Mitutoyo Measuring Projector, PJ-A3000, PJ-A3005F-150, PJ-A3010F-200, PJ-A3010F-100 User Manual

...Page 1

No.99MBA043A

SERIES No.302

PJ-A3000 Series

Measuring Projector

User’s Manual

Read this User's Manual thoroughly

before operating the instrument. After reading,

retain it close at hand for future reference.

Page 2

Conventions Used in this User's Manual

This section describes the symbols (safety warning symbols) used in this manual.

Safety Precautions

This manual uses various symbols to help you use this unit correctly, and prevent danger to

personnel or equipment damage.

• The following symbols indicate general dangers, warnings and cautions.

DANGER

Indicates an imminently hazardous situation which, if not avoided, will result in serious

injury or death.

WARNING

Indicates a potentially hazardous situation which, if not avoided, will result in serious

injury or death.

CAUTION

Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury or property damege.

• The following symbols indicate specific warnings or prohibited actions.

Alerts the user to a specific hazardous situation. The given example means “Caution,

risk of electric shock”.

Prohibits a specific action. The given example means “Do not disassemble”.

No.99MBA043A

i

Page 3

WARNING

Do not modify this instrument.

Risk of fire or electric shock.

Do not bend, twist, pull, or modify the power cord.

Risk of fire or electric shock.

Do not remove the front panel, rear panel, side panel or covers of this

instrument.

Risk of electric shock.

Only operate this instrument at the specified voltage.

Risk of fire or electric shock.

Do not set up this instrument on an unstable bench.

The instrument may fall.

Risk of injury.

Do not place a vessel containing liquid near the instrument.

Risk of fire or electric shock.

Unplug the power cord and contact Mitutoyo if liquid has entered the

instrument.

Risk of fire or electric shock.

Unplug the power cord if replacing a fuse.

Risk of electric shock.

The AC outlet incorporated with the instrument is only available for

Mitutoyo accessories.

Do not plug in other equipment.

Risk of fire.

Should this system be used under abnormal conditions such as heat

radiation, smoking, and nasty smell generation, there is a risk of fire or

electric shock.

Immediately turn off the power switch, then unplug the power plug from

the outlet.

Contact your dealer or the nearest Mitutoyo service network.

No.99MBA043A

ii

Page 4

Unplug the power cord if performing maintenance.

Do not pull the cable to unplug the power cord.

Hold the plug and pull to prevent cord breakage.

Risk of fire or electric shock.

Do not connect/disconnect or touch the plug with wet hands.

Risk of electric shock.

Keep the power cord away from heaters.

Risk of fire or electric shock with melted cable insulation.

Only use the specified fuse.

Risk of fire or electric shock.

Do not block the ventilation outlets.

Risk of fire due to internal heat build up.

For quick power shutoff install this system at a site where the system

power plug can be easily identified and quickly accessed to be

unplugged.

No.99MBA043A

iii

Page 5

CAUTION

CAUTION

Do not apply excessive force to the instrument.

Risk of instrument failure, damage, or decreased accuracy.

Only hold the specified parts of the instrument if transporting.

Risk of instrument failure, damage, or decreased accuracy.

Exercise care so as not to pinch or hurt your fingers if

mounting/dismounting accessories.

Only use the accessories specified in the User’s Manual provided with the

instrument.

Risk of fire, electric shock, and instrument failure.

No.99MBA043A

iv

Page 6

CONVENTIONS USED IN USER'S MANUAL

CONVENTIONS USED IN USER'S MANUAL

On Various Types of NotesOn Various Types of Notes

The Following types of notes are provided to help the operator obtain measurement data

through correct instrument operation.

The Following types of notes are provided to help the operator obtain measurement data

through correct instrument operation.

An important note is a type of note that provides information essential to the

completion of a task. You cannot disregard this note to complete the task.

An important note is a type of note that provides information essential to the

completion of a task. You cannot disregard this note to complete the task.

An important note is a type of precaution, which if neglected could result in a

loss of date, decreased accuracy or instrument malfunction/failure.

An important note is a type of precaution, which if neglected could result in a

loss of date, decreased accuracy or instrument malfunction/failure.

IMPORTANT IMPORTANT

NOTE NOTE

A note emphasizes or supplements important points of the main text. A note

supplies information that may only apply in special cases(e.g.. Memory

limitations, equipment configurations, or details that apply to specific versions

described in the text to their specific needs.

It also provides reference information associated w

described in the text to their specific needs.

It also provides reference information associated w

A note emphasizes or supplements important points of the main text. A note

supplies information that may only apply in special cases(e.g.. Memory

limitations, equipment configurations, or details that apply to specific versions

TIP

A tip is a type of note that helps the user apply the techniques and procedures

ith the topic being

No.99MBA043A

v

TIP

A tip is a type of note that helps the user apply the techniques and procedures

ith the topic being

Mitutoyo assumes no liability to any party for any loss or damage, dir

ect or indirect, caused by use of this instrument not conforming to thi

s manual.

Information in this document is subject to change without notice.

© Copyright Mitutoyo Corporation. All rights reserved.

No.99MBA043A

v

Page 7

Handling Precautions

1. Confirm the input voltage before turning the power switch on

For the input voltage of this microscope, t her e ar e two systems of 100V-system (100

to 120V) and 220V-system (220 to 240V). Connect t he power plug with the plug

socket after conf ir m ing that the rated voltage of the m icroscope corresponds with the

voltage of plug socket.

2. Turn the power sw itch ON or OFF along the order

The counter may display error messages (E51, E52, E53) by the order which turns

the power supply of the microscope main unit and the peripheral equipment such as

personal computer on or off in t he connect ion with some peripher al equipment, when

the peripheral equipment is being connected with the count er unit at RS232C.

Be sure to perform at the following order, when turning the power switch ON or OFF.

• For ON ∙∙∙∙∙ Peripheral equipment Projector main unit

• For OFF ∙∙∙∙ Projector main unit Peripheral equi pment

3. Only use the specified power cord and fuse

Use only the supplied power cord. Replacement fuses must be of t he specified type,

voltage and current.

4. Do not disassemble

Disassembly of any unit or removal of panels may present a hazard to personal or

result in a unit failure. Never att em pt to disassemble, unless absolutely essential, e.g.

for the replacement of a fuse, etc..

This instrument consists of precision components, and its performance cannot be

guaranteed, even within the warranty period, if it is disassembled by the user.

All equipment failures that occur after user disassembly will be repaired on a fee-forservice basis.

Guarantee

This system has been manufactured under Mitutoyo's rigor ous quality control system.

In the event that it proves defective in workmanship or m at erials within one year of the

date of purchase under normal usage, Mitutoyo will repair the instr um ent free of charge.

Contact your dealer or nearest Mitutoyo Service Center.

This guarantee does not apply to the following cases:

Equipment failure or damag e due to incorrect usage or unauthorized modif ication or

repair.

Equipment failure or damage resulting from moving, transporting, or dropping t he

instrument.

Equipment failure or damag e due to fires, salt damage, gas damage, abnormal

voltages, or natural disasters.

No.99MBA043A

vi

Page 8

CONTENTS

Conventions Used in this User's Manual .................................................................1

Safety Precautions.....................................................................................................1

On Various Types of Notes........................................................................................5

Handling precautions.................................................................................................6

Guarantee ....................................................................................................................6

1. Overview ............................................................................................... 1-1

1.1 Outline.................................................................................................................1-1

1.1.1 Name of Each Part ............................................................................................................. 1-1

1.1.2

Control panel..................................................................................................................... 1-2

1.1.3

Angle counter and X, Y counter....................................................................................... 1-3

1.1.4

Power panel....................................................................................................................... 1-4

2. Installation and Setup .......................................................................... 2-1

2.1 Installation ...........................................................................................................2-1

2.1.1 Environmental Conditions................................................................................................ 2-1

2.1.2

Transportation and installation......................................................................................... 2-2

2.1.3

Setting up the main unit.................................................................................................... 2-3

2.1.4

Removing the carrying handles....................................................................................... 2-3

2.2 Assembly.............................................................................................................2-4

2.2.1 Installing the cross-travel stage and Digimatic Head (for PJ-A3005D-50)...................2-4

2.2.2

Installing the cross-travel stage and connecting the Linear Scale cables (PJ-A3010F-200).2-7

2.2.3

Connecting the Optoeye A2 Image Edge Sensor(for PJ-3010F-200).....................2-9

2.2.4 Mounting the projection lens

..........................................................................................2-10

2.2.5

Setting the power voltage............................................................................................2-10

2.2.6

Connecting the power cord .........................................................................................2-11

2.3 Initial Checks (Functional Check)......................................................................2-12

2.3.1 Electrical component connectors................................................................................... 2-12

2.3.2

Main switch (ON-OFF).................................................................................................... 2-12

2.3.3

Switches for Contour illumination and reflected illumination....................................... 2-12

2.3.4

Focusing wheel ............................................................................................................... 2-12

2.3.5

Cross-travel stage........................................................................................................... 2-13

2.3.6

Projection screen ............................................................................................................ 2-13

2.3.7

Others............................................................................................................................... 2-13

2.4 Initial Checks (Performance Check)..................................................................2-14

2.4.1 Checking the position of the contour illumination bulb filament.................................. 2-14

2.4.2

Checking the position of the surface illumination bulb filament.................................. 2-14

2.4.3

Projection with contour illumination............................................................................... 2-16

2.4.4

Projection with reflected illumination............................................................................. 2-17

2.4.5

Color fitter........................................................................................................................ 2-18

2.4.6

Checking the magnification accuracy............................................................................ 2-19

2.4.7

Checking the cross-travel stage travel direction........................................................... 2-21

2.4.8

Checking the cross-travel stage feed error................................................................... 2-23

2.4.9

Checking the resolution (in contour illumination mode)............................................... 2-23

No.99MBA043A

vii

Page 9

2.5 Adjustment ........................................................................................................ 2-24

2.5.1 Adjusting the magnification............................................................................................ 2-24

2.5.2

Aligning the cross-travel stage travel direction to t he cross-hair lines........................ 2-24

2.5.3

Centering the protractor screen..................................................................................... 2-24

3. Operation...............................................................................................3-1

3.1 Projection Lens Selection................................................................................... 3-1

3.1.1 Selecting the projection lens......................................................................................3-1

3.1.2

Replacing the projection lens.................................................................................... 3-2

3.2 Mounting the Workpiece..................................................................................... 3-2

3.3 Focusing and Positioning the Workpiece............................................................ 3-4

3.3.1 Focusing............................................................................................................................. 3-4

3.3.2

Positioning the workpiece................................................................................................. 3-5

3.4 Measurement and Inspection ............................................................................. 3-6

3.4.1 Rectangular coordinate measurement (with the X, Y counter)..................................... 3-6

3.4.2

About parameters ............................................................................................................3-9

3.4.3

Dimensional measurement using a scale..................................................................... 3-15

3.4.4

Comparison with an overlay chart ................................................................................. 3-15

3.4.5

Angle measurement (Using the Angle counter) ...........................................................3-16

4. Troubleshooting....................................................................................4-1

4.1 Main Unit............................................................................................................. 4-1

4.2 Counter Unit........................................................................................................ 4-2

4.3 Error Messages and Remedies.......................................................................... 4-3

4.4 Others................................................................................................................. 4-3

4.4.1 Error is observed in glass scale or overlay chart measurement................................... 4-3

4.4.2

Abnormal cross-travel stage operation, and measurement errors occur.....................4-3

4.4.3

Abnormal protractor screen operation.............................................................................4-4

4.4.4

Partial obscured image..................................................................................................... 4-4

4.4.5

Digimatic Head Key Operation and Counter Display (for PJ-A3005D-50)................... 4-4

5. Maintenance ..........................................................................................5-1

5.1 Maintenance of Optical Components.................................................................. 5-1

5.1.1 Projection lens................................................................................................................... 5-1

5.1.2

Half-reflecting mirror for surface illuminat or....................................................................5-1

5.1.3

Mirror(surface reflecting mirror) ....................................................................................... 5-1

5.1.4

Screen glass...................................................................................................................... 5-1

5.2 Maintenance of Mechanical Components........................................................... 5-2

5.2.1 Projector main unit............................................................................................................ 5-2

5.2.2

Cross-travel stage.............................................................................................................5-2

5.3 Replacing Disposable Parts................................................................................ 5-3

5.3.1 Bulbs for contour and surface illuminators...................................................................... 5-3

5.3.2

Fuse ..................................................................................................................................5-5

5.3.3

Stage glass........................................................................................................................5-6

5.4 Periodic Inspection ............................................................................................. 5-6

5.5 List of Consumable............................................................................................. 5-7

No.99MBA043A

viii

Page 10

6. Specifications....................................................................................... 6-1

6.1 General................................................................................................................6-1

6.1.1 Common Specifications.................................................................................................... 6-1

6.1.2

Individual specifications.................................................................................................... 6-3

6.1.3

Date output(RS232C).................................................................................................. 6-4

6.1.4

Connector specifications.................................................................................................. 6-4

6.1.5

Data output operation....................................................................................................... 6-6

6.1.6

Connecting Micropak........................................................................................................ 6-9

6.1.7

Connecting QM-Data 200............................................................................................... 6-10

6.1.8

Data output (SPC)........................................................................................................... 6-10

6.2 Performance Table for the PJ-A3000 Series Projectors...........................................6-14

6.3 Optical Path.......................................................................................................6-15

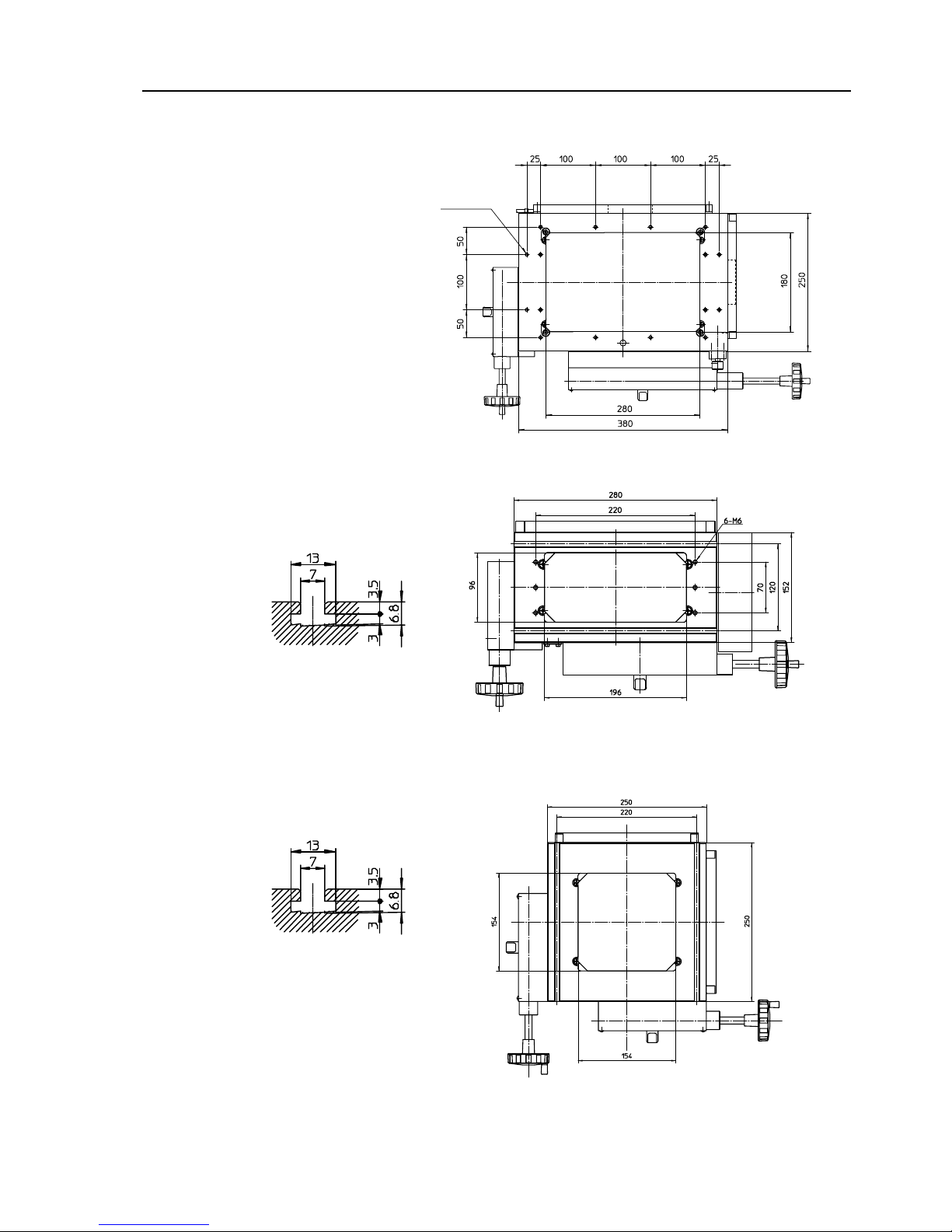

6.4 External dimensions..........................................................................................6-16

6.4.1 Main Unit.......................................................................................................................... 6-16

6.4.2

Cross-travel stage........................................................................................................... 6-19

6.5 Accessories.......................................................................................................6-21

6.5.1 Standard accessories..................................................................................................... 6-21

6.5.2

Optional accessories ...................................................................................................... 6-22

SERVICE NETWORK

No.99MBA043A

ix

Page 11

No.99MBA043A

x

MEMO

Page 12

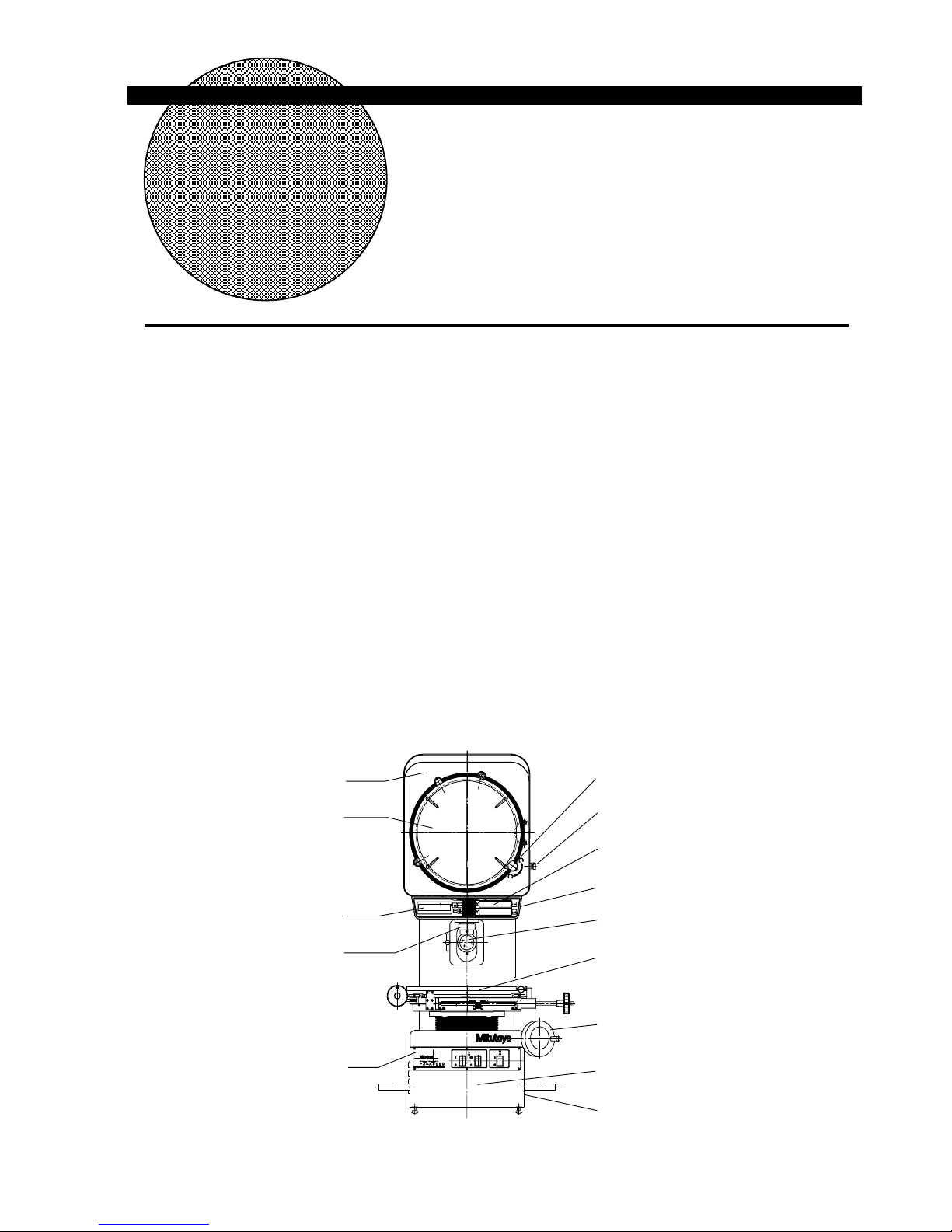

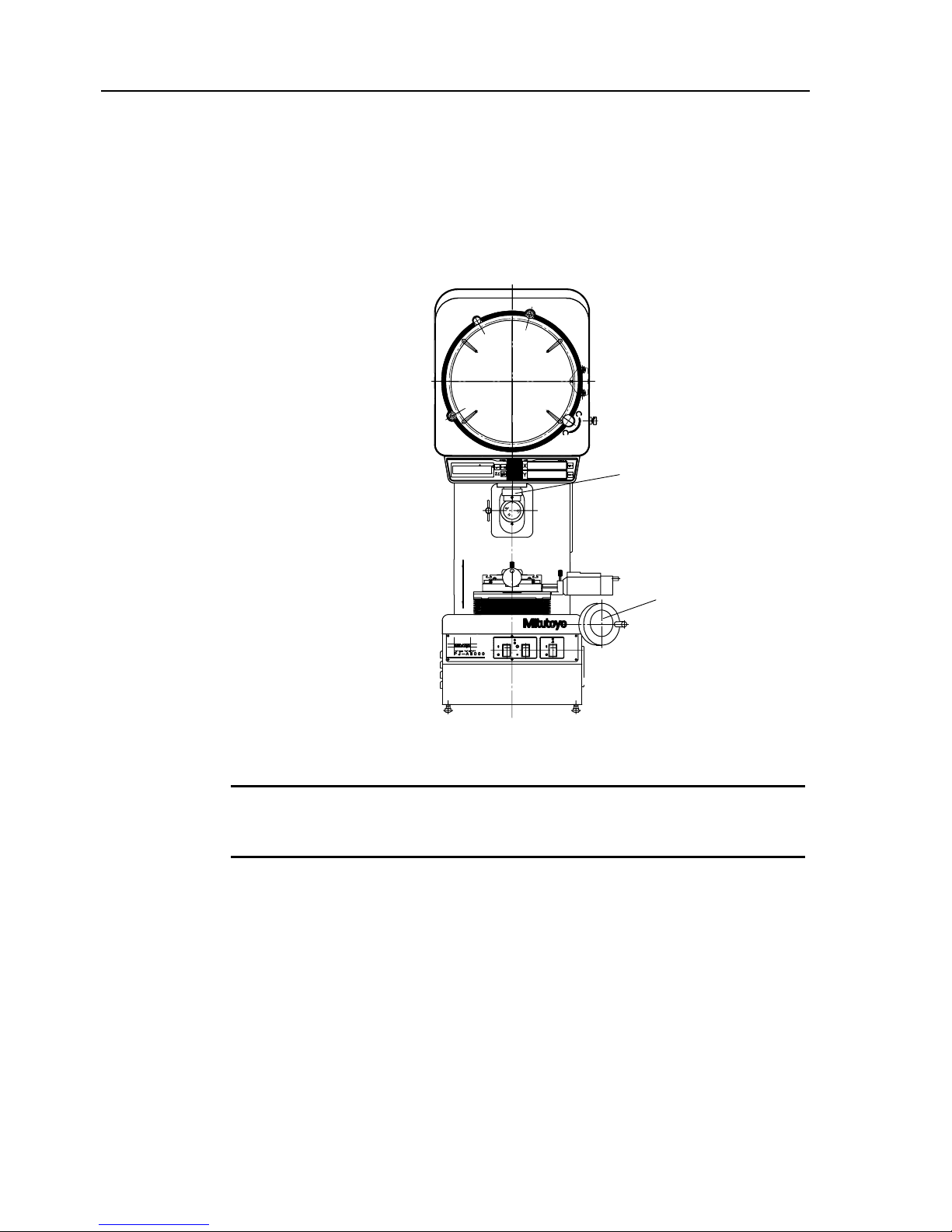

Overview

This chapter describes the system outline, and the name and

function of each part on the PJ-A3000 series Measuring Projector.

1

1.1 Outline

The Mitutoyo PJ-A3000 series Measuring Projector is a multi-purpose measuring microscope for

factory inspection use. It can perform precision measurement of workpiece dimensions, contours

and surface features.

The PJ-A3000 series can be used in a wide range of applications in combination with a variety of

accessories. It is possible to improve the system according to a specific purpose.

The MF-A series has the following features.

• The cross-travel stage with a maximum stroke of 200 X 100mm is available as an option.

• For the counter display, the readout is easy since the characters are large.

• For the counter display unit, following three types are prepared ; angle and X,Y-axis/ only

angle/ no display

• For both the contour and the reflective light source unit, the halogen bulb of 500 hours life with

24V and 150W is used.

• By the slide switching mechanism, the quick bulb exchange is possible.

• The operability is improved still more, because each switches are placed at the front and right

side of main unit.

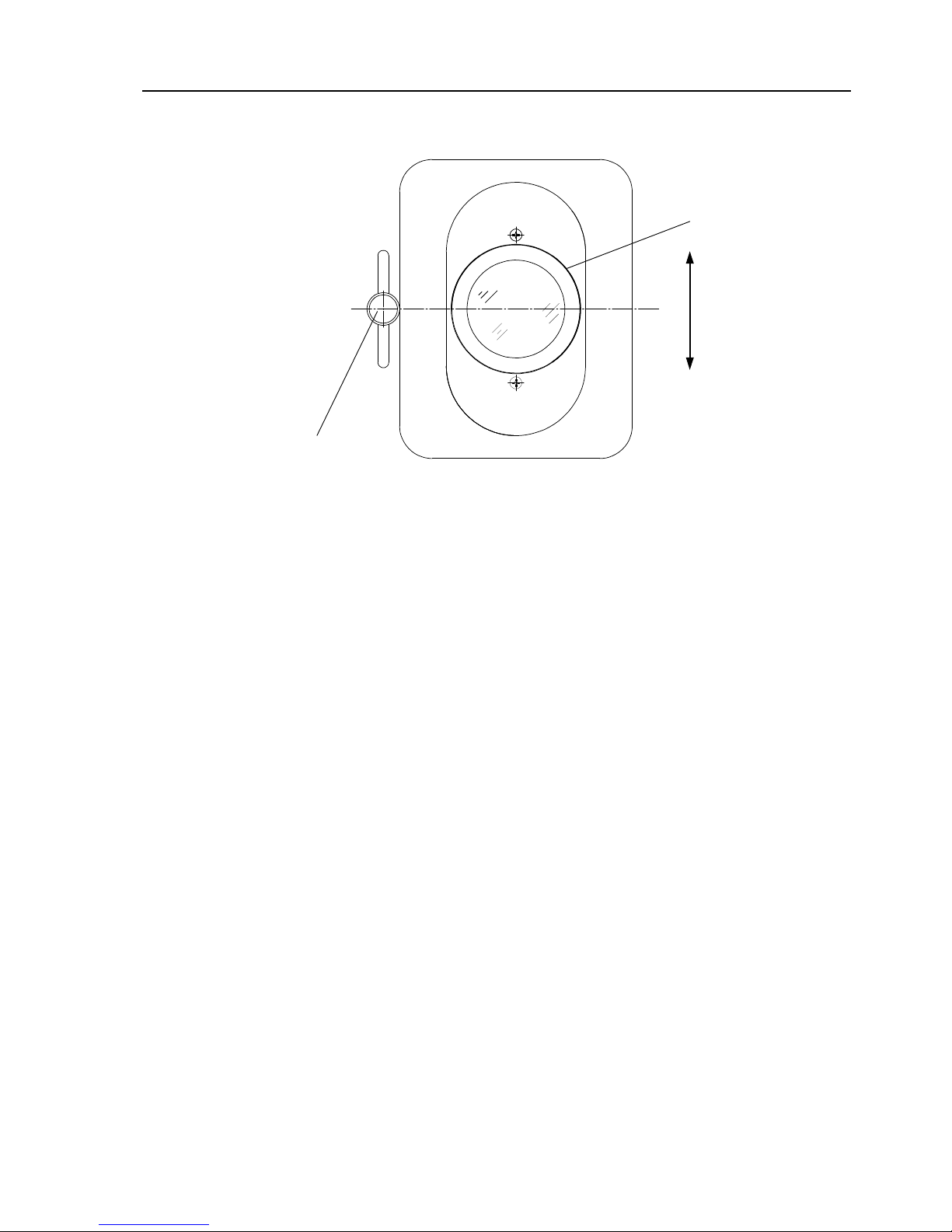

1.1.1 Name of Each Part

[13]

[11]

[12]

[9]

[8]

[14]

[6]

[4]

[3]

[1]

[2]

[5]

[7]

[10]

No.99MBA043A 1 - 1

Page 13

[1] Projector head

[2] Projection screen

[3] Screen rotating knob

[4] Screen clamp knob

[5] Angle counter

[6] XY counter

[7] Projection lens

[8] Reflected illuminator, Condenser lens for reflected illuminator

[9] Cross-travel stage

[10] Control panel

[11] Contour illuminator (interior)

[12] Focusing wheel

[13] Power panel

[14] XY counter out put connect or

1.1.2 Control panel

[3] [2] [1]

[1] Main switch (Power switch) (|:ON / }:OFF)

[2]

Contour illumination brightness selector sw it ch

[3] Reflected illumination switch (

|:ON / }:OFF)

1 - 2 No.99MBA043A

Page 14

1. Overview

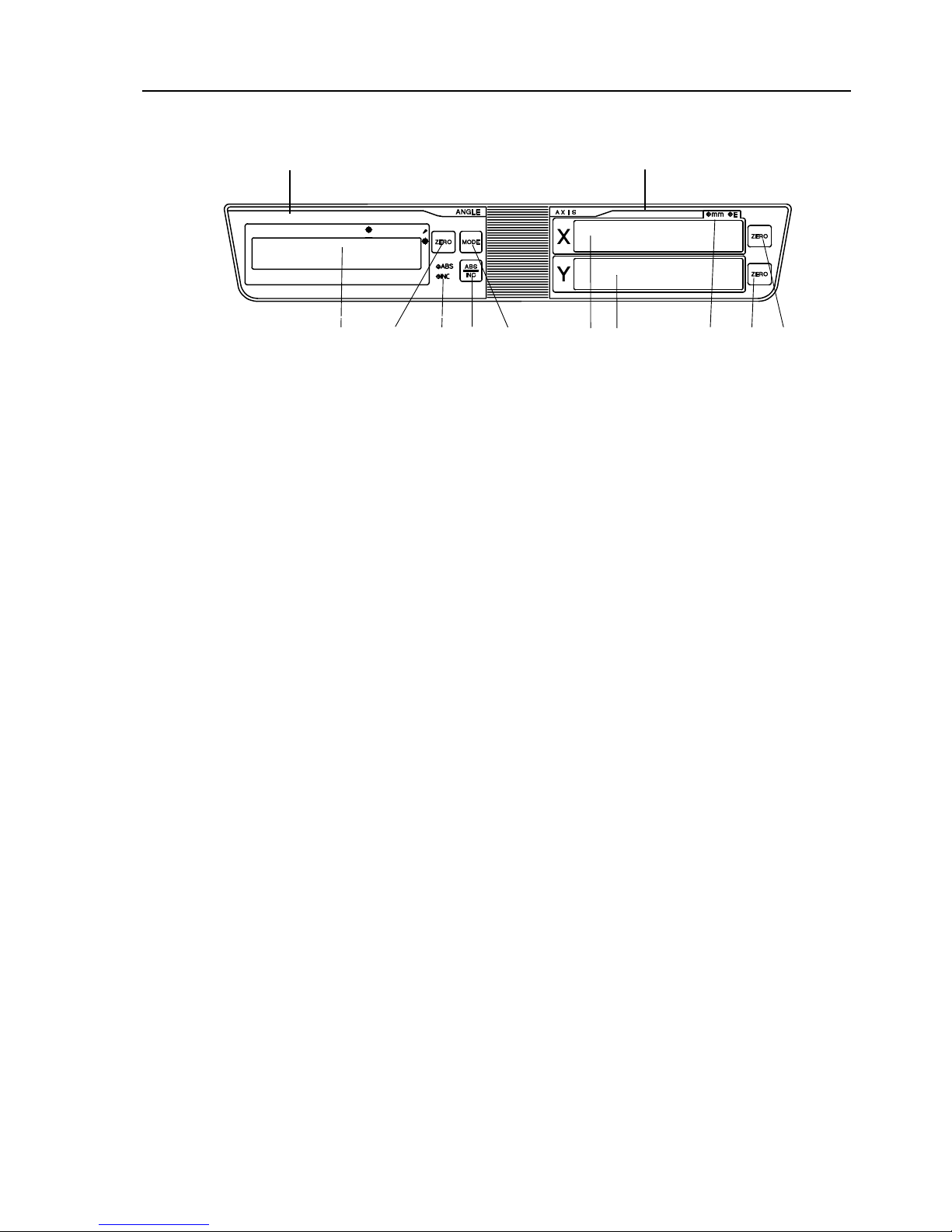

1.1.3 Angle counter and X, Y counter

(1) Angle counter (2) X, Y-axis counter

[2] [7] [8] [6]

[10]

[9] [3] [5] [4] [1]

(1) Angle counter

[1] Angle display unit

[2]

Zero-set key

[3]

ABS/INC mode indicator

[4]

Angle unit selector / offset switch

[5]

ABS/INC mode selector switch

(2) X, Y-axis counter

[6] mm/E indicator or inch/mm indicator

[7]

X-axis counter

[8]

Y-axis counter

[9]

X-axis zero-set switch

[10]

Y-axis zero-set switch

No.99MBA043A 1 - 3

Page 15

1 - 4 No.99MBA043A

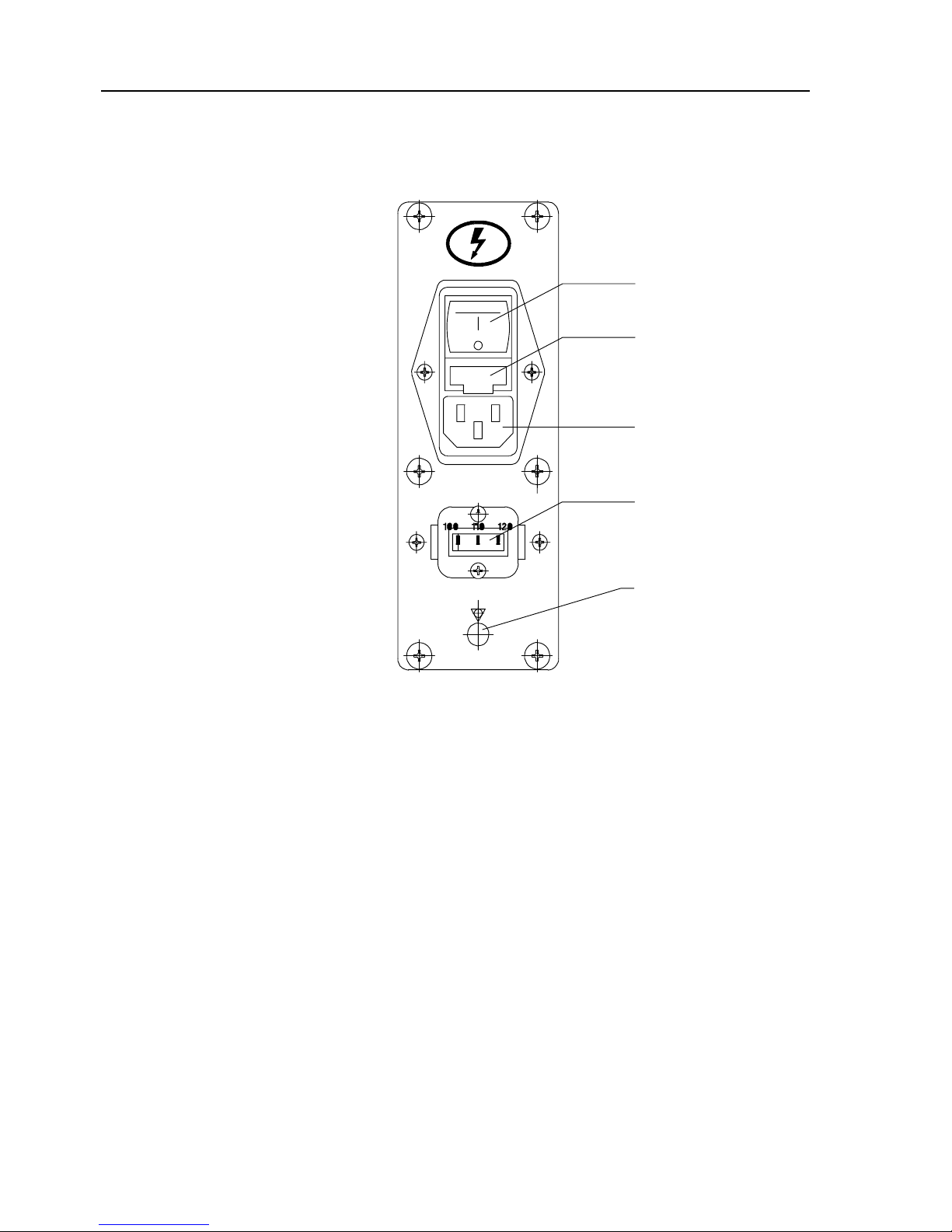

1.1.4 Power panel (Right lateral front part of main unit)

[5]

[2]

[1]

[3]

[4]

[1] Plug socket

[2]

Fuse holder

[3]

Voltage selector

[4]

GND terminal

[5]

Power switch

Page 16

Installation and Setup

This chapter describes the installation environments and connection

method of the PJ-A3000 series Measuring Projector.

2.1 Installation

2

2.1.1 Environmental Conditions

2.1.1.1 Temperature

The PJ-A3000 series Measuring Projector has been assembled and adjusted at 20°C in a

temperature controlled room. To ensure the rated measuring accuracy, the temperature at

the installation site must be maintained as close to 20°C as possible, with minimal

fluctuation. (For reference, the conditions specified by JMAS5011 are: 20°C ± 1°C with a

temperature gradient of less than 2°C per 8 hours.) In poor temperature conditions, the

accuracy performance may not be satisfied. It is illegal to make any machine adjustments

affecting the accuracy at ambient temperatures other than 20°C. After such adjustment,

accuracy is no longer guaranteed at 20°C.

2.1.1.2 Humidity

Humidity will not affect the measuring ac cur ac y directly. However, high humidity may

corrode machined surfaces and may adversely affect electronic parts. The environmental

humidity should be maintained within a range of 55% to 65%RH.

2.1.1.3 Dust and dirt

The PJ-A3000 series Measuring Projector consists of high-precision parts, including guide

faces, linear scale units, and optical unit, that must be kept free of dust and dirt. Use and

store the PJ-A3000 series Measuring Projector in a place where it w ill not be subjected to

dust and dirt.

2.1.1.4 Grounding

Connect the ground terminal with the ground terminal of grounding resistance 100 Ω or less

so that the measuring microscope may normally operate.

On the Reinstallation yyyyy The projector main unit reinstallation performed on the client's

own may deteriorate the required accuracy due to vibrations and shocks during

transportation. Therefore, it is recommended that the main unit be reinstalled by Mitutoyo. If

the system is desired to be reinstalled, be sure to contact the Mitut oyo sales office.

TIP

No.99MBA043A 2 - 1

Page 17

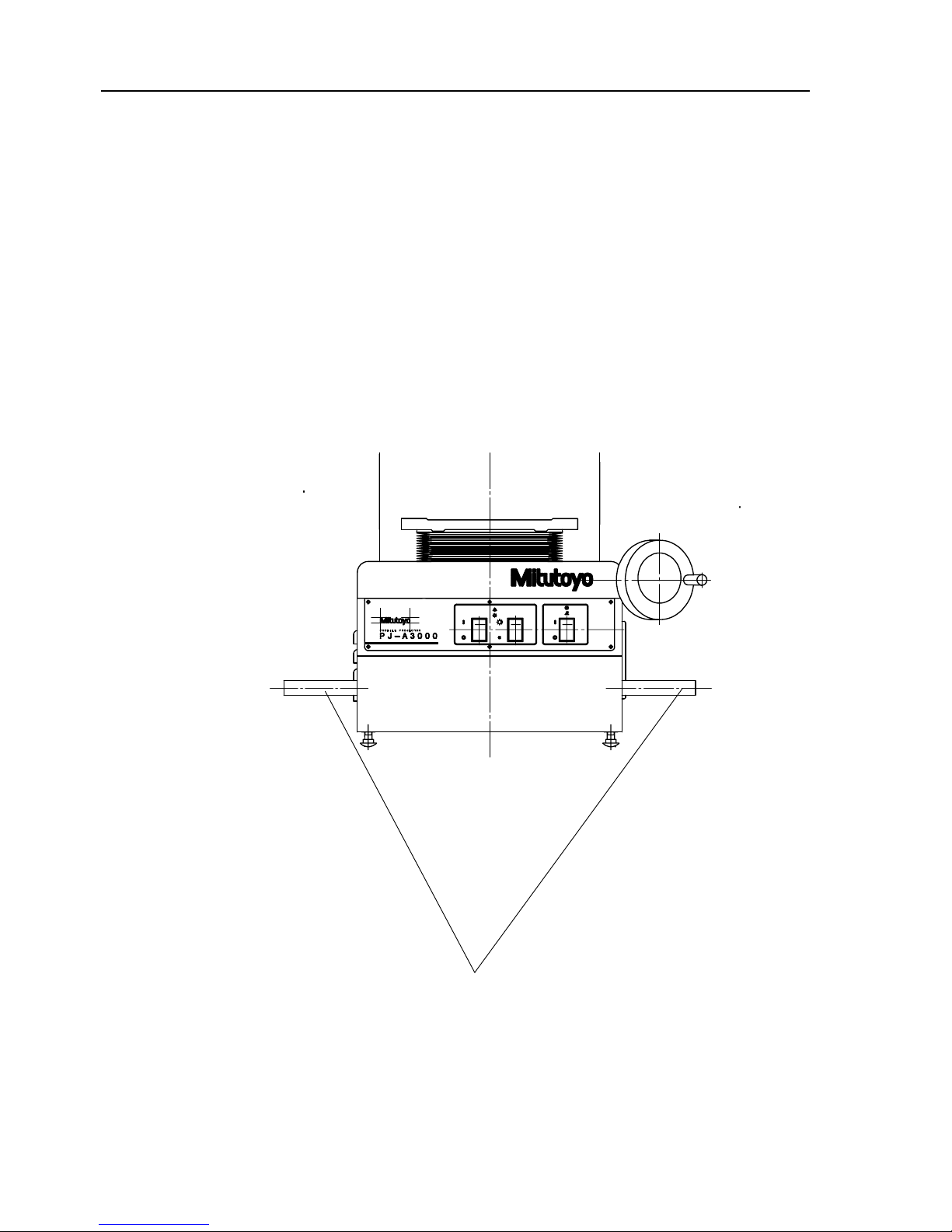

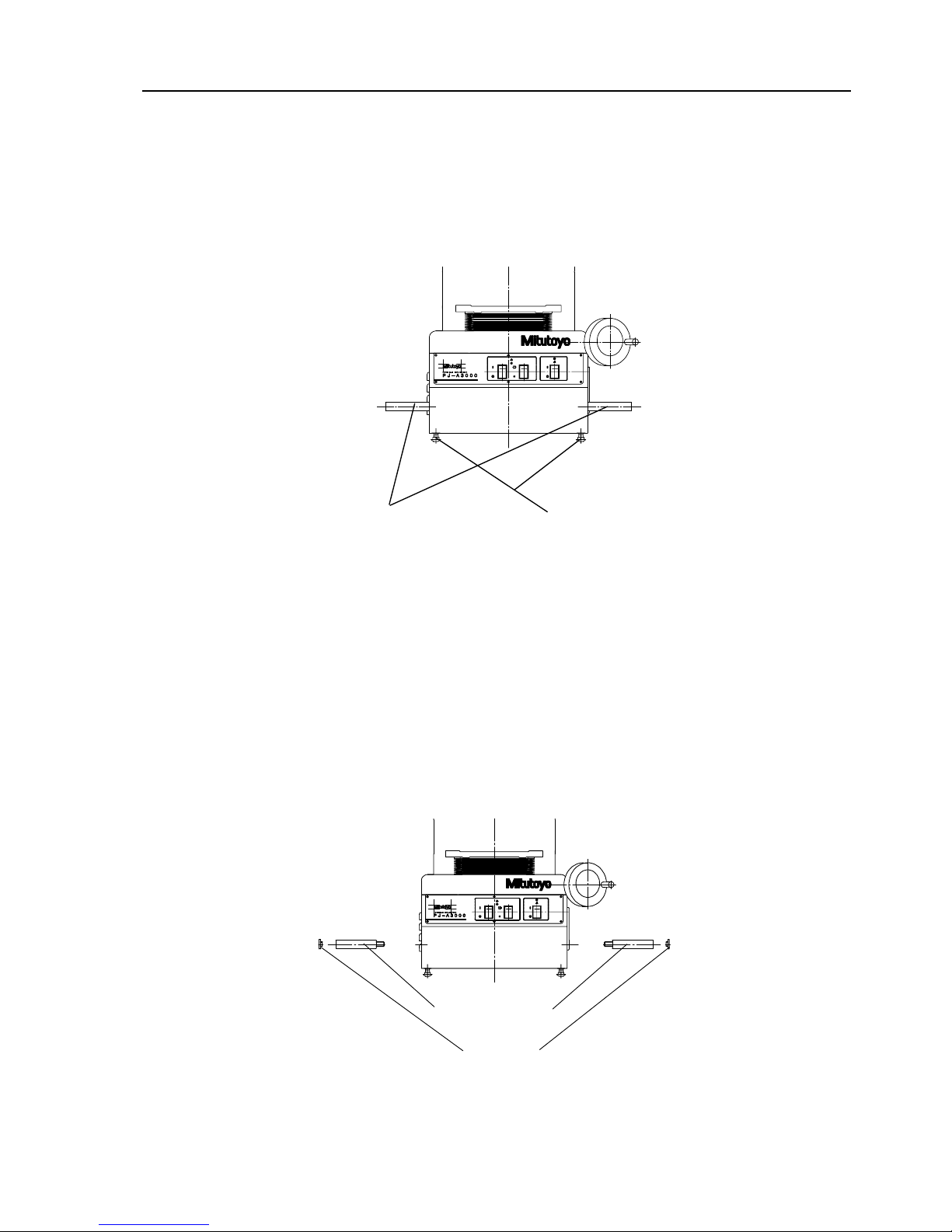

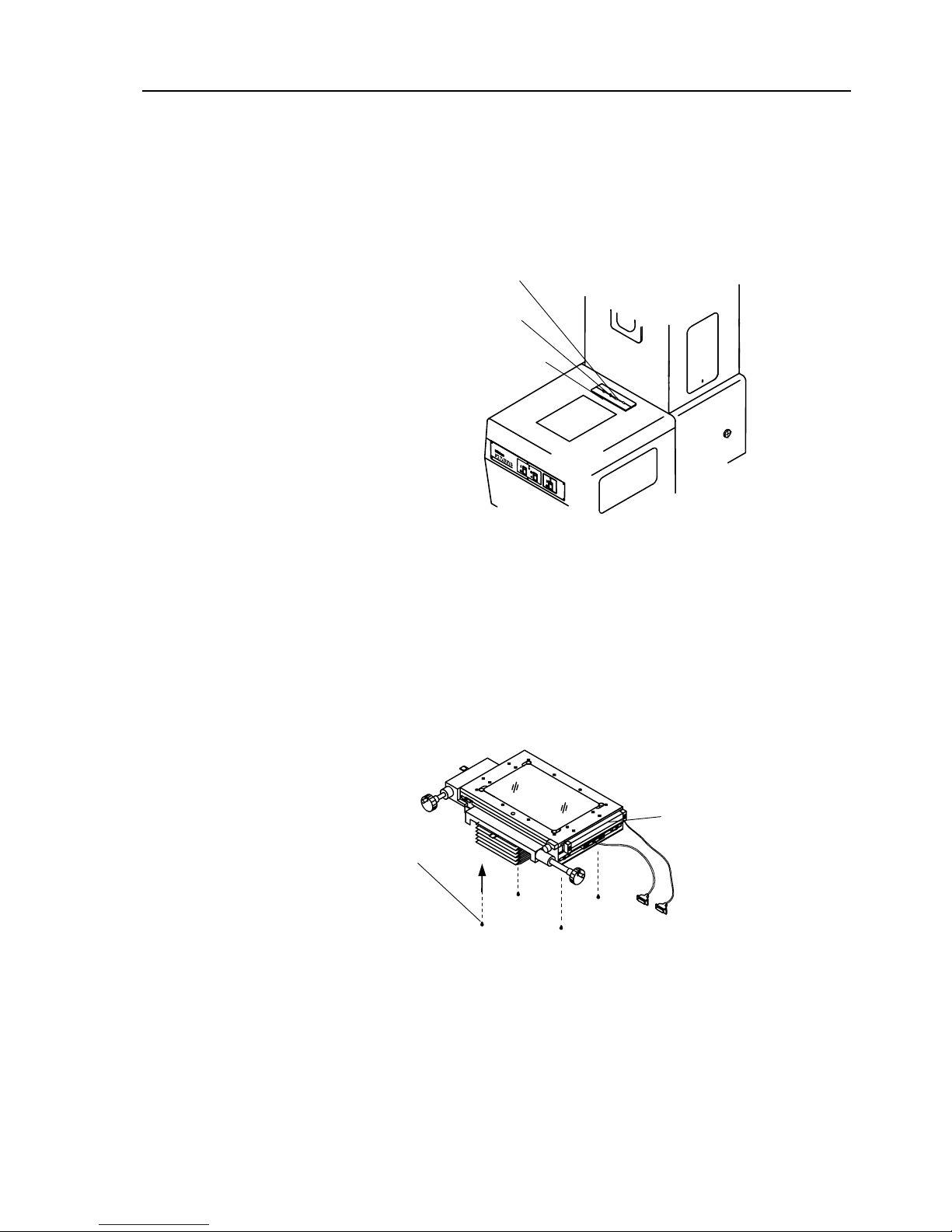

2.1.2 Transportation and installation

Be sure to use the supplied carrying handles when handling, shift ing or installing the projector

and due to its heavy weight (for PJ-A3010F-200, about 120kg) four people are required to

carry it. The PJ-A3000 series has been fully adjusted at the plant, therefore take special care

when handling and setting up the projector so that no part of the projector is subjected to

impact or vibration.

Carrying handles

2 - 2 No.99MBA043A

Page 18

2. Installation and Setup

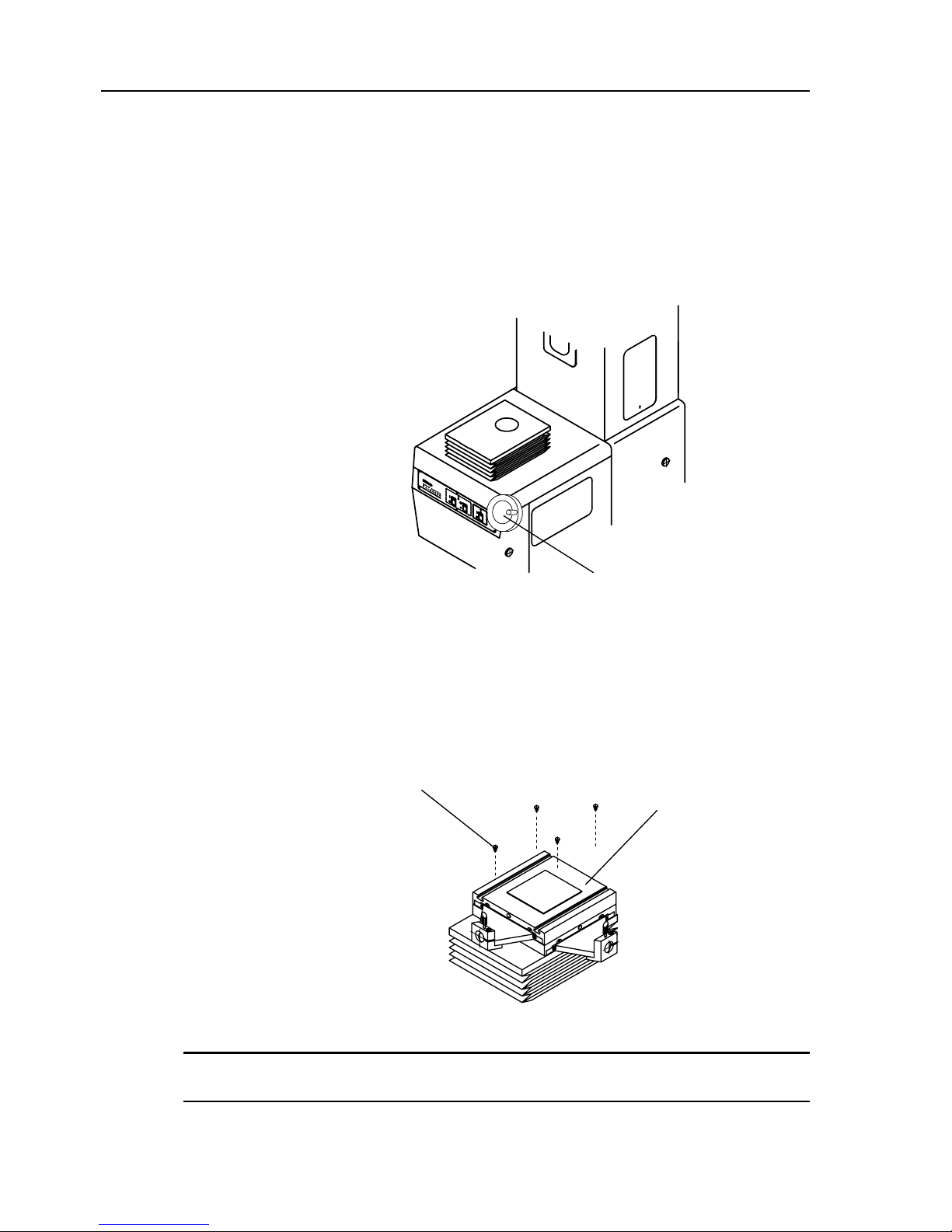

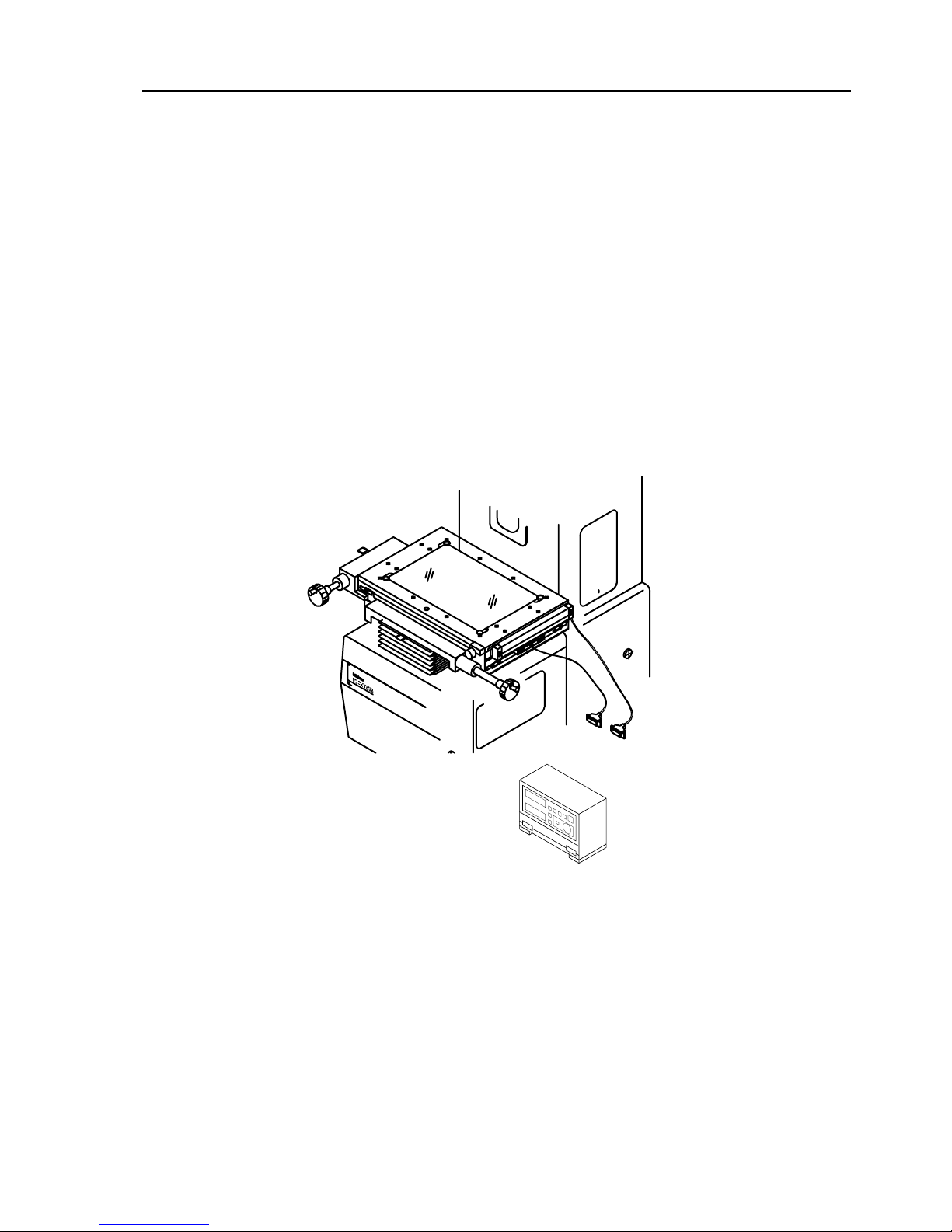

2.1.3 Setting up the main unit

The projector must be set up on the optional stand or a rigid, stable mount. Use the leveling

bolts on the projector base to compensate for any inclination.

Carrying handles

Leveling bolts

2.1.4 Removing the carrying handles

After setup, remove the carrying handles and cover the screw holes with the supplied hole

caps.

Hole caps

Carrying handles

No.99MBA043A 2 - 3

Page 19

2.2 Assembly

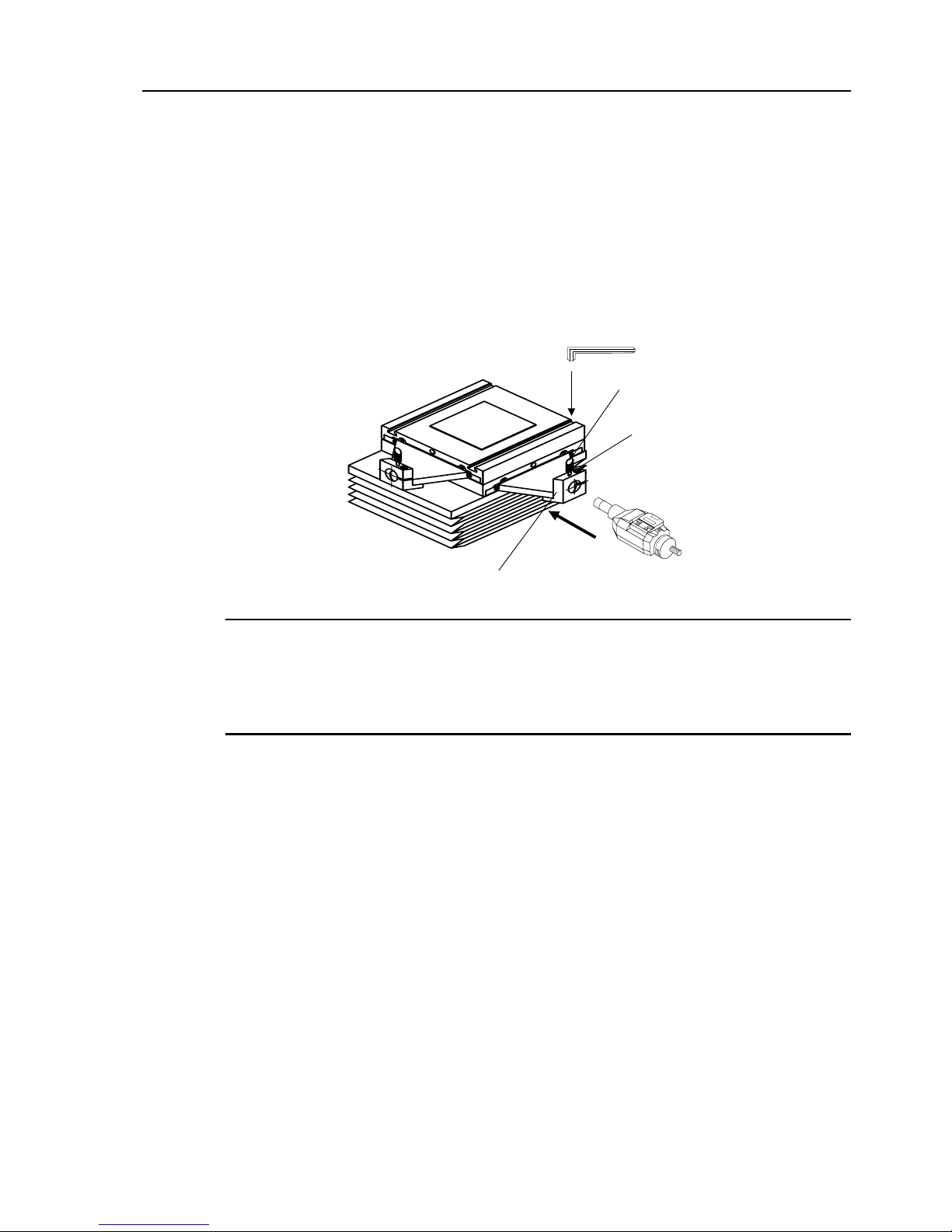

2.2.1 Installing the cross-travel stage and Digimatic Head (for PJ-A3005D-50)

1. Turn the focusing wheel clockwise to lower the cross-travel stage mount down to the

end of its displacement.

Focusing wheel

2. Gently place the cross-travel stage on the mount. Slide the moving sections to the

left and right to check the screw hole positions, then use the four hex-socket head

screws (supplied in the standard accessory box) to temporarily fix the cross-travel

stage in place.

Cross-travel stage

Hex-socket head screw

The cross-travel stage should be secured when the adjustment of its travel direction is complete.

(Refer to 2.5.2 Aligning the cross-travel stage travel direction to the cross-hair lines.)

TIP

2 - 4 No.99MBA043A

Page 20

2. Installation and Setup

3. Installing the Digimatic Head

y Loosen the clamp screw and hex-socket head screw on the bracket.

y Slowly insert the stem of the Digimatic Head into the bracket as far as it can go, then

secure it in place with the hex-socket head screw. Do not fasten the screw too tight,

otherwise the spindle of the Digimatic Head will not move smoot hly.

Hex-socket head screw

Bracket

Clamp screw

Allen spanner

Digimatic Head

y When using a Digimatic Head or other types of heads that are not provided with a hole to clamp

the spindle, the clamp screw is not used to secure it, lightly fasten the screw.

TIP

y The Micrometer Head is provided with a hole for damping the spindle. Align this hole with the

clamp screw. If the display is not in a good viewing position, loosen the clamp screw on the

Micrometer Head sleeve, and adjust the display position.

No.99MBA043A 2 - 5

Page 21

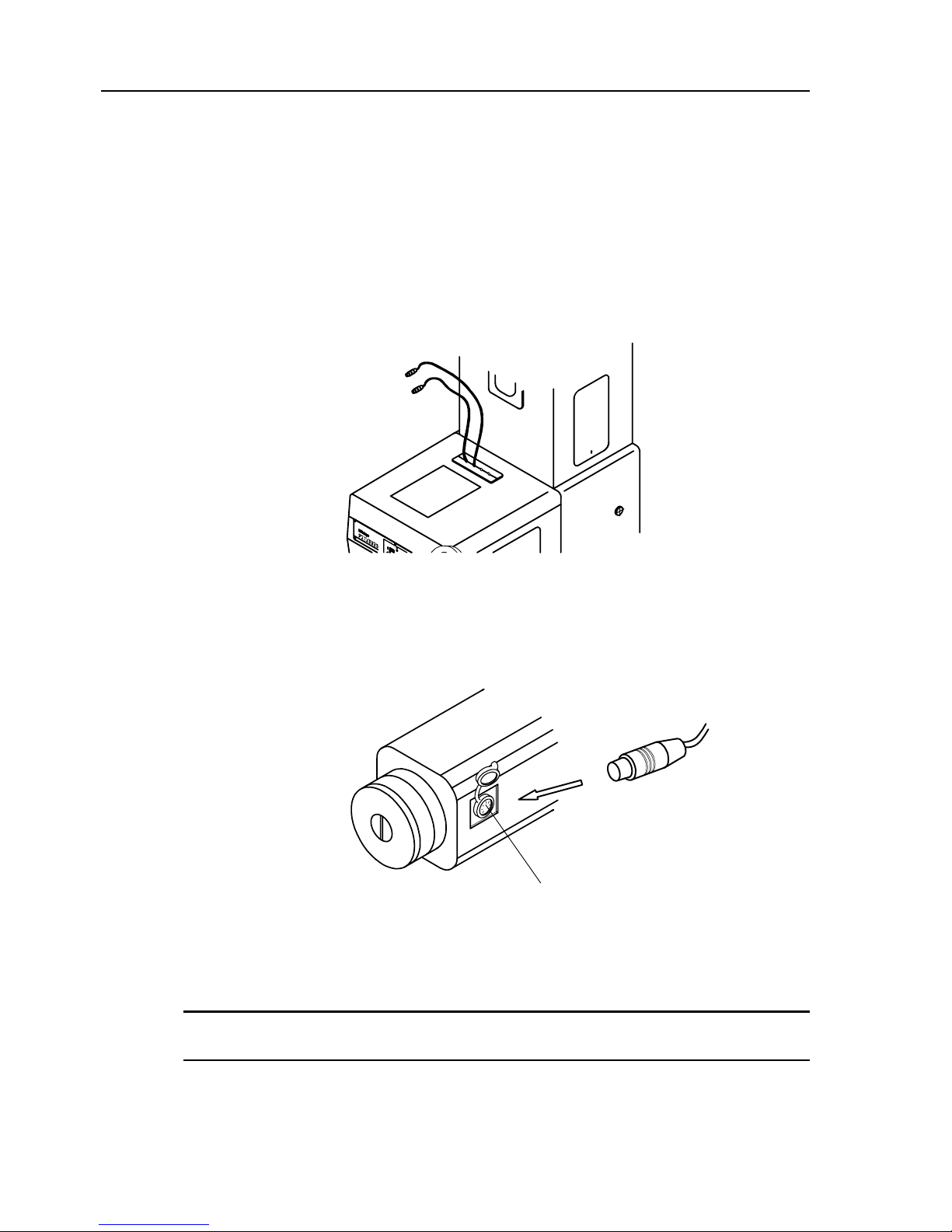

4. Connecting the Digimatic Head cables (for PJ-A3005D-50)

Remove the dust-prevention cap from the output connector on a side of the Digimatic

Head. Connect the cable for the counter to the output connector.

Output connector

Confirm sufficiently to connect so that the connection of X-axis and Y-axis may be not

wrong.

NOTE

2 - 6 No.99MBA043A

Page 22

2. Installation and Setup

2.2.2 Installing the cross-travel stage and connecting the Linear Scale cables

(for PJ-A3010F-200)

1. Remove the cable outlet cover.

Cable outlet cover

Y-axis

X-axis

2. Gently place the cross travel stage on the cross travel stage mount. Slide the

moving parts to the left and right to align the screw holes, then use the four

hex-socket head screws supplied to temporarily fix the cross travel stage in

place.

Hex-socket

head screw

Connector for

Linear encoder

Linear encoder

3. Rotate the focusing wheel to raise the cross-travel stage as far as it will go.

No.99MBA043A 2 - 7

Page 23

4. Place the linear encoder connector into the projector.

5.

Connect the signal cables from the circuit board in the projector to the connector.

6. Attach the cable outlet cover.

Connector for

Linear encoder

The cross-travel stage should be secured when the adjustment of its travel direction is complete.

(Refer to “2.5.2 Aligning the cross-travel stage travel direction to the cross-hair lines”.)

TIP

2 - 8 No.99MBA043A

Page 24

2. Installation and Setup

2.2.3 Connecting the Optoeye A2 Image Edge Sensor for PJ-3010F-200

1. Remove the cable outlet cover.

2. Disconnect the linear encoder connectors from the P.C.B inside the Profile Projector.

3. Attach the cable outlet cover.

4. Connect the linear encoder connectors to the Optoeye A2 Counter.

Connector for

Linear encoder

Optoeye A2 Counter

No.99MBA043A 2 - 9

Page 25

2.2.4 Mounting the projection lens

1. Remove the lens mount cap and the projection lens cap.

2. Hold the lens so that the red index dot of the projection lens faces you. Align the

index dot of the projection lens with that of the lens mount, push the projection lens

upwards, then rotate the lens clockwise approximately 60° until the lens stops.

Projection lens

Front view From right side view

Red index dot

Red index dot

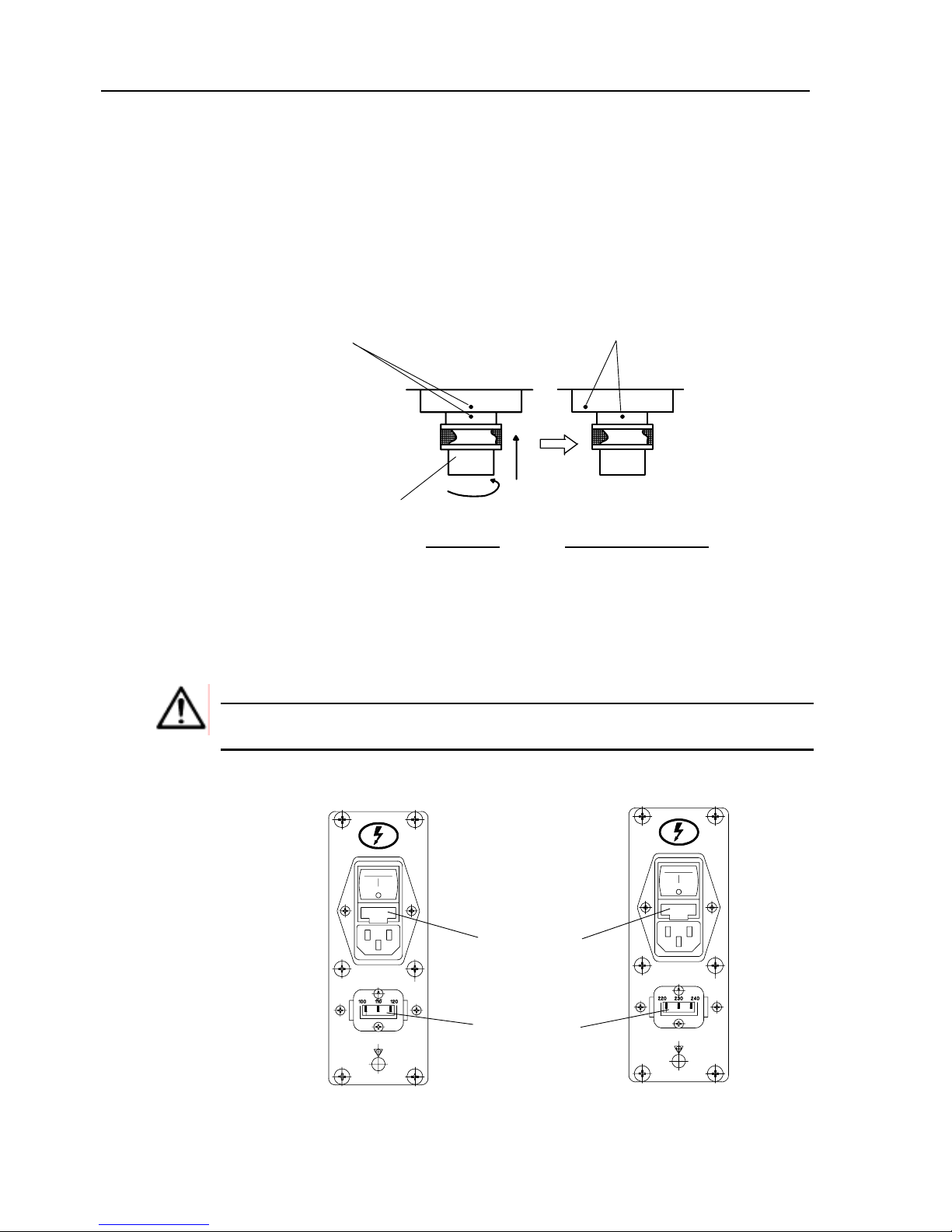

2.2.5 Setting the power voltage

Set the voltage selector plug to the supply voltage as follows.

Be sure to unplug the power cord before setting the voltage selector.

Set the voltage selector at the rated voltage.

CAUTION

100 VAC-system

Fuse holder

Voltage selector

200 VAC-system

2 - 10 No.99MBA043A

Page 26

2. Installation and Setup

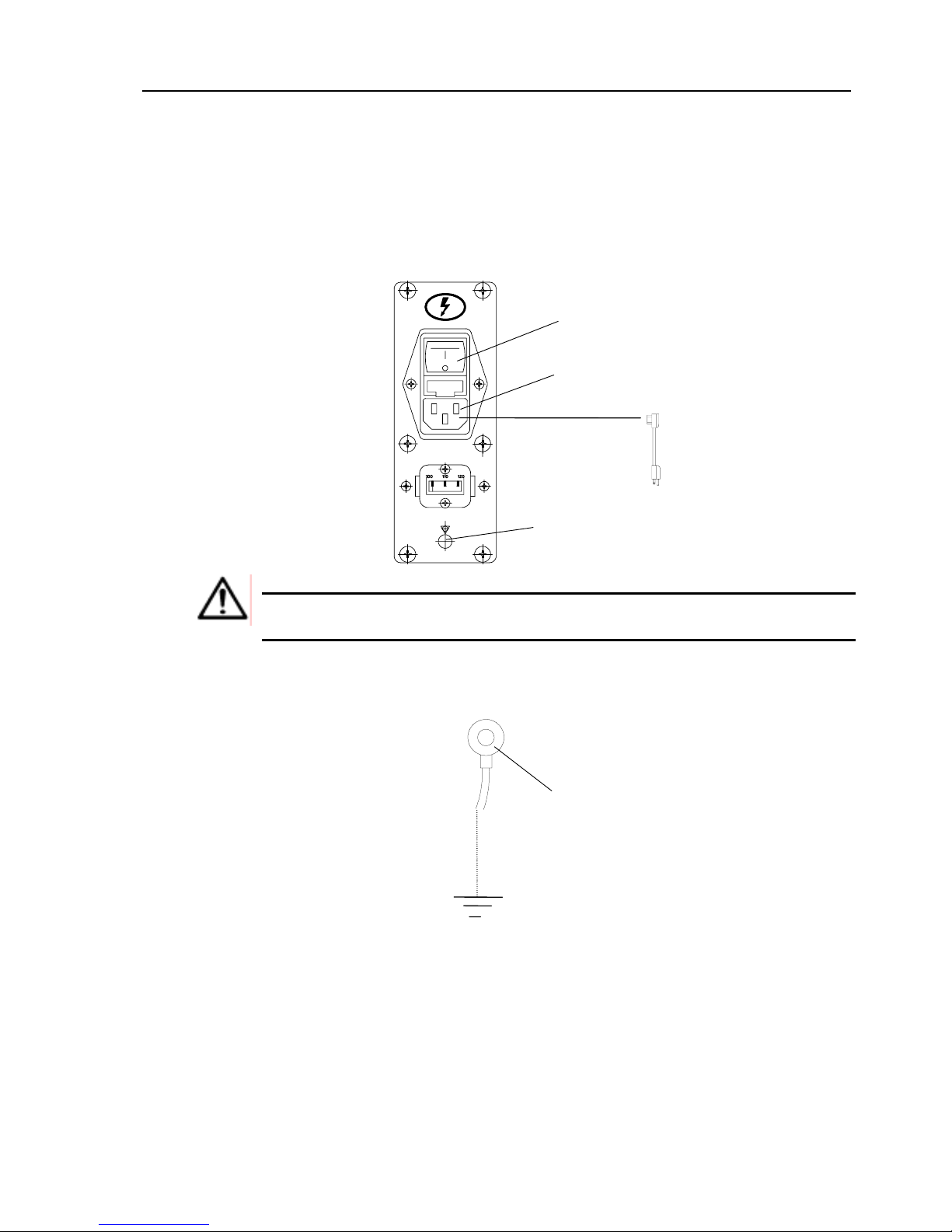

2.2.6 Connecting the power cord

1. Turn off the main switch.

2. Connect the power cord to the power panel and plug it into the power outlet.

GND

Plug socket

Main switch

Power cord

Use the power cord supplied with the projector.

Use the GND terminal for grounding.

CAUTION

GND terminal

No.99MBA043A 2 - 11

Page 27

2.3 Initial Checks (Functional Check)

Each projector is factory-inspected and adjusted, and has been safeguarded at all stages of

shipment and transport, but prior to first time use, perform the following checks.

NOTE

While checking cables, make sure that all switches are tuned OFF.

2.3.1 Electrical component connectors

Make sure that the power cord, plug socket, voltage selector, power switch, and GND

terminal are securely connected.

2.3.2 Main switch (ON-OFF)

• Does the switch operate normally?

• Does the fan motor operate?

2.3.3 Switches for Contour illumination and reflected illumination

Contour illumination switch : OFFÎON

Contour illumination brightness selector

: HIGHÎLOW

Reflected illuminator switch

: OFFÎON

• Do the switches operate normally?

• Do the illumination bulbs turn on?

• Does the brightness change normally?

2.3.4 Focusing wheel

Turn the wheel.

• Is there any play or noise?

2 - 12 No.99MBA043A

Page 28

2. Installation and Setup

2.3.5 Cross-travel stage

• Is the stage glass clean and free of scratches?

Move the stage by hand over its full range.

• Does it move smoothly?

• Is there any play or noise?

(Use the Micrometer Head to move the cross-travel stage and check the above

points.)

2.3.6 Projection screen

• Is the screen glass clean and free of scratches?

• Do the fine adjustment knob, clamp and chart clips work correctly?

2.3.7 Others

• Check the other parts of the projector and accessories for appearance and

functionality. (Refer to "5.Maintenance" in case of any malfunction.)

No.99MBA043A 2 - 13

Page 29

2.4 Initial Checks (Performance Check)

2.4.1 Checking the position of the contour illumination bulb filament

1. Carefully remove the projection lens.

2. Turn on the power switch and contour illumination switch to project the filament

of the contour illumination bulb on the screen.

3. Confirm that the filament image is projected in the approximate center of the

screen.

2.4.2 Checking the position of the surface illumination bulb filament

1. Carefully remove the projection lens.

2. Rotate the frame of the surface illuminator condenser lens clockwise until it is

fully inserted.

3. Place the half-reflecting mirror (for 10x or 20X lens) on the cross-travel stage.

Adjust the mirror position so that the light from the reflected illuminator is

reflected at right angles. Adjust t he reflected illuminator position so t hat the light

beam is directed at the center of the mirror.

4. Turn on the main switch and contour illumination switch to project the filament of

the contour illumination bulb on the screen.

5. Confirm that the filament image is proj ected in the approximate center of the

screen.

2 - 14 No.99MBA043A

Page 30

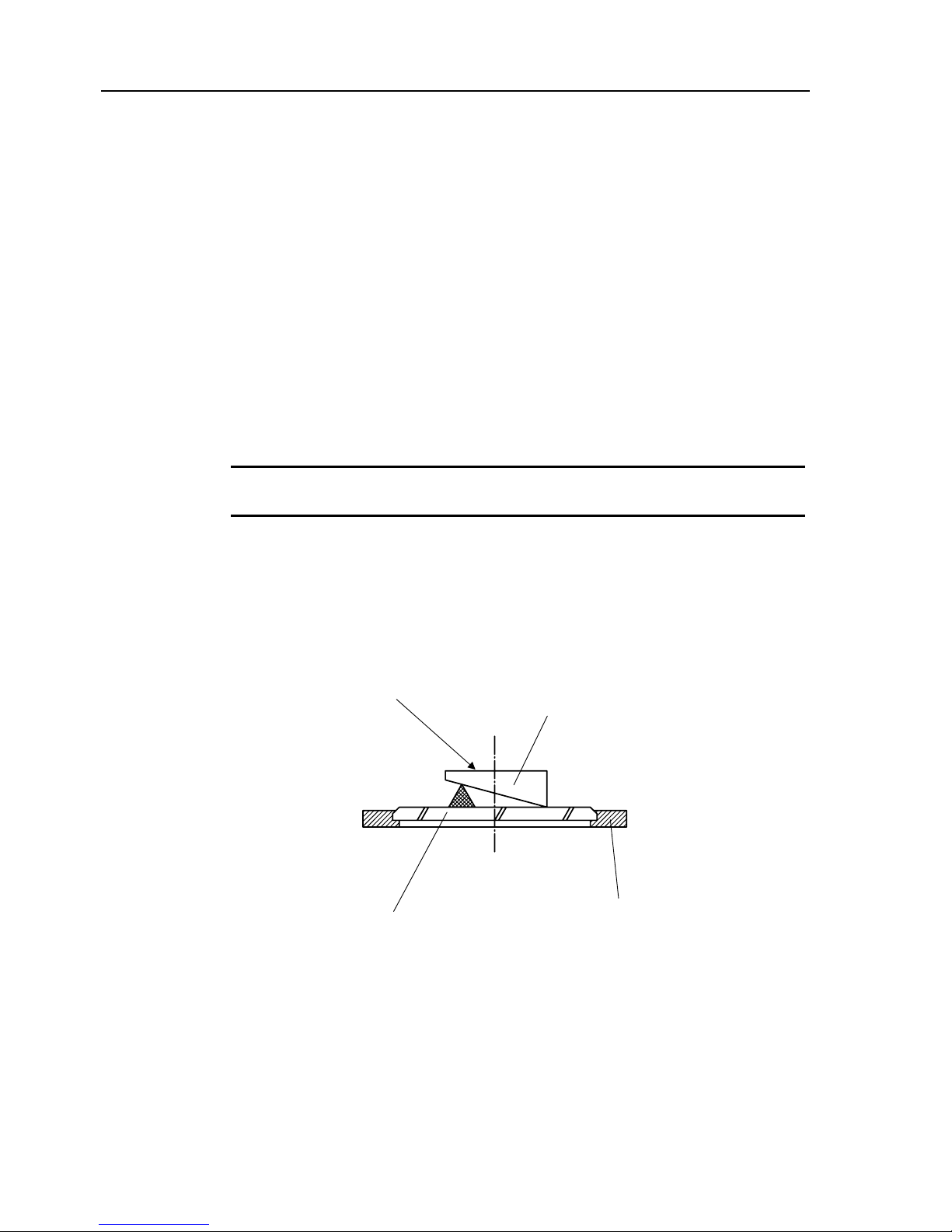

2. Installation and Setup

Clamp knob

Frame of the reflected

illumination condenser

lens

• For the vertical position adjust ment of reflected illuminator, loosen the clamp knob to adjust with t he

clamp knob or the frame of reflected illumination condenser lens.

No.99MBA043A 2 - 15

Page 31

2.4.3 Projection with contour illumination

1. Turn on the contour illuminat ion bulb.

(Use the brightness selector switch (HIGH and LOW) to select the light intensity.)

2. The workpiece profile is projected on the screen.

Projection screen

Workpiece profile

2 - 16 No.99MBA043A

Page 32

2. Installation and Setup

2.4.4 Projection with reflected illumination

1. Turn on the reflect ed illuminat ion bulb.

2. The image of the workpiece surface is projected on the screen.

3. Mount the half-reflecting mirror at the top of the projection lens frame so that the mirror

is aimed towards the surface illuminator, as shown below. Use the frame of the

reflected illumination condenser lens or the clamp knob to adjust the height of the

reflected illuminator so that the light beam is directed t o the surface of the w orkpiece.

NOTE

Refer to Note in p.2-15 for the operation of the vertical position adjustment of

reflected illuminator.

Projection lens

Half-reflecting mirror

Reflected illuminator

Projection screen

Workpiece profile

No.99MBA043A 2 - 17

Page 33

2.4.5 Color fitter

This filter reduces eye fatigue. See the following for the insertion method.

Color fitter

Main unit left side

2 - 18 No.99MBA043A

Page 34

2. Installation and Setup

2.4.6 Checking the magnification accuracy

1. Mount the projection lens. (Refer t o “2. 2. 4 Mount ing t he project ion lens”)

2. Place a standard scale (optional accessory, No. 172-116) on the cross-travel stage to

project its image on the screen.

3. Measure the projected image of the standard scale on the screen using a reading scale

(optional accessory, No. 172-161 ).

4. Take measurements at two reference points (100mm, 140mm) in four or more radial

directions along the cross-hair lines on the screen.

5. Calculate the magnification error using the following formula.

∆M =X 100 %

lM

L - lM

∆M

: magnification error

L : measured length of the standard scale

l :

length of the standard scale

M :

magnification of the projection lens

No.99MBA043A 2 - 19

Page 35

The magnification error is specified as

±0.1% or less for contour illumination, and the

tolerance for each measured point is tabulated below. (If the magnification error for

contour illumination falls within the tolerance, that for reflected illumination will also fall

within the specified tolerance of

±0.15%)

Measured point

(on the reading scale)

Tolerance Permissible range

100 mm

140 mm

±0.1 mm

±0.14 mm

99.9-100.1 mm

139.86-140.14 mm

TIP

A positive error, i.e. where ∆M is a positive value, m eans that the measured length L is

larger than the normal size (l×M), and vice versa for a negative error.

2 - 20 No.99MBA043A

Page 36

2. Installation and Setup

2.4.7 Checking the cross-travel stage travel direction

1. Mount the least magnified projection lens.

2.

Place a reference piece on the stage to project its image on the screen.

Stage glass

Reference piece

Cross-travel stage

3. Set the protractor screen reference line to "0".

“0” line

Screen rotation knob

Clamp knob

No.99MBA043A 2 - 21

Page 37

4. Move the cross-travel stage along the Y-axis (back and forth), and align the edge of the

reference piece with the horizontal cross-hair line.

5. Move the cross-travel stage along the X-axis (left and right), and confirm that the edge

of the reference piece is aligned with the horizontal cross-hair line over the entire length

of stage X-axis travel.

Projection screen

Cross-hair line

(horizontal)

Reference piece

• If a deviation from the horizontal cross-hair lines is observed, refer to 2.5 Adjustment for

remedy.

2 - 22 No.99MBA043A

Page 38

2. Installation and Setup

2.4.8 Checking the cross-travel stage feed error

If the stage moves normally in 2.4.7, checking of feed error over a 5 mm travel may be

sufficient. In this checking, many factors must be taken into consideration, including

environmental conditions and alignment error.

Any feed error should be less than 0.01 mm per 5mm of travel.

1. Mount a projection lens.

2. Place a standard scale or other reference of known size on the cross-travel stage

to project its image on the screen.

3. Feed the stage and determine the feed error by measuring the standard scale

along the X-axis (left-right) and Y-axis (front-rear).

4. Check the feed error in the opposite travel directions (i.e. returning directions) for

both X- and Y-axes.

• Contact Mitutoyo if the error is excessive.

2.4.9 Checking the resolution (in contour illumination mode)

1. Mount a projection lens.

2. Place a workpiece on the cross-travel stage and project its image on the screen.

Ensure that the image is clear over the entire screen without any obscured regions.

• Refer to 4.4.4 if an obscure region is present.

No.99MBA043A 2 - 23

Page 39

2 - 24 No.99MBA043A

2.5 Adjustment

Read this section as required after reading “2.3 Initial Checks (Function Check)” and “2.4

Initial Checks (Performance Check)”.

2.5.1 Adjusting the magnification

Magnification adjustment requires experience. When the adjustment of a projection lens

is required, contact Mitutoyo for assistance.

2.5.2 Aligning the cross-travel stage travel direction to the cross-hair lines

1. With the cross-travel stage mounting screws fastened but not tightened, carefully swivel

the stage so that the reference piece does not deviate from the horizontal cross-hair line

of the screen while feeding the stage in the X-axis direction.

Cross-travel stage

Reference piece

Sta

ge g

lass

2. When the adjustment is complete, tighten the stage mounting screws. Re-check the

stage travel direction.

Projection screen

Reference

p

iece

Cross-hair line of

the screen

2.5.3 Centering the protractor screen

• This adjustment is performed by Mitutoyo service personal.

Page 40

Operation

This chapter explains the setup for measurement including the

optical system installation and workpiece set-up.

3

3.1 Projection Lens Selection

3.1.1 Selecting the projection lens

Select the appropriate projection lens magnification according to the required field of view,

measuring method and accuracy requirements. (Refer to “6. Specifications”.)

10X 20X

50X 100X

20X

10X

Built-in

Half-reflecting

mirr

o

r

Half-reflecting mirror

Oblique mirror for rough surface

No.99MBA043A 3 - 1

Page 41

3.1.2 Replacing the projection lens

This projector has adopted the fixed focus lens to 10X to 100X.

When replacing the projection lens in order to change the magnification, it is required to

switch the condenser lens according to the magnification of projection lens.

3.2 Mounting the Workpiece

Mount a workpiece on the stage glass or use a fixture or a jig to hold it in position. Use the

T-grooves for securing fixtures and jigs to the cross-travel stage.

TIP

The surface or contour to be projected must face the projection lens. Position the surface

to be measured so that it is normal to the optical axis of the projection lens.

Cross-travel stage

Workpiece

Surface to be measured

Stage glass

3 - 2 No.99MBA043A

Page 42

3. Operation

• For cylindrical workpieces : V-block and clamp (No. 172-378)

• For light-weight, flat workpieces which are difficult to fix : Clamp (No.176-107)

• For screws or cylindrical workpieces with center holes : Swivel center support

(No.176-105, No.172-197)

• Detach the stage glass, when the Swivel center support is installed. (refer to “5.3.3”)

Swivel center support

Workpiece

Stage glass

T-groove

T-groove

Cross-travel stage

Cross-travel sta

g

e

Workpiece

Clam

p

V-block and clam

p

Workpiece

Stage glass

No.99MBA043A 3 - 3

Page 43

3.3 Focusing and Positioning the Workpiece

3.3.1 Focusing

Bring the workpiece into focus by rotating the focusing wheel to move the cross-travel

stage up and down.

Projection lens

Focusing wheel

NOTE

Be careful not to bump the Projection lens against a workpiece or fixture during

focusing. Pay special attention when an stepped workpiece is mounted, or when

the workpiece is supported by a swivel center support or a V-block.

3 - 4 No.99MBA043A

Page 44

3. Operation

3.3.2 Positioning the workpiece

When the image is in focus on the screen, align the measured edge of the workpiece to

the measuring axis of the cross-travel stage. Move the workpiece or the fixture so as to

align the workpiece image with the cross-hair lines on the screen.

• Rotary table (No.176-106, 172-196) is suitable for performing alignment.

No.99MBA043A 3 - 5

Page 45

3.4 Measurement and Inspection

The measuring method for each application should be determined by the measurement

factors involved : shape, size and quantity of workpieces, purpose, required accuracy, etc.

The following methods are basic examples and can be developed further depending on

the particular requirement.

3.4.1 Rectangular coordinate measurement (with the X, Y counter)

Use the cross travel of stage to make dimensional measurements.

Align the datum point of the workpiece with a cross-hair line and take a reading off the

Micrometer Head or built-in counter. Move the cross-travel stage to align the point to be

measured to the same cross-hair line and take a reading. The difference between the two

readings is the dimension of the workpiece (or the distance between the two points).

Dimension

3 - 6 No.99MBA043A

Page 46

3. Operation

• Operation

Operation When using the X, Y counter (PJ-A3005D,

PJ-A3005F, PJ-3010F)

Move the stage so that one

end of the workpiece is

aligned with the cross-hair.

Press the zero button of

the X-axis to set the

counter to zero.

Move the stage so as to

align the other end of the

workpiece with the

cross-hair.

Take a reading from the

counter.

Zero setting

Dimension is displayed

NOTE

The following procedure must be performed on the PJ-A3005D-50:

Set the Digimaldc Head to zero when the counter has been zeroed. Otherwise, the

displayed values on the counter and Digimatic Head will not be the same.

No.99MBA043A 3 - 7

Page 47

• X, Y-axis counter (PJ-A3005D-50, PJ-A3010F-100, PJ-A3005F-150, PJ-A3010F-200)

1

mm/E indicator or inch/mm indicat or The LED for the active unit is lit.

PJ-A3005D

PJ-A3005F

2 X-axis counter Resolution

PJ-A3010F

0.001 mm

PJ-A3005D 0.001 mm

PJ-A3005F 0.001 mm

3 Y-axis counter Resolution

PJ-A3010F 0.001 mm

4 X-axis zero-set switch

Sets the X-axis counter to zero at any X- axis

position of the stage.

5 Y-axis zero-set switch

Sets the Y-axis counter to zero at any Y-axis

position of the stage.

[1]

X, Y-axis counter

[4]

[5]

[2]

[3]

TIP

A value in units of E is displayed by dividing a displacement in units of mm by 25.4.

3 - 8 No.99MBA043A

Page 48

3. Operation

3.4.2 About parameters

To actually perform measurement, it is necessary to set up the count direction (count-up or

count-down direction), resolution, etc. Also, if setting compensation constant s for measuring errors

generated according to mechanical operation and various conditions, you can make a

measurement more easily and correctly. These conditions and constants are referred to as

parameters. This subsection describes the function and setting procedure of each parameter.

(1) Function

Some parameters are effective for all axes and other parameters are necessary to be set for each

axis. All axes

is described for the parameters that are effective for all axes and Individual axis

is described for the parameters to be set for each axis, respectively, in the Setting column of the

following table.

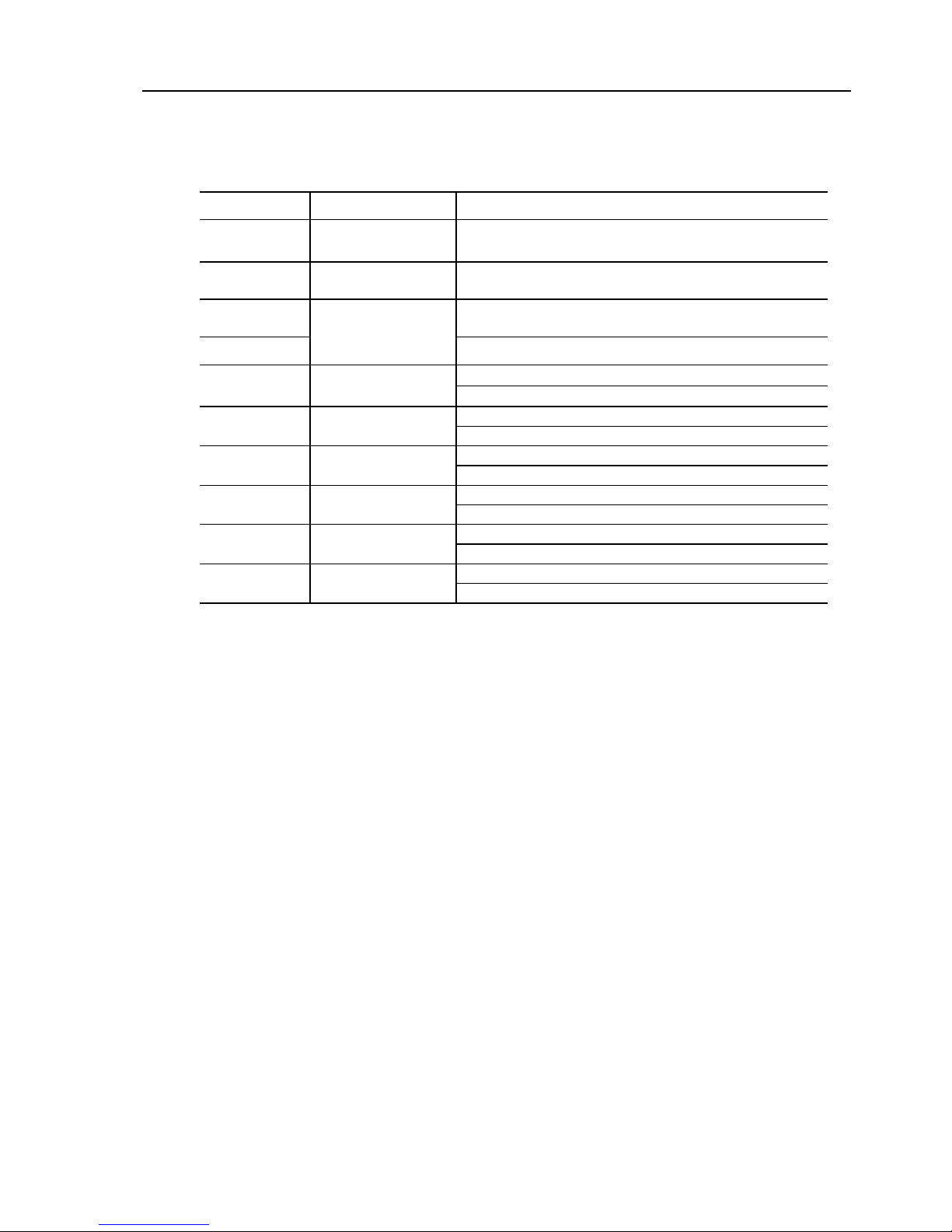

No. Parameter function Setting

F1

Display unit [mm/E (inch)] setup

All axes

Each time the Q-axis zero-set button on the

counter is pressed, the count unit display

LED [mm] or [E] is selected (lit) alternately.

F2.1

Count direction of X-axis(count-up or

count-down direction) setup

F2.2

Count direction of Y-axis(count-up or

count-down direction) setup

Individual axis

Each time the Q-axis zero-set button on the

counter is pressed, the display of [UP] or

[dn] is selected (displayed) alternately and

the count direction is switched.

F4.1

Linear error correction value setup for

X-axis

F4.2

Linear error correction value setup for

Y-axis

Individual axis

0 :No correction

20 :Correction value of 20mm/m

40 :Correction value of 40mm/m

80 :Correction value of 80mm/m

160 :Correction value of 160mm/m

320 :Correction value of 320mm/m

-20 :Correction value of -20mm/m

-40 :Correction value of -40mm/m

-80 :Correction value of -80mm/m

-160 :Correction value of -160mm/m

-320 :Correction value of -320mm/m

For the projectors of the type using Digimatic Head, pay attention to next points.

1.

Be sure to use after the setup of No. F1 par amete r ( s etup of the display unit ) and Digimatic

Head are agreed.

NOTE

2.

It is not possible to reverse the counting direction by the counter, because No. F2.1 and F2.2

parameter ( setup of the count direction ) are invalid.

3.

Use as correction quantity set value "0", because No. F4.1 and F4.2 parameters ( linear error

correction ) are invalid.

No.99MBA043A 3 - 9

Page 49

No. Parameter function Setting

F5

Setup for the number of smoothing

times

(Smoothing : Function to suppress

flickering of the least significant digit by

averaging detected values for several

times of sampling, if these LED display

values are difficult to read due to

flickering caused by vibration, etc., of

the installation site.)

All axes

1 : One time of sampling

8 : 8 times of sampling

16 : 16 times of sampling

32 : 32 times of sampling

F7.1

RS-232C communication condition

setup

[Baud rate]

1200 bPS : 1200 bps

2400 bPS : 2400 bps

4800 bPS : 4800 bps

9600 bPS : 9600 bps

19200 bPS : 19200 bps

F7.2

RS-232C communication condition

setup

[Data length]

7 b : 7 bits

8 b : 8 bits

F7.3

RS-232C communication condition

setup

[Parity]

non : None

En : Even

odd : Odd

F7.4

RS-232C communication condition

setup

[Stop bit]

1 b : 1 bit

2 b : 2 bits

F7.5

RS-232C communication condition

setup

[Flow control (Xon/Xoff)]

on : (Xon/Xoff) enabled

OFF : (Xon/Xoff) disabled

F8

Setup for the number of output axes

(Sets the serial output to either two-axis

of X and Y or three-axis of X, Y, and Q)

2AS : X,Y-axis

3AS : X,Y,Q-axis

F9

RS-232C output format setup

(Sets RS-232C data to the output format

of Mitutoyo data processing unit

MPK-9/7/5)

1 : MPK-9/7/5 specification

2 : Special use

For the projectors of the type using Digimatic Head, pay attention to next points.

NOTE

Use as one time of sampling, because No. F5 parameter ( setup for the number of

smoothing times ) is invalid.

1.

Use the setting "1" at No. F9 parameter. The setting "2" is the special use.

NOTE

2. No. F10 to F13 parameters are the special use.

Don't modify the setting (the initial value is "1" for F10, "2" for F11, "1" for F12, and "1"

for F13).

3 - 10 No.99MBA043A

Page 50

3. Operation

(2) Parameter setting procedure

Q-axis

Y-axis display unit

X-axis displa y unit

Parameter

setup

example

Button

operation

Q-axis display Operating procedure

cStarting the

parameter

setup mode

MODE

+

ABS/INC

Hold down the “MODE” and

“ABS/INC” buttons at a time

more than 3 seconds.

dSwitching

parameters

MODE

F1 → F2.1 → ∙∙∙

F8 → F9 → ∙∙∙

Each time the “MODE” button is

pressed, the parameter display

changes to the next in

incremental order. The

parameters are looped.

eSwitching

parameter

settings

ZERO

0.1 → 0.5 → 1.0 → 0.1 ∙∙∙

(For a resolution)

Each time the Q-axis zero-set

button is pressed, the parameter

setting changes to the next. The

parameter settings are looped.

fExiting the

parameter

setup mode

(Loading the

set content)

MODE

+

ABS/INC

Hold down the “MODE” and

“ABS/INC” buttons at a time

more than 3 seconds.

NOTE

The set content is not memorized in the counter , if tur ning the power switch of

projector off without performing the operation of f. Be sure to perform the

operation of

f when setting the parameter.

(3)

Correction of the angle counter

Correct the angle counter in order to perform the accurate measurement, before it is used for the

first time.

1.Turn the power switch ON, while the “ABS/INC” button of angle counter is pressed.

2. Adjust the intersection point with the cross hairs of screen glass and index to continue

pressing the angle display zero-set key for about three seconds. (I t is possible to perform the

zero-set at the condition of ABS mode.)

No.99MBA043A 3 - 11

Page 51

3.Rotate the screen glass so that the rotation knob and the display of angle counter is counted

in the plus direction. Revolve the screen glass to adjust the cross hairs of screen glass with

the index once again.

4.The angle counter is corrected, when the display unit switching key and the angle display

zero-set key are pressed in the condition of step 3 simultaneously. (The display is 360

°00’ or

360.00

°.)

• The correction value after the correction is preserved even if the power switch is turned OFF.

• The correction is not possible, when the screen glass is rotated in the negative direction.

3 - 12 No.99MBA043A

Page 52

3. Operation

Parameter

setup

example

Button

operation

Counter display Operating procedure

Setting the

display unit

(Selecting mm)

MODE

ZERO

1.Press the “MODE” button to

select parameter [F1].

2.Press the “ZERO” button to

select [mm].

Setting the

count direction

(Reversing the

count direction

of X-axis)

MODE

ZERO

1.Press the “MODE” button to

select parameter [F2.1].

2.Press the “ZERO” button to

select the setting (here [dn])

unlike present setting (here

[UP]).

Setting the

count direction

(Reversing the

count direction

of Y-axis)

MODE

ZERO

1.Press the “MODE” button to

select parameter [F2.2].

2.Press the “ZERO” button to

select the setting (here [UP])

unlike present setting (here

[dn]).

Setting the

linear error

correction

value(Selecti ng

the X-axis

correction value

of 40mm/m)

MODE

ZERO

1.Press the “MODE” button to

select parameter [F4.1].

2.Press the “ZERO” button to

select [40].

Setting the

linear error

correction

value(Selecti ng

the Y-axis

correction value

of 20mm/m)

MODE

ZERO

1.Press the “MODE” button to

select parameter [F4.2].

2.Press the “ZERO” button to

select [20].

Setting the

number of

smoothing

times(Selecting

8 times of

smoothing)

MODE

ZERO

1.Press the “MODE” button to

select parameter [F5].

2.Press the “ZERO” button to

select [8].

No.99MBA043A 3 - 13

Page 53

Parameter

setup

example

Button

operation

Counter display Operating procedure

Setting the

RS-232C

communication

condition(Selectin

g a baud rate of

9600bps)

MODE

ZERO

1.Press the “MODE” button to

select parameter [F7.1].

2.Press the “ZERO” button to

select [96].

Setting the

RS-232C

communication

condition(Selecti

ng a data length

of 7 bits)

MODE

ZERO

1.Press the “MODE” button to

select parameter [F7.2].

2.Press the “ZERO” button to

select [7b].

Setting the

RS-232C

communication

condition(Selecti

ng the even

parity)

MODE

ZERO

1.Press the “MODE” button to

select parameter [F7.3].

2.Press the “ZERO” button to

select [En].

Setting the

RS-232C

communication

condition(Selecti

ng one stop bit)

MODE

ZERO

1.Press the “MODE” button to

select parameter [F7.4].

2.Press the “ZERO” button to

select [1b].

Setting the

RS-232C

communication

condition(Selecti

ng the flow

control of

enabled

Xon/Xoff)

MODE

ZERO

1.Press the “MODE” button to

select parameter [F7.5].

2.Press the “ZERO” button to

select [on].

Setting the

number of

output

axes(Selecting

3 axes)

MODE

ZERO

1.Press the “MODE” button to

select parameter [F8].

2.Press the “ZERO” button to

select [3AS].

3 - 14 No.99MBA043A

Page 54

3. Operation

3.4.3 Dimensional measurement using a scale

Place the scale on the screen and measure the enlarged image.

Divide the measurements by the magnification of the projection lens to determine the

actual dimensions.

[Example]

Measured value on the screen: 150mm

Projection lens magnification: 10X

150/10=15

Actual dimension of the workpiece: 15mm

Work

p

iece

Projection screen

Scale

Magnified

dimension

y The optional reading scale is ideal for this type of measurement because the graduated

surface of the scale fits on the screen glass, providing parallax-free measurement.

3.4.4 Comparison with an overlay chart

Measurement and inspection are performed by comparing the workpiece image with the

standard overlay chart which is custom-made for the selected magnification. Use this

method for measurement of shapes, multiple points and dimensions.

This method of measurement is suitable for checking a compl icated part feature which

cannot be inspected in a simple one-dimensional measurement.

Adding tolerance lines onto the standard overlay chart will improve inspection efficiency,

since workpieces can be inspected with reference to these lines.

Standard charts can be made from the workpiece blue print, or the master workpi ece

image projected on the screen. Use transparent or semi-transparent tracing sheets(or

film) to make them. For close inspecti on or for long-term storage, plastic tracing sheets

are recommended because of their greater dimensional stability.

Tolerance lines

No.99MBA043A 3 - 15

Page 55

3.4.5 Angle measurement (Using the Angle counter)

Using the protractor screen and the rotary table for measuring angles:

• Loosen the clamp knob and use the rotation knob to turn the protractor screen.

Screen rotation knob

0” line

Clamp knob

NOTE

Always use the rotation knob to rotate the protractor screen. Other methods of

screen rotation may cause an error in angle measurement.

• Angle counter

The angle counter has two measurement modes : ABS mode for absolute measurement

and INC mode for comparative measurement. Use the [ABS/INC] key to select the mode.

Pressing the [ZERO] key sets the counter to zero at any angular position.

At power on, the counter is in ABS mode with 0 being displayed. Holding down the

[MODE] key for about 2 seconds can toggle the smallest unit of the angle counter

between 0.0

° and 1'.

Each time the [MODE] key is pressed, the display of smallest unit is switched.

3 - 16 No.99MBA043A

Page 56

3. Operation

[4][5][3][2][1]

Angle counter

[1] Angle display

Range : ±360° (±370° in ABS mode)

Resolution : 1' (or 0.01

° )

[2]

Zero-set key

Sets the angle counter to zero at any position desired.

ABC mode : Hold down the key for about 3 seconds.

INC mode : Press then release the key.

[3]

ABS/INC mode indicator

The LED for the active mode is lit.

[4]

Angle unit selector/offset switch

Unit of angle display : Switches the smallest unit of the angle counter between 0.01°

and 1'(Default is 1' at power on). For this switching hold down the switch for about 2

seconds.

Offset function : Enables an easy angle measurement. Each time the switch is

pressed the displayed angle increments by 90

°.

[5]

ABS/INC mode selector switch

Switches between ABS and INC modes. (Default is ABS mode at power ON.)

• INC mode

Use the INC mode to perform comparative measurement. Pressing the [ABS/INC] key

when in ABS mode switches to INC mode and the counter is Set to Zero.

Press the [ABS/INC] key again to return to ABS mode where the current screen angle

from the datum is displayed.

• Error codes

E-oF :

Counter overflow

E-oS :

Overspeed error

If one of the above errors are displayed, press the [ZERO] key to clear the error. Then

set the datum edge again in ABS mode.

No.99MBA043A 3 - 17

Page 57

• Measuring in ABS mode

(Angle counter setting : 1')

Step Procedure Screen Counter Display

1

Align the vertrex of the angle

to be measured with the

intersection of the cross-hair

lines, then rotate the

protractor screen to align

one edge of the angle with a

cross-hair line. Set the angle

counter to ABS mode and

establish a datum on the

edge by setting the counter

to Zero.

2

Rotate the protractor screen

to align the other edge of the

angle with the same

cross-hair line used in (1).

The measured angle is

displayed on the angle

counter.

1

It is also possible to measure

angles by using stage cross

travel to align the edges with

the cross-hair lines. Align on

edge of the angle with a

cross-hair line. Set the angle

counter to ABS mode and

establish a datum on the

edge by setting the counter

to zero.

2 Feed the stage in the X-axis

direction as shown on the

left.

3

Rotate the protractor screen

to align the other edge of the

angle with the same

cross-hair line used in (1).

The measured angle is

displayed on the angle

counter.

3 sec.

3 sec.

3 - 18 No.99MBA043A

Page 58

3. Operation

• Measuring in ABS/INC mode

(Angle counter setting : 1')

Step Procedure Screen Counter Display

1

Align a cross-hair line on the

screen with the datum. Set

the angle counter to ABS to

mode, then set it to zero.

2

Rotate the protractor screen to

measure angle

θ

A

(=θ1).

3

Switch to INC mode to set

the counter to zero.

4

Rotate the protractor screen

to measure angle

θ

B

.

5

Measure θ2.

(

θ

2

is displayed when

switching to the ABS mode.

)

6

Switch to INC mode to set

the counter to zero.

3 sec.

No.99MBA043A 3 - 19

Page 59

Step Procedure Screen Counter Display

7 Rotate the protractor screen to

measure

θc.

8 Measure θ

3

.

(

θ

3

is displayed when switching

to the ABS mode.

)

3 - 20 No.99MBA043A

Page 60

3. Operation

(2) Using the protractor screen and the rotary table for measuring angles:

The cross travel of the stage is normally used in conjunction with the rotary movement of

the table for measuring angles, because it is difficult to align the center of the rotary table

with the vertex of the measured angle.

Align one of the screen cross-hair lines with an edge of the angle to be measured and

read the angle. Rotate the table to align the other edge with the hair line and read its

angle. the difference between the two readings represents the angle of the workpiece

edge. It is not necessary for the angle vertex to remain positioned in the center for

angular measurement, only that the edges be correctly aligned with the cross hair when

readings are taken.

The rotary table No.172-196 can be read in 2' and No.176-106 in 6' increments (using

the vernier scale).

No.172-196 No.176-106

Diameter of the stage top φ 146 mm φ 112 mm

Effective diameter of the stage glass φ 97 mm φ 60 mm

Vernier scale

No.99MBA043A 3 - 21

Page 61

3 - 22 No.99MBA043A

MEMO

Page 62

Troubleshooting

4

4.1 Main Unit

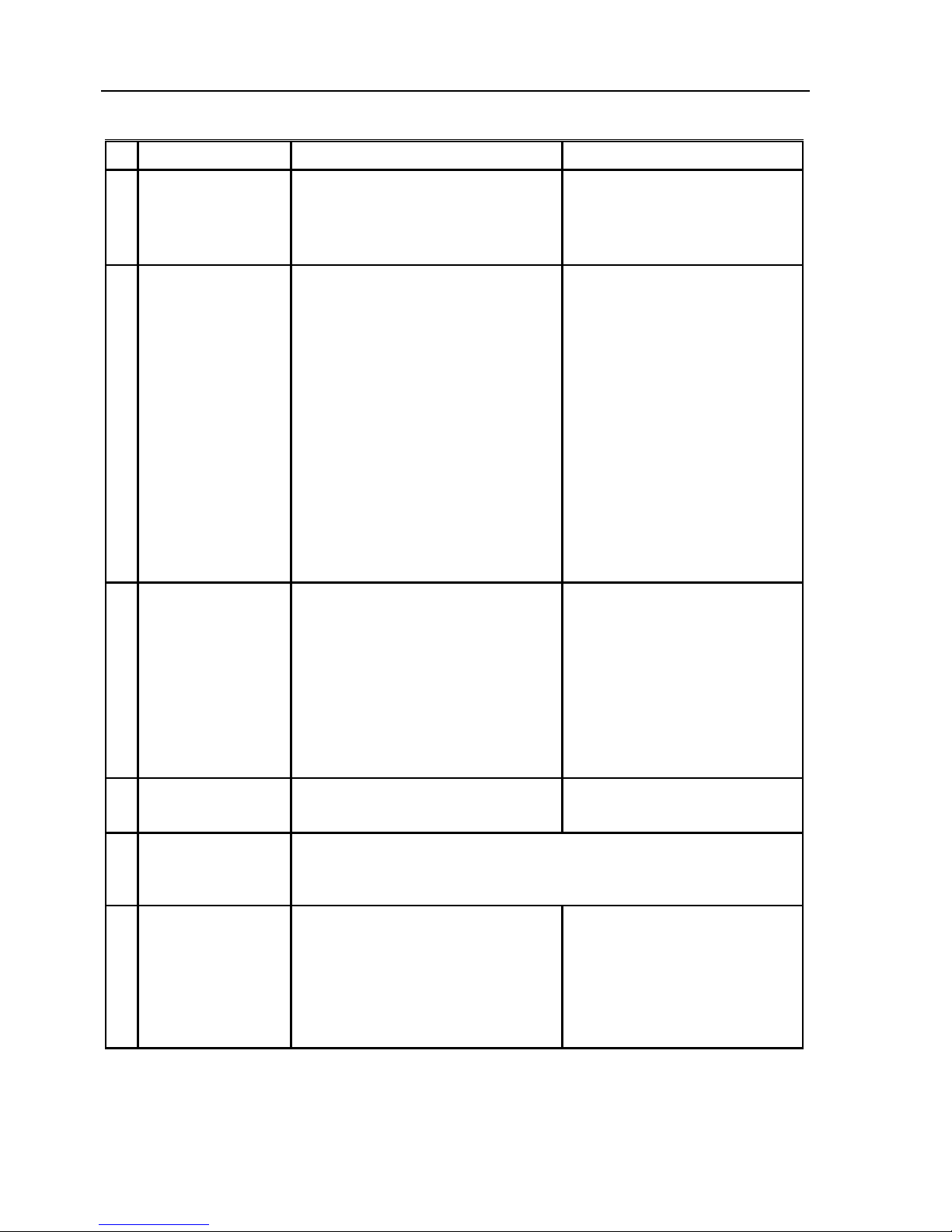

Symptom Check point Remedy

1)

The fan motor

does not operate,

even if the power

switch is on.

1)Is the power cord securely

connected?

2)

Is the power supply voltage

consistent with the rated voltage?

3)

Is the fuse OK? (not blown)

1)

Connect the power cord

securely.

2)

Adjust the power supply

voltage to the rated voltage.

3)

Replace the fuse.

2)

The transmitted

illumination

halogen bulb dose

not light up

1)Is the pilot lamp on?

2)Is the cable for the transmitted

illuminator properly connected.

3)Is the illumination halogen bulb OK?

1) Refer to the symptom1.

2) Connect the cable properly.

3)Replace the halogen bulb.

3)

The vertical

reflected

illumination

halogen bulb dose

not light up.

1)Is the pilot lamp on?

2)Is the cable for the vertical reflected

illuminator properly connected.

3)Is the illumination halogen bulb OK?

1) Refer to the symptom1.

2) Connect the cable properly.

3)Replace the halogen bulb.

4)

The image is

unclear.

1)Check if the lens and workpiece are

stained.

2)Check if the light intensity of the

illumination is improper.

3)Check if the lens is loosened.

4)Check the environments for

vibration and electric noise.

1) Clean the lens and workpiece.

2)Adjust the light intensity.

3)Tighten the lens.

4)Optimize the environmental

conditions.

5)

Abnormal sound

and vibration are

generated.

1)Check if the legs on the main

unit/installation stand are loose.

2)Check if the main unit/installation

stand is not level.

1)Tighten the legs on the main

unit/installation stand correctly.

2)Perform leveling of the main

unit/installation stand.

6)

The measurement

data will not be

steady.

1)Check if the stage glass is fixed.

2)Check if the lens is loosened.

3)Check if the workpiece is fixed

properly.

4)Check if the lens and

glass are

contaminated.

5)Check if the environmental

conditions such as the temperature

and vibration are within the

tolerance range.

1)Fix the stage glass

2)Tighten the lens.

3) Fix the workpiece properly.

4) Clean the lens and

glass.

5)Optimize the environmental

conditions.

No.99MBA043A 4 - 1

Page 63

4.2 Counter Unit

Symptom Check point Remedy

1)

Nothing is

displayed when

the power switch

is on.

1) Is the power cord securely

connected?

2) Turn the power switch off, then turn

it on after at least five seconds.

1) Connect the power cord

securely.

2) Try a few times. If the light still

dose not come on, contact

Mitutoyo.

2)

Counter display is

locked (no

counting.)

1) Turn the power switch off, then turn

it on after at least 5 seconds.

2) Check the following.

(Example) If the X-axis counter

operates correctly and the Y-axis

counter dose not, swap the X-and

Y-axis Linear Scale connections.

•

•

If the same problem persists on the

same counter (i.e. X-axis counter

operates correctly, Y-axis counter

does not operate correctly),the

counter is damaged.

If the problem occurs on the other

counter (i.e. X-axis counter does

not operate correctly, Y-axis

counter operates correctly),the

Y-axis Linear Scale is damaged.

1) Try a few times. If the counter

display is still locked, go to

check point.

2) If the counter or any Linear

Scale is found to be damaged,

contact your dealer or the

nearest Mitutoyo sales office.

3) Miscounting

1)Is the wire from the main unit GND

terminal grounded securely?

2)Is there any noise source nearby?

3)See “Counter display is locked”

category in Malfunction column.

1)Securely ground the wire from

the main unit GND terminal.

2)The counter should be

separated by at least 0.5m from

high-voltage or large-current

sources and high-capacity

relays.

3)If the counter or any Linear

Scale is found to be damaged,

contact your dealer or the

nearest Mitutoyo sales office.

4)

Count value

fluctuates

1)Are vibrations affecting the Linear

Scales?

1)Take countermeasures to

minimize the effects of the

vibration.

5)

Errors of "E20"

and "F30" are

displayed.

1)

Refer to “4.3 Error Messages and Remedies”.

6)

Errors of "E51"

and "E52" and

"E53" are

displayed.

1)

Refer to “4.3 Error Messages and

Remedies”.

2)

Have the power switches been

turned on or off according to the

right column?

1)

Refer to “4.3 Error Messages

and Remedies”.

2)

Turn the power switches on or

off in the following order.

For ON Peripheral equipment →

Projector main unit

For OFF Projector main unit →

Peripheral equipment

If any other trouble than those listed above is encountered, contact your dealer or the nearest

Mitutoyo service center.

4 - 2 No.99MBA043A

Page 64

4. Troubleshooting

4.3 Error Messages and Remedies

LED display

Meaning and remedy

Overspeed arising ; Traverse speed of the axis which displayed the error is so fast.

xxxPress the zero-set button of the axis which displayed the error or restart t he

microscope main unit.

Overcount arising ; The scale of the axis which displayed the error exceeds the

possible counting range.

xxx

Return the scale of the axis which displayed the error to the possible counting

range or restart the microscope main unit.

RS232C parity error

xxx

Press the X-axis zero-set button. Restart bot h of the equipment connected with the

counter at RS232C and the microscope main unit, when the communication is not

resumed.

RS232C over-run error

xxx

Press the X-axis zero-set button. Restart bot h of the equipment connected with the

counter at RS232C and the microscope main unit, when the communication is not

resumed.

RS232C framing error

xxx

Press the X-axis zero-set button. Restart bot h of the equipment connected with the

counter at RS232C and the microscope main unit, when the communication is not

resumed.

When an error code has been cleared (power is turned on), the counter displays all zeros. Perform

measurement from the start.

TIP

If there is play or abnormal noise present, contact Mit utoyo. Do not disassemble the unit or unit

or force the wheel.

4.4 Others

4.4.1 Error is observed in glass scale or overlay chart measurement.

This may be a magnification error. Check the magnification accuracy by referring to 2.4.6.

Contact Mitutoyo if adjustment or repair is required.

4.4.2 Abnormal cross-travel stage operation, and measurement errors occur.

Check the cross-travel stage operation by referring to 2.4.7 and 2.4.8. Contact Mitutoyo if

adjustment or repair is required.

No.99MBA043A 4 - 3

Page 65

4 - 4 No.99MBA043A

4.4.3 Abnormal protractor screen operation.

If the screen rotation, fine adjustment, or clamp dose not work normally, contact Mitutoyo. Do

not force them.

4.4.4 Partial obscured image.

Check the following points. Contact Mitutoyo when required depending on the problem:

(1)

Is the projection lens properly mounted?

(2)

Focusing

(3) Oil stains on the workpiece or stage glass

(4) Stains or damage to the projection lens

(5) Stains or damage to the surface reflecting mirror

4.4.5 Digimatic Head Key Operation and Counter Display

(for PJ-A3005D-50)

Digimatic Head Counter

Press the [+/-] key. The sign changes.

Press the [RESET] key.

Start of presetting (“P” blinks).

“E81” is displayed.

Press the

[ZERO/ABS] key

c ZERO

d ABS

c “0.000” is displayed.

d The value displayed on the

Digimatic Head is displayed.

Press the

[ON/OF] key

c OFF

d ABS

c “E81” is displayed.

d “0.000” is displayed.

Page 66

Maintenance

This chapter explains the daily maintenance that must be performed

on the Measuring Projector PJ-A3000 series, including cleaning and

the replacement of consumable parts.

5

5.1 Maintenance of Optical Components

5.1.1 Projection lens

Compared with ordinary hard glass, the optical glass of the projection lens used for the

projector is soft and subject to scratches. In order to remove dust do not use a cloth to

wipe the lens, but use a blower brush instead.

To remove oil or fingerprints, dampen clean gauze with a mixture of high-grade alcohol

and ether in a ratio of 8 to 2, and wipe gently using a circular motion.

For lens storage, replace the lens cap and store it in its case.

Also replace the lens cap when the projector is not in use, although the lens does not

have to be removed from the projector.

5.1.2 Half-reflecting mirror for surface illuminator

The half mirror for 10x and 20X is coated with a plastic film which tends to collect dust.

Since the mirror surface is subject to scratches, take sufficient care when handling it.

Use a blower brush to remove any dust from the mirror.

5.1.3 Mirror (surface reflecting mirror)