Page 1

MAINTENANCE MANUAL

CV-160

Page 2

INTRODUCTION

Repair and maintenance of this product requires highly specialized knowledge and techniques.

We recommend that you contact an Olympus service center in your area if a problem develops

with the product. If repairs or modifications are made by personnel not authorized by Olympus,

the warranty is void, and Olympus shall not be liable for damage that occurs to or as a result of

use of the modified product.

Page 3

CONTENTS

1. SPECIFICATIONS

2. CONNECTION DIAGRAM

3. BLOCK DIAGRAM

4. TROUBLESHOOTING

5. DISASSEMBLING/ASSEMBLING PROCEDURE

6. EXPLODED PARTS DIAGRAM

7. PARTS LIST

CONTENTS CV-160

1-1

2-1

3-1

4-1

5-1

6-1

7-1

CONTENTS

Page 4

SPECIFICATIONS CV-160

SPECIFICATIONS

Specifications

Item Specification

1. Applicable scope 1. EVIS100 series scope

2. EVIS130 series scope

3. EVIS140 series scope

4. V series scope

5. EVIS EXERA 160 series scope

6. EVIS EXERA 145 series scope

7. Ultrasonic endoscope(100 series)

Note) Applicable scope cable is MAJ-843 only.

2. Applicable video converter 1. OES video converter

OVC-100

OVC-140

Connectable with OES fiberscopes.

3. Applicable light source unit

4. Applicable monitor 1. Recommended monitor

1 System specifications

5. Applicable keyboard

1. Color system 1. Signal system

2. Monitor standard color

2. Television system

temperature

3. Synchronizing method Synchronizing only with the SYNC signal in CV-160.

1. Video output signal 1. Signal system

2. Light control output signal 1. Output connector

1. EVIS universal light source unit

CLV-U40

2. High intensity light source

CLV-E, CLE-E

3. EVIS EXERA high intensity light source unit

CLV-160, CLE-145

(1) 14” observation monitor

OEV141/142/143

(2) 20” observation monitor

OEV201/202/203

1. CV-160 exclusive keyboard (MAJ-845)

2. Structure

(1) ASCII key layout

(2) Provided with keyboard drip-proof cover (removable).

(3) Mountable on WM-60 series keyboard tray.

(4) Removable from CV-160.

(5) Flat keys and stroke keys are mixed.

(1) NTSC

Primary supply voltage 100V class (North America,

Asia specification 1)

(2) PAL

Primary supply voltage 200V class (Asia specification 2)

Primary supply voltage 200V class (Europe

specification)

1. Color temperature setting

(1) 6500K

(1) VBS composite

(2) Y/C

(3) RGBS

* Simultaneous output of (1), (2) and (3) is possible.

•All specifications: Front scope cable connector and rear light

control connector

3. Input/output conditions

1-1

Page 5

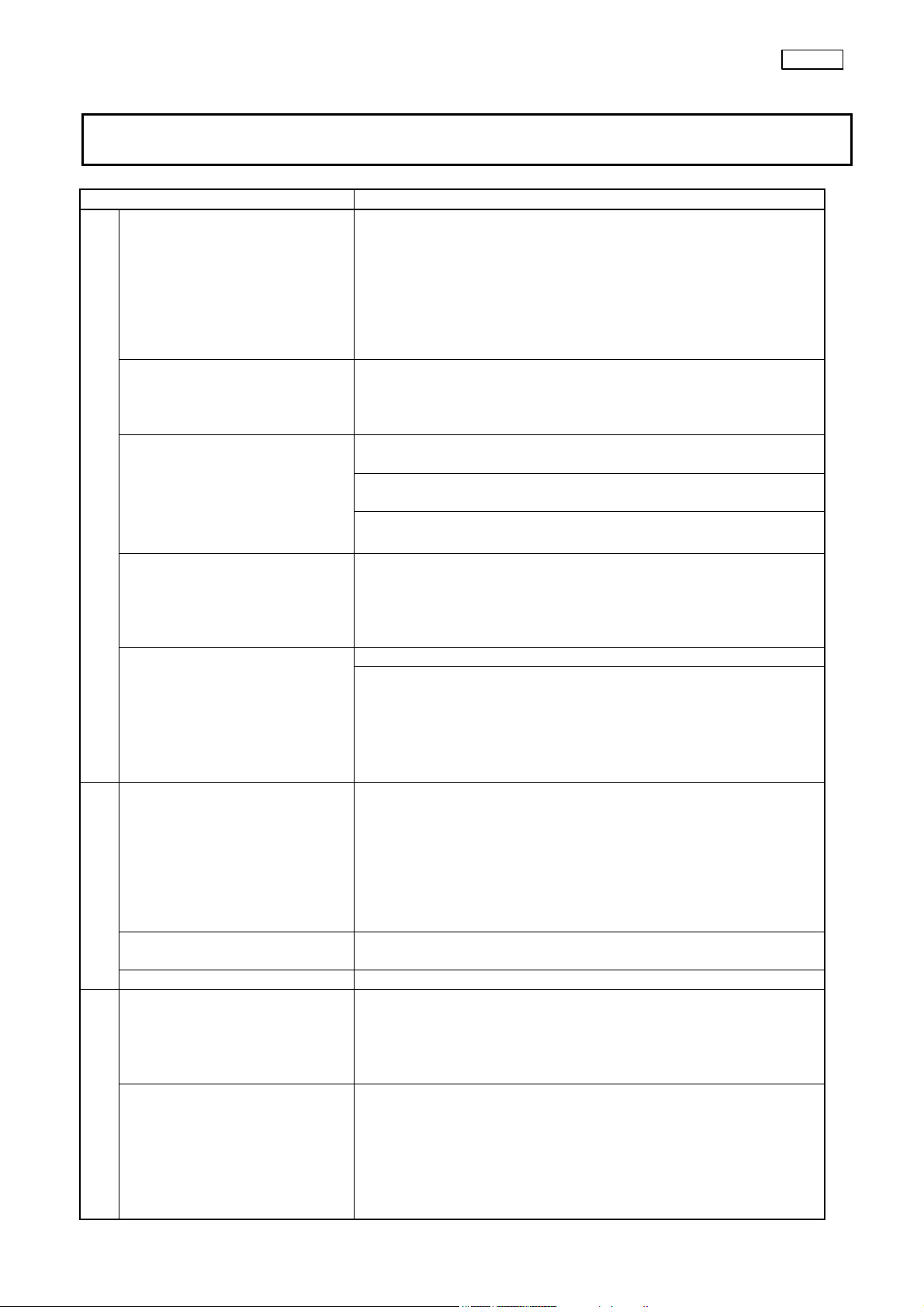

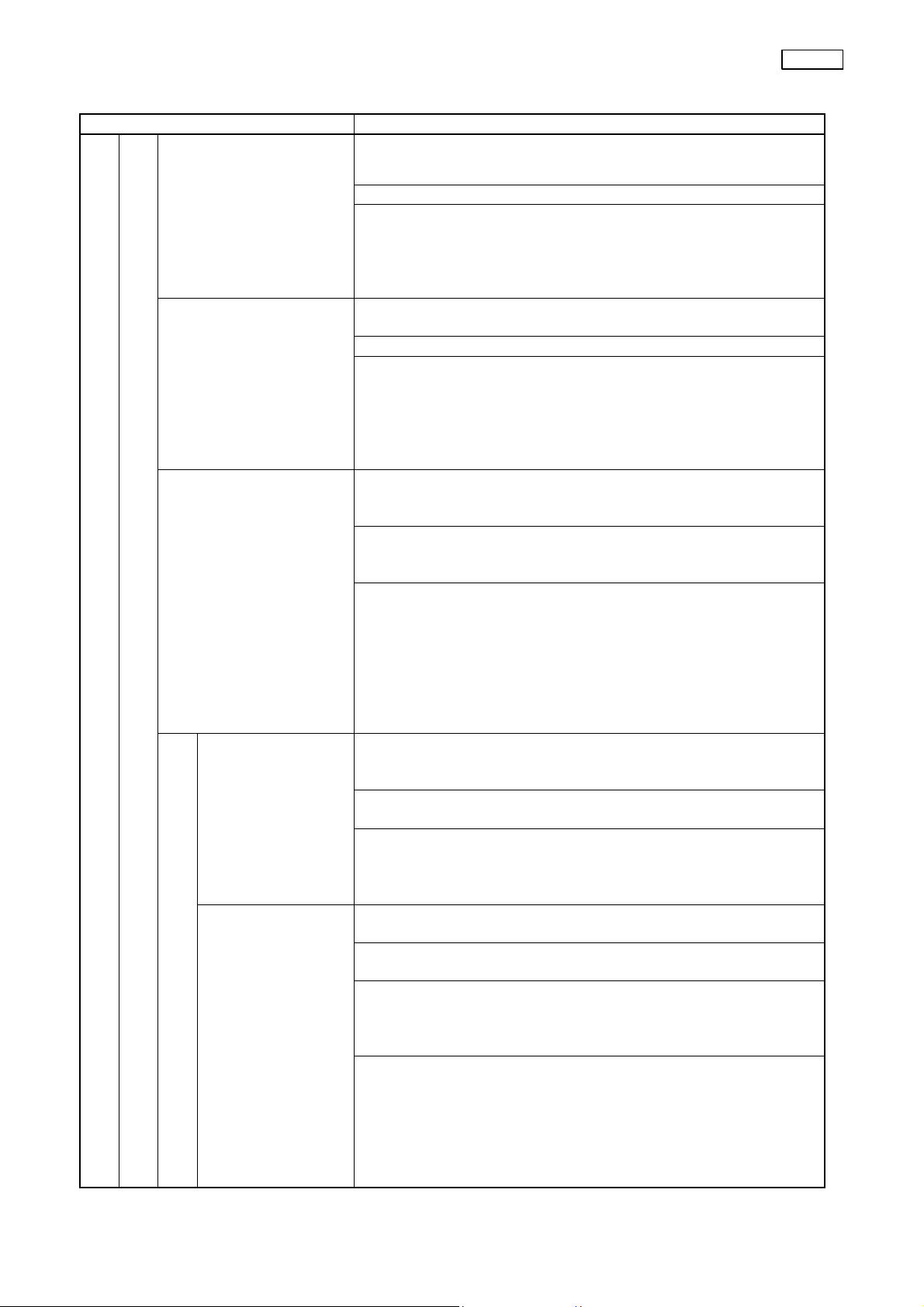

Item Specification

2. Light control output signal 2. Output signal level

The output signal level for the automatic light control of an

applicable light source is defined by the following input

standard.

3. Power supply

3. Input/output conditions

1. Type

(1) 100V class: North America (OAI), Asia 1 (OLA)

(2) 200V class: Europe (OE), Asia 2 (OLA)

2. Rated voltage and input current

(1) 100V class: 100 to 120V, 1.0A

(2) 200V class: 220 to 240V, 0.5A

3. Voltage fluctuation

• The unit performance shall be guaranteed within ±10% of

the rating.

• The unit operation shall be guaranteed within ±15% of the

rating and the temperature increase in ordinary operation

of IEC.

4. Frequency

• 50/60Hz

5. Frequency fluctuation

• The unit performance shall be guaranteed with ±1Hz of

the rating.

6. Power consumption

• 240VA

7. Power cable

(1) 100V class (3 ±0.05m cord set)

3-pin hospital grade plug

(2) 200V class (3.2m cord set)

3-pin plug-less with uneven end

(Attach an appropriate plug in the destination.)

Input signal [mV]

F 30 or more

1 15

2 12.6

3 10.8

4 9.1

5 7.5

6 6.3

7 5.4

8 4.5

9 3.8

10 3.2

11 2.7

12 2.3

13 1.9

14 1.6

15 1.4

16 1.2

17 0.95

SPECIFICATIONS CV-160

1-2

Page 6

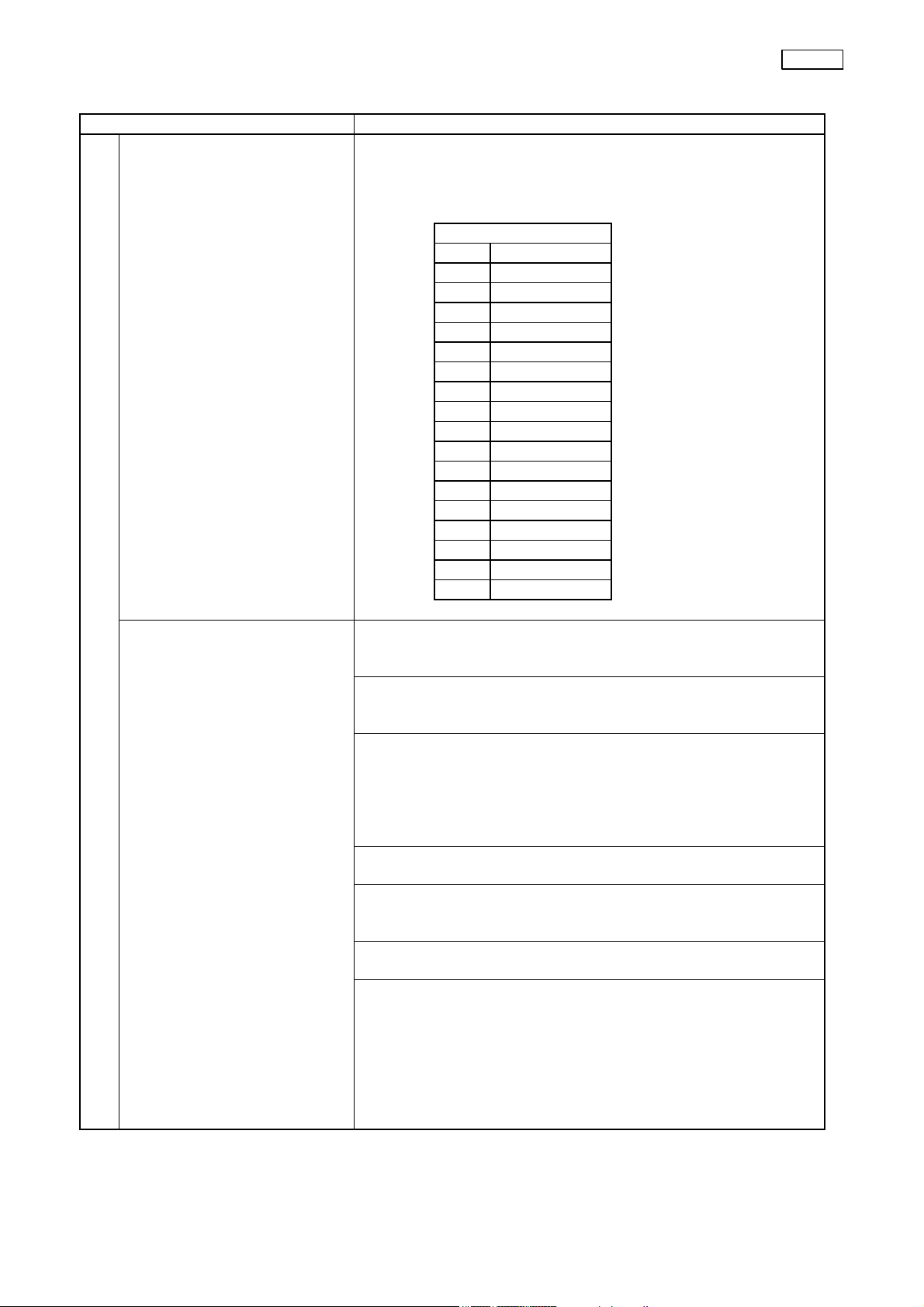

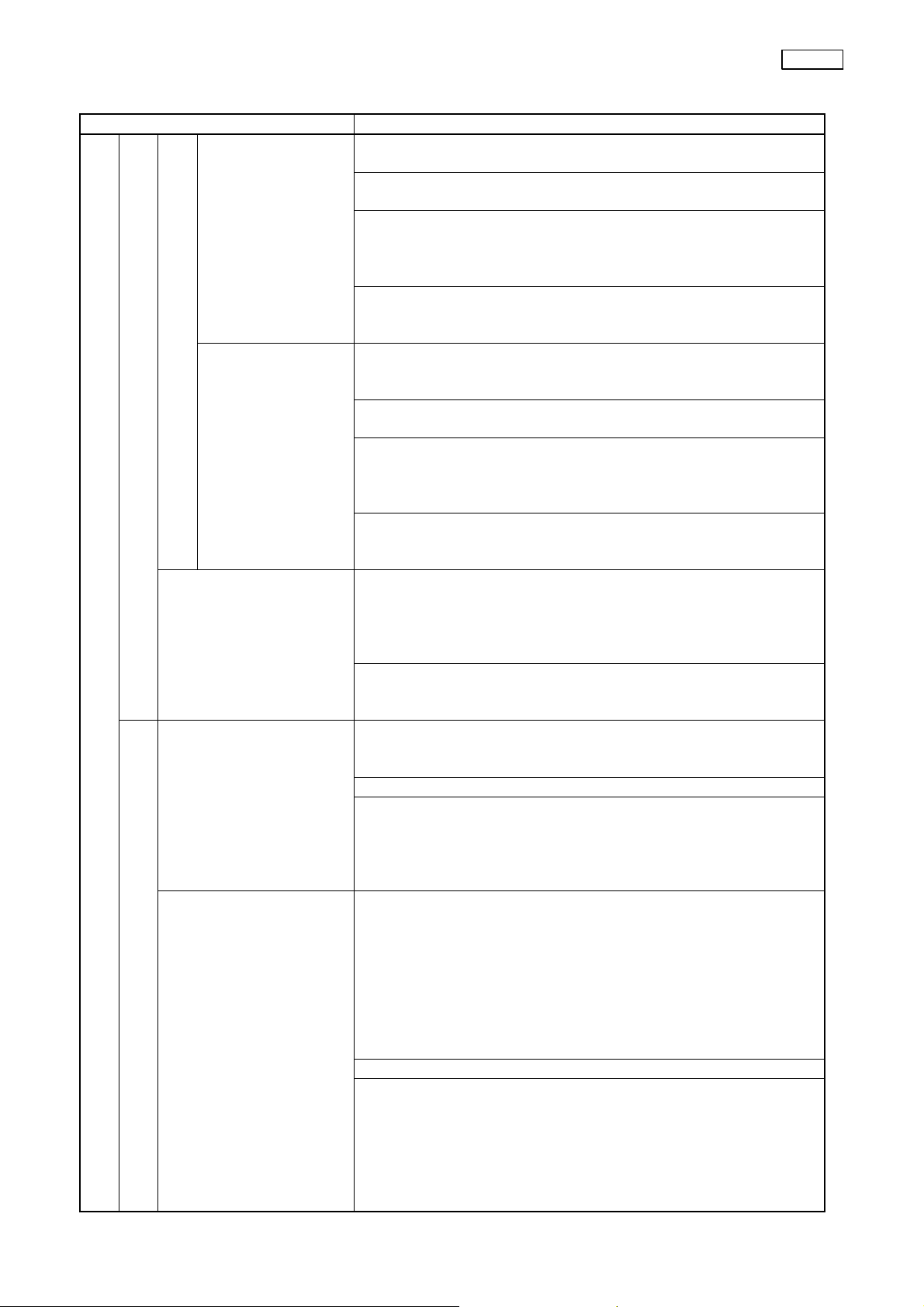

1. Type of observation

1. Observation image display position

1. White balance

4. Observation

2. Front panel picture quality adjustment

SPECIFICATIONS CV-160

Item Specification

The user can select the endoscopic image display size from the

image

followings depending on the scope (CCD) applied.

North America specification (NTSC) Europe specification (PAL)

CCD 3700,01,08 3704 37071 3700,01,08 3704 37071

Display

size

2 steps

Medium

↓

Full-height

1 step

Full-high

only

2 steps

Semi

full-height

↓

Full-height

2 steps

Small

↓

Medium

2 steps

Small

↓

Medium

3 steps

Medium

↓

Semi

full-height

↓

Full-height

Note 1)

Change the display size on the keyboard or with the scope

switch or RS-232C communication.

Note 2)

Standard setting is as follows.

• 3700/01/08: NTSC = Medium

PAL = Medium

• 3704: NTSC = Full-height

PAL = Semi full-height

• 37071: NTSC = Small

PAL = Small

1. Specifications

• When replacing the scope with a different type,adjust the

white balance using the supplied white cap.

• A memory function is provided to hold the previous white

balance data even if the power switch is turned off.

• Calibrate the white balance automatically if the scope

with the scope ID function (EVIS EXERA 160 series) is

connected to the CV-160.

Note) It is necessary to calibrate manually again if the light

source changed.

2. Setting method

• Select the type of light source(xenon=CLV/halogen=CLE)

on the system setup screen.

• Depress the white balance switch on the front panel.(It is

not necessary for scopes with the scope ID function.)

3. Switch depression detection time

• Approx. 1 second

4. Time required by correction operation

• Approx. 1 second

1-3

Page 7

2. Automatic light

3. Edge enhancement

4. Structure

4. Observation

2. Front panel picture quality adjustment

Item Specification

1. Specification

control

enhancement

1. Selection of

adjustment

color

2. Red group color

adjustment

(when R is

selected)

5. Color tone adjustment

• Switch the peak/average iris mode depending on a subject.

2. Standard setting: Average

3. Setting method

(1) Switch on the front panel

(2) Scope switch

(3) RS-232C communication

Note) Assign the scope switch on the user preset screen.

1. Specification

A subject image is enhanced in three steps (Low/Med./High).

2. Standard setting: Low

3. Setting method

(1) Set the edge enhancement mode (Enh.Type: Edg.) on

the user preset screen.

(2) Switch on the front panel

(3) Scope switch

(4) RS-232C communication

1. Specification

A subject image is enhanced in three steps

(Low/Med./High).

2. Standard setting

The standard setting of each level:

Low:Level1, Med.:Level3, High:Level5

3. Setting method

(1) Set the structure enhancement mode (Enh.Type: Str.)

on the user preset screen.

(2) Select the set value (Level 0 to 8) for each enhancement

level (L/M/H) on the user preset screen.

(3) Switch on the front panel

(4) Scope switch

(5) RS-232C communication

1. Specification

Desired color can be selected.

(Select from four types of R, B, C and Light off.)

2. Standard setting

Light off (not selected)

3. Setting method

Color tone selector switch on the front panel

(Each time the switch is depressed, the color is changed in

the order of R, B, C, Light off and R.)

1. Specification

Color tone of red group can be adjusted.

2. Standard setting

Center of the variable range (±0 step)

3. Setting method

(1) Adjust with the color tone adjustment switch on the

front panel.

(2) Adjust with RS-232C communication.

4. Variable range

±7 steps

(LED indicates step values on the front panel.)

SPECIFICATIONS CV-160

1-4

Page 8

2. Front panel picture quality adjustment

6. Reset switch

4. Observation

1. AGC

2. γ (contrast)

3. Other picture quality adjustment

Item Specification

3. Blue group

color

adjustment

(when B is

selected)

4. Color density

adjustment

(when C is

selected)

5. Color tone adjustment

1. Specification

Color tone of blue group can be adjusted.

2. Standard setting

Center of the variable range (±0 step)

3. Setting method

(1) Adjust with the color tone adjustment switch on the

front panel.

(2) Adjust with RS-232C communication.

4. Variable range

±7 steps

(LED indicates step values on the front panel.)

1. Specification

Color density (chroma) can be adjusted without changing the

hue.

2. Standard setting

Center of the variable range (±0 step)

3. Setting method

(1) Adjust with the color tone adjustment switch on the

front panel.

(2) Adjust with RS-232C communication.

4. Variable range

±7 steps

(LED indicates step values on the front panel.)

1. Specification

The output image to the observation monitor is changed to

the scope image, and the light control, edge/structure

enhancement and color tone and contrast etc. are set on

User Preset 1.

2. Setting method

Press the reset switch on the front panel. (Depress the

switch more than 1 second)

1. Specifications

Turn ON/OFF as needed, depending on the endoscopic

image.

2. Standard setting: ON

3. Setting method

(1) Switch with the keys (Shift + F2 key) on the keyboard.

(2) Switch with the scope switch.

(3) Switch with RS-232C communication.

Note) Assign the scope switch on the user preset screen.

1. Specifications

Selectable from the three modes.

Normal :Ordinary observation

Low :Low contrast mode

(Brighten the dark portion, and darken the bright

portion.)

High :High contrast mode

(Brighten the bright portion, and darken the dark

portion.)

2. Standard setting: ON

3. Setting method

(1) Select with the keys (Shift + F5 key) on the keyboard.

(2) Switch with the scope switch.

(3) Switch with RS-232C communication.

Note) Assign the scope switch on the user preset screen.

SPECIFICATIONS CV-160

1-5

Page 9

3. Freeze

3. Other picture

quality adjustment

1. Display area change

(Electric

function

4. Image display

1. Standard chart image

4. Observation

5. Picture quality

2. Selection of output

5. Input/Output switching function

1. Luminance

1. Resolution

Item Specification

1. Specifications

Make a moving image a still image.

(Field freeze system)

2. Setting method

(1) Freeze with the freeze switch on the keyboard.

(2) Freeze with the scope switch.

(3) Freeze with RS-232C communication.

Note) Assign the scope switch on the user preset screen.

1. Specifications

(1) The observing image size is selectable.

magnification)

output

signal to the monitor

Horizontal resolution

(Magnify in the

horizontal direction

so that the aspect

ratio (H:V) becomes

4:3 with the vertical

magnification rate of

1X, and adjust the

view angle.)

2. Setting method

(1) Set with the switch (Function key F5) on the keyboard.

(2) Change with the scope switch.

(3) Change with RS-232C communication.

Note) Assign the scope switch on the user preset screen.

1. Specifications

100% Color bar is displayed on the screen for adjustment of

the monitor.

2. Setting method

(1) Select with the key (Function key F2) on the keyboard.

(2) Select with RS-232C communication.

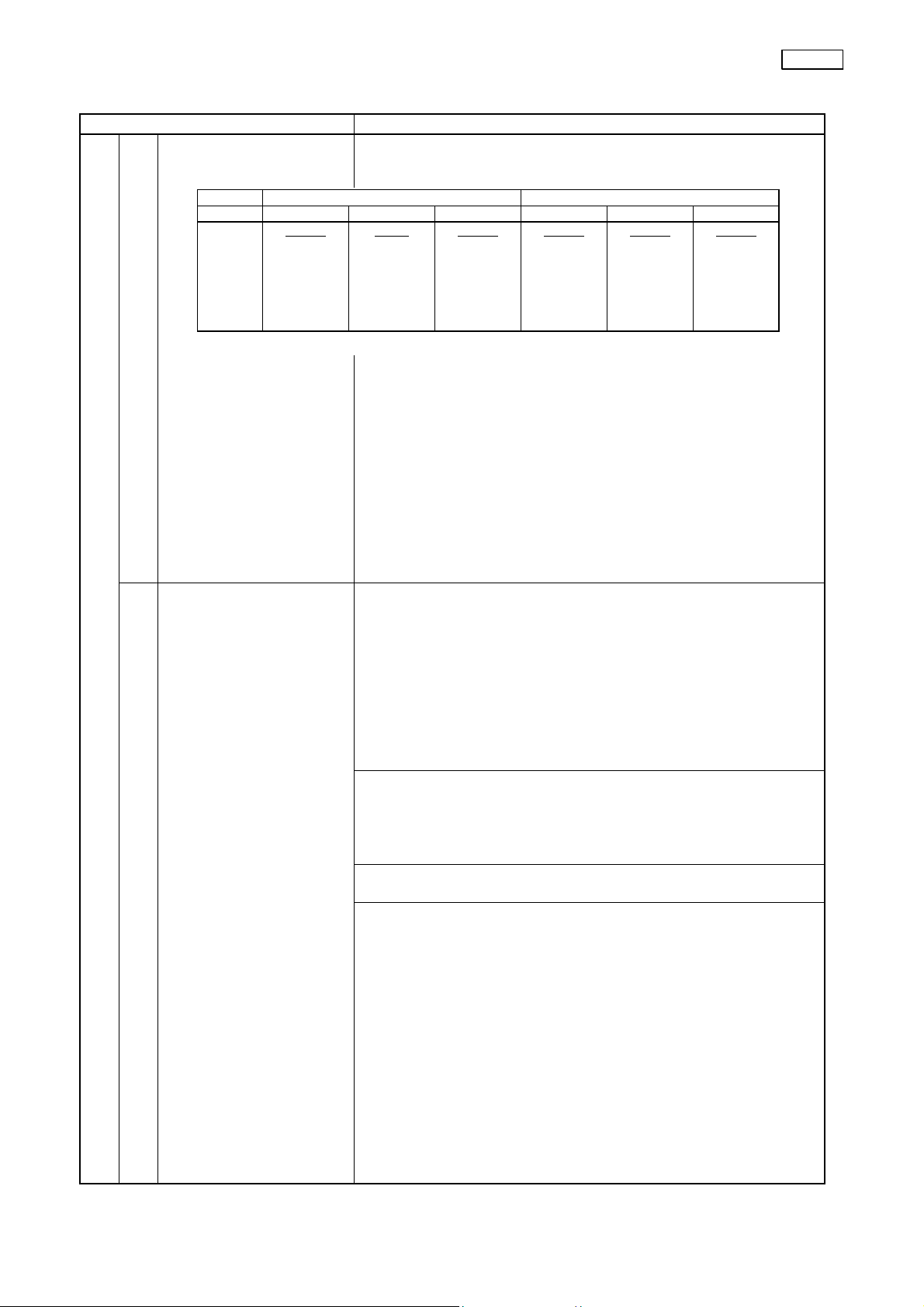

1. Specifications

(1) Select the signal to the monitor from the inputs (scope,

printer, VTR and digital file).

2. Setting method

(1) Select with the switch on the front panel (Image

Source).

(2) Select with RS-232C communication.

SOURCE

SCOPE

PRINTER

VTR

D.F.

・The scope image is displayed at marked ×.

・Switching the monitor image is controlled by the monitor

remote signal.

Near the center:

1. 3700/01/08

(1) Composite signal, RGB signal, Y/C signal outputs

(240TV lines or more)

2. 3704

(1) Composite signal output

(350TV lines or more)

(2) RGB signal, Y/C signal outputs

(400TV lines or more)

3. 37071

(1) Composite signal, RGB signal, Y/C signal outputs

(400TV lines or more)

Output to the monitor IMAGE

RGB Y/C VBS

○ ○ ○

× × ○

× ○ ○

○ × ×

SPECIFICATIONS CV-160

1-6

Page 10

Item Specification

2. Luminance

Vertical resolution

(Magnify in the

horizontal direction

so that the aspect

ratio (H:V) becomes

1. Resolution

5. Picture quality

2. S/N 1. (37dB or more)

1. Registration and access of

2. Recording and displaying

6. Recording

4:3 with the vertical

magnification rate of

1X, and adjust the

view angle.)

patient data

of patient data

Near the center:

1. 3700/01/08

(1) Composite signal, RGB signal, Y/C signal outputs

2. 3704

(1) Composite signal, RGB signal, Y/C signal outputs

3. 37071

(1) Composite signal, RGB signal, Y/C signal outputs

[Conditions]

AGC: OFF

Contrast: Normal

Image enhancement: Edge enhancement (Low)

1. Specifications

40 patient data can be registered and accessed.

2. Setting method

Input from the keyboard on the patient data screen.

3. Input items

(1) ID No.

(2) Patient name

(3) Sex and age

(4) Date of birth (Date of inspection is automatically

1. Specifications

The patient data to register, the comment to input after

registration, the number of video print, etc. can be displayed

on the screen.

2. Setting method

(1) Input from the keyboard.

(2) Input with RS-232C communication.

3. Display items

(1) ID No.

(2) Patient name

(3) Sex and age

(4) Date of birth

(5) Date of inspection, time (stopwatch)

(6) Comment

(7) Dr. name

(8) (Video print number/divided number)

(9) (Image enhancement mode: Enhance level)

(10) (Contrast mode)

Note) Only the item in ( ) is indicated.

(320TV lines or more)

(320TV lines or more)

(320TV lines or more)

displayed.)

SPECIFICATIONS CV-160

1-7

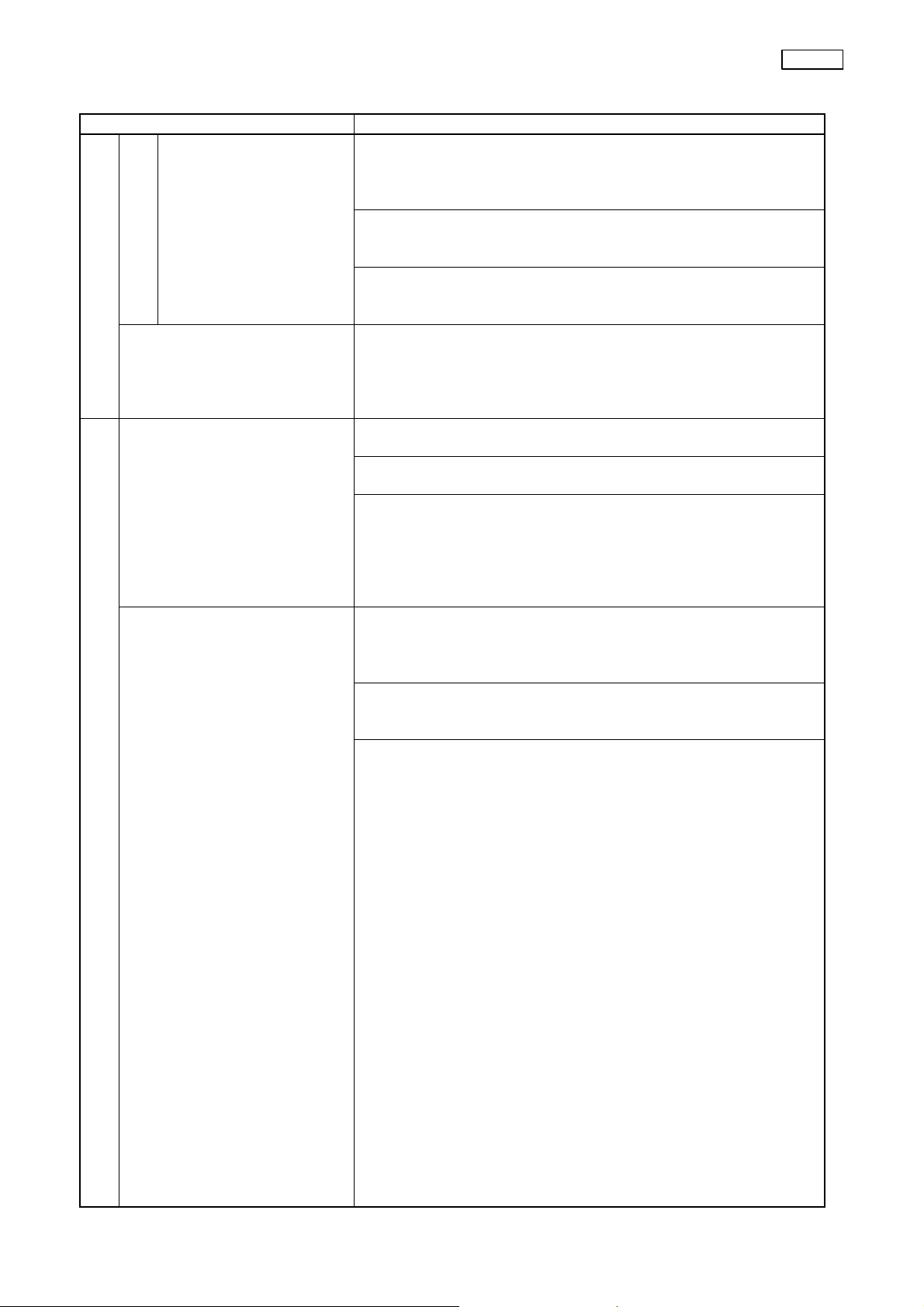

Page 11

Item Specification

3. Control of the recording

unit (video printer)

6. Recording

1. Specifications

(1) #PER PAGE

The dividing mode of the video printer connected to the

CV can be switched to 1/2/4/N (N: User setting) mode.

(2) DEL IMAGE

Delete the divided image stored in the printer, then

return the cursor to the previous position.

(3) PRINT

Print out the image stored in the printer.

(4) PRINT QTY.

The number of prints can be switched to 1/2/4/N(N:User

setting) mode.

(5) Data can be stored also during printing. Print image can

be confirmed.

Note) Print out automatically after capturing the images set

up in (1).

2. Setting method

(1) Select the type of printer.

(2) Control with the exclusive key(PRINTER REMOTE) on

the keyboard.

3. Applicable video printer

* NTSC:

OEP (OLYMPUS)

OEP-3 (OLYMPUS)

UP-2900MD (SONY)

UP-2950MD (SONY)

[UP-1800 (SONY)]

[UP-1850 (SONY)]

[UP-5000MD (SONY)]

[UP-5200MD (SONY)]

[UP-5250MD (SONY)]

* PAL:

OEP (OLYMPUS)

UP-2800P (SONY)

UP-2850P (SONY)

[UP-1800 EPM(SONY)]

[UP-1850 EPM (SONY)]

[UP-5000MDP (SONY)]

[UP-5200MDP (SONY)]

[UP-5250MDP (SONY)]

UP-2100P

Note) [ ] Products already sold.

Remote cable: MH-995 (RS-232C)

MAJ-854 (X-contact)

SPECIFICATIONS CV-160

1-8

Page 12

SPECIFICATIONS CV-160

Item Specification

4. VTR recording/playback

control

6. Recording

5. Release continuous

recording

1. Scope Connect the scope and CV-160 with the scope cable(MAJ-843).

2. OES video converter Can be directly connected to the CV-160.

7. Connection

1. Display (1) English 100 to 120V: NTSC (OAI, OLA 1)

2. Structure Dripproof required as medical equipment.

8. Panel

1. Specifications

The following operations are possible from the exclusive key

on the keyboard, RS-232C and scope switch for the VTR

connected to the CV.

• Recording(REC)

• Playback(PLAY)

• Stop(STOP)

• Fast forward(FWD)

• Rewind(REW)

• Pause(PAUSE)

• Fast forward during playing (RS-232C control only)

• Rewind during playing (RS-232C control only)

2. Setting method

(1) Use the exclusive key on the keyboard.

(2) Use the scope switch.

Note) Scope switch can control [REC/REC_PAUSE] only.

(Scope switch is assigned to [VTR]).

3. Applicable VTR

* NTSC

VO-7600 (SONY)

VO-9600 (SONY)

SVO-9500MD (SONY)

[BR-S611 (JVC)]

[BR-S811 (JVC)]

* PAL

VO-7630 (SONY)

VO-9600P (SONY)

SVO-9500MDP (SONY)

[BR-S611E (JVC)]

[BR-S811E (JVC)]

1. Specifications

Release of each connected unit can be controlled from the

CV-160.

2. Setting method

(1) Release with the scope switch.

(2) Release from the keyboard.

Note) Assign the scope switch on the user preset screen.

3. Controllable units

(1) Applicable video printers

(2) Applicable digital files

220 to 240V: PAL (OLA 2)

(2) Symbol 220 to 240V: PAL (OE)

1-9

Page 13

SPECIFICATIONS CV-160

Item Specification

3. Storage (1) Storage items

Color tone set value

Image enhancement level

8. Panel

1. Panel To remove dust, dirt, and non-patient debris, wipe the unit

9. For cleaning

1. Laws and regulations

applied

10. Safety

Iris mode,

White balance data.

using a soft, lint-free cloth moistened with 70% ethyl or

isopropyl alcohol. If the unit is soiled with blood or other

potentially infectious materials, first wipe off all gross debris

using neutral detergent and then decontaminate its surface

using lint-free cloth moistened with 70% ethyl or isopropyl

alcohol.

Country/area

1. EU/FETA MDD Class: Class I

3. Japan/

Korea

Classification of medical

instruments

OAI/Asia Protection type against an

Laws and

regulations applied

Medical Equipment

Safety Laws (510K)

UL/C-UL UL544

The Drugs,

Cosmetics and

Medical

Instruments Act

General name:

Light source,

processor

Approval No.

07BZ0043

Standards to be

conformed to

EN 60601-1

EN 60601-1-1

EN 60601-1-2

EN 60601-1-2-18

IEC 513

IEC 529

ISO 9000-3

ISO 3740

ISO 8600-1

ISO 8600-1.3

Class: Class II 2. USA

CSA22.2 No. 125

JIST1001 (medical

electronics safety)

JIST1002 (medical

electronics safety test)

electrical shock: Class I

Protection level against

an electrical shock: BF

type

1-10

Page 14

Item Specification

1. Laws and regulations

applied

10. Safety

1. Dimensions (maximum

outer dimensions)

2. Weight 8kg

3. Standard setting of

display/function

11. Others

SPECIFICATIONS CV-160

EU area (OE) Protection type against an

electrical shock:

Class I

Protection level against

an electrical shock:

BF type

Note) When the fitting

part has no

indication of

protection level

against an electric

shock, it is the BF

type fitting part.

370 (W) × 72 (H) × 420 (D) mm

Front panel

Front Panel

Function/dis

play

Image

selection

(IMAGE

SOURCE)

IRIS AVE

ENH L

R ±0 ±0 Stored

B ±0 ±0 Stored

C ±0 ±0 Stored

SELECT Not selected Not selected Not selected

WB – (Cleared) Stored Stored

Factory

setting

SCOPE SCOPE SCOPE

Reset Power ON

User Preset1

IRIS

User Preset1

ENH.Pos.

Stored

Stored

1-11

Page 15

3. Standard setting of

display/function

11. Others

SPECIFICATIONS CV-160

Item Specification

System Setup

System setup

Function/dis

play

[Printer]

Type

Qty.,”N”

Caption

[Release

Time]

Printer

D.F.

[Clock]

Date

Time

Disp.

[Patient

Data]

[Remote

Control]

Mon. Type

Mon. VTR

VTR

[Light

Source]

[Network]

Use DHCP

IP Address

Net Mask

Factory

setting

OEP

4

– (Cleared)

0.5

2

Note 1

Note 1

Note 1

Resume Stored Stored

OEV2

S-Video

RS-232C

CLV Stored Stored

No

Note 2

255.255.255.0

Reset Power ON

Stored

Stored

Stored

Stored

Stored

Stored

Stored

Stored

Stored

Stored

Stored

Stored

Stored

Stored

Stored

Stored

Stored

Stored

Stored

Stored

Stored

Stored

Stored

Stored

Stored

Stored

Stored

Stored

Note 1) Set to the local time on shipment.

Note 2) The high order 3-byte of the initial IP address is

192.168.0. The lower order 1-byte is the fixed value

for each CPU number.

User Preset

Function/display

[Scope Switch]

Switch1

Switch2

Switch3

Switch4

[Image Size]

160

Q160

XP160

[Image Control]

User Preset

Iris

AGC

Contrast

Enh.Pos.

Enh.Type

Enh.Low

Enh.Med.

Enh.High

Factory

setting

Freeze

Iris

Enhance

Release

Medium

Semi-Full

Small

Ave

On

Normal

Low

Str.

1

3

5

Reset Power ON

Stored

Stored

Stored

Stored

Stored

Stored

Stored

Stored

Stored

Stored

Stored

Stored

Stored

Stored

Stored

Stored

Stored

Stored

Stored

Stored

Stored

Stored

Stored

Stored

Stored

Stored

Stored

Stored

Stored

Stored

1-12

Page 16

3. Standard setting of

display/function

11. Others

SPECIFICATIONS CV-160

Item Specification

Patient Data

Function/display

ID No.

Name

Sex

D.O.Birth

Age

Patient Data

Phy.Name

Factory

setting

Cleared

Cleared

Cleared

Cleared

Cleared

Cleared

Reset Power ON

Stored

Stored

Stored

Stored

Stored

Stored

Stored

Stored

Stored

Stored

Stored

Stored

Scope Info.

(1) For the user

Function/display

[Scope Infomation]

Scope Model

Serial No.

Comments

Cumulative Uses

Check Period

Service Contract

Warranty Date

Scope Information

Owner

Customer ID No.

ID Ver.

Factory

setting

Stored

Stored

Cleared

Cleared

180

Cleared

Cleared

Cleared

Cleared

Cleared

Reset Power ON

Stored

Stored

Cleared

Stored

Stored

Stored

Stored

Stored

Stored

Stored

(Data read

out from

the scope)

(2) For service

Function/display

[Scope Infomation]

Scope Model

Serial No.

Comments

Cumulative Uses

Check Period

Service Contract

Warranty Date

Owner

Customer ID No.

ID Ver.

Mfg. Comments

Ctrl+Shift+Scope Information

Service Comments

Repair Info.

Checkup Info.

Factory

setting

Stored

Stored

Cleared

Cleared

180

Cleared

Cleared

Cleared

Cleared

Cleared

Cleared

Cleared

Cleared

Cleared

Reset Power ON

Stored

Stored

Cleared

Stored

Stored

Stored

Stored

Stored

Stored

Stored

Stored

Stored

Stored

Stored

(Data read

out from the

scope)

* Press the Ctrl + Shift + Scope Info. keys on the keyboard to

shift from the Scope Information screen to the above screen.

1-13

Page 17

3. Standard setting of

display/function

11. Others

SPECIFICATIONS CV-160

Item Specification

Hidden screen

Function/display

[Shipping]

Country

[Printer]

Print Time

Auto Clear

[Color]

Mon.Red

Mon.Blue

Prt.Red

Prt.Blue

[Clock]

Total

Trim

Ctrl+Shift+Systemsetup

[CPU Board]

Serial No.

[Video Board] – Stored Stored

[Pat.Board]

Iris spd.

Iris L

Iris D

Factory

setting

Destination Stored

40

ON

±0

±0

±0

±0

–

±0

-

–

Med.

1

1

Reset Power ON

Stored

Stored

Stored

Stored

Stored

Stored

Stored

Stored

Stored

Stored

Stored

Stored

Stored

Stored

Stored

Stored

Stored

Stored

Stored

Stored

Stored

Stored

Stored

Stored

Stored

Press the Ctrl + Shift + System Setup keys on the keyboard to

shift from the System Setup screen to the above screen.

1-14

Page 18

1

OLYMPUS

2

3

4

5

8

9

10

11

12

VTRREMOTE

123456789

101112131415161718

A A

YOUTVTR

NOUTVTR

COUTVTR

YINVTR

NINVTR

CINVTR

(NC)

VTR6V

PLAYCMD

FFCMD

RECCMD

STOPCMD

REWCMD

PAUSECMD

(J1)

20212223242526272829303132333435363738394041424344454647484950515253545556575859606162

19

STOPLVL

REC239

TXDVTR

RTSVTR

DSRVTR

(NC)

(NC)

(NC)

(NC)

(NC)

(NC)

(NC)

(NC)

(NC)

(NC)

(NC)

(NC)

(NC)

(NC)

(NC)

(NC)

(NC)

(NC)

(NC)

(NC)

(NC)

(NC)

(NC)

GND

GND

GND

GND

GND

GND

GND

(J2)

(J3)

GND

PLAYTAL

FFTAL

RECTAL

STOPTAL

REWTAL

PAUSETAL

TAL239

RXDVTR

CTSVTR

DTRVTR

(NC)

(NC)

UPCV16PNDF

(J2)

NCNCNCNCGND1DF

RXDDF

123456789

TXDDF

CTSDF

RTSDF

DTRDF

GND2DF

101112131415161718

DSRDF

RELDF

DMR2DF

GND3DF

UPCV16PNRP

PRIMARY

B B

SECONDARYCIRCUIT

C C

CIRCUIT

+12V

GND

121

2

DCFAN

YOUTVTR

GND

NOUTVTR

GND

COUTVTR

GND

YINVTR

123456789

GND

NINVTR

GND

CINVTR

GNDNCNCNCNCNCNC

101112131415161718

NC

GND

GND

VTR6V

PLAYCMD

PLAYTAL

FFCMD

123456789

FFTAL

RECCMD

RECTAL

STOPCMD

STOPTAL

REWCMD

REWTAL

PAUSECMD

101112131415161718

PAUSETAL

STUPLVL

TAL239

REC239

GND

20212223242526

19

RXDVTR

TXDVTR

CTSVTR

RTSVTR

DTRVTR

DSRVTR

POWER

SUPPLY

PATIENTCIRCUIT

D D

R‑EESIG

R‑EEGND

R‑EE+5V

ABC

123

4

R‑EEGND

R‑EE+5V

GND

UPCV16AP

(J202)

GND

CCDSIG

GND

4

4

3

VOUT

1234567

+8V

GND

‑10.5V

‑15V

GND

(J200)

SW1

SW2

SW3

SW4

COM(+5V)

LIVE1

123456789

123456789

BRN

23

SW1

F‑EE

RED

ORN

YEL

PNK

BLU

24

22

30

13

14

11

SW2

SW3

SW4

COM

KENCHI

EE+

CONNECTORBROCKU

+19V

GND

12

EE‑

+5V

WHT

SCID

PRP

26

SCOPEID

(J201)

φR

GND

φH2

LIVE3

123456789

10

123456789

10

18596

LIVE3φRNC

φH2NCφH1

GND

φH1

10

GND

φV1

GND

φV3

GND

φV2

GND

φV4

101112131415161718

101112131415161718

29

2119202827

φV1

GNDφV1

φV3

GNDφV3

φV2

GNDφV2

GND

φVSUBVL+15V.CCD

GND

BRN

RED

YEL

BLK

7

2

18

17

16

φV4

GNDφV4

φVSUBVL+15VCCD

15

GND

GND.P

GND.P

25

GND.P

GND

GND

#FFPCLR

FPDATA

FFPCLK

#FFPSTB

FPDOUT

DMY

GND

CAPACITOR1603EU

GND

+5V

+5V

+5V

+5V

GND

GND

GND

GND

PANEL

SHEET160

FLED

GND

FERRITE

GND

+5VP

GND

2PCLK

GND

PCLK

GND

+5VF

GND

+5VF

(J205)

GND

AD9

GND

AD8

GND

AD7

GND

AD6

(J207)(J2)

FLAT

CORE

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

1

2

GND

GND

#FFPCLR

FPDATA

FFPCLK

#FFPSTB

FPDOUT

DMY

GND

GND

+5V

+5V

+5V

+5V

GND

GND

GND

GND

12FLED

GND

(J1)(J1)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

1

1

2

2

AD5

AD4

AD3

AD2

AD1

AD0

FPDIN

FPCK

FPDOUT

#FPCLR

OVD

PTCLK

PTDIN

PTDOUT

IDRX

IDTX

CJD4

CJD3

CJD2

CJD1

CJD0

VRTIM

(J206)

UPCL16ZZ

CORE

10

10

9

9

8

8

7

7

6

6

5

5

4

4

3

3

2

2

1

1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

FLAT

CORE

E E

12341234567

R‑EESIG

(J204)

F F

LIVE2/DMY

(J203)

123

123

G G

4

H H

VDMY

NC(TXDSCV)

ENDE

DATEDF

(J1)

NC

18

NC

17

NC

16

NC

15

NC

14

NC

13

GND

12

CINVTR

11

GND

10

NINVTR

9

GND

8

YINVTR

7

GND

6

COUTVTR

5

GND

4

NOUTVTR

3

GND

2

YOUTVTR

1

1

+5V

1

2

GND

2

1

+6VA

1

2

GND

2

3

‑5VA

3

1

1

+5VP

2

2

GND

3

3

2PCLK

4

4

GND

5

5

PCLK2

6

6

GND

7

7

+5VF

8

8

GND

9

9

+5VF

GND

10

10

1

GND

2

AD9

3

GND

4

AD8

5

GND

6

AD7

7

GND

8

AD6

9

AD5

AD4

10

AD3

11

AD2

12

AD1

13

AD0

14

FPDIN

15

FPCK

16

FPDOUT

17

#FPCLR

18

OVD

19

PTCLK

20

PTDIN

21

PTDOUT

22

IDRX

23

IDTX

24

CJD4

25

CJD3

26

CJD2

27

CJD1

28

CJD0

29

VRTIM

30

GND1DF

TXDDF

RISDF

GND2DF

RELDF

GND3DF

ENDF

RXDDF

CTSDF

DTRDF

DSRDF

DMR2DF

NC(TXDSCV)

DATADF

1

2

3

4

5

6

7

8

9

10

11

12

13

14

(J9)

(J5)

(J4)

(J2) (J1)

DFREMOTE

DATEDF

18

ENDF

17

NC(TXDSCV)

16

GNDDF

15

DMR2DF

14

DMR1DF

13

DSRDF

12

GNDDF

11

DTRDF

10

RTSDF

9

CTSDF

8

TXDDF

7

RXDDF

6

GNDDF

5

NC

4

NC

3

NC

2

NC

1

DSRVTR

26

DTRVTR

25

RTSVTR

24

CTSVTR

23

TXDVTR

22

RXDVTR

21

GNDVTR

20

REC239

19

TAL239

18

STUPLVL

17

PAUSETAL

16

PAUSECMD

15

REWTAL

14

REWCMD

13

STOPTAL

12

STOPCMD

11

RECTAL

10

RECCMD

9

EETAL

8

EECMD

7

PLAYTAL

6

PLAYCMD

5

VTR6V

4

GNDVTR

3

GNDVTR

2

NC

1

(J11)

121

+5V

2

GND

(J1)

EVRDIN

EVRDIN

(J3)

REMOTE

1234567812345678123

MON1

MON2

MON3

MON4

MON5

MON6NCGNDMON

VBUSKB1

D‑KB1

ENCCLK

EVRDOUT

EVRCLK

ENCCLK

EVRDOUT

EVRCLK

(J9)

#ZOOMCS

#ENHCS

ENCDATA

#ZOOMCS

#ENHCS

ENCDATA

#LPE1CS

#LPE2CS

#GAMCS

#LPE1CS

#LPE2CS

#GAMCS

(J6)(J8)

#MAT1CS

#MAT2CS

#MAT1CS

#MAT2CS

#PORT2

#WBCS

#PORT2

#WBCS

(J3)

#WRI

#ROM

#PORT1

#WRITE

#ROM

#PORT1

D+KB1

#RD

#READ

GNDKB1

VBUSKB2

D‑KB2

D+KB2

GNDKB2

UPCV16CP

CPUADR3

CPUADR2

CPUADR1

CPUADR0

#RESET

CPUADR3

CPUADR2

CPUADR1

CPUADR0

#CPURESET

VBUSPC

(J4)

CPUADR6

CPUADR5

CPUADR4

CPUADR6

CPUADR5

CPUADR4

4

D‑PC

D+PC

GNDPC

CPUADR9

CPUADR8

CPUADR7

CPUADR9

CPUADR8

CPUADR7

NETWORKPCKEYBOARDMONITOR

1234567

TD+

TD‑

(J5)

CPUADR13

CPUADR12

CPUADR11

CPUADR10

CPUADR13

CPUADR12

CPUADR11

CPUADR10

RD+NCNC

RD‑NCNC

CPUADR17

CPUADR16

CPUADR15

CPUADR14

CPUADR17

CPUADR16

CPUADR15

CPUADR14

8

CPUADR19

CPUADR18

proprietary and Confidential

123456789

GNDCVP

TXDCVP

RTSCVP

(J7)

CPUDATA3

CPUDATA2

CPUDATA1

CPUDATA0

CPUADR20

CPUDATA3

CPUDATA2

CPUDATA1

CPUDATA0

NCNCCPUADR18

PRINTER

REMOTE

GNDCVP

DMRICVP

GNDCVP

ENCVP

GND

GND

GND

GND

CK27M

CK27MGND

#HD

#VD2

ODD

CSYNC

#CK13M

#CK13MGND

#VD1

LCADATA

LCACLK

NC(INIT)

NC(TCK)

NC(TMS)

NC(TDO)

NC(TD1)

GND

GND

GND

GND

YMAIN7

YMAIN6

YMAIN5

YMAIN4

YMAIN3

YMAIN2

YMAIN1

YMAIN0

PRMAIN7

PRMAIN6

PRMAIN5

PRMAIN4

PRMAIN3

PRMAIN2

PRMAIN1

PRMAIN0

PBMAIN7

PBMAIN6

PBMAIN5

PBMAIN4

PBMAIN3

PBMAIN2

PBMAIN1

PBMAIN0

GND

GND

GND

GND

YMIX7

YMIX6

YMIX5

YMIX4

YMIX3

YMIX2

YMIX1

YMIX0

PRMIX7

PRMIX6

PRMIX5

PRMIX4

PRMIX3

PRMIX2

PRMIX1

PRMIX0

PBMIX7

PBMIX6

PBMIX5

PBMIX4

PBMIX3

PBMIX2

PBMIX1

PBMIX0

GND

GND

GND

GND

(J2)

CPUDATA7

CPUDATA6

CPUDATA5

CPUDATA4

CPUDATA7

CPUDATA6

CPUDATA5

CPUDATA4

1011121314

RXDCVP

CTSCVP

DTRCVP

DSRCVP

CJDO

CJD1

CJD2

CJD3

CJD4

CJDO

CJD1

CJD2

CJD3

CJD4

DATE

2000‑04

DMR2CVP

NC(TXDSCV)

DATACVP

1

1

GND

2

2

IDRX

IDRX

PTDUMMY

IDTX

NC

IDTX

3

4

5

6

7

8

9

10

10

11

11

12

12

13

13

14

14

15

15

16

16

17

17

18

18

19

19

20

20

21

21

22

22

23

23

24

24

25

25

26

26

27

27

28

28

29

29

30

30

31

31

32

32

33

33

34

34

35

35

36

36

37

37

38

38

39

39

40

40

41

41

42

42

43

43

44

44

45

45

46

46

47

47

48

48

49

49

50

50

51

51

52

52

53

53

54

54

55

55

56

56

57

57

58

58

59

59

60

60

61

61

62

62

63

63

64

64

65

65

66

66

67

67

68

68

69

69

70

70

71

71

72

72

73

73

74

74

75

75

76

76

77

77

78

78

79

79

80

80

PTDOUT

PTDIN

PTDOUT

PTDIN

GND

3

GND

4

GND

5

CK27M

6

CK27MGND

7

#HD

8

#VD2

9

OABSELS

CSYNC

#CK13M

#CK13MGND

#VD1

TXS0

CCLK

NC(INIT)

NC(TCK)

NC(TMS)

NC(TDO)

NC(TD1)

GND

GND

GND

GND

YMAIN7

YMAIN6

YMAIN5

YMAIN4

YMAIN3

YMAIN2

YMAIN1

YMAIN0

PRMAIN7

PRMAIN6

PRMAIN5

PRMAIN4

PRMAIN3

PRMAIN2

PRMAIN1

PRMAIN0

PBMAIN7

PBMAIN6

PBMAIN5

PBMAIN4

PBMAIN3

PBMAIN2

PBMAIN1

PBMAIN0

GND

GND

GND

GND

YMIX7

YMIX6

YMIX5

YMIX4

YMIX3

YMIX2

YMIX1

YMIX0

PRMIX7

PRMIX6

PRMIX5

PRMIX4

PRMIX3

PRMIX2

PRMIX1

PRMIX0

PBMIX7

PBMIX6

PBMIX5

PBMIX4

PBMIX3

PBMIX2

PBMIX1

PBMIX0

GND

GND

GND

GND

#FPCLR

FPDUMMY

PTCLK

20212223242526272829303132333435363738394041424344454647484950515253545556575859606162636465666768697071727374757677787980

20212223242526272829303132333435363738394041424344454647484950515253545556575859606162636465666768697071727374757677787980

#FPCLR

NC

PTCLK

FPDOUT

FPDIN

19

19

FPDOUT

FPDIN

GND

FPCLK

GND

FPCLK

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

(J6)

GND

101112131415161718

101112131415161718

GND

GND

GND

+5VD

+5VD

(J11)

PRNTERIN

(J13)

PRINTER

OUT

(J10)

COMPOUT

(J8)

MONITOR

OUT

(J7)

DFOUT

(J7)

DFIN

+5VD

+5VD

UPCV16DP

TITLE MODEL

PRNIN

COMPGND

NC

RGND

RPRN

GPRN

RPRN

GGND

BGND

SPRN

SGND

VBSOUT

COMPGND

RGND

GGND

BGND

SGND

Y/CGND

NC

NC

VBSGND

RMON

GMON

BMON

SMON

YMON

CMON

VBSMON

NC

RGND

RDF

GDF

BDF

GGND

BGND

SYDF

SGND

NC

RGND

RDF

GDF

BDF

GGND

BGND

SYDF

SGND

+5VD

+5VD

+5VD

+5VD

+5VD

+5VD

+5VD

+5VD

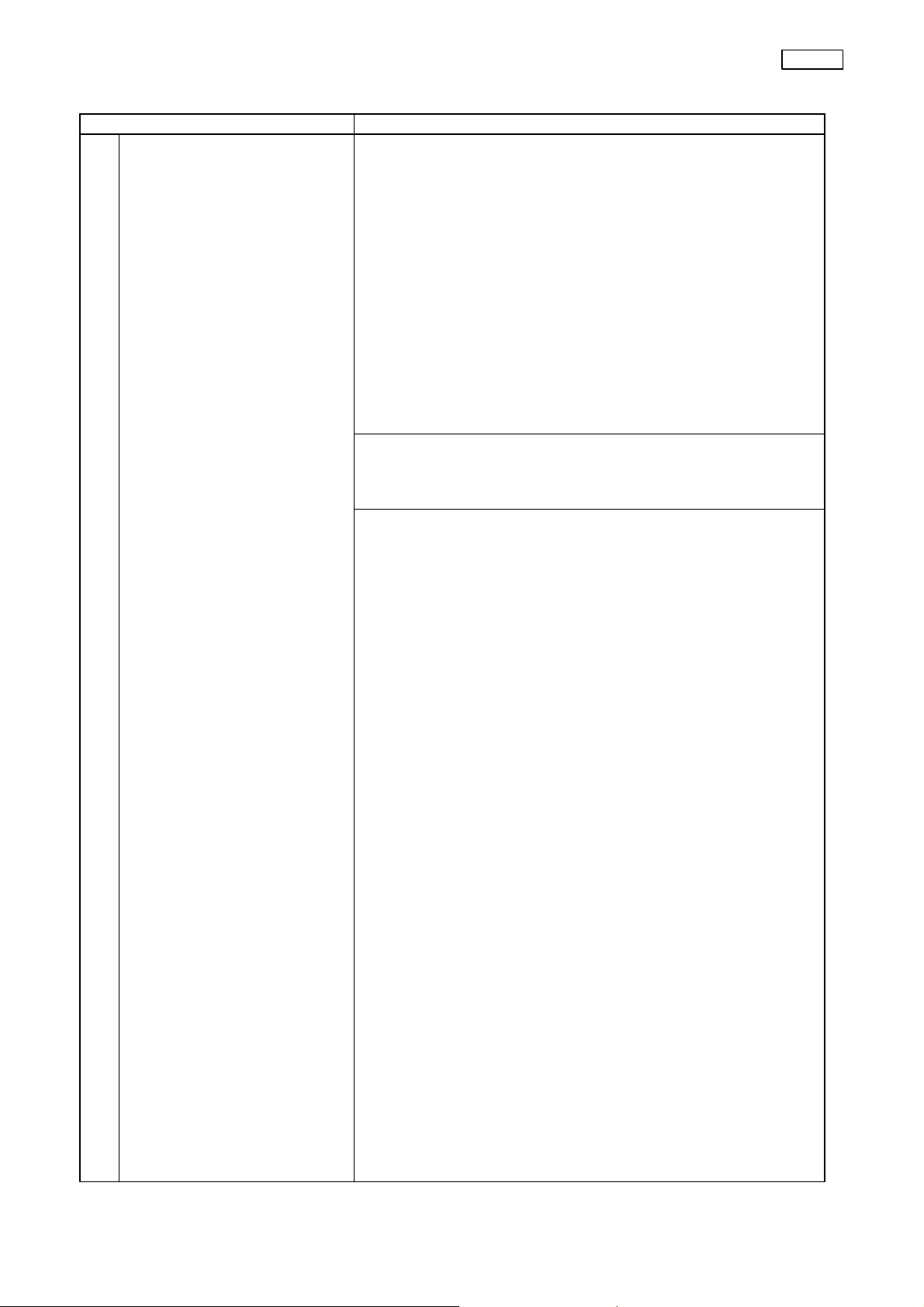

CV‑160CONNECTIONDIAGRAM

+5VD

+5VD

123456789

123456789

+5VD

+5VD

Page

1/1

1

2

1

2

3

4

5

6

7

8

9

1

2

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

7

8

9

1

2

3

4

567

OLYMPUS

OLYMPUS

8

9

10

11

12

2‑1

Page 19

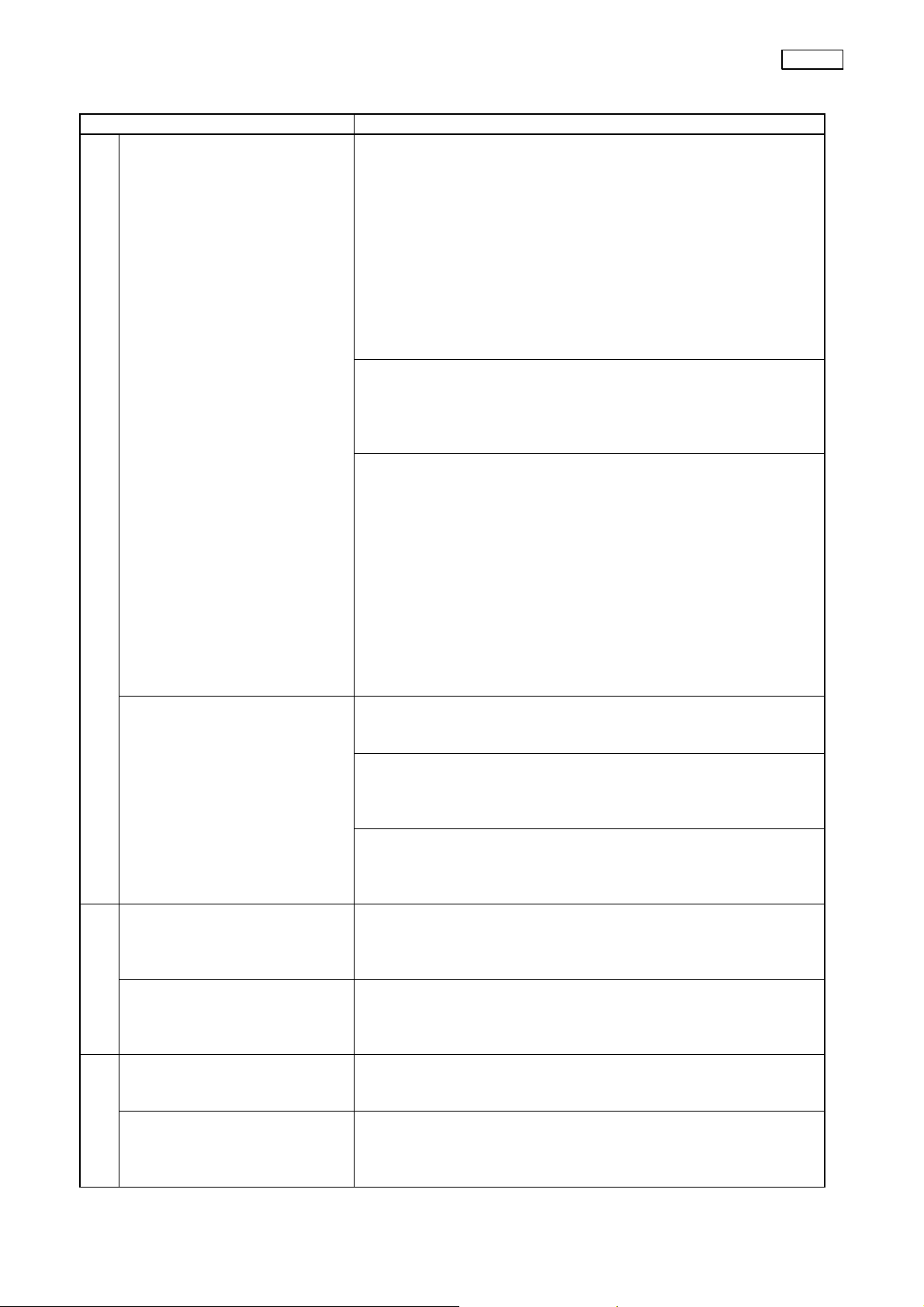

BLOCK DIAGRAM CV-160

BLOCK DIAGRAM

AC IN

VIDEO OUT

VIDEO PROCESS

POWER

SUPPLY

UPCV16AP UPCV16DP

VIDEO PROCESSER

CCD DRIVER

PRE AMP CDS A/D

Cable

Scope

CCD

Scope

REMOTE

CONTROL SIG.

I/F

CPU

UPCV16CP

3-1

Page 20

1. Contents

2. CV-160 troubleshooting

TRUBLESHOOTING CV-160

TROUBLESHOOTING

1. Defective units 4-2

2. Symptoms and object units 4-2

4-1

Page 21

TRUBLESHOOTING CV-160

2. CV-160 troubleshooting

2-1 Defective units

Unit

A AP (patient) board (UPCV16Apxx)

B DP (video) board (UPCV16DPxx)

C CP (CPU) board (UPCV16CPxx)

D FP (front panel) unit

E RP (rear) board

F SWP (power supply) unit

G Connector block unit (including harness)

H AP-DP flat harness

I AP-DP coaxial harness

J AP-FP flat harness

K RP-DP flat harness

L RP-CP flat harness

M DF board & harness (CV-160 only)

N Light control cable harness

O Keyboard

P FPLED (front panel power SWLED) board (UPCL)

2-2 Symptoms and object units

• The following table shows the order of checking doubtful units when a defect occurs.

※ For the relation with the alphabets of the object units, refer to 2-1 Defective units.

No. Symptom

1 Character is blurring. B C

2 Character is fluctuating. B F

3 Character is flying. C

4 Character is not displayed. B C

5 Character is displaced. B C

6 RGB signal is not obtained. B

7 Y/C signal is not obtained. B

8 Composite signal is not obtained. B

9 Keyboard is not accepted. O C

10 Smears A

11

12 Blooming A

13 Mosaic-like noises appear on the scope image. B C A H

14 Digital noises or other noises appear. B A H

15 Horizontal stripes appear on the screen. A B

16 Vertical stripes appear on the screen. A B

17 Vertical wave noises A N F

18 Contour line noises B A C

19 High frequency application noises A

20 Mask shape is defective. C

21 The image in the mask is displaced. H A B

22 The screen is unstable. B A C F

23 Monochrome image is displayed. B C

24 Noises appear on the magnified screen. B C

25

26 Color reproduction of only the RGB signal is bad. B

Single noises appear in the horizontal/vertical

direction.

Color reproductions of RGB, Y/C and composite

signal are bad.

4-2

Order of checking doubtful units

1 2 3 4 5 6

A

B A C

Page 22

TRUBLESHOOTING CV-160

No. Symptom

27 Color reproduction of only the Y/C signal is bad. B

28 Color reproduction of only the composite signal is

bad.

29 The hue is abnormal. J H C D

30 The endoscopic image is not displayed. I H A B F C

31 The endoscopic image is wavering. H A B

32 Image enhancement is strong. B C

33 Image enhancement is weak. B C

34 Image enhancement does not function. B C

35 The AGC malfunctions. A C

36 Latitude is narrow. A B

37 The screen is hunching. A C

38 The screen is dark. N G A

39 The screen is bright. N G A

40 The automatic light control responds late. A C

41 The automatic light control does not function. N G A

42 The digital image is abnormally displayed. B C

43 The screen sways. B C

44 Sandstorm-like noises B C

45 The screen is white. B C

46 The screen is black. B C

47 AGC is not switched. O C A

48 LED is not lit on the front panel. J H F

49 The power switch LED is not lit. J H P F

50 VTR is not controlled. C L E

51 Video printer is not interlocked. C

52 Buzzer does not sound. C

53 Fail to freeze (from the scope switch). G A C B

54 Fail to freeze (from the keyboard). O C B

55 Fail to release the freeze (from the scope switch). G A C

56 Fail to release the freeze (from the keyboard). O C

57 Fail to release (from the scope switch). G A C

58 Fail to release (from the keyboard). O C

59 White balance is invalid. C B A

60 Fail to switch the output. D C B

61 Fail to change the measurement mode. D C A

62 Fail to change the contrast. O C B

63 Color tone step is invalid. J H F C D

64 Data is not stored. C

1 2 3 4 5 6

Order of checking doubtful units

1 2 3 4 5 6

B

4-3

Page 23

DISASSEMBLING/ASSEMBLING PROCEDURE CV-160

DISASSEMBLING/ASSEMBLING PROCEDURE

1. General Precautions on Disassembling/Assembling

• Replace the parts and wires to the original positions.

• For electrical safety and standard, be sure to reassemble the following parts to the original

states.

① Insulation tube and mylar sheet

② Cables clamped and separated from the heating parts or high-voltage parts

③ Cover screws with a toothed lock washer to suppress a radiation noise

• Use the specified parts.

• The parts used in this unit are designed protective against vibration, heat and high voltage. Be

sure to select the parts with the same characteristics from the parts list when replacing the

parts.

• Be careful when disconnecting the cable housing.

• Don’t pull the cable. Be sure to use the special tool.

• Be careful not to be injured.

Some metallic parts have sharp corner or edge. Be careful when handling such parts.

• Be sure to observe the specified torque and dimensions.

Observe the torque and dimensions when they are specified.

As for the H-band which secures each tube, first tighten it by the specified torque and then pull

the tube to check whether the tube becomes loose or it comes off.

• Clean the parts to be used.

When re-using the same parts, eliminate the sealing material and tape and clean. For the

O-ring and packing, clean the surface of the parts on which the O-ring or packing is mounted.

Otherwise, it may cause water leakage.

• Don't forget to tighten the screws and nuts.

Failure in tightening the screws and nuts may cause water leakage.

2. Jigs and Tools

No Name No. Specification Remarks

1

Monkey wrench OT0537

2

Phillips screwdriver No. 2 OT0376

3

Phillips screwdriver No. 1 OT0544

4

Precision screwdriver OT0011

5

Box screwdriver set OT0545

6

L-wrench OT0215

7

8

5-1

Page 24

3. Disassembling Procedure

3-1. Top cover

DISASSEMBLING/ASSEMBLING PROCEDURE CV-160

(1) Remove the eleven screws (HCBK3x6SA)

that secure the top cover.

3-2. Front panel unit

Flexible cord

Top cover

Phillips screwdriver No. 2

(2) Remove the top cover from the main unit.

(1) Remove the flexible cord from the

connector as shown on the left.

(2) Remove the three screws (CCUK3x4SZ)

that secure the front panel unit.

Front panel unit

Phillips screwdriver No. 2

(3) Remove the front panel unit from the

main unit.

5-2

Page 25

3-3. Connector block unit

①

DISASSEMBLING/ASSEMBLING PROCEDURE CV-160

(1) Remove the screw (① CCUK3x6SZ) that

secures the capacitor unit.

Shield case

J203

J202

J201

②

③

Capacitor unit

Phillips screwdriver No. 2

(2) Remove the two screws (②/③ CBK3x6SA)

that secure the capacitor unit.

Phillips screwdriver No. 2

(3) Remove the capacitor unit.

※ Tighten the screws ① to ③

completely when assembling the unit.

(4) Remove the six screws (CCUK3x6SZ) that

secure the shield case.

Phillips screwdriver No. 2

(5) Remove the shield case from the main

unit.

(6) Remove the connector as shown on the

left.

※ When assembling the unit, check that

the connector is securely inserted.

5-3

Page 26

DISASSEMBLING/ASSEMBLING PROCEDURE CV-160

(7) Remove the screw (CCUK3x6SZ) that

secure the conductive spring.

(8) Remove the conductive spring.

※ Precaution on assembling

Conductive

spring

(9) Remove the four screws (CCUK4x10SZ)

Connector unit

that secure the connector unit.

(10) Remove the connector unit from the main

unit.

3-4. CPU board (UPCV16CPxx) and video board (UPCV16DPxx)

(1) Remove the cables from the CPU board,

the video board and the rear panel.

(2) Remove the eight screws (HCBK3x6SA)

that secure the rear panel.

Phillips screwdriver No. 2

Set the conductive spring with

the convex side down.

The conductive spring shall

not interfere with the parts

mounted on the board.

Conductive spring

Phillips screwdriver No. 2

Phillips screwdriver No. 2

(3) Remove the rear panel.

Rear panel

5-4

Page 27

UPCV16PNDF

DISASSEMBLING/ASSEMBLING PROCEDURE CV-160

(4) Remove the two screws (CBK2.5x4SA)

that secure the UPCV16PNDF.

Phillips screwdriver No. 1

(5) Remove the UPCV16PNDF.

(6) Remove the screw (CBK2.5x8SA) that

secure the connector of the CPU board.

Phillips screwdriver No. 1

(7) Remove the two screws (CBK2.5x4SA)

that secure the connector of the CPU

board.

Phillips screwdriver No. 1

(8) Remove the two screws (CUKSK3x6SA)

that secure the connector of the CPU

board.

CPU board

②

Phillips screwdriver No. 2

①

(9) Remove the six screws (CCUK3x6SZ) that

secure the CPU board.

Phillips screwdriver No. 2

(10) Remove the CPU board from the main

unit.

※ When assembling, tighten optionally

after the screws ① and ②.

5-5

Page 28

DISASSEMBLING/ASSEMBLING PROCEDURE CV-160

(11) Remove the four screws (CCUK3x4SZ)

that secure the plate 160.

Plate 160

Phillips screwdriver No. 2

(12) Remove the plate 160 from the main unit.

(13) Remove the eight screws (DK774300) that

secure the connector of the video board.

Box screwdriver (opposite side 5mm)

(14) Remove the two screws (T2CUK3x10SA)

that secure the connector of the video

board.

Video board

Plate 160

Phillips screwdriver No. 2

(15) Remove the five screws (CCUK3x4SZ)

that secure the video board.

Phillips screwdriver No. 2

(16) Remove the video board from the plate

160.

5-6

Page 29

3-5. Patient board (UPCV16Apxx)

Patient board

DISASSEMBLING/ASSEMBLING PROCEDURE CV-160

(1) Do steps (6) and (7) of 3-3. Connector block

unit.

(2) Remove the connector from the patient

board.

(3) Remove the four screws (CCUK3x6SZ)

that secure the patient board.

Patient board

3-6. Front panel LED board (UPCL)

Panel chassis

②

Phillips screwdriver No. 2

(4) Remove the patient board from the main

unit.

(1) Remove the six screws (T2CCUK3x8SZ)

that secure the panel chassis.

Phillips screwdriver No. 2

①

(2) Remove the panel chassis from the main

unit.

※ When assembling, tighten optionally

after the screws ① and ②.

Note) The unused hole is the spare when

the screw becomes loose.

5-7

Page 30

DISASSEMBLING/ASSEMBLING PROCEDURE CV-160

(3) Remove the connector.

Front panel LED board

(4) Remove the screw (T2CCUK3x8SZ) that

secures the front panel LED board.

3-7. Power supply unit

Phillips screwdriver No. 2

(5) Remove the front panel LED board from

the main unit.

(1) Remove the cable from the connectors of

the CPU board and the video board.

(2) Remove the connector from the fan unit.

(3) Remove the four screws (CCUK3x4SZ)

that secure the power supply unit.

Phillips screwdriver No. 2

3-8. Fan and switch unit

Power supply unit

(4) Remove the power supply unit from the

chassis.

(1) Remove the two nuts (C6N3Z) that secure

the fan and the switch unit.

Box screwdriver (opposite side 5.5mm)

(2) Remove the fan and the switch unit from

the chassis.

5-8

Page 31

DISASSEMBLING/ASSEMBLING PROCEDURE CV-160

(3) Remove the two nuts (CCUK3x6SZ) and

two switch washers that secure the switch

Switch washer

plate.

Switch plate

Fan unit

Fan BK

Switch plate

Switch collar

Box screwdriver (opposite side 5.5mm)

※ Precaution on assembling

Assemble so that the switch plate moves

smooth.

(4) Remove the switch plate and the switch

collar.

(5) Remove the two screws (ABSB3x8SZ) that

secure the fan unit.

L-wrench set

(6) Remove the fan unit from the fan BK.

5-9

Page 32

DISASSEMBLING/ASSEMBLING PROCEDURE CV-160

4. Assembling Procedure

Reverse the disassembling procedure.

Pay attention to the direction of the parts when assembling the following part.

4-1. Light control cable

Assemble with the inside

pin set up.

Light control base

Lag plate A

(1) Pass the light control cable through the

hole marked “LIGHT CONTROL”.

※ Pay attention to the direction.

※ Take care that the lag plate A does not

project from the light control base.

(2) Secure the light control cable with two

screws (CBK3x6SA).

Phillips screwdriver No. 2

5-10

Page 33

ABCD

DF RemoteVTR Remote

J1 J1

UPCV16PNRP UPCV16PNDF

J2

J3

J2

1

LIGHT CABLE

GJ758300

2

POWER

SUPPLY

FAN U

GJ758600

DW533800

DW531200

DW533700

Monitor

Remote

J9

J4

J5

Key

Board

J9 J3 J4 J5 J7

J6

J8

J11

Network

Printer

RemotePC

J2

J11

J13

J10

J8

J7

J7

J6

Printer

IN

Printer

Out

Comp.

Out

Monitor

Out

DF Out

DF In

3

4

J204

GJ758700

UPCV16AP

J203 J202

CONNECTOR

BROCK U

J201

J205J200

J206

J207

J2

PANEL SHEET

GJ758800

DZ115300

DZ271400

DW533900

DW533600

1

1

DZ276300

CORE

CORE

J1

UPCV16CP

J1

J2

J3

1

GJ760800

J1J1

UPCL BOARD

EXPLODED PARTS DIAGRAM

MODEL UNIT

UPCV16DP

FR.1181

ISSUE1

CV-160

CABLE

OLYMPUS OPTICAL CO.,LTD. TOKYO JAPAN

FIG.5/5

Page 34

ABCD

GC253700

(100V CLASS ENGLISH)

1

GC686900

HCBK3x6SA

2

DW427300(100V CLASS)

DW417000(200V CLASS)

HCBK3x6SA

CUKS3x8SA

GC711000

1 GC688200

1 GC687800

1 DO048800

1 DZ276300

1

DW533600

GJ840800

HCBK3x6SA

GJ757800(ENGLISH)

1

GJ767600(SYMBOL)

1 GC687900

1 GC688000

3

GC687000

T2CCUK3x8SZ

1 GC688400

CUKS3x6SZ

GC687500

1 GJ760800

GJ756900

1

1 GC688300

1 GC688500

CCUK4x10SZ

1

1

GC688100

CCUK3x6SZ

DY266300(ENGLISH)

DY266400(SYMBOL)

GC687100

4

GJ780500

ISSUE1

CCUK3x6SZ CBK3x6SA

GJ758700

GJ758100

GC687700

EXPLODED PARTS DIAGRAM

MODEL UNIT

TOP COVER & CHASSIS

OLYMPUS OPTICAL CO.,LTD. TOKYO JAPAN

FR.1181

FIG.1/5CV-160

Page 35

ABCD

CCUK3x4SZ

1

2

GJ744800(NTSC)

3

GJ744900(PAL)

CCUK3x4SZ

CCUK3x4SZ

GC710400

GJ745000(NTSC)

2

GJ745100(PAL)

2

CCUK3x4SZ

DZ190900

GC710400

CCUK3x4SZ

3

GC689000

CCUK3x4SZ

4

ISSUE1

EXPLODED PARTS DIAGRAM

MODEL UNIT

PC BOARD

OLYMPUS OPTICAL CO.,LTD. TOKYO JAPAN

FR.1181

FIG.2/5CV-160

Page 36

1

ABCD

CCUK3x6SZ

GH462900

GC687400

DO048800

DZ276400

GC705600

GJ758800

CCUK3x6SZ

CCUK3x6SZ

C6N3SZ

GC689400

GC689200

GC689300

2

GC689100

4

4

3

DP087800(100V CLASS)

DP087900(200V CLASS)

4

DB060900

GJ758600

ABSB3x8SZ

DZ115300

C6N3SZ

GJ744600(NTSC)

GJ744700(PAL)

CCUK3x4SZ

GC687300

GC705500

4

4

4

DY266000

GC687200

EXPLODED PARTS DIAGRAM

MODEL UNIT

POWER SUPPLY

ISSUE1

OLYMPUS OPTICAL CO.,LTD. TOKYO JAPAN

FR.1181

FIG.3/5CV-160

Page 37

ABCD

HCBK3x6SA

GJ758300

5

DH227100

1

DK774300

2

CBK2x4SA

GC688900(ENGLISH)

GC688600(SYMBOL)

5

GJ750800

CBK2.5x8SA

DK774300

T2CUKSK3x10SA

CUKSK3x6SA

CBK2.5x8SA

DK468500

2

2

2

DK756900

HWB6SA

6N6SN

GJ750900

2

DK630900

2

DK756800

DK756700

3

4

ISSUE1

3

DK785100

3

DK568800

3

DK774500

3

DK568800

3

DK762300

EXPLODED PARTS DIAGRAM

MODEL UNIT

REAR PANEL

OLYMPUS OPTICAL CO.,LTD. TOKYO JAPAN

FR.1181

FIG.4/5CV-160

Page 38

CV-160

PARTS No. INDEX PARTS NAME E. SPECIFICATION REMARK CHECK

DB060900 3-A3 FUSE DH227100 4-B1 TERMINAL DK468500 4-C2 PC CONNECTOR Printer Remote DK568800 4-C3 PC CONNECTOR Comp Out,Printer IN DK630900 4-D2 PC CONNECTOR Monitor Remote DK756700 4-D2 PC CONNECTOR Key Board DK756800 4-D2 PC CONNECTOR PC DK756900 4-D2 PC CONNECTOR Net work DK762300 4-C3 PC CONNECTOR DF IN/Out DK774300 4-A1 SCREW DK774500 4-C3 PC CONNECTOR Printer Out DK785100 4-C3 PC CONNECTOR Monitor Out DO048800 1-C2 CABLE HOLDER DP087800 3-A2 POWER SUPPLY 100V CLASS DP087900 3-A2 POWER SUPPLY 200V CLASS DW417000 1-A2 POWER CABLE 2U 200V CLASS DW427300 1-A2 POWER CABLE 1U 100V CLASS DW531200 5-B1 CABLE CPU - DF Board DW533600 1-C2 CABLE Patient - Panel Sheet DW533700 5-B2 CABLE Video - Rear Panel Board DW533800 5-B1 CABLE CPU - Rear Panel Board DW533900 5-B3 CABLE Video - Patient DY266000 3-B4 PUSH BUTTON SW DY266300 1-D3 PANEL SHEET160E ENGLISH DY266400 1-D3 PANEL SHEET160S SYMBOL DZ115300 3-C2 FERRITE CORE DZ190900 2-D1 BATTERY DZ276300 1-C2 FLAT CORE DZ276400 3-D1 FLAT CORE GC253700 1-C1 PLATE

GC686900 1-A2 TOP COVER GC687000 1-A4 CV CHASSIS GC687100 1-D4 FOOT 5-5 GC687200 3-D3 SPACER GC687300 3-C3 P SHIELD BASE GC687400 3-D1 P SHIELD COVER GC687500 1-B4 SPRING GC687700 1-C4 HOLE COVER GC687800 1-C2 GASKET F GC687900 1-D2 WATERPROOF RUBBER GC688000 1-D2 FP BOARD160E GC688100 1-D3 CONNETCTOR COVER GC688200 1-B2 CVFP CHASSIS GC688300 1-C3 SW SPRING GC688400 1-B3 SW COLLAR GC688500 1-C3 MAIN SW GC688600 4-A1 REAR PANEL160S SYMBOL GC688900 4-A1 REAR PANEL160E ENGLISH GC689000 2-A2 SECOND BOARD160 GC689100 3-A2 FAN BK GC689200 3-A2 SW BOARD -

100V CLASS ENGLISH -

1/2

ISSUE1

Page 39

CV-160

A

PARTS No. INDEX PARTS NAME E. SPECIFICATION REMARK CHECK

GC689300 3-A2 SW BOARD COLLAR GC689400 3-A2 SW WASHER GC705500 3-C3 P GASKET GC705600 3-D1 CORE BK GC710400 2-B1 CV SPACER1 GC711000 1-B2 EL CORD HOLDER GH462900 3-D1 MYLAR SHEET GJ744600 3-B2 UPCV16APN1 Patient Board NTSC GJ744700 3-B2 UPCV16APP1 Patient Board PAL GJ744800 2-A2 UPCV16DPN1 Video Board NTSC GJ744900 2-A2 UPCV16DPP1 Video Board PAL GJ745000 2-D1 UPCV16CPN1 CPU Board NTSC GJ745100 2-D1 UPCV16CPP1 CPU Board PAL GJ750800 4-B2 UPCV16PNRP Rear Panel Board GJ750900 4-D1 UPCV16PNDF DF Borad GJ756900 1-C2 UPCL16ZZ SW LED Board GJ757800 1-D2 F PANEL1603EU ENGLISH GJ758100 1-B4 CONNECTOR BROCK U GJ758300 4-A1 LIGHT CABLE Light Cable GJ758600 3-B2 FAN U FAN U GJ758700 1-B4 CAPACITOR 1603EU Patient - Chassis GJ758800 3-B1 CABLE Video - Patient GJ760800 1-C2 CABLE Panel Sheet - SW LED Board GJ767600 1-D2 F PANEL1606SU SYMBOL GJ780500 1-A4 KEY BOARD 160U GJ780900 - E KEY TOP GU GERMAN GJ781000 - E KEY TOP FU FRENCH GJ801800 - E KEY SEAL GU GERMAN GJ801900 - E KEY SEAL FU FRENCH GJ840800 1-D1 CAP HOLDER 6N6SZ 4-D1 NUT WE501049 ABSB3x8SZ 3-B2 SCREW WE403011 C6N3SZ 3-A2 NUT WE178001 CBK2.5x8SA 4-B2 SCREW WE128047 CBK2x4SA 4-A2 SCREW WE128014 CBK3x6SA 1-B4 SCREW WE128012 CCUK3x4SZ 2-A2 SCREW WE139018 CCUK3x6SZ 1-D4 SCREW WE139002 CCUK4x10SZ 1-C3 SCREW WE139015 CUKS3x6SZ 1-B3 SCREW WE168011 CUKS3x8SA 1-B2 SCREW WE168004 CUKSK3x6SA 4-C1 SCREW WE168011 HCBK3x6SA 1-A2 SCREW WE129002 HWB6SA 4-D1 SCREW WE306016 T2CCUK3x8SZ 1-B3 SCREW WE155001 T2CUKSK3x10S

4-C1 SCREW WE142013 -

2/2

ISSUE1

Page 40

OLYMPUS OPTICAL CO.,LTD.

San-Ei Building,22-2,Nishi Shinjuku 1-chome,Shinjuku-ku,Tokyo,Japan

OLYMPUS OPTICAL CO.,(EUROPA) GMBH

(Premises/Goods delivery)Wendenstrasse 14-18,D-20097 Hamburg,Germany

(Letters:Postfach 104908,D-20034 Hamburg,Germany)

OLYMPUS WINTER & IBE GMBH

Kuehnstrasse 61,d-22045 Hanburg,Germany

OL YMPUS AMERICA INC.

Two corporate Center Drive Melville,N.Y.

KEYMED (MEDICAL & INDUSTRIAL EQUIPMENT)LTD.

Keymed House,Stock Road,Southend-on-Ses,Essex SS2 5QH,United Kingdom

OLYMPUS SINGAPORE PTE LTD

BLK 211,Henderson Road No.14-02,Henderson Industrial Park,Singapore 159552

OLYMPUS BEIJING REPRESENTATIVE OFFICE

Room No.3406 Beijing jing Guang Center,Hu Jia Lou,Chao Yang Qu,Beijing,China

OLYMPUS MOSCOW CORPORATION

117071,Moscow,Malaya Kaluzhskaya 19,bld. 1,fl.2,Russia

OL YMPUS AUSTRALIA PTY.LTD.

1/104 Ferntree Gully Road,Oakleigh,VIC 3166,Australia

PRINTED IN JAPAN Marketing Department Endoscope Division

05. 2002 W077B

Loading...

Loading...