Page 1

Modules described

in this manual

IX2-RF AEVA-2

FV5-LAAR

IX2-COMB

FV5-FUR

ILLUMINATION SYSTEM

INSTRUCTIONS

TOTAL INTERNAL

REFLECTION

This instruction manual is for the Olympus Total Internal Reflection Illumination System. To ensure the

safety, obtain optimum performance and to familiarize yourself fully with the use of this system, we

recommend that you study this manual thoroughly before operating the system.

This system employs a laser light source. Take special care for safety and please also read the

instruction manual for the laser light source.

Retain this instruction manual in an easily accessible place near the work desk for future reference.

AX7385

Page 2

This device complies with the requirements of directive 98/79/EC concerning in vitro diagnostic

medical devices. CE marking means the conformity to the directive.

NOTE: This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference in which case

the user will be required to correct the interference at his own expense.

FCC WARNING: Changes or modifications not expressly approved by the party responsible for compliance

could void the user’s authority to operate the equipment.

Page 3

CONTENTS

IX2-RFAEVA-2

CAUTION

This system employs a laser light source and should be assembled and adjusted by qualified

service personnel from Olympus.

Never attempt to assemble or adjust the system for it is extremely hazardous.

IMPORTANT – Be sure to read this section for safe use of the equipment. –

1 MODULE NOMENCLATURE

2 CONTROLS

TOTAL INTERNAL REFLECTION FLUORESCENCE OBSERVATION

3

3-1 Conditions of Observation...................................................................................................................................................... 11

3-2 Preparation for Observation ................................................................................................................................................ 12

1 Preparing for Laser Beam Introduction 2 Introducing the Laser Beam

3-3 Observation Procedure .............................................................................................................................................................. 13

1-7

8

9, 10

11- 14

1 Adjusting the Focus 2 Adjusting the Laser Beam Incidence Angle

4 REFLECTED LIGHT FLUORESCENCE OBSERVATION

5 USING THE CONTROLS

1 Using the Binocular Tube Shutter 2 Using the Specimen Cover

3 Field Iris Aperture Diaphram 4 Filter Slider

6 TROUBLESHOOTING GUIDE

7 SPECIFICATIONS

PROPER SELECTION OF THE POWER SUPPLY CORD............................................................. 19 , 20

15

15, 16

17

18

Page 4

IMPORTANT

This system has been designed to be used in combination with an IX2 series (IX81/IX71/IX51) or IX

series (IX70/IX50) microscope to provide it with total internal reflection fluorescence illumination* using

a laser light source.

* Total internal reflection fluorescence illumination utilizes the “evanescent light”, a very small amount of

light at the sub-micrometric order penetrating beyond the total reflection of the cover glass (on the

specimen side), to excite only the fluorescent molecules exiting near the cover glass surface. By eliminating the background fluorescence, it enables fluorescence observation with very high contrast.

LASER SAFETY PRECAUTIONS

1. The laser used in combination with this system is designated as a laser product of the following class.

CLASS IIIb (CDRH)

CLASS 3B (IEC60825-1)

A CLASS 3B laser product is permitted to be used exclusively under control of a laser safety manager. Before

using this product, read “USER’S SAFETY PROTECTION MEASURES ACCORDING TO IEC60825-1 ‘LASER PRODUCT RADIATION SAFETY STANDARD’” carefully to apply sufficient safety measures before use.

If there is any question concerning the laser product, please consult Olympus.

2. The laser beam output from the objective position or objective top lens may injure the skin exposed to it. Avoid exposing

your finger or hand to the laser beam. Also, do not output the laser beam externally by engaging a mirror in the light path,

for this is extremely hazardous if the output beam enters your eye.

3. Place the specimen horizontally on the stage. If the specimen is tilted, the laser beam may be reflected around the

microscope and cause a hazard.

4. Never remove a unit while the laser beam output, for this may cause the laser beam to be output from there. Removal of

any unit should be performed by Olympus qualified service personnel. When removal is required, please consult Olympus.

5. Be sure to cap the revolving nosepiece positions where no objective is attached.

6. Do not bend or pull excessively or step on the laser fiber cable, for this may damage the laser fiber cable and cause laser

beam leakage that is extremely hazardous. Should laser beam leakage occur, immediately turn off the laser light source

and contact Olympus.

7. The laser-cooling fans output warm winds through the air outlets. Do not place an object that is flammable or nonresistant to heat near an air outlet.

To prevent electric shock or fire hazard, be sure to consult Olympus if you want to use a remote interlock

connector.

1

Page 5

IX2-RFAEVA-2

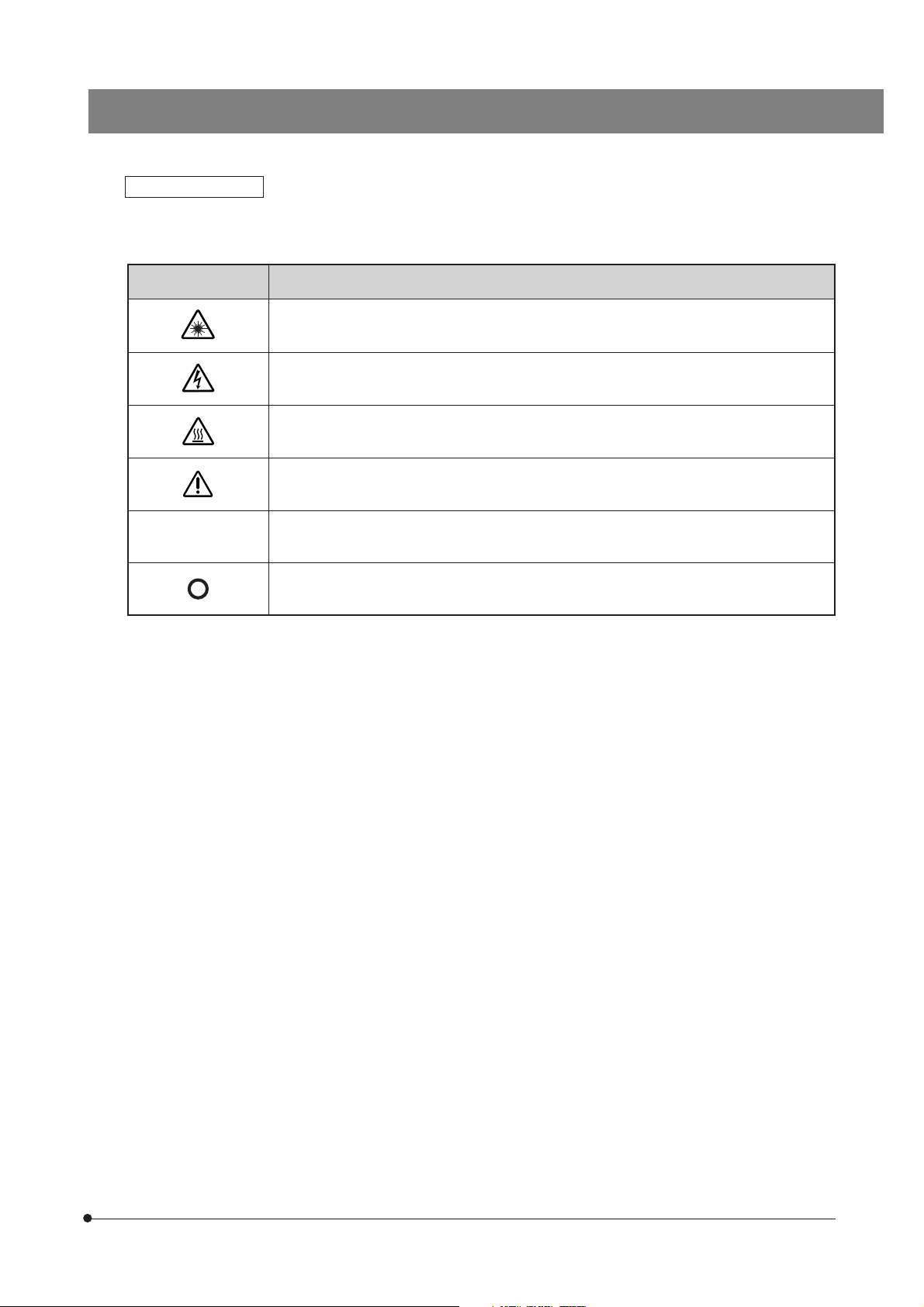

Safety Symbols

The following symbols are found on the system. Study the meaning of the symbols and always use the equipment in the

safest possible manner.

Symbol

l

Explanation

Indicates the use of a laser beam. Take special care in handling the part.

Indicates presence of a high voltage (1 kV or more). Take care against electric shock.

Indicates that the surface becomes hot, and should not be touched with bare hands.

Before use, carefully read the instruction manual. Improper use could result in personal injury

to the user and/or damage to the equipment.

Indicates that the main switch is ON.

Indicates that the main switch is OFF.

2

Page 6

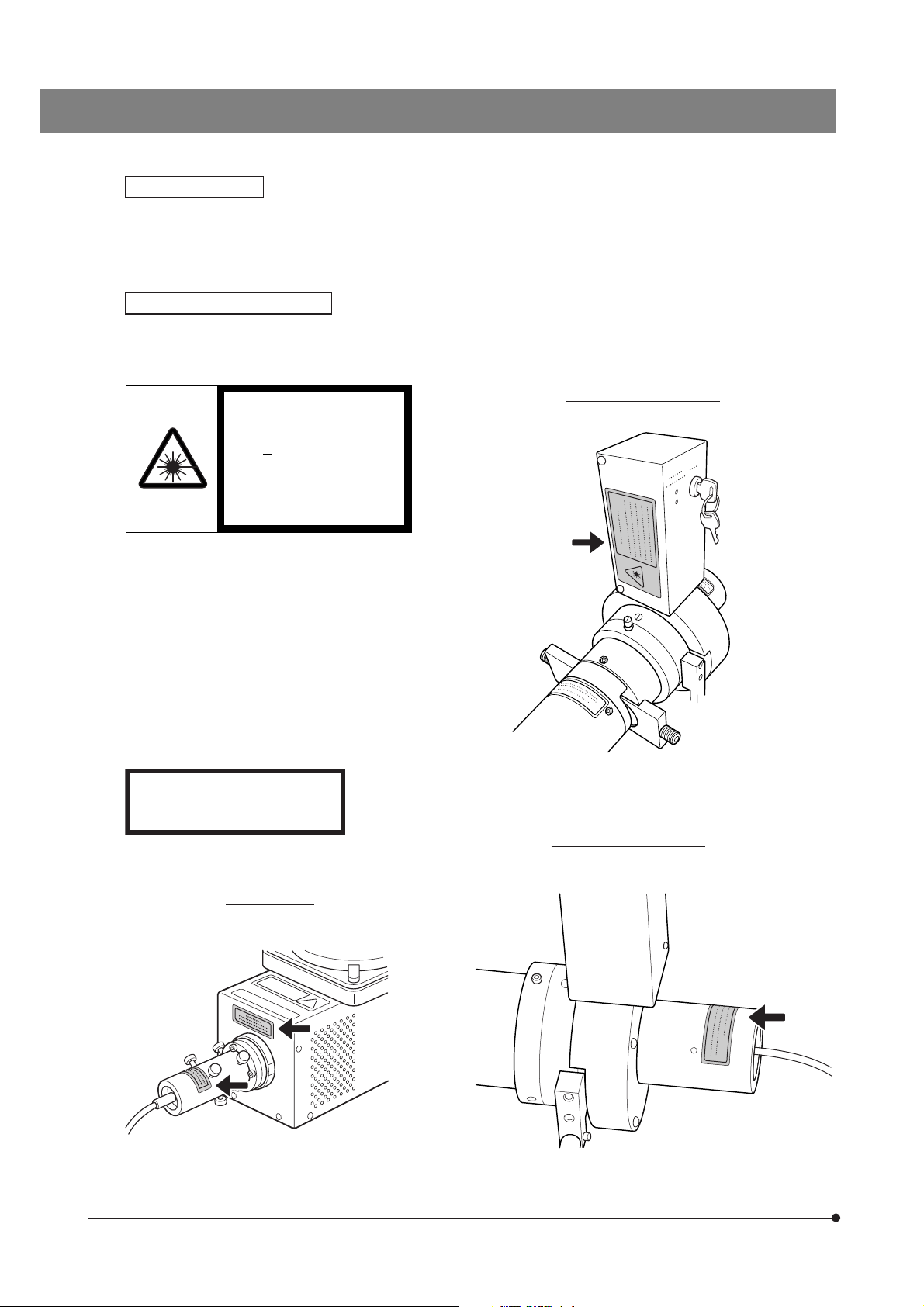

Warning Labels

Warning labels are placed at parts where special precaution is required when handling and using the system. Always

heed the warnings.

If warning labels become soiled, peel off, etc., contact your local Olympus representative to have them replaced.

Warning Label Positions

}Warning labels are attached to the positions indicated by the arrows.

Fiber light illuminator

LASER LIGHT

AVOID EXPOSURE TO BEAM

CLASS IIIb LASER PRODUCT (CDRH)

CLASS 3B LASER PRODUCT

(IEC60825-1 : 1993+A1 : 1997+A2 : 2001)

50mW MAX CW 400-700nm

3

CAUTION-CLASS 3B

LASER RADIATION WHEN OPEN.

AVOID EXPOSURE TO THE BEAM.

Fiber light illuminator

Ar laser unit

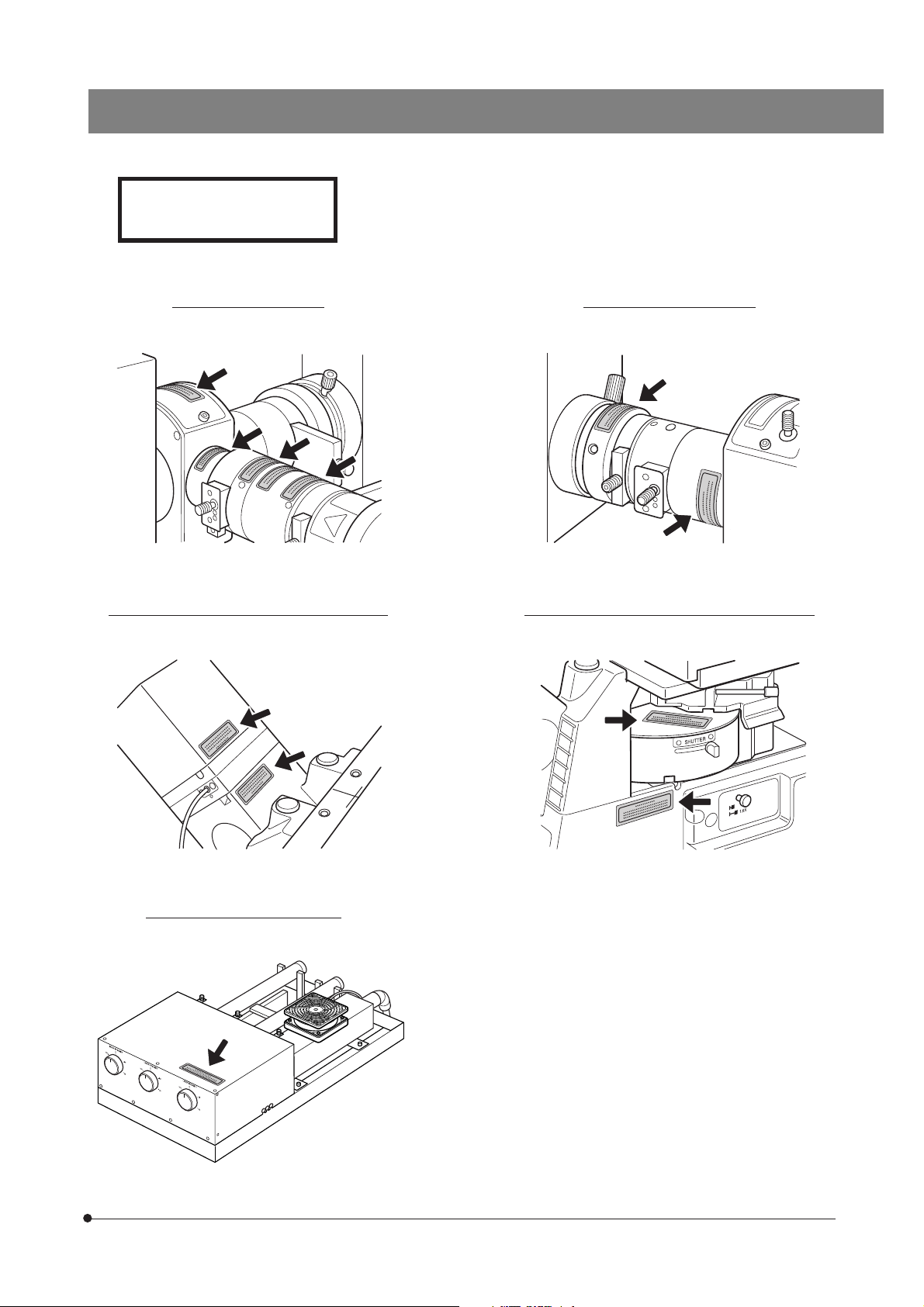

Page 7

CAUTION-CLASS 3B

LASER RADIATION WHEN OPEN.

AVOID EXPOSURE TO THE BEAM.

Fiber light illuminator Straight light illuminator

IX2-RFAEVA-2

Binocular tube & binocular tube shutter Microscope frame & revolving nosepiece

Laser combiner IX2-COMB

4

Page 8

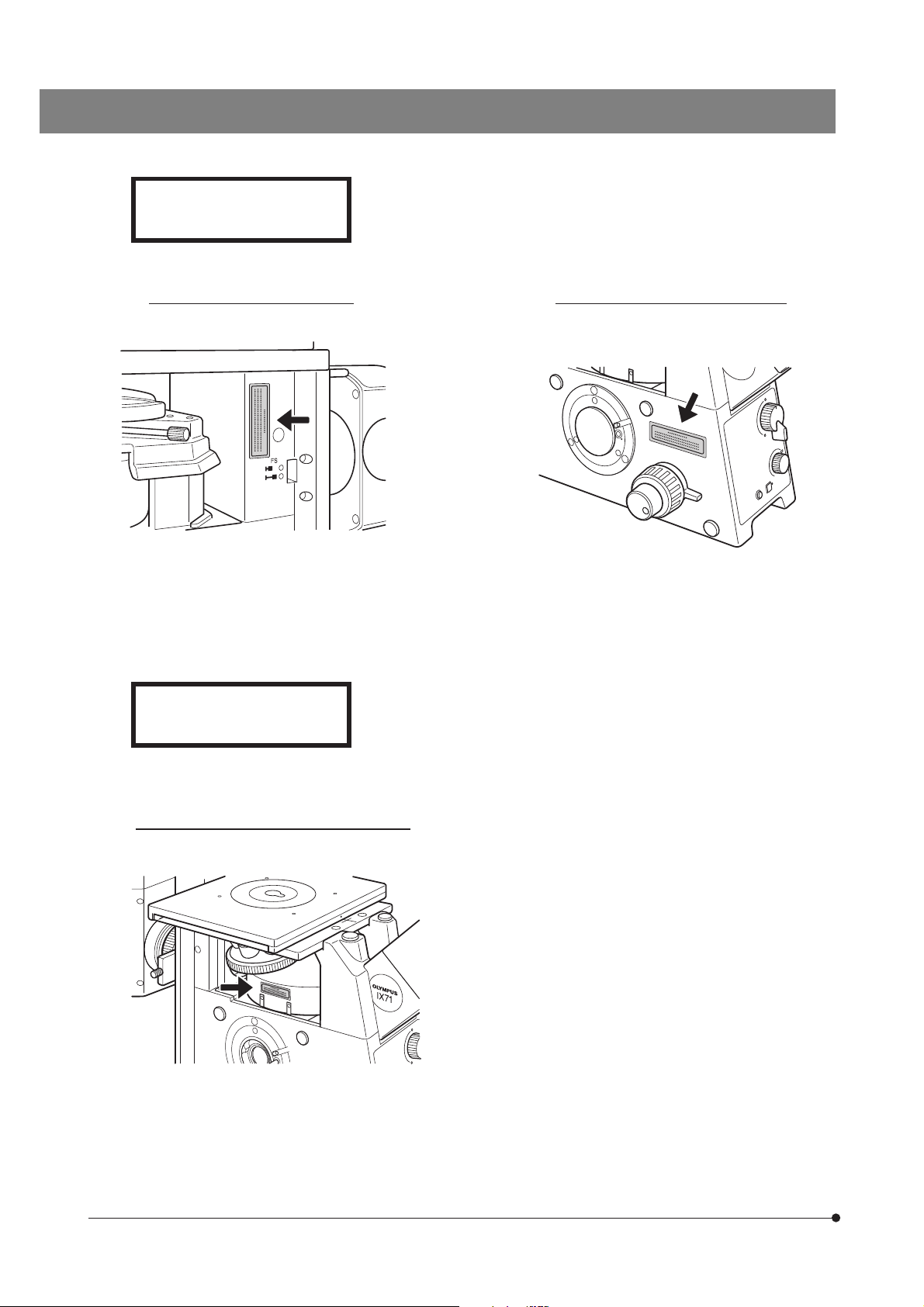

CAUTION-CLASS 3B

LASER RADIATION WHEN OPEN.

AVOID EXPOSURE TO THE BEAM.

Microscope frame (rear right)

AVOID EXPOSURE

LASER RADIATION IS EMITTED

FROM THIS APERTURE.

Microscope frame (left side port)

5

Microscope left side (Reflected

illumination and observation light path)

Page 9

IX2-RFAEVA-2

SAFETY PRECAUTIONS

Movement of the System

The system is assembled and set up by qualified service personnel. Avoid moving the system for this may deviate the

optical adjustments. Consult Olympus when you wish to move the system. If the system is moved by the customer,

Olympus will not assume liabilities for the system malfunctions and damage that may result.

Disposal of the System

1. The laser tube used in the system should be disposed of according to your local industrial waste disposal regulations. If

disposal by you is forbidden, please contact Olympus.

2. The mercury burner used in the illumination of the system should be disposed of according to your local industrial waste

disposal regulations.

Handling Precautions

1. After the equipment has been used in an observation of a specimen that is accompanied with a potential of

infection, clean the parts coming in contact with the specimen to prevent infection.

· Moving this product is accompanied with the risk of dropping the specimen. Be sure to remove the specimen before

moving this product.

· In case the specimen is damaged by erroneous operation, promptly take the infection prevention measures.

· The product becomes unstable if its height is increased by an accessory mounted on it. In this case, take

anti-toppling measures to prevent the specimen from being dropped when the product topples down.

2. The system is composed of precision equipment. Handle it with care and avoid subjecting it to sudden or severe impact.

3. Do not bend or pull excessively or step on the fiber cable, for this may degrade the performance considerably.

4. When the reflected light source is turned off, do not turn it again for at lease 10 minutes. Otherwise, the service life of the

mercury burner may be reduced.

5. Do not apply cool air from an air conditioner, etc., to the laser beam. Otherwise, the operation may become unstable.

6. To avoid destruction of the laser tube, absolutely avoid causing condensation in it. When the laser tube has been left

under a cold environment for a long period, condensation by avoided by not starting to warm the operation room until the

laser operation has started.

7. When a laser is not used for more than a month, it should be subjected to idle operation (aging) for more than 8

continuous hours at least every month. Otherwise, the laser oscillation may become unstable, causing sudden stopping

of oscillation during operation or shortening of service life.

8. The laser-cooling fans output warm winds through the air outlets. Do not place an object that is flammable or nonresistant to heat near an air outlet. Leave a space of 50 cm or more in front of each air outlet to facilitate heat ventilation.

(Overheating of laser tube may make the laser oscillation unstable, causing sudden stopping of oscillation during

operation. The rise in the equipment internal temperature may also cause malfunction or failure.)

9. As cooling fans are installed at the front and rear of the laser power supply, this should be installed by leaving spaces of

30 cm or more from the surrounding walls so as not to block ventilation from the cooling fans as well as from the splits

on the top and side panels. Do not leave an object such as documents or a book on the top of the laser power supply,

for this may cause overheating, which leads to sudden stopping of laser oscillation due to activation of the protection

circuitry.

. Install the system so that the power supply to the system can be shut down easily by switching the power switch or

10

unplugging the power cord from the power outlet. Also, the power supply for the system should be positioned in a place

allowing easy shutdown of the power supply.

6

Page 10

Getting Ready

1

1. This manual pertains only to the handling of the total internal reflection fluorescence illumination system. Please also

read the instruction manuals for the IX2 series (IX series) microscope and associated options to understand the

comprehensive operating instructions of the microscope system.

2. The total internal reflection fluorescence illumination system is composed of precision instruments. Handle it with care

and avoid subjecting it to sudden or severe impact.

3. Do not use the system where it is subjected to direct sunlight, high temperature and humidity, dust or vibrations.

4. Reserves spaces of 10 cm or more around the lamp housing and power supply to facilitate their ventilation.

Maintenance and Storage

2

1. To clean the lenses and other glass components, simply blow dirty away using a commercially available blower and

wipe gently using a piece of cleaning paper (or clean gauze).

If a lens is stained with fingerprints or oil smudges, wipe it gauze slightly moistened with commercially available absolute

alcohol.

Since the absolute alcohol is highly flammable, it must be handled carefully.

Be sure to keep it away from open flames or potential sources of electrical sparks –– for example, electrical

equipment that is being switched on or off.

Also remember to always use it only in a well-ventilated room.

2. Do not attempt to use organic solvents to clean the non-optical components. To clean them, use a lint-free, soft cloth

slightly moistened with a diluted neutral detergent.

3. Never attempt to disassemble any part of the system, for this may degrade the performance and the laser beam output.

Caution

3

If the system is used in a manner not specified by this manual, the safety of the user may be imperiled. In addition, the

equipment may also be damaged. Always use the equipment as outlined in this instruction manual.

The following symbols are used to set off text in this instruction manual.

: Indicates that the instructions are related to the hazard of laser beam.

: Indicates that failure to follow the instructions in the warning could result in bodily harm to the

user and/or damage to equipment (including objects in the vicinity of the equipment).

# : Indicates that failure to follow the instructions could result in damage to the equipment.

} : Indicates commentary (for ease of operation and maintenance).

7

Page 11

IX2-RFAEVA-2

1

Specimen Cover

MODULE NOMENCLATURE

? The modules enclosed ( ) belong to the IX2-RFAEVA-2 total internal reflection fluorescence illumination

system.

*Remove the excitation filter from each laser

wavelength compatible excitation mirror unit

For IX2/IX series:

· Fluorescence mirror unit cassette

· Fluorescence mirror unit (for mercury burner)

· Fluorescence mirror unit (for laser)*

Objectives

Straight light illuminator

**

*Remove the excitation filter from the IB

before use. (See the chart on page 11.)

excitation mirror unit before use. (488 nm Ar

**

For cell specimens and fluorescent molecules:

laser)

Apo100XOHR/PlanApoN60XO

**

For cell specimens:

Note1)

order)

Apo100XOHR, PlanApo60XO

For fluorescent molecules: UPlanSApo100XO/

custom order)

PlanApoN60XO

For fluorescent molecules: PlanApo100XO,

PlanApo60XO2

Note2)

For IX2/IX series:

Mercury lamp housing

TIRFM (made to

Power Supply Unit

U-RFL-T

TIRFM (made to

Binocular tube

shutter

Microscope frame

IX2 series (IX81/IX71/IX51)

IX series (IX70/IX50)

Safety interlock cable

Fiber light illuminator

Laser adapter

Fiber unit

FV5-FUR

Note 1) The PlanApo60XO

be used.

Note 2) The PlanApo100XO3 and PlanApo60XO3 for the

UIS series can also be used (ones with model

numbers 3, 2 and none are all usable).

for the UIS series can also

TIRFM

Ar laser unit

(488 nm)

FV5-LAAR

Laser power supply

FV5-LAAR

Laser combiner

IX2-COMB

Optional.

See the separate instruction

( )

manual for details.

8

Page 12

CONTROLS

Straight Light Illuminator and Fiber Light Illuminator

Laser emission indicators

ON : Laser being emitted

Illumination selector knob

: Laser light path

: Mercury burner light path

OFF : Shuttered

1

Field iris diaphragm (FS) centering screw

IX2 series adapter

Field iris diaphragm (FS) lever

Filter slider

Pushed in: Filter engaged

Pulled out: Shutter engaged

View in the direction of arrow 1

Filter slider

Pushed in : Filter

Pulled• out : Shutter

engaged

engaged

Laser incidence angle

adjustment knob

2

Laser interlock key switch

ON : Interlocked

OFF : Laser beam blocked

Support foot

View in the direction of arrow 2

Laser interlock connector

AC adapter connector

Field iris diaphragm (FS) lever

Field iris diaphragm (FS) centering screw

Binocular Tube Shutter

Shutter

Pushed in: Shutter engaged (IN)

Pulled out: Shutter disengaged (OUT)

9

User interlock cable connector

For the use of this connector,

contact Olympus.

AC Adapter

U-ACAD4515

Page 13

IX2-RFAEVA-2

Specimen Cover

?Lighting the specimen replacement lid activates the interlock key switch and the motorized shutters ( x 2) of the

fiber light illuminator blocks the laser beam.

Knobs

Specimen box

Ar Laser Power Supply (488 nm)

FV5-LAAR

Specimen replacement lid

Interlock connector

Key

Main switch

10

Page 14

TOTAL INTERNAL REFLECTION FLUORESCENCE

OBSERVATION

Because this observation method employs laser beam, be sure to observe the

following precautions.

· Never remove a part on which a warning panel is attached.

· Be sure to set the interlock key switch to OFF and make sure that the laser emission indicator

is OFF before proceeding to the objective switching or fluorescence turret switching.

3-1 Conditions of Observation

Be sure to observe the following laser operating environment conditions.

· Temperature: 18 to 28°C (performance guaranteed), 10 to 35°C (laser oscillation guaranteed).

· Humidity: 30% to 80% (without condensation)

· Excitation wavelengths: 400 to 750 nm with both laser and mercury burner.

Observe the following precautions in the total internal reflection fluorescence observation.

· Applicable objectives for total internal reflection fluorescence observation

Cell specimens and fluorescent molecules: Apo100XOHR (NA 1.65), PlanApoN60XO

Fluorescent molecules: UPlanSApo100XO (NA 1.40), PlanApoN60XO (NA 1.42).

· A special cover glass and immersion oil are required when using the Apo100XOHR.

· The total internal reflection fluorescence mirror unit can be used by removing the excitation filter of the excitation mirror unit.

TIRFM (made to order, NA 1.45).

Excitation Mirror Unit Laser (Wavelength)

IB excitation U-M)IB3

U-M)IBA3

G excitation U-M)G2 HeNe-G laser (543 nm)

U-MWIG3 Nd-YAG laser (532 nm)

U-M)IGA3

R excitation (Commercially HeNe-R laser (633 nm)

available product)

IY excitation U-MWIY2 Kr laser (568 nm)

BV excitation U-M)BV2 He-Cd laser (442 nm)

· The character(s) in ) can be SW, W or N. Type 2 excitation mirror units can also be used.

· For the multi-excitation mirror units, consult Olympus.

· For IB excitation fluorescence observation using the mercury burner, it is required to prepare a separate IB

excitation mirror unit incorporating an excitation filter, apart from the total internal reflection fluorescence mirror

unit.

· Total internal reflection observation is not available with the binocular tube light path (because the laser will not

be emitted unless the binocular tube shutter is engaged in the light path).

· The observation field number is 11.7 with both laser and mercury burner.

Ar laser (488 nm)

11

Page 15

IX2-RFAEVA-2

3-2 Preparation for Observation

Never peel off warning label from a position it is attached. Otherwise, the laser beam may enter your eyes.

²

4

@

Fig. 1

5

Preparing for Laser Beam Introduction (Fig. 1)

1

1. Set the light path selector knob of the microscope for the camera light

path.

2. Push in the illumination selector knob @ for the laser light path.

3. Rotate the fluorescence mirror unit turret to engage an excitation mirror

unit that is compatible with total internal reflection fluorescence observation.

4. Engage the objective for total internal reflection observation in the light

path.

5. Push in the shutter of the binocular tube shutter to engage it in the light

path.

6. Push in the filter slider ² of the fiber light illuminator to engage the

released shutter.

7. Release the shutter of the fluorescence mirror unit turret (by setting the

shutter to position marked “\" ).

8. Put the specimen replacement lid on the specimen box.

Introducing the Laser Beam

2

}To ensure stable laser beam output, warm up the system (for about 10

minutes) after turning the laser power supply on.

1. Set the main switch 3 to “ I ” (ON).

2. Turn the key 4 till the ON position. This also starts the laser-cooling fans.

The laser will start oscillation in about 10 seconds to 1 minute.

3. Set the laser interlock key switch (5 in Fig. 1) to ON.

(Fig. 2)

3

Fig. 2

12

Page 16

3-3 Observation Procedure

@

@

²

Fig. 3

Fig. 4

Adjusting the Focus

1

1. Remove the specimen replacement lid @ from the stage.

2. Apply immersion oil on the objective top lens and place the specimen on

the stage.

3. Place the specimen replacement lid @ on the specimen box ²; the laser

beam will be output. When the image is displayed on the monitor for the TV

camera, bring the displayed specimen image into focus.

Adjusting the Laser Beam Incidence Angle

2

}Perform the laser beam incidence angle adjustment by referring to the

“Explanation Diagrams” on the next page.

}When the laser beam incidence angle adjustment knob 1 of the fiber

light illuminator is set to the fully clockwise position, the angle of the laser

beam output from the objective is smaller than the critical angle and total

internal reflection is not obtained (see Explanation 1).

# Do not turn the adjustment knob further clockwise from the above

condition by force.

1. While observing the monitored image, turn the adjustment knob 1 slowly

counterclockwise until total internal reflection fluorescence is obtained

(Explanation 3).

(Fig. 3)

(Fig. 4)

When the laser incidence angle approaches the critical angle (Explanation 2), the bright part of the fluorescence image flows in the

vertical or horizontal direction of the field of view. When the angle

is increased further, the background fluorescence darkens suddenly and the total internal reflection fluorescence is obtained (Explanation 3).

2. Turning the adjustment knob 1 further counterclockwise decreases the

range where total internal reflection fluorescence is observed (depth from

the cover glass surface). Turning the adjustment knob clockwise increase

the above range.

}If the adjustment knob is turned too much counterclockwise, nothing will

be visible eventually (Explanation 4).

13

Page 17

Explanation Diagrams (Laser Beam Incidence Angle Adjustment)

Explanation 1 : Condition before laser incidence angle adjustment

IX2-RFAEVA-2

Glass

Laser beam

· The laser beam is transmitting through the

glass and specimen.

Specimen

Immersion oil

Objective

Explanation 2 : Critical angle condition

· The laser beam travels on the upper surface of the glass.

Monitored image

Field iris diaphragm

image

Fluorescence image

of specimen

· The fluorescence image of specimen is observed even

when it is defocused by moving the objective upward.

· The image flows in the horizontal direction (also in the

vertical direction depending on the camera installation orientation).

Explanation 3 : Total internal reflection condition

· When total internal reflection is achieved, the reflected

laser beam returns to the objective and forms an evanescence field on the glass.

Explanation 4 : Condition before laser incidence

· The laser beam hits the inner frame of objective and

does not reach the specimen.

· The image darkens

suddenly.

· The focused plane

is thin.

· The fluorescence image of specimen becomes invisible

when it is defocused by moving the objective upward.

· The image is

completely dark.

· When the camera gain is increased, vague light may be

visible due to the stray light.

14

Page 18

REFLECTED LIGHT FLUORESCENCE OBSERVATION

(Observation Using the Mercury Burner)

}Follow the instructions given by the instruction manual for the reflected light fluorescence system in use.

For this observation, be sure to attach the original fluorescence mirror unit, which incorporates the excitation filter,

to the turret.

USING THE CONTROLS

@

@

²

Fig. 5

Fig. 6

1 Using the Binocular Tube Shutter

}When the shutter @ of the binocular shutter is pulled out, the laser inter-

lock key switch is activated, blocking the laser beam output and, for

safety, making the total internal reflection observation unavailable for the

binocular tube.

1. To observe the specimen through the binocular tube, pull out the shutter

@ to open the light path.

In this case, the laser beam is not output because it is blocked by the

motorized shutter.

2. To perform total internal reflection observation, push in the shutter @ all

the way until it is stopped.

This activates the laser interlock key switch, causing the laser beam to be

output.

Using the Specimen Cover

2

}Removal of the specimen replacement lid @ activates the laser interlock

key switch and blocks the laser beam output.

1. For transmitted light observation or for changing the specimen, remove

the specimen replacement lid @.

In this case, the laser beam is not output because it is blocked by the

motorized shutter.

2. To perform total internal reflection observation, place the specimen

replacement lid @ on the specimen box 2.

This activates the laser interlock key switch, causing the laser beam to be

output.

# When a condenser with short working distance (IX2-LWUCD, IX2-

LWUCDA2, IX2-DICD or U-UCD8) is used, push down the transmitted

light illumination column toward the rear or swing the condenser

holder upward in advance.

(Fig. 5)

(Fig. 6)

15

Page 19

IX2-RFAEVA-2

@

²

³

Fig. 7

Fig. 8

Field Iris Aperture Diaphragm

3

}To prevent progress of specimen fading, stop down the field iris aperture

diaphragm to cover only the observed area.

· The field iris diaphragm can be stopped down by pulling out the field iris

diaphragm lever @.

Centering the Field Iris Diaphragm (Figs. 7 & 8)

1. Place a specimen on the stage and bring the specimen image displayed

on the monitor into focus.

2. Pull out the field iris diaphragm lever @ so that the field iris diaphragm

image ² is displayed on the monitor screen.

3. Insert the Allen screwdriver, provided with the microscope frame, alternately into the two centering screws ³ to bring the field iris diaphragm

image ² at the center of the monitor screen.

4. After completing centering, push in the field iris diaphragm lever @ until

the field iris diaphragm image ² circumscribes the monitor screen.

}If the TV camera uses image pickup devices that are larger than 2/3 inch,

the field iris diaphragm image will not circumscribe the monitor screen

even when the field iris diaphragm is opened at maximum.

(Fig. 7)

@

Fig. 9

@

Filter Slider

4

}The filter slider has the same structure with both the straight light illumina-

tor and fiber light illuminator, allowing either the shutter or filter pocket to

be engaged in the light path according to the left and right sliding of the

slider.

}When observation is not performed, engage the shutter in the light path

to prevent the specimen from fading.

1. Pull out the filter slider @ in the direction of the arrow to engage the

shutter in the light path.

2. The filter pocket accepts brightness adjustment ND filters, which can be

dropped into the pocket for insertion.

· Up to five ND filters, including the 32ND6, 32ND12, 32ND25 and 32ND50

can be inserted.

If the ND filters in the fiber light illuminator are tilted, irregularities due

to interference of laser beam may be observed in the field of view. To

prevent this, keep the ND filters vertical by means of the ring spring

inside the filter pocket.

The filter slider becomes very hot when the system has been on for a

long period. Be careful not touch the filter slider parts other than the

knob.

(Fig. 9)

16

Page 20

TROUBLESHOOTING GUIDE

Caution

Never look into an objective

to check if the laser beam is

output.

Remedy

Be sure to pulled out the shut-

ter to block the laser beam be-

fore proceeding to treatment.

Be sure to pulled out the shut-

ter to block the laser beam be-

fore proceeding to treatment.

If the interference stripe does

not disappear after treatment,

please consult Olympus.

Push in the illumination selector knob to select the laser

illuminator light path.

Set the main switch and key of the laser oscillator to ON.

Push in the filter slider to open the light path.

Release the manual shutter.

Engage a total internal reflection fluorescence mirror unit

in the light path.

Turn the laser beam incidence angle adjustment knob all

the way clockwise.

Cause

The illumination selector knob is set for the mer-

cury burner illuminator.

The manual shutter of the fluorescence mirror unit

cassette is closed.

Other fluorescence mirror unit than a total internal

reflection fluorescence mirror unit is engaged in

the light path.

The laser beam incidence angle adjustment knob

The filter slider of the fiber light illuminator is pulled

The laser oscillator is not ON.

Problem

out.

is turned too much counterclockwise.

Set the interlock key switch to ON.

Push in the binocular tube shutter.

Place the specimen replacement lid on the specimen

box.

The interlock key switch is set to OFF.

The specimen replacement lid is removed.

The binocular tube shutter is pulled out.

Connect it properly.

The AC adapter connector is connected im-

Turn the laser incidence angle adjustment knob counter

clockwise.

Turn the laser beam incidence angle adjustment knob

clockwise.

Engage a total internal reflection fluorescence objective in

the light path.

Place the cover glass so that it is parallel with the stage

center plate.

Use the Apo100XOHR objective (NA 1.65) to observe a speci-

Wait until the laser beam is output.

properly.

The laser incidence angle is not the critical angle.

The equipment is normal if the laser beam is out-

put within about 1 minute.

An objective other than the total internal reflection

fluorescence objective is engaged in the light path.

The laser beam incidence angle adjustment knob

is turned too much counterclockwise.

men with a refractive index of 1.38 (index of cytoplasm) or

The specimen being observed has a refractive

index of 1.38 or more (glycerin sealed specimen,

The specimen is tilted.

Stand the ND filter vertically using the ring spring provided

Special immersion oil and cover glass are required when

using the Apo100XOHR (NA 1.65).

more.

etc.)

The immersion oil or cover glass is not suitable.

The ND filter in the filter slider is tilted.

in the filter slider.

If the interference stripe still does not disappear, rotate the

Put the specimen (cell) in close and perfect contact with

the cover glass.

Engage a total reflection fluorescence mirror unit without

excitation filter in the light path.

ND filter to minimize the interference stripe.

A fluorescence mirror unit incorporating an excita-

tion filter is engaged in the light path.

Wipe off the immersion oil and attach new oil by avoiding

bubble penetration.

The specimen (cell) is not in close contact with

the cover glass but is separated from it at some

positions.

The immersion oil contains bubbles.

The objective is dirty. Clean the objective top lens with the cleaning mixture fluid.

Blow dust away using a blower, etc.

Dust is attached to the dichroic mirror or barrier

filter.

17

No laser beam is output.

Classification

Laser beam

output

Total internal reflection fluorescence cannot

be obtained.

It takes long time after the laser oscillator is

switched ON till the laser beam is output.

Laser beam

observation

Linear or elliptical interference stripes are

observed in the field.

Random interference stripe is observed in the

field, and the stripe moves when the stage is

moved.

Random interference stripe is observed in

the field, and the stripe does not move even

when the stage is moved.

An interference stripe with a concentric pat-

tern is observed.

Page 21

SPECIFICATIONS

Item Specification

Applicable microscope frames

Applicable reflected fluorescence

systems

Total internal reflection illumination

system

IX2-RFAEVA

Ar laser unit/power supply

FV5-LAAR

Operating environment

Storage environment

IX2-RFAEVA-2

· IX2 series (IX81/IX71/IX51)

· IX series (IX70/IX50)

· IX2 and IX series systems

(Reflected light illuminator unnecessary)

Straight (mercury burner)/Fiber light (laser) double illuminator

· Either illuminator can be selected using the illumination selector

knob.

· Interlock mechanism (Laser interlock/User interlock).

· Field iris diaphragm (Diameter adjustable between 1.7 and 13 mm)

· Filter slider

· Maximum FN 11.7

· Interlock key switch

· Laser emission indicators

Binocular tube shutter

· Laser interlock mechanism with the binocular tube shutter.

(Releasing the shutter engages the shutter in the laser light path.)

Specimen cover

· Laser interlock mechanism with the specimen replacement lid.

(Removing the specimen replacement lid engages the shutter in

the laser light path.)

· 10 mW power, linear polarization

· Forced air-cooled Ar ion laser (488 nm)

· Connection with the fiber light illuminator: Polarization plane saving

fiber cable FV5-FUR (3 m)

· Power consumption: 115 V, 10 A (max.)

230 V, 10 A (max.)

· Indoor use

· Altitude: Max. 2000 m

· Temperature: 18 to 28°C (performance guaranteed), 10 to 35°C (laser

oscillation guaranteed)

· Relative humidity: 30% 80% (without condensation)

· Supply voltage fluctuations: ±10%

· Pollution degree: 2 (in accordance with IEC60664)

· Installation (overvoltage) category: II (in accordance with IEC60664)

· Temperature: –25 to 65°C

· Relative humidity: 10% to 90%

Safety

EN61010-1(1993 +A2 1995): Safety requirements for electrical equipment for measurement, control and laboratory

use.

EN60825-1(1994 +A2 2001): Safety of laser products.

Electromagnetic Compatibility

EN61326(1997 +A1 1998): Electrical equipment for measurement, control and laboratory use EMC requirements.

EN61326 defines two categories according to the location for use.

Class A: Equipment suitable for use in establishments other than domestic, and those directly connected

to a low voltage power supply network which supplies buildings used for domestic purposes.

Class B: Equipment for use in domestic establishments, and in establishments directly connected to a low

voltage power supply network which supplies buildings used for domestic purposes.

This system is applied Class A. Some interference may occur if this system is used in domestic location.

18

Page 22

PROPER SELECTION OF THE POWER SUPPLY CORD

If no power supply cord is provided, please select the proper power supply cord for the equipment by referring to “Specifications”

and “Certified Cord” below:

CAUTION: In case you use a non-approved power supply cord for Olympus products, Olympus can no longer warrant

the electrical safety of the equipment.

Specifications

Voltage Rating

Current Rating

Temperature Rating

Length

Fittings Configuration

125V AC (for 100-120V AC area) or, 250V AC (for 220-240V AC area)

6A minimum

60°C minimum

3.05 m maximum

Grounding type attachment plug cap. Opposite terminates in molded-on IEC configuration appliance coupling.

Table 1 Certified Cord

A power supply cord should be certified by one of the agencies listed in Table 1, or comprised of cordage marked with

an agency marking per Table 1 or marked per Table 2. The fittings are to be marked with at least one of agencies listed

in Table 1. In case you are unable to buy locally in your country the power supply cord which is approved by one of the

agencies mentioned in Table 1, please use replacements approved by any other equivalent and authorized agencies

in your country.

Country Agency

Argentina IRAM

Australia SAA Japan

Certification

Mark

Country Agency

Italy IMQ

JET, JQA, TÜV,

UL-APEX / MITI

Certification

Mark

19

Austria ÖVE Netherlands KEMA

Belgium CEBEC Norway NEMKO

Canada CSA Spain AEE

Denmark DEMKO Sweden SEMKO

Finland FEI Switzerland SEV

France UTE

Germany VDE U.S.A. UL

Ireland NSAI

United

Kingdom

ASTA

BSI

Page 23

Table 2 HAR Flexible Cord

APPROVAL ORGANIZATIONS AND CORDAGE HARMONIZATION MARKING METHODS

IX2-RFAEVA-2

Approval Organization

Comité Électrotechnique Belge

(CEBEC)

VDE Verband der Elektrotechnik

Elektronik Informationstechnik e.V.

Union Technique de l’Électricité

(UTE)

Istituto Italiano del Marchio di Qualità

(IMQ)

British Approvals Service for Cables

(BASEC)

N.V. KEMA KEMA-KEUR <HAR> 10 30 30

SEMKO AB Svenska Elektriska

Materielkontrollanstalten

Österreichischer Verband für

Elektrotechnik (ÖVE)

Danmarks Elektriske Materielkontrol

(DEMKO)

Printed or Embossed Harmonization

Marking (May be located on jacket

or insulation of internal wiring)

CEBEC <HAR> 10 30 10

<VDE> <HAR> 30 10 10

USE <HAR> 30 10 30

IEMMEQU <HAR> 10 30 50

BASEC <HAR> 10 10 30

SEMKO <HAR> 10 10 50

<ÖVE> <HAR> 30 10 50

<DEMKO> <HAR> 30 10 30

Alternative Marking Utilizing

Black-Red-Yellow Thread (Length

of color section in mm)

Black Red Yellow

National Standards Authority of Ireland

(NSAI)

Norges Elektriske Materiellkontroll

(NEMKO)

Asociación Electrotécnica Española

(AEE)

Hellenic Organization for

Standardization (ELOT)

Instituto Português da Qualidade (IPQ) np <HAR> 10 10 90

Schweizerischer Elektrotechnischer

Verein (SEV)

Elektriska Inspektoratet SETI <HAR> 10 30 90

Underwriters Laboratories Inc. (UL) SV, SVT, SJ or SJT, 3 X 18AWG

Canadian Standards Association (CSA) SV, SVT, SJ or SJT, 3 X 18AWG

<NSAI> <HAR> 30 30 50

NEMKO <HAR> 10 10 70

<UNED> <HAR> 30 10 70

ELOT <HAR> 30 30 70

SEV <HAR> 10 30 90

20

Page 24

EC REP

Shinjuku Monolith, 3-1, Nishi Shinjuku 2-chome, Shinjuku-ku, Tokyo, Japan

Wendenstraße 14-18, 20097 Hamburg, Germany

3500 Corporate Parkway, P.O. Box 610, Center Valley, PA 18034-0610, U.S.A.

One Corporate Drive, Orangeburg, NY 10962, U.S.A.

491B River Valley Road, #12-01/04 Valley Point Office Tower, Singapore 248373

31 Gilby Road, Mount Waverley, VIC., 3149, Australia

Blue Lagoon Drive, Suite 290 Miami, FL 33126, U.S.A.

5301

01/10

Loading...

Loading...