Page 1

be certain.

m

SWIFT® 50 GLP Sensor

Product Information

Spinning Wheel Integrated Force Transducer

For Medium and Heavy Trucks

100-162-722 E

Page 2

Copyright information © 20012 MTS Systems Corporation. All rights reserved.

Trademark information MTS, SWIFT, T estStar, TestWare, MTS Remote Parameter Control, and RPC are

registered trademarks of MTS Systems Corporation within the United States.

These trademarks may be protected in other countries.

All other trademarks or service marks are property of their respective owners.

Proprietary information Software use and license is governed by MTS’s End User License Agreement

which defines all rights retained by MTS and granted to the End User. All

Software is proprietary, confidential, and owned by MTS Systems Corporation

and cannot be copied, reproduced, disassembled, decompiled, reverse

engineered, or distributed without express written consent of MTS.

Software validation and

verification

Publication information

MTS software is developed using established quality practices in accordance

with the requirements detailed in the ISO 9001 quality standards. Because MTSauthored software is delivered in binary format, it is not user accessible. This

software will not change over time. Many releases are written to be backwards

compatible, creating another form of verification.

The status and validity of MTS’s operating software is also checked during

system verification and routine calibration of MTS hardware. These controlled

calibration processes compare the final test results after statistical analysis

against the predicted response of the calibration standards. With these established

methods, MTS assures its customers that MTS products meet MTS’s exacting

quality standards when initially installed and will continue to perform as intended

over time.

Manual Part Number Publication Date

100-162-722 A March 2006

100-162-722 B April 2006

100-162-722 C January 2007

100-162-722 D January 2009

100-162-722 E June 2012

Page 3

Contents

Technical Support 5

How to Get Technical Support 5

Before You Contact MTS 5

If You Contact MTS by Phone 7

Problem Submittal Form in MTS Manuals 8

Preface 9

Before You Begin 9

Conventions 10

Documentation Conventions 10

Hardware Overview 13

Overview 14

Spinning Applications (Track or Road) 16

Non-spinning Applications (Laboratory) 17

Construction 18

Design Features 21

Coordinate System 22

Specifications 24

Calibration 26

Interfacing with RPC 27

Installation 29

Hazard Icons 30

Road and Track Vehicles 31

Attaching SWIFT Components to the Vehicle 36

Attaching SWIFT and Wheel Assembly to the Vehicle 40

Attaching SWIFT Components to the Fixturing 48

Analyzing SWIFT Data 53

The Data 54

SWIFT 50 GLP Sensors

3

Page 4

Fx Data (Longitudinal Force) 55

Fz Data (Vertical Force) 57

Mx Data (Overturning Moment) 58

My Data (Brake Moment) 61

Acceleration and Braking Events Example 63

Slalom Curve Driving Example 65

Maintenance 67

Transducer 68

Cables 69

Troubleshooting 71

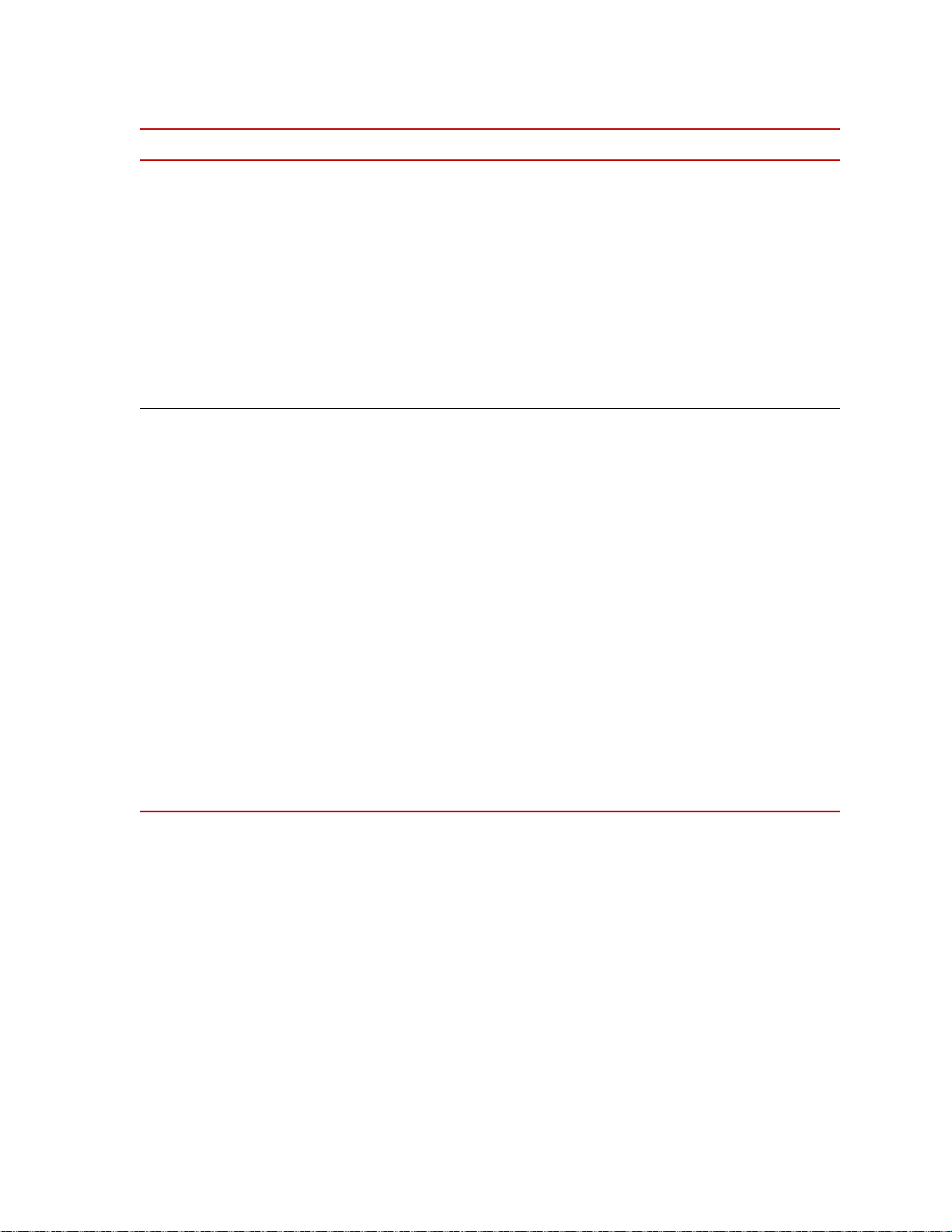

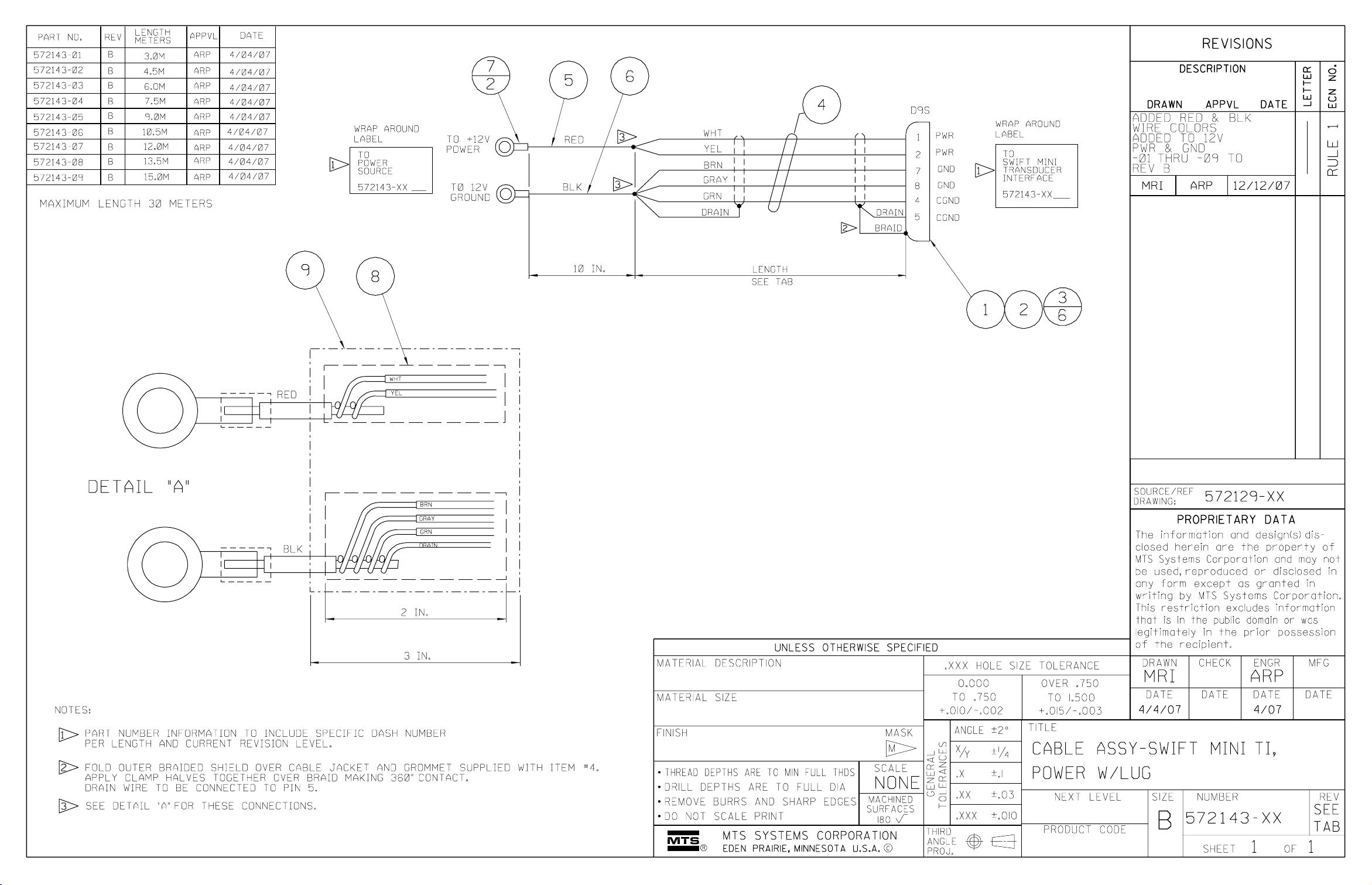

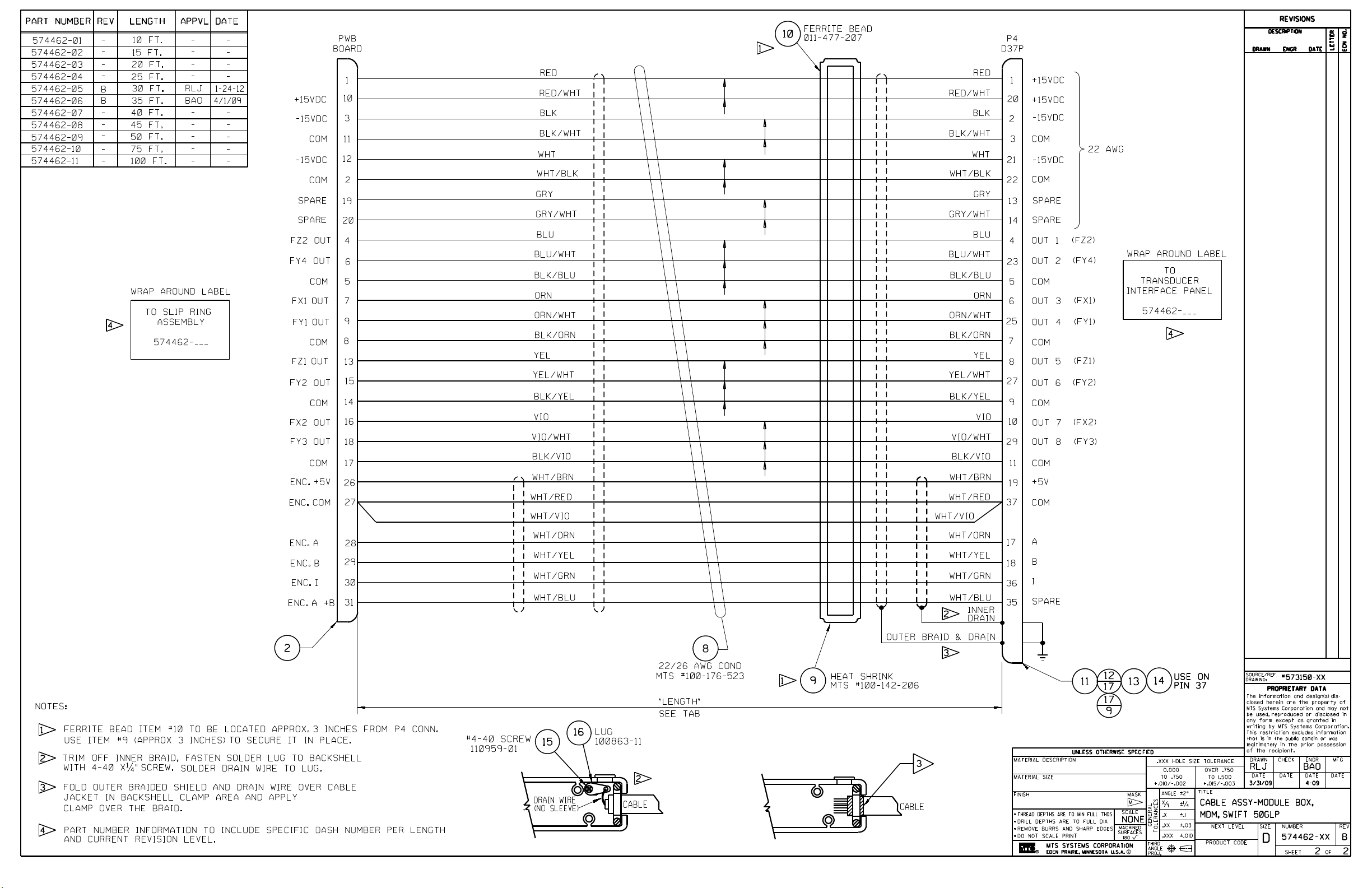

Assembly Drawings 83

Cable Drawings 84

SWIFT 50 GLP Mechanical Drawings 95

4

SWIFT 50 GLP Sensors

Page 5

Technical Support

How to Get Technical Support

Start with your

manuals

Technical support

methods

The manuals supplied by MTS provide most of the information you need to use

and maintain your equipment. If your equipment includes software, look for

online help and README files that contain additional product inform ation.

If you cannot find answers to your technical questions from these sources, you

can use the Internet, e-mail, telephone, or fax to contact MTS for assistance.

MTS provides a full range of support services after your system is installed. If

you have any questions about a system or product, contact Technical Support in

one of the following ways.

www.mts.com The web site provides access to our technical support staff by means of an online

form:

www.mts.com > Contact MTS > Service & Technical Support button

E-mail tech.support@mts.com

Telephone MTS Call Center 800-328-2255

Weekdays 7:00 A.M. to 5:00 P.M., Central Time

Fax 952-937-4515

Please include “Technical Support” in the subject line.

Outside the U.S. For technical support outside the United States, contact your local sales and

service office. For a list of worldwide sales and service locations and contact

information, use the Global MTS link at the MTS web site:

www.mts.com > Global MTS > (choose your region in the right-hand

column) > (choose the location closest to you)

Before You Contact MTS

MTS can help you more efficiently if you have the following information

available when you contact us for support.

Know your site

number and system

number

SWIFT 50 GLP Sensors Technical Support

The site number contains your company number and identifies your equipment

type (such as material testing or simulation). The number is typically written on a

label on your equipment before the system leaves MTS. If you do not know your

MTS site number, contact your sales engineer.

Example site number: 571167

When you have more than one MTS system, the system job number identifies

your system. You can find your job number in your order pape rwork.

Example system number: US1.42460

5

Page 6

Know information from

prior technical

If you have contacted MTS about this problem before, we can recall your file

based on the:

assistance

• MTS notification number

• Name of the person who helped you

Identify the problem Describe the problem and know the answers to the following questions:

• How long and how often has the problem occurred?

• Can you reproduce the problem?

• Were any hardware or software changes made to the system before the

problem started?

• What are the equipment model numbers?

• What is the controller model (if applicable)?

• What is the system configuration?

Know relevant

computer information

Know relevant

software information

For a computer problem, have the following information available:

• Manufacturer’s name and model number

• Operating software type and service patch information

• Amount of system memory

• Amount of free space on the hard drive where the application resides

• Current status of hard-drive fragmentation

• Connection status to a corporate network

For software application problems, have the following information available:

• The software application’s name, version number, build number, and (if

available) software patch number. This information can typically be found

in the About selection in the Help menu.

• The names of other applications on your computer, such as:

– Anti-virus software

– Screen savers

– Keyboard enhancers

– Print spoolers

Technical Support

6

– Messaging applications

SWIFT 50 GLP Sensors

Page 7

If You Contact MTS by Phone

A Call Center agent registers your call before connecting you with a technical

support specialist. The agent asks you for your:

• Site number

• Name

• Company name

• Company address

• Phone number where you can be reached

If your issue has a notification number, please provide that number. A new issue

will be assigned a unique notification number.

Identify system type To enable the Call Center agent to connect you with the most qualified technical

support specialist available, identify your system as one of the following types:

• Electromechanical material test system

• Hydromechanical material test system

• Vehicle test system

• Vehicle component test system

Be prepared to

troubleshoot

Write down relevant

information

After you call MTS logs and tracks all calls to ensure that you receive assistance for your

• Aero test system

Prepare to perform troubleshooting while on the phone:

• Call from a telephone close to the system so that you can implement

suggestions made over the phone.

• Have the original operating and application software media available.

• If you are not familiar with all aspects of the equipment operation, have an

experienced user nearby to assist you.

In case Technical Support must call you:

• Verify the notification number.

• Record the name of the person who helped you.

• Write down any specific instructions.

problem or request. If you have questions about the status of your problem or

have additional information to report, please contact Technical Support again and

provide your original notification number.

SWIFT 50 GLP Sensors Technical Support

7

Page 8

Problem Submittal Form in MTS Manuals

Use the Problem Submittal Form to communicate problems with your software,

hardware, manuals, or service that are not resolved to your satisfaction through

the technical support process. The form includes check boxes that allow you to

indicate the urgency of your problem and your expectation of an acceptable

response time. We guarantee a timely respon se—your feedback is important to

us.

Access the Problem Submittal Form:

• In the back of many MTS manuals (postage paid form to be mailed to MTS)

• www.mts.com > Contact Us > Problem Submittal Form button (electronic

form to be e-mailed to MTS)

Technical Support

8

SWIFT 50 GLP Sensors

Page 9

Before You Begin

Preface

Before You Begin

Safety first! Before you use your MTS product or system, read and understand the Safety

manual and any other safety information provided with your system. Improper

installation, operation, or maintenance can result in hazardous conditions that can

cause severe personal injury or death, or damage to your equipment and

specimen. Again, read and understand the safety information provided with your

system before you continue. It is very important that you remain aware of

hazards that apply to your system.

Other MTS manuals In addition to this manual, you may receive additional manuals in paper or

electronic form.

You may also receive an MTS System Documentation CD. It contains an

electronic copy of the manuals that pertain to your test system, such as:

• Hydraulic and mechanical component manuals

• Assembly drawings

• Parts lists

• Operation manual

• Preventive maintenance manual

Controller and application software manuals are typically included on the

software CD distribution disc(s).

Model 505G2.60 - 505G2.180 SilentFlo™ HPU Preface

9

Page 10

Conventions

DANGER

WARNING

CAUTION

Conventions

Documentation Conventions

The following paragraphs describe some of the conventions that are used in your

MTS manuals.

Hazard conventions Hazard notices may be embedded in this manual. These notices contain safety

information that is specific to the activity to be performed. Hazard notices

immediately precede the step or procedure that may lead to an associated hazard.

Read all hazard notices carefully and follow all directions and recommendations.

Three different levels of hazard notices may appear in your manuals. Following

are examples of all three levels.

Note For general safety information, see the safety information provided with

your system.

Danger notices indicate the presence of a hazard with a high level of risk which,

if ignored, will result in death, severe personal injury, or substantial property

damage.

Warning notices indicate the presence of a hazard with a medium level of risk

which, if ignored, can result in death, severe personal injury, or substantial

property damage.

Caution notices indicate the presence of a hazard with a low level of risk which,

if ignored, could cause moderate or minor personal injury or equipment damage,

or could endanger test integrity.

Notes Notes provide additional information about operating your system or highlight

easily overlooked items. For example:

Note Resources that are put back on the hardware lists show up at the end of

the list.

Special terms The first occurrence of special terms is shown in italics.

Illustrations Illustrations appear in this manual to clarify text. They are examples only and do

Electronic manual

conventions

Preface

10

not necessarily represent your actual system configuration, test application, or

software.

This manual is available as an electronic document in the Portable Document

File (PDF) format. It can be viewed on any computer that has Adobe Acrobat

Reader installed.

Model 505G2.60 - 505G2.180 SilentFlo™ HPU

Page 11

Documentation Conventions

Hypertext links The electronic document has many hypertext links displayed in a blue font. All

blue words in the body text, along with all contents entries and index page

numbers, are hypertext links. When you click a hypertext link, the application

jumps to the corresponding topic.

Model 505G2.60 - 505G2.180 SilentFlo™ HPU Preface

11

Page 12

Documentation Conventions

12

Preface

Model 505G2.60 - 505G2.180 SilentFlo™ HPU

Page 13

Hardware Overview

Contents Overview 14

Spinning Applications (Track or Road) 16

Non-spinning Applications (Laboratory) 17

Construction 18

Design Features 21

Coordinate System 22

Specifications 24

Calibration 26

Interfacing with RPC 27

SWIFT 50 GLP Sensors Hardware Overview

13

Page 14

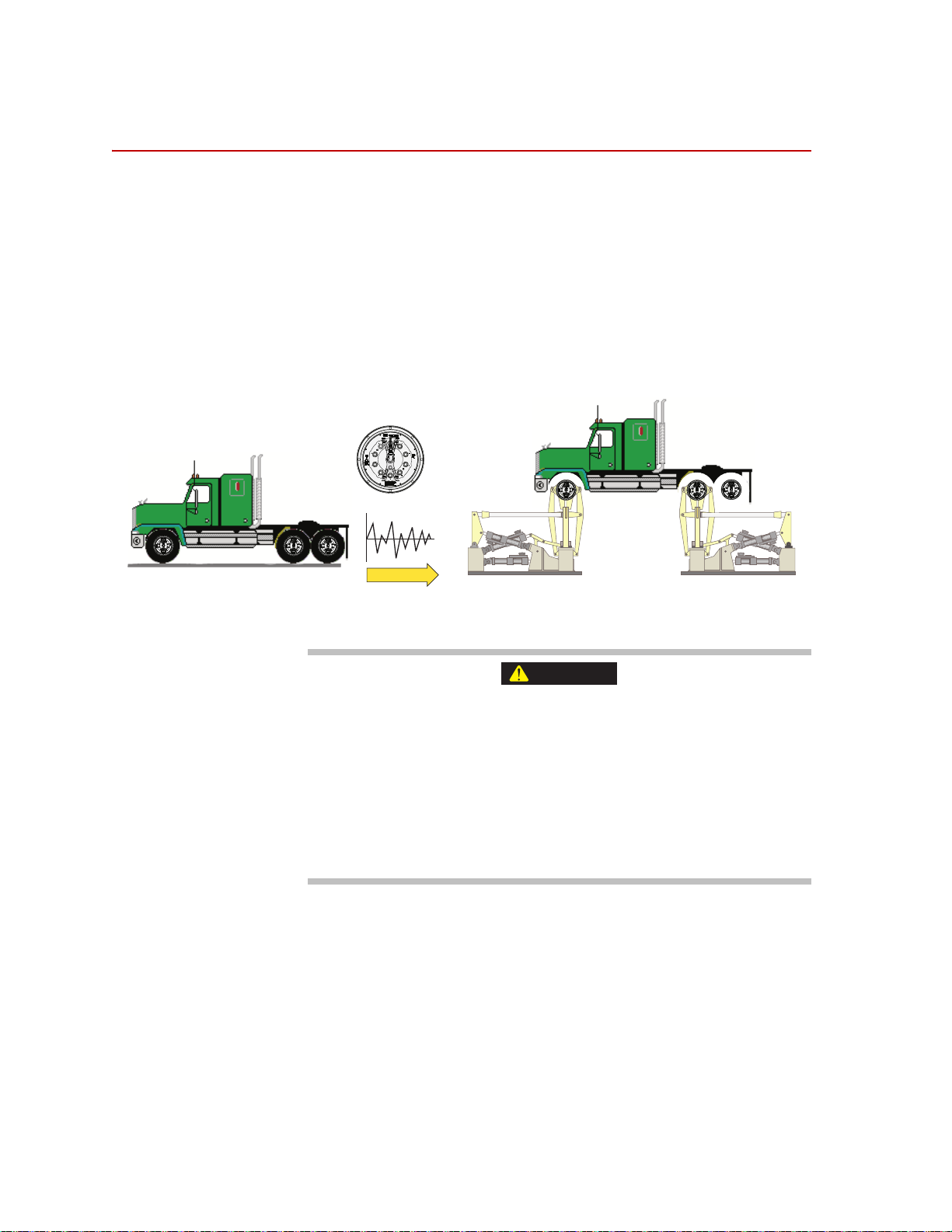

Overview

Data

S50-001

Track or Road

Laboratory Simulation

WARNING

Overview

The MTS Spinning Wheel Integrated Force Transducer (SWIFT®) sensor is a

light-weight, easy-to-use transducer that enables you to conduct faster, less

expensive data acquisition and road simulation testing.

The transducer is designed for use on the test track and public roads, as well as,

in the test laboratory. It attaches to the test vehicle or an MTS Series 329 Road

Simulator using an adapter and a modified wheel rim.

You can achieve excellent data correlation using the same transducer and vehicle

on the test track or public road and on a road simulator. It is available in various

sizes and materials to fit various vehicle and loading requirements.

Parts Replacement,

Disassembly, and Care

Driving a vehicle with SWIFT sensors mounted on it will change the

handling characteristics of the vehicle.

Driving a vehicle configured in this way on public roads can pose

unexpected dangers to pedestrians and other vehicle traffic.

Only authorized, licensed drivers, who are experienced driving a vehicle with

SWIFT sensors mounted on it, should be allowed to operate the vehicle on public

roads. Drive the vehicle with the SWIFT sensor attached on closed courses only

until you have proper experience.

The SWIFT sensor assembly, Transducer Interface box, and the accessory

components have no user serviceable parts. These components should not be

disassembled other than as outlined in “Troubleshooting” beginning on page 71.

Hardware Overview

14

SWIFT 50 GLP Sensors

Page 15

Overview

CAUTION

Do not disassemble the SWIFT sensor, Transducer Interface (TI) electronics,

and accessory components.

The SWIFT sensor, TI electronics, and accessory components are not

intended to be disassembled, other than as outlined in “Troubleshooting”.

Disassembling or tampering with these components may result in damage to the

sensor, loss of watertight seal, and voiding of the warranty.

• The sensor assembly should be returned to MTS annually for recalibration

and inspection.

• Clean the sensor assembly after each use, as described in Maintenance

beginning on page 67, especially if it is exposed to corrosive or abrasive

material, such as salt or sand.

• Read and follow all warnings and cautions affixed to the transducer and in

this manual especially those warnings and cautions that deal with

installation, use, inspection and maintenance of the transducer.

The SWIFT sensor

assembly should not:

• Be bumped into hard surfaces or objects while driving the vehicle.

• Be driven through grass or brush that is taller than the bottom edge of the

sensor.

• Be exposed to loads that exceed the full scale calibrated ranges, as listed in

“Specifications” on page 24.

• Be used if the integrity of the sealed cover has been compromised or the

warning labels removed.

• Be used if the sensor assembly shows indications of damage (such as dents,

bent slip ring bracket arms, a bent anti-rotate assembly, etc.).

• Be used if any part of the assembly has been modified without explicit,

written authorization from MTS.

SWIFT 50 GLP Sensors Hardware Overview

15

Page 16

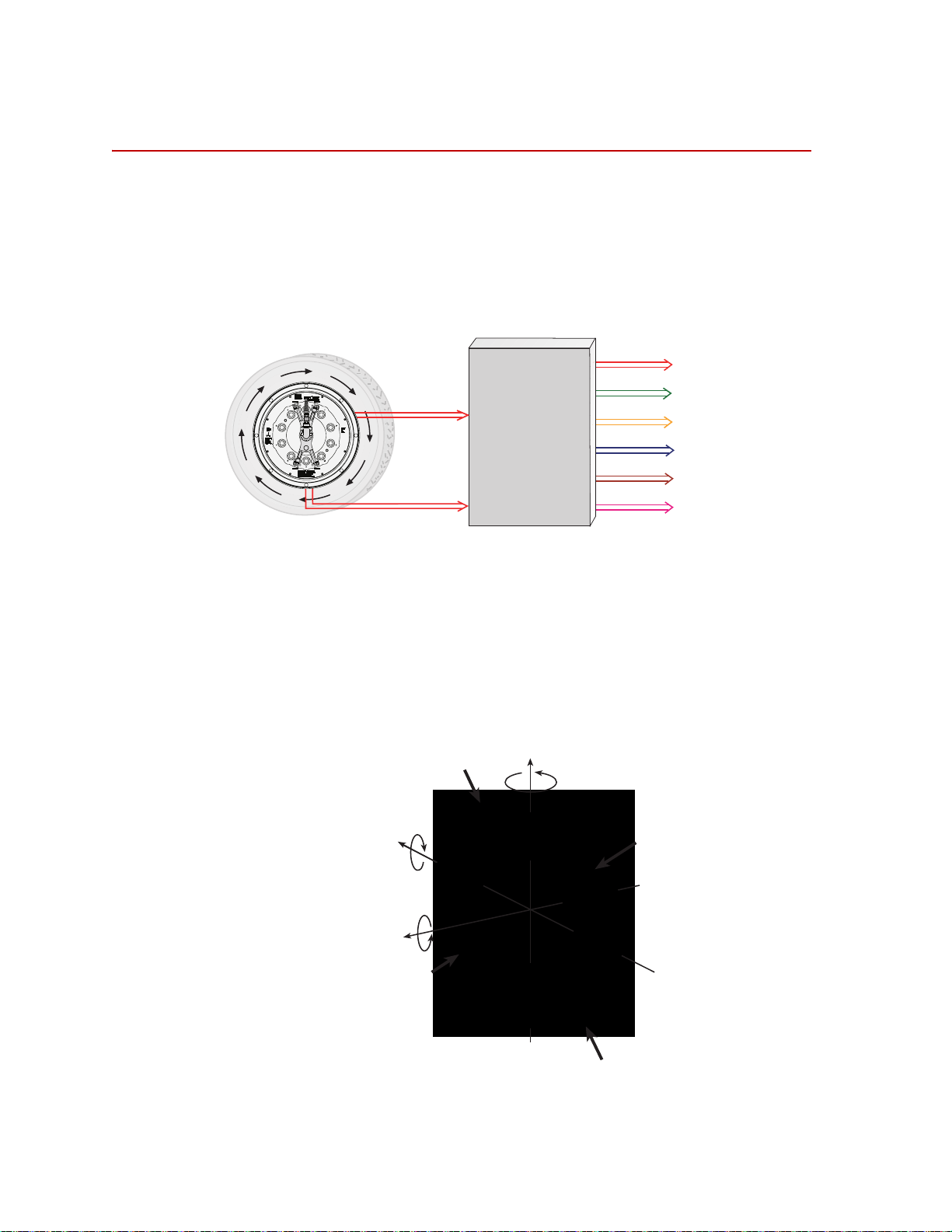

Spinning Applications (Track or Road)

Customer Supplied

Power Supply

Customer Supplied

Data Recorder

Transducer Interface

(TI)

Transducer Signals

Output

Signals

S50-002

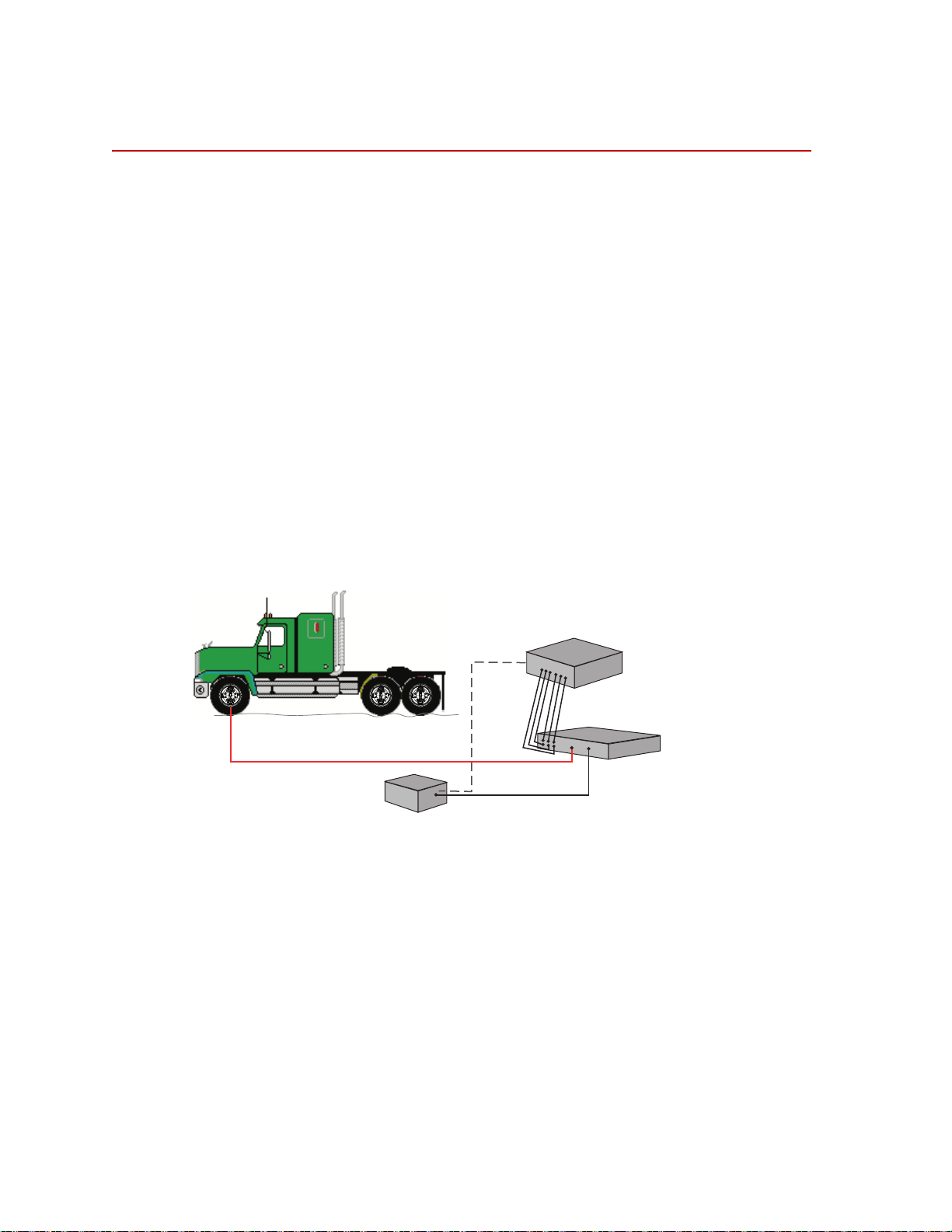

Spinning Applications (Track or Road)

The SWIFT sensor can be used for road load data acquisition (RLDA)

applications:

• Durability

• Noise, Vibration and Harshness (NVH)

• Ride and Handling

• Tire Performance

The transducer is durable enough to withstand harsh road testing and data

acquisition environments. The transducer is splash resistant and suitable for use

in conditions where the test vehicle will encounter occasional standing or running

water, or will be exposed to precipitation. However, it should not be submerged.

In a typical spinning application, the transducer is mounted on a modified rim of

a tire on a test vehicle, as shown in the following figure. The Transducer

Interface (TI), customer supplied power supply, and data recorder can be located

inside the vehicle or in the trunk.

Note For track applications, the power supply is usually the vehicle’s power

system or an auxiliary battery.

Spinning Application (Track or Road)

Hardware Overview

16

SWIFT 50 GLP Sensors

Page 17

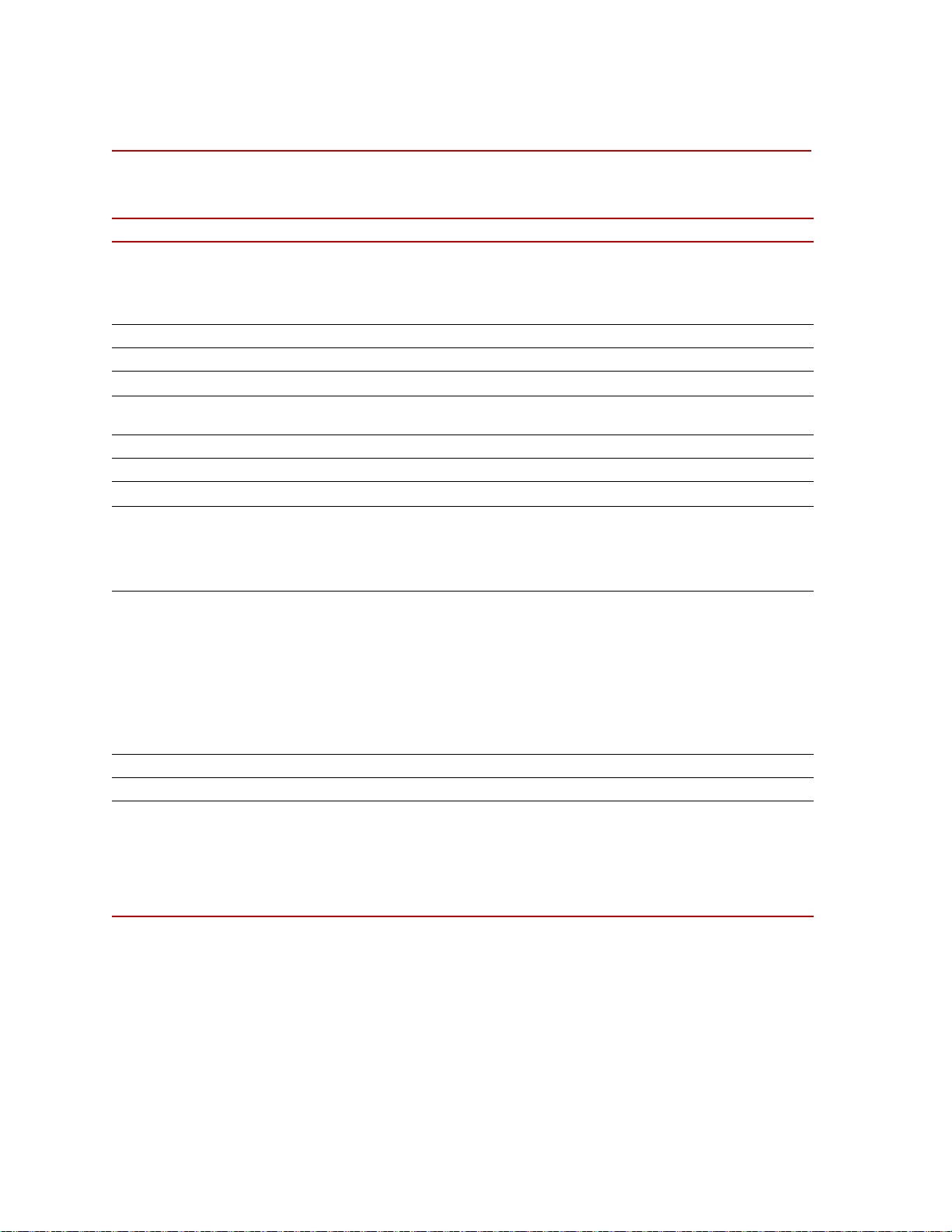

Non-spinning Applications (Laboratory)

Power Supply (with 4

connections)

Customer-Supplied

Test Control System

Transducer Interface

(TI)

Transducer Signals

Output

Signals

PC Communication

S50-003

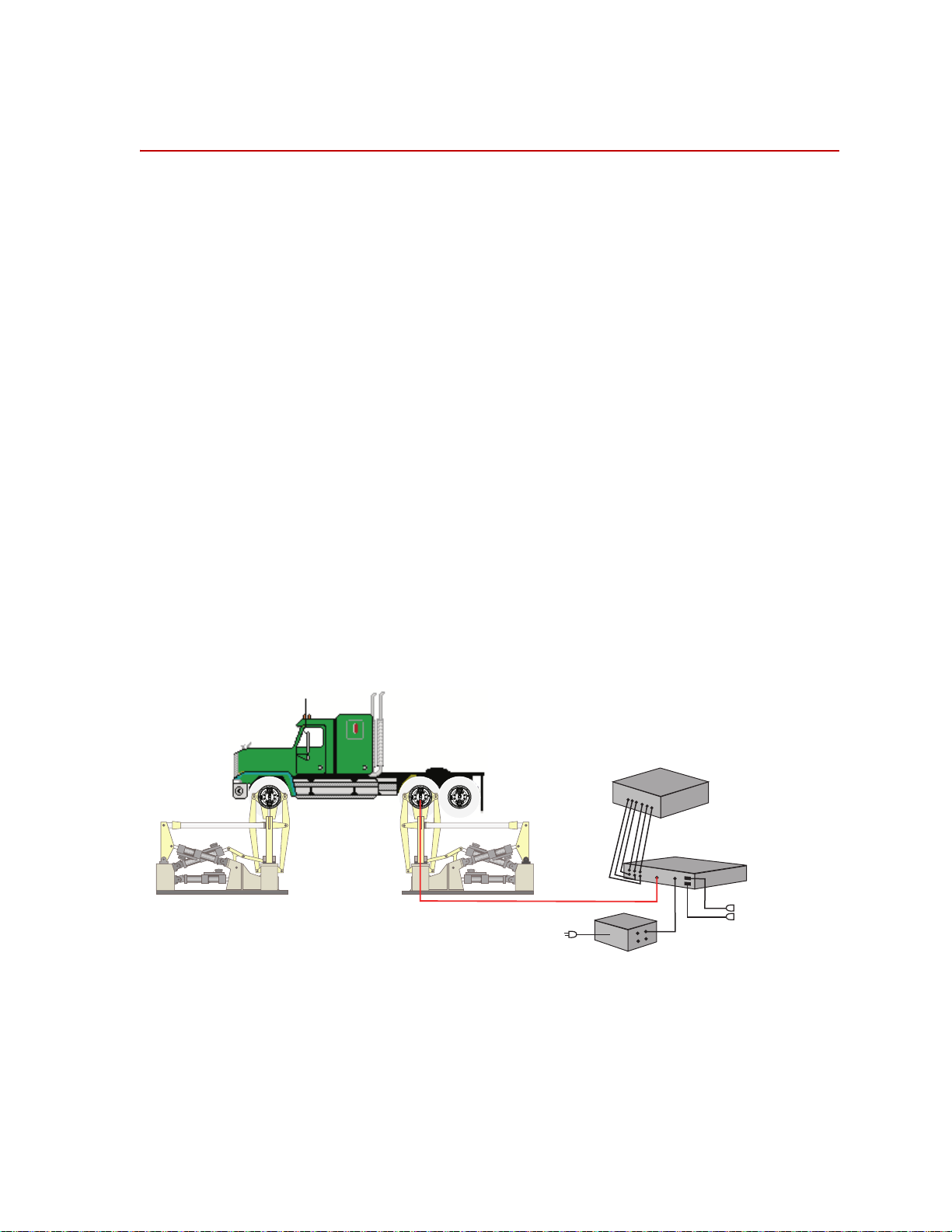

Non-spinning Applications (Laboratory)

The SWIFT sensor can be fully integrated into the simulation process, since it is

an optimal feedback transducer for use with MTS Remote Parameter Control

®

) software. The transducer takes data at points where fixturing inputs are

(RPC

located rather than at traditional instrumentation points along the vehicle’s

suspension. Using the SWIFT sensor saves you instrumentation time, and fewer

iterations are required to achieve good simulation accuracy.

Measuring spindle loads allows engineers to generate generic road profiles.

Generic road profiles are portable across various vehicle models, do not require

new test track load measurements for each vehicle, and eliminate additional

RLDA tasks.

Four of the six loads measured by the transducer directly correlate to the MTS

Model 329 Road Simulator inputs: vertical force, longitudinal force, lateral force,

and braking input.

The same transducers used to collect road data can be mounted directly in the

wheel adapters of the MTS Model 329 Road Simulator. For durability testing, a

titanium SWIFT sensor can be used for iterations within the RPC process. The

titanium SWIFT sensor should then be removed for the durability cycles, to

preserve its fatigue life. It can be replaced by an adapter plate, available from

MTS, to duplicate the mass and center of gravity of the actual SWIFT sensor. If a

SWIFT sensor is to be used during full durabilit y tests, we suggest using the

stainless steel model, which has a higher fatigue rating.

®

In a typical non-spinning application, a SWIFT sensor is mounted on a road

simulation test fixture, as shown in the following figure.

Non-spinning Application (Laboratory Simulation)

SWIFT 50 GLP Sensors Hardware Overview

17

Page 18

Construction

Slip Ring

Bracket

(with encoder)

Lug Nuts and

Shim Washers (10)

Spindle Adapter

Spacer

Transducer

Modified

Wheel Rim

(front wheel)

S50-008

Spacer-to-Transducer

Fasteners

Rim-to-Transducer

Assembly Fasteners

Construction

The SWIFT sensor has one-piece construction for outstanding fatigue life, low

hysteresis, and high stiffness. Its compact package has a minimal effect on inertia

calculations, and a minimal dynamic effect on the test vehicle.

The transducer can be used for developing conventional durability tests on the

MTS Model 329 Road Simulator. Normally, the transducer is replaced with an

equivalent wheel adapter after the simulation drive signals are developed and

prior to the start of the test.

The SWIFT sensor includes several mechanical and electrical components.

Transducer The transducer attaches directly to a modified wheel rim. On the test track

vehicle, it spins with the wheel. It does not spin on a road simulator. The

transducer is available in two materials: titanium, for spinning applications,

where the priority is light weight, and stainless steel, for non-spinning

applications, where the priority is maximum load capacity and durability.

The transducer’s unibody design means there are no multiple parts welded or

screwed together.

The transducer has four beams with strain gages that measure six orthogonal

outputs:

Fx—longitudinal force

Fy—lateral force

Fz—vertical force

Mx—overturning moment

My—acceleration and brake torque

Mz—steering moment

It has onboard conditioning and amplifiers to improve the signal-to-noise ratio.

Hardware Overview

18

SWIFT 50 GLP Sensors

Page 19

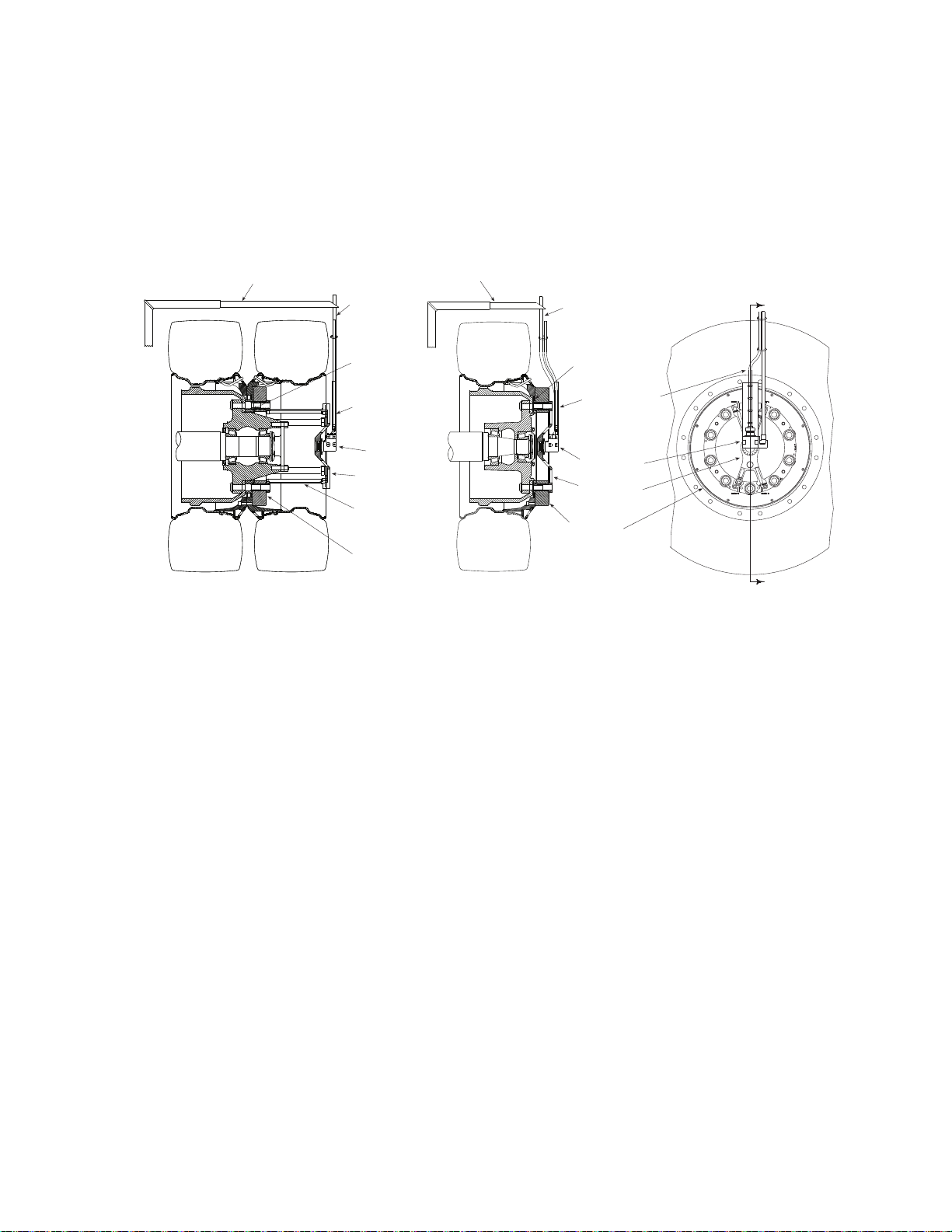

Construction

Dual Rim Configuration Front Rim Configuration

Slip Ring

Slip Ring

Anti-Rotate

Assembly

Anti-Rotate

Assembly

SWIFT 50

Transducer

SWIFT 50

Transducer

Tire Tire

Tire

Spindle

Adapter

Spacer

Spindle

Adapter

Spacer

Anti-Rotate

Mounting Bracket

(customer supplied)

Anti-Rotate

Mounting Bracket

(customer supplied)

Slip-Ring

Bracket

Slip Ring

Bracket

Transducer

Interface

Cable

Transducer

Interface

Cable

S50-004a

Slip-Ring

Extension

Bracket

(Component configuration is typical. Your specific

configuration might vary slightly.)

Spindle adapter spacer The spindle adapter spacer attaches to the inner diameter of the transducer,

allowing you to place it at the original position of the spindle face of the vehicle.

The spindle adapter spacer enables you to maintain the original position of the

tire on the vehicle (the tire will not protrude from the vehicle) while the

transducer is attached to the vehicle. In addition, the spindle adapter spacer helps

minimize brake heat from being transferred to the transducer.

Components Set Up for Test Track

Slip-ring bracket The slip-ring bracket is used to attach the slip ring to the transducer. It has

internal wiring that provides excitation power to the strain gage bridges and

brings signals out from the transducer to the slip ring.

Encoder An encoder measures the angular position of the transducer. The SWIFT sensor

uses an optical encoder, integrated into the slip ring assembly, that counts off

“ticks” to measure the angular position as the wheel rotates. It measures 2048

(512 plus quadrature) points per revolution (ppr) with a resolution of 0.18

Slip ring The slip ring allows you to output the transducer bridge signals and angular

SWIFT 50 GLP Sensors Hardware Overview

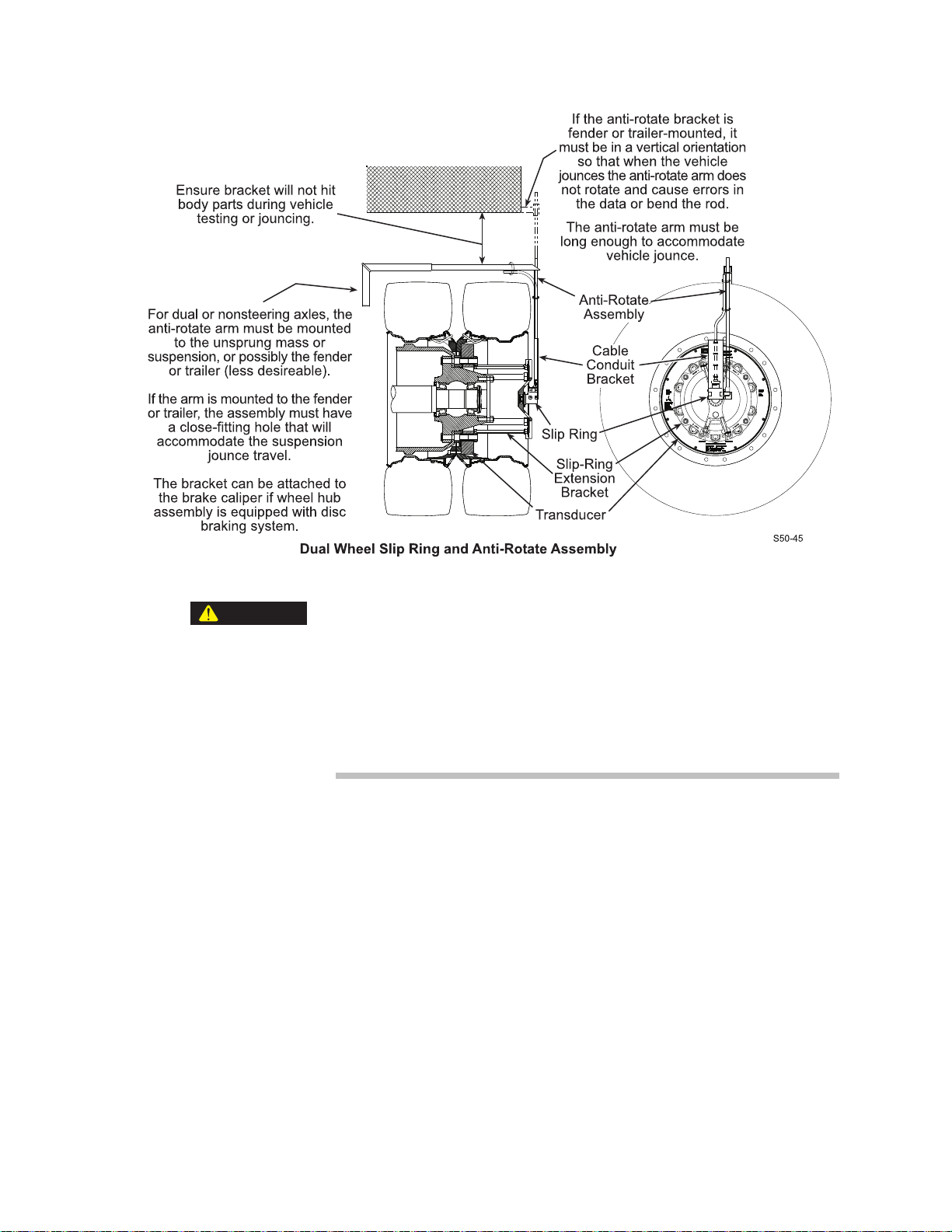

Anti-rotate device The anti-rotate device is attached to the slip ring and the vehicle’ s suspension (or

degrees and an accuracy of 0.18 degrees.

position to the TI. A transducer data cable attaches from the slip ring to the back

panel of the TI. The slip ring is not used for non-spinning applications.

other non-rotating point). It is able to move up and down with the vehicle. Its

primary function is to provide a fixed reference point for the optical encoder. Its

secondary function is to prevent the cable from rotating with the wheel and

becoming tangled or breaking.

19

Page 20

Construction

The anti-rotate device is mainly used for road data collection. Although it can

also be used for short periods of time on a road simulator. MTS does not

recommend this use. Due to the extreme fatigue loading characteristics of

durability testing on road simulators, we suggest that you either remove the slip

ring assembly before installing the vehicle on a road simulator, or use it only for

iteration passes, then promptly remove it.

The anti-rotate device should be configured such that no loading occurs to the

slip ring throughout all loading and suspension travel. This means that when you

attach the anti-rotate device to the vehicle, you must consider all possible motion

of the suspension. The anti-rotate device should not bump against the wheel well

at any time; any jarring of the anti-rotate arm will damage the slip ring. For

steering axles, the anti-rotate bracket must be mounted to part of the unsprung

suspension that steers with the tire, such as the brake caliper. For additional antirotate device mounting recommendations, refer to the Anti-Rotate Customer/

User Assembly drawing at the back of this manual.

Transducer Interface

(TI)

Additional

components

The TI conditions the power supply, and uses previously stored calibration values

to convert the eight bridge outputs and the encoder signal to six non-rotating

analog outputs (Fx, Fy, Fz, Mx, My, Mz) plus an angle output. The force and

moment outputs have a value of 10 V full scale, unless a different full-scale

output is requested by a customer. The angle output is a 0–5 V sawtooth output.

Additional components that are supplied with your SWIFT sensor include shunt

and transducer data cables, TI power cable, a SWIFT Transducer Interface

Utilities CD or disk, and the calibration file. MTS can also provide a 12 V DC or

24 V DC power converter for use in the test laboratory.

Hardware Overview

20

SWIFT 50 GLP Sensors

Page 21

Design Features

Flexure isolation The SWIFT sensor has a very stiff outer ring and flexured beam isolation which

render it relatively insensitive to stiffness variations in matings with rims and

road simulator fixtures.

Flexure isolation minimizes thermal expansion stresses. With flexure isolation, if

the inner hub experiences thermal expansion the beams are allowed to expand

out, resulting in lower compressive stress on the beams.

Thermal stability The entire sensor is machined from a solid, specially forged billet of high

strength stainless steel or titanium. The absence of bolted joints permits an

efficient transfer of heat across the sensor structure, minimizing temperature

differentials in the gaged area.

As mentioned earlier, flexure isolation allows thermal expansion with minimal

stresses.

The transducer is designed to accommodate the high temperature environments

that occur during severe driving and braking events. Individual temperature

compensation of each strain gage bridge minimize temperature induced

variations in accuracy. Since minimal electronics reside on the SWIFT sensor, it

can easily tolerate high temperatures. The temperature rating for the SWIFT

sensor is 125° C (257° F) at the spindle hub.

Construction

Temperature compensation is done on each bridge for better performance in

transient or non-uniform temperature occurrences.

Low hysteresis The SWIFT sensor has very low hysteresis, since the sensing structure is

constructed with no bolted joints. Micro slippage in bolted joints contributes

most of the hysteresis in highly stressed structures. Hysteresis errors due to

micro-slip at joints can contribute to unresolvable compounding errors in

coordinate transformation of the rotating sensor.

Low noise The SWIFT sensor uses a slip ring rather than telemetry for the transducer output

signals. On-board amplification of the transducer bridges minimizes any slip ring

noise contribution.

Low cross talk The advanced design of the SWIFT sensor means that it has very low cross talk.

The alignment of the sensing element is precision machined. This alignment is

critical to achieving minimum cross talk error between axes and minimum errors

in coordinate transformation (from a rotating to a non rotating coordinate

system). Any small amount of cross talk present is compensated by the TI.

Velocity information Angular output is available from the TI when it is used in the spinning mode with

the encoder. This angular output can be used to calculate wheel velocity. The

mini TI can have an analog output configured to be proportional to angular

velocity.

In non-spinning applications, accelerometers can be integrated into the

transducer connector housing. However, the SWIFT conditioning circuitry does

not support accelerometers; external conditioners must be used. Contact MTS for

additional information.

SWIFT 50 GLP Sensors Hardware Overview

21

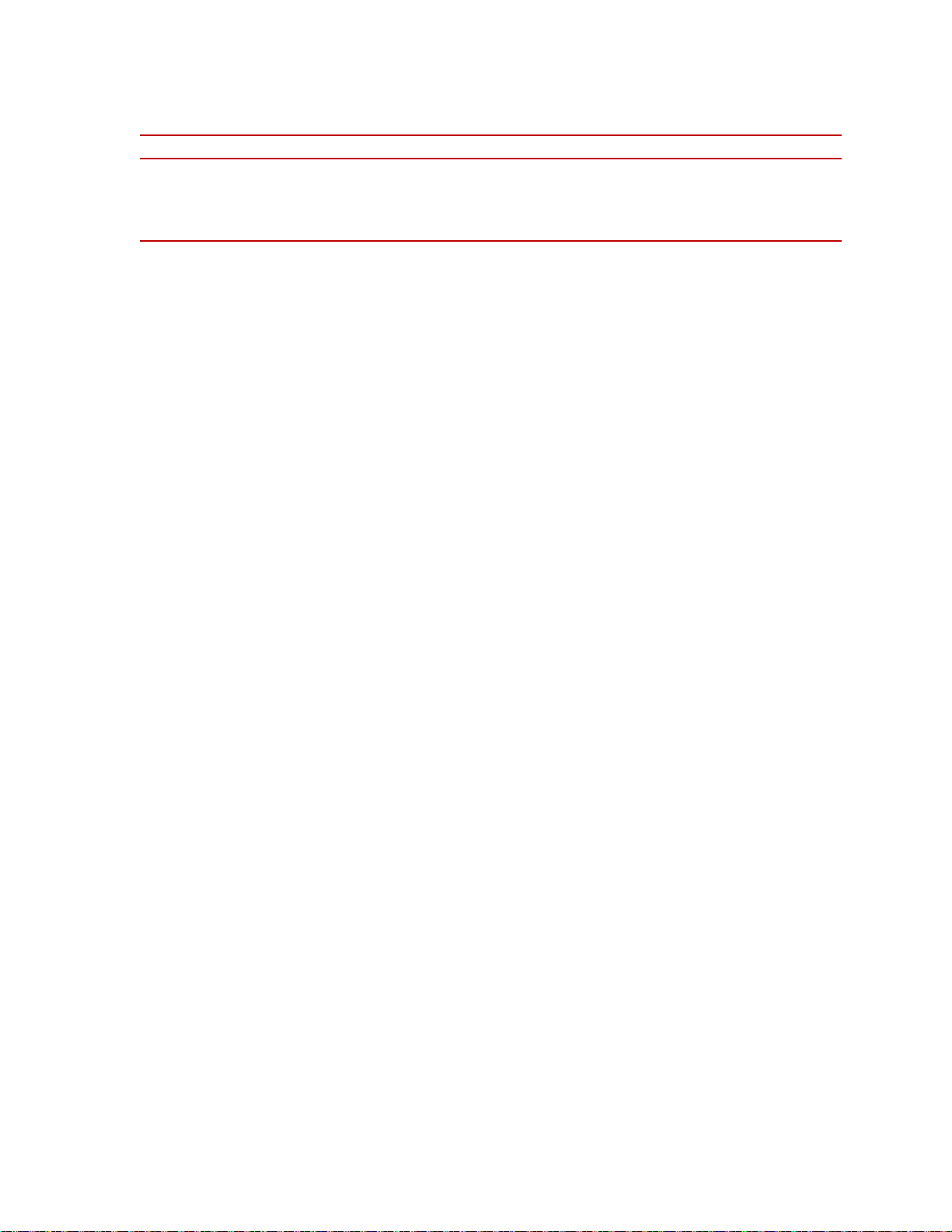

Page 22

Coordinate System

Fx

Fy

Fz

Mz

Mx

My

Transducer

Interface

Output signals

±10 Volts

Angular

Position

Bridge

Outputs

S50-010

+Fz

+Mz

+Fx

+Fy

S50-009

Forces Acting on Rim-side of Transducer

Hub Adapter

Mounting Side

Rim Flange

Mounting Side

+Mx

+My

Coordinate System

In the transducer, independent strain gage bridges measure forces and moments

about three orthogonal axes. The signals are amplified to reduce the signal-tonoise ratio. An encoder signal indicates angular position, which is used to

convert raw force and moment data from the rotating transducer to a vehiclebased coordinate system. The force and moment and encoder information is sent

to the transducer interface (TI).

The TI performs cross talk compensation and converts the rotating force and

moment data to a vehicle coordinate system. The result is six forces and moments

that are measured at the spindle: Fx, Fy, Fz, Mx, My, and Mz. A seventh

(angular) output is available for tire uniformity information, angular position, or

to determine wheel speed (depending on the data acquisition configuration).

The coordinate system shown below was originally loaded into the TI settings by

MTS. It uses the right-hand rule.

Hardware Overview

22

SWIFT 50 GLP Sensors

Page 23

Coordinate System

The SWIFT coordinate system is transducer-based, with the origin located at the

center of the transducer. Positive loads are defined as applied to the outer ring of

the transducer.

• Vertical force (Fz) is positive up

• Lateral force (Fy) is positive out of the vehicle

• Longitudinal force (Fx) is positive out of the transducer

You can change to the MTS Model 329 Road Simulator convention (lateral load

into the vehicle is always positive) or to any coordinate system by changing the

polarities in the calibration file. For instructions on how to change the coordinate

system polarities, see the chapter, “Setting up the Transducer Interface”.

SWIFT 50 GLP Sensors Hardware Overview

23

Page 24

Specifications

Specifications

SWIFT 50 GLP Transducer Performance (part 1 of 2)

Parameter Specification

Use

SWIFT 50 GLP S (stainless steel) for

SWIFT 50 GLP T (titanium) for

Maximum usable rpm

Maximum speed

Fits rim size (usable range)

Maximum hub bolt circle diameter

accommodates M22 studs

Input voltage required (mini TI)

Input power required (mini TI)

Output voltage ± full scale calibrated load

SAE J267

Rated load capacity

Bending moment

Full scale calibrated ranges#

Longitudinal force (Fx)

Lateral force range (Fy)

Vertical force range (Fz)

Overturning moment (Mx)

Driving/braking moment (My)

Steering moment (Mz)

Resolution (analog system)

Noise level (peak-to-peak 0-500 Hz)

Performance accuracy

Nonlinearity

Hysteresis

Modulation**

Cross talk

††

‡

§

high fatigue life, durability

low weight, high sensitivity

2,200

200 kph (125 mph)

22.5–24.5 inch

*

335 mm (13.189 in)

10–28 V DC

8 W maximum (6 W typical)

†

±10 V

Stainless SteelTitanium

64.50 kN (14,500 lbf)44.48 kN (10,000 lbf)

55.8 kN•m (494,075 lbf•in)38.5 kN•m (340,740 lbf•in)

±220 kN (±49,458 lbf) ±150 kN (±33,721 lbf)

±100 kN (±22,481 lbf) ±60 kN (±13,489 lbf)

±220 kN (±49,458 lbf) 150 kN (±33,721 lbf)

±50 kN•m (±442,537 lbf•in) ±37 kN•m (±327,478 lbf•in)

±50 kN•m (±442,537 lbf•in) ±40 kN•m (±354,030 lbf•in)

±50 kN•m (±442,537 lbf•in) ±37 kN•m (±327,478 lbf•in)

Infinite

40 N (9.0 lbf) 30 N (6.7 lbf)

1.0% full scale

0.75% full scale

≤5.0% reading

1.5% full scale

Hardware Overview

24

SWIFT 50 GLP Sensors

Page 25

SWIFT 50 GLP Transducer Performance (part 2 of 2)

Parameter Specification

Maximum operating temperature

Specifications

Low level amplifiers

Transducer interface

* Contact MTS for other rim sizes.Larger diameter rims can be used, provided that overall clearance from

brake calipers and suspension components is maintained.

† Load impedance >1 k

‡ Half axle rated capacity per SAE 267.

§ Seen on the transducer for 100,000 cycles.

# The actual calibrated range may be different based on individual customer requirements. Consult the

calibration range sheet that accompanies each transducer for the correct calibration range.

** Typical value on most steel rims. Stainless steel rims typically have slightly higher modulation, but at a

lower added weight.

†† Each SWIFT sensor is calibrated on an MTS calibration machine. MTS provides complete documentation

of calibration values for each SWIFT unit. Unique calibration values are stored electronicall y and

transferred to the transducer interface unit (TI box) shipped with each SWIFT 50.

Ω; 0.01 µF (maximum) load capacitance.

70°C (158°F)

50°C (122°F)

SWIFT 50 GLP Sensors Hardware Overview

25

Page 26

Calibration

Calibration

Each transducer is calibrated by MTS before shipment. The transducer and TI

may be returned to MTS for repair and recalibration as required.

Calibration is performed at MTS on a special fixture that is capable of applying

multiple loads to the transducer. During calibration, raw signals are measured.

The calibration gains and cross talk compensation values are computed from this

raw data. These gains are recorded in a calibration file.

A unique calibration file is supplied for each transducer. The serial number of the

TI associated with the transducer is listed at the top of the calibration file. A label

with the serial number of the TI box (and the SWIFT sensor with which it was

originally calibrated) is attached to the back of each TI box.

The calibration file is loaded into the TI non-volatile RAM by MTS before the

transducer is shipped. A copy of the file is also provided on a diskette.

MTS verifies the calibration by applying loads to the transducer, measuring the

main outputs and checking for accuracy. Final calibration reports are provided

with each transducer.

Shunt calibration Shunt calibration information can be found in the SWIFT

Interface product manual, part number 100-214-316.

®

Mini Transducer

Hardware Overview

26

SWIFT 50 GLP Sensors

Page 27

Interfacing with RPC

The SWIFT sensor is directly compatible with the MTS Remote Parameter

Control (RPC) simulation software. The SWIFT system produces outputs that

directly correspond to the uncoupled spindle forces that the MTS Model 329

Road Simulator applies to the vehicle. Traditional instrumentation techniques

provide coupled suspension loads data. Using the SWIFT sensor, the RPC

simulation software needs to apply less correction to obtain the road simulator

drive signals. Fewer iterations are required to recreate the measured loads.

You must ensure that the full scale value for your data recorder and the MTS

electronics match. MTS electronics are typically set at ±10 V full scale, while

some data recorders are ±5 V full scale.

The SWIFT sensor is calibrated for ±10 V full scale. T o recompute the TI gains

for ±5 V full scale, a verification pass must be run or the calibration will not be

traceable. Upon special request, MTS can evaluate and may provide calibration

for ±5 V or other full scale voltages.

Interfacing with RPC

SWIFT 50 GLP Sensors Hardware Overview

27

Page 28

Interfacing with RPC

Hardware Overview

28

SWIFT 50 GLP Sensors

Page 29

Installation

Contents Hazard Icons 30

The SWIFT sensor can be installed on a vehicle at the test track or on an MTS

Series 329 Road Simulator in the test laboratory.

Road and Track Vehicles 31

Attaching SWIFT Components to the Vehicle 36

Attaching SWIFT Components to the Fixturing 48

SWIFT 50 GLP Sensors Installation

29

Page 30

Hazard Icons

Hazard Icons

Read, understand, and

follow the instructions

in the manual

The following hazard icon is part of the label affixed to the side of the SWIFT 50

GLP Sensor.

30

Installation

SWIFT 50 GLP Sensors

Page 31

Road and Track Vehicles

Road and Track Vehicles

Equipment required This procedure requires two people. T o install the SWIFT 50 GLPS or SWIFT 50

GLPT sensor, you will need the following equipment:

• Spindle adapter spacers (see next figure)

• Modified rim (see next figure)

• Anti-rotate assembly (including customer-supplied mounting arm)

• Small set of metric hex-head wrenches

• Tube bender for the restraint tube

• Tube cutter

• Metric socket head drive set (up to 14 mm) with extension

• Molykote g-n paste, 2.8 oz. tube (MTS part number 011-010-217)

• Nikal based anti-galling compound (MTS part number 011-354-902)

• Transducer mounting bolts (per transducer)

For dual rims

16 size M16 X 1.5 mm

8 size M10 X 1.5 mm

4 size M5 X 0.5 mm

lug nuts and shim washers

For front rims

16 size M16 X 1.5 mm

8 size M10 X 1.5 mm

4 size M5 X 0.5 mm

lug nuts and shim washers

• For dual rims

Slip ring extension assembly

Four size M12 X 1.75 mm X 30 mm long bolts

• Slip ring assembly fasteners

Four size M8 X 1.25 mm X 20 mm long bolts

• Torque wrenches, capable of the following ranges:

2.3–23 N•m (20–200 lbf•in)

24–74 N•m (18–55 lbf•ft),

SWIFT 50 GLP Sensors Installation

31

Page 32

Road and Track Vehicles

Slip Ring

Bracket

(with encoder)

Lug Nuts and

Shim Washers (10)

Spindle Adapter

Spacer

Transducer

Modified

Wheel Rim

(front wheel)

S50-008

Spacer-to-Transducer

Fasteners

Rim-to-Transducer

Assembly Fasteners

Modified

Wheel Rim

(dual wheel)

Transducer

Spindle

Adapter

Spacer

Lug Nuts and

Shim Washers (10)

S50-013

Slip Ring

Extension

Bracket

Slip Ring

Bracket

(with encoder)

Spacer-to-Transducer

Fasteners

Rim-to-Transducer

Assembly Fasteners

203–815 N•m (150-600 lbf•ft);

108–325 N•m (80–240 lbf •ft)

93 N•m (69 lbf•ft)

• Cables (transducer and BNC, plus customer-supplied from transducer

interface to data recorder)

• Tie wr aps

• Data recorder

• Power supply–12 V DC (optionally 24 V DC; for example, a truck battery)

Installation Components (Test Track–Front)

Installation Components (Test Track–Duals)

Installation

32

SWIFT 50 GLP Sensors

Page 33

Road and Track Vehicles

Importance of bolts Bolts provide exceptional clamp force at the transducer to rim/spindle interface.

• Bolts on the inner hub secure the hub adapter to the SWIFT sensor.

• Bolts on the outer ring secure the SWIFT sensor to the wheel rim (or road

simulator spindle adapter).

Note Make sure all bolts are in place and fully torqued during all tests. Correct

use of bolts reduces the safety hazard and ensures optimal transducer

performance.

SWIFT 50 GLP Sensors Installation

33

Page 34

Road and Track Vehicles

CAUTION

CAUTION

CAUTION

WARNING

Before you begin Observe the following safety conditions while you are attaching the SWIFT

sensor and components to the vehicle.

Do not pressure-wash the transducer or clean it with solvents.

Pressure-washing the transducer or cleaning it with solvents can damage it

or degrade the silastic seal and may void the warranty.

Using strong cleaners or solvents can damage the RTV seal and may void

the warranty .

Use only a soft sponge or brush with non-metal bristles and a gentle detergent

(such as dish soap) to wash the transducer.

Do not use high-pressure air to clean debris from around the transducer

connectors.

High-pressure air can damage the silastic seals and may void the warranty.

Use a brush with fine, non-metal bristles and low air-pressure [0.07 MPa (10 psi)]

to clean debris from around the transducer connectors.

Do not lay the wheel down on top of the transducer without proper padding.

If the wheel is laid down with the transducer under it, the transducer could

be scratched and the connectors damaged.

Always hold the wheel upright when the transducer is attached to it. If needed,

have another person hold the wheel upright while you tighten the bolts, if laying

the wheel down cannot be avoided, place the wheel on a layer of foam or a pad to

protect the connectors.

Do not under-torque the lug nuts.

Lug nuts that are not properly tightened can become loose during testing.

Loss of a wheel can cause damage to the test vehicle and transducer and

result in serious injury, death, or property damage.

34

Installation

Always tighten the lug nuts to the torque rating recommended for the vehicle/

wheel. Recheck the torque daily and/or before each testing session.

SWIFT 50 GLP Sensors

Page 35

Road and Track Vehicles

CAUTION

CAUTION

Do not drop the slip-ring bracket.

Dropping the slip-ring bracket can damage the slip ring or a connector.

Always use care when you handle the slip-ring bracket.

Do not allow the mounting arm or anti-rotate arm to bump against any

portion of the wheel or wheel well.

Any jarring of the mounting arm or anti-rotate arm will damage the slip ring

and/or the encoder.

Position the mounting arm and anti-rotate assembly so that full suspension travel

will not cause interference with the wheel well or any other part of the vehicle.

SWIFT 50 GLP Sensors Installation

35

Page 36

Road and Track Vehicles

Attaching SWIFT Components to the Vehicle

SWIFT 50 GLP Fasteners

Front Rim Dual Rims

M16 X 1.5 mm

M10 X 1.5 mm

M5 X 0.8 mm

MTS modified lug nuts an d sh im washers

* The length of these fasteners is dependant on the thickness of the

rim flange. The fastener length must ensure a minimum thread

engagement of 37 mm (1.46 in) but must not exceed 43 mm (1.69

in).

† The length of these fasteners is dependant on the thickness of the

rim flange. The fastener length must ensure a minimum thread

engagement of 28 mm (1.10 in) but must not exceed 34 mm (1.33

in).

‡ These fasteners secure the spindle adapter spacer to the

transducer. The length of these fasteners is dependant on the

thickness of the spindle adapter spacer which is a function of the

customer wheel geometry.

§ The standard lug nuts provided have a thread size of M22 X 1.50

mm. Other thread sizes can be ordered at customer request.

*

†

‡

M16 X 1.5 mm*

M10 X 1.5 mm

M5 X 0.8 mm

‡

§

†

Material required:

• Molykote g-n paste (MTS part number 011-010-217).

36

Procedure 1. Remove the current wheel from the test vehicle.

Installation

• Nikal based anti-galling compound (MTS part number 011-354-902)

2. Clean all surfaces of the vehicle tire(s) and the modified rim(s). It is critical

that all surfaces be free of stones, burrs, and grease. Use a mild detergent

such as dish soap.

Important It is imperative that the mounting surfaces of the transducer be

protected from getting scratched. Any wheel components and work

surfaces that might come in contact with the transducer must be

clean, smooth, and free of debris

Mount the tire(s) on the modified rim(s).

3. Wipe the unpainted mating surfaces of the modified rim, the spindle adapter

spacer and the transducer with a clean dry cloth.

SWIFT 50 GLP Sensors

Page 37

Road and Track Vehicles

4. Attach the spindle adapter spacer to the rim side of the transducer (see the

next figure) using the four M5 fasteners provided (see the previous table).

Ensure the pilot surface of the spindle adapter spacer is facing the

transducer.

Lubricate the threads and under the head of each fastener with Molykote g-n

paste and torque to 6.5 N•m (4.8 lbf-ft).

SWIFT 50 GLP Sensors Installation

37

Page 38

Road and Track Vehicles

Dual Rim

Front Rim

Hub Side

Connector Side

S50-006

Rim and Hub Mount Side

1 through 10 = M22

(modified lug nuts)

A through H = M10 bolts

1 through 16 = M16 bolts

Spindle

Adapter

Spacer

Transducer

Transducer

Hub Side

Spindle

Adapter

Spacer

M5 Threaded

Holes (4)

Modified

Lug Nuts

Modified

Lug Nuts

5. Attach the transducer to the modified wheel rim using the fasteners provided

(see the previous table). Hand tighten the bolts.

If environmental conditions warrant, coat each fastener with Birchwood

Casey Sheath RB1 rust preventative (or equivalent).

Lubricate the threads and under the head of each fastener with Molykote g-n

paste.

Bolt Torque Sequence

38

Installation

SWIFT 50 GLP Sensors

Page 39

Road and Track Vehicles

6. Tighten the M10 mounting bolts.

A. Following the sequence shown in the previous figure, torq ue the eigh t

M10 bolts (A through H) to the value for the first increment shown in

the following table.

B. Repeat Step 6A for the second increment.

C. Repeat Step 6A for the final torque.

7. Tighten the M16 mounting bolts.

A. Following the sequence shown in the previous figure, torque the

sixteen M16 bolts (1 through 16) to the value for the first increment

shown in the following table.

B. Repeat Step 7A for the second increment.

C. Repeat Step 7A for the final torque.

Note To minimize negative clamping effects, you must torque the bolts in the

sequence shown.

Bolt Size

Torque Increment M10 M16

1st Increment

2nd Increment

Final Torque

24 N•m (18 lbf•ft) 108 N•m (80 lbf•ft)

48 N•m (36 lbf•ft) 317 N•m (160 lbf•ft)

74 N•m (55 lbf•ft) 325 N•m (240 lbf•ft)

SWIFT 50 GLP Sensors Installation

39

Page 40

Road and Track Vehicles

For front or steering axles,

anti-rotate arm must be

mounted to a part of the

unsprung suspension that

steers with the tire, such as

the brake caliper.

Front Wheel Slip Ring and Anti-Rotate Assembly

Anti-Rotate Bracket

(customer supplied)

Anti-Rotate

Assembly

Slip Ring

Slip-Ring

Bracket

S50-44

Transducer

Cable

Conduit

Bracket

Attaching SWIFT and Wheel Assembly to the Vehicle

1. Before installing the SWIFT and wheel assembly, attach the anti-rotate

bracket to the vehicle.

Since the bracket is unique to each vehicle the anti-rotate bracket must be

provided by the customer. The following are guidelines for manufacturing

and locating the bracket. See the next two figures.

• The bracket must be stiff, preferably steel or stiff stainless steel tubing,

so as not to move or rotate when connected to an unsprung mass or

spindle which will allow the slip ring assembly to move with the tire as

the vehicle is moving or testing.

• The bracket must be positioned so as not to hit the fender at the

extreme end of the suspension travel.

• The bracket must maintain a minimum clearance from the tire so as not

to hit the tire when it is loaded and rotating.

Installation

40

SWIFT 50 GLP Sensors

Page 41

Road and Track Vehicles

CAUTION

2. Attach the wheel/transducer to the test vehicle.

Installing the lug bolts directly against the transducer face, without the antigalling compound and the shim washers, can cause galling of the

transducer face.

Galling of the transducer face can result in uneven torquing (and possible

over-torquing) of the lug bolts.

To prevent galling, always use the shim washers provided. Always lubricate the

bolts and shim washers as described below.

Lubricate the lug bolt threads, under the bolt head, and both faces of the

shim washers with the Nikal based anti-galling compound.

Tighten the lug nuts in 203 N•m (150 lbf•ft) increments, in the sequence

shown in the next figure to the torque rating recommended for the wheel.

SWIFT 50 GLP Sensors Installation

41

Page 42

Road and Track Vehicles

54

36

9 7

8 10

2

1

S50-41

Modified

Lug Nuts (10)

Transducer

Important Do not exceed a torque of 815 N•m (600 lbf•ft).

3. If necessary, assemble the cable conduit brackets and hinge base with antirotate tube onto the slip ring. See the next figure.

Note Typically this step is only required for new slip rings. After the assembly

is complete, there should be no need to disassemble it except if a

component becomes damaged.

A. Connect the cable to the slip ring.

B. Wrap the slip-ring connector and cable connector with butyl rubber

shrink tape (MTS part number 100-175-781 or equivalent).

Cut approximately 150 mm (6 in) of tape from the roll.

Remove the backing from the tape.

Stretch the tape until it is approximately 1/2 of its original width.

Begin by putting two wraps of tape tightly around the slip ring

connector and cable connector.

Continue wrapping up the connector and cable approximately 150 mm

(6 in). Overlap the tape by approximately 1/2 of its width.

42

Installation

SWIFT 50 GLP Sensors

Page 43

Road and Track Vehicles

2

C. Install the cable conduit bracket onto the slip ring and secure the left

side with the four M5 X 0.8 mm fasteners.

Lubricate the fasteners with Molykote g-n paste and torque to 6.5 N•m

(56 lbf•in).

D. Align the hinge base to the holes on the right side of the cond uit cable

bracket and slip ring. Rotate the hinge coupling and tube 90° to access

the top hole.

Secure the hinge base with the four M5 X 0.8 mm fasteners.

Lubricate the fasteners with Molykote g-n paste and torque to 6.5 N•m

(56 lbf•in).

E. Rotate the anti-rotate tu be parallel to the cable conduit bracket.

Secure the cable to the cable conduit bracket using tie-wraps through

the holes in the bracket and two M5 x 0.8 mm fasteners.

Use tie-wraps to also secure the cable to the anti-rotate tube.

4. For front rim configurations (see the next figure): Attach the slip-ring

bracket with the slip ring, conduit bracket, and restraint tube to the

transducer.

A. The slip-ring bracket fit s over the 9-pin connectors on the front of the

transducer at the locations labeled Board A and Board B. The slip-ring

bracket is similarly labeled to prevent connecting it the wrong way.

SWIFT 50 GLP Sensors Installation

43

Page 44

Road and Track Vehicles

For front or steering axles,

anti-rotate arm must be

mounted to a part of the

unsprung suspension that

steers with the tire, such as

the brake caliper.

Front Wheel Slip Ring and Anti-Rotate Assembly

Anti-Rotate Bracket

(customer supplied)

Anti-Rotate

Assembly

Slip Ring

Slip-Ring

Bracket

S50-44

Transducer

Cable

Conduit

Bracket

Note Use care when installing the slip-ring bracket. The 9-pin connectors are

keyed. The slip-ring bracket should be fitted on straight (without bending

or angling it) to make sure it engages all four connectors simultaneously

and evenly.

B. Lubricate the threads and under the bolt heads of the four M8 X 1.25

mm bolts with Molykote g-n paste. Insert them through the mounting

hole in the slip-ring bracket and thread them into the transducer . T orque

each to 27 N•m (20 lbf•ft).

C. Make sure that the covers on the shunt connectors are in place and

secure.

Press the covers over the shunt connector. Secure the covers by

tightening the two SST 10-32 UNF screws (one for each cover), using

an M4 or 5/32 inch hex key wrench, to 3.8 N•m (2.8 ft-lbf).

Installation

44

5. For dual rim configurations (see the next figure): Attach the extension

assembly and slip-ring bracket with slip ring to the transducer.

A. Thread the standoffs, with the M12 threaded studs, into the four M12

threaded holes in the face of the transducer.

Lubricate the threads on each threaded stud with Molykote g-n paste

and torque to 93 N•m (69 lbf•ft).

B. Attach the four extension brackets to the top plate using the M5 X 10

mm long fasteners provided (2 fasteners each).

Orient the short side of the dovetail on the connector toward the center

of the top plate.

Lubricate each fastener with Molykote g-n paste and torque each to 6.5

N•m (58 lbf•in).

SWIFT 50 GLP Sensors

Page 45

Road and Track Vehicles

Standoffs (4)

Top Plate

Slip-Ring

Bracket

M12 Threaded

Studs (4)

Extension

Brackets (4)

S50-40

M12 Bolts (4)

and Washers

Anti-rotate

Hinge

Assembly

Tube

Cable

Cable

Conduit

Bracket

Slip

Ring

Hinge

M8 Bolts (4)

C. Place the top plate, with extensions attached, over the standoffs.

Orient the top plate such that the Board A extension (see the labeling

on the top plate) is aligned with the Board A connector on the

transducer.

Note Use care when installing the top plate and extensions. The 9-pin

connectors are keyed. The top plate and extensio ns should be fitted on

straight (without bending or angling it) to make sure they engage the four

connectors simultaneously and evenly.

D. Secure the top plate to the st andoffs using the four M12 bolts and

washers.

Lubricate the threads with Molykote g-n paste and torque to 93 N•m

(69 lbf•ft).

SWIFT 50 GLP Sensors Installation

45

Page 46

Road and Track Vehicles

E. Install the slip-ring bracket with the slip ring, conduit bracket, and

restraint tube.

Slide the restraint tube through the hole in the anti-rotate bracket

(installed earlier) as far as necessary to align the slip-ring bracket to the

connectors on the top plate.

The slip-ring bracket fits over the 9-pin connectors on the top plate at

the locations labeled Board A and Board B. The slip-ring bracket is

similarly labeled to prevent connecting it the wrong way.

46

Installation

SWIFT 50 GLP Sensors

Page 47

Road and Track Vehicles

Note Use care when installing the slip-ring bracket. The 9-pin connectors are

keyed. The slip-ring bracket should be fitted on straight (without bending

or angling it) to make sure it engages both connectors simultaneously

and evenly.

F. Lubricate the threads and under the bolt heads of the four M8 X 1.25

mm bolts with Molykote g-n paste. Insert them through the mounting

holes in the slip-ring bracket and thread them into the transducer.

Torque them to 27 N•m (20 lbf•ft).

G. Make sure that the covers on the shunt connectors are in place and

secure.

Press the covers over the shunt connector. Secure the covers by

tightening the two SST 10-32 UNF screws (one for each cover), using

an M4 or 5/32 inch hex key wrench, to 3.8 N•m (2.8 ft-lbf).

6. Secure the cable along the restraint tube, as necessary, to prevent it from

rubbing against the tire.

7. Secure the cable along the remainder of its length so that it will not become

damaged during data collection. (For example, tape it to the fender or

frame.)

Important Be sure to leave enough slack in the cable to allow for the full

range of wheel travel (jounce and steer) so the cable does not

become stretched or damaged during testing.

8. Install the Transducer Interface.

At this point, you should install the transducer interface, verify the quality of

the zero algorithm, and set up data collection. Refer to the SWIFT

®

Mini

Transducer Interface product manual, part number 100-214-316.

SWIFT 50 GLP Sensors Installation

47

Page 48

Road and Track Vehicles

Attaching SWIFT Components to the Fixturing

Note Install the transducer in so that the orientation labeling is consistent with

the reference orientation. In most cases, this means installing it so the

labels are upright. If an additional angle correction is required after

installation, you will need to measure the angle from zero, and then enter

a new offset value for the AngleOffset in the TI calibration file (see

SWIFT® Mini Transducer Interface product manual, part number

100-214-316.).

SWIFT 50 GLP Fasteners

Front Rim Dual Rims

M16 X 1.5 mm

M10 X 1.5 mm

M5 X 0.8 mm

MTS modified lug nuts an d sh im washers

* The length of these fasteners is dependant on the thickness of the

rim flange. The fastener length must ensure a minimum thread

engagement of 37 mm (1.46 in) but must not exceed 43 mm (1.69

in).

† The length of these fasteners is dependant on the thickness of the

rim flange. The fastener length must ensure a minimum thread

engagement of 28 mm (1.10 in) but must not exceed 34 mm (1.33

in).

‡ These fasteners secure the spindle adapter spacer to the

transducer. The length of these fasteners is dependant on the

thickness of the spindle adapter spacer which is a function of the

customer wheel geometry.

§ The standard lug nuts provided have a thread size of M22 X 1.50

mm. Other thread sizes can be ordered at customer request.

*

†

‡

M16 X 1.5 mm*

M10 X 1.5 mm

M5 X 0.8 mm

‡

§

Material required • Molykote g-n paste (MTS part number 011-010-217).

• Nikal based anti-galling compound (MTS part number 011-354-902)

†

48

Installation

1. Clean all surfaces with a mild detergent such as dish soap. It is critical that

all surfaces be free of stones, burrs, and grease.

2. Attach the spindle adapter spacer to the rim side of the transducer (see the

next figure) using the four M5 fasteners provided (see the previous table).

Ensure the pilot surface of the spindle adapter spacer is facing the

transducer.

Lubricate the threads and under the head of each fastener with Molykote g-n

paste and torque to 6.5 N•m (4.8 lbf-ft).

SWIFT 50 GLP Sensors

Page 49

Road and Track Vehicles

CAUTION

3. Tighten the M10 mounting bolts.

A. Following the sequence shown in the previous figure, torq ue the eigh t

M10 bolts (A through H) to the value for the first increment shown in

the following table.

B. Repeat Step 3A for the second increment.

C. Repeat Step 3A for the final torque.

4. Tighten the M16 mounting bolts.

A. Following the sequence shown in the previous figure, torque the

sixteen M16 bolts (1 through 16) to the value for the first increment

shown in the following table.

B. Repeat Step 4A for the second increment.

C. Repeat Step 4A for the final torque.

Note To minimize negative clamping effects, you must torque the bolts in the

sequence shown.

Bolt Size

Torque Increment M10 M16

1st Increment

2nd Increment

24 N•m (18 lbf•ft) 108 N•m (80 lbf•ft)

48 N•m (36 lbf•ft) 317 N•m (160

lbf•ft)

Final Torque

74 N•m (55 lbf•ft) 325 N•m (240

lbf•ft)

5. Bolt the transducer/hub adapter to the road simulator fixture using the

modified lug nuts and shim washers provided.

Installing the lug bolts directly against the transducer face, without the antigalling compound and the shim washers, can cause galling of the

transducer face.

Galling of the transducer face can result in uneven torquing (and possible

over-torquing) of the lug bolts.

To prevent galling, always use the shim washers provided. Always lubricate the

bolts and shim washers as described below.

Lubricate the lug bolt threads, under the bolt head, and both faces of the

shim washers with the Nikal based anti-galling compound.

(Refer to the documentation provided with the road simulator.)

Tighten the lug nuts in 203 N•m (150 lbf•ft) increments, in the sequence

shown in the next figure to the torque rating recommended for the wheel.

Important Do not exceed a torque of 815 N•m (600 lbf•ft).

SWIFT 50 GLP Sensors Installation

49

Page 50

Road and Track Vehicles

Connector Side

S50-47

329 Simulator and Hub Mount Side

1 through 10 = M22

(modified lug nuts)

A through H = M10 bolts

1 through 16 = M16 bolts

M5 Threaded

Holes (4)

6. Repeat steps 1 through 5 for each corner.

7. Install the vehicle on the road simulator.

Refer to the instructions in your road simulator operation manual.

8. Attach the connector housing (or the slip ring bracket and slip ring) to each

transducer.

9. Attach the appropriate cables from the connector housing or one cable from

the slip ring to the TI or data acquisition.

A. Connect the cable from the Load connector on the connector housing,

B. If used, connect the cable from the Accel connector on the connector

Bolt Torque Sequence

or from the slip-ring connector, to the transducer connector on the slipring daughter board of the TI box(es).

housing to your data acquisition device.

Installation

50

SWIFT 50 GLP Sensors

Page 51

Road and Track Vehicles

C. Connect the cables from the Shunt A and Shunt B connectors on the

connector housing or the slip-ring bracket to the Shunt A and Shunt B

connectors on the TI box(es)

D. Secure the cables to the lateral strut of the road simulator so that it will

not become damaged during testing.

Be sure to leave enough slack for the full range of movement of the

simulation fixture.

10. Connect the power supply (12 V DC or optiona l 24 V DC) to the TI.

You might need to first convert from 120 or 240 V AC to 12 V DC or 24 V

DC.

11. Connect the data cables from the TI to the data recorder or your test control

system. There is one cable per channel of data from the TI to the data

recorder.

SWIFT 50 GLP Sensors Installation

51

Page 52

Road and Track Vehicles

52

Installation

SWIFT 50 GLP Sensors

Page 53

Analyzing SWIFT Data

Overview This chapter contains examples of data collected from SWIFT installations, and

explains how the data can be analyzed.

Contents The Data 54

Fx Data (Longitudinal Force) 55

Fz Data (Vertical Force) 57

Mx Data (Overturning Moment) 58

My Data (Brake Moment) 61

Acceleration and Braking Events Example 63

Slalom Curve Driving Example 65

SWIFT 50 GLP Sensors Analyzing SWIFT Data

53

Page 54

The Data

The Data

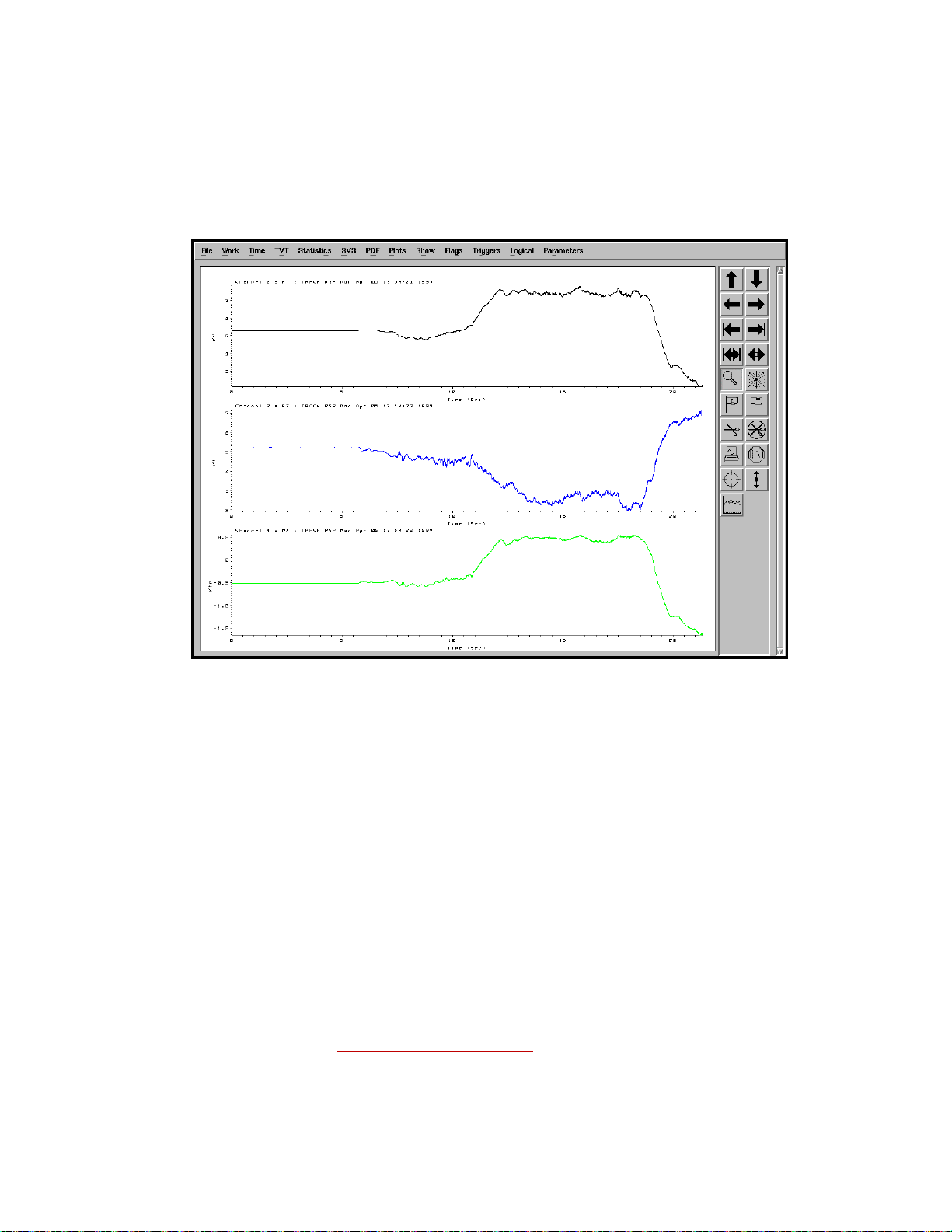

The following figure shows handling data taken on a flat, winding surface, using

a SWIFT sensor and SOMAT software. The driving speed was between 30 and

100 kph (18–62 mph).

Analyzing SWIFT Data

54

SWIFT 50 GLP Sensors

Page 55

Fx Data (Longitudinal Force)

Mz+

Distance

Fx+

S50-016

Direction

of Motion

Distance

Fx+

S50-015

Mz+

Direction

of Motion

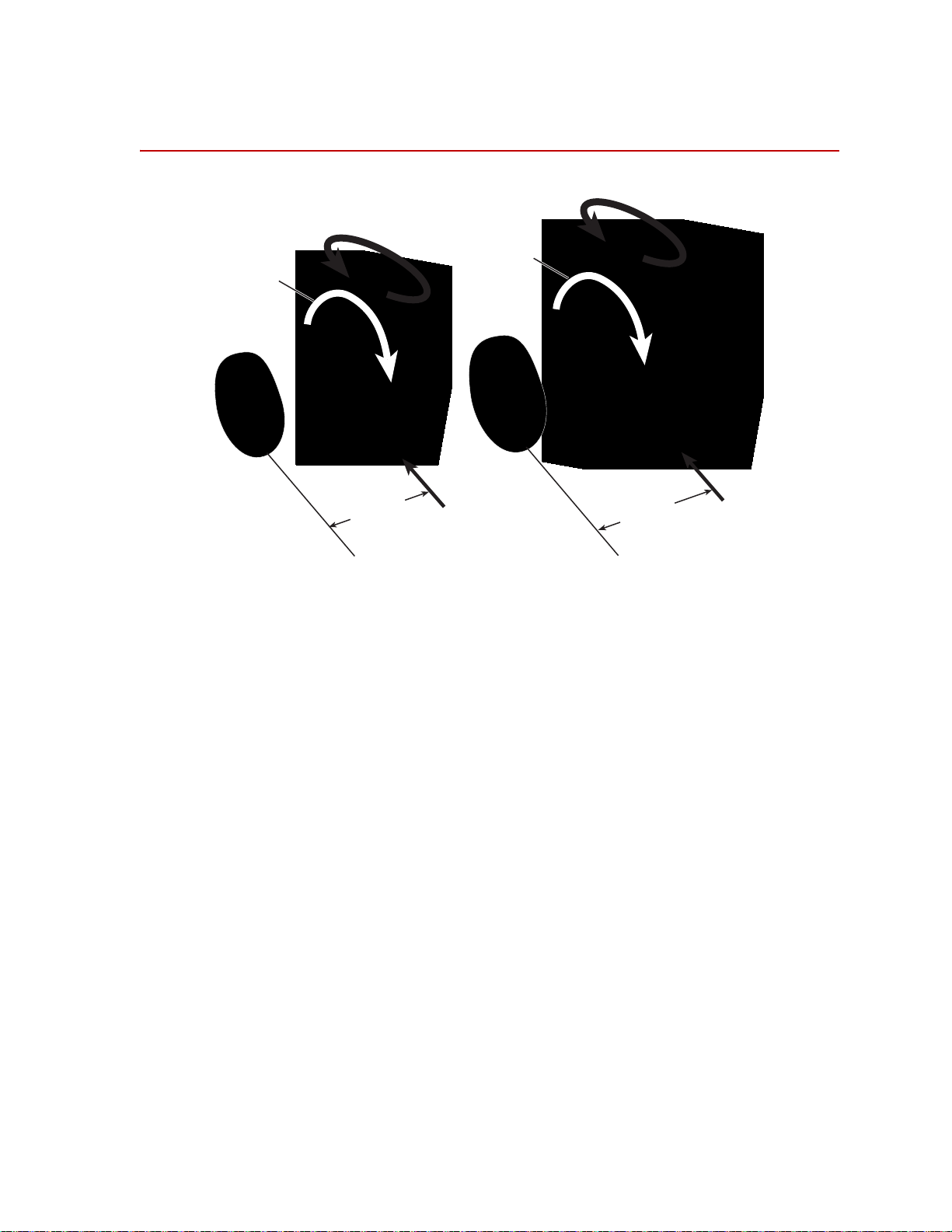

Fx Data (Longitudinal Force)

This figure shows the Fx (longitudinal force) data.

• The offset in Fx after zeroing the SWIFT sensor is due to frictional force

and rolling resistance on a flat road.

• There is a strong similarity between Fx and Mz, due to the SWIFT sensor

measurement characteristics. That is, the SWIFT sensor measures at the

transducer centerline. As a result, any Fx load results in an additional Mz

output:

Mz due to Fx loading = Fx load x Distance

SWIFT 50 GLP Sensors Analyzing SWIFT Data

55

Page 56

Fx Data (Longitudinal Force)

Friction/Rolling

resistance Offset

Mz Offset due to

Fx=28Nm

The following figure illustrates the relationship between Fx and Mz, for this test

case, which had a 170 mm (6.7 inch) offset from the tire centerline to the SWIFT

sensor centerline:

Fx = 165 N observed

Distance = 170 mm

Mz = Fx x Distance = 165 N x 170 mm = 28 N•m

Analyzing SWIFT Data

56

SWIFT 50 GLP Sensors

Page 57

Fz Data (Vertical Force)

The offset force in the Z direction is the combined weight of the car, equipment,

and driver at that corner.

5.2 kN = 530 kg (force) = 1169 lb for this vehicle at static loading.

Fz Data (Vertical Force)

SWIFT 50 GLP Sensors Analyzing SWIFT Data

57

Page 58

Mx Data (Overturning Moment)

S50-018

Fz

Distance Y

Distance Z

S50-017

Fz

Distance Z

Distance Y

Mx

Mx Data (Overturning Moment)

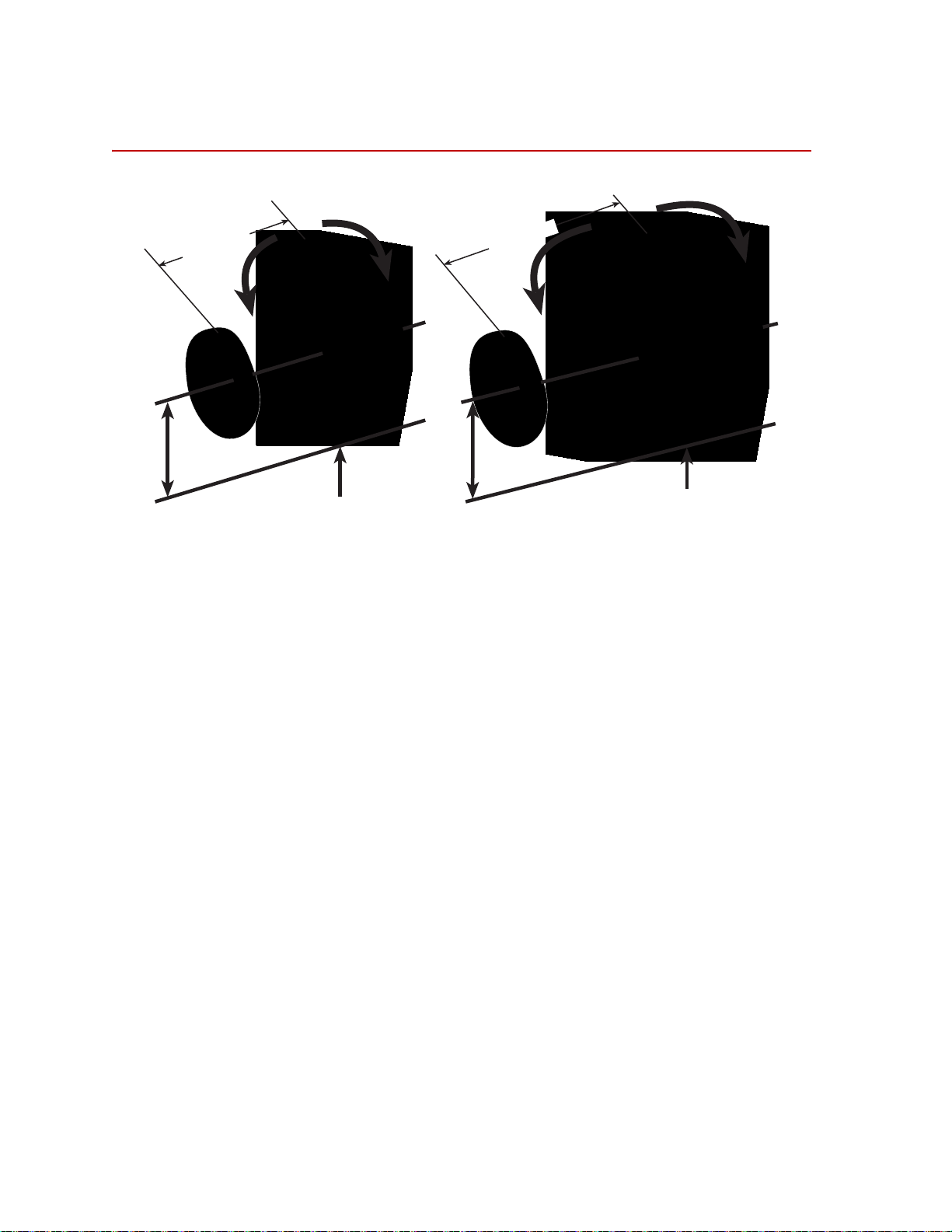

The moment Mx is the resultant of the forces Fz and Fy, and their respective

distances to the center of the SWIFT sensor.

After zeroing the SWIFT sensor, with the wheel off the ground, there will always

be a small moment Mx present. This is due to the offset of the tire assembly

center of gravity from the SWIFT sensor centerline.

Analyzing SWIFT Data

58

SWIFT 50 GLP Sensors

Page 59

Mx Data (Overturning Moment)

Fy

Fz

Mx

Channel 4 Mx Data The following figure shows the relationship between Mx, Fz, and Fy, during a

cornering event. Fz decreases as the vertical force is shifted to the opposite

wheel. Fy, the lateral force, increases to prevent side slip resulting in an increase

in the overturning moment, Mx.

1

Mx = Fy x Distance Z +

Fz x Distance Y

After zeroing the SWIFT sensor with the wheel off the ground, a moment Mx

will still be present, as the following figure shows.

1 Actual polarities depend upon how the polarity for each signal is set in the

TI.

(See “OutputPolarities” in, “Setting up the Transducer Interface.”)

SWIFT 50 GLP Sensors Analyzing SWIFT Data

59

Page 60

Mx Data (Overturning Moment)

Fz

CG

x

Fz

CG

x

Mx offset with

the wheel off

the ground

Mx offset with

the wheel off

the ground

Mx (wheel off ground) = Fz (active weight of the tire and rim outside the

transducer) x Distance (CG to SWIFT sensor centerline)

Analyzing SWIFT Data

60

SWIFT 50 GLP Sensors

Page 61

My Data (Brake Moment)

S50-020

My

Distance Y

Distance Z

My

Fx

Distance Z

S50-019

Fx

My

My

Distance Y

The moment My should show strong similarities with the force Fx and is

calculated by the SWIFT sensor using the distance Z.

My Data (Brake Moment)

∝ Fx x Distance Z

My

SWIFT 50 GLP Sensors Analyzing SWIFT Data

61

Page 62

My Data (Brake Moment)

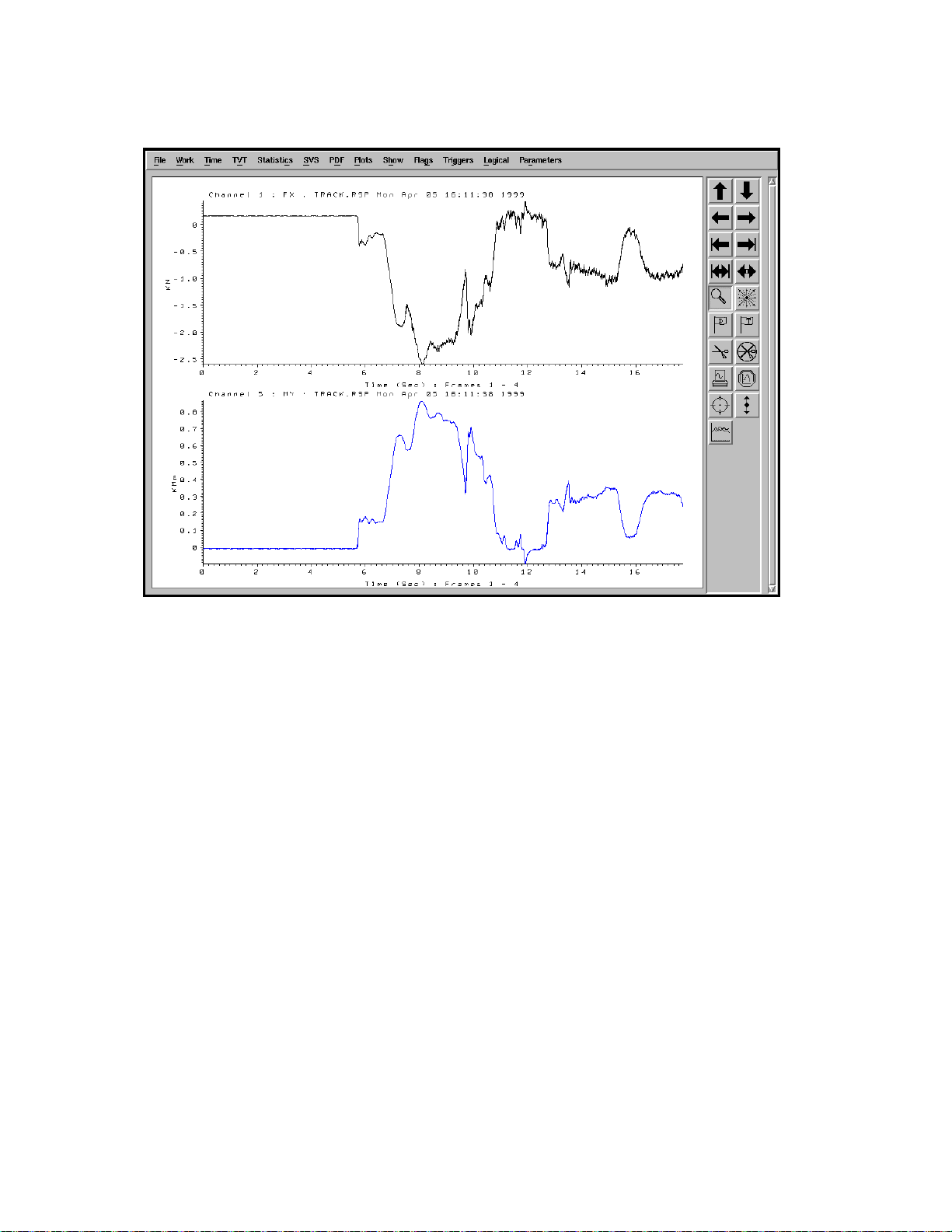

The relationship between Fx and My is shown in the following time history plot:

Analyzing SWIFT Data

62

SWIFT 50 GLP Sensors

Page 63

Acceleration and Braking Events Example

Acceleration and Braking Events

-2000

-1500

-1000

-500

0

500

1000

1500

2000

02468101214

time in seconds

Output - Lbs

-15000

-10000

-5000

0

5000

10000

15000

Output- In-Lbs

Fx (trac t i ve force) - Lbs

Fy ( l ateral force) - Lbs

Fz (nor m a l force) - Lbs

n

My (wheel torque) - In-Lbs

Mz (aligni ng torque) -In-Lbs

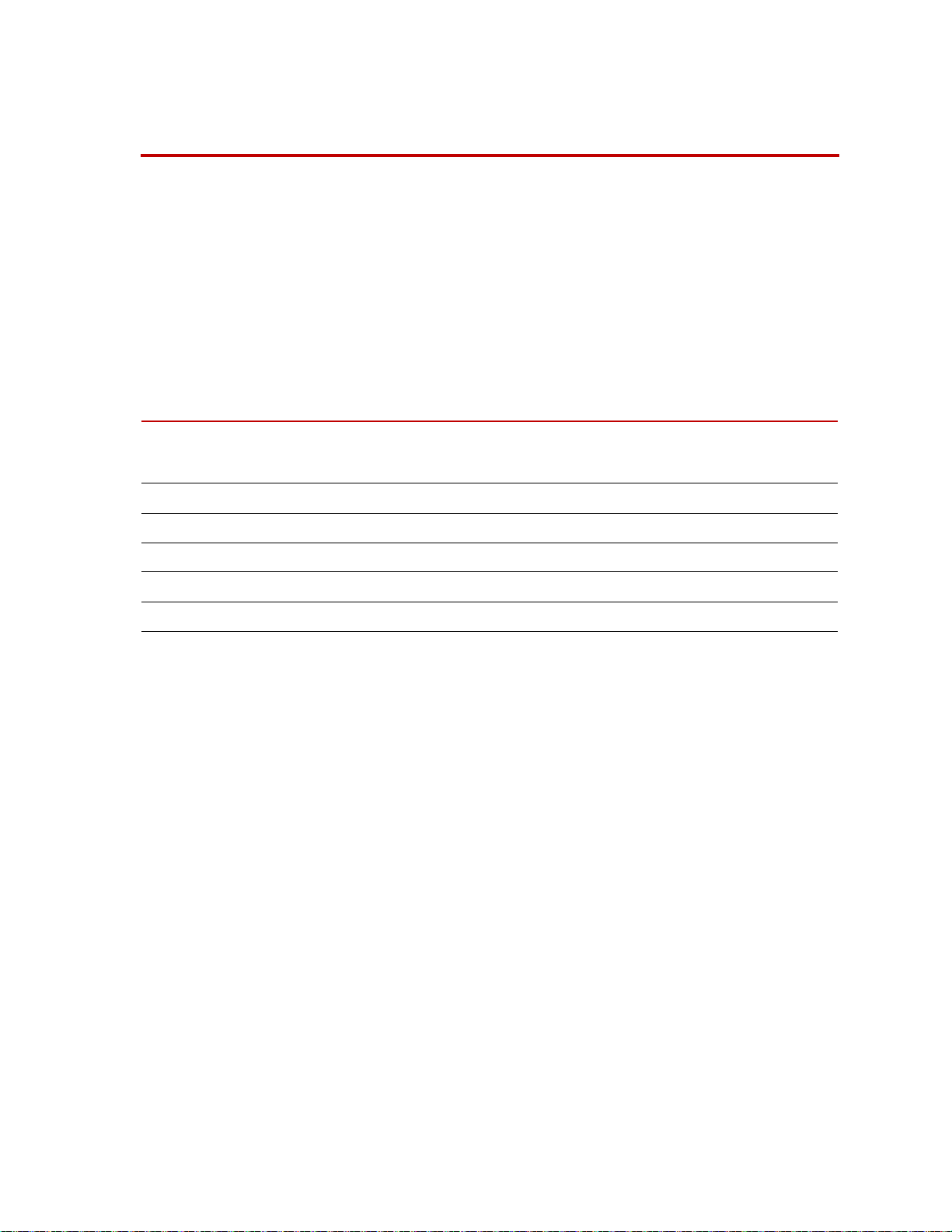

Acceleration and Braking Events Example

Shown below is actual road data taken with the MTS SWIFT Sensor, located at

the front passenger side of a mid-size passenger vehicle. Data shown is postprocessed to translate the forces and moments from the center of the transducer to

the center of the tire.

Mx (overturning mom en t) - I

The outputs from this acceleration and braking event are shown above. It should

be noted that output fluctuations are primarily due to actual road surface

irregularities.

Time 0 to 3.8 seconds: The car is at rest, with the brakes applied; no motion. The

vertical force of the vehicle on this wheel is noted as slightly over 1000 lb.

Time 3.8 to 4.3 seconds: The brake pedal is released with the transmission

engaged. Note the forces generated from th e slight drive torque of the idle in this

automatic transmission vehicle.

Time 4.3 to 6 seconds: Acceleration begins and transient forces and moments

are shown.

Fx: Slightly less than 1000 lb of tractive force is reacting at the tire patch.

Fy: Minimal Fy force is noted as the steering angle is maintained roughly

straight. Slight variations are noted with steering angle and vehicle suspension

toe-in geometry effects.

Fz: The normal force is the result of weight transfer from the front wheel to the

rear of the vehicle, and the anti-squat forces present in this front wheel drive

vehicle.

Mx: The Mx output noted is corrected to give the overturning moment at the

center of the tire. Minimal Mx moments are generated during these acceleration

and braking events.

SWIFT 50 GLP Sensors Analyzing SWIFT Data

My: The acceleration torque of roughly 12000 in•lb acting on the vehicle is

directly measured.

63

Page 64

Acceleration and Braking Events Example

Mz: The Mz output noted is corrected to give the aligning moment at the center

of the tire. Minimal Mz moments are generated during these straight line

acceleration and braking events.

Time 6 to 10 seconds: During the relatively steady state acceleration of the

vehicle, note the forces recorded.

Fz: Approximately 100 lb of the weight of the vehicle can be seen transferring

from each front wheel to the rear of the vehicle during steady state acceleration.

Time 10 to 13 seconds: During the braking, many of the acceleration forces and

moments described above are reversed.

Analyzing SWIFT Data

64

SWIFT 50 GLP Sensors

Page 65

Slalom Curve Driving Example

Slalom Curve Driving

-2000

-1500

-1000

-500

0

500

1000

1500

2000

02468101214

tim e in seconds

Output - Lbs

-8000

-6000

-4000

-2000

0

2000

4000

6000

8000

Output- In-Lbs

Fx (t ractive force) - Lbs

Fy ( l ateral force) - Lbs

Fz (normal force) - Lbs

-

My (wh eel torque) - In-L bs

Mz (ali gni ng t orque ) -In-Lbs

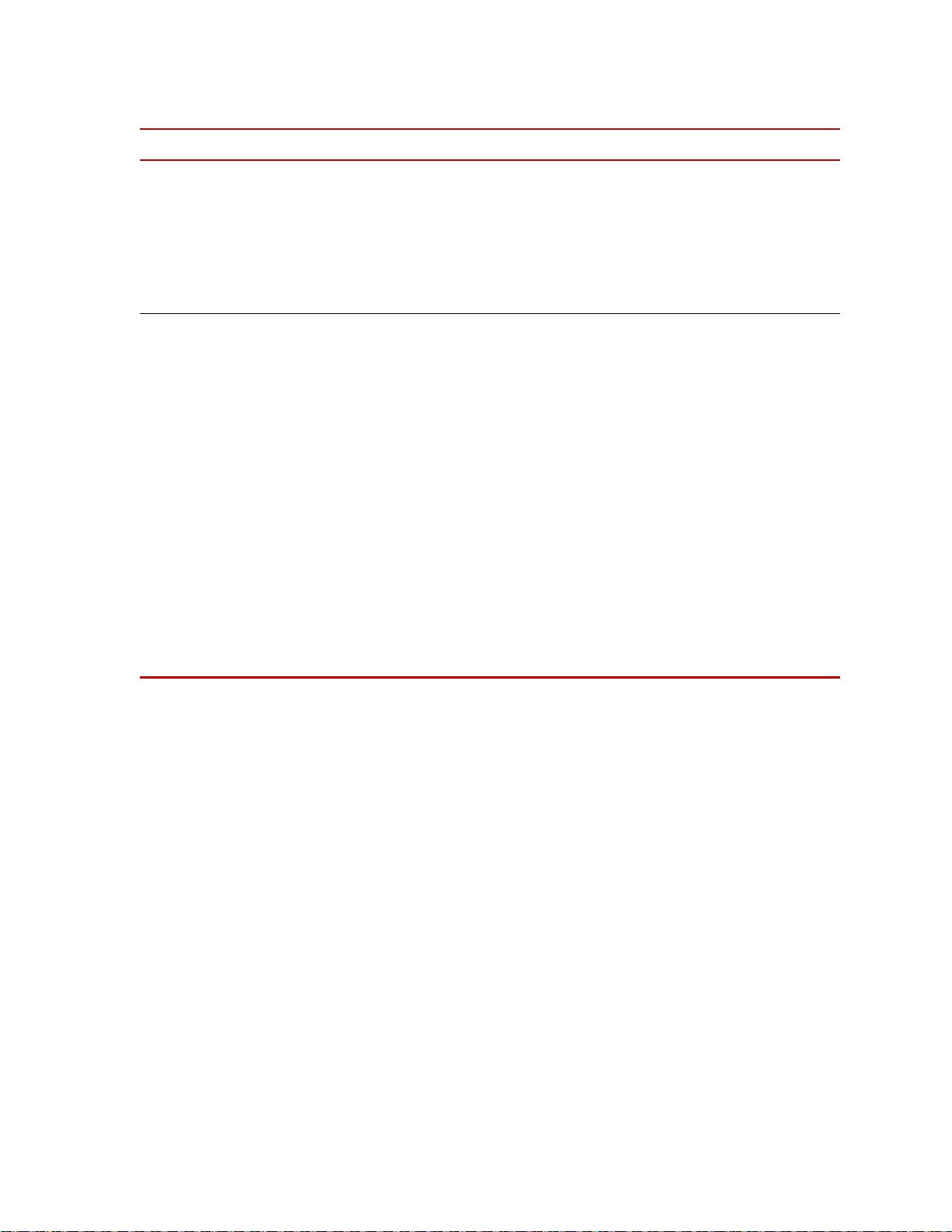

Shown below is actual road data taken with the MTS SWIFT Sensor, located at

the front passenger side of a mid-size passenger vehicle. Data shown is corrected

to translate the forces and moments from the center of the transducer to the center

of the tire.

Slalom Curve Driving Example

Mx (overturning mom ent ) - In

The outputs from slalom (side to side steering) curve driving can be noted in the

graph above:

Time 4 to 12 seconds shows the steering maneuvers. All other times show

straight driving on an average road surface.

Fx: The tractive force remains relatively constant since no acceleration nor

deceleration is occurring during these driving maneuvers.

Fy: The lateral force can be seen alternating from positive to negative with an

amplitude of roughly 500 lb force as the vehicle changes directions with steering

maneuvers.

Fz: The side to side weight distribution of the vehicle during these steering

maneuvers can be noted in the vertical force outputs. The stationary vertical force

of slightly over 1000 lb as noted above is seen to vary by nearly 400 lb.

Mx: The Mx output noted is corrected to give the overturning moment at the

center of the tire, primarily caused by the lateral force Fy at the rolling radius of

the tire.

My: There is little acceleration or brake torque applied during the steering

maneuvers, as noted in the My output.

Mz: The aligning moments generated from the steering maneuvers can be noted

to be in the order of 1000 in•lb for this particular test.

SWIFT 50 GLP Sensors Analyzing SWIFT Data

65

Page 66

Slalom Curve Driving Example

Analyzing SWIFT Data

66

SWIFT 50 GLP Sensors

Page 67

Maintenance

Overview This chapter contains scheduling guidelines and detailed instructions for

performing preventive maintenance. Preventive maintenance is a set of routine

procedures that allow you to extend the operating life of your transducer and the

transducer interface electronics. You can prevent excessive wear or possible

component failure through regular inspections and simple procedures, such as

filter cleaning.

The information provided in this chapter is a recommendation only. The actual

time intervals will depend on the operating conditions at your facility.

Maintenance Schedule

Activity Customer Preventive Maintenance Contact MTS

Calendar Time As Required 1 Day 1 Week 1 Month 1 Year Suggested