Page 1

No. 99MCA081

A

SERIES No. 198

QM-Data

QM-Data 300

3D Data Processing Unit

User’s Manual

(Hardware Guide)

Read this User’s Manual thoroughly

before operating the instrument. After reading,

retain it close at hand for future reference.

Page 2

CONVENTIONS USED IN THIS MANUAL

Safety Precautions

To ensure that instrum ents are operated correc tly and safely, Mitutoyo manuals use

various safety symbols (Signal Words and Safety Alert Symbols) to identify and warn against

hazards and potential accidents.

The following signs indicate general warnings:

DANGER

Indicates an imminently hazardous situation which, if not avoided, will result in s er ious inj ur

y

or death.

WARNING

Indicates a potentially hazardous situation which, if not avoided, could result in serious injur

y

or death.

CAUTION

Indicates a potentially hazardous situation which, if not avoided, may result in minor o

r

moderate injury or property damage.

The following signs indicate specific warnings or prohibited actions, or indicate a

mandatory action:

Alerts the user to a specific hazardous situation. The given example means “Caution, risk of

electric shock”.

Prohibits a specific action. The given example means “Do not disassemble”.

Specifies a required action. The given example means “Ground”.

No. 99MCA081A

i

Page 3

CONVENTIONS USED IN THIS MANUAL

Types of Notes

The following types of notes are used in this manual to help the operator obtain

reliable measurement data through correct instrument operation.

IMPORTANT

• An important note provides information es sential to the c ompletion of a task. You c annot

disregard this note to complete the task.

• An important note is a type of precaution, which if neglected could result in a loss of data,

decreased accuracy or instrument malfunction/failure.

NOTE

A note emphasizes or supplements important points of the main text. It also supplies

information about specific situations (e.g., memory limitations, equipment configurations, or

details that apply to specific versions of a program).

TIP

A tip is a type of note that helps the user apply the techniques and procedures described in

the text to his or her specific needs.

It also provides reference information associated with the topic being discussed.

Mitutoyo assumes no liability to any party for any loss or damage, direct or

indirect, caused by use of this instrument not conforming to this manual.

Information in this document is subject to change without notice.

© 2000 Mitutoyo Corporation. All rights reserved.

No. 99MCA081A

ii

Page 4

WARRANTY

In the event that the Mitutoyo data processing unit “QM-Data” should prove def ective

in workmanship or material, within one year from the date of original purchase for use, it will

be repaired or replaced, at our option, free of charge upon its prepaid return to us.

If the unit fails or is dam aged for any of the following reas ons, it will be s ubject to a

repair charge, even if it is still under warranty.

1. Failure or damage owing to inappropriate handling or unauthorized modification.

2. Failure or damage owing to transport, dropping, or relocation of the instrument after

purchase.

3. Failure or damage owing to fire, salt, gas, abnormal voltage, or natural disaster.

This warranty is effective only where the instrument is properly installed and operated

in conformance with the instructions in this manual.

No. 99MCA081A

ii

i

Page 5

PRECAUTIONS FOR USE

1. Prohibition of Disassembly or Unauthorized Modification

Do not disassemble or modify the data processing unit “QM-Data”. Otherwise, the

measuring accuracy or functions may be adversely affected, or an accident may occur. For

inspection or repair the internal parts of the data processing unit, please contact the Mitutoyo

office.

2. Batteries

A Li (lithium) battery is used for memory backup. Please observe the following

precautions.

CAUTION

Li (lithium) battery

• The Li battery is mounted on the printed circuit board in the data processing unit “QM-Data”.

Do not dispose of the data processing unit by burning it. If the data processing unit is thrown

into fire, the battery may leak chemicals, bur st, or burn violently. Comply with government

regulations regarding the disposal method.

3. General Precautions for Handling the Data Processing Unit “QM-Data”

WARNING

Action to take if a problem occurs

• When overheating, smoke, or an abnormal smell occurs in the data processing unit, turn of

f

the power switch immediately, then unplug the AC adapter from the power outlet. Contact

the Mitutoyo office for repair. If you continue to use the data processing unit “QM-Data”

under such conditions, electric shock or fire may occur.

• If foreign matter (such as water or metal) enters the data processing unit “QM-Data”, turn of

f

the power switch immediately, then unplug the AC adapter from the power outlet. Then,

contact the Mitutoyo office for repair. If you continue to use the data processing unit

“QM-Data” when there is foreign m atter in the data processing unit, electric shock or f ire

may occur.

• If the data processing unit “QM-Data” is bumped so har d that the cover or other part is

broken, turn off the power switch, then unplug the AC adapter from the power outlet. Contact

the Mitutoyo office for repair. If you continue to use the data processing unit “QM-Data” in its

damaged condition, electric shock or fire may occur.

No. 99MCA081A

iv

Page 6

WARNING

Handling

• If a malfunction occ urs, such as no picture is displayed on the LCD (liquid crystal display)

even though the power switch is on, do not use the data processing unit “QM-Data”. Contact

the Mitutoyo office for repair. If you continue to use the data processing unit in its damaged

condition, electric shock or fire may occur.

• Do not let any foreign matter such as metal or water, or other liquids get into the data

processing unit “QM-Data” through the opening around the connector s on the rear panel.

Otherwise, electric shock or fire may occur.

• Do not damage or modify the cord of the AC adapter. If a heavy object is placed on the cord,

or if the cord is pulled, bent, twisted, or heated, the AC adapter could be damaged, and

electric shock or fire may occur.

• When a thunderstorm occurs nearby, unplug the AC adapter and the modular jack.

Otherwise, a malfunction, electric shock, or fire may occur.

• Do not touch the power plug of the AC adapter or the modular jack with wet hands.

Otherwise, electric shock may occur.

• When the power plug is inserted in the power outlet, do not touch the metallic portions of the

modular jack of the AC adapter with your hands. Doing so could result in an electric shock.

• Do not directly touch the pin of the connector on the rear panel with your hands. Otherwise,

the resultant static electricity could cause a m alf unction or a f ailure in the internal c ircuitr y.

Use the supplied covers to cover any unused connectors.

• If the power cord or the modular jack of the AC adapter is damaged, or if the power outlet is

loose, do not use the data processing unit “QM-Data”. Contact the Mitutoyo office for repair.

If you continue to use the data processing unit under such conditions, electric shock or f ire

may occur.

• Do not connect the AC adapter to a power supply in which large electric current is flowing, fo

r

example, to a machine tool or a large CNC measuring machine. Furthermore, avoid

complicated wiring.

• If the metallic portion of the AC adapter’s modular jack or the power outlet is dus ty, wet o

r

greasy, wipe with a dry cloth. Otherwise, fire may occur.

• Do not disassemble or m odify the data processing unit “Q M-Data”. Doing so m ay result in

failure. If the data processing unit needs to be ins pected or repaired, contact the Mitutoyo

office.

No. 99MCA081A

v

Page 7

CAUTION

Handling

• Do not bump the LCD panel. Furthermore, do not press against the LCD panel with a sharp

implement. Doing so can crack the LCD panel. If the LCD panel cracks and the liquid

contents get on your skin, wash your skin under running water for at least 15 minutes. If the

liquid enters your eyes, flush them with running water for at least 15 minutes, then consult a

doctor. The LCD contains acutely irritating substances.

• Be sure to press the keys with your fingers. Do not press them with a pencil, a ball-point pen,

or a sharp metal implement. Doing so may break the keys.

• Be sure to use the specified AC adapter only. Otherwise, failure of the internal circuit, fire, o

r

injury may occur.

• When pulling out the power plug or the modular jack of the AC adapter, be sure to hold the

plug or the jack, not the cord. Otherwise, the core of the cord may be exposed or brok en,

possibly resulting in electric shock or fire.

• Be sure to securely insert the modular jack and the power plug of the AC adapter.

Otherwise, fire or failure may occur.

4. Optional Accessories

4.1. Receipt Printer (Small Thermal Printer) (Part No. 06AAX264, 06AAX266, or 06AAX265)

CAUTION

• Before connecting the receipt printer to the data processing unit “QM-Data”, be sure to turn

off the power switch of the data process ing unit and unplug the AC adapter. When the

battery operating time becomes very short, the battery may be depleted. In that case,

contact the Mitutoyo office.

• The receipt printer uses a Ni-MH (nickel-metal hydride) battery for its power supply. Be sure

to read the precautions in the User’s Manual and to observe the following precautions.

• When charging the battery, be sure to keep the ambient tem perature between 0°C and

40°C. Otherwise, the battery may leak or overheat, adversely affecting the performance

and life of the battery.

• Refer to the instructions supplied with the receipt printer to see how the battery is charged.

No. 99MCA081A

vi

Page 8

4.2. Floppy Disk Drive (Part No. 06AAX263)

CAUTION

• Before mounting or removing the floppy disk drive from the data processing unit “QM-Data”,

be sure to turn off the power switch on the data proc essing unit. Furtherm ore, if you are

using the AC adapter, unplug the modular jack.

• When setting or removing a f loppy disk, do not insert your finger into the slot of the f lopp

y

disk drive. Doing so could cause injury.

No. 99MCA081A

vi

i

Page 9

CONTENTS

CONVENTIONS USED IN T HIS MANUAL ..............................................................................................i

WARRANTY...................................................................................................................................................... iii

PRECAUTIONS FOR USE................................................................................................................................iv

1 INTRODUCTION ........................................................................................................................................1-1

1.1 Outline............................................................................................................................................. 1-1

1.2 Component Names and Functions............................................................................................... 1-2

2 SETTING UP ..............................................................................................................................................2-1

2.1 Required Environment for Installation......................................................................................... 2-1

2.2 Mounting the Data Processing Unit ............................................................................................. 2-1

3 BASIC OPERATIONS................................................................................................................................3-1

3.1 Start-up............................................................................................................................................ 3-1

3.2 Compensation Functions.............................................................................................................. 3-2

3.3 Optional Accessories..................................................................................................................... 3-3

3.3.1 Printer...................................................................................................................................3-3

3.3.1.1 Receipt Printer............................................................................................................ 3-3

3.3.1.2 ESC/P Printer.............................................................................................................. 3-3

3.3.2 Floppy Disk Drive................................................................................................................ 3-4

3.3.3 RS-232C Interface................................................................................................................ 3-6

3.3.3.1 RS-232C No. 1............................................................................................................ 3-6

3.3.3.2 RS-232C No. 2............................................................................................................ 3-6

3.3.4 Foot Switch.......................................................................................................................... 3-7

4 MAINTENANCE AND TROUBLESHOOTING........................................................................................... 4-1

4.1 Daily Care........................................................................................................................................4-1

4.2 Troubleshooting.............................................................................................................................4-2

5 SPECIFICATIONS...................................................................................................................................... 5-1

5.1 Basic Specifications ......................................................................................................................5-1

5.2 Power Supply Specifications........................................................................................................ 5-2

5.3 Input and Output Specifications for the Data Processing Unit................................................. 5-3

5.3.1 Output to Printer (Centronics; 8-bit parallel)....................................................................5-3

5.3.2 RS-232C Input and Output.................................................................................................. 5-4

5.3.2.1 RS-232C No. 1............................................................................................................ 5-4

5.3.2.2 RS-232C No. 2............................................................................................................ 5-5

5.4 Standard Accessories.................................................................................................................... 5-5

5.5 Optional Accessories..................................................................................................................... 5-6

No. 99MCA081A

viii

Page 10

5.5.1 List of Optional Accessories...............................................................................................5-6

5.5.2 Floppy Disk Drive.................................................................................................................5-7

5.5.3 Foot Switch...........................................................................................................................5-7

SERVICE NETWORK

No. 99MCA081A

i

x

Page 11

No. 99MCA081A

x

MEMO

Page 12

1 INTRODUCTION

This chapter describes the outline of the data processing unit

“QM-Data”, and the name and function of each component.

1

1.1 Outline

This data processing unit “QM-Data” is used to process data from a manual

coordinate measuring machine (manual CMM).

In this data processing unit, measurement instructions, measurement values, and

various calculation results are displayed graphically on an LCD in a form that is easy to

understand.

Measurement results can be output using the receipt printer, which is a small thermal

printer (an optional accessory), or on a printer handling A4-size paper or continuous paper.

Created part programs, measured data, and measurement results can be stored on a

floppy disk (in this case, the optional floppy disk drive is necessary); the stored part programs,

measured data, and measurement results can then be used when necessary.

No. 99MCA081A

1-1

Page 13

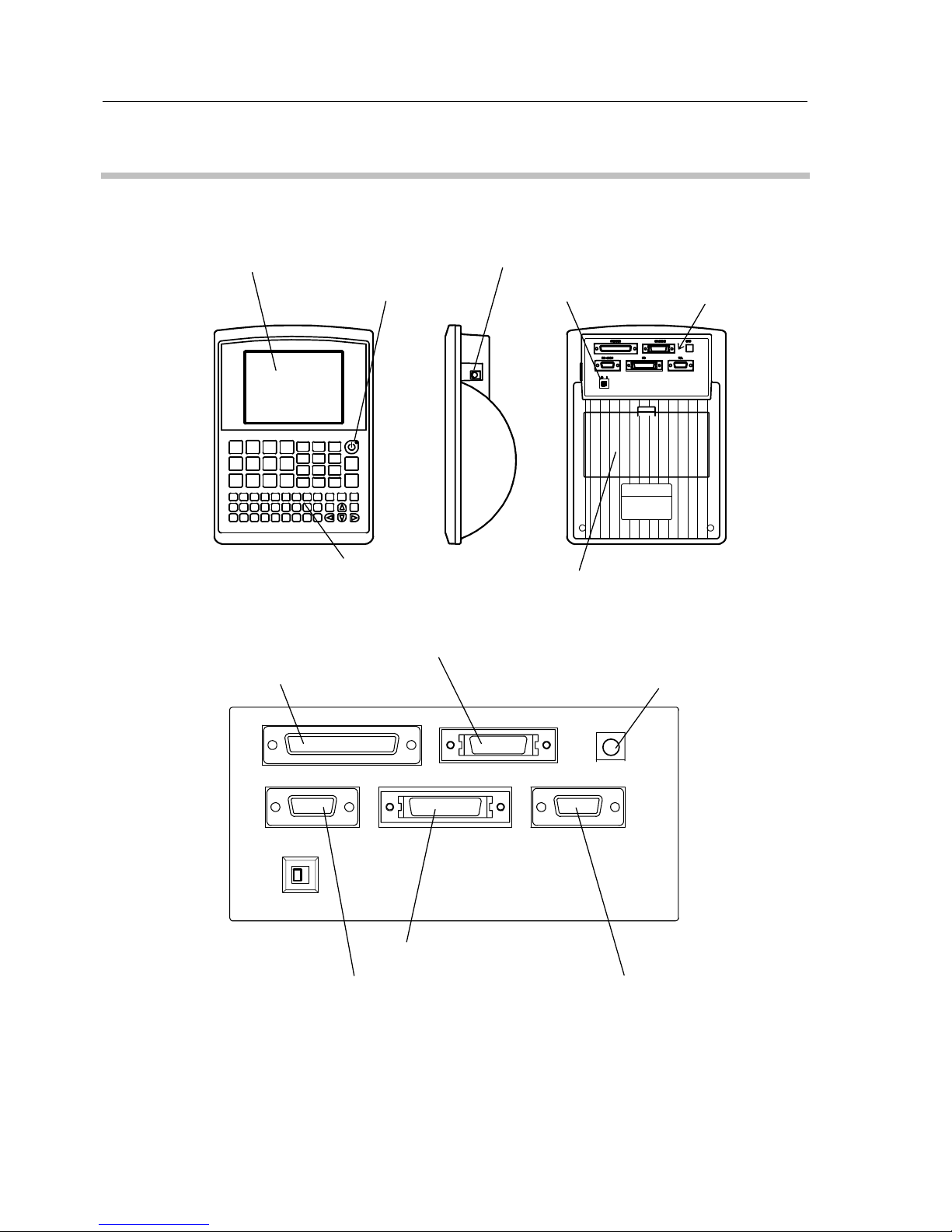

1.2 Component Names and Functions

This section describes the names and functions of the components of the data

processing unit “QM-Data”.

(5) Key panel

(3) DC jack

(4) Power switch

(6) Back cover

(2) Suspend key

(1) Display portion (LCD)

Connectors

Fig. 1-1

(8) CMM connector

(9) Foot switch input jack

(11) FDD connector

(10) RS-232C connector No. 1

(12) RS-232C connector No. 2

(7) Printer connector

FS

RS-232C 1

PRINTER

RS-232C 2

FD

CMM

O |

Fig. 1-2

No. 99MCA081A

1-2

Page 14

1. INTRODUCTION

(1) LCD

The LCD (Liquid Crystal Display) displays measurement result.

(2) Suspend key

When the data processing unit “QM-Data” is in Suspend Mode, the LED

corresponding to this Suspend key lights. If this key is pressed in Suspend Mode, then

the system starts up in the state prior to Suspend Mode. The measured data, obtained

before the Suspend Mode was entered, is retained.

When the data processing unit will not be used for some tim e, for example

during lunch, activate the Suspend Mode to reduce the power consumed by the data

processing unit.

Unlike when the power switch is OFF, a sm all amount of electric ity is used in

Suspend Mode. Consequently, if you do not intend to use the data processing unit for

a long time, for example over a holiday, turn off the power switch on the data

processing unit.

(3) DC jack

This is a jack used to connect the AC adapter which is a standard accessory.

(4) Power switch

Setting the power switch knob to the “|” position turns the power ON; and setting

the power switch knob to the “O” position turns the power OFF.

When electric power is supplied from the AC adapter, the built-in green LED

lights.

When you turn off the power switch, internal setting will be retained, but

measured data that has not been stored will be lost.

(5) Key panel

From this key panel, you can create various settings and perform input. This key

panel includes the measurement command keys.

(6) Back cover

Do not open the back cover. The back cover is for maintenance.

(7) Printer connector (PRINTER connector)

This is a connector for connecting the printer.

(8) CMM connector (CMM connector)

This is a connector for connecting the CMM (Coordinate Measuring Machine).

No. 99MCA081A

1-3

Page 15

No. 99MCA081A

1-4

(9) Foot switch input jack (FS jack)

This is a jack for connecting the optional foot switch.

(10) RS-232C connector No. 1 (RS-232C 1 connector)

This is a connector for connecting a personal computer.

(11) FDD connector (FD connector)

This is a connector for connecting the optional floppy disk drive (Part No.

06AAX263).

(12) RS-232C connector No. 2 (RS-232C 2 connector)

This is a connector for connecting the optional temperature sensors via the

temperature sensor unit.

Page 16

2 SETTING UP

This chapter describes the required environment for installing the data

processing unit “QM-Data”, and the installation of the data processing

unit.

2

2.1 Required Environment for Installation

Because this data processing unit “QM-Data” is used along with a CMM (Coor dinate

Measuring Machine), mak e sure to install the data processing unit in an environment that

satisfies the conditions required for ins talling the CMM in terms of temperature, hum idity,

vibration, and dust. Furthermore, the ins tallation environment should satisfy the following

conditions.

(1) Power supply

Confirm that the power outlet meets the power requirements of the AC adapter

before connecting the AC adapter to the power outlet.

Do not use any AC adapter other than the one provided.

(2) Electromagnetic noise

Do not connect the AC adapter to a power supply that has a large electric

current flowing through it, such as one f or machine tools or large CNC measuring

instruments.

Place the data processing unit “QM-Data” well away from equipment that

generates electromagnetic noise, such as welding equipment or electric discharge

machines (EDMs).

2.2 Mounting the Data Processing Unit

Refer to the User’s Manual of the m ain unit of the CMM f or the m ethod to m ount the

data processing unit “QM-Data” on the CMM (Coordinate Measuring Machine).

No. 99MCA081A

2-1

Page 17

No. 99MCA081A

2-2

MEMO

Page 18

3 BASIC OPERATIONS

This chapter describes the basic operations of the data pr ocessing

unit “QM-Data” and its optional accessories.

3

3.1 Start-up

(1) Connect the AC adapter.

(2) Turn on the power switch. Then wait until the screen shown in Fig. 3-1 is displayed.

F1 F2 F3 F4

Fig. 3-1

TIP

Refer to the “User’s Manual (Software Guide (1) & (2)) (MANUAL Nos. 99MCA082 &

99MCA083)” for information on the settings and measurement methods.

No. 99MCA081A

3-1

Page 19

3.2 Compensation Functions

You can utilize the following compensation functions.

(1) Volumetric error compensation

Volumetric error compensation can be used by setting the scale absolute origin

for each axis in the CMM (Coordinate Measur ing Machine) in accordance with the

instructions displayed.

TIP

Refer to Chapter 1 of the “User’s Manual (Operation Guide) (MANUAL No. 99MCA084)” for

an explanation of the volumetric error compensation function.

(2) Temperature compensation (optional)

By inputting data from the temperature sensors attached to the CMM and the

workpiece, the relative amount of thermal expans ion in the work piece and the CMM

can be compensated for.

TIP

Refer to the “Temperature Compensation Function (MANUAL No. 99MCA089)” for an

explanation of the temperature compensation function.

No. 99MCA081A

3-2

Page 20

3. BASIC OPERATIONS

3.3 Optional Accessories

3.3.1 Printer

Use the printer cable to connect the printer to the PRINTER connector on the rear of

the data processing unit.

Refer to the printer’s operation manual for an explanation of how to set up and operate

the printer.

3.3.1.1 Receipt Printer

The receipt printer is a sm all thermal printer. Measured data can be printed on the

receipt printer.

Refer to the “User’s Manual” of the Main Unit of the CMM (Coordinate Measuring

Machine) for an explanation of how to mount the receipt printer.

IMPORTANT

• Do not use any other AC adapter than the AC adapter supplied with the receipt printer.

Otherwise, the receipt printer might be damaged.

• Before connecting the receipt printer and the data processing unit, be sure to turn off their

power switches.

3.3.1.2 ESC/P Printer

The measured data, the measurement res ults, and the part progr am s can be pr inted

on the ESC/P printer.

IMPORTANT

Be sure to turn off their power switches bef ore connec ting the ESC/P printer and the data

processing unit.

TIP

Check the specifications described in 5.3.1 "Output to Printer” to find out which printers are

compatible.

No. 99MCA081A

3-3

Page 21

3.3.2 Floppy Disk Drive

Use the supplied connection cable to connect the floppy disk drive (FDD) with the FD

connector on the rear of the data processing unit.

The floppy disk drive is used to store and retrieve the part programs or measured data

on the floppy disk.

Connection cable

Eject button

Access LED

Fig. 3-2

IMPORTANT

• Make sure to turn off the power switch on the data processing unit before connecting the

floppy disk drive and the data processing unit.

• For the floppy disk drive, use a 3.5” floppy disk (2HD, 1.44 MB) that has been form atted

for MS-DOS.

• Do not use a cleaning disk in the floppy disk drive.

• When the access LED on the front of the floppy disk drive is lit, do not use the eject button

or connect or disconnect the connection cable.

No. 99MCA081A

3-4

Page 22

3. BASIC OPERATIONS

NOTE

Handling floppy disk

When using a floppy disk, pay attention to the following matters. Mishandling c an result in

damaged data.

1) Do not touch the disk surface directly.

2) Do not put the floppy disk near a magnet or magnetized item.

3) Do not leave the floppy disk where the temperatur e is outside the range of 0°C

through 60°C.

TIP

Refer to the “User’s Manual” of the Main Unit of the CMM (Coordinate Measuring Machine)

for information on how to mount the floppy disk drive.

No. 99MCA081A

3-5

Page 23

3.3.3 RS-232C Interface

3.3.3.1 RS-232C No. 1

The RS-232C No. 1 interface of the data processing unit is used to communicate with

a personal computer or equipment having an RS-232C interface.

IMPORTANT

• The signal names and pin numbers may be different depending on the equipment. Before

setting up the connection, be sure to check that equipment’s manual.

• If the connection cable you are using has been manufactured by a vendor other than

Mitutoyo Corporation, or if you set up the connection cable by yourself, be sure to use core

wire shielded by a knitted shield and ground each end of the knitted shield to the shell of

the RS-232C connector. If you use a core wire without a knitted shield, the data

processing unit “QM-Data” may malfunction owing to outside noise, or the television or the

radio may malfunction owing to high-frequency noise from the data processing unit.

NOTE

Before using the RS-232C No. 1 interface, set up the communication conditions (namely,

baud rate, word length, parity check, stop bit) for the other piece of equipment.

TIP

• Refer to Section 5.3.2 “RS-232C Input and Output” for the connection specifications and

the pin arrangement of the connector.

• Refer to Chapter 14 of the “User’s Manual (Software Guide (2)) (MANUAL No.

99MCA083)” for information on how to set up the RS-232C No. 1 interface.

3.3.3.2 RS-232C No. 2

The RS-232C No. 2 interface on the data processing unit is connected to the

temperature sensors via the temperature sensor unit.

IMPORTANT

Do not use any other temperature sensor than Mitutoyo’s temperature sensor.

Furthermore, do not use any other cable than the specified cable.

No. 99MCA081A

3-6

Page 24

3. BASIC OPERATIONS

TIP

• The communication conditions (namely, baud rate, word length, parity check, stop bit)

were set when the unit shipped.

3.3.4 Foot Switch

Insert the foot switch plug into the foot switch input jack (FS jack ) on the rear of the

data processing unit.

If you step on the foot switch during a measurem ent, the meas ured data at that tim e

will be input to the data processing unit.

No. 99MCA081A

3-7

Page 25

No. 99MCA081A

3-8

MEMO

Page 26

4 MAINTENANCE AND

TROUBLESHOOTING

This chapter describes maintenance and troubleshooting.

4

4.1 Daily Care

Wipe the plastic portion of the data proces s ing unit “Q M-Data” lightly with a cloth that

was moistened with a neutral detergent diluted in water, and then wrung out.

IMPORTANT

Do not apply any solvent to the plastic portion of the data processing unit.

No. 99MCA081A

4-1

Page 27

4.2 Troubleshooting

If you think that operation is abnormal, follow the troubleshooting instructions below.

IMPORTANT

If you cannot solve the problem, make a note of the model name, model number, and serial

number, and then contact your supplier.

(1) No picture is displayed even when the power switch is on.

Point to check Cause and remedy

Is the AC adapter connected correctly?

• Confirm that the plug and the modular jack of the AC adapter

are securely connected. When those connections are normal,

the green LED built in the power switch will light up.

• Confirm that the voltage of the power supply meets the AC

adapter ratings.

Is the Suspend Mode LED lit? Press the Suspend key.

(2) The displayed characters are hard to read.

Point to check Cause and remedy

Has the contrast been adjusted?

• Adjust the contrast of the LCD, referring to Chapter 14 of the “User’s

Manual (Software Guide (2)) (MANUAL No. 99MCA083)”.

• The LCD display quality varies depending on the ambient temperature.

Slight variation is normal. Adjust the contrast so that you can clearly

read the characters.

No. 99MCA081A

4-2

Page 28

4. MAINTENANCE AND TROUBLESHOOTING

(3) It is not possible to move from the initial screen to the next screen; or, although no

operation has been done, the screen returns to the initial screen.

Point to check Cause and remedy

Is there any source generating noise, for

example a machine tool, an electric

discharge machine, a welding machine etc.,

near the data processing unit “QM-Data”?

Move the data processing unit “QM-Data” away from the source

generating the noise. If the data processing unit uses the same

power supply as the source generating the noise, use a different

power outlet.

Does the power supply voltage fluctuate?

If the wiring is complicated, or if the data processing unit

“QM-Data” uses the same power supply as an equipment

through which a large current flows even briefly, use a different

power outlet.

(4) The buzzer volume is too low or too high.

Point to check Cause and remedy

Have you adjusted the volume setting?

Adjust the volume setting, referring to Chapter 14 of the “User’s

Manual (Software Guide (2)) (MANUAL No. 99MCA083)”.

(5) The displayed date and time are not correct.

Point to check Cause and remedy

Have you set the date and time?

Have you set the date and time correctly?

Set the date and time, referring to Chapter 14 of the “User’s

Manual (Software Guide (2)) (MANUAL No. 99MCA083)”.

Input the date and time according to the specified format.

Are you resetting the time periodically?

Since the built-in clock bears a slight error, set the time

periodically.

(6) An error message concerning the memory backup battery appears.

Point to check Cause and remedy

(Memory backup battery error)

• This error message indicates that the memory backup battery is low,

and that if you continue to use the data processing unit “QM-Data”,

backup will not be performed. Save the part programs and measured

data stored in the internal memory of the data processing unit to the

floppy disk or to a personal computer.

• Contact your supplier to replace the battery.

IMPORTANT

Replacing the battery will initialize the internal memory. Be sure to create the necess ary

backups.

No. 99MCA081A

4-3

Page 29

(7) The retained values are different from the values that were set.

Point to check Cause and remedy

Is there an error message about the

memory backup battery?

The data processing unit “QM-Data” is in a state in which it cannot

back up memory. Those part programs or measured data not

saved to a personal computer or floppy disk will be lost.

(8) Errors related to the Digital Scale unit occur frequently.

Point to check Cause and remedy

Is the ambient noise appropriate?

• Connect the AC adapter to a different power supply, one that does

not have large current flowing through it.

• Use the data processing unit “QM-Data” away from equipment

generating electromagnetic noise, for example a welding machine or

electric discharge machine.

• If the problem persists, it may be necessary to adjust the Digital Scale

unit. In that case, contact your supplier.

(9) It is not possible to print from the printer.

1) Confirm that the connector attached to the connection cable is securely connected.

2) Check whether or not an error message is displayed on the printer. If an error

message is displayed, correct the error by following the instructions in the printer

manual.

3) Disconnect the connection cable between the printer and the data processing unit,

then try the test print described in the printer manual.

No. 99MCA081A

4-4

Page 30

4. MAINTENANCE AND TROUBLESHOOTING

(10) It is not possible to write or read data using a floppy disk.

Point to check Cause and remedy

Is the floppy disk set to write-protect?

Shift the write-protect tab on the floppy disk to the

write-enable position.

Is the floppy disk inserted correctly? Insert the floppy disk correctly, then try again.

Are the connectors in the connection cable between

the floppy disk drive and the data processing unit

“QM-Data” securely connected?

Confirm the connection of the connectors in the

connection cable.

Is the floppy disk formatted properly?

Reformat the floppy disk using your personal

computer (1.44 MB; 2HD).

Is the floppy disk formatted?

Format the floppy disk using your personal computer

(1.44 MB; 2HD).

The contents of the floppy disk might be damaged.

The damaged contents cannot be recovered. If there

is a backup floppy disk, use it.

(11) Data cannot be input using the touch signal probe.

Point to check Cause and remedy

Is the touch signal probe’s cable connection OK?

Check the connection between the touch signal

probe's cable and the main unit of the CMM

(Coordinate Measuring Machine).

(12) Data cannot be input by stepping on the foot switch.

Point to check Cause and remedy

Is the foot switch cable connection OK?

Check the connection between the foot switch cable

and the data processing unit “QM-Data” .

No. 99MCA081A

4-5

Page 31

No. 99MCA081A

4-6

MEMO

Page 32

5 SPECIFICATIONS

This chapter describes the specif ic ations f or the data pr oc es sing unit

“QM-Data”, the standard accessories, and the optional accessories.

5

5.1 Basic Specifications

Item Specification

Monitor Graphic LCD (320 × 240 dots; with backlight)

Displayable languages Japanese / English / German / French / Italian / Spanish / Portuguese

Power supply AC adapter

Electric power consumption Max. 24 W (not including any optional accessories)

Dimensions 200 (W) × 90 (D) × 280 (H) mm

Mass 1.2 kg

Operating temperature range 10 ~ 30 °C

Operating humidity range 20 ~ 80 %RH (Must be free from condensation)

Storage temperature range -10 ~ 50 °C

Storage humidity range 5 ~ 90 %RH (Must be free from condensation)

TIP

Refer to the “User’s Manual (Software Guide (1) & (2)) (MANUAL Nos. 99MCA082 &

99MCA083)” for information on the data processing functions.

No. 99MCA081A

5-1

Page 33

5.2 Power Supply Specifications

Standard accessories include an AC adapter and a power cord for the AC adapter.

The power cord corresponds to the power sour ce voltage in the country where the data

processing unit “QM-Data” is used.

1) Specifications of the AC adapter

Item Specification

Part No. 357651

External dimensions 121 (D) x 60 (W) x 34.5 (H) mm

Mass 0.35 kg

Range of input voltage from

power supply

100 ~ 240 V ±10%

DC output

+12 V ± 5% (Output current: 0.3 ~ 3.5A)

0 V

MAIN (12 V)

Device

specifications

Display When the power supply is on, the green LED is lit.

2) Power cord for the AC adapter

Part No. Corresponding country

930966T For 100 V / for Japan

930966T Meeting the UL, CSA regulations / for United States of America, Canada

930967 Meeting the CEE regulation / for Germany, Europe

930968 Meeting the BS regulation / for the United Kingdom

933098 Meeting the SAA regulation / for Australia

No. 99MCA081A

5-2

Page 34

5. SPECIFICATIONS

5.3 Input and Output Specifications for the Data

Processing Unit

The data processing unit “QM-Data” has the following input and output connectors for

connecting to external devices.

5.3.1 Output to Printer (Centronics; 8-bit parallel)

The measured data and graphs can be output to the receipt printer (optional

accessory) or the ESC/P printer. Graphs can be output only to the ESC/P printer.

1) Printer specifications

(1) Centronics; 8-bit parallel input.

(2) Printer control code: ESC/P.

(3) Being operable by MS-DOS.

(4) Paper size: A4-size or Letter-size for pieces of paper; and 8-inch width (80

characters) for continuous paper.

(5) Color mode printout using a color ribbon cartridge.

<Recommended printer model>: LQ-300 or LQ570+ (by EPSON Inc.)

2) Printer connection cable

Use the following dedicated cable to connect the printer.

(1) Cable for connecting the receipt printer

Use the cable supplied with the receipt printer.

(2) Cable for connecting the ESC/P printer

2 m (Part No. 12AAA804) or 4 m (Part No. 12AAA805)

No. 99MCA081A

5-3

Page 35

5.3.2 RS-232C Input and Output

5.3.2.1 RS-232C No. 1

The RS-232C No. 1 interface is used storing and reading measured data or part

programs on a personal computer.

1) Specifications

• Communication specification: Half-duplex

• Communication method: Asynchronous

• Communication speed: 1200, 2400, 4800, or 9600 bps.

2) Pin arrangement of the connector

Connector: JES-9P-2A3A (9-pin, D-sub)

manufactured by Nihon Attyaku Tanshi Inc.

5

1

6

9

Fig. 5-1

The connection specifications for connecting the RS-232C No. 1 interface to data

terminal equipment (DTE), such as a personal computer are as follows:

Data terminal equipment (DTE),

such as personal computer Data processing unit “QM-Data”:

(PC/AT compatible) (Data terminal equipment (DTE))

Signal name Pin No. Pin No. Signal name Description

DCD 1 1 NC No connection

RxD 2 2 RxD Received data

TxD 3 3 TxD Transmit data

DTR 4 4 DTR Data terminal ready

SG 5 5 SG Signal ground

DSR 6 6 DSR Data set ready

RTS 7 7 RTS Request to send

CTS 8 8 CTS Clear to send

RI 9 9 NC No connection

Shield Shell Shell Shield Frame ground

9-pin, D-sub 9-pin, D-sub

Fig. 5-2

No. 99MCA081A

5-4

Page 36

5. SPECIFICATIONS

5.3.2.2 RS-232C No. 2

RS-232C connector No. 2 (RS-232C 2 connector) is used to connect the temperature

sensors via the temperature sensor unit.

NOTE

RS-232C connector No. 2 (RS-232C 2 connector) is exclusively used for connecting the

temperature sensors via the temperature sensor unit. Do not connect any device other than

the temperature sensor unit to this connector.

5.4 Standard Accessories

Part No. Part name Quantity

357651 AC adapter 1

- Power cord for AC adapter 1

06AAE848A CMM connection cord (3 m) (UD cable-2) 1

99MCA081

99MCA082

99MCA083

99MCA084

99MCA085

User’s manual (hardware guide)

User’s manual (software guide (1))

User’s manual (software guide (2))

User’s manual (operation guide)

Quick help manual

1 set

- Inspection certificate 1

No. 99MCA081A

5-5

Page 37

5.5 Optional Accessories

5.5.1 List of Optional Accessories

Part No. Part name

Receipt printer (with cable)

06AAX264 For 100 V

06AAX266 For 230 V

06AAX265 For 120 V

06AAX290 Printer paper for receipt printer (10 pieces)

12AAA804 Printer cable for ESC/P printer (2 m)

12AAA805 Printer cable for ESC/P printer (4 m)

06AAX263 Floppy disk drive (with exclusively used cable)

12AAA807 RS-232C cable (2 m)

12AAA808 RS-232C cable (4 m)

937179T Foot switch

No. 99MCA081A

5-6

Page 38

5. SPECIFICATIONS

5.5.2 Floppy Disk Drive

Item Specification

Part No. 06AAX263

External dimensions 44 (W) x 200 (D) x 125 (H) mm

Mass 1.1 kg

Power consumption Max. 3.85 W

Device specifications

Storage media

3.5” formatted floppy disk

(2HD, 1.44 MB, MS-DOS format)

5.5.3 Foot Switch

Item Specification

Part No. 937179T

External dimensions 80 (W) x 75 (D) x 35 (H) mm

Mass 200 g

Device specifications

Cable length 1.8 m

No. 99MCA081A

5-7

Page 39

No. 99MCA081A

5-8

MEMO

Page 40

[MEMO]

Page 41

Mitutoyo Corporation

20-1, Sakado 1-chome, Takatsu-ku, Kawasaki, Kanagawa 213-0012, Japan

Cable: MITUTOYO Kawasaki

Phone: (044)813-8230 Fax: (044)813-8231

Loading...

Loading...