Page 1

CCS Technical Documentation

RH-3 Series Transceivers

Troubleshooting — Antenna

Issue 1 06/2003 Confidential Nokia Corporation

Page 2

RH-3

Troubleshooting — Antenna CCS Technical Documentation

Page 2 Nokia Corporation Confidential Issue 1 06/2003

Page 3

RH-3

CCS Technical Documentation Troubleshooting — Antenna

Contents

Page No

Troubleshooting - Antenna ............................................................................................ 5

Whip Antenna ..............................................................................................................5

Visual Quality Requirements.................................................................................... 5

PIFA Antenna ..............................................................................................................6

Visual Quality Requirements.................................................................................... 6

Failures and Corrective Measures.................................................................................. 8

Appearance of Phone ...................................................................................................8

Antenna Position into D-cover.................................................................................. 8

Internal Antenna ..........................................................................................................9

Damaged RF Feed or Ground Pins ........................................................................... 9

Wrong Internal Antenna Installed........................................................................... 10

Obstructed RF Feed and/or Ground Pads for the Main and GPS Antennas ........... 11

Broken or Missing Bottom Antenna Clip ............................................................... 12

Obstructed Whip Stopper........................................................................................ 12

Grounding of Display Frame................................................................................... 13

Misinstalled Whip................................................................................................... 14

Damaged Whips...................................................................................................... 15

Detuning Circuit for Bottom Antenna Clip............................................................. 15

Testing CDMA Antenna.............................................................................................. 15

Calibration Factors.................................................................................................. 15

Calibration Factor for Cell800 frequency ............................................................... 15

Measurement Procedure for Cell800/PCS1900 phones.......................................... 15

Testing GPS Antenna................................................................................................... 16

Calibration Factor for GPS...................................................................................... 16

Measurement Procedure for GPS Antenna ............................................................. 16

Issue 1 06/2003 Nokia Corporation Confidential Page 3

Page 4

RH-3

Troubleshooting — Antenna CCS Technical Documentation

Page 4 Nokia Corporation Confidential Issue 1 06/2003

Page 5

RH-3

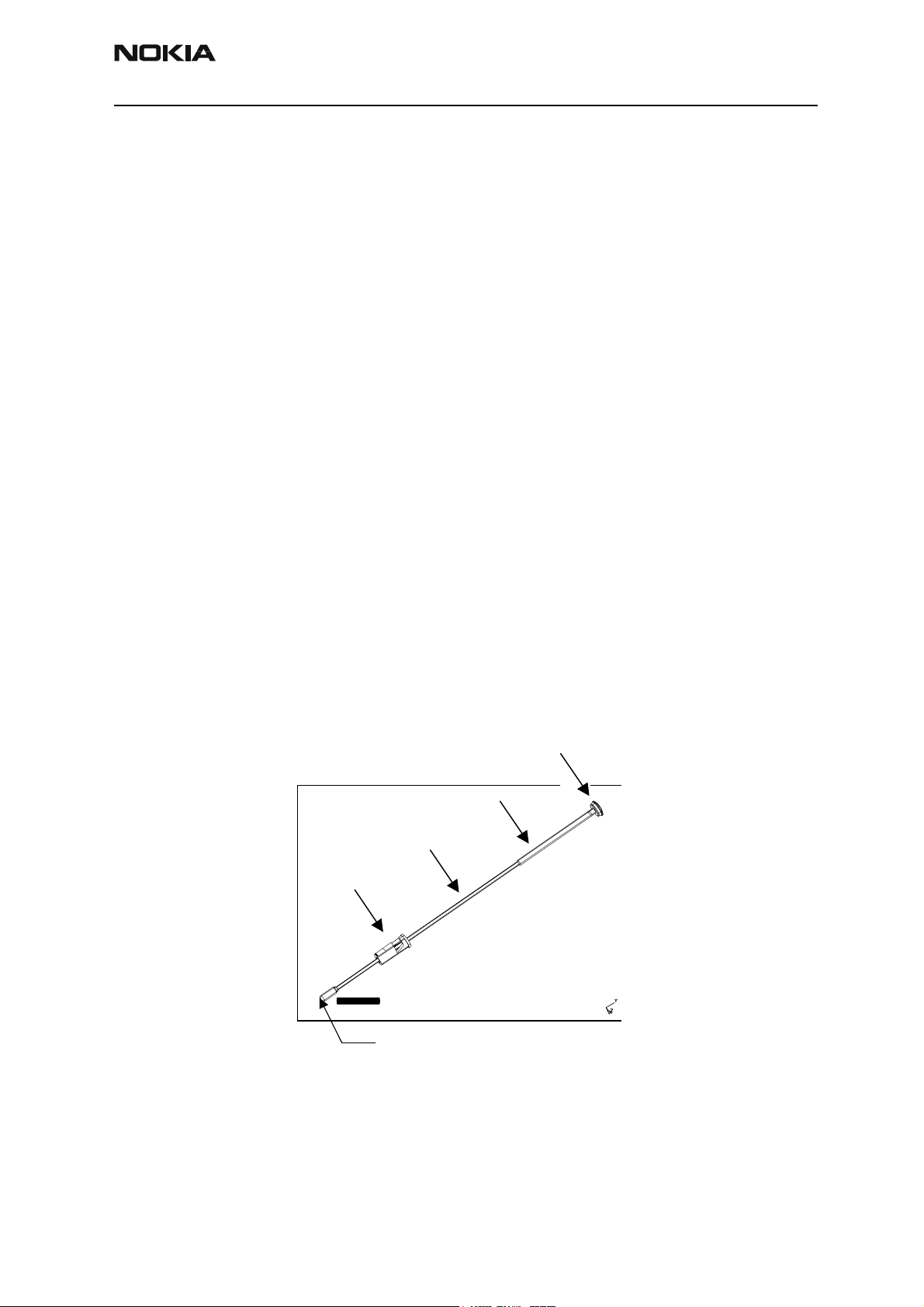

Button

Button

Wire

Cap

Tube

CCS Technical Documentation Troubleshooting — Antenna

Troubleshooting - Antenna

This troubleshooting guide addresses potential failures that will affect antenna performance of the RH-3/RH-3P phone, and discusses methods for correction of these failures.

Whip Antenna

Visual Quality Requirements

Following are the minimum acceptable visual quality standards of the RH-3/RH-3P whip

assembly. This information may be used as an inspection guideline.

• No physical crack or any mechanical defects.

• No oil, dirt or particles are presented on parts.

• Button parting line (flash or offset) less than 0.1 mm.

• Color match to code Nokia Jonathan Gray (GY7999).

• Wire tube must completely cover the NiTi wire. No uncovered NiTi wire

can be seen from the tube side.

• No wire burr gr eater than 0.1 mm can be se en from the stopper.

• Check if the proper pr inti n g i s pres en t (ca n be found on the plastic cap).

• The button must be perpendicular to the tube. This can be interpreted

as maximum of 5°.

No wire burr greater than

0.1 mm can be seen

outside of the stopper.

Figure 1: Whip Assembly

Issue 1 06/2003 Nokia Corporation Confidential Page 5

Page 6

RH-3

offset) must be less than

Check the part printing.

Button must be perpendicular to the tube

Troubleshooting — Antenna CCS Technical Documentation

Parting line (flash or

PIFA Antenna

Visual Quality Requirements

Following are the minimum acceptable visual quality standards of the RH-3/RH-3P PIFA

antenna assembly. This information may be used as an inspection guideline.

• Gloves must be used when handling antennas. Do not touch radiator

with bare hands.

• Maximum burrs of any met al part must be less than 0.01 mm, except for

burrs on radiator resulted by antenna tuning.

• General parting lines, or flash lines (including gate) must be less than

0.20 mm.

• No visual crack or any mechanical defects.

0.1 mm.

Figure 2: Whip Assembly

• Proper marking must present.

• No oil, dirt, or particles are present on parts.

• Radiator must be aligned with plastic housing.

• GPS antenna contacts must be inside the plastic housing.

• Radiator must be flat and no warp.

Page 6 Nokia Corporation Confidential Issue 1 06/2003

Page 7

RH-3

Proper printing must be present. (See Figure 10).

CCS Technical Documentation Troubleshooting — Antenna

• All pins must be at same level.

• Check if proper printing is present.

Pins must be at

the same level.

Figure 3: PIFA Module showing antenna feed pins

Figure 4: PIFA Actual Element

Issue 1 06/2003 Nokia Corporation Confidential Page 7

Page 8

RH-3

Troubleshooting — Antenna CCS Technical Documentation

Failures and Corrective Measures

Appearance of Phone

Figure 6: Back of RH-3/RH-3P phone, whip retracted and whip extended

Note in Figure 6 that when the whip is properly installed that the cap clicks into the

D-cover when the whip is fully retracted.

Antenna Position into D-cover

Internal antenna and whip are assembled into D-cover as shown in Figure 7. Whip must

be inserted prior to inserting internal antenna

Figure 5: Front of RH-3/RH-3P handset

Page 8 Nokia Corporation Confidential Issue 1 06/2003

Page 9

RH-3

CCS Technical Documentation Troubleshooting — Antenna

.

Figure 7: RH-3 D-cover assembly

If the internal antenna is missing, install one. If the radiator looks obviously damaged,

then replace the internal antenna.

If no internal antenna is installed, the antenna gain will be degraded by more than

25 dB.

If the whip is missing, then remove the internal antenna, install a whip and reinstall the

internal antenna.

Internal Antenna

RH-3/RH-3P internal antenna shown in Figure 8 has a metal sheet (main antenna radiator) and a metal strip (GPS antenna) attached to a plastic carrier (Models 2285 and 2270

only).

Figure 8: RH-3/RH-3P internal antenna from two different view angles

Damaged RF Feed or Ground Pins

Both main and GPS antennas have pins (spring clips) that should properly touch the

PWB. Positioning of these pins is shown in Figure 9.

Issue 1 06/2003 Nokia Corporation Confidential Page 9

Page 10

RH-3

Troubleshooting — Antenna CCS Technical Documentation

Figure 9: Back view of RH-3/RH-3P internal antenna

If either the RF feed pin or ground pin are broken, or bent such that either pin will not

touch the PWB, then the internal antenna must be replaced. If the springs for the RF or

ground pin appear damaged, then the internal antenna must be replaced.

If the RF feed pin of main antenna doesn't touch the PWB, then the antenna gain will

degrade by more than 25 dB and GPS antenna will be detuned. If the ground pin of main

antenna doesn't touch the PWB then the antenna gain may degrade about 5 to 10 dB

and GPS antenna will be detuned.

If the RF feed pin of GPS antenna doesn't touch the PWB, then the GPS antenna gain will

degrade by more than 20dB. If the ground pin of GPS antenna doesn't touch the PWB,

then the GPS antenna gain may degrade more than 5dB.

Wrong Internal Antenna Installed

The RH-3/RH-3P and RH-17 antennas share the same mechanical interface with the

D-cover. So either antenna can be installed in either phone. However, there are three

important differences between RH-3/RH-3P and RH-17 internal antennas:

1 Models 2285 and 2270 RH-3/RH-3P antenna have a GPS strip (antenna) while

the RH-17 antenna does not

2 The slot pattern is very different between the two antennas; and

3 RH-3/RH-3P and RH-17 antennas are marked on their radiators with "F" and "H"

respectively. See Figure 10.

Page 10 Nokia Corporation Confidential Issue 1 06/2003

Page 11

RH-3

CCS Technical Documentation Troubleshooting — Antenna

Figure 10: Top views of internal antenna (RH-3 at left; RH-17 at right)

Installing the RH-17 antenna in the RH-3/RH-3P phone will not be compliant with

Nokia’s FCC submission, as RH-17 is a single-band antenna (no PCS) and it doesn't have

a GPS antenna.

If the wrong antenna is installed, install the correct one.

If the slot in the radiator has a significantly different shape, then the correct internal

antenna must be installed. Be aware that the shape of the slot can vary slightly. The

length of the horizontal slot and the opening of the vertical slot can vary by few millimeters, because the antennas are tuned for each batch of plastic frames. If there is any

other obvious damage to the radiator (dents, corrosion), then the antenna should be

replaced. If the pin gets stuck or has excessive friction in the plastic tube/guiding feature, then the spring will not work properly, and the antenna should be replaced.

Obstructed RF Feed and/or Ground Pads for the Main and GPS Antennas

Figure 11: PWB layout of RF feed and ground pads, and bottom antenna clip

If the any of RF feed or ground pins are obstructed, removed, or covered, then the RF pin

will not touch the PWB and the antenna performance will degrade. See the antenna per-

Issue 1 06/2003 Nokia Corporation Confidential Page 11

Page 12

RH-3

Troubleshooting — Antenna CCS Technical Documentation

formance degradation section if any pin doesn't touch the PWB.

If corrosion is present or the pad is missing, then most likely the PWB and the phone

needs to be replaced. If either pad is obstructed or covered, the pad should be cleared

and/or cleaned.

Broken or Missing Bottom Antenna Clip

If the bottom antenna clip does not contact the whip stopper, when the whip is fully

retracted, the internal antenna gain will degrade by about 4-5dB at Cell band and

3-10dB at PCS band when whip is retracted. If the antenna clip is installed backwards, is

damaged, or is missing, then install a new bottom antenna clip in the correct position.

Obstructed Whip Stopper

Figure 12: Bottom antenna clip

Figure 13: Whip stopper as shown when the whip is fully retracted

If the whip stopper is corroded or blocked by the whip straw, then the whip assembly

needs to be replaced. If the whip stopper is obstructed or dirty, then the obstruction

Page 12 Nokia Corporation Confidential Issue 1 06/2003

Page 13

RH-3

CCS Technical Documentation Troubleshooting — Antenna

and/or dirt needs to be removed. If the whip stopper doesn't properly contact the bottom antenna clip, then the internal antenna gain will degrade by about 4-5dB at Cell

band and 3-10dB at PCS band when whip is retracted.

Grounding of Display Frame

Figure 14: Back view of display assembly

Note that the display frame is grounded to the PWB through the two ground clips. The

grounding of the display frame will impact the radiation performance of the phone. If

the clips are not touching the PWB, or are corroded or obstructed, then the display frame

should be replaced.

The following figures show the contact between the display frame ground clips and the

PWB in greater detail.

Figure 15: Contacts of display frame clips with side plating of PWB

Issue 1 06/2003 Nokia Corporation Confidential Page 13

Page 14

RH-3

Troubleshooting — Antenna CCS Technical Documentation

Figure 16: View of display ground clip in assembled phone with A-cover removed

Misinstalled Whip

The whip is locked into the D-cover when the internal antenna frame is installed. There is

a feature in the plastic frame of the internal antenna that interlocks with the locking

feature of the whip. The whip plug has the locking feature, and also has a key that is

designed to make it difficult to install the whip plug with the wrong rotation. If the whip

plug does get installed with the wrong rotation, then the whip will not be visible as seen

through the locking feature as shown in Figure 17. In this case, if the whip cannot be

removed, then the D-cover assembly will need to be replaced. Otherwise, simply replace

the whip.

Figure 17: Locking feature for whip

Page 14 Nokia Corporation Confidential Issue 1 06/2003

Page 15

RH-3

CCS Technical Documentation Troubleshooting — Antenna

Damaged Whips

Figure 18: Whip stand-alone in retracted and extended positions

The above figure shows what the whip should look like when it is retracted and

extended. If the whip is damaged, simply use another.

Detuning Circuit for Bottom Antenna Clip

Figure 12 shows the bottom antenna clip. The detuning circuit is right next to the bottom antenna clip. If the detuning circuit is not installed properly, then the internal

antenna gain will degrade by about 4-5dB at Cell band and 3-10dB at PCS band. The

detuning circuit consists of a 1nH coil inductor. If the inductor is missing, then install

one.

Testing CDMA Antenna

Calibration Factors

Defining AMS RF coupler CPL-8 calibration numbers will be conducted in the test

adapter MJF-28. The calibration numbers will be obtained by utilizing a phone with

known RF and antenna performance. Each test adapter should only require a single calibration on PCS1900 and GPS bands at used test frequencies. Additional calibrations

should only be needed if the test adapter is substantially modified (reassembled, changed

parts, dropped, etc.).

Calibration Factor for PCS1900 frequency

Transmitter of the phone with known output power and antenna performance will be

turned on at the maximum output power (all bits up) by using call box. The transmitted

power will be measured on the RF connector and through coupler at CDMA PCS channel

1175. The difference between the transmitted and received powers will be used as the

calibration number (path loss on Cell band including coupler, cable, and attenuator path

losses) for the coupler on Cell band.

Nominal value for power measured at RF connector is 23 dBm. Coupler path loss is normally ~17…18 dB at PCS band. If 10 dB attenuator and cable with ~1 dB loss is used,

total path loss is 28…29 dB and measured power would be from -5 to -6 dBm [23 dBm (28…29 dB)]. However path loss has to be measured separately for every coupler since

path losses vary depending on used setup, cables, and attenuator.

Measurement Procedure for Cell800/PCS1900 phones

1 The phone will be placed display up in the test adapter MJF-28 with its whip

retracted.

Issue 1 06/2003 Nokia Corporation Confidential Page 15

Page 16

RH-3

Troubleshooting — Antenna CCS Technical Documentation

2 The phone's transmitter will be turned on at PCS band on CDMA mode channel

1175 at maximum output power (nominal 23 dBm at RF connector).

3 Measure the RF power with CPL-8 coupler. This will represent the internal

antenna to RF coupler measurement.

4 Turn the phone's transmitter off.

5 CDMA antenna test fails measured power is outside test limits

Min

Measured power + coupler, cable

and attenuator path loss

20,0 dBm 23 dBm 26,0 dBm

Nominal

Max

Measured power + coupler, cable

and attenuator path loss

Testing GPS Antenna (Models 2285 and 2270)

Calibration Factor for GPS

GPS test mode 3: GPS receiver will be fed with CW signal. With -110 dBm signal level on

RF connector [(-110 dBm + cable loss) at signal generator output] GPS receiver should

report C/No ratio of 35 dBHz. Reported C/No figure will be recorded with signal fed to RF

connector. C/No value will be read with coupler engaged. GPS signal level must be

increased until same C/No value is recorded. The difference between the CW signal levels

at the generator will be used as the calibration number (path loss on GPS band including

coupler, cable, and attenuator losses).

Nominal coupler path loss at GPS band is 14…17 dB. If 10 dB attenuator and cable with

1 dB loss is used total path loss is 25…28 dB. Signal level at generator output has to be

-85…-82 dBm [-110 dBm -(-25 dB…-28 dB)]. However path loss has to be measured separately for every coupler since path losses vary depending on used setup, cables, and

attenuator.

Measurement Procedure for GPS Antenna

1 The phone will be placed display up in the test adapter MJF-28 with whip

retracted.

2 CW Signal generator will be turned on [with power -110 dBm + coupler, cable,

and attenuator path loss at GPS band] fed to RF coupler.

3 Read reported C/No figure with test mode 3 three to four times to see if it is sta-

ble.

4 GPS Antenna test fails if C/No value is outside test limits

Min

31,0 dBHz 35,0 dBHz 38,5 dBHz

Nominal Max

Page 16 Nokia Corporation Confidential Issue 1 06/2003

Loading...

Loading...