Page 1

OLYMPUS SYSTEM MICROSCOP

MODEL

REPAIR

CH

MANUA

OLYMPUS

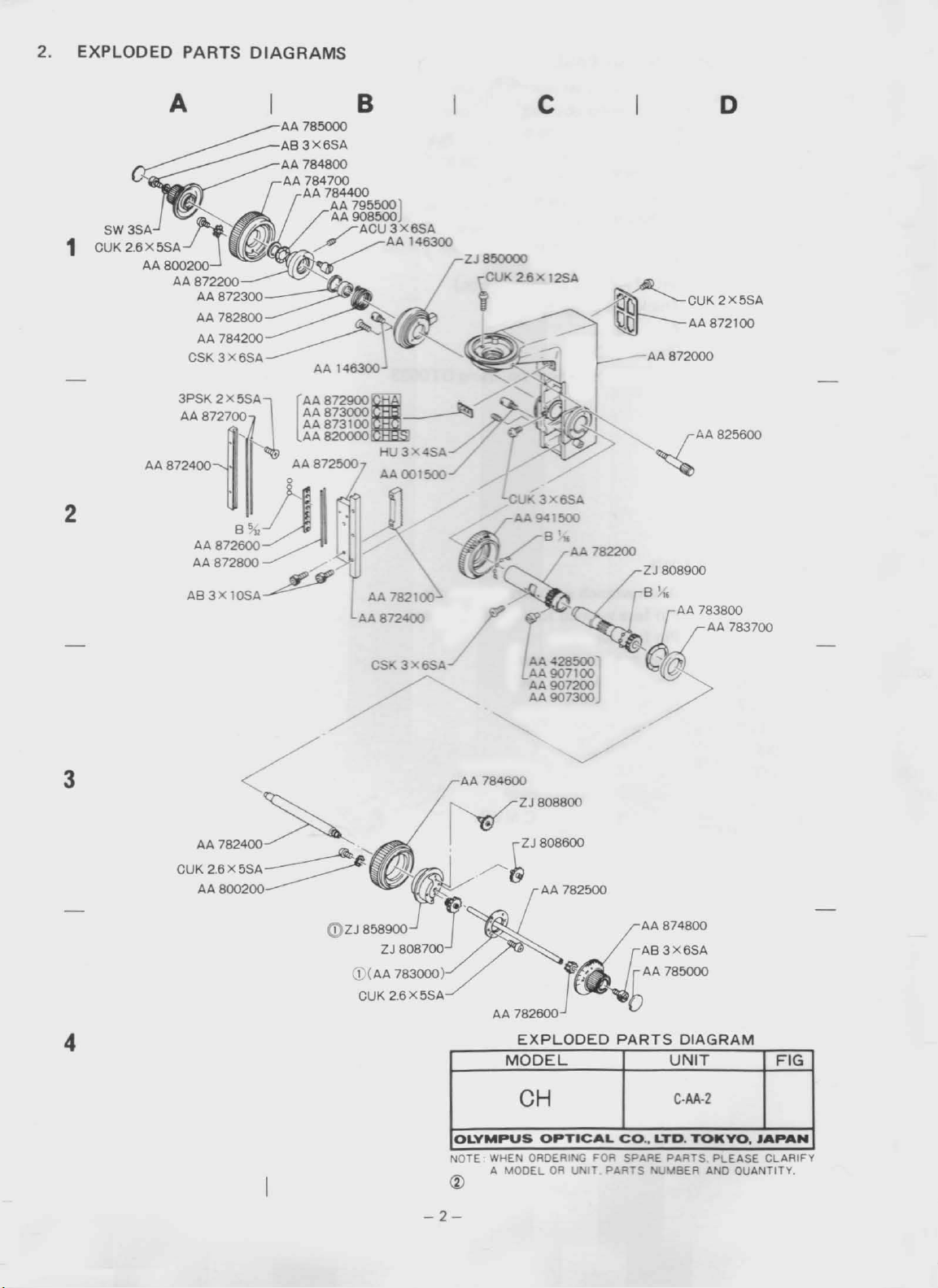

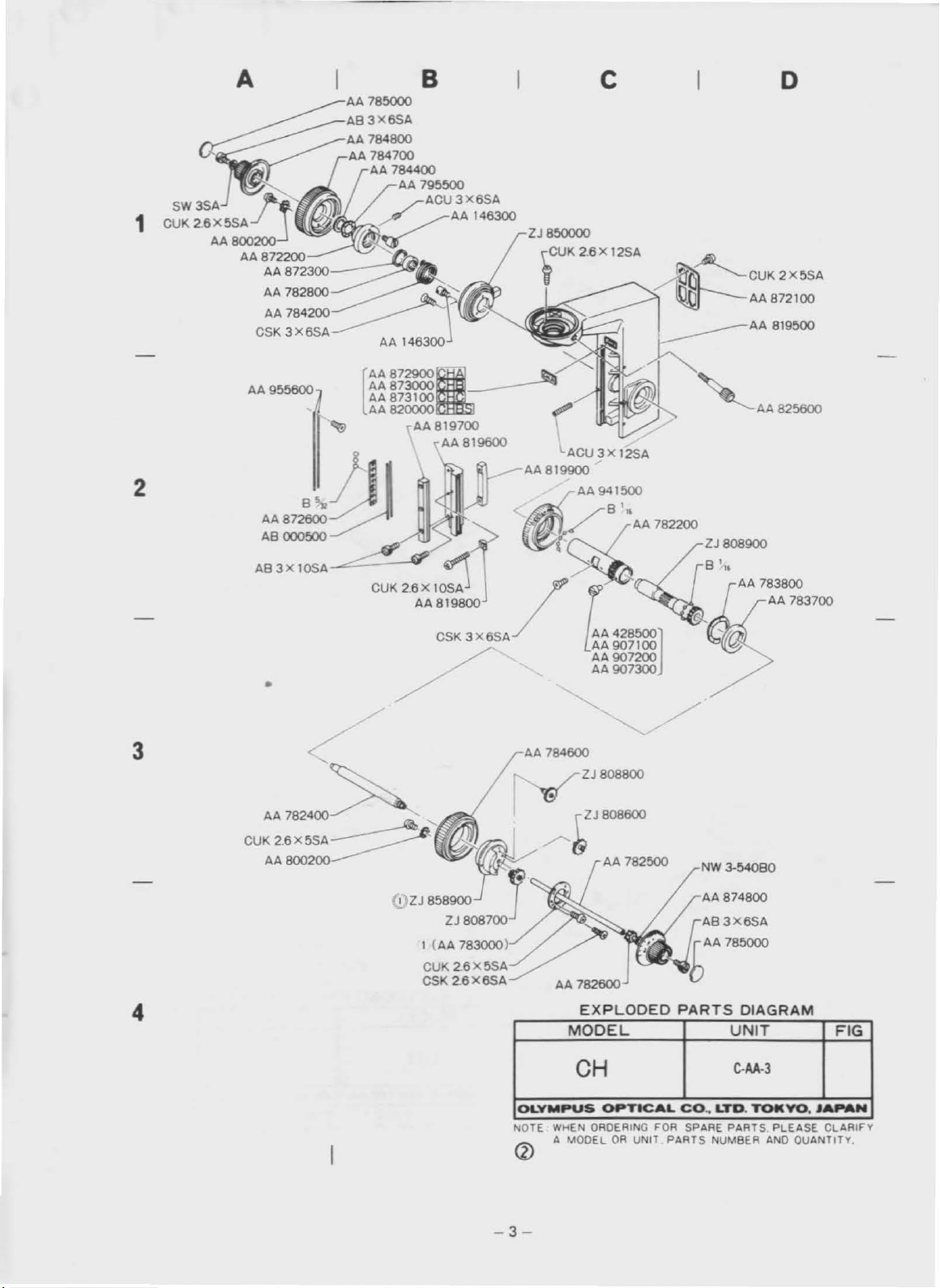

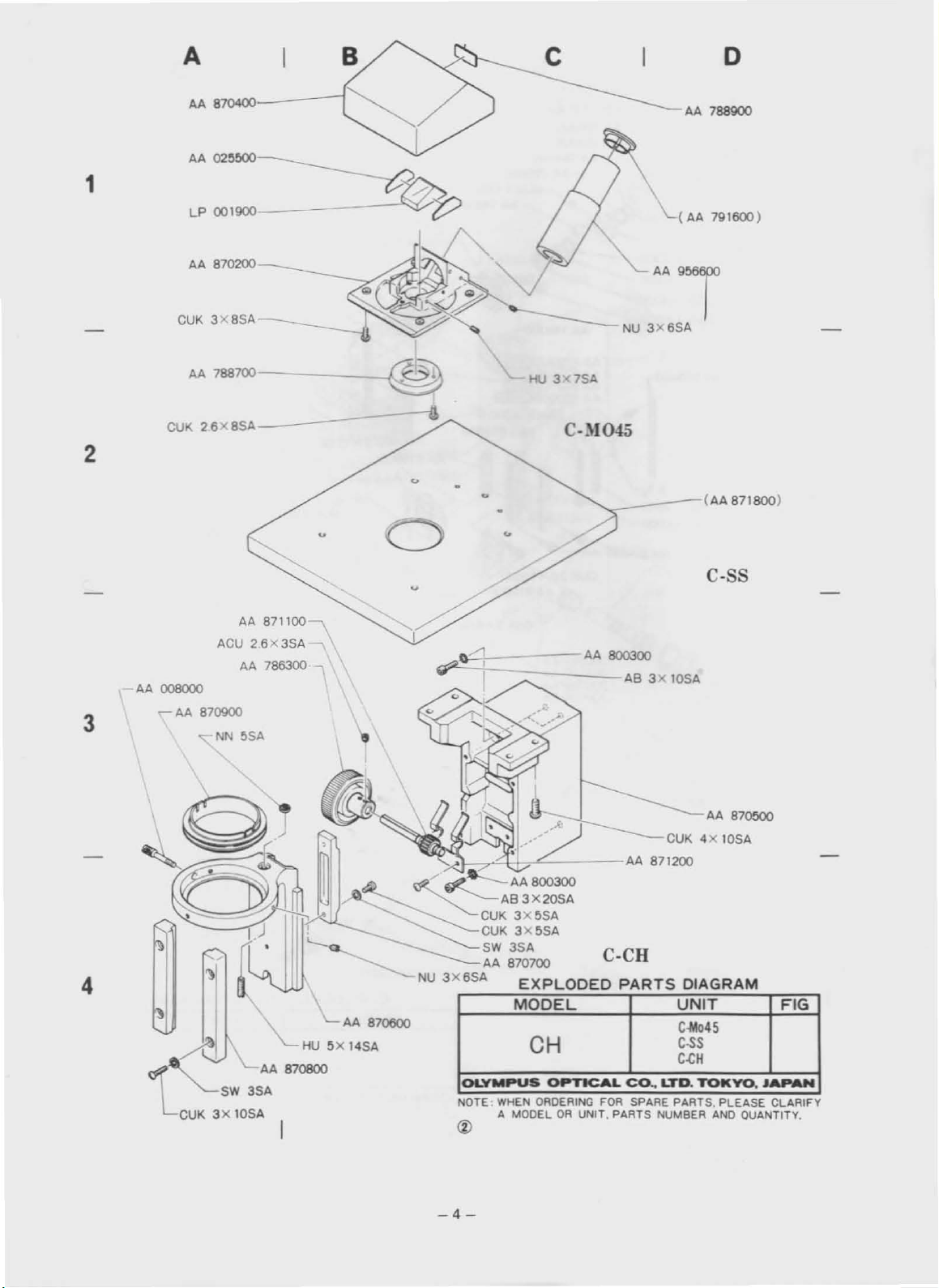

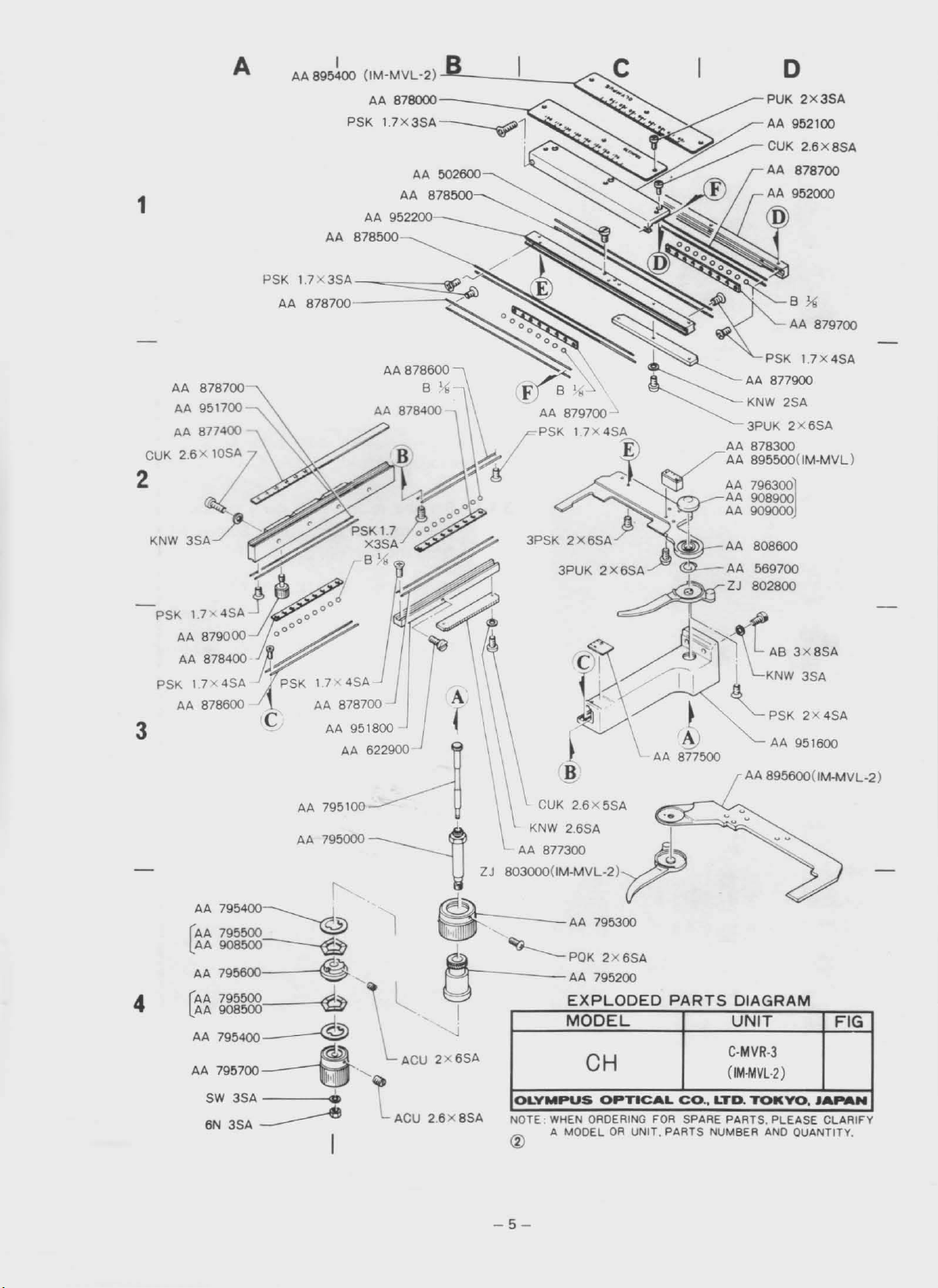

Page 2

1.

REPAIR TOOLS

AND

GREASE

CONTENTS

..

2. EXPLODED PARTS

DIAGRAMS

....................•......•.....•.....

3. DISASSEMBLING PROCEDURES FOR CHA·F-3 6

4. REASSEMBLING PROCEDURES FOR CHA·F-3

5. DISASSEMBLING PROCEDURES FOR C·CH CONDENSER

6. REASSEMBLING PROCEDURES FOR C·CH CONDENSER

7. DISASSEMBLING PROCEDURES FOR C-CL

8. REASSEMBLING PROCEDURES FOR C-CL

9.

OVERALL

10. DISASSEMBLING

11. DISASSEMBLING

REASSEMBLY

AND

AND

AND

ADJUSTMENT

REASSEMBLING PROCEDURES FOR CHA-F

REASSEMBLING PROCEDURES FOR C-MVR -45

LIGHT

LIGHT

EXiT

EXiT

HOLDER

HOLDER

2

17

31

34

37

38

38

40

Page 3

TO

OLYMPUS

MICROSCOPE

SERVICING

PERSONNEL

CH Series Microscopeiswidely

specimens. Since

at

your

shop.

As

you

know,

preceding BH Series.

this

microscopeisfrequently

Accordingly,

this

the coarse and fine adjustment mechanismofCH Seriesisnearly the

The

servicing personnel having experience in repairofBH Series

repair CH Series.

However,

ment

The

as

illustrated below.

attention

mustbepaidtothe

guide, and accordingly

old and new types

The

CHA-F

this

of

the

old

one was switchedtothe

(Old type)

AA872000

used

throughout

the

operated

manual shouldbehighly

fact

that

CH Series

series

current

currently

CH Series can

uses

new and

new one at

world

for

for

routine

helpful

has

undergone

old

be

discriminated

training

for

servicing personnel.

students and inspecting various

microscopy,itistobe

often

sameasthatofthe

can

therefore easily

modificationofits coarse adjust-

typesofcoarse adjustment guides.

from

each

other

by

a vertical line

the

beginningof1979.

CHA-F-3

(New type)

AA819500

repaired

Vertical

This

manual describes repairing procedures

separatelyatthe

CH Series adopts

cedures

"R

ight

of

the

side" and

last part.

the

binocular

"left

binocular

tube, reference should thereforebemadetothe

side" used in descriptions denote thoseasseenbythe

position.

In

addition,

personnel should refer

the mechanical stageofModel

to

this

manual.

line marked

tube

whichisquite

for

the new

typeofmicroscope

the

sameasthatofthe BH Series.

IMTisnearly the

first,

and those

repair manual

for

microscopist in his observing

sameasthatofCH-MVR,

for

the

For

repairing pro-

BH Series.

and

the

old

type

servicing

Page 4

Requisites

1. First

2. Never fail

a)

b)

for

of

all, ascertain

to

Find

out

Prior

to

repairs:

check

what

repair,

efficicent way.

3. After completing

microscope

Be

4.

carefu I

specified

5. Make repairs

to

not

for

make

purpose.

promptly

what

partsofthe

the

entire

functionofthe

prts are defective and

think

the

sure no

to

deform repair

of

the

repair, check

defect

and accurately.

microscope

the

.userorownerofwhich wishes youtorepair.

microscope before you commence its repair.

how

much

they

are damaged.

best possible

the

functionsofnot

orderofdisassembling

only

shouldbeleft unremedied.

parts

during

the

assembly; make it practicetouse tools and jigs

the

the

re-assembled parts

defective partsina most

but

also

the

entire

Page 5

1.

REPAIR

1-1

Regular Tools

TOOLS

AND

GREASE

OTOOll

OT0015

OT0016

OT0017

OT0023

OT0035

OT0044

OT0216

OT0317

OT1027

OTl131

OTl141

Setofscrewdrivers (6 pes.)

Phillips screwdriver (medium size)

Phillips screwdriver (large size)

Screwdriver (small size)

Handle

Tweezers (special made)

Torque

Set

Thickness

Alon

Shellac (20

Phillips screwdriver tiP. using

1-2 Grease

OT2006

OT2008

OT2010

OT2012

1-3 Special Jigs and Tools

KKACU2.5

KKAA7828

KAA8716

K

KC-2010

8-KC0026

8-KC0027

Allen

Pin face wrench

Pin face wrench

Tool

Jig

Spoon

B-KC0028 Jig

SKN0003

Gauge

CHKC0001 Jig

CHKC0002

CHKC0003

Jig

Support

of

small sizeofPhillips screwdriver

screwdriver

of

Allen

wrenches (8 pes.)

gauge

Alpha

g)

wrench

for

for

receptacle balls

for

for

receptacle balls

for

for

adjusting movementofC-MVR

for

adjusting movementofC-MVR

with

holding

balls

checking

frame

straight handle

for

fine adjustment

gear

stage

for

C-MVR

tilt

OT0023

alignment

-1-

Page 6

2.

EXPLODED

PARTS

DIAGRAMS

I B

c

A AA 785000

AB3X6SA

AA

~

;:~~.!f~/~

1

2

AA8002OO2200~~

AA87

U"'~.~~

AA872300

AA 782800

AA 784200

3X6SA

CSK

3PSK

2X5SA

AA872700

AA872800

AB3X

Q

10SA

784800

84700

AA

~A

/

AA

AA87

AA

[

AA 820000

• AA 872500

~

7844OO795500J

AA

500

AA~U3X6SA

AAI46300

ZJ850000

i

8729003000

873100

AA

AA872

782100"

• -

CUK 2.6 x 12SA

--CU

...

3X6SA

A.>

941500

~ .

B.

h(

r

AA

~

82200

7

/B'"

~G

lO

r

o

CUK2X5SA

AA 872100

AA 872000

~AA825800

ZJ

808900

AA

783800

AA 783700

CSK 3 6SA

/'

l~~~

AA907200

AA 907300J

/

3

AA 784600

ZJ

808800

~ZJ808600

(;

AA

782500

""""'!l4::

AA 7

82600

4

I

OLYMPUS

NOTE:MODELORUN

~

EXPLODED

MODEL

CH

OPT

HEN ORDERING

ICAL

FOR SPARE

IT

PARTS

::

PARTS

CO..LTD.

filUM

GRAM

DIA

UNIT

C-AA·2

YO

TOk

P~~~SA~~

EASE CLARIFY

OUANTITY.

JAPAN

.

FIG

~

-2-

Page 7

~

AA78~

B

c

AB3X6SA

~

O:~;:~~?f

1

AA800200

AA872200

~

AA

872300

AA782800~

AA 784200

CSK

3 XBSA

AA 784800

AA

~~4i~400

AA

795500 XBSA

ACU3

~!~

/.

AAI46300

~~

"-

_______

~

AA14B3OO

2J850000

~CUK

2.B

X 12SA

o

~~CUK2X5SA

~AA872100

AA 819500

AA

------

8729003000.

AA955600

2

,,",~gJ

AB 000500

AB3X10SA

•

3

AA

782400

CUK 2.BX5SA

AA800200

AA87

[

AA8=

AA 8 AA 819700

J

CUK2.BX10SA

~

AA 819800

/'

AA819600

~

CSK 3XBSA

'AA825600

lACUjX12SA

AA 819900

AA941500

<

K/"~

/

,~

l:

AA

428500]

AA

907200

AA

907100

AA907300

AA

784600

2J808800

2J

808600

/"~

AA 782500

:"7~~

AA 783700

/

NW

3-54080

4

FIG

toLYMPUS

NOTE

-3-

WHEN

A

MODEL

CH

QRDERIN

OP

TICAL

OR

CO.,

G FOR SPARE

UNIT

PARTS

D

LT.

PAB~~S

NUM

TOt(

yo

PLEASE

AND

........

•

CLARIFY

QUANTITY,

Page 8

AA

87ססoo

CUK4X10SA

~~-r'*l/~C-_--

<

fIZ...~AA

____

-z::::--

CUK

CUK3X5SA

NU

4

CUK

3X

SW

10SA

\.

AA 870800

3SA

"-

L

AA

HU5X14SA

870600

3X6SA

OLYMPUS

NOTE:

800300

AS

3X 20SA

3X5SA

SW

3SA

AA

870700

EXPLODED

MODEL

CH

OPTICAL

WHEN

ORDERING

A MODELORUNIT. PARTS NUMBER

AA

871200

C-CR

PARTS

DIAGRAM

UNIT

C-Mo45

C-SS

FIG

C<:H

Co..

lro.

TOKYO.

FDA SPARE PARTS. PLEASE CLARIFY

AND

JAPAN

QUANTITY,

-4-

Page 9

1

AA 878700

AA

951700

AA 877400

CUK 2.6x 10SA

2

A

PSK

AA

AA 895400

1.7

I

(IM-MVL

AA

PSK

X3SA

-~==::::5Il

878700-------,'"

-2)

878000-

--'--_--..!..

__

---/

-.<

PUK

o

2x3SA

-PSK

3

4

17'

PSK

AA

879000

AA

878400

17x4SA

AA

878600 C

4SA j

000000

~oo"

/ I

J~~

J'i

PSK

17<4SA

AA

878700

AA

AA

795100 \ \

AA

79!iOOO

AA

f'

AA795400~

AA

795600

[:

AA

908600"'<=l7

A""

. a POK

AA 795600

(AA

795600·.L

lAA

908600 g I

AA

795400

AA

795700~·'

SW

3SA

6N

3SA

--------e

~

--®

~

..

I

951800

622900

'1

I

l

'-ACU

ACU

;:---

~

2X6SA

2.6X8SA

3PSK 2X

A(

\ l

6SA.J

3PUK

K~~\:::5SA~

~

AA

877300

ZJ

803000(lM-MVL-2) -

~

--J

----

I

~

OLYMPUS

NOTE

<Z)

AA

795300

AA

795200

EXPLODED

MODEL

CH

WHEN

ORDERING FOR SPARE PARTS, PLEASE CLARIFY

A MODELORUNIT. PARTS NUMBER

AA

808600

2X6SA~

-_.

~ZJ

~-

-d~,).n.

AA

802600

~

569700

AS

/~~

2x6SA

OPTICAL

II

AA

877500

.•

PARTS

CO.•LTD.

~

r

I

KNW

.g

'-

PSK2X4SA

AA

AA 895600(IM-MVL-2)

DIAGRAM

UNIT

C·MVR-3

(IM-MVL-2)

TOKYO.

AND

3x8SA

3SA

951600

FIG

JA

....

QUANTlTV,

N

-5-

Page 10

3.

DISASSEMBLING

PROCEDURES FOR CHA-F-3

Fig. 3-1

",--

..

C-AA:

C-CH:

~

C-AA

C-BDA

C-CL:

C-BDA:

3- Detaeh Electrical

Arm

Condenser holder

Light

exit

Electrical

base

plate

base

plate C-BDA

from

the

m croscope stand.

-1

AB4x16SA

SW4SA

C-BDA

CUK3x6SA

3-

3-'-2

3-1-3

Set the microscope stand upside

en

remove

from

the

Remove Screw

base

four

fixing

plate.

CUK3x6SA

Screws

from

,ng line.

Detaeh

the

electrical

base

platebylihing

down

AB4x16SA

(See

Fig. 3-2)

the ground-

(See

Fig. 3-2)

and

it.

Fig. 3-2

Fig. 3-3

CUK3x6SA

3-2

By

removing three Screws

mount

Light

exit

C-CL.

CUK3x6SA,

(See

Fig. 3-3)

dis-

-6-

Page 11

3-3 Disassemble Condenser holder C-CH

ing three Screws

AA800300.

AB3xlOSA

and three

by

remov·

Washers

Fig.34

3-3-1 Rack

limit.

visible through the notch formed under

Holder

3-3-2 Rack

limit

up

the condenser holder

Remove Screw

AA870600.

down

and then remove

the condenser holdertoits lower

AB3xl0SA

two

Screws

to

its upper

which

(See

Fig. 3-4)

AB3x1OSA.

(See

Fig. 3-5)

is

Fig. 3-5

Fig. 3-6

, '

..

. .

'1'

'

...

AA819800

j-

..

•

3-4 Disassembling procedures

guide.

NOTE:

For disassembling procedures

adjustment guide

ofthis

3-4-1 Detach

manual.

removing

two

of

CHA-F (old type),

Fixing pieces

two

ScrewsCUK2.6x10SA.

for

coarse adjustment

of

the coarse

AA819800

(See

see

10-1

by

Fig. 3-6)

-7-

Page 12

3-4-2 Remove three Screws

gu

ide

AA819700.

AB3x1OSA

from

(See

Inner

Fig. 3-7)

AA819700

.'

,

-.

-~-

-

J .

"

Fig, 3-7

•.•

AB3xl0SA

-

. 1 .

~

.,

3-4-3 Loosen

AA819900_

two

Screws

AB3x10SA

(See

on Rack

Fig. 3-8)

Fig.

3-8

3-4-4 Disassemble Inner guide

Bal.s B 5/32 and Casing

isassembled together

with

AA819700.

AA872600

the inner guide.

Eight

are

-8-

Page 13

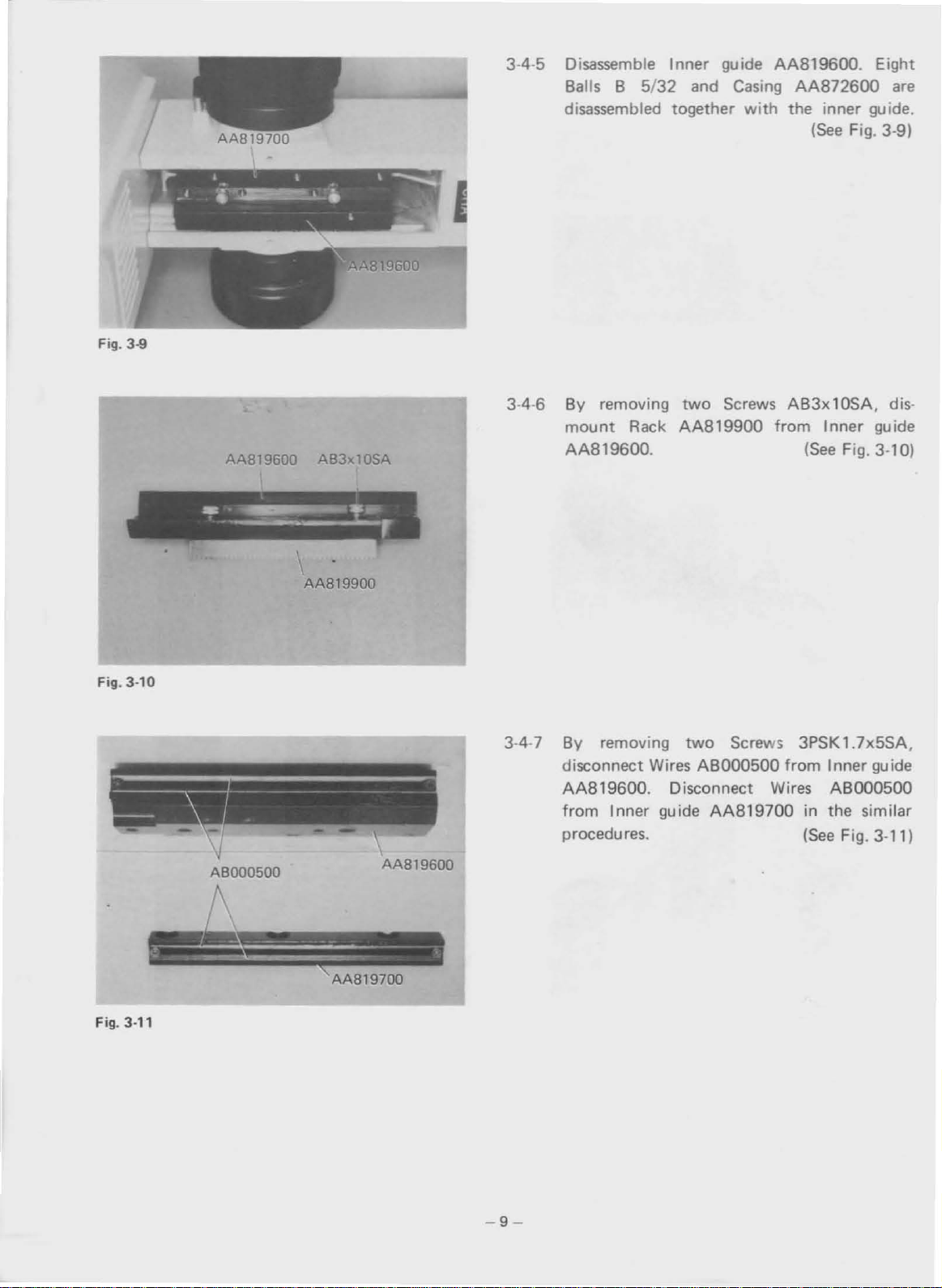

3-4-5 Disassemble Inner guide AA819600. Eight

8alls 8 5/32 and

disassembled together

Casing

with

AA872600

the inner guide.

(See

are

Fig. 3-9)

Fig. 3-9

-,~..

I

· ,

AA819600

,

AB3xl0SA

AAB19900

'-"'"

,..

'

3-4-6

By removing

mount

AA819600.

Rack

two

Screws AB3x10SA. dis·

AA819900

from Inner guide

(See

Fig. 3-10)

Fig. 3-10

Fig. 3-11

ABOO0500

AA819600

AA819700

3·4-7 By removing

disconnect Wires

AA819600. Disconnect Wires ABOO0500

from Inner guide

procedures.

two

Screws 3PSK 1.7x5SA.

ABOOO500

AA819700

from Inner guide

in the similar

(See

Fig. 3-11)

-9-

Page 14

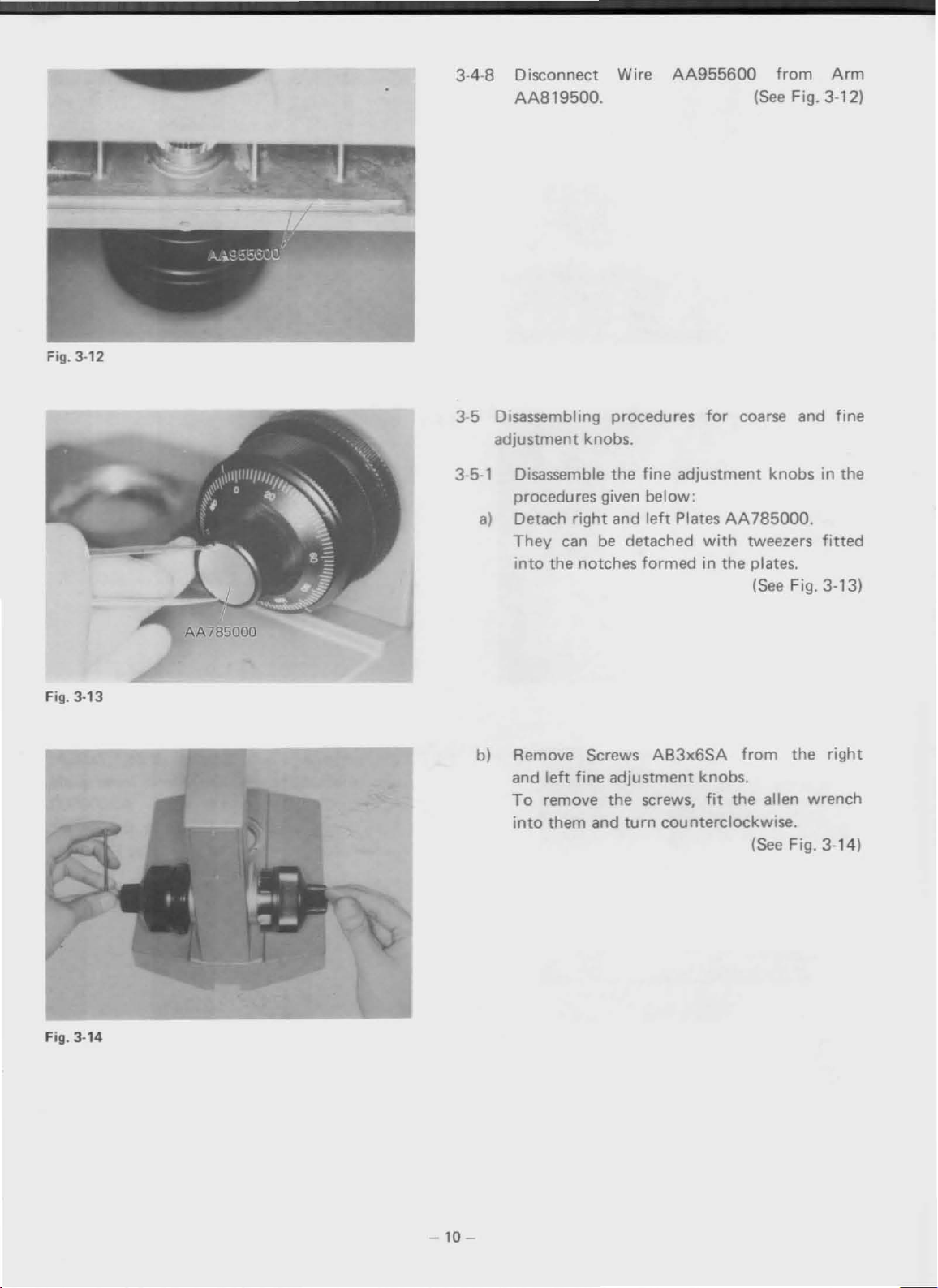

Fig. 3-12

3-4-8 Disconnect Wire

AA819500.

AA955600

(See

from

Fig. 3-12)

Arm

Fig. 3-13

AA785000

3-5 Disassembling procedures

adjustment knobs.

3-5-1 Disassemble

the

fine

adjustment knobs in the

procedures given below:

a)

Detach

They

into

b) Remove Screws

and

To

into

right

can

be

the

notches

left

fine

remove

them and

and

left

PlatesAA785000.

detached

formed

AB3x6SA

adjustment knobs.

the

screws,

turn

counterclockwise.

for

coarse and fine

with

tweezers

in the plates.

(See

from

fit

the alien wrench

(See Fig. 3-14)

fitted

Fig. 3-13)

the

right

Fig. 3-14

-10

-

Page 15

Fig.

3·15

c)

Pull

directions.

3-5-2 Detach

out

the fine adjustment knobs in both

(See

Washer

AA784400.

(See

Fig:

3-15)

Fig. 3-16)

Fig.

Fig.

AA784400

3·16

3·17

3-5-3 Detach Spring AA795500.

(See

Fig. 3-17)

-11-

Page 16

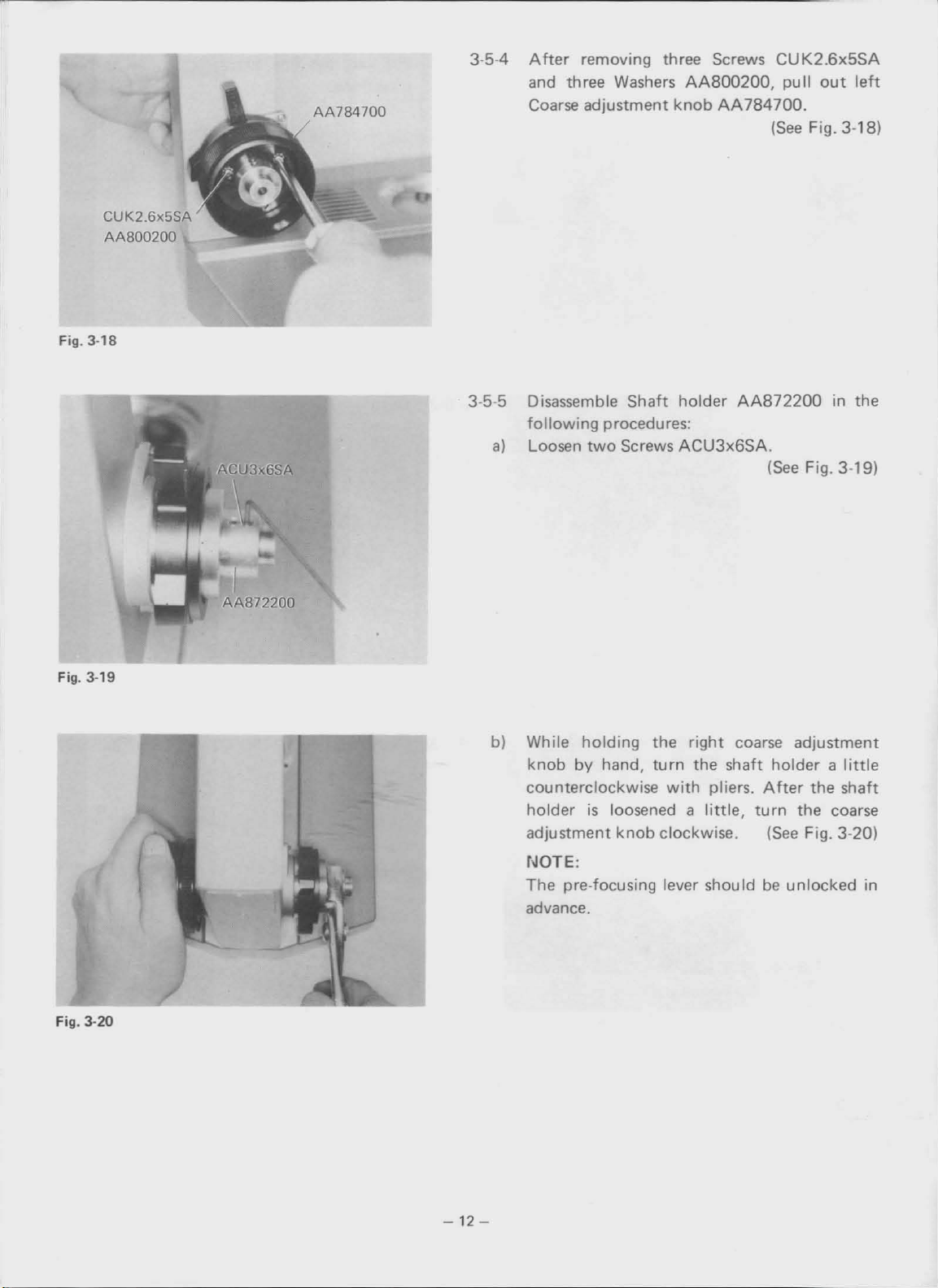

Fig.

3·18

CUK2_6x5SA

AA800200

AA784700

3-5-4

Aher

removing three Screws

and three Washers

Coarse adjustment

AA800200,

knob

AA784700.

CUK2.6x5SA

pull

out

(See

Fig. 3-18)

leh

Fig. 3-19

3-5-5 Disassemble Shaft

following

a)

Loosen

b) While

•

knob

procedures:

two

Screws

holding

by hand,

counterclockwise

is

holder

adjustment

loosened a

knob

holder

AA872200

ACU3x6SA.

the

right

coarse adjustment

turn

the shaft holder a

with

pliers.

little,

clockwise.

(See

After

turn

(See

in the

Fig. 3-19)

little

the shaft

the coarse

Fig. 3-20)

NOTE:

The

pre-focusing lever shouldbeunlocked in

advance.

Fig. 3-20

-12-

Page 17

Fig. 3-21

3-5-6 Remove Spring

AA784200.

(See

Fig. 3-21)

Fig. 3-22

3-5-7

Pullout

the right coarse adjustment

the direction indicated

3-5-8 Disassel]lble the

unit

a)

8y

Washers

adjustment

in the

removing three Screws

following

AA800200,

knob

by

arrow.

right

coarse adjustment

procedures:

disassemble Coarse

AA784600.

knob

(See

Fig. 3-22)

CUK2.6x5SA

(See

Fig. 3-23)

in

knob

and

Fig. 3-23

AA800200

AA784600

-13

-

Page 18

Fig. 3-24

AA783000

b)

By

removing three Screws CUK2.6x5SA,

detach Circular plate

c)

Detach

gears

AA787800.

AA783000.

(See

Fig. 3-24)

ZJ808600, ZJ808700 and

(See

Fig. 3-25)

Fig.

AA787800

3·25

ZJ808600

KC-2010

ZJ808700

3·5-9 Disassemble Pinion

following procedures:

a)

Set

Tool

808900, and set

Nut

AA782800.

b)

Remove the

KC-2010 on the right Gear ZJ·

Tool

nut

by

clockwise.

NOTE:

The

nutisfixed

The bearing

unit

unit

ZJ808900 in the

KKAA7828

on the

(See

turning the

with

adhesive agent.

tool

contains308alls B

left

Fig. 3-26)

counter·

1/16.

Fig.

3·26

-14

-

Page 19

Fig. 3-27

Pullout

cl

indicated

d)

Remove 8alls 8 1/16.

Pinion ZJ808900

by

arrow.

in the direction

(See

Fig. 3-27)

Fig. 3-28

AA783700

\

3-5-10

3-5-11 Disassemble the pinion bearing in the pro-

After

Screw CSK3x6SA,

bearing.

by

cedures given below:

a)

Detach Washer

It

can

arrow

removing

be

two

Screws

dismount

pulled

after the screws have

out

in the direction indicated

AA783700.

CUK3x6SA

the

been

removed.

(See

Fig. 3-28)

(See

Fig. 3-29)

and

pinion

Fig. 3-29

-15-

Page 20

Fig. 3-30

AA783800

AA941500

b) Detach Spring

c)

Remove

Knob

clockwise (in

arrow).

AA783800.

AA941500

the

direction indicated

(See

by

(See

Fig. 3-30)

turning

Fig. 3-31)

it

by

Fig. 3·31

Fig.

3·32

3·5-12 Disassemble the pre-focusing lever in the

following procedures:

a)

Remove Stopper

AA001500.

(See

Fig. 3-32)

-16-

Page 21

Fig. 3-33

AA784100

AA941600

b) Remove Lever

counterclockwise.

NOTE:

Lever ZJ850000

three parts:

Lever

Ring

Outer ring

c)

Detach Ring

AA941600

AA784100

AA784000

AA784100.

AA941600

consists

of

by

(See

the

(See

turning

Fig. 3-33)

following

Fig. 3·34)

it

Fig. 3-34

4. REASSEMBLING PROCEDURES FOR CHA-F-3

4-1

Fig.

AA941500

4-'

4-1-1

Reassemble the coarse adjustment knob.

Reassemble the pinion bearing

following

a)

Reassemble Knob

procedures:

AA783800

AA782200.

Apply

Grease

OT2006tothe thread.

unit

with

(See

in the

Bearing

Fig. 4·1)

-

17-

Page 22

Fig. 4-2

AA783700

b)

Apply

Spring

c)

Apply

and reassemble

Grease

AA783800

OT2006tothe thread crests

and reassemble

Grease OT2006toWasher

it.

it.

(See

Fig. 4-2)

AA783700

(See

Fig. 4-3)

of

Fig_

Fig_

4-3

4-4

4-1-2 Reassemble the

AA819500

by

and Screw CSK3x6SA.

pinion

using

two

bearing

Screws

with

CUK3x6SA

(See

Fig. 4-4)

Arm

-18

-

Page 23

Fig.4·5

ZJ808900

}

Thread

ZJ808900

B·KCOO27

B

1/16

4·1·3 Reassemble Pinion shaft

procedures given below:

a)

Apply

Grease

OT2012

ZJ808900.

NOTE:

Take care

b)

Set 30 Balls B 1/16

nottoapply

into

greasetothe thread.

(1) Set Jig B·KC0026 on the

(2)

Apply

set

Drop

(3)

(4) Pull

Grease

them

the

out

OT2012tothe30balls and

into

Jig B-KC0027.

ballsindirection

Jig B·KC0026 in direction (B).

ZJ808900

to

the Pinion shaft

(See

the

pinion

pinion

(A).

(See

in the

Fig. 4·5)

shaft.

shaft.

Fig. 4-6)

8·KC0026

Fig.4-6

/

c)

Reassemble the

With

(1)

the microscope stand kept

insert the

pinion

pinion

shaft

with

the bearing.

upright,

shaft while taking

care

nottodrop the balls.

(2) Fell

down

holding

the balls.

the microscope stand while

the

pinion

shaftsoas

nottodrop

(See

Fig. 4·7)

Fig.

4·7

-19

-

Page 24

Fig. 4-8

B·KC0028

I

,

d) Set the

0028.

(1) Set Jig

30

Balls B

B-KC0028inposition.

1/16

by

using Jig B-KC

(See

Fig. 4-8)

Fig. 4-9

AA782800

(2) While taking care

the threadofPinion shaft

the

ballsbyusing tweezers.

(3) Remove Jig

NOTE:

Take

sufficient

be

applied

shaft.

e)

Reassemble

such a degree

dropping

out.

B·KC0028.

to

Nut

AA782800

as

not

to

apply

care

to

prevent

the thread

and

to

prevent the balls

(See

grease

ZJ808900.

(See

Fig.

grease

of

the

pinion

tightenitto

Fig. 4-10)

to

set

4·9)

to

from

Fig. 4-10

-20-

Page 25

Fig. 4-11

f)

Set

the

microscope stand

in

its initial posi-

tion.

Adjust

(1) Tighten

the

pinion shaft and

the

nuttosuch a degree

is

pinion shaft

free from unsmooth rota-

tionorplayinthe

thrust

Nut

AA782800:

direction.

(See Fig. 4-11)

(2) Note

pinion shaft

cannot

that

the

smooth if Nut AA782800istightened

much.

g)

Apply Alon Alpha OT1027tothe thread

Nut AA782800. (See Fig. 4-12)

that

rotate

the

too

of

Fig. 4-12

ZJ856400

AA782800----IU

OTl027

AB023600

~~

4-1-4 Reassemble

a)

After

making sure

free from contamination by oil

reassemble itinposition. (See Fig. 4-13)

the

pre-focusing lever:

that

Ring

AA784100

or

flaw,

is

Fig. 4-13

-21-

Page 26

Fig. 4·14

b)

Reassemble Lever AA941600 by screwing

it clockwise as far as it can

turn.

(See Fig. 4-14)

c)

Reassemble

Stopper

AA001500.

(See Fig. 4-15)

Fig. 4-15

Fig.4-16

ZJ808600

ZJ808700

4-1-5 Reassemble the right coarse adjustment

knob:

a)

Reassemble Gear

787800,

Grease

applied

ZJ808600

OT2012

to

the

mount

with Gears AA·

and ZJ808700.

should preliminarily be

shafts and th readofthe

gears.

(See Fig. 4-16)

-

22-

Page 27

Fig. 4-17

AA783000

b)

Reassemble

Screws

CU

c) Check the

as

described below:

(1)

8y

turning the

sure

creaking noise.

(2)

If

the

the following items:

Set condition

n Flaw and du

Flaw and burrs on Cover

in the bearing hole

782900.

Cover

K2.6x5SA.

gears

that

they

gears

st

AA783000

for

their

gears

can

rotating conditions

with

turn smooth

with

(See

three

Fig. 4·17)

a finger, make

with

no

cannot turn smooth, check

of

CoverAA783000

on the

gear

teeth

AA783000

of

Gear mountAA·

and

Fig.

4-18

CUK2.6x5SA

AA800200

AA784600

4·1

d)

three

~

Reassemble

Adjust

ones

Reassemble

784600

the partsorreplace them

if

necessary.

Coarse adjustment

with

three Screws CUK2.6x5SA and

Washers

AA800200.

the right coarse adjustment knob

in the following procedures:

a)

Reassemble

the knob

unit.

(See

(See

with

knob

Fig. 4-18)

Fig. 4-19)

new

AA·

Fig.

4·19

-23

-

Page 28

Fig. 4·20

b)

Reassemble Spring

c)

Reassemble 8earing

(1)

Fit

Stopper

Bearing

attached

AA784200

depressing the bearing

microscope stand.

wise

When

the

stopper

be

a

stand once again.

AA784200.

AA782200.

screw

AA872200

at

as

AA

146300

into

the

other

shown in Fig. 4-20. While

turn

as

farasit

can go. (Fig. 4-21)

itisstopped, ride the

while

allowing the bearing

little

apart

from

(See

the

end

lightly

the

the

(See

Fig. 4-20)

located on

circular

of

part

Spring

to

knob

clock-

knob

over

microscope

Fig. 4-22)

the

to

Fig. 4-21

AA784200

Fig. 4-22

Screws

Screws

AA146300onAA784100

AA

146300onAA872200

Reassembly

knob

quence

shouIdbe

ofA....B....

4-22.

of

the coarse adjustment

performed

in

C illustrated in Fig.

the

se-

-

24-

Page 29

Fig.

4·23

(2) With the bearing depressed lightiytothe

microscope stand by hand, tighten the

right coarse adjustment knob by turning

it

clockwise. Finally, tighten it firmly

while holding

the

similar tool. (See Fig. 4-23)

NOTE:

the

bearing with pliers

or

Coarse adjustment knob AA784600 can·

not

turn smooth unless Gear

assembled

in

the

gear

properly with Pinion

mountisengaged

ZJ808900

ZJ808900

in

tightening the knob.

Fig.

4·24

(3) Tighten

two

Setscrews ACU3x5SA on

8earing AA872200. (See Fig. 4·24)

4-1·7 Reassemble Coarse adjustment knob AA·

874700

and

with three Screws

CU

K2.6x5SA

three Washers AA800200. (See Fig. 4·25)

Fig.

4·25

-

25-

Page 30

Fig.

4·26

4-1-8 Reassemble Spring

2008 should

thread crests

preliminarily

of

the spring.

AA795500.

be

Grease

applied

(See

Fig. 4·26)

to

QT-

the

Fig. 4·27

AA784400

4-1-9 Reassemble Washer

2008

should

preliminarily

AA784400.

be

washer.

4-1-10 Reassemble the fine adjustment

procedures given below:

a)

Insert the

Knob

Gear

Shaft

b)

Reassemble the

right

knob

AA874800

AA782600

AA

783000

left

unit:

knob

AA784800.

Greas~

applied

(See

Fig. 4-27)

knob

(See

QT-

to

the

in the

Fig. 4-28)

Fig.

4·28

-

26-

Page 31

Fig. 4-29

c)

Tighten right and

left

Screws AB3x6SA_

(See

Fig. 4-29)

Fig. 4-30

AA819600

4-1-11 Reassemble right and

4-2 Reassembling procedures

left

Plates

for

coarse adjustment

guide.

NOTE:

For reassembling the coarse adjustment guide

CHA-F (old type), proceed

to

manual.

AA

(See

10-2

785000.

Fig. 4·30)

of

of

this

Fig. 4-31

AA819900

4-2-1

-

27-

Reassemble Inner guide

a)

Temporarily reassemble Rack

with

Inner guide

AA819600.

unit

AA819600.

AA819900

(See

Fig. 4-31)

Page 32

b)

Reassemble

9uide

AA819600

1.7x5SA and apply

two

Wires

by

Grease

AB000500

using

two

OT2010.

with

Inner

Screws 3PSK

(See

Fig. 4-32)

Fig. 4-32

- -

---

AB000500 3PSK 1.7x5SA

AA819700

AB000500

-------

3PSK1.7x5SA

/

4-2-2 Reassemble

guide

1.7x5SA and apply

two

AA819700

Wires

by

Grease

AB000500

using

two

OT2010.

with

Inner

Screws 3PSK

(See

Fig. 4-33)

Fig. 4·33

Fig.4-34

4-2-3 Connect

of

Arm

Apply

them

for

four

Wires

AA819500.

grease

OT2010tothe wires and bond

connection.

AA955600

to

(See

the guide

Fig. 4-34)

-

28-

Page 33

Fig. 4-35

4-2-4

Mount

Casing

B 5/32.

o

Apply

Grease

advance.

o The casing

pinion.

AA872600

OT2010

shouIdbe

and eight Balls

(See

Fig. 4-35)

to

the balls in

centered

with

the

Fig. 4-36

ABB77600

B

5/32

4-2·5

4-2-6

a)

Reassemble

step

4-2-1

Reassemble

step 4-2-2

Mount

the inner guide

above.

the inner guide

above_

Casing

AA872600

B 5/32 on the Inner guide

This step

is

quite similarto4-2-4

unit

prepared in

(See

Fig. 4-36)

unit

prepared in

and eight Balls

AA819700.

(See

Fig. 4-37)

above_

Fig. 4-37

AAB19700

-

29-

Page 34

Fig.4-38

AB3xl0SA

b)

Reassemble the Inner guide in alignment

that

reassembled in step 4-2-5 above.

NOTE:

The

inner guide shouldbefixedbytightening

Screw

haifa

AB3x1OSA,

turn

(180°).

and then loosened

(See

with

Fig. 4-38)

about

Fig.

4·39

4-2-7 Reassemble

using Screw

NOTE:

The

screw shouIdbe

that

Rack

about

which

fter

position ing the rack snugly by moving

the inner guide

4-2-8

a)

b)

4-2-9

a)

degree

Adjust

Loosen

10SA

A

the inner guide

adjustment knob,

AB3x1OSA.

Adjustmentofinner guide

Adjust

movable range.

two

Fixing

CUK2.6x10SA.

the guideisfree

AA819900.

half

are

used

up

pieces

tightened

a turn

for

fixing

and

down

firmly

unittothe centerofits

from

two

with

tighten

unit

AA819800

(See

Fig.

to

such a

play.

Screws

the

rack.

the coarse

two

Screws

(See

Fig. 4-40)

by

4-391

AB3x

Fig.440

-30-

Page 35

Fig.441

b)

By using a screwdriverortweezers, adjust the

to

casing

the centerofthe inner guide

(See

c)

By using Torque screwdriver

two

Setscrews GUK2.6x10SA

piece.

Tightening torque:

d)

Apply

Shellac OT1131

800

OT0044,

for

(See

g-cm

to

the screws to

prevent loosening.

e)

Finally

fix

inner guide

AA819700bytighten-

ing three Screws AB3x10SA.

unit.

Fig. 4-41)

tighten

the

fixing

Fig. 4-42)

Fig.

442

5.

DISASSEMBLING

Fig. 5-1

PROCEDURES FOR

C-GH

-31-

CONDENSER

5-1

By removing

mount

left

HOLDER

two

Dovetail

Screws

GUK3x10SA,

AA870800.

(See

dis-

Fig. 5-1)

Page 36

Fig. 5·2

AA870800

5-2

By removing

mount

two

right

Dovetail AAB70BOO.

Screws

CUK3x10SA.

(See

Fig. 5-2)

dis·

Fig. 5-3

klA008000

5-3 Dismount the condenser holder.

5-4 Disassembling procedures

5-4·1 By removing

mount

Rack

two

AA870700.

for

Screws

(See

Fig. 5-3)

condenser holder.

CUK3x5SA.

(See

dis·

Fig. 5-4)

Fig. 5-4

O''+--

CUK3x5SA

-32

-

Page 37

5-4-2 Detach

NOTE:

/AA870900

Sleeve

correct the following defects only:

(1) Miscentering

(2) Breakage

a)

Remove Setscrew AA008000.

b)

Loosen three Screws NU3x6SA_

c)

Detach

5-4-3 Remove Condenser height adjusting screw

HU5x14SA.

Fig. 5-5 NOTE:

The height adjusting screw shouldberemoved

only

ed.

a)

Remove

b)

Remove Screw HU5x14SA.

(See

Sleeve

AA870900.

AA870900

of

Sleeve

Sleeve

AA870900.

should

of

condenser

be

AA870900

Fig. 5-5)

detached

to

when the condenser heightismisadjust-

Nut

NN5SA.

(See

Fig. 5-5)

Fig. 5-6

AA871100

5-4-4 Disassemble Pinion AA871100.

5-4-5 Detach Knob

871100 by removing

AA786300

two

from Pinion

Screws ACU2.6x

3SA.

(See

(See

Fig. 5-6)

AA-

Fig. 5-7)

Fig. 5-7

AA786300

ACU2.6x3SA

-33

-

Page 38

Fig. 5-8

5-4-6

Dismount

removing

two

Pinion

Screws

holder

AA871200

CUK3x5SA.

(See

by

Fig. 5-8)

Fig. 5-9

6_

REASSEMBLING

5-4-7 Detach Stage plate

four

Screws

NOTE:

CUK4xl0SA The

stage

itisdefective

proper.

PROCEDURES FOR C-CH CONDENSER

6-1

Reassemble Stage plate

AA870500

AA871800

CUK4x10SA.

plate shouldbedetached

or

its perpendicularityisim-

HOLDER

AA871800

by

using

four

Screws

by removing

(See

Fig. 5-9)

only

when

with

Block

CUK4x10SA.

(See

Fig. 6-1)

Fill-

6-1

-34-

Page 39

Fig. 6-2

6-2 Reassemble Pinion holder

two

Screws

CUK3x5SA.

AA871200

(See

by using

Fig. 6-2)

Fig.

6·3

NU3x6SA

6-3 Set Pinion AA871100 in position.

6-4 Reassembling procedures

for

condenser holder

unit.

6-4-1 Reassemble

denser holder

Sleeve

AA870600

AA870900

Screws NU3x6SA.

(See

Fig. 6-3)

with

Con-

by using three

(See

Fig. 6-4)

Fig.64

-

6-4-2

35-

Reassemble

Setscrew

AA008000.

Page 40

6-4-3 Reassemble Rack

Washers

SW

3SA

5SA_

AA870700

and

two

by

Screws

(See

using

CUK3x

Fig. 6-5)

two

Fig. 6-5

;;;""'~AA870700

6-4-4

Apply

Grease

OT2008tothe dovetail.

6-5 Reassemble Condenser height adjusting screw

HU5x14SA.

6-6 Set

the

condenser holder

unit

in position.

(See

Fig. 6-6)

Fig. 6-6

Fig. 6-7

AA870500-

AA870800

CUK3xl0SA

6-7 Reassemble right Dovetail

two

Screws

CUK3xl0SA

3SA.

be

The dovetail should

with

the sideofBlock

reassembled in alignment

AA870500.

AA870800

and

two

by using

Washers

(See

Fig. 6-7)

SW

-

36-

Page 41

6-8 Reassemble

two

Screws

3SA.

While pushing the dovetail

left

CU

Dovetail

K3x

10SA and

AA870800

two

(See

uniformly

direction indicated by arrows, tighten the

screws.

by

Washers

Fig. 6-8)

in the

using

SW

Fig. 6-8

Fig. 6-9

AA870800

/'

6-9 Reassemble

Knob

AA876300

by

using

two

Screws ACU2.6x3SA.

knob

The

6-10 Check

shouldbeapart

the

condenser holder

about

2 mm.

for

its vertical

(See

6-9)

motion.

6-10-1

Check the dovetail

a)

When

the

tip

for

its play.

of

the condenser holder

is

swung in the right-left direction, play must

notbefeltbyhand.

b)

If

the dovetail plays, tighten the

firmly

sufficiently

arrow.

while depressing

in

the

direction indicated by

(See

the

two

screws

left

dovetail

step 6-8 above)

7.

DISASSEMBLING

PROCEDURES FOR C-CL

1L--_AA290200

LIGHT

7-1

EXIT

Remove Ring

AA871600.

NOTE:

The ring

If

it

wrench

tweezers

is

bonded at one

cannot

KKAA8716,

or

the

be loosened

similar

7-2 Disassemble the lens system:

Lens

Ring

Filter

Ring

Lens

-

37-

LA410800

AA290100

LP072100

AA290200

LA510900

cut

tool.

point

off

with

with

Araldite

Araldite.

the Pin face

by

using

Page 42

8.

REASSEMBLING

PROCEDURES FOR C-CL

LIGHT

8-1

EXIT

Reassemble Lens

AA871500.

AA410900

with

Lens

tube

9.

OVERALL

_LA410900

-

~

I

ASSEMBLY

AA87,SOll

AA290200

LP072,00

AA290,00

LA41

0800

AA87,600

AND

ADJUSTMENT

8-2 Reassemble Ring

8·3 Reassemble

8-4 Reassemble Ring

8-5 Reassemble Lens

8-6 Tighten Ring

KKAA8716.

8·7 Loosen Ring

as

not

Araldite

ing.

9-1

Reassemble C·CH

three Screws

AA800300.

See

step 3-3 above.

Filter

AA871600tosuch a slight degree

to

allow

OT1028ata

AA290200.

LP0721 00.

AA290100.

LA41

0800.

AA871600

the lens

point

unit

A83x

10SA and three Screws

by using Wrench

to

play, and apply

to

prevent loosen-

with

the arm by using

(See

Fig. 8·1)

/

•

Fig. 9-1

Adjust

9-2

9-2-1

a)

b)

c)

Measure

Thickness

and

If

d)

of

10SA.

9-2-2

Adjustment

a)

Proceedasdescribed in 9-2-1·b) above.

b) Proceed

c)

If

inserting

871800

perpendicularityofthe

Adjust

Set Stage perpendicularity

the

Apply

X direction.

in X

direction

nose

piece.

SKN0003

gaps

gauge

stage

surface.

Standard:

the standardisnot

C-CH

the standard

by

as

described in 9-2·1-e) above.

tin

and Block

in the X

Within

turning

in Y

foil

on the

OT0317

direction

is

between Stage plate

AA870500.

0.15 mm

satisfied, adjust position

three Setscrews

not

stage

.

gauge

SKN0003

stage

surface in the

direction

between

satisfied, adjust by

by

SKN0003

(See

(See

on

using

Fig. 9-1)

A83x

Fig. 9·2)

AA-

Fig. 9-2

-

38-

Page 43

9-3 Reassemble Light

Screws CUK3x6SA.

NOTE:

The

notches formed

on

positioned

the

Fig. 3-3.

exit

C-CL by using three

in

the

light

front

and rearasshown

exit

must

be

in

Sreciman

B2KC0010-

Fig. 9-3

9-4 Reassemble Electric base plate C-BDA.

(See Fig. 3-2)

9-5 Check and

adjustment

of

fine

sensitivity.

Set

the

9-5-1

components

in

Fig. 9-3.

Microscope

Objective

following accessories and checking

in

the

microscope as shown

tube}

40x

Need

notbeof

specific types

Eyepiece lOx

Condenser

Specimen (matched with objective 40x)

Block B2KC0010

9-5-2 Check fine

adjustment

sensitivity

following procedures:

a)

Bring

indication

b)

Turn

divisions) and bring

once again.

fine

Difference between readings

a)

c) Remove Block B2KC0010, and

the

specimen

on

the

fine

adjustment

andb)must

into

focus and read

the

fine

adjustment

adjustment

Then

scale

the

read indication

once

knob

specimen into focus

again.

obtainedinstep

be within 1.5 divisions.

then

scale.

stepsa)andb)above.

adjustment

in

the

±25Il(10

on

the

carry

out

9-5-3 When

a)

b) Check

c) Check

For details, refer

above parentheses.

-

39-

the

standardisnot

Check

the

pinion shaft (assembledin4-1·3)

for its assembled

the

right coarse

condition

satisfied:

and

parts.

adjustment

knob

(assembledin4·1-5) for its assembled condi·

the

tion and parts (especially

the

right coarse

gears).

adjustment

knob

unit

for its assembled condition.

to

the

steps

mentionedinthe

Page 44

10. DISASSEMBLING

AND

REASSEMBLING PROCEDURES FOR CHA-F

(OLD

TYPE)

Fig. 10·1

10-1-1 Loosen

the

left

coarse adjustment guide.

10-1-2 Dismount

removing three Screws

two

Adjusting screws

left

Outer guide

AB3x

(See

HU3x4SA

(See

Fig. 10-1)

AA872400

lOSA.

Figs. 10-2, 10-3)

on

by

Fig. 10-2

Fig. 10-3

I

-40-

Page 45

Fig.

104

10-1-3 Remove eight Balls B 5/32, Casing AAB72600

and Inner

10-1-4 Remove eight Balls B 5/32

872600.

gu

ide

AA872500.

and

(See

(See

Casing

Fig. 10-4)

AA-

Fig. 10-5)

Fig. 10-6

Fig. 10-6

10-1-5 Disassemble right Outer guide

removing three Screws

AB3xl0SA.

AA872400

(See

Fig. 10-6)

by

-41-

Page 46

AA872400

10-1-6 Disconnect

of

right

removing

\

guide.

two

Wires

and

left

Outer

two

Screws 3PSK2x5SA

AA872700

guides

AA872400

(See

from

each

from

each

Fig. 10-7)

by

--

.

Fig. 10-7

AA872500

AA872700

----

---~

-

- -

AA782100

..........

3PSK2x5SA AA872800

3PSK2x5SA

10-1-7 Disconnect

10-1-8

guide

3PSK2x5SA.

Dismount

AA872500

lOSA.

NOTE:

For

AA872500

later steps, proceedto3-5ofthis manual.

four

Rack

by

wires

AA872800

by removing

AA782100

removing

from

two

from Inner

four

(See

Fig. 10-8)

Inner guide

Screws

(See

Fig. 10-8)

Screws

AB3x

Fig. 10-8

Fig. 10-9

AA872400

L

3PSK2x5SA

10-2

Reassembl

guide.

10-2-1 Connect

right and

using

NOTE:

•

Check the wires

wires which

ing procedu

two

Wires

left

Outer

two

Screws 3PSK2x5SA

for

have

no flaworbending.

res

for

AA872700

guides

flaws

coarse adjustment

to

each

of

AA872400

for

(See

and

bending.

each

Fig. 10-9)

by

guide.

Use

-42-

Page 47

Fig. 10-10

10·2·2 Reassemble

three Screws AB3xl0SA. (See Fig, 10-10)

Attach

sion formed

reassemble the

the

the

right

right

outer

at

the center

gu

ide parallelly.

ouler

guide

guidetothe

of

the

-by

using

protru·

arm and

~

Fig. 10-11

AA782100

I

.

• I

AA872500

AA872800

~

1\.

AB3xl0SA

10-2-3

•

10-2-4

Reassemble

a)

Reassemble Rack AA782100 with Inner guide

AA872500 by using two Screws AB3xl0SA.

b)

Connect four wires AA872800 by tightening

four Screws 3PSK2x5SA. (See Fig. 10-11)

NOTE:

Check the wires for flaws and bending.

wires which have no flaworbending.

Set

eight Balls B

the

into

Apply Grease

the

inner guide into unit.

right

outer

OT2010tothe

(See Fig. 10·11)

5/32

and Casing AA872600

guide. (See Fig. 10-12)

ballsinadvance.

Use

IJ

Fig. 10-12

-43-

Page 48

Fig. 10-13

10-2-5 Set the

stand.

inner

guide

unit

into

the microscope

(See

Fig. 10-13)

Fig. 10-14

...~,,

" • e

..

q )

'A'.·

.

..

- .

AA872500

10-2-6 Set eight Balls B

Apply

-

Grease

5/32

and Casing

OT2010tothe balls in advance.

AA872600.

(See

Fig. 10-14)

•

10·2·7 Reassemble

using three Screws

NOTE:

Three Screws

temporarily

tightening them

left

Inner

AB3x10SA.

AB3x10SA

(loosen

firmly).

guide

about

AA872400

(See

Fig. 10-15)

shouldbetightened

1/6

turn

by

after

Fig.

10·15

-44-

Page 49

Fig.

10·16

10·2-8 Adjust the guide

a)

Tighten

using Torque screwdriver OT0044.

b) Finally tighten three Screws

the outerguide.

NOTE.

For later steps, proceed

manual.

two

Adjusting screws

Tightening force:

700

HU3x4SA

(See

Fig. 10-16)

g·cm

AB3x10SA

to

Section 5ofthis

by

on

-

-;.

11. DISASSEMBLING

J

QJ

AA877900

Fig.11·1

•

o

AA878000

----------

AND

REASSEMBLING PROCEDURES FOR C·MVR

11-1

Disassembly procedure

guide

11·1·1 Remove Specimen holder

4 Screws 3PSK2x6SA.

11-1-2 Remove Rack

o

3PSK2x6SA

11-1-3 Remove East·West Graduated plate

--------

Screws 3PUK2x6SA.

878000

by

of

East-West Drive

unit

by

drawing

(See

Fig. 11·1)

AA877900

drawing 3 Screws PUK2x3SA.

by

drawing 3

(See

(See

Fig. 11-1)

AA-

Fig. 11-2)

Fig. 11·2

PUK2x3SA

-45-

Page 50

Fig. 11·3

AA952100

®

CUK2.6x8SA

11-1-4 Remove East·West Drive guide AA952100

by drawing 3 Screws CUK2.6x8SA_

(See Fig. 11-3)

At

the

same time,

the

following parts can

be removed:

Feed plate AA952200 1

pc_

Casings AA879700 2 pes.

Balls

B-l/8

18 pcs.

AA952000

PSK

1.7x4SA -----#

AA878700

AA878500

AA952200-

AA878700

AA952100-----r

Fig.114

AA952000

----~:>-

./

""..

""

~~=~~~

--------.,

----_€'

11-1-5 Draw 2 Screws PSK1.7x4SA from East-West

Drive guide AA952100, 4 Screws from Feed

plate AA952200, and 2 Screws from EastWest Drive guide AA952000; and then

4

Wires

of

AA878700 and AA878500 each

can be removed. (See Fig. 11-4)

11-2 Reassembly procedureofEast-West Drive guide

PSK1.7x4SA

AA878700

AA878500

AA952200-

AA878700

AA952100

Fig. 11-5

-4

-S~=Q:~~

-------,-.

~'"

11-2-1 Clean each part.

NOTE:

If

you find bent wires or flaws on

faces, replace.

11-2-2 Connect 2 Wires AA878700 to East-West

Drive guide AA952100 with 2 Screws

1.7x4SA, 4

Wires

AA878500

to

Feed plate

AA952200 with 4 Screws, and 2 Wires

to

AA878700

952000

with 2 Screws respectively.

East-West Drive guide

(See Fig. 11-5)

-46

-

Ball

sur-

PSK-

AA-

Page 51

AA952200

11·2-3

Place

on

the reassembled East-West Drive guide

Support

frame

CHKCOOO3.

(See

Fig. 11-6)

Fig. 11-6

AA502600

CHKC0003

AA879700

__

11-2-4

Place

East-West Drive guide

9 Balls

Casing

B-l/8

AA879700

AA952000

into

the holesofCasing.

in the middle

and set

(See

Fig. 11-6)

of

NOTE:

Apply

B

1/8

11-2-5

to

Place

Feed

--81/8

a small

these Balls.

Casing

plate

AA952200

amount

AA879700

and set 9 Balls.

of

Grease

in the middle

(See

Fig. 11-7)

OT2008

of

NOTE:

AA879700

o Stopper

to

center Casing

with.

plate

o

Apply

to

Balls.

AA502600

a small

can

AA879700

amount

be

usedasa mark

of

Grease

on Feed

OT2008

Fig. 11·7

AA952200

AA952000

Fig. 11-8

AA952200

o

CHKC0003

o

o

AA502600

11-2-6

Place

Feed plate

AA952200

on East-West Drive guide

step 11-2-3).

NOTE:

Align the positions

Casings

with

each

other

of

vertically.

(in step

AA952000

upper and

(See

Fig. 11-8)

11-24)

(in

lower

-47

-

Page 52

AA952100

Fig. 11·9

CUK2.6x8SA

o

11-2-7 Reassemble East·West Drive guide

temporarily

NOTE:

Do

not

clamp

with

too

3 Screws

tight.

CUK2.6xBSA.

(See

AA952100

Fig. 11·9)

Screwdriver

Fig.11·10

Adjusting knob

o

AA952100

o

AA952000

11-2-B Set the jig

11-2-9

Adjust

then clamp.

a)

Tighten

plates

AA952200

NOTE:

Be

careful

Adjusting

Clamp East-West Drive guide

b)

firmly

c)

Loosen

Manipulating Feed plate

d)

whetheritstill

movements

(1) In

(2) In

(3) In

with

Adjusting

case

impaired. Replace.

case

steps over again

case

from

CHKC0002asshown in Fig. 11-10.

East-West Drive guide

Adjusting

not

knobs

3 Screws

or

of

11-2-9 (a).

knobs evenlysothat

have no play.

to

impair

too

knobs.

has

play.

of

uneven stiffness, Wires are

of

irregular movements, repeat

play, repeat steps over again

Wires

much.

CUK2.6xBSA.

AA9522oo,

uneven stiffness, irregular

from

11-2-9 (a).

AA952100,

(See

Fig. 11-10)

by

AA952100

tightening

Feed

check

3PUK2x6SA

"/

AA877900

Fig. 11·11

eJ

AA95\OO

Gl

,

/

AA952000

I 0 0

0

l

AA952200

11-2-10 Assemble Rack

3PUK2x6SA.

a)

By

manipulating

check

irregular movements

b)

If

I

-48

play, adjust

-

it

whether

has

stiff

the

AAB77900

East-West Drive knob,

Rack

or

position

has

or

play.

erregular movements

with

(See

Fig. 11-11)

uneven stiffness,

of

Rack

AAB779oo.

3 Screws

or

Page 53

AA878000

11-2-11 Assemble East-West Graduated plate

878000

with

3 Screws PUK2x3SA.

AA-

Fig.11-12

AA951700

CUK2.6xlOSA

Fig. 11-13

q""space

AA878300

11-2-12 Assemble Specimen holder

Screws 3PSK2x6SA.

11-2-13 Adjust the

ated plate

by

moving the position

Graduated plate AA878000.

Standard

11-3 Disassembly Procedure

guide

11-3-1 Remove Specimen holder

4 Screws 3PSK2x6SA.

11-3-2 Remove 4 Screws

clamped North-South Guide

Mounting

Then, the following parts

Mounting

North-South Guide

Balls

Casings

space

AA878000

space:

8ase

AA951700.

base

between East-West Gradu-

and Vernier

0.1

mm ± 0.05mm

of

North-South Drive

unit

GUK2.6xl0SA

AA951700

AA951800

B-l/8

AA878400

unit

(See

Fig. 11-1)

AA878300

of

East-West

(See

Fig. 11-12)

by

(See

Fig. 11-1)

that

AA951800

(See

Fig. 11-3)

will

come

1 pc.

1 pc.

18

pcs.

2

pcs.

with

drawing

have

to

off:

4

Fig. 11-14

AA878700

AA951800

AA951800

~II

AA951600

11-3-3 Remove 2 Screws PSK1.7x4SA

ing

base

AA951700,

South Guide

Specimen holder Main Body

and then 4 Wires

AA878700

AA951800.

will

come

4 Screws

and 2 Screws

AA878600

off.

(See

from

Mount-

from

North-

from

AA951600;

and 4 Wires

Fig. 17-14)

-

49-

Page 54

AA951800

11-3-4 Remove Rack

Drive guide

CUK2.6x5SA.

AA877300

AA951800

from

North-South

by

drawing 2 Screws

(See

Fig. 11-15)

Fig. 11-15

AA951800

AA877300

~CUK2.6x10SA

~

AA622900

-KNW3SA

11-4 Reassembly Procedure

of

North-South Drive

guide

11-4-1 Clean

each

part.

NOTE:

If

you

find

bent Wires

faces,

replace.

11-4-2 Connect 2 Wires

base

AA951700,

North-South Drive guide

4 Wires

Main

body

AA878600

AA951600

(RefertoFigs.

or

flaws on 8all sur-

AA878700

2 Wires

AA951800,

to

Specimen Holder

respectively.

11-14and

to

Mounting

AA878700

11-4-3 Reassemble North-South Drive guide

951800

temporarily

to

Mounting

with

3

washers

base

AA951700

KNW3SA and

3 Screws CUK2.6x10SA.

to

and

11-16)

AA-

Fig. 11-16

* Loosen PSK1.

Wire to the upper

Main

AA951600

Body.

AA951700

7x4SA

screw which afixes

sideofSpecimen Holder

CHKC0003

11-4-4

11-4-5

Place

reassembled North-South Drive guide

on Frame CHKC0003 in a manner

East-West Drive knob fits

of

CHKC0003.

Place

of

and set 9 8alls

Casing

AA878400

Specimen holder Main body

8-1/8

into

the opening

at the lower side

AA951600

in the holesofCasing_

NOTE:

Apply

to

a small smount

8alls.

of

Grease

OT2008

that

Fig. 11-17

-

50-

Page 55

AA951600

CHKC0003

Fig. 11-18

I I

,1---1.,

I I

AA951700

11-4-6 Reassemble

Specimen holder Main

NOTE:

Be

careful

position.

Mounting

not

to

base

AA951700

body

AA951600_

disperse Balls

out

to

of

Fig. 11-19

AA951600

Cltk:

COO

V,J

AA878400

/

11-4-7 Holding

above

Casing and Balls

a)

Pull

out

arrow

Stopper and

b) Insert Casing

rection

holder

one

or

Casing.

c)

After

setting

insert Casing

NOTE:

Repeat step above

place.

After

d)

entire Casing

screwdriver

AA878400

Mounting

with

the finger in position, assemble

Mounting

direction

(=)

until

Main

two

base

as

follows:

(-+) up

hold

AA878400

its

body

Balls

B-l/8

other

Balls

into

reassembled in step

(See

Base

AA951700

to

the

position

there

with

the

in the

tip

enters Specimen

AA951800,

into

the holes

into

Casing,

Main

until

body

9 Balls

AA951600.

Fig. 11-19)

arrow

then

further

are

setting all Balls in place, push

AA878400

into

a same position

with

the

tip

as

Casing

was positioned in step 11-4-5.

in the

of

finger.

di-

put

of

set in

the

of

a

-51-

Page 56

CHKC0001

Fig. 11·20

AA951700

CUK2.6xlOSA

11-4-8 Keeping Balls in Casing

remove the assembly

guide

jig CHKCOOOl in position.

a)

Screw the Jig CHKCOOOl

base

of

from

AA951700,

Mounting

Frame CHKC0003, and set the

base.

of

aligning

with

the finger,

North·So~th

to

to

screw thread

(See

Drive

Mounting

Fig. 11-20)

CHKC0001

Fig. 11·21

CHKCOOOl

Adjusting knobs

'"

AA951600

Fixing knob

AA951700

CUK2.6xlOSA

--

Fixing knob

b)

11·4·9

a)

b)

c)

d)

e)

Aligning threaded

Jig and Specimen

2 Adjusting knobs.

Adjust

Loosen 4 Screws

base

Clamp 2 Adjusting knobs evely

playisleft.

Clamp 4 Screws

Remove the Jig CHKC0001.

By mainpulating

check whether

irregular movement

(1) In

(2) In

North·South

AA951700

case

of

Repeat steps over again

caseofuneven stiffness:

Wires

B-l/8

over again

AA878600,

are defective. Make readjustment

holes (1)

holder Main body, clamp

(See

Drive guide.

CUK2.6xlOSAofMounting

slightly.

CUK2.6xl0SA

Mounting

it

still

or

irregular movement

from

step 11·3.

base

has

uneven stiffness,

play.

AA878700

& (2)

Fig. 11·21)

so

that

securely.

AA951700,

or

from

and Balls

of

the

no

play:

11-4·8.

Fig. 11·22

-52-

Page 57

AA951700

AA951800

•

•

AA877300

o

11-4-10 Clamp Rack

CUK2.6x5SA

a)

Insert Rack

and aligning the threaded holes, clamp

screws temporarily.

b)

8y

manipulating North-South Drive knob,

check whether

irregular movement

c)

If

any, adjust the

Rack AA877300_

AA877300

AA877300

and 2

it

or

Washers

in the

has

play.

mounting

with

uneven stiffness,

2 Screws

KNW2.6SA.

arrow

(See

Fig. 11-23)

position

direction

with

of

Fig.

"·23

AA951600

Knob

11-4-11

Mount

3PSK2x6SA.

al Makeadjustmentbetween east-West Graduated

plate

Specimen holder

AA878000

and Vernier

unit

with

4 Screws

AA878300.

(Refertostep 11-2-13)

-

53-

Page 58

San-ei

Building,

OLYMPUS

Post

Box

OLYMPUS

OLYMPUS

22-2.

Nishi-shinjuku1<home.

OPTICAL

104908·Wendenstrasse

CORPORATION

4 Nevada

Drive.

New

OPTICAL

CO.

14-16.

2000

Hyde

Park,N.Y ,

CO.,

Shinjuku.

(EUROPA)

Hamburg

OF

1042,

LTD.

Tokyo.

GMBH.

1, West

Germany

AMERICA

U.S.A.

Japan

COPYRIGHT RESERVED

BY

OLYMPUS OPTICAL CO., LTD.

PRINTED IN JAPAN

04B2. MRM

KY

Loading...

Loading...