Page 1

No.99MBE032A5

SERIES No.174

KA Counter

KA Counter

for Linear ScaleUnits

User’s Manual

Read this User’s M anua l thor ough l y

before operating the i nstr um ent. After read ing,

retain it close at hand f or f uture refer ence .

Page 2

CONVENTIONS USED IN THIS MANUAL

Safety Precautions

To ensure that instruments are operated correctly and safely, Mitutoyo manuals use

various safety symbols (Signal Words and Safety Alert Symbols) to identify and warn

against hazards and potential accidents.

The following signs indicate general warni ngs:

Indicates an imm inently hazardous situation whic h, if not avoided, will result in ser ious

DANGER

WARNING

injury or death.

Indicates a potent ially hazar dous situation whic h, if not avoide d, could result i n serious

injury or death.

CAUTION

Indicates a potent ially haza rdous situatio n which, if not avoided, m ay result in m inor or

moderate injury or property damage.

The following signs indicate specific warnings or prohibited actions, or indicate a

mandatory action:

Alerts the user to a specific hazardous s ituation. The given example m eans “Caution,

risk of electric shock”.

Prohibits a specific action. The given example means “Do not disassemble”.

No. 99MBA040A

Specifies a required action. The given example means “Ground”.

i

Page 3

CONVENTIONS USED IN THIS MANUAL

Types of Notes

The following types of notes are used in this manual to hel p the operator obtain relia ble

measurement data through correct instrument operation.

IMPORTANT

NOTE

TIP

• An important note provides information essential to the completion of a task. You cannot

disregard this note to complete the task.

• An important note is a type of precaut ion, which if neglected co uld result in a loss of

data, decreased accuracy or instrument malfunction/failure.

A note emphasizes or s upplements important points of the main text. It also suppl ies

information about specific situations (e.g., memory limitations, equipment

configurations, or details that apply to specific versions of a program).

A tip is a type of note that helps the user apply the techniques and procedures described

in the text to his or her specific needs.

It also provides reference information associated with the topic being discussed.

Mitutoyo assumes no liability to an y party for any loss or dam age, direct or ind irect,

ii

caused by use of this instrument not conforming to this manual.

Information in this document is subject to change without notice.

2003 Mitutoyo Corporation. All rights reserved.

No. 99MBA040A

Page 4

SAFETY PRECAUTIONS

Be sure to read this section and obey the following precautions in order to use the counter

safely.

WARNING

• This counter is intended to be used with general measuring instruments, machine tools,

etc. Do not use this counter with control equipment associated with medical

instruments, aerospace eq uipment, nuclear-energy relate d equipment or the like that,

due to malfunction or accident, could cause injury or death. Consult with Mitutoyo

before using it in such equipment.

• Risk of fire or electric shock. If there is smoke or bad odor coming from the counter, or if

the counter is not operating properl y, imm ediately turn OFF the m ain power swi tch on

the rear panel and unplug the power cord, then contact the dealer for repairs.

• Ris k of fire or el ectric shoc k. If the cou nter is drop ped or dam aged, turn OFF the main

power switch on the rear panel and unplug the power cord, then contact the dealer.

• Risk of fire or electric shock. The user should absolutely not repair or modify the

counter.

CAUTION

• If something gets inside the counter, first turn OFF the main power switch on the rear

panel and unplug the power cord, then contact the dealer.

• Be sure to use the specified power-supply voltage. Operating the counter on other

voltage than the specified could cause circuit failure, fire or electric shock.

• Do not expose the counter to direct sunlight or to excessively hot areas. The

temperature inside the counter could rise, causing fire.

• Do not place t he counter direc tly against a wall or the like. The tem perature inside the

counter could rise, ca using counter failure. Place t he counter at least 10 cm from the

wall so that the power cord can be removed easily.

• Be sure to ground the counter by connecting to the machine tool with the supplied

ground lead. This prevents the counter from malfunctioning.

No. 99MBA040A

iii

Page 5

WARRANTY

In the event that the Mitutoyo KA Counter should prove defective in workmanship or

material, within one year from the date of original purchas e for use, it will be repaired, at

our option, free of charge upon its prepaid return to us.

This warranty shall n ot apply if the product has been s ubject to fair wear and tear, abuse

through misuse or im proper use/handling/storage/m aintenance/service/repair or through

adaptation/modification by the original purchaser or an y third part y without prior written

consent of Mitutoyo or as a result of damage by an actual disaster or circumstances

beyond the control of Mitutoyo.

To obtain service under this warranty the product must be returned to the nearest Mitutoyo

Service Center. Any postage, insurance, or shipping charges incurred in returning the

product for service are the responsibility of the purchaser.

* This warranty is not transferable and is only valid within the country of the original

purchase.

* You may have additional rights under the laws of country of original purchase that do not

allow the exclusion of implied warranties or the exclusion or limitation of certain

damages. If these la ws apply, Mitutoyo’s limitations and exclusions may not apply to

you.

iv

No. 99MBA040A

Page 6

CONTENTS

CONVENTIONS USED IN THIS MANUAL.........................................................................................................i

SAFETY PRECAUTIONS .................................................................................................................................iii

WARRANTY......................................................................................................................................................iv

CONTENTS........................................................................................................................................................v

1 INTRODUCTION.................................................................................................................................... 1-1

1.1 Outline ....................................................................................................................................................1-1

1.2 Name and Function of Each Part .........................................................................................................1-2

1.2.1 Main unit.................................................................................................................................................1-2

1.2.2 Display....................................................................................................................................................1-4

1.2.3 Name and function of keys for the standard counter.........................................................................1-5

1.2.4 Name and function of keys for the lathe counter ...............................................................................1-6

1.2.5 3-axis counter........................................................................................................................................1-8

2 SETUP.................................................................................................................................................... 2-1

2.1 Opening the Package............................................................................................................................2-1

2.2 Installation..............................................................................................................................................2-2

2.3 Connecting to the Counter ...................................................................................................................2-3

3 BASIC OPERATION.............................................................................................................................. 3-1

3.1 Explanatory Notes.................................................................................................................................3-1

3.2 Basic Operations in the Standard Counter .........................................................................................3-2

3.2.1 Turning ON/OFF the power...................................................................................................................3-2

3.2.2 Counting and displaying.......................................................................................................................3-4

3.2.3 Switching the coordinate......................................................................................................................3-5

3.2.4 Zero-set..................................................................................................................................................3-5

3.2.5 Preset.....................................................................................................................................................3-5

3.2.6 Saving and recalling a datum point using the scale reference point

(When the AT100 series is connected.) ...............................................................................................3-8

3.2.7 Setting the machine origin using the AT700 series ..........................................................................3-11

3.2.8 Datum setting, centering and measuring with the touch signal probe

(Possible only when the AT100 series is connected.)......................................................................3-13

3.2.9 Halving the display..............................................................................................................................3-16

3.2.10 Bolt-hole circle machining..................................................................................................................3-17

3.2.11 Pitch machining...................................................................................................................................3-21

3.2.12 Zero approach machining...................................................................................................................3-24

3.2.13 Changing the unit of measurement...................................................................................................3-25

3.2.14 Addition mode.....................................................................................................................................3-26

3.3 Outline of the Lathe Counter..............................................................................................................3-28

3.3.1 Setting parameters for the lathe counter ..........................................................................................3-28

3.3.2 Lathe counter operation modes.........................................................................................................3-28

3.3.3 Configuration of coordinates.............................................................................................................3-29

3.3.4 Setup for tool offset............................................................................................................................3-29

No. 99MBA040A

v

Page 7

3.3.5 Count mode......................................................................................................................................... 3-31

3.3.6 Zero-setting/Presetting...................................................................................................................... 3-32

3.3.7 Tool number switch............................................................................................................................ 3-32

3.3.8 A/I coordinate switch..........................................................................................................................3-33

3.3.9 Halving the display............................................................................................................................. 3-35

3.3.10 Zero approach machining.................................................................................................................. 3-36

3.3.11 Changing the unit of measurement................................................................................................... 3-38

3.3.12 Saving and recalling a datum point using the scale reference point............................................. 3-38

3.3.13 Setting the machine origin using the AT100 series......................................................................... 3-38

4 PARAMETERS....................................................................................................................................... 4-1

4.1 Overview of Parameters .......................................................................................................................4-1

4.2 Types of Parameters .............................................................................................................................4-2

4.2.1 Parameters set for each axis............................................................................................................... 4-2

4.2.2 Parameters common to all axes.......................................................................................................... 4-6

4.2.3 Special parameters............................................................................................................................... 4-8

4.2.4 Display resolution when used for the AT100 series........................................................................4-10

4.3 Parameter Settings..............................................................................................................................4-13

4.3.1 Checking the parameter settings...................................................................................................... 4-13

4.3.2 Setting parameters for each axis ...................................................................................................... 4-14

4.3.3 Setting parameters common to all axes........................................................................................... 4-16

4.3.4 Parameters for the lathe counter mode............................................................................................ 4-18

4.3.5 Initializing the internal memory......................................................................................................... 4-19

4.3.6 Display contents and parameters in the addition mode..................................................................4-20

5 MAINTENANCE..................................................................................................................................... 5-1

5.1 Troubleshooting....................................................................................................................................5-1

5.1.1 Error messages .................................................................................................................................... 5-1

5.1.2 Error messages in the addition mode................................................................................................. 5-1

5.1.3 Wrong key operation............................................................................................................................ 5-3

5.1.4 Troubleshooting....................................................................................................................................5-3

5.2 Daily Maintenance for the Counter ......................................................................................................5-4

6 SPECIFICATIONS.................................................................................................................................. 6-1

6.1 Main Unit ................................................................................................................................................6-1

6.2 Connector Specifications.....................................................................................................................6-2

6.3 Accessories ...........................................................................................................................................6-2

6.3.1 Standard accessories........................................................................................................................... 6-2

6.3.2 Optional accessories............................................................................................................................ 6-3

6.4 Precautions for Using the Code Out Unit............................................................................................6-3

6.5 Precautions for Using the Linear Scale Adapter and Micrometer Head Adapter.........6-3

6.6 Conformance to CE...............................................................................................................................6-4

SERVICE NETWORK

vi

No. 99MBA040A

Page 8

1 INTRODUCTION

1

1.1 Outline

The KA Counter shall be connected to the following Mitutoyo linear scales:

・Optical scale : AT100 series

・Electromagnetic ind uc tio n sc ale : AT700 series

This chapter describes the name and function of each part.

The user is allowed to cho ose either of the “standard counter” or “lathe counter” modes

through the modification of related parameter.

In addition, it has incor porated various us eful functions that c an meet various needs at a

machining shop, thus realizing a general-purpose multi-performance counter.

No. 99MBE032A

1-1

Page 9

1.2 Name and Function of Each Part

The name and function of each part of the KA counter is given below.

On this product the user c an switch between the “standar d counter” and “lathe counter ”

modes through the s election of related parameter. Since each counter has the specific

display method and key functions, refer to the descriptions corresponding to each counter.

For the method of switching the counter model, refer to Section 4.2.2, Parameters

commonly set on all models.

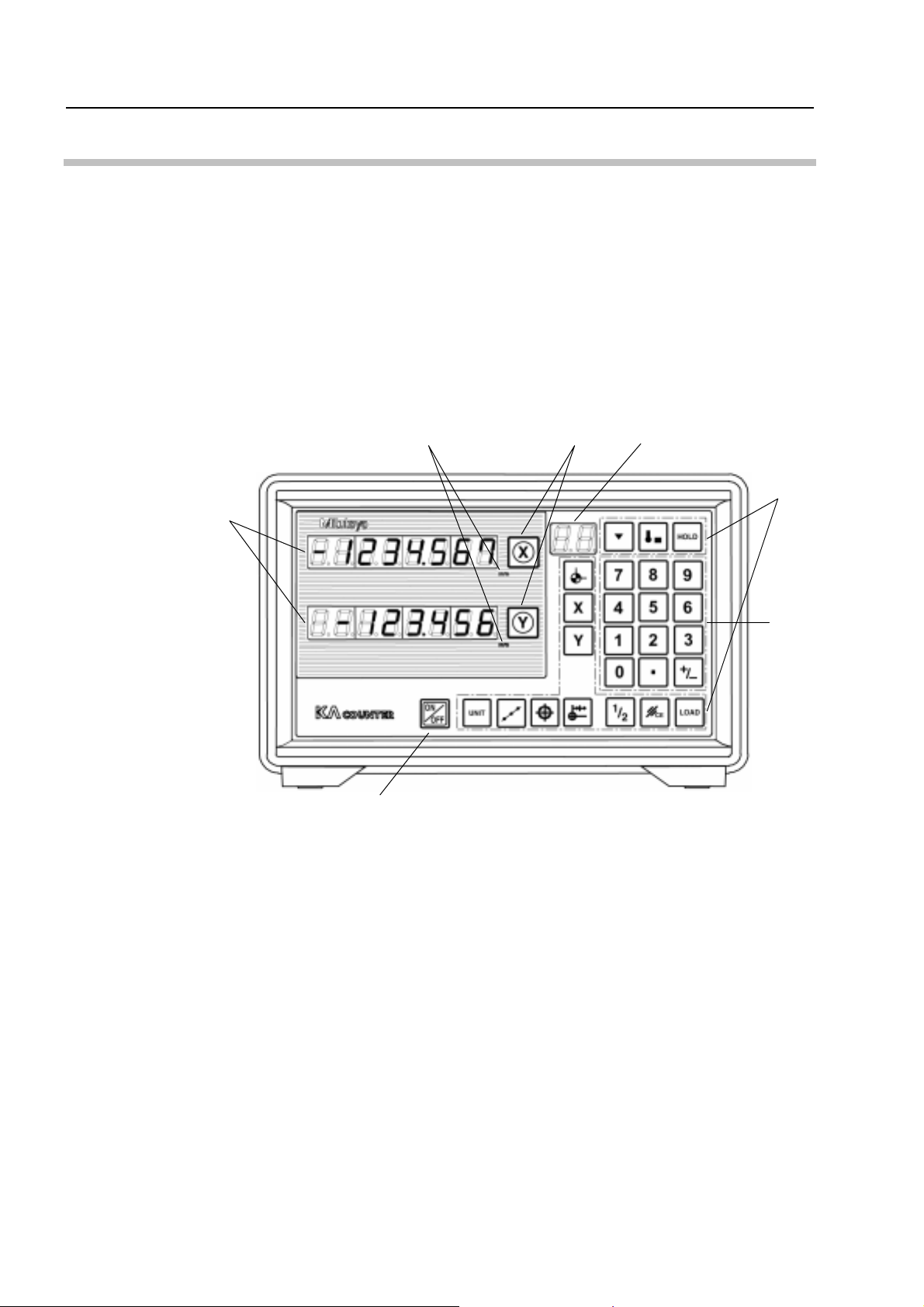

1.2.1 Main unit

1) Front panel

1

1 Display: Displays the values for the X-, Y-, and Z-axis, with a 1-digit sign and

7-digit number.

2 Sub-display: Displays set coordinates and display units.

3 Zero reset key: Resets the display for each axis to zero.

4 Ten-key pad: Keys used for entering numerical data.

5 Function keys: Keys for controlling the normal basic functions.

6 Display ON/OFF switch: Turns ON/OFF the display on the front panel.

7 Counting unit display: Displays the set unit of measurement.

6

7

3

2

5

4

1-2

No. 99MBE032A

Page 10

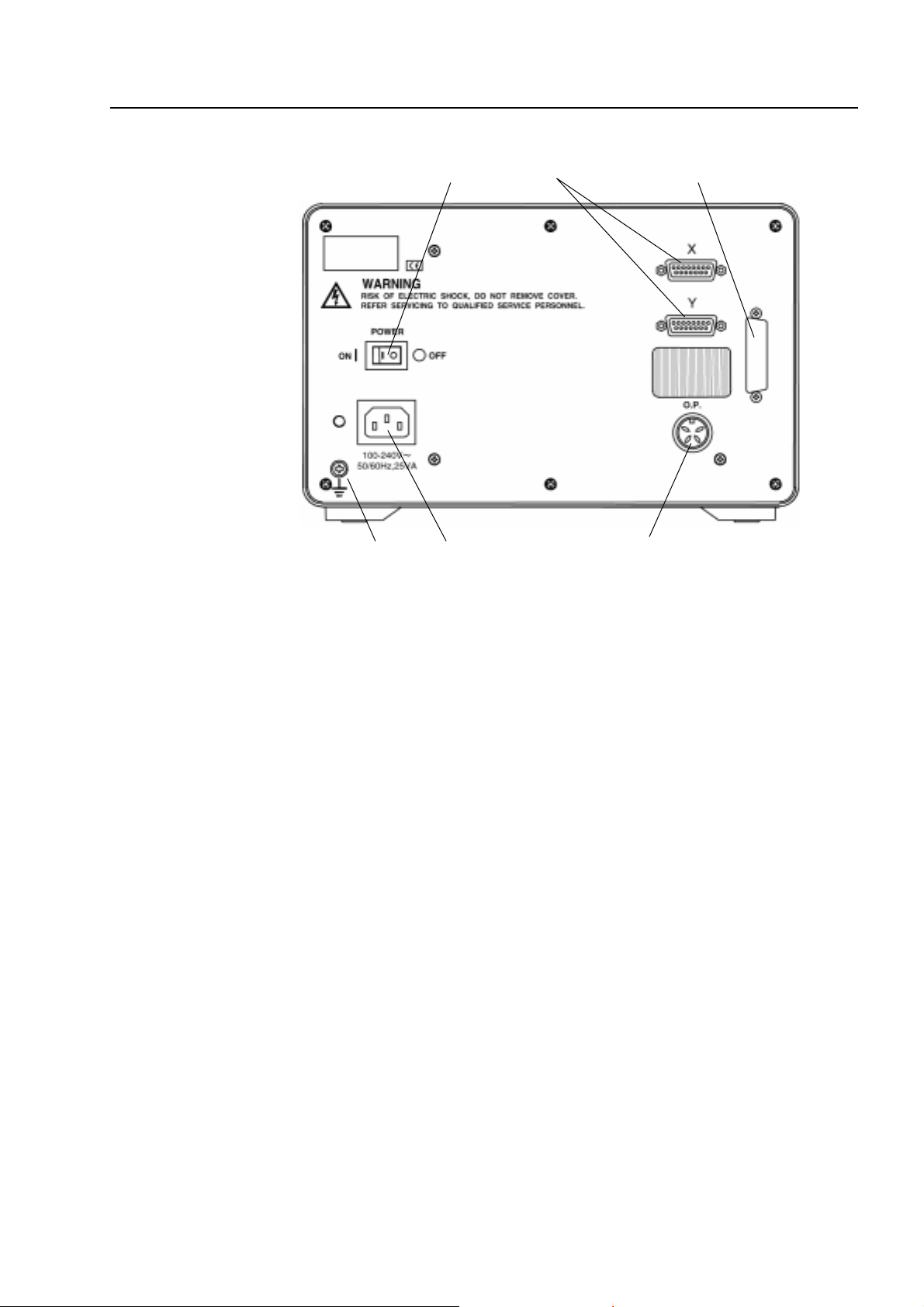

2) Rear panel

1. INTRODUCTION

1 AC inlet: Connects to the power cord.

2 Main switch: Main switch for turning ON/OFF the power.

3 Linear scale input connectors: Connect the X-, Y-, and Z-axis scale units.

4 Touch signal probe connector: Connects the touch signal probe.

5 Ground terminal: Terminal for connec ting to the grounding wire for gr ounding the

6 RS232C code out unit installation: For installing an optional RS232C code out unit.

51

main unit.

4

6 32

No. 99MBE032A

1-3

Page 11

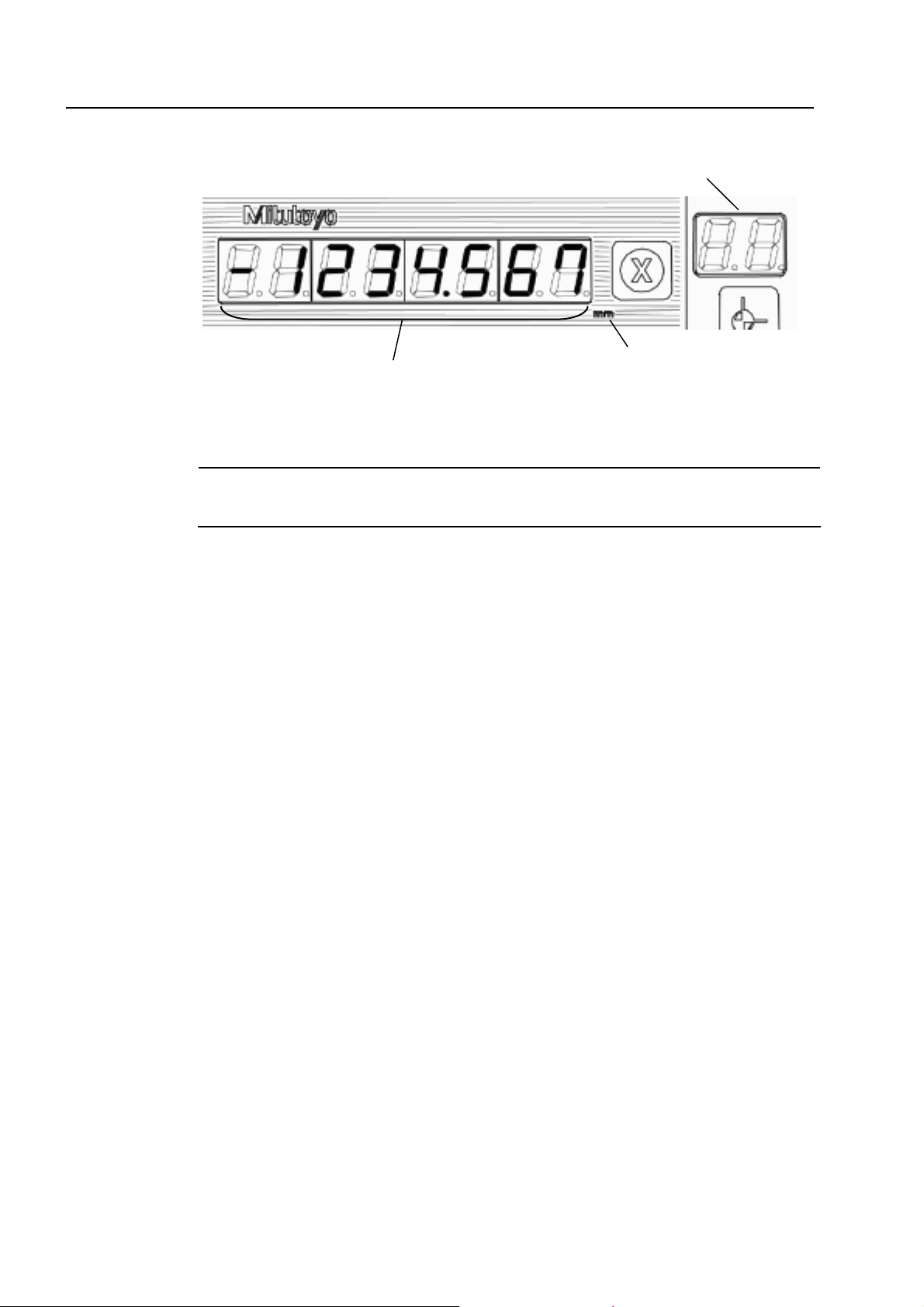

1.2.2 Display

1

2

3

1 Data display: Displays a 7-digit number (maximum) and decimal point.

2 Counting unit display: Displays the set unit of measurement.

NOTE

This display is only used when “mm” is selected. Nothing is displayed when inch or

1/25.4 is selected.

3 Shows the displayed coordinate number. This can be used to show the operation

mode.

1-4

No. 99MBE032A

Page 12

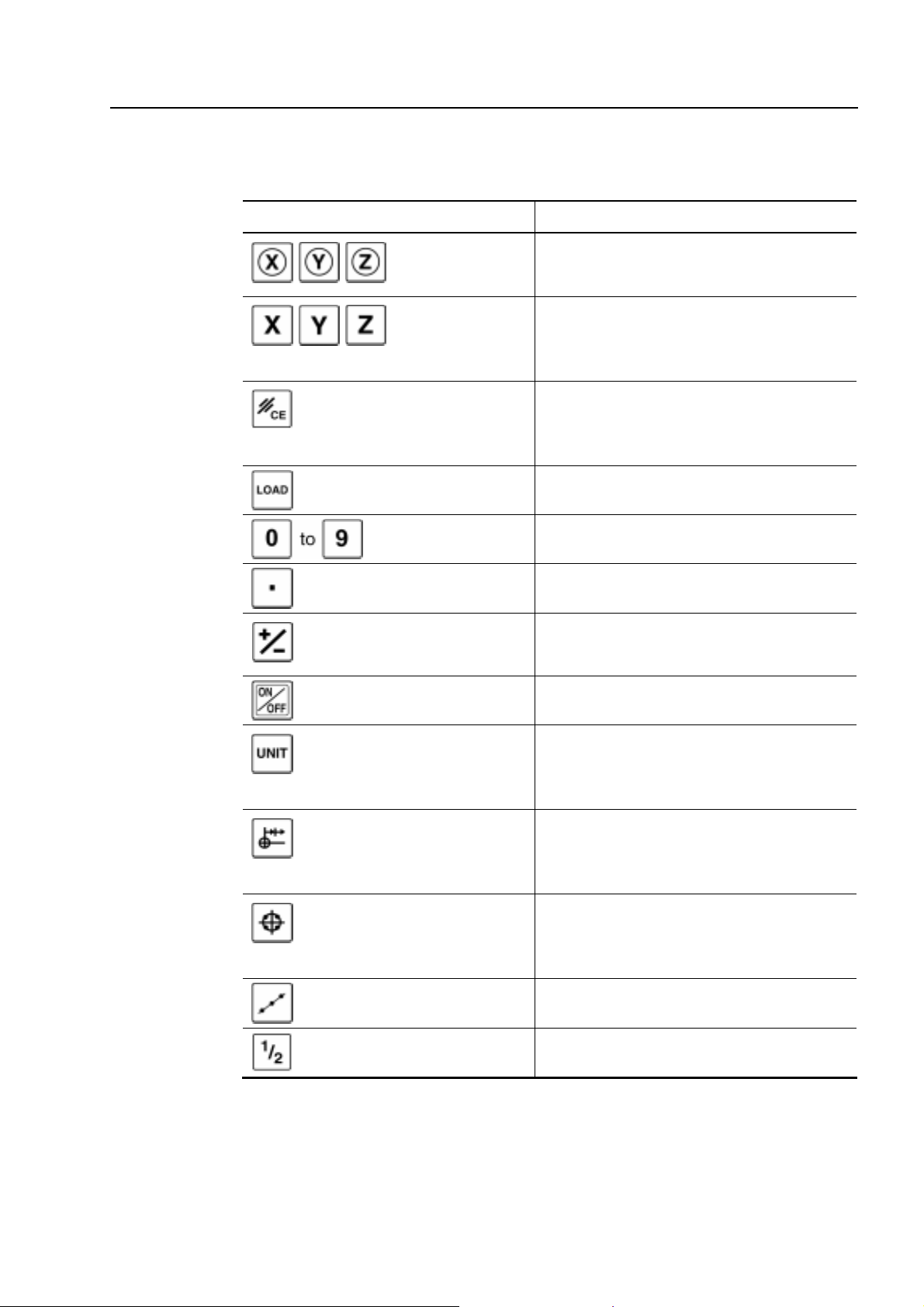

1.2.3 Name and function of keys for the standard counter

The name and function of the function keys and ten-key are given below.

Symbol and name Function

Zero-set k ey Resets the displayed value of the specified

axis to zero.

1. INTRODUCTION

Axis-designation

key

Cancel key • Cancels the number being entered.

Load key Loads the entered values.

Number keys Used to enter numbers 0 to 9.

Decimal-point key Sets the decimal point.

Sign key Switches the en tered number to negative or

ON/OFF switch Turns ON/OFF the display on the counter.

Display-unit switch key Switches the display unit.

• Designates the axis to be set.

• Calls up the previous setting.

• Enables ten-key input.

• Cancels the operation being executed.

• Cancels the error.

positive.

If mm is select ed, then the mm displa y ligh ts

up.

No. 99MBE032A

Zero-approach key The target value is automatically displa yed,

Bolt-hole circle key (av aila ble

with 2- and 3-axis counter)

Pitch machining key Used to perform a pitch machining.

1/2 key Halves the displayed value.

and sets the function to perform machining

until the displayed value is zeroed.

If holes are machined along a circumference,

this sets the function to automatically display

the target coordinates.

1-5

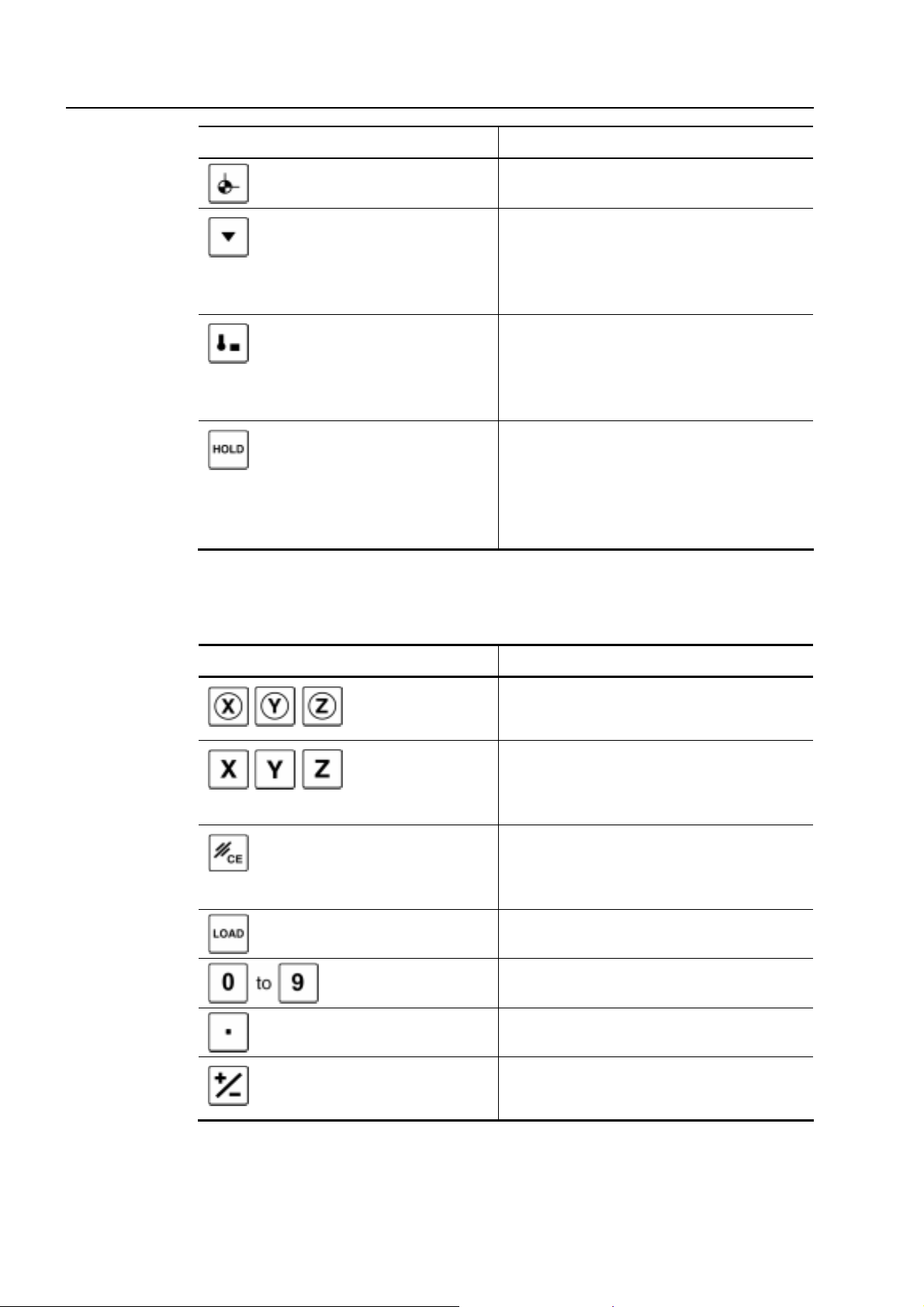

Page 13

Symbol and name Function

Coordinate switch Switches the coordinate between 0 and 9.

Datum point set key Sets the function for datum point recall

using a scale reference point.

(Possible only when the AT100 series is

connected.)

Touch signal set key Sets the function for datum point setting

with the touch signal.

(Possible only when the AT100 series is

connected.)

Hold key Sets the function to hold the counter display

using the signal from the scale reference

point and touch signal probe.

(Possible only when the AT100 series is

connected.)

1.2.4 Name and function of keys for the lathe counter

The name and function of the function keys and ten-key are given below.

Symbol and name Function

Zero-set key Resets the displayed value of the s pecified

axis to zero.

Axis-designation

key

Cancel key • Cancels the number being entered.

Load key Loads the entered values.

Number keys Used to enter numbers 0 to 9.

Decimal-point key Sets the decimal point.

• Designates the axis to be set.

• Calls up the previous setting.

• Enables ten-key input.

• Cancels the operation being executed.

• Cancels the error.

1-6

Sign key Switches the entered number to negative or

positive.

No. 99MBE032A

Page 14

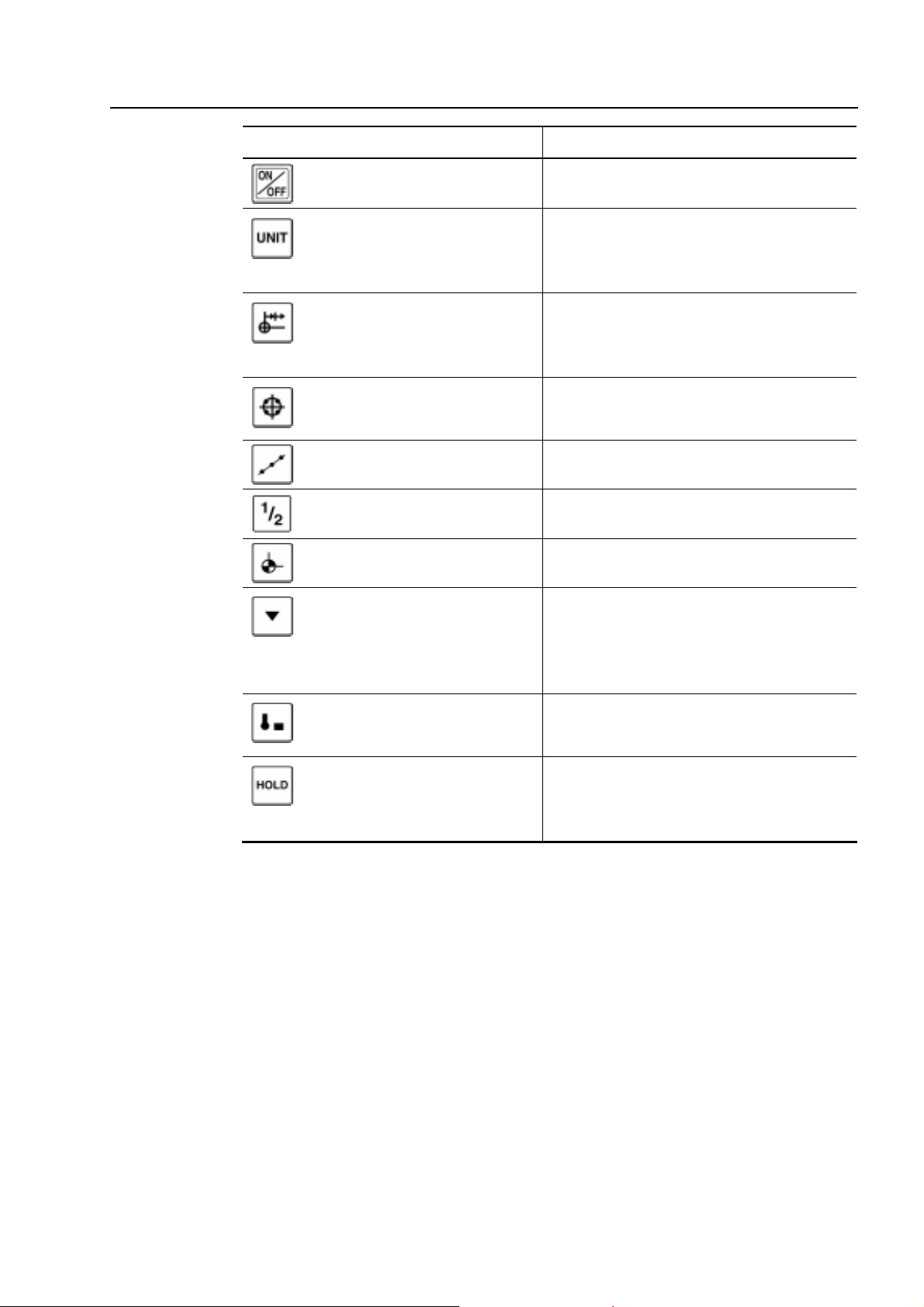

1. INTRODUCTION

Symbol and name Function

ON/OFF switch Turns ON/OFF the display on the counter.

Display-unit switch key Switches the display unit.

If mm is selected, then the mm display

lights up.

Zero-approach key The target value is autom aticall y displa yed,

and sets the function to perf orm machining

until the displayed value is zeroed.

Bolt-hole circle key (available

with 2- and 3-axis counter)

Pitch machining key Not used.

1/2 key Halves the displayed value.

Tool number switching key Switches the tool number between 1 and 4.

Datum point set key Sets the function for datum point recall

T ool’ s machining coordinate

switching key

Hold key Sets the function to hold the counter display

Not used.

using scale reference point.

(Possible only when the AT100 series is

connected.)

Switches the tool’s machining coordinate

over ABS and INC.

using the signal from the scale reference

point and touch signal probe.

No. 99MBE032A

1-7

Page 15

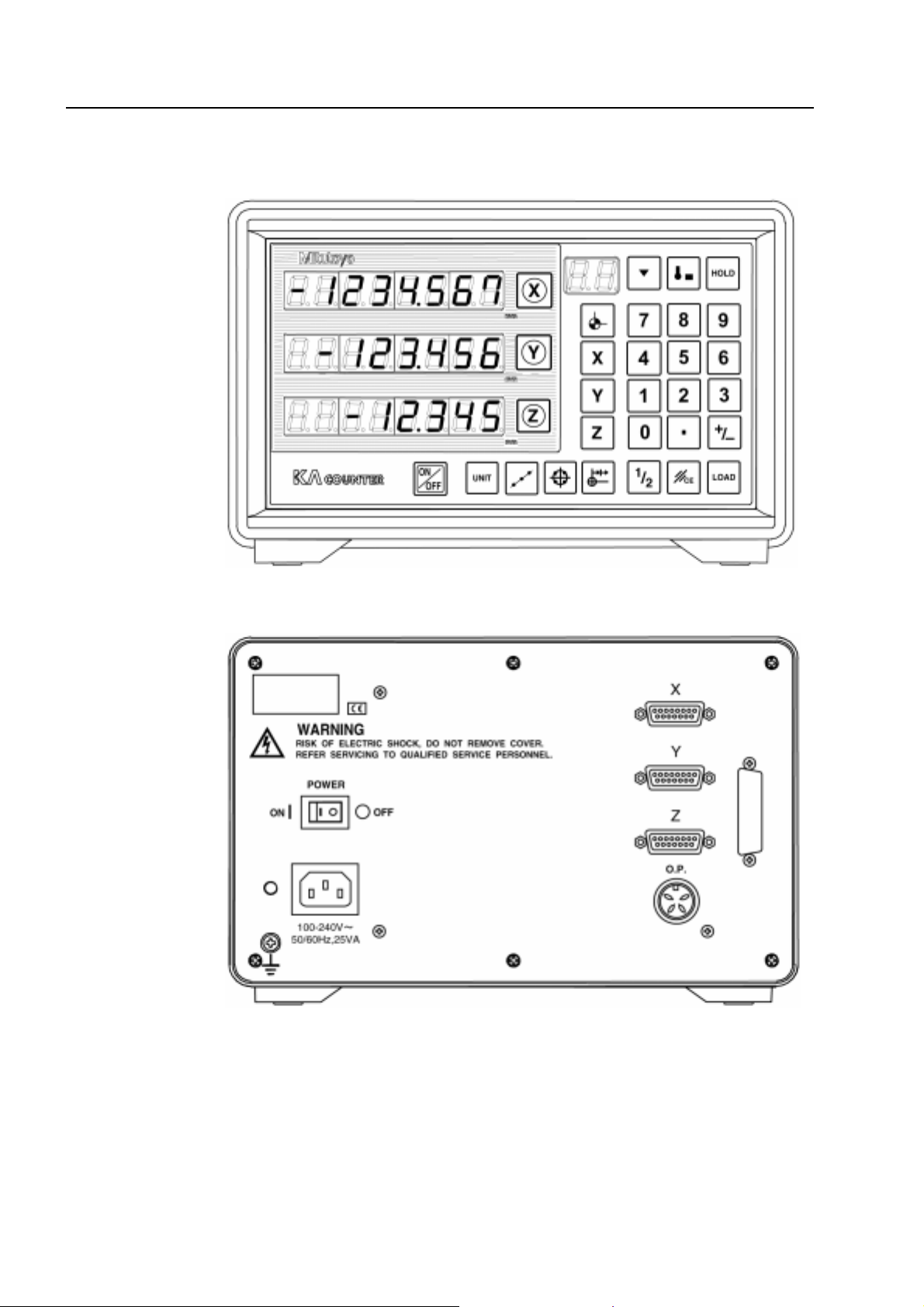

1.2.5 3-axis counter

1) Front panel of the main unit

2) Rear panel of the main unit

1-8

No. 99MBE032A

Page 16

1 SETUP

2

2.1 Opening the Package

The package includes the following items.

KA counter 1

This chapter explains the procedures for setting up the KA counter.

Description of goods Quantity

NOTE

Power cord (1.8 m)

(2 m only for Australia-oriented specification)

Grounding wire (4 m) 1

Dust cover 1

User’s Manual 1

Warranty 1

After opening the package, check to make sure that the counter and standard

accessories are all there and that there are no nonconforming parts, and check that

nothing was damaged during shipment.

1

No. 99MBE032A

2-1

Page 17

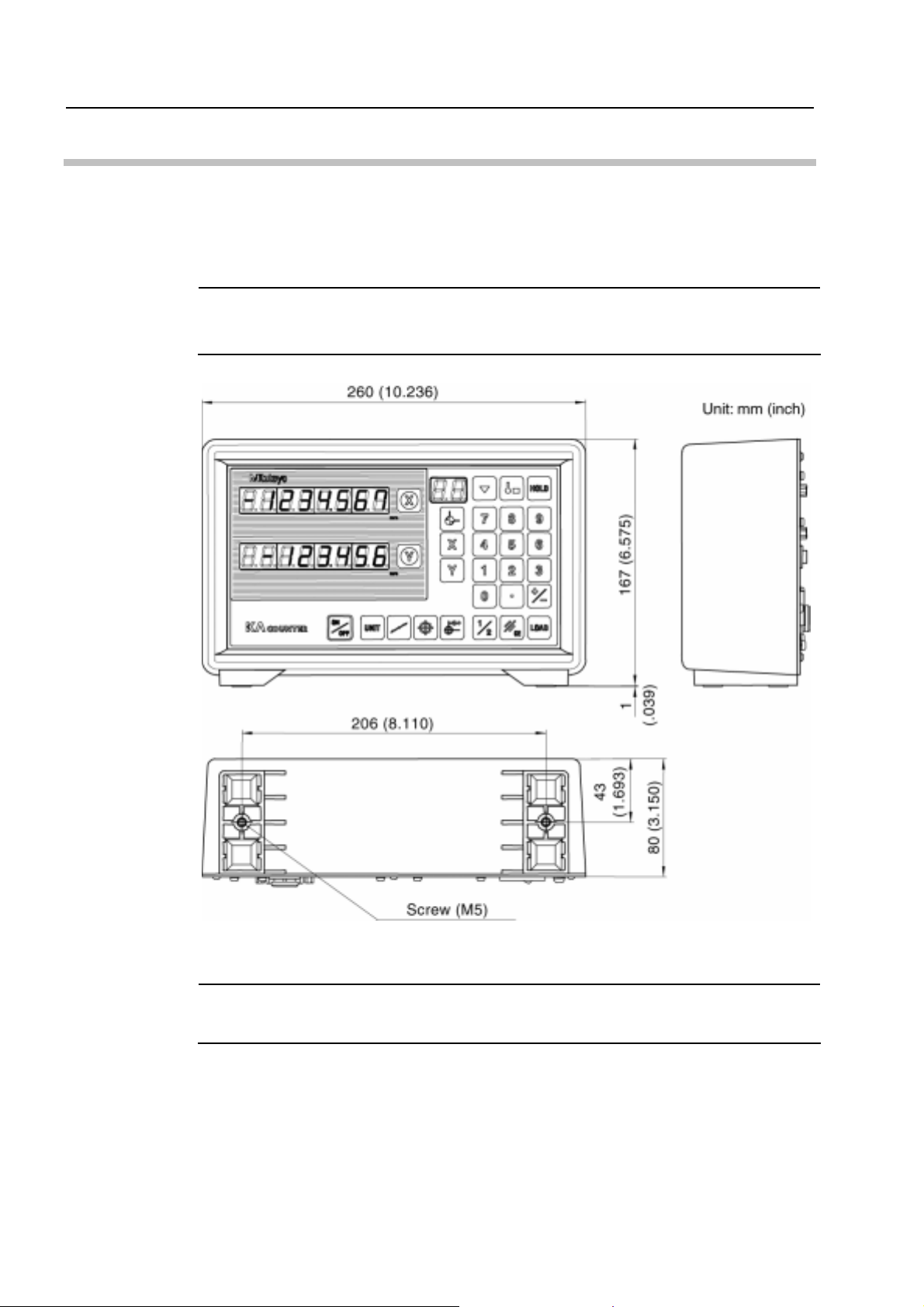

2.2 Installation

Use the M5 screw holes at the bottom of the counter for installing it to the counter stand or

the main unit of the machine tool.

The external dimens ions of the count er and the l ocati on of the scr ew holes f or installati on

are shown in the figure below.

NOTE

• There are no special installation fixtures supplied with this counter.

• External dimensions given below apply to 1-, 2-, and 3-axis counters.

2-2

NOTE

The fastening torque of screws ranges from 0.0015 to 0.002N • m (0.15 to 0.2kg • m).

Fastening with a torque exceeding this range may cause the counter case to be

damaged.

No. 99MBE032A

Page 18

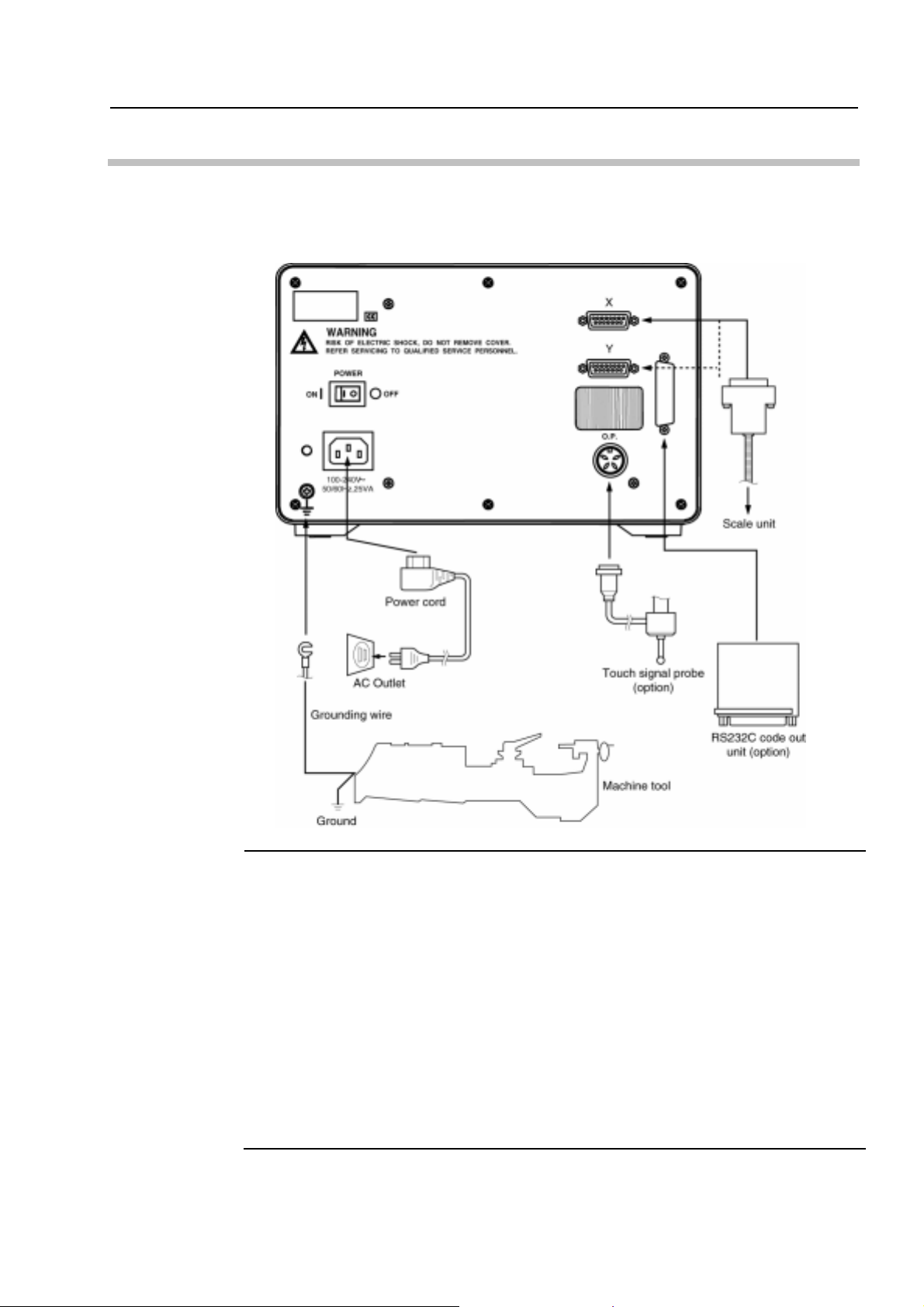

2.3 Connecting to the Counter

When connecting the power cord and external equipment to this counter, connect the

connectors to the rear panel as shown below. (Below diagram is applied for 2-axis

counter.)

2. SETUP

IMPORTANT

When connecting to external equipment, take note of the following items.

• Make sure the main power switch on the rear panel is off.

(This is not the display ON/OFF switch on the front panel.)

• Use the supplied power cord only.

• Connect this counter with the machine tool using the supplied grounding wire to avoid a

risk of electric shock.

• The power-supply line for this counter should be separate from that for the machine tool,

and if possible should be supplied from a dedicated outlet.

• Make sure the cables and external equipment are connected to the counter securely.

• If the Linear Scale is not connected to this counter, the least significant digit may flicker,

but this is not a malfunction.

• Since the scale m odel (AT100 series or AT700 series) is identified at a tim ing when the

main switch is turned to ON, always turn the main switch to ON with the desirable scale

being connected.

No. 99MBE032A

2-3

Page 19

2-4

No. 99MBE032A

Page 20

1 BASIC OPERATIONS

3

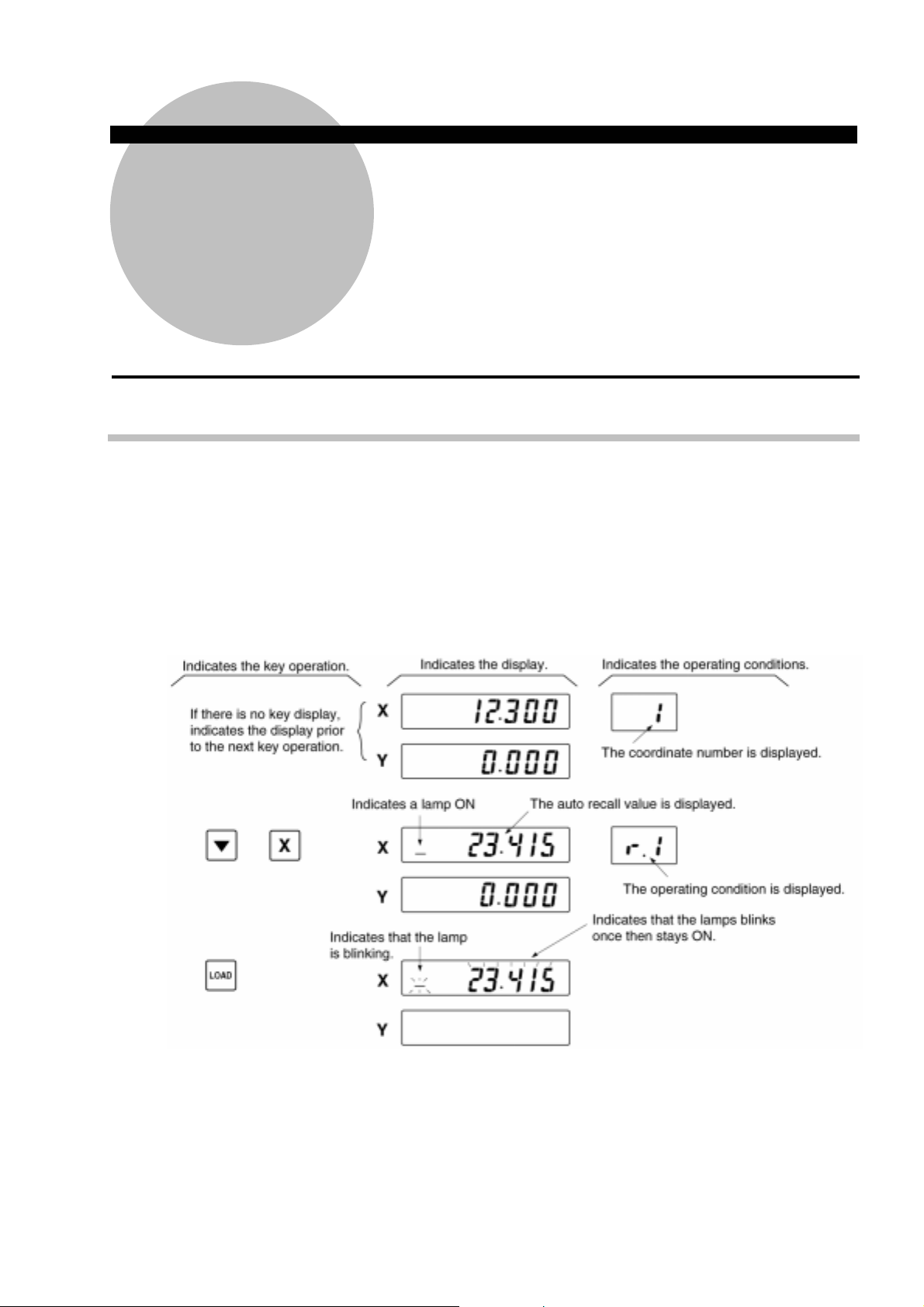

3.1 Explanatory Notes

The explanations of operations in this chapter are organized in such a manner as shown

below. Read this chapter with understanding of the way of explanation. Operation

procedures described in this manual are mainly based on the case of using the 2-axis

counter. Operation procedures unique to 1- or 3-axis counters are described when

necessary.

This chapter describes the basic operation of the KA counter.

Q Operation example display

No. 99MBE032A

3-1

Page 21

3.2 Basic Operations in the Standard Counter

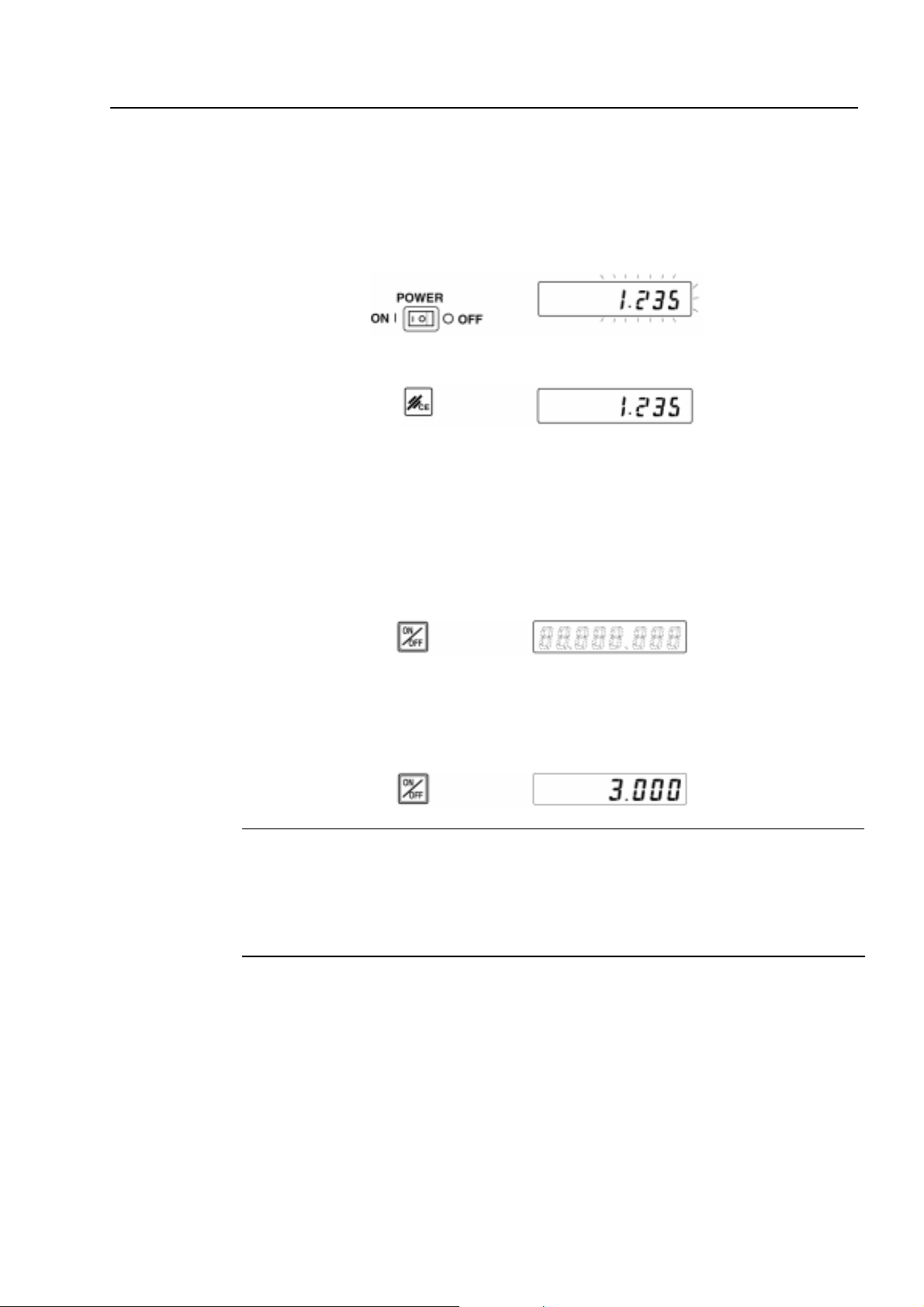

3.2.1 Turning ON/OFF the power

• Main power switch on the rear panel

The switch on the rear panel is

the main power switch. It turns

ON/OFF of the main power to

the counter.

• Display ON/OFF switch on the front panel

This is the switch to ON/OFF

the counter display. The display

will be on/off every time the

switch is pressed. If the main

power switch is on and this

switch is off, only the display

will be off, although the power

is supplied to the counting

circuits and the Linear Scales.

NOTE

• For normal operation after the power has been turned on the main power switch on the

rear panel should be left on, and the counter should be turned ON/OFF using the

display ON/OFF switch on the front panel.

• If the display is blinking after the power is turned on using the display ON/OFF switch,

this indicates that the displayed value is of no use. If this happens, cancel the value

using the Cancel key, then reset the machining datum point.

• Always operate the keys only with fingers. If a key is pressed with a sharp tip such as a

screwdriver, it may be damaged.

3-2

No. 99MBE032A

Page 22

3. BASIC OPERATIONS

● Where AT100 series is connected:

1) Turning the power on

To turn the power on, turn on the main power switch on the rear panel.

If this is the first time since setting up the KA counter, the display will blink.

(This indicates that the displayed value is of no use.)

By pressing the Cancel key, the counter is ready to display a normal count value.

By referring to “3.2.3 Zero-set”, “3.2.4 Preset”, and “3.2.5 Saving and recalling a

datum point using the scale reference point”, set a machining datum point.

2) Turning the power off

NOTE

Use the display ON/FF switch on the front panel to turn the power off while remaining

the main power switch on the rear panel on.

By pressing the display ON/OFF switch, the display can be off.

3) Turning the power on again

Press the display ON/OFF switch on the front panel.

The display will be on.

• If there happened an abnormality in the power line, such as a power failure, the next

time the power is turned on using the display ON/OFF switch, the display will blink as

described in 1) above. If this happens, set the reference point for machining again.

• When the display is blinked even if parameter No. 15, described in Chapter 4, has been

set to “Save display”, this indicates that the displayed value is of no use. If this happens,

set the reference point for machining again.

No. 99MBE032A

3-3

Page 23

● Where AT700 series is connected:

1) Turning the power on

To turn the power on, turn on the main power switch on the rear panel.

At this time, the display indicates the distance from the scale reference point.

By referring to “3.2.3 Zero-set”, “3.2.4 Preset”, and “3.2.6 Setting the machine origin

with the AT700 series”, set a machining datum point.

2) Turning the power off

Use the display ON/FF switch on the front panel to turn the power off while remaining

the main power switch on the rear panel on.

By pressing the display ON/OFF switch, the display can be off.

3) Turning the power on again

Press the display ON/OFF switch on the front panel.

The display will be on.

3.2.2 Counting and displaying

This section is for the user who is using the KA counter with a minimum resolution of

0.0005 or 0.0001mm (0.5 or 0.1µm).

The user who is using it with a minimum resolution of 0.005 or 0.001mm (5 or 1µm) may

skip this section.

• In order to expand the display range of the KA counter, the counting range in the +

count direction and the - count direction are different.

The counting range when the KA counter is used with the minimum resolution of

0.0005 or 0.0001mm (0.5 or 0.1µm) is as follows:

+9999.9999 to -999.999 (approximately +10m to -1m)

3-4

No. 99MBE032A

Page 24

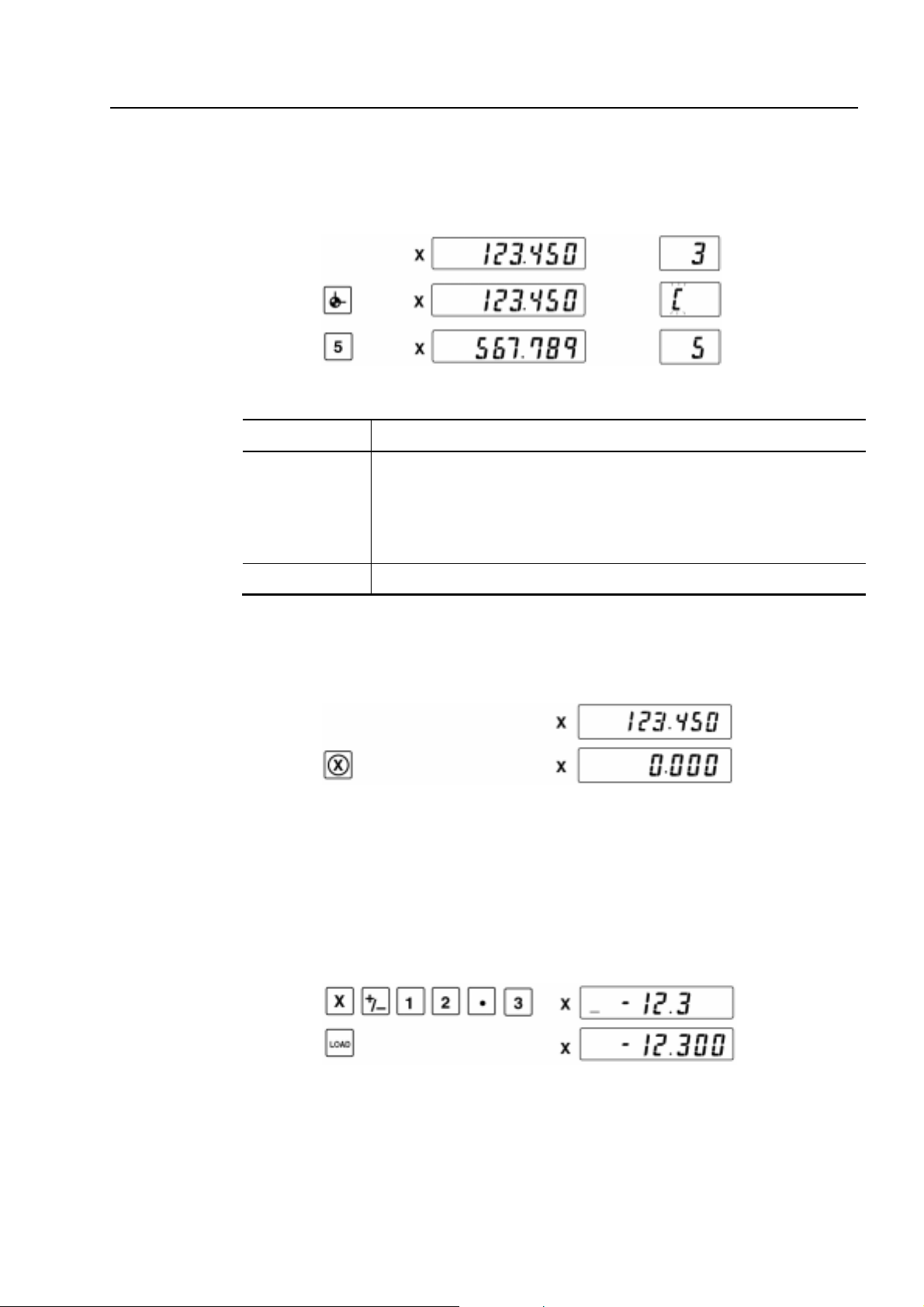

3.2.3 Switching the coordinate

Moves from the current Coordinate to the specified coordinate.

• Moves from the current Coordinate 3 to Coordinate 5.

KA counter coordinate

Coordinate No. Function

0 A coordinate system that displays coordinate values from the machine

origin. It does not allow zero-setting and presetting. To use this

function, perform either of “3.2.5 Saving and recalling a datum point

using the scale reference point” or “3.2.6 Setting the machine origin

with the AT700 series”.

3. BASIC OPERATIONS

1 to 9 A coordinate system used for performing usual machining operation.

3.2.4 Zero-set

Resets the display value for each axis to zero.

• Resets the X-axis value to zero.

* Zero-adjustment cannot be performed at coordinate 0.

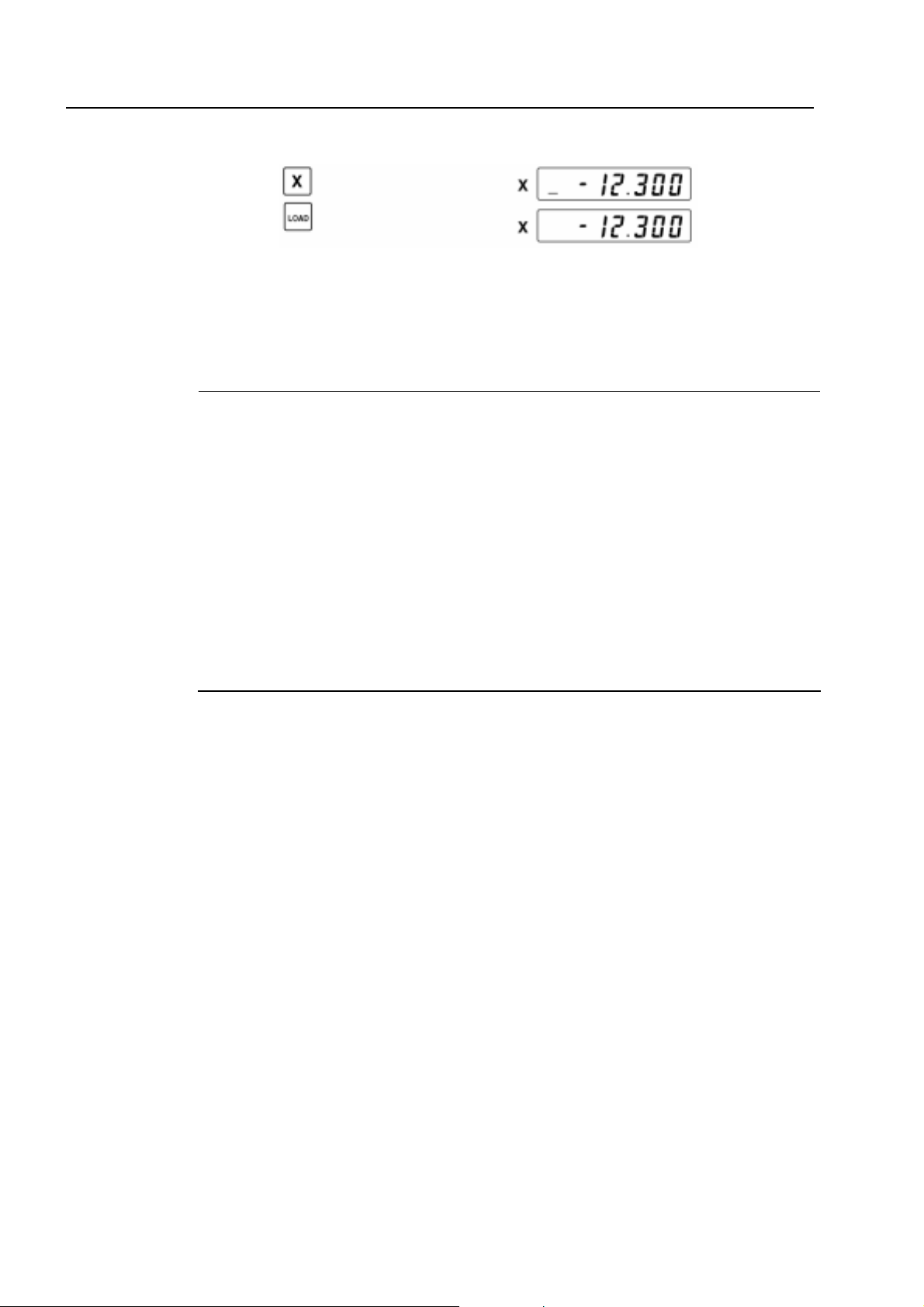

3.2.5 Preset

Set an arbitrary value onto the arbitrary axis through the key entry. Preset values can be

saved in memory for each coordinate so that they can be retrieved even after the system

power is reset.

• Preset -12.3 for the X-axis.

No. 99MBE032A

3-5

Page 25

• Call up the value preset to preset it as is for the X-axis.

• Canceling the key input before loading the preset value.

If the Load key has not yet been pressed, it is possible to cancel all of the input

numbers by pressing the Cancel key. After the numbers have been canceled, the

display returns to the value before key input. If the Load key has already been pressed,

use the preset operation again to set the correct value.

IMPORTANT

• Preset data stored in the KA counter is the data input by the most recent preset

operation.

• The preset data stored in the KA counter has been saved on the basis of coordinate

systems described later.

• If data is preset through operation of the touch signal probe or zero-approach function

(described later), the preset data stored in the KA counter will be changed to those

values.

• Do not displace any axis scale during numeric entry. If displaced during entry for

presetting, etc., the scale unit may be damaged due to an overrun.

• Even if the counter exceeds the counting range, Error 30 will not be displayed during

numeric entry. The error message will be displayed after numeric entry has been

completed.

• Do not displace any axis scale too much while presetting is being performed.

• Zero-adjustment cannot be performed at Coordinate 0.

3-6

No. 99MBE032A

Page 26

3. BASIC OPERATIONS

NOTE

If the following operations 1 and 2 are repeated at the occurrence of an overflow when

using the AT100 series linear scale, an overflow error (Error30) may occur even if a value

smaller than the maximum preset value shown below is preset.

If presetting a large value and error occurrence are repeated multiple times, the

above-mentioned situation will be encountered due to overflow of offsetting in the

counter. If this is the case, perform offset correction procedure described below for the

axis where Error30 has occurred, then the normal state will be restored.

Exercise care when presetting a large value exceeding the maximum preset value.

• Operation at the occurrence of an overflow

1. Preset a value (larger than the maximum preset value).

2. An error occurs. (E.g. Error20)

3. Repeat steps 1 and 2.

• Maximum preset value

Resolution Maximum preset value

0.01/0.05 mm

0.001/0.005 inch

0.001/0.005 mm

0.0001/0.0005 inch

+500000.00 (500 m)

+200000.00 inch

+50000.000 (50 m)

+2000.0000 inch

0.0001/0.0005 mm

0.00001/0.00005 inch

• Overflow correction procedure

a. Press the [▼], [SET], [X] (or [Y] or [Z]), [0], and [LOAD] keys in this order.

b. Move the linear scale to pass through the origin mark.

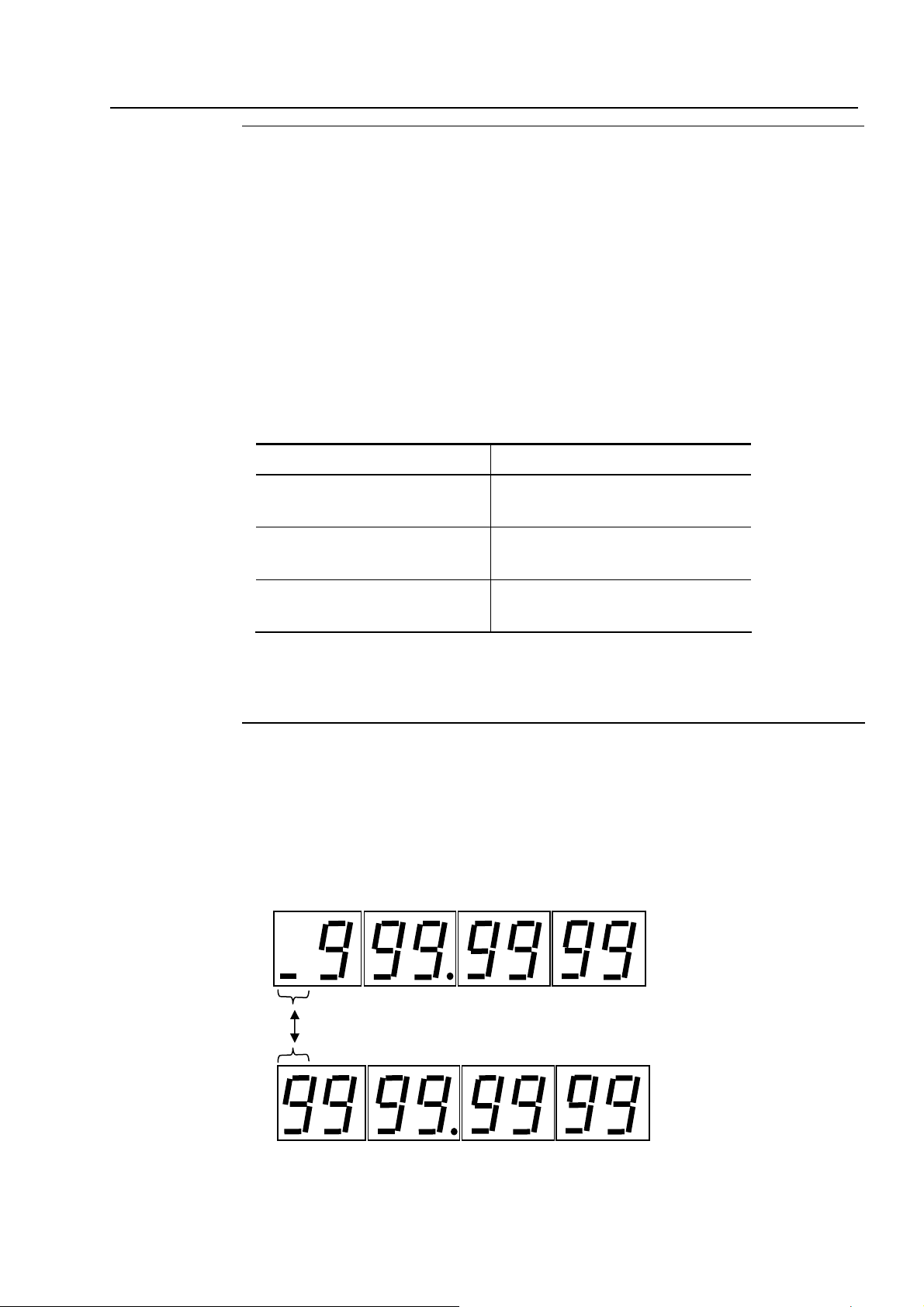

For the user who is using the KA counter with a minimum resolution of 0.0005 or

0.0001mm.

When data to be preset is smaller than or equal to 1m, the display method of the most

significant digit and the sign differ from the normal preset. It alternately displays the sign

and the most significant digit as shown in the figure below.

• Example) +9999.9999

+5000.0000 (5 m)

+200.00000 inch

Alternately displays a cursor and a numeric.

No. 99MBE032A

3-7

Page 27

3.2.6 Saving and recalling a datum point using the scale reference point

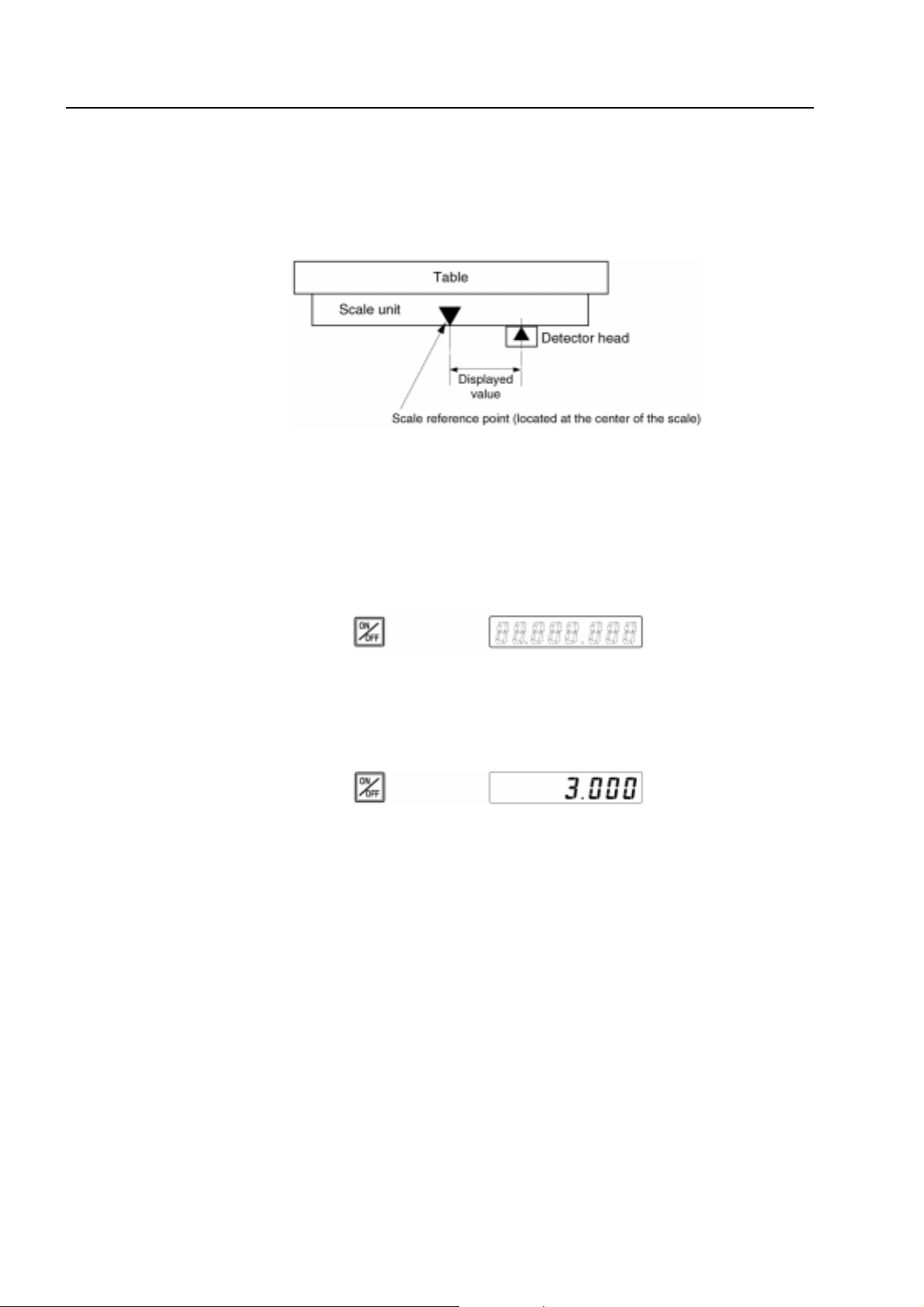

(when the AT100 series is connected.)

Where the AT700 series is connected, refer to “3.2.6 Setting the machine origin with the

AT700 series”.

1) Saving the scale reference point

This operation saves the dimension between an appropriate reference point of the

Linear Scale and the datum point of the workpiece being machined, in the KA counter

as “origin data”. When the scale reference point is detected, the display is held for two

seconds, and this value is saved in the counter as “origin data”. The saved origin data

is not lost when the power is turned off, so it is possible to easily recall the machining

datum point on the workpiece being machined using the scale reference point recall

operation described in 2).

NOTE

Immediately after the power has been turned on, if the scale reference point recall

operation is performed at the beginning of work, as described in 2) below, it is not

necessary to perform this datum point recall operation.

• Saving the machining datum point in the X-axis direction using the scale reference

point.

Step 1 Use the keys so that the displayed value can be held when the scale reference

point is detected.

Step 2 Move the machine table in the direction of detecting the scale reference point.

When the scale reference point is detected, the displayed value is held, and a

buzzer sounds for two seconds. This display value (L) at this time is the

dimension to the scale reference point from the machining datum point, and is

automatically saved in the KA counter as “origin data”.

3-8

No. 99MBE032A

Page 28

3. BASIC OPERATIONS

After the buzzer sounds off, the counter automatically returns to normal counting.

IMPORTANT

• When detecting the scale reference point move the worktable at a traveling speed of

50mm/s or less. If the worktable is moved faster than 50mm/s, the measuring error will

increase.

• When saving the scale reference point, be sure to remember the following two points. In

order to recall the machining datum point, the same scale reference point that was

saved must be used.

1. Which coordinate system, ABS or INC, was used?

2. The position of the machine table for both the X- and Y-axis when the buzzer

sounded.

• After saving the scale reference point, if an operation is performed which translates the

origin of the coordinate system such as zero-set or preset, the origin data is also

automatically offset corresponding to the translation.

• Perform scale reference point save and recall operation for the X- and Y-axis separately.

• Do not displace any axis scale during numeric entry. If displaced during entry for

presetting, etc., the scale unit may be damaged due to an overrun.

• Even if the counter exceeds the counting range, Error 30 will not be displayed during

numeric entry. The error message will be displayed after numeric entry has been

completed.

• Do not displace any axis scale too much while presetting is being performed.

2) Recalling the scale reference point

With this operation, the machining datum point at the time the power was turned off is

recalled from the origin data saved in the KA counter.

IMPORTANT

• This operation should be performed for the coordinate (1 to 9) for which the scale

reference point was saved. If scale reference point recall operation is performed for one

coordinate, the machining datum point for the remaining coordinates will also be

recalled automatically.

• The scale reference point should be recalled at the beginning of work just after the

power has been turned on.

• Recalling the machining datum point from the scale reference point in X-axis direction.

Step 1 Call up the saved origin data, and after detecting the scale reference point,

perform the key operation to start counting.

No. 99MBE032A

3-9

Page 29

If the axis was specified in the scale reference point recall operation, the saved origin

TIP

data will be called up, however it is possible to key in a different value using the ten-key

pad.

Step 2 Move the machine table and detect the same scale reference point that was

saved by the scale reference point save operation. At the instant the reference

point is detected, the KA counter starts counting. The machining datum point is

recalled.

IMPORTANT

NOTE

The scale reference point is set at 50mm intervals along the Linear Scale, so find the

scale reference point that was saved by the save operation.

If datum setting and machining is performed without having recalled the scale reference

point prior to work, and if it is necessary that the machining datum point be saved for

future work, save the scale reference point as described in 1) above, then turn off the

display ON/OFF switch.

• About the machine origin (Coordinate 0 is used.)

The user is allowed to set specifically for each machine a reference point (machine

origin) that will not be affected by the normal operation including zero-point setting.

(1) Setting the machine origin data

Obtain the machine origin data (offset value) with the following procedure, then set

it to Parameter 33.

1. On Coordinate 1, zero-set at the position of the machine origin.

2. Perform the scale origin memorizing operation.

3-10

3. If the axis designation key is pressed following the having been pressed

in 2) Recalling the scale reference point, the origin data (offset value) will be

displayed.

Take a note of this value and set it to Parameter 33.

For the setting method refer to Chapter 4, Parameters.

(2) Recalling the machine origin

On Coordinate 0, perform the above described “2) Recalling the scale reference

point”.

No. 99MBE032A

Page 30

3.2.7 Setting the machine origin using the AT700 series

With the AT700 series if the machine origin is once determined, that reference point

cannot only be maintained through the subsequent normal operations such as zero setting,

etc., but also be protected from being lost even when the power is off.

Use the following procedure to set the machine origin offset value to Parameter 33.

(1) Make sure that Parameter 33 is 0.000.

1. While pressing the key turn the main switch on the rear panel to ON.

2. Make sure that the display looks like the following.

3. BASIC OPERATIONS

3. Enter Parameter 33.

4. Make sure that the display shows 0.000, then turn the main switch on the rear panel

to OFF.

(2) Measure the machine origin offset value.

1. Turn on the counter power and display Coordinate 0.

No. 99MBE032A

3-11

Page 31

2. Feed the table to align with the machine origin.

3. Record the displayed value.

(3) Enter the machine origin offset value.

1. Turn off the power.

2. Substitute the machine origin offset value in Parameter 33.

In this substitution, note that the sign of the value recorded in above 3. of (2) must

be reversed.

+

3-12

No. 99MBE032A

Page 32

3. BASIC OPERATIONS

3.2.8 Datum setting, centering and measuring with the touch signal probe

(Possible only when the AT100 series is connected.)

1) Datum setting with the touch signal probe

The KA counter can be connected to a touch signal probe (optional), and it is possible

to set the datum point for a workpiece.

• Setting up the datum point in the X-axis direction of the workpiece.

Step 1 Preset the radius of the ball tip of the touch signal probe in the X-axis of the

counter as shown below. With this setup, when the touch signal probe comes in

contact with the surface of the workpiece, the counter starts counting from the

value of the radius of the ball tip.

In the following explanation, the probe ball tip diameter is set to φ10mm and the

center of the ball is on the minus count side of the datum surface to be

determined. Because of this a minus sign is given to the preset value.

IMPORTANT

For datum setting with the touch signal probe, the radius of the ball tip must be preset in

the counter for offsetting. The sign (+/-) for this offset value depends on the count

direction in which the machine moves.

Step 2 Bring the touch signal probe into contact with the reference surface of the

workpiece. This will set the datum point for machining.

A buzzer will sound when the probe is brought into contact with the workpiece,

and counting will start.

No. 99MBE032A

2) Centering with the touch signal probe

It is possible to perform centering of the workpiece with a touch signal probe (optional)

connected to the counter.

3-13

Page 33

• Determine the center in the X-axis direction of the workpiece

Step 1 Set up using keys so that the counter starts counting from zero in the X-axis at

the time the touch signal probe comes into contact with the reference surface of

the workpiece. (For centering, it is not necessary to correct for the radius of the

probe ball tip.)

Step 2 After setting us a function of holding the display move the touch signal probe to

the opposite end, and bring it into contact. The displayed value at this time is the

dimension of the workpiece, including the ball tip diameter of the probe. If this

value is halved, the center point of the measured dimension is displayed.

3-14

No. 99MBE032A

Page 34

3. BASIC OPERATIONS

Step 3 With the Cancel key, release the Hold mode of the display, and move the

machine table so the counter reads zero. Centering is now complete.

IMPORTANT

• Leave an interval of at least one second from the time the touch signal probe comes in

contact with the workpiece until the next contact. If the interval is less than one second,

it may be impossible for the counter to detect the measurement point.

• Do not displace any axis scale during numeric entry. If displaced during entry for

presetting, etc., the scale unit may be damaged due to an overrun.

• Even if the counter exceeds the counting range, Error 30 will not be displayed during

numeric entry. The error message will be displayed after numeric entry has been

completed.

• Do not displace any axis scale too much while presetting is being performed.

3) Measuring with the touch signal probe

The KA counter can be connected to a touch signal probe (optional) and can measure

the dimensions of the workpiece.

The display value is held while the touch signal probe is in contact with the workpiece.

This operation can be performed repeatedly until quitting the touch signal probe

measurement function. Press the Cancel key to quit.

• Measuring the dimensions of the workpiece in the X-axis direction

Step 1 In order to subtract the diameter of the ball tip of the touch signal probe from the

measured value, perform key operation to start counting from that value.

In the example below, the diameter of the ball tip of the touch signal probe is

taken to be 10mm.

IMPORTANT

No. 99MBE032A

The touch signal probe comes in contact with both ends of the workpiece, so preset the

KA counter to correct for the diameter of the probe ball tip. The sign of the corrected

value should be negative when measuring the outside diameter, and positive when

measuring the inside diameter.

Step 2 Bring the touch signal probe in contact with reference surface of the workpiece.

A buzzer sounds during contact, and when it is removed counting starts.

3-15

Page 35

Step 3 Before the touch signal probe is in contact with the measured surface on the

other side, set up the Hold mode using the key.

Step 4 Bring the touch signal probe in contact with the opposite end. The held display

value is the dimension of the workpiece.

Step 5 Quit the touch signal probe measurement function.

IMPORTANT

• When measuring with the touch signal probe move the worktable at a traveling speed of

50mm/s or less. If the worktable is moved faster than 50mm/s, the measuring error will

increase.

• Leave an interval of at least one second from the time the touch signal probe comes in

contact with the workpiece until the next contact. If the interval is less than one second,

it may be impossible for the counter to detect the measurement point.

• Do not displace any axis scale during numeric entry. If displaced during entry for

presetting, etc., the scale unit may be damaged due to an overrun.

• Even if the counter exceeds the counting range, Error 30 will not be displayed during

numeric entry. The error message will be displayed after numeric entry has been

completed.

• Do not displace any axis scale too much while presetting is being performed.

3.2.9 Halving the display

The KA counter is capable of halving the display value or preset value and displaying the

halved value.

1) Halve the display value for the X-axis.

• Halve the currently displayed value, 123.000.

3-16

No. 99MBE032A

Page 36

2) Halve the preset value for the X-axis.

• Halve the preset value, 469.000.

3. BASIC OPERATIONS

IMPORTANT

• The value displayed at the time of the axis designation during the preset operation is the

previous preset data.

• The data entered with this operation is saved in the counter as preset data.

3.2.10 Bolt-hole circle machining

This function is available exclusively with both 2- and 3-axis counters. (In case of using

3-axis counter, this function is available with X- and Y-axis settings.)

The bolt-hole circle machining function is used to perform bolt-hole circle machining.

By setting the center position, diameter, number of divisions and offset angle of the circle,

the bolt-hole circle machining function calculates the positions around the circumference

for boring holes, and displays the target coordinate value for each machining point.

When boring a hole, displace the machine table to the position so the display becomes

zero. The position of the tip of the cutting tool at the time of data setting is taken as the

center for the circle to be calculated. The position for boring the first hole is the point offset

by the offset angle (Ang) in the positive direction of the X-axis (see the figure below), and

the location of the holes to be bored successively at equal interval is determined along the

circumference of the circle having the diameter (d) and divided by the number of divisions

(n).

No. 99MBE032A

3-17

Page 37

IMPORTANT

The input range for the setting items are as follows:

Setting item Input range

Diameter ± 9999.999mm or ± 999.9999”

Number of divisions 2 to 360 divisions

Offset angle 0 to 359.9 degrees (unit: 0.1 degree)

• When using the bolt-hole circle machining function, the resolution for the X- and Y-axis

should be the same.

• If an error occurs in the KA counter, press the Cancel key to quit the bolt-hole circle

mode.

• After the bolt-hole circle machining is complete, the coordinate system returns to that of

the mode prior to the bolt-hole circle mode.

• Do not displace any axis scale during numeric entry. If displaced during entry for

presetting, etc., the scale unit may be damaged by an overrun.

• Even if the counter exceeds the counting range, Error 30 will not be displayed during

numeric entry. The error message will be displayed after numeric entry has been

completed.

• Do not displace any axis scale too much while numeric entry is being performed.

• When in inch mode, due to the setting of the counter, there may be cases where the

input range shall be ± 99.99999”.

• Performing the bolt-hole circle machining

Step 1 Position the tip of the drill at the center of the circle on the workpiece.

Step 2 Press the bolt-hole circle key. The diameter and the number of divisions are

recalled on the X-axis and Y-axis, respectively (already input values).

Step 3 While the “d” at the left end of the display is blinking, enter the diameter using the

ten-key and press the Load key. If using an auto-recalled value, only press the

Load key.

3-18

No. 99MBE032A

Page 38

3. BASIC OPERATIONS

Step 4 While the “n” at the left end of the display is blinking, enter the number of

divisions using the ten-key and press the Load key. If an auto-recalled value is

used, only press the Load key. The KA counter display becomes ready for input

of the offset angle.

Step 5 While the “Ang” at the left end of the display is blinking, enter the offset angle

using the ten-key and press the Load key. If an auto-recalled value is used, only

press the Load key. After this value is entered, the setting complete code (000)

followed by the number of divisions is displayed for two seconds.

Step 6 Press the Load key and call up the first target value, and execute the bolt-hole

circle machining at the specified location.

No. 99MBE032A

3-19

Page 39

Step 7 After the hole has been made, press the Load key and call up the target value for

the next hole, then move the machine table and drill the next hole. Each time the

Load key is pressed, the target value is updated, so repeat the same procedure.

Step 8 After machining the holes according to the set number of divisions, the counter

returns to the display of the target value of the first hole.

If machining is complete, or to abort machining, press the Cancel key and quit

the bolt-hole circle machining function.

NOTE

• The input settings are not lost even when the power is turned off. Those setting data is

called up automatically (auto recall) and can be used if desired.

• When the bolt-hole circle machining function ends, the coordinate system used before

the start of the function is returned.

3-20

No. 99MBE032A

Page 40

3.2.11 Pitch machining

This is the mode in which a certain interval between two points on the X-Y plane can be

machined at even spaces.

For this pitch machining the errors produced from positioning the table can be

automatically corrected.

Setup items and their ranges are shown below:

Setup item Input range

X-axis start point ± 9999.999 mm

Y-axis start point ± 9999.999 mm

X-axis end point ± 9999.999 mm

Y-axis end point ± 9999.999 mm

Number of divisions 999

3. BASIC OPERATIONS

• Operate with the following procedures.

Step 1 Press the Pitch Machining key.

Step 2 Enter the X coordinate of the start point.

Blinking of the X-axis cursor shows its time to enter the X coordinate of the end

point.

No. 99MBE032A

3-21

Page 41

Step 3 Enter the Y coordinate of the start point.

Step 4 Enter the X coordinate of the end point.

Use the auto-recall value without modifying it.

Step 5 Enter the Y coordinate of the end point.

Use the auto-recall value without modifying it.

Step 6 Enter the number of divisions.

The maximum number of divisions is 999.

Step 7 Perform the machining.

000 implies the completion of setting, while 010 shows implies the number of

divisions.

3-22

In two seconds the display will change to the following, showing that the pitch

machining is ready.

Now it is ready to perform the pitch machining.

Recall the first target point.

No. 99MBE032A

Page 42

3. BASIC OPERATIONS

Feed the table so that the display shows 0.000.

Even when a machining error is produced, it will never be accumulated because

the error correction to the next target is automatically undertaken.

Continue the machining while recalling the target values successively by

pressing the LOAD key.

Step 8 If the set numbers of the pitch machining is completed, the counter returns to the

display of the first target value.

If the machining is complete, or to abort machining, press the Cancel key and

quit the pitch machining function.

NOTE

• The entered setup item data will not be lost even after the power is off. Each piece of

data can be saved in memory as the independent setup data for each coordinate. At the

next input of the setup data they will be automatically recalled (auto-recall).

• When the pitch machining function is terminated, the table will be restored to the

coordinate existed before the pitch machining function began.

• Pitch machining data will be saved in memory for each coordinate.

No. 99MBE032A

3-23

Page 43

3.2.12 Zero approach machining

If this function is used in the drilling process, the given pitch of the hole is entered in the

counter and the target value from the current position to the hole is automatically displayed.

The machine table is fed until the displayed value becomes zero, and the hole is drilled. By

repeating this procedure, holes can be drilled efficiently.

NOTE

Errors involved in positioning the machine table are automatically corrected for the

target value of the next hole.

An example of drilling

• Drilling the above holes using zero approach

Step 1 Press the Zero-approach key.

Step 2 Feed the machine table to the datum point, and set the counter display to zero.

Step 3 Enter the distance (10mm) for the first drilling point.

Step 4 Feed the machine table to the machining position, where the counter displays

-0.010mm, and drill a hole.

3-24

No. 99MBE032A

Page 44

3. BASIC OPERATIONS

Step 5 Enter 12mm, the distance to the next machining point.

The KA counter corrects the previous positioning error, -0.010mm and displays

the actual distance the machine needs to move to reach the next machining

point.

Step 6 To quit the zero-approach machining function, press the Cancel key.

IMPORTANT

NOTE

• Do not displace any axis scale during numeric entry. If displaced during entry for

presetting, etc., the scale unit may be damaged due to an overrun.

• Even if the counter exceeds the counting range, Error 30 will not be displayed during

numeric entry. The error message will be displayed after numeric entry has been

completed.

• Do not displace any axis scale too much while numeric entry is being performed.

• It is possible to zero-set the counter during the zero-approach mode. However, if the

counter is zero-set, the accumulated error up to that point cannot be corrected.

• If the zero-approach mode is canceled, the display restores the state in which

zero-approach was selected.

• When the zero-approach mode is entered, the counter value remains unchanged.

• The zero-approach data can be set for each coordinate, however, note that it is shared

also as the preset data.

3.2.13 Changing the unit of measurement

It is possible to switch the unit of measurement between mm and inch (1/25.4).

NOTE

The indicator “mm” on the front panel turns on if mm is selected. The indicator turns off if

inch (1/25.4) is selected.

No. 99MBE032A

NOTE

• Changing the unit of measurement

When the display ON/OFF switch is turned on, the unit set when the switch was turned

off is selected.

For the accuracy of conversion between mm and inch counts, refer to the table in page

4-5.

3-25

Page 45

3.2.14 Addition mode

This function applies only to the 3-axis counter.

By setting parameter 43, the KA counter will display the summed value of the Y- and

Z-axis display values on the Y-axis display. (For information about parameter setup, refer

to the appropriate parameter section.)

An example of using the addition mode

This mode is used if the feed table consists of two stages.

If the addition mode has been set, “o” is displayed in the position of the most significant

digit of the Z-axis display. Other digits on the Z-axis display are unlit.

3-26

No. 99MBE032A

Page 46

3. BASIC OPERATIONS

- Restrictions when the addition mode is set Origin and touch signal setup operations

If the addition mode is selected, the touch signal SET/HOLD and origin SET/HOLD

functions on the Y- and Z-axis cannot be used.

Example No. 1

▼

[ Y ] The buzzer sounds twice.

Example No. 2

[TSP]

[HOLD]

[Z] The buzzer sounds twice.

The X-axis touch signal HOLD function can be used.

Presetting

• The presetting operation for only the Z-axis cannot be performed. The buzzer sounds

twice if the Z-axis designation key is pressed.

• If the Y-axis presetting operation is performed, a preset value will be stored for the

Y-axis where the summed value (Y + Z) is displayed.

Zero-setting

• The zero-setting operation for the Z-axis cannot be performed. The buzzer sounds

twice if the Z-axis zero-set key is pressed.

• If the Y-axis zero-setting operation is performed, the summed value (Y + Z) displayed

on the Y-axis display will be zero-set.

Zero approach machining

• Zero approach data cannot be set for the Z-axis.

• If Y-axis zero approach data is entered, zero approach calculation will be performed

for the Y-axis where the summed value (Y + Z) is displayed.

Bolt-hole circle machining

• The bolt-hole circle machining function cannot be used in the addition mode. The

buzzer sounds twice if the Bolt-hole circle key is pressed.

No. 99MBE032A

Display-halving (1/2) function

• The display-halving (1/2) function cannot be performed for the Z-axis.

• If the Y-axis display-halving (1/2) operation is performed, display-halving calculation

will be performed for the Y-axis where the summed value (Y + Z) is displayed.

3-27

Page 47

3.3 Outline of the Lathe Counter

3.3.1 Setting parameters for the lathe counter

When this counter is used as the lathe counter, it is required to modify the initial values of

parameters. For detail refer to “4.3.4 Setting parameters for the lathe counter”.

Also for the method of turning on and off the power, refer to “3.2.1 Turning ON/OFF the

power”.

3.3.2 Lathe counter operation modes

The lathe counter operation modes in the KA counter are as illustrated below.

3-28

No. 99MBE032A

Page 48

3. BASIC OPERATIONS

• Explanation of each operation mode is as mentioned below.

No. Item Description

0 Power OFF The main power is turned off.

3 Count mode

4 Display OFF mode

5 Parameter mode Parameters are input in this mode.

6 Origin recall Recalls the scale origin.

7 Origin storage Stores the scale origin.

8 Zero approach mode

9 Tool number switching Switches to the number of the tool to be used.

10 Tool offsetting A compensation value for a tool length is set in this mode.

IMPORTANT

Before proceeding to the machining in 3: Count mode, it is necessary to perform 10:

Tool offsetting.

3.3.3 Configuration of coordinates

Coordinates of the KA counter have the following configuration:

Counter basic mode in which machining operation is

performed.

Entered from the count mode with the [ON/OFF] key.

Counting is still performed.

By inputting a desired size, zero approach

machining that is to perform machining to approach

the display value to zero is performed.

approach buzzer is available.

The zero

1 2 3 4

ABS

INC

3.3.4 Setup for tool offset

The KA counter is provided with the function for compensating the difference in each tool

length and displaying always the center of a workpiece (ABS coordinate) or the depth of

cut (INC coordinate) with respect to the tool tip. To use this function, the counter needs to

store the lengths of each tool to be used. The setting up of these lengths in the counter is

called tool-offset setup. The tool offset is set in the too offset setup mode.

This section explains the procedure for setting tool offset values.

The following figure shows a state in which some tools are set on a lathe.

Four tools are attached to the tool post and each tool is assigned a tool number as shown

in the figure.

Trial machining is performed using the tools sequentially, the dimensions of a workpiece

are measured with a caliper or a micrometer, and then those values are entered in the

counter.

○ ○ ○ ○

○ ○ ○ ○

No. 99MBE032A

3-29

Page 49

Step 1 Check that the counter is set to the ABS coordinate in the count mode. If it is not

NOTE

set to the ABS coordinate, press the key to switch to the ABS coordinate.

After confirming the display, press the key twice.

“t” on the sub-display blinks to indicate that the counter is in the tool offset setup

mode.

If the current coordinate is the ABS coordinate, the decimal point in the sub-display is

illuminating.

For more information about the ABS coordinate, refer to “3.3.8 A/I coordinate switch”.

Step 2 To change the tool number, press a numeric key corresponding to the tool

number assigned to the tool used. Specify the tool number 1 by pressing the 1

key. The tool number 1 will be displayed.

(Press twice)

3-30

No. 99MBE032A

Page 50

3. BASIC OPERATIONS

Step 3 Perform trial machining using the tool number 1. After moving the tool aside,

measure the diameter of a workpiece with a caliper or a micrometer, then preset

the measured value. Here, set 50.000 as the measured value. This completes

the tool offset of tool number 1.

Step 4 Switch the offset tool number to 2.

Press the 2 key to select tool number 2. Tool number 2 will be displayed.

Step 5 Perform trial machining using the tool number 2. After moving the tool aside,

measure the diameter of the workpiece with the caliper or the micrometer, then

preset the measured value. Here, set 45.263 as the measured value.

Step 6 From this point, repeat the tool presetting procedure for the necessary tools.

Press the key or the Cancel key to quit the tool offset mode.

NOTE

If a tool wears from machining, the counter display may deviate. If this is the case, set

up the tool offset again only for the worn tool.

If tool offset setup has been completed, the counter will display correct values.

3.3.5 Count mode

After the tool offset value is set or the coordinate is restored, the KA counter does display

the correct values. This allows you to perform the machining easily.

Before commencing your machining note the following points for improving the efficiency

of operation.

NOTE

• There are two coordinate displays; ABS coordinate and INC coordinate. The ABS

coordinate shows the diameter of a workpiece using the center of the workpiece as the

reference point. The reference point of the INC coordinate can be optionally translated.

In general, the INC coordinate is used to display the cutting depth based on the result of

zero-setting on the workpiece surface.

No. 99MBE032A

• Choose the tool number that corresponds to the actually used tool. Machining with a

wrong tool number will result in an inaccurate machining.

3-31

Page 51

3.3.6 Zero-setting/Presetting

The KA counter appends convenient capabilities to the zero-set and preset functions to

facilitate lathe-machining operation.

Zero-setting or presetting in the KA counter is

performed not only for the currently displayed

value, but also for the display values of other

tools. Each reference point is parallel

translated. If the tool No. 1 tip is on the

workpiece surface as shown in the figure, the

reference point of tool No. 1 is translated to

the workpiece surface and the counter

display becomes 0.000 when zero-setting is

performed. At the same time the reference

points of other tools are also translated to this

position.

Since the reference points of all tools are

calculated into the same point, the operator

can concentrate on machining without being

aware of the tool length difference.

TIP

If zero-setting and presetting are repeated some times for all tools after setting the

X-axis resolution to 0.002mm, the display values may be indicated as if they had a

dispersion of 0.002mm (actual length: 0.001mm). This is because the counter counts as

precisely as possible and rounds off the display value. The counter will operate properly

since it is not a malfunction.

3.3.7 Tool number switch

The tool number can be changed from 1 to 2 by observing the following procedure.

3-32

No. 99MBE032A

Page 52

3.3.8 A/I coordinate system switch

The KA counter has two kinds of coordinate systems: Absolute (ABS) coordinate system,

and Incremental (INC) coordinate system.

• Change the coordinate system currently used.

The coordinate system changes in the following order:

ABS coordinate system INC coordinate system ABS coordinate system

3. BASIC OPERATIONS

Illumination of the dot (.) in the sub-display shows they are ABS coordinates.

No. 99MBE032A

3-33

Page 53

NOTE

1. Features of ABS and INC coordinates on the X-axis

• The reference point in the ABS coordinate is designated as the center of a

workpiece. Therefore, the display value in the ABS coordinate indicates the diameter

of the workpiece.

• In the INC coordinate zero-setting and presetting can be performed at an arbitrary

position. For example, this function allows the real-time depth of cut to be displayed

by zero-setting on a workpiece surface.

Coordinate features

ABS coordinate Center of a workpiece Disabled Diameter

INC coordinate Arbitrary position on a

Appropriate use of two coordinates

Reference point of

coordinate (0 point)

workpiece

Zero-setting/presetting Display

content

Enabled Depth of cut

2. Features of ABS and INC coordinates on the Y- and Z-axis

Although there is no functional difference between the ABS and INC coordinates on

each axis, it is recommended to use the coordinate separately as shown in the figure

below.

3-34

No. 99MBE032A

Page 54

3.3.9 Halving the display

The KA counter is capable of halving the display value or preset value and displaying the

halved value.

1) Halve the display value for the X-axis.

• Halve the currently displayed value, 100.000.

3. BASIC OPERATIONS

NOTE

Halving the displayed value on the ABS coordinate system cannot be performed.

If the ABS coordinate is selected on the counter, select the INC coordinate using

the key, then perform the halving operation.

2) Halve the preset value for the X-axis.

• Halve the preset value, 123.000.

No. 99MBE032A

3-35

Page 55

3.3.10 Zero approach machining

If the pitch given on the design drawing is entered in the counter, the target value from the

current position to the machining position is automatically displayed. Perform the

machining until the displayed value becomes zero. By repeating this procedure, machining

can be performed efficiently.

NOTE

Errors occurred in performing the machining are automatically corrected for the next

target value.

• Perform the machining on the Z-axis as shown below.

Zero approach operation

Step 1 Press the Zero-approach key.

3-36

Step 2 Feed the machine table to the datum point, and set the counter display to zero.

Step 3 Enter the distance (20mm) for the first drilling point.

Step 4 Feed the machine table to the machining position, where the counter displays

0.005mm, and drill a hole.

No. 99MBE032A

Page 56

3. BASIC OPERATIONS

Step 5 Enter 30mm, the distance to the next machining point.

The KA counter corrects the previous positioning error, -0.005mm and displays

the actual distance the machine needs to move to reach the next machining

point.

Feed the machine table to the machining position.

Step 6 To quit the zero-approach machining function, press the Zero-approach key or

the Cancel key.

NOTE

TIP

• It is recommended not to perform zero-approach machining on the X-axis. (For more

information, refer to the “Zero-approach machining on the X-axis” shown below.)

• It is possible to zero-set the counter during zero-approach mode. However, if the

counter is zero-set, the accumulated error up to that point cannot be corrected.

• If the zero-approach mode is entered from the ABS coordinate, zero-setting of the

X-axis cannot be performed.

• If the zero-approach machining function is deselected, the display contents will restore

those before selecting the function. Zero-setting, machining point setting, etc., which

were performed in the zero-approach mode will not affect the counter operation.

• Zero-approach operation on the X-axis

To machine according to the figure shown on the left, the value

to be entered in the counter must be twice the value a and b (2a

and 2b).

No. 99MBE032A

Generally, the diameter is used in the drawings for lathe

machining (see the figure on the left). Therefore, it is

recommended to machine using the displayed ABS coordinate

value instead of using the zero-approach function, since the

displayed ABS coordinate value is equal to the dimension to be

machined.

3-37

Page 57

3.3.11 Changing the unit of measurement

It is possible to switch the unit of measurement between mm and inch (1/25.4).

NOTE

• The indicator “mm” on the front panel turns on if mm is selected. The indicator turns off if

inch is selected.

• When the display ON/OFF switch is turned on, the unit set when the switch was turned

off will be displayed.

3.3.12 Saving and recalling a datum point using the scale reference point

Refer to “3.2.5 Saving and recalling a datum point using the scale reference point”.

3.3.13 Setting the machine origin using the AT100 series

Refer to “3.2.6 Setting the machine origin using the AT700 series”.

No. 99MBE032A

3-38

Page 58

1 PARAMETERS

4

4.1 Overview of Parameters

In order to use the K A counter (and co nnec t ed linear scales) f or machining operat ion, it is

necessary to set up co nditions such as the count direction or the scale reference point

detection direction.

Also, by setting the resolution and diameter display required for machining and corrections

for machine tool errors, the counter can be customized to your requirement and more

accurate machining is insur ed. These c onditions t o be set up are called par ameters, and

setting them in the counter is called parameter setup.

This chapter describes the parameters available with the KA counter.

The parameters are com prised of a param eter num ber and set up data. The set up data is

selected from among data already saved in the counter memory, or is entered directly from

the ten-key.

The setup data for parameters that have already been set up once is saved in the counter

memory even when the power is off. Also, it is possible t o check or initialize ( restore the

factory settings) the parameters.

No. 99MBE032A

4-1

Page 59

4.2 Types of Parameters

There are following two types of parameters:

• Parameters to be set for each axis

• Parameters to be set for all axes in common

For example, the paramete r 50, “Changes the count direct ion” is a parameter set for each

axis, whereas the parameter 12, “Linear error correction selection” is a parameter

common for all axes.

The setup data for parameters that have already been set up once is saved in the

TIP

counter memory even when the power is off.

4.2.1 Parameters set for each axis

Parameter

No.

15

Note 1)

20