Page 1

LSM-6200

No.99MBC095A

SERIES No.544

Laser Scan

Micrometer

(Display Unit)

User's Manual

Read this User’s Manual thoroughly

before operating the instrument. After reading,

retain it close at hand for future reference.

Page 2

CONVENTIONS USED IN USER'S MANUAL

Safety Precautions

To operate the instrument correctly and safely, Mitutoyo manuals use various safety signs (Signal

Words and Safety Alert Symbols) to identify and warn against hazards and potential accidents.

The following signs indicate general warnings:

Indicates an imminently hazardous situation which, if not avoided, will result in serious

DANGER

WARNING

CAUTION

injury or death.

Indicates a potentially hazardous situation which, if not avoided, could result in serious

injury or death.

Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury or property damage.

The following signs indicate specific warnings or prohibited actions, or indicate a mandatory action:

Alerts the user to a specific hazardous situation. The given example means “Caution,

risk of electric shock”.

Prohibits a specific action. The given example means “ Do not disassemble”.

Specifies a required action. The given example means “Ground”.

No. 99MBC095A

i

Page 3

CONVENTIONS USED IN USER'S MANUAL

On Various Types of Notes

The following types of notes are provided to help the operator obtain reliable measurement data

through correct instrument operation.

IMPORTANT •An

of a task. You cannot disregard this note to complete the task.

• An important note is a type of precaution, which if neglected could result in a loss of

data, decreased accuracy or instrument malfunction/failure.

NOTE A note emphasizes or supplements important points of the main text. A note supplies infor-

mation that may only apply in special cases (e.g.. Memory limitations, equipment configurations, or details that apply to specific versions of a program).

TIP A tip is a type of note that helps the user apply the techniques and procedures described in

the text to their specific needs.

It also provides reference information associated with the topic being discussed.

Mitutoyo assumes no liability to any party for any loss or damage, direct or indirect,

caused by use of this instrument not conforming to this manual.

Information in this document is subject to change without notice.

© Copyright Mitutoyo Corporation2005. All rights reserved.

important note is a type of note that provides information essential to the completion

NOTES FOR EXPORTING

Before exporting this product confirm the final purpose of use at the export destination to

prevent the product from being used for developing weapons of mass destruction or military

affairs. In the case of export to the U.S., this product requires an application for prior

approval of CDRH (Center for Devices and Radiological Health) in FDA (Food and Drug

Administration). For detailed information consult a Mitutoyo sales office. Also, if this

product is exported with it incorporated in equipment, the final product requires an application for FDA approval. If this is the case, note that the client must file an application for

approval.

ii

No. 99MBC095A

Page 4

PRECAUTIONS

1. Safety Precautions

The Measuring Unit connected to the Display Unit uses a very low power laser.

Use of controls or adjustments or performance of procedures other than those specified

herein may result in hazardous radiation exposure.

1) An applicable laser product class of the IEC standard: a Class 2 laser product uses a

visible laser (maximum power: 1.3 mW for scanning; laser device: semiconductor laser;

wavelength: 650 nm).

2) Do not look directly into the laser beam. (Even if it seems that no light is being emitted

from the emission window, do not look into it.)

3) If measuring flat objects with mirror finishes, avoid looking at the reflection on the

surface.

4) Close the beam shutter when the instrument is not in use.

5) Do not remove the laser class identification labels attached to the Measuring Unit.

6) Before using this unit, carefully read the “Measuring Unit Specifications” and “Precautions on Use of Laser” sections provided in the manual supplied with the Measuring

Unit.

2. Before making the connection between the Measuring Unit and the Display Unit, turn off the

power. If an optional device is to be connected to this system, make sure that the optional

device is also turned off.

3. Firmly tighten the screws of the cable connectors and interfaces to ensure shielding.

4. Do not touch the terminals of the connectors, otherwise contact may be poor.

5. Positively ground the Display Unit.

6. An error display may appear during operation. However, it may not always indicate a fault. If

an error display appears, consult the “Maintenance and Inspection” section.

7. Unplug the power cord when a system failure is encountered.

Do not open the covers provided on the emission unit and reception unit.

No. 99MBC095A

iii

Page 5

INSTALLING CONDITIONS

The Mitutoyo Laser Scan Micrometer LSM-6100 series is both a precision optical instrument

and a precision electronic instrument, and this unit is the instrument suitable for indoor use as

well. Therefore, it must be carefully installed and the following conditions must be taken into

consideration to attain the highest possible accuracy.

1. Vibration

Install this unit if possible in a place where it will not be subject to vibration. If this unit is

used for a long period of time in an environment where there are significant vibrations, the

precision parts in this unit may be affected, resulting in the deterioration of measuring

accuracy.

If this unit has to be used in an environment where vibration is significant, measures such as

the laying of a vibration damping rubber pad under the unit must be applied to reduce the

effect of vibration.

2. Dust

Dust and airborne particles at the installation site adversely affect optical parts including the

protective glass and electronic parts of the Measuring Unit. Place this unit in a place with as

little dust and as few airborne particles as possible.

3. Direct sunlight

If this unit is subjected to direct sunlight, the heat may deform this unit and affect the

measuring accuracy.

4. Draft from air-conditioning equipment

5. Ambient temperature and humidity

WARRANTY

If this unit must be placed by a window where it will be subjected to direct sunlight, protect

the unit by shading it.

If the measuring area is subject to such as warm or cold draft from any air-conditioning

equipment, the laser beam may be artificially refracted due to the unevenness of ambient air

concentration, affecting the measurement accuracy.

If this is the case, block the draft in the mid-way to the measuring area by such as a curtain, etc.

This unit must be operated in an environment where the temperature is between 0 and 40˚C

and the humidity is between 35 and 85% RH. Avoid installing this unit where there is

significant temperature or humidity change.

Significant temperature and humidity changes may reduce measuring accuracy.

In the event that the Mitutoyo Laser Scan Micrometer (LSM) should prove defective in

workmanship or material, within one year from the date of original purchase for use, it will

be repaired or replaced, at our option, free of charge upon its prepaid return to us.

If the unit fails or is damaged because of the following causes it will be subject to a repair

change, even if it is still under warranty.

iv

1. Failure or damage due to inappropriate handling or unauthorized modification.

2. Failure or damage due to transport, droppage, or relocation of the machine after

purchase.

3. Failure or damage due to fire, salt, gas, abnormal voltage, or natural catastrophe.

This warranty is effective only where the machine is properly installed and operated following this manual.

No. 99MBC095A

Page 6

CONTENTS

CONVENTIONS USED IN USER'S MANUAL ................................................................. i

NOTES FOR EXPORTING ............................................................................................... ii

PRECAUTIONS ...............................................................................................................iii

INSTALLING CONDITIONS ........................................................................................... iv

WARRANTY.................................................................................................................... iv

1. INTRODUCTION................................................................................................... 1-1

2. SETUP .................................................................................................................. 2-1

1.1 Outline ........................................................................................................... 1-1

1.2 Foreword ....................................................................................................... 1-1

1.2.1 Measuring units available ................................................................. 1-1

1.2.2 Using the Measuring Unit separately ............................................... 1-1

1.3 Nomenclature ................................................................................................ 1-2

1.3.1 Display Unit....................................................................................... 1-2

1.3.2 Measuring Unit.................................................................................. 1-4

2.1 Unpacking and Acceptance Check............................................................... 2-1

2.2 Connecting the Cables ................................................................................. 2-1

2.3 Preliminary Checks ....................................................................................... 2-5

2.4 Initializing the LSM-6200 Display Unit .......................................................... 2-6

No. 99MBC095A

3. DISPLAYS AND KEY OPERATIONS.................................................................. 3-1

3.1 Outline of the Operation Modes ................................................................... 3-1

3.1.1 Measurement Principle ..................................................................... 3-1

3.1.1.1 Overview ................................................................................. 3-1

3.1.1.2 Setting the segment ............................................................... 3-3

3.1.1.3 Measurement interval (measurement time) ........................... 3-4

3.1.2 Outline of the Operation Modes ....................................................... 3-5

3.1.2.1 Basic setup mode ................................................................... 3-6

3.1.2.2 Calibration mode .................................................................... 3-6

3.1.2.3 Measuring condition setup mode ........................................... 3-6

3.1.2.4 Other setup mode................................................................... 3-6

3.1.2.5 Statistic display mode............................................................. 3-6

3.1.2.6 Measurement mode................................................................ 3-7

3.2 Techniques and Terminology of Setup Functions ........................................ 3-9

3.2.1 Program ............................................................................................ 3-9

3.2.2 Basic setup ..................................................................................... 3-10

3.2.3 Function setup ................................................................................ 3-11

3.2.4 Setups according to the property of each workpiece..................... 3-11

3.2.4.1 Transparent object (Workpiece that transmits light) ............ 3-11

3.2.4.2 Ultra-fine wire measurement ................................................ 3-14

3.2.5 Measurement of an odd-numbered-edge cutting tool .................... 3-16

3.2.6

3.2.7 Latch (holding) of the displayed value ........................................... 3-22

3.2.8 Automatic measurement with an edge specification...................... 3-23

3.2.9 GO/NG judgment ............................................................................ 3-24

3.2.10 Abnormal data elimination .............................................................. 3-26

3.2.11 Preset/Zero-set ............................................................................... 3-27

Measurement with two Measuring Units (dual-unit measurement)...

3.2.6.1 DW type ................................................................................ 3-18

3.2.6.2 DXY type .............................................................................. 3-19

3.2.6.3 DF type ................................................................................. 3-20

3-17

v

Page 7

3.2.12 Mastering ........................................................................................ 3-27

3.2.13 Reference value.............................................................................. 3-28

3.2.14 Data output conditions .................................................................... 3-28

3.2.15 Automatic workpiece detection <OD detection method,

Position detection method> ............................................................ 3-29

3.2.16 Group judgment .............................................................................. 3-31

3.2.17 Recording the amount of light ........................................................ 3-32

3.3 Outline of the Display Contents .................................................................. 3-33

3.3.1 Display unit ..................................................................................... 3-33

3.3.2 Data display unit ............................................................................. 3-33

3.4 Outline of Key Operations .......................................................................... 3-35

3.4.1 Description of key functions ........................................................... 3-37

3.4.2 Example key operations ................................................................. 3-41

4. SETTING UP THE MEASURING CONDITIONS ................................................. 4-1

4.1 Basic Setup ................................................................................................... 4-1

4.1.1 Outline of the basic setup procedure ............................................... 4-2

4.1.2 Description of each mode................................................................. 4-4

4.1.2.1 Selecting and setting the function in the B0 mode ................ 4-5

a. Setting the resolution (Guidance: RES) ............................ 4-5

b. Setting the number of blank-out digits (Guidance: BLN) .. 4-6

c. Putting a comma after the thousandths digit

(Guidance: (,)) ................................................................... 4-6

d. Setting the buzzer function (Guidance: BUZZER) ............ 4-7

e. Setting the display latch timer (Guidance: LATCH)........... 4-7

4.1.2.2 Selecting and setting the function in the B1 mode ................ 4-8

a. Setting the output function in the ready state

(Guidance: D.OUT) ............................................................ 4-8

b. Setting the analog output voltage if Err-0 occurs

(Guidance: ERR-0 V) ........................................................ 4-8

c. Selecting the display message if Err-0 occurs

(Guidance: ERR-0 D) ........................................................ 4-8

d. Selecting the display message at the start of measurement

(Guidance: RUN D) ........................................................... 4-9

e. Selecting the averaging method (Guidance: AVG.M)....... 4-9

f. Setting the GO/NG judgment method

(Guidance: JDG.M) ............................................................ 4-9

g. Setting whether the target value is copied to the reference

value (Guidance: COPY)................................................. 4-10

4.1.2.3 Selecting and setting the function in the B2 mode .............. 4-11

a. Setting the workpiece type (Guidance: WORK.P) .......... 4-11

b. Setting whether to perform ultra-fine wire measurement

(Guidance: FINE) ............................................................. 4-11

c. Setting the simultaneous measurement

(Guidance: PROG) .......................................................... 4-12

d. Setting the dual-unit measurement (Guidance: TYPE) ... 4-12

e. Setting the DXY-type calculation (Guidance: CALC)...... 4-13

f. Selecting the method of specifying segments

(Guidance: SEG) ............................................................. 4-13

4.1.2.4 Selecting and setting the function in the B3 mode .............. 4-14

a. Setting the abnormal value elimination function

(Guidance: ADE) ............................................................. 4-14

vi

No. 99MBC095A

Page 8

b. Setting the automatic workpiece detecting function

(Guidance: AWDT) .......................................................... 4-14

c. Setting the number of scans (Guidance: SCAN) ............ 4-15

d. Setting the group judgment (Guidance: GTJ) ................. 4-15

e.

Setting the group judgement output (Guidance: GTJ D)...

f. Setting the odd-numbered-edge cutting tool measurement

function (Guidance : TOOL)............................................ 4-16

4.1.2.5 Selecting and setting the function in the B4 mode .............. 4-17

a. Setting the use of RS-232C port

(Guidance: RE-232C) ...................................................... 4-17

b. Setting the RS-232C communication baud rate

(Guidance: BAUD)........................................................... 4-17

c. Setting the RS-232C communication data bits

(Guidance: LENGTH) ...................................................... 4-17

d. Setting the RS-232C communication parity bit

(Guidance: PARITY)........................................................ 4-18

e. Setting the delimiter for communication

(Guidance DELIMT) ......................................................... 4-18

f. Setting the RS-232C line control

(Guidance: CONTRL) ...................................................... 4-18

4.1.2.6 Selecting and setting the function in the B5 mode .............. 4-19

a. Setting the RUN input function from the I/O interface

(Guidance: RUN) ............................................................. 4-19

b. Setting the PSET input function from the I/O interface

(Guidance: PSET) ........................................................... 4-19

c. Setting the GO output function from the I/O interface

(Guidance: GO) ............................................................... 4-20

4.1.2.7 Selecting and setting the function in the B6 mode .............. 4-20

a. Setting the use of DCU (Guidance: DCU) ...................... 4-20

4.1.2.8 Setting in the B7 mode (expanded items) ........................... 4-21

a. Setting expanded items (Guidance: ADD) ...................... 4-21

b. Reservation (Guidance: SEG_LIM)................................. 4-21

c. Reservation (Guidance: SEG_ER0) ................................ 4-21

d. Reservation (Guidance: SEG_COR)............................... 4-21

e. SHL setting (Guidance: SHL).......................................... 4-21

f. Setting for detecting dirty protection glass

(Guidance: DIRT) ............................................................ 4-22

g. Setting the measurement mode (Guidance: DLC) .......... 4-22

h. Space for additional functions (Guidance: A.5V) ............ 4-23

i. Space for additional functions (Guidance: A.0V) ............ 4-23

j. Space for additional functions (Guidance: A2.0V) .......... 4-23

k. Setting the STB length of I/O analog interface

(Guidance: STB).............................................................. 4-23

l. Setting the input software filter (Guidance: IFF) ............. 4-23

m. Setting the application range of calibration

(Guidance: CAL).............................................................. 4-24

n. Setting the application range of presetting and mastering

(Guidance: PST).............................................................. 4-24

o. Setting the number of programs to be used

(Guidance: PRGM).......................................................... 4-24

4.2 Calibration ................................................................................................... 4-25

4.2.1 Calibration gages and gage stand ................................................. 4-25

4-15

No. 99MBC095A

vii

Page 9

4.2.2 Entering the calibration mode......................................................... 4-25

4.2.3 Combined calibration ...................................................................... 4-27

4.3 Positioning a Gage or a Workpiece............................................................ 4-29

4.4 How to read-in the amount of light ............................................................. 4-29

4.5 Setting Up the Functions ............................................................................ 4-31

4.5.1 Outline of the function setup mode ................................................ 4-31

4.5.2 Outline of each function setup mode ............................................. 4-32

4.5.3 Function setup mode ...................................................................... 4-33

4.5.3.1 F0: Setting the segment ....................................................... 4-34

4.5.3.2 F1:

4.5.3.3 F2: Setting the GO/NG judgment criteria ............................. 4-38

4.5.3.4 F3: Setting the reference value ............................................ 4-42

4.5.3.5 Analog voltage output and scale value ................................ 4-43

4.5.3.6 F4: Setting the preset/zero-set values ................................. 4-45

4.5.3.7 F5: Setting the data output conditions ................................. 4-47

4.5.3.8 F6: Setting the sample measurement .................................. 4-48

4.5.3.9 F7: Automatic workpiece detection setting .......................... 4-50

4.5.3.10 F8: Setting the group judgment............................................ 4-51

4.5.3.11 Confirming the function setup contents................................ 4-52

5. MEASUREMENT MODE ...................................................................................... 5-1

5.1 Outline of the Measurement Mode ............................................................... 5-1

5.1.1 Settings made in the measurement mode ....................................... 5-1

5.1.1.1 Setup operation from the arrow key....................................... 5-2

5.1.1.2 Setup that can be made directly from each setup item key .. 5-4

5.2 Other Functions ............................................................................................ 5-6

5.2.1 Key lock ............................................................................................ 5-6

5.2.2 Displaying the measuring position .................................................... 5-6

5.3 Applied Measurement ................................................................................... 5-7

5.3.1 OD measurement of a precision-machined workpiece .................... 5-7

5.3.2 Measurement of magnet coil wire that runs at high speed.............. 5-8

5.3.3 Measurement of the lead pitch of a multiple-pin IC ....................... 5-10

5.3.4 Applied Measurement with Preset/Zero-Set Functions.................. 5-12

5.3.5 Sample measurement..................................................................... 5-16

5.3.6

5.3.7 Applied measurement with automatic workpiece detection ........... 5-22

5.3.8 Applied measurement on a stepped round bar .............................. 5-24

Application of the odd-numbered-edge cutting tool measurement ...

5.3.6.1 Odd-numbered-edge cutting tool outside diameter

5.3.6.2 Odd-numbered-edge cutting tool run-out measurement ...... 5-20

Setting the measurement interval (measurement time) ...

measurement........................................................................ 5-18

4-36

5-18

viii

6. INTERFACE UNIT ................................................................................................ 6-1

6.1 Standard Interface ........................................................................................ 6-1

6.1.1 I/O Analog Interface.......................................................................... 6-1

6.1.1.1 External view of the connector ............................................... 6-1

6.1.1.2 Terminal names ...................................................................... 6-2

6.1.1.3 Input/output equivalent circuit................................................. 6-2

6.1.1.4 Timing chart ............................................................................ 6-5

6.1.2 RS-232C Interface ............................................................................ 6-7

6.1.2.1 Specifications.......................................................................... 6-7

6.1.2.2 Connections ............................................................................ 6-8

6.1.2.3 Printer interface .................................................................... 6-10

No. 99MBC095A

Page 10

6.1.2.4 RS-232C/GP-IB commands ................................................. 6-10

6.1.2.5 List of commands ................................................................. 6-12

6.1.2.6 List of response commands if an error occurs .................... 6-14

6.1.2.7 Format of response commands ........................................... 6-15

6.1.2.8 Other commands .................................................................. 6-16

6.1.2.9 Details of command descriptions ......................................... 6-17

6.2 Optional Interface........................................................................................ 6-24

6.2.1 Digimatic Output Unit interface....................................................... 6-24

6.2.1.1 Method of use....................................................................... 6-24

6.2.1.2 Name of each part................................................................ 6-25

6.2.1.3 I/O specifications .................................................................. 6-26

6.2.1.4 Timing chart .......................................................................... 6-27

6.2.1.5 Data format ........................................................................... 6-28

6.2.2 Second Analog I/O Interface .......................................................... 6-30

6.2.2.1 Method of use....................................................................... 6-30

6.2.2.2 Name of each part................................................................ 6-30

6.2.2.3 I/O Interface .......................................................................... 6-31

6.2.2.4 Analog output ....................................................................... 6-39

6.2.3 BCD interface ................................................................................. 6-40

6.2.3.1 Method of use....................................................................... 6-40

6.2.3.2 Name of each part................................................................ 6-40

6.2.3.3 Specification ......................................................................... 6-41

6.2.4 GP-IB interface ............................................................................... 6-46

6.2.4.1 Method of use....................................................................... 6-46

6.2.4.2 Name of each part................................................................ 6-46

6.2.4.3 Specification ......................................................................... 6-47

6.2.4.4 Functions .............................................................................. 6-49

6.2.4.5 Operations ............................................................................ 6-50

6.2.5 Dual-type add-on unit ..................................................................... 6-50

6.3 Installing the Optional Interface Unit .......................................................... 6-51

6.3.1 Digimatic Output Unit...................................................................... 6-52

6.3.2 Second Analog I/O, BCD, and GP-IB interfaces ............................ 6-52

No. 99MBC095A

7. INSPECTION AND MAINTENANCE.................................................................... 7-1

7.1 Display Unit ................................................................................................... 7-1

7.1.1 Display check.................................................................................... 7-1

7.1.2 Cleaning method............................................................................... 7-1

7.2 Error Messages and Remedies .................................................................... 7-2

7.3 Troubleshooting and Remedies .................................................................... 7-3

7.4 Fuse replacement ......................................................................................... 7-4

8. SPECIFICATIONS ................................................................................................ 8-1

8.1 LSM-6200 Display Unit ................................................................................. 8-1

9. RESTRICTIONS ASSOCIATED WITH THE COMBINATION OF FUNCTIONS,

TABLES OF THE BASIC SETUP MODES ......................................................... 9-1

9.1 Restrictions Associated with the Particular Combination of Functions ........ 9-1

9.2 List of Setup Modes ...................................................................................... 9-2

9.2.1 List of basic setup modes................................................................. 9-3

9.2.2 List of calibration functions ............................................................... 9-5

9.2.3 Reading in the amount of light ......................................................... 9-5

9.2.4 List of function setup modes ............................................................ 9-6

ix

Page 11

MEMO

No. 99MBC095A

Page 12

INTRODUCTION

1

1.1 Outline

This system is an accurate, non-contact measurement system capable of measuring workpiece

dimensions at a high speed using a highly directional scanning laser beam.

This non-contact optical measuring system is capable of measuring workpieces which are

difficult to measure with conventional measuring instruments. It performs simple and

accurate measurement of brittle or elastic objects, objects at high temperature, objects which

must be kept clean, and soft objects which may be deformed and suffer dimensional changes

under the measuring forces used.

1.2 Foreword

This user’s manual primarily explains the functions of the Display Unit. For information

about the safety precautions, specifications, dimensions, standard accessories, and options for

each Measuring Unit, refer to the user’s manual supplied with the Measuring Unit.

This chapter describes the Laser Scan Micrometer (LSM) models and

nomenclature of the Display unit and the Measuring unit.

1.2.1 Measuring units available

This Display Unit can be used with the following Measuring Units.

sledoM

S005-MSL

S105-MSL

S305-MSL

S605-MSL

S215-MSL

S615-MSL

1.2.2 Using the Measuring Unit separately

All models, excluding the LSM-500S, can be used separately (the laser emission unit and

reception unit can be separated) by removing the mount from the Measuring Unit.

For information about using an LSM separately, refer to the measuring unit user’s manual.

No. 99MBC095A

1 - 1

Page 13

1.3 Nomenclature

This section gives the name of each part in the LSM system.

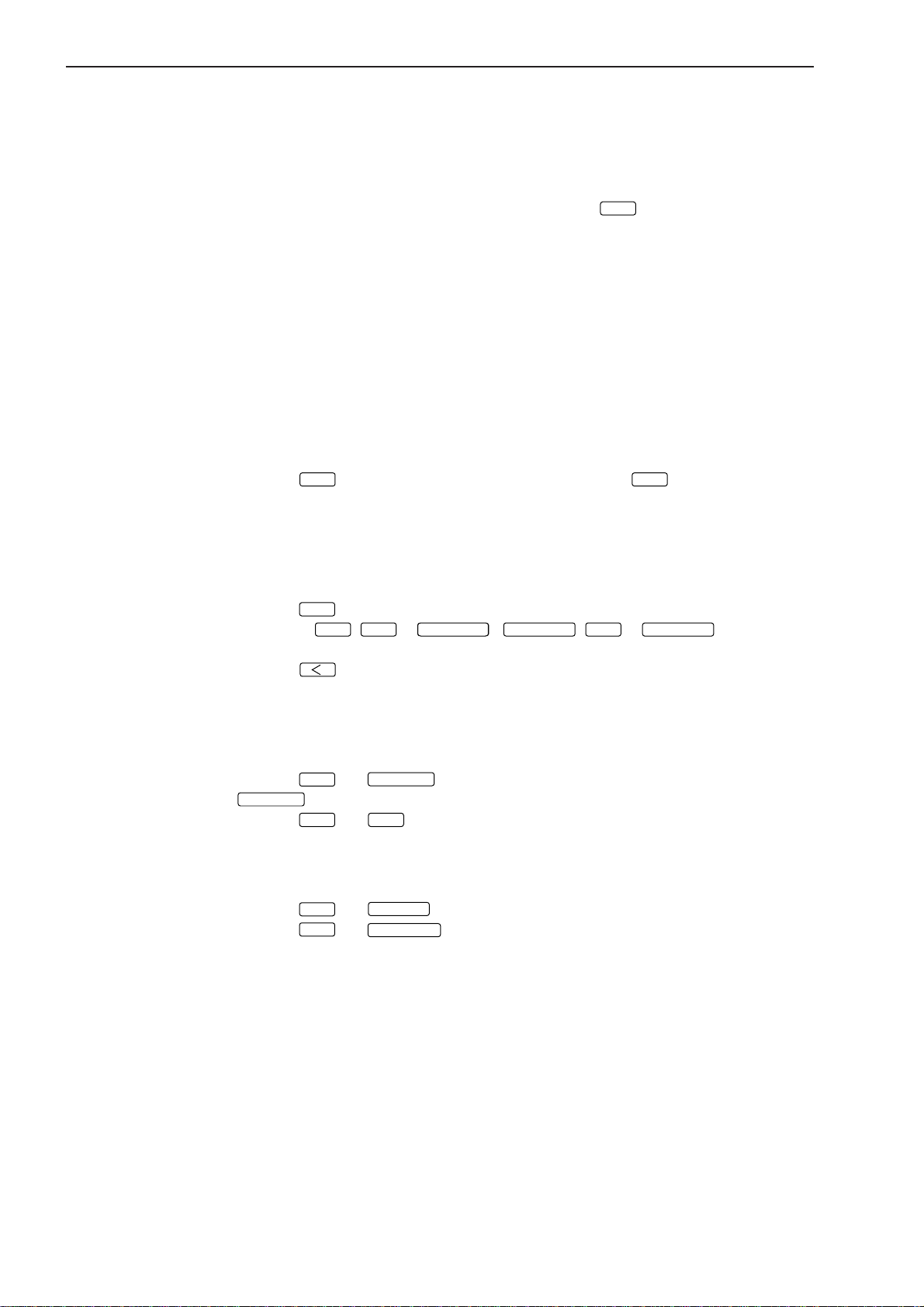

1.3.1 Display Unit

(1) Front panel

(2) Displays and keys

Mitutoyo

Power switch

SHIFT

READ

Data display

LASER SCAN MICROMETER LSM-6200

PROG.

LOCK CAL P.SET S.E DUAL

LD1 ON

LD2 ON

BUSYRUN+NGGO-NG

Status indicator LEDs (lit/unlit)

Workpiece position indicator LED

DATA C

RUN

7

C.RUN

8

S.PR

PRINT

SET

C9

Operation keys

DATA C

SHIFT

RUN

READ

7

H.CAL

4

L.CAL

1

LOCK

UNIT

C.RUN

8

5

2

•0

A.CL

M.CL

S.PR

PRINT

+/-

STAT

S.E

SET

C9

6

LIMIT

P.S V

3

P.SET

MASTER

REF

ENT

Stand

1 - 2

H.CAL

L.CAL

4

1

LOCK

UNIT

5

2

•0

A.CL

M.CL

6

3

+/-

STAT

S.E

LIMIT

P.S V

P.SET

MASTER

REF

ENT

No. 99MBC095A

Page 14

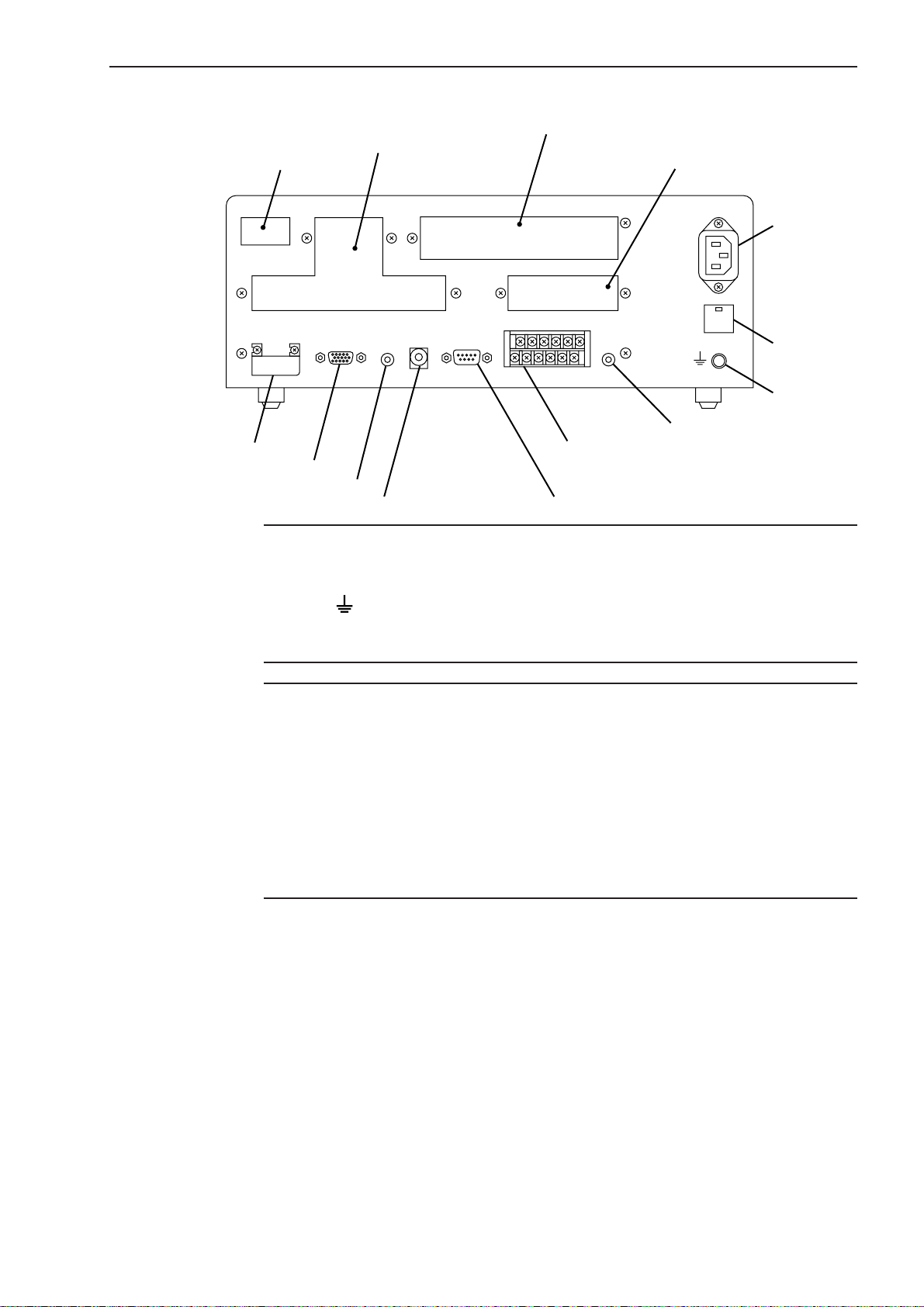

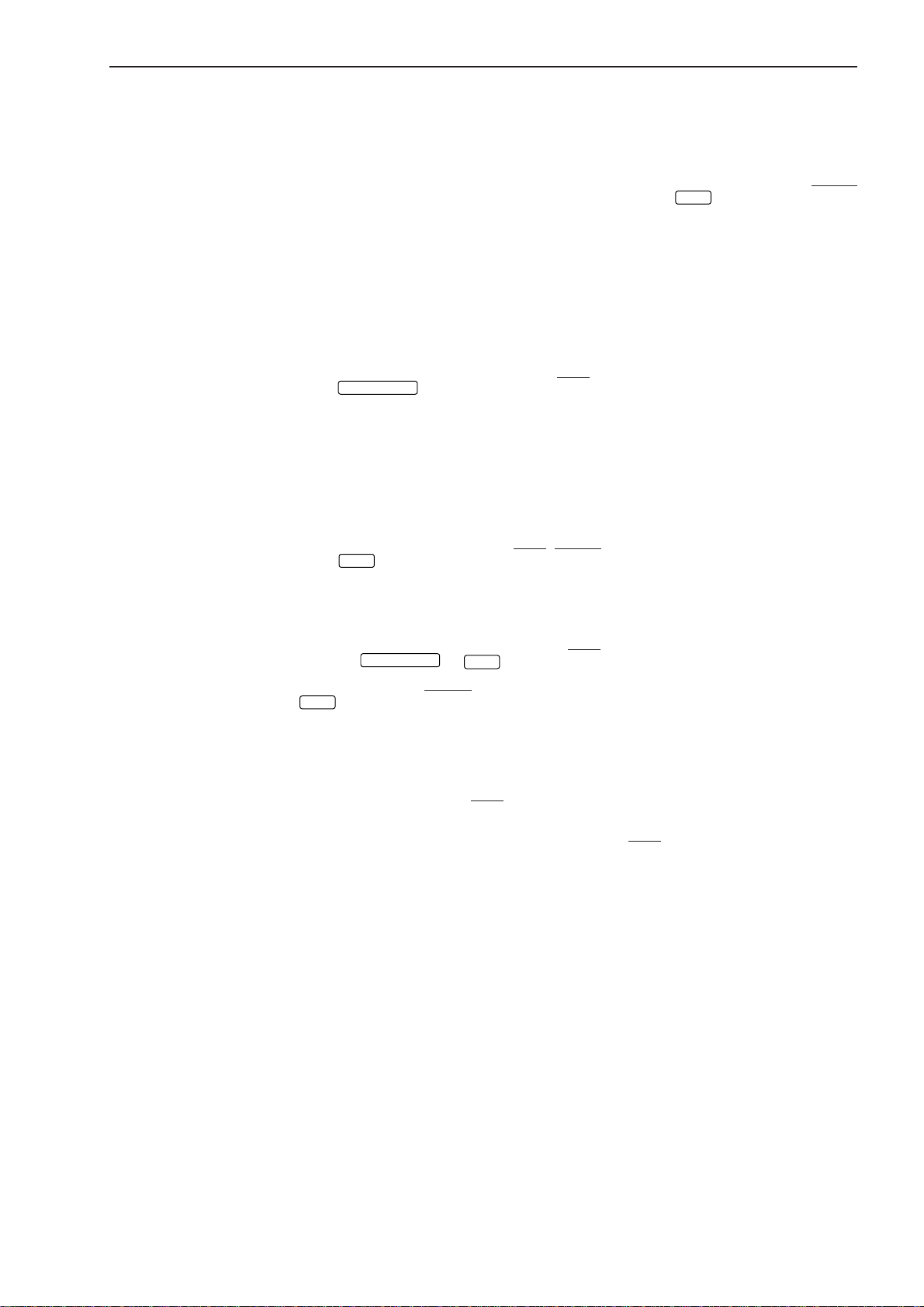

(3) Rear panel

1. INTRODUCTION

Add-on Unit installation space

Name plate

ID Unit Protection cover

Signal cable connector

Scanning signal connector

Remote interlock connector

TIP 1. A label which describes the terminal block name “I/O ANALOG” can be seen if the

Optional Dual-type

ID UNIT 1

ID

TRANSMITTER-1

SCAN SIG.-1

REMOTE INTERLOCK

Optional Interface add-on space

(Second Analog I/O Unit, BCD Output Unit, GP-IB Unit)

Optional Digimatic Output Unit

add-on space

AC power inlet

FOOT

SW.

I/O ANALOGRS-232C

Analog I/O connector

RS-232C connector

Foot switch

Fuse holder

AC power inlet

protective cover of the Analog I/O terminal block is opened. Use this for wiring.

2. The terminal located at the left end of the power input terminal and marked (by a

symbol ) is the grounding terminal to keep the potential of signal line of this

unit equal with other instrument connected. It is used to enhance resistance

against electrical interference.

NOTE Precautions for wiring the terminal block

1. If wiring the I/O analog terminal and Power input terminal, do not directly touch the

output terminals of the terminal block by hand, which has static charges, because

the internal circuit may be damaged by static discharge.

If your hands are charged, discharge the static energy by touching the metallic

surface of the Display Unit in advance. In addition, unplug the power cable from

the outlet before commencing wiring.

2. After wiring has been completed, close the protective cover.

3. Do not touch the input terminals on the terminal block during operation, otherwise

an operation error may result.

No. 99MBC095A

1 - 3

Page 15

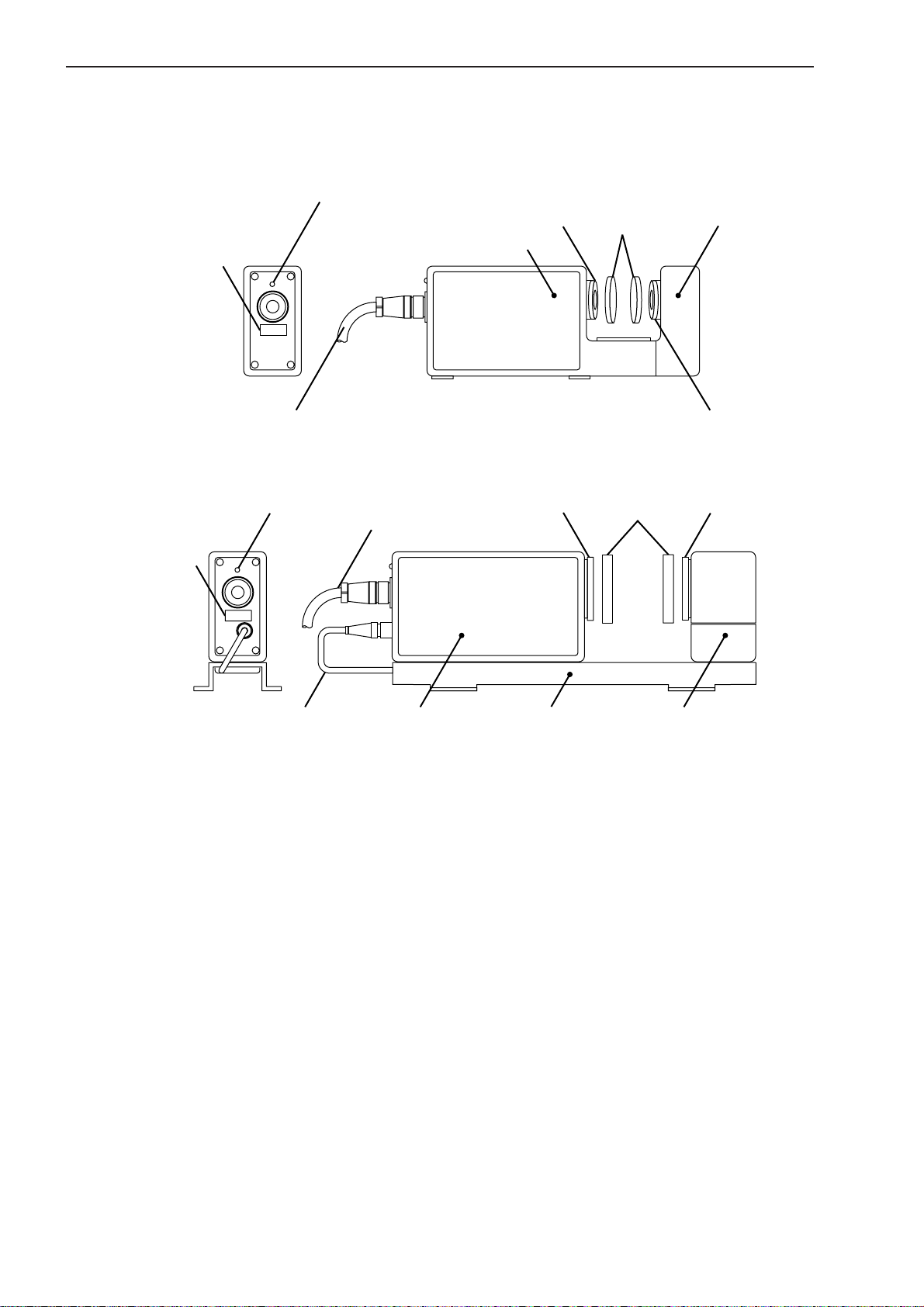

1.3.2 Measuring Unit

(1) Measuring Unit (integrated-type Measuring Unit)

LSM-500S

Laser emission indicator LED

Serial number label

Emission window

Emission unit

Mitutoyo

LSM-500S

LASER SCAN MICROMETER

Lens caps

Reception unit

Signal cable

(2) Measuring Unit (separate-type Measuring Unit)

LSM-501S, 503S, 506S, 512S, 516S

Laser emission

indicator LED

Serial number label

Connection cable

Signal cable

Mitutoyo

LASER SCAN MICROMETER

Emission window

LSM-501S

Mount

Reception unitEmission unit

Shutter

Reception window

Reception window

1 - 4

No. 99MBC095A

Page 16

SETUP

2

This chapter describes the connection between the Display Unit and

Measuring Unit.

2.1 Unpacking and Acceptance Check

Your LSM has been thoroughly inspected prior to shipment. The mechanical, electrical, and

optical systems are guaranteed to operate properly.

Unpack the package and check that the accessories, for the Display Unit or Measuring Unit,

and signal cables, etc., are intact and not damaged.

Contact Mitutoyo if anything is damaged or missing.

2.2 Connecting the Cables

Make sure that the power switch is turned off (turn the key switch counterclockwise to align

with “O”, then pull it out), then connect the cables according to the following procedure.

Step 1: Integrating the option interface

For the option interface (Dual-type Add-on Unit, Second Analog I/O Unit, BCD

Output Unit, GP-IB Unit, and Digimatic Output Unit) to become available with the

LSM, it must be installed by referring to Section 6.3 “Installing the Optional Interface Unit”.

For information about the setup switches on the BCD and GP-IB interface units refer

to Section 6.2.3, “BCD Interface” and Section 6.2.4, “GP-IB Interface”, respectively.

No. 99MBC095A

2 - 1

Page 17

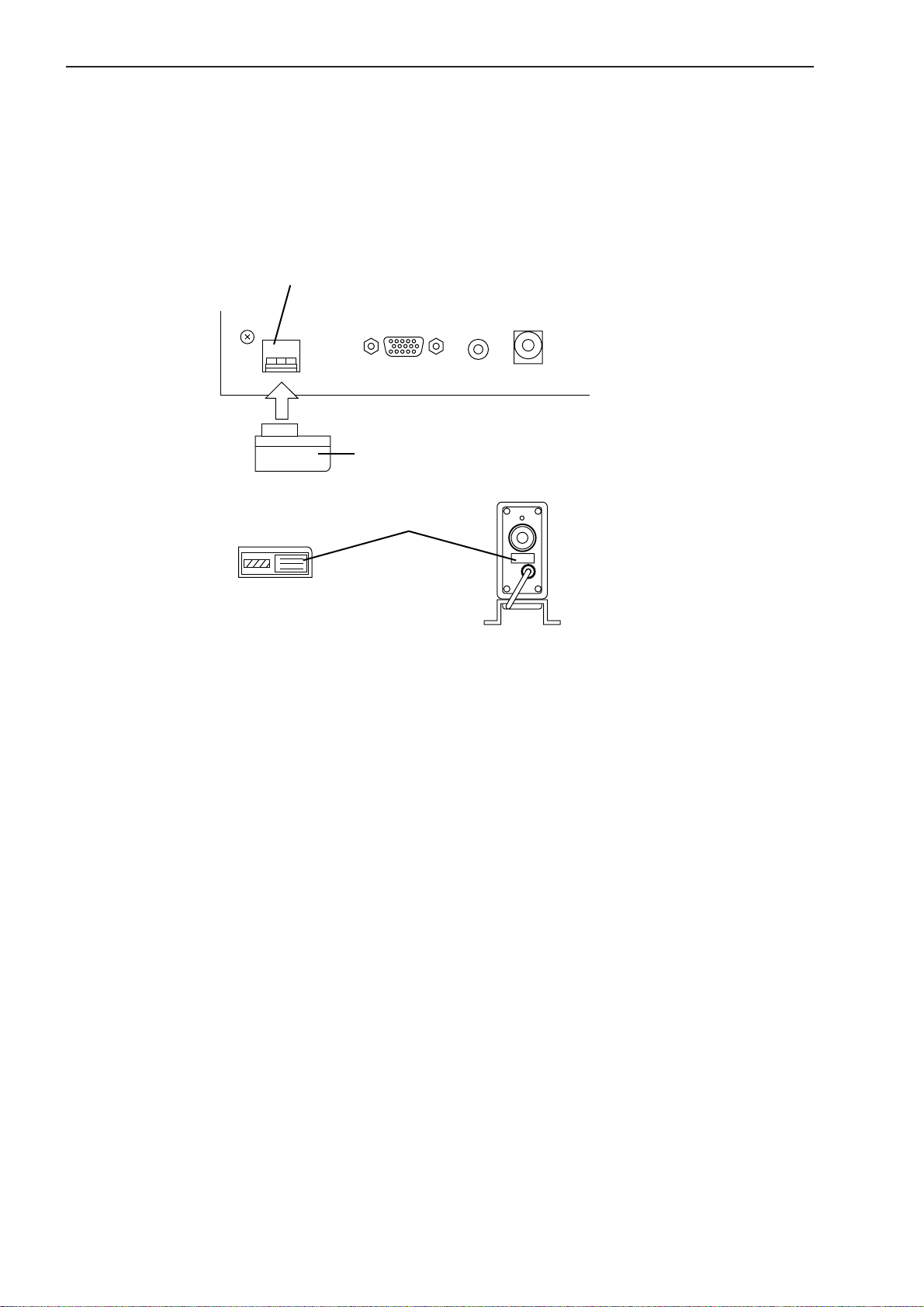

Step 2: Attaching the ID unit

1. Loosen the two screws that secure the ID unit protection cover at the left on the

real panel of the Display Unit and remove the cover by sliding it rightward.

2. Remove the dummy ID unit (amber) that has been mounted at the left of the

“TRANSMITTER-1” connector on the rear panel of the Display Unit, then insert

the ID unit (beige) that comes in the same package as the Measuring Unit.

This ID unit stores critical data that ensures the accuracy of the Measuring Unit

and has the same serial number as the accompanying Measuring Unit. Confirm that

these two numbers are identical before inserting the ID unit.

ID unit slot

SCAN SIG.-1ID UNIT 1

TRANSMITTER-1

ID

ID unit Measuring unit

ID unit

Serial number label

REMOTE INTERLOCK

If a Dual-type Add-on Unit is used, install the ID unit in the ID UNIT 2 slot above

the ID UNIT 1.

3. Replace and secure the ID unit protection cover revering the procedures in step 1

above.

2 - 2

No. 99MBC095A

Page 18

2. SETUP

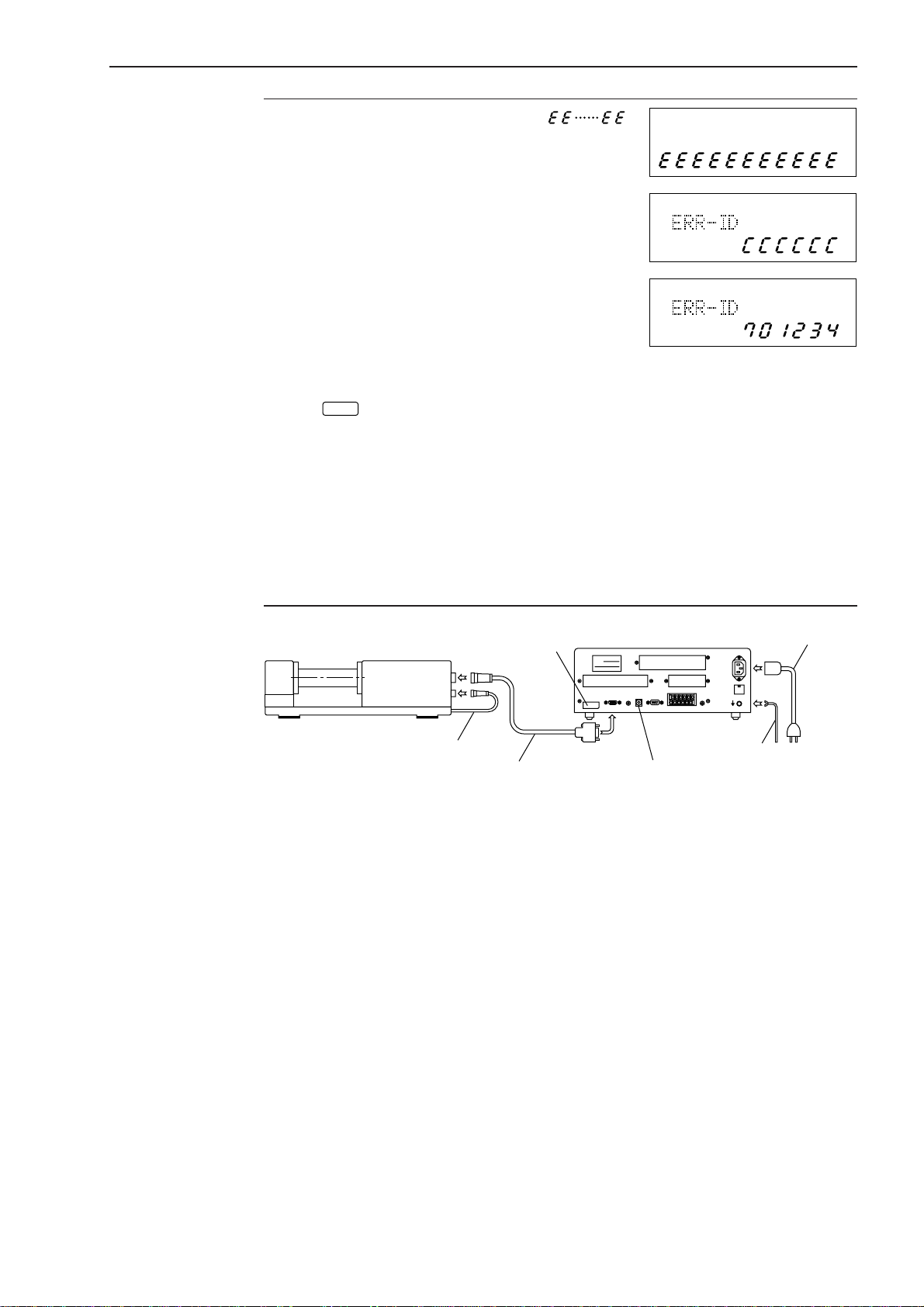

IMPORTANT • If the dummy ID unit is still mounted, “ ”

is displayed in the lower section of the display. If

this is the case, turn off the power and replace the

dummy ID unit with a proper ID unit.

• If the ID unit has not been installed, an error

display as shown at the right will appear in the

upper section of the data display unit and the

operation of this unit stops.

• If the ID unit is not installed or if the serial number of

the Measuring Unit is not consistent with that on the

ID unit, the system will not work and an error code

as shown at the right will be displayed at power on.

At the same time, the 6-digit serial number of the

measuring unit is displayed for confirmation.

If the

automatically started. However, the measuring accuracy can not be guaranteed. If

the optional dual-type add-on unit is used to perform measurement with two

Measuring Units, make sure that the serial numbers of the two Measuring Units,

which are connected to the “TRANSMITTER-1” connector and “TRANSMITTER-2”

connector, are identical. If neither of the two Measuring Units has a serial number

identical to that of the ID unit, a serial number of the Measuring Unit on the

“TRANSMITTER-1” side will be displayed in the upper display section, and that of

the Measuring Unit on the “TRANSMITTER-2” side will be displayed in the lower

display section.

key has been pressed to enter the ready state, measurement can be

C

PROG

PROG

PROG

No. 99MBC095A

ID unit

ID

Connecting cable

Signal cable

GND lead wire

Remote interlock

Step 3: Connecting the connecting cable (except for the LSM-500S)

Connect the cable which runs from the base of the Measuring Unit to the lower

connector (5-pin) on the rear panel of the emission unit.

Step 4: Connecting the signal cable

Insert the round plug (12-pin) of the signal cable into the upper connector (12-pin)

on the rear panel of the emission unit. Tighten the ring screw to firmly secure the

connectors.

Insert the square connector (15-pin) on the other end of the signal cable into the

connector “TRANSMITTER-1” at the upper left of the display rear panel and tighten

the securing screws.

If measurement is performed with two Measuring Units while using the optional

dual-type add-on unit, plug the cable from the second Measuring Unit into the

“TRANSMITTER-2” connector, then firmly tighten the screws.

Step 5: Connecting the power cord and GND lead wire

Connect the supplied power cord to the AC connector at the upper right on the rear

panel of the Display unit. Also be sure to ground the Display unit with the GND lead

wire for improved resistance to noise.

Power

cord

2 - 3

Page 19

Terminal to which a grounding wire is connected.

(

)

Ground the system using the provided grounding wire to avoid the effect of interference noise caused in the setup environment.

Step 6: Checking the remote interlock connector

Make sure that the short-circuiting pin is inserted into the “REMOTE INTERLOCK”

connector on the rear panel of the Display Unit. If this short-circuiting pin is not

inserted, laser emission is disabled, even if the power switch is on.

To emergency stop laser emission, refer to the following diagram.

Switch ON: Laser emission ON

Switch OFF: Laser emission OFF

Short-circuiting pin

Switch

5V, 3mA

Applicable connector: PJ-2

Manufacturer: Sato Parts

NOTE Recovering operation is not guaranteed. Never use this function for other than

emergency stop.

Step 7: Connecting the interface

For information about the procedure used to connect the interface, refer to Section

6.1.1, “I/O Analog Interface” and Section 6.1.2, “RS-232C Interface”.

NOTE 1. Note the following when connecting the signal cable.

For information about the precautions to be observed when connecting the signal

cable refer to the measuring unit user’s manual.

2. Note the following when making cable connections.

Always make connection or disconnection with the power cord unplugged. In

addition, before connecting to the interface make sure that the power to all other

units connected or to be connected are also off.

2 - 4

No. 99MBC095A

Page 20

2.3 Preliminary Checks

The necessary connections should be completed by following the procedure described in the

previous chapter. Simplified operation checks are described here.

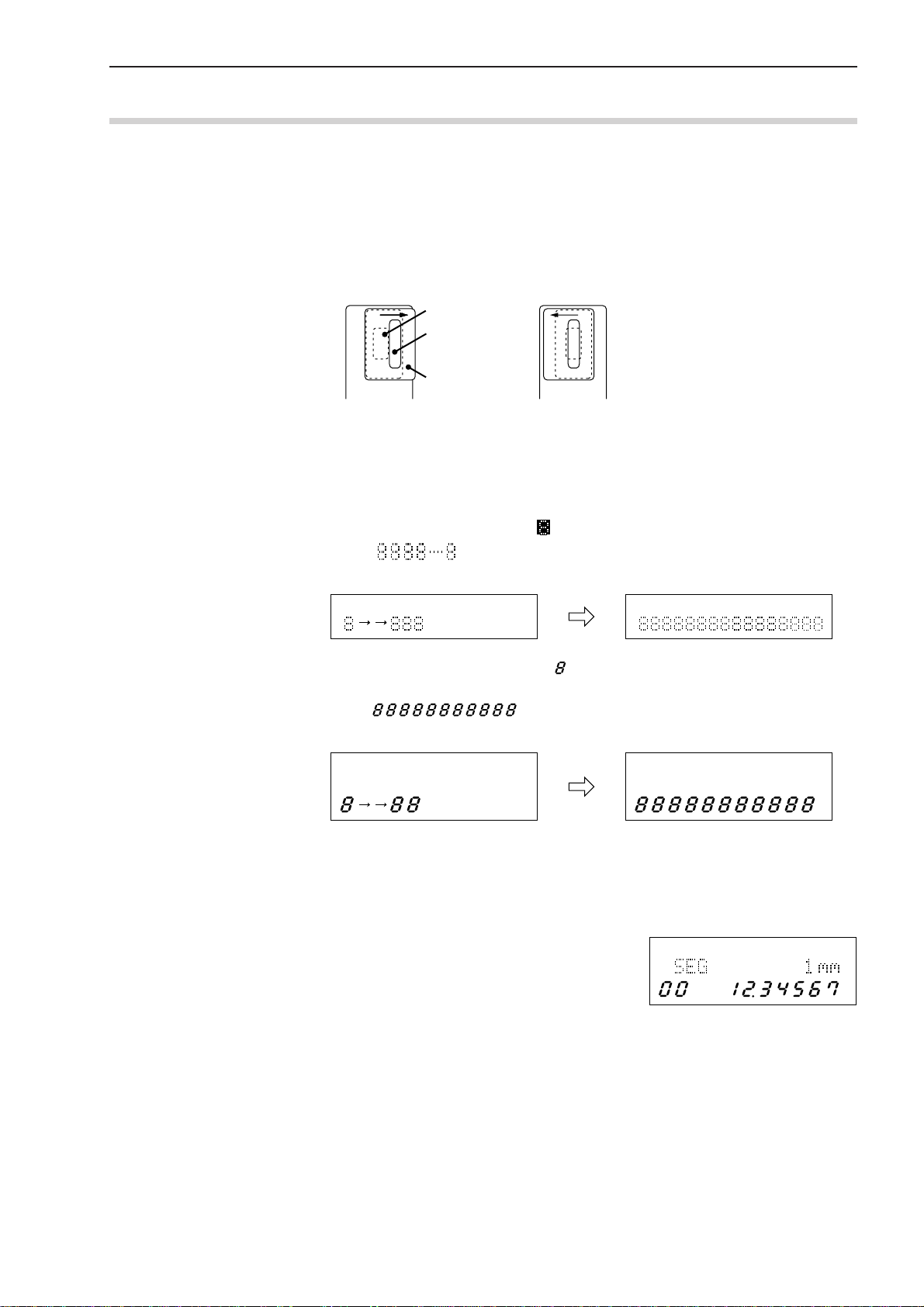

Step 1: Fully open the lens cap and shutter of the Measuring Unit.

Fully open the lens caps and beam shutters of both the emission unit and reception

unit to ready the laser beam for emission.

The lens caps should be completely removed, and the shutters should be as shown in

the diagram below.

If the shutter is closed If the shutter is open

Step 2: Power on

• Turn the power key switch on the Display Unit clockwise until it is in the I

(power on) position and the power is on.

• This unit enters the self check mode and all the LEDs and segments turn on. They

will turn off shortly, and eights will be displayed in the upper display section.

When is displayed across the upper display section, the unit will turn

off shortly. This is followed by the self check on the lower display section.

2. SETUP

Emission window

Shutter window

Shutter

PROG PROG

PROG

• In the lower display section eights will appear sequentially from the left to

right.

• After is displayed across the lower display section, it will

turn off shortly.

PROG PROG

• Measurement is started.

The LD1 ON (LD1 ON and LD2 ON in the dual-unit measurement) LED turns on

and the BUSY LED starts flashing to indicate the measurement has started from

the ready state.

Since the objective segment has been set to

PROG

“SEG 1” at the factory, the displayed measurement shows the laser scanning range of the

Measuring Unit.

Here, the Display Unit is found to be normal

because the scanning range is displayed.

Proceed to Chapter 3, “DISPLAYS AND KEY

OPERATIONS”, to custom set up each

function.

No. 99MBC095A

2 - 5

Page 21

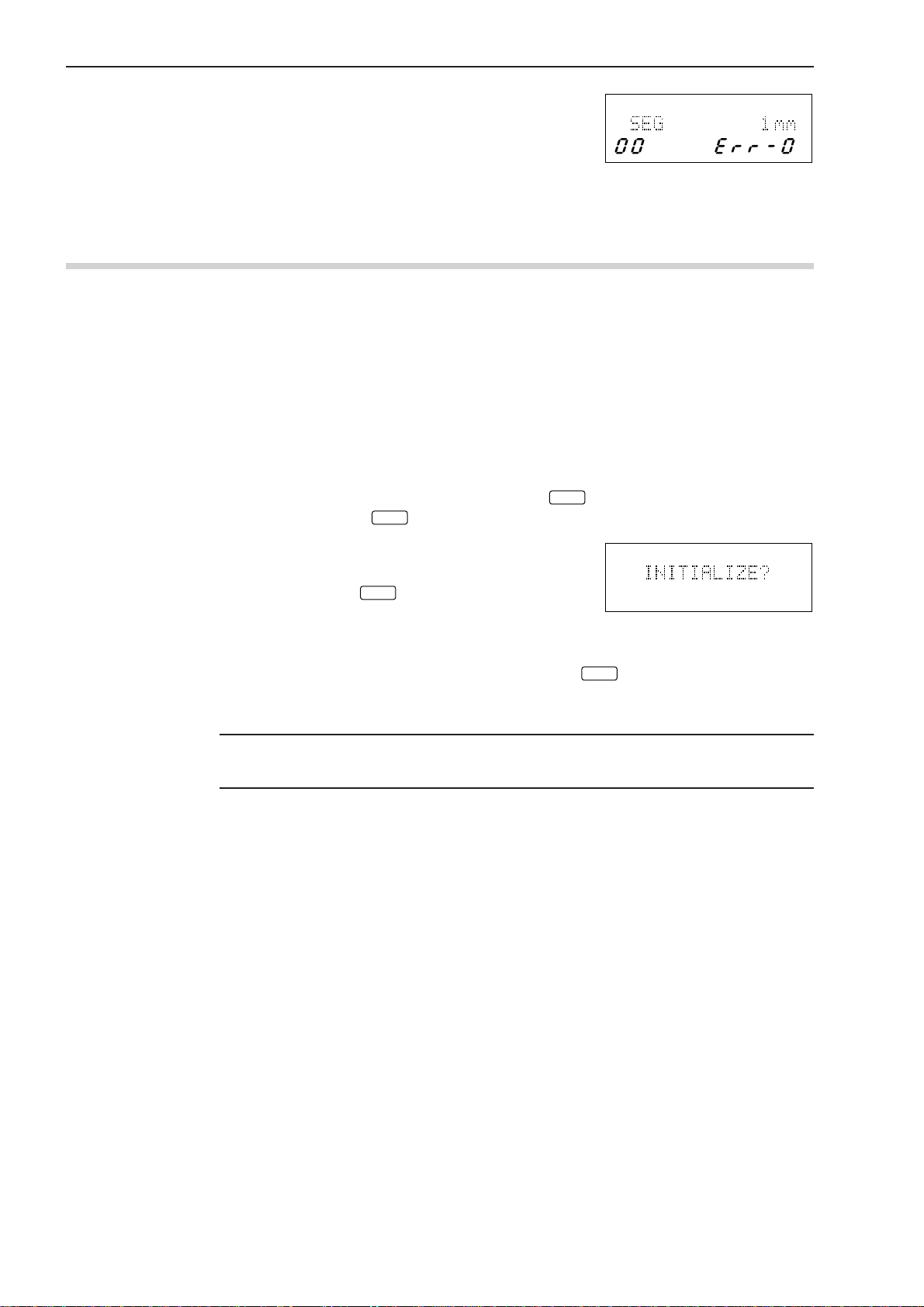

• An error may be displayed at this stage,

however, the display at the right is not actually

an error. Check the shutter of the Measuring

Unit.

For information about other errors that may result refer to Section 8.3, “Error

Messages and Remedies”.

2.4 Initializing the LSM-6200 Display Unit

After making sure that this unit is operating normally, initialize the Display Unit so it can

recognize the Measuring Unit(s) to be used.

Initialization of the Display Unit is also required if the Measuring Unit needs to be changed.

In addition to replacing the ID unit that is associated with the Measuring Unit, initialize the

Display Unit (i.e. restore the factory setups) with the following procedure.

The initialization procedure is as follows:

Step 1: Turn off the power and connect the Measuring Unit with the ID unit that comes with

the Measuring Unit installed.

PROG

Step 2: Turn on the power while holding down the

Hold down the

key for approximately 2 seconds, even after the power is on.

C

Step 3: When the self check has been completed, the

key.

C

PROG

display shown at the right will appear. To initialize, press the

key. When the initialization

ENT

process has been completed, the display restors

the initial conditions that existed just after the

power on.

To abort initialization press a key other than the

key or turn the power off.

ENT

In the former case the initialization process will be aborted and the initial display at

power-on will be restored.

NOTE Initialization will clear all the customer setup data and will restore the factory-setups.

Customize the setups again as necessary.

2 - 6

No. 99MBC095A

Page 22

DISPLAYS AND KEY

3

OPERATIONS

This Display Unit is provided with many useful functions that can be

customized according to the user's needs.

This chapter describes these functions and key operations.

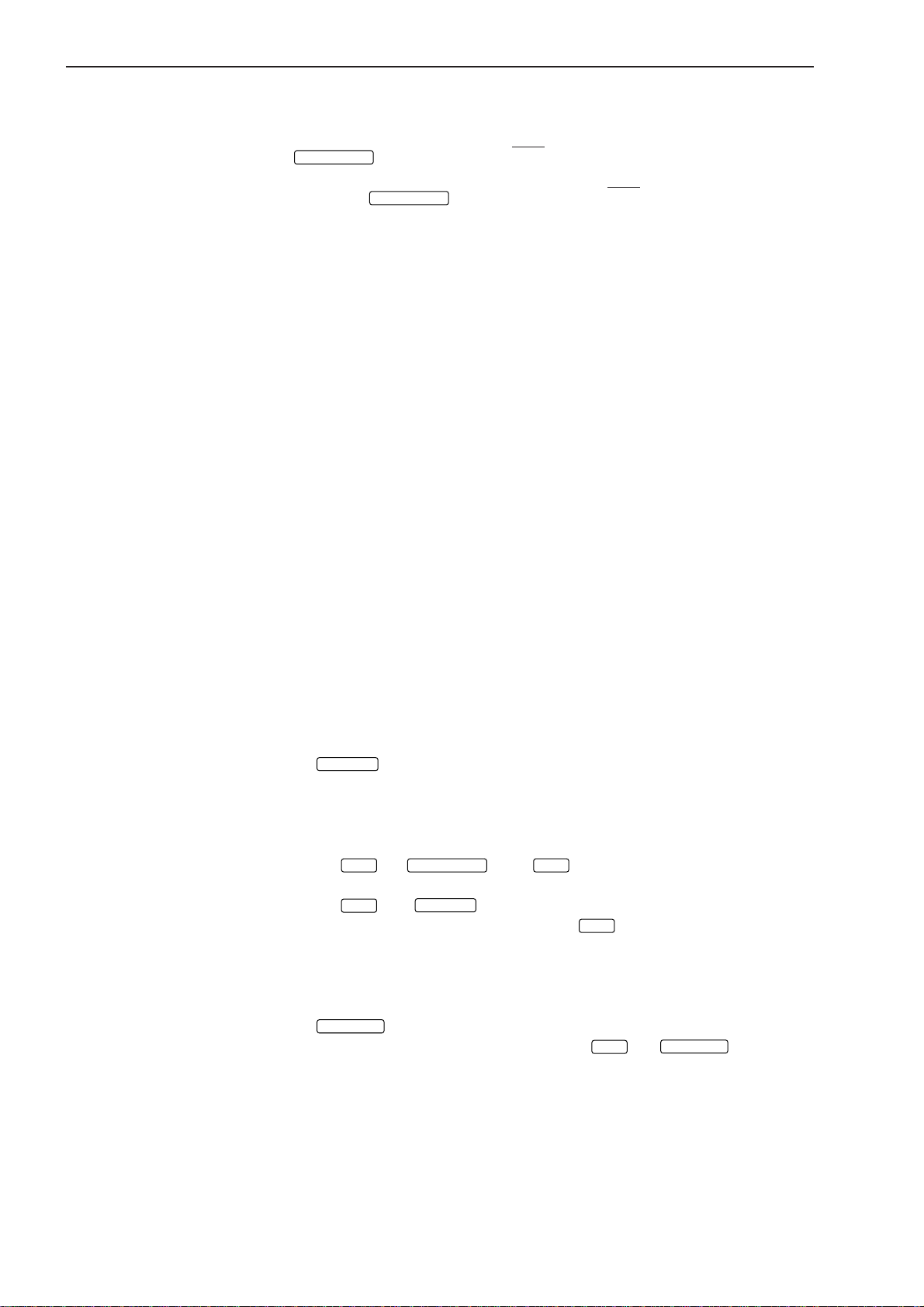

3.1 Outline of the Operation Modes

3.1.1 Measurement Principle

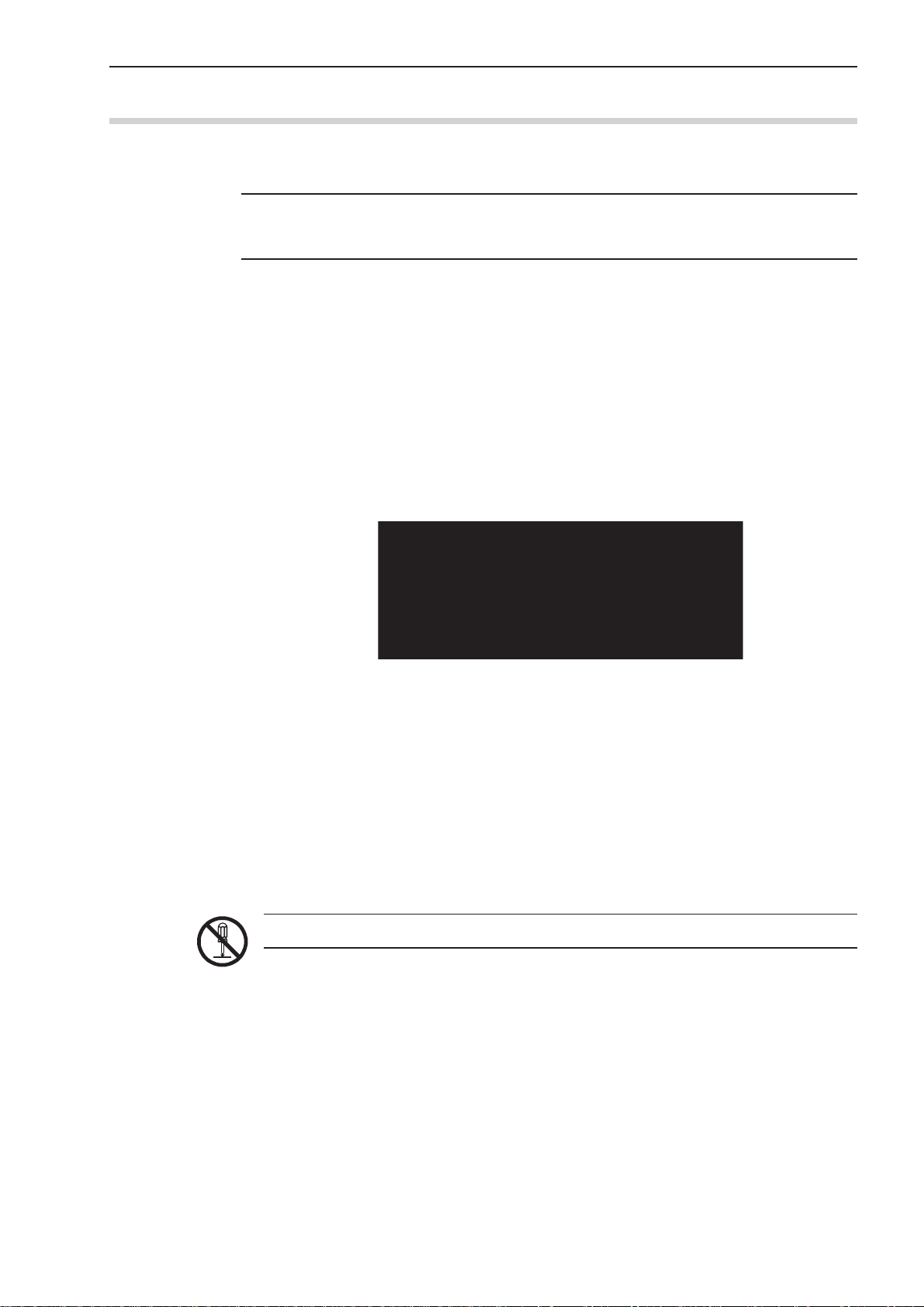

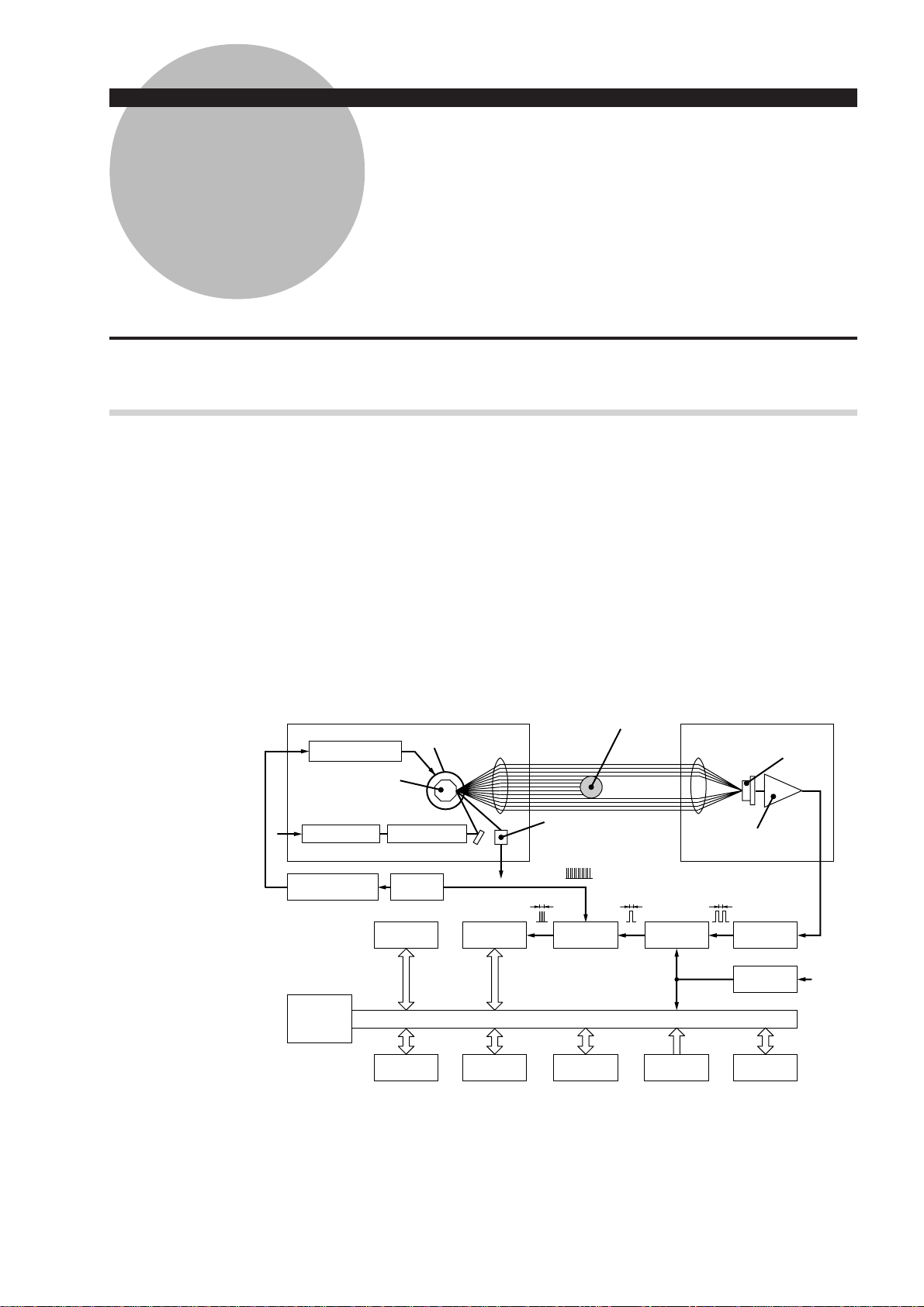

In order for the user to understand the measurement principle of the LSM, the following

paragraphs describe about the system block diagram, segments (measurement positions) and

measurement interval (measurement time).

3.1.1.1 Overview

Unlike light emitted from natural sources, a laser provides extremely fine, rectilinear beams

which do not diffuse (coherent light beams).

Using the properties of the laser beam, the Mitutoyo Laser Scan Micrometer (LSM) moves a

scanning laser beam over the workpiece and determines its dimensions by measuring the

duration in which the beam is obstructed by the workpiece.

No. 99MBC095A

Emission unit Reception unit

Polygon mirror

Polygon mirror

Laser power source Semiconductor laser

MP

Motor driving pulse

CPU

Motor Colimator lens

Clock pulse

ROM RAM

Data display

Keyboard

Counter

RS-232C

Photoelectric element

(reset signal generation)

RS

Gate Edge signal

I/O analog

interface

Workpiece

Segment

selection circuit

Foot switch

Condenser lens

Amplifier

ttt

Edge signal

Option I/F

Reception

device S

RS

3 - 1

Page 23

The configuration of the system is shown in the above block diagram. A laser beam emitted

from the laser oscillator is directed at the polygon mirror which rotates at high speed and is

synchronized by clock pulses. The laser beam that is reflected by the polygon mirror is then

collimated by the collimator lens towards the workpiece. As the polygon mirror rotates, this

horizontal beam scans the workpiece and the beam not obstructed by the workpiece will

reach the photoelectric element through the condenser lens and induce an output voltage in

the photoelectric element. The output voltage will change according to the duration over

which the laser beam is obstructed. Counting pulses generated during that period are used to

determine the dimension of the obstructed portion. This data is sent to the CPU for processing and the dimensions are displayed digitally.

Consequently, either the dimensions of the workpiece (shadowed areas) or workpiece

clearances (highlighted areas) can be determined by specifying the segments to be measured.

TIP In the system block diagram described in the previous page, the laser beam passed

through the collimator lens is made parallel and, at the same time, stopped down so

that the beam diameter is minimized at the measurement position.

3 - 2

No. 99MBC095A

Page 24

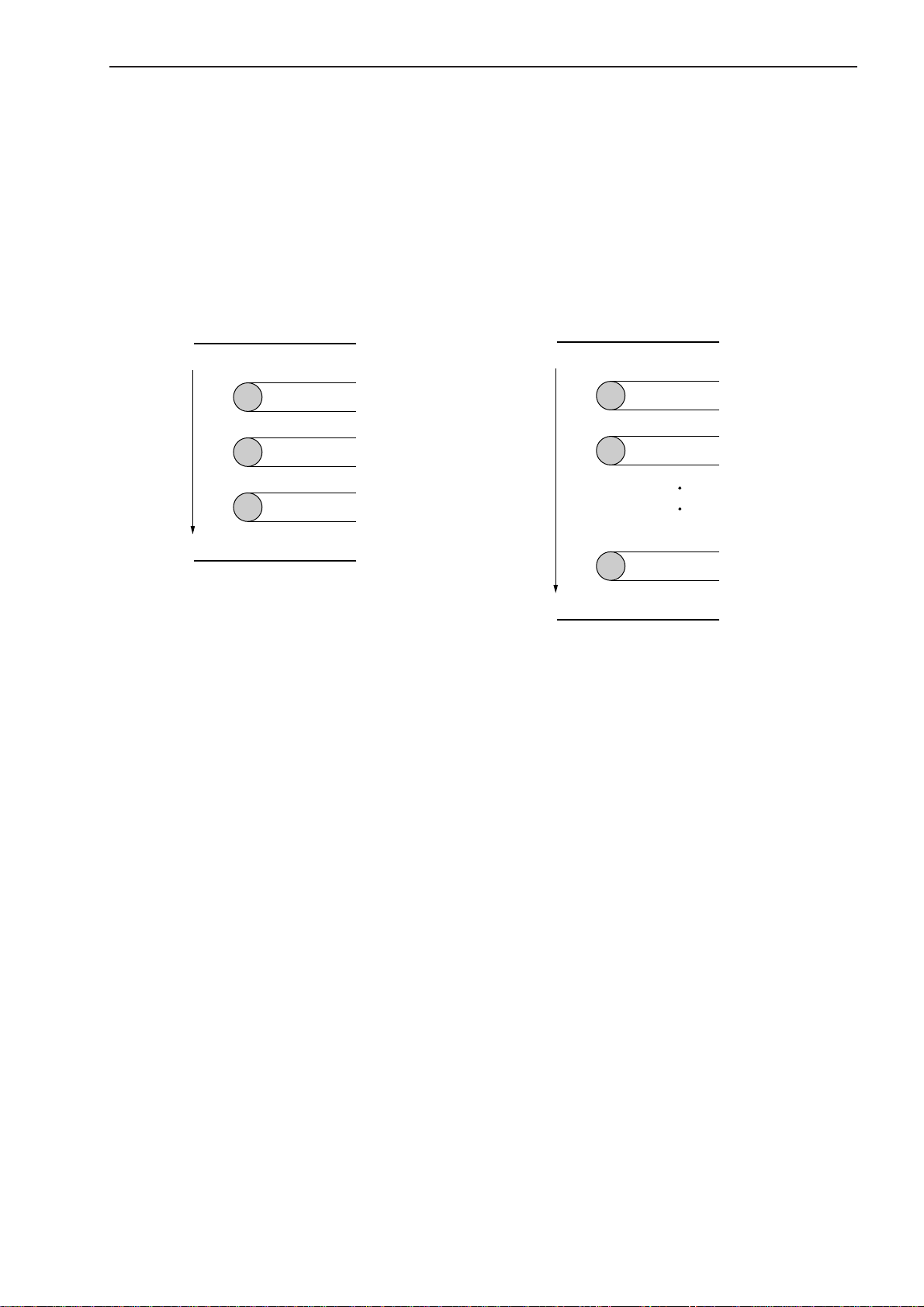

3.1.1.2 Setting the segment

Set the objective portion of a workpiece to be measured.

The highlighted and shaded portions created when the laser scans over the workpiece are

controlled with each assigned number. In the basic setup a selection must be made from one

of two cases: case where there are 1 to 4 highlighted and shaded sections, and case where

there are 1 to 127 similar sections. In the former case the portions are controlled through the

segment number, and are simply called segments. In the latter case the portions are controlled

by the edge number (edge number is between 1 and 255) and called edges. Edge numbers

equal to or greater than 256 are not available.

3. DISPLAYS AND KEY OPERATIONS

Segment specification

Highlight 1

Shade 1

Highlight 2

Shade 2

Highlight 3

Direction of laser scanning

Shade 3

Highlight 4

SEG1

SEG2

SEG3

SEG4

SEG5

SEG6

SEG7

• A maximum of 4 highlighted sections and a

maximum of 3 shaded sections can be measured.

• Multiple segments can be specified at the same

time.

• Specify segments 1 to 3 for a transparent object.

Edge specification

EDGE1

Highlight 1

Shade 1

Highlight 2

Shade 2

Highlight 127

Direction of laser scanning

Shade 127

Highlight 128

EDGE2

EDGE3

EDGE4

EDGE5

EDGE254

EDGE255

EDGE256

• A maximum of 127 highlighted sections and a

maximum of 127 shaded sections can be measured.

• Always specify the start edge and finish edge

numbers. These two edges can be either continued or separated. However, they must not be

identical.

• Edge numbers can not be specified for a transparent object.

• If automatic measurement is specified in the basic

setup, intervals, outside diameters, or gaps

between the same shape of multiple pins can be

automatically measured.

No. 99MBC095A

3 - 3

Page 25

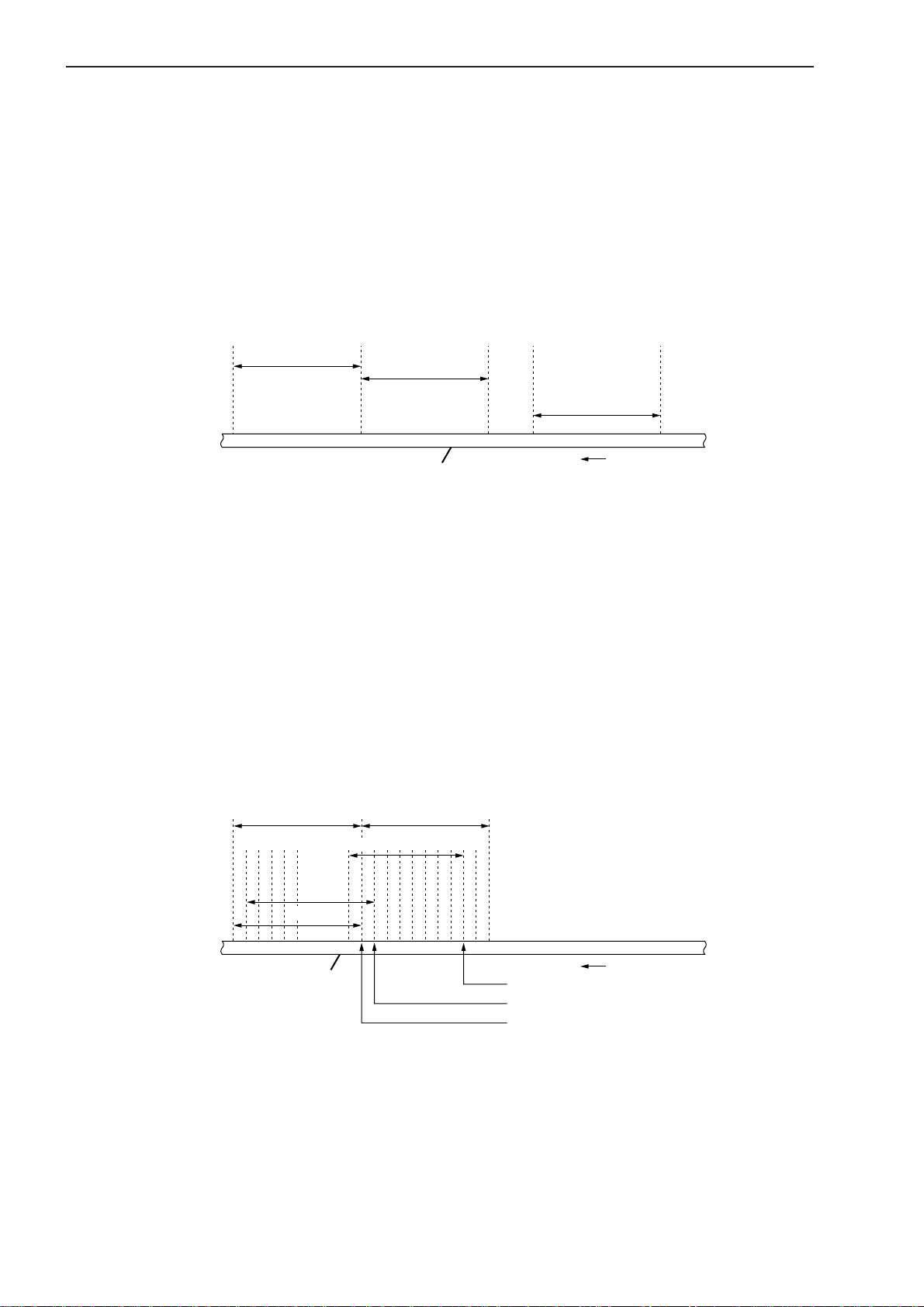

3.1.1.3 Measurement interval (measurement time)

A measurement interval (measurement time) varies depending on the averaging method and

the number of scans selected for the measurement data.

There are two types of averaging method: the arithmetical average and the moving average.

Select the one best suited for the user’s purpose.

1) Arithmetical average

• If a moving workpiece is measured, the OD of the workpiece is determined by averaging

the measured data taken from each section (a: first measurement, b: second measurement,

.... n: nth measurement) of the workpiece the specified number of averaging times, as

shown below.

2) Moving average

first measurement

second measurement

ban

Moving workpiece

. . .

nth measurement

Moving direction

• One of the following number of averaging times can be selected: 1, 2, 4, 8, ....1024, 2048.

(If extra fine wire measurement is specified in the basic setup, the number of averaging

times can be selected from between 16 and 2048.)

• This is suitable for measuring a still object or the run-out of rollers, etc.

In the moving average method, a measurement interval identical to that in the arithmetical

average is divided into finer sections such as a1 (1st measurement), a2 (2nd measurement), -

- - , an (nth measurement). Each measurement is performed almost in parallel. If, for ex-

ample, the number of averaging times is set to 512, the first measurement requires the

amount of time that corresponds to 512 scans. However, for the second measurement onward,

only the time for 16 scannings is required. With respect to a workpiece with a changing OD,

this method provides data with smooth variation because of the many pieces of data, and also

quickly detects the trend of workpiece OD variation.

Measurement with

arithmetical averaging

Measurement with

arithmetical averaging

3 - 4

an

. . .

a2

a1

Moving workpiece

an measurement

. . .

a2 measurement

a1 measurement

Moving direction

Output of an measurement

Output of a2 measurement

Output of a1 measurement

• One of the following number of scans can be selected: 32, 64, 128, ....1024, 2048.

• This method is suitable for the feedback control of wire drawing machines and extruding

machines.

No. 99MBC095A

Page 26

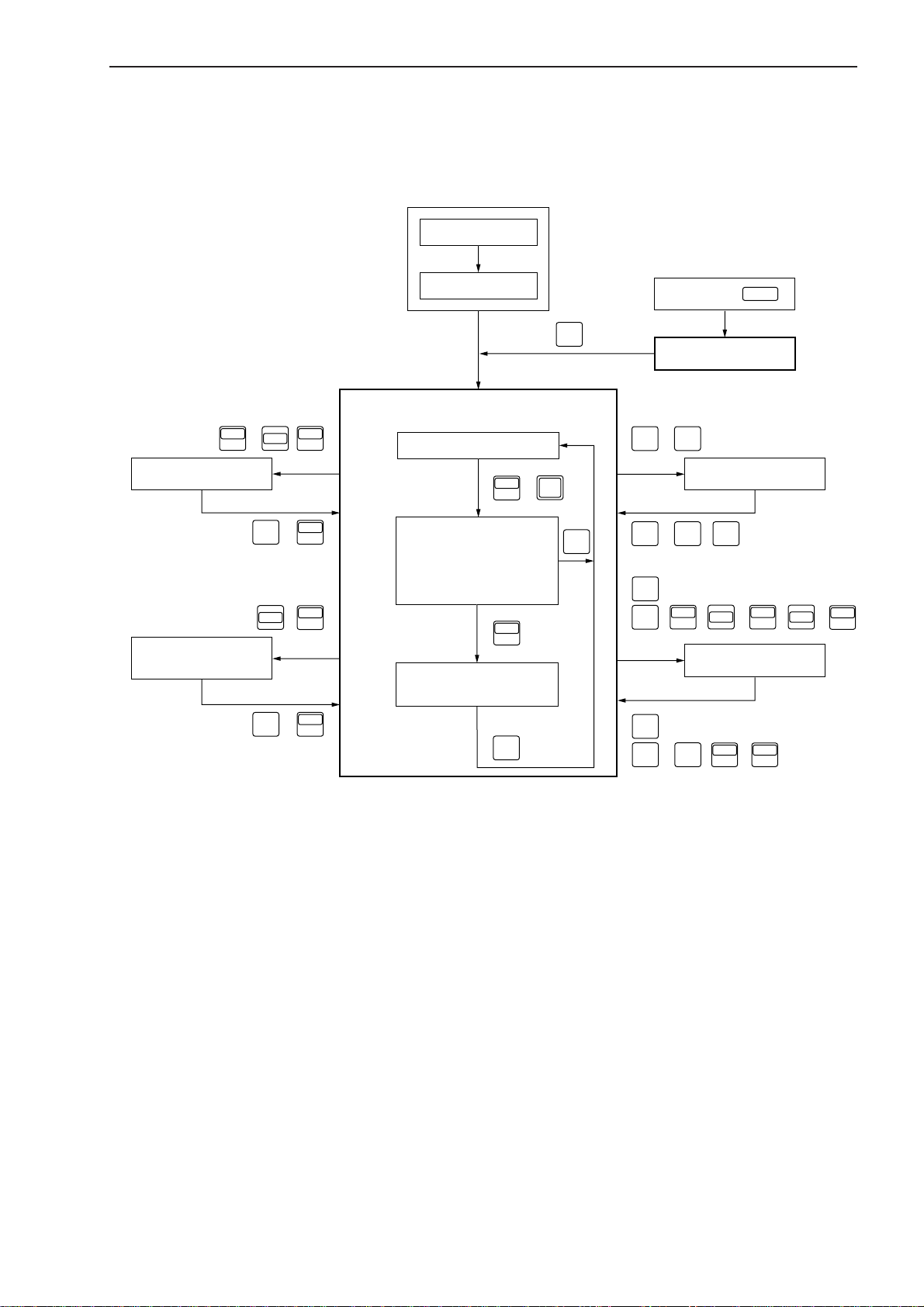

3.1.2 Outline of the Operation Modes

The LSM system has the following modes:

1: Basic setup mode, 2: Calibration mode, 3: Function setup mode, 4: Other setup mode, 5:

Statistical result display mode, and 6: Measurement mode.

3. DISPLAYS AND KEY OPERATIONS

Power ON

LOCK

4: Other setup mode

5 : Statistical result

display mode

Error check

SET

6 : Measurement mode

, ,

ENT

UNITUNIT

LOCK

( )

UNIT

Ready state

DATA C

,

RUN

Measurement in progress

(Program being executed)

C.RUN

C

LOCK

SHIFT

H.CAL L.CAL

ENT

• Single-run measurement

SHIFT

S.PR

PRINT

• Continuous-run

• measurement

( )

DATA C

RUN

SET

•

LIMIT

• , , + , +

Measured data display

(Latched display)

S.PR

SET

( )

PRINT

• Latch timer

C

•

SET

•

ENT

• ( , , )

Power ON +

SET

1 : Basic setup mode

2 : Calibration mode

( , )

H.CAL L.CAL

MASTER

REF

SHIFT

MASTER

REF

3 : Function setup mode

P.S V

MASTER

LIMIT

REF

P.SET

SHIFT

P.S V

P.SET

No. 99MBC095A

3 - 5

Page 27

3.1.2.1 Basic setup mode

• This mode is used to customize the basic setup conditions, including the resolution,

interface conditions, and available functions, according to the measurement requirements.

For more information, refer to Section 4.1, “Basic Setup”.

• To enter the basic setup mode turn on the power (turn the key switch clockwise from the

“O” position to the “I” position) while holding down the

key for about 2 seconds to initiate the basic setup mode.

3.1.2.2 Calibration mode

• Depending on the environment in which the LSM is used and the Display Unit - Measuring Unit combination, measurement errors may result. Therefore, always perform calibration prior to use, taking the measuring range and environmental conditions into account.

If calibration is performed, the errors described above will be reduced and high accuracy

will be ensured.

• Before performing calibration, always make the setups for resolution, simultaneousmeasurement, dual-unit measurement and available segments in the basic setup mode. If

this order is reverse, the previously set calibration values may be discarded.

• For more information, refer to Section 4.2, “Calibration”.

• Press the

key to enter the HI CAL mode; and press the

H.CAL

CAL mode.

3.1.2.3 Measuring condition setup mode

key. Hold down the

SET

key to enter the LOW

L.CAL

• This mode is used to set up measuring conditions, including segments (objective portion of

workpiece to be measured) and GO/NG judgment criteria.

• Press the

• Each of the

the individual function setup item to be established.

• Press the key to enter the setup operation for the setup item which is used most

often.

3.1.2.4 Other setup mode

• This mode is used to set the key lock and to set the unit of measurement.

• Press the

LOCK/

UNIT

• Press the

3.1.2.5 Statistic display mode

• Displays the statistical processing results.

• Press the

• Press the

results to be printed.

key to enable all the function setup items established to be set in a batch.

SET

LIMIT, SHIFT

and

SHIFT

LOCK/

→

P.S V/

key to turn on and off the key lock; and press only the

UNIT

P.SET

,

MASTER/REF

,

SHIFT

→

MASTER/REF

keys allows

key to enter the unit change mode.

SHIFT

SHIFT

SHIFT

and

and

and

key to enter the measuring position display mode.

READ

STAT/S.E

S.PR/

keys in the ready state to enter the statistic display mode.

keys in the ready state to allow the statistical processing

PRINT

3 - 6

No. 99MBC095A

Page 28

3.1.2.6 Measurement mode

This mode can be divided into the following operational states:

1) Measurement in the ready state

• This is the measurement mode that is entered immediately after the power is turned on

or if another measurement mode is aborted by pressing the

signal from the I/O interface or the “CL” command from the RS-232C/GP-IB interface).

• It is used to establish setups for calibration and available functions, which are not part

of the basic setup items, or to enter another measurement mode including single-run

measurement.

• Usually GO/NG judgment and analog output will not take place for measurement in the

ready state, however, these specifications can be made in the basic setup mode.

• Measurements in the ready state are unavailable for statistical processing.

2) Single-run measurement

• If the

the RS-232C/GP-IB interface) is pressed, one session of measurement is performed and

the results will be automatically subject to GO/NG judgment and analog output. In

addition, the measured data will be outputted for the RS-232C/GP-IB interface,

Digimatic Output Unit, and printer. The measured data will be held (latched for the

specified period) in the display.

• This data will be available for statistical processing.

DATA C/RUN

3. DISPLAYS AND KEY OPERATIONS

key (or by the RESET

C

key (otherwise input RUN via the I/O interface or “R” command via

3) Continuous-run measurement

• If the

key (otherwise input RUN+RESET via the I/O interface or “CR” command

C.RUN

via the RS-232C/GP-IB interface) is pressed, one session of measurement is started and

repeated the specified number of times. The measured data will be automatically subject

to GO/NG judgment and analog output. In addition, the measured data will be outputted

for the RS-232C/GP-IB interface, Digimatic Output Unit, and printer.

• Press the

DATA C/RUN

or

key (or if RUN is received from the I/O interface)

C.RUN

again to terminate the measurement and hold the measured data on the display. If the

key (or input RESET via the I/O interface or “CL” command via the RS-232C/GP-

C

IB interface) is pressed halfway, the measurement is aborted and the ready state is

returned to.

• The measurements are available for statistical processing.

4) Continuous measurement with a term specification

• This will take place where RUN input from the I/O interface has been assigned so as to

start a term-specified continuous-run measurement in the basic setup.

• Repeatedly performs single-run measurement while RUN signal input continues, which

is basically the same as the continuous-run measurement. Therefore, hereafter, continuous-run measurement includes the ones with a term specification.

• The measurements are available for statistical processing.

No. 99MBC095A

3 - 7

Page 29

5) Zero-run measurement

• A measurement where the number of samples is set to “0” is called a “zero-run measurement”.

• If the

DATA C/RUN

key (otherwise input RUN via the I/O interface or the “R” command

via the RS-232C/GP-IB interface) is pressed, single-run measurement is started and

repeated until the

DATA C/RUN

key is pressed again (or RUN is inputted via the I/O

interface or the “STOP” command is inputted via the RS-232C/GP-IB interface). From

the measured data the calculation items (mean, maximum value, minimum value, and

range) that have been set for the sample measurement will be calculated and the

resulting data will be automatically subject to GO/NG judgment and analog output. In

addition, the measured data will be outputted for the RS-232C/GP-IB interface,

Digimatic Output Unit, and printer. The measured data will be held on the display.

• The measured data are available for statistical processing.

• This is suitable for run-out measurement and cylindricity measurement.

6) Sample measurement

• A measurement where the number of samples is set to “2~999” is called a “sample

measurement”.

• In practice this will take place as a single-run measurement or a continuous-run measurement (with a term specification).

From the measured data the calculation items (mean, maximum value, minimum value,

and range) that have been set for the sample measurement will be calculated and the

resulting data will be automatically subject to GO/NG judgment and analog output. In

addition, the measured data will be outputted for the RS-232C/GP-IB interface,

Digimatic Output Unit, and printer.

• The measured data are available for statistical processing.

• This is suitable for run-out measurement and cylindricity measurement.

7) Statistical processing

• Measured data from single-run and continuous-run measurements can be statistically

processed (i.e. the number of measurement times, standard deviation, maximum value,

minimum value, mean, and range are calculated).

These statistical processing results can be outputted for the display, printer (statistical

memory for all programs will be cleared after printout), and RS-232C/GP-IB interface.

• Press the

STAT/S.E

key (or input “ST” command via the RS-232C/GP-IB interface) to

start statistical processing, and press it again (or input the “NST” command via the RS232C/GP-IB interface) to terminate statistical processing.

• Performs single-run measurements or continuous-run measurements to store statistical

data after statistical processing has been started.

• Pressing the

SHIFT

→

DATA C/RUN

, and

keys in this order will cancel the last

ENT

measurement.

• Pressing the

The item displayed will change each time the key

SHIFT

and

STAT/S.E

keys will display the results of statistical processing.

is pressed.

ENT

The display item will change in this sequence: [N: Measurement number], [S.D:

Standard deviation], [MAX: Maximum value], [MIN: Minimum value], [AVG: Mean

value], and [R: Range (Max - Min)].

Statistical processing will be performed independently for each program.

• Press the

A.CL/M.CL

(case of a simultaneous measurement), and press the

key to clear the statistical memory of the foreground program

SHIFT

and

A.CL/M.CL

keys to

clear the statistical memory of all the programs.

• These statistical results data will be stored in memory while the power is on, and will

be lost when the power is turned off.

3 - 8

No. 99MBC095A

Page 30

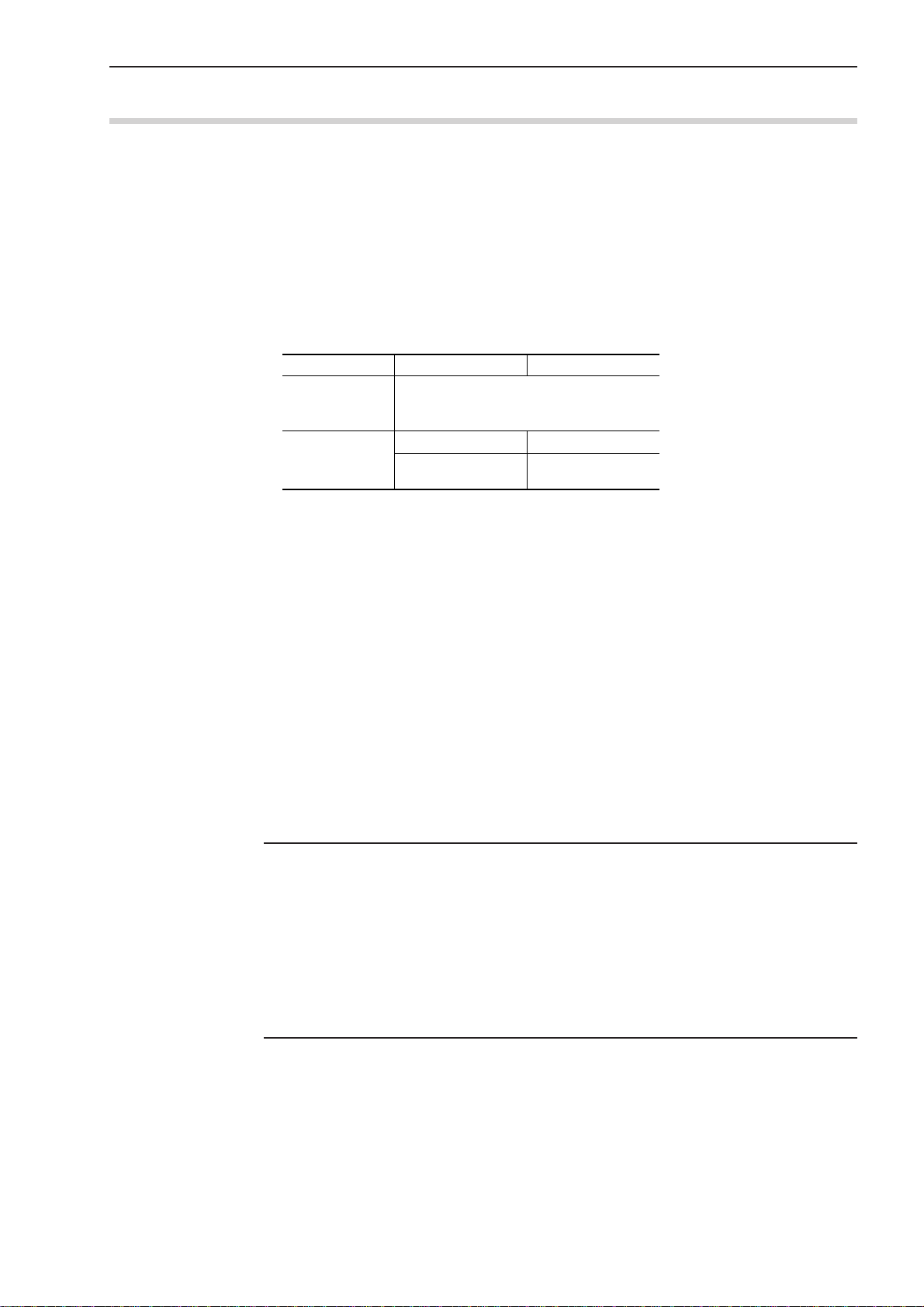

3. DISPLAYS AND KEY OPERATIONS

3.2 Techniques and Terminology of Setup Functions

3.2.1 Program

• A measurement will be automatically performed according to the registered (programmed)

contents including the segment (feature to be measured) and GO/NG judgment criteria,

etc., in advance. Registration is performed in the function setup mode.

• This unit can hold a maximum 100 programs, which may include various settings suitable

for up to hundred kinds of workpieces.

• Program numbers are divided into groups, each of which has up to ten programs and is

referred to as a channel (CH).

These two-digit program numbers define the meanings as shown in the table below.

Digit of ten

Program No.

Channel No.

Application

• As the expanded basic setup it is possible to select the range of applying calibration.

1. Applies uniformly to the entire 100 programs (factory default).

2. Applies individually to each channel (10 programs).

• With the expanded basic setup it is possible to select the range of applying presetting and

mastering.

1. Applies uniformly to the entire 100 programs (factory default).

2. Applies individually to each channel (10 programs).

3. Applies individually to each program.

• As the expanded basic setup it is possible to select either the “100 Program mode” or “10

program mode”, which limits the number of available programs to ten. (The factory

default setting is the 100 program mode.)

• As the basic setup it is possible to select either the “Single measurement mode” which

uses 100 programs (10 programs in the 10 program mode) as independent programs or the

“Simultaneous measurement mode” which uses two specific programs as a pair.

0 to 9

16

Digit of one

Individual No.

For each channel

0 to 9

No. 99MBC095A

NOTE • If the program must be switched to another with the RS-232C/GP-IB command, it

is necessary to use a separate command for the 100 program mode or 10 program mode.

For more information about the RS-232C/GP-IB command refer to Section 6.1.2.4

“RS-232C/GP-IB Commands”.

• In the 10 program mode the user can make use of the RS-232C/GP-IB commands

provided for Mitutoyo old models (LSM-6000, 6100) without further modification. It

is advised for the customers, who are operating Mitutoyo old models (LSM-6000,

6100) with the RS-232C communication commands, to use the 10 program mode.

3 - 9

Page 31

a) Single measurement

One session of measurement will be performed according to the one specified program.

The factory default setting is this single measurement.

b) Simultaneous measurement

• In one measurement session two specific programs are executed at one time as a pair.

Combinations of program numbers to form these pairs are shown in the following table.

• To run a pair of programs, either of the two can be specified via one of the numeric

keys and the one specified is called “foreground program”, and its counterpart is called

“background program”.

<<Possible combinations in the 100 program mode>>

Channel No. (Digit of ten of the program number) [0 to 4]

01234

00 & 05 10 & 15 20 & 25 30 & 35 40 & 45

Program

numbers pairs

Program

numbers pairs

01 & 06 11 & 16 21 & 26 31 & 36 41 & 46

02 & 07 12 & 17 22 & 27 32 & 37 42 & 47

03 & 08 13 & 18 23 & 28 33 & 38 43 & 48

04 & 09 14 & 19 24 & 29 34 & 39 44 & 49

Channel No. (Digit of ten of the program number) [5 to 9]

56789

50 & 55 60 & 65 70 & 75 80 & 85 90 & 95

51 & 56 61 & 66 71 & 76 81 & 86 91 & 96

52 & 57 62 & 67 72 & 77 82 & 87 92 & 97

53 & 58 63 & 68 73 & 78 83 & 88 93 & 98

54 & 59 64 & 69 74 & 79 84 & 89 94 & 99

3.2.2 Basic setup

<< Possible combinations in the 10 program mode>>

00 & 05

Program

numbers pairs

01 & 06

02 & 07

03 & 08

04 & 09

• This is used to customize the basic setup conditions, including the resolution, available

functions, and interface conditions, according to the measurement requirements.

• This basic setup must be performed at the beginning of a measurement. Note that changing

the setup of resolution, simultaneous measurement, or dual-unit measurement in this basic

setup cancel the existing calibration values and function setup.

• The basic setup mode is entered by turning on the power while holding down the

SET

key.

Note that no response will be made to an I/O interface input and RS-232C/GP-IB command in the basic setup mode.

• For more information, refer to Section 4.1, “Basic Setup”.

3 - 10

No. 99MBC095A

Page 32

3. DISPLAYS AND KEY OPERATIONS

3.2.3 Function setup

• Use this procedure to set up the conditions necessary for measurement.]

For each program number register measurement conditions including the segment (part

feature to be measured), measurement interval (measurement time), and GO/NG judgment

criteria that are the best suited for the objective workpiece.

• To enter the function setup mode press the

LIMIT, SHIFT

→

P.S V/

P.SET

,

MASTER/REF

setup item to be established, and the

SET

,

SHIFT

key enters the setup operation for items which

are most frequently accessed for set up.

• For more information refer to Section 4.5, “Setting Up the Functions”.

3.2.4 Setups according to the property of each workpiece

For measuring workpieces that transmit light or have a dimension smaller than the diameter

of the scanning beam it is critical to make setups that take into account the properties of the

workpiece.

3.2.4.1 Transparent object (Workpiece that transmits light)

a) Round bar

• Workpieces such as fiber optics and glass tubes are more or less transparent, while

workpieces made of steel are not. This requires different segment settings.

The segment settings for an opaque object and a transparent object are as follows:

• Setup for measurement of transparent or opaque object is possible in the basic setup.

key in the ready state. Each of the

→

MASTER/REF

keys allows the individual

Laser scan direction

Transparent

Workpiece

Photo-electric signal

For opaque object

Binary voltage (SHL)

Segment 1Segment 1

Segment 2

Segment 3 Segment 2

Segment 4

Segment 5 Segment 3

For transparent object

No. 99MBC095A

3 - 11

Page 33

b) Plate (Sheet)

W

Workpiece

Direction of light is turned,

and is not incidental to the

photo-electric element.

• In the case of the width measurement of a transparent plate with no chamfer on edges,

measurement may not be possible since acute-edge signals cannot be produced for such

edges.

Photo-electric signal

Laser scan direction

Transparent Workpiece

Measurement is aborted

Ideal edge signal

Binary voltage level (SHL)

because a sharp edge

can not be determined.

• For measuring a transparent plate-shaped workpiece

Take the following precautions:

1. Incline the workpiece.

By inclining the workpiece it is possible to attain a sharp edge from the light contrast. In this case:

Measurement : W = W0 (workpiece dimension) x cos θ

θ

W

2. Chamfering

Chamfer the workpiece edge by W. W will vary depending on the model. Always

use values larger than those in the table below.

Workpiece

0

ledomtinUgnirusaeMW:tnuomagnirefmahC

S005-MSLmm1.0

S105-MSLmm1.0

S305-MSLmm2.0

S605-MSLmm4.0

S215-MSLmm8.0

S615-MSLmm2.1

Direction of light is turned, and is not incidental to the photo-electric element.

W

3 - 12

No. 99MBC095A

Page 34

3. DISPLAYS AND KEY OPERATIONS

3. Changing the SHL

• With the reference workpiece set up on the Measuring Unit, connect the oscilloscope

to the [SCAN SIG.] terminal on the rear panel of the Display Unit and observe the

signal.

• SHL is the signal level for detecting a workpiece. Changing the level from the

standard level of 50% to a level such as 75% will enable the measurement of a

transparent sheet. The measurement accuracy, however, will be degraded since

measured data fluctuates according to the edge conditions of the sheet.

• It is possible to set the SHL level between 5% to 95% for "7 SHL" by setting up

"7 ADD"="USE" and "7 DLC"="OFF" in the expanded basic setup.

NOTE Measuring accuracy differs from that of the standard set up.

• Measured data differs with the change of the SHL. Perform calibration again if the

SHL setting has been changed.

• Measurement error can be reduced by performing calibration with the reference

standard, the edges of which have been made in the same condition as those of the

sheet to be measured.

Photo-electric signal

Laser scan direction

Transparent Workpiece

Standard SHL (50%)

New SHL: Set to 50 (1+v2/v1)%

v 1

v 2

v1: Peak voltage of photo-electric signal

v2: Larger voltage of the two at edges

(as generated at the edge with

better transmittance)

IMPORTANT • When the SHL (signal level for detecting a workpiece) is modified, the measure-

ment accuracy will be inevitably reduced, since the measured data may easily

fluctuate with the edge conditions.

• Once the SHL (signal level for detecting a workpiece) has been modified, always

perform another calibration.

• If an identical edge form is selected for both for the calibration standard and

workpiece (sheet), it may be possible to reduce these measurement errors.

No. 99MBC095A

3 - 13

Page 35

3.2.4.2 Ultra-fine wire measurement

• In the special ultra-fine wire measuring region, a clear shade can not be obtained because a

workpiece, with a finer diameter than that of the laser beam at the focal position, must be

measured. Therefore, this wire diameter must be calculated according to a special algorithm. This requires the following restrictions to be taken into account in the basic setup

where an ultra-fine wire measurement is designated.

a) Measuring interval (measurement time)

Note that the measurement time for the first measurement becomes 0.02 seconds longer

than the first interval since the wire diameter must be identified at the start of ultra-fine

wire measurement.

• Single-run measurement: (Measurement interval + 0.02 seconds)

• Continuous-run measurement: (Measurement interval + 0.02 seconds) for the first

b) Number of averaging times

Select a number between 16 and 2048.

c) Designation of the objective portion of workpiece to be measured

Only a segment specification is allowed, but an edge specification is not. If an edge

specification has been made before the setup for the ultra-fine wire measurement is

established, it is automatically changed to segment specification.

In other cases where multiple segments are set for the LSM-500S, the minimum