Page 1

MAINTENANCE MANUAL

CLH-SC

Page 2

INTRODUCTION

Repairs of this product require high-grade special knowledge and technique.

We recommend to contact the Olympus agent in your country when product

Goes out of order.

For remodeling or repairs to be done by the agent or person not authorized

by us, we will not warrant the product and not be liable for any result.

Page 3

CONTENTS

1. SPECIFICATION OF PRODUCTS

2. DESCRIPTION OF BLOCK

3. CIRCUIT DIAGRAM

120V

220V

230V

240V

4. TROUBLESHOOTING

5. DISASSEMBLING PROCEDURE

6 . EXPLODED PARTS DIAGRAM

7. PARTS LIST

1-1

2-1

3-1

3-2

3-3

3-4

4-1

5-1

6-1

7-1

Page 4

1. Features

The CLH-SC is a simple high intensity light source designed for use with a medical rigid scope or

an endoscope with an eyepiece of the same shape as of a medical rigidscope.

2. Specifications

PRODUCT SPECIFICATIONS

1. SPECIFICATION OF PRODUCTS

guide

guide

light

light

and

and

scope

scope

of

Type

Applicable

light

function

Illumination

tion

Illumina

Brightness

adjustment

Method

Item

Light guide f or rigid scope

Rigid scope

Endoscope (with the same

eyepiece as that of a rigid

scope)

Illumination lamp

Method

Specifications

A3061, A3062, A3071, A3072, A3081, A3082, A3091, A3092,

A3093, A3094, A3095, A3096

Rigid scope connectable wit h the light guides A3061, A3062,

A3071, A3072, A3081, A3082, A3091, A3092, A3093, A3094,

A3095, and A3096.

The others are not applicable.

CYF, CYF-2, URF, URF-2, URF-P2, HYF-P, HYF-1T, ENF-P,

ENF-L3, ENF-P4, ENF-XP, PF-14, PF-22, PF-28, LTF, LF-1,

LP-2 , LP-P, LF-T, CHF-CB30

Symbol in Olympus: MD-151

Type: Halogen lamp 15 V/150 W

Manufacture: USHIO

Model: JCM15-150FP

Service life: Average 50 hours

Color t e m perature: 3250° K (published by the

manufacturer's catalog)

Manual adjustment by the brightness control on the front panel

(light path shielding diaphragm)

Forced air cooling by a fan

Cooling

1-1

Page 5

PRODUCT SPECIFICATIONS

Safety

Laws and

Others

Item

For destinations

EU/EFTA

applied

USA

regulations

Panel and outer casing

Cleaning

Classification of medical

instruments

Supply voltage

Supply voltage fluctuation

conditions

Power consumption

Using

Specifications

Applied laws and regulations, classifications, etc.

MDD

Class: I

CE marking

FDC law

UL mark/CUL mark

Clea n with the gauze moistened with 70% ethyl alcohol, 70%

isopropyl alcohol or neutral cleanser. Dry sufficiently after

cleaning with alcohol.

1 00 V: BF type instruments

1 20 V , 200 V : BF type mounting units

Protection against an electrical shock: Class I instruments

1 0 0 V, 12 0 V, 220 V, 230 V, 240 V (depending on destinations)

± 10% or less

100 V, 1.7 A

120V,

1.7 A

220/230/240 V, 1. 0 A

User service

Fuse

parts

Replaceable

Dimensions

Weight

Panel

Others

Power cord

Illumination lamp JCM15-150FP (MD-151)

Delay channel 250 V, 2 A

T2A 250 V

220 (W) x 290 (D) x 74 (H) m m (excluding the projections)

5kg

1 type

100/120 V: Cord set with a 3-core hospital grade plug

220/230/240 V: 3-core (plug-less) set

1-2

Page 6

3. Using Conditions

Use in medical facilities under the direction of doctor.

Don't use directly to the heart. (BF instrument)

Ground the outer casing for safety.

Don't use in an inflammable atmosphere.

Don't use with the following electronic devices.

a. Among the devices designed to apply medical treatment with electronics to a patient, those

which are not confirmed in safety when combined with the CLH-SC.

b. Among the devices not designed to apply medical treatment with electronics to a patient,

those which are not confirmed in safety such as a leakage current, etc.

Power supply

PRODUCT SPECIFICATIONS

Rated voltage

Input power supply

Frequency

Voltage fluctuation

Environmental conditions

Ambient temperature:

Relative humidity:

Atmospheric pressure:

100 V

1. 7 A

10 - 40°C

30 - 80%

700 -

120V

1. 7 A

50/60 Hz

± 10% or less

1060

hPa

220,

230,

1. 7 A

240 V

1-3

Page 7

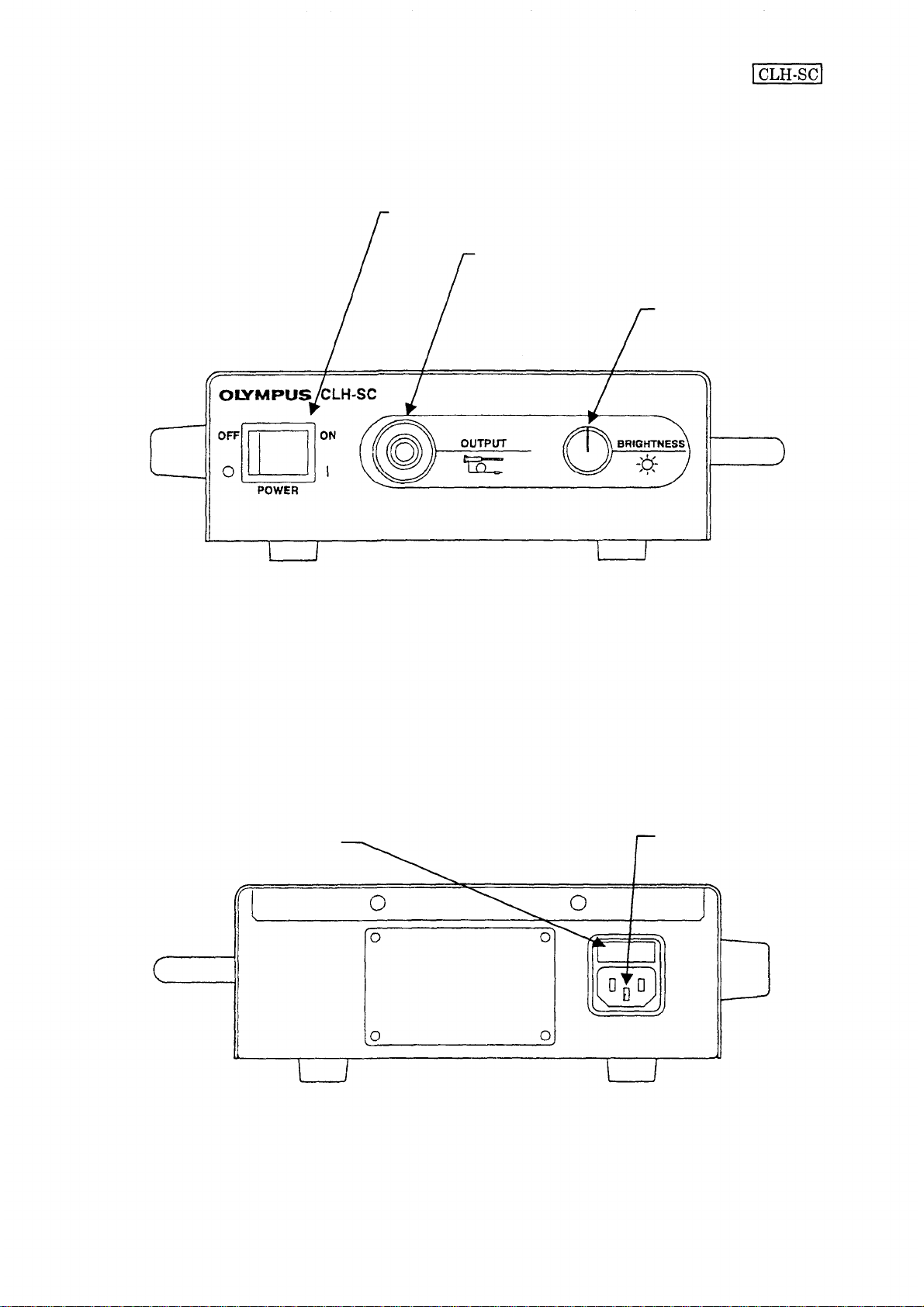

4. Nomenclature

4-1. Front panel

PRODUCT SPECIFICATIONS

1. Power switch

2. Outpu t connector

3. Brightness control

1. Power switch

Push the right side t o turn on the unit. The switch lamp lights and the illumination lamp

(halogen) lights up.

2. Output connector

Supplies an illumination light to the scope and light guide cable connected.

3. Brightness control

Turn clockwise to increase brightness and counterclockwise to darken.

4-2. Rear panel

1 . Fuse box

2. Inlet

1. Fuse box

Contains the fuse to prevent a fire due to the light source or oth e r danger when en error occurs.

2. Inlet

Connects the power cord.

1-4

Page 8

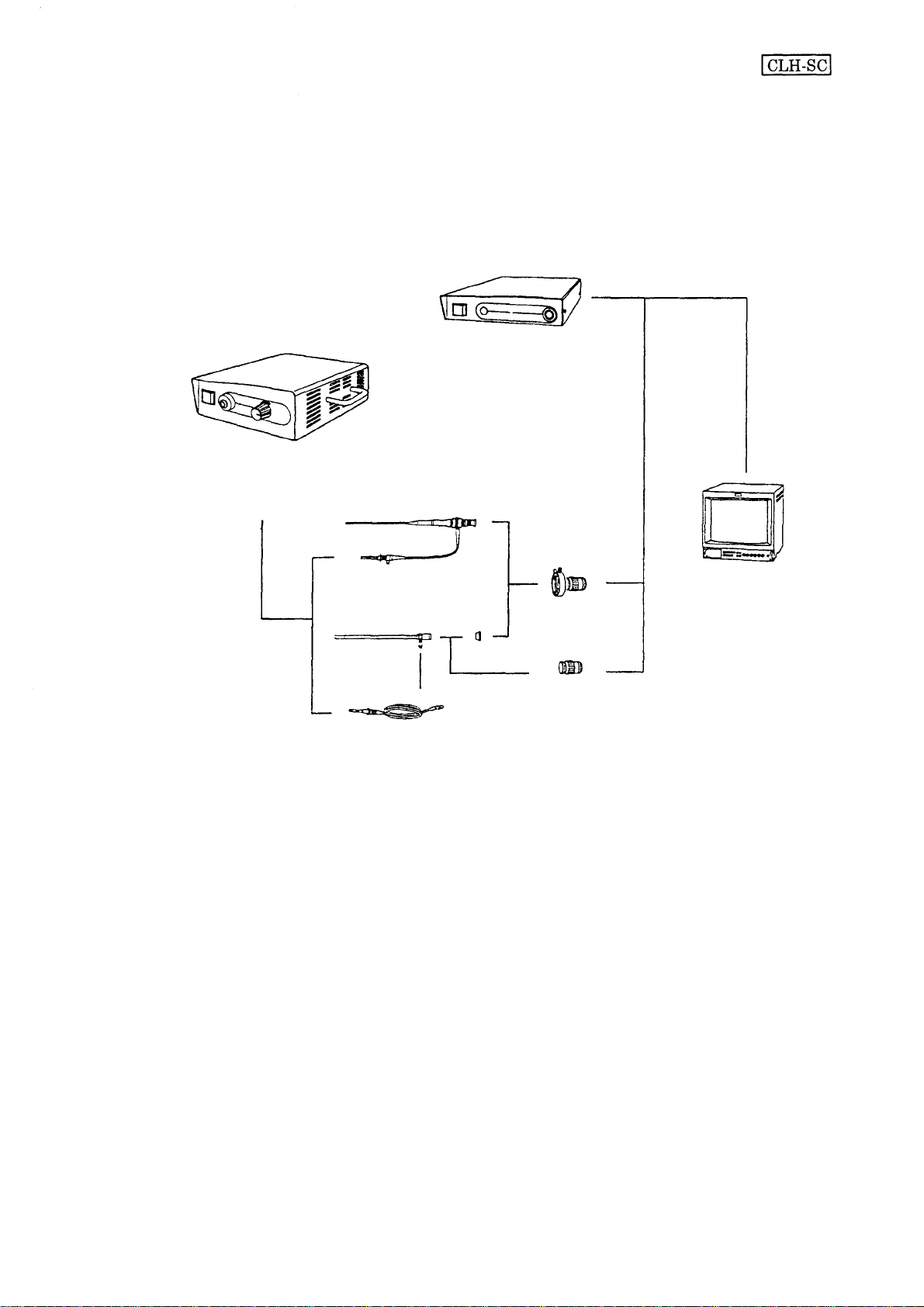

System Diagram

High intensity light

source unit

(CLH-SC)

PRODUCT SPECIFICATIONS

OES video system

(OTV-SC)

Endoscope

Rigid scope

Light guide

Video adapter

Video adapter

Video mon ito r

for endoscope

OEV

series

1-5

Page 9

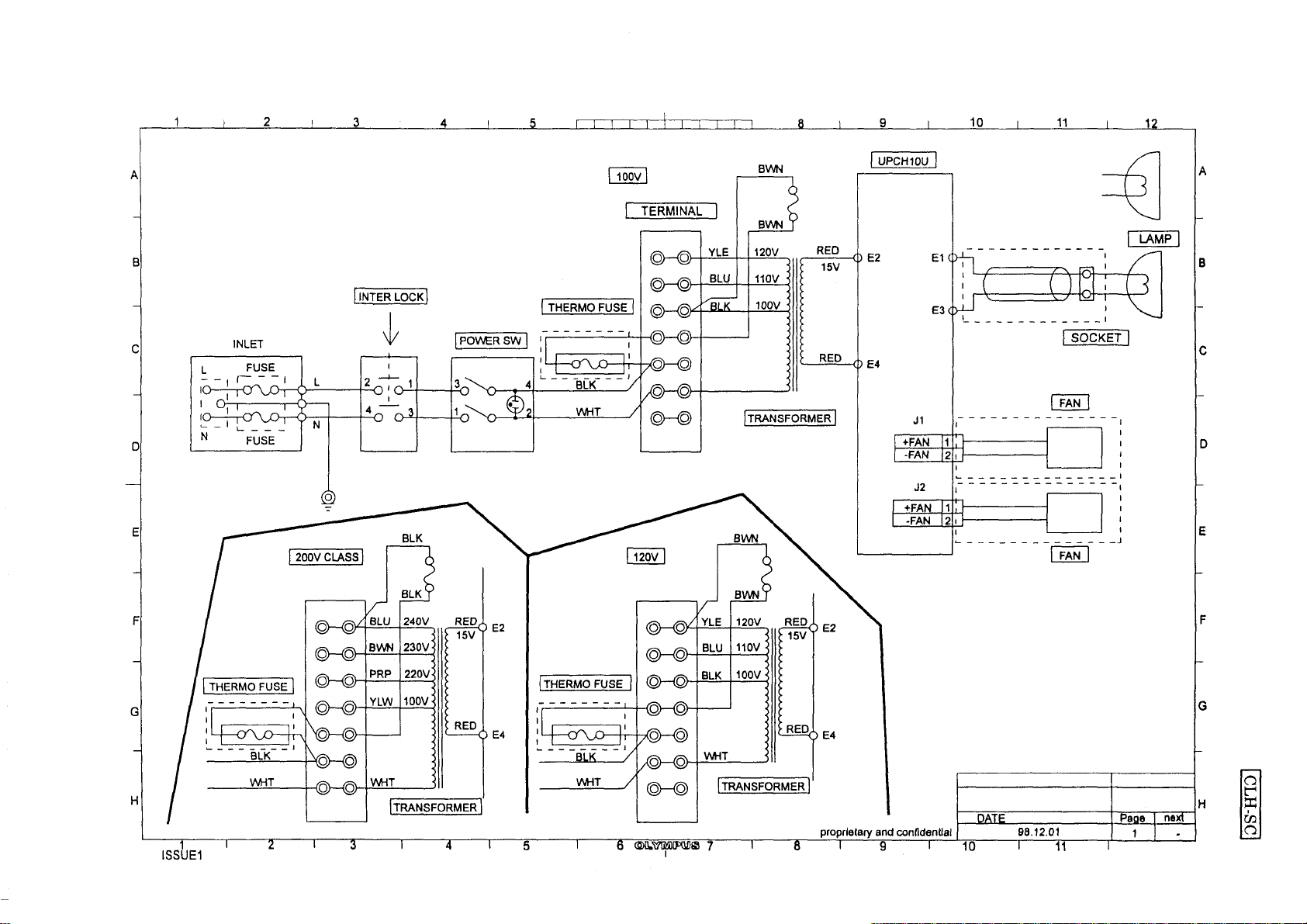

DESCRIPTION OF BLOCK

2. DESCRIPTION OF BLOCK

1. Operation of Block

Operation of the CLH-SC is described using a block diagram (2-2).

Power supplied on the power cable is applied to the interlock switch through two fuses. The power

passing through the interlock switch is applied to the power switch on the front panel and is then sent

to the terminal block. The power is returned from the live side to the terminal block through the

thermo-fuse provided on the side of the power switch. The thermo-fuse operates to stop all functions

and avoid a danger wh en the fan stops, t he air duc t is blocked and the main body is abnormally heated.

The nominal operating temperature of the thermo-fuse is 117°C.

The power of 15 VAC for lighting the lamp is decreased by the transformer and is applied to the

secondary side to supply power to the lamp. The DC fan is supplied with the power that is obtained by

rectifying the lamp power supply by a diode and then smoothing by a capacitor. The transformer is

provided with a thermo-fuse of 135°C to prevent overheat, but the fuse can not be replaced. If the fuse

blows, the transformer must be replaced. This power supply circuit is provided on the UPCH10 board.

A branch from the transformer to the lamp socket, a fa n rectifying/smoothing circuit and two

connectors to supply power to the f an are provided.

2-1

Page 10

2-2

DESCRIPTION

OF

BLOCK

UNIT NAM E

BLOCK DIAGRAM

MODEL

CLH-SC

Page 11

3-1

120V

3.

CIRCUIT

DIAGRAM

CIRCUIT

UNIT NAME

120V

DATE

99-01

DIAGRAM

MODEL

CLH-SC

PAGE

1/4

Page 12

3-2

220V

CIRCUIT

UNIT NAME

220V

DATE

99-01

DIAGRAM

MODEL

CLH-SC

PAGE

2/4

Page 13

3-3

230V

CIRCUIT DIAGRAM

UNIT NAME

230V

DATE

99-01

MODEL

CLH-SC

PAGE

3/4

Page 14

3-4

240V

CIRCUIT

UNIT NAME

240V

DATE

99-01

DIAGRAM

MODEL

CLH-SC

PAGE

4/4

Page 15

Symptoms

TROUBLESHOOTING

4. TROUBLESHOOTING

1. Power is not supplied.

2. The lamp does not light at all, burns out soon or turns off after once turning on.

3. The fa n does not work.

4. Brightness is insufficient.

5. Light can not be controlled.

4-2

4-3

4-4

4-5

4-6

4-1

Page 16

[Symptom: Power is not supplied.]

Start

Is power provided at

the inlet?

TROUBLESHOOTING

NO

The supply voltage is abnormal,

or the power cord is defective.

Is power provided in the

input side of the power

switch?

Is power provided in the

output side of the power

switch?

Is the thermo-fuse

conducting?

Is the voltage at the

terminals E1 and E3 of

UPCH10U 15 V AC?

NO

The interlock switch is

defective.

NO

The power switch is defective.

NO

The thermo-fuse is broken.

NO

The transformer is defective.

Check conduction of the wires and

connection of the terminals and

connectors.

End

4-2

Page 17

TROUBLESHOOTING

[Symptom: The lamp does not light at all, burns out soon or turns off after once

turning on.]

Start

Is the lamp burnt?

YES

Measure the voltage applied to

the lamp (with the lamp

connected).

1 00 V c l ass 15 V±0.75 V

200 V class 14.6 V±0.75 V

Does the voltage meet

the standard?

NO

Replace the lamp, and

age it for a while.

YES

Is the lamp burnt

soon?

Check the voltage

supplied to the

transformer.

NO

Does the voltage meet

the rating?

YES

Is the contact of the lamp

socket deteriorated?

Check connection of the

terminals and boards, and

check the state of the harness.

End

YES

YES

The transformer is defective.

(Replace the transformer)

Replace the lamp socket.

Connect power that

meets the rating.

4-3

Page 18

[Symptom: The fan does not work.]

Start

TROUBLESHOOTING

Do the both t w o fans

work?

NO

Check the voltage applied to

the fan.

Is l6.5±0.75 V DC

applied?

Only one fan works.

Check wiring and connection

of the connectors.

YES

The fan is defective.

Change connection o f

the connectors.

Do the fans work?

YES

The fa n is defective

(on e fan).

Measure the voltag e applied to

the lamp (with the lamp

connected).

10 0 V class 15 V±0.75 V

200 V class 14. 6 V±0.75 V

Does the applied voltage

meet the rating?

NO

* The rated voltage of the fan is 24 V

DC, but the f an works normally if the

supply voltage is in the operating

range o f 1 0 - 2 7 . 6 V DC.

YES

The power supply board UPCH10U

is defective. (diode/capacitor)

Check wiring and connection of the

connectors.

4-4

Page 19

[Symptom: Brightness is insufficient.]

Start

Check the lamp for

deterioration (darkness).

NO

Is the lamp normal?

TROUBLESHOOTING

Replace the lamp.

Is the lamp correctly

mounted?

Measure the voltage applied to

the lamp (with the lamp

connected).

10 0 V class 15 V±0.75 V

200 V class 14.6 V±0.75 V

Does the applied

voltage meet the

rating?

Is the mechanical iris

normal?

NO

NO

NO

Mount the lamp correctly.

Check the supply voltage.

Does the supply

voltage meet the

rating?

Connect power that

meets the rating.

The transformer is defective.

NO

Replace the lamp.

Repair the mechanical iris.

4-5

Page 20

[Symptom: Light can not be controlled.]

Start

Check to see if t he control

knob on the front panel

makes idle rotation?

TROUBLESHOOTING

Does the control

rotate idly?

Does the shaft rotate?

Check the structures of the

mechanical iris and others.

Does the mechanical

iris work?

YES

NO

NO

Tighten the ACU screw

to fix the control.

Check to see if the shaft

is caught by the stopper

screw?

Replace the mechanical

iris unit.

End

4-6

Page 21

DISASSEMBLING/ASSEMBLING PROCEDURE

5. DISASSEMBLING/ASSEMBLING PROCEDURE

1. Precautions on Disassembling/Assembling

Replace the parts and wires to the original positions.

For electrical safety and standard, be sure to reassemble the following parts to the original

states.

Insulation tube and mylar sheet

Cables clamped and separated from the heating parts or high-voltage parts

Cover screws with a toothed lock washer to suppress a radiation noise

Use the specified parts.

The parts used in this unit are designed protective against vibration, heat and high voltage. Be

sure to select the parts with the same characteristics from the parts list when replacing the

parts.

Be careful when disconnecting the cable housing.

Don't pull the cable. Be sure to use the special tool.

2. Jigs and Tools

No.

1

2

3

4

Phillips screwdriver No. 2

Name

No.

OT0376

Specification

Remarks

3. Assembling

Reverse the disassembling procedure.

5-1

Page 22

4. Disassembling

DISASSEMBLING/ASSEMBLING PROCEDURE

1. Top cover

(1) Remove the door by turning the knob.

(2) Remove the eight screws which secure the

top cover to the m ai n body.

Phillips screwdriver No. 2

(3) Remove the top cover from the main body.

5-2

Page 23

DISASSEMBLING/ASSEMBLING PROCEDURE

2. Upper he a t shielding plate

(1) Remove the three screws which secure the

upper heat shielding plate to the main

body.

Phillips screwdriver No. 2

(2 ) Remove the upper heat shielding plate

from the main body.

E1

E3

3. UPCH10U

(1 ) Remove the terminal of Socket harness

from the UPCH10U board.

(2) Remove the lead terminal of the

transformer from the UPCH10U board.

E4

(3) Remove the connector of the fa n U fro m the

UPCH10U board.

5-3

Page 24

DISASSEMBLING/ASSEMBLING PROCEDURE

(4) Remove the two screws which secure the

UPCH10U to the chassis.

Phillips screwdriver No. 2

(5) Remove the UPCH10U from the chassis.

4. Fan

(1) Re m ov e th e t w o screws which secure the

fan to the chassis.

Phillips screwdriver No. 2

(2) Remove the fan from the chassis.

5. Terminal block

(1) Remo ve t he t w o screws which secure the

terminal block to the chassis.

Phillips screwdriver No. 2

(2) Remove the terminal block fro m the

chassis.

5-4

Page 25

DISASSEMBLING/ASSEMBLING PROCEDURE

6. Transformer

(1) Remove the four screws which secure the

tr ansforme r to the chassis.

Phillips screwdriver No. 2

(2) Remove the transformer from the chassis.

7. Frame

(1) Remove the three screws which secure the

frame to the chassis.

Phillips screwdriver No. 2

(2) Remove the frame from the chassis.

8. Diaphragm

(1) Remove the three screws which secure the.

diaphragm to the chassis.

Phillips screwdriver No. 2

(2) Remove the diaphragm from the chassis.

5-5

Page 26

EXPLODED PARTS DIAGRAM

6. EXPLODED PARTS DIAGRAM

6-1

CLH-SC

COVER & SHASSY

FIG.

1/3

Page 27

EXPLODED PARTS DIAGRAM

6-2

CLH-SC

MAIN UNIT

FIG.2/3

Page 28

EXPLODED PARTS DIAGRAM

6-3

CLH-SC

CABLE

FIG.3/3

Page 29

7. PARTS LIST

PARTS LIST

PARTS No.

DB068500

DH205100

DH305600

DK521600

DY243000

DY243100

DY249300

GC224100

GC482000

GC499200

GC501500

GC505000

GC520300

GC520400

GC520500

GC520600

GC521000

GC521100

GC521200

GC521300

GC521700

GC521900

GC522000

GC624700

GD462300

GD462400

GD462700

GH371300

GH374300

GH377000

GJ423400

GJ423500

GJ423600

GJ423700

GJ440600

GJ440700

GJ449600

GJ530200

GJ558800

GJ558900

GJ559000

GR326800

GS285000

GS321800

GU1 96200

GU1

98900

SM370900

BNW4SZ

C6N4SZ

CBK3x8SA

CCUK3x16SZ

CCUK3x30SZ

CCUK3x4SZ

INDEX

PARTS NAME

1-A1

FUSE

2-A3

TERMINAL

1-A3

FUSE

POWER CONNECTOR

1-A3

1-D4

POWER SW

1-D4

POWER SW

2-A2

INTER L O CK SW

1-A2

CE PLATE

PLATE MD151

1-A1

1-A2

SCREW

WASHER

1-B2

J CAUTION PLATE

1-D1

MAIN SHASSY

1-D3

COVER

1-A1

FRAME

2-B3

LAMP BASE

2-A2

TOP HEAT STOPPER BOARD

1-C2

DOOR

1-B2

HEAT STOPPER BOARD

2-B2

2-D3

1-D1

1-D3

2-A2

2-C4

1-A3

2-C2

2-B1

3-D3

1-C4

1-B4

2-D1

2-B4

2-B4

1-A2

2-C2

1-D1

2-A1

2-A4

1-B2

2-A3

2-A3

1-B2

2-A3

2-D3

1-B2

1-D3

1-B2

1-A2

1-A2

1-A1

1-D4

1-A1

1-C4

FAN HOLDER

HANDLE

KNOB

KNOB CAP

SPACER

J PLATE

E PLATE

J LAMP PLATE

SLIDE SCREW

RING

E LAMP PLATE

UPCH10U

INLET INTER-HU

INTER SW-HU

SOKET-HU

THERMO-HU

FAN-U

PANEL PLATE

FOOT

IRIS U

TRANSFORM

TRANSFORM

CUL SEAL

BOUL BOARD

PLATE

SPRING U

GND-HU

SUB FOOT

WASHER

SCREW

SCREW

SCREW

SCREW

SCREW

SPECIFICATION

POWER SW

POWER SW

INTER LOCK

INLET INTER-HU

INTER SW-HU

SOKET-HU

THERMO-HU

FAN-U

GND-HU

WE303014

WE1

78003

WE1 39006

WE139017

WE1 39034

WE139006

REMARK

100V CLASS

200V CLASS

200V CLASS

JAPANESE

ENGLISH

100V

120V

100V CLASS

200V CLASS

7-1

Page 30

PARTS LIST

PARTS No.

CCUK3x6SZ

CCUK4x6SZ

AB6x8SB

CSK3x6SA

CUKSK3x10SZ

HCBK3x6SA

HWB4SA

INDEX

1-C2

2-C2

1-A1

1-A2

1-B4

1-A3

2-A3

PARTS NAME

SCREW

SCREW

SCREW

SCREW

SCREW

SCREW

WASHER

SPECIFICATION

WE1 39002

WE1 39005

WE402456

WE1 06060

WE168012

WE1 29002

WE306009

REMARK

7-2

Page 31

OLYMPUS OPTICAL CO., LTD.

San-Ei Building, 22-2, Nishi Shinjuku 1-chome, Shinjuku-ku, Tokyo, Japan

OLYMPUS OPTICAL CO., (EUROPA) GMBH

(Premises/ Goods delivery) Wendenstrasse 14-16, D -2 00 9 7 Hamburg, Germany

(Letters: Postfach 104908, D-20034 Hamburg, Germany)

OLYMPUS AMERICA INC.

Two corporate Center Drive Melville, N. Y.

KEYMED (MEDICAL & INSTRUMENT EQUIPMENT) LTD.

KeyMed House, Stock Road, Southend-on-Sea, Ess ex SS2 5QH, United Kingdom

OLYMPUS SINGAPORE PTE LTD

BLK 211, Henderson Road No. 13-03, Henderson Industrial Park, Singapore 0315

ENDOSCOPE MARKETING DIVISION

Printed in Japan

02.'99 W067B

Loading...

Loading...