Page 1

INSTRUCTIONS

SUCTION PUMP

KV--5

CAUTION

Federal (USA) law restricts this device to sale

by or on the order of a physician.

0086

Page 2

IMPORTANT

Please read this manualcarefully before attempting to use the Olympus KV--5 suction pump as it contains important information on

the proper care, handling and use ofthe equipment. In addition, read the manuals of any other units (endoscope, light source, etc.)

that form part of the system.

The safety andperformance ofan endoscopic systemdepends notonly onthe endoscopebut also on the ancillary equipment used

with it. Ensure any ancillary equipment is compatible with the endoscope and other equipment used. These instructions should be

retained for reference during the life of the pr oduct. If you have any questions concerning the material contained in this manual,

please contact your Olympus representative or nearest Olympus office.

INTENDED USE

The Olympus KV-5 suction pump is a simple, r eliable pump intended for aspiration use during flexible endoscopy and general

medical or surgicalsuction. The c ompact sizeof the unit enablesit to be convenientlyused and stored onan endoscopy workstation.

It is intended for use within a health care facility, not for domiciliary or field and transport use.

The KV--5 is not designed for thoracic drainage.

Do not use the equipment for any purpose other than its intended use.

WARNING SYMBOLS USED ON DEVICE

Refer to instructions

SIGNAL WORDS

WARNING: D Indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

CAUTION: D Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury. It may

also be used to alert against unsafe practices or potential equipment damage.

NOTE: D Indicates additional, helpful information.

Page 3

CONTENTS

PAGE

1 ST ANDARD SETS & FEATURES 1.........................................

2 OPERATING PRECAUTIONS 5............................................

3 INSTRUCTIONS FOR USE 6..............................................

4 CLEANING CARE AND STORAGE 11.......................................

5 MAINTENANCE AND REPAIR 12..........................................

6 SPECIFICATIONS 14...................................................

7 TECHNICAL DESCRIPTION 15............................................

8 ENVIRONMENTAL PROTECTION 16.......................................

Page 4

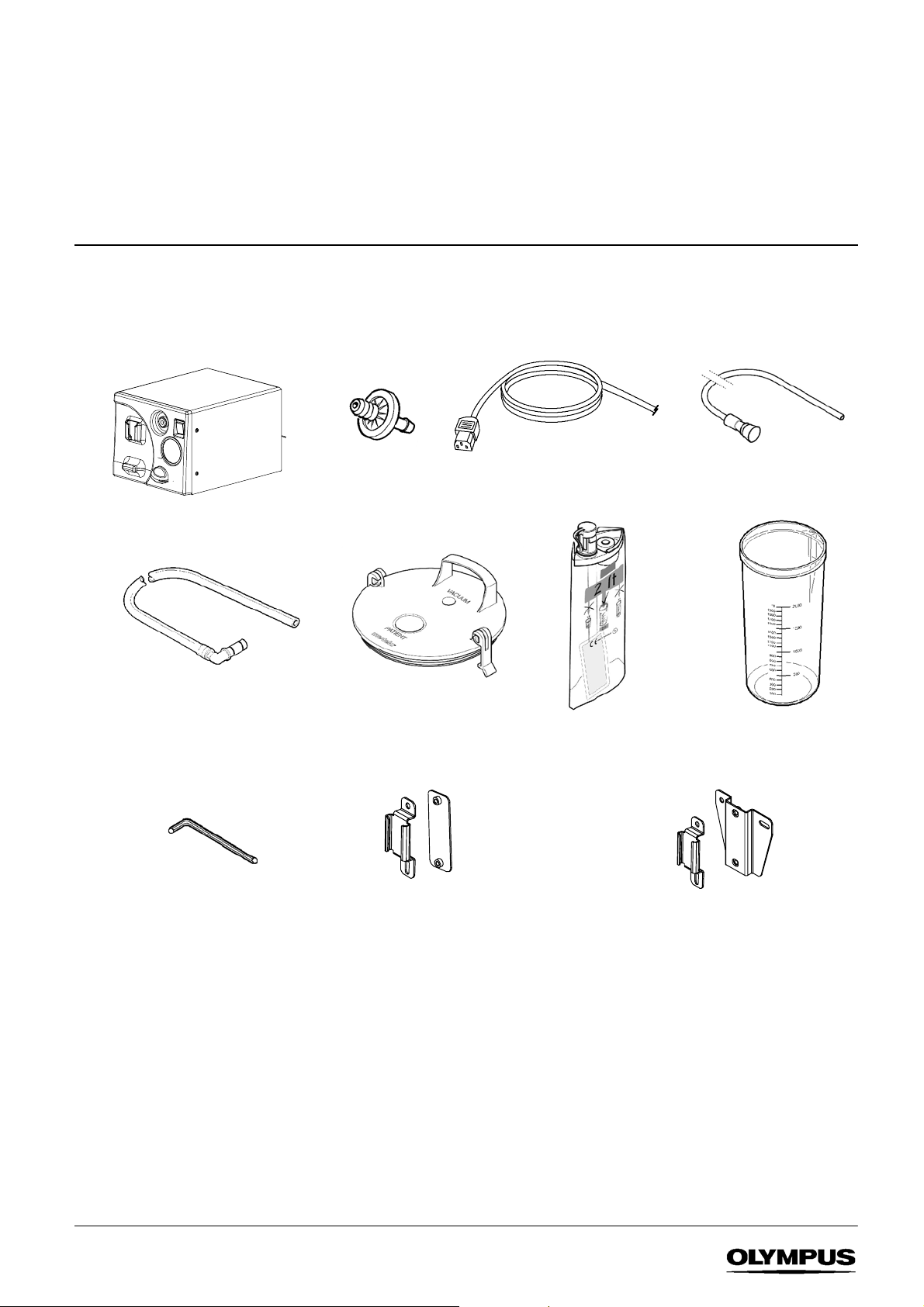

1 STANDARD SETS & FEATURES

The KV--5 is available in two configurations -- as a single--use suction system or a reusable suction system. Unpack the

equipment and confirm the items in the standard set ordered are present and undamaged. Retain the packaging for future use.

Contact Olympus if any parts are damaged or missing.

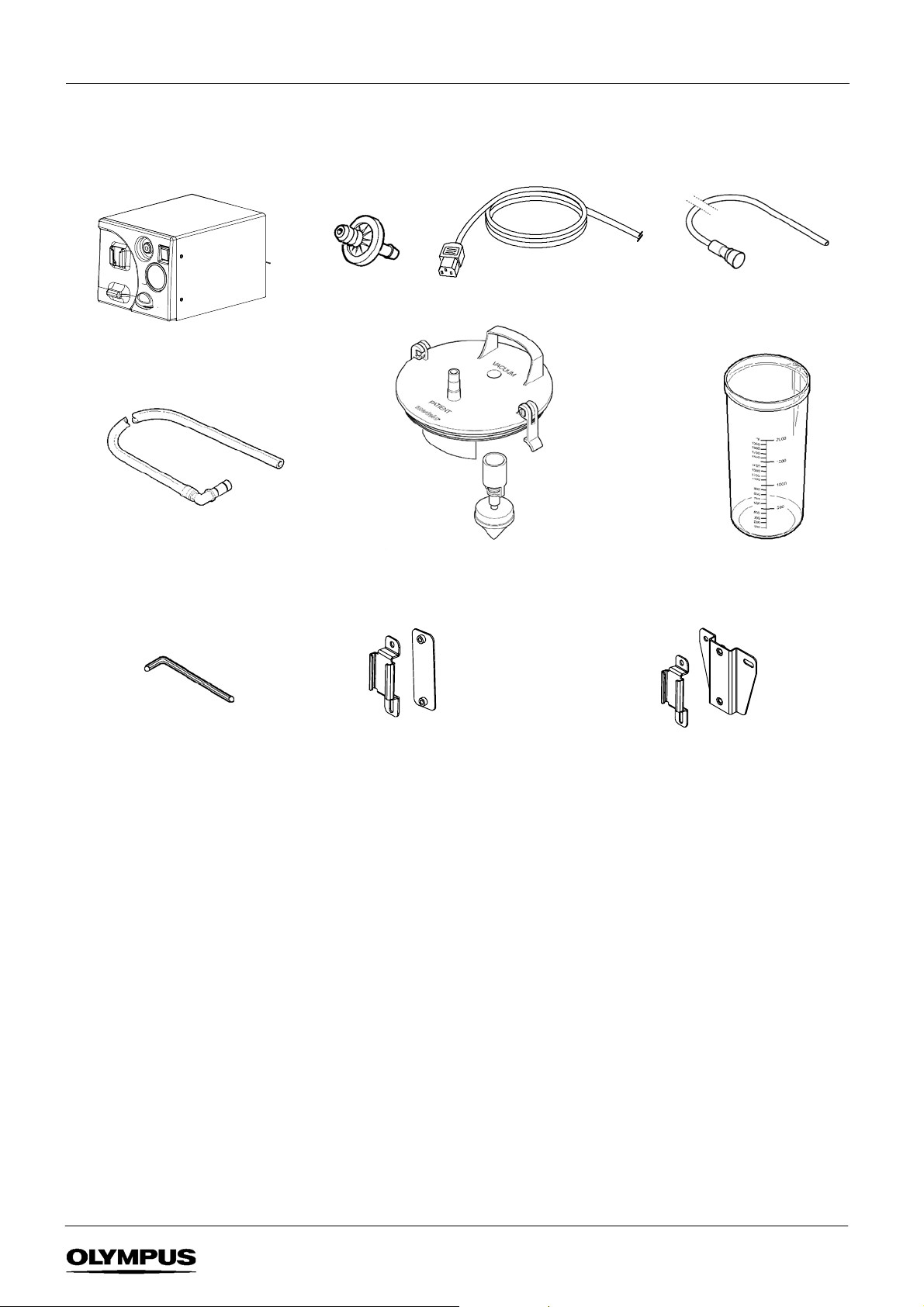

1.1 Standard set - Single- use suction system

KV-- 5 suction pump

Filter connecting tube 900mm

pk 10 (non --sterile)

K7503657

4mm A/F Allen key x1

Microbial F ilter

(pack of 10)

Lid for use with single--use liner*

K7503761

Suction jar mounting kit for

Olympus WM--30/60

K7503555

Supplied with standard sets:

p/no 2000455, 2000456

Power

cable

Single--use liner 2 ltr pk 25

K7503430

or

Suction jar mounting kit for

Olympus WM--N60/D60, Olympus TC-- C1/NE

K7503556

Supplied with standard sets:

p/no 2000450, 2000451

Patient connecting tube 2m

pk 5 (

sterile)

Suctionjar2ltr

K7503763

1

SUCTION PUMP KV--5

Page 5

1.2 Standard set - Reusable suction system

KV-- 5 suction pump

Filter connecting tube 900mm

pk 10 (non --sterile)

K7503657

Microbial F ilter

(pack of 10)

Power

cable

Lid with float mechanism*

K7503760

Patient connecting tube 2m

pk 5 (

sterile)

Suctionjar2ltr

K7503763

4mm A/F Allen key x1

Suction jar mounting kit for

Olympus WM--30/60

K7503555

Supplied with standard sets:

p/no 2000455, 2000456

or

Suction jar mounting kit for

Olympus WM--N60/D60, Olympus TC-- C1/NE

K7503556

Supplied with standard sets:

p/no 2000450, 2000451

SUCTION PUMP KV--5

2

Page 6

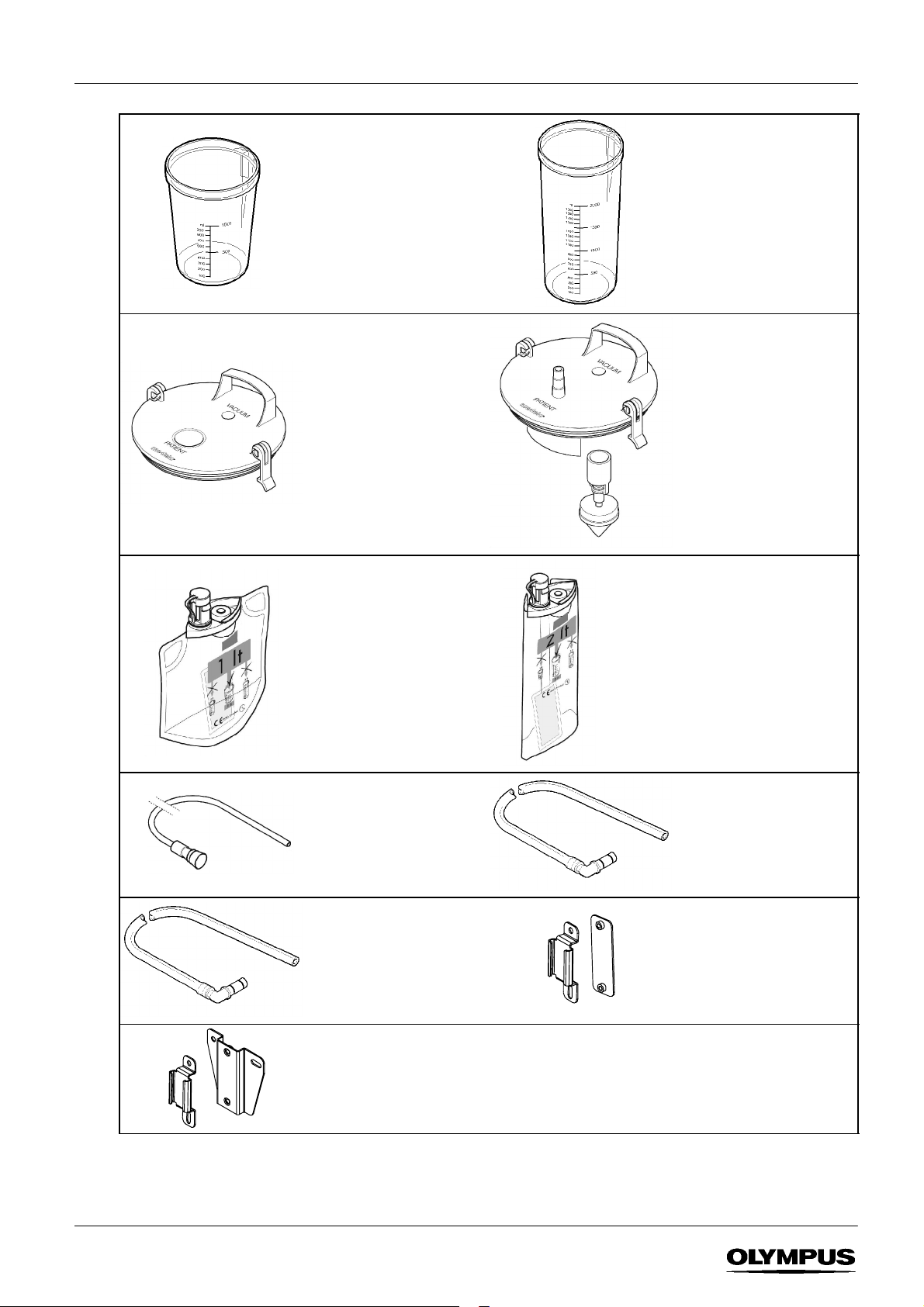

1.3 Replacement / Optional parts

Suctionjar1ltr

K7503762

Lid for use with single--use liner*

K7503761

Single--use liner 1 ltr

pk 30

K7503428

Suctionjar2ltr

K7503763

Lid with float mechanism*

K7503760

Single--use liner 2 ltr

pk 25

K7503430

Patient connecting tube 2m

pk 50 (sterile)

K7503432 (Rest of World)

K7505595 (Americas only)

Filter connecting tube 900mm

pk 10 (non --sterile)

K7503657

For use with trolley mounted

suction jar

Suction jar mounting kit for

Olympus WM--N60/D60

Olympus TC--C1/NE

K7503556

*Thesuctionjarlidcanbeusedwithboth1and2litresuctionjars.

Filter connecting tube 340mm

pk 10 (non --sterile)

K7503486

For use with1 litre KV--5

mounted suction jar

Suction jar mounting kit for

Olympus WM--30/60

K7503555

3

SUCTION PUMP KV--5

Page 7

1.4 Features

Label 5

Single--use

suction liner

Filter

connecting tube

Suction jar and lid

Rear panel

Microbial filter

Power switch

Label 1

Label 2

V acuum gauge

(for indication only)

Label 3

V acuum

regulator

Label 6

FIGURE 1-1

Label 4

Potential

equalisation

terminal

1.5 Labels

Label 1 CHANGE FIL TER DAILY OR WHEN

Label 3 MAXIMUM LEVEL OF VACUUM 85kPa

Label 5 CAUTION: REMOVE TRANSIT SCREWS

IEC power receptacle

(with integral fuses)

Exhaust outlet

Label 2 SUCTION

CONT AMI NATED

Label 4 RATING PLATE

HIGH VACUUM / HIGH FLOW

Label 6 CAUTION: REMOVE TRANSIT SCREWS

FROM BASE BEFORE USE. REPLACE

BEFORE TRANSPORTA TI O N.

BEFORE USE. REPLACE BEFORE

TRANSPORTATION.

NOTE

Label 5 should be removed and stored safely when the transit screws have been removed (Section 2.1). When

the unit is to be transported, replace the transit screws and affix the label on top of the unit.

Label 6 is permanent.

SUCTION PUMP KV--5

4

Page 8

2 OPERATING PRECAUTIONS

2.1 Before use

D The unit must be used solely for its designed purpose, that is endoscopic aspiration and general medical or surgical

suction in a health care facility. This device is a ‘high vacuum, high flow’ device and is not intended for thoracic

drainage.

D Explosion hazard -- never install or use the KV--5 within the zone of risk of flammable gases.

D The unit is fitted with two M6 transit screws to protect the pump during transportation. Before use, remove both

screws with fibre washers using the 4mm A/F Allen key provided (Figure 2-1), then remove the label from the top of

the unit. Store these items safely as they must be refitted when transporting the unit.

FIGURE 2-1

CAUTION: REMOVE TRANSIT

SCREWS BEFORE USE. REPLACE

BEFORE TRANSPORTATION.

D Excessive frothing in the suction jar during use may inhibit oper ation of the fluid cut--off mechanism -- use a

proprietary anti--foam agent as necessary to minimise frothing.

D The electrical installation of the room where the unit is to be used must comply with local or national regulations.

D The KV-5 is not intended to be used when positioned on inclined surfaces as the suction jar fluid cut--off mechanism

may not function correctly.

D The unit is only to be used by suitably qualified personnel in accordance with these instructions.

D Replace the microbial filter daily or when contaminated.

D Do not use anti-static tubing to connect the endoscope to the suction pump as patient safety may be compromised.

D The suction jar must never be used ‘free standing’ on the workstation or any surface. The 1 litre suction jar simply

slides into the bracket pr ovided on the front panel of the unit as shown on page 2, the 2 litre suction jar should be

secured to workstation using the suction jar bracket.

D Periodically inspect the suction jar for obvious signs of wear/damage and replace if necessary.

D If the suction jar is dropped, it must be thoroughly inspected to ensure there are no cracks and tested to ensure the

lid is sealing correctly. If damage or a leak is evident, discard the suction jar and replace.

D When a suction jar is attached to a workstation using the optional suction jar bracket, remove the suction jar before

manoeuvring the workstation.

5

SUCTION PUMP KV--5

Page 9

D Ensure the exhaust at the rear of the unit is unobstructed when the unit is operational.

D Store and use the KV--5 within the environmental conditions described in Section 6; failure to do so may lead to

equipment malfunction or failure.

D Only use replacement parts and accessories as specified in Section 5.3. Failure to do so may lead to equipment

malfunction or failure.

2.2 During use

D Do NOT lift the suction jar by the lid, always grip with two hands on either side of the suction jar, otherwise the cap

and jar may become separated and spillage of its contents may result.

D If aspirated material has been drawn past the microbial filter and into the pump, the unit must be removed from use

and returned to Olympus for service.

D To prevent liquid backflow within the patient connecting tube, always leave the unit running until the patient tube is

disconnected from the suction jar.

2.3 After use

D If single use suction liners are not being used, the suction jar will contain potentially infectious body fluids. Take

suitable precautions, as dictated by local hospital policy, such as use of personal protective equipment, and empty

into a suitable waste disposal system, together with an appropriate quantity of water to dilute the jar contents.

D Single use suction liners, used filters and suction tubing will contain potentially infectious material. Dispose of

carefully as dictated by local hospital policy as clinical waste for incineration.

D Always empty the suction jar before moving the equipment. Care should be taken to obtain a firm grip underneath

the body of the equipment before moving. The suction jar holder must never be used as a hand hold or carrying

handle.

3 INSTRUCTIONS FOR USE

3.1 Place the KV--5 on a level flat surface.

3.2 Thoroughly inspect the suction jar for cracks or signs of damage and any suction tubing to be used for signs of wear or

damage. Do not use if damage is noted.

WARNING

Defects in the suction jar may cause the jar to implode when under vacuum.

NOTE

The suction jar may be used with or without single--use suction liners. Use without requires an optional suction

jar lid with integral float mechanism (p/no K7503760).

3.3 Use with single- use suction liners

NOTE

The standard set supplied is a 2 litre suction system. If a 1 litre system is required, a 1 litre suction jar, a 1 litre

single--use suction liner and 340mm filter connecting tube will be required. These items are optional and are

detailed in Section 1.3.

(1) Refer to the instructions supplied with the single use suction liner and fit the liner to the suction jar.

NOTE

The single--use liners incorporate a solidifier to aid disposal.

SUCTION PUMP KV--5

6

Page 10

(2) Referring to Figure 3-1, locate the suction jar into the suction jar holder located on the front panel of the unit.

NOTE

The suction jar holder will only accommodate the 1 litre suction jar. 2 litre suction jars should be mounted on

the workstation and require the use of a suction jar mounting bracket (see Section 1). Fitting instructions for the

suction jar mounting brackets are provided with the brackets.

FIGURE 3-1

1 litre suction jar

Suction jar holder

(3) Remove the transit bung from the filter housing (retain for transportation) on the front of the unit and insert the

microbial filter with the word ‘Olympus’ facing outermost (see Figure 3-2)

FIGURE 3-2

Filter housing

Microbial filter

Filter connecting tube

Microbial filter

Filter connecting tube 90 ˚ connector

(4) Connect the patient tube between the suction jar lid (Figure 3-3) and endoscope or other equipment as required.

FIGURE 3-3

Patient connecting tube

(5) Push the open end of the filter connecting tube onto the microbial filter and fully insert the 90˚ connector into the

suction jar lid marked VACUUM (Figure 3-4).

7

SUCTION PUMP KV--5

Page 11

FIGURE 3-4

Filter connecting tube

Microbial filter

Filter connecting tube 90 ˚ connector

(6) Ensure the KV--5 power switch is OFF and the vacuum regulator is set to ‘MIN’, then connect the power cable into

the IEC receptacle on the rear of the unit and a suitably grounded AC wall outlet or isolation transformer socket.

(7) Set the power switch to the ‘l’ position, the switch will illuminate and the pump will start to run.

(8) The suction level can be increased and set as required by turning the vacuum regulator in a clockwise direction. To

obtain suction via an endoscope, refer to the instructions for the endoscope.

(9) Suction should be stopped when the fluid reaches the 1 litre / 2 litre mark.

NOTE

If the liner is overfilled, an integral hydrophobic filter will prevent further suction. To allow suction to continue,

proceed as below.

(10) Change the liner as follows:

CAUTION

The single--use suction liner, filters and suction tubing will contain potentially infectious body fluids. Take

suitable precautions, as dictated by local hospital policy, such as use of personal protective equipment, and

dispose of carefully as clinical waste for incineration.

Do NOT lift the suction jar by the lid, otherwise the lid and jar may become separated and spillage of its

contents may result.

When using single--use liners, if the liner is over filled or filled rapidly and the KV--5 is switched OFF with the

patient tube disconnected from the endoscope, aspirated fluid may syphon from the single use suction liner into

the patient connecting tube. Always leave the unit running until the patient connecting tube is disconnected

from the suction jar to prevent liquid back flow..

The patient tube may contain residual fluid so carry holding both ends of the tube upright, taking care to ensure

it is properly drained before disposal in line with local hospital policy.

a) Keep the KV--5 switched ON and disconnect the patient connecting tube from the single use suction liner.

b) Replace the cap on the single use suction liner and press the cap firmly downwards, through the lid into the

suction jar. The contents of the liner are now sealed.

FIGURE 3-5

c) Switch OFF the KV--5, remove the filter connecting tube if required and then remove the suction jar lid. Finally,

remove the single use suction liner from the suction jar and dispose of in line with local hospital policy.

SUCTION PUMP KV--5

8

Page 12

3.4 Use with reusable suction system

NOTE

The standard set supplied is a 2 litre suction system. If a 1 litre system is required, a 1 litre suction jar and a

340mm filter connecting tube will be required. These items are optional and are detailed in Section 1.3.

(1) Push the float fully onto the vacuum spigot inside the lid (see Figure 3-6).

(2) Position the suction jar lid with float mechanism onto the jar with the word PATIENT on the lid facing the front of the

jar, then press the lid down firmly and secure the two fasteners, see Figure 3-6.

Suction jar lid with float

FIGURE 3-6

(3) Referring to Figure 3-7, locate the suction jar into the suction jar holder located on the front panel of the unit.

NOTE

The suction jar holder will only accommodate the 1 litre suction jar. 2 litre suction jars should be mounted on

the workstation and require the use of a suction jar mounting bracket (see Section 1). Fitting instructions for the

suction jar mounting brackets are provided with the brackets.

FIGURE 3-7

1 litre suction jar

Suction jar holder

(4) Remove the transit bung from the filter housing on the front of the unit and insert the microbial filter with the word

“Olympus” facing outermost (see Figure 3-2)

FIGURE 3-8

Filter housing

Microbial filter

(5) Connect the patient tube between the suction jar lid (Figure 3-9) and endoscope or other equipment as required.

9

SUCTION PUMP KV--5

Page 13

FIGURE 3-9

Patient connecting tube

(6) Push the open end of the filter connecting tube onto the microbial filter and fully insert the 90˚ connector into the

suction jar lid marked VACUUM (Figure 3-10).

FIGURE 3-10

Filter connecting tube

Microbial filter

Filter connecting tube 90 ˚ connector

(7) Ensure the KV--5 power switch is set to O and the vacuum regulator set to ‘MIN’, then connect the power cable into

the IEC receptacle on the rear of the unit and a suitably grounded AC wall outlet or isolation transformer socket.

(8) Set the power switch to the ‘l’ position, the switch will illuminate and the pump will start to run.

(9) The suction level can be increased and set as required by turning the vacuum regulator in a clockwise direction. To

obtain suction via an endoscope, refer to the instructions for the endoscope.

(10) Suction should be stopped when the fluid reaches the 1 litre / 2 litre mark.

NOTE

When the fluid in the suction jar reaches the float, the float will rise and seal the patient tube when capacity is

reached, preventing further suction. Empty the suction jar replace the lid to allow suction to continue.

(11) Empty the suction jar as follows:

CAUTION

The suction jar, filters and suction tubing will contain potentially infectious body fluids. Take suitable

precautions, as dictated by local hospital policy, such as use of personal protective equipment, and dispose of

carefully as clinical waste for incineration.

Do NOT lift the suction jar by the lid, otherwise the lid and jar may become separated and spillage of its

contents may result.

The patient tube may contain residual fluid so carry holding both ends of the tube upright, taking care to ensure

it is properly drained before disposal in line with local hospital policy.

a) Keep the KV--5 switched ON and disconnect the patient connecting tube from the suction jar lid.

b) Turn off the unit and remove the filter tube from the suction jar lid.

SUCTION PUMP KV--5

10

Page 14

c) Taking suitable precautions, as dictated by local hospital policy, such as use of personal protective equipment,

empty the jar into a s uitable waste disposal system, together with an appropriate quantity of water to dilute the

jar contents.

d) Clean the suction jar and lid as described in Section 4 before re--use.

4 CLE ANING CARE AND STORAGE

4.1 Remove the filter connecting tube and clean using neutral detergent and water. The tube may be sterilised by autoclaving

(upto137˚C max) after removing the 90˚connector, which should bereplaced.The microbial filter should bereplaced daily

or when contaminated. Replace the patient connecting tube when contaminated or at the end of each patient list.

CAUTION

The patient tube is not autoclavable.

4.2 Following use, remove the lid from the jar by disconnecting the lid clips and where applicable remove the float assembly.

Clean thoroughly using a soft brush and mild detergent solution. The suction jar cap may be sterilised by autoclaving up

to 137˚C max according to hospital policy, then reassembled for further use.

CAUTION

Do not use phenol-- or chlorine--based disinfectants to decontaminate the suction jar lid as damage and rapid

deterioration of these components will result.

4.3 The suction jar may be sterilised by autoclaving up to 137˚C max according to hospital policy, or disinfected by cold fluid

immersion.

CAUTION

Do not use phenol or chlorine based disinfectants to clean the suction jar as damage to the jar may result.

Do not place alcohol or aldehyde-based detergents, antiseptics or antifoam agents in the suction jar prior to

use, as any vapour released may damage the hydrophobic filter. This may result in fluid ingress to the vacuum

pump, which will then need to be serviced or replaced.

Do not stack suction jars when autoclaving as damage to the jar may result.

Contact with non-ionic detergents, such as those found in thermo-chemical disinfection can cause cracking of

the suction jar.

Ensure the suction jar is thoroughly rinsed with fresh water following disinfection.

4.4 Clean the KV-5 casing, including the microbial filter housing, by wiping with a cloth dampened with detergent and water or

alcohol impregnated swab. Thoroughly rinse off any detergent using a soft cloth dampened with clean water.

4.5 Before storing the KV-5, ensure the unit has been thoroughly cleaned and its accessories have been sterilised or

disinfected. Do not leave a single use liner in the suction jar.

11

CAUTION

Do not store single use liners in damp or wet conditions as damage to the hydrophobic filter will result and the

liners will be unusable

SUCTION PUMP KV--5

Page 15

4.6 If the KV-5 is to be transported, ensure that:

(1) The unit is thoroughly cleaned.

(2) The filter is removed and the transit bung fitted.

(3) The two transit screws with fibre washers are replaced and tightened using the 4mm A/F Allen key.

(4) The label (label 5) is affixed to the top of the unit.

(5) The unit is packed in its transit packing.

CAUTION

Failure to fit the transport screws when transporting the unit may result in damage to the pump.

5 MAINTENANCE AND REPAIR

There are nooperator--serviceablecomponentsinsidethe KV--5.Refer servicing to qualifiedservice personnel. IfrepairoftheKV-5

is required, contact Olympus.

Olympus will not be liable for any incident resulting from repair, adjustment or modification carried out by other than personnel

authorised by Olympus.

5.1 Preventive Maintenance

Daily - by user

D Check that the filter connecting tube, suction jar and lid are in good condition.

D Replace the microbial filter and or filter connecting tube (with 90˚ connector) if contaminated.

D Clean (and disinfect/sterilise if required by local policy) the suction jar, suction jar lid and filter connecting tube.

Weekly - by user:

D Clean the unit’s casework, ensuring the exhaust at the rear of the unit is clear.

D Inspect the suction jar for cracks or signs of wear, replace if necessary.

D Check the maximum v acuum available by sealing the patient connection of the suction jar lid. This should be at least

85 kPa.

Six-monthly - by qualified hospital engineer or Olympus agent:

D Check internal condition of unit, wiring security, etc.

D Check the flow rate by timing how long it takes to reach 60 kpa with a 2 litre suction jar connected -- should be

approximately 10 seconds. Contact Olympus if less than this for the pump to be serviced.

A maintenance & repair manual is available from Olympus, part number 5070225.

SUCTION PUMP KV--5

12

Page 16

5.2 Troubleshooting

haveoperated.Checktheventsareclear.Whenthetemperature

fasp

NOTE:

Ifaspiratedfluidorsolidmaterialhasbeendrawnintoth

e

Symptom Possible cause

Pump fails to operate Check that the unit is corr ectly connected to the power supply

and that the power switch illuminates when set to l.

Check the fuses, located within the pull-out fuseholder above the

power plug connector

NOTE: Always replace a fuse with one of the correct type and

rating. If a fuse continues to blow, contact Olympus.

The thermal cut-out within the windings of the pump motor may

have operated. Check the vents are clear. When the temperature

of the windings falls to an acceptable level normal operation will

resume. If the problem r ecurs, contact Olympus.

Pump operates but no suction or suction level is too low. Check that all connections are secured.

Check the unit is correctly connected to the endoscope or other

device.

Check that the microbial filter is not blocked and suction tubes

are correctly positioned and are not kinked, blocked or punctured.

Check the jar liner is not full and that the float mechanism (if

used) is not stuck in the closed position.

Check performance of the pump as per Section 5.1.

Check the vacuum regulator is set to the correct position.

Check all connections and tubing for air leakage.

NOTE: I

unit, the pump will continue to operate, but the unit should be

returned to Olympus for inspection and repair.

iratedfluid or solid material has been drawn into the

5.3 Replacement parts & accessories

Fuse T1.25H (20mm) 220--240V units 7146299......................

Fuse T2.5H (20mm) 100--120V units 7146302.......................

Microbial filter (pack of 10) 7048271...............................

Power cable 230V (UK) 7145454.................................

Power cable 230V (Europe) 7145462..............................

Power cable 110V (USA) 7146311................................

Power cable 100V (Japan) 7146329...............................

Suction jar 1ltr K7503762.......................................

Suction jar 2ltr K7503763.......................................

Lid for single--use liner K7503761..................................

Lid with float mechanism K7503760................................

Single--use liner 1ltr pk 30 K7503428...............................

Single--use liner 2ltr pk 25 K7503430...............................

Patient connecting tube 2m pk 50 (Rest of World) K7503432..............

Patient connecting tube 2m pk 50 (Americas only) K7505595..............

Filter connecting tube 340mm pk 10 K7503486........................

Filter connecting tube 900mm pk 10 K7503657........................

Jar mounting kit Olympus WM--30/60 K7503555.......................

Jar mounting kit Olympus WM--D60/N60, TC range K7503556.............

Transit screw K3921028........................................

Fibre washer K3921029........................................

13

SUCTION PUMP KV--5

Page 17

6 SPECIFICATIONS

y

Regulator

y

/EE

Crelati

d

ical

devi

C

l

I

Ia.T

h

Dimensionsand

Power

condition

s

Items Specifications

Product name Olympus Suction Pump KV--5

Classification

(electromedical

equipment)

Standards

compliance

Electro-magnetic

compatibility

Type of protection

against electrical

shock

Degree of protection

against electrical

shock

Degree of protection

against explosion

Mode of operation Continuous

Complies with EN ISO 10079--1 and EN IEC 60601--1 (220--240V model), UL 2601--1 and

Certified to CAN/CSA Std. No. C22.2 No. 601.1--M90 (100-120V model).

This product complies with the requirements of EN IEC 60601-1-2 for emissions and

immunity, and as such, its operation is unlikely to be affected by , or cause interference

with, equipment meeting appropriate EMC standards. As a precaution, equipment which

may be sensitive to interference outside the limits specified by EN IEC 60601--1--2 should

not be placed in close proximity t o the KV--5.

Classification according to EN IEC 60601-1 / UL 2601--1:

Class I with Type BF applied part.

In accordance with EN IEC 60601-1 and UL 2601--1, the KV--5 is marked with the

symbol to indicate the provision of an adequate degree of protection against electrical

shock and that it has an applied part isolated from all other parts of the equipment.

None: the Olympus KV--5 must NOT be used in the zone of risk of flammable anaesthetic

gases.

Regulator

status

European Economic

Area (EEA)

End of life

Dimensions and

weight

Power switch Marking The power switch is marked: l - on, O -off.

Power

requirements

Environmental

Fluid ingress

Resistance to

chemicals

Pump

specification

Thermal cut-out

Dimensions Height: 220 mm Width: 255 mm Depth: 310 mm

Weight 12.7 kg

Power supply Frequency Fusing Power rating

220-240V~ 50/60Hz 2 x T1.25H 130V A

100-120V~ 50/60Hz 2 x T2.5H 130V A

Marking: The mark ~ on the product indicates the requirement for an AC power supply.

Ambient

temperature

Relative humidity Maximum: 95% at 40˚C relative non-condensing

Atmospheric

pressure

In accordance with EN IEC 60601-1/UL 2601--1, the product is marked IPX1 to indicate that it is provided with an

enclosure that prevents entry of such an amount of falling liquid as might interfere with its safe and satisfactory

operation when correctly positioned.

The external surfaces of the Olympus KV--5 are resistant to: 2% aqueous neutral detergent, 70% ethyl alcohol,

isopropyl alcohol, water.

Nominal vacuum: 85 kPa ±10%

Minimum free air flow rate: 20 l/min

In accordance with ISO 10079-1, the unit is marked with the words ‘HIGH VACUUM, HIGH FLOW’ to indicate it

attains a vacuum of at least 60 kPa in 10 seconds and a free air flow rate of 20 l/min or greater.

A thermal cut-out is contained within the windings of the pump motor, set to operate if the temperature of the

windings exceeds 125˚C (257˚F).

This mark on the product (220-240V model) indicates compliance with Directive

93/42

0086

given in the first two digits of the serial number.

In accordance with European Directive 2002/96/EC on Waste Electrical and

Electronic Equipment, this symbol indicates that the product must not be

disposed of as unsorted municipal waste, but should be collected separately.

Refer to your local Olympus distributor for return and/or collection systems

available in your country.

Operational: +10˚Cto+40˚C(+50˚F to +104˚F)

Storage: -40˚Cto+70˚C (-40˚F to +158˚F)

Operational: 70 to 106 kPa

Storage: 23.5 to 106 kPa

ng to me

ces,

ass

e year ofmanufactureis

SUCTION PUMP KV--5

14

Page 18

Single--use

suction liner

Suction jar

Suction jar lid

Suction tubing

V acuum gauge Range: 0 to 100 kPa Accuracy: better than±2.5% of full scale

Olympus is continually developing its product range and reserves the right to alter the above specification without notice. The

Olympus KV--5 is manufactured in the UK by KeyMed (Medical & Industrial Equipment) Ltd.

To prevent fluid from being drawn up to the pump, the single--use suction liners, available in 1 or 2 litre versions,

contain a mechanism to shut off the flow when the liner is overfilled. This mechanism is activated when contact

is made with aspirated fluid. The single--use liners also contain a solidifier to aid safe disposal.

The 1 and 2 litre suction jars are manufactured from polysulfone, allowing them to be autoclaved up to 137˚C

max. The suction jar is impact resistant.

The suction jar lid clips and where applicable the float mechanism, are autoclavable up to 137˚C max. The inlet

connection (from the endoscope) is marked with the word PATIENT, the outlet connection (to the filter) is marked

with the word VACUUM. An optional lid is available having an integral float mechanism for use without

single--use suction liners.

The filter tubing supplied is silicone rubber, 6.0mm internal diameter, 12.0mm external diameter. The sterile

patient tubing supplied is PVC, 7.0mm internal diameter, 10.0mm external diameter. Use only tubing with the

specified dimensions, otherwise equipment malfunction may result.

The patient tube connects to a barbed connector on the suction jar cap and the filter tube has a removable 90˚

connector which is a push--fit into the suction jar cap.

7 TECHNICAL DESCRIPTION

7.1 Mechanical Operation

RefertoFigure7-1

The pump used in the KV-5 is a piston unit. The pump is connected to the suction jar by silicone tubing and has an

in-line microbial filter. A suction tube connects the endoscope or other devices to the suction jar. When the KV-5 is

switched on, a vacuum is created in the suction jar, which results in suction through the endoscope when the

appropriate endoscope control is operated, or through other devices. The vacuum level is controlled by a regulator

located on the front panel to which a vacuum gauge is connected. Air is drawn through the pump and is then exhausted

to atmosphere, passing through the exhaust at the rear of the unit.

7.2 Electrical Operation

RefertoFigure7-2

Power is provided to the unit from the AC power supply by the power supply lead.

The power socket at the rear of the unit has an integral fuseholder through which power is supplied to the power switch.

When the power switch is switched to the ‘l’ position, power is supplied to the motor, enabling the pump to operate.

Technical information regarding this product is available on request to assist suitably qualified personnel with repairs.

Contact Olympus regarding this information.

15

SUCTION PUMP KV--5

Page 19

Endoscope umbilical connector

(or other applied part)

Microbial filter

FIGURE 7-1

Suction jar

Single use

suction liner

Patient tube

Brown

Filter tube

Vacuum gauge

Power socket

Fuseholder

LNE

Blue

Green/Yellow

Black

Red

Vacuum pump

Exhaust

Exhaust silencer

Vacuum regulator

FIGURE 7-2

Vacuum pump

L5 N1 N2 L4

Illuminated

power switch

8 ENVIRONMENTAL PROTECTION

There are no known risks associated with disposal of the KV--5 at the end of its working life. If however, aspirated fluid

has entered the pump, it may be contaminated with infectious material and should therefore be disposed of in

accordance with local regulations or policy.

SUCTION PUMP KV--5

16

Page 20

OLYMPUS MEDICAL SYSTEMS CORP.

2951 Ishikawa-cho, Hachioji-shi, Tokyo 192-8507, Japan

Fax: (0426) 46-2429 Telephone: (0426) 42-2111

OLYMPUS MEDICAL SYSTEMS EUROPA GMBH

(Premises/Goods delivery) Wendenstrasse 14-18, D-20097 Hamburg, Germany

(Letters) Postfach 10 49 08, D-20034 Hamburg, Germany Telephone: (040) 237730

OLYMPUS AMERICA INC.

3500 Corporate Parkway, P.O. Box 610 Center Valley, PA 18034-0610, U.S.A.

Fax: (484) 896-7128 Telephone: (484) 896-5000

OLYMPUS SURGICAL & INDUSTRIAL AMERICA INC.

One Corporate Drive, Orangeburg, N.Y. 10962, U.S.A.

Fax: (845) 398-9444 Telephone: (845) 398-9400

KEYMED LTD.

KeyMed House, Stock Road, Southend-on-Sea, Essex SS2 5QH, United Kingdom

Fax: (01702) 465677 Telephone: (01702) 616333

OLYMPUS SINGAPORE PTE LTD.

491B, River Valley Road #12-01/04, Valley Point Office Tower, Singapore 248373

Fax: 6834-2438 Telephone: 6834-0010

OLYMPUS (BEIJING) SALES & SERVICE CO,. LTD.

No.6 GongYuanXijie, Jian Guo Men Nei, DongCheng District, Beijing, 100005, China

Room 1406 E Tower, GongYuan No. 6 Royal Palace,

Fax: (10) 6518-0865 Telephone: (10) 6518-8080

OLYMPUS MOSCOW LIMITED LIABILITY COMPANY

117071, Moscow, Malaya Kaluzhskaya 19, bld. 1, fl.2, Russia

Fax: (095) 958-2277 Telephone: (095) 958-2245

Issue

7

J

anuary 2008

OLYMPUS AUSTRALIA PTY. LTD.

31 Gilby Road, Mount Waverley, Victoria 3149, Australia

Fax: (03) 9543-1350 Telephone: (03) 9265-5400

OLYMPUS LATIN AMERICA INC.

6100 Blue Lagoon Drive, Suite 390 Miami, FL 33126-2087, U.S.A.

Fax: (305) 261-4421 Telephone: (305) 266-2332

OLYMPUS KOREA CO,. LTD.

8F, Hyundai Marines Bldg., 646-1 Yeoksam-Dong, Kangnam-Gu, Seoul 135-080 Korea

Fax: (02) 6255-3499 Telephone: (02) 1544-3200

EKeyMed 2008

PrintedinUK

KT5070196/108

Loading...

Loading...