Nidek RT-5100 Service manual

MRT10*RDA001A/E

Table of Contents

§1 INTRODUCTION |

Page |

|

1-1 |

||

§2 |

SAFETYPRECAUTIONS ............................................................................................ |

2-1 |

§3 |

TROUBLE SHOOTING............................................................................................... |

3-1 |

§4 |

SUB TOUBLE SHOOTING ......................................................................................... |

4-1 |

|

4.1 Initialization screen does not appear on the CB display. ............................................... |

4-1 |

|

4.1.1 Backlight of the LCD module does not light up. .................................................. |

4-2 |

|

4.2 Initialization is not completed properly. ........................................................................ |

4-3 |

|

4.2.1 The battery AS does not move to the right and left. ............................................ |

4-4 |

|

4.2.2 The R disk AS does not turn.............................................................................. |

4-5 |

|

4.2.3 The L disk AS does not turn. ............................................................................. |

4-7 |

|

4.2.4 The PD and convergence of the MB is not initialized properly. ............................ |

4-9 |

|

4.2.5 The right disk of the MB is not initialized properly. ............................................ |

4-10 |

|

4.2.6 The left disk of the MB is not initialized properly. .............................................. |

4-11 |

|

4.3 An error message appears. ....................................................................................... |

4-12 |

|

4.3.1 “Error 01: Communication Error CB-MB” appears. ......................................... |

4-13 |

|

4.3.2 “Error 11: Communication Error CB-RB” appears. .......................................... |

4-14 |

|

4.3.3 “No appointment data!!” appears. ................................................................... |

4-14 |

|

4.3.4 “Chart doesn’t work.” appears. ....................................................................... |

4-15 |

|

4.3.5 “Setup data is initialized.” appears. ................................................................... |

4-16 |

|

4.3.6 “CF card -- Read Error!!” appears. ................................................................ |

4-16 |

|

4.3.7 “CF card -- Write Error!!” appears. ................................................................ |

4-16 |

|

4.3.8 “CF card -- File Error!!” appears. ................................................................... |

4-16 |

|

4.3.9 “CF card -- File not found!!” appears. ............................................................. |

4-16 |

|

4.3.10 “CF card -- Card not found!!” appears. ........................................................ |

4-16 |

|

4.3.11 “No data!!” appears. ..................................................................................... |

4-16 |

|

4.4 The instrument cannot be operated with the control box............................................. |

4-17 |

|

4.4.1 The instrument cannot be operated with the switches. ....................................... |

4-17 |

|

4.4.2 The instrument cannot be operated by turning the dial. ...................................... |

4-18 |

|

4.4.3 The instrument cannot be operated with the touch-screen panel. ....................... |

4-18 |

|

4.5 The compact flash memory card cannot be used........................................................ |

4-19 |

|

4.6 The IC card cannot be used...................................................................................... |

4-19 |

|

4.7 The printer does not print.......................................................................................... |

4-20 |

|

4.8 The communication with the auto refractometers or lensmeter cannot be done. ........... |

4-21 |

|

4.9 The chart projector does not work as specified with the control box. ......................... |

4-22 |

MRT10*RDA001A/E |

|

Page |

||

§5 REMOVING COVERS |

||||

5-1 |

||||

|

5.1 Covers of the main body............................................................................................. |

5-1 |

||

|

5.1.1 Face shields R and L ......................................................................................... |

5-1 |

||

|

5.1.2 Rear covers |

...................................................................................................... |

5-1 |

|

|

5.1.2.1 Rear cover R ........................................................................................ |

5-1 |

||

|

5.1.2.2 Rear cover L ......................................................................................... |

5-1 |

||

|

5.1.3 Front covers ..................................................................................................... |

5-2 |

||

|

5.1.3.1 Front cover R ....................................................................................... |

5-2 |

||

|

5.1.3.2 Front cover L ........................................................................................ |

5-2 |

||

|

5.1.4 Knob S AS |

....................................................................................................... |

5-2 |

|

|

5.1.5 Upper cover ...................................................................................................J |

5-3 |

||

|

5.1.6 Upper rear cover .............................................................................................. |

5-3 |

||

|

5.1.7 Upper cover ..................................................................................................F |

5-3 |

||

|

5.2 Control box covers..................................................................................................... |

5-4 |

||

|

5.2.1 Rear cover AS .................................................................................................. |

5-4 |

||

§6 |

5.2.2 EMC cover ....................................................................................................... |

|

5-4 |

|

REPLACEMENT.......................................................................................................... |

|

6-1 |

||

|

6.1 Battery AS ................................................................................................................. |

|

6-1 |

|

|

6.2 Disk AS ..................................................................................................................... |

|

6-2 |

|

|

6.2.1 R disk AS ( ................................................................................................. |

) |

6-2 |

|

|

6.2.2 L disk AS ( .................................................................................................. |

) |

6-2 |

|

|

6.3 Boards R and L.......................................................................................................... |

|

6-2 |

|

|

6.3.1 Board R ............................................................................................................ |

|

6-2 |

|

|

6.3.2 Board L ............................................................................................................ |

|

6-3 |

|

|

6.4 Plates ......................................................................................................................... |

|

6-3 |

|

|

6.4.1 Plate FR ( .................................................................................................... |

) |

6-3 |

|

|

6.4.2 Plate FL ( .................................................................................................... |

) |

6-3 |

|

|

6.4.3 Plate BR ( ................................................................................................... |

) |

6-4 |

|

|

6.4.4 Plate BL ( .................................................................................................... |

) |

6-4 |

|

|

6.5 Sensor 1 .................................................................................................................... |

|

6-4 |

|

|

6.5.1 Sensor 1R ......................................................................................................... |

|

6-4 |

|

|

6.5.2 Sensor 1L ......................................................................................................... |

|

6-5 |

|

|

6.6 Frames....................................................................................................................... |

|

6-5 |

|

|

6.6.1 Frame R ( .................................................................................................... |

) |

6-5 |

|

|

6.6.2 Frame L ( .................................................................................................... |

) |

6-5 |

|

|

6.7 PD motors ................................................................................................................. |

|

6-5 |

|

|

6.7.1 PD motor R ...................................................................................................... |

|

6-5 |

|

|

6.7.2 PD motor L ...................................................................................................... |

|

6-6 |

|

|

6.8 CON motors.............................................................................................................. |

|

6-6 |

|

|

6.8.1 CON motor ..................................................................................................R |

6-6 |

||

|

6.8.2 CON motor ...................................................................................................L |

6-6 |

||

|

6.9 PI sensor boards ........................................................................................................ |

|

6-7 |

|

|

6.9.1 CON sensor ..................................................................................................... |

6-7 |

||

|

|

MRT10*RDA001A/E |

|

|

Page |

6.9.1.1 CON sensor of the upper brace R |

......................................................... 6-7 |

|

6.9.1.2 CON sensor of the upper brace L ......................................................... |

6-7 |

|

6.9.2 PD sensors ....................................................................................................... |

|

6-8 |

6.9.2.1 PD sensor of the upper brace R ............................................................. |

6-8 |

|

6.9.2.2 PD sensor of the upper brace L ............................................................. |

6-8 |

|

6.10 Motors and sensors of frame R ................................................................................. |

|

6-9 |

6.10.1 Motor SCA .................................................................................................... |

|

6-9 |

6.10.1.1 Motor for the S2 disk .......................................................................... |

|

6-9 |

6.10.1.2 Motor for the C2 disk ......................................................................... |

|

6-9 |

6.10.1.3 Motor for the S1 disk ........................................................................ |

|

6-10 |

6.10.1.4 Motor for the A1 disk ( |

) ................................................................ |

6-10 |

6.10.1.5 Motor for the C1 disk ( |

) ............................................................... |

6-11 |

6.10.1.6 Motor for the A2 disk ( |

) ................................................................ |

6-11 |

6.10.2 Motor PCA .................................................................................................. |

|

6-12 |

6.10.2.1 Motor for the CA disk ( |

) ............................................................... |

6-12 |

6.10.2.2 Motor for the P1 disk ( |

) ................................................................ |

6-12 |

6.10.2.3 Motor for the P2 disk ( |

) ................................................................ |

6-12 |

6.10.3 Sensor 2 ....................................................................................................... |

|

6-13 |

6.10.3.1 Sensor for the CA disk ...................................................................... |

|

6-13 |

6.10.3.2 Sensor for the P1 disk ....................................................................... |

|

6-13 |

6.10.3.3 Sensor for the P2 disk ....................................................................... |

|

6-13 |

6.11 Motors or sensors of frame L.................................................................................. |

|

6-14 |

6.11.1 Motor SCA .................................................................................................. |

|

6-14 |

6.11.1.1 Motor for the S2 disk ........................................................................ |

|

6-14 |

6.11.1.2 Motor for the C2 disk ....................................................................... |

|

6-14 |

6.11.1.3 Motor for the S1 disk ........................................................................ |

|

6-15 |

6.11.1.4 Motor for the A1 disk ( |

) ................................................................ |

6-15 |

6.11.1.5 Motor for the C1 disk ( |

) ................................................................ |

6-16 |

6.11.1.6 Motor for the A2 disk ( |

) ................................................................ |

6-16 |

6.11.2 Motor for the CA disk ................................................................................... |

|

6-17 |

6.11.2.1 Motor for the CA disk ( |

) ............................................................... |

6-17 |

6.11.2.2 Motor for the P1 disk ( |

) ................................................................ |

6-17 |

6.11.2.3 Motor for the P2 disk ( |

) ................................................................ |

6-17 |

6.11.3 Sensor 2 ....................................................................................................... |

|

6-18 |

6.11.3.1 Motor for the CA disk ( |

) ............................................................... |

6-18 |

6.11.3.2 Motor for the P1 disk ( |

) ................................................................ |

6-18 |

6.11.3.3 Motor for the P2 disk ( |

) ................................................................ |

6-18 |

6.12 VD LED unit .......................................................................................................... |

|

6-19 |

6.12.1 VD LED unit of frame R ................................................................................ |

|

6-19 |

6.12.2 VD LED unit of frame L ................................................................................ |

|

6-19 |

6.13 L motor CPU board ............................................................................................... |

|

6-20 |

6.14 L motor driver board .............................................................................................. |

|

6-20 |

6.15 R motor CPU board............................................................................................... |

|

6-20 |

MRT10*RDA001A/E

§7

§8

6.16 R motor driver board.............................................................................................. |

6-20 |

6.17 MB main board ...................................................................................................... |

6-21 |

6.18 LCD AS ................................................................................................................ |

6-21 |

6.19 CB main board....................................................................................................... |

6-22 |

6.20 Key I/F board ........................................................................................................ |

6-22 |

6.21 Link board ............................................................................................................. |

6-23 |

6.22 Rotary encoder ...................................................................................................... |

6-23 |

6.23 LCD I/F board....................................................................................................... |

6-24 |

6.24 Inverter .................................................................................................................. |

6-24 |

6.25 Color LCD module ................................................................................................ |

6-25 |

6.26 RB main board ....................................................................................................... |

6-26 |

6.27 RB I/F board ......................................................................................................... |

6-26 |

ADJUSTMENT............................................................................................................. |

7-1 |

7.1 Entering the Information/Adjustment screen ................................................................. |

7-1 |

7.2 Adjustment mode of the MB ....................................................................................... |

7-1 |

7.2.1Adjustment of the initial pulse for the MB ........................................................... |

7-1 |

7.2.2 Lens cleaning mode ........................................................................................... |

7-2 |

7.2.3 Adjustment mode for gear ................................................................................. |

7-2 |

7.3 Chart selection ........................................................................................................... |

7-3 |

7.4 Chart adjustment ........................................................................................................ |

7-3 |

7.5 Mirror adjustment....................................................................................................... |

7-3 |

7.6 Parameter setting ....................................................................................................... |

7-4 |

7.7 Printing the adjustment value ....................................................................................... |

7-4 |

7.8 Resetting the setup data .............................................................................................. |

7-4 |

7.9 Communication setting with other brandAR/LM ......................................................... |

7-5 |

7.10Adjusting the clock ................................................................................................... |

7-5 |

7.11 Updating the software ............................................................................................... |

7-6 |

7.12 Clearing theAR/LM data.......................................................................................... |

7-6 |

7.13 Touch-screen panel calibration .................................................................................. |

7-7 |

REFERENCE ................................................................................................................ |

8-1 |

8.1Wiringdiagram ........................................................................................................... |

8-1 |

8.2 Connector cables ....................................................................................................... |

8-2 |

8.3 Error messages........................................................................................................... |

8-5 |

8.4 Parameters ................................................................................................................. |

8-6 |

MRT10*RDA001A/E

§1 INTRODUCTION

•This service manual provides information for after-sales service for the NIDEK refractor, model: RT-5100.

•Refer to the RT-5100 Operator’s Manual and Parts List.

•Specifications are subject to change without notice for improvement. Refer to the Technical Bulletins (T.B.) for important changes.

•In case the device cannot be repaired according to the procedures described in this manual, please report the serial number and details of the symptom or symptoms.

1 - 1

MRT10*RDA001A/E

1 - 2

MRT10*RDA001A/E

§2 SAFETY PRECAUTIONS

<General precautions>

•Only the service persons who are accustomed to using tools, and have a deep knowledge of this instrument are allowed to repair the instrument.

•Proceed right work in accordance with the procedure. If not, accidents or failure of the instrument may result.

•When performing maintenance works, turn off the power switch, and disconnect the power cord from the wall outlet unless necessary.

•Never wipe the covers, etc. using an organic solvent such as a paint thinner.

The surface may be ruined, and as a result, the appearance of the instrument will be impaired.

<Maintenance precautions>

• In case of instrument malfunction, turn the power switch off after checking the symptom.

• Never drop parts or screws inside the instrument, nor bump it against the surrounding objects.

• Have storage cases ready to ensure the loss of the removed screws or parts.

• In screwing or unscrewing, use a proper tool for the screw

• After loosening the screws fixed by a thread-locking adhesive, and tightening them again, be sure to apply the thread-locking adhesive to them.

• After replacing parts, make sure that they are fixed securely before turning on the power.

• If you observe strange odors or smoke being emitted from the instrument, immediately turn off the instrument and locate the causes after disconnecting the power cord from the walloutlet.

If the instrument is continuously powered under such abnormal conditions, a fire, electric shock or total loss of the instrument may result.

• Referring to “8.1 Wiring diagram” and “8.2 Connector cables”, check cables for the following: 1. Connectors are connected securely.

2. No contact failure occurs after re-connection of connectors. 3. No failure in soldering

Do not pull the cables strongly. It may cause a breaking of wire.

Never work with wet hands. It may result in an electric shock or instrument malfunction.

<Adjustment precautions>

•Perform adjustment work in a vibration-free, flat and stable place. Tilted floor or vibratory place may affect a proper adjustment adversely.

•Do not use an adjustment jig for other usage described in this manual.

• Be sure to readjust the optical axis of the prism and cylinder after performing the marked ( )

procedures. The special jigs (the chart projector and the test scale for checking) are necessary for the readjustment.

2 - 1

MRT10*RDA001A/E

2 - 2

MRT10*RDA001A/E

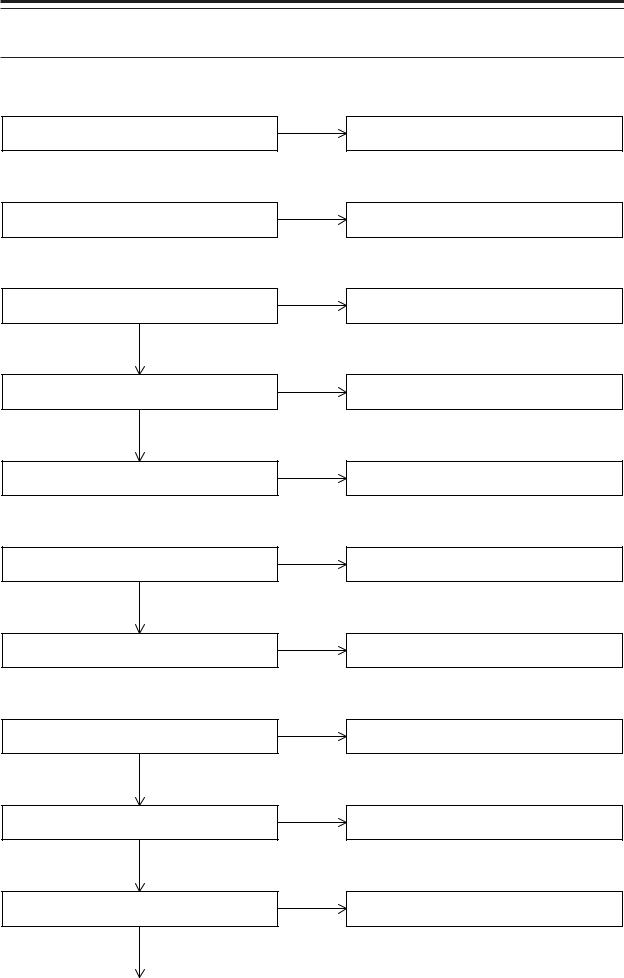

§3 TROUBLESHOOTING

Turn ON the main switch.

|

No |

|

Does the starting screen appear on the control box? |

||

|

||

|

|

|

Yes |

|

|

|

No |

|

Is the initialization completed properly? |

||

|

||

|

|

|

Yes |

|

|

|

Yes |

|

Does any error message appear? |

||

|

||

|

|

|

No |

|

|

|

No |

|

Can the instrument operated with the control box? |

||

|

||

|

|

|

Yes |

|

|

|

No |

|

Can the compact flash memory card be used? |

||

|

||

|

|

|

Yes |

|

|

|

No |

|

Can the IC card be used? |

||

|

||

|

|

|

Yes |

|

|

|

No |

|

Does the printer print? |

||

|

||

|

|

|

Yes |

|

Can the communication between the autorefractometer No

and lensmeter be done? Yes

Does the chart projector operate as specified with the No

control box? Yes

Turn OFF the main switch.

4.1The starting screen does not appear on the control box.

4.2Initialization is not completed properly.

4.3An error message appears.

4.4The instrument cannot be operated with the control box.

4.5The compact flash memory card cannot be used.

4.6The IC card cannot be used.

4.7The printer does not print.

4.8The communication between the autorefractometer and lensmeter cannot be done.

4.9The chart projector does not operate as specified with the control box.

3 - 1

MRT10*RDA001A/E

3 - 2

MRT10*RDA001A/E

§4 SUB TROUBLESHOOTING

4.1 Initialization screen does not appear on the CB display.

Is the power supply voltage within the specified range? Yes

Does the fuse of the RB blow? No

Is the voltage setting of the RB correct? Yes

Is the voltage between 1-2 pins of connector P8 on the RB I/F board (34085-BA22) AC24±3V?

Yes

Is the voltage between A1-B3 pins of connector J3 on the RB I/F board (34085-BA22) DC+15V?

Yes

Does cable CB break? No

Is the voltage between A1-A6 pins of connector P14 on the LINK board (34085-BA14) DC+15V?

Yes

Does the backlight of the color LCD module light up? Yes

Is the voltage between 1-3 pins of connector J3 on the CB main board (34085-BA11) DC+3.3V?

Yes

Is cable LCD3 (34085-E305) disconnected from the connector?

No

No

Yes

No

No

No

Yes

No

No

No

Yes

Obtain the specified voltage.

Replace the fuse of the RB.

Set the correct voltage of the RB.

Replace the RB (34085-5000).

Replace the RB I/F board (34085-BA22). (See 6.27.)

Replace cable CB.

Replace the LINK board (34085-BA14). (See 6.21.)

4.1.1Backlight of the color LCD module does not light up.

Replace the CB main board (34085-BA11). (See 6.19.)

Reconnect cable LCD3 (34085-E305).

4 - 1

MRT10*RDA001A/E

Is the voltage between 1-3 pins of connector J33 on the No

LCD I/F board (34085-BA13) DC+3.3V? Yes

Replace the color LCD module (42203-E016). (See 6.25.)

|

No |

|

Is the symptom relieved? |

||

|

||

|

|

|

Yes |

|

|

|

|

|

Completion |

|

|

|

|

Replace the LCD I/F board (34085-BA13). (See 6.23.)

Replace the CB main board (34085-BA11). (See 6.19.)

4.1.1 Backlight of the LCD module does not light up.

Is the voltage between 5-7 pins of connector J12 on the CB main board (34085-BA11) DC+15V?

Yes

Does cable LCD2 (34085-E304) break? No

Is the voltage between 1-2 pins of connector J35 on the LCD I/F board (34085-BA13) DC+12V?

Yes

Is cable BL (34085-EA11) disconnected from the connector?

No

Replace the inverter (42203-E17). (See 6.24.)

Is the symptom relieved?

Yes

Completion

No

Yes

No

Yes

No

Replace the CB main board (34085-BA11). (See 6.19.)

Replace cable LCD2 (34085-E304).

Replace the LCD I/F board (34085-BA13). (See 6.23.)

Reconnect cable BL (34085-EA11).

Replace the CB main board (34085-BA11). (See 6.19.)

4 - 2

MRT10*RDA001A/E

4.2 Initialization is not completed properly.

Is the voltage between A1-A4 pins of connector J1 on No the MB main board (34085-BA01) DC+5V, and the voltage between A12-A8 pins DC+16.5V?

Yes

Does the battery AS (34085-1000) move to the right No

and left? Yes

|

No |

|

Does the R disk AS (34085-1100) turn? |

||

|

||

|

|

|

Yes |

|

|

|

No |

|

Does the L disk AS (34085-1200) turn? |

||

|

||

|

|

|

Yes |

|

|

|

|

Is the PD of the MB and the convergence initialized |

No |

|

properly? |

|

|

|

|

|

Yes |

|

|

|

No |

|

Is the right disk of the MB initialized properly? |

||

|

||

|

|

|

Yes |

|

|

|

No |

|

Is the left disk of the MB initialized properly? |

||

|

||

|

|

|

Yes |

|

|

|

|

|

Completion |

|

|

|

|

Check the wiring of cable MB and replace it.

4.2.1The battery AS (34085-1000) does not move to the right and left.

4.2.2The R disk AS (34085-1100) does not turn.

4.2.3The L disk AS (34085-1200) does not turn.

4.2.4The PD of the MB and convergence is not initialized properly.

4.2.5The right disk of the MB is not initialized properly.

4.2.6The left disk of the MB is not initialized properly.

4 - 3

MRT10*RDA001A/E

4.2.1 The battery AS does not move to the right and left.

|

|

|

Does motor CON (34085-E013) of the PD motor R |

Yes |

|

(34085-2510) break? |

|

|

|

|

|

No |

|

|

|

|

|

Does motor CON (34085-E013) of the CON motor R |

Yes |

|

(34085-2520) break? |

|

|

|

|

|

No |

|

|

|

|

|

Does motor CON (34085-E013) of the PD motor L |

Yes |

|

(34085-2610) break? |

|

|

|

|

|

No |

|

|

|

|

|

Does motor CON (34085-E013) of the CON motor L |

Yes |

|

(34085-2620) break? |

|

|

No |

|

|

|

|

|

Is the voltage as described below when disconnecting |

|

|

each connector on the MB main board (34085-BA01)? |

No |

|

1-2 pins of connector J8 |

: DC+5V |

|

1-2 pins of connector J9 |

: DC+5V |

|

1-2 pins of connector J10 |

: DC+5V |

|

1-2 pins of connector J11 |

: DC+5V |

|

|

|

|

Yes |

|

|

|

|

|

Does the PI sensor board (34085-BA08) for PD of the |

Yes |

|

upper brace R (34085-2500) break? |

|

|

No |

|

|

|

|

|

Does the PI sensor board (34085-BA08) for CON of |

Yes |

|

the upper brace R (34085-2500) break? |

|

|

|

|

|

No |

|

|

|

|

|

Does the PI sensor board (34085-BA08) for PD of the |

Yes |

|

upper brace L (34085-2600) break? |

|

|

|

|

|

No |

|

|

|

|

|

Does the PI sensor board (34085-BA08) for CON of |

Yes |

|

the upper brace L (34085-2600) break? |

|

|

|

|

|

No |

|

|

|

|

|

Replace the MB main board (34085-BA01). (See 6.17.) |

|

|

|

|

|

Replace the PD motor R (34085-2510). (See 6.7.1.)

Replace the CON motor R (34085-2520). (See 6.8.1.)

Replace the PD motor L (34085-2610). (See 6.7.2.)

Replace the CON motor L (34085-2620). (See 6.8.2.)

Replace the MB main board (34085-BA01). (See 6.17.)

Replace the PI sensor board (34085-BA08) for PD of the upper brace R (34085-2500). (See 6.9.2.1.)

Replace the PI sensor board (34085-BA08) for CON of the upper brace R (34085-2500). (See 6.9.1.1.)

Replace the PI sensor board (34085-BA08) for PD of the upper brace L (34085-2600). (See 6.9.2.2.)

Replace the PI sensor board (34085-BA08) for CON of the upper brace L (34085-2600). (See 6.9.1.2.)

4 - 4

MRT10*RDA001A/E

4.2.2 The R disk AS does not turn.

Is the voltage of connector J3 on the R motor CPU |

|

|||

board (34085-BA04) as described below? |

No |

|||

A3-A1 pins |

:DC+5V |

|

|

|

A4-A1 pins |

:DC+16.5V |

|

||

|

|

|

|

|

|

Yes |

|

|

|

|

|

|||

Is the voltage of connector P1 on the R motor CPU |

|

|||

board (34085-BA04) as described below? |

No |

|||

1-3 pins :DC+5V |

|

|

|

|

11-1 pins :DC+16.5V |

|

|

||

|

|

|

|

|

|

Yes |

|

|

|

|

|

|||

Is the voltage as described below when disconnecting |

|

|||

each connector of the R motor CPU board (34085- |

|

|||

BA04)? |

|

|

No |

|

1-2 pins of connector J4 |

: DC+5V |

|||

|

||||

1-2 pins of connector J5 |

: DC+5V |

|

||

1-2 pins of connector J6 |

: DC+5V |

|

||

1-2 pins of connector J7 |

: DC+5V |

|

||

|

|

|

|

|

|

Yes |

|

|

|

|

|

|

Yes |

|

Does motor SCA (34085-1310) for S2 disk R break? |

||||

|

||||

|

|

|

|

|

|

No |

|

|

|

|

|

|

Yes |

|

Does motor SCA (34085-1310) for S1 disk R break? |

||||

|

||||

|

|

|

|

|

|

No |

|

|

|

|

|

|

Yes |

|

Does motor SCA (34085-1310) for C2 disk R break? |

||||

|

||||

|

|

|

|

|

|

No |

|

|

|

|

|

|

Yes |

|

Does motor SCA (34085-1310) for C1 disk R break? |

||||

|

||||

|

|

|

|

|

|

No |

|

|

|

|

|

|

Yes |

|

Does motor SCA (34085-1310) for A1 disk R break? |

||||

|

||||

|

|

|

|

|

|

No |

|

|

|

|

|

|

Yes |

|

Does motor SCA (34085-1310) for A2 disk R break? |

||||

|

||||

|

|

|

|

|

|

No |

|

|

|

Replace the MB main board (34085-BA01). (See 6.17.)

Replace the R motor CPU board (34085-BA04). (See 6.15.)

Replace the R motor CPU board (34085-BA04). (See 6.15.)

Replace motor SCA (34085-1310) for the S2 disk R. (See 6.10.1.)

Replace motor SCA (34085-1310) for the S1 disk R. (See 6.10.3.)

Replace motor SCA (34085-1310) for the C2 disk R. (See 6.10.1.2.)

Replace motor SCA (34085-1310) for the C1 disk R. (See 6.10.1.5.)

Replace motor SCA (34085-1310) for the A1 disk R. (See 6.10.1.4.)

Replace motor SCA (34085-1310) for the A2 disk R. (See 6.10.16.)

4 - 5

MRT10*RDA001A/E

|

|

|

Does motor PCA (34085-1320) for the CA disk R |

Yes |

|

break? |

|

|

No |

|

|

|

|

|

Does motor PCA (34085-1320) for the P1 disk R |

Yes |

|

break? |

|

|

|

|

|

No |

|

|

|

|

|

Does motor PCA (34085-1320) for the P2 disk R |

Yes |

|

break? |

|

|

|

|

|

No |

|

|

|

|

|

Is the voltage between 3-2 pins of connector J4 on the |

|

|

R motor CPU board (34085-BA04) as described |

No |

|

below? |

|

|

Sensor 2 for CA disk R is shaded. |

:5V |

|

Sensor 2 for CA disk R is not shaded. |

:0V |

|

|

|

|

Yes |

|

|

|

|

|

Is the voltage between 3-2 pins of connector J5 on the |

|

|

R motor CPU board (34085-BA04) as described |

No |

|

below? |

|

|

Sensor 2 for P1 disk R is shaded. |

:5V |

|

Sensor 2 for P1 disk R is not shaded. |

:0V |

|

|

|

|

Yes |

|

|

|

|

|

Is the voltage between 3-2 pins of connector J6 on the |

|

|

R motor CPU board (34085-BA04) as described |

No |

|

below? |

|

|

Sensor 2 for P2 disk R is shaded. |

:5V |

|

Sensor 2 for P2 disk R is not shaded. |

:0V |

|

|

|

|

Yes |

|

|

Replace the R motor driver board (34085-BA05). (See 6.16.)

|

No |

|

Is the symptom relieved? |

||

|

||

|

|

|

Yes |

|

|

|

|

|

Completion |

|

|

|

|

Replace motor PCA (34085-1320) for the CA disk R. (See 6.10.2.1.)

Replace motor PCA (34085-1320) for the P1 disk R. (See 6.10.2.2.)

Replace motor PCA (34085-1320) for the P2 disk R. (See 6.10.2.3.)

Replace sensor 2 (34085-1330) for the CA disk R. (See 6.10.3.1.)

Replace sensor 2 (34085-1330) for the P1 disk R. (See 6.10.3.2.)

Replace sensor 2 (34085-1330) for the P2 disk R. (See 6.10.3.3.)

Replace the R motor CPU board (34085-BA04). (See 6.15.)

4 - 6

MRT10*RDA001A/E

4.2.3 The L disk AS does not turn.

Is the voltage of connector J3 on the L motor CPU |

|

|||

board (34085-BA02) as described below? |

No |

|||

A3-A1 pins |

:DC+5V |

|

|

|

A4-A1 pins |

:DC+16.5V |

|

||

|

|

|

|

|

|

Yes |

|

|

|

|

|

|||

Is the voltage of connector P1 on the L motor CPU |

|

|||

board (34085-BA02) as described below? |

No |

|||

1-3 pins :DC+5V |

|

|

|

|

11-1 pins :DC+16.5V |

|

|

||

|

|

|

|

|

|

Yes |

|

|

|

|

|

|||

Is the voltage as described below when disconnecting |

|

|||

each connector on the L motor CPU board (34085- |

|

|||

BA02)? |

|

|

No |

|

1-2 pins of connector J4 |

:DC+5V |

|||

|

||||

1-2 pins of connector J5 |

:DC+5V |

|

||

1-2 pins of connector J6 |

:DC+5V |

|

||

1-2 pins of connector J7 |

:DC+5V |

|

||

|

|

|

|

|

|

Yes |

|

|

|

|

|

|||

Does motor SCA (34085-1310) for the S2 disk L |

Yes |

|||

break? |

|

|

|

|

|

No |

|

|

|

Does motor SCA (34085-1310) for the S1 disk L Yes

break? No

Does motor SCA (34085-1310) for the C2 disk L Yes

break? No

Does motor SCA (34085-1310) for the C1 disk L Yes

break? No

Does motor SCA (34085-1310) for the A1 disk L Yes

break? No

Does motor SCA (34085-1310) for the A2 disk L Yes

break? No

Replace the MB main board (34085-BA01). (See 6.17.)

Replace the L motor CPU board (34085-BA02). (See 6.13.)

Replace the L motor CPU board (34085-BA02). (See 6.13.)

Replace motor SCA (34085-1310) for the S2 disk L. (See 6.11.1.1.)

Replace motor SCA (34085-1310) for the S1 disk L. (See 6.11.1.3.)

Replace motor SCA (34085-1310) for the C2 disk L. (See 6.11.1.2.)

Replace motor SCA (34085-1310) for the C1 disk L. (See 6.11.1.5.)

Replace motor SCA (34085-1310) for the A1 disk L. (See 6.11.1.4.)

Replace motor SCA (34085-1310) for the A2 disk L. (See 6.11.1.6.)

4 - 7

MRT10*RDA001A/E

|

|

|

Does motor PCA (34085-1320) for the CA disk L |

Yes |

|

break? |

|

|

No |

|

|

|

|

|

Does motor PCA (34085-1320) for the PA disk L |

Yes |

|

break? |

|

|

|

|

|

No |

|

|

|

|

|

Does motor PCA (34085-1320) for the P2 disk L |

Yes |

|

break? |

|

|

|

|

|

No |

|

|

|

|

|

Is the voltage between 3-2 pins of connector J4 on the |

|

|

L motor CPU board (34085-BA02) as described |

No |

|

below? |

|

|

Sensor 2 for the CA disk R is shaded. |

:5V |

|

Sensor 2 for the CA disk R is not shaded |

:0V |

|

|

|

|

Yes |

|

|

|

|

|

Is the voltage between 3-2 pins of connector J5 on the |

|

|

L motor CPU board (34085-BA02) as described |

No |

|

below? |

|

|

Sensor 2 for the P1 disk is shaded. |

:5V |

|

Sensor 2 for the P1 disk is not shaded. |

:0V |

|

|

|

|

Yes |

|

|

|

|

|

Is the voltage between 3-2 pins of connector J6 on the |

|

|

L motor CPU board (34085-BA02) as described |

No |

|

below? |

|

|

Sensor 2 for the P2 disk R is shaded. |

:5V |

|

Sensor 2 for the P2 disk R is not shaded. :0V |

|

|

|

|

|

Yes |

|

|

Replace the L motor driver board (34085-BA03). (See 6.14.)

|

No |

|

Is the symptom relieved? |

||

|

||

|

|

|

Yes |

|

|

|

|

|

Completion |

|

|

|

|

Replace motor PCA (34085-1320) for the CA disk L. (See 6.11.2.1.)

Replace motor PCA (34085-1320) for the P1 disk L. (See 6.11.2.2.)

Replace motor PCA (34085-1320) for the P2 disk L. (See 6.11.2.3.)

Replace sensor 2 (34085-1330) for the CA disk L. (See 6.11.3.1.)

Replace sensor 2 (34085-1330) for the P1 disk L. (See 6.11.3.2.)

Replace sensor 2 (34085-1330) for the P2 disk L. (See 6.11.3.3.)

Replace the L motor CPU board (34085-BA02). (See 6.13.)

4 - 8

MRT10*RDA001A/E

4.2.4 The PD and convergence of the MB is not initialized properly.

Turn OFF the main switch. Does the driving gear of the step-out motor turn smoothly when turning it by hand?

Yes

Is the MB initial pulse the same as the one on the label attached to the upper rear cover (34085-2900)?

Yes

Does the PI sensor board (34085-BA08) for PD of the upper brace R (34085-2500) break?

No

Does the PI sensor board (34085-BA08) for CON of the upper brace R (34085-2500) break?

No

Does the PI sensor board (34085-BA08) for PD of the upper brace L (34085-2600) break?

No

Does the PI sensor board (34085-BA08) for CON of the upper brace L (34085-2600) break?

No

Replace the MB main board (34085-BA01). (See 6.17.)

No

No

Yes

Yes

Yes

Yes

Adjust the engagement of the PD gear that does not turn smoothly.

Set the MB initial pulse to a proper one. (See 7.2.1.)

Replace the PI sensor board (34085-BA08) for PD of the upper brace R (34085-2500). (See 6.9.2.1.)

Replace the PI sensor board (34085-BA08) for CON of the upper brace R (34085-2500). (See 6.9.1.1.)

Replace the PI sensor board (34085-BA08) for PD of the upper brace R (34085-2600). (See 6.9.2.2.)

Replace the PI sensor board (34085-BA08) for CON of the upper brace L (34085-2600). (See 6.9.1.2.)

4 - 9

MRT10*RDA001A/E

4.2.5 The right disk of the MB is not initialized properly.

Turn OFF the main switch. Does the driving gear of the step-out motor turn smoothly when turning it by hand?

Yes

Is the MB initial pulse the same as the one on the label attached to the upper rear cover (34085-2900)?

Yes

Is the voltage between 3-2 pins of connector J4 on the R motor CPU board (34085-BA04) as described below?

Sensor 2 for the CA disk R is shaded. :5V Sensor 2 for the CA disk R is not shaded. :0V

Yes

Is the voltage between 3-2 pins of connector J5 on the R motor CPU board (34085-BA04) as described below?

Sensor 2 for the P1 disk R is shaded. :5V Sensor 2 for the P1 disk R is not shaded. :0V

Yes

Is the voltage between 3-2 pins of connector J6 on the R motor CPU board (34085-BA04) as described below?

Sensor 2 for the P2 disk R is shaded. :5V Sensor 2 for the P2 disk R is not shaded. :0V

Yes

Is the symptom relieved? Yes

Completion

No

No

No

No

No

No

Adjust the gear engagement of the disk, axis and such that do not turn smoothly.

Set the MB initial pulse to a proper one. (See 7.2.1.)

Replace the sensor 2 (34085-1330) for the CA disk R. (See 6.10.3.1.)

Replace the sensor 2 (34085-1330) for the P1 disk R. (See 6.10.3.2.)

Replace sensor 2 (34085-1330) for the P2 disk R. (See 6.10.3.3.)

Replace sensor 1R (34085-1180). (See 6.5.1.)

4 - 10

MRT10*RDA001A/E

4.2.6 The left disk of the MB is not initialized properly.

Turn OFF the main switch. Does the driving gear of the step-out motor turn smoothly when turning it by hand?

Yes

Is the MB initial pulse the same as the one on the label attached to the upper rear cover (34085-2900)?

Yes

Is the voltage between 3-2 pins of connector J4 on the L motor CPU board (34085-BA02) as described below?

Sensor 2 for the CA disk R is shaded. :5V Sensor 2 for the CA disk R is not shaded. :0V

Yes

Is the voltage between 3-2 pins of connector J5 on the L motor CPU board (34085-BA02) as described below?

Sensor 2 for the P2 disk R is shaded. :5V Sensor 2 for the P2 disk R is not shaded. :0V

Yes

Is the voltage between 3-2 pins of connector J6 on the L motor CPU board (34085-BA02) as described below?

Sensor 2 for the P2 disk R is shaded. :5V Sensor 2 for the P2 disk R is not shaded. :0V

Yes

Is the symptom relieved? Yes

Completion

No

No

No

No

No

No

Adjust the gear engagement of the disk, axis and such that do not turn smoothly.

Set the MB initial pulse to a proper one. (See 7.2.1.)

Replace sensor 2 (34085-1330) for the CA disk L. (See 6.11.3.1.)

Replace sensor 2 (34085-1330) for the P1 disk L. (See 6.11.3.2.)

Replace sensor 2 (34085-1330) for the P2 disk L. (See 6.11.3.3.)

Replace sensor 1L (34085-1280). (See 6.5.2.)

4 - 11

MRT10*RDA001A/E

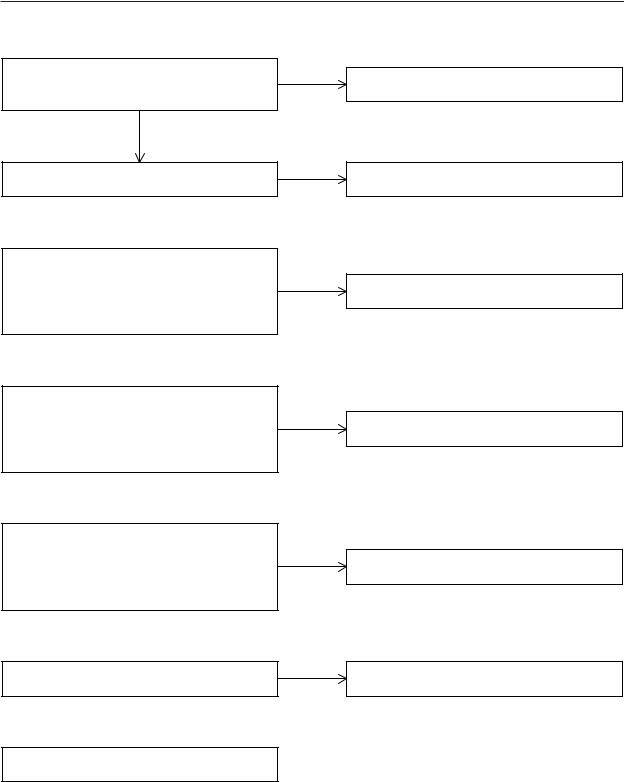

4.3 An error message appears.

|

Yes |

|

Does error 01: communication error CB-MB appear? |

||

|

||

|

|

|

No |

|

|

|

Yes |

|

Does error 11: communication error CB-RB appear? |

||

|

||

|

|

|

No |

|

|

|

Yes |

|

Does “No appointment data!!” appear? |

||

|

||

|

|

|

No |

|

|

|

Yes |

|

Does “Chart doesn’t work.” appear? |

||

|

||

|

|

|

No |

|

|

|

Yes |

|

Does “Setup data is initialized.” appear? |

||

|

||

|

|

|

No |

|

|

|

Yes |

|

Does “CF card Read Error!!” appear? |

||

|

||

|

|

|

No |

|

|

|

Yes |

|

Does “CF card -- Write Error !!” appear? |

||

|

||

|

|

|

No |

|

|

|

Yes |

|

Does “CF card -- File Error” appear? |

||

|

||

|

|

|

No |

|

|

|

Yes |

|

Does “CF card -- File not found!!” appear? |

||

|

||

|

|

|

No |

|

|

|

Yes |

|

Does “CF card -- Card not found!!” appear? |

||

|

||

|

|

|

No |

|

|

|

Yes |

|

Does “No data!!” appear? |

||

|

||

|

|

|

No |

|

|

|

|

|

Completion |

|

|

|

|

4.3.1 “Error01: Communication Error CB-RB”

appears.

4.3.2 “Error11: Communication Error CB-RB”

appears.

4.3.3“No appointment data!!” appears.

4.3.4“Chart doesn’t work.” appears.

4.3.5“Setup data is initialized.” appears.

4.3.6“CF card -- Read Error!!” appears.

4.3.7“CF card -- Write Error !!” appears.

4.3.8“CF card -- File Error” appears.

4.3.9“CF card -- File not found!!” appears.

4.3.10“CF card -- Card not found!!” appears.

4.3.11“No data!!” appears.

4 - 12

MRT10*RDA001A/E

4.3.1 “Error 01: Communication Error CB-MB” appears.

Is the voltage of the following connector on the RB I/F board (834085-BA22) as described below?

A1-A4 pins of connector J5: DC+5V

A12-A8 pins of connector J5: DC+15V

Yes

Does cable MB break?

No

Does the MB work properly?

Yes

Does cable CB break?

No

Replace the RB I/F board (834085-BA22). (See 6.27.)

Is the symptom relieved?

No

No

Yes

No

Yes

Yes

Replace the RB I/F board (34085-BA22). (See 6.27.)

Replace cable MB.

4.2 Initialization is not completed properly.

Replace cable CB.

Completion

Replace the CB main board (34085-BA11). (See 6.19.)

4 - 13

Loading...

Loading...