MACTURN 350

MACTURN 350-W

OPERATION & MAINTENANCE

(1st Edition)

Pub No. 6097-E (LE11-240-R1) Oct. 2012

6097-E P-(i)

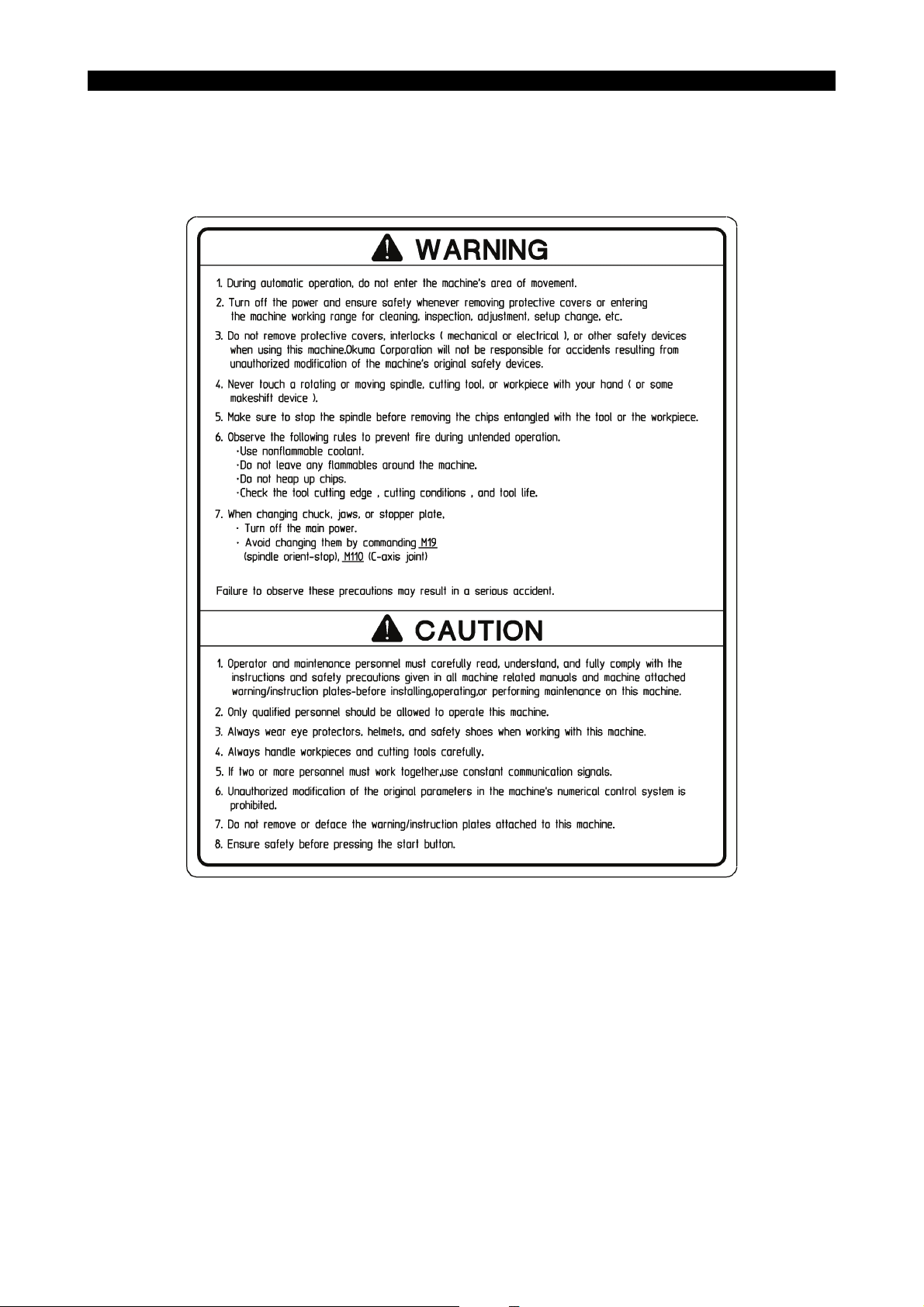

SAFETY PRECAUTIONS

SAFETY PRECAUTIONS

The machine is equipped with safety devices which serve to protect personnel and the machine itself from

hazards arising from unforeseen accidents. However, operators must not rely exclusively on these safety

devices: they must also become fully familiar with the safety guidelines presented below to ensure accidentfree operation.

This instruction manual and the warning signs attached to the machine cover only those hazards which

Okuma can predict. Be aware that they do not cover all possible hazards.

1. Moving and Installing the Machine

• There are three methods of moving the machine to any desired location; lifting the machine

using the attached lifting hooks, pushing the machine on rollers, and moving with a forklift

truck. Perform any of them with following precautions below.

Precautions for Lifting:

a. Use the wire rope of 24 mm (0.94 in.) or over in diameter.

b. Check the wire rope angles so that the ropes do not interfere with the machine.

(Do not slant the machine more than 40 degrees from the vertical.)

c. Lift the machine carefully while balancing the machine.

d. When placing the machine on the floor, lower the machine slowly using care not to give

shocks to the machine.

Approximate Machine Mass

13,700 kg (30,140 lb) (44-tool magazine)

(Machine weight including hydraulic unit, control cabinet, NC unit, and tool magazine)

Precautions for Rolling

a. Do not tip over or hit the machine against the ground.

Notes on forklift :

a. Watch the lower surface of the machine when you move it by forklift and treat with care so

as not to damage the jack bolts or rotary joints with the forklift forks.

The machine may come out of the bottom surface of the bed, depending on its

specification.

LE11240R0100100020001

6097-E P-(ii)

SAFETY PRECAUTIONS

• When selecting the machine installation site, ensure that the following conditions are met.

If not, it may be difficult to perform safe operation or maintain the guaranteed accuracy.

a. The machine ambient temperature is within the range from 5 to 40°C (41 to 104°F).

b. The machine ambient humidity is within the range from 40 to 75% at 20°C and no

condensation is allowed.

c. Avoid installation near the factory door because the machine is subject to rapid

temperature change by warm or cool air blowing against the machine.

d. Also avoid installation in a place which is subject to direct sunlight.

e. For the installation ground conditions, refer to Section 2 “Transportation and Installation

(Relocation).”

f. To maintain the guaranteed accuracy, you are advised to care and control the factory

temperature.

Recommended temperature change for 24 hours: : Within ±2°C (36°F)

Temperature difference between the measurement near

the floor and the measurement at a position 3 m (10 ft.)

high from the floor

: Within 1°C (34°F)

2. Before Turning on the Power

• Make sure that the doors to the operation panel and the electric control cabinet are closed.

• Make sure that there are no obstacles around the machine.

• Turn on the main power disconnect switch before turning on the CONTROL on the operation

panel.

3. Chuck Precautions

• Always close the front shield before starting the spindle or cutting operations.

• Always observe the spindle speed maximums for the installed chuck.

Never run the spindle exceeding the maximum allowable chuck speed.

• If a chuck or fixture is unique to your application, check the maximum allowable spindle speed

and stay within the limit. Also, take note of the workpiece gripping force and balance.

• The maximum spindle speed can be limited by inputting a G50 command with the spindle

speed. The G50 command helps to ensure safety in operation.

• If the spindle must be rotated close to the maximum allowable chuck speed, observe the

following points:

The maximum allowable spindle speed and application pressure are indicated on the name

plate on the front shield and on the chuck body. The allowable maximum speed and the

applicable pressure ensure a chucking force that is more than one-third of the original chuck

gripping force with the standard soft-top jaw set in line with the periphery of the chuck body.

a. Make sure that the workpiece clamped in the chuck is balanced.

6097-E P-(iii)

SAFETY PRECAUTIONS

b. Apply the allowable maximum amount of pressure to grip the workpiece because

centrifugal force reduces the chuck gripping force.

• If special jaws (larger than standard soft-top jaws) are used, observe the following points:

a. Lower the spindle speed because centrifugal force and lower efficiency reduce the chuck

gripping force.

b. If the jaw tightening nut (jaw nut) is outside of the periphery of the chuck, only one

tightening bolt is holding the jaws in place. This is a potentially dangerous condition. Jaw

nuts must always be within the periphery of the chuck.

c. Machine the jaws to the workpiece shape.

• Securely tighten the bolts on the chuck body, the jaws, and the block to the specified torque.

Use lubrication oil. Make sure that the torque is at least 392 to 490 N (88 to 110 lbf).

4. General Checks

• Check the amount of lubricating oil every day before starting operation.

• Always use the specified brand of lubricating oil.

• Use the recommended type of cutting fluid (coolant) when possible.

• It is recommended to use a water-soluble coolant to prevent fire. Do not attempt unmanned

operation if a non-soluble coolant is used.

• Change and replenish the lubricating oil and coolant in each reservoir according to the

schedules in the manual.

• Clean the filters according to the schedules in the manual.

• Make sure that each pressure gauge on the air and hydraulic lines display the correct value as

described in this manual.

• Always turn off the power before beginning any work inside the front shield. In addition, turn off

the power before beginning work at the back of the machine that requires an operator to enter

the machine operating zone.

6097-E P-(iv)

SAFETY PRECAUTIONS

5. Before Starting Operation

• Always follow the instructions in the operation manual.

• Always make sure that all of the protective covers including the front door and the chuck cover

are in place before operating the machine.

• Always close the front shield before starting operation.

• Never attempt to run a new program without checking its operation. Run the program without a

workpiece set in the chuck and make sure that there is no interference. After making sure that

the program has no bugs, cut a workpiece in the single block mode. If no problems are

discovered, automatic operation may be started.

• Before attempting the following operations, make sure that they can be accomplished safety.

a. Spindle rotation

b. Turret indexing

c. Axis movement

6097-E P-(v)

SAFETY PRECAUTIONS

• Never touch chips or the workpiece while the spindle is rotating.

• Never attempt to stop a moving object by hand or with a tool.

• Check the jaw installation conditions, the hydraulic pressure, and the maximum allowable

spindle speed for the power chuck.

• Check the installation and arrangement of the tools.

• Check the tool offset settings.

• Check the zero offset settings.

• Make sure that the spindle speed and feedrate override settings are at 100%.

• Before feeding the turret, check the software limit setting position for both the X- and Z- axes.

• Check the turret index/rotation position.

• Check the tailstock body position.

• Make sure the cutting operation is within the allowable transmission power and torque ranges.

• Make sure that the workpiece securely fitted in the chuck or fixture.

• Check the cutting fluid nozzle positions. They must be set to properly supply cutting fluid to the

appropriate points.

6. Precautions against Fire

• Selecting Coolant

Use nonflammable coolant.

a. Never use oil coolant because it could catch fire from heated chips, tool’s frictional heat, or

grinding spark.

When using oil coolant for unavoidable reason, observe the following:

a. Check the tool edge condition, tool life, and set the cutting conditions that never cause fire

before you start machining.

b. Clean the coolant filter at regular intervals to maintain sufficient coolant discharge, and

always check the coolant for normal discharge.

c. Take every measures so that you can extinguish the fire immediately by placing a fire

extinguisher near the machine and have an operator always watch the machining

condition, or installing an auto extinguisher.

d. Do not place any flammable objects near the machine.

6097-E P-(vi)

SAFETY PRECAUTIONS

e. Dispose of chips not to allow them to stack.

f. Periodically clean the inside and surrounding of the machine while checking that all the

devices are normally operating.

g. Never attempt untended operation.

h. When using oil coolant for grinding, you are requested to install fire-fighting equipment

such as auto extinguisher. In this case, inform us of your intention in the stage of

examining your facility.

• When machining flammable material

a. Before machining any of the flammable solid materials such as resin, rubber, or wood,

carefully study and understand the material characteristics and observe the above

precautions to take all possible measures to prevent fire.

b. Use particular care when machining magnesium, because its chips react to the water-

soluble coolant and generate hydrogen. The hydrogen may catch fire from burnt chips,

resulting in explosive fire.

• Performing Dry Machining

a. Dry machining is a fire hazard because workpiece, tool, or chips are not cooled. Therefore,

never place any flammable objects near the machine and dispose of chips not to allow

them to stack.

b. Take the same safety measures as in the case of using oil coolant described above, such

as checking the tool edge state and tool life, and setting cutting conditions that never cause

fire.

• Emergency Measures in Door-close and Power-OFF State

a. Should fire break out in the machine when the door is closed and the power is OFF, open

the door using the door lock switch release key and extinguish the fire.

(For details, refer to “Safety door switch” in SECTION 3. 3-2-11. Interlock.)

7. Setup

• Make sure that setup is complete.

• If the setup is changed, operate the machine step-by-step to make sure that cutting can be

performed without any problems.

• Before changing the chuck and/or chuck jaws, make sure that the chuck fits the intended job.

• If two or more workers must work together, establish signals so that they can communicate (for

example, when lifting or setting heavy objects). Each worker should be aware when a new

process is about to begin.

• Use a crane or equivalent tool to handle heavy objects.

• When attempting an unfamiliar setup, recheck the setup before beginning operation.

• Remove unnecessary toolholders from the turret.

• Ensure that the bolts for fixing the toolholders to the turret are securely tightened.

• Remove the bolts which are not used for fixing the toolholders.

6097-E P-(vii)

SAFETY PRECAUTIONS

8. Workpiece Loading and Unloading

• Make sure that workpieces are loaded and unloaded securely.

• Before loading or unloading a workpiece, retract the turret so that the cutting tools in the turret

cannot injure the operator.

• Before loading and unloading a workpiece, make sure that the spindle has come to a complete

stop.

• Before running a new program, rotate the spindle to make sure that the workpiece is securely

clamped in the chuck.

• Before machining an irregularly-shaped workpiece, make sure that it is balanced properly.

• When handling heavy workpieces, use a crane, hoist, or other similar tool.

• Before loading a workpiece, make sure that the workpiece has a portion that can be used for

proper chucking.

9. At the End of the Day

• Clean the machine.

• Move the turret to the predetermined retraction position.

• Turn off the CONTROL, before turning off the main power disconnect switch.

• Make sure all power switches are turned off.

10. When a Problem Occurs

• Stop the machine immediately by pressing the EMERGENCY STOP switch on the operation

panel.

• Consult with the person in charge of maintenance to determine what corrective measures need

to be taken.

• If two or more workers must work together, establish signals so that they can communicate (for

example, when lifting or setting heavy objects). Each worker should be aware when a new

process is about to begin.

• Only use specified replacement parts and fuses.

11. Powerful Magnet inside the Product

Some products contain powerful magnets, which could be dangerous if exposed by disassembling

the products. Those which contain powerful magnets are provided with a caution plate to indicate

where such magnets are used.

6097-E P-(viii)

SAFETY PRECAUTIONS

(1) Get assistance from Okuma for disassembling or repairing the powerful magnet housing unit.

• It is dangerous as strong magnetic attraction is exposed while/after disassembling the

strong magnetic housing unit.

• Disassembling work requires special knowledge and jigs.

(2) Danger of powerful magnet

Following are the examples of possible damage caused by being close to powerful magnet.

• Medical electronic instruments such as pacemaker produce malfunction, resulting in

serious bodily injury or loss of life.

• Implanted magnetic metal devices such as artificial eye, clip used for artery of the brain,

etc. get attracted by powerful magnet, resulting in loss of life.

• Metal clothing accessories get attracted by powerful magnet, resulting in bodily injury.

• Tools or parts get attracted by powerful magnet, resulting in bodily injury.

• Precision instrument becomes out of order.

• Magnetic memory device causes data loss.

(3) Contact Okuma when disassembling a magnet housing unit is necessary to dispose of the

machine.

12. General Precautions

• Wear appropriate clothing.

• Keep the machine and the area around it clean and organized.

• Never touch controls or switches with wet hands.

6097-E P-(ix)

SAFETY PRECAUTIONS

13. Safety Devices and Functions

Contents Location Remark

Front shield with safety glass and polycarbonate Machine

Shield open/close interlock Machine

Chuck interlock Electric control cabinet

Tailstock sleeve interlock Electric control cabinet

Tailstock sleeve position confirmation Electric control cabinet optional

Foot pedal protection cover Machine optional

Software limit Operation panel

Chuck barrier Operation panel

Turret barrier Operation panel

Tailstock barrier Operation panel optional

Emergency stop button Operation panel

Slide hold button Operation panel

Alarm display Operation panel

Short circuit breaker Electric control cabinet optional

Self-lock cylinder for chuck Machine

Cycle start requiring simultaneous depression of both buttons Machine optional

Turret rotation at low speeds (manual) Machine

Tool magazine door open/close interlock Machine

14. Symbols Used in This Manual

The following warning indications are used in this manual to draw attention to information of

particular importance. Read the instructions marked with these symbols carefully and follow them.

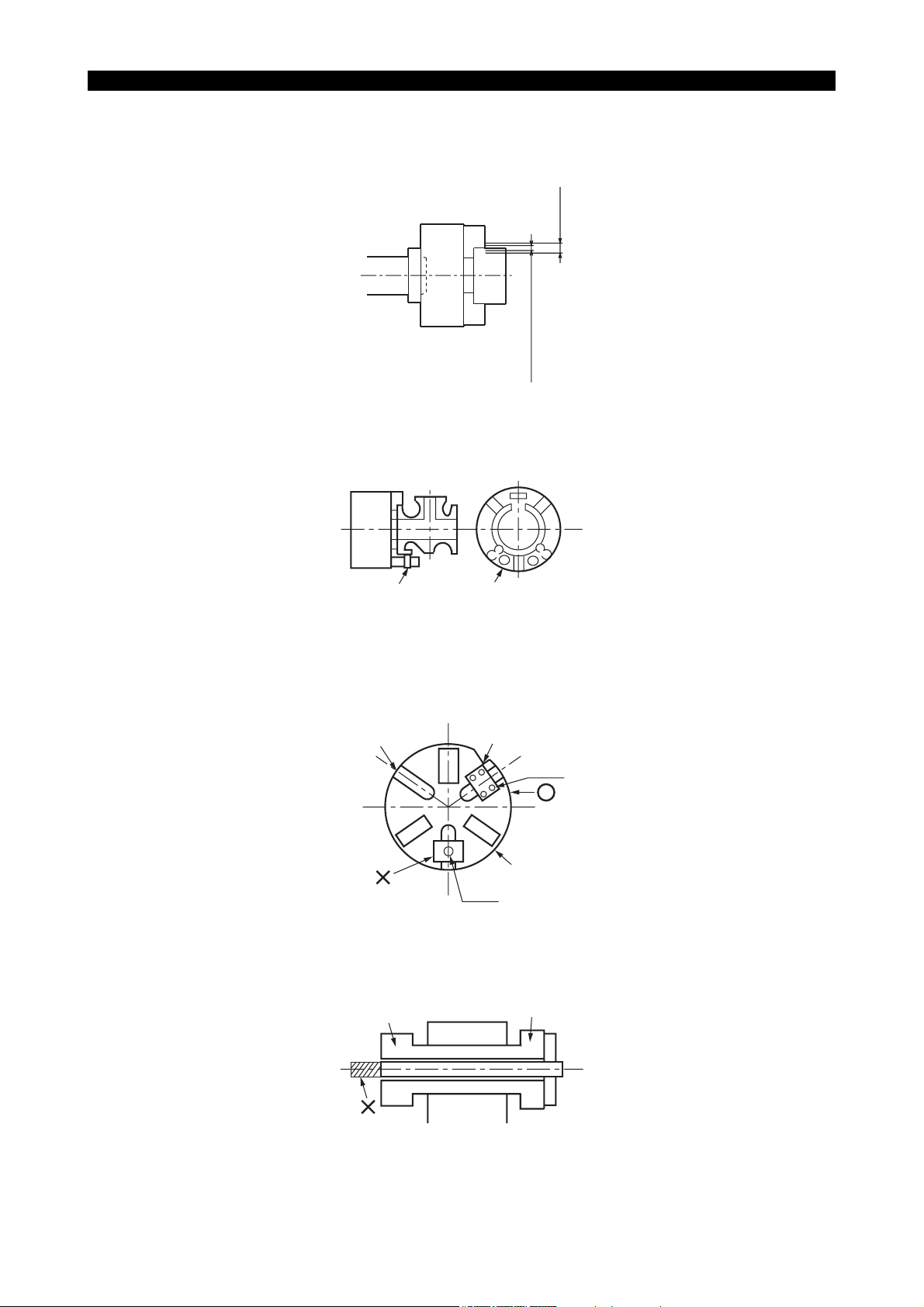

15. For Safe Chuck Work

• When using a chuck, refer to the instruction manual provided by the manufacture of the chuck.

And strictly observe the safety items stated in the manual.

• Set the chuck gripping force by ensuring sufficient margin of safety (2 to 3 or over). Run the

spindle within the allowable speed range set at this time.

6097-E P-(x)

SAFETY PRECAUTIONS

Centrifugal force

F0

R0

μ× (F0-f)×R0>F1×R1

F1

(Cutting force)

R1

LE11240R0100100160001

• In constant peripheral speed cutting, calculate the actual machining speed before designating

G50 (max. speed limit function).

N = (1000 × V) / (π × D

N:Spindle speed

V:Cutting speed

π:Circumference-to-diameter

ratio, 3.14

D:Machining diameter

)

LE11240R0100100160002

• Secure the jaw gripping depth as much as possible.

Must be

deep

LE11240R0100100160003

6097-E P-(xi)

SAFETY PRECAUTIONS

• When gripping a workpiece, soft top jaws must be at the central area of the entire jaws stroke

(see the illustration) or the base line mark on the master jaws must be located within the

appropriate chuck stroke range.

Entire stroke

Appropriate stroke range

Central one third of the entire stroke

LE11240R0100100160004

• Before machining an unbalanced workpiece, carry out balancing of the workpiece weight by

gradually changing the spindle speed.

Clamping block Balance weight

LE11240R0100100160005

• Never attempt to install jigs using T-nut.

Be sure to fix the jigs with bolts.

No chucks prepared by Okuma have T-groove.

T-slot

Jig

Bolt

Jaw

T-nut

LE11240R0100100160006

• When inserting a bar material into the hollow chuck, ensure that the bar does not protrude from

the rear end of the cylinder.

Cylinder

Hollow chuck

LE11240R0100100160007

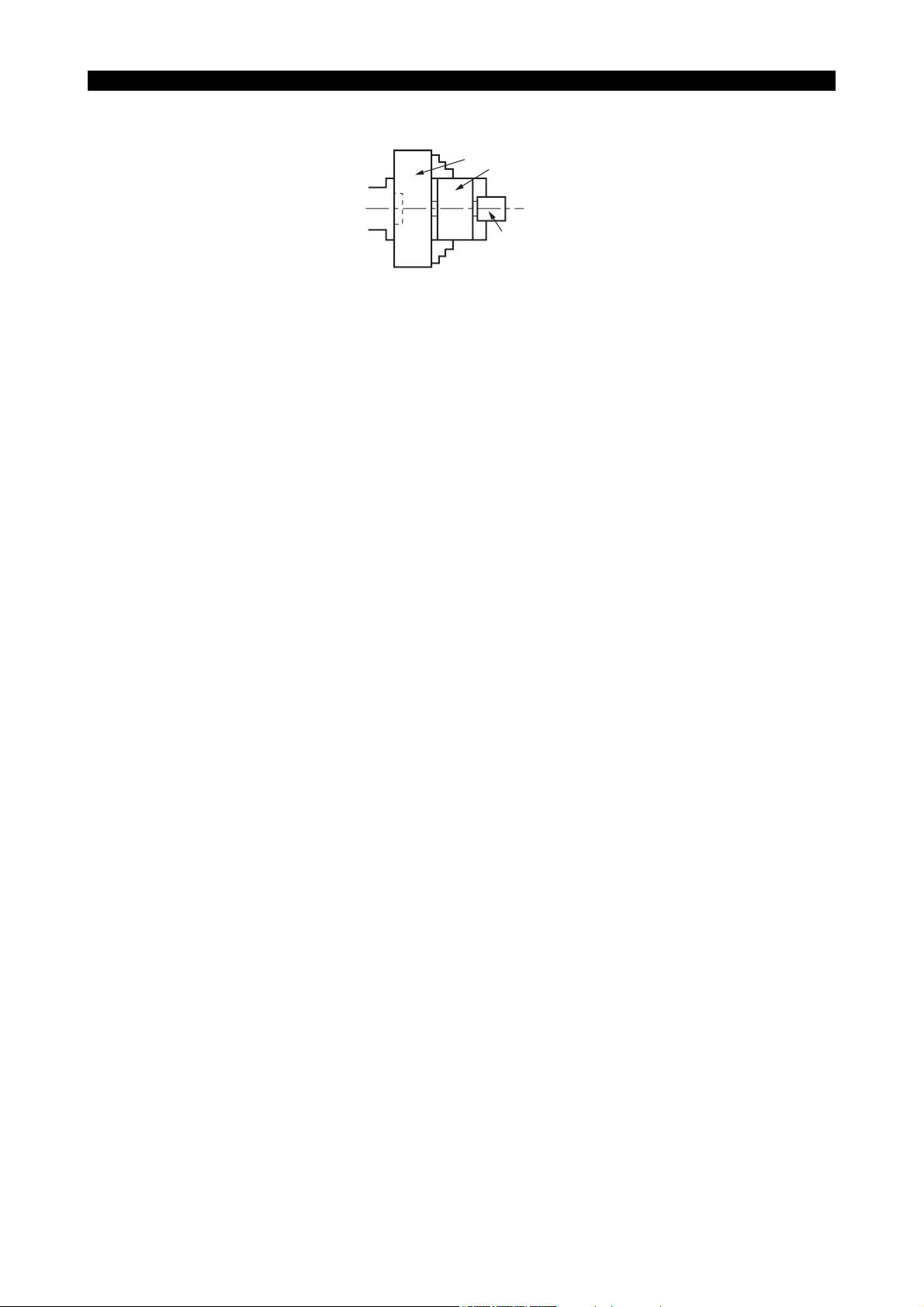

• Never use double chucking method.

16. Caution Plate

• The machine and its components are fitted with various caution plates. Carefully read these

plates and follow the instructions described there.

• Do not tear or damage the caution plates. In case a plate has been lost or become illegible, ask

us for a new plate, quoting the Okuma part number written in this manual.

6097-E P-(xii)

SAFETY PRECAUTIONS

Chuck

Workpiece

LE11240R0100100160008

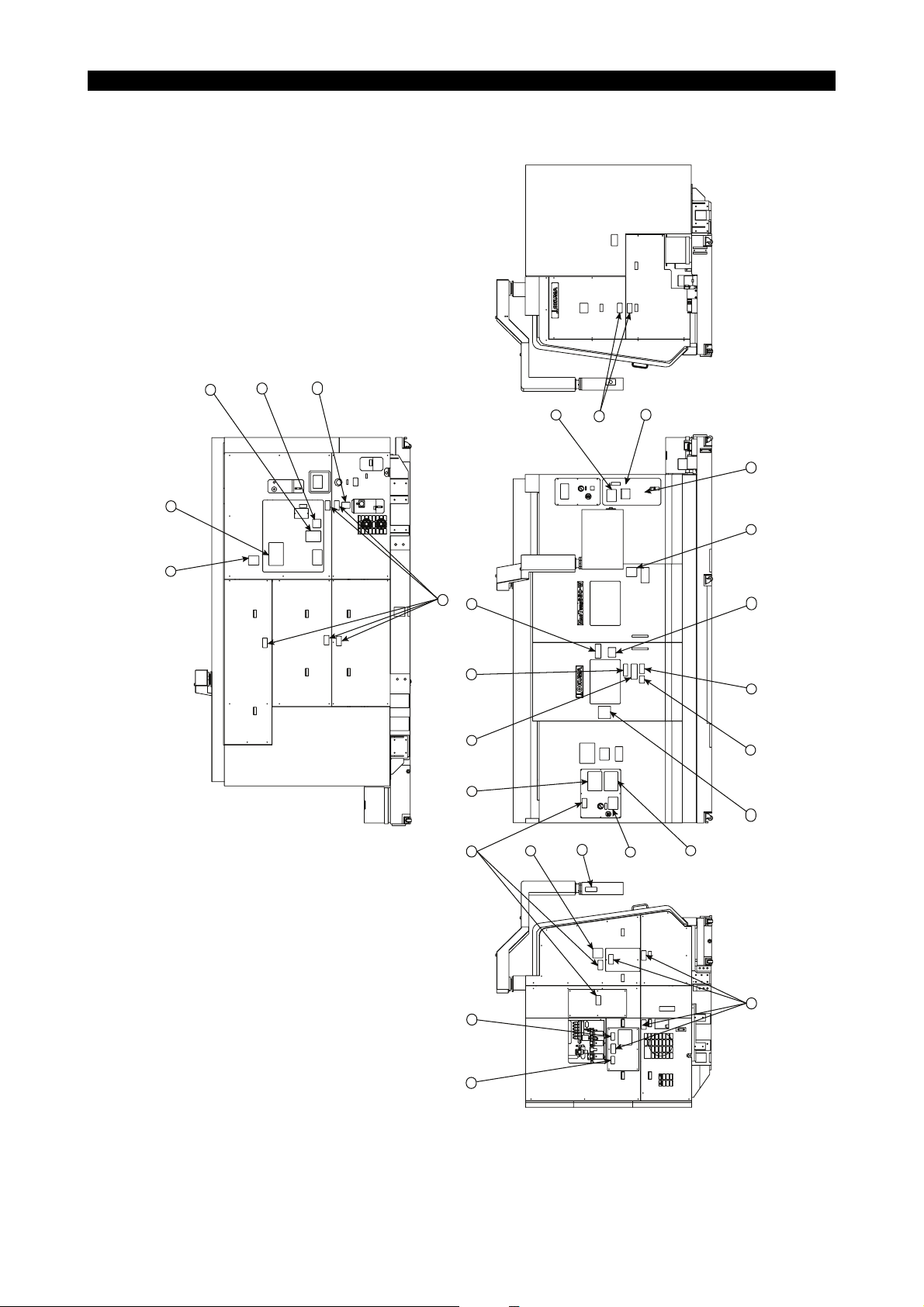

16-1. Caution Plate Positions

6097-E P-(xiii)

SAFETY PRECAUTIONS

14

16

9

13

23

4

10

10

21

19

5

1

18

17

9

22

8

7

20

10

12

11

6

15

3

2

10

LE11240R0100100180001

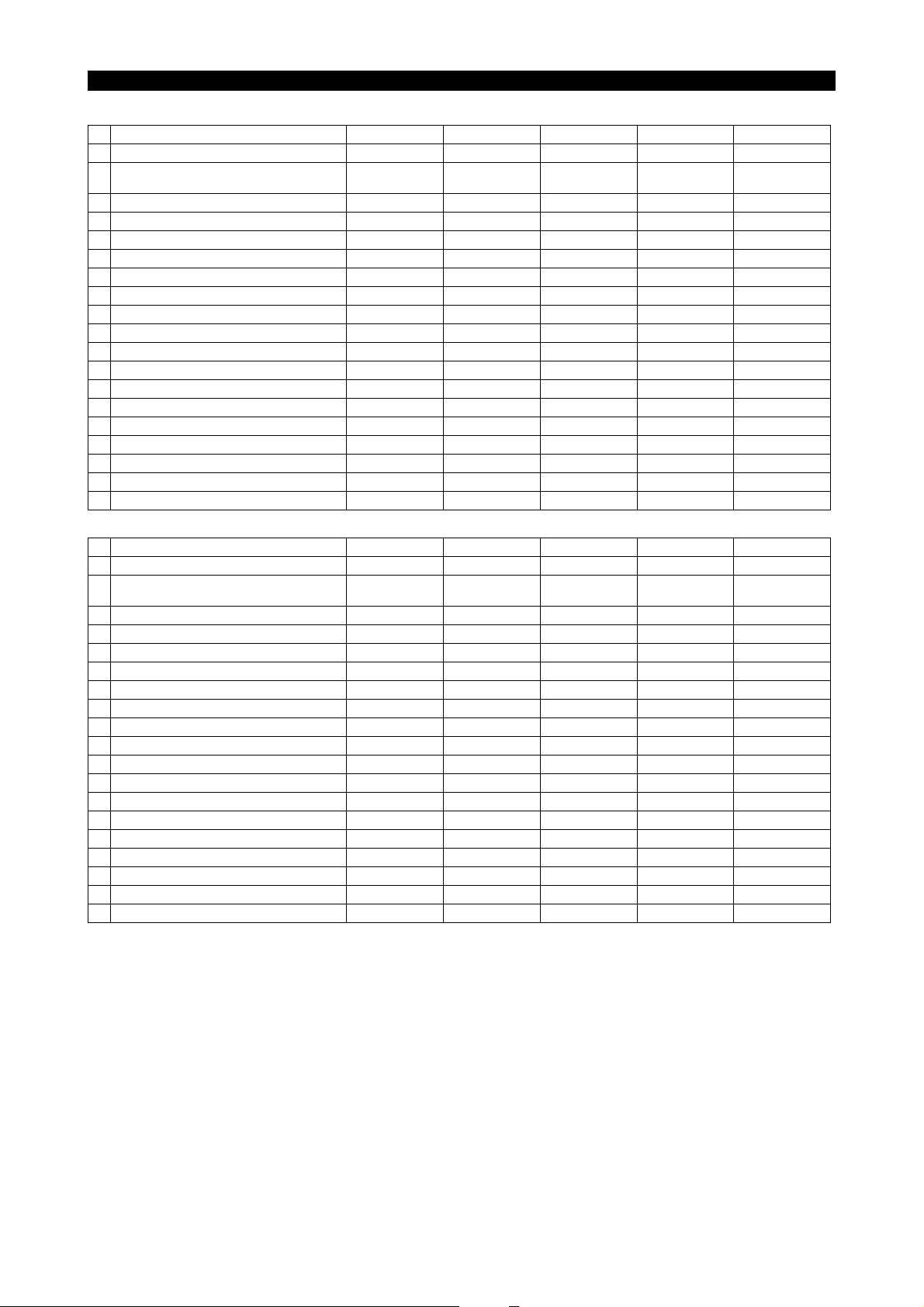

6097-E P-(xiv)

SAFETY PRECAUTIONS

Japanese English German Swedish Dutch

1 Warning caution H1090-1023-68-1 H1090-1164-54 H1090-1019-31-3 H1090-1029-74-3 H1044-1104-04-1

2 Instruction for oil supply to the machine body

(Model with sub spindle-OP)

3 Instruction for chuck pressure setting H1042-1173-79-3 H1044-1096-46-3 H1044-1099-06-3 H1044-1098-88-3 H1044-1103-96-2

4 Instruction for sub-chuck pressure setting (OP) H1042-1173-80-3 H1044-1096-47-4 H1044-1099-07-3 H1044-1098-89-4 H1044-1103-97-2

5 Warning H1090-1164-51-1 H1090-1164-52-1 H1090-1166-87-1 H1090-1166-88-1 H1090-1166-89-1

6 Warning against X-axis turret falling H1090-1046-45 H1090-1047-93 H1090-1048-23 H1090-1048-02 H1044-1104-08

7 Caution for cover removal H1090-1020-35 H1090-1018-33 H1090-1020-36-1 H1090-1020-37-2 H1090-1020-38-2

8 Caution for oil mist filter clogging H1090-1074-26 H1090-1074-27 H1090-1074-28-1 H1090-1074-29-1 H1090-1074-30

9 Caution for ABSOSCALE (OP) H1090-1074-33 H1090-1074-34 H1090-1074-35-1 H1090-1074-36-1 H1090-1074-37

10 Notice for ATC H1090-1019-87-1 H1090-1019-77-1 H1090-1019-82-2 H1090-1029-71-2 H1090-1074-42

11 Caution for magazine operation H1090-1039-34-3 H1090-1047-91-2 H1090-1048-21-3 H1090-1047-99-2 H1044-1104-06-2

12 Notice for touch setter (OP) H1090-1017-48-1 H1090-1024-07-1 H1090-1028-87-2 H1090-1029-96-1 H1090-1029-03-1

13 Notice for MG manual exchanging H1090-1054-39-1 H1090-1054-40-1 H1090-1054-63-2 H1090-1054-64-1 H1090-1074-43

14 Oil mist unit working pressure setting H1042-1156-74-2 H1044-1099-78 H1044-1099-82 H1044-1099-84 H1044-1104-02

15 Oil mist manifold pressure setting H1042-1156-73-2 H1044-1099-77 H1044-1099-81 H1044-1099-83-1 H1044-1104-01

16 Caution for safety glass H1090-1042-24 H1090-1041-56 H1090-1042-26-2 H1090-1042-30-2 H1090-1042-28-1

17 Caution for tool change H1090-1079-14 H1090-1079-48 H1090-1079-50-1 H1090-1080-05-1 H1090-1080-03

18 Door lock warning H1090-1050-06 H1090-1050-26 H1090-1057-69 H1090-1057-70 H1090-1057-71

19 Caution for footstep (OP) H1090-1090-62 H1090-1091-84 H1090-1091-85 H1090-1091-91 H1090-1091-94

H1090-1046-44-9 H1090-1187-47 H1090-1048-22-6 H1090-1048-01-7 H1090-1074-41-1

Danish French Italian Spanish Turkish

1 Warning caution H1090-1052-35-2 H1090-1019-23-2 H1090-1019-24-2 H1090-1032-96-2 H1090-1094-22-1

2 Instruction for oil supply to the machine body

(Model with sub spindle-OP)

3 Instruction for chuck pressure setting H1044-1101-33-3 H1044-1105-22-2 H1044-1101-79-2 H1044-1109-76-1 H1044-1115-33

4 Instruction for sub-chuck pressure setting (OP) H1044-1101-34-2 H1044-1106-22-2 H1044-1101-80-2 H1044-1109-80-1 H1044-1115-34

5 Warning H1090-1166-91-1 H1090-1166-92-1 H1090-1166-93-1 H1090-1166-94-1 H1090-1166-96-1

6 Warning against X-axis turret falling H1090-1052-79-1 H1090-1062-69 H1090-1053-72 H1090-1079-54-1 H1090-1095-91

7 Caution for cover removal H1090-1020-40-2 H1090-1018-34-1 H1090-1020-41 H1090-1024-12-1 H1090-1038-75-2

8 Caution for oil mist filter clogging H1090-1074-31-1 H1090-1062-65-1 H1090-1074-32 H1090-1079-59-1 H1090-1094-26

9 Caution for ABSOSCALE (OP) H1090-1074-38-1 H1090-1074-39 H1090-1074-40 H1090-1030-72-1 H1090-1078-95

10 Notice for ATC H1090-1019-86-2 H1090-1025-88-1 H1090-1029-83-1 H1090-1079-55 H1090-1094-27

11 Caution for magazine operation H1090-1052-34-4 H1090-1062-67-2 H1090-1053-36-2 H1090-1081-77-1 H1090-1094-28

12 Notice for touch setter (OP) H1090-1028-94-2 H1090-1028-88-1 H1090-1028-89-1 H1090-1029-63-2 H1090-1066-01-1

13 Notice for MG manual exchanging H1090-1054-65-2 H1090-1062-66-2 H1090-1054-66-1 H1090-1079-58 H1090-1095-94

14 Oil mist unit working pressure setting H1044-1101-16-1 H1044-1105-21 H1044-1101-48 H1090-1079-78-1 H1044-1115-35

15 Oil mist manifold pressure setting H1044-1101-15-1 H1044-1105-20 H1044-1101-47 H1090-1079-77-1 H1044-1115-36

16 Caution for safety glass H1090-1042-31-2 H1090-1042-27 H1090-1042-29-1 H1090-1042-25-1 H1090-1066-02-1

17 Caution for tool change H1090-1080-04-1 H1090-1079-51 H1090-1079-52 H1090-1081-79 H1090-1094-37

18 Door lock warning H1090-1057-73 H1090-1057-74 H1090-1057-75-1 H1090-1057-76 H1090-1057-41-1

19 Caution for footstep (OP) H1090-1091-90 H1090-1091-86 H1090-1091-87 H1090-1091-88 H1090-1091-93

H1090-1052-36-4 H1090-1065-76-3 H1090-1053-38-4 H1090-1079-57-1 H1090-1095-90

16-2. Caution Plates and Okuma Part Numbers

• [1] Warning caution

Okuma Part No. H1090-1164-54

6097-E P-(xv)

SAFETY PRECAUTIONS

LE11240R0100100190024

SAFETY PRECAUTIONS

• [2] Instruction for oil supply to the machine body (Model with sub spindle-OP)

Okuma Part No. H1090-1187-47

6097-E P-(xvi)

LE11240R0100100190025

• [3] Instruction for chuck pressure setting

Okuma Part No. H1044-1096-46-3

6097-E P-(xvii)

SAFETY PRECAUTIONS

• [4] Instruction for sub-chuck pressure setting (OP)

Okuma Part No. H1044-1096-47-4

LE11240R0100100190026

LE11240R0100100190027

• [5] Warning

Okuma Part No. H1090-1164-52-1

6097-E P-(xviii)

SAFETY PRECAUTIONS

• [6] Warning against X-axis turret falling

Okuma Part No. H1090-1047-93

Before removing X-axis feed servomotor for maintenance or

inspection of X-axis ball screw, servomotor or other related

parts, be sure to prevent the upper and lower turrets from

slipping down using wood blocks or the like.

Negligence of this may cause a turret to slip accidentally,

resulting in serious injury.

Example of Slip Preventive Measure

Optional

WARNING

Prop up the turrets

using wood blocks

LE11240R0100100190028

LE11240R0100100190029

• [7] Caution for cover removal

Okuma Part No. H1090-1018-33

CAUTION

ALWAYS TURN THE MAIN POWER SWITCH "OFF" BEFORE

REMOVING THIS COVER.

FAILURE TO FOLLOW THIS INSTRUCTION MAY RESULT IN

PERSONAL INJURY.

• [8] Caution for oil mist filter clogging

Okuma Part No. H1090-1074-27

6097-E P-(xix)

SAFETY PRECAUTIONS

LE11240R0100100190030

• [9] Caution for ABSOSCALE (OP)

Okuma Part No. H1090-1074-34

LE11240R0100100190031

LE11240R0100100190032

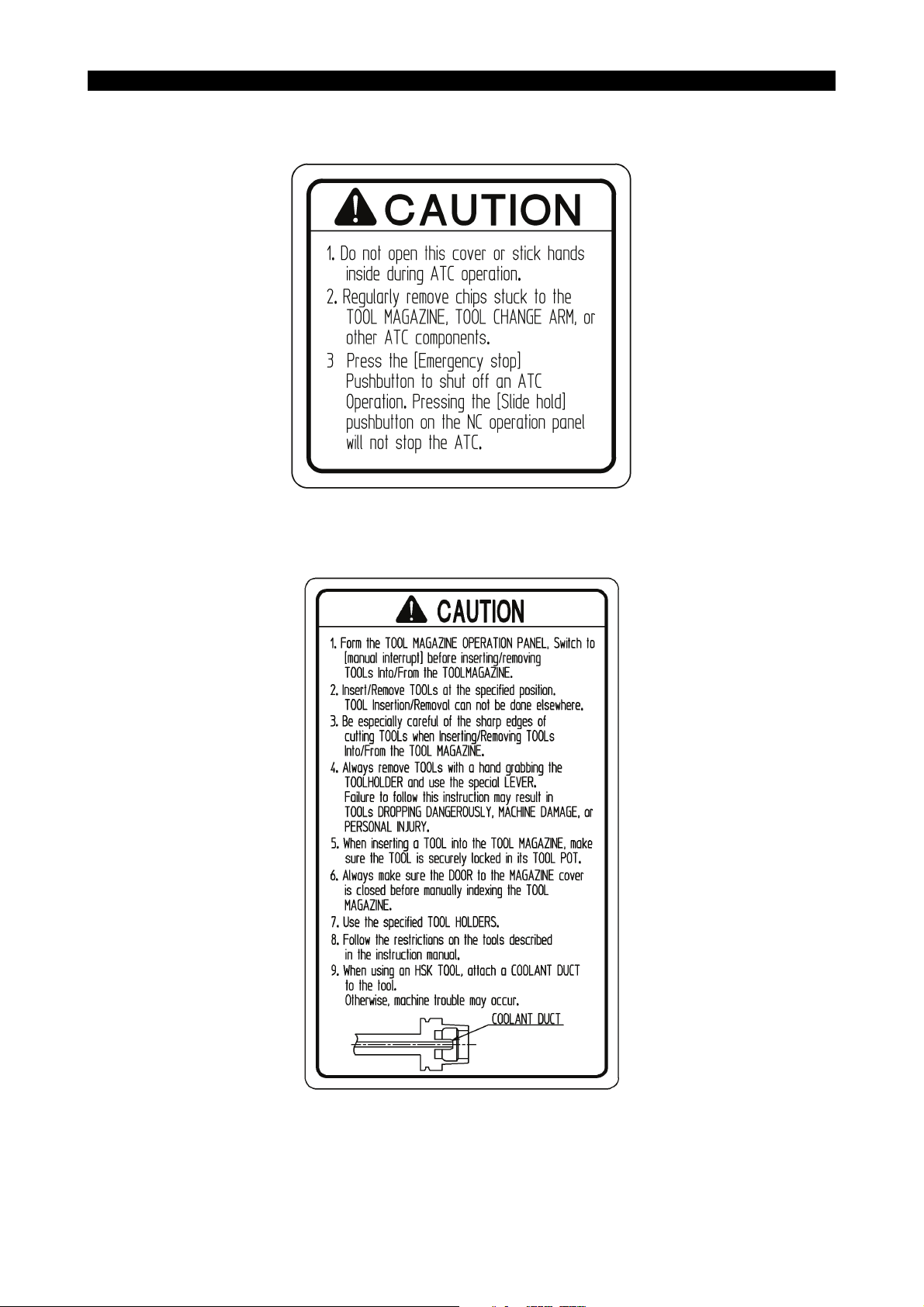

• [10] Notice for ATC

Okuma Part No. H1090-1019-77-1

6097-E P-(xx)

SAFETY PRECAUTIONS

LE11240R0100100190033

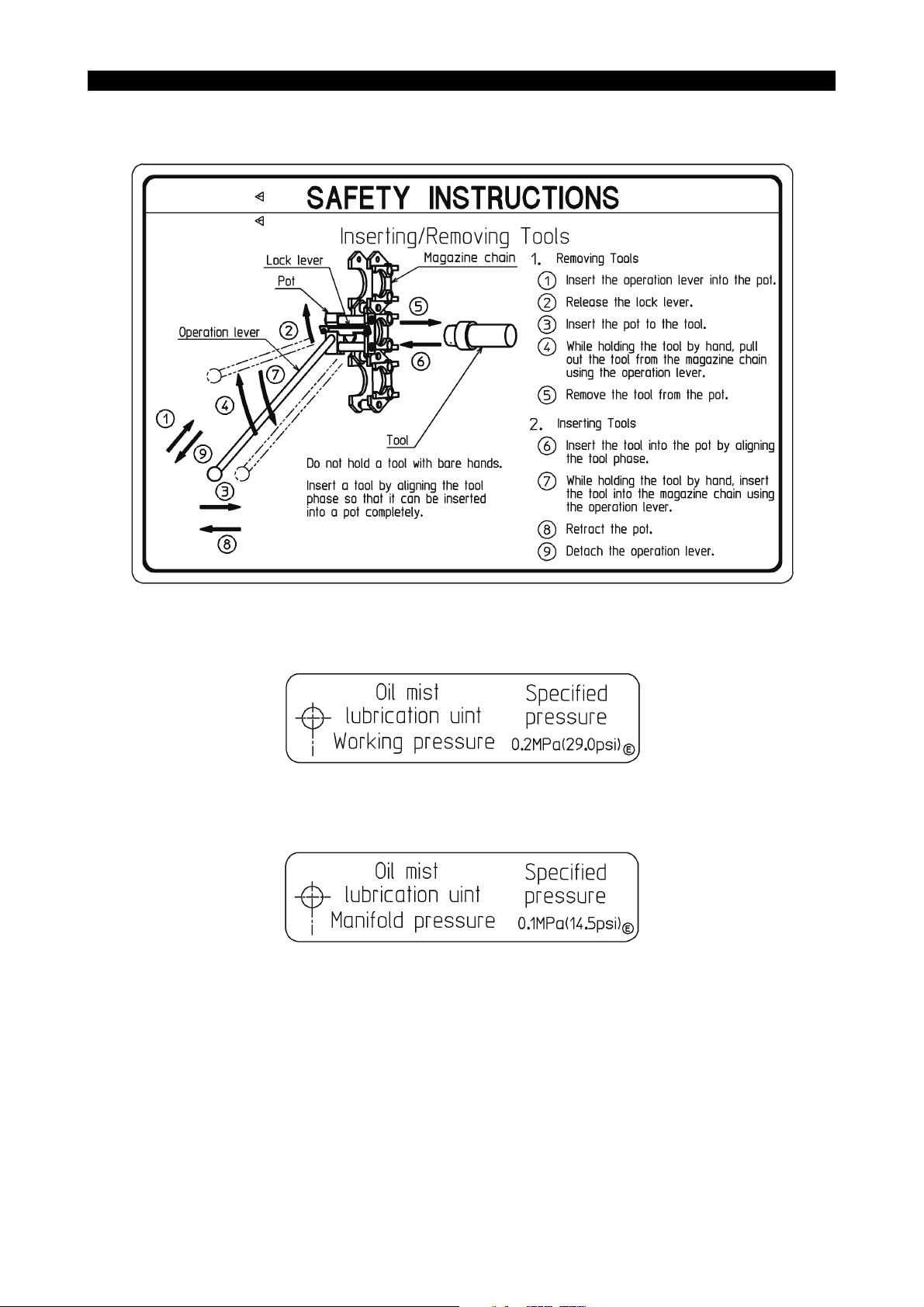

• [11] Caution for magazine operation

Okuma Part No. H1090-1047-91-2

LE11240R0100100190034

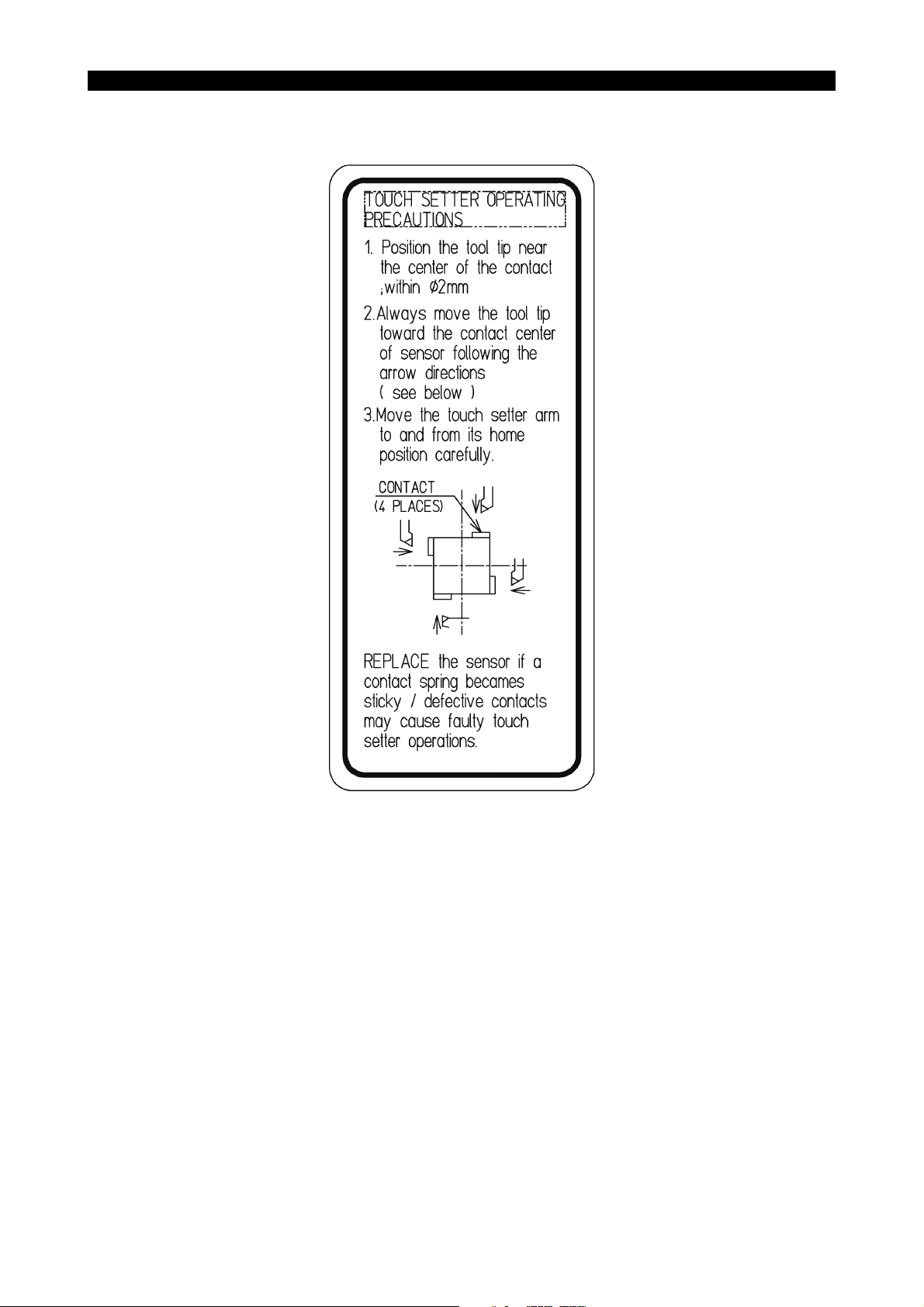

• [12] Notice for touch setter (OP)

Okuma Part No. H1090-1024-07-1

6097-E P-(xxi)

SAFETY PRECAUTIONS

LE11240R0100100190035

• [13] Notice for MG manual exchanging

Okuma Part No. H1090-1054-40-1

6097-E P-(xxii)

SAFETY PRECAUTIONS

• [14] Oil mist unit working pressure setting

Okuma Part No. H1044-1099-78

• [15] Oil mist manifold pressure setting

Okuma Part No. H1044-1099-77

LE11240R0100100190036

LE11240R0100100190037

LE11240R0100100190038

• [16] Caution for safety glass

Okuma Part No. H1090-1041-56

• [17] Caution for tool change

Okuma Part No. H1090-1079-48

6097-E P-(xxiii)

SAFETY PRECAUTIONS

LE11240R0100100190039

LE11240R0100100190040

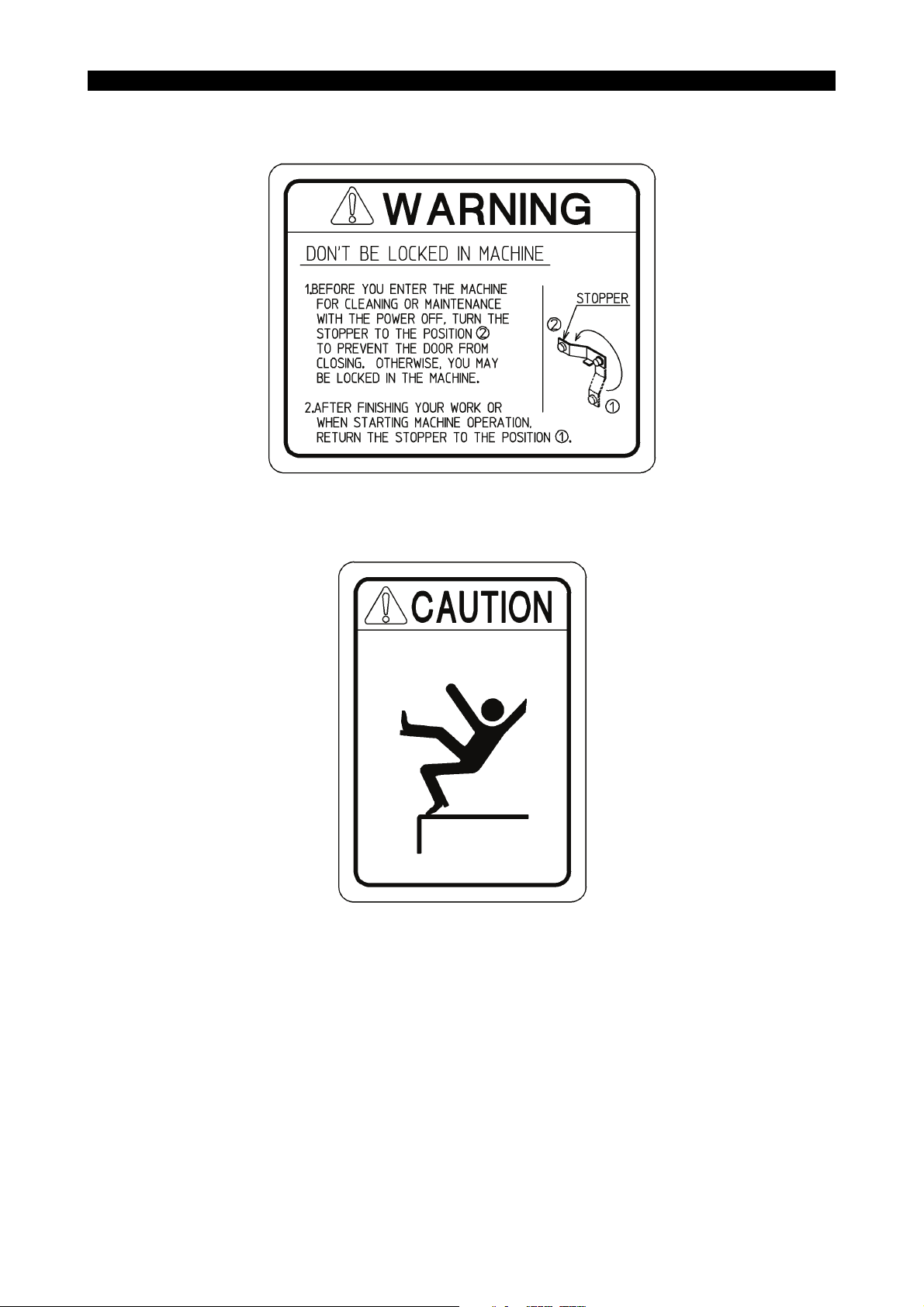

• [18] Door lock warning

Okuma Part No. H1090-1050-26

6097-E P-(xxiv)

SAFETY PRECAUTIONS

LE11240R0100100190041

• [19] Caution for footstep (OP)

Okuma Part No. H1090-1091-84

LE11240R0100100190023

6097-E P-(i)

INTRODUCTION

INTRODUCTION

This manual explains the proper handling of the machine to make the best use of its performance and the

maintenance inspection to maintain the machining accuracy for a long period of time. Carefully read this

manual and follow the instructions described there.

6097-E P-(i)

TABLE OF CONTENTS

TABLE OF CONTENTS

SECTION 1 OUTLINE...............................................................................................1

1-1. Machine Overview ............................................................................................................. 1

1-1-1. Features of Machine Components ...................................................................... 2

1-1-2. Features of Machine Functions ........................................................................... 2

1-1-3. Workpieces and Tools......................................................................................... 3

1-2. Machine Specifications ......................................................................................................4

1-2-1. Specification Table .............................................................................................. 4

1-2-2. Dimensional Drawing .......................................................................................... 7

SECTION 2 TRANSPORTATION AND INSTALLATION (RELOCATION).................8

2-1. Site Selection Guidelines...................................................................................................8

2-1-1. Water for Plant .................................................................................................... 8

2-1-2. Care in Machine Transportation .......................................................................... 8

2-2. Foundation Requirements ............................................................................................... 10

2-2-1. Safety Instructions for Foundation Work ........................................................... 10

2-3. General Procedure for Installation ................................................................................... 11

2-3-1. Installation Procedure........................................................................................ 11

2-3-2. Precautions for Installation ................................................................................ 11

2-4. Leveling the Machine....................................................................................................... 12

2-4-1. Leveling Procedure ........................................................................................... 12

2-5. Foundation Plan .............................................................................................................. 13

2-6. Power Requirements and Fuse Capacity ........................................................................ 14

2-6-1. Inspection of Cable Connection ........................................................................ 15

2-7. Oils to Be Prepared before Installation ............................................................................ 16

SECTION 3 OPERATION (OF CNC LATHE) ..........................................................17

3-1. Before Starting Operations .............................................................................................. 17

3-1-1. NC Operation .................................................................................................... 17

3-2. Machine Operation .......................................................................................................... 18

3-2-1. Axis Direction .................................................................................................... 18

3-2-2. Hydraulic Power Unit ......................................................................................... 19

3-2-3. Spindle Speed Selection (Transmission Power/Torque Diagram) .................... 23

3-2-4. Rotary Tool (M-tool) Spindle Power-Torque Diagram ....................................... 29

3-2-5. C-axis Brake...................................................................................................... 32

3-2-6. Hydraulic Power Chuck ..................................................................................... 33

3-2-7. Cutting Soft Top Jaws of Power Chuck............................................................. 45

3-2-8. Hydraulic Tailstock Operation ........................................................................... 46

3-2-9. Precautions in Handling Turret .......................................................................... 51

3-2-10. ATC ................................................................................................................... 52

3-2-11. Interlock............................................................................................................. 67

TABLE OF CONTENTS

3-2-12. After Completion of a Day’s Operation.............................................................. 68

3-2-13. Manually Operated Chuck ................................................................................. 69

SECTION 4 INSPECTION/MAINTENANCE (FOR TROUBLE-FREE

OPERATION) ......................................................................................75

4-1. Preparation of Air Source ................................................................................................ 76

4-1-1. Moisture............................................................................................................. 76

4-1-2. Filter Drain......................................................................................................... 76

4-1-3. Selecting a Compressor .................................................................................... 76

4-2. Lubrication ....................................................................................................................... 77

4-2-1. Lubricating Oil Specification .............................................................................. 79

4-2-2. Spindle Lubrication System ............................................................................... 80

4-2-3. Lubrication System for Bed/Saddle/Cross-slide Slideways ............................... 80

4-2-4. Turret ................................................................................................................. 81

4-2-5. ATC Cam Box ................................................................................................... 81

4-2-6. Maintenance and Inspection of HSK Tool Clamping Unit (HSK Tool

Specification) ..................................................................................................... 82

6097-E P-(ii)

4-3. Adjusting Centralized Lubrication Unit............................................................................. 84

4-3-1. Adjusting Pump Delivery ................................................................................... 84

4-3-2. Maintenance and Countermeasure ................................................................... 84

4-3-3. Other Remarks .................................................................................................. 85

4-4. Inspecting and Replenishing Oil Mist Lubrication Unit..................................................... 86

4-4-1. Air Flow Rate..................................................................................................... 86

4-4-2. Checking Air Pressure....................................................................................... 86

4-4-3. Replenishment .................................................................................................. 87

4-5. Lubrication and Cleaning of Spindle Cooling Unit ........................................................... 88

4-5-1. Main Spindle Cooling Unit ................................................................................. 88

4-5-2. Rotary Tool (M-tool) Spindle Cooling Unit......................................................... 90

4-5-3. Sub Spindle Cooling Unit .................................................................................. 92

4-6. Removing Sludge from Coolant Unit ............................................................................... 94

4-6-1. Procedure for Cleaning Separate Coolant Tank ............................................... 94

4-6-2. Cleaning the Filter ............................................................................................. 95

4-6-3. Cleaning the Fine Chips Collection Bucket ....................................................... 95

4-6-4. Thickener Bag Filter (Changing Procedure of Element).................................... 96

4-7. Collecting Used Lubricating Oil ....................................................................................... 97

4-8. Tensioning Belts .............................................................................................................. 98

4-8-1. Timing Belt for the XB-axis Servomotor ............................................................ 98

4-9. Adjusting the ATC............................................................................................................ 99

4-10. Other Maintenance Items .............................................................................................. 101

4-10-1. Alignment of Headstock .................................................................................. 101

4-10-2. Measures to Be Taken when Inspecting X-axis Ball Screw ............................ 102

4-11. Front Door Safety Window Glass Replacement ............................................................ 103

4-11-1. Replacement Interval ...................................................................................... 103

4-11-2. Replacement Procedure.................................................................................. 104

6097-E P-(iii)

TABLE OF CONTENTS

4-12. Troubleshooting ............................................................................................................. 111

4-12-1. Trouble with Headstock................................................................................... 111

4-12-2. Trouble with Turret .......................................................................................... 112

4-12-3. Others.............................................................................................................. 113

SECTION 5 SPARE PARTS LIST .........................................................................114

5-1. Air Unit........................................................................................................................... 114

5-2. Hydraulic Equipment ..................................................................................................... 115

5-3. Electrical Parts (Mounted in Machine)........................................................................... 116

5-4. Consumable Parts ......................................................................................................... 117

SECTION 6 TECHNICAL DATA ............................................................................121

6-1. Tooling System ..............................................................................................................121

6-1-1. BT-40 Tooling (BIG-PLUS Specifications) ...................................................... 121

6-1-2. HSK-A63 Tooling............................................................................................. 122

6-1-3. CAPTO-C6 Tooling ......................................................................................... 123

6-1-4. Tooling System (Lower Turret) ........................................................................ 124

6-2. Toolholder Dimensions .................................................................................................. 125

6-2-1. BT40 (BIG PLUS Specifications)..................................................................... 125

6-2-2. HSK Tool ......................................................................................................... 132

6-2-3. CAPTO-C6 Tool .............................................................................................. 141

6-2-4. Toolholder Dimensions (Lower Turret) ............................................................ 149

6-3. Lower Turret Tool Interference Diagram (Turret Rotation) ............................................ 154

6-4. Classification of Tools.................................................................................................... 155

6-4-1. BT40 (BIG PLUS Tooling) ............................................................................... 157

6-4-2. HSK-A63 ......................................................................................................... 160

6-4-3. CAPTO-C6 ...................................................................................................... 163

6-5. Working Ranges ............................................................................................................ 166

6-5-1. Turning Tool (BT40 BIG PLUS) [Tailstock Model]........................................... 166

6-5-2. Turning Tool (BT40 BIG PLUS) [Sub Spindle Model] ..................................... 170

6-5-3. Turning Tool (HSK-A63) [Tailstock Model]...................................................... 178

6-5-4. Turning Tool (HSK-A63) [Sub Spindle Model]................................................. 186

6-5-5. Turning Tool (CAPTO-C6) [Tailstock Model]................................................... 202

6-5-6. Turning Tool (CAPTO-C6) [Sub Spindle Model] ............................................. 210

6-5-7. Rotary Tool (BT40 BBT40-NBS20-90) ............................................................ 222

6-5-8. Rotary Tool (HSK-A63 tool A63DN-CTH20-90S06)........................................ 228

6-5-9. Turning Tool (Lower Turret) ............................................................................ 234

6-5-10. Working Ranges of Upper and Lower Turrets in Longitudinal Direction.............. 244

6-5-11. B-axis Rotation Range .................................................................................... 245

6-6. Dimensions of Spindle Nose ......................................................................................... 246

6-7. Hydraulic Power Chuck and Cylinder ............................................................................ 249

6-8. Hydraulic Circuit Diagram .............................................................................................. 252

6-9. Air Circuit Diagram ........................................................................................................ 254

6097-E P-(iv)

TABLE OF CONTENTS

6-10. Piping Drawings............................................................................................................. 255

6-10-1. Hydraulic Piping .............................................................................................. 255

6-10-2. Pneumatic Piping ............................................................................................ 265

SECTION 1 OUTLINE

1-1. Machine Overview

This machine is an NC-controlled, high-speed, high-precision multitasking machine. The machine

has a main spindle for turning, opposite spindle or tailstock for turning, milling spindle, lower turret,

and ATC unit. Besides turning, it can perform multitask machining such as milling, drilling, boring,

tapping and grinding using the indexing function (B-axis) for indexing the H1 turret at a desired angle

in a single setup. The lower turret greatly reduces machining time. The opposite spindle model can

transfer a workpiece between the main spindle and the opposing spindle, enabling front-back

machining of the workpiece.

The machine, designed for high-speed and high-precision machining, can also promote automation

and labor saving. With high productivity and machining accuracy, the machine is suitably used for

machining of parts in a wide application range including automobiles, construction equipment,

airplanes, hydraulic/pneumatic equipment, and molds.

The machine is available in six types; "2ST type" having no opposing spindle or tailstock, "2SC type"

having a tailstock, "2SW type" having an opposing spindle, "1ST type" having no opposing spindle,

tailstock or lower turret, "1SC type" having a tailstock but no lower turret, and "1SW type" having an

opposing spindle but no lower turret.

6097-E P-1

SECTION 1 OUTLINE

Axis Moving Directions in the Machine Coordinate System

B-axis (-)

H1 turret

M spindle

forward rotation

C-axis (+)

C-axis (-)

Main spindle

XB-axis (-)

B-axis (+)

M spindle

reverse rotation

W-axis (-)

ZA-axis (-)

C-axis (-)

C-axis (+)

Y-axis (+)

Opposing spindle or tailstock

XA-axis (+)

XA-axis (-)

W-axis (+)

ZA-axis (+)

Y-axis (-)

ZB-axis (-)

XB-axis (+)

Axis moving directions

ZB-axis (+)

Lower turret

LE11240R0100300010001

1-1-1. Features of Machine Components

(1) Main spindle

6097-E P-2

SECTION 1 OUTLINE

• Bearing diameter: Φ100 (3.94), driven by a built-in motor, max speed: 5,000 min

(Optional bearing diameter: Φ120 (4.72), and max speed: 3,800 min

• High power spindle: 22/15 kW (30/20 hp) (20 min/cont at 5,000 min

(Optional: 22/15 kW (30/20 hp), max 3,800 min

(2) Opposing spindle

• Bearing diameter: Φ80 (3.15), driven by a built-in motor, max speed: 6,000 min

(Optional bearing diameter: Φ100 (3.94), and max speed: 5,000 min-1)

• High power spindle: 11/7.5 kW (15/10 hp) (20 min/cont at 6,000 min

(Optional: 11/7.5 kW (15/10 hp), max 5,000 min

(3) Milling tool spindle (M spindle)

• Driven by a built-in motor, max speed 6,000 min

• High power spindle: 11/7.5/5.5 kW (15/10/7.5 hp)

-1

(3 min/20 min/cont at 6,000 min

, 12,000 min-1, 11/7.5/5.5 kW (15/10/7.5 hp))

1-1-2. Features of Machine Functions

-1

-1

-1

)

-1

-1

)

-1

(Optional: 12,000 min-1)

-1

)

)

-1

)

(1) High-speed positioning at a rapid traverse of 40 m/min (1,574.80 ipm) (ZA-, ZB-, W-axis), 30 m/

min (1,181.10 ipm) (XA-, XB-axis), and 26 m/min (1,023.62 ipm) (Y-axis)

(2) Extremely low thermal deformation realized by a unique construction and control of the

machine

(3) ATC storage capacity: up to 44 tools (with options)

(4) A wide variety of options are available such as coolant unit, chip handling equipment, automatic

gauging unit, tool management, and fixtures.

(5) A full-enclosure shielding is provided as standard equipment to keep the working environment

clean.

1-1-3. Workpieces and Tools

(1) Workpiece materials

The machine can cut ordinary structural steels represented by carbon steel, ferrous material

such as castings, and non-ferrous material such as aluminum.

The machine can also cut non-metallic materials such as ceramics or graphite. These

materials, however, require dust preventive measures to protect the human body and the

machine from dust. Consult us for the measures.

When cutting an ignitable material, provide sufficient safety measures according to 6.

Precautions against Fire under "Safety Precautions" at the beginning of this operation manual.

(2) Max Workpiece Size and Mass

For the maximum machining dimensions, refer to 1-2-1. "Specification Table" of the subsection

1-2 "Machine Specifications" under SECTION 1 of this operation manual. The machine can

handle up to the following workpiece mass (including the chuck weight):

One-side support (chuck work)= 110 kg (242 lb) [OP. 180 kg (396 lb)]

Support between centers (center work)= 350 kg (770 lb)

An imbalanced workpiece may disable the machine to exert its full performance even if the

workpiece size and mass are within the allowable ranges. Take the workpiece balance into

consideration and make sure that the workpiece is securely chucked to ensure safety in

machining.

6097-E P-3

SECTION 1 OUTLINE

(3) Maximum Tool Size and Mass

For the maximum tool size, see the requirements specified in 6-4-1, 6-4-2 and 6-4-3 of

SECTION 6 in this manual. The machine can handle a maximum tool mass of 7 kg (15 lb).

Even if the tool does not exceed the maximum mass, it cannot be used exceeding the

maximum tool mass moment specified in 3-2-10. of SECTION 3. If the tool is used at a rotation

speed exceeding the allowable limit, the tool breakage may result.

1-2. Machine Specifications

1-2-1. Specification Table

Item Unit MACTURN 350 MACTURN 350-W

CAPACITY

Swing over bed mm (in.) Φ530 (20.87)

Distance between noses mm (in.) 1940 (76.38)

Max. turning diameter mm (in.) Φ550 (21.65)

MAX. WORKPIECE

WEIGHT (including chuck

weight)

Main-spindle

Sub-spindle

MAIN SPINDLE

Spindle speed

Spindle diameter mm (in.) Φ100 (3.94) [OP. Φ120 (4.72)]

SUB SPINDLE

Spindle speed

Spindle diameter mm (in.) Φ80 (3.15) [OP. Φ100 (3.94)]

Z-AXIS

W-AXIS

X-AXIS

Y-AX I S

C-AXIS

Control angle degree 360 (Min. control angle 0.001)

B-AXIS

B-axis index range degree -15 to 195

One-side

support

Support

between

centers

One-side

support

Spindle nose JIS A2-6 (OP. JIS A2-8)

Spindle nose Φ140 (5.51) flat nose (OP. JIS A2-6)

Axis travel mm (in.) ZA: 1670 (65.75), ZB: 1655 (65.16)

Feedrate mm/min (ipm) 40,000 (1574.80)

Axis travel mm (in.) - 1680 (66.14)

Feedrate mm/min (ipm) - 40,000(1574.80)

Axis travel mm (in.) XA: 505 (19.88), XB: 210 (8.27)

Feedrate mm/min (ipm) 30,000 (1181.10)

Axis travel mm (in.) -95 (-3.74) to +95 (+3.74)

Feedrate mm/min (ipm) 26,000 (1023.62)

Feedrate

Index angle degree 1 (OP. 0.001)

kg (lb) 110 (242) [OP. 180 (396)]

kg (lb) 350 (770)

kg (lb) 50 (110) [OP. 110 (242)]

min

min

min

-1

-1

-1

38 to 5000 (OP. 38 to 3800)

50 to 6000 (OP. 50 to 5000)

6097-E P-4

SECTION 1 OUTLINE

200

SECTION 1 OUTLINE

Item Unit MACTURN 350 MACTURN 350-W

UPPER TURRET

Type H1

No. of tools 1 L or M tool

Tool

OD mm (in.) 25 sq. (0.98)

ID mm (in.) Φ40 (1.57)

Milling tool spindle speed

Milling tool spindle max.

min

-1

6000 (OP.12000)

N-m 65.1/47.7 (48.0/35.2) (5 min/20 min)

torque

TAI LSTO CK

Tailstock diameter mm (in.) Φ90 (3.54) -

Tailstock TAPERED BORE MT. No. 5 -

Tailstock travel mm (in.) 150 (5.91) -

LOWER TURRET (Option)

Type V12, VDI

No. of tools 12 L tools

Tool

OD mm (in.) 25 sq. (0.98)

ID mm (in.) Φ40 (1.57)

ATC M AGAZINE

Tool shank BT40 BIG PLUS or HSK-A63 or CAPTO-C6 or KM63

Max. tool mass kg (lb) 7 (15) [10 (22)]

Max. tool length mm (in.) 300 (11.81) (except shank part)

Max. tool diameter mm (in.) Φ130 (5.12)

Tool storage capacity No. of tools 30 (OP. 44)

MOTOR

Main spindle kW (hp) 22/15 (30/20) (20 min/cont.)

Sub spindle kW (hp) 11/7.5 (15/10) (30 min/cont.)

XB-axis kW (hp) 4 (5.3) × 1

XA-axis, ZA-axis, ZB-axis,

kW (hp) 6 (8.0) × 3 6 (8.0) × 4

W-axis

YS-axis kW (hp) 3 (4.0)

B-axis kW (hp) 2.8 (3.73)

Hydraulic pump kW (hp) 2.2 (3)

Lubrication pump kW (hp) 0.017 (0.0227)

Coolant pump kW (hp) 0.25 (0.333) × 2, 0.8 (1.07) x 2

Milling tool kW (hp) VAC 7.5/5.5 (10/7.5) (5 min/20 min)

Magazine rotary kW (hp) 0.75 (1)

ATC kW (hp) 3.6 (4.80)

POWER SOURCE

General power kVA 37.4 52.2

Voltage V 200

Primary voltage tap of

the transformer supplied

V 220/240/380/415/440/480

from Okuma

6097-E P-5

6097-E P-6

SECTION 1 OUTLINE

Item Unit MACTURN 350 MACTURN 350-W

Frequency Hz 50/60

Protect level for

control cabinet

MACHINE HEIGHT mm (in.) 2950 (116.14)

REQUIRED FLOOR

SPACE

NET MASS kg (lb) 13,700 (30,140) 13,700 (30,140)

mm × mm

(in. × in.)

IEC IP54

4560 × 2640

(179.53 × 103.94)

1-2-2. Dimensional Drawing

Side chip disposal type

1930 (75.98)722 (28.43)

3002 (118.19)

502

No. of magazine tools: 44

No. of magazine tools: 30

1966 (77.40)

436

(17.17)

(9.84)

250

(19.76)

796 (31.34)

2950 (116.14)

6097-E P-7

SECTION 1 OUTLINE

1147 (45.16)

Unit: mm (in.)

1200 (47.24)

Filter unit

Coolant pump

(for upper turret)

Coolant pump

(for lower turret, optional)

Coolant pump

(for chip flusher)

900 (35.43)

OSP control

2698 (106.22)

Magazine maintenance door

(37.24)

946

1857 (73.11)

1784.8 (70.268)

(2.56)

65

Opposing spindle cooling unit

Magazine operation panel

H1 upper turret cooling unit

cabinet

Hydraulic unit

Mesh filter

Coolant pump

(for suction)

1476 (58.11) 1100 (43.31)

Main spindle

cooling unit

Tailstock or

Opposing spindle

495

(19.49)

H1 upper turret

ATC

Lower turret

Main spindle

1630 (64.17)

Operation panel

Opposing spindle pressure

switch (optional)

Air panel

Centralized lubrication unit

H1 upper turret mist

lubrication unit

Main spindle pressure

switch (optional)

765(30.12)

Chip conveyor (optional) L type for side disposal

Chip bucket (optional)

700 (27.56)

185 (7.28)

1036 (40.79)

4555 (179.33)

450

(17.72)

Maintenance space

LE11240R0100300060001

6097-E P-8

SECTION 2 TRANSPORTATION AND INSTALLATION (RELOCATION)

SECTION 2 TRANSPORTATION AND INSTALLATION

(RELOCATION)

2-1. Site Selection Guidelines

Pay attention to the following points regarding machine installation in order to ensure machine

efficiency and performance.

(1) We recommend appropriate foundation work where the soil is soft or apt to sag after initial

installation. See [Foundation Requirements] for reference.

(2) The installation site should be kept as far as possible from vibration sources, such as roads,

stamping/press type equipment, or planer type machine tools. If nearby sources of vibration

are unavoidable, dampening pits around the machine foundation, for example, should help

lessen vibrations.

(3) Where there are high-frequency power generators, electric discharge machines or electric

welding machines around or when power is supplied from the same shop power distributor

panel, electrical interference may cause NC malfunctions. Please consult with the OKUMA

service engineer dispatched during machine installation.

(4) The ideal operating environment calls for an ambient temperature between 10 and 40°C (50

and 104°F) with humidity between 40 to 75% at 20°C (68°F).

(5) Keeping ambient temperature at a constant level is an essential factor for accurate machining.

(6) In order to maintain static machine accuracy within guaranteed values, the machine should be

installed in an area where it is not affected by airflow. Air conditioning is not essential, but an

ambient temperature between 17°C and 25°C (63 and 77°F) is recommended.

(7) To maintain static machine accuracy within the Standard Guaranteed Values:

a. Keep ambient temperature variance for a full day or 24 hours within ±2°C (36°F).

b. Ambient temperature variances from the floor level to a height of the machine (3 m (10 ft))

should be held within 1°C (34°F).

(8) Usually, no consideration is required on heat insulation against the machine foundation.

(9) Keep the floor level error within 10 mm (0.39 in.).

2-1-1. Water for Plant

Use potable water to dilute coolant.

Using water contains bacteria and salt may lead to malfunction of the machine parts.

2-1-2. Care in Machine Transportation

This machine integrates hydraulic unit, control cabinet, and NC unit into one construction instead of

having them as separate units, and so the machine can be easily moved or transported.

(Note that the coolant tank is installed separately.)

There are two different methods for moving the entire machine to any desired location; by an

overhead crane, using lifting hooks supplied together with the machine and by rolls over which the

machine is pushed by manual labor.

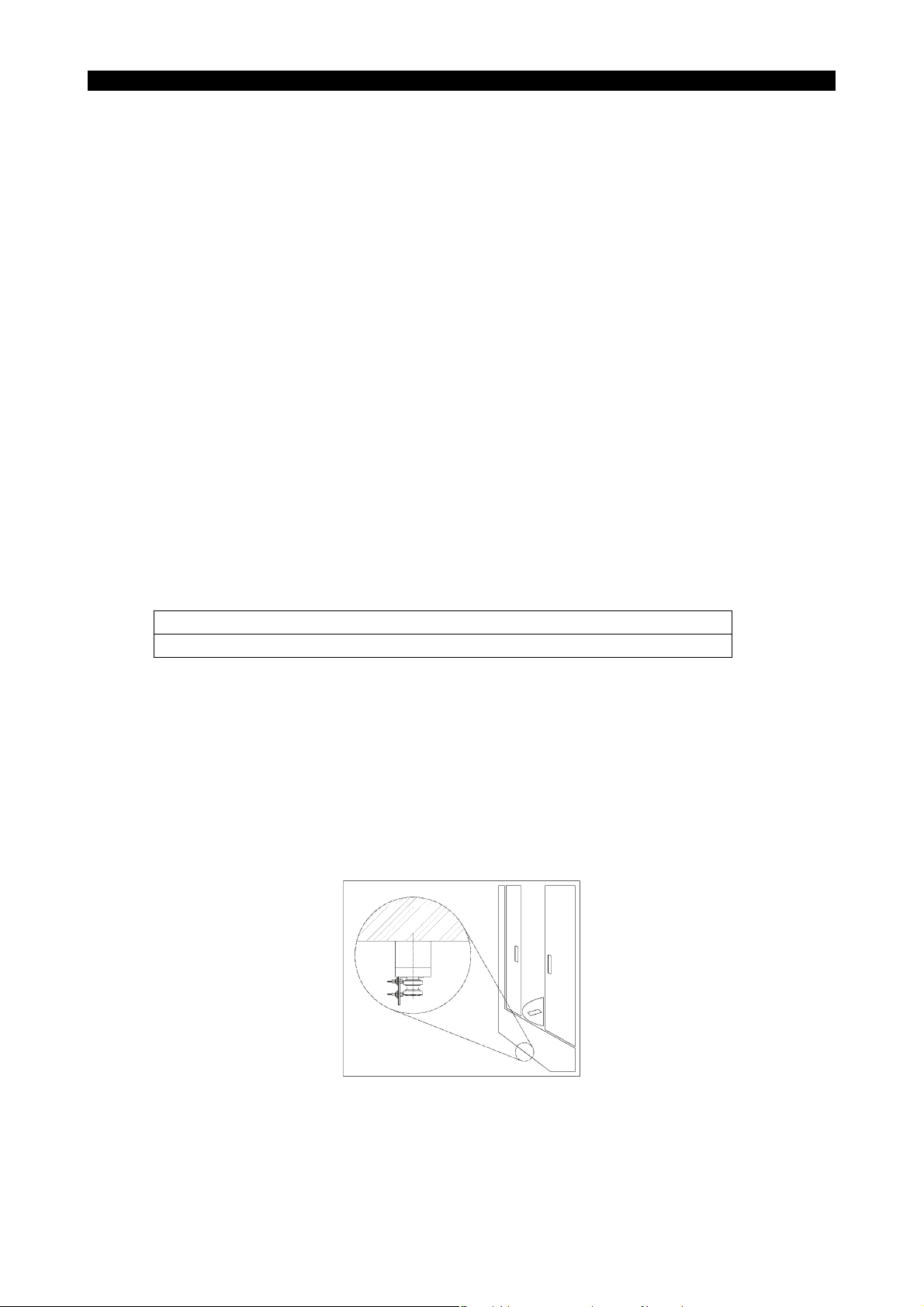

Lifting the Machine

6097-E P-9

SECTION 2 TRANSPORTATION AND INSTALLATION (RELOCATION)

Lifting frame

Pendant swing stopper

Upper saddle

Tailstock or

2nd headstock

Lifting hook

Lower saddle

(Optional)

Procedure :

Lifting hook

LE11240R0100400030001

1- Move the upper saddle to +600 (ZA-axis), the lower saddle to the negative limit (ZB-axis),

and the sub headstock to -700 (W-axis). Then, fasten them with the attached fixtures.

2- Remove the cables and pipes (coolant pump, lubricating oil collection tank and level switch)

between the machine and the coolant tank.

3- Pull out the coolant tank.

4- Locate the full-enclosure shielding cover doors in the positions shown in the above figure.

5- Remove the swing stopper from the pendant operation panel and fix the pendant with the

fixture as shown above.

6- Remove the cover at the upper part of the headstock and the upper part of the sub headstock

to pass the wire.

7- Mount the lifting hook at the 4 positions.

8- Mount the wire using the lifting tools.

Now, the machine is ready to be lifted.

6097-E P-10

SECTION 2 TRANSPORTATION AND INSTALLATION (RELOCATION)

Precautions for Lifting

• The cables should have a nominal diameter of 24 mm (0.94 in.) or larger.

• Change an angle formed by each cable line so that the cables will not contact the finished

surfaces of the machine.

(Do not tilt any wire rope exceeding 40 degrees away from the vertical direction.)

• Check for balance and be very careful when lifting the machine.

• Use extra care to lower the machine gently onto the floor; NEVER APPLY SHOCKS TO THE

MACHINE WHEN PLACING IT ON THE FLOOR.

Approximate Weight of Machine

Machine with 44-tool magazine: 13,700 kg (30,140 lb)

(Including the hydraulic power unit, the electrical control box, NC unit, and tool magazine)

Rolling

Be careful that the machine does not tip over on any side so that the machine base may not strike

the ground.

2-2. Foundation Requirements

2-2-1. Safety Instructions for Foundation Work

With a solid ground, a concrete floor about 200 mm (7.87 in.) thick and no gaps between ground

and floor, foundation work or anchoring is not required. The structural rigidity of the machine

permits normal machining.

For long-maintained accuracy and where sub-soil or ground under the floor is not strong enough,

a new concrete foundation should be set up in accordance with the “2-5. Foundation Plan” in this

section.

• Foundation requirements vary depending on the characteristics of the sub-soil. Under any soil

conditions, it is important that sub-soil should be well compacted to keep the foundation from

unsettling once the machine has been installed.

• Where sub-soil is too soft, it is necessary to drive concrete piles into the sub-soil.

• The Foundation Plan attached to this Manual is prepared for laying a typical concrete

foundation specifically for the machine. The concrete thickness or depth should be determined

in terms of the ground condition in each case.

SECTION 2 TRANSPORTATION AND INSTALLATION (RELOCATION)

2-3. General Procedure for Installation

2-3-1. Installation Procedure

Procedure :

1- Place leveling plates, 200 mm x 200 mm x 19 mm (7.87 x 7.87 x 0.75 in.) over individual

foundation bolt-holes.

Refer to the Foundation Plan.

2- Place foundation washers (furnished together with the machine) on the leveling plates and

then place the machine on them.

3- Pass foundation bolts through the hole in the leveling plate and a center bore through the

built-in jack screw assembly.

Secure each foundation bolt carefully, using a washer and a nut on its upper end.

4- Use wedge pieces, shims, or leveling blocks under the machine base to level the machine

approximately.

6097-E P-11

5- Pour mortar into the foundation bolt holes and allow it to set.

6- After the mixture has become hard enough, remove the shims or leveling blocks from under

the machine base, and level the machine within the specified limits.

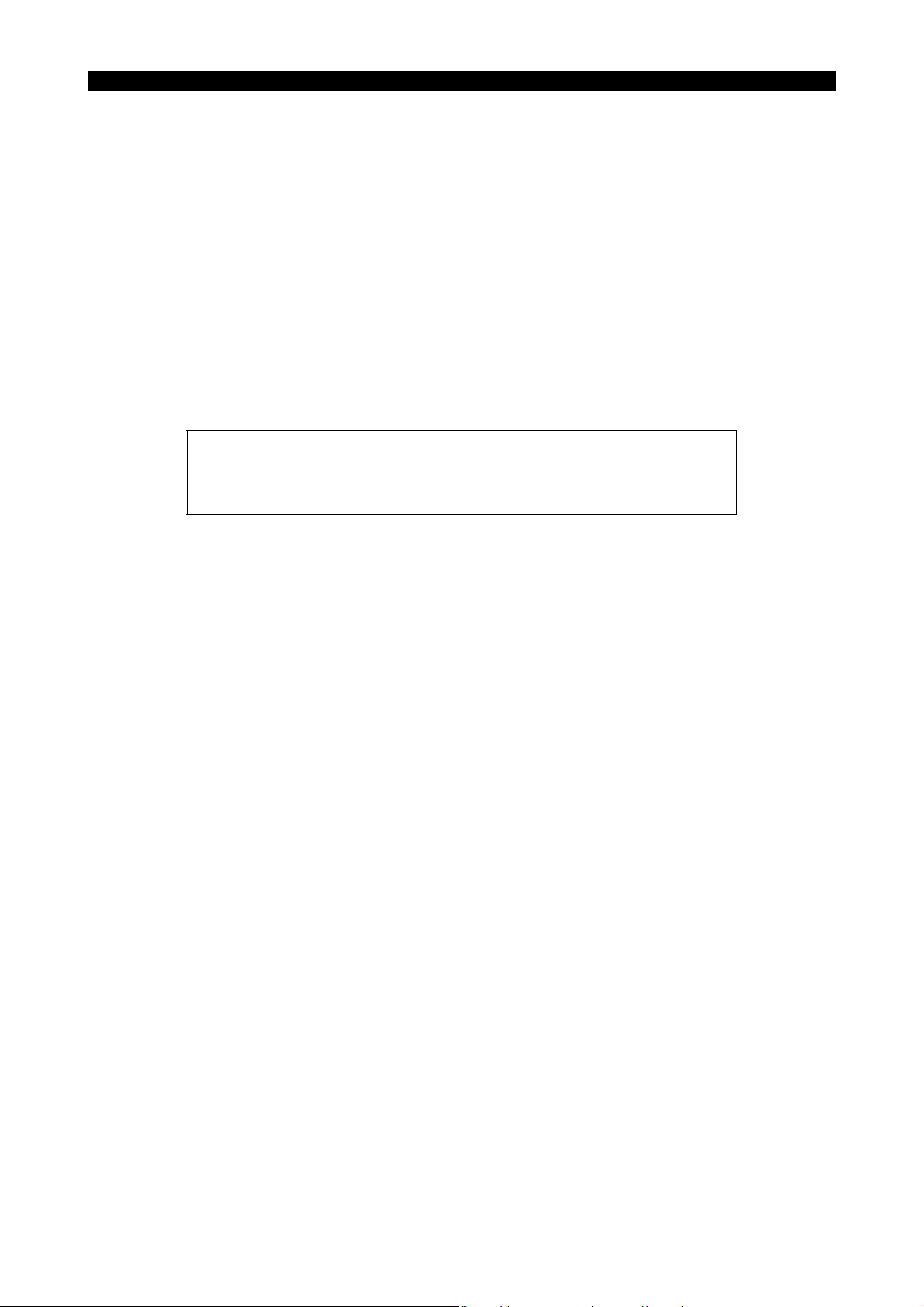

2-3-2. Precautions for Installation

• Keep the underside of the leveling plates free from any oily substance.

• With leveling jack screws resting on foundation washers, the bottom surfaces of the machine

base casting should be about 10 - 20 mm (0.39 - 0.79 in.) above concrete floor level.

• Fill the foundation bolt holes with mortar so as to reach the underside of the respective leveling

plates. Be sure to compact the mortar thoroughly.

Leveling jack screw

Lock nut

Machine base

Nut and washer

Foundation bolt

Foundation washer

Leveling plate

The part names shown in are not supplied as standard equipment.

10 (0.39) to 20 (0.79)

Unit: mm (in.)

LE11240R0100400080001

SECTION 2 TRANSPORTATION AND INSTALLATION (RELOCATION)

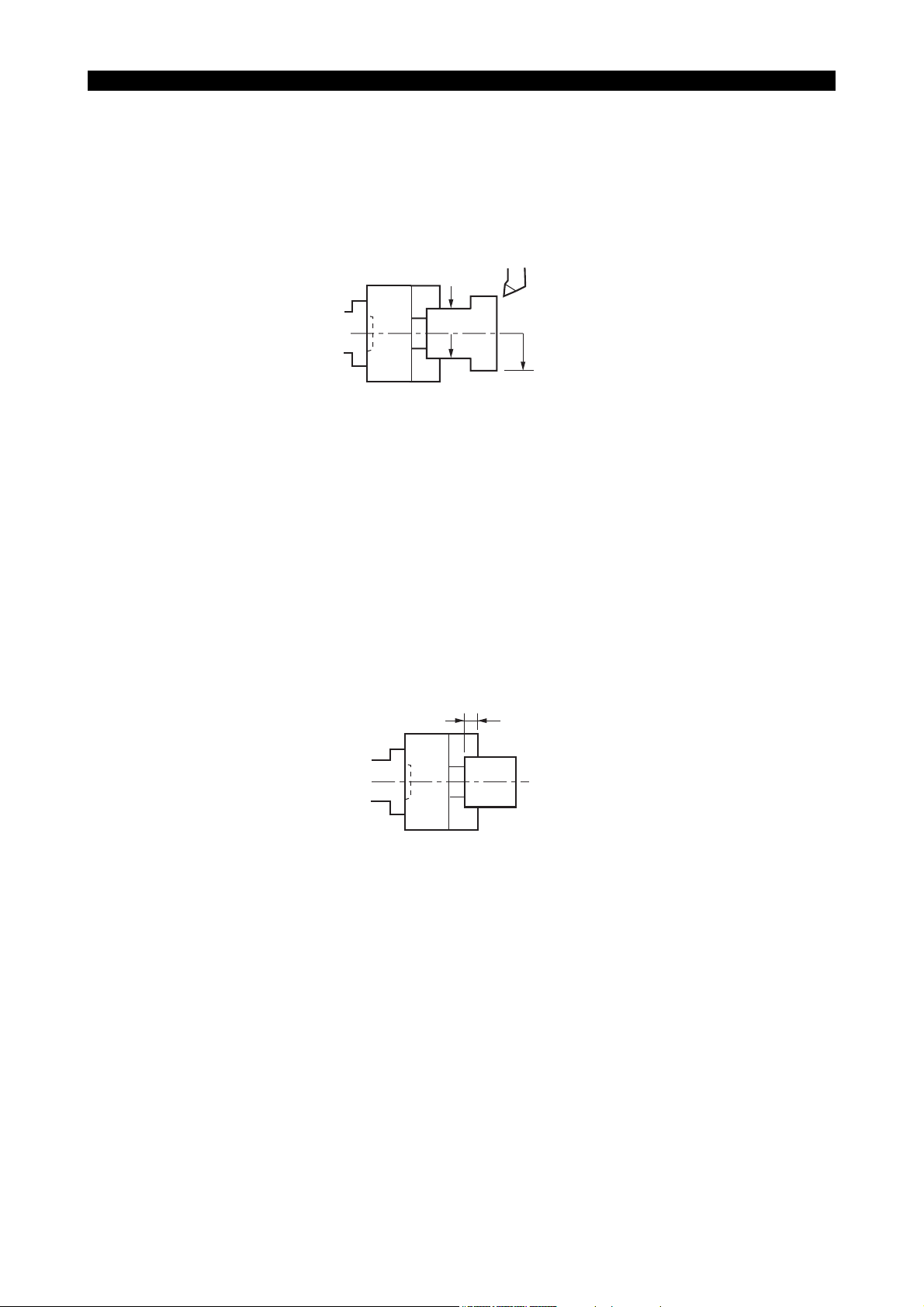

2-4. Leveling the Machine

Levelness of the machine has great influence on machining accuracy and machine life. Therefore,

use particular care to level the machine when installing the machine.

6097-E P-12

Model No. of Leveling

Between centers: 1500 10 Pass foundation bolt.

2-4-1. Leveling Procedure

(1) When leveling the machine, index the spindlehead (B-axis) to 0° or 180°.

Mount the level stand to the turret. Put levels on the stand as shown in the figure below. Then,

check the levelness in X- and Y-axis directions at the right end and the left end of the bed

guideway.

Turret

Remarks

Jack Screws

Level

Level stand

LE11240R0100400100001

(2) Ensure that the leveling jack screws and the foundation bolts are firmly tightening before

checking the levelness.

Tolerance: 0.04 mm (0.0016 in.) per 1,000 mm (39.37 in.)

Leveling accuracy: 1 division (0.02 mm (0.0008 in.) per 1,000 mm (39.37 in.))

SECTION 2 TRANSPORTATION AND INSTALLATION (RELOCATION)

2-5. Foundation Plan

6097-E P-13

Levelling plate

Foundation

washer

Nut and washer

Foundation bolt

Lock nut

Jaw screw

40 (1.57)

300 (11.81)

(11.81)

300

Mortar injection port

485 (19.09)

Stop collar

380 (14.96)

700 (27.56)

1000 (39.37)

1000 (39.37)

1145 (45.08)

60 (2.36)

200

(7.87)

380

(14.96)

120

(4.72)

2445 (96.26)

128 (5.04)

Details of Installation

Detail of Foundation Bolt Assembly

815 (32.09)

1. This foundation plan is typical.

Note:

Spindle center

10 pc

10 pc each

10 pc

10 pc

M16

M16

Concrete thickness is determined in accordance with sub-soil conditions.

2. Customers should have on hand the parts for installation of machine

Unit: mm (in.)

60 (2.36)

1. Foundation bolt

20 (0.79)

These parts are available as options.

2. Nut and washer for above.

3. Levelling plate (150 x 150 x 19)

4. Stop collar

(7.87)

200

600 (23.62)

Control

497 (19.57)

983 (38.70)

860 (33.86)

860 (33.86)

Bed

840

(33.07)

480 (18.90)

Outline of full-enclosure shield

cabinet

(19.69)

500

480 (18.90)

250 (9.84)

(9.25)

235

20 (0.79)

895 (35.24)

10 (0.39)

1150 (45.28)

1758 (69.21)687 (27.05) 172 (6.77)

Standard spindle

nose end

815 (32.09)

710 (27.95) 1930 (75.98)

527 (20.75)

913 (35.94)

Operation panel

900 (35.43)

4560 (179.53)

900 (35.43)

750 (29.53)

Concrete range

530 (20.87)

100 (3.94)

4520 (177.95)

(6.30)

160

Concrete

Rubble

500 (19.69)

(78.74)

2000

φ150

(5.91)

100 (3.94)

LE11240R0100400110001

Concrete pile

(used for soft ground)

SECTION 2 TRANSPORTATION AND INSTALLATION (RELOCATION)

2-6. Power Requirements and Fuse Capacity

Power source: 3-phase, 200V±10%, 50/60Hz

6097-E P-14

Main motor AC

22/15kW (30/20 hp) (main spindle)

7.5/5.5 kW (10/7.5 hp) (sub spindle)

5.5/3.7 kW (7.5/5 hp) (M-tool spindle)

200 A or more

(for the machine with lower

turret)

Automatic circuit

breaker

Refer to Table 1

for breaker capacity.

Cable size

Ground

Refer to Table 1.

RST

E

Table 1 Capacity and Cable Size of Automatic Breaker for Branch Circuit

MT350 Breaker capacity

Main spindle

Sub spindle

1S-C

1S-W

2S-C

2S-W

Capacity

Cable size

Capacity

Cable size

Capacity

Cable size

Capacity

Cable size

11/7.5 kW

(15/10 hp)

80 mm

Rated current (A)

22/15 kW (30/20 hp)

15/11 kW

(20/15 hp)

150 A or over

50 mm

175 A or over

60 mm

150 A or over

50 mm

200 A or over

2

or over

22/15 kW

(30/20 hp)

2

or over

2

or over

2

or over

225 A or over

100 mm2 or over

Electrical

control box

Main switch

LE11240R0100400120001

SECTION 2 TRANSPORTATION AND INSTALLATION (RELOCATION)

2-6-1. Inspection of Cable Connection

The operator can check correctness of cable connection by reading the pressure gauge whether it

indicates the specified pressure level.

Confirm that the pressure gauge indicates the set pressure 4.4 MPa (638.4 psi).

When it indicates the specified pressure level, the electrical connection is correct.

1) Connect the ground wire to the external protective earth terminal (PE) in the control box.

2) Do not connect the power cord and the grounding wire in serial; if attempted, it will give

adverse affect to other equipment or cause malfunctioning of the leak breaker, etc.

3) When a leak breaker is used, select the one meeting the following rating.

• For inverter circuit use

• Sensitive current of 100 mA or more

• Middle-sensitivity high-speed inverter type

4) Check that the momentary voltage variation rate is 15% or less as shown in the diagram

below.

If the momentary voltage variation rate exceeds 15%, the acceleration/deceleration time of the

spindle may be lengthened or the protection circuit of the servo power unit may be activated.

5) For further information on instantaneous power regulation and power source inductance,

please inquire at your Okuma representative.

6) To furnish the power supply line in the machine, pull the cable under the control cabinet, which

is advantageous for the dust and water prevention. Apply the protection against dust and

water to the cable. The protection measurement is required also when pulled over the

cabinet.

In addition, hold the power supply cable appropriately so that the tension wire will not hang on

to the connection part of the main breaker of the power supply line.

6097-E P-15

R

3-phase power source

AC voltmeter

Spindle drive

S

motor control

T

unit

V

0

V

: Voltage applied to the motor at a standstill

V1: Maximum voltage in motor deceleration

Instantaneous voltage regulation=

Spindle drive

motor

V1-V

0

V

0

LE11240R0100400130001

× 100

Procedure :

1- Connect the AC voltmeter to the spindle drive motor control unit or the machine power

terminal as shown in the above figure.

2- Measure the voltage (V

3- Measure the maximum voltage (V

) applied to the spindle drive motor at a standstill.

0

) during deceleration of the spindle drive motor.

1

SECTION 2 TRANSPORTATION AND INSTALLATION (RELOCATION)

4- Calculate the instantaneous voltage regulation by the following formula:

Instantaneous voltage regulation = (V

Note

• The digital AC voltmeter makes a slow response, and therefore the measured value tends to be

a little lower than the actual value. It is recommended to use the analogue AC voltmeter.

• Shorter deceleration time makes the measurement difficult. Measure the voltage while

decelerating the motor from the possible highest speed.

• Obtain the instantaneous voltage regulation after ensuring that the alarm “Voltage regulation too

large” is not activated. This is because the alarm causes the motor control unit to restrict the

motor output.

- V0) / V

1

0 × 100

2-7. Oils to Be Prepared before Installation

Prepare the oils specified in “4-2. Lubrication” and “4-2-1. Lubrication Oil Specification” in Section

“Inspection/Maintenance”.

(For oils to be supplied to an optional kit, check with us separately.)

6097-E P-16

6097-E P-17

SECTION 3 OPERATION (OF CNC LATHE)

SECTION 3 OPERATION (OF CNC LATHE)

This manual mainly explains the manual operation so that the operator can get used to the machine operation

as soon as possible.

3-1. Before Starting Operations

This section deals mainly with the operating procedures of your CNC lathe under manual control.

So the information given here is essential to every operator, whether you are new to a CNC lathe or

an “old pro”.

Follow these three points:

• Actually operate the CNC lathe by yourself in reference to this Instruction Manual.

• Learn the symbols for the numerical control terms.

• After you have a general idea of how your CNC lathe operates, read this manual repeatedly and

also the Programming Manual.

Bring the machine to a complete stop by turning off the main switch before operations such as

setup or adjustments inside the chip guard are carried out.

Also turn off the main switch before you attempt to work inside the machine at the rear side of the

machine.

3-1-1. NC Operation

Before you begin to operate the machine automatically by tape, make it a rule to check the following

points against a process sheet, a program manuscript, or any other chart giving detailed machining

instructions:

(1) Setting of hydraulic power chuck jaws and their gripping pressure

(2) Installation and arrangement of individual cutting tools with respect to their operating sequence

(3) Setting of tool offsets

(4) Setting of zero offsets

(5) Setting of feedrate override to 100%

(6) Setting of software limit positions for each axis

(7) Positioning of the turret to the turret indexing position

(8) Positioning of tailstock (when the machine is equipped with tailstock)

All essential information on the setup and check-up procedures is described in the sections that

follow.

3-2. Machine Operation

3-2-1. Axis Direction

6097-E P-18

SECTION 3 OPERATION (OF CNC LATHE)

B-axis (-)

H1 turret

forward rotation

Main spindle

XB-axis (-)

M spindle

C-axis (-)

C-axis (+)

B-axis (+)

M spindle

reverse rotation

W-axis (-)

C-axis (-)

C-axis (+)

Y-axis (+)

XA-axis (+)

ZA-axis (-)

XA-axis (-)

Opposing spindle or tailstock

W-axis (+)

ZA-axis (+)

Y-axis (-)

ZB-axis (-)

XB-axis (+)

ZB-axis (+)

Lower turret

LE11240R0100500100001

3-2-2. Hydraulic Power Unit

6097-E P-19

SECTION 3 OPERATION (OF CNC LATHE)

Pressure switchPressure gauge

System pressure

adjusting valve

Variable delivery pump

Suction filter

Radiator

Oil filler port

Oil level gauge

Level switch

Drain port

Line filter

LE11240R0100500110001

Pressure Indication

The pressure gauge should indicate the following set pressure:

Pressure setting 4.4 MPa (638.4 psi)

Adjustment of Pressure

The following outlines the methods of setting individual functional units for operating pressure.

Since the pressure lines for the turret(s) have been adjusted at our factory before shipment, they

will not require readjustments, during the initial installation and subsequent normal service of the

machine.

When readjustment is to be made by your plant personnel, extreme caution must be taken in

accordance with the instructions given here to avert any mechanical trouble in the drive lines.

• System pressure adjustment (Adjustment is not usually required.)

Pressure decrease Pressure increase

System Pressure Adjusting Valve

• Hydraulic pressure for main spindle chuck

Refer to “Adjustment of Oil Pressure for Hydraulic Chuck” in “3-2-6. Hydraulic Power

Chuck”described later.

6097-E P-20

SECTION 3 OPERATION (OF CNC LATHE)

Source pressure abnormal alarm setting pressure: 2 MPa (290 psi)

LE11240R0100500130001

• Tailstock pressure adjustment

Adjust the pressure using the tailstock thrust adjusting valve.

Tailstock thrust pressure gauge

Tailstock thrust adjusting valve

Main spindle hydraulic chuck pressure gauge

Main spindle hydraulic chuck pressure adjusting valve

LE11240R0100500130002

SECTION 3 OPERATION (OF CNC LATHE)

• Hydraulic pressure for sub spindle chuck

Adjust with the sub spindle hydraulic chuck pressure adjusting valve.

Pressure gauge for the hydraulic chuck of the opposing spindle

Pressure adjusting valve for the hydraulic chuck of the opposing spindle

6097-E P-21

Main spindle hydraulic chuck pressure gauge

Main spindle hydraulic chuck pressure adjusting valve

LE11240R0100500130003

Hydraulic Oil

Oil Specification HM32 (ISO)

Amount 20 liter (5.3 gal)

Oil Change Interval Change after first month of operation and every 6 months thereafter.

Clean the suction filter, the line filter, and the tank when changing the oil. Check the pressure for

respective actuators.

A clogged filter element causes contaminated oil to circulate through the hydraulic system, which

may lead to a machine trouble.

6097-E P-22

SECTION 3 OPERATION (OF CNC LATHE)

When changing the element, proceed as follows:

Filter Element Specifications

Procedure :

1- Turn off the power (be sure to turn off the main switch).

2- Unscrew and remove the filter housing by turning the nut portion of the housing provided at

the bottom.

3- Pull out the filter element downward.

4- Clean the inside of the housing.

5- Insert a new element into the body.

6- Screw and fit the housing onto the body.

Body

Housing

Filter element

(Housing removing margin needed to

change the element: 157 (6.18))

24

(0.94)

[27.7 (1.091)]

Nut portion of the housing

Unit: mm (in.)

Maker Yamashin

Type PX040A with a filtering accuracy of 10 μm (400 μin.)

Part No. H0032-0009-96

LE11240R0100500140001

6097-E P-23

(

(

)

SECTION 3 OPERATION (OF CNC LATHE)

3-2-3. Spindle Speed Selection (Transmission Power/Torque Diagram)

Main Spindle Power-Torque Diagram - 5,000 min-1 (Φ100 (3.94 in.) spindle)

VAC 22/15 kW (30/20 hp) (20 min/cont.) specification

1000

500

300

200

100

Spindle Torque [N-m (lbf-ft)]

420.2 N

286.5 N

168.1 N⋅m (124.1 lbf-ft)

114.6 N⋅m (84.6 lbf-ft)

50

30

20

10

5

3

2

⋅m (310.1 lbf-ft)

⋅m (211.5 lbf-ft)

22 kW (30 hp)

(20 min)

15 kW (20 hp)

(cont.)

100

50

30

20

10

5

3

2

1

]

hp

kW

Spindle Motor Output [

1

38

30 50 100

Spindle Speed min

2000 5000200 300 500 1000

-1

LE11240R0100500150001

6097-E P-24

SECTION 3 OPERATION (OF CNC LATHE)

For heavy-duty cutting, select a spindle speed in the shaded area so that cutting is performed within

a constant output range.

• Low-speed/high-speed range is changed by switching the VAC motor coil connection (switching

takes approx. 1 sec.)

5000

1250

M42

1250

500

3838

M41

LE11240R0100500150002

In conjunction with the above graph, refer to the Hydraulic Chuck Clamping Force characteristics

Diagram (the graph that shows the relation between the chuck rotation speed and its gripping

force).

6097-E P-25

SECTION 3 OPERATION (OF CNC LATHE)

Main Big-Bore Spindle (OP.) Power-Torque Diagram 3,800 min-1, Φ120 (4.72

in.), VAC 22/15 kW (30/20 hp) (20 min/cont.)

1000

500

300

200

100

Spindle Torque [N-m (lbf-ft)]

420.2 N-m (310.1 lbf-ft)

286.5 N-m (211.5 lbf-ft)

168.1 N-m (124.1 lbf-ft)

114.6 N-m (84.6 lbf-ft)

50

30

20

10

5

3

2

22 kw (30 hp)

(20 min)

15 kw (20 hp)

(cont.)

100

50

30

20

10

5

3

2

1

Spindle Motor Output [kW (hp)]

1

38

30 50 100