Page 1

,!5.!-%#)62%3

#OMPACT$ISC0LAYER

#6"%%

#6"%%

#OMPACT$ISC0LAYER

Page 2

PRODUCT SAFETY SERVICING GUIDELINES.......................................................................................... 1-4

SERVICING PRECAUTIONS ....................................................................................................................... 1-5

* General Servicing Precautions

* Insulation checking prodedure

* Electrostatically Sensitive Devices

SPECIFICATIONS ......................................................................................................................................... 1-6

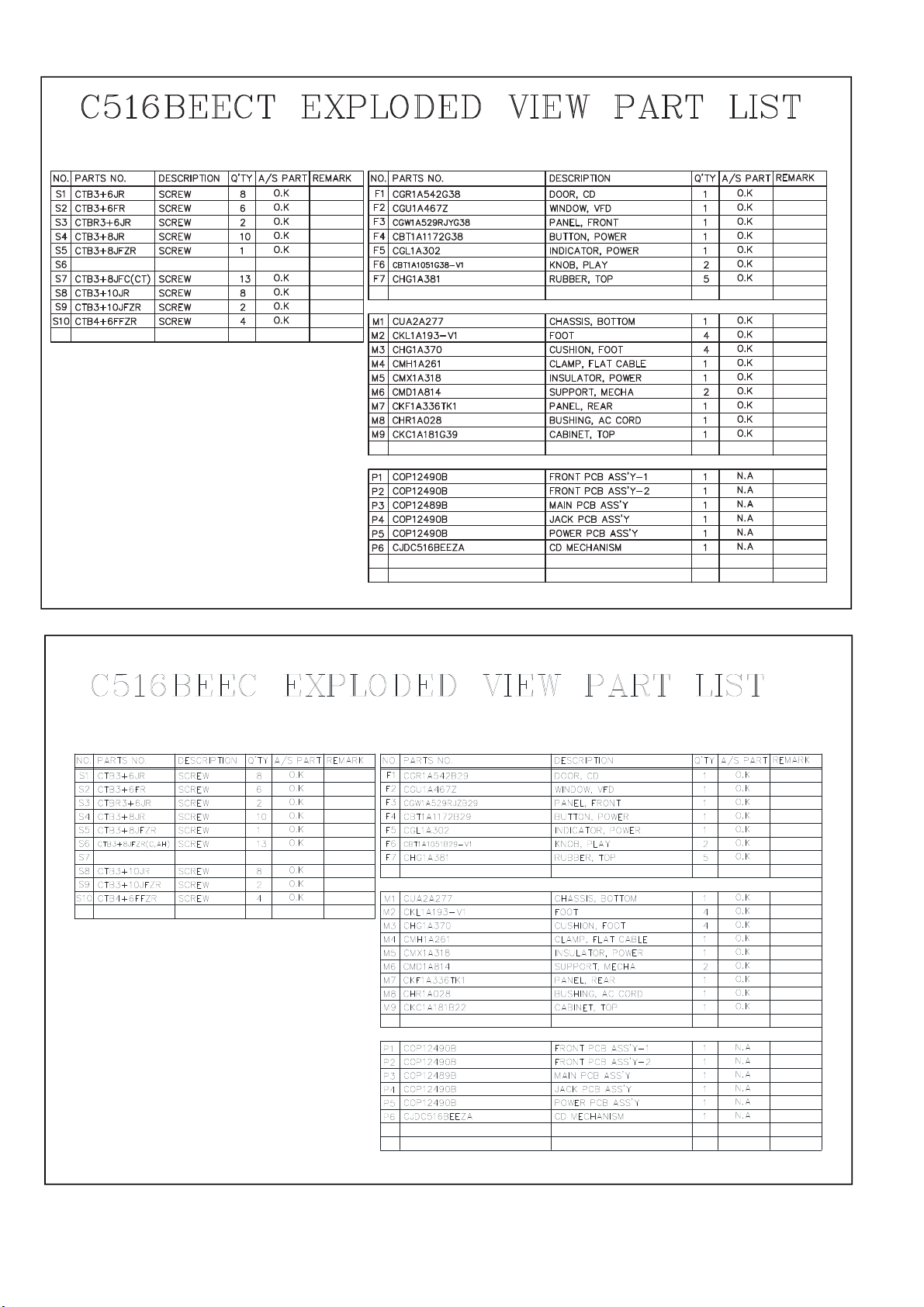

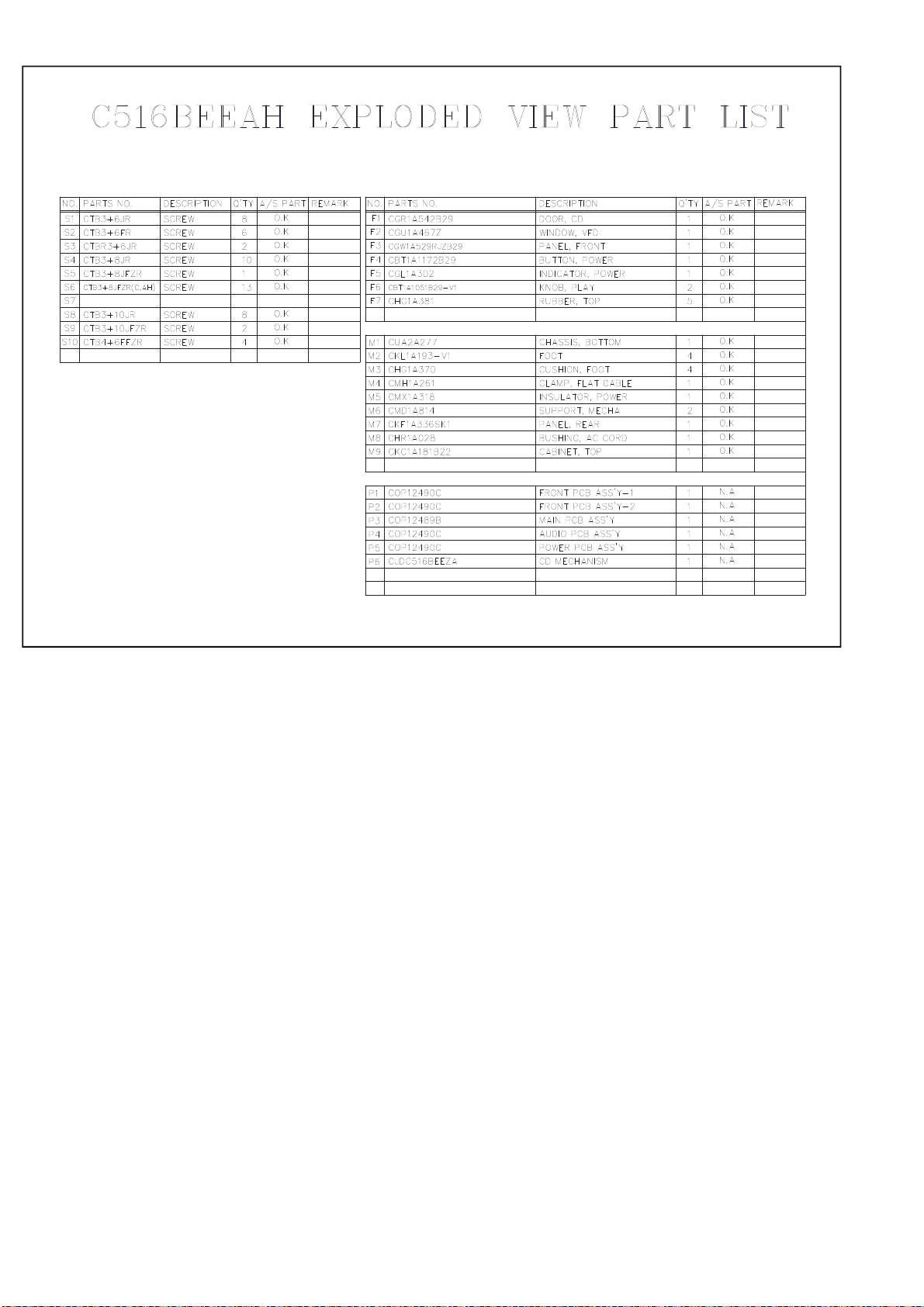

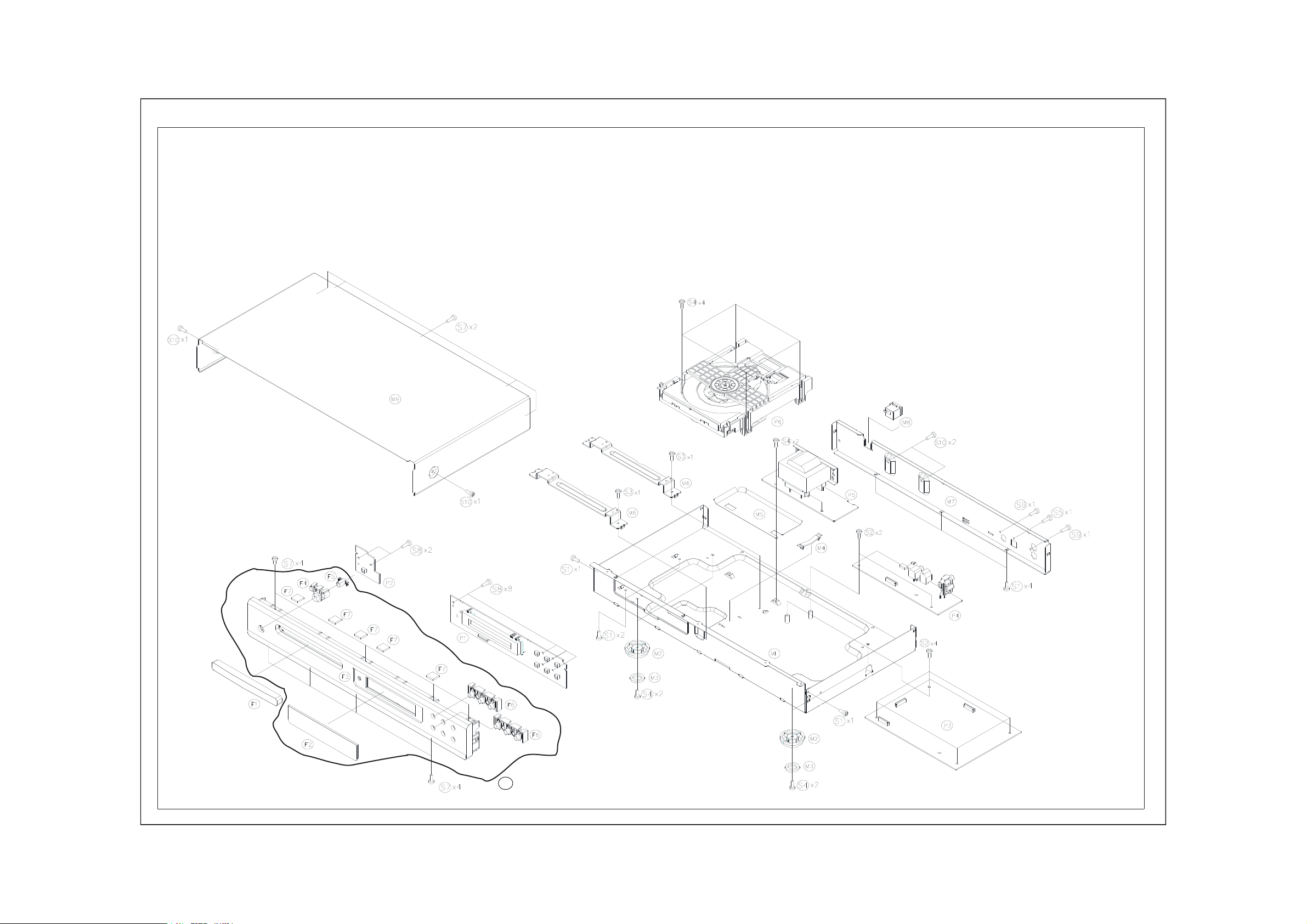

EXPLODED VIEWS & PARTS LISTS .................................................................................................... ...... 1-7

NOTES .................................................................................................................................................1-11

Page 3

PRODUCT SAFETY SERVICING GUIDELINES

CAUTION : DO NOT ATTEMPT TO MODIFY THIS PRODUCT IN

ANY WAY. NEVER PERFORM CUSTOMIZED INSTALLATIONS

WITHOUT MANUFACTURER’S APPROVAL. UNAUTHORIZED

MODIFICATIONS WILL NOT ONLY VOID THE WARRANTY, BUT

MAY LEAD TO YOUR BEING LIABLE FOR ANY RESULTING

PROPERTY DAMAGE OR USER INJURY.

SERVICE WORK SHOULD BE PERFORMED ONLY AFTER YOU

ARE THOROUGHLY FAMILIAR WITH ALL OF THE FOLLOWING

SAFETY CHECKS AND SERVICING GUIDELINES. TO DO

OTHERWISE, INCREASES THE RISK OF POTENTIAL HAZARDS

AND INJURY TO THE USER.

WHILE SERVICING, USE AN ISOLATION TRANSFORMER FOR

PROTECTION FROM AC LINE SHOCK.

SAFETY CHECKS

AFTER THE ORIGINAL SERVICE PROBLEM HAS BEEN

CORRECTED. A CHECK SHOULD BE MADE OF THE

FOLLOWING.

SUBJECT : FIRE & SHOCK HAZARD

1. BE SURE THAT ALL COMPONENTS ARE POSITIONED IN

SUCH A WAY AS TO AVOID POSSIBILITY OF ADJACENT

COMPONENT SHORTS. THIS IS ESPECIALLY IMPORTANT

ON THOSE MODULES WHICH ARE TRANSPORTED TO AND

FROM THE REPAIR SHOP.

2. NEVER RELEASE A REPAIR UNLESS ALL PROTECTIVE

DEVICES SUCH AS INSULATORS, BARRIERS, COVERS,

SHIELDS, STRAIN RELIEFS, POWER SUPPLY CORDS, AND

OTHER HARDWARE HAVE BEEN REINSTALLED PER

ORIGINAL DESIGN. BE SURE THAT THE SAFETY PURPOSE

OF THE POLARIZED LINE PLUG HAS NOT BEEN DEFEATED.

3. SOLDERING MUST BE INSPECTED TO DISCOVER POSSIBLE

COLD SOLDER JOINTS, SOLDER SPLASHES OR SHARP

SOLDER POINTS. BE CERTAIN TO REMOVE ALL LOOSE

FOREIGN PARTICLES.

4. CHECK FOR PHYSICAL EVIDENCE OF DAMAGE OR

DETERIORATION TO PARTS AND COMPONENTS. FOR

FRAYED LEADS, DAMAGED INSULATION (INCLUDING AC

CORD). AND REPLACE IF NECESSARY FOLLOW ORIGINAL

LAYOUT, LEAD LENGTH AND DRESS.

5. NO LEAD OR COMPONENT SHOULD TOUCH A RECEIVING

TUBE OR A RESISTOR RATED AT 1 WATT OR MORE. LEAD

TENSION AROUND PROTRUDING METAL SURFACES MUST

BE AVOIDED.

6. ALL CRITICAL COMPONENTS SUCH AS FUSES,

FLAMEPROOF RESISTORS, CAPACITORS, ETC. MUST BE

REPLACED WITH EXACT FACTORY TYPES, DO NOT USE

REPLACEMENT COMPONENTS OTHER THAN THOSE

SPECIFIED OR MAKE UNRECOMMENDED CIRCUIT

MODIFICATIONS.

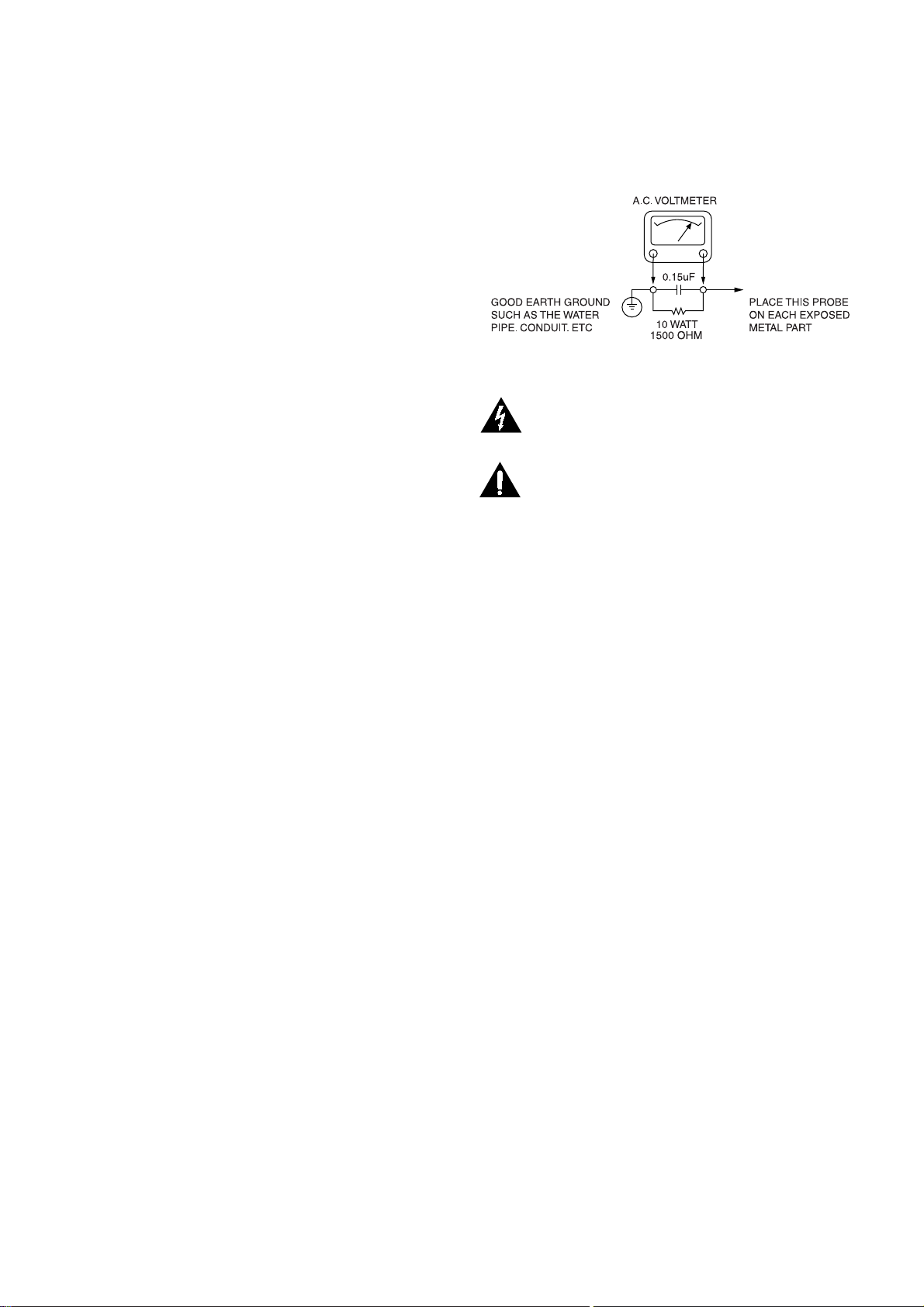

7. AFTER RE-ASSEMBLY OF THE SET ALWAYS PERFORM AN

AC LEAKAGE TEST ON ALL EXPOSED METALLIC PARTS OF

THE CABINET, (THE CHANNEL SELECTOR KNOB, ANTENNA

TERMINALS. HANDLE AND SCREWS) TO BE SURE THE SET

IS SAFET TO OPERATE WITHOUT DANGER OF ELECTRICAL

SHOCK. DO NOT USE A LINE ISOLATION TRANSFORMER

DURING THIS TEST USE AN AC VOLTMETER, HAVING 5000

OHMS PER VOLT OR MORE SENSITIVITY, IN THE

FOLLOWING MANNER; CONNECT A 1500 OHM 10 WATT

RESISTOR, PARALLELED BY A .15 MFD, 150V AC TYPE

CAPACITOR BETWEEN A KNOWN GOOD EARTH GROUND

(WATER PIPE, CONDUIT, ETC.) AND THE EXPOSED

METALLIC PARTS, ONE AT A TIME.

MEASURE THE AC VOLTAGE ACROSS THE COMBINATION

OF 1500 OHM RESISTOR AND .15 MFD CAPACITOR.

REVERSE THE AC PLUG AND REPEAT AC VOLTAGE

MEASUREMENTS FOR EACH EXPOSED METALLIC PART.

VOLTAGE MEASURE MUST NOT EXCEED 75 VOLTS R.M.S.

THIS CORRESPONDS TO 0.5 MILLIAMP AC ANY VALUE

EXCEEDING THIS LIMIT CONSTITUTES A POTENTIAL

SHOCK HAZARD AND MUST BE CORRECTED IMMEDIATELY.

SUBJECT : GRAPHIC SYMBOLS

THE LIGHTNING FLASH WITH ARROWHEAD SYMBOL, WITHIN AN

EQUILATERAL TRIANGLE, IS INTENDED TO ALERT THE USER TO THE

PRESENCE OF UNINSULATED “DANGEROUS VOLTAGE” WITHIN THE

PRODUCT’S ENCLOSURE THAT MAY BE OF SUFFICIENT MAGNITUDE TO

CONSTITUTE A RISK OF ELECTRIC SHOCK.

THE EXCLAMATION POINT WITHIN AN EQUILATERAL TRIANGLE IS

INTENDED TO ALERT THE USER TO THE PRESENCE OF IMPORTANT

OPERATING AND MAINTENANCE (SERVICING) INSTRUCTIONS IN THE

LITERATURE ACCOMPANYING THE APPLIANCE.

SUBJECT : TIPS ON PROPER INSTALLATION

1. NEVER INSTALL ANY PRODUCT IN A CLOSED-IN RECESS,

CUBBYHOLE OR CLOSELY FITTING SHELF SPACE. OVER

OR CLOSE TO HEAT DUCT, OR IN THE PATH OF HEATED

AIR FLOW.

2. AVOID CONDITIONS OF HIGH HUMIDITY SUCH AS:

OUTDOOR PATIO INSTALLATIONS WHERE DEW IS A

FACTOR, NEAR STEAM RADIATORS WHERE STEAM

LEAKAGE IS A FACTOR, ETC.

3. AVOID PLACEMENT WHERE DRAPERIES MAY OBSTRUCT

REAR VENTING. THE CUSTOMER SHOULD ALSO AVOID THE

USE OF DECORATIVE SCARVES OR OTHER COVERINGS

WHICH MIGHT OBSTRUCT VENTILATION.

4. WALL AND SHELF MOUNTED INSTALLATIONS USING A

COMMERCAL MOUNTING KIT MUST FOLLOW THE FACTORY

APPROVED MOUNTING INSTRUCTIONS A PRODUCT

MOUNTED TO A SHELF OR PLATFORM MUST RETAIN ITS

ORIGINAL FEET (OR THE EQUIVALENT THICKNESS IN

SPACERS) TO PROVIDE ADEQUATE AIR FLOW ACROSS

THE BOTTOM, BOLTS OR SCREWS USED FOR FASTENERS

MUST NOT TOUCH ANY PARTS OR WIRING. PERFORM

LEAKAGE TEST ON CUSTOMIZED INSTALLATIONS.

5. CAUTION CUSTOMERS AGAINST THE MOUNTING OF A

PRODUCT ON SLOPING SHELF OR A TILTED POSITION,

UNLESS THE PRODUCT IS PROPERLY SECURED.

6. A PRODUCT ON A ROLL-ABOUT CART SHOULD BE STABLE

ON ITS MOUNTING TO THE CART. CAUTION THE

CUSTOMER ON THE HAZARDS OF TRYING TO ROLL A CART

WITH SMALL CASTERS ACROSS THRESHOLDS OR DEEP

PILE CARPETS.

7. CAUTION CUSTOMERS AGAINST THE USE OF A CART OR

STAND WHICH HAS NOT BEEN LISTED BY UNDERWRITERS

LABORATORIES, INC. FOR USE WITH THEIR SPECIFIC

MODEL OF TELEVISION RECEIVER OR GENERICALLY

APPROVED FOR USE WITH T.V.’S OF THE SAME OR

LARGER SCREEN SIZE.

8. CAUTION CUSTOMERS AGAINST THE USE OF EXTENSION

CORDS, EXPLAIN THAT A FOREST OF EXTENSIONS

SPROUTING FROM A SINGLE OUTLET CAN LEAD TO

DISASTROUS CONSEQUENCES TO HOME AND FAMILY.

1-4

Page 4

SERVICING PRECAUTIONS

CAUTION : Before servicing the A/V Receiver covered by this

service data and its supplements and addends, read and follow the

SAFETY PRECAUTIONS. NOTE : if unforeseen circumstances

create conflict between the following servicing precautions and any

of the safety precautions in this publication, always follow the safety

precautions.

Remember Safety First:

General Servicing Precautions

1. Always unplug the A/V Receiver AC power cord from the AC

power source before:

(1) Removing or reinstalling any component, circuit board,

module, or any other assembly.

(2) Disconnecting or reconnecting any internal electrical plug or

other electrical connection.

(3) Connecting a test substitute in parallel with an electrolytic

capacitor.

Caution : A wrong part substitution or incorrect polarity installation

of electrolytic capacitors may result in an explosion hazard.

2. Do not spray chemicals on or near this A/V Receiver or any of its

assemblies.

3. Unless specified otherwise in this service data, clean electrical

contacts by applying an appropriate contact cleaning solution to

the contacts with a pipe cleaner, cottontipped swab, or

comparable soft applicator.

Unless specified otherwise in this service data, lubrication of

contacts is not required.

4. Do not defeat any plug/socket B+ voltage interlocks with which

instruments covered by this service manual might be equipped.

5. Do not apply AC power to this A/V Receiver and/or any of its

electrical assemblies unless all solid-state device heat sinks are

correctly installed.

6. Always connect test instrument ground lead to the appropriate

ground before connecting the test instrument positive lead. Always

remove the test instrument ground lead last.

Insulation Checking Procedure

Disconnect the attachment plug from the AC outlet and turn the

power on. Connect an insulation resistance meter(500V) to the

blades of the attachment plug. The insulation resistance between

each blade of the attachment plug and accessible conductive parts

(Note 1) should be more than 1M-ohm.

Note 1 : Accessible Conductive Parts including Metal panels, Input

terminals, Earphone jacks, etc.

Electrostatically Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged easily by

static electricity. Such components commonly are called

Electrostatically Sensitive (ES) Devices. Examples of typical Es

devices are integrated circuits and some field effect transistors and

semiconductor chip components.

The following techniques should be used to help reduce the

incidence of component damage caused by static electricity.

1. Immediately before handling any semiconductor component or

semiconductor-equipped assembly, drain off any electrostatic

charge on your body by touching a known earth ground.

Alternatively, obtain and wear a commercially available

discharging wrist strap device, which should be removed for

potential shock reasons prior to applying power to the unit under

test.

2. After removing an electrical assembly equipped with ES devices,

place the assembly on a conductive surface such as aluminum

foil, to prevent electrostatic charge buildup or exposure of the

assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES

devices.

4. Use only an antistatic solder removal device. Some solder

removal devices not classified a “anti-static” can generate

electrical charges sufficient to damage ES devices.

5. Do not use freonpropelled chemicals. These can generate

electrical charge sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective

package until immediately before you are ready to install it. (Most

replacement ES devices are packaged with leads electrically

shorted together by conductive foam, aluminum foil, or

comparable conductive material).

7. lmmediately before removing the protective material from the

leads of a replacement ES device, touch the protective material to

the chassis or circuit assembly into which the device will be

installed.

Caution : Be sure no power is applied to the chassis or circuit, and

observe all other safety precautions.

8. Minimize bodily motions when handing unpackaged replacement

ES devices. (Normally harmless motion such as the brushing

together of your clothes fabric or the lifting of your foot from a

carpeted floor can generate static electricity sufficient to damage

an ES device.)

1-5

Page 5

SPECIFICATIONS

[ELECTRICAL SYSTEM]

OUTPUT LEVEL (Vrms)

CHANNEL BALANCE(dB)

FREQUENCY RESPONSE (dB)

S/N RATIO (dB) /('A'- weight)

CHANNEL SEPARAITION

( 20KHz LPF )

2Vrms@1KHz Full Scale

+/-0.5dB(0.13v)

+/-0.3dB@20Hz

+/-0.1dB@10KHz

+/-0.5dB@20KHz

110dB

95dB@1KHz

95dB@10KHz

DE-EMPHASIS(dB)

-20dB ±0.2 @5KHz

-20dB ±0.4 @16KHz

T.H.D (%)

(20KHz LPF)

DYNAMIC RANGE / (W/20KHz LPF)

PLAYABILITY

0.005% @100Hz

0.002% @1KHz

0.005% @10KHz

0.005% @20KHz

110dB

Φ0.9mm↓

Φ0.8mm↓

Φ0.65um↓

210±10um ECCENTRICITY (12cm)

± 0.5 mm VERTICAL DEVIATION

INTERRUPTION

BLACK DOTS

FINGER PRINTS

[GENERAL ELECTRICAL SPECIFICATION]

Power Requirements

'AH' Version: 120Vac /60Hz

'C', 'CT' Version: 230Vac /50Hz

Power Consumption

0.33Watts @Standby

8.8Watts @Normal Play

1-6

Page 6

F10 C516 FASCIA COMPLETE T TITANIUM 1

F10 C516 FASCIA COMPLETE G GRAPHITE 1

1-7

Page 7

*, *Ê*,/-Ê"/"

F10 C516 FASCIA COMPLETE G GRAPHITE 1

1-8

Page 8

EXPLODED VIEW (C516BEE)

F10

1-9 1-10

Page 9

NOTES

1.11

Page 10

NOTES

1-12

Page 11

-/" ÊÓ

/,Ê" / /-

" / /-

)#",/#+$)!'2!-30).$%3#2)04)/.. 2

%,%#42)#!,42/5",%3(//4).''5)$%19

$)!'2!-3

£°Ê"Ê,Ê°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°

Ó°Ê7, Ê,Ê °°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°

ΰÊ-/Ê,Ê °°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°

{°Ê*, / ,1/ ",-Ê °°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°°

ÓÓÎ

ÓÓx

ÓÓÇ

ÓΣ

2-1

Page 12

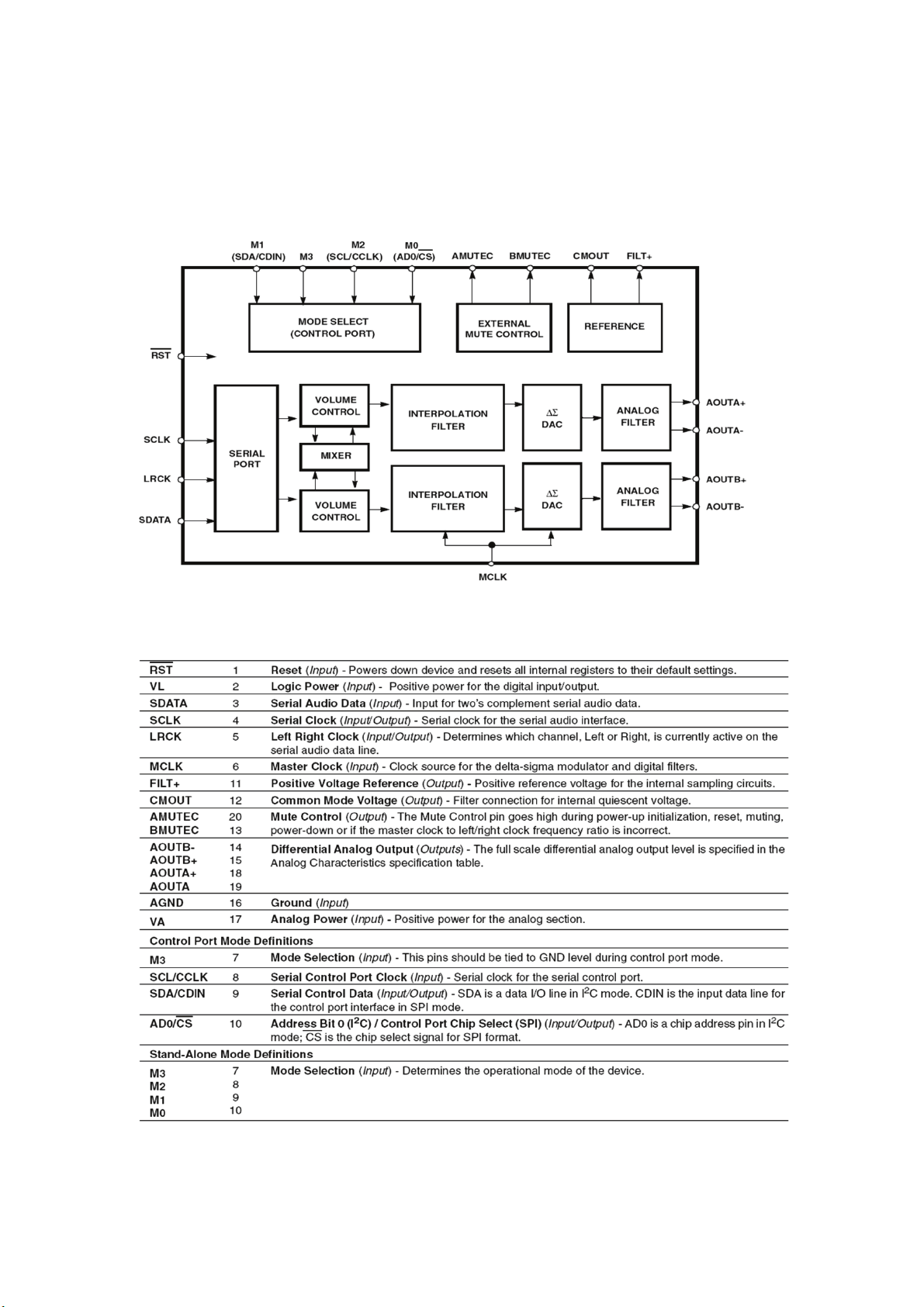

IC BLOCK DIAGRAMS & PIN DESCRIPTION

IC11 CS4392 D/A CONVERTOR

IC BLOCK DIAGRAMS

IC PIN DESCRIPTION

2-2

Page 13

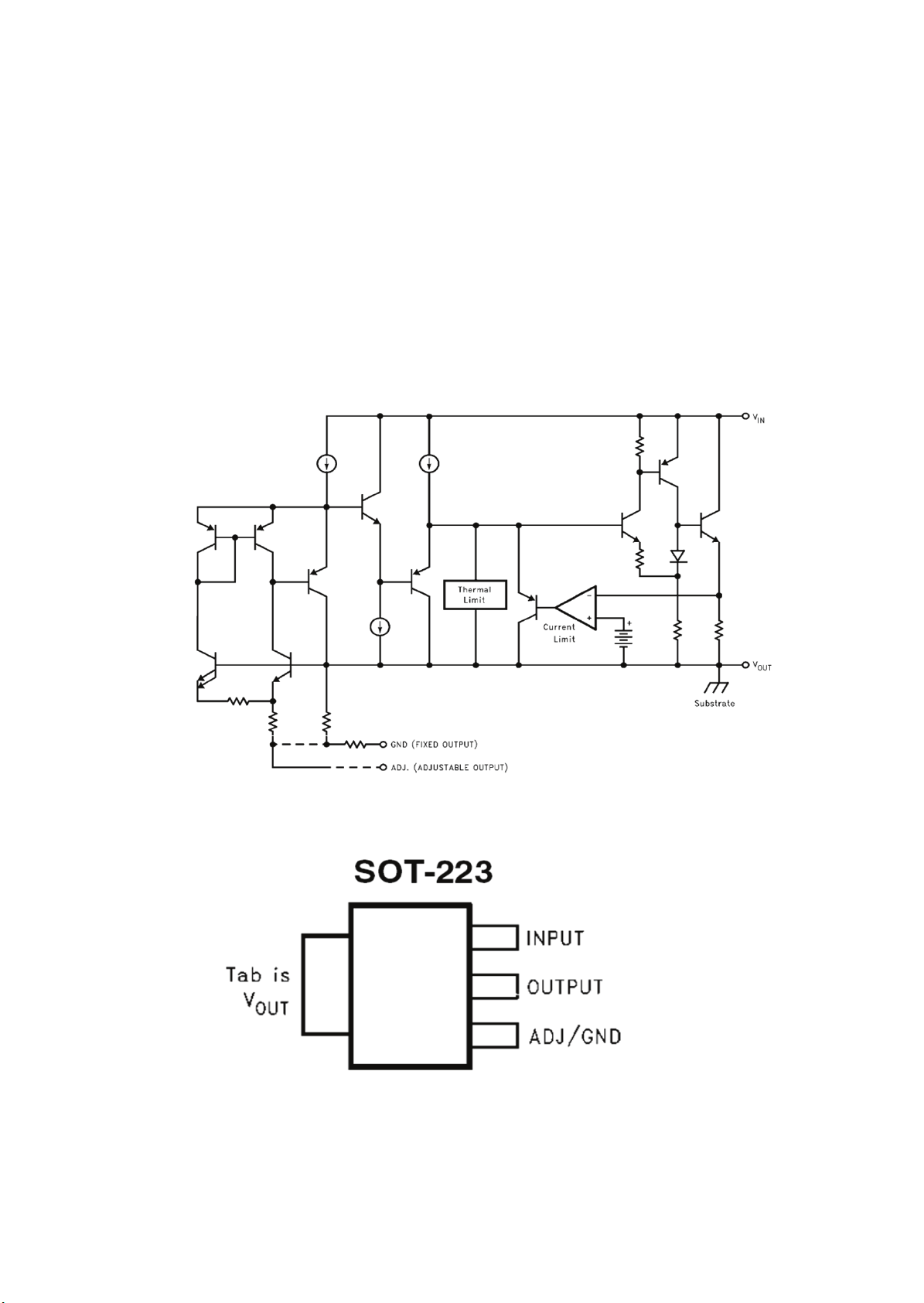

IC06, IC07, IC15, IC18, IC19 LM1117SXX

1A LDO REGULATOR

IC BLOCK DIAGRAMS

IC PIN DESCRIPTION

2-3

Page 14

IC20 LM7808RTRL IC, REGULATOR 1A, 8V

IC21, LM7908RTRL IC, REGULATOR 1A, -8V

IC BLOCK DIAGRAM

LM7808RTRL

LM7908RTRL

2-4

Page 15

IC PIN MAP

LM7808RTRL

LM7908RTRL

2-5

Page 16

IC12, IC13 SAA5532DR, OP AMPLIFIER

IC BLOCK DIAGRAMS

IC PIN MAP

2-6

Page 17

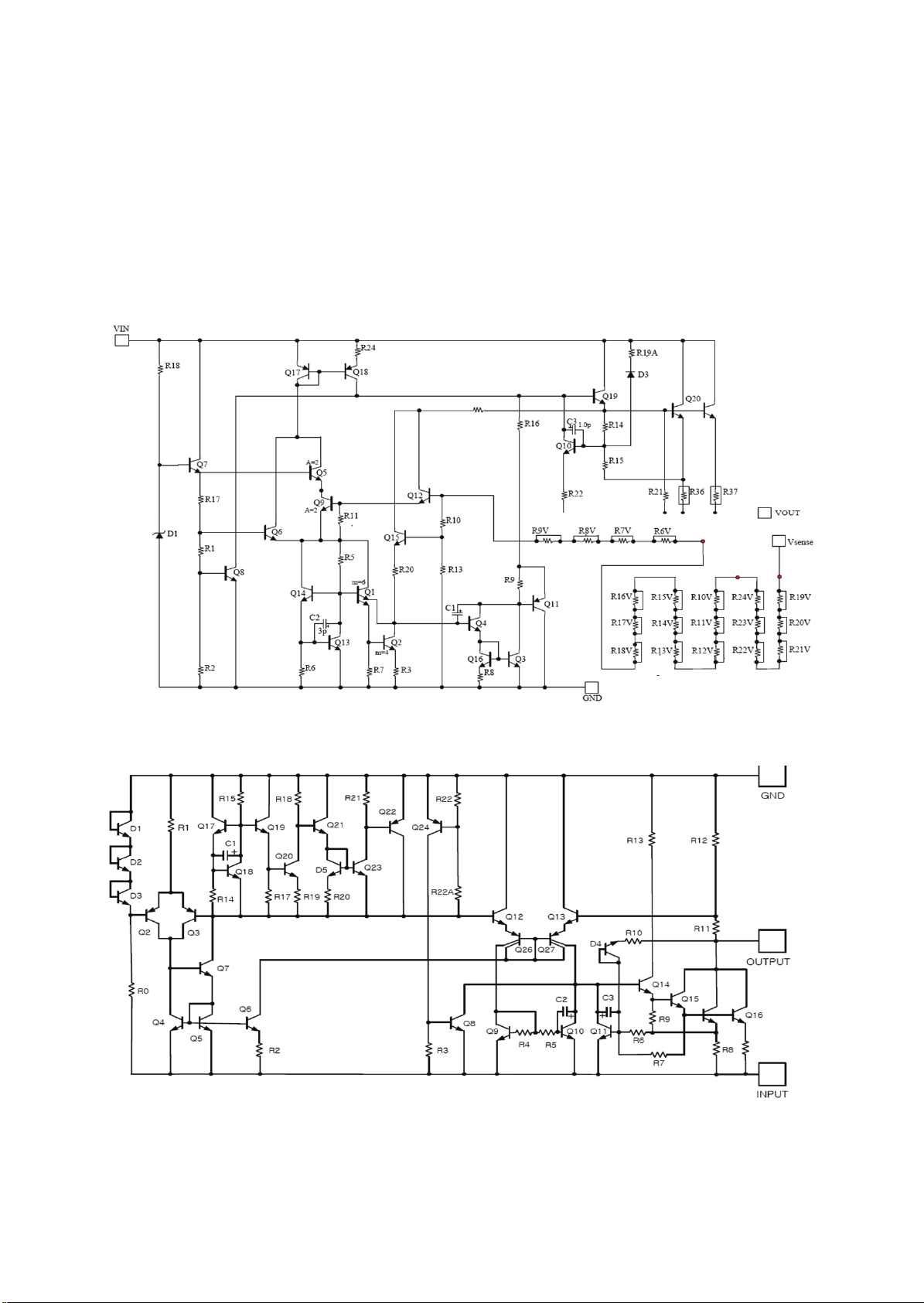

[BLOCKDIAGRAM AND PIN DESCRIPTION of ICs]

IC01 TMPM330FWFG (SYSTEM CONTROLLER)

IC BLOCK DIAGRAMS

2-7

Page 18

IC PIN DESCRIPTION

IC02 S80124CLMCJIJT2 (RESET IC)

IC BLOCK DIAGRAMS

2-8

Page 19

IC PIN DESCRIPTION

IC03 SN74ACT04DR HEX INVERTER

IC BLOCK DIAGRAMS

NC

mt_stby_p

RESERVED

cd_reseet_p

2-9

Page 20

IC PIN DESCRIPTION

IC04

IP4001CRLTF_CN 5-CH MOTOR DRIVER

IC BLOCK DIAGRAMS

2-10

Page 21

IC PIN DESCRIPTION

IC05 TC94A92FG CD DSP

IC BLOCK DIAGRAMS

2-11

Page 22

IC PIN MAP

2-12

Page 23

IC07 AT24C08N10SC EEPROM

IC BLOCK DIAGRAMS

IC PIN DESCRIPTION

2-13

Page 24

ELECTRICAL TROUBLESHOOTING GUIDE

1. No Power, No Display

a

2-19

Page 25

2. Disc Tray Not Opened

2-20

Page 26

3. Disc is not Played

2-21

Page 27

4. Disc is playing but No Audio output (Audio Path)

2-22

Page 28

1. BLOCK DIAGRAM

2-23 2-24

Page 29

2. WIRING DIAGRAM

AC Power Cord

M

BOTTO

BOARD

POWER

PCB

z

CD MECHANISM

[LOADER]

2-15

(4)

17P FLAT

BN81

(1)

CN01

13P

CN07

Connector PCB

CN92 BN91

13P

13P FLAT 6p

(2) (3)

CN09 CN08

MAIN PCB

6p

No. Ref Part Number

1 BN81 CWB1C913120EN

2 CWC4C4A13B100B10

3 BN91 CWB2B905080EN

4 CWC4F2A16A250B10

5 CWB2B005100GG

6 CWB5A906100GG

7 CWC4C4A17B100B10

8 BN41 CWB1B905180EN

S/W PCB

(5)

6P

5P

CN05

CN04

(6)

CN03

17P FLAT

(7)

BN41

5P

(8)

CN41

CN42

FRONT PCB

FRONT

PANEL

2-25 2-26

Page 30

3. SCHEMATIC DIAGRAM

FRONT + TRANSFORMER + AUDIO PART

FRONT PCB

1.8K

R400

12

CVD1SS355T

D407

12345

CN41

OB

120

R401

STAND-BY

WAKEUP

POWER

S307

SGND

[1]

D302

R402 68

OPEN/CLOSE

PLAY

BLUE(ON)

Amber(OFF)

54321

DGND

POWER_ON

12

D403

CVD1SS355T

S305

DGND

12

D406

S306

BN41

SGND

SW+3.3

[1]

Q401

RT1P144C

Q402

RT1N141C

R405

1.5K

SKIP-

CVD1SS355T

R408

1.5K

PAUSE

12

12

MCU+3.3V

D402

CVD1SS355T

R404

S303

D405

CVD1SS355T

R407

S304

CN42

1

3

24567891011121314

KEY1

KEY0

GND

GND

VFD-DI

VFD-CE

VFD-CLK

STBY-LED

LOW-ON / HIGH-OFF (3,3V)

DGND

MCU+3.3V

12

D401

10K

R403

CVD1SS355T

1K

S301

SKIP+

12

D404

CVD1SS355T

1K

STOP

S302

0.1uF

C400

MCU+3.3V

R406

C401

C403

100u/16V

10K

0.1uF

MCU+3.3V

220

R409

+5V

C402

DGND

DGND

VFD-RST

1K

220

220

R412

R411

R410

0.1uF

15 17

16

MCU+3.3V

SW+3.3

FL+

+5V

+5V

WAKEUP

[1]

[1]

C410

0.1uF

C409

10u/50V

DGND DGND

C407

1u/50V

0.1uF

C408

DGND

DGND

3

Q400

C3875S

1SS355T

2

1

D400

4.7K

R414

10K

R413

VP

FL-

REMO

47P

47P

C404

47P

C405

C406

DGND

0.1uF

C414

DGND

RS01

CRVKSM603TH5B

VccGNDVOUT

321

C301

DGND

DGND

47P

C411

3.3K

R415

47P

C412

DGND

0.1uF

DGND

MCU+3.3V

10u/50V

C413

DGND

0.1uF

AUDIO PCB

BN91

1

2

CWB05

3

4

54321

5

C320

1

CN92

2

3

4

5

CJP13GA115ZY

6

7

8

9

10

11

12

13

GND

LEFT

GND

RIGHT

GND

OPTICAL

1

+5V

2

GND

3

SPDIF

4

AGND

5

MCU+3.3V

6

/RESET_DOWNLOAD

7

UPDATE_RX

8

UPDATE_TX

9

/BOOT

10

AGND

11

12

13

CLZ9R001Z

L901

60

CJP07GB113ZY

VIN

VCC

GND

2

3

1

321

CJJ4M046Z

2

1

3

1

2

3

4

5

6

7

JK91

CJJ4N067Z

AUDIO

(RCA)

JK92

CJSJST1124

TX

OPTICAL

JK93

SPDIF

CN93

1

24

MCU

5

DOWNLOAD

6

73

DGND

TRANS PCB

AC_STBY

AC_STBY

RELAY_I

RELAY_O

AC_AUDIO

GND

AC_AUDIO

BN81

CWB13

AC_MAIN

AC_MAIN

VP

GNP

AC_FILA

AC_FILA

13 12 11 10 9 8 7 6 5 4 3 2 1

16

F2

F2

FL41

CFLHCA14SM19

4

5

6

7

8

9

10

11

NC

GR1

VDD

DIN

CLKB

CSB

RSTB

OSCO

OSCI

1G

RY81

CSL1E002ZE

1

4

2

3

C800

23

1

4700P

T802

CLT5M028ZES

VEE

8

2

C516BEEAH: T 630mA L 250V

C516BEEC: T 315mA L 250V

12567891011121314154950

GND

F1

F1

T801

CLT51009ZE

46

F801

KJCFC5S

12

HF81HF82

CN82

CJP02KA060ZY

FUSE (F801)

1

21

MODEL

REVISION

SCHEMATIC DIAGRAM

JW.RYU BD.JANG

2

3

C516BEE

JH.PARK

MP

4

5

DRAWING NODESIGN CHECK APPROVE

6

7

SHEET

1

2-27 2-28

Page 31

RESET

MCU

KEY1

STBY-LED

KEY0

DGND

DGND

MCU+3.3V

VFD-DI

VFD-CLK

VFD-CE

VFD-RST

REMO

FL-

VP

FL+

+5V

n.c

n.c

n.c

n.c

n.c

n.c

n.c

n.c

n.c

n.c

n.c

n.c

n.c

n.c

n.c

n.c

n.c

n.c

n.c

n.c

n.c

n.c

n.c

n.c

n.c

n.c

n.c

n.c

n.c

n.c

n.c

n.c

n.c

n.c

n.c

n.c

n.c

n.c

n.c

n.c

n.c

n.c

n.c

n.c

n.c

EX_INTERRUPT

TMPM33OFWFG(128K)

n.c

MCU & EEPROM

1

PD6/AN10

2

PD7/AN11

3

AVSS

4

VREFH

5

AVCC

6

PG3 /IN T4

7

PK2/TB9OUT

8

PJ5/TB7OUT

9

PH4/TB2IN0

10

PH5/TB2IN1

11

PG7/TB8OUT

12

TEST2

13

DVSS

14

DVCC

15

PG4/SO2/SDA2

16

PG5/SI2/SCL2

17

PG6/SCK2

18

TEST1

19

PF7/IN T5

20

PE0/T X D 0

21

PE1/RXD0

22

PE2/SCLK 0

23

PE4/T X D 1

24

PE5/RXD1

25

PE6/SCLK 1

26

PG0/SO0/SDA027PG1/SI0/SCL028PG2/SCK029PB330PH0/TB0IN0//BOOT31PH1/TB0IN032PH2/TB1IN033PF0/T X D 234PF1/RXD235PF2/SCLK 236PH3/TB1IN137PB438PI0/TB0OUT39PJ6/IN T640PI1/TB1OUT41PB542PI2/TB2OUT43PB644PF4/SO1/SDA145PF5/SI1/SCL146PF6/SCK147PB748PI3/TB3OUT49PJ1/IN T150PK0/CEC

51

PK1/SCOUT

52

PI4/TB4OUT

53

PI5/TB5OUT

54

PB0/T D O / SWV

55

PA0/TMS/SWDIO

56

PA1/TCK/SWCLK

57

TEST3

58

PJ7/IN T7

59

PB1/T D I

60

PB2/T R ST

61

PF3/RXIN1

62

DVCC

63

DVSS

64

PA2/T R A C E C LK

65

PA3/TRACEDATA0

66

PA4/TRACEDATA1

67

PA5/TRACEDATA2

68

PA6/TRACEDATA3

69

PA7

70

PJ0/IN T0

71

CVCC

72

X2

73

CVSS

74

X1

75

REGVSS

76

REGVCC

77

XT178XT2

79

PI6/TB4IN0

80

/NMI

81

MODE

82

/RESET

83

PI7/TB4IN1

84

PH6/TB3IN0

85

PH7/TB3IN1

86

PJ2/IN T287PJ3/IN T3

88

PJ4/TB6OUT

89

PE3/RXIN0

90

TEST4

91

PC0/ AN 092PC1/ AN 193PC2/ AN 294PC3/ AN 3

95

PD0/ A N 496PD1/ A N 597PD2/ A N 698PD3/ A N 799PD4/ A N 8

100

PD5/ A N 9

IC01

TMP330FWFGA

1

45

2

VDD

VSS

DS

OUT

NC

3

IC02

CVIS80124CLMCJIJT2

C405

1uF

C406

0.1uF

R413

1K

C403

100P

C402

100P

C401

100P

R400

47

R402

47

R401

47

D401

RB160L60

D402

1SS355T

R407

100K

R405

47

C418

0.1uF

C417

0.1uF

R420

10K

R419

10K

R417

10K

R416

10K

R418

10K

C415

12P

C416

15P

R414

1M

X001

10MHz

R415

33

C410

0.1uF

R409

10K

R411

10K

R410

10K

R412

10K

C407

0.1uF

C408

0.1uF

C409

0.1uF

C411

0.1uF

C412

0.1uF

C413

0.1uF

R406

47

R403

10K

R404

10K

C404

100P

R408

10K

12345678

CN02

CJP08GA19ZY

1

2

IC03-A

CVISN74ACT04DR_

3

4

IC03-B

CVISN74ACT04DR_

5

6

IC03-C

CVISN74ACT04DR_

9

8

IC03-D

CVISN74ACT04DR_

11

10

IC03-E

CVISN74ACT04DR_

13

12

IC03-F

CVISN74ACT04DR_

C419

10/50V

C420

1uF

C421

47/25V

1234

5678

A0

A1

A2

GNDSDA

SCL

WP

VCC

IC07

HVIAT24C08N10SC

R423

33

R424

33

R421

10K

R422

10K

C422

0.1uF

1

2

3

4

5

6

7

8

9

10

11

12

13

14

1517

16

CN03

CJP17GA115ZY

R425

33K

C423

0.1uF

CD_BUS3

[2]

CD_BUCK

[2]

CD_CCE

[2]

CD_BUS2

[2]

CD_CLOSE_M

[2]

CD_OPEN_M

[2]

CD_CLOSE_SW

[2]

CD_OPEN_SW

[2]

CD_LIMIT_SW

[2]

MT_ STBY

[2]

FRONT

KEY0

KEY1

DSP_RST

[2]

MCU+3.3V

DAC_SCL

[3]

DAC_RESET

[3]

VFD-RST

VFD-DI

VFD-CE

VFD-CLK

STBY-LED

VFD-DI

VFD-CLK

VFD-CE

VFD-RST

KEY1

STBY-LED

KEY0

MCU+3.3V

LD_CHK

[2]

TRANS_ON/OFF

[4]

MCU+3.3V

F_MUTE

[3]

DAC_SDA

[3]

MCU+3.3V

MCU+3.3V

MCU+3.3V

+5V

FL-VPFL+

REMOTE_IN

REMOTE_IN

MCU+3.3V

MCU+3.3V

MCU+3.3V

RESET RESET

RESET

+5V

RESET

[1,3]

/BOOT

[3]

UPDATE_TX

[3]

UPDATE_RX

[3]

/RESET_DOWNLOAD

[3]

POWER_DN

[4]

MCU+3.3V

MCU+3.3V

EX_INTERRUPT

EX_INTERRUPT

MCU+3.3V

+3.3V

Page 32

LOADING-

LOADING+

MGND

CLSW

OPSW

SPINDLE+

SPINDLE-

SLED-

SLED+

MGND

LMSW

TRK-

FCS+

TRK+

FCS-

VR

GND

LD

MD

C

A

B

F

E

VC (VREF)

VCC

D

CD DSP

PVREF

n.c

n.c

n.c

n.c

n.c

n.c

n.c

n.c

n.c

n.c

n.c

n.c

GND <-> AGND

TC94A92FG

DSP & MECHA INTERFACE

Open Open

1

VCOI

2

RVDD3

3

SLCO

4

RFI

5

RFRPI

6

RFEQO

7

DCOFC

8

AGCI

9

RFO

10

RVSS3

11

FNI2

12

FNI1

13

FPI2

14

FPI1

15

TPI

16

TNI

17

VRO

18

AVSS3

19

MDI

20

LDO

60

PIO7

59

PIO6

58

PIO5

57

PIO4

56

PIO3

55

PIO2

54

PIO1

53

PIO0

52

VSS-2

51

VDD1-2

50

XVDD3

49

XO

48

XI

47

XVSS3

46

DVSS3L

45

LO

44

DVDD3L

43

DVDD3R

42

RO

41

DVSS3R

61

VDD362BUS063BUS164BUS265BUS366BUCK67/CCE68MS69/RST70TEST71VDD1-172VSS-173/SRAM S TB74VDDM175PDO76TMAX77LPFN78LPFO79PVREF80VCOF

40

CDMON3

39

PIO14/CDMON238PIO13/CDMON1

37

PIO12/CDMON0/FGIN

36

PIO1135PIO10

34

PIO933PIO8

32

VDD1-3

31

DMO

30

FMOS

29

FMO

28

VSS-3

27

TRO

26

FOO

25

AVDD3

24

TEI

23

RFRP

22

RFZI

21

FSM ONIT

IC05

TC94A92FG

1234567 891011121314

1516171819202122232425262728

SP-

SP+

FIN-R

FIN

REB

REO

MUTE

GND1

OPIN

SPIN

F+

F-

GND2

CLIN OPO

CLO

T-

T+

SLIN

LD_CTL

VCC2

VCC2

VREF

TIN

TIN-R

SL-

SL+

GND3

IC0 4

IP4001CRLTF

C104

0.1uF

C102

0.1uF

C108

0.1uF

R110

33

R111

33

R112

33

R109

33

R150

0

R148

18K

R149

18K

C161

OPEN

C160

OPEN

C163

OPEN(0.1uF)

R152

0

R151

18K

R113

33

C164

0.1uF

C130

2200P

C129

0.1uF

R129

220

C126

0.01uF

C131

0.01uF

C127

0.1uF

C133

0.1uF

C132

4700P

RFEQO

C134

0.015u

C135

0.1uF

C136

OPEN

RFO

R126

47K

R125

15K

R124

330K

C122

0.015u

R118

100K

C106

0.1uF

R120

15K

R119

15K

R121

15K

R122

15K

R123

10K

C121

0.1uF

R114

10K

C171

1000P

R115

10K

R116

10K

R117

10K

C115

0.1uF

C114

0.1uF

C113

0.1uF

C112

0.1uF

C109

0.1uF

C110

0.1uF

C111

0.1uF

R100

33

C148

0.01uF

C138

0.1uF

R139

OPEN

C146

470P

C145

470P

C141

0.047u

C142

0.047u

R130

0

R131

0

R132

0

C139

0.033u

C140

5600P

C144

0.1uF

R138

OPEN

C143

OPEN

FEI

R134

0

R135

0

TEI

AGND

R133

0

R137

0

R136

0

R143

4.7K

R142

4.7K

C154

0.1uF

C150

0.1uF

C151

OPEN

R144

47K

R145

47K

C152

0.1uF

C153

470/16V

R146

OPEN

R147

470

C156

0.1uF

C157

OPEN

R140

OPEN

R141

470

C149

OPEN

C125

OPEN(0.1uF)

R127

0

VC1

R158

91

D100

1SS355T

L201

10uH

Q101

A1504S

R157

1K

C166

0.1uF

C167

0.1uF

C123

47P

C237

0.1uF

C124

47uF/10V

L253

220

L001

220

C162

OPEN

C159

0.1uF

R105

1M

C119

12P

C120

12P

X002

16.9344MHz

R104

33

R108

0

C712

100/16V

C107

47uF/10V

C158

OPEN

C169

0.1uF

C170

0.1uF

R128

0

R153

39

R154

39

R155

39

R156

39

C103

47/25V

C116

47/25V

C147

47/25V

C137

47/25V

C128

47/25V

C155

47/25V

C165

47/25V

C168

47/25V

123

GND

OUT

IN

IC10

CVILM1117S33

123

GND

OUT

IN

IC19

CVILM1117S15

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

CN01

R170

0

R171

0

12345

CN04

CJP05GA208ZY

123456

CN05

CJP06GA208ZY

R172

47K

C173

0.1uF

C172

0.1uF

C174

0.1uF

R173

0

+1.5V

CD_BUS3

[1]

CD_BUCK

[1]

CD_CCE

[1]

CD_BUS2

[1]

CD_CLOSE_SW

[1]

CD_OPEN_SW

[1]

CHGND

CHGND

GND_DRV

CD_LIMIT_SW

[1]

DSP_RST

[1]

MOTOR_MECHA

FC-

TRTR+

FC+

SPINDLE+

SPINDLE-

SLED+

SLED-

LOADING+

LOADING-

DAC_LRCK

[3]

DAC_BCK

[3]

DAC_DATA

[3]

DAC_MCLK

[3]

DSP_AGND

D+3.3V

+3.3V

+1.5V

D+3.3V

OPTICAL

[3]

+VREF

CD_CLOSE_M

[1]

CD_OPEN_M[1]

LOADING-

LOADING+

TR-

TR+

+VREF

+VREF

GND_DRV

GND_DRV

TRO

+8V_DRV

GND_DRV

GND_DRV

SLED+

SPINDLE-

SPINDLE+

MECHA

PD

E

F

B

D

A

C

F

C

B

A

D

E

PD

MT_ STBY

[1]

FCO

TRO

FC-

FC+

A+3.3V

A+3.3V

GND_DRV

A+3.3V

SLED-

LD_CHK

[1]

A+3.3V

+VREF

+3.3V

+5V +5V

FCO

+3.3V

A+3.3VD+3.3V

GND_DRV

CHGNDGND_DRV

CHGND

D

SP_AGND

D

SP_AGNDDSP_AGND

DSP_AGND

DSP_AGND

DSP_AGND DSP_AGND

DSP_AGNDDSP_AGND

DSP_AGND

DSP_AGND

GND_DRV

CHGND

AGND

Page 33

OUT_L

OUT_R

LCH

RCH

OPTICAL

+5V

GND

SPDIF

AGND RT1N141C 10K/10K

RT1N144C 10K/47K

DAC & AUDIO

Open

R225

220

R224

4.7K

R229

4.7K

R228

4.7K

R221

4.7K

R230

220

C217

10uF/50V

C218

10uF/50V

R211

8.2K

R212

8.2K

R214

8.2K

R213

3.3K

R215

3.3K

C220

100V/220pF

C224

47uF/25V

C221

390P

R216

10K

C219

1200P

R219

220

R232

220

C227

47uF/25V

C225

1800P

C226

1800P

R220

47K

R231

47K

C232

1200P

R240

10K

C230

390P

C231

100V/220pF

R239

3.3K

R237

3.3K

R235

8.2K

R236

8.2K

R238

8.2K

C233

10uF/50V

C234

10uF/50V

R218

820

C222

100uF/25V

C223

100uF/25V

C229

100uF/25V

C228

100uF/25V

R217

2.7K

R233

2.7K

R234

820

R227

100K

R223

100K

R222

470K

R226

470K

R204

33

R203

100

R202

100

R201

100

13 14 2019181716151211

10987654321

/RST

VL

SDATA

SCLK

LRCK

MCLK

M3

SCL

SDA

AD0 FILT+

CMOUT

BMUTEC

AOUTB-

AOUTB+

AGND

VA

AOUTA+

AOUTA-

AMUTEC

IC11

CS4392KZZ

C203

0.1uF

C205

0.1uF

C204

1/50

C206

10/50V

C201

0.1uF

ET41

HJT1A025

C236

0.01uF

C202

47/25V

C207

0.1uF

C214

0.1uF

R210

1.0

C215

47/25V

C212

100P

C213

0.1uF

C216

0.1uF

R205

100

R206

180

R209

1.2K

R208

100K

R207

180

R200

10

C210

12P

C208

47/25V

C209

0.1uF

C211

0.1uF

1234

5678

A

+-

B

+-

A OUTPUT

A-INPUT

A+INPUT

V-

B+INPUT

B-INPUT

B OUTPUT

V+

IC12

CVISA5532DR

Q202

KTC2875B

Q200

KTC2875B

Q201

KTC2875B

Q203

KTC2875B

D203

1SS355T

D202

1SS355T

Q205

RT1N141C

Q204

RT1P144C

Q206

RT1P144C

D206

1SS355T

D201

1SS355T

D200

1SS355T

D207

1SS355T

D204

1SS355T

D205

1SS355T

C200

47/25V

123

GND

OUT

IN

IC1 5

CVILM1117S33

123

GND

OUT

IN

IC06

CVILM1117S50

C235

0.1uF

1234567

8 9 10 11 12 13 14

IC14

CVISN74ACT04DR

1234

5678

A

+-

B

+-

A OUTPUT

A-INPUT

A+INPUT

V-

B+INPUT

B-INPUT

B OUTPUT

V+

IC13

CVISA5532DR

1

2

3

4

5

6

7

8

9

10

11

12

13

CN09

CJP13GA115ZY

12345

1

2

3

4

5

CN08

CJP05GA19ZY

Q208

RT1P144C

Q207

RT1P144C

12

L202

CLZ9R001Z

12

L203

CLZ9R001Z

AGND

AGND

AGND

AGND

AGND

AGND

AGND

AGND

AGND

AGND

B_MUTE [3 ]

A_MUTE [3 ]

AGND

+10V_A

AGND

AGND

AGND

AGND

3.3V_DAC

3.3V_DAC

+5V_DAC

+5V_DAC

B_MUTE

[3]

A_MUTE

[3]

DAC_SDA

[1]

DAC_SCL

[1]

DAC_DATA

[2]

DAC_BCK

[2]

DAC_LRCK

[2]

DAC_MCLK

[2]

OPTICAL

[2]

AGND

DAC_RESET

[1]

-8V_A

+8V_A

+8V_A

-8V_A

-8V_A

+5V

+5V

F_MUTE

[1]

RESET

[1]

AGND

MCU+3.3V

AGND

MCU+3.3V +8V_A

AGND

MCU+3.3V

/RESET_DOWNLOA D

[1]

UPDATE_RX

[1]

UPDATE_TX

[1]

/BOOT

[1]

AGND

AGND

AGND

Page 34

AC_STBY

AC_STBY

RELAY_I

RELAY_O

AC_AUDIO

AC_AUDIO

GND

AC_MAIN

AC_MAIN

VP

GND

AC_FILA

AC_FILA

POWER

D310

CVD1N4003SRT

D311

CVD1N4003SRT

D308

CVD1N4003SRT

D309

CVD1N4003SRT

C311

100/16V

C310

3300/25V

C304

100/25V

R301

39

D300

CVD1N4003SRT

D301

CVD1N4003SRT

C301

2200/16V

C305

1000/35V

D316

CVD1N4003SRT

D315

CVD1N4003SRT

C306

470/16V

C308

470/16V

C307

1000/35V

D307

CVD1N4003SRT

D306

CVD1N4003SRT

Q301

A916

C312

220u/63V

R305

1K

D312

CVD1N4003SRT

R309

47K

C315

0.1uF

C316

22u/50V

C314

10/50V

R307

10K

R306

1.2K

C313

0.1uF

R311

220

R310

220

F101

KBA2D1000A3EYT

F102

KBA2D1000A3EYT

12345678910111213

CN07

12

3

4

VIN VOUT

GND

CTRL

IC16

LM78R08

R304

1.0

R302

2.2K

R300

1.0

R308

1K

C302

0.1uF

D305

1SS355T

D304

1SS355T

1

2

3

Q300

C3875S

R303

22K

C303

0.01uF

R312

4.7

C309

100/25V

D302

CVD1N4003SRT

D303

CVD1N4003SRT

C300

0.022u

C322

100/16V

3

2

1

VIN

GND

OUT

IC20

CVILM7808RTRL

3

1

2

IN

GND

OUT

IC21

CVILM7908RTRL

123

GND

OUT

IN

IC18

CVILM1117S33

3

2

1

VIN

GND

OUT

IC17

CVILM7805RTRL

1

23

Q302

CVTRT1N144C

1

23

Q303

CVTRT1N144C

D317

1SS355T

R313

10K

C323

CCEA1HH1R0T

D313

27V

D314

6.8V

C324

0.1uF

C325

0.1uF

AGND

+8V_DRV

+8V_A

-8V_A

TRANS _ ON/OF F[1]

FL-FL+

VP

+5V

MCU+3.3V

AGND

AGND

+10V_A

MCU+3.3V

MCU+3.3V

POWER_DN

[1]

Page 35

4. PRINTED CIRCUIT BOARDS

DSP PCB VIEW

2-31 2-32

Page 36

FRONT + POWER PCB VIEW)

2-33 2-34

Page 37

SECTION 3

ELECTRICAL PARTS LIST

[FRONT & POWER PCB Ass'y] COP12490B(C516BEEC, C516BEECT) , COP12490C(C516BEEAH)

CUP12489Z-1

Ref NO PART NUMBER Description REMARK

C301 CCUS1H104KC CAP, CHIP(1608, 50V/0.1uF)

C400 CCUS1H104KC CAP, CHIP(1608, 50V/0.1uF)

C401 CCUS1H104KC CAP, CHIP(1608, 50V/0.1uF)

C402 CCUS1H104KC CAP, CHIP(1608, 50V/0.1uF)

C404 CCUS1H470JA CAP, CHIP(1608, 50V/47pF)

C405 CCUS1H470JA CAP, CHIP(1608, 50V/47pF)

C406 CCUS1H470JA CAP, CHIP(1608, 50V/47pF)

C408 CCUS1H104KC CAP, CHIP(1608, 50V/0.1uF)

C409 CCUS1H104KC CAP, CHIP(1608, 50V/0.1uF)

C411 CCUS1H470JA CAP, CHIP(1608, 50V/47pF)

C412 CCUS1H470JA CAP, CHIP(1608, 50V/47pF)

C413 CCUS1H104KC CAP, CHIP(1608, 50V/0.1uF)

C414 CCUS1H104KC CAP, CHIP(1608, 50V/0.1uF)

D400 CVD1SS355T DIODE , CHIP , SWITCHING

D401 CVD1SS355T DIODE , CHIP , SWITCHING

D402 CVD1SS355T DIODE , CHIP , SWITCHING

D403 CVD1SS355T DIODE , CHIP , SWITCHING

D404 CVD1SS355T DIODE , CHIP , SWITCHING

D405 CVD1SS355T DIODE , CHIP , SWITCHING

D406 CVD1SS355T DIODE , CHIP , SWITCHING

D407 CVD1SS355T DIODE , CHIP , SWITCHING

L901 CLZ9R001Z FERRITE , CHIP BEAD(60ohm, 2012)

Q400 HVTKTC3875SYRTK T.R , CHIP , SOT-23

Q401 CVTRT1P144C T.R,RT1P144C(10K-47K)

Q402 CVTRT1N141C T.R,RT1N141C(10K-10K)

R400 CRJ10DJ182T RES, CHIP(1608/5%/1.8Kohm)

R401 CRJ10DJ121T RES, CHIP(1608/5%/120ohm)

R402 CRJ10DJ680T RES, CHIP(1608/5%/68ohm)

R403 CRJ10DJ103T RES, CHIP(1608/5%/10Kohm)

R404 CRJ10DJ102T RES, CHIP(1608/5%/1Kohm)

R405 CRJ10DJ152T RES, CHIP(1608/5%/1.5Kohm)

R406 CRJ10DJ103T RES, CHIP(1608/5%/10Kohm)

R407 CRJ10DJ102T RES, CHIP(1608/5%/1Kohm)

R408 CRJ10DJ152T RES, CHIP(1608/5%/1.5Kohm)

R409 CRJ10DJ221T RES, CHIP(1608/5%/220ohm)

R410 CRJ10DJ221T RES, CHIP(1608/5%/220ohm)

R411 CRJ10DJ221T RES, CHIP(1608/5%/220ohm)

R412 CRJ10DJ102T RES, CHIP(1608/5%/1Kohm)

R413 CRJ10DJ103T RES, CHIP(1608/5%/10Kohm)

R414 CRJ10DJ472T RES, CHIP(1608/5%/4.7Kohm)

R415 CRJ10DJ332T RES, CHIP(1608/5%/3.3Kohm)

C320 CCEA1HKS100T CAP, ELECT(50V/10uF)-S

C403 CCEA1CKS101T CAP, ELECT(16V/100uF)-S

C407 CCEA1HKS1R0T CAP, ELECT(50V/1uF)-S

C410 CCEA1HKS100T CAP, ELECT(50V/10uF)-S

S301 CST1A012ZT SW , TACT

S302 CST1A012ZT SW , TACT

S303 CST1A012ZT SW , TACT

S304 CST1A012ZT SW , TACT

S305 CST1A012ZT SW , TACT

S306 CST1A012ZT SW , TACT

BK10 CMD1A807 BRACKET , FIP

BK11 CMD1A807 BRACKET , FIP

CN41 CJP05GA19ZY WAFER , STRAIGHT

CN42 CJP17GB116ZY WAFER, FFC(17P-1.25mm, ANGEL)

FL41 CFLCIG201411 VFD , ZBOE , CIG20-1411 , CIG-TYPE

RS01 CRVKSM603TH5B SENSOR , REMOTE/U

CWC4C4A13B100B10

CWC4C4A17B100B10 CABLE , CARD (17P,1.25MM100MM,,B,10MM)

C4FJ104 TAPE , BOTH SID

CABLE , CARD (13P,1.25MM,100MM,B,10MM)

3-1

Page 38

Ref NO PART NUMBER Description REMARK

Switch PCB Ass'y CUP12490Z-2 : C516BEEAH, C516BEEC, C516BEECT

S307 CST1A012ZT SW , TACT

D302 CVD50BOBBWGA L.E.D , 2 COLOR (ORG , BLUE)

BN41 CWB1B905180EN WIRE ASS'Y

Trans PCB Ass'y CUP12490Z-3 : C516BEEC, C516BEECT

T801 CLT5I009ZE TRANS , SUB CD6002/N C516BEEC/CT

T802 CLT5M028ZES TRANS , POWER(EUR/UK) C516BEEC/CT

F801 KBA2C0315TLEY

RY81 CSL1E002ZE RELAY,G5PA-1,DC6V,1C1P

CN82 CJP02KA060ZY WAFER, 2P, 3.96mm

HF81 KJCFC5S HOLDER , FUSE

HF82 KJCFC5S HOLDER , FUSE

BN81 CWB1C913120EN WIRE ASS'Y(13P, 120mm)

C800 KCKDKS472ME CAP , CERAMIC(X1/Y2/SC)

FUSE(218Series, 250V/315mA)

C516BEEC/CT

Trans PCB Ass'y CUP12490Z-3 : C516BEEAH

T801 CLT5I009ZU TRANS , SUB C515 C516BEEAH

T802 CLT5M028ZUS TRANS , POWER C515 C516BEEAH

F801 KBA2C0630TLEY FUSE(218Series, 250V/630mA) C516BEEAH

RY81 CSL1E002ZE RELAY,G5PA-1,DC6V,1C1P

CN82 CJP02KA060ZY WAFER, 2P, 3.96mm

HF81 KJCFC5S HOLDER , FUSE

HF82 KJCFC5S HOLDER , FUSE

BN81 CWB1C913120EN WIRE ASS'Y(13P, 120mm)

C800 KCKDKS472ME CAP , CERAMIC(X1/Y2/SC)

Jack PCB Ass'y CUP12490Z-5 : C516BEEAH, C516BEEC, C516BEECT

BN91 CWB2B905080EN WIRE ASS'Y

JK91 CJJ4N067Z JACK , 2P

JK92 CJSJST1124 MODULE , OPTICAL(TX 16MHz)

JK93 CJJ4M045Z JACK , BOARD

CN92 CJP13GA115ZY WAFER, FFC(13P-1.25mm, STRAIGHT)

CN93 CJP07GB113ZY WAFER, FFC(5P-1mm, ANGLE)

3-2

Page 39

ELECTRICAL PARTS LIST

[Main PCB Ass'y COP12489B] -- C516BEEAH, C516BEEC, C516BEECT

CUP12489Z

Ref NO PART NUMBER Description REMARK

CN04 CJP05GA208ZY WAFER , SMD (2MM PITCH)

CN05 CJP06GA208ZY WAFER , SMD (2MM PITCH)

C102 CCUS1H104KC CAP, CHIP(1608, 50V/0.1uF)

C104 CCUS1H104KC CAP, CHIP(1608, 50V/0.1uF)

C106 CCUS1H104KC CAP, CHIP(1608, 50V/0.1uF)

C108 CCUS1H104KC CAP, CHIP(1608, 50V/0.1uF)

C109 CCUS1H104KC CAP, CHIP(1608, 50V/0.1uF)

C110 CCUS1H104KC CAP, CHIP(1608, 50V/0.1uF)

C111 CCUS1H104KC CAP, CHIP(1608, 50V/0.1uF)

C112 CCUS1H104KC CAP, CHIP(1608, 50V/0.1uF)

C113 CCUS1H104KC CAP, CHIP(1608, 50V/0.1uF)

C114 CCUS1H104KC CAP, CHIP(1608, 50V/0.1uF)

C115 CCUS1H104KC CAP, CHIP(1608, 50V/0.1uF)

C119 CCUS1H120JA CAP, CHIP(1608, 50V/12pF)

C120 CCUS1H120JA CAP, CHIP(1608, 50V/12pF)

C121 CCUS1H104KC CAP, CHIP(1608, 50V/0.1uF)

C122 CCUS1H153KC CAP, CHIP(1608, 50V/0.015uF)

C123 CCUS1H470JA CAP, CHIP(1608, 50V/47pF)

C126 CCUS1H103KC CAP, CHIP(1608, 50V/0.01uF)

C127 CCUS1H104KC CAP, CHIP(1608, 50V/0.1uF)

C129 CCUS1H104KC CAP, CHIP(1608, 50V/0.1uF)

C130 CCUS1H222KC CAP, CHIP(1608, 50V/2200pF)

C131 CCUS1H103KC CAP, CHIP(1608, 50V/0.01uF)

C132 CCUS1H472KC CAP, CHIP(1608, 50V/4700pF)

C133 CCUS1H104KC CAP, CHIP(1608, 50V/0.1uF)

C134 CCUS1H153KC CAP, CHIP(1608, 50V/0.015uF)

C135 CCUS1H104KC CAP, CHIP(1608, 50V/0.1uF)

C138 CCUS1H104KC CAP, CHIP(1608, 50V/0.1uF)

C139 CCUS1H333KC CAP, CHIP(1608, 50V/0.033uF)

C140 CCUS1H562KC CAP, CHIP(1608, 50V/5600pF)

C141 CCUS1H473KC CAP, CHIP(1608, 50V/0.047uF)

C142 CCUS1H473KC CAP, CHIP(1608, 50V/0.047uF)

C144 CCUS1H104KC CAP, CHIP(1608, 50V/0.1uF)

C145 CCUS1H471JA CAP, CHIP(1608, 50V/470pF)

C146 CCUS1H471JA CAP, CHIP(1608, 50V/470pF)

C148 CCUS1H103KC CAP, CHIP(1608, 50V/0.01uF)

C150 CCUS1H104KC CAP, CHIP(1608, 50V/0.1uF)

C152 CCUS1H104KC CAP, CHIP(1608, 50V/0.1uF)

C154 CCUS1H104KC CAP, CHIP(1608, 50V/0.1uF)

C156 CCUS1H104KC CAP, CHIP(1608, 50V/0.1uF)

C159 CCUS1H104KC CAP, CHIP(1608, 50V/0.1uF)

C164 CCUS1H104KC CAP, CHIP(1608, 50V/0.1uF)

C166 CCUS1H104KC CAP, CHIP(1608, 50V/0.1uF)

C167 CCUS1H104KC CAP, CHIP(1608, 50V/0.1uF)

C171 CCUS1H102KC CAP, CHIP(1608, 50V/1000pF)

C172 CCUS1H104KC CAP, CHIP(1608, 50V/0.1uF)

C173 CCUS1H104KC CAP, CHIP(1608, 50V/0.1uF)

C201 CCUS1H104KC CAP, CHIP(1608, 50V/0.1uF)

C203 CCUS1H104KC CAP, CHIP(1608, 50V/0.1uF)

C205 CCUS1H104KC CAP, CHIP(1608, 50V/0.1uF)

C207 CCUS1H104KC CAP, CHIP(1608, 50V/0.1uF)

C209 CCUS1H104KC CAP, CHIP(1608, 50V/0.1uF)

C210 CCUS1H120JA CAP, CHIP(1608, 50V/12pF)

C211 CCUS1H104KC CAP, CHIP(1608, 50V/0.1uF)

C212 CCUS1H101JA CAP, CHIP(1608, 50V/100pF)

C213 CCUS1H104KC CAP, CHIP(1608, 50V/0.1uF)

C214 CCUS1H104KC CAP, CHIP(1608, 50V/0.1uF)

C216 CCUS1H104KC CAP, CHIP(1608, 50V/0.1uF)

C221 CCUS1H391JA CAP, CHIP(1608, 50V/390pF)

3-3

Page 40

Ref NO PART NUMBER Description REMARK

C225 CCUS1H182KC CAP, CHIP(1608, 50V/1800pF)

C226 CCUS1H182KC CAP, CHIP(1608, 50V/1800pF)

C230 CCUS1H391JA CAP, CHIP(1608, 50V/390pF)

C235 CCUS1H104KC CAP, CHIP(1608, 50V/0.1uF)

C236 CCUS1H103KC CAP, CHIP(1608, 50V/0.01uF)

C237 CCUS1H104KC CAP, CHIP(1608, 50V/0.1uF)

C300 CCUS1H223KC CAP, CHIP(1608, 50V/0.022uF)

C302 CCUS1H104KC CAP, CHIP(1608, 50V/0.1uF)

C303 CCUS1H103KC CAP, CHIP(1608, 50V/0.01uF)

C313 CCUS1H104KC CAP, CHIP(1608, 50V/0.1uF)

C315 CCUS1H104KC CAP, CHIP(1608, 50V/0.1uF)

C324 CCUS1H104KC CAP, CHIP(1608, 50V/0.1uF)

C325 CCUS1H104KC CAP, CHIP(1608, 50V/0.1uF)

C401 CCUS1H101JA CAP, CHIP(1608, 50V/100pF)

C402 CCUS1H101JA CAP, CHIP(1608, 50V/100pF)

C403 CCUS1H101JA CAP, CHIP(1608, 50V/100pF)

C404 CCUS1H101JA CAP, CHIP(1608, 50V/100pF)

C405 CCUS1A105KC CAP, CHIP(1608, 10V/1uF)

C406 CCUS1H104KC CAP, CHIP(1608, 50V/0.1uF)

C407 CCUS1H104KC CAP, CHIP(1608, 50V/0.1uF)

C408 CCUS1H104KC CAP, CHIP(1608, 50V/0.1uF)

C409 CCUS1H104KC CAP, CHIP(1608, 50V/0.1uF)

C410 CCUS1H104KC CAP, CHIP(1608, 50V/0.1uF)

C411 CCUS1H104KC CAP, CHIP(1608, 50V/0.1uF)

C412 CCUS1H104KC CAP, CHIP(1608, 50V/0.1uF)

C413 CCUS1H104KC CAP, CHIP(1608, 50V/0.1uF)

C415 CCUS1H120JA CAP, CHIP(1608, 50V/12pF)

C416 CCUS1H150JA CAP, CHIP(1608, 50V/15pF)

C417 CCUS1H104KC CAP, CHIP(1608, 50V/0.1uF)

C418 CCUS1H104KC CAP, CHIP(1608, 50V/0.1uF)

C420 CCUS1A105KC CAP, CHIP(1608, 10V/1uF)

C422 CCUS1H104KC CAP, CHIP(1608, 50V/0.1uF)

C423 CCUS1H104KC CAP, CHIP(1608, 50V/0.1uF)

D100 CVD1SS355T DIODE , CHIP , SWITCHING

D200 CVD1SS355T DIODE , CHIP , SWITCHING

D201 CVD1SS355T DIODE , CHIP , SWITCHING

D202 CVD1SS355T DIODE , CHIP , SWITCHING

D203 CVD1SS355T DIODE , CHIP , SWITCHING

D204 CVD1SS355T DIODE , CHIP , SWITCHING

D205 CVD1SS355T DIODE , CHIP , SWITCHING

D206 CVD1SS355T DIODE , CHIP , SWITCHING

D207 CVD1SS355T DIODE , CHIP , SWITCHING

D304 CVD1SS355T DIODE , CHIP , SWITCHING

D305 CVD1SS355T DIODE , CHIP , SWITCHING

D313 HVDUDZS27BSR DIODE , ZENER(CHIP,27V)

D314 HVDUDZS6.8BSR DIODE , ZENER(CHIP,6.8V)

D317 CVD1SS355T DIODE , CHIP , SWITCHING

D401 HVDRB160L60TE25 DIODE, SCHOTTKEY BARRIER

D402 CVD1SS355T DIODE , CHIP , SWITCHING

IC01 CVIANAM1734C I.C , U-COM (TOSHIBA , TMPM330TWFG)

CVITMPM330FWFG I.C , U-COM (TOSHIBA,128KB/8KB,LQFP-100P)

IC02 CVIS80124CLMCJIJT2 I.C , RESET 2.4V (200ms,C-MOS,SOT23-5P)

IC03 CVISN74ACT04DR I.C , HEX INVERTERS(SOIC/D-14P)

IC04 CVIIP4001CRLTF_CN I.C , 5-CH MOTOR DRIVE(REG,SSOP-28P)

IC05 CVITC94A92FG I.C , CD DSP (SERVO,AMPLIFIER,DSP,LQFP-80P)

IC06 CVILM1117S50 I.C, REGULATOR(1.0A, 5.0V, SOT-223)

IC07 HVIAT24C08N10SC I.C

IC10 CVILM1117S33 I.C, REGULATOR(1.0A, 3.3V, SOT-223)

IC11 HVICS4392KZZ I.C , DAC

IC12 CVISA5532DR I.C , OP AMP

IC13 CVISA5532DR I.C , OP AMP

IC14 CVISN74ACT04DR I.C , HEX INVERTERS(SOIC/D-14P)

IC15 CVILM1117S33 I.C, REGULATOR(1.0A, 3.3V, SOT-223)

3-4

Page 41

Ref NO PART NUMBER Description REMARK

IC17 CVILM7805RTRL I.C, REGULATOR(1.0A, 5V , D-PAK)

IC18 CVILM1117S33 I.C, REGULATOR(1.0A, 3.3V, SOT-223)

IC19 CVILM1117S15 I.C, REGULATOR(1.0A, 1.5V, SOT-223)

IC20 CVILM7808RTRL IC, REGULATOR(1A, 8V)

IC21 CVILM7908RTRL IC, REGULATOR(1A, -8V)

L001 CLZ9R006Z FERRITE CHIP BEAD(2012/220R)

L201 HLQ10E100KRZ INDUCTOR CHIP 10UH (3225 PKG)

L202 CLZ9R001Z FERRITE , CHIP BEAD(60ohm, 2012)

L203 CLZ9R001Z FERRITE , CHIP BEAD(60ohm, 2012)

L253 CLZ9R006Z FERRITE CHIP BEAD(2012/220R)

Q101 HVTKTA1504SYRTK T.R , CHIP , SOT-23

Q200 HVTKTC2875B T.R , CHIP , SOT-23

Q201 HVTKTC2875B T.R , CHIP , SOT-23

Q202 HVTKTC2875B T.R , CHIP , SOT-23

Q203 HVTKTC2875B T.R , CHIP , SOT-23

Q204 CVTRT1P144C T.R,RT1P144C(10K-47K)

Q205 CVTRT1N141C T.R,RT1N141C(10K-10K)

Q206 CVTRT1P144C T.R,RT1P144C(10K-47K)

Q207 CVTRT1P144C T.R,RT1P144C(10K-47K)

Q208 CVTRT1P144C T.R,RT1P144C(10K-47K)

Q300 HVTKTC3875SYRTK T.R , CHIP , SOT-23

Q302 CVTRT1N144C T.R,RT1N144C(10K-47K)

Q303 CVTRT1N144C T.R,RT1N144C(10K-47K)

R100 CRJ10DJ330T RES, CHIP(1608/5%/33ohm)

R104 CRJ10DJ330T RES, CHIP(1608/5%/33ohm)

R105 CRJ10DJ105T RES, CHIP(1608/5%/1Mohm)

R108 CRJ10DJ0R0T RES, CHIP(1608/5%/0ohm)

R109 CRJ10DJ330T RES, CHIP(1608/5%/33ohm)

R110 CRJ10DJ330T RES, CHIP(1608/5%/33ohm)

R111 CRJ10DJ330T RES, CHIP(1608/5%/33ohm)

R112 CRJ10DJ330T RES, CHIP(1608/5%/33ohm)

R113 CRJ10DJ330T RES, CHIP(1608/5%/33ohm)

R114 CRJ10DJ103T RES, CHIP(1608/5%/10Kohm)

R115 CRJ10DJ103T RES, CHIP(1608/5%/10Kohm)

R116 CRJ10DJ103T RES, CHIP(1608/5%/10Kohm)

R117 CRJ10DJ103T RES, CHIP(1608/5%/10Kohm)

R118 CRJ10DJ104T RES, CHIP(1608/5%/100Kohm)

R119 CRJ10DJ153T RES, CHIP(1608/5%/15Kohm)

R120 CRJ10DJ153T RES, CHIP(1608/5%/15Kohm)

R121 CRJ10DJ153T RES, CHIP(1608/5%/15Kohm)

R122 CRJ10DJ153T RES, CHIP(1608/5%/15Kohm)

R123 CRJ10DJ103T RES, CHIP(1608/5%/10Kohm)

R124 CRJ10DJ334T RES, CHIP(1608/5%/330Kohm)

R125 CRJ10DJ153T RES, CHIP(1608/5%/15Kohm)

R126 CRJ10DJ473T RES, CHIP(1608/5%/47Kohm)

R127 CRJ10DJ0R0T RES, CHIP(1608/5%/0ohm)

R128 CRJ10DJ0R0T RES, CHIP(1608/5%/0ohm)

R129 CRJ10DJ221T RES, CHIP(1608/5%/220ohm)

R130 CRJ10DJ0R0T RES, CHIP(1608/5%/0ohm)

R131 CRJ10DJ0R0T RES, CHIP(1608/5%/0ohm)

R132 CRJ10DJ0R0T RES, CHIP(1608/5%/0ohm)

R133 CRJ10DJ0R0T RES, CHIP(1608/5%/0ohm)

R134 CRJ10DJ0R0T RES, CHIP(1608/5%/0ohm)

R135 CRJ10DJ0R0T RES, CHIP(1608/5%/0ohm)

R136 CRJ10DJ0R0T RES, CHIP(1608/5%/0ohm)

R137 CRJ10DJ0R0T RES, CHIP(1608/5%/0ohm)

R141 CRJ10DJ471T RES, CHIP(1608/5%/470ohm)

R142 CRJ10DJ472T RES, CHIP(1608/5%/4.7Kohm)

R143 CRJ10DJ472T RES, CHIP(1608/5%/4.7Kohm)

R144 CRJ10DJ473T RES, CHIP(1608/5%/47Kohm)

R145 CRJ10DJ473T RES, CHIP(1608/5%/47Kohm)

R147 CRJ10DJ471T RES, CHIP(1608/5%/470ohm)

R148 CRJ10DJ183T RES, CHIP(1608/5%/18Kohm)

3-5

Page 42

Ref NO PART NUMBER Description REMARK

R149 CRJ10DJ183T RES, CHIP(1608/5%/18Kohm)

R150 CRJ10DJ0R0T RES, CHIP(1608/5%/0ohm)

R151 CRJ10DJ183T RES, CHIP(1608/5%/18Kohm)

R152 CRJ10DJ0R0T RES, CHIP(1608/5%/0ohm)

R153 CRJ10DJ390T RES, CHIP(1608/5%/39ohm)

R154 CRJ10DJ390T RES, CHIP(1608/5%/39ohm)

R155 CRJ10DJ390T RES, CHIP(1608/5%/39ohm)

R156 CRJ10DJ390T RES, CHIP(1608/5%/39ohm)

R157 CRJ10DJ102T RES, CHIP(1608/5%/1Kohm)

R158 CRJ10DJ910T RES, CHIP(1608/5%/91ohm)

R170 CRJ10DJ0R0T RES, CHIP(1608/5%/0ohm)

R171 CRJ10DJ0R0T RES, CHIP(1608/5%/0ohm)

R172 CRJ10DJ473T RES, CHIP(1608/5%/47Kohm)

R173 CRJ10DJ0R0T RES, CHIP(1608/5%/0ohm)

R200 CRJ10DJ100T RES, CHIP(1608/5%/10ohm)

R201 CRJ10DJ101T RES, CHIP(1608/5%/100ohm)

R202 CRJ10DJ101T RES, CHIP(1608/5%/100ohm)

R203 CRJ10DJ101T RES, CHIP(1608/5%/100ohm)

R204 CRJ10DJ330T RES, CHIP(1608/5%/33ohm)

R205 CRJ10DJ101T RES, CHIP(1608/5%/100ohm)

R206 CRJ10DJ181T RES, CHIP(1608/5%/180ohm)

R207 CRJ10DJ181T RES, CHIP(1608/5%/180ohm)

R208 CRJ10DJ104T RES, CHIP(1608/5%/100Kohm)

R209 CRJ10DJ122T RES, CHIP(1608/5%/1.2Kohm)

R210 CRJ10DJ1R0T RES, CHIP(1608/5%/1ohm)

R211 CRJ10DJ822T RES, CHIP(1608/5%/8.2Kohm)

R212 CRJ10DJ822T RES, CHIP(1608/5%/8.2Kohm)

R213 CRJ10DJ332T RES, CHIP(1608/5%/3.3Kohm)

R214 CRJ10DJ822T RES, CHIP(1608/5%/8.2Kohm)

R215 CRJ10DJ332T RES, CHIP(1608/5%/3.3Kohm)

R216 CRJ10DJ103T RES, CHIP(1608/5%/10Kohm)

R217 CRJ10DJ272T RES, CHIP(1608/5%/2.7Kohm)

R218 CRJ10DJ821T RES, CHIP(1608/5%/820ohm)

R219 CRJ10DJ221T RES, CHIP(1608/5%/220ohm)

R220 CRJ10DJ473T RES, CHIP(1608/5%/47Kohm)

R221 CRJ10DJ472T RES, CHIP(1608/5%/4.7Kohm)

R222 CRJ10DJ474T RES, CHIP(1608/5%/470Kohm)

R223 CRJ10DJ104T RES, CHIP(1608/5%/100Kohm)

R224 CRJ10DJ472T RES, CHIP(1608/5%/4.7Kohm)

R225 CRJ10DJ221T RES, CHIP(1608/5%/220ohm)

R226 CRJ10DJ474T RES, CHIP(1608/5%/470Kohm)

R227 CRJ10DJ104T RES, CHIP(1608/5%/100Kohm)

R228 CRJ10DJ472T RES, CHIP(1608/5%/4.7Kohm)

R229 CRJ10DJ472T RES, CHIP(1608/5%/4.7Kohm)

R230 CRJ10DJ221T RES, CHIP(1608/5%/220ohm)

R231 CRJ10DJ473T RES, CHIP(1608/5%/47Kohm)

R232 CRJ10DJ221T RES, CHIP(1608/5%/220ohm)

R233 CRJ10DJ272T RES, CHIP(1608/5%/2.7Kohm)

R234 CRJ10DJ821T RES, CHIP(1608/5%/820ohm)

R235 CRJ10DJ822T RES, CHIP(1608/5%/8.2Kohm)

R236 CRJ10DJ822T RES, CHIP(1608/5%/8.2Kohm)

R237 CRJ10DJ332T RES, CHIP(1608/5%/3.3Kohm)

R238 CRJ10DJ822T RES, CHIP(1608/5%/8.2Kohm)

R239 CRJ10DJ332T RES, CHIP(1608/5%/3.3Kohm)

R240 CRJ10DJ103T RES, CHIP(1608/5%/10Kohm)

R300 CRJ10DJ1R0T RES, CHIP(1608/5%/1ohm)

R301 CRJ10DJ390T RES, CHIP(1608/5%/39ohm)

R302 CRJ10DJ222T RES, CHIP(1608/5%/2.2Kohm)

R303 CRJ10DJ223T RES, CHIP(1608/5%/22Kohm)

R304 CRJ10DJ1R0T RES, CHIP(1608/5%/1ohm)

R305 CRJ10DJ102T RES, CHIP(1608/5%/1Kohm)

R306 CRJ10DJ122T RES, CHIP(1608/5%/1.2Kohm)

R307 CRJ10DJ103T RES, CHIP(1608/5%/10Kohm)

3-6

Page 43

Ref NO PART NUMBER Description REMARK

R308 CRJ10DJ102T RES, CHIP(1608/5%/1Kohm)

R309 CRJ10DJ473T RES, CHIP(1608/5%/47Kohm)

R310 CRJ10DJ221T RES, CHIP(1608/5%/220ohm)

R311 CRJ10DJ221T RES, CHIP(1608/5%/220ohm)

R312 CRJ10DJ4R7T RES, CHIP(1608/5%/4.7ohm)

R313 CRJ10DJ103T RES, CHIP(1608/5%/10Kohm)

R400 CRJ10DJ470T RES, CHIP(1608/5%/47ohm)

R401 CRJ10DJ470T RES, CHIP(1608/5%/47ohm)

R402 CRJ10DJ470T RES, CHIP(1608/5%/47ohm)

R403 CRJ10DJ103T RES, CHIP(1608/5%/10Kohm)

R404 CRJ10DJ103T RES, CHIP(1608/5%/10Kohm)

R405 CRJ10DJ470T RES, CHIP(1608/5%/47ohm)

R406 CRJ10DJ470T RES, CHIP(1608/5%/47ohm)

R407 CRJ10DJ104T RES, CHIP(1608/5%/100Kohm)

R408 CRJ10DJ103T RES, CHIP(1608/5%/10Kohm)

R409 CRJ10DJ103T RES, CHIP(1608/5%/10Kohm)

R410 CRJ10DJ103T RES, CHIP(1608/5%/10Kohm)

R411 CRJ10DJ103T RES, CHIP(1608/5%/10Kohm)

R412 CRJ10DJ103T RES, CHIP(1608/5%/10Kohm)

R413 CRJ10DJ102T RES, CHIP(1608/5%/1Kohm)

R414 CRJ10DJ105T RES, CHIP(1608/5%/1Mohm)

R415 CRJ10DJ330T RES, CHIP(1608/5%/33ohm)

R416 CRJ10DJ103T RES, CHIP(1608/5%/10Kohm)

R417 CRJ10DJ103T RES, CHIP(1608/5%/10Kohm)

R418 CRJ10DJ103T RES, CHIP(1608/5%/10Kohm)

R419 CRJ10DJ103T RES, CHIP(1608/5%/10Kohm)

R420 CRJ10DJ103T RES, CHIP(1608/5%/10Kohm)

R421 CRJ10DJ103T RES, CHIP(1608/5%/10Kohm)

R422 CRJ10DJ103T RES, CHIP(1608/5%/10Kohm)

R423 CRJ10DJ330T RES, CHIP(1608/5%/33ohm)

R424 CRJ10DJ330T RES, CHIP(1608/5%/33ohm)

R425 CRJ10DJ333T RES, CHIP(1608/5%/33Kohm)

X001 COX10000E120S X-TAL, 10MHz, HC-49/SMD, 12pF

X002 COX16934E120S X-TAL, 16.934MHz, HC-49/SMD, 12pF, 25PPM

C103 CCEA1EH470TC CAP, ELECT(25V/47uF)

C107 CCEA1AH470TC CAP, ELECT(10V/47uF)

C116 CCEA1EH470TC CAP, ELECT(25V/47uF)

C124 CCEA1AH470TC CAP, ELECT(10V/47uF)

C128 CCEA1EH470TC CAP, ELECT(25V/47uF)

C137 CCEA1EH470TC CAP, ELECT(25V/47uF)

C147 CCEA1EH470TC CAP, ELECT(25V/47uF)

C153 CCEA1CH471TC CAP, ELECT(16V/470uF)

C155 CCEA1EH470TC CAP, ELECT(25V/47uF)

C165 CCEA1EH470TC CAP, ELECT(25V/47uF)

C168 CCEA1EH470TC CAP, ELECT(25V/47uF)

C200 CCEA1EH470TC CAP, ELECT(25V/47uF)

C202 CCEA1EH470TC CAP, ELECT(25V/47uF)

C204 CCEA1HH1R0TC CAP, ELECT(50V/1uF)

C206 CCEA1HH100TC CAP, ELECT(50V/10uF)

C208 CCEA1EH470TC CAP, ELECT(25V/47uF)

C215 CCEA1EH470TC CAP, ELECT(25V/47uF)

C217 HCEA1HRA100T ELECT , CAP(ELNA/RA-2)

C218 HCEA1HRA100T ELECT , CAP(ELNA/RA-2)

C219 HCQI1H122JZT CAP, MYLAR(50V/1200pF/J)

C220 CCME2A221JR11T CAP, PE-FILM(100V/220pF/J)

C222 HCEA1ERA101T ELECT , CAP (ELNA/RA-2)

C223 HCEA1ERA101T ELECT , CAP (ELNA/RA-2)

C224 CCEA1ERA470T CAP, ELECT(16V/47uF,ELNA/RA2, 5X11)

C227 CCEA1ERA470T CAP, ELECT(16V/47uF,ELNA/RA2, 5X11)

C228 HCEA1ERA101T ELECT , CAP (ELNA/RA-2)

C229 HCEA1ERA101T ELECT , CAP (ELNA/RA-2)

C231 CCME2A221JR11T CAP, PE-FILM(100V/220pF/J)

C232 HCQI1H122JZT CAP, MYLAR(50V/1200pF/J)

3-7

Page 44

Ref NO PART NUMBER Description REMARK

C233 HCEA1HRA100T ELECT , CAP(ELNA/RA-2)

C234 HCEA1HRA100T ELECT , CAP(ELNA/RA-2)

C304 CCEA1EH101TC CAP, ELECT(25V/100uF)

C306 CCEA1CH471TC CAP, ELECT(16V/470uF)

C308 CCEA1CH471TC CAP, ELECT(16V/470uF)

C309 CCEA1EH101TC CAP, ELECT(25V/100uF)

C311 CCEA1CH101TC CAP, ELECT(16V/100uF)

C314 CCEA1HH100TC CAP, ELECT(50V/10uF)

C316 CCEA1HH220TC CAP, ELECT(50V/22uF)

C322 CCEA1CH101TC CAP, ELECT(16V/100uF)

C323 CCEA1HH2R2TC CAP, ELECT(50V/2.2uF)

C419 CCEA1HH100TC CAP, ELECT(50V/10uF)

C421 CCEA1EH470TC CAP, ELECT(25V/47uF)

C712 CCEA1CH101TC CAP, ELECT(16V/100uF)

D300 CVD1N4003SRT DIODE , RECT

D301 CVD1N4003SRT DIODE , RECT

D302 CVD1N4003SRT DIODE , RECT

D303 CVD1N4003SRT DIODE , RECT

D306 CVD1N4003SRT DIODE , RECT

D307 CVD1N4003SRT DIODE , RECT

D308 CVD1N4003SRT DIODE , RECT

D309 CVD1N4003SRT DIODE , RECT

D310 CVD1N4003SRT DIODE , RECT

D311 CVD1N4003SRT DIODE , RECT

D312 CVD1N4003SRT DIODE , RECT

D315 CVD1N4003SRT DIODE , RECT

D316 CVD1N4003SRT DIODE , RECT

ET41 CJT1A026 PLATE , EARTH(TRONIC ELECTRONICS)

F101 KBA2D1000A3EYT FUSE(1A, 372 SERIES/TR5)

F102 KBA2D1000A3EYT FUSE(1A, 372 SERIES/TR5)

Q301 HVTKSA916YT T.R

CN01 CJP16GA117ZY WAFER, FFC(17P-1mm, STRAIGHT)

CN02 CJP08GA19ZY WAFER, STRAIGHT, 8PIN

CN03 CJP17GA115ZY WAFER, FFC(17P-1.25mm, STRAIGHT)

CN07 CJP13GA19ZY WAFER, STRAIGHT, 13PIN

CN08 CJP05GA19ZY WAFER , STRAIGHT

CN09 CJP13GA115ZY WAFER, FFC(13P-1.25mm, STRAIGHT)

C301 CCEA1CH222EC CAP, ELECT(16V/2200uF)

C305 CCEA1VH102EC CAP, ELECT(35V/1000uF)

C307 CCEA1VH102EC CAP, ELECT(35V/1000uF)

C310 CCEA1EH332E CAP, ELECT(25V/3300uF)

C312 CCEA1JH221EC CAP , ELECT(63V/220uF)

IC16 CVIKIA78R08PIBA I.C HEAT SINK ASS'Y(CMY3A222)

CMY3A222-V1 HEAT SINK

CTB3+8JR SCREW

CVIKIA78R08PI I.C , REGULATOR(TO220IS-4)

K8AYG6260 COMPOUND , SILICONE

Loading...

Loading...