Maintenance Manual

for maintenance engineer

CX21

Thank you for purchasing the Olympus microscope CX21.

In order to fully utilize its performance and secure optimum condition, please read this manual before

maintenance work.

Please also keep it at hand during maintenance as well as for future reference.

All rights reserved, Reproduction in whole or in part without written permission is prohibited.

CX21 MAINTENANCE MANUAL

INTRODUCTION

The purpose of this manual is to satisfy any requirements for maintenance material that maybe

considered as necessary to professionals in the maintenance field, such as Maintenance engineer

in Hospitals.

It is intended to be used as a tool for performing basic maintenance procedures if needed or when

required as per the recommended maintenance schedule.

The sections from this manual only cover procedure pertaining maintenance ’s that are considered

to be easily performed. For more involved maintenance’s or repairs, it is recommended that you

contact a qualified service engineer from your local Authorized Olympus dealer.

Maintenance parts, grease, and other items specified in the manual can be ordered from your

Authorized Olympus dealer, and subject to change without notice.

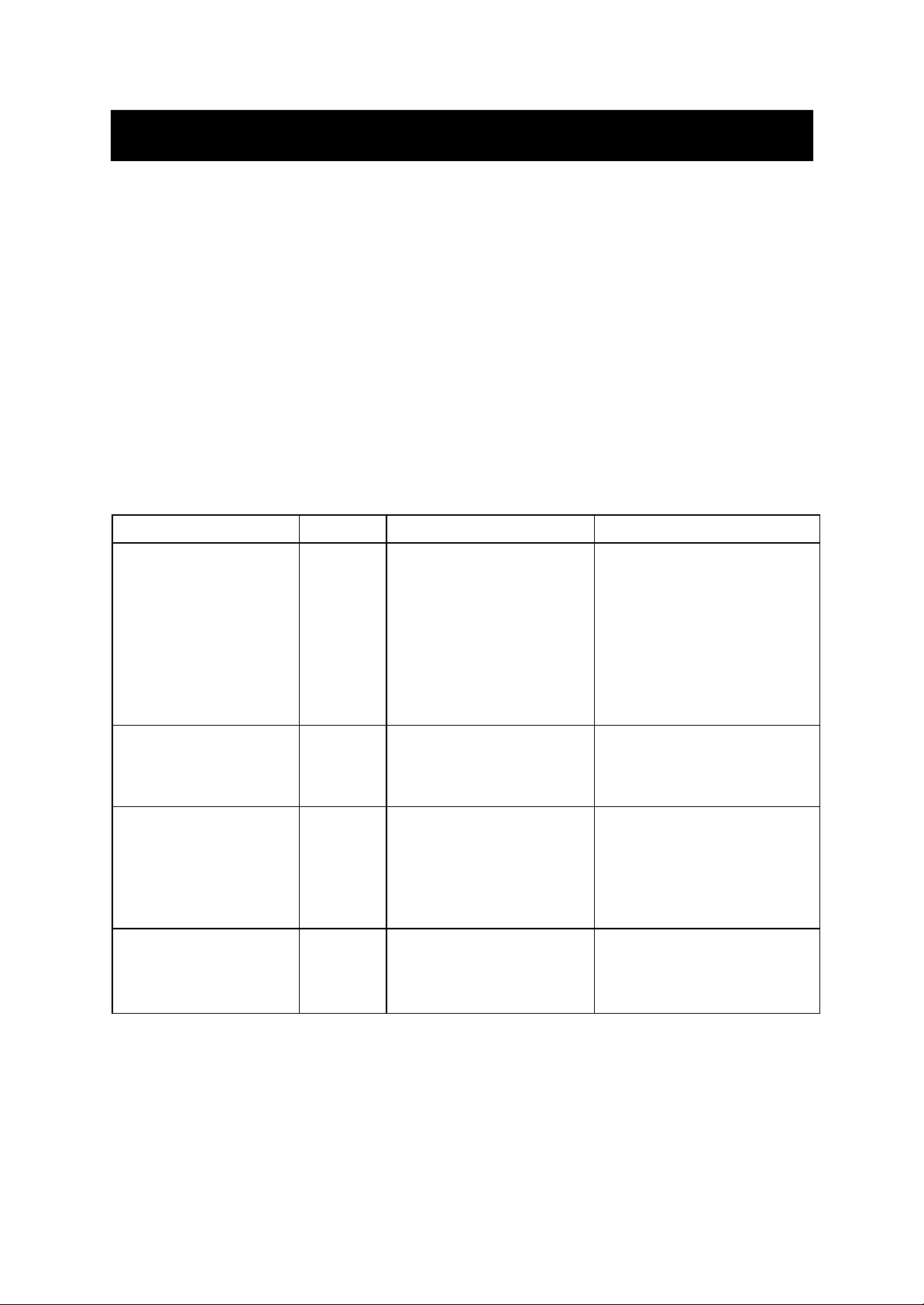

The recommended maintenance schedule is shown below as reference. ( * Necessary item)

Portion Cleaning Optical/mechanical check Maintenance schedule

Optical components

1) Outer surface

Eyepiece, objective ,

condenser lens, filter,

2) Inner part Prism,

internal lenses

Appearance

Microscope frame,

mechanical part

Observation tube

Mechanical part

Focusing unit, stage,

revolving nosepiece,

aperture iris diaphragm

*

*

*

*

Optical adjustment :

1) Optical axis (standard)

2) Left/right optical axis

3) Revolving axis

4) Parfocality

*

Mechanical movement :

Grease replacement

Mechanical adjustment

Once in a year

(If dirt is conspicuous or oil

immersion objec tive is used,

cleaning should be made after

every use.)

Once in a year

Once in a year

(If dirt is conspicuous, cleaning

should be made after every

use.)

Once in a year

Once in two to three years

CX21 MAINTENANCE MANUAL

CONTENTS

CHAPTER 1 MAINTENANCE PROCEDURE........................................................................ 1

1. Maintenance of Microscope............................................................................................ 1

2. Guide to Maintenance.................................................................................................... 2

2-1 Overview of maintenance....................................................................................... 2

2-2 Cleaning method for the optical components.......................................................... 3

3. Preparing for Inspection................................................................................................. 6

4. CX 21 Inspection Sheet...................................................................................................7

CHAPTER 2 INSPECTION PROCEDURE............................................................................. 8

1. Checking Performance of Microscope............................................................................ 8

2. Checking Dirty Portion.................................................................................................... 8

2-1 Image influence caused by dirt on each component............................................... 8

2-2 How to find dirty portion through observation.......................................................... 9

2-3 How to check cleaning condition .......................................................................... 10

CHAPTER 3 REPAIR PROCEDURE.....................................................................................11

1. Optical Adjustment ........................................................................................................11

2. Mechanical Adjustment................................................................................................. 14

2-1 Preparation for the tension adjustment of X/Y-wire................................................ 14

2-2 Adjustment method for the tension of X -wire.........................................................15

2-3 Adjustment method for the tension of Y-wire......................................................... 15

2-4 Final adjustment................................................................................................... 16

3. Replacing Grease for Coarse/Fine Adjustment Knob Ass’y........................................... 17

4. Replacing Circuit Board................................................................................................ 18

4-1 CX 21 wiring diagram............................................................................................ 18

4-2 Replacement of circuit board / socket................................................................... 18

5.

Replacing Pinion Ass'y of Plane Stage......................................................................... 19

CHAPTER 4 JIGS AND TOOLS / GREASES ..................................................................... 20

1. List of Jigs and Tools.................................................................................................... 20

2. List of Greases............................................................................................................. 20

CHAPTER 5 MAINTENANCE PARTS................................................................................... 1

1. List of Maintenance Parts............................................................................................... 1

CX21 MAINTENANCE MANUAL MAINTENANCE PROCEDURE

CHAPTER 1

MAINTENANCE PROCEDURE

1. Maintenance of Microscope

1) Fundamental handling

a. Read the instruction manual thoroughly, handle the microscope correctly.

b. Be sure to make a usual cleaning, especially after every use of microscope.

c. When handling the microscope, do not expose it to shock, moisture, heat and dust.

d. If the problem occurs, do not treat it in self-judgement.

2) Using and storing conditions

a. The microscope should be used under no vibration.

If it is placed in such environment as vibration, this causes disturbance and fatigue in

observation.

b. It should not be stored in high humidity.

Such condition causes fungus, corrosion on lens and rust on metal part.

Therefore, special caution is exercised if stored in a long period of time.

c. Intense temperature change should be avoided.

Be careful not to place the microscope near window exposed to direct sunlight and air

conditioner. When bringing it into warm room from cold storage location in winter,

condensation occurs on lens and metal part, it causes fungus and rust.

d. It should be kept clean.

The microscope is required to keep away from dust that causes contamination, fungus

on lens and failure of sliding part in the frame.

Be careful not to place it in the environment where the corrodent chemicals such as

hydrogen sulfide, hydrogen fluoride and acid are handled.

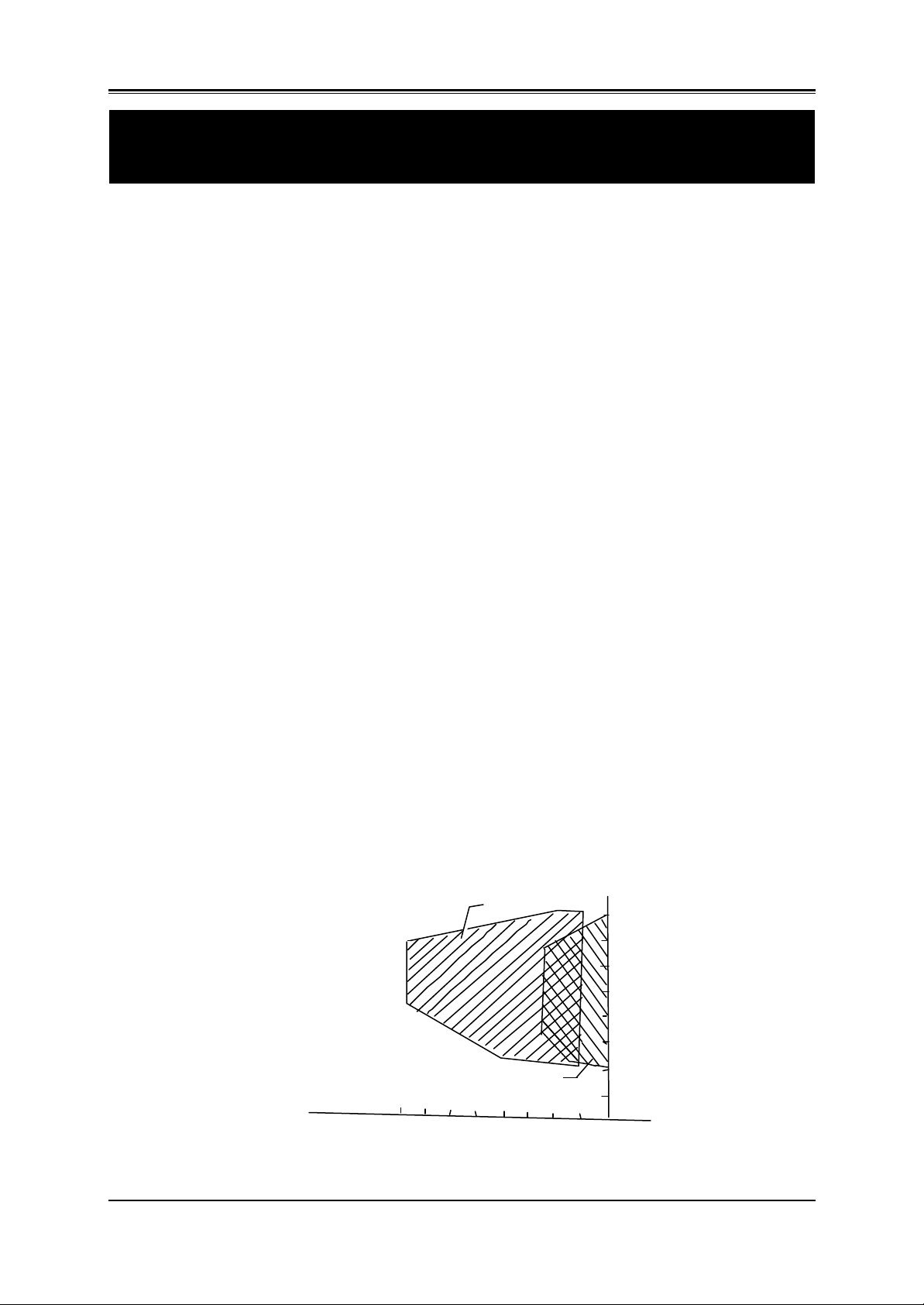

<Reference> fungus: occurrence conditions

Temperature

Dry blue aspergillus

Degree(C)

40

30

Humidity

%

60 70

- 1 -

80

Aspergillus

20

10

90

100

CX21 MAINTENANCE MANUAL MAINTENANCE PROCEDURE

with the soft brush. If there are stains on

Remove the eyepieces and objectives,

solution. (When removing the objective,

Wipe off any dirt spots on the surface of

Take off the mechanical stage from the

Clean the surface of stage and filter on

2. Guide to Maintenance

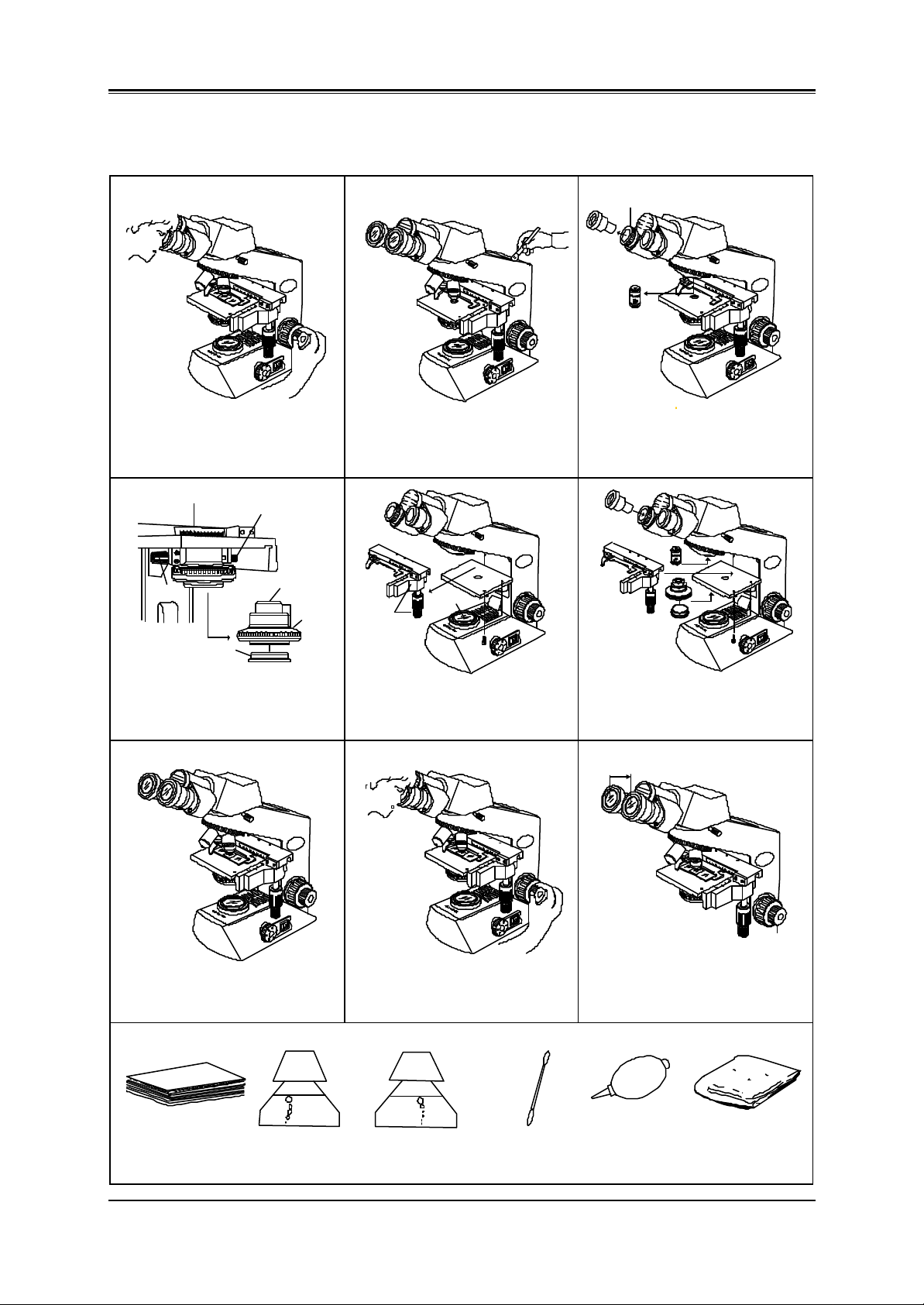

2-1 Overview of maintenance

1)

100

Set your correct interpupillary distance.

Note any areas suggesting a need for

mechanical and/or optical maintenance

by operating it or observing a specimen.

4)

(A)

Turn knob (A).

Remove it from groove.

Filter

( plastic )

Remove the condenser downward.

top lens, filter. The plastic parts should

be cleaned with netural detergent.

OLYMPUS

CX21

110

120

130

140

150

160

17

30

20

10

0

Top lens

(glass)

Plastic

7)

2)

100

Sweep off dust on the outer surfaces

the microscope frame, clean them with

neutral detergent.

5)

Plastic

75

70

60

50

100

110

120

130

140

150

160

17

30

20

10

0

glass

plane stage by removing two screws.

the base cover.

OLYMPUS

110

CX21

120

130

140

150

160

17

30

20

10

0

OLYMPUS

CX21

8)

3)

Loosen the screw securing eyepiece.

75

70

60

50

100

OLYMPUS

110

CX21

120

130

140

150

160

17

30

20

10

0

then clean their lenses with cleaning

use the rubber band.)

6)

75

70

60

50

100

110

120

130

140

150

160

17

30

20

10

0

OLYMPUS

CX21

Mount the removed components and

mechanical stage to the frame.

9)

100

OLYMPUS

CX21

110

120

130

140

150

160

17

30

20

10

0

Polish all plastic components and the

frame with silicon cloth.

Tool required:

Lens tissue Neutral detergent

(For plastic part or

frame)

100

OLYMPUS

CX21

110

120

130

140

150

160

17

30

20

10

0

Return the interpupillary distance to

original condition and prepare for the

inspection. (see page 6)

Cleaning solution

(For lens or filter

etc.)

Cotton swab

or tweezers

etc.

- 2 -

100

110

OLYMPUS

CX21

120

130

140

150

160

17

30

20

10

0

Do a final check following the inspection

sheet in this manual. (See page 7)

Blower Silicon cloth

(For finishing)

CX21 MAINTENANCE MANUAL MAINTENANCE PROCEDURE

Put it on the desk

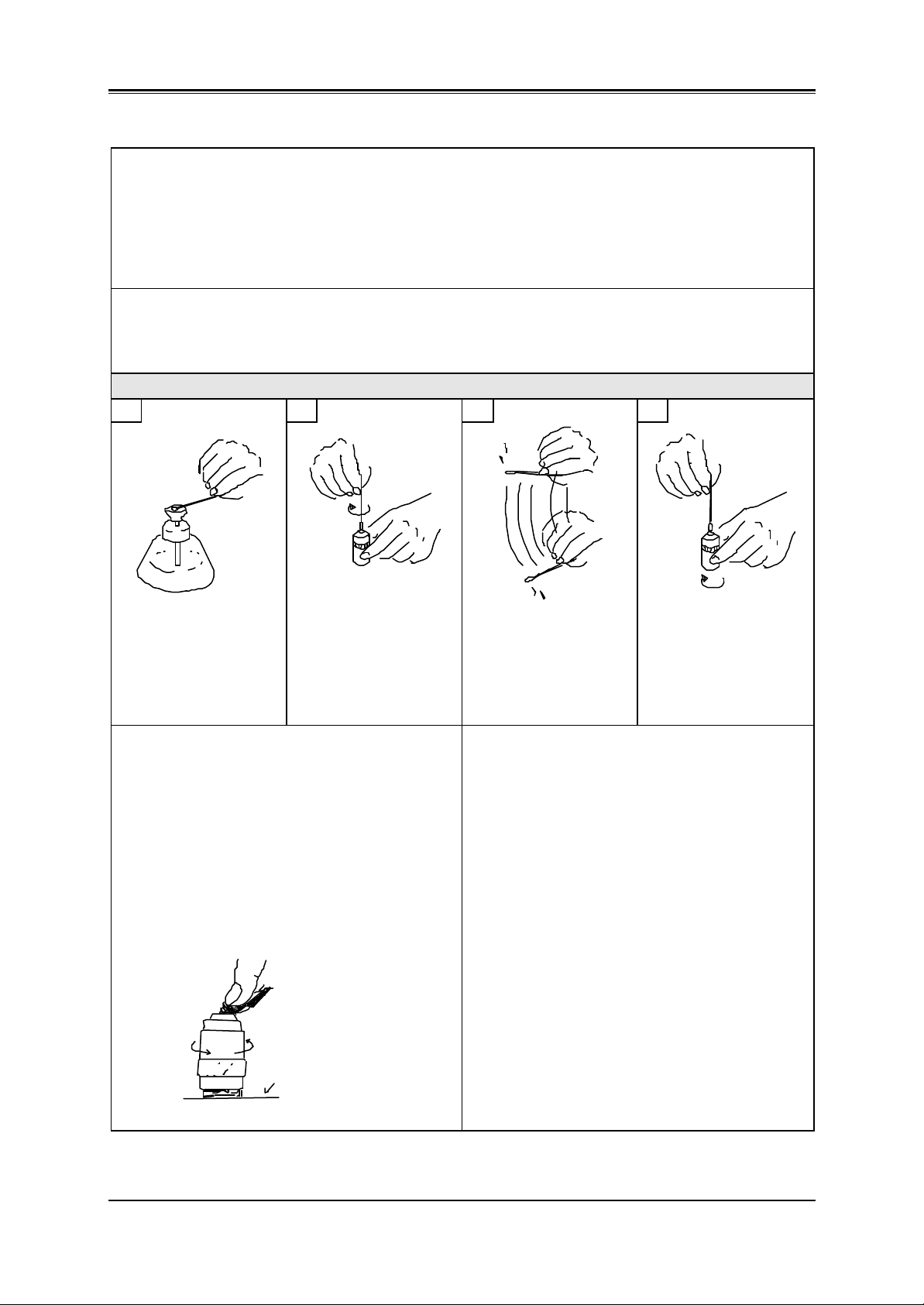

2-2 Cleaning method for the optical components

Required tools:

1) Lens tissue

2) Cotton swab or tweezers etc.

3) Blower

4) Magnifier (Eyepiece is possible to be used by turning it upside down. Refer to page 10.)

5) Cleaning solution: e.g. Alcohol

Before cleaning: Lightly brush the lens surface or blow with the blower before wiping with tissue.

This removes particles that may scratch the lens surface. (to protect the lens

coating)

HOW TO CLEAN THE OBJECTIVE LENS

1 2 3 4

Moisten the tip of

cotton swab with

cleaning solution.

When the lens size is large and difference in level

between the lens and the lens frame is small:

Fold the lens tissue several times and moisten it

with cleaning solution.

After that, apply the folded line edge to the center

of lens, push it with index finger and turn the

objective by the other hand to clean the lens

while moving it from the center towards the

periphery.

With a circular motion,

wipe the top lens

surface with the cotton

swab, to thoroughly

remove any oil or dirt

from the lens.

Dip a new cotton swab

in the cleaning solution

and shake vigorously

to remove any excess

cleaning solution.

Cleaning the immersion objective:

Wipe off the immersion oil while absorbing it with

lens tissue that is not moistened. After that, clean

the lens as the same manner mentioned on the

left. When the top surface of lens frame is higher

than that of lens and remained dirty portion on

the periphery of lens can not be wiped off, clean

the lens referring the above figures, 1 to 4.

Wipe the objective lens

from the center

towards the periphery,

while rotating the lens.

- 3 -

CX21 MAINTENANCE MANUAL MAINTENANCE PROCEDURE

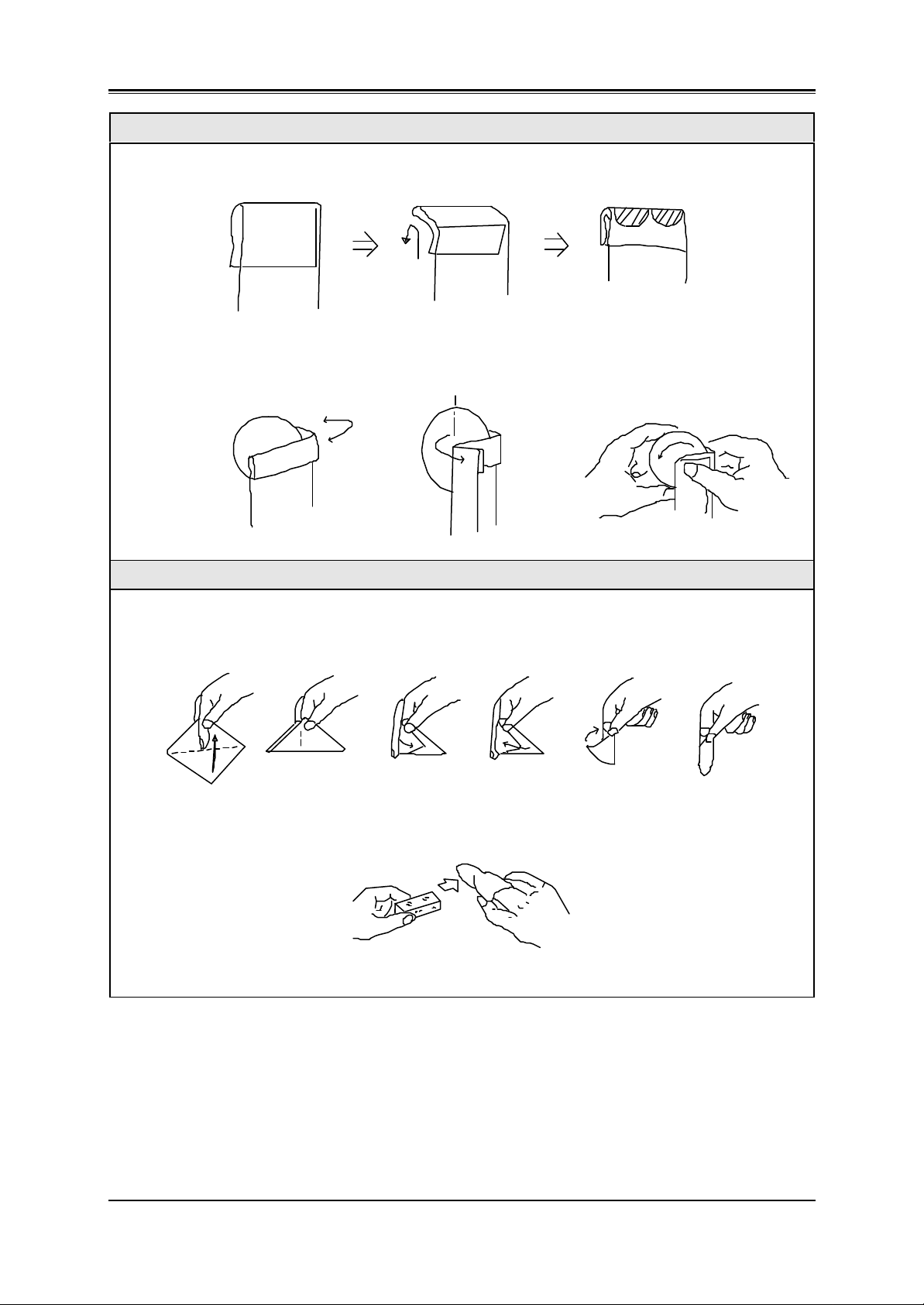

HOW TO CLEAN THE FILTER

Fold the lens tissue into two or three layers and moisten its shaded part with cleaning solution.

Hold the filter at its edge and fold the lens paper from the lens center to outside as illustrated.

Move the lens tissue gradually to outside while turning the filter by left hand.

HOW TO CLEAN THE PRISM

Hold a sheet of lens tissue between your middle and index fingers, then fold and wrap it around your

index finger. Hold the tissue down with your thumb and moisten it with sufficient cleaning solution.

1)

2) 3)

4)

Wipe the prism surfaces from front to backward at a stroke, applying even pressure.

5)

6)

- 4 -

CX21 MAINTENANCE MANUAL MAINTENANCE PROCEDURE

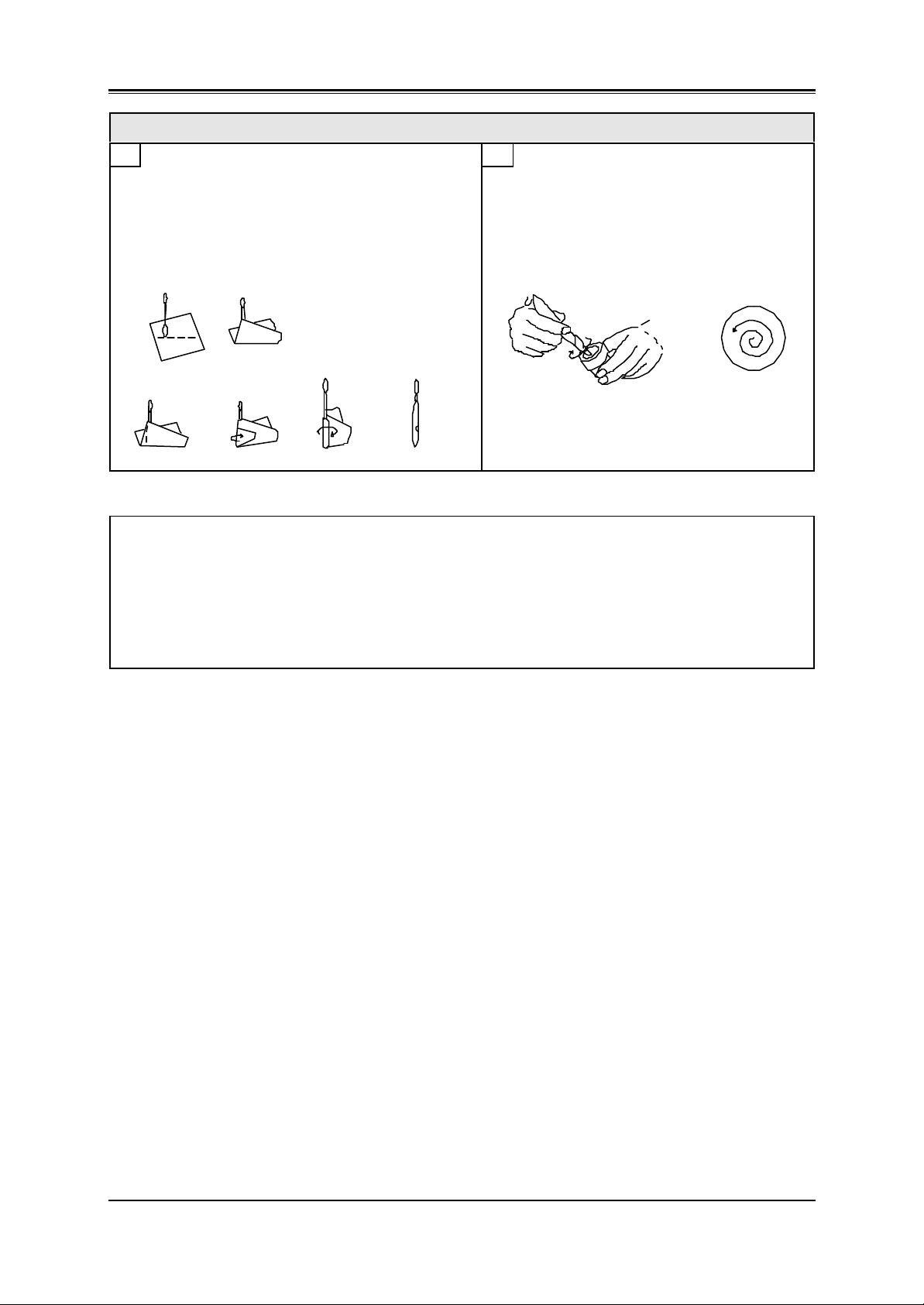

HOW TO CLEAN THE EYEPIECE

1 2

Wrap a sheet of lens tissue around a cotton swab

as illustrated. If the area to be cleaned is large,

wrap the lens tissue looser and thicker. Otherwise,

make a thin, tight wrap.

Dip the wrapped lens tissue in the cleaning

solution, and wipe the eyepiece from the

center towards the periphery in a circular

motion.

Important notes:

1) Never rub the lens surface strongly.

2) Do not use the same lens tissue to clean more than one lens.

3) Do not moisten the lens tissue with an excessive amount of cleaning solution.

4) When cleaning with tweezers, be careful not to protrude its tip from the lens tissue.

- 5 -

CX21 MAINTENANCE MANUAL MAINTENANCE PROCEDURE

4x10x

3. Preparing for Inspection

1) Set the main switch “A” to “I” (ON).

2) Adjust the brightness by turning the adjustment knob “B” .

3) Place a specimen on the stage.

4) Engage the 10X objective in the light path.

5) Rotate the condenser height adjustment knob ”C” to move the condenser to the highest position.

* The condenser is usually used in the highest position. If the entire observed field of view is

not bright enough, brightness may be improved by lowering the condenser slightly.

6) Looking through the eyepiece in the right sleeve without the diopter adjustment ring, turn the

coarse and fine focus adjustment knobs “D” to bring the specimen into focus.

7) Looking through the eyepiece in the left sleeve with the diopter adjustment ring, turn only the

diopter adjustment ring “E” to focus on the specimen.

(At this time, adjust the interpupillary distance so that the binocular visions on the left and right

fields of view coincide completely.)

8) Adjust the aperture iris diaphragm;

Since the aperture irirs diaphragm has an objective magnification scale (4X, 10X, 40X,100X),

rotate the diaphragm ring “F” so that the magnification scale corresponding to the objective

in use faces frontward.

(E)

(C)

(F)

100

110

120

130

140

150

160

30

20

10

0

OLYMPUS

CX21

17

(D)

(A)

(B)

- 6 -

CX21 MAINTENANCE MANUAL MAINTENANCE PROCEDURE

4. CX21 Inspection Sheet

Model : Check Date :

S/N : Checking by :

Check Point Check Contents Result Ref. Page

1. Electrical unit 1) When the power switch is turned on, the lamp is lit

and the brightness can be varied by adjustment

knob.

2. Coarse/fine focus

adjustment knob

3. Stage

4. Observation tube

5. Revolving

nosepiece

6. Condenser 1) The vertical movement of condenser is smooth. OK / NO

1) The coarse/fine focus adjustment knob is

smoothly moved without any stress or

unevenness.

2) The tension of coarse focus adjustment knob can

be adjusted by the adjustment ring.

3) The upper limit is changed by turning the stopper

on the upper side

1) The plane stage should not fall spontaneously. OK / NO

2) A specimen is held securely by the specimen

holder.

3) The X/Y movement of mechanical stage is

smooth without unevenness, backlash or slipping.

1) The interpupillary distance adjustment can be

operated smoothly in working range.

2) When changing the interpupillary distance, the

displacement of optical axis is not apparent.

3) The diopter adjustment ring is moved smoothly in

working range.

4) The optical axis of left side coincides with that of

right side.

1) The revolving nosepiece can be rotated smoothly

and stops at the click position.

OK / NO 18

OK / NO 17

OK / NO

OK / NO

OK / NO

OK / NO 15

OK / NO

OK / NO

OK / NO

OK / NO 11, 12, 13

OK / NO

(Observation)

Remarks:

1) Observation image is normal.

Without flares /ghosts / vignetting /uneven

illumination

2) Dust and dirt are not noticeable in observation . OK / NO 8, 9

OK / NO7. Visibility

- 7 -

CX21 MAINTENANCE MANUAL INSPECTION PROCEDURE

CHAPTER 2

INSPECTION PROCEDURE

1. Checking Performance of Microscope

Using the CX21 inspection sheet (P.7), check the electrical unit, mechanical and optical

performance.

2. Checking Dirty Portion

2-1 Image influence caused by dirt on each component

The following figure shows the influence of image on each optical component if stains

or dust is adhered to that portion.

In general, the microscope image is largely affected by dirt adhered on the nearer

portion to a specimen and image surfaces.

Therefore, the optical components should be kept clean and dust-free.

B Eyepiece

D Objective

A Specimen

B Condenser lens

B or A Glass

(Frosted : underside)

C Frosted glass

C Collector lens

C Prism

A: Dirt is clearly seen.

B: Blurred contours of dirt is seen.

C: Dirt is seen when the aperture iris diaphragm is stopped down.

D: Dirt is not directly seen, but contrast of image deteriorates.

- 8 -

CX21 MAINTENANCE MANUAL INSPECTION PROCEDURE

2-2 How to find dirty portion through observation

1) Close the aperture iris diaphragm.

(When the aperture iris diaphragm is closed, it facilitates finding the dirt particles

because the depth of focus increases and the dirt position bring into focus. However,

very small dirt particle may not be found in this method.)

2) Observe a specimen through the eyepiece.

If dirt is seen by observing it, look for the portion where stains or dust is adhered by

following the description below.

Check it by rotating the eyepiece

after clamping screw is loosened.

(Wipe carefully and gently so as

not to damage the lens coating.)

Objective

Dirt is not directly seen, but

dirt and dust particles affect

the microscope image.

100

110

120

130

140

150

160

17

30

20

10

0

OLYMPUS

CX21

Specimen

Check it by moving the stage.

Condenser

Eyepiece

Check the top lens and filter if

conspicuous dirt is not seen.

Collector lens part

Check it if conspicuous dirt

is not seen.

(Dust and dirt particles here

have minimal effect on the

image. However, the overall

appearance requires inside

lens cleaning.)

Note: If dirty portion can not be identified in the above, it is assumed that internal lens and

prism are contaminated.

In this case, please contact your Authorized Olympus dealer.

- 9 -

CX21 MAINTENANCE MANUAL INSPECTION PROCEDURE

2-3 How to check cleaning condition

1) When a large lens is checked, look at the lens while putting it toward bright side or

breathe on the lens and observe the condition that the haze on the whole surface of

the lens disappears evenly.

Light

Dust becomes conspicuous when

looking at it with the lens

inclination changed.

2) For a small lens such as top lens of objective, check it by magnifier.

If there is a dirty part or a remained part that

is not cleaned completely, the haze of this

part will disappear slower than that of the

other part.

An eyepiece can be substituted for

magnifier by turning the eyepiece upside

down.

- 10 -

CX21 MAINTENANCE MANUAL REPAIR PROCEDURE

CHAPTER 3

REPAIR PROCEDURE

1. Optical Adjustment

PREPARATION

*Eyepiece

for CX21

*It is necessary to set the

cross micrometer disk to

the above eyepiece.

Adjusting the left/right optical axis

If the left/right optical axis is remarkably displaced at

checking, perform the following adjustment.

*Insert the cross eyepiece

into the right sleeve.

Objective 10X

Specimen

whose center is

identified

(concentric circles etc.)

Align the specimen center with the cross center of the

eyepiece by turning the control knob of the stage.

Adjust the interpupillary

distance to about 62mm

(See the illustration)

75

70

60

50

Position of

approx. 62mm

Before adjustment After adjustment

Cross center of

eyepiece

Specimen center

Control knob

- 11 -

CX21 MAINTENANCE MANUAL REPAIR PROCEDURE

ADJUSTMENT THE LEFT/RIGHT OPTICAL AXIS

(1) Moving the cross eyepiece to the left sleeve

Work Image seen through the cross eyepiece

Move the cross eyepiece to the left sleeve.

If the optical axis between left and right

sleeve is deviated, the center of the

75

70

60

50

specimen and the cross center of eyepiece

are also deviated.

(2) Aligning the cross center of eyepiece with the specimen center

Work Image seen through the cross eyepiece

1. Loosen the two screws slightly which

Image at first

secure the left sleeve.

75

70

60

50

2. Align the center of eyepiece with the

specimen center while observing

through the eyepiece. (Change the left

sleeve position by hand.)

75

70

60

50

The center is aligned.

- 12 -

CX21 MAINTENANCE MANUAL REPAIR PROCEDURE

3. Firmly tighten the screws which secure

Image at the end of adjustment

the left sleeve.

75

70

60

50

* If this adjustment could not be done, inside mechanism may be damaged.

Please contact your Authorized dealer.

- 13 -

CX21 MAINTENANCE MANUAL REPAIR PROCEDURE

2. Mechanical Adjustment

2-1 Preparation for the tension adjustment of X/Y-wire

If a specimen image is moved when the stage is brought into the desired position of

specimen, it is necessary to adjust the wire tension of stage.

1)

Take off the mechanical stage (A) from the plane stage (B)

by removing the two screws (*1).

75

70

60

50

(B)

(A)

100

110

(B)

120

130

140

150

160

17

30

20

10

0

OLYMPUS

CX21

(a)

*1

2) 3)

Remove the specimen holder (C) from the

inner guide (D).

Screw: 3PSK2X4SA (*2), 3pcs.

*2

(D)

*1

(A)

arrow view (a): bottom

*1: Fixing screws of mechanical stage

Screw: AB3X10SA (*1), 2 pcs.

Remove the Y-cover (E).

Screw: CUTB3X8SA (*3), 3pcs.

<indicated by arrows>

Y-wire

X-wire

(E)

(C)

*3

* For the tension adjustment of Y-wire,* For the tension adjustment of X-wire,

refer to next page. refer to next page.

- 14 -

CX21 MAINTENANCE MANUAL REPAIR PROCEDURE

2-2 Adjustment method for the tension of X-wire

(B)

(C)

(B)

(a)

< Fig. 1 >

(A)

(D)

*1

1) Loosen the screws (*1) securing the holder

(A).

Screws: CUK 3X6SA (*1) 2pcs.

2) Adjust the tension of the X-wire (B) by

moving the holder (A) in arrow directions as

shown in the left figure.

3) Temporarily tighten the screws (*1).

4) Check the tension of X-wire if it is too tight or

loose while pushing the X-wire (B) to the

wall (a) in arrow direction. <Fig.1>

If the tension of wire is loose, slip may occur

between the X-knob and X-wire.

Therefore, check that X-knob (C) is rotated

following the movement of guide (D) when

moving the guide in stroke by a hand.

If the tension is too tight and the X-wire does

not come in contact with wall (a) due to no

deflection, it may cause image backlash.

Therefore, confirm it in observation state as

described below.

2-3 Adjustment method for the tension of Y-wire

(C)

(B)

(b)

Confirmation of X/Y-wire tension in observation state :

1) After checking the above condition, Install the mechanical stage to the plane stage in reverse

order of disassembly 1) on page 14, set the microscope at observation state and check that

image is brought into the desired position without backlash (2 microns: with100 X objective).

2) If it is out of standard, repeat the above procedures until the condition is satisfied.

3) In case where the image backlash can not be eliminated, perform the knob tension adjustment

referring to 2-4 on page 16.

*Check that Y-knob (C) is

rotated following the

movement of Y-body-1(D)

when moving the Y-body-1

in stroke by a hand.

*Push the wire (B) to the

wall (b) to check the tension

in the same manner as

X-wire.

(A)

*1

(D)

1) Loosen the screws (*1) securing the holder

(A)

Screws: CUK 3X6SA (*1) 2pcs.

2) Adjust the tension of the Y-wire (B) by

moving the holder (A) in arrow directions as

shown in the left figure.

3) Temporarily tighten the screws (*1).

4) Check the tension of Y-wire if it is too tight or

loose while pushing the Y-wire (B) to the

wall (b) in arrow direction.

- 15 -

CX21 MAINTENANCE MANUAL REPAIR PROCEDURE

2-4 Final adjustment

Image backlash adjustment:

1) Under observation state (with 100X objective), move the stage to the desired image

position by turning the Y-knob (A).

At that stop position, check image backlash.

If it is over 2 microns, conduct the following

adjustment.

2) When adjusting the Y-movement, loosen the

two screws (*1) and turn the Y-knob (A) to

bring backlash within 2 microns.

* After turning the knob and temporarily

tighten the screws, check image backlash in

the observation state. Repeat the

adjustment until image backlash is within the

standard.

(B)

A001

(A)

*1

*2

< Fig. 2 >

Screws: AWU3 X4SA (*1) 2pcs.

3) For the X-movement, adjust image backlash

by turning the X-knob (B) and check it in the

same manner as the Y-knob.

Screws: AWU3 X4SA (*2) 2pcs.

* The tension of X/Y knob becomes heavy or light

by turning the knob as following direction.

<Fig.2>

clockwise counterclockwise

X-knob (B) light heavy

Y-knob (A) heavy light

- 16 -

CX21 MAINTENANCE MANUAL REPAIR PROCEDURE

3. Replacing Grease for Coarse/fine Adjustment Knob Ass’y

If the coarse/fine adjustment knob is not turned smoothly, replace greases on the portions

described below.

(In case where the coarse adjustment knob is not turned evenly or the stage can not be

moved vertically, please contact your Authorized Olympus dealer because it is necessary to

disassemble the left coarse adjustment knob (F) with shaft and/or guide unit.)

< Disassembling coarse/ fine adjustment knob>

1) Remove the fine adj. knob ass’y (A) and fine adj. knob (B) by turning them in arrow

directions.

(In fine adj. knob ass’y, the left fine adj. knob is fixed to the shaft with adhesive,OT1006)

2) Remove the spring washer (C) and washer (D).

3) Remove the fine shaft mount (E) with a spanner while holding the coarse adj. knob (F).

4) Remove the coarse adj. knob (G) by turning it counterclockwise while holding the coarse

adj. knob (F).

5) Remove the tension knob (H) by turning it counterclockwise.

(The washer (I) is attached to tension knob (H) with grease.)

6) Pull out the tension ring (J) while holding the convex part using a plier.

7) Reassemble them in the reverse order.

(For applied portions of greases, refer to the figure on the right below.)

(F)

(A)

A002

OLYMPUS

CX21

clearance

in gear

attachment part

a

Grease

(OT2012)

b

Grease

(OT2006)

Applied part:

(about 20mm)

b

(I)

sliding surface

Grease

(OT2008)

(J)

contact point

of spring

Grease

(OT2006)

a

Grease

(OT2006)

end surface

(G)

- 17 -

groove

and whole

surface

(character

indication

surface)

(E)

(H)

(D)

(C)

Grease

(OT2006)

(B)

A003

CX21 MAINTENANCE MANUAL REPAIR PROCEDURE

the base plate (B).

the circuit board (E).

4. Replacing Circuit Board

4-1 CX21 wiring diagram

(I)

A007

INPUT

100-120/

220-240VAC

50/60Hz

(Inlet)

E

L

Circuit Board

N

U1

1

X12X2

X1/X2 : Binder

X3 : Tube

XDS1

X3

XDS1 : Socket

6V20W

Halogen Lamp

If the lamp is not lit, check if the halogen bulb (6V20W) is broken or lamp socket is burned and

also check that the voltage is being outputted each from (1), (2), (3) using multimeter to identify

the defective part. (Refer to the figure below.)

In case where there is a problem in the circuit board, replace the circuit board as a whole because

the components can not be supplied. Since the rheostat ass’y is incorporated in the circuit board,

the voltage adjustment is not necessary. ( It has been already adjusted: Min. 1.5V or less, Max. 4.5V +/-0.3 )

4-2 Replacement of circuit board / socket

(1) Insert a Allen wrench from the slit of bottom

and loosen the screw (*1) as shown in Fig.1.

Screw : ACU3X5SA (*1), 1pc.

(2) Pull out the dial (A) in arrow direction.

(3) Take off the bottom plate (B) by removing the

screws (*2) indicated by (a) as shown in Fig.1

and Fig.2.

Screws : CUK3X6SA (*2), 5pcs.

Washer : HWB3SA, 1pc.

(only use it on the lower right as show in Fig. 1.)

(4) Remove the spacers (C) by removing the

screw (*3) indicated by (b) as shown in Fig.1

and Fig. 2.

Screws : CUKSK3X6SA (*3), 10pcs.

(Spacer: 5pcs; 2 screws are used in 1 spacer

as shown in Fig.2.)

(5) Remove the ground wire (D) from the bottom

*4

plate (B).

Screw : CUKSK4X6SA (*4), 1pc.

Washer : HWB4SA, (*5), 1pc.

(6) Disconnect the socket cable from the part (2)

by unsoldering it.

(7) Take off the circuit board (E) and replace it.

* If the socket (G) is replaced, remove the screws

(*6) from the socket mount (F), cut the two

binders (H) and remove the tube (I).

(8) Assemble them in reverse order .

(H)

(B)

D

(3)

(G)

A005

< Fig. 1 >

Socket

(H)

A006

D

C

(a)

< Fig. 2 >

*3 (b)

soldering

cable

*6

6V20WHAL

(a)

D-cut surface

*1*2 (a)

slit

(a): screw (*2) for fixing

(A)

A008

(b): screw (*3) for fixing

< 5 pcs. , 5 pcs. on board>

Screw with washer

*3

(b)

(2)

(C)

C

(a)

(b)

D

(F)

D

(a)

*2

(b)

*3

Dial side

Shaft

< 5 pcs. >

(1)

Rheostat ass’y

(E)

A004

(B)

(b)

(b)

(a)

Only use it

on this side.

( refer to Fig.1. )

100-120V /

220-240VAC

(D)

*5

*2

- 18 -

CX21 MAINTENANCE MANUAL REPAIR PROCEDURE

the groove of

5. Replacing Pinion Ass’y of Plane Stage

Grease;

OT2008

Left and right

dovetails

Loosen the stopper

until it removes from

condenser.

Grease;

OT2008

sliding

surface

(D)

(E)

(A)

(B)

*2

Grease;

OT2008

Front side

: Pushing direction

: Adjust the position of

dovetail (C).

*1

(C)

(F)

A009

sliding

surface

(1) Loosen the stopper (A) and remove the condenser (B) downward by turning

the knob (F).

(2) Remove the left dovetail (C) as seen from the front side.

Screws : AB3X8SA, 2pcs. (*1)

(3) Remove the right dovetail (D).

Screws : AB3X8SA, 2pcs. (*2)

(4) Remove the pinion spring (E).

(5) Remove the pinion ass’y (F).

(6) Assemble the reverse order of disassembly.

Note on assembly :

1) Apply grease to the portions shown as the above figure.

2) The right dovetail (D) is mounted by pushing it in the arrow directions.

3) The left dovetail (C) is mounted by pushing it in the upward direction.

At this time, adjust the position of dovetail (C) in the left and right directions so that

the condenser moves smoothly without a play (vertical movement).

- 19 -

CX21 MAINTENANCE MANUAL JIGS AND TOOLS /GREASES

CHAPTER 4

JIGS AND TOOLS / GREASES

1. List of Jigs and Tools

No. Description Ref. page

Cleaning tools 2, 3, 4, 5

*1 Eyepiece for CX21

(It is necessary to set the cross micrometer disk *1.)

Digital multimeter 18

Philips screwdriver 12, 13, 15

Allen screwdriver (2.5mm) 2, 14

Allen wrench (1.5mm) 16

Precision screwdriver 14

Spanner 17

Plier 17

Dust cover

11, 12, 13

*1 Contact your Authorized dealer.

2. List of Greases

No. Description Ref. page

OT2006 Grease (heavy) 17

OT2008 Grease (medium) 17, 19

OT2012 Mo grease 17

- 20 -

CX21 MAINTENANCE MANUAL MAINTENANCE PARTS

CHAPTER 5

MAINTENANCE PARTS

1. List of Maintenance Parts

Index No. Order No. Description Ref. page

*1 CX21 Instruction manual

A001 AE085600 X-knob 16

A002 AW037500 Fine adjustment knob ass’y

A003 AE087300 Fine adjustment knob

A004 DZ320900 Circuit board

A005 DH197500 Socket

A006 DO008200 Binder

A007 DO166600 Tube

A008 AE088000 Dial

*1 6V20W halogen bulb

A009 AW037600 Pinion ass’y 19

17

18

H

The index No. are shown on the figures in “REPAIR PROCEDURE” instead of parts No.

*1 Contact your Authorized dealer.

- 21 -

OLYMPUS OPTICAL CO., LTD

2-3-1, Nishi shinjuku shinjuku-ku, Tokyo, Japan

Issued by Customer Support Dept.

Printed in Japan 2003 06 SK9216

Loading...

Loading...