Page 1

®

INSTRUCTIONS

&

IMAGING HARDWARE FOR

LIFE SCIENCE MICROSCOPY

This instruction manual describes the hardware components of the Olympus and Imaging

Stations. To ensure safety, obtain optimum performance and familiarize yourself fully with the use of

these products, we recommend that you study this manual thoroughly before operation. Together with

this manual, please also read the and software manual and the instruction manual of the

microscope in order to understand overall operation methods. Retain this manual in an easily accessible

place near a system for future reference.

Page 2

OLYMPUS SOFT IMAGING SOLUTIONS GMBH

Rupert-Mayer-Strasse 44

D-81379 München

Tel: +49 89 - 89 55 805 660

Fax +49 89 - 89 55 805 6606

Email: info@olympus-sis.com

www.olympus-sis.com

Page 3

Imaging Excellence

We at Olympus Soft Imaging Solutions GmbH have tried to make the information in this manual as accurate and

reliable as possible. Nevertheless, Olympus Soft Imaging Solutions GmbH disclaims any warranty of any kind,

whether expressed or implied, as to any matter whatsoever relating to this manual, including without limitation

the merchantability or fitness for any particular purpose. Olympus Soft Imaging Solutions GmbH will from time

to time revise the software described in this manual and reserves the right to make such changes without obligation to notify the purchaser. In no event shall Olympus Soft Imaging Solutions GmbH be liable for any indirect,

special, incidental, or consequential damages arising out of purchase or use of this manual or the information

contained therein.

No part of this document may be reproduced or transmitted in any form or by any means, electronic or mechanical, for any purpose, without the prior permission of Olympus Soft Imaging Solutions GmbH.

2003 – 2009 by Olympus Soft Imaging Solutions GmbH. All rights reserved.

Manual version: March 2009

Page 4

ΧΧΧΧ Declaration of Conformity

Robert-Koch-Strasse 9

D-82152 Planegg

declares under its own responsibility that the following products

Imaging Station for Life Science Applications

and

Imaging Station for Life Science Applications

to which this declaration refers are in conformity with the

Low Voltage Directive 73/23/EEC

and the

EMC Directives 89/336/EEC and 93/68/EEC

and the following standards:

EN 61010-1: 2001 (Low Voltage)

EN 61326:1997 + A1: 1998 + A2: 2001 (EMC).

Michael Czempiel and Dr. Matthias Seel, Managing Directors

June 11, 2003 and

October 08, 2005

Page 5

& Hardware Manual Contents

Contents

1 Introduction and Overview .................................................................................1

1.1 Abstract .............................................................................................................. 2

1.2 Technical Support ............................................................................................... 2

1.3 Symbols .............................................................................................................. 3

1.4 Checklist: cell^M / cell^R Components................................................................. 4

1.4.1 Standard Components: ....................................................................................... 4

1.4.2 Additional Components....................................................................................... 5

2 Illumination System MT10 / MT20.......................................................................7

2.1 Safety Precautions and Handling Instructions...................................................... 8

2.1.1 MT20 / MT10 Safety Precautions ......................................................................... 8

2.1.2 Special Safety Precautions Regarding the Arc Burners......................................... 9

2.1.3 Handling Instructions and Recommendations.................................................... 10

2.1.4 Safety Labels......................................................................................................11

2.2 Illumination System MT10 / MT20 Overview...................................................... 12

2.2.1 The Front Panel................................................................................................. 12

2.2.2 Top: the Burner Flap...........................................................................................13

2.2.3 Right Side: the Filter Wheel Flap.........................................................................13

2.2.4 The Back Panel.................................................................................................. 14

2.2.5 Operation.......................................................................................................... 14

2.2.6 Specifications and Technical Data of the MT10 / MT20 .......................................15

2.2.7 Fuse Exchange .................................................................................................. 16

2.2.8 Specifications and Technical Data of the Real-Time Controller /

System Coordinator Connectors........................................................................ 16

3 Epi-Fluorescence Illuminators ........................................................................... 17

3.1 Features ............................................................................................................ 18

3.1.1 Light Guide Port ................................................................................................ 18

3.1.2 Adjustment Screws for Centering the Field of Illumination ................................ 18

3.1.3 Filter Slider for Dispersion Filter and Exciter Balancers ...................................... 19

3.1.4 Light Sensor ...................................................................................................... 19

3.2 IX2 Illuminators with Field Stop Slider ............................................................... 19

3.3 Flange for the IX2 Microscopes .......................................................................... 20

3.4 Fluorescence Illuminator Unit for the BX2 Microscopes: BX_MTA, BX_MTAA.... 20

3.5 Fluorescence Illuminator Unit for the MVX Microscope...................................... 21

4 System Assembly and Adjustment .................................................................... 23

4.1 Overview: Connectivity of System Components ................................................ 24

4.2 Connecting the Modules of the cell^M / cell^R Imaging Station ......................... 25

4.2.1 Connecting the MT10 / MT20............................................................................. 25

4.2.2 Mounting and Connecting the Epi-Fluorescence Illuminator .............................. 26

4.2.3 Connecting the Camera......................................................................................27

4.2.4 Connecting the Imaging PC to the Modules ....................................................... 28

Page 6

Contents

4.2.5 Configuring the Imaging PC Network Connections ............................................29

4.3 Preparing the Illumination System MT10 / MT20................................................ 30

4.3.1 Burner Installation and Exchange....................................................................... 30

4.3.2 Burner Alignment .............................................................................................. 31

4.3.3 Filter Exchange .................................................................................................. 33

4.4 Centering the Illumination ................................................................................. 35

4.5 Optimizing the Illuminator Tube Position........................................................... 36

5 Optional Hardware Modules .............................................................................39

5.1 Mounting and Connecting the Piezo-Electric Objective Drive (PIFOC)................ 41

5.2 Connecting the Piezo-Electric Nosepiece Drive (Nosepiece PIFOC for

IX2 Microscopes)................................................................................................ 43

5.3 Connecting the Corvus Controller of a Motorized Märzhäuser Stage ..................44

5.4 Installing Illuminators with Pinhole Field Stop Sliders......................................... 45

5.4.1 Centering the pinhole ........................................................................................46

5.5 Installing the OptiGrid ....................................................................................... 47

5.5.1 The OptiGrid Illuminator.................................................................................... 47

5.5.2 Connecting the OptiGrid.................................................................................... 47

5.5.3 Configuring the OptiGrid ...................................................................................48

5.5.4 Optical Alignment of OptiGrid and Camera........................................................49

5.5.5 Calibrating the OptiGrid.....................................................................................50

5.5.6 Calibrating the OptiGrid Z-Position for Different Image Types ........................... 52

5.5.7 Stripe Filter for Snapshots ................................................................................. 54

Page 7

& Hardware Manual Chapter 1 – Introduction and Overview 1

1 Introduction and Overview

Thank you very much for purchasing Olympus’ state of art Imaging Station cell^M or cell^R and for your confidence in our products and service. It is Olympus main objective to provide you with solutions able to meet your

experimental demands and thus pave the way to your scientific success.

1.1 Abstract .............................................................................................................. 2

1.2 Technical Support ............................................................................................... 2

1.3 Symbols .............................................................................................................. 3

1.4 Checklist: cell^M / cell^R Components................................................................. 4

1.4.1 Standard Components: ....................................................................................... 4

1.4.2 Additional Components....................................................................................... 5

Page 8

2 Chapter 1 – Introduction and Overview

1.1 Abstract

The Imaging Station cell^M / cell^R consists of the following hardware components:

—

Illumination System MT10 / MT20

—

Illumination Coupling to the microscope (epi-fluorescence illuminator with light fiber)

—

Real-time Controller (cell^R) / System Coordinator (cell^M)

—

controller board inside PC

—

CCD camera (several models optional)

—

Optional peripherals such as piezo-electric z-drive (PIFOC)

You will find a detailed description of these components, handling and alignment instructions as well as advice

how to maintain the performance of your system on the following pages. Keep in mind that all the components

are designed to work together as an integrated system. Taking away or replacing single components without

prior consultation of Olympus BioSystems is strongly discouraged and will most probably impair the performance of the system dramatically. Any damages to the system due to such mishandling will not be covered by the

guarantee.

All necessary tools for handling and alignment are shipped with the system.

The Imaging Station cell^M / cell^R is compatible with the following Olympus microscopes: IX50, IX70, IX51,

IX71, IX81, BX50, BX50WI, BX51, BX51WI, BX61, BX61WI. Other microscopes may be supported on request.

An additional installation of a standard Olympus epi-fluorescence Xe, Xe/Hg or Hg lamp house (e.g.,

U-LH100HGAPO, U-LH75XEAPO) is not possible because the OBS epi-fluorescence illuminator occupies the

microscope’s fluorescence excitation port.

This instructions manual is for the hardware components of the Olympus BioSystems Imaging Station cell^M /

cell^R. To ensure safety and optimum performance as well as to familiarize yourself with the use of the system

we recommend you to study this manual thoroughly before operating the system. Keep this manual in an easily

accessible place near the Imaging Station for future reference.

The cell^M / cell^R system meets the CE, UL and FCC requirements.

IEC/EN 61010-1(2nd ed.), UL61010-1,

EN61326 Class A, FCC Part 15 Class A (Illumination System MT10 / MT20: class A and B).

1.2 Technical Support

If you find any information missing in this manual or you need additional support, please contact your local

Olympus representative.

Page 9

& Hardware Manual Chapter 1 – Introduction and Overview 3

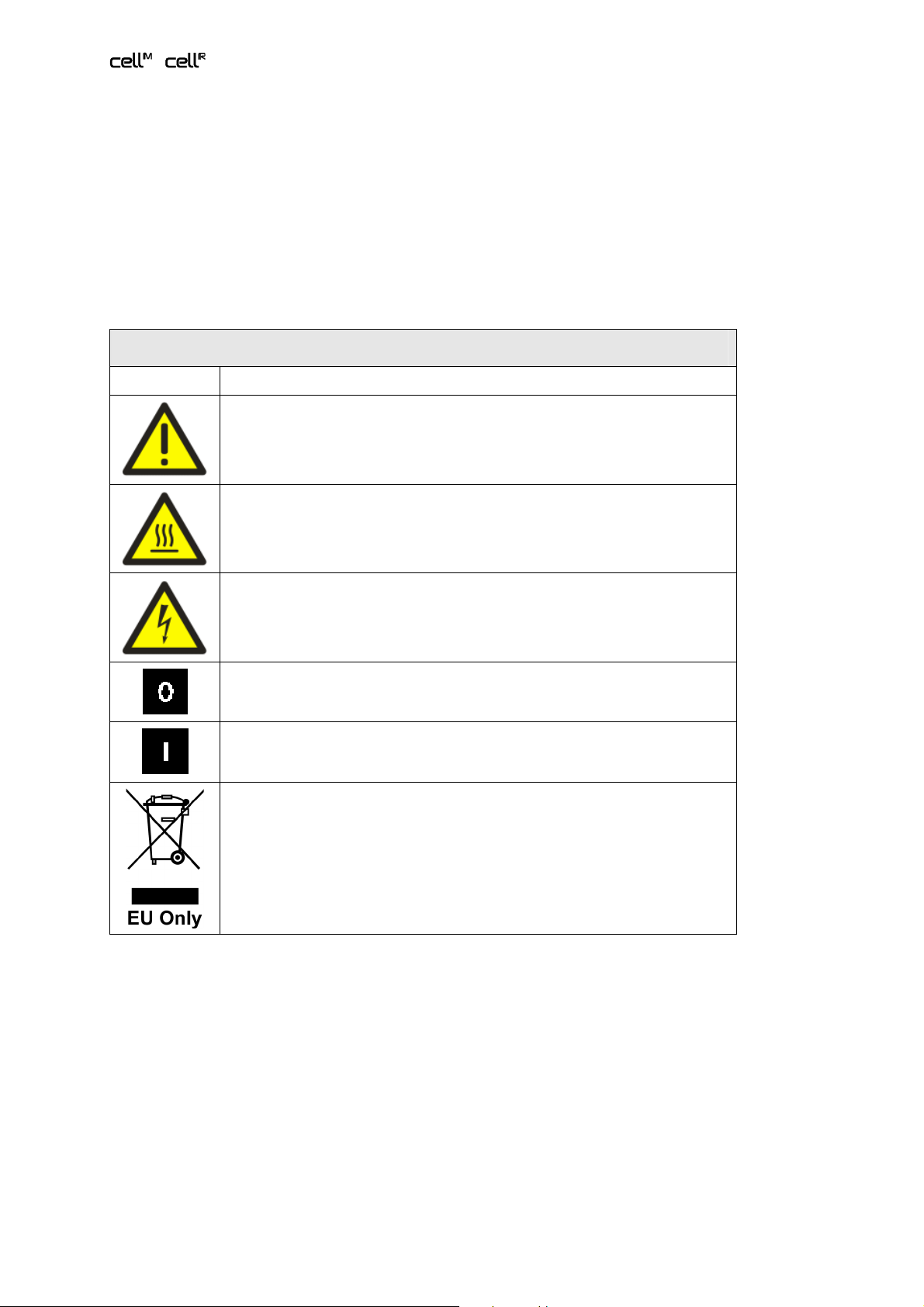

1.3 Symbols

The following symbols are placed on the Illumination System MT20 / MT10. Study the meaning of the symbols

and always use the equipment in the safest possible manner.

General symbols

Symbol Explanation

Carefully read the instructions on the label and the manual before use. Improper use could result

in personal injury to the user and/or damage the equipment.

The surface becomes hot and should not be touched with bare hands

Parts may be under high voltage and should not be touched.

The main switch is turned OFF.

The main switch is turned ON.

This symbol indicates separate collection of waste electrical and electronic equipment in the EU

countries.

Do not throw the equipment into the domestic refuse

Please use the return and collection systems available in your country for the disposal of this

product

Page 10

4 Chapter 1 – Introduction and Overview

1.4 Checklist: cell^M / cell^R Components

Before assembly, please check whether you have the complete set of cell^M / cell^R system components as

listed below.

1.4.1 Standard Components:

a Microscope, upright or in various configurations.

b Illumination System MT10 / MT20 consisting of:

—

MT10 / MT20 housing with integrated lamp house, filter wheel, shutter and attenuator

—

short arc burner

—

power cord

—

Illumination System connector cord (blue RJ45 cable)

—

light sensor connector cord (see photo in Chapter 7, System Assembly and Adjustment)

—

optical fiber (quartz light guide; see photo in Chapter 7, System Assembly and Adjustment)

—

set of hex-wrenches

—

cotton gloves

c Fluorescence filter set consisting of:

—

Dichroic mirror and emission filter mounted in Olympus filter cube

—

Excitation filter(s) to be mounted in the MT10 / MT20 filter wheel

d MT10 / MT20 epi-fluorescence illuminator to couple the illumination system to the microscope via the optical

fiber

e CCD camera (or EMCCD camera) of choice, typically with

—

FireWireTM (IEEE 1394) cable

—

trigger cable

f cell^R / cell^M imaging computer including

—

cell^R Real-time Controller board / cell^M System Coordinator board

—

cell^R / cell^M network card

—

FireWireTM (IEEE 1394) card

—

front panel with three digital I/O ports (optional for cell^M)

—

cell^R / cell^M imaging software installed

—

computer monitor with cable

—

2 power cords

—

software protection key (dongle)

g cell^R / cell^M imaging software on CD-ROM

h Manuals

Page 11

& Hardware Manual Chapter 1 – Introduction and Overview 5

1.4.2 Additional Components

The following components are optional and may or may not be part of your cell^R / cell^M imaging workstation.

a Motorized microscope modules in various configurations; all include

—

universal microscope control box (UCB)

—

microscope manual control (optional)

—

power cord

—

connection cords

b Fast piezo-electric objective mover (PIFOC, Physik Instrumente GmbH, see Chapter 5.1, Mounting and Con-

necting the Piezo-Electric Objective Drive PIFOC) consisting of

—

Objective mover

—

PIFOC controller

—

power cord

—

PIFOC connector cable

—

spacers to lift the stage (for Olympus IX microscopes)

—

objective distance rings

—

extension cords

c Fast piezo-electric nosepiece mover (nosepiece PIFOC, Physik Instrumente GmbH, see Chapter 5.2, Mount-

ing and Connecting the Piezo-Electric Objective Drive PIFOC) consisting of

—

nosepiece mover

—

nosepiece PIFOC controller

—

power cord

—

PIFOC connector cable

—

extension cords

d motorized stage by different manufacturers

e climate chamber

f Optigrid for resolution enhancement via structural fluorescence illumination

Page 12

6 Chapter 1 – Introduction and Overview

Page 13

& Hardware Manual Chapter 2 – Illumination System MT20 / MT10 7

2 Illuminat ion System MT10 / MT20

This chapter refers only to the fluorescence Illumination System MT10 / MT20. Before using this unit together

with the other system components, the microscope and associated devices, make sure that you have carefully

read and understood their respective manuals, and understand how the entire system should be operated.

2.1 Safety Precautions and Handling Instructions...................................................... 8

2.1.1 MT20 / MT10 Safety Precautions ......................................................................... 8

2.1.2 Special Safety Precautions Regarding the Arc Burners......................................... 9

2.1.3 Handling Instructions and Recommendations.................................................... 10

2.1.4 Safety Labels......................................................................................................11

2.2 Illumination System MT10 / MT20 Overview...................................................... 12

2.2.1 The Front Panel................................................................................................. 12

2.2.2 Top: the Burner Flap...........................................................................................13

2.2.3 Right Side: the Filter Wheel Flap.........................................................................13

2.2.4 The Back Panel.................................................................................................. 14

2.2.5 Operation.......................................................................................................... 14

2.2.6 Specifications and Technical Data of the MT10 / MT20 .......................................15

2.2.7 Fuse Exchange .................................................................................................. 16

2.2.8 Specifications and Technical Data of the Real-Time Controller /

System Coordinator Connectors........................................................................ 16

Page 14

8 Chapter 2 – Illumination System MT20 / MT10

2.1 Safety Precautions and Handling Instructions

For Laboratory Use Only.

Danger: Ultraviolet radiation is emitted from this product. Avoid exposure. ALWAYS WARE

PROTECTIVE CLOTHING. EXPOSURE MAY CAUSE PREMATURE AGING OF THE SKIN AND

CANCER. ALWAYS WARE PROTECTIVE EYEWEAR; FAILURE TO DO SO MAY RESULT IN SEVERE

BURNS OR LONG TERM INJURE TO THE EYE. Never look directly into the lamp. Exposure can

cause eye and skin allergy and allergic reactions. Medications or cosmetics may increase your sensitivity to ultraviolet radiation. Consult a physician before operating this product if you are using

medications or have a history of skin problems or believe yourself particularly sensitive to sunlight.

Always have the microscope's UV cut plate mounted as protection against UV radiation.

Color fading of specimens: This system features high excitation light intensity to ensure bright observation of dim fluorescent specimens. Consequently, after longer periods of observations using

high-power objectives, the colors of specimens will fade quicker than usual, causing the intensity

and contrast of fluorescent images to deteriorate. In such cases it is advisable to reduce excitation

light intensity to slow down color fading. To reduce the light intensity use the built-in attenuator as

explained in this manual.

Engage the shutter of MT20 / MT10 as explained in this manual (or use the shutter of the micro-

scope) even if you interrupt observation only for a short time.

2.1.1 MT20 / MT10 Safety Precautions

a Always use a power cord provided or approved by Olympus BioSystems.

b Provide unimpaired access to the main power switch at the rear panel.

c No electrical cord should be connected or disconnected while the power switch is set on (“I”). Make sure that

the unit's main power switch is set off (“O”) before plugging or unplugging the power cord to the power outlet.

d Always make sure that the grounding terminal of the Illumination System MT10 / MT20 and the wall outlet

are connected properly. If the System is not grounded, Olympus BioSystems cannot warrant the electrical

safety and performance of the system.

e When installing the Illumination System MT10 / MT20 leave at least 100 mm free air space at the rear panel

and at least 50 mm at the sides and on top to allow air circulation. The Illumination System MT10 / MT20 has

an internal fan to cool the arc burner. The air outlet is located at the rear of the housing while the inlet grid is

at the bottom.

Page 15

& Hardware Manual Chapter 2 – Illumination System MT20 / MT10 9

f The Illumination System MT10 / MT20 must be placed on an even, stable and flat surface and standing on its

supports. Make sure that no cloth or paper can clog the air inlet slits at the bottom of the housing.

g The arc burner has to be exclusively one of the two types specified by Olympus BioSystems. No other arc

burner may be used with the Illumination System MT10 / MT20.

h Do not open the burner flap of the Illumination System MT10 / MT20 while the arc burner is turned on. First

turn off the arc burner by software and wait for at least 30 minutes while the cooling fan is operating. Set the

main power switch on “O” (OFF) before opening the burner flap. The arc burner socket and all parts in the vicinity of the burner will be extremely hot during operation and will cause thermal injury if touched.

i Never attempt to disassemble the Illumination System MT10 / MT20 or to open its housing. The internal

power supply units and electrical circuits contain high voltage components and can cause severe electrical

shock and thus are not serviceable by the user. Warranty will be lost if the housing is opened.

j Do not operate the Illumination System MT10 / MT20 under environmental conditions other than specified in

this manual (see Chapter 2.2.6, Specifications and Technical Data).

k Do not look directly into the light emitted by the arc burner with unprotected eyes under any circumstances.

The emitted light is very intense and has a very high UV-content that may cause irreversible damage to your

eyes.

l Avoid direct exposure of unprotected skin to the light emitted by the arc burner. It can cause severe burns.

m Direct exposure to the arc burner light may occur at the following positions:

—

Illumination System’s housing at the fiber port if the fiber is removed

—

Exit of the optical fiber

—

Exit of the illumination coupling (epi-fluorescence illuminator)

—

Beam path of the microscope (which upon proper usage is not accessible by the user)

—

Exit of the objective (or at the nose piece, if no objective is mounted)

n If the equipment is used not as specified by this manual, the safety and performance of the equipment may

be impaired. In addition, the equipment may also be damaged and warranty may be lost. Always use the

equipment as outlined in this instruction manual.

2.1.2 Special Safety Precautions Regarding the Arc Burners

a Handling the arc burner bulb is potentially dangerous. Wear a protective mask, leather gloves and a thick

long-sleeved shirt or coat during handling and disposal (see below).

b The arc burner bulb is under high internal pressure. Do not hit the arc burner bulb against anything nor

scratch it or apply excessive stress. Avoid vibrations. Otherwise the arc burner bulb could explode and cause

injuries.

c For transport and storage always place the arc burner in the provided protective case.

d Take care to avoid leaving fingerprints or dirt on any part of the high-pressure arc burners. If contaminated,

clean by wiping gently with gauze. To remove fingerprints or oil stains, wipe with gauze slightly moistened

with lens cleansing fluid.

Since these fluids are highly inflammable, be careful to keep them away from open fire, heat or hot surfaces

and potential sources of electrical sparks, such as main switches.

Page 16

10 Chapter 2 – Illumination System MT20 / MT10

e The arc burners have an average lifetime as specified in this manual (see Chapter 2.2.6, Specifications and

Technical Data). When the arc burner hour counter (see Chapter 4.3.2, Burner Alignment) gives a reading

higher than the specified lifetime, replace the burner with a new one following the instructions for replacement (see Chapter 4.3.1, Burner Installation and Exchange) and disposal of used burners (see below). Arc

burners that are used longer than the rated service lifetime will have a reduced intensity and stability; they

are likely to fail and might explode because of the deteriorated glass condition.

f Arc burners not in service must always be kept in the provided protective case.

g Hg/Xe burner bulbs contain poisonous mercury. They have to be treated with special care. If they explode

during service mercury gas might be dispersed in the environment.

h Hg/Xe burners must be treated as hazardous waste. Always follow national and local laws and guidelines

when disposing of Hg/Xe burners. It is recommended to commission a professional waste disposal company

with the disposal. Hand over the burner in its original packaging.

i Xe burners: It is recommended to commission a professional waste disposal company with the disposal.

Hand over the burner in its original packaging. Disposal without breaking the glass part may result in burner

bulb explosion. Follow the instructions below to prevent harmful repercussions.

—

Ware protective clothing.

—

Wrap the used lamp in a thick cloth.

—

Break the glass part of the lamp into pieces using a hammer.

—

Dispose of as industrial waste (except Hg/Xe burners, see above).

2.1.3 Handling Instructions and Recommendations

a The Illumination System MT10 / MT20 is a precision instrument. Handle it with great care and avoid subject-

ing it to sudden or severe impact. Also connect each cable gently.

b The built-in ventilating fan and the built-in filter wheels may generate vibrations and sound. Therefore it is

recommended not to place the Illumination System MT10 / MT20 on the same table as the microscope.

c With exception of the burner flap and the filter flap the Illumination System MT10 / MT20 may only be

opened and disassembled by authorized service personal. Otherwise warranty is lost.

d Before using the Illumination System MT10 / MT20 for the first time check that the burner is installed cor-

rectly and that all cords are connected correctly.

e Before opening the burner flap for replacement of the burner, turn it off by software (cell^R / cell^M or OBS

System Configuration) and wait for at least 30 minutes while the cooling fan is operating. Then set the main

power switch on “O” (OFF) and open the burner flap. (Do not open the burner flap of the Illumination System

MT10 / MT20 while the arc burner is turned on.)

f Do not place the unit inside a climate chamber.

g Do not bend the optical fiber to a diameter of less than 45 cm. The optical fiber is fragile and may brake if

bent too strongly or if torsional stress is applied.

h Cover the ends of the optical fiber with the protection cover if they are not attached to the Illumination Sys-

tem MT10 / MT20 or to the microscope.

Page 17

& Hardware Manual Chapter 2 – Illumination System MT20 / MT10 11

i Always operate the Illumination System MT10 / MT20 in an upright position. Never lay it on the side during

operation. This could cause the lamp to burst, damage the equipment and cause injury.

j Before transport of the system remove the lamp and store it safely in the provided protective case.

k Mind that turning the arc burner on and off repeatedly will shorten the life span.

l To clean the surface of the Illumination System MT10 / MT20, use a lint-free, dry and soft cloth. Never at-

tempt to use organic solvents or strong detergents.

m Take care to avoid leaving fingerprints or dirt on the optical filters, the lenses at the ends of the light guide or

the optics of the illumination coupling. If contaminated, clean by wiping gently with special optical cleansing

tissue. To remove fingerprints or oil stains, wipe with special optical cleansing tissue slightly moistened with

lens cleansing fluid. Use the cotton gloves when handling light filters.

* Since these fluids are highly inflammable, be careful to keep them away from open fire, heat or hot surfaces and potential sources of electrical sparks, such as main switches.

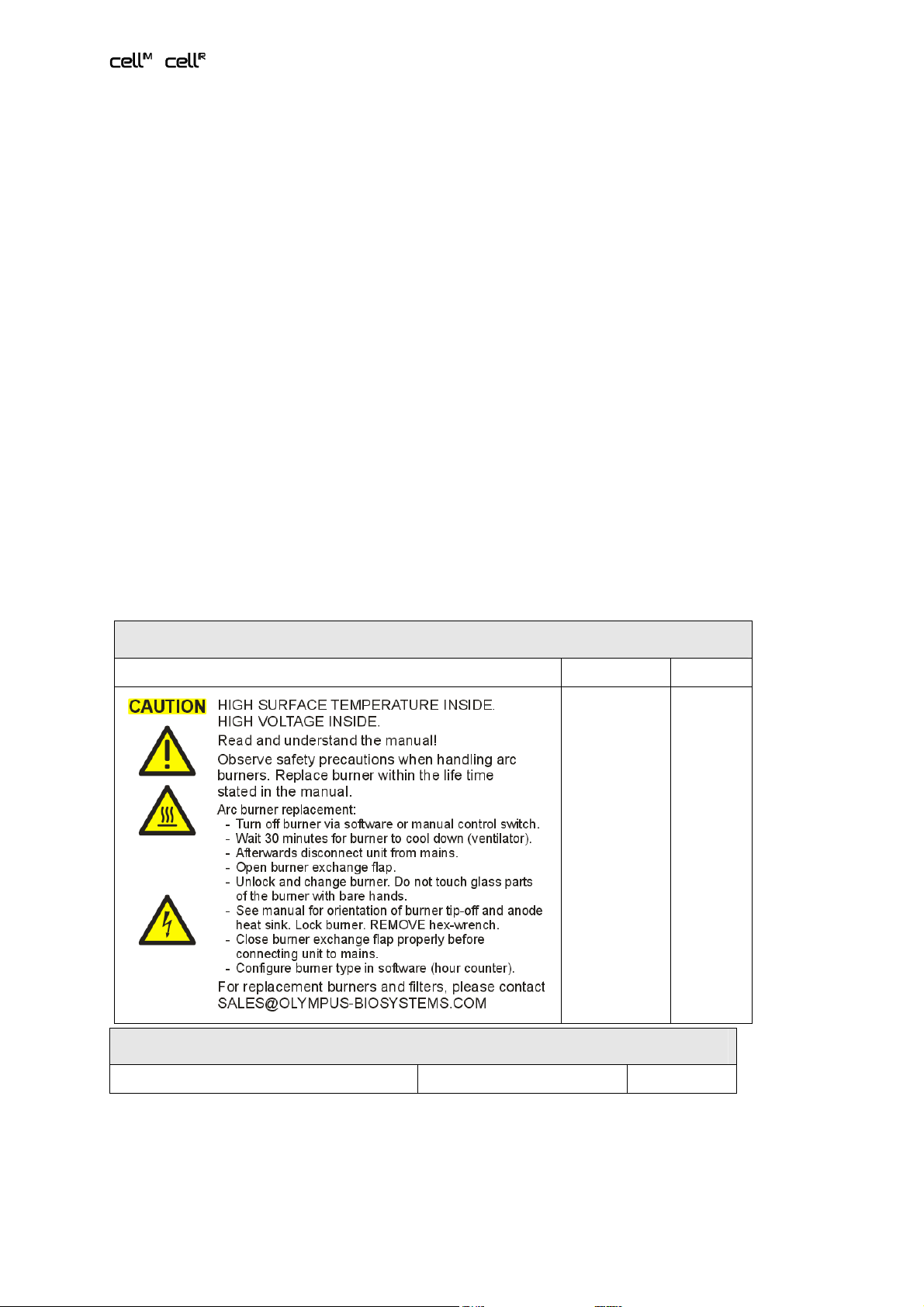

2.1.4 Safety Labels

The following symbols are found on the Illumination System MT10 / MT20. Study the meaning of the symbols

and always use the equipment in the safest possible manner.

Lamp housing safety label

Label Note Location

Carefully read the

instructions on the

label and the

manual before use.

Improper use could

result in personal

injury to the user

and/or damage the

equipment.

Top side of

the Illumination System

MT20 / MT10

Fiber port safety label

Label Note Location

Page 18

12 Chapter 2 – Illumination System MT20 / MT10

Status

connector

Carefully read the instructions on the

label and the manual before use.

Improper use could result in personal

injury to the user and/or damage the

equipment.

2.2 Illumination System MT10 / MT20 Overview

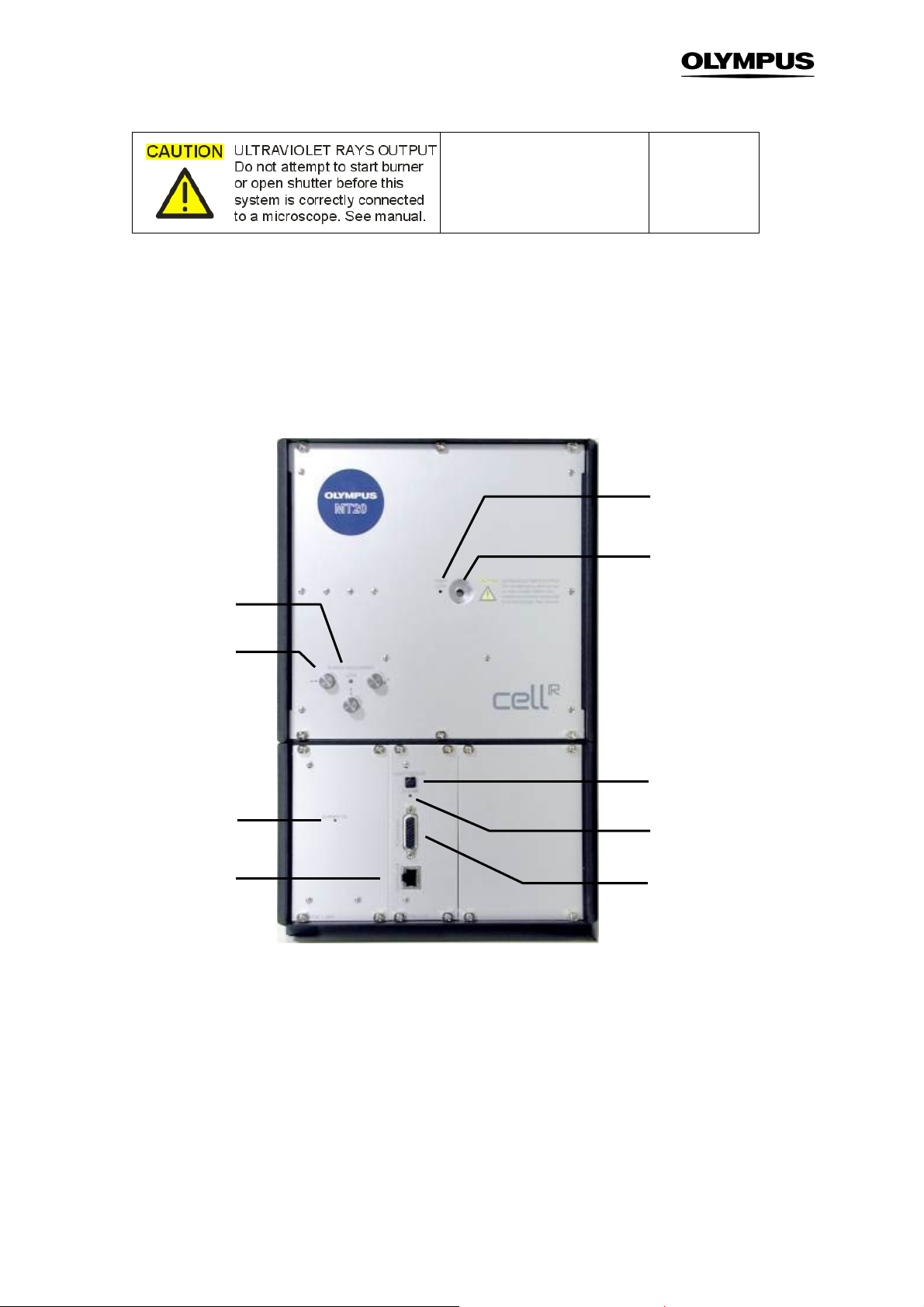

2.2.1 The Front Panel

Front side of the

Illumination

System MT20 /

MT10

FIBER lock

Fiber

port

LOCK

BURNER

ADJUSTMENT

Light sensor

LED:

BURNER ON

CONTROLLER

connector

LED:

AUXILIARY

connector (MT20 only)

LOCK: 2 mm hex-wrench opening to lock or release the arc burner for installation and replacement.

BURNER ADJUSTMENT: three handles to align the burner.

BURNER ON LED: On / off arc burner on / off

CONTROLLER connector, MT20 only: RJ45 plug to connect the Illumination System MT20 to the cell^R Real-

Time Controller.

ODB connectors (two), MT10 only: OBS Device Bus plug to connect the Illumination System MT10 to the

cell^M System Coordinator.

FIBER LOCK: 1.5 mm hex-wrench opening to lock or release the optical fiber in the fiber port.

Page 19

& Hardware Manual Chapter 2 – Illumination System MT20 / MT10 13

Fiber port: Opening for the optical fiber.

LIGHT SENSOR connector: 3-pin connector for light sensor cable.

AUXILIARY connector (MT20 only): 15-pin sub-D port, currently without use.

STATUS LED: Off no connection to cell^R Real-Time Controller / cell^M System Coordinator.

On active connection to cell^R Real-Time Controller / cell^M System Coordinator, ready for operation.

Regular flashing Illumination System MT10 / MT20 in stand-by mode.

Irregular activity Illumination System MT10 / MT20 in action.

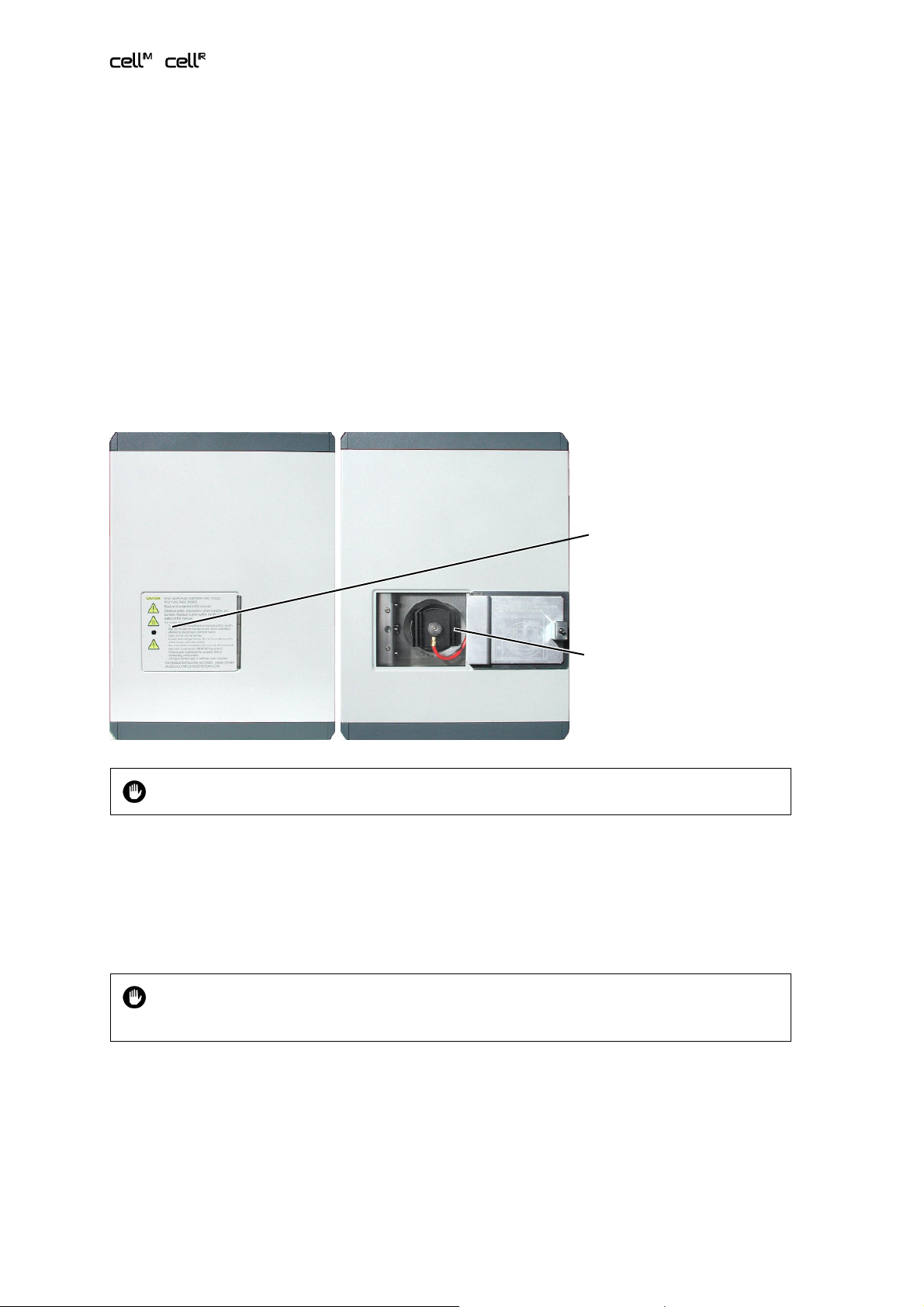

2.2.2 Top: the Burner Flap

Before opening: Wait until system has cooled down, then switch main power off!

2.2.3 Right Side: the Filter Wheel Flap

Opening for a 3 mm hexwrench

Access to the arc burner

for replacement

The flap has to be closed and the subsequent automatic initialization has to be completed for operation.

Page 20

14 Chapter 2 – Illumination System MT20 / MT10

2.2.4 The Back Panel

Do not block ventilation slits! Keep 10 cm distance from wall.

Arc burner cooling air

outlet

Main power switch, fuse-holder

and AC power input connector.

2.2.5 Operation

Only operate the system when completely installed and connected to a microscope.

For operating set main power switch on “I” (ON). By doing so the System will execute a routine to initialize and

test the electro-mechanical components and motors.

Page 21

& Hardware Manual Chapter 2 – Illumination System MT20 / MT10 15

For further operation run the cell^R / cell^M software or the OBS System Configuration on your computer according to the software manual.

2.2.6 Specifications and Technical Data of the MT10 / MT20

Dimensions and weight: H 354 x W 236 x D 315 mm, 13 kg

Power supply rating: 100 to 120 V and 200 to 240 V AC, 50 – 60 Hz (47 – 63 Hz), 4.0 / 2.1A

Fuse: 250VAC, T4AH (5 x 20mm)

Enclosure rating: IP20

Short arc burner:

—

Type 1: 150 W Xe, high-pressure arc burner, Olympus _MT_ARC/XE, article No. E0435001, expected

minimal lifetime under standard laboratory conditions: 1000 h

—

Type 2: 150 W Hg/Xe, mixed gas arc burner, Olympus _MT_ARC/HG, article No. E0435002, expected

minimal lifetime under standard laboratory conditions: 1000 h

Light output range, MT10 / MT20: between 320 and 720 nm; MT10_NIR / MT20_NIR: between 380 and 800 nm

Light output power: up to 50% higher for MT10E / MT20E as compared to MT10 / MT20

Mechanical shutter: opening/closing time MT20 1.0 +/- 0.2 ms, MT10 < 5 ms

Filter wheel: 8 positions

Optical filter dimensions: ∅ 24.8 mm +/- 0.1, thickness 2 – 6 mm, maximum weight 7 g each

Filter and attenuator switching time: This is dependent on the filter load and the number of positions to be

moved.

Switching times

Load [g]

Next position

2nd position

3rd position

4th position

< 10.5 < 21 > 21 > 28 > 35 attenuator < 10.5 < 21 > 21 > 28 > 35 attenuator

58 64 72 80 91 35 85 103 115 125 135 85

86 92 102 114 129 40 141 158 170 181 194 133

113 119 130 142 158 50 196 213 225 236 249 149

141 147 157 169 186 60 etc. 251 269 281 292 304

MT20 [ms] MT10 [ms]

Attenuator transmission [%]

—

MT20, 14 positions: 1, 3.1, 6.3, 10, 12.5, 25, 33.3, 37.5, 50, 62.5, 66.6, 75, 87.5, 100

—

MT10, 7 positions: 3.1, 10, 25, 37.5, 62.5, 75, 100

LED indicators, MT10 / MT20 front: BURNER ON (lower left), STATUS (lower center)

Connectors, MT20 front:

—

CONTROLLER: RJ45 connection to Real-Time Controller board (PC back panel)

—

AUXILIARY: sub-D, 15-pin connection (MT20 only)

—

LIGHT SENSOR: 3 pin connection to light sensor (epi-fluorescence illuminator)

Connectors, MT10 front:

—

ODB: ODB Device Bus connection to System Coordinator board (PC back panel)

—

LIGHT SENSOR: 3 pin connection to light sensor (epi-fluorescence illuminator)

Page 22

16 Chapter 2 – Illumination System MT20 / MT10

Connectors, MT10 / MT20 rear:

—

3-pin AC input plug with ground

—

Main switch (I: on, O: off)

Optical fiber: minimum bend diameter 45 cm short term, avoid torsional stress

—

Type 1: 2 m solid quartz fiber, Olympus MT-FIB/2m, article No. E0435007

—

Type 2: 3 m solid quartz fiber, Olympus MT-FIB/3m, article No. E0435008

Operating environmental conditions: indoor use only.

—

Altitude: up to 2000 m

—

Ambient temperature: 5 to 40°C

—

Maximum relative humidity: 80% up to 31°C, 70% at 34°C, 60% at 37°C, 50% at 40°C

—

Supply voltage fluctuation: +/- 10%

—

Pollution degree 2 (in accordance with IEC664)

—

Over-voltage category II (in accordance with IEC664)

2.2.7 Fuse Exchange

During standard operation the fuses will not blow. In case the fuse blows switch off the unit and contact your

local Olympus service specialist or the Olympus BioSystems support team to avoid potential hazard because the

unit might be severely damaged.

The system is equipped with 2 fuses (high breaking, delayed action fuse, 250 V AC, 4 A, size: 5 x 20 mm) located

below the main switch of the Illumination System MT20 / MT10 at the rear of the housing.

2.2.8 Specifications and Technical Data of the Real-Time Controller / System Coordinator Connectors

Connectors, cell^R / cell^M Imaging Computer, front, DIGITAL I/O:

—

Input: R(in) > 10 kΩ, low V < 0.8 V, high V > 2.0 V,

—

Output, low level: R(out) < 90 Ω, V < 0.8 V @ I < 5.8 mA

Output, high level: R(out) < 870 Ω, V > 2.2 V @ I < 3.2 mA

If a high level voltage of 5 V is required, please contact your local support specialist.

Camera Trigger: open collector with 330 Ω pull-up to 5 V

—

TTL high level: R(out) = 330 Ω, V > 2.0 V @ I < 9 mA

—

TTL low level: R(out) < 90 Ω, V < 0.8 V @ I < 9 mA

PIFOC controller (analog out): SMB, 14 Bit DAC, V = 0 – 10 V (±2 mV) @ 1 MΩ R(load),

I < 1 mA, R(out) = 47 Ω @ DC, suggested R(load) > 50 KΩ

Page 23

& Hardware Manual Chapter 3 – Epi-Fluorescence Illuminators 17

3 Epi-Fluorescence Illuminators

The optical design of the epi-fluorescence illuminators is identical for all microscopes supported. For the two

Olympus IX series (IX50 and IX70 vs. IX51, IX71 and IX81) different flanges have to be used to mount the illuminators on the microscope frames. For the two BX series (BX50 and BX50WI vs. BX51, BX51WI, BX61 and BX61WI)

the illuminators are connected to the respective special reflective Olympus illuminators for fiber coupling.

3.1 Features ............................................................................................................ 18

3.1.1 Light Guide Port ................................................................................................ 18

3.1.2 Adjustment Screws for Centering the Field of Illumination ................................ 18

3.1.3 Filter Slider for Dispersion Filter and Exciter Balancers ...................................... 19

3.1.4 Light Sensor ...................................................................................................... 19

3.2 IX2 Illuminators with Field Stop Slider ............................................................... 19

3.3 Flange for the IX2 Microscopes .......................................................................... 20

3.4 Fluorescence Illuminator Unit for the BX2 Microscopes: BX_MTA, BX_MTAA.... 20

3.5 Fluorescence Illuminator Unit for the MVX Microscope...................................... 21

Page 24

18 Chapter 3 – Epi-Fluorescence Illuminators

4

3.1 Features

The MT20 / MT10 epi-fluorescence illuminator (MT_CON) is a tube which houses the different lenses and features the fiber port, the filter slider, the adjustments screws to center the field of illumination and the light sensor to measure the light output during the optimization of the lamp position in the MT20 / MT10. These items

are referred to in detail below.

6

9

3

1

6

2

8

7

5

1: illuminator tube containing the optical elements

2: light guide with fiber connector and ring to adjust

depth of penetration for focus optimization

3: light guide port

4: set screw to fix the light guide

5: light sensor with cable

Optionally the illuminator may have a space-saving L-shape form for the IX2 microscopes. Furthermore, a dualport illuminator is available for the IX2 microscopes.

6: adjustment screws for centering the field of

illumination

7: filter slider with dispersion filter

8: flange for IX2 microscope frame (IX2_RFA)

9: screw to fix the illuminator tube inside the flange

3.1.1 Light Guide Port

The light guide features a distance ring that assures the optimum position of the fiber exit when the fiber is

moved all the way into the port. The position of the distance ring is set by Olympus BioSystems and fixed by a

small screw. The fiber exit is fixed inside the port by a form-fit screw. Thus, the fiber cannot be pulled out if the

fixing screw is just slightly loose.

3.1.2 Adjustment Screws for Centering the Field of Illumination

The illumination has to be centered in order to illuminate the entire chip of the CCD camera. No tool is needed to

turn the screws. See Chapter 7.4, Centering the Illumination.

Page 25

& Hardware Manual Chapter 3 – Epi-Fluorescence Illuminators 19

3.1.3 Filter Slider for Dispersion Filter and Exciter Balancers

The slider has four openings to hold filters of 12 mm diameter. The first position contains a dispersion filter that

allows illuminating the entire ocular's field of view. One position should always remain free for unaltered light

throughput and illumination of the CCD chip with maximum brightness. The two other positions are empty by

default. They can be equipped with filters that are to be fixed by easily removable plastic rings.

3.1.4 Light Sensor

A light sensor (photodiode) is mounted inside the illuminator tube (but outside the light path) and measures the

intensity of back-scattered light. The more intense the scattered light, the higher the overall light intensity leaving the fiber and the better correspondingly the position of the short arc burner in the MT20 / MT10 lamp house.

The light sensor cable is connected to a plug in the front plate of the MT20 / MT10.

3.2 IX2 Illuminators with Field Stop Slider

Certain fluorescence imaging techniques with intentional bleaching of fluorophores require exclusive illumination of a small region of the field of view. This can be realized with MT20 / MT10 illumination systems by using

illuminators that contain a field stop slider in the field plane. The slider can be equipped with pinhole inserts of

different diameter. Due to the pinhole that is projected into the focus plane only a circular region in the center of

the field of view is exposed to incident light.

Page 26

20 Chapter 3 – Epi-Fluorescence Illuminators

3.3 Flange for the IX2 Microscopes

The MT_CON illuminators are inserted into special flanges (IX2_MTA, see photo in chapter 3.1) mounted on the

epi-fluorescence port of IX2 microscopes; see Chapter 4.2.2, Mounting and Connecting the Epi-Fluorescence Illu-

minator.

3.4 Fluorescence Illuminator Unit for the BX2 Microscopes:

BX_MTA, BX_MTAA

5

3

4

2

1: illuminator tube containing the optical elements

2: flange

3: set screw to fix the illuminator

A special flange mounted to the back of the housing of a modified BX-RFA or a modified, motorized BX-RFAA

illuminator unit hosts the illuminator tube in case of BX2 microscopes. The mounting to the microscope frame is

the same as described in the microscope manual for the unmodified BX-RFA or BX-RFAA units.

4:filter slider with dispersion filter

5: housing of filter cube turret unit identical to standard BX-RFA

or BX-RFAA fluorescence illuminator

1

Page 27

& Hardware Manual Chapter 3 – Epi-Fluorescence Illuminators 21

3.5 Fluorescence Illuminator Unit for the MVX Microscope

3

1

2

4

1: fluorescence illuminator MT_CON

2: flange IX2_MTA

3:filter slider with dispersion filter

4: housing of filter cube turret unit identical to standard

MVX_RFA fluorescence illuminator

The IX2_MTA flange can be mounted to the mirror unit housing of the MVX-RFA illuminator when the standard

direct light coupling optics are removed. The MT_CON illuminators can then be inserted and fixed as usual.

The mounting of the entire unit to the microscope frame is the same as described in the microscope manual for

the standard MVX-RFA unit.

Page 28

22 Chapter 3 – Epi-Fluorescence Illuminators

Page 29

& Hardware Manual Chapter 4 – System Assembly and Adjustment 23

4 System Assembly and Adjustment

The following chapters explain how all the different hardware modules of the cell^R / cell^M Imaging Stations

have to be connected for correct operation.

4.1 Overview: Connectivity of System Components ................................................ 24

4.2 Connecting the Modules of the cell^M / cell^R Imaging Station ......................... 25

4.2.1 Connecting the MT10 / MT20............................................................................. 25

4.2.2 Mounting and Connecting the Epi-Fluorescence Illuminator .............................. 26

4.2.3 Connecting the Camera......................................................................................27

4.2.4 Connecting the Imaging PC to the Modules ....................................................... 28

4.2.5 Configuring the Imaging PC Network Connections ............................................ 29

4.3 Preparing the Illumination System MT10 / MT20 ............................................... 30

4.3.1 Burner Installation and Exchange ...................................................................... 30

4.3.2 Burner Alignment...............................................................................................31

4.3.3 Filter Exchange...................................................................................................33

4.4 Centering the Illumination..................................................................................35

4.5 Optimizing the Illuminator Tube Position .......................................................... 36

Page 30

24 Chapter 4 – System Assembly and Adjustment

4.1 Overview: Connectivity of System Components

The schematic diagram below shows the connection of standard components of the cell^R station. Before you

switch on any of the cell^R components, make sure that they are correctly connected.

1: Power cords

2: FireWire (IEEE 1394) cable to connect the CCD camera to the FireWire board of the computer for image data transfer.

3: Camera trigger line to connect the CCD camera to the computer-hosted cell^R Real-time Controller for synchronized image acqui-

sition.

4: Illumination System MT20 connection cable: Blue RJ45 cable to connect the MT20 to the computer-hosted cell^R Real-time Controller / cell^M System Coordinator for (synchronized) control of the sample illumination.

5: Light sensor cable to connect the light sensor in the epi-fluorescence illuminator (to monitor the optimization of the illumination

intensity) to the LIGHT SENSOR connector at the front of the MT20 / MT10.

6: Optic quartz light: Blue fiber to guide the light from the MT10 / MT20 to the epi-fluorescence illuminator.

Do not bend the light guide to a radius of less than 45 cm; otherwise the quartz fiber may be dam-

aged.

Page 31

& Hardware Manual Chapter 4 – System Assembly and Adjustment 25

4.2 Connecting the Modules of the cell^M / cell^R Imaging

Station

4.2.1 Connecting the MT10 / MT20

1. Connect the power cord to the main power connector at the MT10 / MT20 rear panel and to a power

outlet. Caution: Make sure that the MT10 / MT20's main power switch is set on OFF before connection.

2. MT20: Connect the CONTROLLER connector at the front of the MT20 with the controller

board at the back of the PC using the blue RJ45 cable.

MT10: Connect the CONTROLLER connector at the front of the MT10 with the same type of 4-pin

Lemo plug at the back of the PC or another ODB device (e.g., IX2_FRFACA or U_FFWO) using an

ODB Device Bus cable.

3. Connect the LIGHT SENSOR connector with the light sensor in the epi-fluorescence illumina-

tor using the black light sensor cable (with small three-pin plugs).

4. Connect the light guide: Gently insert the thin connector of the optical fiber entirely into the fi-

ber port at the front panel. Keep the protective plastic caps for transport purposes.

The fiber is fragile and might break if handled without care.

— Do not bend the fiber more than to a diameter of 45 cm (short term: 35 cm).

— Do not expose the fiber to shear force or torque.

Page 32

26 Chapter 4 – System Assembly and Adjustment

5. Lock the fiber by turning the fiber lock screw with a 1.5 mm hex wrench clockwise. Tighten the screw

gently.

6. For the connection of the other connector of the fiber see the following chapter.

UV radiation output; do NOT disconnect fiber while burner is switched ON.

4.2.2 Mounting and Connecting the Epi-Fluorescence Illuminator

For the BX2 microscopes the installation of the entire epi-fluorescence unit containing the MT20 / MT10 illuminator is explained in the respective microscope manuals.

The IX2_MTA flanges is mounted to the microscope frame as follows (see also the photo in Chapter 3, Epi-

Fluorescence Illuminator):

2

1

1. Insert the flange with the dovetail 1 first all the way into the frame opening.

2. Fix it with the two screws in the two holes that point downward by 45° on the left and right side of

the frame using the 4 mm hex-wrench.

3. Insert the epi-fluorescence illuminator tube into the flange so that the distance between flange and

back end of the illuminator (light guide port) is as listed for the different objectives and in depend-

ence of an installed PIFOC (see Chapter 4.5, Optimizing the Illuminator Tube Position).

4. Fix the illuminator with the fixing screw 2 of the flange using the 2.5 mm hex-wrench.

5. Connect the female end of the light sensor cable.

6. Insert the thick end of the light guide as far as possible (until the ring to adjust the depth of penetra-

tion makes contact with the illuminator) and fix it with the fixing screw using the 2 mm hex-wrench.

The fiber cannot be pulled out if the form-fit fixing screw is just slightly loose.

Page 33

& Hardware Manual Chapter 4 – System Assembly and Adjustment 27

UV radiation output; do NOT disconnect fiber while burner is switched ON.

4.2.3 Connecting the Camera

The camera has to be mounted on the microscope camera port using a c-mount adapter as described in the

microscope manual.

4.2.3.1 Camera Olympus XM10-T

1. Use the 3m FireWire cable to connect the FireWire port of the camera with the FireWire card at

the back of the computer.

2. Connect the trigger-out BNC port of the controller at the back of the computer to the trigger-in port

of the camera with the trigger cable. Note that both the camera plug of the cable and the camera

port are marked with a red dot, the two of which have to be lined up to enable the connection.

4.2.3.2 Camera Hamamatsu Orca R2

1. Make sure that the camera controller unit is switched off and disconnected from the power outlet.

2. Use the 3m FireWire cable to connect the FireWire port at the back of the camera controller unit

to the FireWire card at the back of the computer.

3. Connect the trigger-out BNC port of the controller at the back of the computer to the trigger-in BNC

port of the camera controller unit.

4. Connect camera and camera controller to the special multi-pin cable.

Page 34

28 Chapter 4 – System Assembly and Adjustment

4.2.4 Connecting the Imaging PC to the Modules

1 USB port for

cell^M / cell^R

hardware key

4 BNC port for

camera trigger cable

8 Controller serial

port for motorized

stage connection

7 Binder plug for

3 Lemo plug to

connect with

MT10 or other

ODB device

(U_FFWO or

IX2_FRFACA)

5 FireWire ports

ODB device

power supply

6 SMB port for

PIFOC controller

cable

2 Connection to

MT20

1. Insert the cell^R / cell^M hardware key into one of the USB ports of the computer. In case your sys-

tem is equipped with a parallel dongle insert it into the parallel port.

2. MT20 (cell^R): Insert the blue RJ45 cable coming from the CONTROLLER plug on the MT20 front

panel into the central RJ45 port of the cell^R controller board.

3. MT10 (cell^M): Insert the 4-pin ODB Device Bus cable coming from the CONTROLLER plug on the

MT10 front panel into the Lemo plug of the cell^R controller board.

4. Camera: Connect the BNC plug of the trigger cable to the BNC port of the cell^R / cell^M controller

board.

5. Camera: Plug the FireWireTM cable coming from the camera or the camera controller (in case of the

Hamamatsu Orca AGR) into any one of the two ports of the FireWireTM card.

Page 35

& Hardware Manual Chapter 4 – System Assembly and Adjustment 29

6. PIFOC (optional): The SMB plug of the PIFOC controller cable coming from the PIFOC controller

(CONTROL INPUT) has to be connected to the corresponding port on the right hand side of the

cell^R / cell^M controller board.

In addition to the interfaces at the back the cell^R / cell^M imaging computer features a DIGITAL I/O interface

on the front panel. It contains seven BNC ports. The TTL OUT ports A, B and C enable to send TTL trigger pulses

to peripheral devices during an experiment. The DIGITAL I/O ports 1, 2, 3 and 4 serve the same purpose but they

can be defined additionally as TTL IN (trigger IN) ports in the cell^M / cell^R Experiment Manager.

4.2.5 Configuring the Imaging PC Network Connections

When the factory settings of the network connections to the cell^R Real-time Controller / cell^M

System Coordinator are changed, the communication will be lost and the Imaging Station cannot

be operated anymore.

It may happen that the settings of the network connections are changed, especially when the operating system

is upgraded or the imaging PC is hooked to an intranet. The following instructions allow resetting connection

settings.

1. Go to Control PanelNetwork Connections.

2. Make sure that the connection to the cell^R Real-time Controller / cell^M System Coordinator is

called CTR_R.

3. Go to PropertiesGeneral.

4. Make sure that Internet Protocol (TCP/IP) is activated and go to Properties.

5. Use the IP address 42.42.42.17 and the Subnet mask 255.255.255.0.

6. Confirm with OK. And go to the Advanced tab.

7. Make sure that the Window FirewallSettings are off.

8. Confirm with OK.

Page 36

30 Chapter 4 – System Assembly and Adjustment

tip-off

4.3 Preparing the Illumination System MT10 / MT20

4.3.1 Burner Installation and Exchange

Wear protective glasses, clothes and gloves. Avoid any kind of mechanical stress to the burner. Allow the illumination system to cool down for at least 30 minutes with the main power on to keep

the cooling fan in the back operating. Then set the main power switch on O (OFF). Do not touch

glass parts of the burner.

1. Loosen the burner flap screw (3mm hex wrench). The flap will lift slightly. Open the flap.

2. If a burner is installed and has to be exchanged gently hold the heat sink and unscrew the nut. Re-

move nut, anode cable and heat sink from the burner socket.

3. Loosen the lock screw at the front panel and take out the burner. (Storage and/or disposal see Chap-

ter 2.1.2, Special Safety Precautions Regarding the Arc Burners).

4. Insert the new burner with the flat end (cathode) downwards and with the tip-off pointing in the di-

rection indicated in the scheme engraved on the inside of the flap (see scheme below). Be sure not to

scratch the surface of the reflector when inserting the burner into the funnel of a MT10E or MT20E.

top (anode)

burner

socket

tip-off

reflector

anode cable

nut

heat sink

Page 37

& Hardware Manual Chapter 4 – System Assembly and Adjustment 31

5. Tighten the lock screw at the front panel gently but firmly until the burner socket is fixed; force is not

necessary. The lock screw is spring loaded; you will feel the resistance of the spring once the screw is

tight.

6. Attach the heat sink, the anode cable and the nut to the screw (anode) at the top of the burner. Hold

the heat sink with the orientation as shown in the photo below while tightening the nut.

7. Close the burner flap and gently tighten the burner flap screw. The lamp will not ignite for safety rea-

sons if the flap is open or just loosely closed due to an interlock mechanism.

4.3.2 Burner Alignment

The burner has to be aligned after installation for maximum performance. To facilitate this, the light sensor in

the epi-fluorescence illuminator constantly monitors the light output.

ObsConfig.exe

1. Start the OBS System Configuration software by clicking the OBSConfig button and go to the

Burner page.

2. Check if the burner type listed is correct. If not, click the Exchange burner button to open the Select

burner type… dialog box that enables you to choose the type of arc burner. Confirm by clicking Ok.

Page 38

32 Chapter 4 – System Assembly and Adjustment

If you install a different type of burner, that is, if you switch from a Xe to a Hg/Xe burner, you will be

asked if the one installed is used or not. If it is new, the hour counter will start with 0 h, otherwise it

will start with the last reading of this particular type of burner. Thus, if you frequently exchange the

type, you will still have control of the expired lifetime of each.

3. Start the burner by clicking on the Burner ON/OFF button and wait for about 10 min until the light intensity stabilizes. The light sensor in the epi-fluorescence illuminator has to be connected to the

MT20 / MT10 (see Chapter 4.2.1, Connecting the MT20 / MT10).

4. Move the dispersion filter mounted in the filter slider in the back of the epi-fluorescence illuminator

into the light path to increase scattered light intensity.

5. Open the shutter by clicking on the Shutter OPEN/CLOSE button.

6. The two blue bars indicate the light output. They do not represent an absolute value but are re-

scaled frequently. The red lines indicate the maximum that was reached so far.

coarse reading

fine reading

reset button

The upper bar gives a coarse reading. When the maximum reaches the right end the display is reset

so that the maximum is repositioned at 80% of the length. This may happen several

times during the adjustment.

The lower bar shows an area of ±10% around the maximum of the upper bar and therefore gives a

finer reading. However, it is updated independently once its maximum reaches the right end and

thus does not necessarily show a fivefold magnification of the current display

of the upper bar. The reset may happen frequently.

In cases, upon reset no lower blue bar is visible. This may occur if immediately afterwards the maximum is lost due to a wrong turn of one of the adjustment screws (see next step). A click on the reset

button on the right moves the lower blue bar to the center.

Page 39

& Hardware Manual Chapter 4 – System Assembly and Adjustment 33

7. Use the adjustment screws in the order left/right, up/down and back/forth. Use the first screw and

check in which direction to turn in order to increase the length of the blue bars. Turn as long as the

reading increases and then switch to the second screw and repeat the procedure. Then switch to the

third one and do the same. Usually it is sufficient to go through this routine two or three times. Mind

that the automatic resetting of the bars does

NOT indicate a worsening of the adjustment (see step above)!

left/right

back/forth

up/down

8. Display warning message. You can activate a display warning message to remind you that the

burner is still turned on if you did not switch it off before exiting the cell^R / cell^M Imaging Software

(see bottom of the OBS System Configuration screenshot at the beginning of this chapter).

4.3.3 Filter Exchange

1. Start the OBS System Configuration software as described in the chapter above and go to Excitation Filters. Select the filter position that you want to exchange with the slider bar.

2. Open the flap at the right side of the MT20 / MT10. The selected filter position is now accessible and

allows the easy removal or insertion of a 25 mm filter. The filter wheel position is indicated by labels.

The filters are held in place by metal clips. Insertion is easiest if the filter is moved into position

tilted from the left side and then turned as shown in the series of drawings below. It is thus moved

under the clips and sits tightly. Likewise, the easiest way to remove a filter is to turn it left and then

pull it out. The left drawing below shows a filter moved halfway into position, still tilted to the left.

Page 40

34 Chapter 4 – System Assembly and Adjustment

Metal clips hold the

filters in position.

Label ∇ 5 indicating

filter position Nr. 5

Arrows have to point into

the same direction.

Many filters are coated on one side and their performance is direction dependent. Make sure to insert the filters so that the little arrow on its frame points into the same direction as the arrow engraved on the right side of the filter wheel compartment.

3. Close the flap. The system will perform a mechanical initialization that takes about 18 seconds. If you

listen closely you can hear the filter wheel and attenuator disk turn. After initialization the STATUS

LED is turned on automatically to indicate that the system is ready.

4. For the configuration of the excitation filters and the corresponding image types, see Software Man-

ual, Chapter 15, cell^R / cell^M Configuration.

Note that the filter wheel cannot be used via software for safety reasons while the flap is open. It

can be moved by hand but a certain mechanical resistance has to be overcome.

Note that all changes to the Illumination System MT20 / MT10 (besides filter and burner exchange)

have to be done by Olympus BioSystems. Use optional equipment provided or approved by Olympus BioSystems only. Usage of other equipment may impair the performance or cause damage to

the system. Safety of the system cannot be guaranteed in that case. Any damage to the system resulting from such action will void the warranty.

All filters provided by Olympus BioSystems have the standard size and fit into the filter wheel. In

case you use other filters you should check their thickness and diameter using the templates on the

inside of the filter flap.

Page 41

& Hardware Manual Chapter 4 – System Assembly and Adjustment 35

Filters should not exceed the size given by the templates in the top row (Filters must fit in here.)

nor should they be so small that they would fit into the templates in the lower row (Filters must

NOT fit in here.). The slits on the side are for testing the thickness of the filters. The same rules ap-

ply here as for the diameter.

4.4 Centering the Illumination

1. Put a fluorescent sample onto the microscope stage. Most suitably the fluorescence covers the entire

field-of-view.

2. Move a suitable filter cube in the microscope into position.

3. Select the corresponding excitation wavelength of the Illumination System MT20 / MT10 and open

the shutter using the cell^R / cell^M software or the OBS System Configuration software.

4. Make sure that the dispersion filter mounted in the filter slider (see 7 in photo in next chapter) of the

illuminator is NOT in the light path.

5. Look through the eyepiece. You might find that the bright illumination circle is off center as shown in

the left image below.

6. If you chose to observe the adjustment via the live view of cell^R / cell^M (see Software Manual,

Chapter 4, Image Acquisition and Illumination Control), you will get an image similar to the one inside

the highlighted rectangle in the sketch above, which corresponds to the field-of-view of the 2/3" CCD

chip of the camera.

7. Iteratively center the bright disk by turning the two adjustment screws at the epi-fluorescence illumi-

nator (see 8 in the photo in the next chapter).

Page 42

36 Chapter 4 – System Assembly and Adjustment

1

2

3

4

5

6

7

8

8

4.5 Optimizing the Illuminator Tube Position

For an optimally homogeneous illumination of the specimen, it is necessary for the light cone leaving the illuminator exit lens to match the position of the objective back aperture. Radial intensity gradients will result in case

the distance between exit lens and back aperture is severely off; the images are brighter in the center than at the

periphery.

Furthermore, in order to achieve maximum brightness, the exit plane of the light fiber has to be focused onto

the specimen plane. This depends on the distance between the fiber exit and the illuminator optics, in other

words, the depth of insertion of the light fiber into the illuminator. It is roughly optimized before delivery of the

system by positioning the stopper ring 3 that sets the depth of penetration of the fiber port adapter. Usually this

will be sufficient for a good illumination. However, if it is obviously defocused the light fiber position has to be readjusted by slightly turning the stopper ring. To be able to do that, the setscrew 4 of the illuminator tube has to

be slightly loosened by about half a turn.

1: illuminator tube containing the optical elements

2: light guide with port adapter

3: stopper ring to adjust depth of penetration

4: set screw to fix the light guide

5: flange for IX2 microscope frame

6: screw to fix the illuminator tube inside the flange

7: filter slider with dispersion filter

8: adjustment screws for centering the illuminated field

The optical path length, which is (partly) determined by the penetration depth of the illuminator tube 1 into the

microscope frame, is likewise crucial. In this context, it is important to realize that the objective's position relative to the illuminator is changed if a piezo-electric z-drive (PIFOC) is mounted: the optical path length increases.

Page 43

& Hardware Manual Chapter 4 – System Assembly and Adjustment 37

The penetration can easily be changed, to take a straight illuminator for IX2 microscopes as example, after

slightly loosening the fixing screw 6 in the flange 7. If the tube is either too far or not far enough inside the microscope, the overall brightness is reduced. However, the effects are hardly visible by the eye, but they can be

monitored by carefully analyzing the images.

The following table lists the optimal distances to be adjusted for the different types of illuminators. These distances are marked in the photo below. In the table you will find entries for the different microscopes that are

supported, both for the standard setup and for the cases when an objective PIFOC is installed. The objectives are

sorted in three groups.

It is inconvenient to change the illuminator position every time if objectives of all three groups are frequently

used: here, the distance of group B objectives can be chosen as a compromise.

Different illuminators, clockwise from top left: BX2, IX2 standard, IX2 L-shape, IX2 L-shape, IX2 with field stop slider. The arrows mark

the distances that have to be adjusted. The distances for illuminators mounted to the MVX microscope are the same as for the IX2

microscopes.

Optimal distance between flange and illuminator tube end [mm]

IX2 & MVX BX2

Objectives Standard Field stop L-shape BX51/61 BX51WI

A 231 79 41 139 99

B 221 69 31 129 89

C 211 59 21 119 79

A with PIFOC 215 63 25 123 99

B with PIFOC 205 53 15 113 89

C with PIFOC 195 43 5 103 79

The illumination will still be bright and homogeneous if, for example, a group C objective is used

but the illuminator is installed with the group A distance. However, for experiments that are very

critical with respect to the brightness of illumination, it might be useful to readjust the illuminator

position.

Page 44

38 Chapter 4 – System Assembly and Adjustment

Groups of objectives:

A LCPLFL 20x, LCPLFL 20x PH, PLAPO 1,25x, PLAPO 2x, UPLAPO 4x, UPLFL 4x, UPLFL 20x, UPLFL 4x P,

UPLFL 20x PH, UPLFL 4x PH, UPLFL 20x PH

B CPLFL 10x PH, LCPLFL 40x, LCPLFL 40x PH, LCPLFL 60x, LCPLFL 60x PH, PLAPO 40x, PLAPO 100x O3,

PLFL 100x, SLCPLFL 40x, SLCPLFL 40x PH, UAPO 40x /340, UMPLFL 5x, UMPLFL 10x, UMPLFL 10x W,

UMPLFL 20x, UMPLFL 40x, UMPLFL 50x, UMPLFL 100x, UPLAPO 10x, UPLAPO 10x W, UPLAPO 10x PH,

UPLAPO 20x, UPLAPO 20x O, UPLAPO 20x PH, UPLAPO 40x, UPLAPO 60x, UPLFL 10x, UPLFL 10x PH,

UPLFL 10x P, UPLFL 40x, UPLFL 40x PH, UPLFL 40x PH

C all UIS2 objectives, APO100x OHR, LUMPLFL 40x W, LUMPLFL 40x W/IR, LUMPLFL 60x W, LUMPLFL 60x W/IR, PLAPO 60x O3,

PLAPO 60x O3PH, PLAPO 60X O/TIRFM-SP, UAPO 20x /340, UAPO 20x W/340, UAPO 40x W/340, UAPO 40x OI/340, UMPLFL

20x W, UPLAPO 40x OI, UPLAPO 40x OI3PH, UPLAPO 60x W, UPLAPO 100x OI, UPLAPO 100x OI3PH, UPLFL 60x OI, UPLFL 60x

OI3PH, UPLFL 100x O, UPLFL 100x OI, UPLFL 100x OP,

UPLFL 100x O3PH, XLUMPLFL20XW

The objectives highlighted bold are the most sensitive with respect to an optimal adjustment. If they are frequently used, the distance should be set as corresponds to their group. If you cannot find a certain objective in

this list, please contact your local Olympus specialist.

Page 45

& Hardware Manual Chapter 5 – Optional Hardware Modules 39

5 Optional Hardware Modules

A variety of additional hardware modules are available for cell^R and cell^M but do not form part of a standard

system. The following chapters may be ignored in cases where these modules are absent.

5.1 Mounting and Connecting the Piezo-Electric Objective Drive (PIFOC) ............... 41

5.2 Connecting the Piezo-Electric Nosepiece Drive (Nosepiece PIFOC for

IX2 Microscopes) ............................................................................................... 43

5.3 Connecting the Corvus Controller of a Motorized Märzhäuser Stage ................. 44

5.4 Installing Illuminators with Pinhole Field Stop Sliders ........................................ 45

5.4.1 Centering the pinhole........................................................................................ 46

5.5 Installing the OptiGrid ....................................................................................... 47

5.5.1 The OptiGrid Illuminator ................................................................................... 47

5.5.2 Connecting the OptiGrid ................................................................................... 47

5.5.3 Configuring the OptiGrid ................................................................................... 48

5.5.4 Optical Alignment of OptiGrid and Camera ....................................................... 49

5.5.5 Calibrating the OptiGrid .................................................................................... 50

5.5.6 Calibrating the OptiGrid Z-Position for Different Image Types........................... 52

Page 46

40 Chapter 5 – Optional Hardware Modules

5.5.7 Stripe Filter for Snapshots ................................................................................. 54

Page 47

& Hardware Manual Chapter 5 – Optional Hardware Modules 41

stage spacers

5.1 Mounting and Connecting the Piezo-Electric Objective

Drive (PIFOC)

This optional device by Physik Instrumente GmbH, Germany, may not be part of your system.

The stage of an Olympus IX / IX2 microscope has to be lifted with the four spacer elements provided to enable the

installation of the PIFOC. The PIFOC is mounted onto the nosepiece like an objective. The electronics' housing has

to point inwards to enable free movement of the nosepiece. Due to the size of the PIFOC the neighboring objective

positions of the nosepiece are inevitably partly blocked and cannot be used.

fixing screws for the plastic

cover of the IX81 nose

piece (2 of 3 visible, the

other one is hidden on the

left side in this photo)

objective spacer

Microscope IX81 only: In order to be able to mount the PIFOC, the black plastic cover of the nosepiece

has to be removed (3 screws, see photo above). If the cover has been modified by Olympus BioSystems

it can be reinstalled after the PIFOC is mounted. The original piece is incompatible with the mounted

PIFOC.

Page 48

42 Chapter 5 – Optional Hardware Modules

1. Disconnect the socket from the piezo-drive housing.

2. Screw the socket into the nosepiece. A special "screw driver" is provided to tighten it (see the photo be-

low).

3. Place the PIFOC on top of the socket with the electronics' housing pointing inwards to enable free

movement of the nosepiece.

4. Fix the socket by turning the silver socket ring, which is accessible through the slit in the front of the

PIFOC, into direction "close" with help of the pin (see the photo below) that is likewise included.

5. The remaining free nosepiece positions can be equipped with objective spacer elements to enable parfo-

cality with the objective mounted on the PIFOC with all other objectives. Two

counter screw rings allow the fine-tuning of the objective elevation.

Counter screw rings

6. Connect the thicker black cable of the PIFOC to the port labeled SENSOR on the PIFOC controller (E-662

LVPZT-Amplifier). Your set contains an extension cord for this cable in case the length is insufficient.

7. Connect the thinner gray cable to the PIFOC controller port labeled PZT. Your set contains an extension

cord for this cable in case the length is insufficient.

8. Connect the BNC plug of the cell^R / cell^M PIFOC controller cable to the CONTROL INPUT port of the

PIFOC controller. The other end has to be plugged into the SMB port of the cell^R / cell^M controller at

the back of the PC (see Chapter 4.2.4, Connecting the Imaging PC to the Modules).

9. Configure and calibrate the PIFOC as described in the Software Manual, Chapter 15.6, Configuration of

the Pifoc.

Page 49

& Hardware Manual Chapter 5 – Optional Hardware Modules 43

The two cables leaving the PIFOC restrict the possible movements of the nosepiece. Make sure that

you do not move the nosepiece too often in the same direction because eventually the cables get

wound up until no further movement is possible. Also, if you attempt to move one of the other objective positions into the optical path and the electronics' housing is not positioned carefully it may touch

the stage and block the movement.

Note for PIFOC usage via the cell^R / cell^M software:

Make sure that Servo switch on the front panel of the PIFOC controller is set to ON.

Turn the DC OFFSET knob counterclockwise as far as it will go. The PIFOC will thus be set to the 0 Microns position unless otherwise set in the software.

5.2 Connecting the Piezo-Electric Nosepiece Drive (Nosepiece

PIFOC for IX2 Microscopes)

This optional device by Physik Instrumente GmbH, Germany, may not be part of your system.

1. Connect the thicker black cable of the nosepiece PIFOC to the port labeled SENSOR on the PIFOC controller (E-662 LVPZT-Amplifier). Your set contains an extension cord for this cable in case the length is

insufficient.

2. Connect the thinner gray cable to the PIFOC controller port labeled PZT. Your set contains an extension

cord for this cable in case the length is insufficient.

3. Connect the BNC plug of the cell^R / cell^M PIFOC controller cable to the CONTROL INPUT port of the

PIFOC controller. The other end has to be plugged into the SMB port of the cell^R / cell^M controller at