1. Installing the Cabinet

2. PCB Installation

• To use the IntraMail enhancements provided by software versions 03.2*.** and

higher, you must use the NEC IntraMail Utility version 1.2 to upgrade your IntraMail CompactFlash card. If you don’t upgrade your card, the new features will not

be available.

• If upgrading from version 3 software prior to 03.10.08 using telephone programming, you must reprogram the options in

Options , 8005-IntraMail Master Mailbox Options , and 8006-IntraMail Routing Mailboxes after the upgrade.

• To avoid having to reprogram the above options, use the latest version of the

DS1000/2000 System Administrator to backup and restore the site database.

• Go to

http://ws1.necii.com/ds2000

Utility, IntraMail Utility, System Administrator, and system software.

1808-IntraMail Subscriber Mailbox

to download the latest versions of the Update

3. Installing Extensions

and Trunks

4. Optional

Equipment

5. Maintenance

Options and SMDR

6. Specifications

and Parts

Hardware Manual

(03.2*.**)

For additional resources, visit our Technical Support site on the web at

http://ws1.necii.com/ds2000

.

This manual has been developed by NEC Unified Solutions, Inc. It is intended for the use of its customers and service

personnel, and should be read in its entirety before attempting to install or program the system. Any comments or suggestions

for improving this manual would be appreciated. Forward your remarks to:

NEC Unified Solutions, Inc.

4 Forest Parkway

Shelton, CT 06484

www.necunifiedsolutions.com

Nothing contained in this manual shall be deemed to be, and this manual does not constitute, a warranty of, or representation

with respect to, any of the equipment covered. This manual is subject to change without notice and NEC Unified Solutions,

Inc. has no obligation to provide any updates or corrections to this manual. Further, NEC Unified Solutions, Inc. also reserves

the right, without prior notice, to make changes in equipment design or components as it deems appropriate. No

representation is made that this manual is complete or accurate in all respects and NEC Unified Solutions, Inc. shall not be

liable for any errors or omissions. In no event shall NEC Unified Solutions, Inc. be liable for any incidental or consequential

damages in connection with the use of this manual. This document contains proprietary information that is protected by

copyright. All rights are reserved. No part of this document may be photocopied or reproduced without prior written consent

of NEC Unified Solutions, Inc.

©2005 by NEC Unified Solutions, Inc. All Rights Reserved.

Printed in U.S.A.

Table of Contents

Table of Contents

Section 1: Installing the Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

System Preparation and Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Unpacking. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Before Installing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Site Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Expanded Database . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

DS2000 Default Numbering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Automatic Slot Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

System Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

DS2000 Default Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

DS2000 Configuration Guidelines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

DS2000 Load Factor Calculations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Installing the Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Planning the Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Removing the Cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Unpacking the Wall Mount Bracket. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Mounting the Wall Mount Bracket. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Hanging the Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

Grounding the Cabinet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

Removing the Right Side Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

Attaching the Ground Wires. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

RFI Suppressor Assemblies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

Installing RFI Suppressor Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

Power Supply Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

Installing the Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

Section 2: PCB Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

PCB Location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Where to Install the PCBs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Installing PCBs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Central Processing Unit (CPU) PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Installing the CPU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Digital Station (16DSTU) PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Analog Station (8ASTU and 4ASTU) PCBs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

16-Port Analog Station (16ASTU) PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Analog Trunk (8ATRU and 4ATRU) PCBs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

T1 Trunk PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

T1 PCB Leds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

T1 Programming Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Connecting Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Working With 8-Pin Jacks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Punching Down the Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Making Your Own Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

DS2000 Hardware Manual

Table of Contents ◆ i

Table of Contents

Section 3: Installing Extensions and Trunks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Connecting Extensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Connecting Extensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Connecting Trunks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Connecting Analog Trunks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Power Up and System LEDs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Power-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Finishing the Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Reinstalling the Side Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Reinstalling the Front Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Section 4: Optional Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

External Paging. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Installing External Paging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

External Paging Relay Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Connecting the Relay for External Paging Control . . . . . . . . . . . . . . . . . 4-2

Programming the Relay for External Paging Control . . . . . . . . . . . . . . . 4-3

Additional Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Music Source. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Installing a Music Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Programming Background Music. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Programming Music on Hold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Power Failure Telephone . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Power Failure Cut-Through . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

DSS Console . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Installing a DSS Console . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Programming DSS Consoles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

2-OPX Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Installing the 2-OPX Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Programming 2-OPX Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Wall Mounting the 2-OPX Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Wall-Mount Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Installing the Wall-Mount Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Wall-Mounting a Key Telephone. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Desk Stand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

Using the Desk Stand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

REJ Recording Jack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

Installing the REJ Recording Jack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

Keyset Self Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

Testing the Keyset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

Section 5: Maintenance Options and SMDR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Backing Up Site Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

PC Card Data Base Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Backing Up Site Data with a PC Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

ii ◆ Table of Contents

DS2000 Hardware Manual

Table of Contents

PC Card Backup Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Restoring Site Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Restoring Site Data from a PC Card. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

PC Card Restore Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Loading New System Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Loading System Software from a PC Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

SMDR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Installing SMDR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Programming SMDR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Testing the Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Checking the System’s Serial Port Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Modem Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Installing a Modem. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Making Your Own Data Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

System Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

Resetting Your System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10

Section 6: Specifications and Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Index-1

DS2000 Hardware Manual

Table of Contents ◆ iii

Table of Contents

iv ◆ Table of Contents

DS2000 Hardware Manual

System Preparation and Configuration

Section 1: Installing

System Preparation and Configuration

System Preparation and Configuration

Unpacking

Unpack the equipment and check it against your equipment lists. Inspect for physical damage. If you are not

sure about a component’s function, review the Product Description Manual. Contact your Sales Representative if you have additional questions.

1

the Cabinet

Have the appropriate tools for the job on hand, including: a test set, a punch down tool and a digital voltmeter.

Before Installing

Make sure you have a building plan showing the location of the common equipment, extensions, the telco

demarcation and earth ground. In addition, the installation site must meet the requirements outlined in the

Standard Practices Manual.

Site Requirements

The common equipment is contained in the wall-mounted Main Equipment Cabinet. Choose a central location

for the cabinet that allows enough space for the equipment — and provides enough room for you to comfortably

work. Figure 1-1

on page 1-9

Layout

4 Slot Cabinet Installation Layout on page 1-8

show you about how much space your system requires.

and Figure 1-2 8 Slot Cabinet Installation

DS2000 Hardware Manual

Section 1: Installing the Cabinet ◆ 1-1

System Preparation and Configuration

1

1

Expanded Database

The Expanded Database is a new database method that provides database records (memory) for all

possible extensions, trunks, Hunt Groups, Ring Groups, and Voice Mail ports. This new capability

allows for:

●

Automatic Slot Configuration.

●

Simplified installation of Voice Mail, Hunt Groups, and Ring Groups.

●

Support for built-in UltraMail and IntraMail Voice Mail

●

Introduction of the DS-Series PC Program.

To understand the Expanded Database, you’ll need to keep track of three things: port, station (or

trunk) number, and extension number.

●

Port

The port is where the device you are programming connects to the system. For example, each

16DSTU PCB has 16 ports which can connect up to 16 digital telephones. Ports are numbered

consecutively for each slot, and only exist when you plug in the PCB to which the device

should connect.

●

Station Number and Trunk Number

The station or trunk number is the element in software that keeps track of the connected

devices’s programming. Station and trunk numbers (and associated database records) exist for

all possible devices you can connect to the system, even if you don’t have any ports installed

to connect them. You can’t call station and trunk numbers directly - you need the associated

extension numbers to do that (see below).

●

Extension Numbers

Extension numbers allow you to access the stations and trunks. By default, each station and

trunk number has an extension number assigned to it. You can change these assignments if

you want to.

- Digital station ports have primary and secondary station numbers. The primary station’s

extension number is used to call the device connected to the port. The secondary station’s

extension number calls the second channel on 2-channel devices such as 2-OPX Modules

and Digital VANGARD Voice Mail ports.

DS2000 Default Numbering

Here is how the ports, station numbers, trunk numbers, and extension numbers are initially set up.

Stations (Telephones) Ports Station Numbers Extension Numbers

Station

Unassigned

Total Station Ports

•To find out the default extension number for any station number,

- For example, station number

Trunks Ports Trunk Numbers Extension Numbers

Trunk Ports

Total Trunk Ports

•To find out the default extension number for a trunk number,

- For example, trunk number

uses extension number 101 (1 + 100).

1-2 ◆ Section 1: Installing the Cabinet

Default Numbering in DS2000

Set by installed PCB 1-96

1

32 97-128

128

add 299 to the station number.

uses extension number 300 (1 + 299).

Set by installed PCB

64

add 100 to the trunk number.

300-395

396-427

--

1-64 101-164

--

DS2000 Hardware Manual

System Preparation and Configuration

Default Numbering in DS2000

Voice Mail Stations Station Numbers Extension Numbers

201-208 500-507

UCD Groups Total Groups UCD Group Master Extension Numbers

8 700-707

Ring Groups Total Groups Ring Group Master Extension Numbers

8 600-607

1

Available for digital station port secondary station numbers. These are used for the second channels on 2-OPX

Modules and Digital VANGARD Voice Mail.

The following table shows the port capacity of each DS2000 PCB.

DS2000 PCB Port Capacities

PCB Description Port Capacity

Station PCBs

16DSTU PCB 16 Digital Station PCB 16 (1-16)

4ASTU PCB 4 Analog Station PCB 4 (1-4)

8ASTU PCB 8 Analog Station PCB 8 (1-8)

Trunk PCBs

4ATRU PCB 4 Analog Trunk PCB 4 (1-4)

8ATRU PCB 8 Analog Trunk PCB 8 (1-8)

T1 PCB T1/E1 PCB 24 (1-24) when enabled for T1

30 (1-30) when enabled for E1

1

Since the Expanded Database maintains database records for all extensions and trunks, you have

the option of using

Trunks (DS2000)

or DSTU PCB into the slot, the ports on the PCB access the associated station numbers. If you

remove that PCB and plug an ATRU in its place, the ports on the ATRU PCB access the associated

trunk numbers. Refer to the

tem for more.

Program 9902 - Set Up Stations (DS2000) and Program 9903 - Set Up

to assign a station and a trunk PCB to the same slot . When you plug in an ASTU

Software Manual on the System Document CD that came with your sys-

DS2000 Hardware Manual

Section 1: Installing the Cabinet ◆ 1-3

System Preparation and Configuration

Automatic Slot Configuration

Automatic Slot Configuration automatically sets up station and trunk PCBs when you initially

power up the system. This simplifies installation because you no longer have to use system programming to activate station and trunk PCBs after you plug them in.

Here’s how Automatic Slot Configuration works:

● With power off, install your station and trunk PCBs.

With the system powered down, install the station and trunk PCBs from left to right in the

order you want your extension and trunk numbers set up.

- Be sure to install a 16DSTU (16 Digital Station) PCB in the first slot (CN1).

- You don’t have to group your station and trunk PCBs together, although it may be more

convenient to do so. For example, when setting up a 16x32 system, you can install the 2nd

DSTU PCB and your two ATRU PCBs in any slot, in any order. Automatic Slot Configuration will properly handle the numbering.

● Power up the system.

On power up, the system scans the PCBs from left to right and sets up the extension and trunk

numbering as follows.

- Extension numbers will begin with 300 in the first slot and increment from left to right.

- Trunk numbers will begin with 101 (starting from the first installed ATRU PCB) and will

also increment from left to right.

- For example, in a 16x32, the numbering will be:

1st 16DSTU PCB = Extensions 300-315.

2nd 16DSTU PCB = Extensions 316-331.

1st 8ATRU PCB = Trunks 101-108.

2nd 8ATRU PCB = Trunks 109-116.

System Configuration

DS2000 Default Configuration

Automatic Slot Configuration automatically sets up your system’s PCBs when you initially power up the system. There is no longer a factory-installed default configuration, and you don’t have to use system programming

to activate PCBs after you plug them in. Remember, you should always plug a 16DSTU PCB into slot CN1.

To take full advantage of all the new features and enhancements in software version 03.**.**, always use the

latest PCB versions.

1-4

◆ Section 1: Installing the Cabinet DS2000 Hardware Manual

System Preparation and Configuration

DS2000 Configuration Guidelines

The total number of components you can install and connect depends on power supply capacity and the System Load Factor. Review the DS2000 Configuration Guidelines table below and DS2000 Load Factor Cal-

culations on page 1-6 when configuring your system.

DS2000 Configuration Guidelines

4 Slot Cabinets

• Do not install more than 2 16DSTU PCBs under any circumstances.

• The first 16DDSTU PCB you install must be in the first slot (CN1).

• Maximum configuration is

• The total of all extensions and trunks cannot exceed

• Always use the System Load Factor table to check your system configuration.

8 Slot Cabinets

• Do not install more than 2 16DSTU PCBs for each power supply. (Install your power supplies in the

following order: slot CN101

• The first 16DSTU PCB you install must be in the first slot (CN1).

• The total of all extensions and trunks installed cannot exceed

• Maximum configuration is

• Always use the System Load Factor table to check your system configuration.

112 ports.

112.

, slot CN103, slot CN102.)

112.

112 ports.

1

DS2000 Hardware Manual Section 1: Installing the Cabinet ◆ 1-5

System Preparation and Configuration

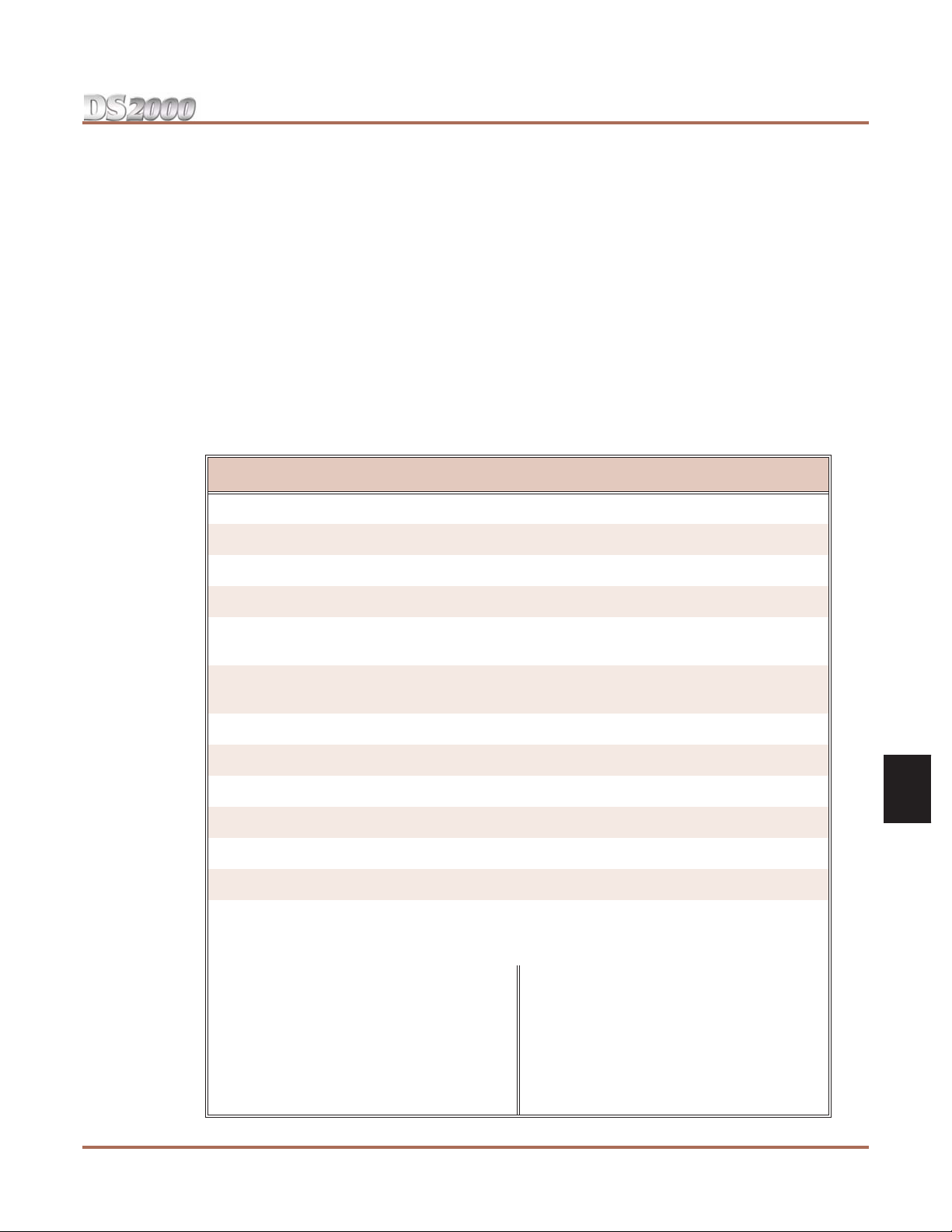

DS2000 Load Factor Calculations

The combination of trunks, extensions, 2-OPX Modules and DSS Consoles you can connect to your DS2000

system may be limited by the System Load Factor. Use the DS2000 System Load Factor Calculations chart

on the next page to verify your system’s configuration. When entering data on the chart, for each installed

item make entries for each Load Type. There are two Load Types to consider: 5 VDC and 40 VDC.

To check your system configuration:

1. Indicate the quantity for each PCB, DSS Console, and 2-OPX Module installed in the

The number of keysets and single line sets does not affect the System Load Factor.

2. For each item for each Load Type, multiply the

column.

For example, two 16DSTU PCBs have a load of 6 for 5 VDC and 40 for 40 VDC.

3. Add up the entries in each

4. Review Item 2: Power Supply Capacity and determine the capacity of the power supplies installed

in your system.

5. Compare the capacities in

the entry in Item 2.

Do not operate your system if the total for either Load Type

exceeds the Power Supply Capacity of your installation.

Total column and enter the values in Item 1: Load Type Totals.

Item 2 to your entries in Item 1. Item 1 must always be equal to or less than

Qty times the Load and enter the value in the Total

!! Important !!

Qty column.

1-6 ◆ Section 1: Installing the Cabinet DS2000 Hardware Manual

System Preparation and Configuration

DS2000 System Load Factor Calculations

Load Type

Description Qty

Load Total Load Total

CPU PCB 1 6 6 0 0

16DSTU PCB 3 20

4ASTU PCB 3 5

8ASTU PCB 5 8

16ASTU PCB 10 17

4ATRU PCB 4 0

8ATRU PCB 8 0

T1 PCB 8 0

UltraMail PCB (FMS) 19 0

UltraMail 2000 PCB (VMS) 0 6

Telephones (Keysets and SLTs) 0 0

110-Button DSS Console 0 2

24-Button DSS Console 0 1

2-OPX Module 0 3

5 VDC 40 VDC

1

(Cannot exceed Item 2: Power Supply Capacity.)

If you have one power supply installed, the capacity is:

If you have two power supplies installed, the capacity is:

If you have three power supplies installed, the capacity is:

Notes:

• A 4 slot cabinet can only have 1 power supply.

• An 8 slot cabinet can have up to 3 power supplies. You cannot have more than two 16DSTU PCBs per power sup-

ply, regardless of System Load Factor calculations.

• Exceeding the allowed Load Type Total (Item 1) will cause the system’s power supplies to automatically shut down

and/or cause erratic system operation.

• Total DSS Consoles installed cannot exceed 4.

• The total of all station, trunk, and UltraMail ports cannot exceed 112.

Item 1: Load Type Totals

Item 2: Power Supply Capacity

5 VDC = 40

5 VDC = 80

5 VDC = 120

40 VDC = 48

40 VDC = 80

40 VDC = 120

DS2000 Hardware Manual Section 1: Installing the Cabinet ◆ 1-7

Installing the Cabinet

Installing the Cabinet

Planning the Installation

Before installing the common equipment, you should mount a Main Distribution Frame (MDF) plywood backboard in a centrally located spot. A 1/2 sheet of plywood (4’ x 4’) should be adequate for a 4 slot cabinet (see

Figure 1-1

an 8 slot cabinet (see Figure 1-2

board using suitable fasteners, taking care to adhere to standard installation practices and local codes.

The equipment cabinet requires a three-prong, dedicated 110 VAC 60 Hz circuit (NEMA 5-15 receptacle).

The AC receptacle must be within 7 feet of the cabinet’s lower left corner.

Normally, you install the extension and trunk blocks to the right of the cabinet. Telco should also install the

RJ21X to the right of the cabinet.

4 Slot Cabinet Installation Layout

Local codes may prohibit you from installing extensions,

below). A full sheet of plywood (8’ x 4’) should be adequate for

8 Slot Cabinet Installation Layout on page 1-9

). Be sure to mount the back-

!! Important !!

trunks and optional equipment in the same blocks.

Plywood backboard

Note: The system will respond to telco ring signal in the

range of 40-130 VAC @ 20 Hz.

80000 - 15A

To telco

ground

Surge

Protector

4'

To earth

ground

Dedicated

AC Outlet

Trunk

Blocks

Station

Blocks

Figure 1-1: 4 Slot Cabinet Installation Layout

Station

Blocks

4'

1-8 ◆ Section 1: Installing the Cabinet DS2000 Hardware Manual

8' X 4' Plywood backboard

80000 - 61

Dedicated

AC Outlet

Trunk

Blocks

Station

Blocks

Installing the Cabinet

Note: The system will respond to telco ring signal in the

range of 40-130 VAC @ 20 Hz.

Station

Blocks

1

Surge

Protector

To telco

ground

Removing the Cover

Before wall-mounting, remove the cover on the Main Equipment Cabinet.

To remove the cover (Figure 1-3):

1. Unscrew the two captive screws on the front of the cabinet cover.

2. Lift up slightly on the front of the cover — then gently slide the cover back to remove it.

To earth

ground

Figure 1-2: 8 Slot Cabinet Installation Layout

80000 - 12

4 Slot Cabinet Shown

Figure 1-3: Removing the Cover

DS2000 Hardware Manual Section 1: Installing the Cabinet ◆ 1-9

Installing the Cabinet

Unpacking the Wall Mount Bracket

The wall mount bracket and screws (see Figure 1-4 Wall Mount Bracket below) are taped to the packing

material in the Main Equipment Cabinet box. Unpack the wall mount bracket and mounting screws.

80000 - 11

Figure 1-4: Wall Mount Bracket

Mounting the Wall Mount Bracket

Mount the wall mount bracket (see Figure 1-5 Mounting the Wall Mount Bracket below) on the MDF in a

convenient location, about 12” higher than where you want the bottom of the cabinet to line up.

Figure 1-5: Mounting the Wall Mount Bracket

80000 - 14

1-10 ◆ Section 1: Installing the Cabinet DS2000 Hardware Manual

Hanging the Cabinet

To hang the cabinet:

1. Hang the Main Equipment Cabinet on the wall mount hanger as shown:

- See Figure 1-6 Hanging the 4 Slot Cabinet below when hanging a 4 slot cabinet.

- See Figure 1-7 Hanging the 8 Slot Cabinet below when hanging an 8 slot cabinet.

2. Using the remaining screws packed with the hanger, secure the cabinet to the plywood backboard.

Installing the Cabinet

1

80000 - 13

Figure 1-6: Hanging the 4 Slot Cabinet

80000 - 60

Figure 1-7: Hanging the 8 Slot Cabinet

DS2000 Hardware Manual Section 1: Installing the Cabinet ◆ 1-11

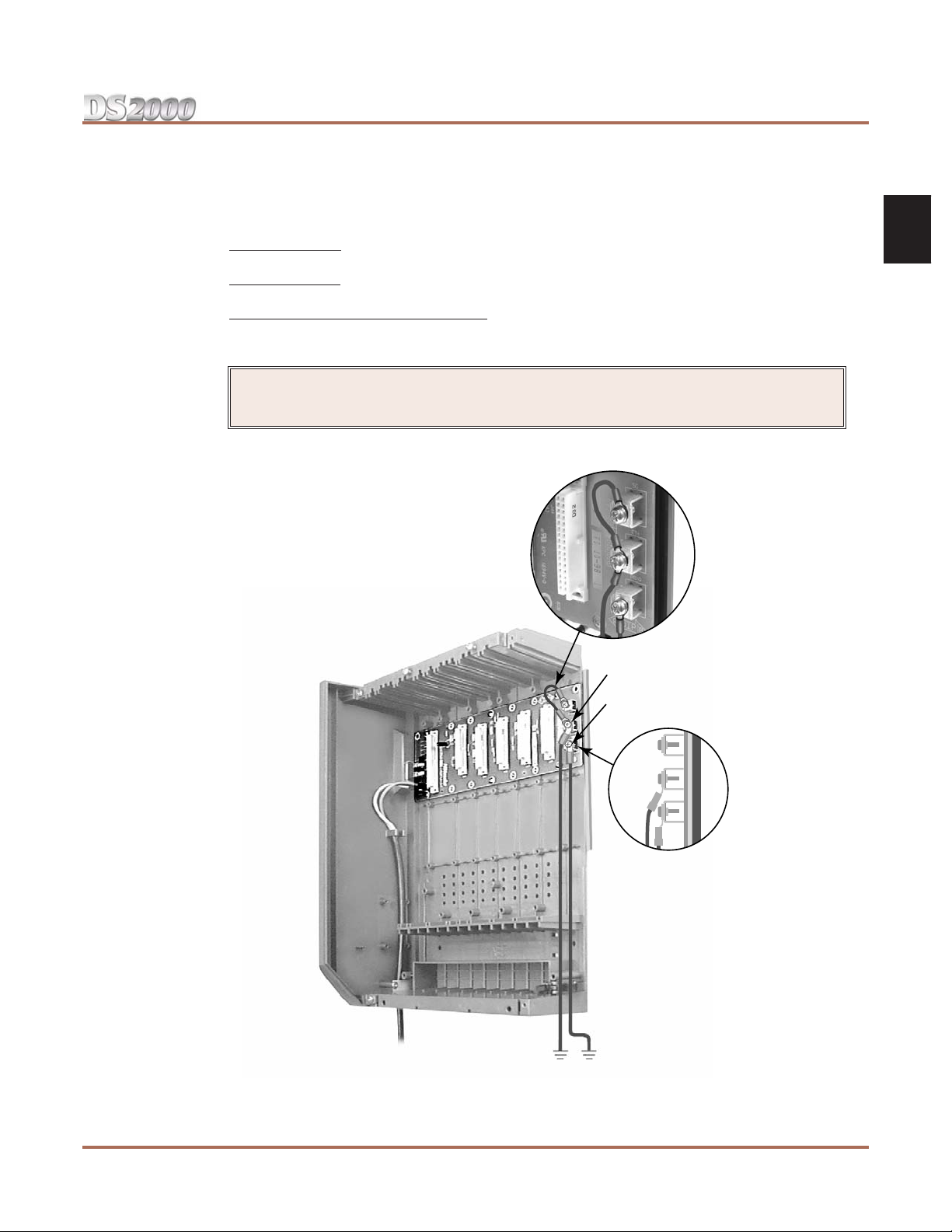

Grounding the Cabinet

Grounding the Cabinet

Removing the Right Side Panel

Remove the cabinet right side panel to gain easy access to the ground lugs and system cabling. The cabinet

has two ground connections: ETH (Earth Ground) and PBXG (PBX Ground).

To remove the right side panel (Figure 1-8):

1. Remove the two screws that secure the right side panel to the cabinet.

2. Carefully slide the right side panel down until it swings clear of the cabinet.

80000 - 16

Figure 1-8: Removing the Right Side Panel

Attaching the Ground Wires

You must connect your system to a known earth

ground according to the following instructions.

The system provides two ground terminations. Each ground connects from the system to the ground termination using 12 AWG stranded copper wire.

●

Use the ETH (Earth Ground) for safety/system ground. You must connect ETH to a known earth ground.

●

Use the PBXG (PBX Ground) if you have trunks that require telco ground (such as ground start trunks).

This ground is not required for loop start trunks.

4 Slot Cabinet Shown

!! Important !!

1-12 ◆ Section 1: Installing the Cabinet DS2000 Hardware Manual

Grounding the Cabinet

To attach the ground wires (Figure 1-9):

1. Remove the lug on the ground connection you want to connect.

2. Follow Figure 1-10

through the RFI Suppressor Assembly as shown.

3. Crimp ring terminals as required to the ground wires.

4. For earth ground:

Run a ground wire from the ETH lug to a known earth ground.

or PBX Ground:

F

Run a ground wire from the PBXG lug to the telco ground.

If your system will have a

Run a 12 AWG jumper wire from the SG (Signal Ground) lug to the ETH (Earth Ground) lug.

5. Reinstall and firmly tighten the lug(s) removed in step 1 above.

Installing RFI Suppressor Assemblies on page 1-14

T1 Trunk PCB:

and run the ground wire(s)

1

Do not plug in the power cord or reinstall the right side panel

until all PCB installation and cabling are complete.

Proper grounding is required.

80000 - 17-1

!! Important !!

For T1 Trunk

PCB only

To earth ground

To telco ground

4 Slot Cabinet Shown

Figure 1-9: Attaching the Ground Wires

DS2000 Hardware Manual Section 1: Installing the Cabinet ◆ 1-13

RFI Suppressor Assemblies

RFI Suppressor Assemblies

Installing RFI Suppressor Assemblies

You must install RFI Suppressor Assemblies as follows (see Figure 1-10

below). The suppressors must be mounted inside the cabinet and as close to the appropriate PCB as possible.

● For Ground Wires

– You must install a separate RFI assembly for the ground wire(s) in all systems.

– If your system has 2 ground wires, install them both in the same assembly.

● For CPU Connections

– You must install a separate RFI assembly for the CPU mod jack and RS-232 cables in all systems.

– Install both cables in the same assembly.

For Ground Wires

• Required for all installations.

Installing RFI Suppressor Assemblies

For CPU Connections

• Required on CPU mod jack

and RS-232 cables for all

installations.

Figure 1-10: Installing RFI Suppressor Assemblies

1-14 ◆ Section 1: Installing the Cabinet DS2000 Hardware Manual

Power Supply Installation

Installing the Power Supply

The power supply provides the DC power sources required to operate the system.

To install a power supply (Figure 1-11) (Figure 1-12):

1. Slide the power supply into the CN101 slot. See Figure 1-12 Installing the Power Supply below.

2. Using a long-shaft phillips head screwdriver, tighten the two screws that secure the power supply.

An 8 slot cabinet may require up to 3 power supplies, using slots CN101, CN102 and CN103. Refer to

System Configuration on page 1-4 for more. Install the first supply in slot CN101. Install the second supply

in slot CN103

. Install the third supply in slot CN102.

Power Supply Installation

1

• Only install Power Supply P/Ns 80005B or 80005C.

• Do not install Power Supply P/Ns 80005 or 80005A.

• You can mix P/Ns 80005B and 80005C in the same system.

• If your system uses UltraMail or UltraMail 2000, you must

install only Power Supply P/Ns 80005C.

Important Compatibility Guidelines

Figure 1-11: Power Supply

4 Slot Cabinet Shown

80000 - 29

Figure 1-12: Installing the Power Supply

DS2000 Hardware Manual Section 1: Installing the Cabinet ◆ 1-15

Power Supply Installation

1-16 ◆ Section 1: Installing the Cabinet DS2000 Hardware Manual

PCB Location

Section 2: PCB

PCB Location

PCB Location

Install telephones connected to DSTU and ASTU PCBs as on-premise extensions only.

Where to Install the PCBs

Review System Configuration on page 1-4 before installing any PCBs. Always observe the System Load

Factor when configuring your system.

● The CPU (Central Processing Unit) PCB must plug into slot CN0.

● A 16DSTU (16 Digital Station) PCB must plug into slot CN1.

● All other PCBs (including 16DSTU PCBs) can plug into slots CN2-CN8.

- Slots CN5-CN8 are only available with the 8 slot cabinet.

- A 4 slot cabinet can only accept two 16DSTU PCBs.

- In an 8 slot cabinet, you can have only two 16DSTU PCBs per power supply.

• Do not plug in the CPU PCB hot (i.e., with the system power applied).

• You can plug in ASTU and ATRU PCBs hot as required.

• You can plug in DSTU PCBs hot provided you first disconnect the station cabling from the PCB.

Installation

2

!! Important !!

!! Caution !!

DS2000 Hardware Manual Section 2: PCB Installation ◆ 2-1

Installing PCBs

Installing PCBs

Central Processing Unit (CPU) PCB

The CPU PCB (Figure 2-1) provides:

● The system’s central processing, stored program and memory for the customer’s site-specific data.

● PC Interface Card.

● Conference circuits, DTMF receivers and DTMF generators.

● External music input and on-board synthesized music source.

● External paging output and associated relay.

● Real Time Clock.

● Battery for short term (14 day) backup of the customer’s site-specific data.

Installing the CPU

The CPU PCB installs in the CN0 slot in the Main Equipment Cabinet.

To install the CPU PCB (Figure 2-2) (Figure 2-3):

1. Slide the Mode Switch to the

2. Insert the battery (Sony CR2032 or NEC P/N EX0254-0040) into the battery clips.

3. Plug the CPU into slot CN0.

Refer to Section 4, Optional Equipment for instructions on

connecting the music source, External Paging, and the auxiliary relay.

Figure 2-1: CPU PCB

RUN position.

80000 - 26

Mode Switch

Battery

Figure 2-2: Setting Up the CPU

2-2 ◆ Section 2: PCB Installation DS2000 Hardware Manual

Installing PCBs

4 Slot Cabinet Shown

2

Figure 2-3: Installing the CPU

Digital Station (16DSTU) PCB

The 16DSTU provides the connection for 16 digital telephones. Refer to Section 3, Installing Extensions and

Trunks for wiring instructions.

To install the 16DSTU PCB (Figure 2-4) (Figure 2-5):

1. Plug the 16DSTU PCB for extensions 300-315 into slot CN1.

2. Plug in additional 16DSTU PCBs as required. See System Configuration on page 1-4 for more.

3. Set the mode switch on each installed 16DSTU PCB to

• In a 4 slot cabinet, you cannot install more than 2 16DSTU PCBs.

• In an 8 slot cabinet, you cannot install more than 2 16DSTU PCBs per power supply.

80000 - 30

RUN.

!! Important !!

DS2000 Hardware Manual Section 2: PCB Installation ◆ 2-3

Installing PCBs

Mode switch

Figure 2-4: Digital Station (16DSTU) PCB

4 Slot Cabinet Shown

80000 - 31

Figure 2-5: Installing the 16DSTU PCB

2-4 ◆ Section 2: PCB Installation DS2000 Hardware Manual

Analog Station (8ASTU and 4ASTU) PCBs

The 8ASTU PCB provides connection for 8 analog extensions. The 4ASTU PCB connects 4 analog extensions.

Refer to Section 3, Installing Extensions and Trunks for wiring instructions.

To install the ASTU PCB (Figure 2-6) (Figure 2-7):

1. Plug in ASTU PCBs as required. See System Configuration on page 1-4 for more.

2. Set the mode switch on each ASTU PCB to

Mode switch

Installing PCBs

RUN.

2

Figure 2-6: Analog Station (ASTU) PCB

80000 - 31A

Figure 2-7: Installing the ASTU PCB

4 Slot Cabinet Shown

DS2000 Hardware Manual Section 2: PCB Installation ◆ 2-5

Installing PCBs

16-Port Analog Station (16ASTU) PCB

The 16ASTU PCB provides connection for 16 analog extensions.

To install the 16ASTU PCB (Figure 2-8) (Figure 2-9):

1. Check your system configuration to be sure you do not exceed the allowable System Load Factor.

2. Plug the 16ASTU PCB into any available slot from

You should reserve

The PCB will auto-ID when you plug it in.

3. Set the mode switch on the 16ASTU PCB to

Mode switch

CN1 for a 16DSTU PCB.

CN2-CN8.

RUN.

Figure 2-8: 16-Port Analog Station (16ASTU) PCB

4 Slot Cabinet Shown

Figure 2-9: Installing the 16ASTU PCB

2-6 ◆ Section 2: PCB Installation DS2000 Hardware Manual

Analog Trunk (8ATRU and 4ATRU) PCBs

The 8ATRU provides connection for 8 loop start analog trunks. The 4ATRU PCB connects 4 loop start

analog trunks.

To install the ATRU PCB (Figure 2-10) (Figure 2-11):

1. Plug in ATRU PCBs as required. See System Configuration on page 1-4 for more.

2. Set the mode switch on each ATRU PCB to

Mode switch

Refer to Section 3, Installing Extensions and Trunks for wiring instructions.

Installing PCBs

RUN.

2

Notes:

• The system will respond to telco ring signal in

the range of 42-103 VAC @ 20 Hz.

• Telco battery must be 44-56 VDC.

Figure 2-10: Analog Trunk (ATRU) PCB

Figure 2-11: Installing the ATRU PCB

4 Slot Cabinet Shown

80000 - 32

DS2000 Hardware Manual Section 2: PCB Installation ◆ 2-7

Installing PCBs

T1 Trunk PCB

The DS2000 T1 PCB requires system software version 03.03.00 or

higher and expanded memory CPU P/N 80025B.

The T1 Trunk PCB (Figure 2-12) provides advanced digital trunking and gives the DS2000 a maximum of

24 trunks in a single PCB slot. The available T1 trunk types include:

● Loop Start and Ground Start (DTMF and Dial Pulse)

● Direct Inward Dialing (DID) Wink Start and Immediate Start (DTMF and Dial Pulse)

● E&M Tie Line Wink Start and Immediate Start (DTMF and Dial Pulse)

Notes

● Although the T1 PCB can connect directly to the telco’s T1 smart jack, a separately-purchased Channel

Service Unit (CSU) between the smart jack and the T1 PCB is recommended. Additionally, your telco

may require a CSU.

● Normally, the T1 PCB connects to the telco’s T1 smart jack or your CSU using a standard straight-

through CAT 5 cable. However, always check the documentation that came with your CSU for cabling

requirements.

● The T1 PCB installs in any universal slot but slot 1.

● A commercially available T1 Tester is recommended.

Figure 2-12: T1 Trunk PCB

To install the T1 Trunk PCB (Figure 2-13) (Figure 2-14):

1. Set jumpers

CN7 and CN9 to the T1 position.

2-8 ◆ Section 2: PCB Installation DS2000 Hardware Manual

Installing PCBs

2. Plug in T1 Trunk PCBs as required. See System Configuration on page 1-4 for more.

3. Set the mode switch on each T1 PCB to RUN.

4. Using a standard straight-through CAT 5 cable, connect the T1 PCB RJ48C connector to the Telco

Smart Jack or your Channel Service Unit.

Although the T1 PCB can connect directly to the telco’s T1 smart jack, a separately purchased

Channel Service Unit (CSU) between the smart jack and the T1 PCB is recommended. Additionally,

your telco may require a CSU.

80061 - 2

RX1 T

Mode switch

CN9

E1

T1

RJ48C Connector

CN9

RX1 R

1 2 3 4 5 6 7 8

Pinouts

TX1 T

TX1 R

T1 Grounding Requirements

Be sure to run a 12 AWG

jumper wire from the SG (Signal Ground) lug to the ETH

(Earth Ground) lug.

2

E1

T1

CN7

CN7

Connector

RS232 Port

RJ48C

Telco

Smart Jack

Straight-Through

CAT 5 Cable

Figure 2-13: T1 Trunk PCB Setup

DS2000 Hardware Manual Section 2: PCB Installation ◆ 2-9

Installing PCBs

4 Slot Cabinet Shown

Figure 2-14: Installing the T1 Trunk PCB

80000 - 76

2-10 ◆ Section 2: PCB Installation DS2000 Hardware Manual

T1 PCB Leds

Installing PCBs

Port Activity

Off: All ports on PCB idle.

Flash: Port(s) busy. The faster the flash, the more

Sync (Master) (Green)

Off: T1 PCB is in the slave mode (i.e., getting the

On: T1 PCB is

Flash:

Loop (Slave) (Green)

Off: T1 PCB is in the master mode (i.e., providing

On: T1 PCB is in sync with the external clock

Flash:

LOS (Loss of Signal) or Red Alarm (Red)

Off: Signal from the connected telco T1 Circuit is

On: Signal from the connected telco T1 circuit is

An LOS alarm means there is a problem upstream

from the T1 PCB.

BPV (Bi-Polar Violation) Alarm (Red)

This alarm indicates that consecutive “one” pulses

have been received in the T1 signal in error.

Off: The telco’s T1 signal does not contain

On: The telco’s T1 signal is in error. It contains

A BPV alarm means there is a problem upstream from

the T1 PCB.

(Yellow)

ports are busy.

clock from the connected T1 circuit).

telco and is in sync.

T1 PCB is providing the master clock but is

not in sync

the clock to the connected T1 circuit).

source (and is not

T1 PCB

source (and is not

present.

not present.

Bi-Polar Violations.

Bi-Polar Violations.

providing the master clock to the

.

providing the master clock).

is not in sync with the external clock

providing the master clock)

PCB Running (Green)

Slow flash: T1 PCB running.

On: T1 PCB starting.

2

.

AIS (Alarm Indication Signal) or Blue Alarm (Red)

The telco sends an AIS alarm signal to the T1 PCB if

the telco receives faulty data from another device on

its network (i.e., upstream). It sends the AIS alarm signal to the PCB instead of the faulty data it received.

Off: AIS signal not received

On: AIS received

An AIS alarm means there is a problem upstream

from the telco (and upstream from the T1 PCB).

from telco.

from telco.

U

pstrea

D

ownstrea

Yellow (RAI or Remote Alarm Indication) Alarm (Red)

The telco sends an RAI alarm to the T1 PCB if it

detects a problem with the T1 signal received from the

installation site. The problem can come from the T1

PCB, the CSU (if any), or be caused by faulty cabling.

Off: RAI signal not received

On: RAI received

An RAI alarm means there is a problem downstream

from the telco (i.e., in the T1 PCB, CSU, or cabling).

m

from T1 PCB

m

from T1 PCB

from telco.

from telco.

T1 PCBCSUTelco

Figure 2-15: T1 PCB LEDs

DS2000 Hardware Manual Section 2: PCB Installation ◆ 2-11

Installing PCBs

T1 Programming Summary

For more in depth feature description and programming details, refer to the following features in the

DS1000/2000 Software Manual (P/N 80000SWG**): Direct Inward Dialing, T1 Trunking, and Tie Lines.

Basic Programming

● 1001 - Trunk Circuit Type

Set the circuit type for each T1 trunk. The available types are:

- 51 (Loop Start DTMF)

- 52 (Loop Start DP)

- 53 (Ground Start DTMF)

- 54 (Ground Start DP)

- 57 (DID DTMF Wink Start)

- 58 (DID DP Wink Start)

- 59 (DID DTMF Immediate Start)

- 60 (DID DP Immediate Start)

- 61 (E&M DTMF Wink Start)

- 62 (E&M DP Wink Start)

- 63 (E&M DTMF Immediate Start)

- 64 (E&M DP Immediate Start)

● 9904 - T1/E1 Configuration

Use this option to set parameters for the T1 PCB.

● Clock Control

Default: T1 PCB is the clock master.

- Transmit Pulse Amplitude

- Framer Type

- Zero Suppression

- Number of PCM Channels

- Loopback

ANI/DNIS Programming

● 1001 - Caller ID

Enter 3 to enable ANI-based Caller ID.

● 1001 - ANI/DNIS

Specify the type of ANI/DNIS Caller ID provided by your T1 trunks. The options are:

- 0 (None)

- 1 (ANI)

- 2 (*ANI*)

- 3 (*DNIS*)

- 4 (*ANI*DNIS)

● l001 - ANI Delimiter

For ANI/DNIS options 2-4 above, specify the ANI delimiter (0-9, # or *).

● 1001 - Number of ANI Digits

For ANI/DNIS option 1, specify the number of digits in the ANI number.

● If a T1 PCB is connected to a telco T1 circuit, it is usually set as clock slave (i.e., uses the

telco clock source).

● If a T1 PCB is connected to a private T1 circuit, set the clock source according to the net-

work configuration.

Default: 0 (0dB), the T1 PCB is within 133’ of smart jack or CSU.

Default: ESF - Extended Super Frame.

Default: Enabled - B8ZS.

Default: 0 - All channels active. The active channels are always the lower-numbered circuits (i.e.,

an entry of 8 means that channels 1-8 are active).

Default: 0 - No loopback options enabled.

2-12 ◆ Section 2: PCB Installation DS2000 Hardware Manual

Installing PCBs

DID Programming (Basic)

● 1401 - Number of DID Digits

Specify the number of DID Digits (1-8) expected from the telco.

● 1402 - DID Translation Table

Set up the system’s DID routing.

Refer to your Software Manual for additional options for setting up DID Camp On and DID Overflow.

Tie Line Programming (Basic)

Refer to your Software Manual for additional options for setting up Tie Line trunk and operator access.

If you don’t have a T1 Tester, you can alternately test Tie Line operation between two T1 PCBs in the same

cabinet or facility using the cable shown below (Figure 2-16).

To T1 PCB To T1 PCB

Latch

faces up

80061 - 3

Pin

1

2

3

4

5

6

7

8

RX1T

RX1R

TX1T

TX1R

TX1R

TX1T

RX1R

RX1T

Pin

8

7

6

5

4

3

2

1

Figure 2-16: Connecting Two T1 PCBs Together without a Telco T1 Circuit

(For Tie Line Testing)

2

DS2000 Hardware Manual Section 2: PCB Installation ◆ 2-13

Connecting Blocks

Connecting Blocks

Working With 8-Pin Jacks

The system uses 8-pin mod jacks to connect extensions, trunks and optional equipment. Using the Installation

Cable (P/N 80892) makes it easy to connect the PCBs to standard 66M1-50 connecting blocks. These cables

have six 8-pin modular jacks on one end and are unterminated on the other. In general, each cabinet needs:

● One 66M1-50 block and Installation Cable (P/N 80892) for extensions and optional equipment.

● One 66M1-50 block and Installation Cable (P/N 80892) for trunks.

● Depending on your PCB configuration and local codes, you may need an additional 66M1-50 block

and Installation Cable (P/N 80892) for optional equipment.

Punching Down the Cables

The Installation Cables have six 8-pin jacks installed on one end and are unterminated on the other. Each

8-pin jack connects 4 extensions or 4 trunks.

To punch down the cables (Figure 2-17) through (Figure 2-21):

1. For each 66M1-50 block, punch down the Installation Cable in standard color-code order.

- Use Figure 2-17 Connecting 16DSTU Digital Station and 4/8ASTU Analog Station PCBs on page 215 when connecting extensions.

- Use Figure 2-19 Connecting 4/8ATRU Trunk PCBs on page 2-17 when connecting trunks.

2. After you have punched down your cables, route them through the side of the cabinet and secure them

with the strain relief (Figure 2-20 Securing the Cables on page 2-18).

Making Your Own Cables

If you want to make your cables (instead of using Installation Cable P/N 80892), follow the pinouts in

Figure 2-21 8-Pin (RJ61X) Jack Pinouts on page 2-19.

2-14 ◆ Section 2: PCB Installation DS2000 Hardware Manual

4

1

8ASTU PCB

6

5

16DSTU PCB

3

2

1

8

RJ61X Plug

For Power Failure Telephone connections, refer to

Section 4, Optional Equipment.

4 Slot Cabinet Shown

PCB Location

Extensions 300-323 Shown

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

25-PAIR CABLE

COLOR

CODE

WHT-BLU

BLU-WHT

WHT-ORN

ORN-WHT

WHT-GRN

GRN-WHT

WHT-BRN

BRN-WHT

WHT-SLT

SLT-WHT

RED-BLU

BLU-RED

RED-ORN

ORN-RED

RED-GRN

GRN-RED

RED-BRN

BRN-RED

RED-SLT

SLT-RED

BLK-BLU

BLU-BLK

BLK-ORN

ORN-BLK

BLK-GRN

GRN-BLK

BLK-BRN

BRN-BLK

BLK-SLT

SLT-BLK

YEL-BLU

BLU-YEL

YEL-ORN

ORN-YEL

YEL-GRN

GRN-YEL

YEL-BRN

BRN-YEL

YEL-SLT

SLT-YEL

VIO-BLU

BLU-VIO

VIO-ORN

ORN-VIO

VIO-GRN

GRN-VIO

VIO-BRN

BRN-VIO

VIO-SLT

SLT-VIO

1

2

3

4

5

6

80000 - 19A

BLOCK

TERM

FUNCTION RJ61XRJ61X

Connecting Blocks

300 T

300 R

301 T

301 R

302 T

302 R

303 T

303 R

304 T

304 R

305 T

305 R

306 T

306 R

307 T

307 R

308 T

308 R

309 T

309 R

310 T

310 R

311 T

311 R

312 T

312 R

313 T

313 R

314 T

314 R

315 T

315 R

316 T

316 R

317 T

317 R

318 T

318 R

319 T

319 R

320 T

320 R

321 T

321 R

322 T

322 R

323 T

323 R

NC

NC

5

4

3

6

2

7

1

8

5

4

3

6

2

7

1

8

5

4

3

6

2

7

1

8

5

4

3

6

2

7

1

8

5

4

3

6

2

7

1

8

5

4

3

6

2

7

1

8

2

Figure 2-17: Connecting 16DSTU Digital Station and 4/8ASTU Analog Station PCBs

DS2000 Hardware Manual Section 2: PCB Installation ◆ 2-15

Connecting Blocks

16ASTU PCB

1

8

1

RJ-61X Plug

For Power Failure Telephone connections,

refer to Section 4, Optional Equipment.

4 Slot Cabinet Shown

PCB Location

4 Slot

Cabinet Shown

Extensions 316-331 Shown

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

25-PAIR CABLE

COLOR

CODE

WHT-BLU

BLU-WHT

WHT-ORN

ORN-WHT

WHT-GRN

GRN-WHT

WHT-BRN

BRN-WHT

WHT-SLT

SLT-WHT

RED-BLU

BLU-RED

RED-ORN

ORN-RED

RED-GRN

GRN-RED

RED-BRN

BRN-RED

RED-SLT

SLT-RED

BLK-BLU

BLU-BLK

BLK-ORN

ORN-BLK

BLK-GRN

GRN-BLK

BLK-BRN

BRN-BLK

BLK-SLT

SLT-BLK

YEL-BLU

BLU-YEL

YEL-ORN

ORN-YEL

YEL-GRN

GRN-YEL

YEL-BRN

BRN-YEL

YEL-SLT

SLT-YEL

VIO-BLU

BLU-VIO

VIO-ORN

ORN-VIO

VIO-GRN

GRN-VIO

VIO-BRN

BRN-VIO

VIO-SLT

SLT-VIO

FUNCTION RJ-61XRJ61X

316 T

316 R

317 T

317 R

318 T

318 R

319 T

319 R

320 T

320 R

321 T

321 R

322 T

322 R

323 T

323 R

324 T

324 R

325 T

325 R

326 T

326 R

327 T

327 R

328 T

328 R

329 T

329 R

330 T

330 R

331 T

331 R

NC

NC

5

4

3

6

2

7

1

8

5

4

3

6

2

7

1

8

5

4

3

6

2

7

1

8

5

4

3

6

2

7

1

8

5

4

3

6

2

7

1

8

5

4

3

6

2

7

1

8

BLOCK

TERM

4

3

2

1

2

3

4

5

6

80000 - 80

Figure 2-18: Connecting 16ASTU Analog Station PCBs

2-16 ◆ Section 2: PCB Installation DS2000 Hardware Manual

PCB Location

Connecting Blocks

8ATRU PCB

2

1

8

1

RJ61X Plug

4 Slot Cabinet Shown

8ATRU PCB

4

3

N/C

5

N/C

2

6

1

2

3

4

NC

80000 - 20

BLOCK

TERM

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

Trunks 1-16

25-PAIR CABLE

COLOR

CODE

WHT-BLU

BLU-WHT

WHT-ORN

ORN-WHT

WHT-GRN

GRN-WHT

WHT-BRN

BRN-WHT

WHT-SLT

SLT-WHT

RED-BLU

BLU-RED

RED-ORN

ORN-RED

RED-GRN

GRN-RED

RED-BRN

BRN-RED

RED-SLT

SLT-RED

BLK-BLU

BLU-BLK

BLK-ORN

ORN-BLK

BLK-GRN

GRN-BLK

BLK-BRN

BRN-BLK

BLK-SLT

SLT-BLK

YEL-BLU

BLU-YEL

YEL-ORN

ORN-YEL

YEL-GRN

GRN-YEL

YEL-BRN

BRN-YEL

YEL-SLT

SLT-YEL

VIO-BLU

BLU-VIO

VIO-ORN

ORN-VIO

VIO-GRN

GRN-VIO

VIO-BRN

BRN-VIO

VIO-SLT

SLT-VIO

FUNCTIONRJ61X

1 T

1 R

2 T

2 R

3 T

3 R

4 T

4 R

5 T

5 R

6 T

6 R

7 T

7 R

8 T

8 R

9 T

9 R

10 T

10 R

11 T

11 R

12 T

12 R

13 T

13 R

14 T

14 R

15 T

15 R

16 T

16 R

RJ61X

5

4

3

6

2

7

1

8

5

4

3

6

2

7

1

8

5

4

3

6

2

7

1

8

5

4

3

6

2

7

1

8

5

4

3

6

2

7

1

8

5

4

3

6

2

7

1

8

Figure 2-19: Connecting 4/8ATRU Trunk PCBs

DS2000 Hardware Manual Section 2: PCB Installation ◆ 2-17

Connecting Blocks

80000 - 33

Figure 2-20: Securing the Cables

2-18 ◆ Section 2: PCB Installation DS2000 Hardware Manual

Connecting Blocks

The following products should help if you make your own cables. The connector is generally referred to as a RJ45 connector wired in an RJ61X configuration.

• Suttle SE-266-8K 8 Position Modular Plug (requires an SE-166 or SE-166-6 modular

crimping tool).

• Hubbell BRFT4P Snap-On 8 Position Modular Plug (does not require a special crimping tool).

Check with your local supplier for other comparable products.

To 66 Block

WHT-BLU (1T)

2

Latch

faces up

To CPU

Mod Jack

80000 - 18C

RJ61X

Pin

1

2

3

4

5

6

7

8

Note

reversal

Port

Designation

4T

3T

2T

1R

1T

2R

3R

4R

Figure 2-21: 8-Pin (RJ61X) Jack Pinouts

BLU-WHT (1R)

WHT-ORN (2T)

ORN-WHT (2R)

WHT-GRN (3T)

GRN-WHT (3R)

WHT-BRN (4T)

BRN-WHT (4R)

DS2000 Hardware Manual Section 2: PCB Installation ◆ 2-19

Connecting Blocks

2-20 ◆ Section 2: PCB Installation DS2000 Hardware Manual

Connecting Extensions

Connecting Extensions

Each 16DSTU PCB connects 16 digital extensions. Each 8ASTU PCB connects 8 analog extensions. Each

4ASTU PCB connects 4 analog extensions.

To connect extensions (Figure 3-1):

1. Using Figure 2-17 Connecting 16DSTU Digital Station and 4/8ASTU Analog Station PCBs on page 215 as a guide, insert the mod jacks into the appropriate connector on the PCB.

2. Install a modular jack for each extension within 6 feet of the telephone’s location.

3. For each extension, run one-pair 24 AWG station cable from the cross-connect block to the modular jack.

4. Terminate the station cable WHT/BLU - BLU/WHT leads to the RED and GRN lugs in the modular jack.

5. Back at the main equipment location, run one pair of cross-connect wire between the pins on the B

block and cross-connect block to complete the connection.

6. Install bridging clips as required.

Connecting Extensions

Section 3: Installing

Extensions and Trunks

3

Station

Block

One-Pair

Cross Connect

Cross

Connect

Block

25-Pair

Installation Cable

(P/N 80892)

You can also connect analog extensions to 2-OPX

Modules. Refer to Section 4, Optional Equipment.

YEL

BLU-WHT

RED

625

Modular

Jack

Figure 3-1: Connecting Extensions

BLK

WHT-BLU

GRN

80000 - 36B

DS2000 Hardware Manual Section 3: Installing Extensions and Trunks ◆ 3-1

Connecting Trunks

Connecting Trunks

Connecting Analog Trunks

Each 8ATRU PCB connects 8 loop start CO trunks. Each 4ATRU PCB connects 4 loop start CO trunks.

To connect analog trunks (Figure 3-2):

1. Using Figure 2-19 Connecting 4/8ATRU Trunk PCBs on page 2-17 as a guide, insert the mod jacks into

the appropriate connector on the PCB.

2. For each trunk, run one pair cross-connect wire between the pins on the cross-connect block and the

CPE (customer side) of the telco’s RJ21X.

3. Install bridging clips as required.

Note: To connect T1 trunks, turn to T1 Trunk PCB on page 2-8.

One-Pair

Cross Connect

80000 - 37

"A"

Block

Telco

RJ21X

25-Pair Cable

to Central Office

25-Pair

Installation Cable

(P/N 80892)

Figure 3-2: Connecting Analog Trunks

3-2 ◆ Section 3: Installing Extensions and Trunks DS2000 Hardware Manual

Power Up and System LEDs

Power-Up

Power Up and System LEDs

Now that all the PCBs you need are installed and you have cabled the system, you can now power-up. The system will automatically set up the station and trunk PCBs on power up, See

page 1-4

You do not need to reattach the right side panel before powering up the system. Leaving the right side panel

removed makes the station and trunk cabling more accessible.

To power up the system (Figure 3-3) through (Figure 3-5):

1. Make sure the system is properly grounded and the PCB bracket is reinstalled and secured.

2. Install a surge protector in the AC outlet you intend to use for system power.

3. Plug the main cabinet’s AC power cord into its surge protector.

4. Turn on the main cabinet power switch. After about 30 seconds, verify the system LEDs.

for more. The system will also automatically set up a station or trunk PCB when you plug it in hot.

LED Normal Power-On Status

Automatic Slot Configuration on

Power Supply • All three LEDs on (green)

CPU PCB • Top LED flashing (slowly green)

DSTU, ASTU, and ATRU PCBs • Top LED flashing (slowly green)

• Bottom LED flashes (yellow) when ports

on the PCB are busy. The faster the flash,

the more ports are busy.

5. Verify that the PCBs have successfully powered up.

3

Figure 3-3: Power Supply Status LEDs

DS2000 Hardware Manual Section 3: Installing Extensions and Trunks ◆ 3-3

Power Up and System LEDs

Figure 3-4: CPU Status LEDs

Figure 3-5: DSTU, ASTU and ATRU Status LEDs

3-4 ◆ Section 3: Installing Extensions and Trunks DS2000 Hardware Manual

Finishing the Installation

Reinstalling the Side Panel

To reinstall the side panel (Figure 3-6):

1. Carefully realign the right side panel and slide it into position.

2. Reattach the two screws that secure the right side panel to the cabinet.

Finishing the Installation

4 Slot Cabinet Shown

80000 - 16 A

3

Figure 3-6: Reinstalling the Side Panel

DS2000 Hardware Manual Section 3: Installing Extensions and Trunks ◆ 3-5

Finishing the Installation

Reinstalling the Front Cover

To reinstall the front cover (Figure 3-7):

1. Hook the tabs on the rear of the cover into their associated slots.

2. Push the front of the cover into place.

3. Screw in the two captive screws that secure the cover to the cabinet.

4 Slot Cabinet Shown

80000 - 12 A

Figure 3-7: Reinstalling the Front Cover

3-6 ◆ Section 3: Installing Extensions and Trunks DS2000 Hardware Manual

External Paging

External Paging

Installing External Paging

The CPU provides an External Paging output. You connect the CPU Paging output to audio inputs on customer provided Paging systems. Be sure the connected Paging equipment is compatible with the following

page output specifications:

External Paging

Section 4: Optional

Equipment

External Paging Output Specifications

Output Impedance: 600 Ohms

Output Level: 0 dBr @ 1.0 kHz

The following products should help if you make your own cables. The connector is generally referred to as a

RJ45 connector wired in an RJ61X configuration. Check with your local supplier for comparable products.

● Suttle SE-266-8K 8 Position Modular Plug (requires an SE-166 or SE-166-6 modular crimping tool).

● Hubbell BRFT4P Snap-On 8 Position Modular Plug (does not require a special crimping tool).

To connect an External Paging amplifier (Figure 4-1):

1. Find an available connector in a station cable and make sure it is correctly punched down at the

66M1-50 block.

Follow standard color code order. Be sure the block is properly cross-connected.

2. For the connector chosen, locate pins 1T and 1R and connect the music source.

3. Plug the modular jack into the CPU modular connector.

To 66 Block

WHT-BLU (1T)

Page Out

Music In

Relay Contacts

No Connection

Latch

faces up

To CPU

Mod Jack

80000 - 18B

RJ61X

Pin

reversal

1

2

3

4

5

6

7

8

Note

Port

Designation

4T

3T

2T

1R

1T

2R

3R

4R

BLU-WHT (1R)

WHT-ORN (2T)

ORN-WHT (2R)

WHT-GRN (3T)

GRN-WHT (3R)

WHT-BRN (4T)

BRN-WHT (4R)

4

Figure 4-1: Connecting External Paging

DS2000 Hardware Manual Section 4: Optional Equipment ◆ 4-1

External Paging

External Paging Relay Control

An announcement broadcast into a Paging zone can additionally activate the system relay in the CPU PCB.

Be sure the device connected to the system’s relay contacts is compatible with the following specifications.

Maximum Initial Contact Resistance: 50 mOhms

The following products should help if you make your own cables. The connector is generally referred to as a

RJ45 connector wired in an RJ61X configuration. Check with your local supplier for comparable products.

● Suttle SE-266-8K 8 Position Modular Plug (requires an SE-166 or SE-166-6 modular crimping tool).

● Hubbell BRFT4P Snap-On 8 Position Modular Plug (does not require a special crimping tool).

Connecting the Relay for External Paging Control

To Connect the CPU Relay for External Paging Control (Figure 4-2)

1. Find an available connector in a station cable and make sure it is correctly punched down at the

66M1-50 block.

Follow standard color code order. Be sure the block is properly cross-connected.

2. For the connector chosen, locate pins 3T and 3R and connect the device the relays will control.

3. Plug the modular jack into the CPU modular connector.

!! Important !!

Relay Contact Specifications

Contact Configuration: Normally Open

Maximum Load: 60mA @ 30 VDC

10 mA @ 90 VDC

To 66 Block

WHT-BLU (1T)

BLU-WHT (1R)

WHT-ORN (2T)

ORN-WHT (2R)

WHT-GRN (3T)

GRN-WHT (3R)

WHT-BRN (4T)

BRN-WHT (4R)

Latch

faces up

To CPU

Mod Jack

80000 - 18

RJ61X

Pin

reversal

1

2

3

4

5

6

7

8

Note

Port

Designation

4T

3T

2T

1R

1T

2R

3R

4R

Figure 4-2: Connecting the Control Relay for External Paging

Page Out

Music In

Relay Contacts

No Connection

4-2 ◆ Section 4: Optional Equipment DS2000 Hardware Manual

Programming the Relay for External Paging Control

● In 0201 - CPRU Relay, to assign the CPU Relay for External Paging control, enter 2.

●

In 0201 - CPRU Relay Page Zone Assignment, enter the Page Zone (1-7) that should activate the CPU

relay. Note that Zone 1 and All Call Paging announcements broadcast from the External Paging output.

Additional Programming

● To adjust the External Paging ring volume:

- In 0202 - Page Ring Volume, adjust the volume of ringing over External Paging (5=low, 6=medium,

4=high).

● To enable Background Music over External Paging:

- In 0201 - Background Music, enter Y (9) to enable Background Music system-wide.

- Make sure your music source is connected (see Music Source on page 4-4 for more).

- In 0202 - Background Music Over External Page, enter Y (9).

● To enable extension ringing over External Paging:

- In 0202 - External Page Ring Source, enter 3 (Extension).

- In 0202 - Extension, enter the number of the extension that will ring over External Paging.

● To enable trunk ringing over External Paging:

- In 0202 - External Page Ring Source, enter 8 (Trunk).

- In 0203 - UNA Ringing Option, specify the type of External Paging ringing for each trunk

(0=None, 1=Ring always, 2=Ring at night only, 3=Delay ring).

Refer to Paging in the DS1000/2000 Software Manual (P/N 80000SWG**) for more on these features.

External Paging

4

DS2000 Hardware Manual Section 4: Optional Equipment ◆ 4-3

Music Source

Music Source

Installing a Music Source

Your system provides connection for a customer provided music source. Use this music source for Background Music and Music on Hold. Be sure the connected music source is compatible with the following

music input specifications:

The following products should help if you make your own cables. The connector is generally referred to as a

RJ45 connector wired in an RJ61X configuration. Check with your local supplier for comparable products.

● Suttle SE-266-8K 8 Position Modular Plug (requires an SE-166 or SE-166-6 modular crimping tool).

● Hubbell BRFT4P Snap-On 8 Position Modular Plug (does not require a special crimping tool).

To connect a music source (Figure 4-3):

1. Find an available connector in a station cable and make sure it is correctly punched down at the

66M1-50 block.

Follow standard color code order. Be sure the block is properly cross-connected.

2. For the connector chosen, locate pins 2T and 2R and connect the music source.

3. Plug the modular jack into the CPU modular connector.

Music Input Specifications

Input Impedance: 10K Ohms

Output Level: +18 dBr (+2 dBr) @ 1.0 KHz

Pin

1

2

3

4

5

6

7

8

Note

reversal

Port

Designation

4T

3T

2T

1R

1T

2R

3R

4R

Latch

faces up

To CPU

Mod Jack

80000 - 18A

RJ61X

Figure 4-3: Installing a Music Source

Programming Background Music

● In 0201 - Background Music, enter Y to enable Background Music system-wide.

● In 1802 - BGM, enter Y to enable Background Music at the extension.

To turn Background Music on and off:

1. Do not lift the handset or press SPK.

2. Press HOLD.

Programming Music on Hold

● In 0201 - Music on Hold, enter Y to enable Music on Hold system-wide.

● In 0201 - MOH on Transfer, enter Y to enable Music on Hold for transferred calls.

● In 1003 - MOH Source, enter 1 (for external) + VOL ▲.

You can optionally enter 2 for a low pitched internal tone; 3 for a high pitched internal tone.

To 66 Block

WHT-BLU (1T)

BLU-WHT (1R)

WHT-ORN (2T)

ORN-WHT (2R)

WHT-GRN (3T)

GRN-WHT (3R)

WHT-BRN (4T)

BRN-WHT (4R)

Page Out

Music In

Relay Contacts

No Connection

4-4 ◆ Section 4: Optional Equipment DS2000 Hardware Manual

Power Failure Telephone

Power Failure Cut-Through

When AC power fails, the system can automatically cut through to a Power Failure Telephone connection.

To install Power Failure Cut-Through (Figure 4-4):

1. Locate an available 8-pin jack in a trunk (A) block or station (B) block.

Local codes may prevent you from using a DDK connector on the A block for optional equipment.

2. For the 8-pin jack chosen, cross-connect the associated wire pair from the A or B block to the crossconnect block.

3. Install a modular jack for each Power Failure Telephone within 6 feet of the telephone’s location.

4. For each Power Failure Telephone, run one-pair of 24 AWG station cable from the cross-connect block

to the telephone’s modular jack.

5. Terminate the station cable WHT/BLU - BLU/WHT leads to the RED and GRN lugs in the modular

jack.

6. Install bridging clips as required.

To test the Power Failure Telephone:

1. Connect the power failure telephone. See the illustration below.

2. Power down the system.

3. At the Power Failure Telephone, lift the handset.

You should hear dial tone on the trunk you connected.

4. Place a test call.

If power is restored while a cut-through call is in progress, the call is maintained until the user

hangs up the Power Failure Telephone.

Power Failure Telephone

4

One-Pair Cross-Connect

8-Pin

Connector

80000 - 40

To Power

Failure

Telephone

connector on

ATRU PCB

25 Pair

Installation Cable

Station

Block

Cross

Connect

Block

Power

Failure

Telephone

Figure 4-4: Connecting a Power Failure Telephone

BLU-WHTWHT-BLU

GRN RED

BLK YEL

625

Modular

Jack

DS2000 Hardware Manual Section 4: Optional Equipment ◆ 4-5

DSS Console

DSS Console

Installing a DSS Console

The DSS Console gives a keyset user one-button access to extensions, trunks and system features. Keep the

following in mind when installing DSS Consoles:

● You can only connect 4 DSS Consoles.

● You can only connect DSS Consoles to Super Display or 34-Button Display telephones.

● A DSS Console does not require a separate station port – it connects directly to the keyset.

To install a DSS Console (Figure 4-5) (Figure 4-6):

1. Turn the telephone upside down and remove the plastic filler plug from the DSS modular connector.

2. Plug the DSS Console’s 8-pin modular line cord into the telephone’s DSS connector.

3. Plug the other end of the 8-pin line cord into the DSS Console’s 8-pin jack.

4. If you have a 24-Button DSS Console, attach the metal plate to both the DSS Console and telephone.

See Figure 4-5 Installing a 24-Button DSS Console below for more.

Programming DSS Consoles

● 1801 - DSS Type