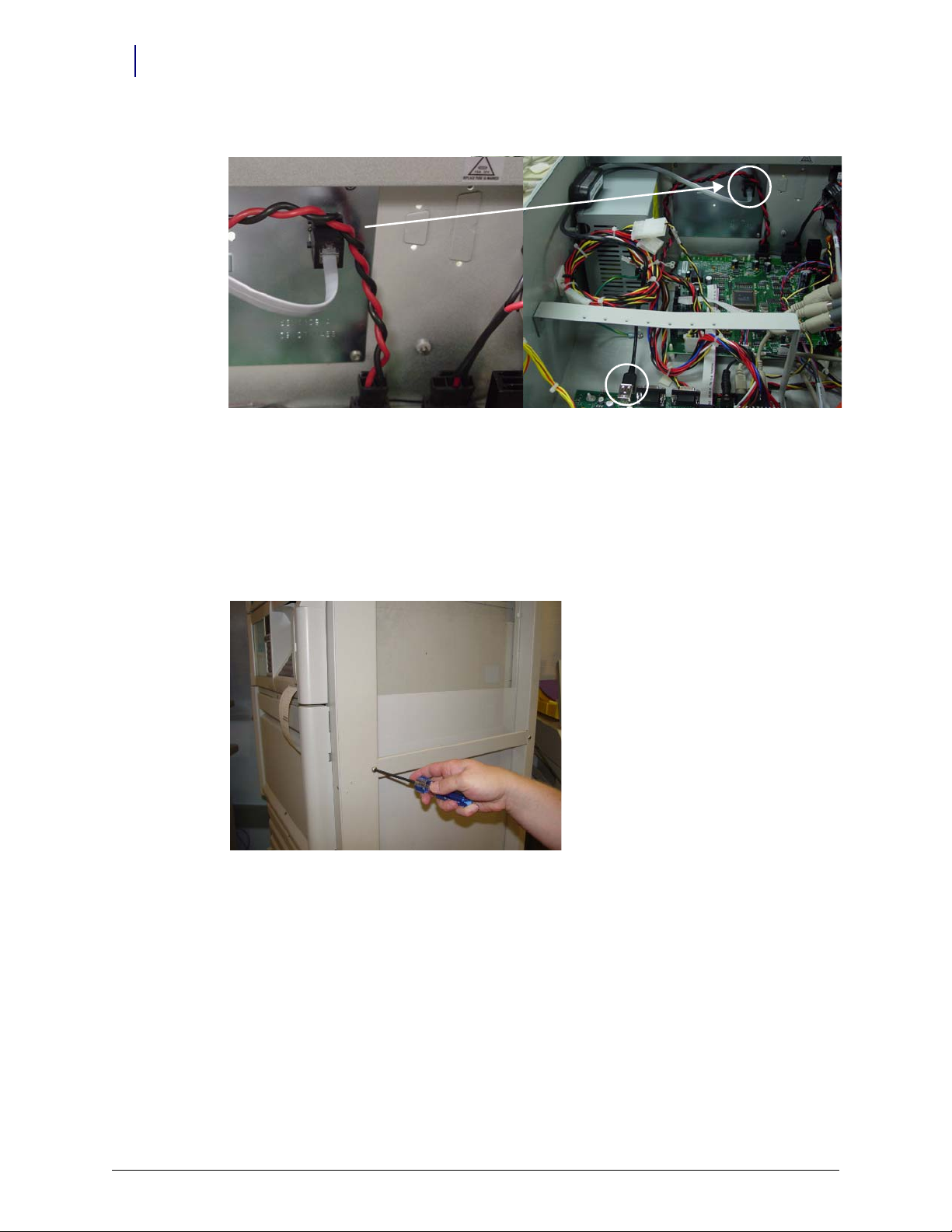

3. [OmniRX] If there is no rear plate bracket and the available Aux port cutout is large enough

for the RJ-12 coupler, perform the following steps:

a. Disconnect the left most AUX coupler (as viewed from the back) and set it inside the sled

with its cable (or) punch out the available cutout if there is no Aux port in place.

b. Install the RJ-12 coupler in the AUX coupler’s place.

c. Connect the adapter cable (#42-1303) to the in side of the RJ-12 coupler.

d. Proceed to Step 7.

4. [OmniRx] If there is no rear plate bracket and the available Aux port cutout is not large enough

for the RJ-12 coupler, perform the following steps:

a. Disconnect the left most AUX coupler (as viewed from the back) and set it inside the sled

with its cable (or) punch out the available cutout if there is no Aux port in place.

b. Thread the adapter cable (#42-1303) through the cutout bracket (#53-7156) inside the sled.

SafetyStock Technical Guide/67-3025 Rev C © 2008 Omnicell, Inc.

Page 9

SafetyStock 1-7

Cutout bracket and

cable tie

Hardware Installation

c. Feed the adapter cable (#42-1303) through the cutout opening.

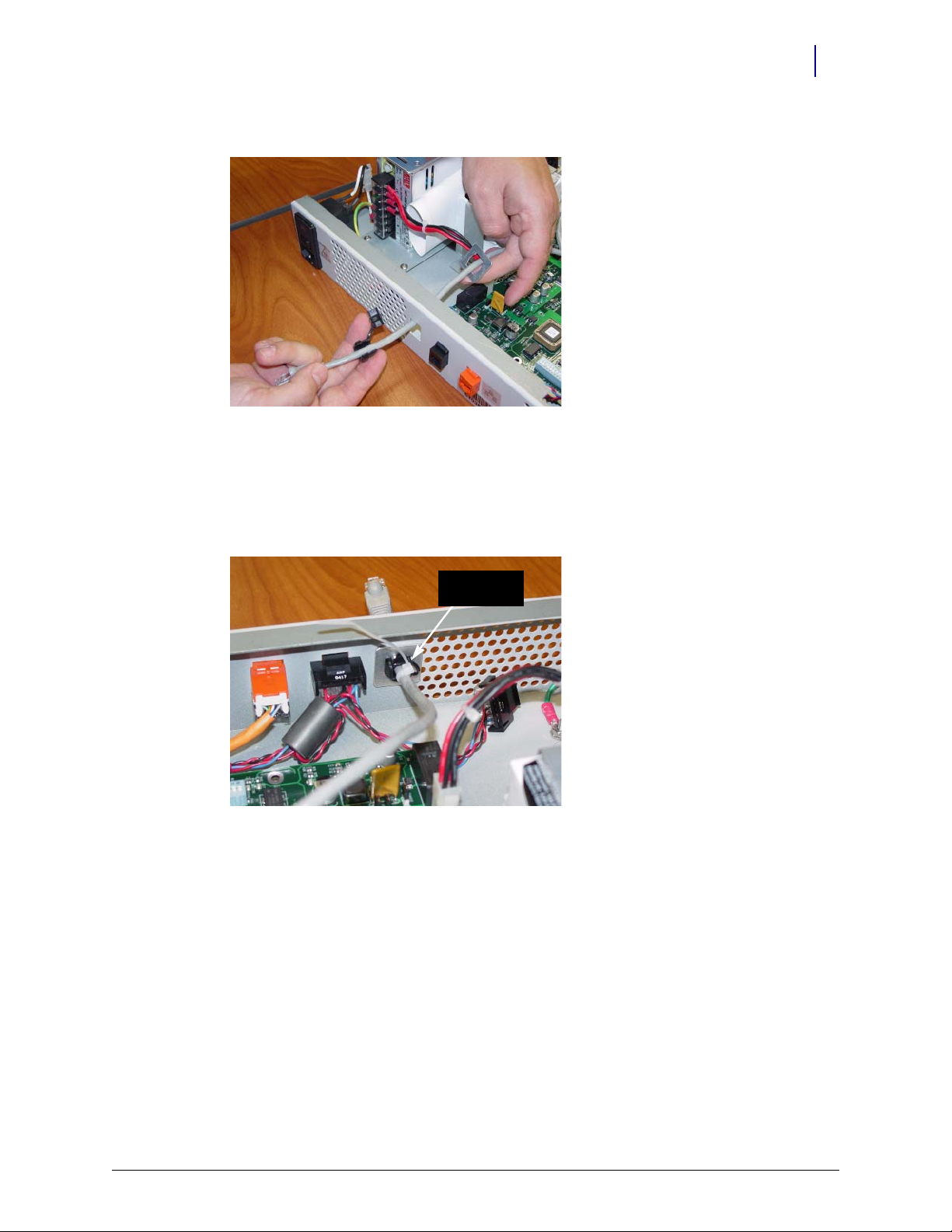

Figure 1-7. Threading the communications cable (OmniRx)

d. Place the strain relief (#91-2052) around the cable on the exterior side.

e. Secure the strain relief around the cable in the cutout opening.

f. Secure cable position on sled interior with a cable tie (#95-6007). This prevents the cable

from being pulled out during scanner use.

Figure 1-8. Securing the adapter cable (#42-1303) (OmniRx)

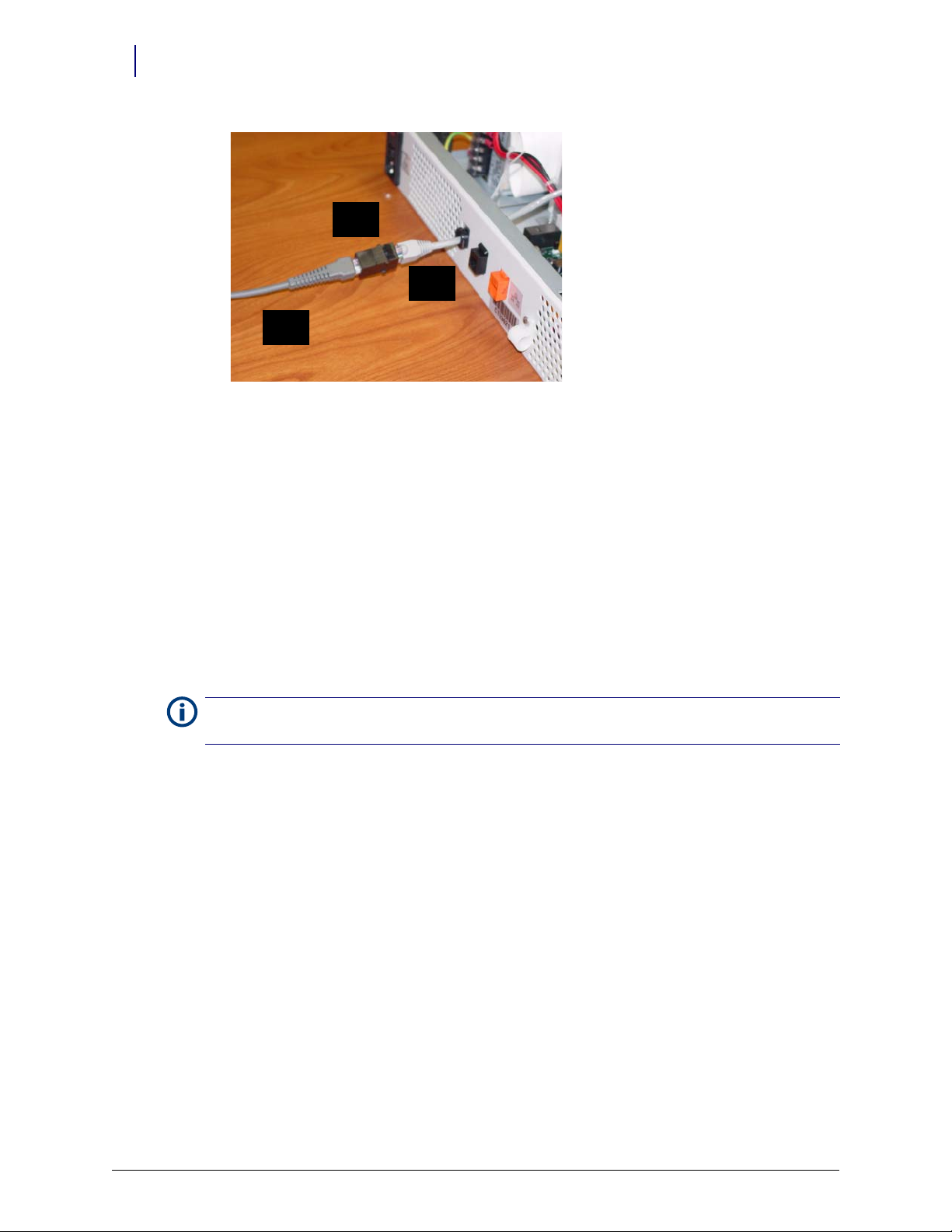

g. Connect the adapter cable (#42-1303) to the RJ-12 coupler.

© 2008 Omnicell, Inc. SafetyStock Technical Guide/67-3025 Rev C

Page 10

1-8 SafetyStock

RJ12

Connector

Adapter

Cable

Scanner

Cable

Hardware Installation

Figure 1-9. Connecting the adapter cable (#42-1303) to the RJ-12 connector (OmniRx)

h. Proceed to Step 7.

5. [OmniRx] If there is no rear plate bracket and all coupler positions are being used, perform the

following steps:

a. Disconnect the AUX cable inside the sled from right-most coupler (as viewed from the

front) and remove the existing coupler.

b. Route both the adapter cable (#42-1303) and the AUX cable through the empty coupler

hole.

c. Connect the cables to their coupler (adapter to RJ12, AUX to RJ-12) outside the sled, then

bundle and secure the cables with a cable tie inside the sled.

d. Proceed to Step 7.

6. If there is a rear plate bracket, perform the following steps:

Note:

bracket.

This step is used for all cabinets (Half Cell, Anesthesia TT and OmniRX TT) and OmniRx with a rear plate

SafetyStock Technical Guide/67-3025 Rev C © 2008 Omnicell, Inc.

Page 11

a. Punch out the cutout on the kit’s rear plate bracket (#53-3081).

Figure 1-10. Punching out the cutout

b. [Other cabinets] Remove the existing rear plate bracket.

c. Install the rear plate bracket with the cutout opening.

SafetyStock 1-9

Hardware Installation

Figure 1-11. Installing the rear plate bracket with a cutout opening

© 2008 Omnicell, Inc. SafetyStock Technical Guide/67-3025 Rev C

Page 12

1-10 SafetyStock

Hardware Installation

d. Install the RJ-12 coupler (#82-6071) in the port opening.

Figure 1-12. Installing the RJ-12 coupler

e. Connect the adapter cable (#42-1303) to the RJ-12 coupler.

Figure 1-13. Connecting the adapter cable to the RJ-12 coupler

f. Route and bundle the cables neatly with existing communications cables using the ties

provided in the kit as needed.

7. Remove the stand (switch panel extrusion) used to prop the cabinet lid.

8. Carefully lower the lid on its hinge from the back.

9. Lock the lid in back with the cam lock key.

SafetyStock Technical Guide/67-3025 Rev C © 2008 Omnicell, Inc.

Page 13

Scanner Connection

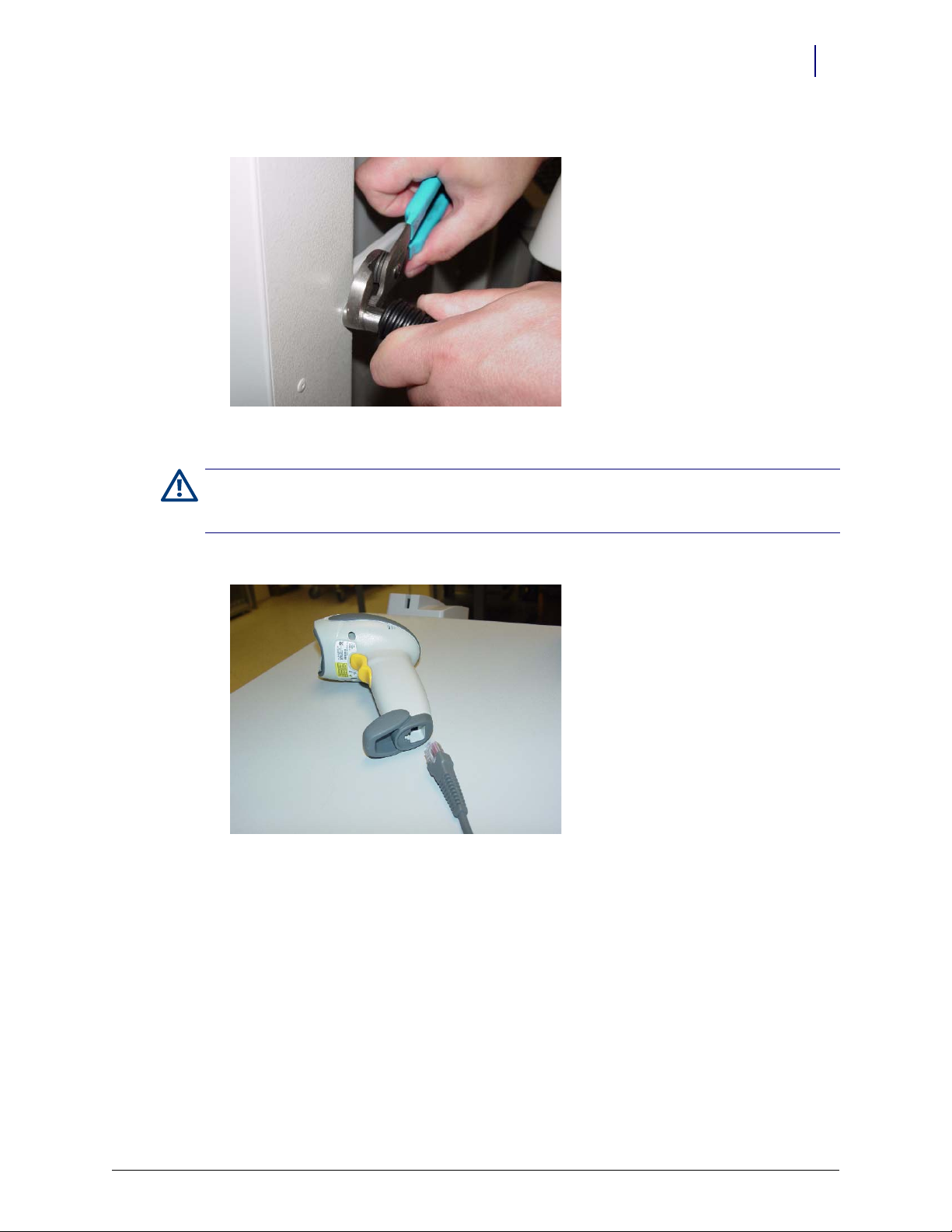

1. Remove the ESD wristband.

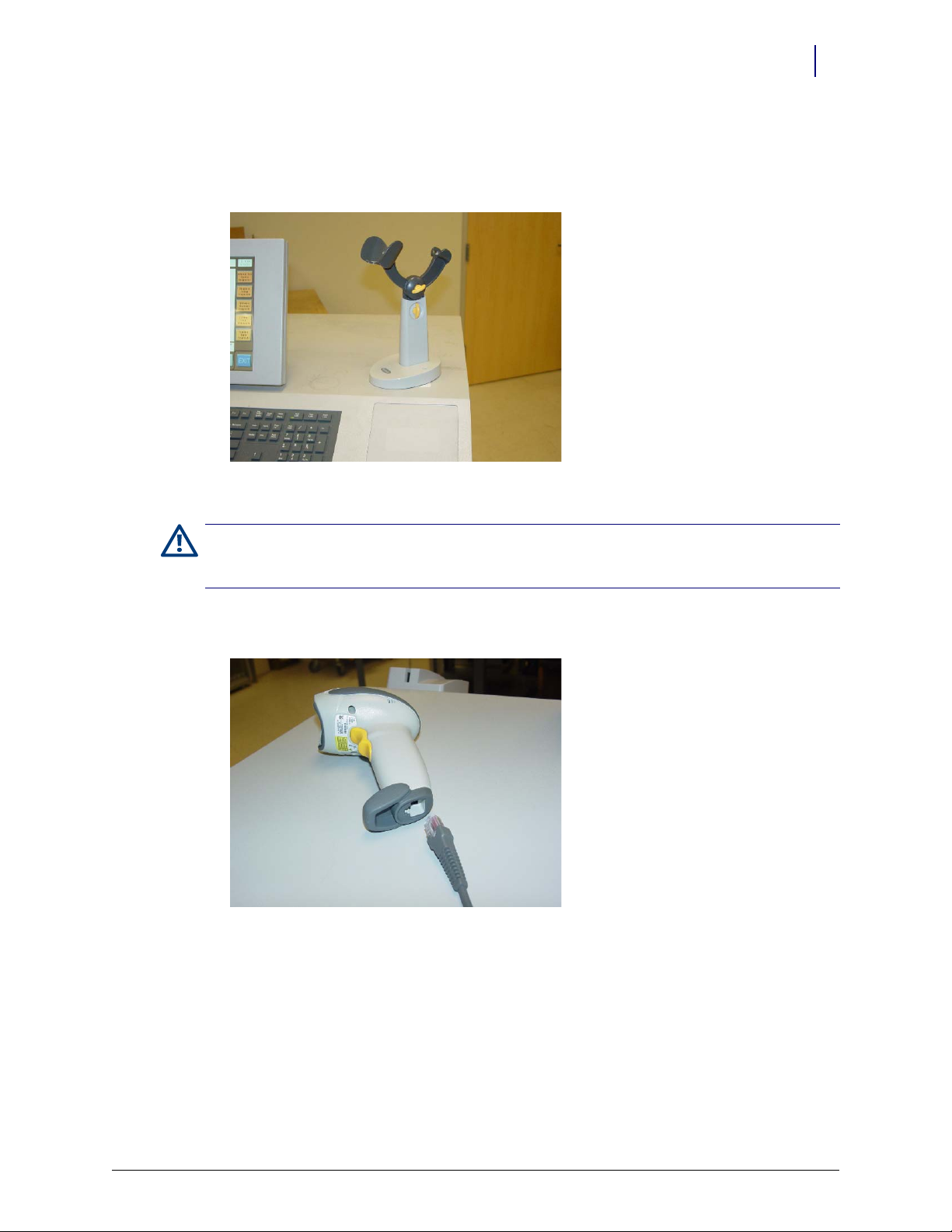

2. Place the scanner stand (#70-6049) in the desired location on the lid.

Figure 1-14. Placing the scanner stand

SafetyStock 1-11

Hardware Installation

Caution: The scanner cable must be connected correctly or the scanner will not work. The 10-pin RJ-45 end of

the scanner cable connects in the scanner handle. The 6-pin RJ-12 end of the scanner cable connects to the RJ12 connector in the back plate where the scanner label (65-1057) is placed. See Figure 1-16.

3. Connect the 10-pin end of the scanner cable (#88-6026) to the scanner (#70-6048) at the base

of the handle, then place the scanner in its cradle.

Figure 1-15. Connecting the scanner cable to the scanner

© 2008 Omnicell, Inc. SafetyStock Technical Guide/67-3025 Rev C

Page 14

1-12 SafetyStock

Hardware Installation

4. Connect the 6-pin end of the scanner cable to the RJ-12 coupler in the back of the sled.

Figure 1-16. Connecting the scanner cable to the RJ-12 coupler and attaching the scanner label

5. Place the scanner label/sticker (#65-1057) next to the scanner’s coupler.

Final Procedures

1. Connect the power cord and power up the cabinet.

Figure 1-17. Tur nin g on t he p owe r

Important:

supported bar code types, reprogramming may be required. For more scanner-specific information, see

the Symbol documentation shipped with the scanner.

The scanner is programmed prior to initial use. Should the scanner fail to recognize

Note: Depending on the cabinet’s operating system version, it may be necessary to install files or drivers

associated with the USB Human Interface Devices.

2. Test the scanner by reading a test bar code twice while the logon screen is displayed. The

window changes to an error message after the first read, then returns to the login screen on the

second read. The bar code information should be listed in the User ID box.

3. Perform the software implementation procedures. See “Implementation” on page 1-53.

SafetyStock Technical Guide/67-3025 Rev C © 2008 Omnicell, Inc.

Page 15

OmniSupplier

SafetyStock 1-13

Hardware Installation

The following instructions apply to SafetyStock scanner installation for OmniSupplier Color

Touch cabinets, using manufacturing kit #20-6033.

Required Tools

T10 torx driver

9/64 Allen wrench

Pliers

ESD wristband

Cam lock key #2036

Required Kit/Parts

The OmniSupplier requires kit #20-6033, which contains: kit #12-1266 (items shown on

“Required Kit/Parts” on page 1-3), #14-1245 (items shown below).

Figure 1-18. Gooseneck assembly and back plate

Cabinet Preparation

1. Perform a graceful shutdown of the cabinet software, then power down the cabinet and

disconnect the power cord.

2. Remove the screws securing the PC box to the frame, and slide the PC box forward.

3. Using key #2036, unlock and remove the PC box cover.

Caution: Put on an ESD wristband and secure it to a ground before working on the PC box.

© 2008 Omnicell, Inc. SafetyStock Technical Guide/67-3025 Rev C

Page 16

1-14 SafetyStock

Hardware Installation

4. Use the T-10 Torx driver to remove the four 6-32 pan head screws which secure the connector

panel plate to the rear of the PC box.

Figure 1-19. Removing the connector plate screws

5. Punch out the cutout on the kit’s connector panel plate (#53-1109) or the existing plate if

applicable.

6. Install the connector panel plate (from the kit or the existing plate) with the cutout removed

with four 6-32 pan head screws and the T-10 Torx driver.

7. Insert the RJ-12 coupler (#82-6071) into the back plate from inside the PC box. The larger

section faces inside the electronics tray. The connector’s outer connector has the locking tab

space facing down. The connector’s inner connector has the locking tab space facing up.

Figure 1-20. Insert RJ-12 coupler

SafetyStock Technical Guide/67-3025 Rev C © 2008 Omnicell, Inc.

Page 17

SafetyStock 1-15

#42-1303

#82-6071

#88-6026

Hardware Installation

Cable Connections

1. Disconnect the RJ-12 coupler from the conversion kit (#12-1266). The adapter cable (#42-

1303) remains connected to the Synapse adapter and the USB cable (#88-0022). The scanner

cable (#88-6026) remains connected to the scanner (#70-6048).

Figure 1-21. RJ-12 coupler from kit

2. Connect the USB Synapse cable (#88-0022) from the kit to the mother board.

It may be necessary to move any existing USB cables to the lower USB port for ease of installment.

Note:

Figure 1-22. USB Synapse cable

3. Properly route the cable. Use cable ties to secure cables as needed.

© 2008 Omnicell, Inc. SafetyStock Technical Guide/67-3025 Rev C

Page 18

1-16 SafetyStock

Hardware Installation

4. Route and connect the adapter cable (#42-1303) to the RJ-12 coupler inside the PC box.

Figure 1-23. Connecting the cable to the coupler inside the PC box; completing cable routing in PC box

5. Replace the PC box lid, then slide in and re-secure the PC box.

6. Remove the ESD wristband.

Scanner Connection

1. Use the 9/64 Allen wrench to remove the front screw (5/16 button head) from the transport

handle on the side of the cabinet.

Figure 1-24. Removing the transport handle screw

2. Screw the gooseneck cradle (#15-6002) into the transport handle until it is secure.

SafetyStock Technical Guide/67-3025 Rev C © 2008 Omnicell, Inc.

Page 19

SafetyStock 1-17

Hardware Installation

3. Pull back the accordion sleeve and tighten the gooseneck base with pliers.

Figure 1-25. Tightening the gooseneck base

Caution: The scanner cable must be connected correctly or the scanner will not work. The 10-pin RJ 45 sized

end of the scanner cable connects in the scanner handle. The 6-pin RJ-12 sized end of the scanner cable

connects to the RJ-12 connector in the back plate.

4. Connect the scanner cable (#88-6026) to the scanner (#70-6048) at the base of the handle.

Figure 1-26. Connecting the scanner cable to the scanner

© 2008 Omnicell, Inc. SafetyStock Technical Guide/67-3025 Rev C

Page 20

1-18 SafetyStock

Hardware Installation

5. Connect the new scanner cable (#88-6026) into the RJ-12 coupler on the back plate.

Figure 1-27. Connect scanner cable to RJ-12 coupler

6. Attach the scanner label/sticker (#65-1057) near the coupler.

Final Procedures

1. Reconnect power and reboot the cabinet software.

Important:

supported bar code types, reprogramming may be required. For more scanner-specific information, see

the Symbol documentation shipped with the scanner.

The scanner is programmed prior to initial use. Should the scanner fail to recognize

Note: Depending on the cabinet’s operating system version, it may be necessary to install files or drivers

associated with the USB Human Interface Devices.

2. Test the scanner by reading a test bar code twice while the logon screen is displayed. The

window changes to an error message after the first read, then returns to the login screen on the

second read. The bar code information should be listed in the User ID box.

3. Perform the software implementation procedures. See “Implementation” on page 1-53.

OmniCenter/Implant Tracking/OCRA Machines/SecureVault

The following instructions apply to:

OmniCenter servers and OCRA machines, (kit #20-6031)

Implant Tracking (kit #12-6006)

SecureVault (kit #20-6039)

Required Tools

None

SafetyStock Technical Guide/67-3025 Rev C © 2008 Omnicell, Inc.

Page 21

SafetyStock 1-19

Scanner

#70-6048

Scanner

USB Cable

#88-6152

Scanner

Stand

#70-6049

Scanner

Document

#60-3003

Hardware Installation

Required Kit/Parts

OmniCenter Servers and OCRA machines use kit #20-6031. See “Required Kit/Parts” on

page 1-3.

Figure 1-28. Scanner kit items for OmniCenter server and OCRA machines

Implant Tracking uses kit #12-6006.

Figure 1-29. Mount bracket and wall mount

SecureVault uses kit #20-6039. The items in this kit are similar to those in kit #14-1243.

Procedure

1. Perform a graceful shutdown of the OmniCenter computer.

© 2008 Omnicell, Inc. SafetyStock Technical Guide/67-3025 Rev C

Page 22

1-20 SafetyStock

Hardware Installation

2. Connect the USB end of the scanner cable (#88-6152) into the USB slot in back of the

computer.

Figure 1-30. Connecting the scanner cable to the keyboard port

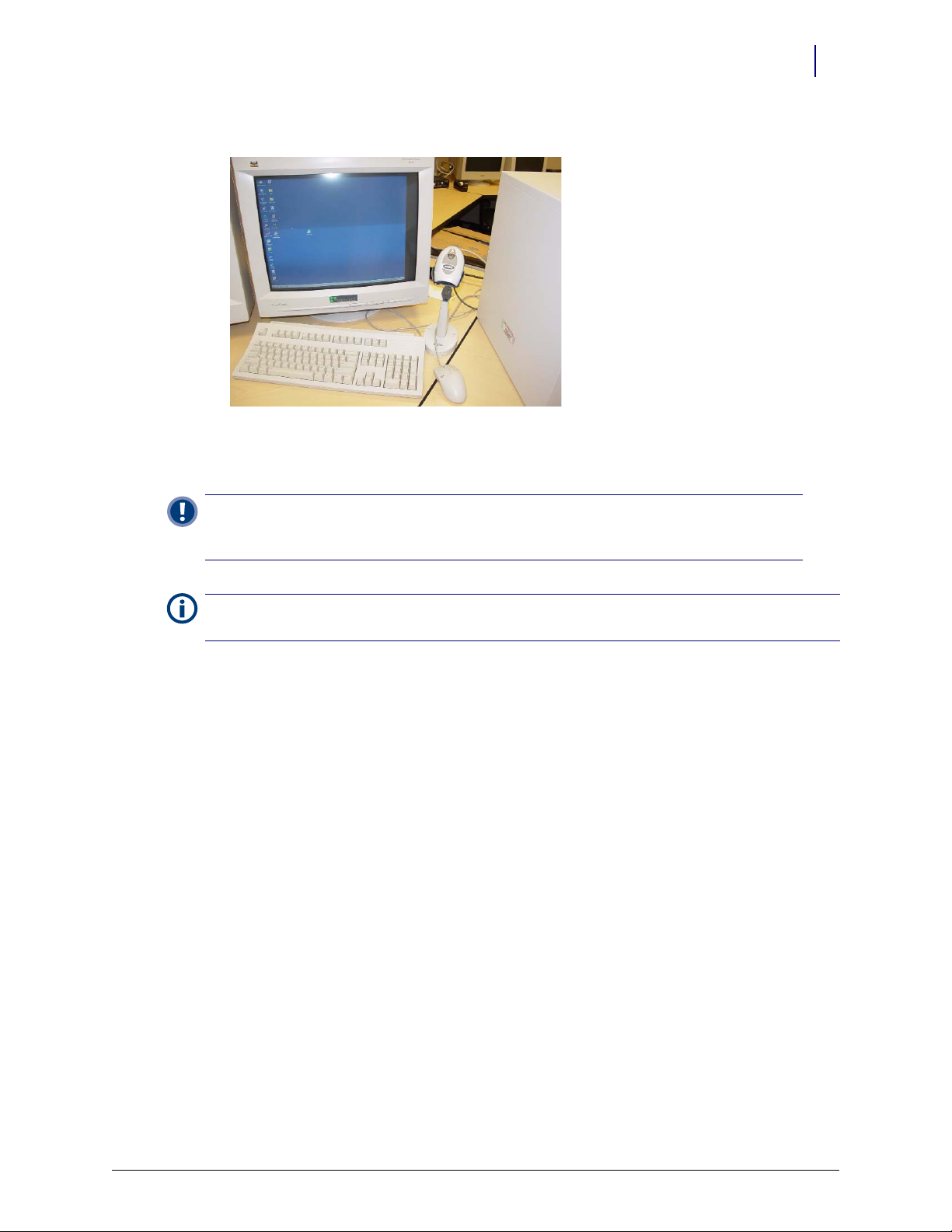

3. Connect the other end of the scanner cable (#88-6152) into the base of the scanner handle.

Figure 1-31. Connecting the scanner cable into the scanner

4. Place the scanner stand (#70-6049) near the OmniCenter.

SafetyStock Technical Guide/67-3025 Rev C © 2008 Omnicell, Inc.

Page 23

5. Place the scanner (#70-6048) in the stand.

Figure 1-32. Placing the scanner into the stand

6. Turn on the computer power.

SafetyStock 1-21

Software Functionality

Important:

supported bar code types, reprogramming may be required. For more scanner-specific information, see

the Symbol documentation shipped with the scanner.

Note: Depending on the cabinet’s operating system version, it may be necessary to install files or drivers

associated with the USB Human Interface Devices.

7. Test the scanner by reading a test bar code twice while the logon screen is displayed. The

window changes to an error message after the first read, then returns to the login screen on the

second read. The bar code information should be listed in the User ID box.

8. Perform the software implementation procedures. Refer to “Implementation” on page 1-53.

The scanner is programmed prior to initial use. Should the scanner fail to recognize

Software Functionality

OmniCenter

In order to support the SafetyStock feature—for both WorkflowRx and non-WorkflowRx

customers—a number of changes have been made at the OmniCenter. These include

modifications to the Administration tab, Restock tab, Database tab Items table, and OmniSupplier

and Transactions tables, as well as new and modified reports.

Administration Tab Modifications

Administration tab modifications include the ability to print Bin Confirmation Labels

(Administration > OmniSuppliers), and the addition of a

Setup).

© 2008 Omnicell, Inc. SafetyStock Technical Guide/67-3025 Rev C

Restock Configuration Setup section (Administration >

Page 24

1-22 SafetyStock

Software Functionality

Printing Bin Confirmation Labels A Bin Confirmation Labels option has been added to the

Administration tab,

code labels, for use with the bin confirmation restock function. Bin confirmation labels are

formatted for Avery 5167 or 5267 labels and print to a standard laser printer (8 1/2” x 11” sheet,

White, Laser, Permanent-Adhesive; 80 labels per sheet.).

To print one or more sheets of labels, the user selects the Bin Confirmation Labels option, types in the

number of pages desired, then clicks Print.

OmniSuppliers Administration type. This allows users to generate and print bin bar

Figure 1-33. Administration Tab, OmniSupplier Admin Type—Print Bin Confirmation Labels

The labels are printed in sequential order. If labels have been printed in the past, numbering for

subsequent jobs start where the last print job left off. The OmniCenter retains this information, to

prevent duplication of bin bar codes.

Note: ID numbers are generated sequentially, starting from 1 and ending at 2,147,483,647. If the maximum

number is reached the sequence starts again at 1.

Once printed, labels are placed in the desired bins. Bin association is performed via the Color

Touch software and scanner. See sample label below.

Figure 1-34. Sample bin confirmation label

SafetyStock Technical Guide/67-3025 Rev C © 2008 Omnicell, Inc.

Page 25

SafetyStock 1-23

Software Functionality

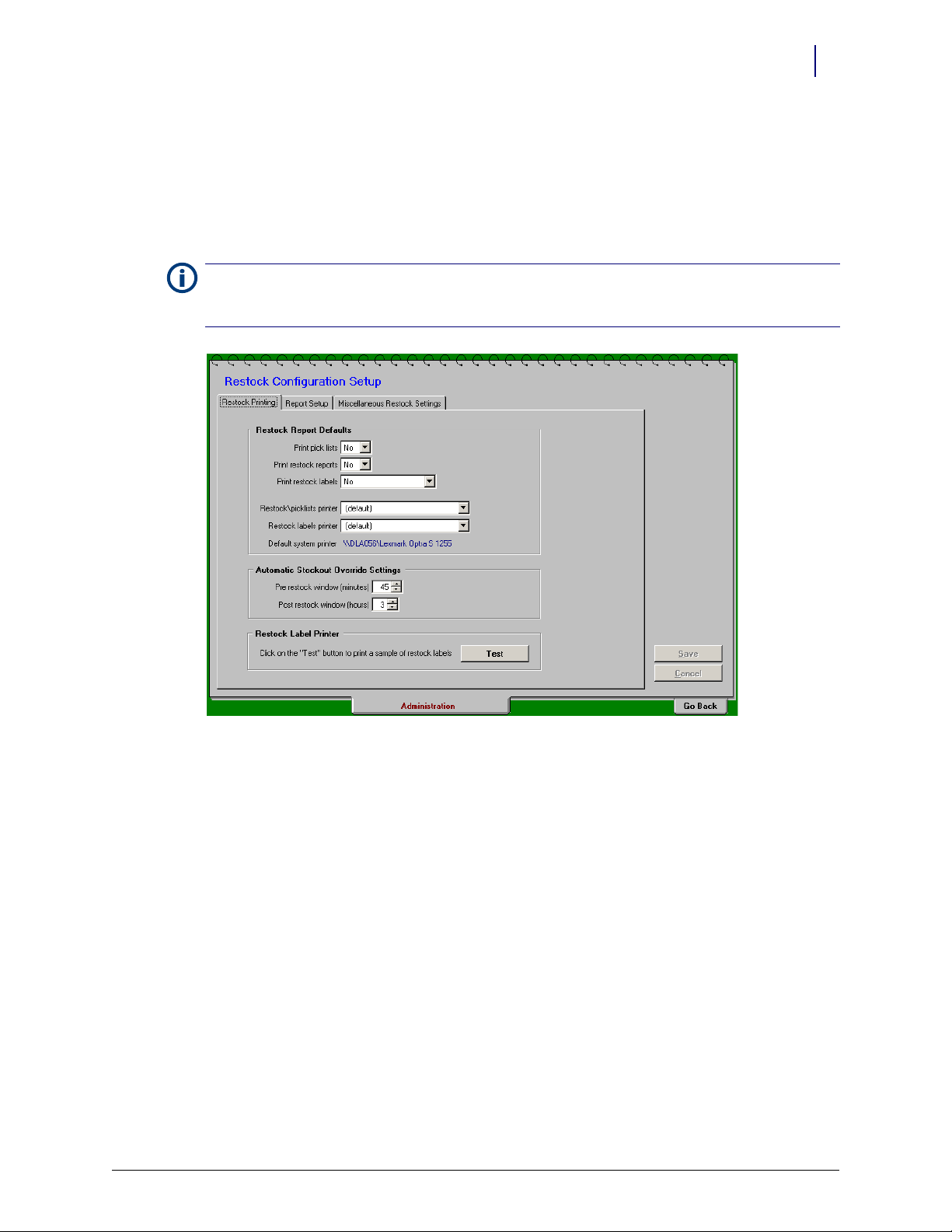

Restock Configuration Setup A Restock Configuration Se tup screen has been added to the Administration

Setup Administration type. Restock Configuration Setup contains three screens:

tab,

Restock Printing

Report Setup

Miscellaneous Restock Settings

The detailed explanation of the Restock Configuration Setup provided here is only for fields with a new

Note:

or revised function. For more information on restock functions, see the Omnicell 9000 Technical Release Guide

(P/N 60-0077, Rev. C or higher) and Omnicell 9000 Color Touch 5.6 User Guide (P/N 60-0095).

Figure 1-35. Administration Tab, Setup Admin Type—Restock Configuration Setup Screens

Restock Printing Screen The Restock Printing screen (see Figure 1-35) allows the user to control the

following settings:

Restock Report Defaults

Print pick lists (Yes/No)

Print restock reports (Yes/No)

Print restock labels (Yes/No/SafetyStock Items Only)

Restock/picklists printer

Restock labels printer

Default system printer (read-only field)

Automatic Stockout Override Settings

Pre-restock window, in minutes (0-720)

Post-restock window, in hours (0-24)

Restock Label Printer (Test button)

For user to test the SafetyStock label printer

© 2008 Omnicell, Inc. SafetyStock Technical Guide/67-3025 Rev C

Page 26

1-24 SafetyStock

Software Functionality

The Restock Report Defaults section has been added to allow users to specify whether or not to print

pick lists, restock reports and/or restock labels. The

Print restock labels option determines if restock

labels will be printed, by default, when generating restocks, and if so, whether to print labels only

for SafetyStock items. If this option is set to Yes or SafetyStock Items Only, restock labels are

generated, by default, at the designated SATO label printer. If SafetyStock Items Only is selected,

labels are only printed for items set to Confirm Restock: ...scan required in the

The

Automatic Stockout Override Settings allow the user to specify the time periods, prior to normal restock

generation and fulfillment, that Automatic Stockout restock generation should not occur. The

restock window

Automatic Restock triggers will be ignored. The

setting determines the amount of time prior to normal restock generation that

Post -restock w indow setting determines the amount of

Items database.

Pre-

time after normal restock generation that Automatic Restock triggers will be ignored.

The Restock/picklists printer and Restock labels printer fields allow the user to specify the default printer for

restock reports and picklists, and the default printer for restock labels. The

Default system printer field is

read-only; it displays the designated OmniCenter/system printer.

Report Setup Screen The Report Setup screen allows the user to control the following settings:

Restock Report (sort order/report type defaults)

Restock report

Standard option provides options by item with on-order info or Standard (by bin)

Custom option selects a custom report

Order restock list

By Omni Bin/Stock Bin/item ID/Item Name

Pick List (sort order/report type defaults)

Pick list report

Standard option includes Standard (by Source); By Omni; By source w/costs; By source w/

item bar codes; By source w/par

Custom option selects a custom report

Order pick list

By Bin Location; Item ID; Item Name

Show quantity

By Unit of Stocking; Unit of Issue

Split

By Omni; Consolidated (read-only field controlled by Pick List Report setting)

Miscellaneous Restock Settings Screen The Miscellaneous Restock Settings screen allows the user to

control the following settings:

Generate restocks (Yes/No) (Yes if selected; No if de-selected)

Days to accumulate restock quantities, in days (0-365)

Restock critically low items to (Par/Reorder Point)

Restock Tab Modifications

The Restock tab now features separate screens for restock by route, by omni (cabinet), and by item

(Selective Restock), as well as for reprints. It also has numerous other user interface

enhancements.

SafetyStock Technical Guide/67-3025 Rev C © 2008 Omnicell, Inc.

Page 27

SafetyStock 1-25

Software Functionality

Detailed explanation is provided here only for fields related to new features (i.e. SafetyStock, Automatic

Note:

Stockout, etc.). For more information on restock functions, see the Omnicell 9000 Technical Release Guide (P/N

60-0077, Rev. C or higher) and Omnicell 9000 Color Touch 5.6 User Guide (P/N 60-0095).

The feature enhancements specifically related to and/or useful for SafetyStock include:

The addition of a Restock By Item option (Selective Restock).

The addition of a Print Labels option, including the ability to limit printing to SafetyStock items.

Labels option is used to print restock labels to the SATO printer.

The

The Reprint option provides the ability to reprint restocks for selected items (see “Reprint

Restock” on page 1-29).

General User Interface Changes The restock screens now function like other OmniCenter

screens. Following are some of the general user interface changes:

Note: A detailed explanation of Restock Configuration Setup is provided here only for fields with new or

revised functionality. For more information on restock functions, see the Omnicell 9000 Technical Release Guide

(P/N 60-0077, Rev. C or higher) and Omnicell 9000 Color Touch 5.6 User Guide (P/N 60-0095).

Sort lists in ascending or descending order by clicking the header columns (marked with an

up/down arrow).

All and Clear All functions help manage lists.

User selected items are retained when users leave, then return to the page. Once the restock is

generated, the selections are cleared automatically.

Additionally, each Restock option page includes the ability to select/de-select Print options.

Although the default settings for these fields are controlled by the Restock Configuration Settings

(Administration tab, Setup Admin Type), the user can choose whether or not to print picklists,

restock reports and/or labels as needed.

© 2008 Omnicell, Inc. SafetyStock Technical Guide/67-3025 Rev C

Page 28

1-26 SafetyStock

Software Functionality

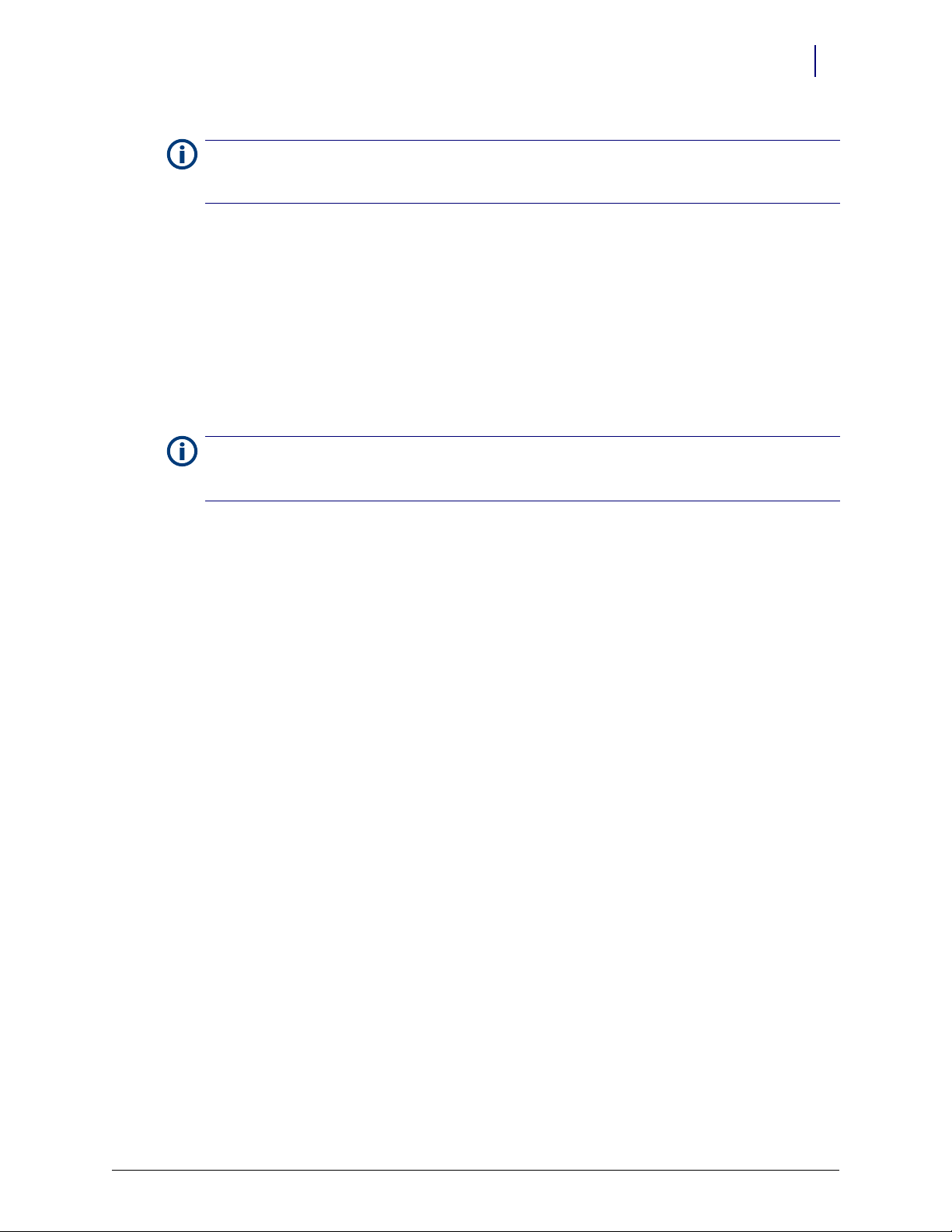

Restock By Route

Figure 1-36. Restock Tab—Restock By Route (default view)

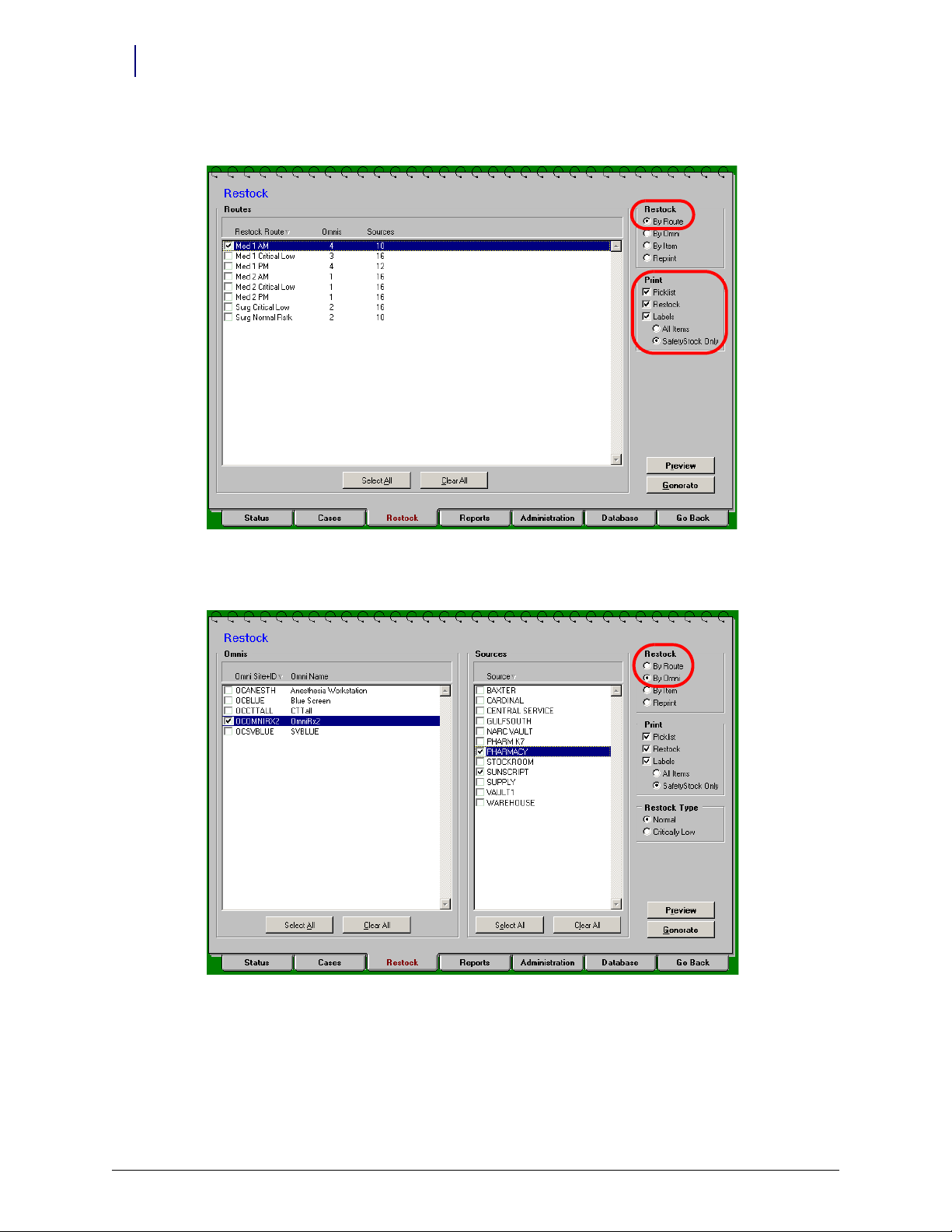

Restock By Omni

Figure 1-37. Restock Tab—Restock By Omni

Restock By Item (Selective Restock) The Restock By Item option, or selective restock, allows users

to generate a restock at the OmniCenter for specific items, apart from the normal restock process.

To do so, the user selects the Restock tab, Restock By Item option, then clicks Add to search for and

add individual items to the list.

SafetyStock Technical Guide/67-3025 Rev C © 2008 Omnicell, Inc.

Page 29

SafetyStock 1-27

Software Functionality

Note: A detailed explanation of Restock Configuration Setup is provided here only for fields related to new or

revised functionality. For more information on restock functions, see the Omnicell 9000 Technical Release Guide

(P/N 60-0077, Rev. C or higher) and Omnicell 9000 Color Touch 5.6 User Guide (P/N 60-0095).

The user can also designate the Item Source as Reorder or Critical Low.

Figure 1-38. Restock Tab, Restock By Item (Selective Restock)—Default View

When an item is added to the list (Figure 1-39), the Qty to Order field can be modified, as needed, by

double-clicking the existing field entry and typing in the new value (Figure 1-40).

Figure 1-39. Restock Tab, Restock By Item (Selective Restock)—Add Item (Search) Function

© 2008 Omnicell, Inc. SafetyStock Technical Guide/67-3025 Rev C

Page 30

1-28 SafetyStock

Software Functionality

Quantity on Order (accumulated restocking) is not shown or included in the calculations for Selective

Note:

Restocks.

Figure 1-40. Restock Tab, Restock ‘By Item’ (Selective Restock)—Modifying the Qty to Order Field

When finished, as with the other restock options, the user can choose to print picklists, a restock

report and/or restock labels. Once the Selective Restock is generated, it is sent to the applicable

cabinet(s) and is accessible via the Normal Restock function.

SafetyStock Technical Guide/67-3025 Rev C © 2008 Omnicell, Inc.

Page 31

SafetyStock 1-29

Software Functionality

Reprint Restock The Reprint option has been enhanced to allow the selection of restock IDs across

multiple routes, during the same reprint transaction.

Figure 1-41. Restock Tab—Restock Reprint Option

If the user selects a single Restock ID, the Limit to specific items in restock option becomes available.

When selected, this option allows users to select individual items for which they can reprint a

picklist, restock report, or labels. This is particularly useful for SafetyStock items, as the user can

reprint individual restock labels as needed.

Figure 1-42. Restock Tab, Restock Reprint Option—Limit to Specific Items in Restock

© 2008 Omnicell, Inc. SafetyStock Technical Guide/67-3025 Rev C

Page 32

1-30 SafetyStock

Software Functionality

Database Tab Modifications

Changes have been made to various screens and tables in the OmniCenter database to support

SafetyStock and the additional restock enhancements. These include visible changes to the

table and

OmniSuppliers table.

Items Table Modifications This section covers changes specific to the Items record, Restock section.

Another facet of bar code support involves associating the item with one or more bar codes (

record,

Bar Code section). This functionality is detailed in the Bar Code Support for Medications and

Supplies chapter of the Omnicell 9000 Technical Release Guide (PN 60-0077, Rev. C or higher).

Additionally, the defaulting rules for Critical Source and Critical Bin Location have changed.

The facility can also require bin bar code confirmation at the time of restock. However, this is set up at

Note:

the cabinet, and is based on the item-bin association. See the “Color Touch Functionality” on page 1-39 for

details.

Restock and/or Item Bar Code Confirmation A Confirm Restock field has been added to the Items

record,

Restock section. For each item, facilities have the option to set this field as follows:

No scan required (default setting)

Item bar code scan required

Item or restock bar code scan required

Items

Items

Figure 1-43. Database Tab, Restocking Section—bar code Confirmation Fields for Restock and Issue

If Confirm Restock is set to No Scan Required, the item is not treated as a SafetyStock item for restock

purposes.

Note: If the Critical Source field is blank when an item is added or modified, it defaults to the Reorder Source.

Critical Bin/Part# field is blank when an item is added or modified (or during upgrade), it defaults to the

If the

Reorder Bin/Part#.

SafetyStock Technical Guide/67-3025 Rev C © 2008 Omnicell, Inc.

Page 33

SafetyStock 1-31

Software Functionality

If set to Item bar code scan required, the item must be scanned at time of restock, and only the item

bar code will be accepted as a valid scan (the item bar code is typically pre-printed on or adhered

to the individual package).

If set to Item or restock bar code scan required, the item must be scanned at time of restock, and either

the item bar code or the corresponding SafetyStock or WorkflowRx restock label is acceptable as a

valid scan. In this case, it is recommended that the item bar code be scanned whenever possible, as

this provides the highest level of error prevention.

The facility can also require bin bar code confirmation at the time of restock. However, this is set

up at the cabinet, and is based on the item-bin association. See the “Color Touch Functionality” on

page 1-39 for details.

This feature can be used independently or in addition to the restock confirmation function. The two are

Note:

neither mutually exclusive or mutually dependent.

Item Bar Code Issue Confirmation A Confirm Issue field has also been added to the Items record,

Restock section. This field allows facilities to require issue confirmation for the item (selected = Yes,

scan required; de-selected = No, scan not required). The field is de-selected by default. If it is

selected, the user must scan the item bar code when removing the item from the cabinet. This

option is especially recommended for high-risk items, such as those that look similar to one

another.

Note: Another facet of bar code support involves associating the item with one or more bar codes (Items

record, Bar Code section). This functionality is detailed in the Bar Code Support for Medications and Supplies

chapter of the Omnicell 9000 Technical Release Guide (PN 60-0077 Rev. C, or higher)

Automatic Stock-Out Restock Configuration An Auto Restock field has been added to the Items record,

Restock section, along with associated fields in which to verify or override default print settings. The

Auto Restock field determines if the item qualifies for Automatic Stock-out restock generation (selected =

Yes, enable auto-restock for this item; de-selected = No, auto-restock disabled for this item). This

field is de-selected by default. If it is selected, restock is automatically generated whenever the item

reaches a zero quantity, unless it is within a configured number of minutes before a normal

restock or a configured number of hours before a scheduled restock.

Note: The time period to ignore Automatic Stock-out triggers before and after normal restock is configurable.

See the “Restock Configuration Setup” on page 1-23 for more information.

If desired, the user can also chose to alter the default print settings for the item when an

Automatic Stock-Out restock is generated. This includes whether or not to print restock reports,

pick lists, and/or restock labels, and to which printers. The defaults displayed for these fields are

determined by the Restock section settings on the associated OmniSupplier record.

Automatic Stock-Out default print settings are determined as follows:

Item-level defaults match the settings on the associated OmniSupplier record.

OmniSupplier-level defaults match the settings on the Restock Configurations Setup, Restock Report Defaults

screen (Administration tab > Setup).

If left unchanged at the Restock Configuration Setup level, restocks will default to the

OmniCenter/system printer.

© 2008 Omnicell, Inc. SafetyStock Technical Guide/67-3025 Rev C

Page 34

1-32 SafetyStock

Software Functionality

OmniSuppliers Table Modifications

Automatic Stock-Out Print Settings A Restock section has been added to the OmniSuppliers record,

providing users the opportunity to modify Automatic Stock-Out settings for the selected cabinet.

At the OmniSupplier level, different print preferences, such as to print or not print labels, can be

specified for pharmacy and supply items.

These fields only need to be modified if the default print settings, derived from

Setup

(Administration tab > Setup), are not acceptable.

Automatic Stock-Out default print settings are determined as follows:

Item-level defaults match the settings on the associated OmniSupplier record.

OmniSupplier-level defaults match the settings on the Restock Configurations Setup, Restock Report Defaults

screen (Administration tab > Setup).

If left unchanged at the Restock Configuration Setup level, restocks will default to the

OmniCenter/system printer.

Automatic Stock-Outs for all items in the cabinet default to the OmniSupplier settings. However, if the

Automatic Stock-Out print settings for an item in the cabinet are changed on the Item record, the

OmniSupplier settings are ignored for that item.

Restock Configuration

Figure 1-44. Database Tab, Restocking Section—Automatic Stock-Out and Related Fields

Licensed Features Settings SafetyStock is an Omnicell option, and thus requires a valid Option

Key in order to be activated. SafetyStock Option Keys are encrypted with the number of licensed

cabinets. For example, if the facility purchases the SafetyStock option for 10 cabinets, only 10

cabinets can be SafetyStock enabled at a given time.

SafetyStock Technical Guide/67-3025 Rev C © 2008 Omnicell, Inc.

Page 35

SafetyStock 1-33

Software Functionality

Once a valid Option Key is entered (via Global Settings, LICENSE Resource Type), the SafetyStock field

must be enabled on each applicable cabinet record. This is done via the

Database tab, OmniSuppliers

table. See “Modifying or Verifying OmniSupplier Records” on page 1-56 for implementation

steps.

Figure 1-45. Database Tab, OmniSuppliers Table—Licensed Features Subtab

For more information about licensing functionality, refer to Licensed Features in the Omnicell

Licensed Features Technical Guide (PN 67-3021).

Transactions Table Modifications The Tra ns ac t io ns table has been modified to include the following

fields:

For other related table changes, such as ItemBins, etc., see the “Color Touch Functionality” section.

Note:

Field Token Lookup Description

iscanover iso isover Scan Override

Table 1-2. Xact Table

Field Token Lookup Description

ss_restock ssr ssrstk Confirm Restock

ss_issue ssi y/n Confirm Issue

binconf bci Bin Conf ID

Table 1-3. Xitem Table

© 2008 Omnicell, Inc. SafetyStock Technical Guide/67-3025 Rev C

Page 36

1-34 SafetyStock

Software Functionality

Reports

The following reports have been added or modified to support SafetyStock and related features:

New Reports

SafetyStock Items report

SafetyStock Override report

SafetyStock Quality Assurance report

Revised Reports

No Items Need Restocking report

Restock and Picklist reports

Null Transactions report

New Reports

SafetyStock Items Report A SafetyStock Items report has been added to the Operational reports list,

to help facilities manage their SafetyStock items.

Figure 1-46. Reports Tab, Operational Type—SafetyStock Items

SafetyStock Technical Guide/67-3025 Rev C © 2008 Omnicell, Inc.

Page 37

SafetyStock 1-35

Software Functionality

This report can be grouped by OmniSupplier, then by Item ID (default), Item Name or Bin

Location, and can be filtered based on the following criteria:

Omni Site+ID

Item ID

Item Control Levels

SafetyStock Types

Restock Confirmation

Issue Confirmation

Bin Confirmation

No Confirmation (de-selected by default)

Note: All bin locations for a multi-bin item will be displayed on the report if at least one of the bins is

configured for bin confirmation.

SafetyStock Override Report A SafetyStock Override Report has been added to the Operational

reports list, to allow for tracking of SafetyStock scan compliance during issue and restock

transactions.

Figure 1-47. Reports Tab, Operational Type—SafetyStock Override Report

© 2008 Omnicell, Inc. SafetyStock Technical Guide/67-3025 Rev C

Page 38

1-36 SafetyStock

Software Functionality

This report can be grouped by OmniSupplier (default), Item ID or User ID, and can be filtered

based on the following criteria:

Date Range

User ID

Omni Site+ID

Item ID

Control Levels

Scan Override Types (based on the override reason entered by the user at the cabinet; see the

Color Touch section for details)

SafetyStock Quality Assurance Report A SafetyStock Quality Assurance report has been added to

Operational reports list, to allow users to verify the SafetyStock rate of effectiveness in error

the

prevention.

Note:

The purpose of this report is to display the number of errors prevented by SafetyStock. The Null

Tra ns act io ns and/or SafetyStock Override reports provide specific transaction details.

Figure 1-48. Reports Tab, Operational Type—SafetyStock Quality Assurance

The Quality Assurance report includes information on the following transaction types:

Null Types: BI, BO, BR, BS, BT, BU, CO, CR, CT, or CU (see “Null Transactions Report” on

page 1-37)

SafetyStock Technical Guide/67-3025 Rev C © 2008 Omnicell, Inc.

Page 39

SafetyStock 1-37

Software Functionality

Issues of Issue Confirmation items

Returns of Restock or Bin Confirmation items

Restocks of Restock or Bin Confirmation items

Supplemental Restocks of Restock or Bin Confirmation items

This report can be grouped by OmniSupplier, Item Description or User Name. It can be ordered

by Group or Percentage, and can be filtered based on the following criteria:

Date Range

OmniSite+ID

Error Types:

Wrong Item Scanned (Null Types: BS, BT or BU)

Wrong Bin Scanned (Null Types: CT or CU)

No Item Scanned (Null Types: BI, BO or BR)

No Bin Scanned (Null Types: CO or CR)

Revised Reports

No Items Need Restocking Report and Labels The No Items Need Restocking report now includes a

label report version, formatted to print on restock labels (SATO printer). The “No Items...” label

displays the restock route, restock type, current date/time, and the number of cabinets in the

route. This report is generated whenever a Restock label report would have been printed, had

there been items to restock.

In addition, the existing No Items Need Restocking report is now generated whenever a Restock or

Picklist report would have printed, had there been items to restock.

Restock and Picklist Report Modifications The Restock and Picklist reports have been modified to

note which items are SafetyStock Restock Confirmation items. Such items are marked with a “c” in

the far right-hand column.

Null Transactions Report The Null Transactions report has been modified to include the new

SafetyStock-related Null Types. (See Figure 1-49.) The new Null Types are as follows:

BI—failed to scan item bar code during issue

BO—failed to scan item or Restock Label Bar Code during restock

BR—failed to scan item bar code during return

BS—wrong item bar code scanned during issue

BT—wrong item or restock label bar code scanned during restock

BU—wrong item bar code scanned during return

CO—failed to scan Bin Confirmation Label Bar Code during restock

CR—failed to scan bin confirmation bar code during return

CT—wrong bin confirmation label bar code scanned during restock

CU—wrong bin confirmation label bar code scanned during return

Additional filter options have also been added allowing the report to be filtered by the following

criteria:

Date Range

© 2008 Omnicell, Inc. SafetyStock Technical Guide/67-3025 Rev C

Page 40

1-38 SafetyStock

Software Functionality

OmniSite+ID

Item ID (new)

User ID

Null Types (new; includes selection screen)

Figure 1-49. Re por ts Tab, Op era tio nal Type, Nul l Tra nsa ctio ns, Null Transaction Types—Filter Select Screen

WorkflowRx Support

SafetyStock and related features also support the integration of WorkflowRx into the restock

process. This includes the communication of restock information and Omnicell cabinet inventory

information.

The following is a sample use-case, demonstrating the process flow between the OmniCenter,

WorkflowRx and Omnicell cabinets during a restock:

1. A restock is generated.

2. All restock information is broadcast to WorkflowRx at the Item level.

3. All restock information is broadcast to OmniSuppliers at the Bin level.

4. The user picks items at WorkflowRx and modifies quantities as necessary.

5. WorkflowRx assigns unique WorkflowRx Transaction IDs at the Item level of the restock.

6. WorkflowRx broadcasts updated restock information to the OmniCenter, at the Item level,

complete with the WorkflowRx Trans acti on ID and any changes in order quantity.

Note:

WorkflowRx Transaction IDs are not communicated to the cabinet. They are stored in the Restock table

for communication purposes between the OmniCenter and WorkflowRx.

7. OmniCenter updates the restock table as needed, distributing item-level quantity changes

among the relevant bins such that the resulting number of bins restocked is minimized. Any

records with quantity changes are broadcast to the affected OmniSuppliers at the bin level.

8. The user restocks each OmniSupplier on the route.

SafetyStock Technical Guide/67-3025 Rev C © 2008 Omnicell, Inc.

Page 41

SafetyStock 1-39

Color Touch Functionality

9. The cabinet sends Restock Transaction (XA-S) and Restock Complete (RC) commands at the

bin level to the OmniCenter. If/when the restock is completed, the Restock End (RC *END*)

record is sent as well.

10. The OmniCenter, as it processes Restock Complete (RC) commands, passes on an aggregate

RI (Restock Information) to WorkflowRx, complete with the total quantity restocked for the

item and the associated WorkflowRx Transaction ID.

Restock Information Communicated to WorkflowRx The following information is sent in an RI or

RA command (Restock Add) whenever restock information is broadcast to WorkflowRx:

Field Token Description

rest_num pon Restock Number (ID)

rest_orig ro Restock Origin

rest_route rrt Restock Route

omni_stid osi Omni Site + ID

rest_type rty Restock Type

item_id item Item ID

item_name ina Item Name

rx_suffix rs Rx Suffix (Pharmacy suffix concatenation)

qty_parlvl qpl Par (Item total at time of order)

qty_alarm qal Critically Low (Item total at time of order)

qty_onhand qoh Qty On Hand (Item total at time of order)

qty_accum qac Qty On Order (Item total at time of order)

qty_order qor Qty Ordered (Item total at time of order)

qty_recd qrc Qty Received (Item total so far)

dati_ordr dor Order Date/Time

rest_dati rdt Restocked Date/Time

rest_user rus Restocked By

Table 1-4. Restock Information Communicated to WorkflowRx

Color Touch Functionality

In order to support SafetyStock and related features at the cabinet, modifications have been made

to the database, as well as to a number of Color Touch functions, including:

Normal Restock,

Supplemental Restock

Issue

Return

Modify Bin

© 2008 Omnicell, Inc. SafetyStock Technical Guide/67-3025 Rev C

Page 42

1-40 SafetyStock

Color Touch Functionality

Bar Code Types Supported

Some Color Touch functions rely on valid bar code scans. The following list of bar code types are

what the SafetyStock scanner supports:

UPC-A

UPC-E

EAN-8

EAN-13

Code 128

UCC/EAN-128

ISBT 128 (non-concatenated)

Code 39 (2-55 characters)

Interleaved 2 of 5 (ITF)

RSS 14

RSS Limited

RSS Expanded

RSS Stacked (Product ID portion only)

RSS Expanded Stacked

RSS Stacked Omni-directional

RSS 14 Truncated

Database

Item Scan Code Table

A Scan Code table has been added to the Color Touch database to store information about item

scan codes. Each item ID can have multiple scan codes associated with it, in order to support any

number of bar codes representing the same item (e.g. bar codes from several different

manufacturers of a like item).

Field Name Token Display Name Description

is_key isk N/A Table key

item_id item Item ID # Item ID

Iscan isc Item Bar Code Item scan code

Note nt Note Scan code description entered by user

add_id adi Add ID User ID of user who first added this record

add_name adn Add Name User Name of person who first added this record

add_dati add Add Dt/Tm Date record first added

xact_dati xdt Last Trans Dt/Tm Last date a transaction was generated using this scan code

lu_dati lud Last Updated DtTm Date/time of last update

lu_from luf Last Updated By User who performed last update

Table 1-5. Item Scan Code Table

SafetyStock Technical Guide/67-3025 Rev C © 2008 Omnicell, Inc.

Page 43

SafetyStock 1-41

Color Touch Functionality

Transactions Table

The following fields have been added to the Transactions table:

Field Name Token Display Name Description

iscan isc Item Bar Code Item scan code

iscantype ist Item Scan Type Type of bar code scanned —see below

iscanover iso Item Scan Override Was required scan was overridden, and if so, why—see below

Table 1-6. Tra nsa cti ons Tabl e

Item Scan Types Possible scan types are:

O—OmniScanner label bar code scan (with a “|” prefix). Not used for this feature.

K—prepack label bar code scan (with a “/” prefix).

P—Product Label Bar Code scan (with no prefix).

R—Restock label bar code scan (with “.” prefix).

N—None.

B—Bin confirmation label bar code scan (with “~” prefix).

Item Scan Override Types Possible scan override types are:

N—No override.

M—No bar code on item.

C—Cannot read item bar code.

W—Item bar code does not match item selected for restock or issue.

U—Item bar code is readable, but not associated with an item.

O—Other, document with supervisor.

Items Table

The following fields have been added to the Items table (set and stored at the OmniCenter):

Field Name Token Display Name Description

ss_restock ssr SafetyStock Support Does item require restock confirmation/type

N—Not enabled

I—Item bar code required

R—Restock bar code label or item bar code label required

ss_issue ssi Issue confirmation Support Does item require issue confirmation, Y/N

ar_item arit Auto Restock Automatic Stock-Out enabled for item, Y/N

ar_pick arp Picklist Print picklist for Automatic Stock-out, Y/N

ar_rest arr Restock Print restock repor t for Automatic Stock-out, Y/N

ar_bar arb Bar Code Print restock labels for Automatic Stock-out, Y/N

ar_pnorm arpn Normal Printer Default restock report/picklist printer

ar_pbar arpb Normal Printer Default label printer

Table 1-7. Items Table

© 2008 Omnicell, Inc. SafetyStock Technical Guide/67-3025 Rev C

Page 44

1-42 SafetyStock

Color Touch Functionality

ItemBins Table The following field has been added to the ItemBins table:

Field Name Token Display Name Description

Binconf bci Bin Confirmation ID The unique bar code associated with the bin.

Table 1-8. ItemBins Table

Omnis Table The following field has been added to the Omnis table:

Field Name Token Display Name Description

ss_lic ssl SafetyStock License Is a valid SafetyStock Option Key on record at the OmniCenter, Y/N

Table 1-9. Omnis Table

Null Transaction Types The following new Null Types have been added to support SafetyStock:

BI—failed to scan item bar code during issue

BO—failed to scan item or restock label bar code during restock

BR—failed to scan item bar code during return

BS—wrong item bar code scanned during issue

BT—wrong item or restock label bar code scanned during restock

BU—wrong item bar code scanned during return

CO—failed to scan bin confirmation label bar code during restock

CR—failed to scan bin confirmation bar code during return

CT—wrong bin confirmation label bar code scanned during restock

CU—wrong bin confirmation label bar code scanned during return

Error Messages

If an incorrect item and/or incorrect bar code is scanned, an applicable error message is displayed

and a null transaction is sent. (Wrong item and unknown item scans generate null transactions;

null includes the bar code scanned and scan type). Possible error messages include:

Wrong Item Scanned

Message is displayed and Null Type is sent: BS - Wrong item bar code scanned during issue.

Message is displayed and Null Type is sent: BT - Wrong item or restock label bar code

scanned during Restock.

Message is displayed and Null Type is sent: BU - Wrong item bar code scanned during

return.

Unknown Item/Bar Code Scanned

Type is sent: BS - Wrong item bar code scanned during issue.

Type is sent: BT - Wrong item or restock label bar code scanned during restock.

Type is sent: BU - Wrong item bar code scanned during return.

SafetyStock Technical Guide/67-3025 Rev C © 2008 Omnicell, Inc.

Page 45

Invalid Bar Code Scanned—If the user scans a bar code that is not valid for the current function,

an applicable message is displayed, such as:

Wrong Bin Scanned—Type is sent: CU - Wrong bin confirmation bar code scanned during

return.

Wrong Bin Scanned-Restock—Message is displayed and Null Type is sent: CT - Wrong bin

confirmation label scanned during Restock.

Wrong Bin Scanned-Return—Type is sent: BU - Wrong item bar code scanned during return.

Restock Functions

SafetyStock 1-43

Color Touch Functionality

Bin bar code not allowed

Prepack bar code not allowed

Product bar code not allowed

Restock bar code not allowed

WorkflowRx bin bar code not allowed

Wo rk f l ow R x Transaction ID Bar Code not allowed

OmniScanner label bar code not allowed

The Normal Restock process has been modified to support SafetyStock and related features.

Changes include:

Inclusion of Selective Restocks in the Normal Restock list (Restock By Item, generated at the

OmniCenter).

Restock selection behavior has not changed. Selective Restocks generated at the OmniCenter (Restock

Note:

By Item

) are sent to the cabinet as a Normal Restock.

Inventory Time-out configuration option also applies to bar code restock functions. If the system times out, it

The

is treated as a skip and the appropriate null transaction is sent.

If the user exits the cabinet during a scan-required function, it is treated as a skip and the appropriate null

transaction is sent.

Bar code scan support for restock confirmation and bin confirmation.

OmniScanner “Accept all Remote Items” support.

Normal Restock

As discussed previously, restock scan requirements are set at the OmniCenter, at the item level. If

Confirm Restock is set to No Scan Required, the item is not treated as a SafetyStock item for restock

purposes.

Item Bar Code Scan Required If set to Item Bar Code Scan Required, the item must be scanned at time

of restock, and only the item bar code will be accepted as a valid scan (the item bar code is

typically pre-printed on or adhered to the individual package).

After selecting the item to restock, the user is prompted to scan the item bar code, and an audible

tone sounds. If anything other than a valid item bar code is scanned, a message is displayed and an

audible error tone sounds. (See “Error Messages” on page 1-42.)

© 2008 Omnicell, Inc. SafetyStock Technical Guide/67-3025 Rev C

Page 46

1-44 SafetyStock

Color Touch Functionality

The item bar code scan is required only once per location. If bin confirmation is enabled, the user

is prompted to scan the bin bar code, following the item bar code scan. (See “Associating Bin Bar

Codes” on page 1-50.)

Figure 1-50. Normal Restock—Scan Item Bar Code Screen

If unable to scan the item bar code, the user can override the bar code scan. In this event, the user

either scans the restock label, then presses Override Bar Code Scan, or presses Override Bar Code Scan,

then scans the restock label at the prompt.

If the user scans a valid item bar code when prompted to scan the restock bar code during override, the

Note:

override is cancelled and the transaction proceeds as normal.

Once a valid restock bar code has been scanned, the user is prompted to select one of the

following override reasons:

No bar code

Unreadable bar code

Wrong item bar code

Unknown item bar code

Other, document with supervisor

The user can also chose to skip the item, per usual functionality. In this event, a null transaction is

sent (Null Type: BO—Failed to scan item or restock label bar code during restock).

Item or Restock Bar Code Scan Required If set to Item or Restock bar code Scan Required, the item must

be scanned at time of restock, and either the item bar code or the corresponding SafetyStock or

WorkflowRx restock label is acceptable as a valid scan. In this case, it is recommended that the

item bar code be scanned whenever possible, as this provides the highest level of error prevention.

SafetyStock Technical Guide/67-3025 Rev C © 2008 Omnicell, Inc.

Page 47

SafetyStock 1-45

Color Touch Functionality

After selecting the item to restock, the user is prompted to scan the item or restock bar code, and

an audible tone sounds. If anything other than a valid item or restock bar code is scanned, a

message displays and an audible error tone sounds. (See “Error Messages” on page 1-42.)

The item or restock bar code scan is required only once per location. If bin confirmation is

enabled, the user is prompted to scan the bin bar code, following the item or restock bar code

scan. See the Bin Bar Code section of “Modify Bin” on page 1-50.

The override option is not available for Item or Restock bar code Scan Required items. However, the

user can chose to skip the item, per usual functionality. In this event, a null transaction is sent

(Null Type: BO—Failed to scan item or restock label bar code during restock).

OmniScanner Remote Items If OmniScanner support is enabled, and a scan-required remote item

is in the selected restock list, the user can press Accept All Remote Items to ignore the items; the items

remain on the restock list. (See Figure 1-51 and Figure 1-52.)

Figure 1-51. Normal Restock, Remote Item List—Accept All Remote Items Button

© 2008 Omnicell, Inc. SafetyStock Technical Guide/67-3025 Rev C

Page 48

1-46 SafetyStock

Color Touch Functionality

Figure 1-52. Normal Restock, Accept All Remote Items Button—Reminder/Warning Screen

Supplemental Restock

The Supplemental Restock process has been modified to support SafetyStock and related features.

As restock reports/labels are not generated for supplemental restocks, only item bar code scans are

supported.

Item Bar Code Scan Required/Item or Restock Bar Code Scan Required If set to Item Bar Code Scan

Required or Item or Restock Bar Code Scan Required, the item must be scanned at time of supplemental

restock, and only the item bar code is acceptable as a valid scan.

After selecting the item for supplemental restock, the user is prompted to scan the item bar code,

and an audible tone sounds. If anything other than a valid item bar code is scanned, a message

displayed and an audible error tone sounds. (See “Error Messages” on page 1-42.)

The item bar code scan is required only once per location. If bin confirmation is enabled, the user

is prompted to scan the bin bar code, following the item bar code scan. See “Associating Bin Bar

Codes” on page 1-50.

SafetyStock Technical Guide/67-3025 Rev C © 2008 Omnicell, Inc.

Page 49

Item Return

SafetyStock 1-47

Color Touch Functionality

Like restock and issue functions, item return scan requirements are set at the OmniCenter, at the

item level. This functionality only applies to items that can be returned to their original bin.

Item Bar Code Scan Required/Item or Restock Bar Code Scan Required

If set to Item Bar Code Scan Required or Item or Restock Bar Code Scan Required, the item must be scanned

at time of return, and only the item bar code is acceptable as a valid scan.

When returning the item, the user is prompted to scan the item bar code, and an audible tone

sounds. If anything other than a valid item bar code is scanned, a message is displayed and an

audible error tone sounds. (See “Error Messages” on page 1-42.)

The item bar code scan is required only once per location, regardless of the quantity removed. If

the item location is configured for bin confirmation, the user is prompted to scan the bin bar code

after successfully scanning the item bar code.

The override option is not available for returns. However, the user can chose to skip the item, per

usual functionality. In this event, a null transaction is sent (Null Type: BR—Failed to scan item

during return).

Figure 1-53. Return Meds—Scan Item Bar Code Screen

© 2008 Omnicell, Inc. SafetyStock Technical Guide/67-3025 Rev C

Page 50

1-48 SafetyStock

Color Touch Functionality

Bin Confirmation

As an additional safety measure, the facility can also require bin confirmation via bin bar code

scan, in addition to, or apart from, the item or restock bar code scan. Bin Confirmation is enabled

at the cabinet, and is based on the bin location (see the “Implementation” section for details).

When enabled, bin confirmation applies to both restock and item return functions.

The

successfully scans the requested bar code (item or restock bar code, as applicable). If anything

other than a valid bin bar code is scanned, a message is displayed and an audible error tone

sounds. See “Error Messages” on page 1-42.

Scan Bin Bar Code screen is displayed after the item is selected, and if applicable, after the user

Figure 1-54. Scan Bin Bar Code Screen (Normal Restock)

The override option is not available for bin confirmation. However, the user can chose to skip the

item, per usual functionality. In this event, a null transaction is sent (Null Type: CO—Failed to

scan bin confirmation label during restock).

SafetyStock Technical Guide/67-3025 Rev C © 2008 Omnicell, Inc.

Page 51

Issue Confirmation

As discussed previously, item issue scan requirements are set at the OmniCenter, at the item level.

If Confirm Issue is enabled for an item, the user is required to scan the item bar code when removing

it from the cabinet during an issue transaction.

Note: Issue confirmation is not supported for items in Anesthesia drawers, Sure-Med Unit Dose

compartments or OmniDispenser modules.

When removing the item, the user is prompted to scan the item bar code, and an audible tone

sounds. If anything other than a valid item bar code is scanned, a message is displayed and an

audible error tone sounds. (See “Error Messages” on page 1-42.)

The item bar code scan is required only once per location, regardless of the quantity removed.

SafetyStock 1-49

Color Touch Functionality

Figure 1-55. Remove Meds—Scan Item Bar Code Screen

© 2008 Omnicell, Inc. SafetyStock Technical Guide/67-3025 Rev C

Page 52

1-50 SafetyStock

Color Touch Functionality

If unable to scan the item bar code, the user can override the bar code scan. In this event, the user

presses Override Bar Code Scan, then is prompted to select one of the following override reasons:

No bar code

Unreadable bar code

Wrong item bar code

Unknown item bar code

Other, document with supervisor

Modify Bin

Figure 1-56. Override Item Bar Code, Select Override Reason Screen

The user can also chose to skip the item, per usual functionality. In this event, a null transaction is

sent (Null Type: BI—Failed to scan item bar code during issue).

The Modify Bin function has been modified to support the bin bar code confirmation feature,

including:

Associating Bin Bar Codes

Removing Bin Bar Code Associations

Associating Bin Bar Codes

Associating a bin bar code simply means selecting the bin, and scanning the bin confirmation

label to associate the bin bar code with the bin. This association is stored at the cabinet and

OmniCenter, until and unless the association is removed. Once a bin is associated, bin

confirmation for the item is enabled, and the user is prompted to scan the bin confirmation label

during restock and return functions (see the “Bin Confirmation” on page 1-48).

SafetyStock Technical Guide/67-3025 Rev C © 2008 Omnicell, Inc.

Page 53

SafetyStock 1-51

Color Touch Functionality

To associate a bin confirmation bar code, the user selects Modify Bin, enters the bin number or

opens the bin lid of an assigned item, then scans the bin confirmation label. If the bin bar code is

currently available (unassociated), the user is prompted to rescan the bar code to confirm the

association, or press Cancel.

The bin bar code association is then sent to the OmniCenter, along with a modify bin transaction

(XactMisc value of “Bin Conf Assign.”)

Figure 1-57. Modify Bin, Associate Bin Confirmation Bar Code—Scan Again Screen

If the bin confirmation label is already associated with another item or location, an audible

warning sounds and an error message is displayed.

Figure 1-58. Modify Bin, Associate Bin Confirmation Bar Code—Bin Assigned Screen

© 2008 Omnicell, Inc. SafetyStock Technical Guide/67-3025 Rev C

Page 54

1-52 SafetyStock

Color Touch Functionality

The warning shows the item description and bin location currently associated with that bin bar

code. The user can the bin bar code or press Cancel. If the user rescans the same bar code, the new

bin bar code association is sent to the OmniCenter, along with a modify bin transaction

(XactMisc value of “Bin Conf Assign”).

Removing Bin Bar Code Associations

Bin confirmation bar codes can only be associated with assigned items. The bin confirmation

label does not need to be replaced when unassigning an associated item. In this event, the user

removes the bin bar code association, then if applicable, re-associates the bin bar code with the

newly assigned item.

To remove an association, the user selects Modify Bin, enters the bin number or opens the bin lid,

and presses Remove Bin Confirmation. The user then presses Confirm or Cancel.

If the user presses Confirm, a command is sent to the OmniCenter along with a modify bin

transaction (XactMisc value of “Bin Conf Delete”).

Figure 1-59. Modify Bin, Remove Bin Association—Verification Screen

SafetyStock Technical Guide/67-3025 Rev C © 2008 Omnicell, Inc.

Page 55

Implementation

This section provides general instructions for implementing SafetyStock at an existing customer

facility. These instructions include enabling Restock Confirmation, Issue Confirmation,

Automatic Stock-out, and Bin Bar Code Confirmation. However, these features can be used (or

not used) independently of one another. For additional information or assistance, contact

Omnicell Technical Support.

Overview

These instructions assume that SafetyStock scanners have been installed at the OmniCenter and

on all applicable cabinets, and that a supported SATO label printer model has been installed,

which prints SafetyStock restock labels.

Implementation requirements for SafetyStock and related features include the following:

Installing the SafetyStock scanner(s) at the OmniCenter and all applicable Color Touch

cabinets (see the “Hardware Implementation” on page 1-58).

Installing and/or verifying operation of the designated SATO label printer.

Note:

See the SATO Printer M84Pro Installation Guide, available on DocuShare (keyword: SATO).

SafetyStock 1-53

Implementation

© 2008 Omnicell, Inc. SafetyStock Technical Guide/67-3025 Rev C

Page 56

1-54 SafetyStock

Implementation

Verifying or modifying the OmniCenter database settings as needed:

Administration tab

1. Modify or verify

2. Print

Database tab > Global Settings table

Bin Confirmation labels, if applicable.

Restock Configuration Settings.

Enter SafetyStock Option Key under LICENSE Resource Type.

Database tab > Items table

1. Modify

Item records as needed.

2. Make sure all applicable items are standardized.

To properly implement SafetyStock and other bar code related features, all associated items must be

Note:

standardized. See the Items Database Standardization and Bar Code Support chapters in OC9000 Technical

Release Guide (P/N 60-0077) for details.

OmniCenter

3. Make sure all applicable items have the necessary bar code associations (

Code

section, Add button).

Items record, Bar

Note: Bar Code support is a related, but separate, Omnicell feature. For more information, see the Bar Code

Support chapter of the OC9000 Technical Release Guide (P/N 60-0077).

4. Enable Confirm Restock; choose applicable scan setting.

5. Enable Automatic Stock-out.

6. Verify/modify Automatic Stock-out Restock Configuration settings.

Database tab > OmniSuppliers table

1. Verify or modify

Automatic Stock-out Restock Default Configurations.

2. Enable SafetyStock in the Lic. Features section.

Configuring the cabinet software

1. Modify or verify cabinet configuration options.

2. Place and associate bin bar code confirmation labels, as applicable.

Use Case

SafetyStock nulls to email or text pager.

These instructions assume that SafetyStock scanners have been installed at the OmniCenter and

on all applicable cabinets, and that a supported model of the SATO label printer has been

installed, which prints SafetyStock restock labels.

Note: For detailed feature/field information, see the applicable “Software Functionality” section earlier in this

guide.

The following instructions assume that all SafetyStock and related features are being

implemented.

SafetyStock Technical Guide/67-3025 Rev C © 2008 Omnicell, Inc.

Page 57

SafetyStock 1-55

Implementation

Note:

If the Option Key is valid and entered correctly, the word Valid is displayed next to the Resource Value

field. If the key is not valid or is entered incorrectly, the word Invalid is displayed, and the key must be reentered.