Page 1

CCS Technical Documentation

RH-3 Series Transceivers

Troubleshooting — GPS

Issue 1 06/2003 Confidential Nokia Corporation

Page 2

RH-3

Troubleshooting — GPS CCS Technical Documentation

Page 2 Nokia Corporation Confidential Issue 1 06/2003

Page 3

RH-3

CCS Technical Documentation Troubleshooting — GPS

Contents

Page No

Troubleshooting - Global Positioning System (GPS) Engine........................................ 5

Acronyms and Abbreviations......................................................................................... 6

Troubleshooting the GPS BB ......................................................................................7

Troubleshooting Flowchart....................................................................................... 7

Flowchart Notes ...................................................................................................... 10

Troubleshooting the GPS RF .....................................................................................13

Limitations .............................................................................................................. 13

GPS Receiver .............................................................................................................13

General Instructions ................................................................................................ 13

Test Equipment ..........................................................................................................14

Path of the Received Signal .......................................................................................14

GPS RF Quick Fault-finding Chart ...........................................................................15

GPS RF Circuitry and Component Placement ...........................................................16

GPS Module Test Points ............................................................................................17

GPS RF General Checking ........................................................................................18

GPS Reference Clock Checking ................................................................................21

GPS RF and GPS BB Interface Checking .................................................................23

GPS RX Chain Checking ...........................................................................................24

Issue 1 06/2003 Nokia Corporation Confidential Page 3

Page 4

RH-3

Troubleshooting — GPS CCS Technical Documentation

Page 4 Nokia Corporation Confidential Issue 1 06/2003

Page 5

RH-3

CCS Technical Documentation Troubleshooting — GPS

Troubleshooting - Global Positioning System (GPS) Engine

The RH-3 Model 2285 handset supports 800 CDMA / 1900 CDMA + GPS with IS 2000

capability. The RH-3P Model 2270 supports PCS and GPS functionality for Enhanced 911

(E911) services.

GPS circuitry utilizes RF signals from satellites stationed in geosynchronous orbit to

determine latitude and longitude of the handset. The GPS circuitry and the cellular

engine (CE) circuitry are completely separate in the handset. The GPS circuitry is located

exclusively on the secondary side of the PWB.

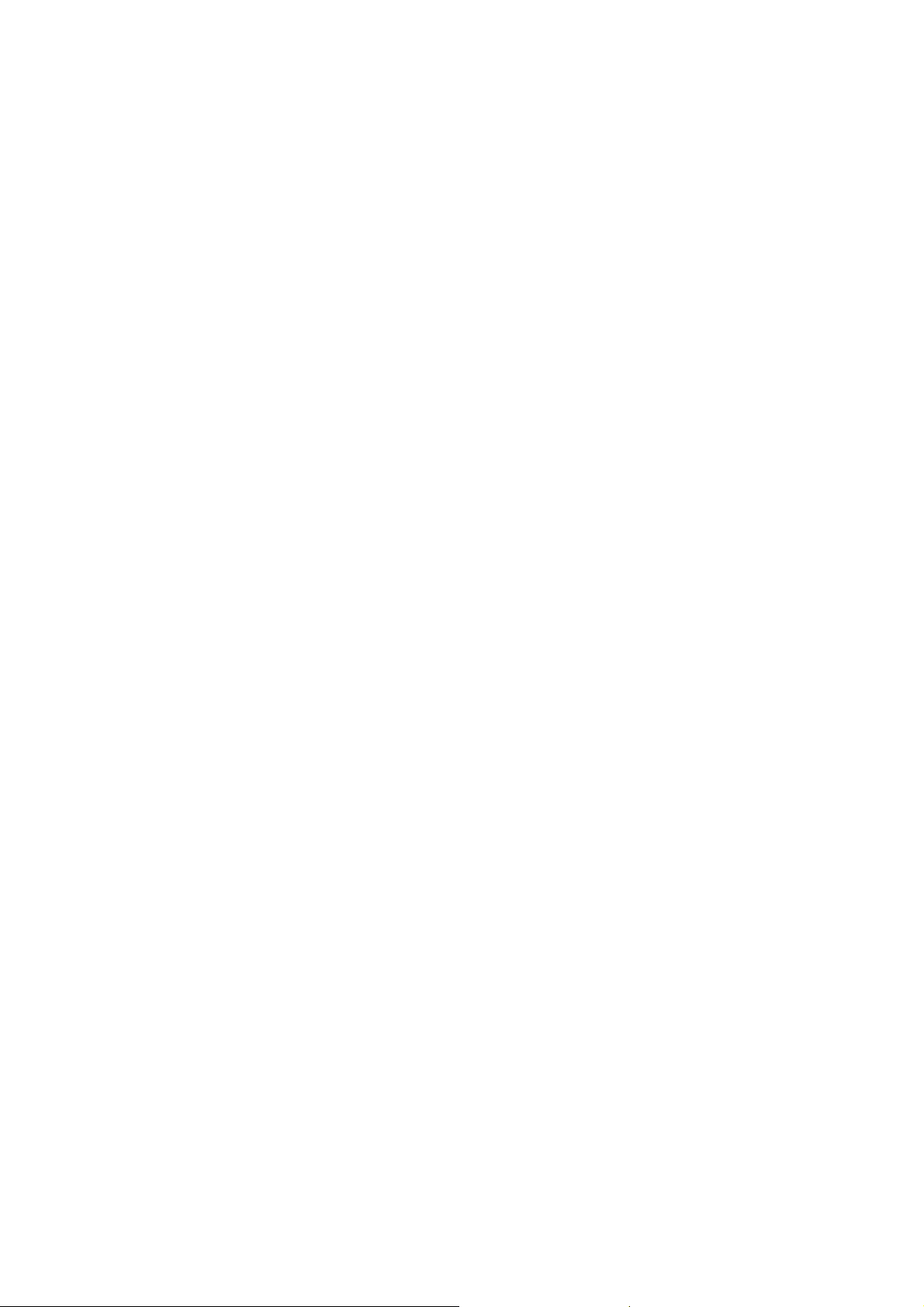

See Figure 1 for the General Block Diagram.

Figure 1: GPS Block Diagram

Issue 1 06/2003 Nokia Corporation Confidential Page 5

Page 6

RH-3

Troubleshooting — GPS CCS Technical Documentation

Acronyms and Abbreviations

AGPS Assisted GPS

AMPS Advanced Mobile Phone Service

ASIC Application Specific Integrated Circuit

E911 Enhanced 911

FCC Federal Communications Commission

BPSK Binary Phase Shift Keying

BT BlueTooth

C/A Coarse Acquisition-Code

CE Concurrent Engineering

CDMA Code Division Multiple Access

C/No Carrier to Noise ratio [dB-Hz]

DCT Digital Core Technology

DSSS Direct Sequence Spread Spectrum

FCC Federal Communications Commission

GPS Navstar Global Positioning System

HW Hardware

IC Integrated Circuit

L1 Link 1

LPRF Low Power RF

NF Noise Figure

PCS Personal Communications Service

PRN Pseudo Random Noise

PSAP Public Safety Answering Point

PWB Printed Wiring Board

Page 6 Nokia Corporation Confidential Issue 1 06/2003

Page 7

RH-3

CCS Technical Documentation Troubleshooting — GPS

RF Radio Frequency

RHCP Right Hand Circular Polarized

SA Selective Availability

SPS Standard Positioning Service

UTC Universal Time Coordinated

WB Wideband

Troubleshooting the GPS BB

Figure 2: GPS RF-BB ASIC Interface

To troubleshoot the GPS BB, put the GPS engine (GE) and cellular engine (CE) in the

proper mode by selecting the GPS Testing drop-down menu item from the “Troubleshooting” dialog box. Ensure that the necessary inputs from the CE are good (e.g., power, clock,

and so on). Next, ensure that these inputs produce the proper outputs. Due to the large

level of integration (most functionality is contained in the two ASIC chips), the diagnostics that may be performed are limited.

Visually inspect the GPS circuitry to determine if the problem is physical (dislodged parts,

corrosion, poor solder joints, and so on) prior to performing any diagnostics.

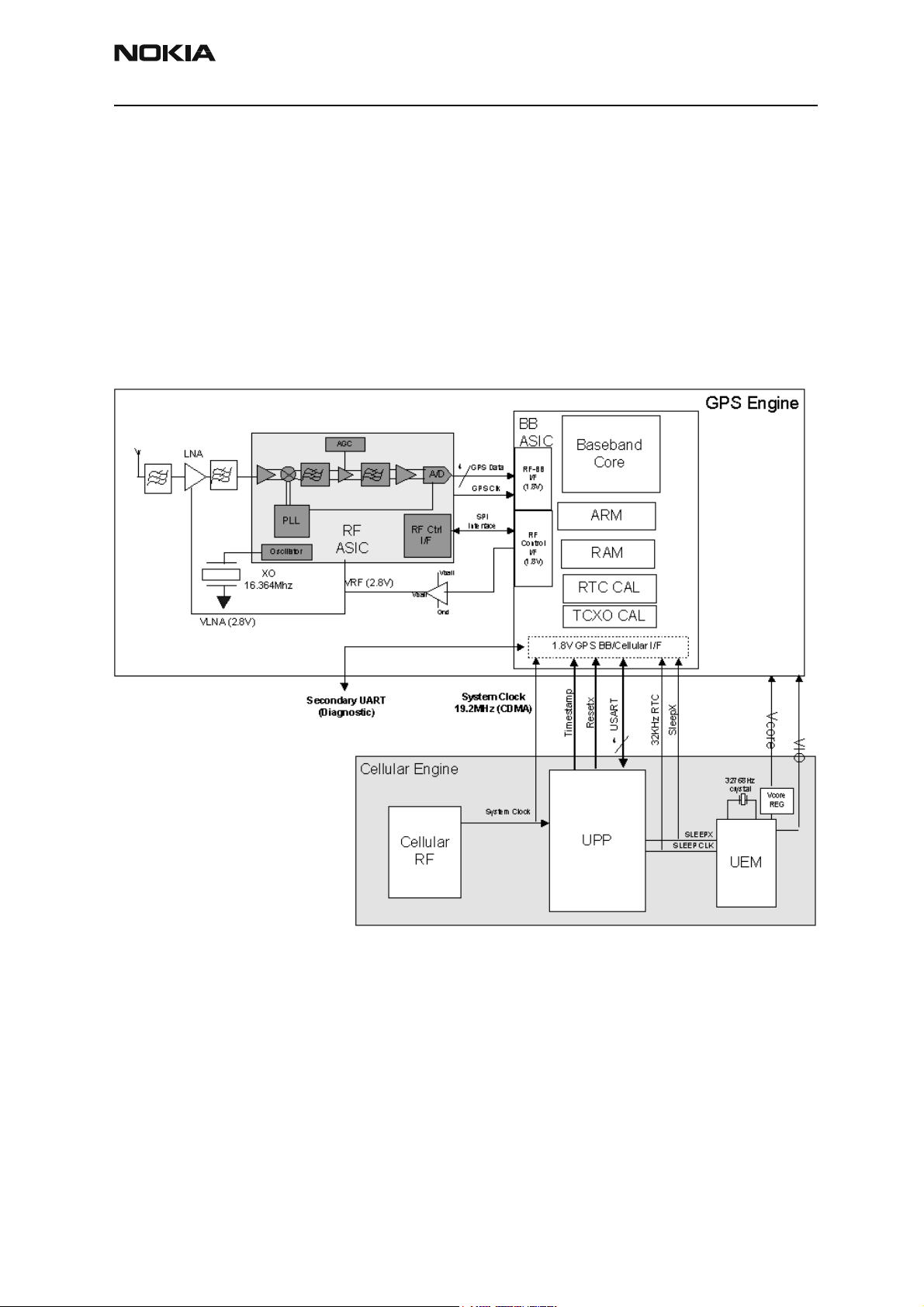

Troubleshooting Flowchart

Before implementing the flowchart, turn the GPS section ON in the “GPS Receiver Control (AMS)” tab of the GPS component in Phoenix.

Reference Table 1 for GPS Test Points assignment and Figure 10 for GPS Test

Points locations.

Issue 1 06/2003 Nokia Corporation Confidential Page 7

Page 8

RH-3

Troubleshooting — GPS CCS Technical Documentation

Vcore at 1.5V?

Yes

VIO at 1.8V ?

(@ C018)

Yes

GPS_RF_CLK

(19.2MHz) OK?

(J062)

Yes

GPS_EN_RESET is

held high?

(J061)

No

No

No

Troubleshoot CE

power supply

Troubleshoot CE

VCTCXO circuit

BB ASIC being held in

reset, troubleshoot

source in CE

Yes

GPS_SLEEPCLK

(32.768KHz) OK?

(J063)

Yes

VRF_GPS OK?

Yes

No

No No

Yes

Troubleshoot CE

sleep clock circuit

VRF_GPS regulator

enable line low?

Replace regulator

N052

Page 8 Nokia Corporation Confidential Issue 1 06/2003

Page 9

RH-3

CCS Technical Documentation Troubleshooting — GPS

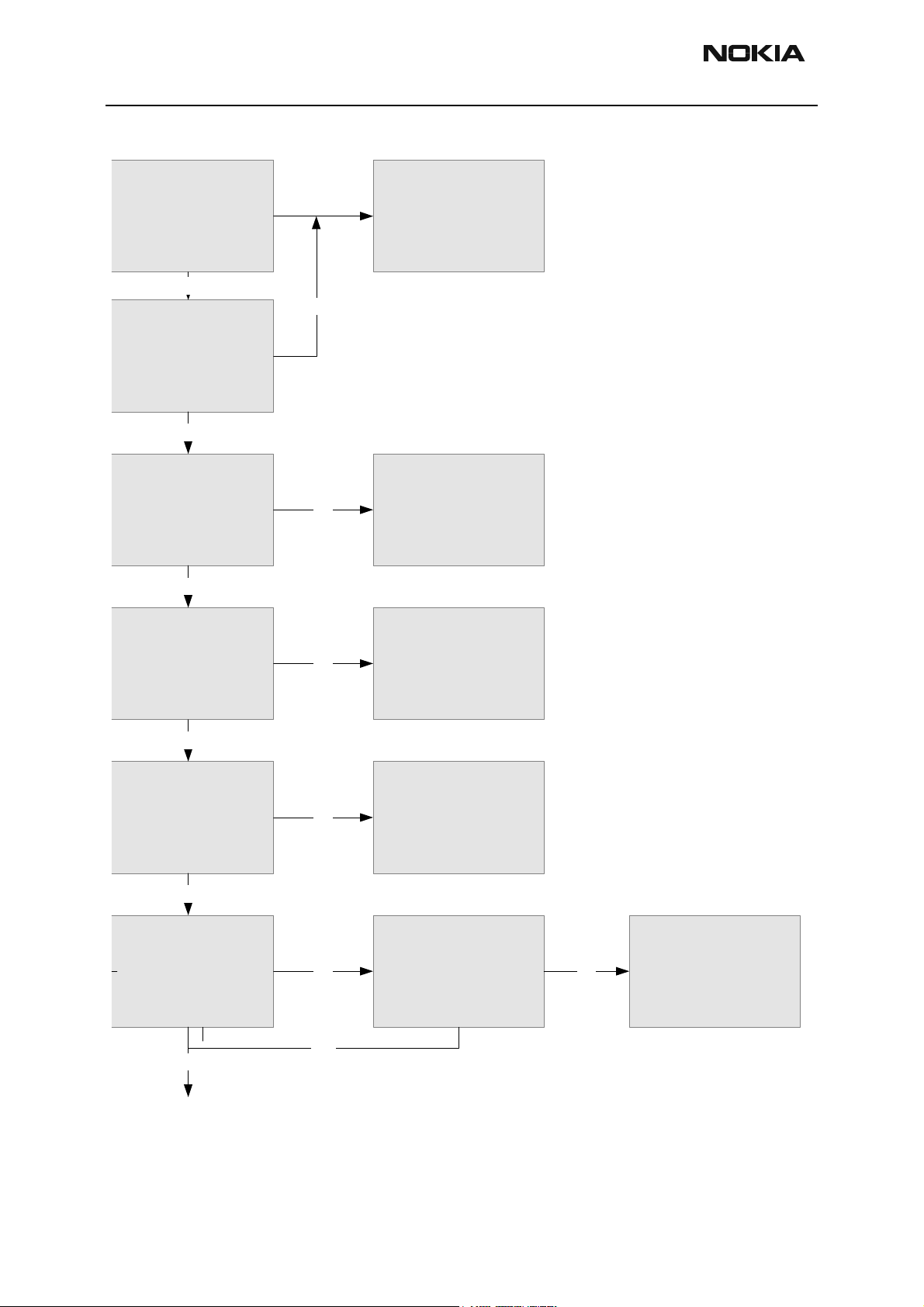

GPS_CLK

(16.368MHz) OK?

(J010)

Yes

Test Mode 1 OK?

Yes

CE sending code

download signals?

Yes

No

No

No

Replace TCXO or

GPS RF ASIC

Replace GPS BB

ASIC

Determine why CE not

sending download

signals

SPI interface active?

Yes

RF data and clock?

Yes

Debug RF front end

No

No

Replace GPS BB

ASIC

Replace GPS RF

ASIC

Issue 1 06/2003 Nokia Corporation Confidential Page 9

Page 10

RH-3

Troubleshooting — GPS CCS Technical Documentation

Flowchart Notes

Clocks and Power

The proper GPS_RF_CLK is a 19.2 MHz, approximately 800mV peak-to-peak sine wave

(see Figure 3).

Figure 3: 19.2MHz System Clock

The GPS_CLK should be a 16.3MHz, 1.8V peak-to-peak square wave (see Figure 4).

Figure 4: GPS_CLK

Page 10 Nokia Corporation Confidential Issue 1 06/2003

Page 11

RH-3

CCS Technical Documentation Troubleshooting — GPS

Test Mode 1

Test Mode 1 is a built-in self-test (BIST) for the GPS BB ASIC that checks for internal

faults. To implement Test Mode 1, select the test mode 1 radio button and then click the

Execute button in the “Rx simple actions” tab of the GPS component in Phoenix.

Code Download

The code store inside the GPS BB ASIC is volatile. As a result, each time power is applied

to the ASIC, the code that runs there must be re-downloaded from the CE. If this process

does not complete correctly, the GE will not work. The interface protocol utilized for this

process is the Universal Synch/Asynch Receiver Transmitter (USART), and the pins on the

GPS BB ASIC are labeled U1Tx, U1Rx, U1_DATA_RDY, and U1_CLK. To determine if this

interface is active, check for activity on these lines at power up. Each of these lines

should have a short burst of activity immediately after power is applied. To capture these

signals, you will need to set the storage scope to single sweep or triggered mode (see

Figure 5).

Figure 5: GPS Code Download U1 CLK U1 RX

SPI Interface

The SPI interface is a three-line synchronous serial interface used by the GPS BB to communicate to the GPS RF. These lines are called SPI_CLK, SPI_DATA, and SPI_EN. Activity

should be seen for a short period on these signals each time a mode switch is made (e.g.,

between idle and off mode in the “Rx simple actions” tab of the GPS component in Phoenix). See Figure 6.

Issue 1 06/2003 Nokia Corporation Confidential Page 11

Page 12

RH-3

Troubleshooting — GPS CCS Technical Documentation

RF Data and Clock

The GPS RF ASIC sends encoded raw GPS data to the GPS BB ASIC for further processing

via a four-line synchronous parallel interface. These signals are data (labeled B0, B1, B2,

and B3) and GPS_CLK. The GPS_CLK has been previously tested (see the flowchart). The

four-data lines should show continuous activity almost immediately after power has

been applied to the phone (see Figure 7).

Figure 6: Spi Data and Clock

Figure 7: RF Data and Clock

Page 12 Nokia Corporation Confidential Issue 1 06/2003

Page 13

RH-3

CCS Technical Documentation Troubleshooting — GPS

Troubleshooting the GPS RF

The purpose of this section is to define GPS test limits on the product line and to guide

the GPS RF troubleshooting.

Limitations

Measurements should be done using High-Frequency Probe with spectrum analyzer in

order to measure local and reference frequencies and RF-power levels in intermediate

stages of chain. Oscilloscope is used to measure DC-voltages and low frequency signals.

Digital multimeter is also useful measurement equipment in faultfinding. Also cellular

tester is needed in order to perform tests mentioned in this section.

External RF connector is implemented for improving reliability of the measurements and

should be used when reasonable.

GPS RF-section is mainly build around of TRF5101 PG2.1 IC (N054) ASIC. The GPS RF

block has a separate front end filter, inter stage filter, LNA, TCXO, and down converter

circuitry.

In this RF troubleshooting section, tolerances are specified for critical GPS RF signals and

voltages.

Before changing a single ASIC or component, please check the following items:

1 The soldering and alignment marks of the GPS ASICs

2 Supply voltages and control signals are OK

NOTE 1: The RF ASIC module is static discharge sensitive! It is recommended that EDS-protected

clothes and shoes are worn and that grounded soldering irons are used.

NOTE 2:The shield lid must be always replaced with new one after it is opened. Check that there are

no short circuits on PWB caused by plate ends.

GPS Receiver

General Instructions

Receiver troubleshooting is divided into four sections:

1 GPS RF general checking

2 GPS reference clock checking

3 GPS RF and GPS BB interface checking

4 GPS RX chain checking

The fastest way to troubleshoot GPS RF is to follow the GPS RF Fault-finding chart Quick

Issue 1 06/2003 Nokia Corporation Confidential Page 13

Page 14

RH-3

C

K

ADCout

IFout

GPS Clock

LO/8 Te

st

1

Troubleshooting — GPS CCS Technical Documentation

Reference (See Figure 9).

Please note that before changing ASICs or filters, soldering and missing components

must be checked visually. There are no parameters in GPS RF, which should be tuned

externally. Accurate signal levels are not shown in the flowcharts below because of the

figures apply with specific measurement probes. It is useful to compare the results

against reference phones.

Test Equipment

1 Signal generator up to 2 GHz

2 Oscilloscope with 10:1 passive probe

3 High Frequency Probe for Spectrum Analyzer (Please note that the signal levels

mentioned in the RX troubleshooting have been measured with an active probe.)

4 Spectrum analyzer up to 6.7 GHz

5 PC with Phoenix SW and GPS option

Path of the Received Signal

575.42 MHz

4.092MH z

LNA

BPF

SAW

16. 36 8 MH z

TCXO

Im age Reject

Mixer

÷ 2

Loop

Filte r

fco mp=16.368 MHz

Oscillator

VCO

Tank

LO =157 1 .328 MHz

÷ 2

÷ 8

÷1 2

Ph ase

Det

AG C

4 Bit

ADC

LO/8 Test Point

196.416 MHz

Programming

In terf ace

IF out Test

Points

DATA

LOC

ENABLE

SPI

Figure 8: GPS RF Functional Diagram

Page 14 Nokia Corporation Confidential Issue 1 06/2003

Page 15

RH-3

CCS Technical Documentation Troubleshooting — GPS

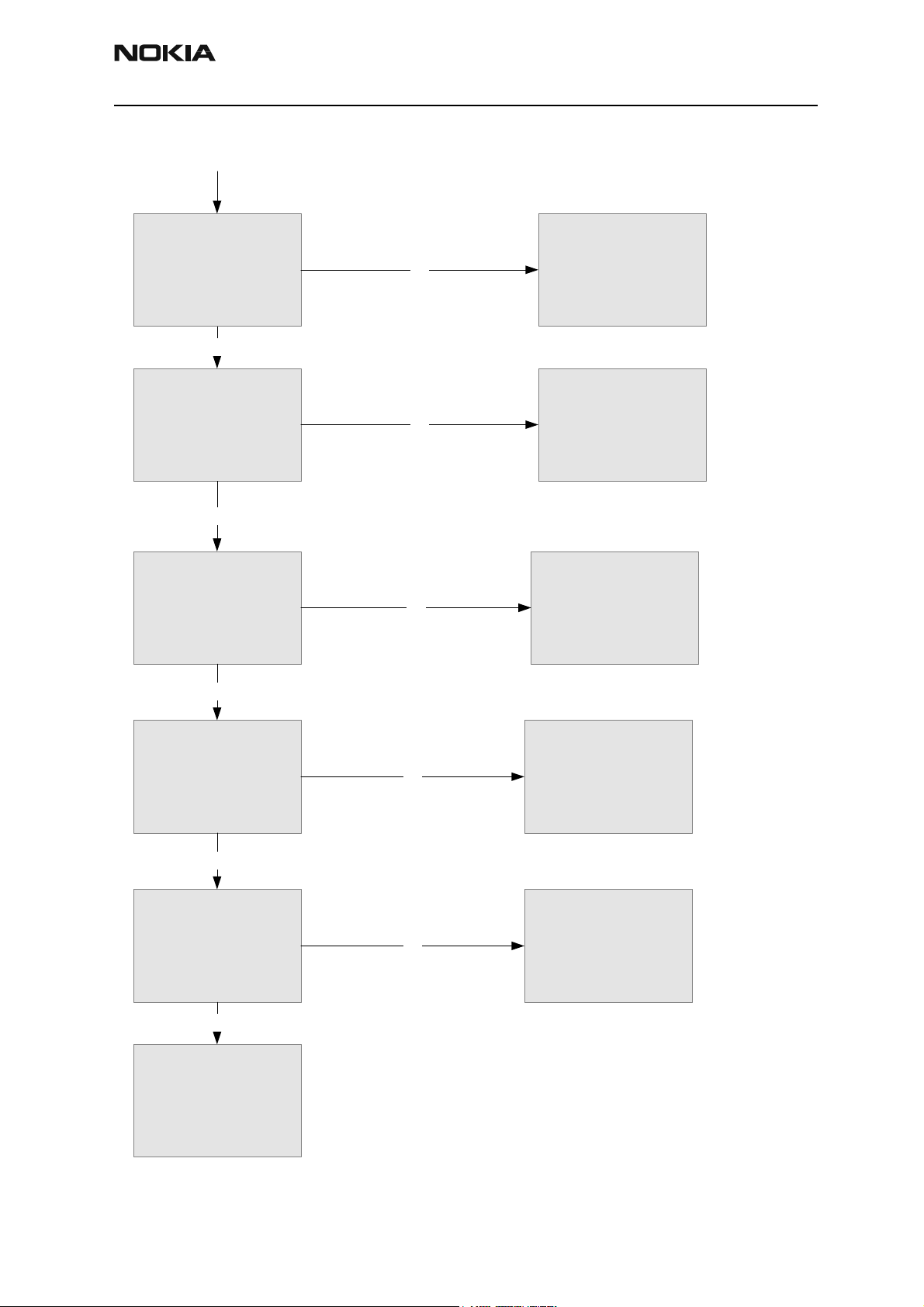

GPS RF Quick Fault-finding Chart

Apply 1575.520152 MHz @ -110 dBm

CW sign al to external GPS RF

connector/ s witch and run

Troubleshooting/GPS Testing/GPS

Quick Test/Galvanic

Not OK

Apply 1575.520152 MHz @ -100 dBm

CW sign al to external GPS RF

connector/ s witch and run

Troubleshooting/GPS Testing/GPS

Receiver Control (AMS)/Receiver ON

Not OK

Check 19.2 MHz

GPS_RFCLK si gnal J009

OK

Check 16.368 MHz

GPS_CLK signal J008

OK

Check the 196 .416 MHz LO/8

at J005

OK

Not OK

Not OK

Not OK

Start CDMA t roubleshooting,

VCTCXO, etc.

Measure VRF_GPS at C017 Replace regulator N051

OK

Replace TCXO B001

Measure VIO at C067

OK

Replace GPS RF ASIC N054

Not OK

Not OK

Start CDMA BB

troubleshooting, UEM, etc.

Check signal level Z003

output (L005)

OK

Check signal level at V001

output (C010)

OK

Check signal level at N054

input (C069)

Not OK

Not OK

Not OK

Replace filter Z003

Replace transistor V001

Replace filter Z004

Figure 9: GPS RF Fault-finding chart (Quick Reference)

Issue 1 06/2003 Nokia Corporation Confidential Page 15

Page 16

RH-3

Troubleshooting — GPS CCS Technical Documentation

GPS RF Circuitry and Component Placement

Note: GPS RF Schematics are located in Schematics section of this Service Manual.

Table 1: GPS Engine Test Points Table

J004 Test_IF_P

J003 Test_IF_M

J005 LO/8

J002 GPS_SPI_CLK

J007 GPS_SPI_DATA

J008 GPS_SPI_EN

J006 XTAL 2

J008 GPS_CLK

GND

J001 GPS_U2TX

R044 GPS_U2RX

J017 GPS_PA_EN

J011 GPS_SLEEPX

J015 GPS_U1_DATA_RDY-TIMESTAMP

J013 GPS_U1_RX

J014 GPS_U1_TX

J016 GPS_INT_U1_CLK

J012 GPS_EN_RESET

J009 GPS_RFCLK (19.2 MHZ)

Page 16 Nokia Corporation Confidential Issue 1 06/2003

Page 17

RH-3

CCS Technical Documentation Troubleshooting — GPS

GPS Module Test Points

J007

J002

J005

C069

J003

J004

C067

J008

C017

J006

J009

J012

R044

J001 J017 J011 J010

L005

J016

J014

J015

J013

C010

Figure 10: GPS Component Placement (PWB Bottom Side)

Issue 1 06/2003 Nokia Corporation Confidential Page 17

Page 18

RH-3

Troubleshooting — GPS CCS Technical Documentation

GPS RF General Checking

The fastest way to get an overview of GPS RF status is to run GPS QUICK TEST. This can

be done by using a CW signal generator and Phoenix. When running Galvanic testing, set

signal generator frequency to 1575.520152 MHz and adjust level to -110 dBm at GPS

antenna port. In radiated testing CW level has to be higher, because of the attenuation in

pad + cable + coupler. With -20 dB pad signal level in signal generator is ~ -110 dBm +

cable attenuation + 20 dB + 18 dB.

The CW analysis is functionality has been added to the GPS to allow end-to-end spectral

purity to be assessed during manufacturing and development.

1 Power cycle transceiver under test

2 Connect CW signal as stated above via GPS RF connector

3 Connect DAU-9T cable to Tomahawk connector

4 On Phoenix, choose connection as FBUS and select File/Scan Product

5 Select Troubleshooting/GPS Testing/GPS Quick Test/Test Mode Galvanic

in Phoenix

6 Execute (see the following diagrams for reference)

Page 18 Nokia Corporation Confidential Issue 1 06/2003

Page 19

RH-3

CCS Technical Documentation Troubleshooting — GPS

7 Check the version of the TWL5001 is v1.2 and TRF5101 is v2.1

8 Check SNR = 32 dB – 37.5 dB in Galvanic testing (or 31 – 38.5 dB in radiated

testing) (or vary +/- 10 dB compared to galvanic SNR result)

9 Check Bin value is between 2448 +/- 105

10 If the test didn’t pass, start to troubleshoot by selecting Troubleshooting/GPS

Issue 1 06/2003 Nokia Corporation Confidential Page 19

Page 20

RH-3

Troubleshooting — GPS CCS Technical Documentation

Testing/GPS Receiver Control (AMS) / Receiver On in Phoenix

11 Execute

Note: When turning the GPS “ON” for the first time via the Phoenix command, the CDMA engine

will switch to “Local Mode”. During this transition the GPS will perform an internal self-test and

may turn the GPS “off” at the end of the self-test. If this is the case, execute the Receiver ON command again. Looking at the current consumption, you can easily monitor this state.

12 Check operating voltages

DC voltages VRF_GPS at C017, LNA VCE at C006 and VIO at C067 should be as presented

in the following picture:

Figure 11: DC level of LNA Collector Emitter Voltage Vce

Page 20 Nokia Corporation Confidential Issue 1 06/2003

Page 21

RH-3

CCS Technical Documentation Troubleshooting — GPS

Figure 12: DC level of VRF_GPS and VLNA_GPS

Figure 13: DC level of VIO

GPS Reference Clock Checking

1 Cycle power

2 Choose connection as FBUS and select File/Scan Product

3 Select Troubleshoot/GPS Testing/GPS Receiver Control (AMS) / Receiver On in

Phoenix

Issue 1 06/2003 Nokia Corporation Confidential Page 21

Page 22

RH-3

Troubleshooting — GPS CCS Technical Documentation

4Execute

5 Connect oscilloscope 10:1 probe to test pad J009

6 CDMA 19.2 MHz system clock to GPS should look like the following picture:

Figure 14: CDMA 19.2 MHz reference clock to GPS

7 Connect oscilloscope 10:1 probe to test pad J006

8 GPS 16.368 MHz system clock for GPS RF ASIC N054 should be within +/- 256

Hz limits if tested with MCU/GPS Control/GPS Quick Test. The 16.368 MHz signal

looks like the following picture:

Figure 15: GPS 16.368 MHz reference clock from TCXO before C029

Page 22 Nokia Corporation Confidential Issue 1 06/2003

Page 23

RH-3

CCS Technical Documentation Troubleshooting — GPS

Figure 16: GPS 16.368 MHz reference clock from TCXO at J006

9 Connect spectrum analyzer probe on test pad J005

10 Check that LO is active by measuring LO/8 signal, which should be within

196.416 MHz +/- 2.946 kHz

GPS RF and GPS BB Interface Checking

1 Next connect oscilloscope 10:1 probe into GPS_CLK output of the N054 between

pin D7 and J008

2 GPS 16.368 MHz system clock to GPS BB should look like the following picture:

Figure 17: GPS 16.368 MHz reference clock to GPS BB

Issue 1 06/2003 Nokia Corporation Confidential Page 23

Page 24

RH-3

Troubleshooting — GPS CCS Technical Documentation

3 Next connect oscilloscope 10:1 probe into J011(GPS_B0), J012(GPS_B1),

J013(GPS_B2) or J014(GPS_B3) outputs of the N001 (pins E7, F7, G7 and G6)

4 Sampled signal going to GPS BB should look like in the following picture:

GPS RX Chain Checking

1 Connect 1575.520152 MHz CW signal generator at the level of –100dBm to GSP

antenna connector. NOTE: Cable loss or attenuator loss has to be taken into

account.

2 Connect spectrum analyzer through active probe with attenuator into filter Z001

output

3 If connector/switch X001 and filter Z001 are OK, the signal level should be simi-

lar to the following picture:

Figure 18: Sampled signal going to GPS BB

Page 24 Nokia Corporation Confidential Issue 1 06/2003

Page 25

RH-3

CCS Technical Documentation Troubleshooting — GPS

Figure 19: Signal level at Z001 output

4 Next connect spectrum analyzer through active probe with attenuator into filter

Z002 input

5 If connector/switch X001, filter Z001 and LNA V001 are OK signal level should be

similar to the following picture:

Figure 20: Signal level at Z002 input

6 Next connect spectrum analyzer through active probe with attenuator into filter

Z002 Output

7 If connector/switch X001, filter Z001, LNA V001 and filter Z002 are OK , the sig-

nal level should be similar to the following picture:

Issue 1 06/2003 Nokia Corporation Confidential Page 25

Page 26

RH-3

Troubleshooting — GPS CCS Technical Documentation

Figure 21: Signal level at Z002 output

Figure 22: Signal level at IF output @-100dBm Input

Page 26 Nokia Corporation Confidential Issue 1 06/2003

Page 27

RH-3

CCS Technical Documentation Troubleshooting — GPS

Figure 23: Signal level at IF output @-110dBm Input

Figure 24: Signal level at IF output @-120dBm Input

Issue 1 06/2003 Nokia Corporation Confidential Page 27

Page 28

RH-3

Troubleshooting — GPS CCS Technical Documentation

Page 28 Nokia Corporation Confidential Issue 1 06/2003

Loading...

Loading...