C TRANSMISSION/TRANSAXLE

A

B

SECTION

CONTENTS

FS5W71C

PREPARATION ..................................... ...................... 3

Special Service Tools ............................................... 3

Commercial Service Tools ........................................ 5

NOISE, VIBRATION, AND HARSHNESS (NVH)

TROUBLESHOOTING .......................... ...................... 6

NVH Troubleshooting Chart ..................................... 6

DESCRIPTION ......................... ................................... 7

CROSS-SECTIONAL VIEW ..................................... 7

ON-VEHICLE SERVICE ............................................. 9

Replacing Rear Oil Seal ........................................... 9

REMOVAL ............................................................. 9

INSTALLATION ..................................................... 9

Position Switch Check .............................................. 9

TRANSMISSION ASSEMBLY .................................. 10

Removal and Installation ........................................ 10

REMOVAL ........................................................... 10

INSTALLATION ....................................................11

Overhaul ......................... .................... .................... 12

CASE COMPONENTS ........................................ 12

GEAR COMPONENTS ....................................... 14

SHIFT CONTROL COMPONENTS ...... ....... ....... 16

CASE COMPONENTS ............................... ....... ....... 18

Disassembly ................... ........................................ 18

Assembly ........................ .................... .................... 19

SHIFT CONTROL COMPONENTS .......................... 22

Disassembly ................... ........................................ 22

Inspection ................. .............................................. 22

Assembly ........................ .................... .................... 23

GEAR COMPONENTS ............................................. 24

Disassembly ................... ........................................ 24

Inspection ................. .............................................. 26

GEARS AND SHAFTS ........................................ 26

SYNCHRONIZERS .................. ........................... 27

BEARINGS ......................... ............. ............. ....... 27

Assembly ........................ .................... .................... 27

SERVICE DATA AND SPECIFICATIONS (SDS) ...... 35

General Specifications ........................................... 35

Gear End Play ........................................................ 35

Clearance Between Baulk Ring and Gear ............. 36

MANUAL TRANSMISSION

2ND & 3RD BAULK RING ................................... 36

Available Snap Rings .............................................36

MAIN DRIVE GEAR BALL BEARING SNAP

RING ................................................................... 36

MAINSHAFT FRONT SNAP RING ......................36

COUNTER DRIVE GEAR SNAP RING ...............36

OD MAINSHAFT BEARING SNAP RING ...........37

Available Shims ......................................................37

COUNTERSHAFT FRONT BEARI NG SHIM ...... 37

FS5R30A

PREPARATION ................................. ........................38

Special Service Tools .............................................38

Commercial Service Tool ........................................ 40

NOISE, VIBRATION, AND HARSHNESS (NVH)

TROUBLESHOOTING ...................... ........................41

NVH Troubleshooting Chart ...................................41

DESCRIPTION ............... ........................................... 42

Description ................... ...... ....... ...... ........................42

CROSS-SECTIONAL VIEW — 2WD MODEL .....42

CROSS-SECTIONAL VIEW — 4WD MODEL .....44

ON-VEHICLE SERVICE ............................................46

Replacing Rear Oil Seal — 2WD Model .................46

REMOVAL ...........................................................46

INSTALLATION ...................................................46

Position Switch Check ....... ....... ...... ....... ...... ....... ....46

TRANSMISSION ASSEMBLY ..................................48

Removal and Installation ........................................ 48

REMOVAL ...........................................................48

INSTALLATION ...................................................50

Overhaul ............... ..................................................51

CASE COMPONENTS ........................................ 51

GEAR COMPONENTS .......................................53

SHIFT CONTROL COMPONENTS (2/4WD

MODELS) ............................................................ 57

CASE COMPONENTS .............................................. 59

Disassembly ........................................................... 59

Assembly ..................... ........................................... 61

MT

D

E

F

G

H

I

J

K

L

M

MT-1

SHIFT CONTROL COMPONENTS ........................... 63

Disassembly ...........................................................63

Inspection ............................................................... 63

Assembly ................................................................63

GEAR COMPONENTS ..............................................65

Disassembly ...........................................................65

Inspection ............................................................... 69

GEARS AND SHAFTS ........................................69

SYNCHRONIZERS .............................................69

BEARINGS ......................... .................................70

Assembly ................................................................70

SERVICE DATA AND SPECIFICATIONS (SDS) ......81

General Specifications ............................................81

Gear End Play ............................. ....... ...... ....... .......81

Clearance Between Single Baulk Ring and Gear ...81

DOUBLE BAULK RING .......................................82

Distance Between Rear Surface of Reverse Cone

and Reverse Baulk Ring .........................................82

Available Snap Ring ................................................82

MAIN DRIVE GEAR SNAP RING ........................82

MAINSHAFT FRONT BEARING SNAP RING .....82

COUNTER GEAR REAR SNAP RING ................83

Available C-ring .......................................................83

MAINSHAFT C-RING ..........................................83

Available Shim and Washer ....................................83

T ABLE FOR SELECTING PROPER COUNTER

GEAR FRONT BEARING SHIM ..........................83

REVERSE IDLER REAR THRUST WASHER .....83

MT-2

PREPARATION

[FS5W71C]

PREPARATION PFP:00002

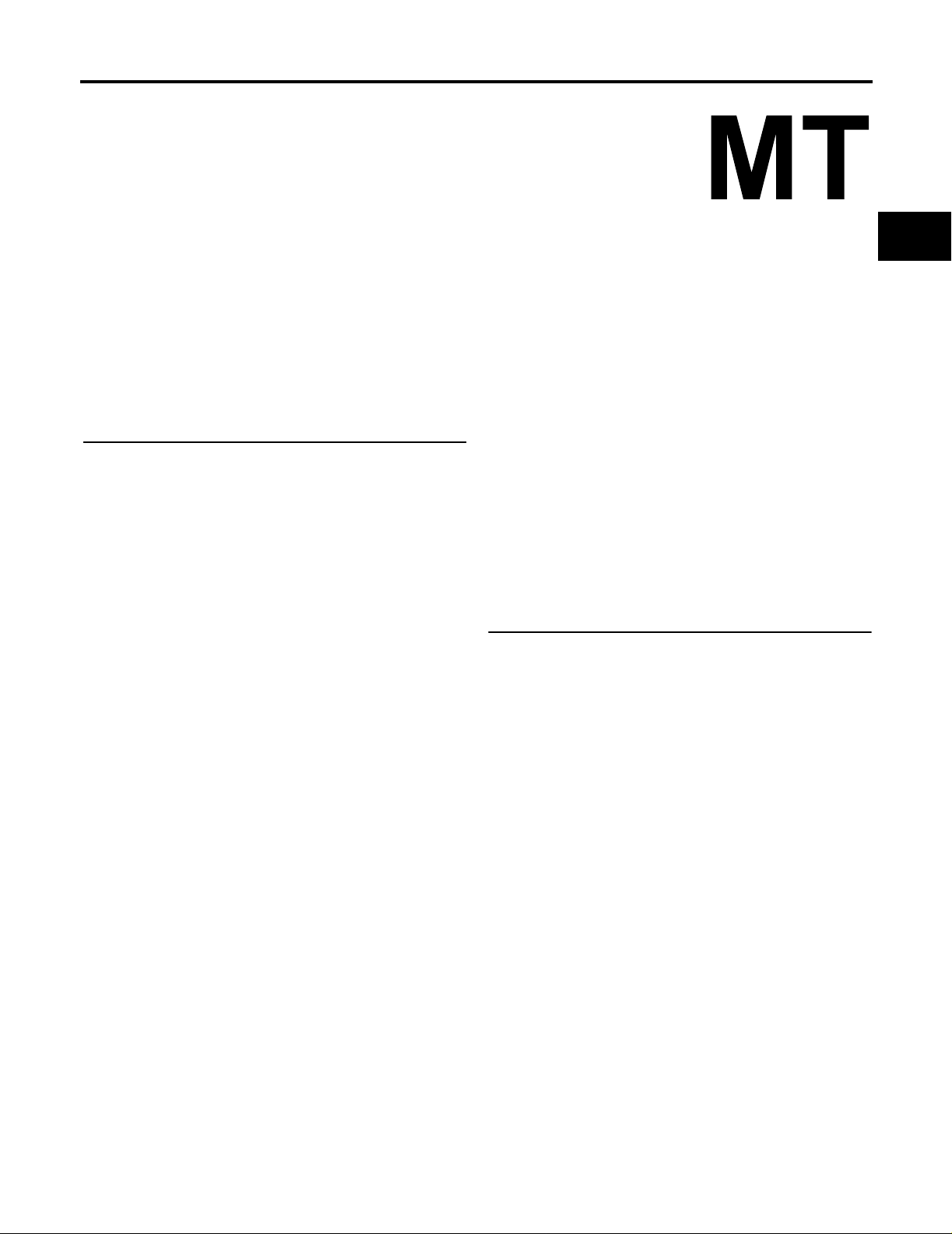

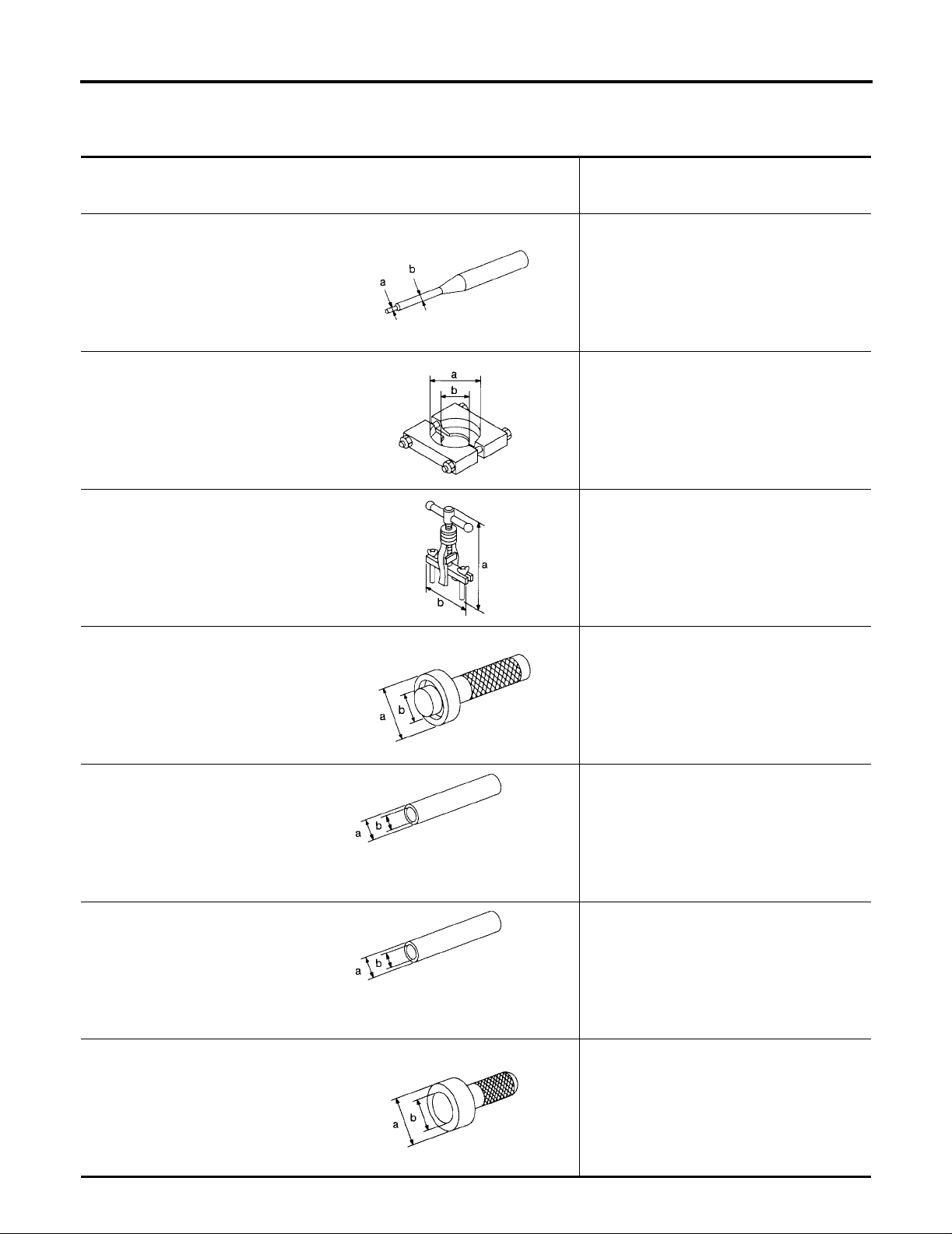

Special Service Tools

The actual shapes of Kent-Moore tools may differ from those of spec ial ser vi ce tool s illust rat ed here.

Tool number (Kent-Moore No.) Tool

name

ST23810001

( — )

Adapter setting plate

NT407

KV32101330

(See J34286)

Puller

NT408

KV31100401

( — )

Transmission press stand

Description

Fixing adapter plate with gear assembl y

a: 166 mm (6.54 in)

b: 270 mm (10.63 in)

Removing overdrive mainshaf t beari ng

a: 447 mm (17.60 in)

b: 100 mm (3.94 in)

Pressing counter gear, mainshaft, count er

drive gear and main drive gear

ECS006I2

A

B

MT

D

E

F

G

ST22520000

(J26348)

Wrench

ST23540000

(J25689-A)

Pin punch

ST30031000

(J22912-01)

Puller

NT068

NT409

NT442

Tightening mainshaft lock nut

a: 100 mm (3.94 in)

b: 41 mm (1.61 in)

Removing and installing fork rod reta inin g pin

a: 2.3 mm (0.091 in) dia.

b: 4 mm (0.16 in) dia.

Removing and installing 1st gear bushi ng

Removing main drive gear ball bearing

a: 90 mm (3.54 in) dia.

b: 50 mm (1.97 in) dia.

H

I

J

K

L

M

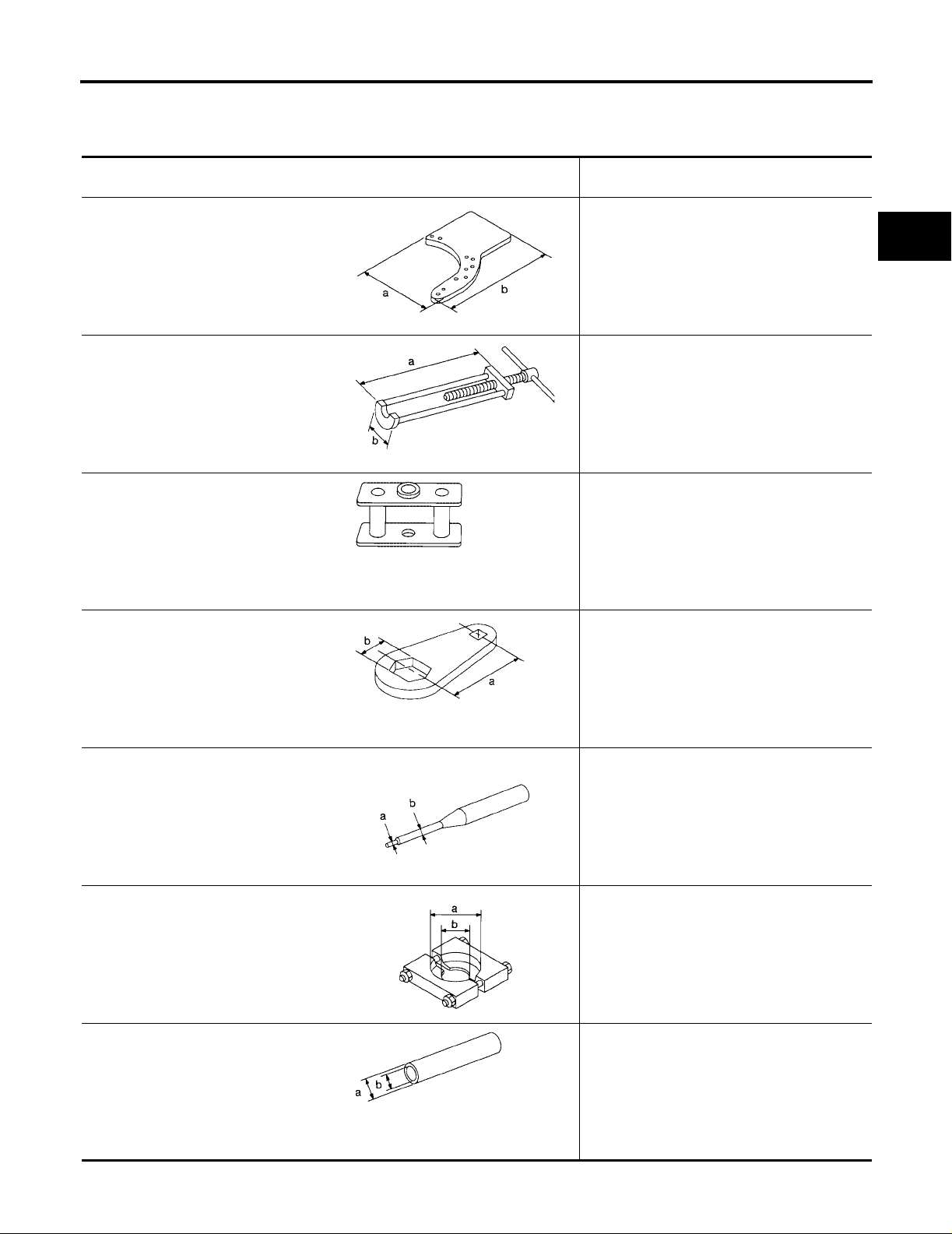

ST23860000

( — )

Drift

NT411

Installing counter drive gear

a: 38 mm (1.50 in) dia.

b: 33 mm (1.30 in) dia.

NT065

MT-3

PREPARATION

[FS5W71C]

Tool number (Kent-Moore No.) Tool

name

ST22360002

(J25679-01)

Drift

ST22350000

(J25678-01)

Drift

ST23800000

(J25691-01)

Drift

ST33400001

(J26082)

Drift

Description

Installing counter gear front and rear end

bearings

a: 29 mm (1.14 in) dia.

b: 23 mm (0.91 in) dia.

NT065

Installing OD gear bushing

a: 34 mm (1.34 in) dia.

b: 28 mm (1.10 in) dia.

NT065

Installing front cover oil seal

a: 44 mm (1.73 in) dia.

b: 31 mm (1.22 in) dia.

NT065

Installing rear oil seal

a: 60 mm (2.36 in) dia.

b: 47 mm (1.85 in) dia.

ST33290001

(J34286)

Puller

ST30720000

(J25405)

Drift

ST30613000

(J25742-3)

Drift

NT086

Removing rear oil seal

a: 250 mm (9.84 in)

b: 160 mm (6.30 in)

NT414

Installing mainshaft ball bearing

a: 77 mm (3.03 in) dia.

b: 55.5 mm (2.185 in) dia.

NT115

Installing main drive gear ball bearing

a: 71.5 mm (2.815 in) dia.

b: 47.5 mm (1.870 in) dia.

NT073

MT-4

PREPARATION

[FS5W71C]

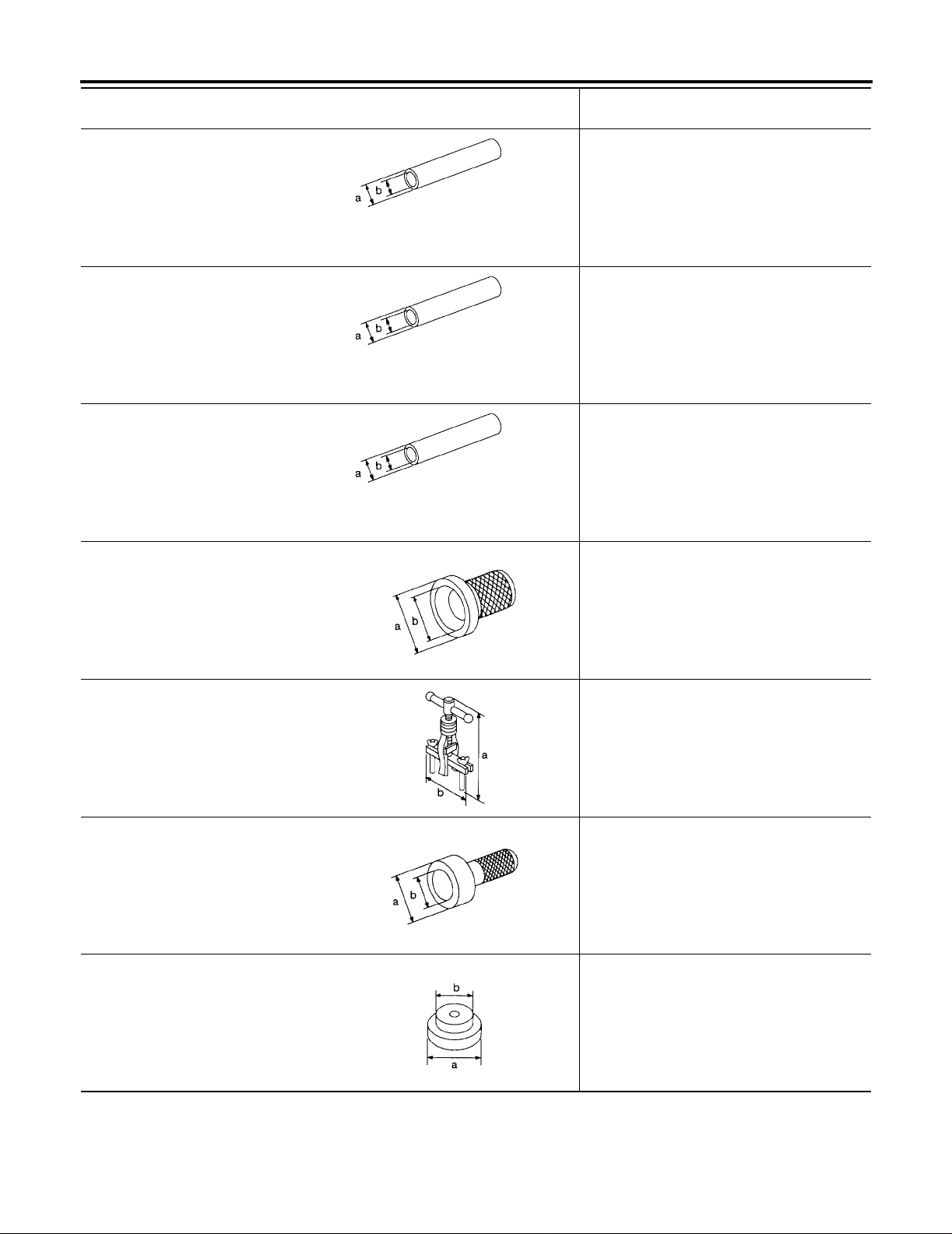

Tool number (Kent-Moore No.) Tool

name

ST33200000

(J26082)

Drift

(J-26349-A)

Bearing Remover and Installer Set

(J-34286)

Rear Race Puller

(J-39856)

Gear and Bearing Removal Kit

NT091

WMT065

WMT066

Description

Installing counter rear bearing and count er

gear assembly

a: 60 mm (2.36 in) dia.

b: 44.5 mm (1.752 in) dia.

Removing and installing mainsh af t bea ring

(Use with J-25726-B)

Removing races

Removing gears and bearings

A

B

MT

D

E

F

G

H

WMT067

Commercial Service Tools

Tool name Description

Puller Removing counter bearings, counter drive

and OD gears

NT077

Drift Installing countershaft rear end bearing

a: 40 mm (1.57 in) dia.

b: 30 mm (1.18 in) dia.

NT074

I

J

ECS006I3

K

L

M

MT-5

NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTING

[FS5W71C]

NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTING

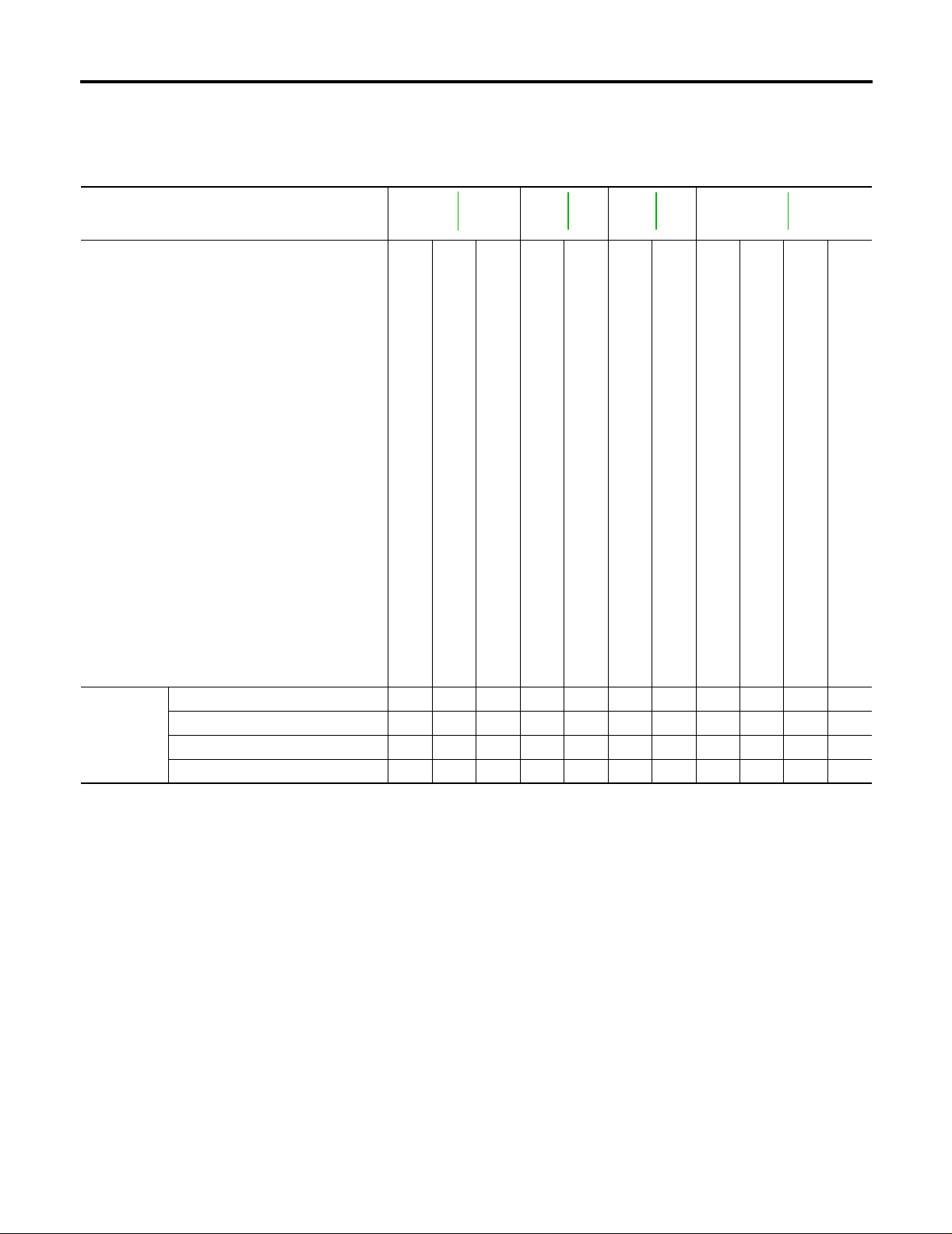

NVH Troubleshooting Chart

PFP:00003

ECS006I4

Use the chart below to help you find the cause of the symptom. The numbers indicate the order of the inspection. If necessary, repair or replace these part s.

Reference page

MA-35

SUSPECTED PARTS

(Possible cause)

MT-18

MT-22

MT-24

Symptom

OIL (Oil level is low .)

OIL (Wrong oil.)

OIL (Oil level is high.)

GASKET (Damaged)

OIL SEAL (Worn or damaged)

CHECK PLUG RETURN SPRING AND CHECK BALL (Worn or damaged)

SHIFT FORK (Worn)

GEAR (Worn or damaged)

BEARING (Worn or damaged)

BAULK RING (Worn or damaged)

Noise 1 2 3 3

Oil leakage 3 1 2 2

Hard to shift or will not shift 1 1 2 2

Jumps out of gear 1 2 2

INSERT SPRING (Damaged)

MT-6

DESCRIPTION

[FS5W71C]

DESCRIPTION PFP:00000

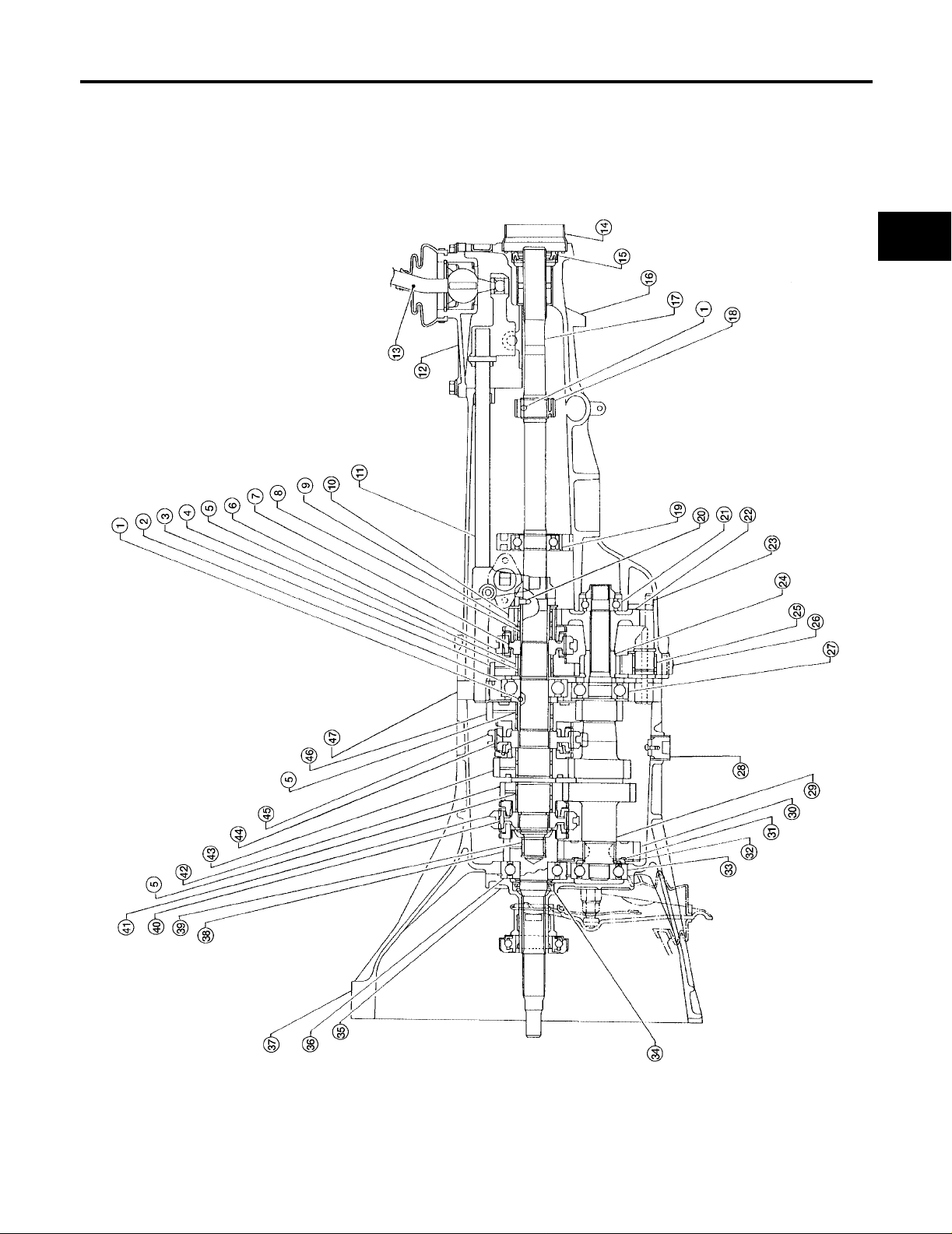

CROSS-SECTIONAL VIEW

ECS006I5

A

B

MT

D

E

F

G

H

K

M

I

J

L

MT-7

WCIA0175E

DESCRIPTION

[FS5W71C]

1. Steel ball 2. Mainshaft front bearing 3. Reverse main gear

4. Bushing 5. Needle bearing 6. OD & Reverse coupling sleeve

7. OD & Reverse synchronizer hub 8. OD gear bushing 9. Needle bearing

10. OD main gear 11. Striking rod 12. Control housing

13. Shift lever 14. Dust cover 15. Oil seal

16. Rear extension 17. Mainshaft 18. Speedometer drive gear

19. OD mainshaft bearing 20. Steel roller 21. Counter gear rear end bearing

22. OD counter gear 23. Reverse idler shaft 24. Reverse counter gear

25. Reverse idler gear bushing 26. Reverse idler gear 27. Counter gear rear bearing

28. Drain plug 29. Counter gear 30. Counter drive gear

31. Sub gear bracket 32. Sub gear 33. counter gear front bearing

34. Oil seal 35. Front cover 36. Main drive gear ball bearing

37. Transmission case 38. Main drive gear 39. Pilot bearing

40. 3rd & 4th synchronizer hub 41. 3rd & 4th coupling sleeve 42. 3rd main gear

43. 2nd main gear 44. 1st & 2nd synchronizer hub 45. 1st & 2nd coupling sleeve

46. 1st ma in gear 47. Adapter plate

MT-8

ON-VEHICLE SERVICE

[FS5W71C]

ON-VEHICLE SERVICE PFP:00000

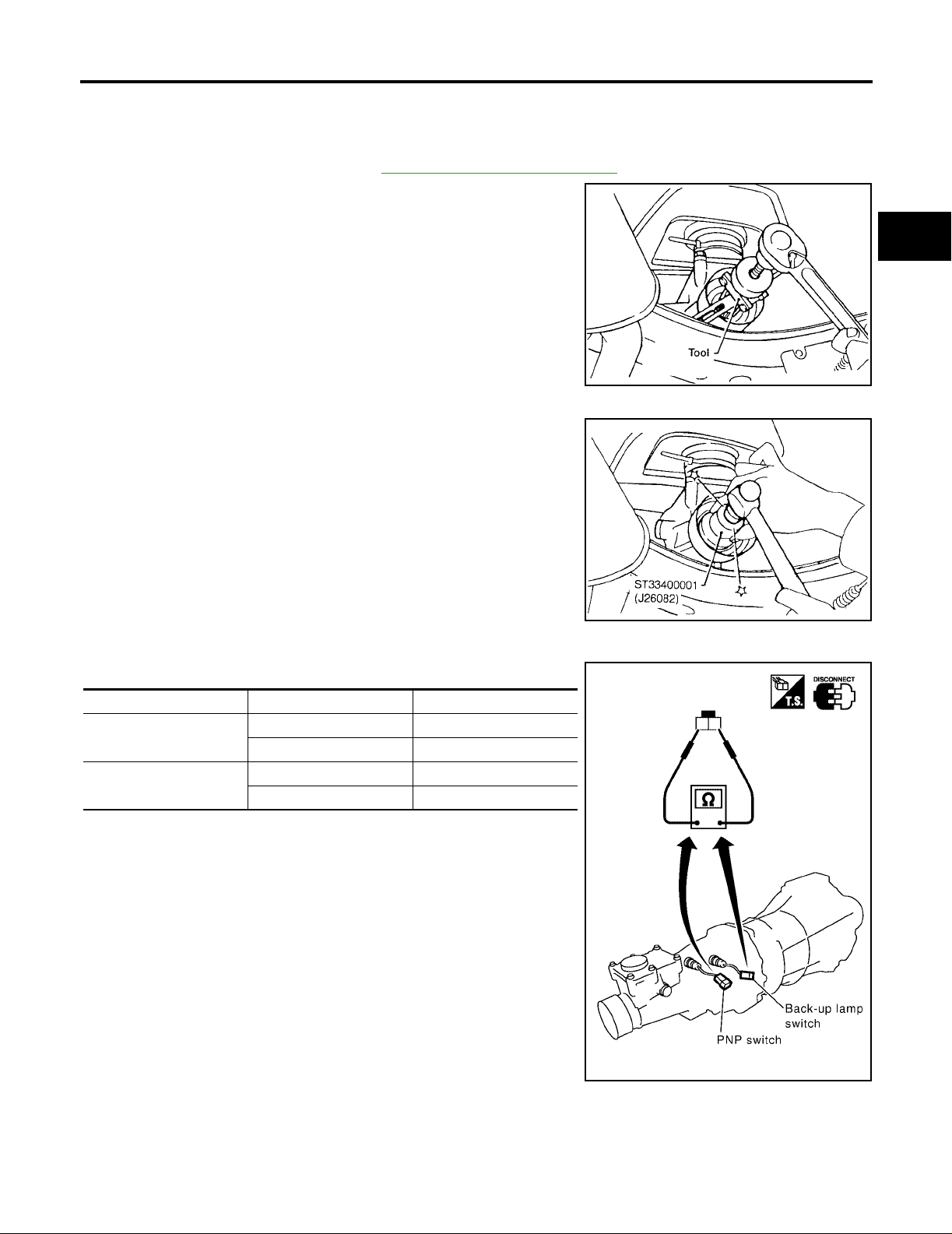

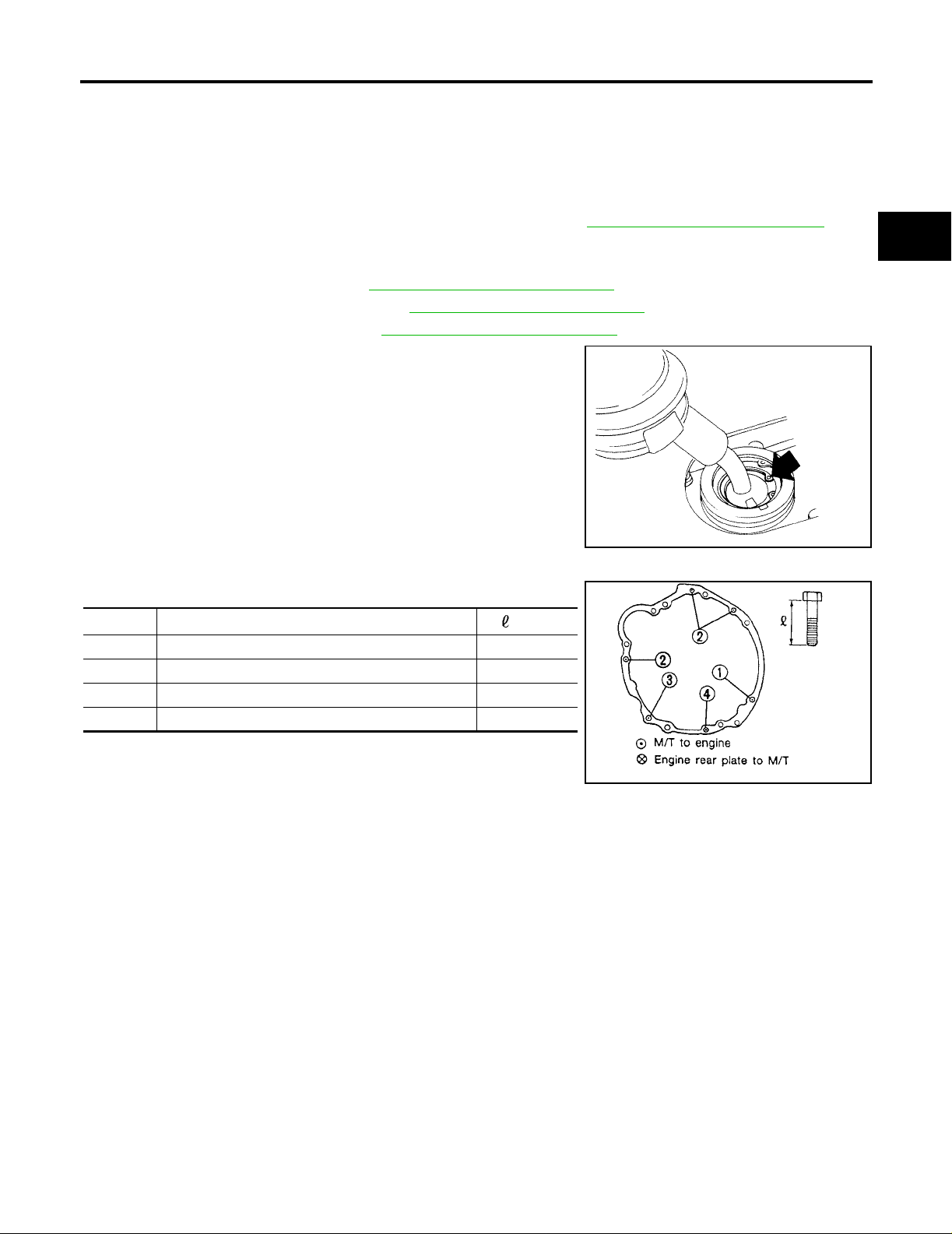

Replacing Rear Oil Seal

REMOVAL

1. Remove the propeller shaft. Refer to PR-8, "Removal an d Installation" .

2. Remove rear oil seal using Tool.

● Always replace with a new seal once it has been

removed.

Tool number : ST33290001 (J34286)

INSTALLATION

1. Install new rear oil seal using Tool until it stops.

● Apply multi-purpose grease to seal lip of oil seal before

installing.

Tool number : ST33400001 (J26082)

ECS006I6

WCIA0176E

A

B

MT

D

E

F

G

2. Installation is in the reverse order of removal.

Position Switch Check

● Check continuity.

Switch Gear position Continuity

Back-up lamp switch

Park/neutral position

(PNP) switch

Reverse Yes

Except reverse No

Neutral Yes

Except neutral No

SMT480CA

ECS006I7

H

I

J

K

L

M

MT-9

SMT981D

TRANSMISSION ASSEMBLY

[FS5W71C]

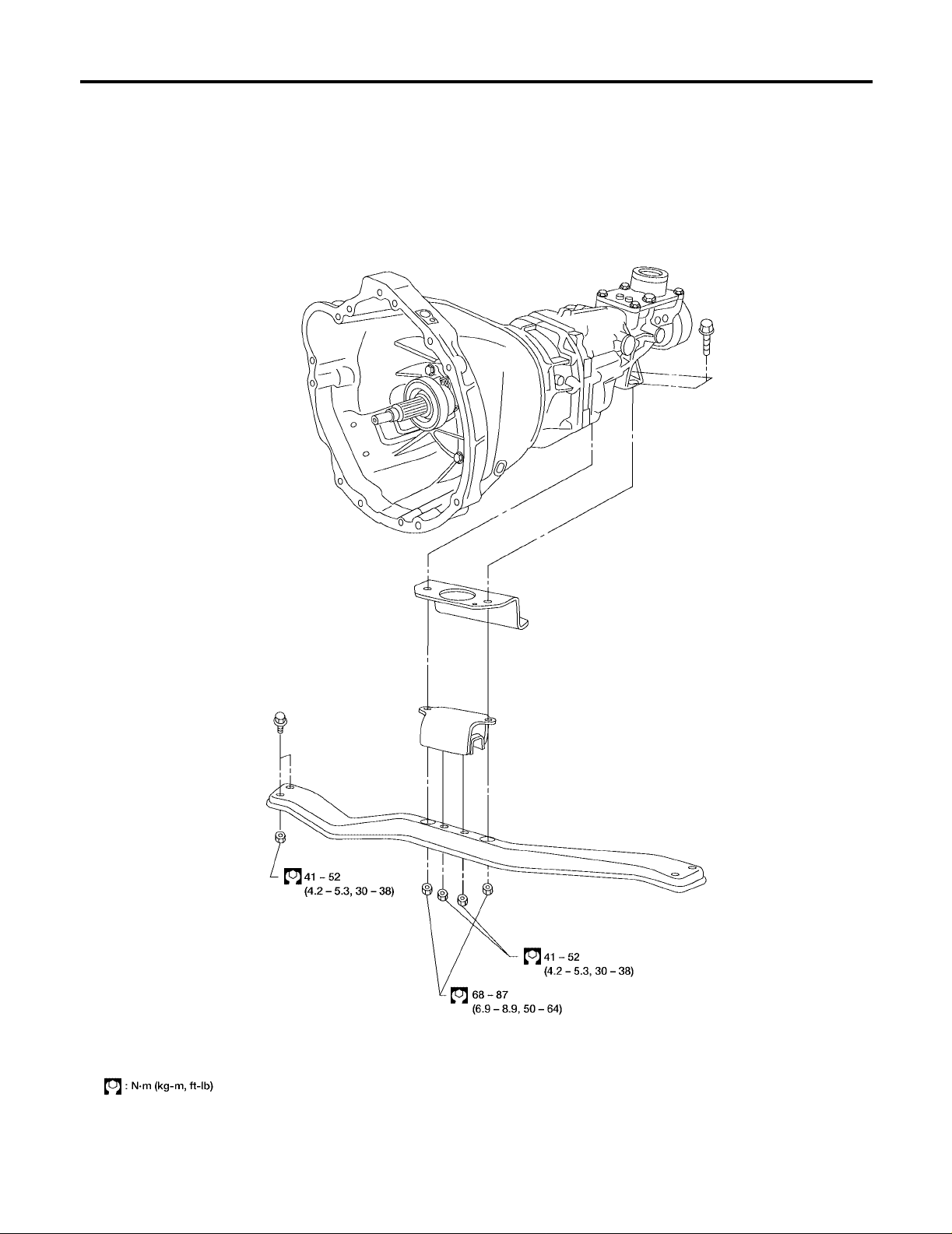

TRANSMISSION ASSEMBLY

Removal and Installation

REMOVAL

PFP:32010

ECS006I8

WMT030

CAUTION:

Before separating the transmission from the engine, remove the crankshaft position sensor (OBD)

from the transmission. Be careful not to damage sensor edge or ring gear teeth.

MT-10

TRANSMISSION ASSEMBLY

[FS5W71C]

NOTE:

To prevent oil s pills, drain transmission oil before remo ving transmission or insert plug into rear oil

seal after removing propeller shaft.

● Be careful not to damage spline, sleeve yoke, and rear oil seal when removing propeller shaft.

1. Remove battery negative terminal.

2. Remove the crankshaft position sensor (OBD) from transmission upper side.

3. Remove the clutch operating cylinder fr om transmission. Refer to CL-9, "

4. Disconnect the vehicle speed sensor, back-up switch, and park/neutral position (PNP) switch harness

connectors.

5. Remove the starter motor. Refer to SC-23, "

6. Disconnect the exhaust hanger. Refer to EX-3, "

7. Remove the propeller shaft. Refer to PR-8, "

Removal and Ins tallation" .

Removal and Installation" .

Removal and Installation" .

8. Remove the shift lever.

9. Support the engine by placing a jack under the oil pan.

● Do not plac e jack under oil pan drain plug.

10. Remove the transmission crossmember.

11. Separate the transmission from the engine.

WARNING:

Support manual transmission while removing it.

OPERATING CYLINDER" .

A

B

MT

D

E

F

G

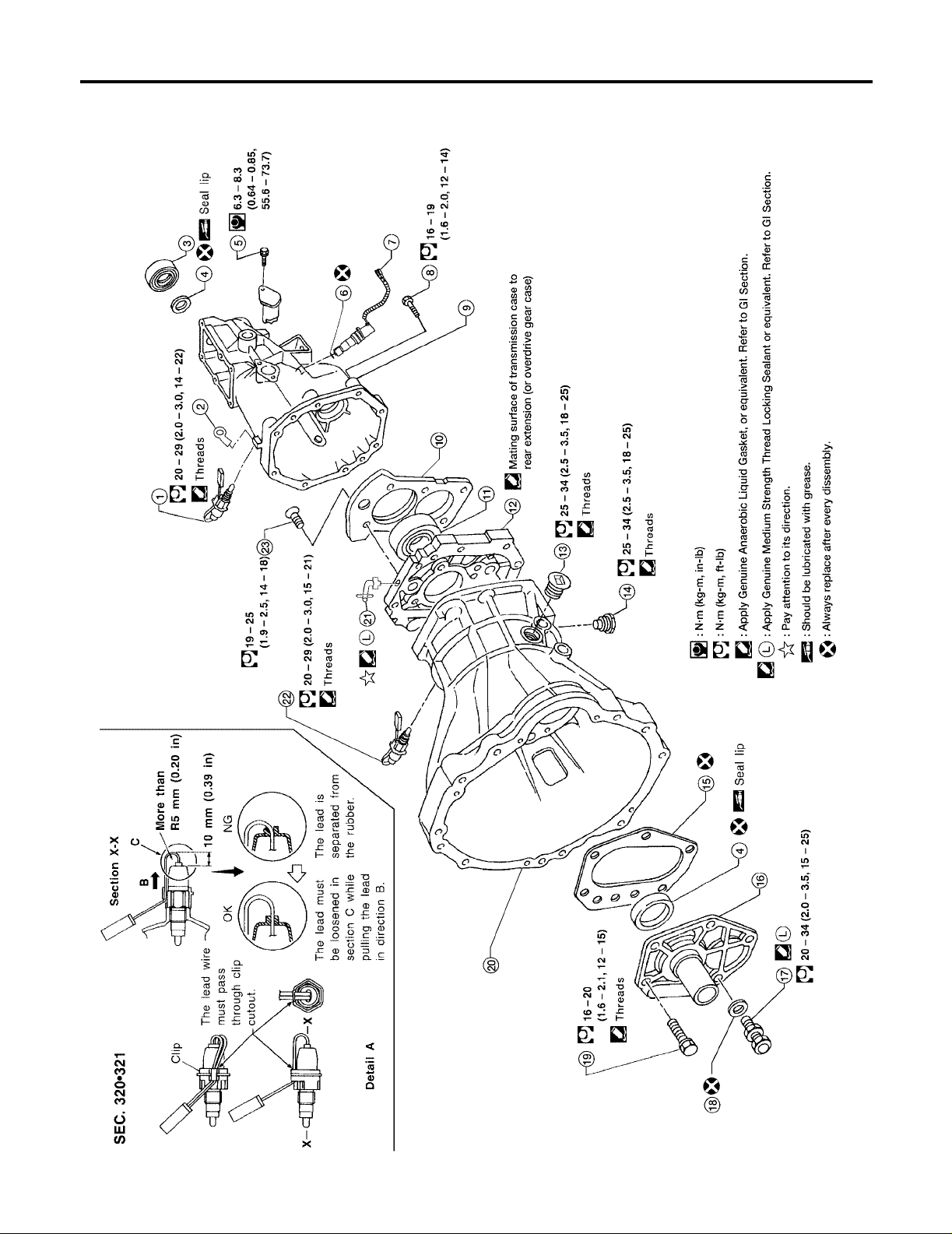

INSTALLATION

1. Tighten transmission bolts.

Bolt No. Tightening torque N·m (kg-m, ft-lb)

1 40 - 49 (4.0 - 5.0, 29 - 36) 65 (2.56)

2 40 - 49 (4.0 - 5.0, 29 - 36) 58 (2.28)

3* 16 - 21 (1.6 - 2.2, 12 - 15) 25 (0.98)

4 16 - 21 (1.6 - 2.2, 12 - 15) 16 (0.63)

*: With nut

2. Installation is in the reverse order of removal.

mm (in)

SMT099A

AMT190

H

I

J

K

L

M

MT-11

TRANSMISSION ASSEMBLY

[FS5W71C]

Overhaul

CASE COMPONENTS

ECS006I9

MT-12

WCIA0177E

TRANSMISSION ASSEMBLY

[FS5W71C]

1. Park/neutral position (PNP) switch 2. Clip 3. Dust cover

4. Oil Seal 5. Reverse check sleeve bolt 6. O-ring

7. Vehicle speed sensor 8. Rear extension bolts 9. Rear extension

10. Bearing retainer 11. Bearing 12. Adapter plate

13. Filler plug 14. Drain plug 15. Gasket

16. Front cover 17. Ball pin 18. Washer

19. Front cover bolt 20. Transmission case 21. Air breather

22. Back-up lamp switch

A

B

MT

D

E

F

G

H

K

M

I

J

L

MT-13

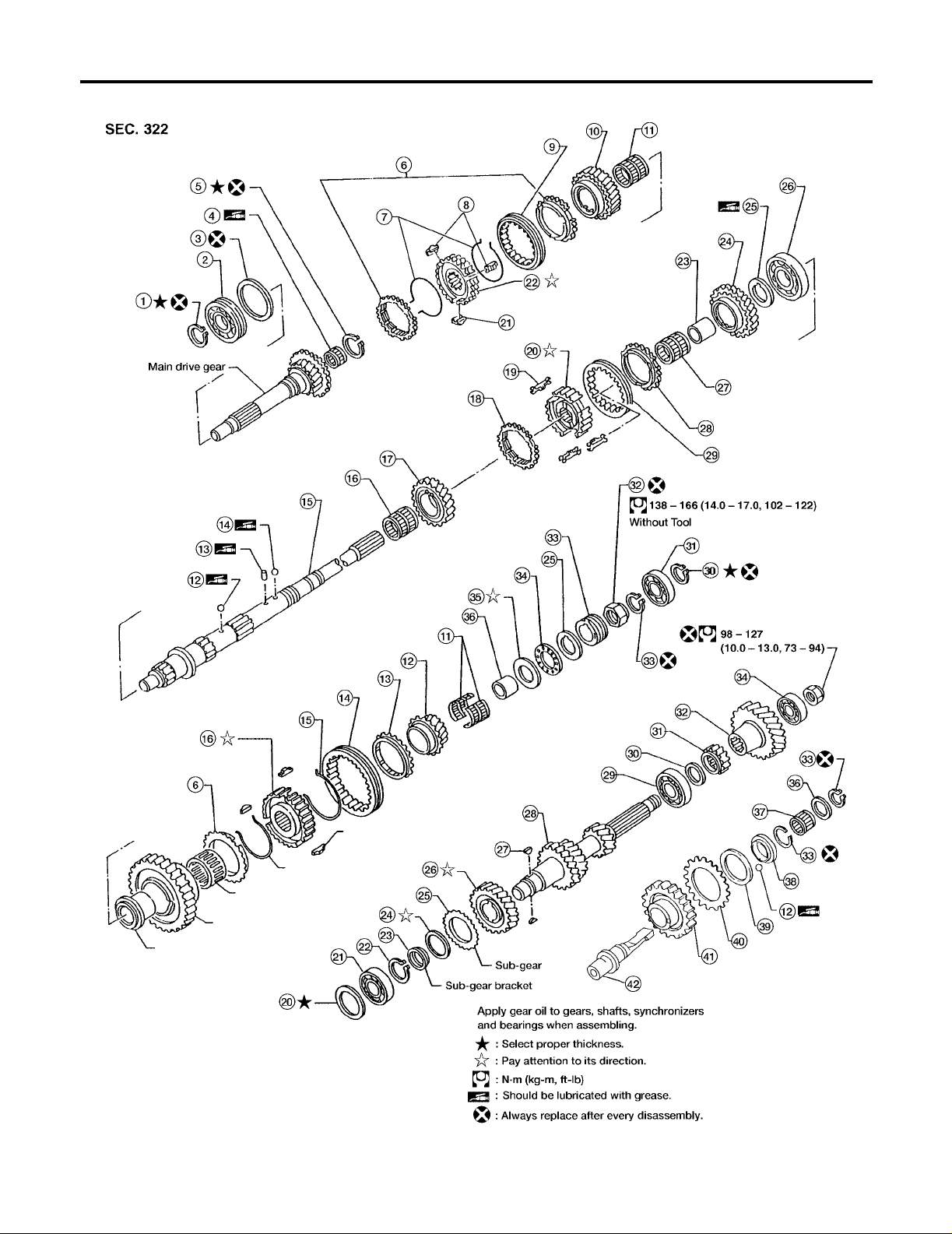

GEAR COMPONENTS

TRANSMISSION ASSEMBLY

[FS5W71C]

MT-14

WCIA0178E

TRANSMISSION ASSEMBLY

[FS5W71C]

1. Main drive gear ball bearing snap ring 2. Main drive gear ball bearing 3. Snap ring

4. Pilot bearing 5. Mainshaft front snap ring 6. Baulk ring

7. Spread spring 8. Shifting insert 9. 3rd and 4th coupling sleeve

10. 3rd main gear 11. Needle bearing 12. Steel ball

13. Steel roller 14. Steel ball 15. Mainshaft

16. 2nd main gear needle bearing 17. 2nd main gear 18. 2nd baulk ring

19. Insert spring 20. 1st and 2nd synchronizer hub 21. Shifting insert

22. 3rd and 4th synchronizer hub 23. 1st gear bushing 24. 1s t main gear

25. 1st gear thrust washer 26. Mainshaft ball bearing 27. N eedle bearing

28. Baulk ring 29. 1st and 2nd coupling sleeve 30. Overdrive mainshaf t be aring snap ring

31. O verdrive mainshaft bearing 32. Mainshaft lock nut 33. Speedometer drive gear

34. C ounter gear rear end bearing 35. Counter gear lock nut 36. Reverse idler thrust wa sher

37. Reverse idler gear bearing 38. Sub-gear bracket 39. Sub-gear spring

40. Sub-gear 41. Reverse idler gear 42. Reverse idler shaf t

A

B

MT

D

E

F

G

H

K

M

I

J

L

MT-15

TRANSMISSION ASSEMBLY

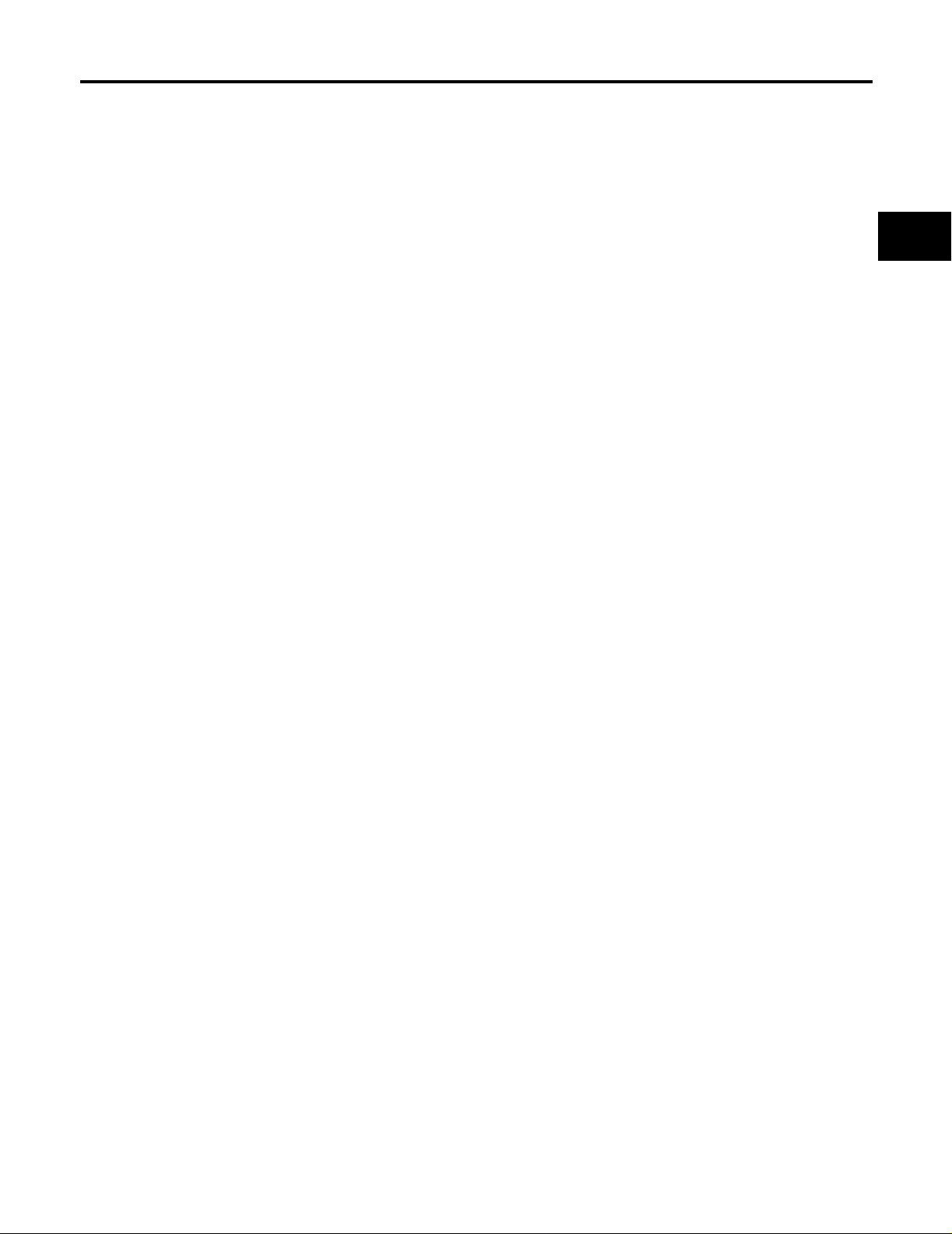

SHIFT CONTROL COMPONENTS

CAUTION:

To avoid damage when replacing shift knob, remove shift lever with knob, as assembled.

[FS5W71C]

1. Striking rod 2. Striking lever retaining pin 3. Select check plunger

4. Retainer pin 5. Return spring 6. Select check plug

7. Bushing 8. Check spring 9. Check ball

10. Striking arm 11. Striking lever 12. Check ball plug

MT-16

WCIA0179E

TRANSMISSION ASSEMBLY

13. Control housing bolt 14. Snap ring 15. Socket

16. Spring 17. Shi f t kno b 18. S hift lev er

19. Upper boot retainer 20. Boot 21. Lower boot retainer

22. Control housing 23. G asket 24. OD and reverse bracket

25. OD and reverse shift fork 26. OD and re verse fork rod 27. 3rd and 4th shift fork

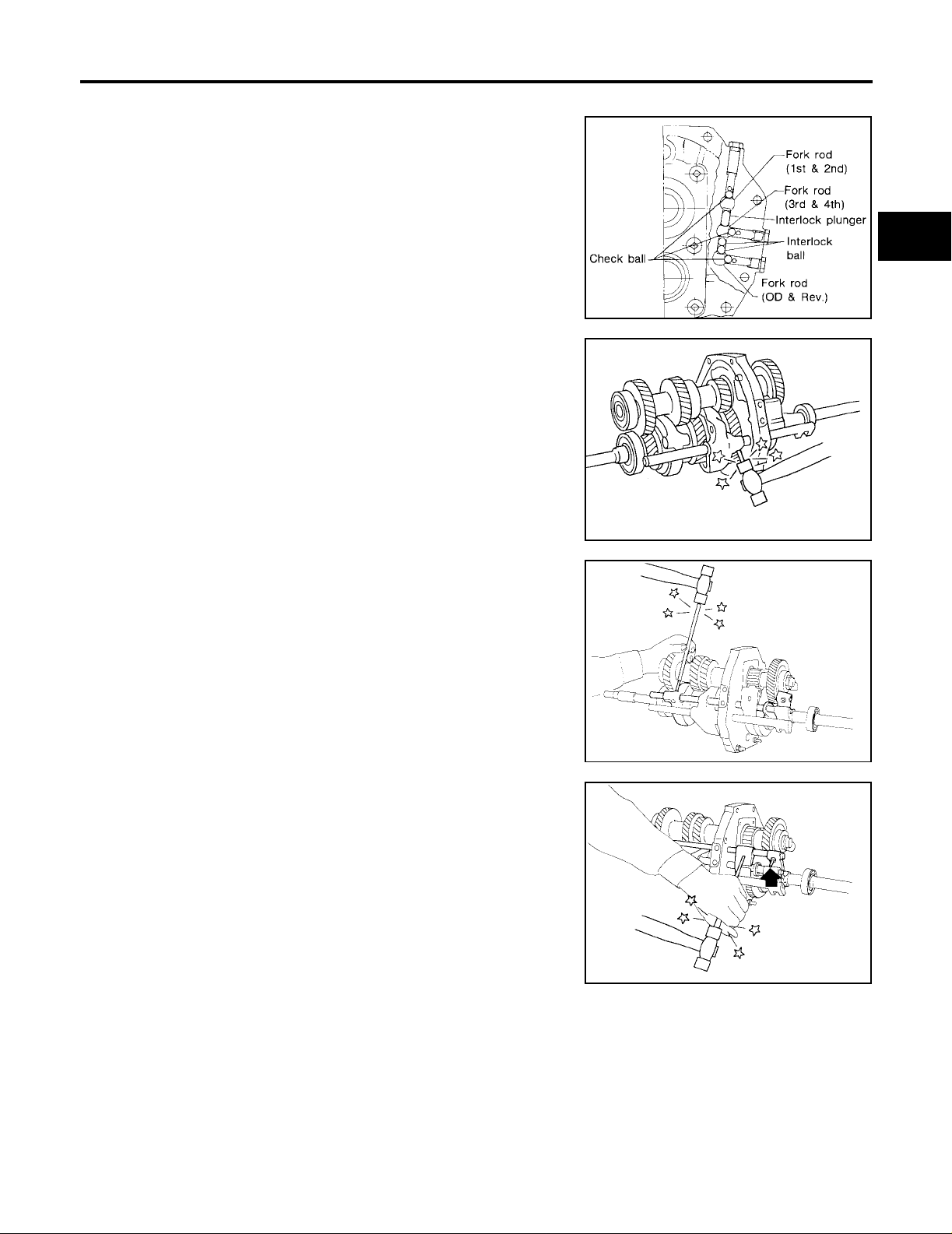

28. 3rd and 4th fork rod 29. I nt erlock plunger 30. 1st and 2nd shift fork

31. 1st and 2nd fork rod 32. Reverse check plug 33. Interlock ball

[FS5W71C]

A

B

MT

D

E

F

G

H

K

M

I

J

L

MT-17

CASE COMPONENTS

[FS5W71C]

CASE COMPONENTS

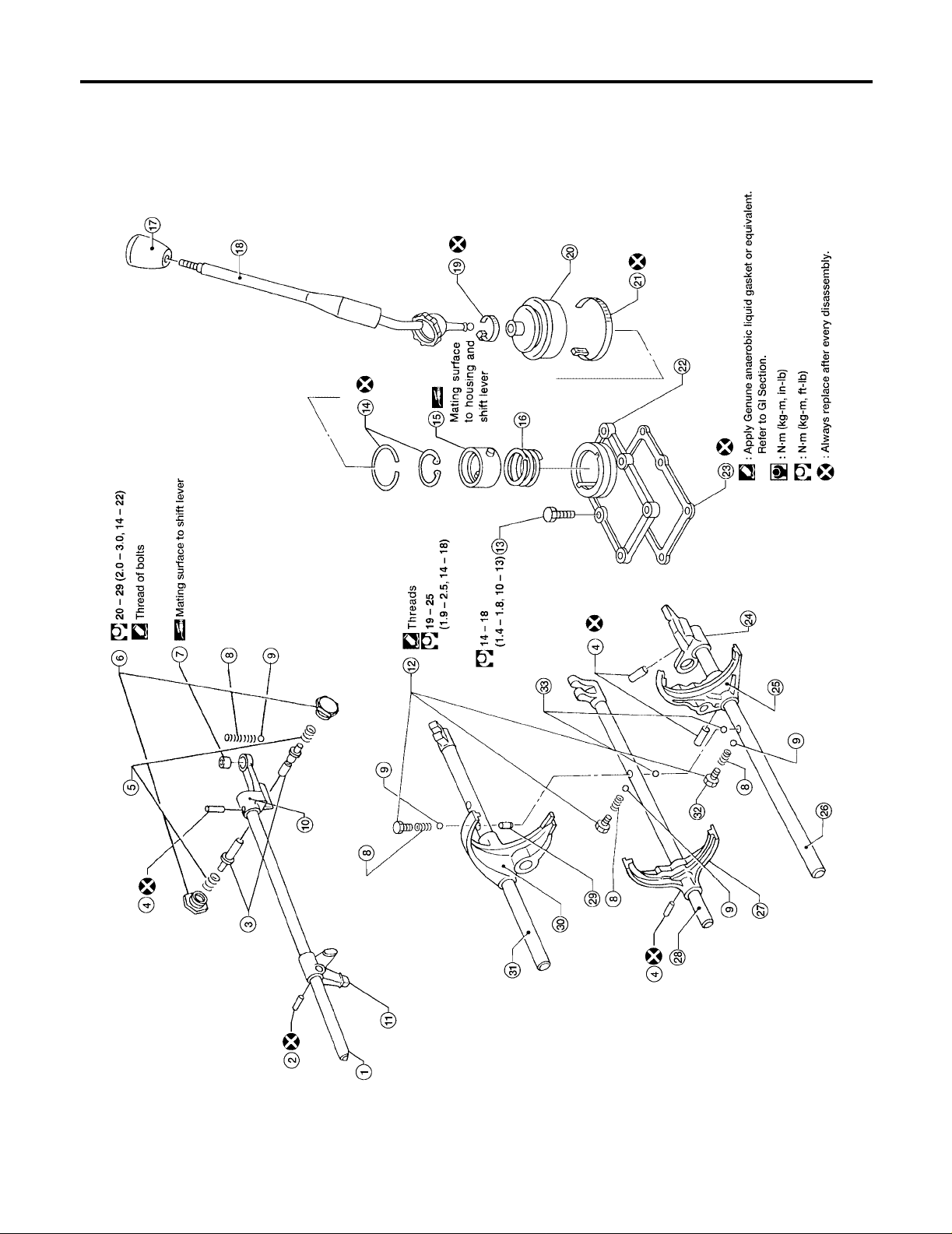

Disassembly

1. Remove rear extension.

a. Remove control housing, check spring, check ball, select check

plugs, return springs and select check plungers. Also remove

reverse check plug, check spring and check ba ll.

● Be careful not to lose check balls.

b. Drive out striking lever retaining pin.

c. Remove striking lever from striking rod.

d. Remove rear extension by lightly tapping on it.

PFP:32100

ECS006IA

WCIA0180E

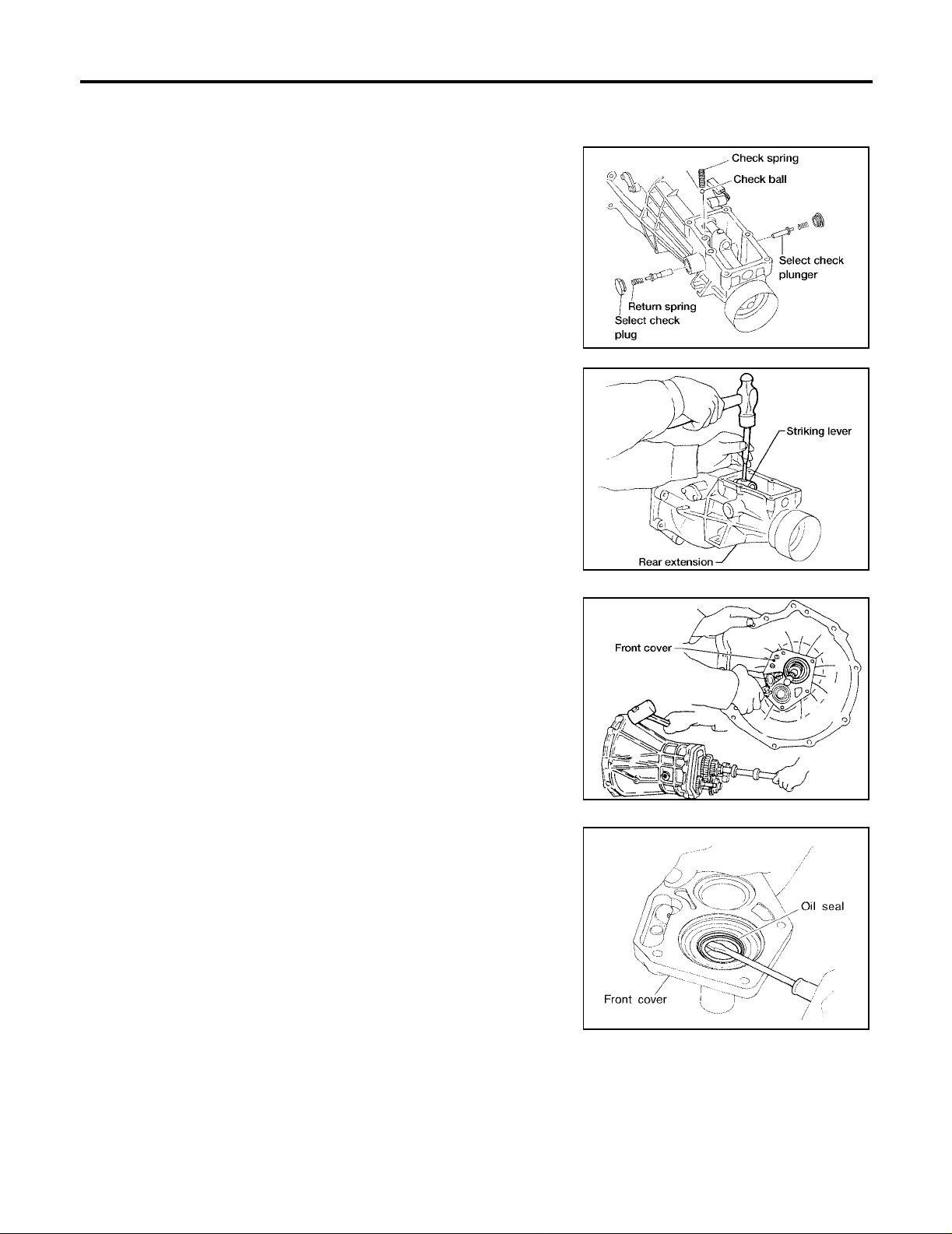

2. Remove front cover, gasket, counter gear front bearing shim

and main drive gear ball bearing snap ring.

3. Separate transmission case from adapter plate by lightly tapping

on it.

4. Remove oil seal from front cover using a screwdriver.

● Be careful not to damage mating surface of front cover.

AMT132

AMT131

MT-18

SMT166D

CASE COMPONENTS

[FS5W71C]

Assembly

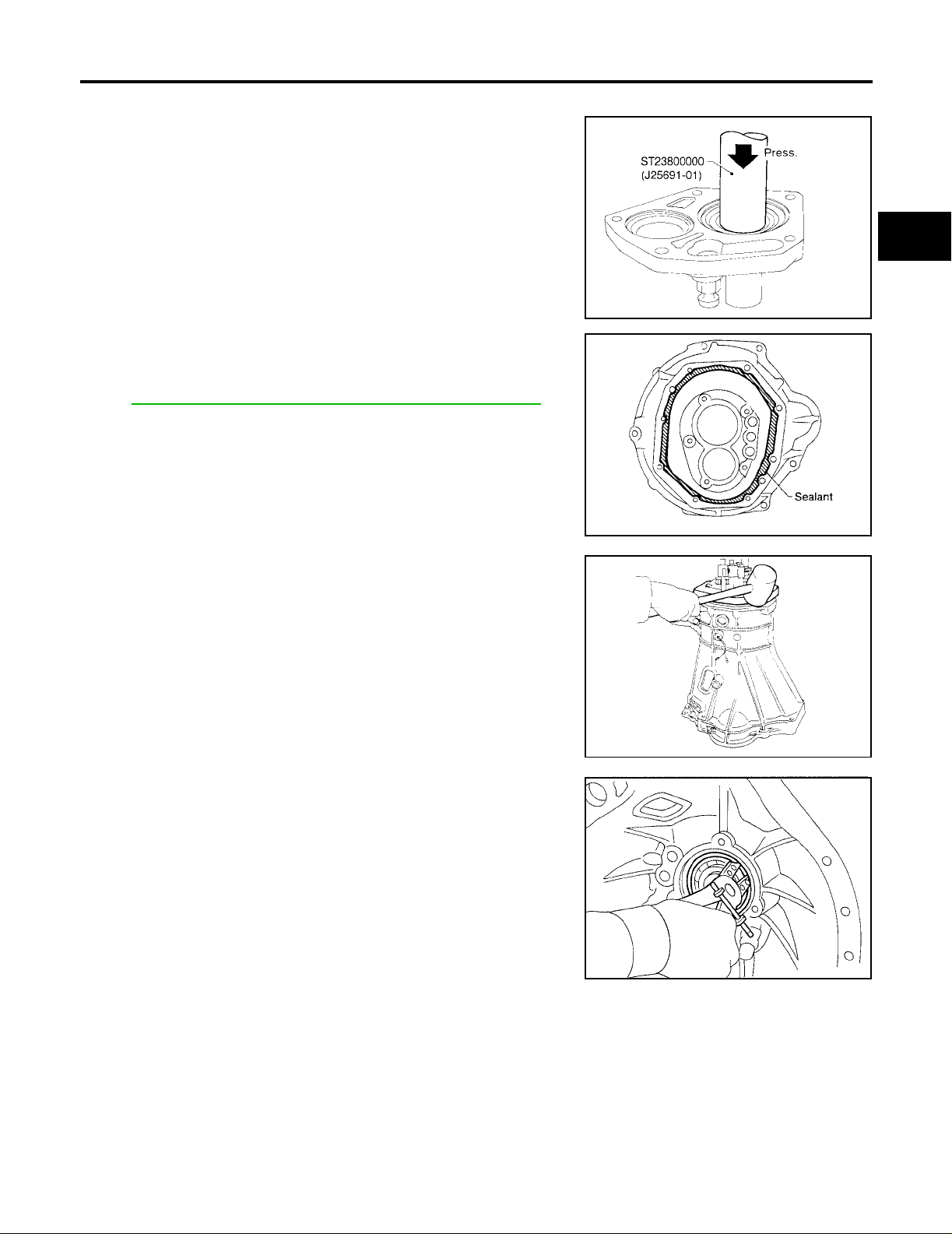

1. Install front cover oil seal using Tool.

● Apply multi-purpose grease to seal lip.

Tool number : ST23800000 (J25691-01)

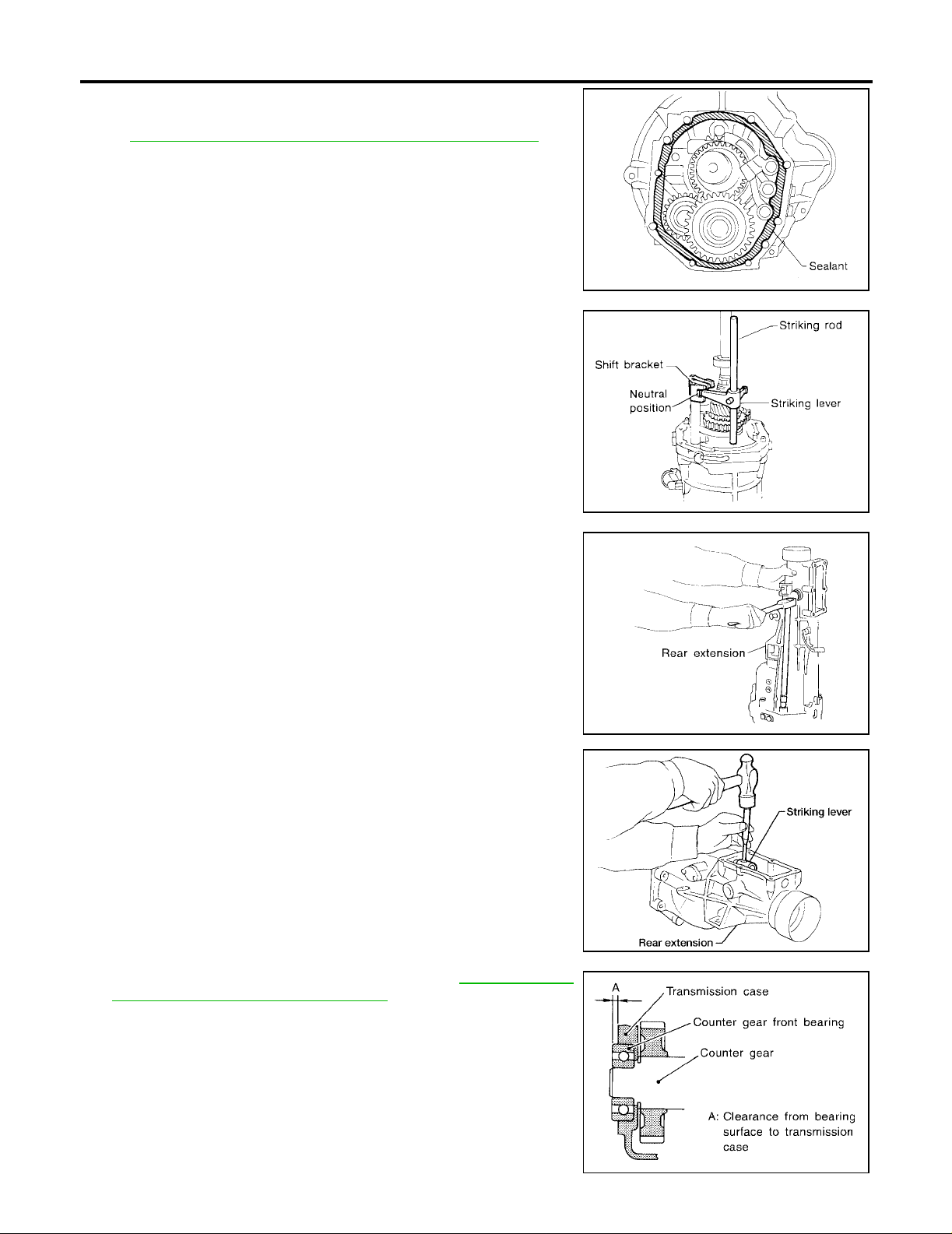

2. Apply sealant to mating surface of transmission case as shown

in the figure.

● Use Genuine Anae rob ic Li quid Gasket , or eq uiva lent. Refer to

MA-12, "

3. Install adapter plate into transmission case by lightly tapping it

using a soft hammer.

RECOMMENDED FLUIDS AND LUBRICANTS" .

ECS006IB

SMT036

SMT061C

A

B

MT

D

E

F

G

H

4. Install main drive gear ball bearing snap ring.

I

J

K

SMT013

L

M

SMT672A

MT-19

CASE COMPONENTS

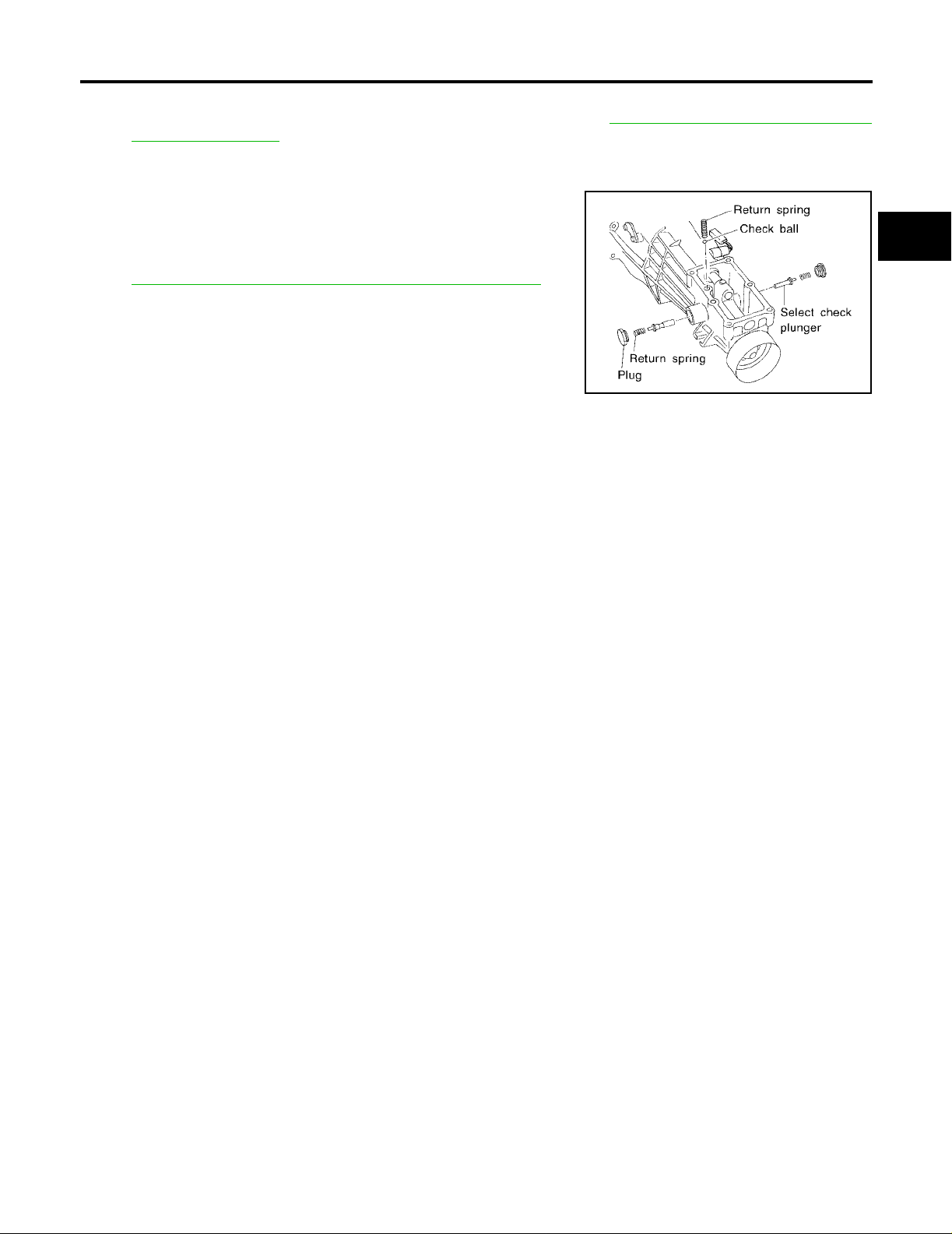

5. Apply sealant to mating surface of adapter plate as shown.

● Use Genuine Anaerobic Liquid Gasket, or equivalent. Refer to

MA-12, "

6. Place shif t forks in neutral position.

7. Install striking leve r and stri ki ng rod on to ad ap te r pla t e an d al ig n

striking lever with shift brackets.

RECOMMENDED FLUIDS AND LUBRICANTS" .

[FS5W71C]

SMT062C

8. Install rear extension.

● Tighten rear extension bolts equally in a crisscross pattern.

Rear extension bolts : 16 - 19 N·m (1.6 - 2.0 kg-m,

12 - 14 ft-lb)

9. Install striking lever retaining pin.

SMT801B

SMT180D

AMT132

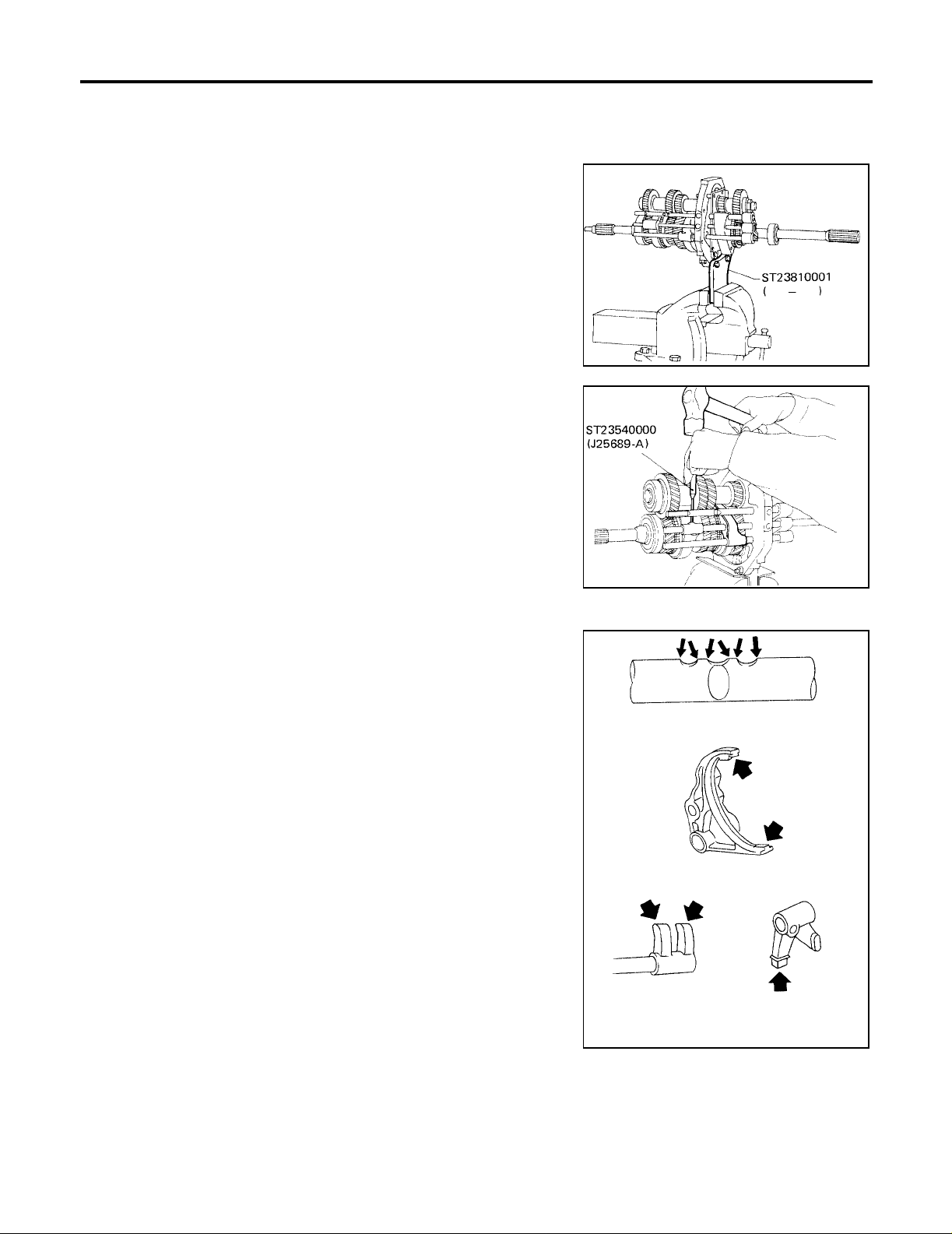

10. Select counter gear front bearing shim. Refer to MT-37, "

TERSHAFT FRONT BEARING SHIM" .

Allowable clear ance (A)

: 0 - 0.16 mm (0 - 0.0063 in)

from bearing su rface to

transmission case

11. Install new gasket and front cover.

MT-20

COUN-

SMT205D

CASE COMPONENTS

[FS5W71C]

12. Apply sealant to front cove r bolts. Tighten front cover bolts.

● Use Genuine Anaerobic Liquid Gasket, or equivalent. Refer to MA-12, "RECOMMENDED FLUIDS

AND LUBRICANTS" .

A

Front cover bolts : 16 - 20 N·m (1.6 - 2.1 kg-m, 12 - 15 ft-lb)

13. Install check ball, check spring, select check plungers and return

springs.

14. Apply sealant to select ch ec k plu gs . Tighten se le ct ch ec k pl ugs.

● Use Genuine Anae rob ic Li quid Gasket , or eq uiva lent. Refer to

MA-12, "

Select check

plugs

RECOMMENDED FLUIDS AND LUBRICANTS" .

: 20 - 29 N·m (2.0 - 3.0 kg-m,

14 - 22 ft-lb)

15. In s tall control housing and new gasket.

Control housing

bolts

: 14 - 18 N·m (1.4 - 1.8 kg-m,

10 - 13 ft-lb)

B

MT

D

E

SMT161D

F

G

H

I

K

M

J

L

MT-21

SHIFT CONTROL COMPONENTS

[FS5W71C]

SHIFT CONTROL COMPONENTS

Disassembly

1. Set up Tool on adapter plate.

Tool number : ST23810001 ( — )

2. Remove striking rod from adapter pl ate.

3. Remove check ball plugs, check springs, and check balls.

NOTE:

Mark locations of interlock balls to ensure proper installation.

4. Drive out retaining pins. Then drive out fork rods and remove

interlock balls.

PFP:32982

ECS006IC

SMT545A

Inspection

● Check contact and sliding surfaces of fork rods for wear,

scratches, projecti on s an d ot h er dama ge.

SMT984

ECS006ID

MT-22

SMT075C

SHIFT CONTROL COMPONENTS

[FS5W71C]

Assembly

1. Install fork rods, interlock plunger, interlock balls and check

balls.

2. Install 1st and 2nd shift fork, then drive in retaining pin.

3. Install 3rd and 4th shift fork, then drive in retaining pin.

ECS006IE

SMT992-A

SMT989

A

B

MT

D

E

F

G

H

4. Install overdrive and reverse shift fork, then drive in retaining

pin.

I

J

K

SMT990

L

M

SMT991

MT-23

GEAR COMPONENTS

[FS5W71C]

GEAR COMPONENTS

Disassembly

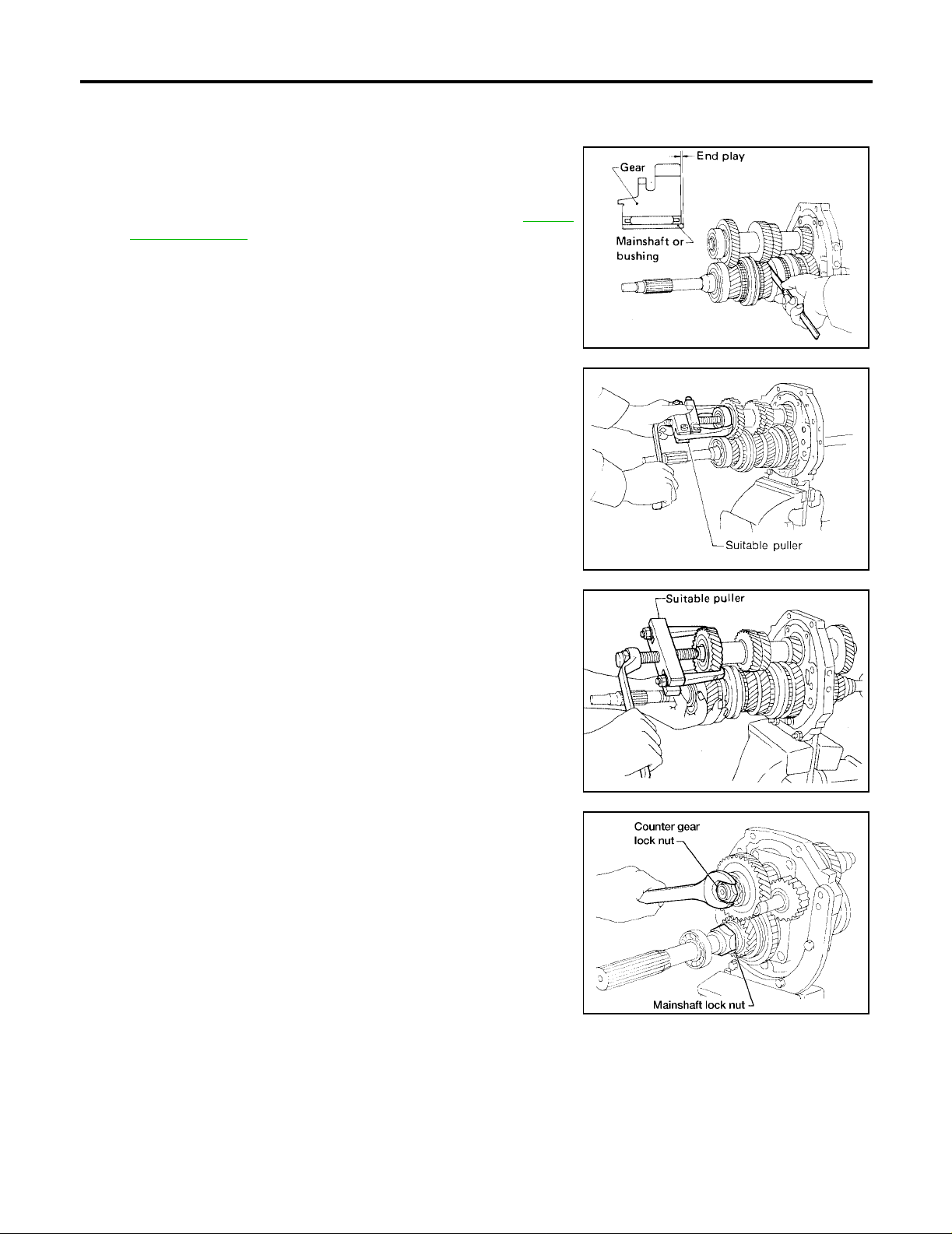

1. Before disassembly, measure the end play of each gear.

● If end play is no t within the specified limit, d isassemble and

inspect the parts.

● Replace any part whic h is worn or da maged. R efer to MT-35,

"Gear End Play" .

2. Mesh 2nd and reverse gear, then remove counter gear front

bearing using a suitable puller.

3. Remove counter gear s nap rin g, then r emove s ub-ge ar brac ket,

sub-gear spring and sub-gear.

PFP:31460

ECS006IF

SMT025

4. Remove counter drive gear together with main drive gear

assembly using a suitable puller. Remove woodruff keys and

pilot bearing.

● When removing main drive gear assembly, be careful not to

drop pilot bear ing or baulk ring.

5. Remove mainshaft front snap ring, then remove 3rd and 4th

synchronizer assembly, 3rd main gear and needle bearing using

suitable puller.

6. Disassemble parts at rear of ad apter plate as follows:

a. Release staking o n both counter gear and main shaft lock nuts,

then loosen both nuts.

Mainshaft lock nut : Left-hand thread

SMT174A

SMT162A

WCIA0181E

MT-24

GEAR COMPONENTS

[FS5W71C]

b. Remove overdrive counter gear together with counter gear rear

end bearing using a suitable puller.

c. Remove reverse counter ge ar an d reve rs e co un ter ge ar spacer.

d. Remove snap rings from reverse idler shaft, then remove

reverse idler gear, sub-gear, sub-gear spring, sub-gear bracket,

steel ball, reverse idler thrust washer and reverse idler gear

bearing.

SMT547A

e. Remove overdrive mainshaft bearing snap ring and pull out overdrive mainshaft bearing using Tool, then

remove snap ring.

A

B

MT

D

Tool number : (J-26349-A), (J-25726-B)

f. Remove mainshaft lock nut.

g. Remove speedometer drive gear and steel ball.

h. Remove thrust w asher, steel roller, roller bearing and washer.

i. Remove overdrive main gear, needle bearing and overdrive baulk ring.

j. Remove counter gear by tapping on rear end of counter gear.

k. Press out overdrive gear bushing and overdrive & reverse synchronizer assembly.

l. Remove reverse main gear and needle bearing.

m. Press out reverse main gear bushing.

n. Remove mainshaft by tapping on rear end of mainshaft.

7. Remove 1st gear thrust washer, steel ball, 1st main gear and

needle bearing and 1st and 2nd synchronizer assembly.

● Be careful not to lose steel ball.

SMT554A

E

F

G

H

I

J

K

L

M

MT-25

SMT383A

GEAR COMPONENTS

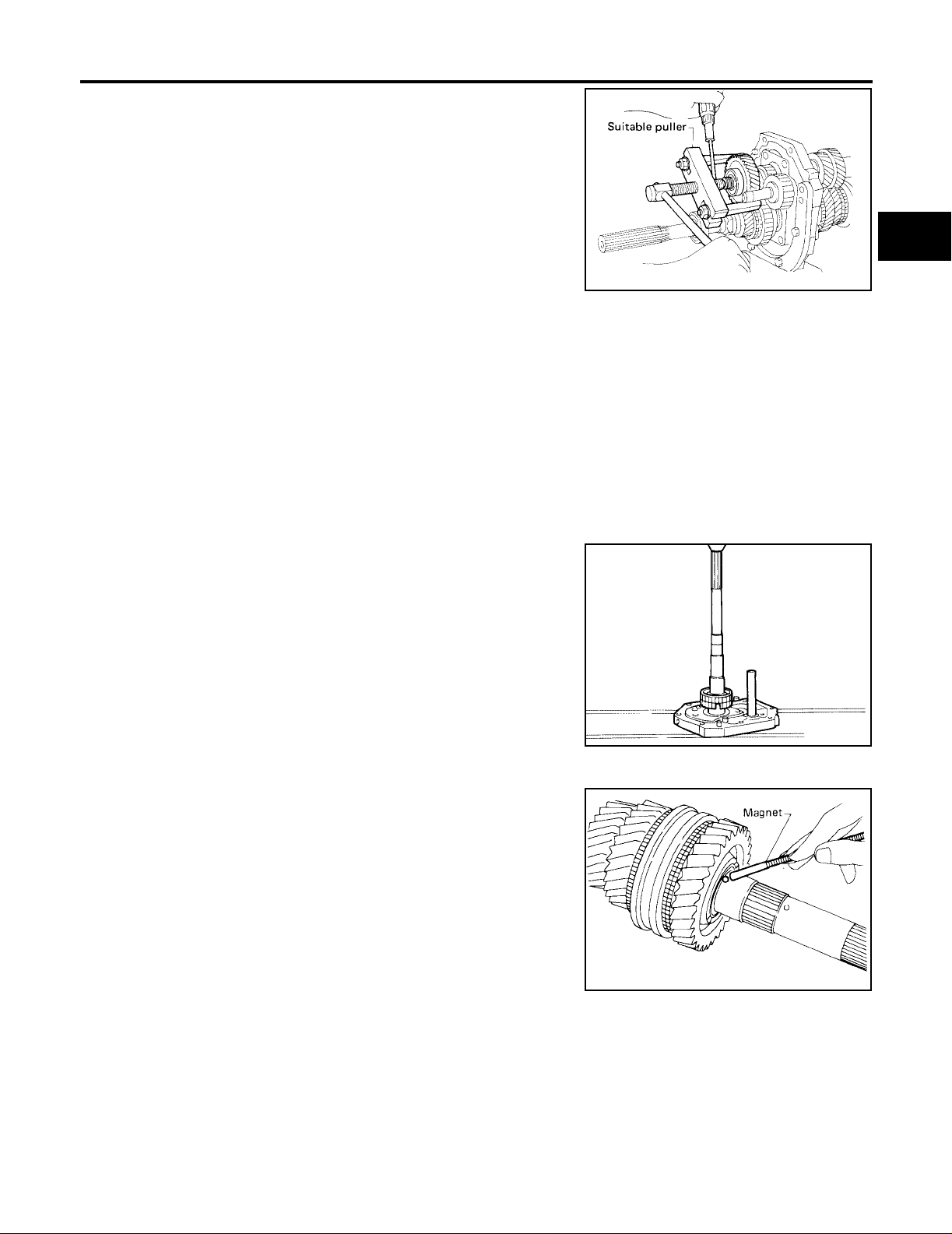

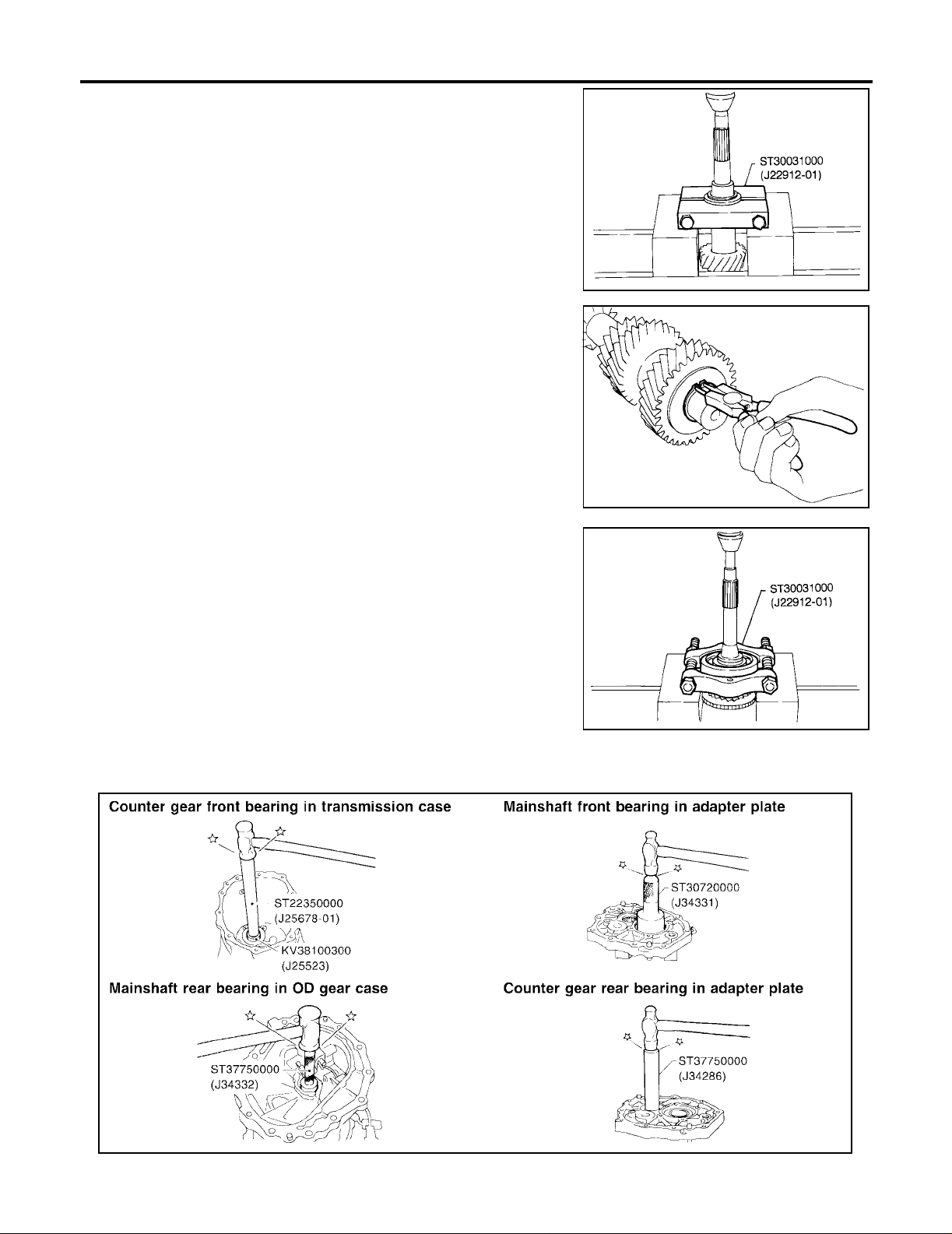

8. Press out 1st gear bushing together with 2nd main gear using

Tool.

Tool number : ST30031000 (J22912-01)

9. Remove 2nd gear needle bearing.

10. Remove main drive gear ball bearing.

a. Remove main drive gear ball bearing snap ring.

b. Remove main drive gear ball bearing using Tool.

Tool number : ST30031000 (J22912-01)

11. Disassemble adapter plate components.

a. Remove bearing retainer.

b. Remove oil gutter

c. Remove reverse idler shaft.

d. Remove main shaft ball bearing and counter rear be aring using

suitable tool.

[FS5W71C]

TM049A

SMT420A

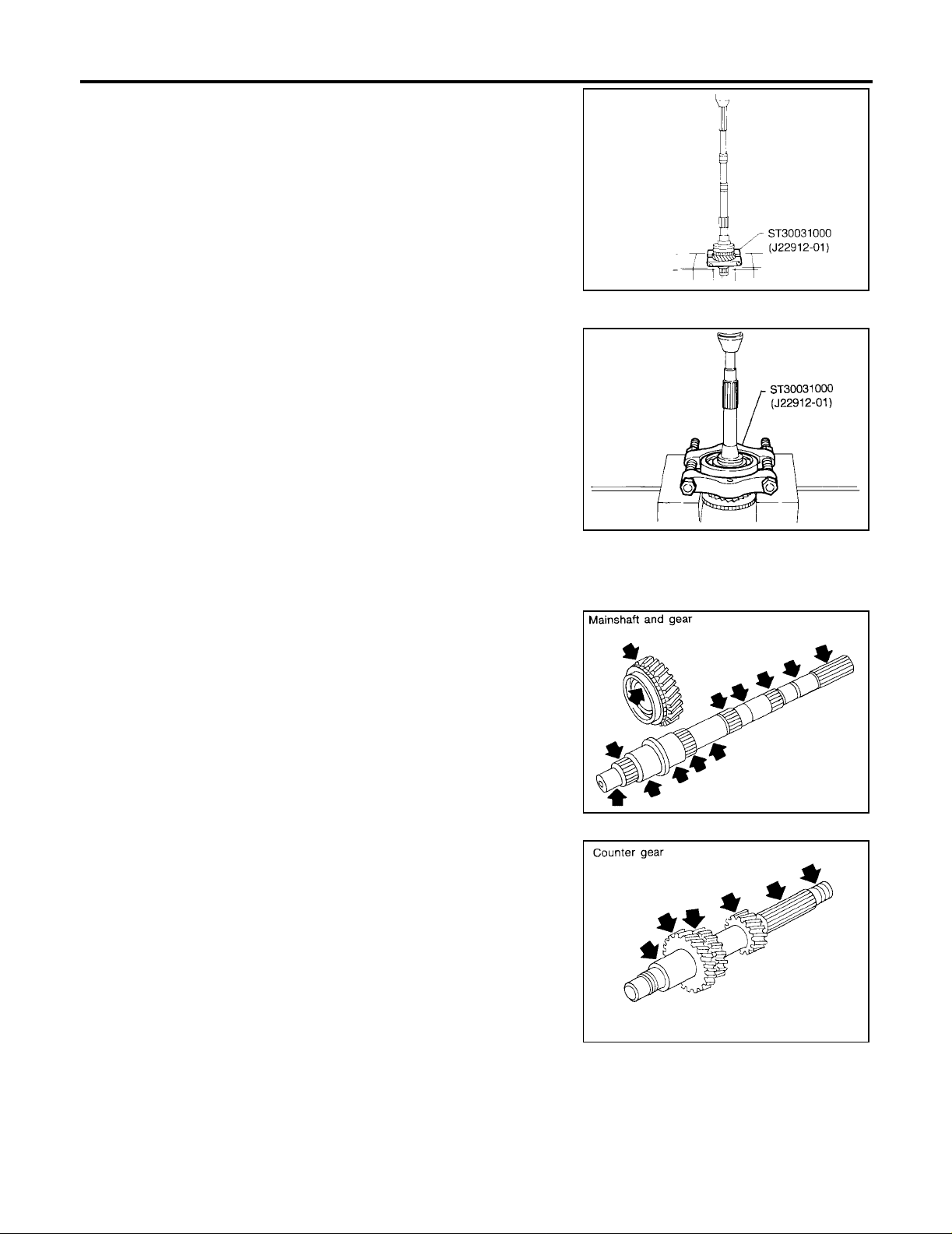

Inspection

GEARS AND SHAFTS

● Check shafts for cracks, wear and bending.

● Check gears for excessive wear, chips and cracks .

ECS006IG

SMT386A

MT-26

SMT550A

GEAR COMPONENTS

SYNCHRONIZERS

● Check spline portion of coupling sleeves, synchronizer hubs,

and gears for wear, chips, and cracks.

● Check baulk ring s for cracks and deformatio n.

● Check shifting inserts for wear and deformation.

[FS5W71C]

A

B

MT

● Check insert spread springs for deformation.

● Measure baulk ring wear.

1. Measure clearance between baulk ring and gear. Refer to MT-

36, "Clearance Between Baulk Ring and Gear" .

● If the clearance is less than the wear limit, replace baulk ring.

BEARINGS

● Make sure all bearings roll freely and are free from noise,

cracks, pitting or wear.

SMT427C

SMT140

D

E

F

G

H

I

J

K

Assembly

1. Install bearings into case components.

Tool numbers

Mainshaft ball bearing : ST30720000 (J25405)

Counter rea r bearing : ST33200000 (J26082)

MT-27

AMT185

SMT418A

ECS006IH

L

M

GEAR COMPONENTS

2. Assemble adapter plate parts.

a. Install oil gutter on adapter plate and expand on rear side.

b. Insert reverse idler shaft, then install bearing retainer.

c. Tighten bearing retainer screws, then stake each one at two

points.

Bearing retainer screws : 19 - 25 (1.9 - 2.5 kg-m,

14 - 18 lb-ft)

[FS5W71C]

SMT778C

3. Instal l main drive gear ball bear ing.

a. Press main drive gear ball bearing using Tool.

Tool number : ST30613000 (J25742-3)

b. Select and install proper main drive ball bearing gear snap ring

to achieve proper clearance of groove. Refer to MT-36 , "

MAIN

DRIVE GEAR BALL BEARING SNAP RING" .

Main drive ball bearing

: 0 - 0.13 mm (0 - 0.0051 in)

gear snap ring groove

allowable clearance

SMT674C

SMT425A

SMT170D

4. Assemble synchronizers.

● Assemble the 1s t and 2nd synchronizer.

SMT054C

MT-28

GEAR COMPONENTS

● Check coupling sleeve and synchronizer hub orientation.

[FS5W71C]

A

B

MT

D

E

F

● Assemble the 3rd and 4th synchronizer.

SMT206C

G

H

I

J

K

L

M

WMT053

MT-29

GEAR COMPONENTS

● Assemble the o verdrive and reverse sync hronizer.

[FS5W71C]

5. Assemble front side components to mainshaft.

a. Instal l 2nd mai n gea r, 2nd main gear n eedle be ari ng an d 1st and

2nd synchronizer assembly; then press 1st gear bushing onto

the mainshaft.

b. Install 1st main gear.

c. Install steel ball and 1st gear thrust washer.

● Before installation, apply multi-purpose grease to steel ball

and to both sides of the 1st gear thrust washer.

SMT207CA

SMT752A

TM358

6. Install mainshaft and counter gear on adapter plate and main

drive gear on mainshaft as follows:

a. Press mainshaft assembly into adapter plate using Tool.

Tool number : KV31100401 ( — )

MT-30

TM439

GEAR COMPONENTS

[FS5W71C]

b. Press coun te r gear in to adapter plate using Tool.

Tool number : ST33200000 (J26082), KV31100401 ( — )

SMT750

c. Install 3rd main gear and needle bearing, then press 3rd and 4th synchronizer assembly onto mainshaft.

● Pay attention to the direction of 3rd and 4th synchronizer.

d. Install mainshaft front snap ring.

Select proper fr ont main shaft sna p ring to achiev e prope r clearance of groove. Refer to MT-36, "

RING" .

Mainshaft front snap

ring groove allowable

clearance

e. Apply ge ar oil to mainshaft pilot be aring and install it on main -

shaft.

MAINSHAFT FRONT SNAP

: 0 - 0.13 mm (0 - 0.0051 in)

TM441

A

B

MT

D

E

F

G

H

f. Press counter drive gear together with main drive gear using

Tool.

● Pay attention to the direction of counter drive gear.

Tool numbers : ST23860000 ( — ), KV31100401 ( — )

g. Install sub-gear and sub-gear bracket on counter drive gear and

then select proper counter gear snap ring that will minimize

clearance of groove in counter gear.

● Do not install sub-gear spring at this time. Refer to MT-36,

"COUNTER DRIVE GEAR SNAP RING" .

Counter gear snap ring

: 0 - 0.13 mm (0 - 0.0051 in)

groove allowable clearance

I

J

K

SMT412C

L

M

SMT201D

MT-31

GEAR COMPONENTS

h. Remove snap ring, sub-gear bracket and sub-gear from counter

gear.

i. Reinstall sub-gear, sub-gear spring, sub-gear bracket and

selected counter gear snap ring.

j. Press counter gear front bearing onto counter gear using Tool.

Tool number : ST22360002 (J25679-01),

KV31100401 ( — )

[FS5W71C]

SMT202D

7. Install rear side comp onents on mainshaft and cou nter gear as

follows:

a. Install sub-gear, sub-gear spring, sub-gear bracket, steel ball

and snap ring on the reverse idler gear.

b. Install reverse idler gear assemb ly, reverse idler thrus t washer,

snap ring and reverse idler gear bearing on the reverse idler

shaft.

c. Install reverse main gear bushing, ne ed le beari ng, reve rse mai n

gear and overdrive and reverse synchronizer to mainshaft.

● Pay attention to the direction of synchronizer hub.

TM443

AMT134

MT-32

SMT207CA

GEAR COMPONENTS

d. Install ov erdrive gear bushing to mainshaft using Tool.

Tool number : ST22350000 (J25678-01)

e. Install overdrive main gear and needle bearing to mainshaft.

f. Install reverse counter gear spacer, reverse counter gear and

overdrive counter gear to counter gear.

● OD main gear a nd OD counter ge ar should be h andled as a

matched set.

g. Install washer, roller bearing, steel roller and thrust washer.

h. Install steel ball and speedometer drive gear.

i. Tighten mainshaft lock nut temporarily.

● Always use new mainshaft lock nut.

[FS5W71C]

SMT531

A

B

MT

D

j. Install counter gear rear end bearing using Tool.

Tool number : ST2236002 (J25679-01)

8. Mesh 2nd and reverse gears, then tighten mainshaft lock nut

using Tool.

● Always use new mainshaft lock nut.

Mainshaft lock nut : 138 - 166 N·m (14.0 - 17.0 kg-m,

102 - 122 ft-lb)

Tool number : ST22520000 (J26348)

● Use the chart shown to determine the proper reading torque.

(Length of torque wrench vs. setting or reading torque)

Reference: F ormul a to co nvert tor que wren ch ind icat ion to the

true torque value:

T = (0.1 m (0.33 ft) + L) /L × C

If the specified torque is T kg-m (ft-lb), the torque wrench

scale indication C is determined using the following for m ula.

C = (T × L)/(0.1 m (0.33 ft) + L)

SMT043

SMT003A

E

F

G

H

I

J

K

L

M

MT-33

SMT004A

GEAR COMPONENTS

9. Tighten counter gear lock nut.

● Always use new lock nut.

Counter gear lock nut : 98 - 127 N·m (10.0 - 13.0 kg-m,

73 - 94 ft-lb)

10. Stake mainshaft lock nut and counter gear lock nut using a

punch.

11. Measure the end play of each gear.

12. Install sna p ri ng an d pres s on OD m ains haft bearin g us ing Tool,

then install snap ring. Refer to MT-37, "

ING SNAP RING" .

OD mainshaft bear-

: 0 - 0.14 mm (0 - 0.0055 in)

ing snap ring

groove allowable

clearance

OD MAINSHAFT BEAR-

[FS5W71C]

WCIA0182E

Tool number : (J-26349-A), (J-25726-B)

SMT025

MT-34

SERVICE DATA AND SPECIFICATIONS (SDS)

[FS5W71C]

SERVICE DATA AND SPECIFICATIONS (SDS) PFP:00030

General Specifications

ECS006II

A

Applied model

Transmission FS5W71C

Number of speed 5

Shift pattern

MT-SDS-2

Synchromesh type Warner

1st 3.592

2nd 2.246

Gear ratio

Mainshaft

(Number of teeth)

Countershaft gear

(Number of teeth)

Reverse idler gear (Number of teeth) 21

Oil capacity

(US pt, Imp pt)

Remarks

3rd 1.415

4th 1.000

OD 0.821

Reverse 3.657

Drive 21

1st 33

2nd 28

3rd 26

OD 21

Reverse 36

Drive 32

1st 14

2nd 19

3rd 28

OD 39

Reverse 15

Reverse synchronizer Installed

Sub gear Counter drive gear and reverse idler gear

KA24DE

2WD

2.0 (4-1/ 4, 3-1/2)

B

MT

D

E

F

G

H

I

J

K

L

M

Gear End Play

1st gear 0.31 - 0.41 (0.0122 - 0.0161)

2nd gear 0.11 - 0.21 (0.0044 - 0.0083)

3rd gear 0.11 - 0.21 (0.0044 - 0.0083)

Overdrive gear 0.24 - 0.41 (0.0095 - 0.0161)

MT-35

ECS006IJ

Unit: mm (in)

SERVICE DATA AND SPECIFICATIONS (SDS)

[FS5W71C]

Clearance Between Baulk Ring and Gear

1st & 2nd 1.20 - 1.60 (0.0473 - 0.0629)

Standard

Wear limit

2ND & 3RD BAULK RING

3rd & main drive 1.20 - 1.60 (0.0473 - 0.0629)

Overdrive 1.20 - 1.60 (0.0473 - 0.0629)

Reverse 1.10 - 1.55 (0.0433 - 0.0610)

1st & 2nd 0.80 (0.0315)

3rd & main drive 0.80 (0.0315)

Overdrive 0.80 (0.0315)

Reverse 0.70 (0.0276)

ECS006IK

Unit: mm (in)

Unit: mm (in)

SMT733C

Dimension Standard Wear limit

A 0.7 - 0.9 (0.028 - 0.035)

B 0.6 - 1.1(0.024 - 0.043)

Available Snap Rings

MAIN DRIVE GEAR BALL BEARING SNAP RING

Main drive gear ball bearing snap ring groove all ow abl e clear ance 0 - 0.13 (0 - 0.0051)

Thickness Part number*

1.87 (0.0736) 32204-78001

1.94 (0.0764) 32204-78002

2.01 (0.0791) 32204-78003

*Always check with the Parts Department for the latest parts information.

MAINSHAFT FRONT SNAP RING

Mainshaft front snap ring groove allowabl e cl ear anc e 0 - 0.18 (0 - 0.0071)

Thickness Part number*

2.4 (0.094) 32263-V5200

2.5 (0.098) 32263-V5201

*Always check with the Parts Department for the latest parts information.

0.2 (0.008)

ECS006IL

Unit: mm (in)

Unit: mm (in)

COUNTER DRIVE GEAR SNAP RING

Counter gear snap ring groove allowable cl ear ance 0 - 0.13 (0 - 0.0051)

Thickness Part number*

1.4 (0.055) 32215-E9000

MT-36

Unit: mm (in)

SERVICE DATA AND SPECIFICATIONS (SDS)

[FS5W71C]

1.5 (0.059) 32215-E9001

1.6 (0.063) 32215-E9002

*Always check with the Parts Department for the late st parts information.

OD MAINSHAFT BEARING SNAP RING

OD mainshaft bearing snap ring groove allow able cl ear ance 0 - 0.14 (0 - 0.0055)

Thickness Part number*

1.1 (0.043) 32228-20100

1.2 (0.047) 32228-20101

1.3 (0.051) 32228-20102

1.4 (0.055) 32228-20103

*Always check with the Parts Department for the late st parts information.

Available Shims

COUNTERSHAFT FRONT BEARING SHIM

Allowable clearance “A” from bearing surfa ce to transm i ssi on case 0 - 0.16 (0 - 0.0063)

Unit: mm (in)

ECS006IM

Unit: mm (in)

A

B

MT

D

E

F

G

H

“A” Thickness of shim Part number*

4.52 - 4.71 (0.1780 - 0.1854) Not necessary

4.42 - 4.51 (0.1741 - 0.1775) 0.1 (0.004) 32218-V5000

4.32 - 4.41 (0.1701 - 0.1736) 0.2 (0.008) 32218-V5001

4.22 - 4.31 (0.1662 - 0.1691) 0.3 (0.012) 32218-V5002

4.12 - 4.21 (0.1622 - 0.1657) 0.4 (0.016) 32218-V5003

4.02 - 4.11 (0.1583 - 0.1618) 0.5 (0.020) 32218 -V50 04

3.92 - 4.01 (0.1544 - 0.1578) 0.6 (0.024) 32218-V5005

*Always check with the Parts Department for the late st parts information.

SMT205D

I

J

K

L

M

MT-37

PREPARATION

[FS5R30A]

PREPARATION

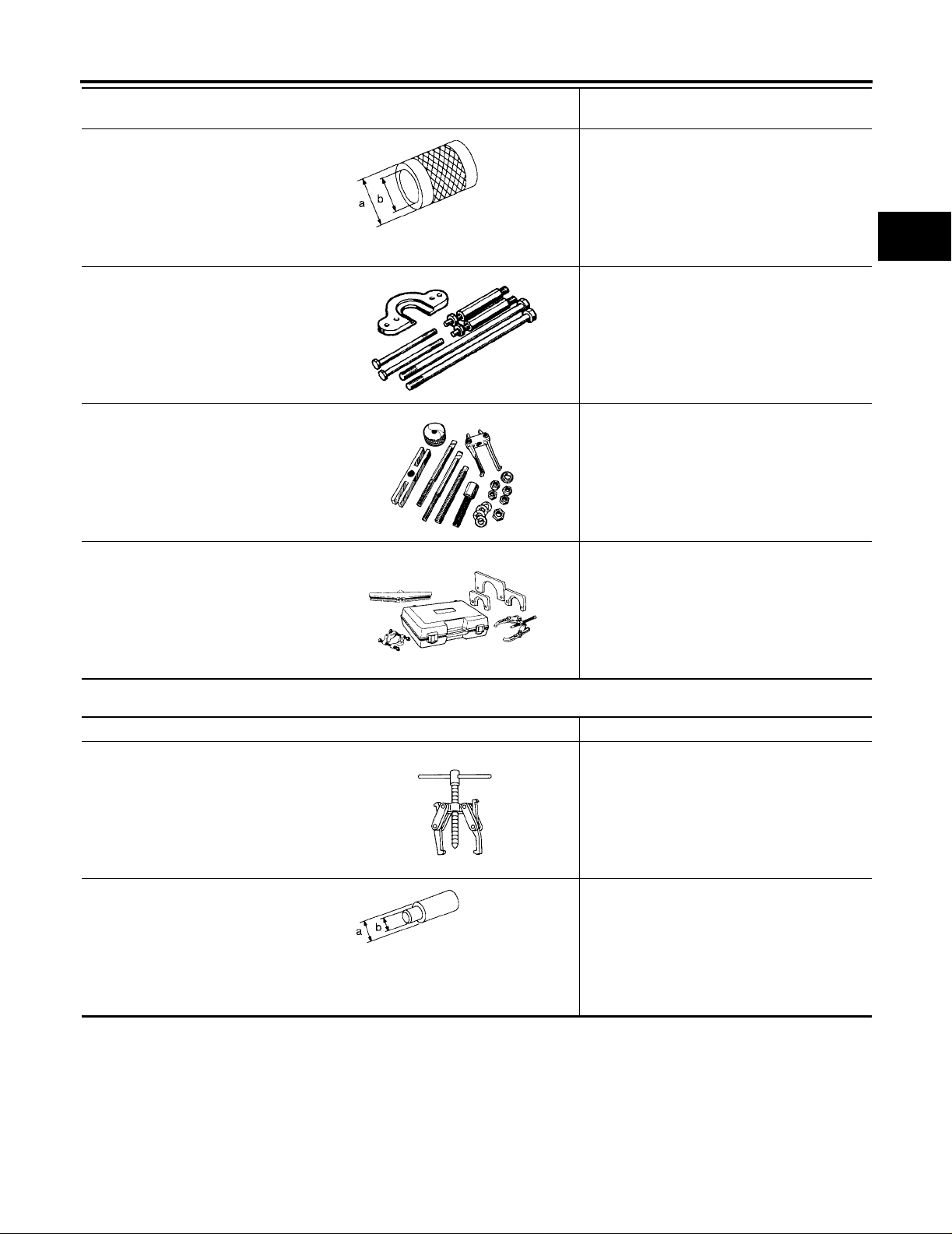

Special Service Tools

The actual shapes of Kent-Moore tools may differ from those of spe ci al se rvice tools illustrated here.

Tool number

(Kent-Moore No.)

Tool name

ST23540000

(J25689-A)

Pin punch

NT442

ST30031000

(J22912-01)

Puller

NT411

ST33290001

(J34286)

Puller

Description

Removing and installing retaining pin

a: 2.3 mm (0.091 in) dia.

b: 4 mm (0.16 in) dia.

Removing 1st & 2nd synchronizer assembly

Removing counter gear rear thrust bearing

Removing main drive bearing

Inspecting baulk ring wear

a: 90 mm (3.54 in) dia.

b: 50 mm (1.97 in) dia.

Removing rear oil seal

a: 250 mm (9.84 in)

b: 160 mm (6.30 in)

PFP:00002

ECS006IN

ST33230000

( — )

Drift

ST22350000

(J25678-01)

Drift

KV38100300

(J25523)

Drift

ST30720000

1 (J34286)

2 (J34331)

Drift

NT414

Removing mainshaft and counter gear

a: 51 mm (2.01 in) dia.

b: 28.5 mm (1.122 in) dia.

NT084

Removing counter gear front bearing (Use

with KV38100300)

a: 34 mm (1.34 in) dia.

b: 28 mm (1.10 in) dia.

NT065

Removing counter gear front bearing (Use

with ST22350000)

Installing counter gear rear bearing

a: 54 mm (2.13 in) dia.

b: 32 mm (1.26 in) dia.

NT065

1 Removing mainshaft front bearing

2 Installing mainshaft front bearing

a: 77 mm (3.03 in) dia.

b: 55.5 mm (2.185 in) dia.

MT-38

NT115

PREPARATION

[FS5R30A]

Tool number

(Kent-Moore No.)

Tool name

ST33210000

1 (J25523)

2 (J25803-01)

Drift

ST30613000

(J25742-3)

Drift

ST37750000

1 (J34286)

2 (J34332)

3 (J34334)

4 (J25679-01)

Drift

ST22452000

(J34337)

Drift

NT084

NT073

NT065

Description

1 Installing counter gear front bearing

2 Installing front cover oil seal

a: 44 mm (1.73 in) dia.

b: 24.5 mm (0.965 in) dia.

Installing main drive gear bearing

a: 72 mm (2.83 in) dia.

b: 48 mm (1.89 in) dia.

1 Removing counter gear rear bearing

2 Installing OD gear bushing

2 Removing and installing mainsh aft rea r

bearing (4WD model)

2 Installing reverse cone

3 Installing reverse counter gear

4 Installing counter gear rear end bearing

a: 40 mm (1.57 in) dia.

b: 31 mm (1.22 in) dia.

Installing reverse synchronizer hub

Installing mainshaft rear bearing (2WD model)

a: 45 mm (1.77 in) dia.

b: 36 mm (1.42 in) dia.

A

B

MT

D

E

F

G

H

I

ST33400001

(J26082)

Drift

(J26349-3)

Puller leg

(J34328)

Puller

NT065

NT086

NT078

NT079

Installing rear oil seal

a: 60 mm (2.36 in) dia.

b: 47 mm (1.85 in) dia.

Installing mainshaft and counter gear

(Use with J34328)

Installing mainshaft and counter gear

(Use with J26349-3)

J

K

L

M

MT-39

Tool number

(Kent-Moore No.)

Tool name

(J26092)

Drift

(J34342)

Drift

ST33220000

(J25804-01)

Drift

PREPARATION

[FS5R30A]

Description

Installing sub-gear snap ring

a: 44.5 mm (1.752 in) dia.

b: 38.5 mm (1.516 in) dia.

NT065

Installing OD main gear

Installing reverse gear bushing

a: 44.5 mm (1.752 in) dia.

b: 40.5 mm (1.594 in) dia.

NT065

Installing mainshaft rear bearing

a: 37 mm (1.46 in) dia.

b: 22 mm (0.87 in) dia.

(J-26349-A)

Bearing Remover and Installer Set

(J-34286)

Rear Race Puller

(J-39856)

Gear and Bearing Removal Kit

Commercial Service Tool

NT084

Removing and installing mainsha ft bear ing

(Use with J-25726-B)

WMT065

Removing races

WMT066

Removing gears and bearings

WMT067

ECS006IO

Tool name Description

Puller Removing counter gear rear end bearing

Removing mainshaft rear bearing (2WD model)

Removing reverse synchronizer hub

Removing reverse counter gear

NT077

MT-40

NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTING

[FS5R30A]

NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTING PFP:00003

NVH Troubleshooting Chart

Use the chart below to help you find the cause of the problem. The numbers indicate the order of the inspection. If necessary, repair or replace these parts.

ECS006IP

A

B

Reference page

SUSPECTED PARTS

(Possible cause)

MA-35

MT-59

MT-63

MT-65

MT

D

E

F

G

H

I

Symptom

OIL (Level low)

OIL (Wrong)

OIL (Level too high)

GASKET (Damaged)

OIL SEAL (Worn or damaged)

O-RING (Worn or damaged)

CHECK PLUG RETURN SPRING AND CHECK BALL (Worn or damaged)

SHIFT FORK (Worn)

GEAR (Worn or damaged)

BEARING (Worn or damaged)

BAULK RING (Worn or damaged)

Noise 1 2 3 3

Oil leakage 3 1 2 2 2

Hard to shift or will not shift 1 1 2 2

Jumps out of gear 1 2 2

J

INSERT SPRING (Damaged)

K

L

M

MT-41

DESCRIPTION

[FS5R30A]

DESCRIPTION

Description

CROSS-SECTIONAL VIEW — 2WD MODEL

PFP:00000

ECS006IQ

MT-42

WCIA0183E

DESCRIPTION

[FS5R30A]

1. Release bearing sleeve 2. Front cover 3. Main drive gear

4. 3rd and 4th shift fork 5. Transmission case 6. 3rd and 4th coupling sleeve

7. Striking interlock 8. 3rd main gear 9. 2nd main gear

10. 1st main gear 11. OD main gear 12. Striking rod

13. Reverse shift fork 14. Shi f t lever 15. M ainshaft

16. Mainshaft rear bearing 17. C ounter gear rear end bearing 18. Reverse main gear

19. Rear extension 20. OD coun ter gear 21. Adapter plate

22. Mainshaft front bearing 23. Drain plug 24. 1st and 2nd coupling sleeve

25. Counter gear 26. Sub-gear 27. Counter gear front bearing

28. Main drive gear bearing 29. Main drive gear

A

B

MT

D

E

F

G

H

K

M

I

J

L

MT-43

DESCRIPTION

CROSS-SECTIONAL VIEW — 4WD MODEL

[FS5R30A]

MT-44

WCIA0184E

DESCRIPTION

[FS5R30A]

1. Release bearing sleeve 2. Front cover 3. Transmission case

4. Main drive gear bearing 5. Main drive gear 6. 3rd and 4th shift fork

7. 3rd and 4th coupling sleeve 8. 3rd main gear 9. Striking interlock

10. 2nd main gear 11. 1st and 2nd coupling sleeve 12. 1st main gear

13. Mainshaft front bearing 14. O D ma in ge ar 15. Rear ex ten si on

16. Reverse main gear 17. Striking rod 18 . Shift lever

19. Mainshaft 20. Counter gear rear end bea ring 21. OD counter gear

22. Adapter plate 23. Drain plug 24. Counter gear

25. Sub-gear 26. Counter gear front bearing

A

B

MT

D

E

F

G

H

K

M

I

J

L

MT-45

ON-VEHICLE SERVICE

[FS5R30A]

ON-VEHICLE SERVICE

Replacing Rear Oil Seal — 2WD Model

REMOVAL

1. Remove the pro peller shaf t. Refer to PR-8, "Removal and Instal-

lation" .

2. Remove rear oil seal using Tool.

● Always replace with a new rear oil seal once it has been

removed.

Tool number : ST33290001 (J25810-A)

INSTALLATION

1. Install new rear oil seal until it stops.

● Apply multi-purpose grease to seal lip of oil seal before install-

ing.

Tool number : ST33400001 (J26082)

2. Installation is in the reverse ord er of rem oval .

PFP:00000

ECS006IR

SMT479CA

Position Switch Check

Switch Gear position Continuity

Back-up lamp switch

Park/neutral position

(PNP) switch

Except reverse No

Except neutral No

SMT480CA

ECS006IS

Reverse Yes

Neutral Yes

MT-46

SMT981D

ON-VEHICLE SERVICE

[FS5R30A]

A

B

MT

D

E

F

AMT205

G

H

I

J

K

L

M

MT-47

TRANSMISSION ASSEMBLY

[FS5R30A]

TRANSMISSION ASSEMBLY

Removal and Installation

PFP:32010

ECS006IT

REMOVAL

CAUTION:

When removing the M/T assembly from engine, first remove the crankshaft position sensor (OBD)

from the M/T assembly. Be careful not to damage sensor edge.

2WD Model

1. Remove battery nega tiv e ter mi na l.

2. Remove shift lever.

3. Remove crankshaft position sensor (OBD) from upper side of

transmission case.

4. Remove operating cylinder from transmission. Refer to CL-5,

"Components" .

5. Disconnect vehicle speed sensor, back-up lamp switch, heated

oxygen sensor (rear) and park/neutral position (PNP) switch

harness connectors.

6. Remove starter motor. Refer to SC-23, "

MODELS" .

7. Remove propeller shaft. Refer to PR-8, "

tion" .

● Insert plug into rear oil seal aft er rem ov in g prope lle r sha ft.

● Be careful not to damage spline, sleeve yoke and rear oil seal when removing propeller shaft.

8. Remove gussets from transmission or engine.

9. Remove exhaust tube mo un tin g bra cket from tran s mi ssio n. Refe r to EX -3, "

10. Support ma nu al trans mi ss io n with a jack.

11. Remove rear mounting member. Refer to EM-127, "

12. Lower manual transmission.

VG33E AND VG33ER

Removal and Installa-

Removal and Installation" .

Removal and Installation" .

AMT189

SMT099A

MT-48

TRANSMISSION ASSEMBLY

WARNING:

Support manual transmission together with transfer while removing it.

[FS5R30A]

A

B

MT

D

E

F

4WD Model

1. Disconnec t the ba tte ry ne ga tiv e term in al .

2. Remove shift lever from transmission and control lever from

transfer.

3. Remove clutch operating cylinder from transmission. Refer to

CL-5, "

4. Disconnect the vehicle speed sensor, back-up lamp switch,

heated oxygen sensor (rear) and Park/neutral position (PNP)

switch harness connectors.

5. Remove the starter motor. Refer to SC-23, "

VG33ER MODELS" .

6. Remove front and rear propeller shafts. Refer to PR-8,

"Removal and Installation" .

● Insert plug into rear oil seal after removing propeller shaft.

● Be careful not to damage spline, sleeve y oke and rear oil seal when removing propeller shaft .

7. Remove exhaust tube mounting bracket from transmission. Refer to EX-3, "

8. Remove front exhaust tubes and center pipe.

9. Remove the torsion bars and mounts. Refer to FSU-14, "

10. Remove the rear torsion bar cross member.

11. Remove the gussets from the transmission or engine.

12. Support the manual transmission with a jack.

13. Remove rear mounting member. Refer to EM-127, "

14. Lower manual transmission.

WARNING:

Support manual transmission together with transfer while removing it.

15. Remove crankshaft position sensor (OBD) from upper side of transmis sion case.

16. Remove transmission bolts.

WARNING:

Support manual transmission together with transfer while removing it.

Components" .

VG33E AND

Removal and Instal la tio n" .

TORSION BAR SPRING" .

Removal and Ins tallation" .

AMT203

SMT558A

G

H

I

J

K

L

M

MT-49

TRANSMISSION ASSEMBLY

INSTALLATION

● Tighten the bolts securing the transmission to the specified

torques in the chart below.

[FS5R30A]

Bolt No. Tightening torque N·m (kg-m, ft-lb)

1 39 - 49 (4.0 - 5.0, 29 - 36) 65 (2.56)

2 39 - 49 (4.0 - 5.0, 29 - 36) 58 (2.28)

3 29 - 39 (3.0 - 4.0, 22 - 29) 20 (0.79)

4 (Sta rte r spacer

and cover plate)

● Installation is in the reverse order of removal .

29 - 39 (3.0 - 4.0, 22 - 29) 25 (0.98)

mm (in)

WCIA0185E

MT-50

TRANSMISSION ASSEMBLY

[FS5R30A]

Overhaul

CASE COMPONENTS

ECS006IU

A

B

MT

D

E

F

G

H

K

M

I

J

L

MT-51

WCIA0187E

TRANSMISSION ASSEMBLY

1. Back-up lamp switch 2. Park/neutral position (PNP) swi t ch 3. Control housing bolts

4. Control housing 5. Plug 6. Clip

7. Dust cover 8. Rear oil seal 9. Rear extension

10. Rear extension bolt 11. Bearing retainer bolt 12. Slide ball bearing

13. Control housing bolt 14. Washer 15. Control housing

16. Baffle plate 17. OD gear case bolt 18. OD gear ca se

19. Back-up lamp switch 20. Drain plug 21. Front cover oil seal

22. Front cover bolt 23. Washer 24. Ball pin

25. Front cover 26. Gasket 27. Slide ball bearing

28. Transmissio n case 29. Filler plug 30. Air breath er

31. A dap te r plate 32. Bearing retainer

[FS5R30A]

MT-52

GEAR COMPONENTS

TRANSMISSION ASSEMBLY

[FS5R30A]

A

B

MT

D

E

F

G

H

K

M

I

J

L

MT-53

WCIA0188E

TRANSMISSION ASSEMBLY

[FS5R30A]

1. Main drive bearing snap ring 2. Main drive gear bearing snap ring 3. Main drive gear bearing

4. Main drive gear 5. Pilot bearing 6. Spacer

7. Mainshaft front snap ring 8. 4th baulk ring 9. 3rd and 4th coupling sleeve

10. Shifting insert 11. Spread spring 12. 3rd and 4th synchronizer hub

13. 3rd outer baulk ring 14. Synchronizer cone 15. 3rd inner baulk ring

16. 3rd main gear 17. 3rd gear needle bearing 18. Steel ball (For 1st gear washer)

19. Mainshaft 20. Co unt er gea r front bear i ng 21. Counter gear front bearing shim

22. S ub- gear bracket 23. Sub-gear spring 24. Sub-gear

25. Steel ball 26. Counter gear 27. Counter gear rear thrust bearing

28. 1st main gear with sub-gear

(VG33ER)

31. 1st gear needle bearing 32. 1st main gear without sub-gear

34. 1st and 2nd coupling sleeve 35. 1st an d 2nd synchronizer hub 36. 2nd outer baulk ring

37. 2nd inner baulk ring 38. 2nd main gear 39. Sub-gear snap ring

40. Counter gear front bearing

29. 1st gear washer 30. 1st gear bushing

33. 1st baulk ring

(VG33E)

MT-54

TRANSMISSION ASSEMBLY

[FS5R30A]

A

B

MT

D

E

F

G

H

K

M

I

J

L

MT-55

WCIA0189E

TRANSMISSION ASSEMBLY

[FS5R30A]

1. Mainshaft front bearing 2. Mainshaft front bearing snap ring 3. OD main gear

4. Speedometer drive gear (2WD

model)

7. Reverse gear needle bearings 8. Reverse syn chr oni zer hu b 9. Reverse coupling sleeve

10. Mainshaft spacer 11. Mainshaft rear bearing 12. Mainshaft C-ring

13. C -r ing hol der 14. Mainshaft rear snap ring 15. Counter gear rear snap ring

16. C ounter gear rear end bearing 17. Reverse counter gear 18. OD baulk ring

19. Reverse baulk ring 20. Reverse cone 21. Sprin g ins ert

22. O D coupl ing sl eeve 23. OD cou nte r gea r 24. OD gear needle bearing

25. O D gear bushi ng 26. Counter gear rear bea ring 27. Retaining pin

28. Reverse idler shaft 29. Reverse idle r need le bearings 30. Reverse idler ge ar (wit hout sub-

31. Reverse idler rear thrust washer 32. Reverse idler gear (with sub-gear)

34. S ub- gear spring 35. Steel ball 3 6. Sub-gea r bra cket

37. Snap ring

5. Reverse gear bushing 6. Reverse main gear

gear) (VG33E model)

33. Sub-gear

(VG33ER model)

MT-56

TRANSMISSION ASSEMBLY

SHIFT CONTROL COMPONENTS (2/4WD MODELS)

[FS5R30A]

A

B

MT

D

E

F

G

H

K

M

I

J

L

MT-57

WCIA0190E

TRANSMISSION ASSEMBLY

1. Snap ring 2. Socket 3. Spring

4. Shift knob 5. Shift lever 6. Upper boot retainer

7. Boot 8. Low er boot retainer 9. Control housing bolt

10. Washer 11. Control housing 12. Bushing

13. Return spring 14. Check ball 15. Select check plunger

16. Select check spring (small) 17. Select check spring (large) 1 8. Select chec k plu g

19. Select check spring 20. Re taining pin 21. Guide plate bolt

22. G ui de pl at e 23. Striking arm 24. O -r in g

25. Reverse check sleeve 26. Reverse check sleeve bolt 27. OD rod bracket

28. O D shi ft fork 29. OD fork rod 30. 1st and 2nd shift fork

31. Striking interlock 32. Striking lever 33. 3rd and 4th shift fork

34. Stopper ring 35. Interlock stopper bolt 36. Interlock stopper

37. Striking rod 38. OD and reverse fork rod 39. Reverse shift fork

40. Check ball 41. Check spring 42. Check ball plug

[FS5R30A]

MT-58

CASE COMPONENTS

[FS5R30A]

CASE COMPONENTS PFP:32100

Disassembly

1. Remove check ball plug, check spring and check ball. Then

remove interl oc k sto pper.

● If interlock assembly is removed as a unit, the check ball can

fall into transmissio n cas e .

● Be careful not to lose check ball.

2. Remove control housing, return spring and check ball.

● Be careful not to lose check ball.

ECS006IV

SMT366A

A

B

MT

D

E

F

G

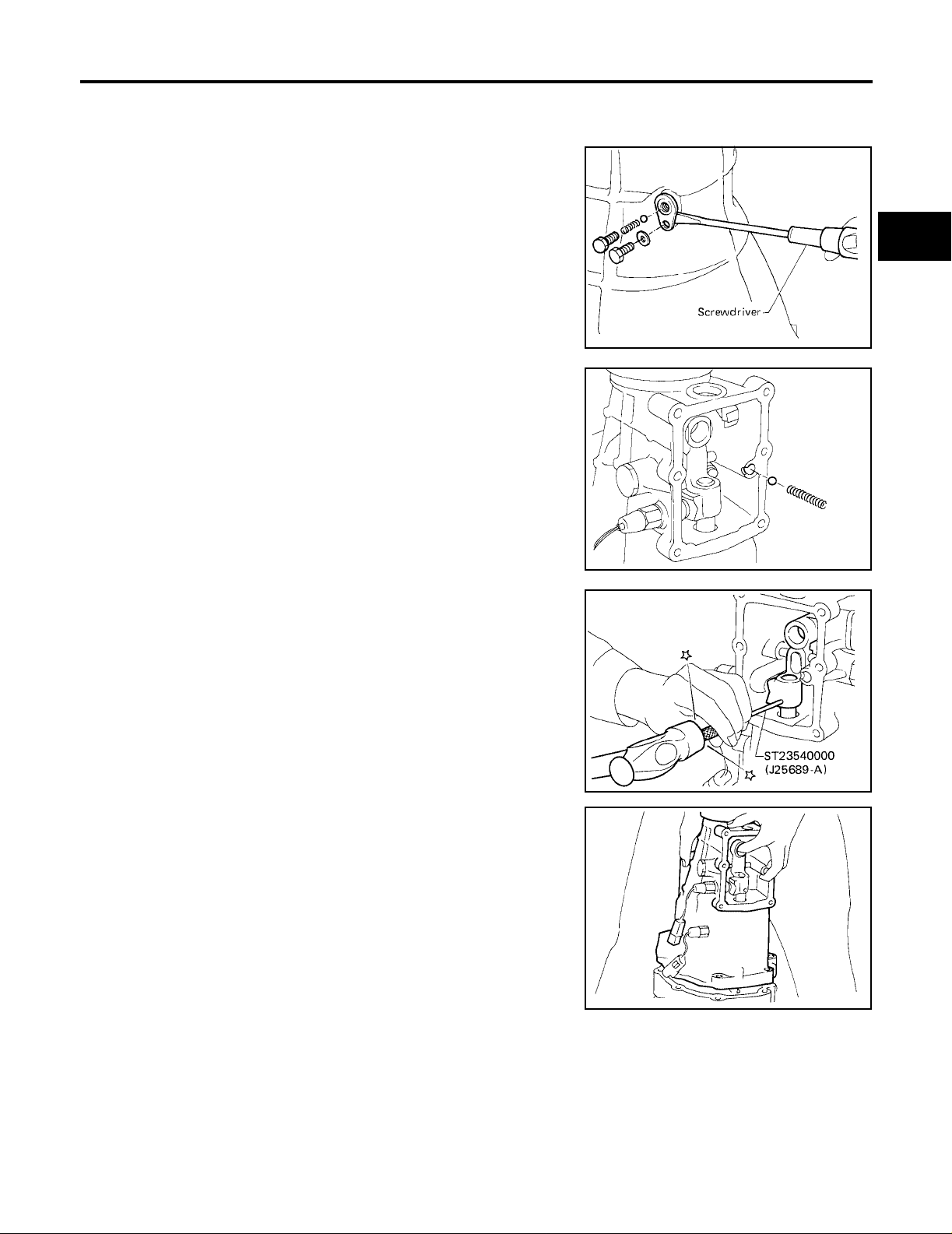

3. Drive out retaining pin from striking arm using Tool.

Tool number : ST23540000 (J25689-A)

4. Remove rear extension (or OD gear case) together with striking

arm by tapping lightly.

SMT367A

SMT368A

H

I

J

K

L

M

MT-59

SMT135C

CASE COMPONENTS

5. Remove fron t cover and gasket.

6. Remove stopper ring and main drive bearing snap ring.

[FS5R30A]

SMT370A

7. Remove tran smission case by tappi ng lightly.

8. Remove counter gear front bearing shim and counter gear front thrust washer.

9. Remove spacer from between main drive gear and mainshaft.

10. Remove front cover oil seal using a screwdriver.

SMT371A

SMT372A

MT-60

SMT392A

CASE COMPONENTS

[FS5R30A]

Assembly

1. Install front cover oil seal using Tool.

● Apply multi-purpose grease to seal lip.

Tool number : ST33210000 (J25803-01)

2. Install selecte d counter gear front bearing shim onto transm ission case.

● Apply multi-purpose grease to counter gear front bearing

shim.

3. Apply sealant to mating surface of tran smission case.

● Use Genuine Anaerobic Liquid Gasket or equivalent. Refer to

MA-12, "

4. Install gear assembly onto transmission case.

5. Install check ball and check spring into interlock stopper.

● Apply multi-purpose grease to check ball.

RECOMMENDED FLUIDS AND LUBRICANTS" .

ECS006IW

SMT393A

SMT588A

A

B

MT

D

E

F

G

H

6. Install interlock stopper assembly and then tighten check ball

plug.

● Apply sealan t to thread of check ball plug.

● Use Genuine Anaerobic Liquid Gasket or equivalent. Refer to

MA-12, "

RECOMMENDED FLUIDS AND LUBRICANTS" .

Interlock stopper bolt : 32 - 42 N·m (3.2 - 4.3 kg-m,

24 - 31 lb-ft)

Check ball plug : 32 - 42 N·m (3.2 - 4.3 kg-m,

24 - 31 lb-ft)

7. Install stopper ring and main drive bearing snap ring.

I

J

K

SMT460A

L

M

SMT371A

MT-61

CASE COMPONENTS

8. Install front cover and gasket.

● Apply sealant to thread of 3 bolts shown.

● Use Genuine Anaerob ic Liqu id Gask et or equiv alen t. Refer to

MA-12, "

Front cover bolts : 16 - 21 N·m (1.6 - 2.1 kg-m,

9. Apply sealant to mating surface of adapter plate.

● Use Genuine Anaerob ic Liqu id Gask et or equiv alen t. Refer to

MA-12, "

10. Install rear extension or (OD gear case) together with striking

arm.

Rear extension bolts

(OD gear case bolts)

RECOMMENDED FLUIDS AND LUBRICANTS" .

12 - 15 lb-ft)

RECOMMENDED FLUIDS AND LUBRICANTS" .

: 32 - 42 N ·m (3 .2 - 4.3 kg- m,

24 - 31 lb-ft)

[FS5R30A]

SMT459A

11. Install retaining pin into striking arm using Tool.

Tool number ST23540000 (J25689-A)

12. Install check ball and return spring and th en apply sealant and

install control housing.

● Use Genuine Anaerob ic Liqu id Gask et or equiv alen t. Refer to

MA-12, "

RECOMMENDED FLUIDS AND LUBRICANTS" .

SMT461A

SMT368A

SMT462A

13. Tighten control housing bolts.

Bolt head size

A bolts : 12 mm (0.47 in)

B bolts : 13 mm (0.51 in)

Control housing

bolts

: 16 - 20 N·m (1.6 - 2.1 kg-m,

12 - 15 lb-ft)

SMT572A

MT-62

SHIFT CONTROL COMPONENTS

[FS5R30A]

SHIFT CONTROL COMPONENTS PFP:32982

Disassembly

1. Mount adapter plate on vise using copper plates to protect

adapter plate.

2. Remove OD and reverse fork rod.

3. Drive out retaining pin from striking lever using Tool.

Tool number : ST23540000 (J25689-A)

4. While pull ing out strikin g rod, remove str iking lever an d striking

interlock. Then remov e 1st and 2nd, 3rd and 4th, and reverse

shift forks.

ECS006IX

SMT373A

A

B

MT

D

E

F

G

5. Drive out retaining pin from OD shif t fork using Tool.

Tool number : ST23540000 (J25689-A)

6. Pull out OD fork rod and the n r emov e OD sh ift fork.

Inspection

● Check contact surfac e and sliding surface for wear, scratches,

projections or other damage.

Assembly

1. Install OD fork rod and OD shift fork. Then i nstall retaining pin

into OD shift fork.

SMT374A

H

I

J

ECS006IY

K

L

M

SMT398A

ECS006IZ

2. Install 1st and 2nd, 3rd and 4th, and reverse shift forks onto coupling sleeve.

MT-63

SMT457A

SHIFT CONTROL COMPONENTS

3. Install striking rod into hole of shift forks, striking lever and interlock and then i nstall retaining pin into striking lever using Tool.

● Make sure that striking rod moves smoothly.

Tool number : ST23540000 (J25689-A)

4. Install OD and reverse fork rod.

● Apply sealant to thread of O D and rev ers e fork rod bolt.

[FS5R30A]

OD and reverse fork rod

bolt

: 25 - 29 N·m (2.5 - 3.0 kg-m,

19 - 21 lb-ft)

SMT374A

MT-64

GEAR COMPONENTS

[FS5R30A]

GEAR COMPONENTS PFP:31460

Disassembly

1. Before removi ng gear s a nd sh af t s , me as ur e eac h g ea r en d pl a y.

Refer to MT-81, "

● If not within specification, disassemble and check contact sur-

face of gear to hub, washer, bushing, needle bearing and

shaft.

2. Remove rear side components on mainshaft and counter gear.

a. Remove rev ers e coupling sleeve.

Gear End Play" .

ECS006J0

SMT376A

A

B

MT

D

E

F

G

b. Remove mai nshaft rear snap ring and counter gear rear snap

ring.

c. Remove C-ring holder and mainshaft C-rings from mainshaft.

Use punch and hammer to remov e C -rin gs.

d. Remove counter gear rear end bearing using a puller.

e. Remove reverse idler thrust washer and reverse idler gear

(VG33E model) or snap ring, sub-gear bracket, steel ball, subgear spring, sub-gear and reverse idler (VG33ER model) and

reverse idler needle be ari ng s.

SMT463A

SMT377A

H

I

J

K

L

M

f. Remove mainshaft rear bearing (2WD model) using Tools.

Tool number : J-26349-A, J-25726-B

g. Remove mainshaft spacer.

MT-65

SMT378A

GEAR COMPONENTS

h. Remove reverse mai n gear together wi th mainshaft spacer an d

reverse synchronizer hub using a puller. Then remove reverse

gear needle bearing s.

i. Remove reverse counter gear using a puller.

j. Remove OD coupling sleeve together with OD baulk ring,

reverse baulk ring and spring inserts.

[FS5R30A]

SMT380A

k. Remove reverse gear bushing using a puller.

l. Remove speedometer drive gear (2WD model).

m. Remove OD gear bushing, OD gear needle bearing, OD counter

gear and reverse cone using puller.

SMT773A

SMT770A

MT-66

SMT771A

GEAR COMPONENTS

3. Press out mainshaft and counter gear alternately using Tool.

Tool number : ST33230000 ( — )

[FS5R30A]

A

B

MT

D

E

F

AMT174A

G

4. Remove front side components on mainshaft.

a. Remove 1st gear washer and steel ball.

● Be careful not to lose steel ball.

b. Remove 1st main gear and 1st gear needle bearing.

c. Press out 2nd main gear together with 1st gear bushing, 2nd

gear needle bearing and 1st and 2nd synchronizer assembly

using Tool.

Tool number : ST30031000 (J22912-01)

d. Remove mainshaft front bearing snap ring.

e. Press out 3rd main gear together with 3rd and 4th synchronizer

assembly and 3rd gear needle bearing.

H

I

J

SMT383A

K

L

M

SMT482C

MT-67

SMT385A

GEAR COMPONENTS

5. Remove fron t side components on counter gear.

a. Remove counter gear rear thrust bearing using Tool.

Tool number : ST30031000 (J22912-01)

b. Remove sub-g ear snap ring, sub-gear bracket, sub-gear s pring,

sub-gear and steel ball.

[FS5R30A]

SMT404A

6. Remove main drive gear bearing.

a. Remove main drive gear snap ring.

b. Press out main drive gear bearing using Tool.

Tool number : ST30031000 (J22912-01)

c. Remove pilot bearing.

7. Remove front bearing snap ring from adapter plate.

8. Remove bearings from case components using Tool.

SMT470A

SMT420A

MT-68

AMT173

GEAR COMPONENTS

[FS5R30A]

Tool numbers

Counter gear front bearing : ST22350000 (J25678-01),

KV38100300 (J25523)

Mainshaft front bearing : ST30720000 (J34331)

Mainshaft rear bearing : ST37750000 (J34332)

Counter gear rear bearing : ST37750000 (J34286)

Inspection

GEARS AND SHAFTS

● Check shafts for cracks, wear or bending.

● Check gears for exc essive wear, chips or cracks.

ECS006J1

SMT386A

A

B

MT

D

E

F

G

H

SYNCHRONIZERS

● Check spline portion of coupling sleeves, hubs, and gears for

wear or cracks.

● Check baulk rings for cracks or deformation.

● Check shifting inserts for wear or deformation.

● Check insert springs for deformation.

● Measure wear of main drive, 1st (VG33E model) and OD baulk

rings. Refer to MT-81, "

and Gear" .

● If the clearance is smaller than the wear limit, replace baulk ring.

Clearance Between Single Baulk Ring

I

J

SMT423A

K

L

M

SMT427C

MT-69

SMT140

GEAR COMPONENTS

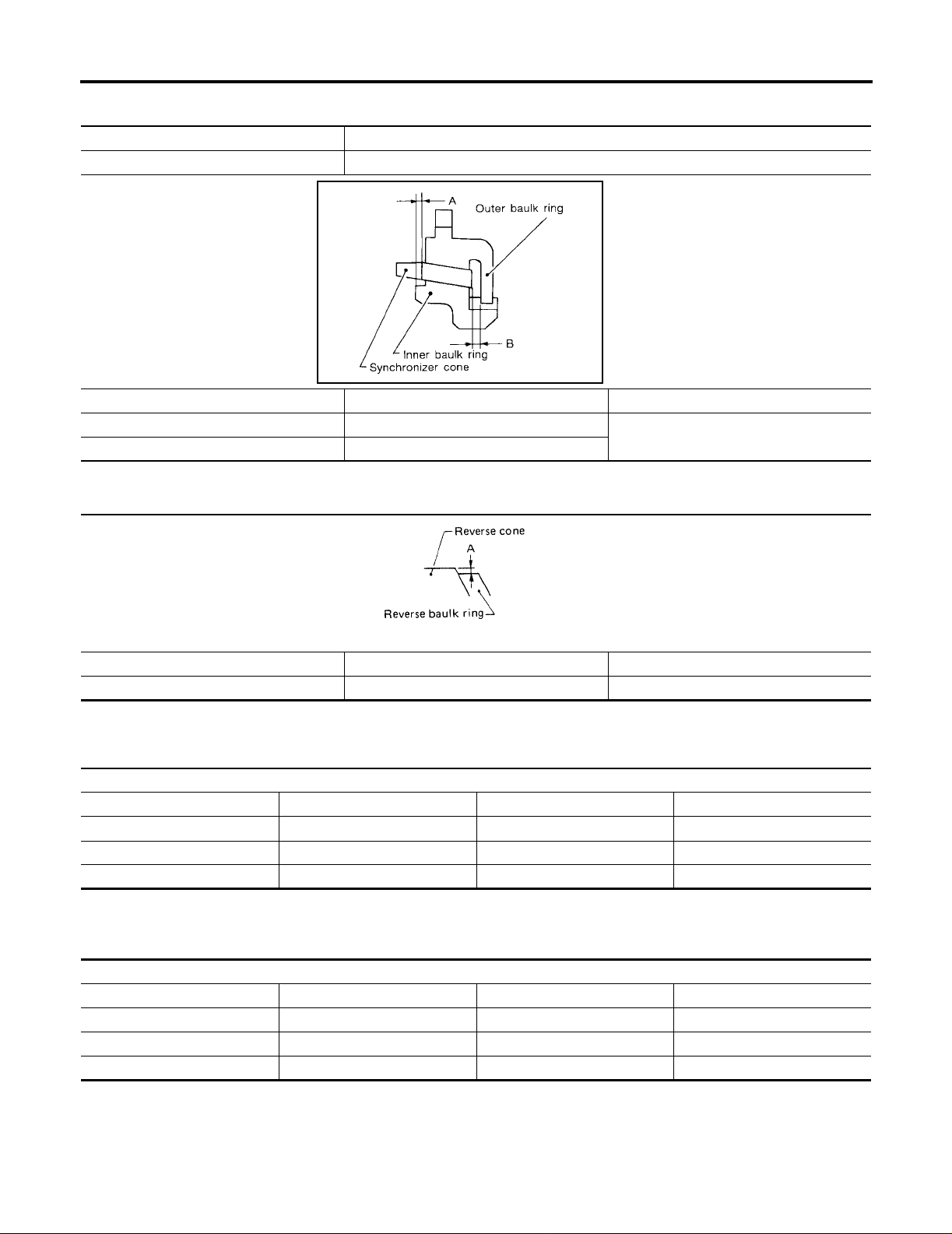

● Measure wear of 1st, 2nd and 3rd double baulk rings.

● 1st, 2nd and 3rd double baulk rings: VG33ER model.

2nd and 3rd double baulk rings: VG33E model.

– Place baulk rings in position on synchronizer cone.

– Wh ile holding baulk rings ag ainst syn chronizer con e as far as it

will go, measure dimensions “A” and “B”.

Standard

Dimension "A" : 0.7 - 0.9 mm (0.028 - 0.035 in)

Dimension "B" : 0.6 - 1.1 mm (0.024 - 0.043 in)

Wear limit : 0.2 mm (0.008 in)

● If dimension “A” or “B” is smaller than the wear limit, replace

outer baulk ring, inner baulk ring and synchronizer cone as a set.

● Measure wear of reverse baul k r ing .

– Place baulk ring in posit ion on reverse cone.

– While holding baulk ring ag ains t r ev ers e con e as far as it wil l go,

measure dimension “A” with dial indicator.

[FS5R30A]

WMT049

WMT050

Standard

Dimension “A” : Standard 0.35 to 0.95 mm

(0.0119 to 0.0295 in)

Wear limit : 1.1 mm (0.043 in)

– If dim e ns io n “A” is larger than the wear l imit, replace baulk ring.

BEARINGS

● Make sure bearings roll freely and are free from noise, crack,

pitting or wear.

Assembly

SMT424A

SMT418A

ECS006J2

MT-70

GEAR COMPONENTS

1. Install bearings into case components.

Tool numbers

Counter gear front bearing : ST33210000 (J25523)

Mainshaft front bearing : ST30720000 (J34331)

Mainshaft rear bearing : ST33220000 (J25804-01)

Counter gear rear bearing : KV38100300 (J25523)

2. Install mainshaft front bearing snap ring into adapter plate.

3. Install be aring retainer.

[FS5R30A]

A

B

MT

D

E

F

AMT172

G

H

I

Bearing retainer bolt : 16 - 20 N·m (1.6 - 2.1 kg-m,

12 - 15 lb-ft)

4. Install main drive gear bearing.

a. Press main drive gear bearing using Tool.

Tool number : ST30613000 (J25742-3)

b. Install pilot bearing.

c. Select proper main drive ge ar s nap ri ng t o min imiz e clear ance of

groove. Refer to MT-82, "

Main drive gear

MAIN DRIVE GEAR SNAP RING" .

: 0 - 0.1 mm (0 - 0.00 3 i n)

snap ring groove

allowable clearanc e

d. Install selected main drive gear snap ring on main drive gear.

J

K

L

M

SMT425A

MT-71

SMT426A

GEAR COMPONENTS

5. Install components on counter gear.

a. Instal l sub- gea r, sub-gear spri ng, s ub-ge ar b racke t and sub-g ear

snap ring.

● When installing sub-gear snap ring, tap sub-gear snap ring

into positio n on counter gear using Tool.

Tool number : (J26092)

b. Install counter gear rear thrust bearing using a brass drift.

[FS5R30A]

SMT577A

6. Install front side components on mainshaft.

a. Assemble 1st and 2nd synchronizer.

b. Assemble 3rd and 4th synchronizer.

SMT405A

SMT614B

SMT615B

c. Press on 3rd and 4th synchronizer assembly together with 3rd

main gear and 3rd gear needle bearing.

● Pay attention to direc tio n of sy nc hronizer assembly.

MT-72

SMT399A

GEAR COMPONENTS

d. Select proper mainshaft front bearing snap ring to minimize

clearance of groove. Refer to MT-82, "

BEARING SNAP RING" .

MAINSHAFT FRONT

[FS5R30A]

A

Mainshaft front bear-

: 0 - 0.1 mm (0 - 0.003 in)

ing snap ring groove

allowable clearanc e

e. Install selected mainshaft front bearing snap ring on mainshaft.

f. Press on 1st and 2nd sync hronizer asse mbly together with 2nd

main gear and 2nd gear needle bearing.

g. Press on 1st gear bushing using 1st gear washer.

B

MT

SMT400A

D

E

F

G

SMT401A

H

I

h. Install 1st main gear and 1st gear needle bearing.

i. Install steel ball and 1st gear washer .

● Apply multi-purpos e grease to steel ball and 1st gea r washer

before installing.

SMT402A

SMT403A

J

K

L

M

MT-73

GEAR COMPONENTS

7. Select proper counter gear front bearing shim when replacing

transmission case, counter gear, counter gear rear thrust bearing or sub-gear components.

a. Install counter gear with sub-gear components, counter gear

front thrust washer and counter gear rear thrust washer on

adapter plate.

b. Remove counter gear front bearing shim from transmission

case.

c. Place adapter plate and cou nter gear assembl y in transmissio n

case (case inverted).

[FS5R30A]

d. Ti ghten adapter plate to transmission case using 2 bolts.

e. Place dial indicator on rear end of counter gear.

f. Move counter gear up and down and measure dial indicator

deflection.

g. Select proper thrust washer using the table as a guide. Refer to

MT-83, "

TABLE FOR SELECTING PROPER COUNTER GEAR

FRONT BEARING SHIM" .

Counter ge ar end play : 0.10 - 0.26 m m (0.0040 -

0.0102 in)

h. Separate adapter plate and transmission case.

i. Remove counter gear assembly.

WCIA0191E

SMT578A

MT-74

GEAR COMPONENTS

8. Select proper reverse idler rear thrust washer when replacing

rear extension (or OD gear case), reverse idler gear, reverse

idler shaft or reverse idler front thrust washer.

a. Install reverse i dler gear, reverse idler need le bearing s, reverse

idler rear thrust wash er and reverse idler shaft into rear e xtension (or OD gear case).

● When replacing reverse idler rear thrust washer, install

either A or B. Refer to MT-83, "

THRUST WASHER" .

REVERSE IDLER REAR

[FS5R30A]

A

B

MT

D

E

F

b. Place dial indicator on front end of reverse idler shaft.

c. Put straightedge on front surface of rear extension (or O/D gear

case) as a stopper of reverse idler shaft.

d. Move reverse id ler sh aft up an d down and meas ure rever se i dler

gear end play.

Reverse idle r gear

: 0.30 - 0.53 mm (0. 0119 - 0.0208 in )

end play

e. If not within specification, replace reverse idler rear thrust

washer with the other (A or B) and check again.

WMT051

G

H

I

J

K

L

M

SMT433A

9. Install mainshaft and counter gear on adapter plate and main

drive gear on mainshaft.

a. Mount adapter plate on vise and apply multi-purpose grease to

counter gear rear bearing.

MT-75

SMT438A

GEAR COMPONENTS

b. Partially install mainshaft on mainshaft front bearing.

● To allow for installation o f counter gear, do not install main-

shaft completely.

c. Install counter gear in counter gear rear bearing and install main

drive gear, pilot bearing and spacer on mains haft.

[FS5R30A]

SMT440A

● When installing counter gear into counter gear rear bearing,

push up on upper roller of counter gear rear bearing with

screwdriver.

d. Instal l Tools (J26349-3) on to a dapter pla te and C-r ing and C-r ing

holder on mainshaft.

e. Install Tool (J34328) on mainshaft.

SMT441A

SMT442A

SMT064C

f. Install mainshaft and counter gear completely by extending

length of Tool (J26349-3 ).

MT-76

SMT579A

GEAR COMPONENTS

[FS5R30A]

10. Install rear side components on mainshaft and counter gear.

a. Install OD gear bushing using Tool while pushing on the front of

counter gear.

Tool number : ST37750000 (J34332)

b. Install OD main gear using Tool.

● Pay attention to direction of OD main gear. (B is wider than A

as shown.)

Tool number : (J34342)

c. Install adapter plate with gear assembly ont o transmission case.

d. Install OD g ea r ne edle bearing and then ins tall O D c ou nt er g ear

and reverse idler shaft.

e. Install reverse gear bushing with speedometer drive gear (2WD

model) using Tool.

Tool number : (J34342)

A

B

MT

SMT444A

D

E

F

G

SMT580AA

H

f. Install reverse cone using Tool.

Tool number : ST37750000 (J34332)

g. Install insert springs and reverse baulk ring on OD coupling

sleeve. Then install them and OD baulk ring on OD counter

gear.

● Pay attention to direction of OD coupling sleeve.

SMT581A

SMT582A

I

J

K

L

M

MT-77

SMT571AA

GEAR COMPONENTS

h. Install reverse counte r gear us in g Tool.

Tool number : ST37750000 (J34332)

i. Install reverse gear needle bearing and then install reverse main

gear, reverse idler gear and reverse idler rear thrust washer.

[FS5R30A]

SMT583A

j. Install reverse synchronizer hub using Tool.

● Pay attention to its direction .

k. Install mainshaft spacer and main sh aft rear bearing (2WD model) using Tool.

Tool number : J-26349-A, J-25726-B

l. Install counte r gear rea r end be ari ng using Tool.

Tool number : ST37750000 (J25679-01)

m. Separate adapter plate from transmission case and mount

adapter plate on vise again.

SMT584A

SMT585A

MT-78

SMT485C

GEAR COMPONENTS

n. Select pr op er m ainshaft C-ring to minimize cl ea rance of groove.