Page 1

AIR CONDITIONING SYSTEMS

INDOOR UNIT OPTIONAL PARTS

SOLENOID VALVE KIT

PAC-SV01PW-E

GBDFEINLPSV

INSTALLATIONSHANDBUCH

Zum sicheren und ordnungsgemäßen Gebrauch der Innenanlage das Installationshandbuch gründlich durchlesen.

MANUEL D’INSTALLATION

Avant d’installer l’appareil intérieur, prière de lire ce manuel d’installation avec attention pour un usage correct et en toute sécurité.

MANUAL DE INSTALACIÓN

Para la utilización segura y correcta, lea detenidamente este manual de instalación antes de instalar la unidad interior.

INSTALLATION MANUAL

For safe and correct use, please read this installation manual thoroughly before installing the indoor unit.

MANUALE DI INSTALLAZIONE

Per un uso sicuro e corretto, leggere attentamente questo manuale di installazione prima di installare l’unità interna.

INSTALLATIEHANDLEIDING

Voor veilig en correct gebruikt dient u deze installatiehandleiding geheel te lezen voor het installeren van het toestel voor binnenshuis.

MANUAL DE INSTALAÇÃO

Para uma utilização segura e correcta, é favor ler este manual de instalação por completo, antes de instalar a unidade interior.

GRRUTRHGPO SLSWHR BGRO CZ

ΕΓΧΕΙΡΙΔΙΟ ΟΔΗΓΙΩΝ ΕΓΚΑΤΑΣΤΑΣΗΣ

Για ασφάλεια και σωστή χρήση, παρακαλείστε να διαβάσετε προσεχτικά αυτό το εγχειρίδιο εγκατάστασης πριν την εγκατάσταση της

εσωτερικής μοvάδας.

РУКОВОДСТВО ПО УСТАНОВКЕ

Для безопасной и правильной эксплуатации аппарата необходимо тщательно ознакомиться с данным руководством по установке

перед выполнением установки внутреннего блока.

MONTAJ ELKİTABI

Emniyetli ve doğru biçimde nasıl kullanılacağını öğrenmek için lütfen iç mekan ünitesini monte etmeden önce bu elkitabını dikkatle okuyunuz.

PŘÍRUČKA K INSTALACI

V zájmu bezpečného a správného používání si před instalací vnitřní jednotky důkladně pročtěte tuto příručku k instalaci.

NÁVOD NA INŠTALÁCIU

Pre bezpečné a správne použitie si prosím pred inštalovaním vnútornej jednotky starostlivo prečítajte tento návod na inštaláciu.

TELEPÍTÉSI KÉZIKÖNYV

A biztonságos és helyes használathoz, kérjük, olvassa el alaposan ezt a telepítési kézikönyvet, mielőtt telepítené a légkondicionáló egységet.

PODRĘCZNIK INSTALACJI

W celu bezpiecznego i poprawnego korzystania, należy przed zainstalowaniem urządzenin dokładnie zapoznać się z niniejszym podręcznikiem instalacji.

PRIROČNIK ZA NAMESTITEV

Za varno in pravilno uporabo pred namestitvijo naprave enote skrbno preberite ta priročnik za namestitev.

INSTALLATIONSHANDBOK

Läs den här installationshandboken noga innan inomhusenheten installeras, för säker och korrekt användning.

PRIRUČNIK ZA UGRADNJU

Radi sigurne i ispravne uporabe, temeljito pročitajte ovaj priručnik prije ugradnje unutarnje jedinice.

РЪКОВОДСТВО ЗА МОНТАЖ

За безопасно и правилно ползване, моля прочетете изцяло това ръководство за монтаж преди инсталацията на вътрешния блок.

MANUAL CU INSTRUCŢIUNI DE INSTALARE

Pentru o utilizare corectă şi sigură, vă rugăm citiţi cu atenţie acest manual înainte de a instala unitatea internă.

Page 2

2

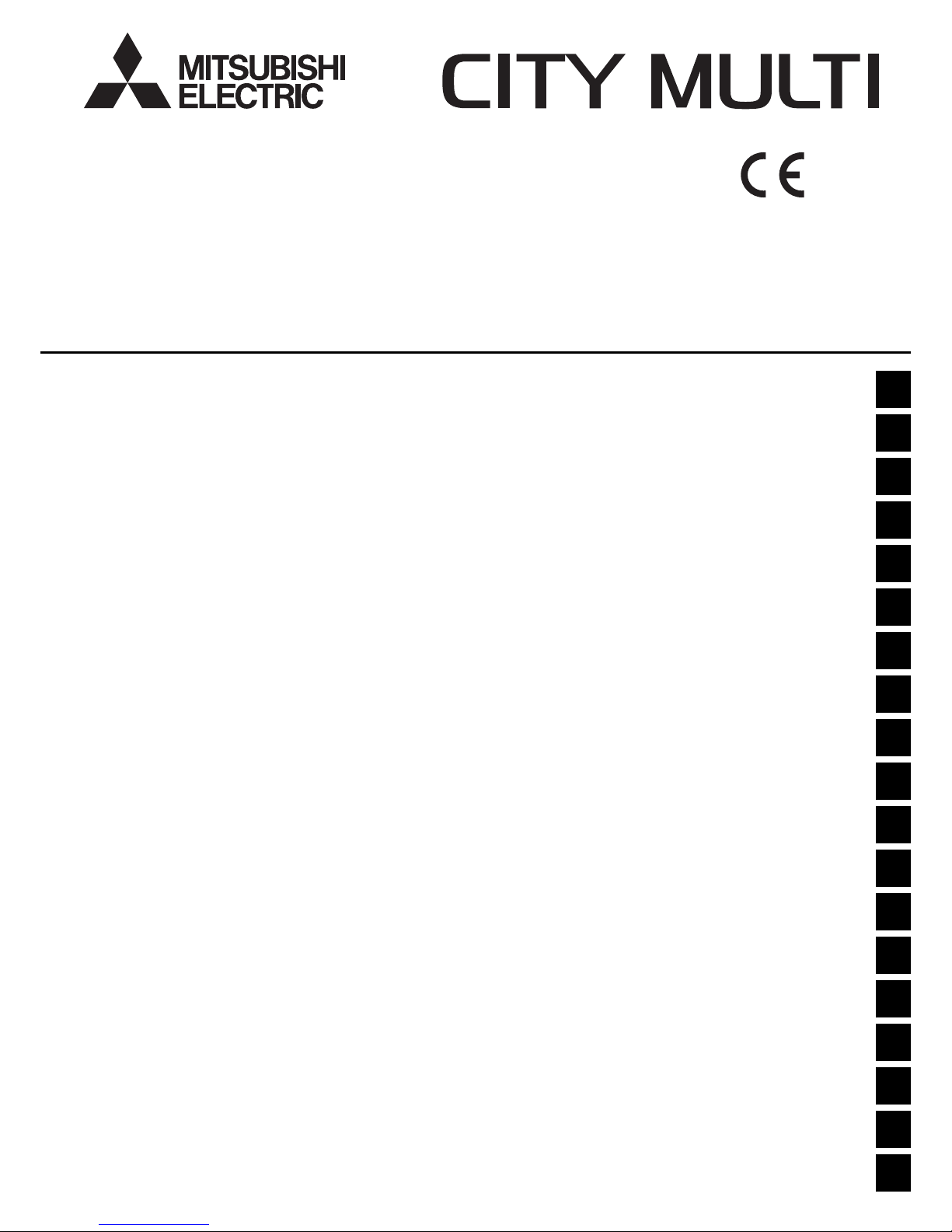

55.1

[Fig. 5.1.1]

5.2

[Fig. 5.2.1]

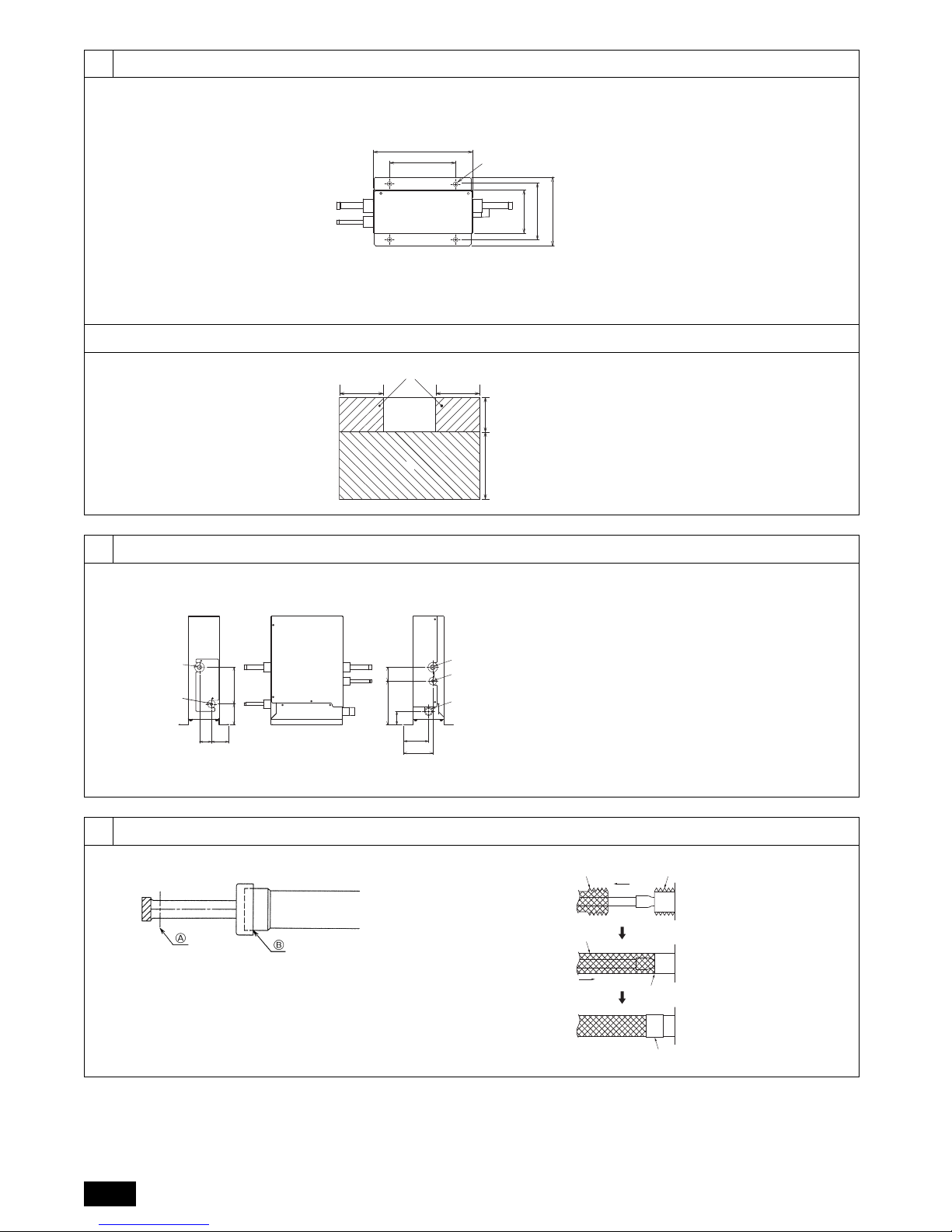

66.1

[Fig. 6.1.1]

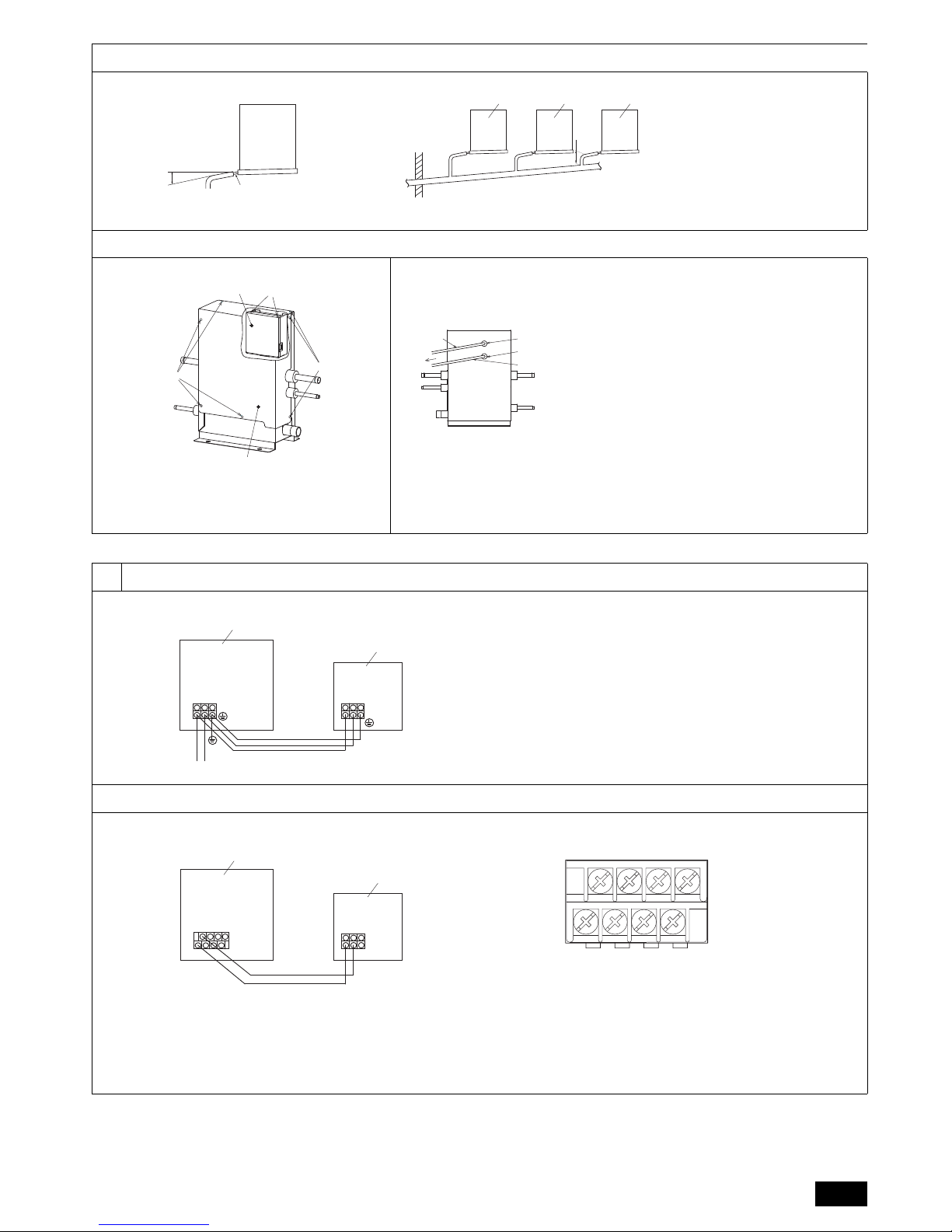

77.1

B

A

320

200

150

171

207

A 4-ø14 (Anchoring hole)

B (Top view)

(Unit: mm)

B

ad

b

c

C

A

A Piping space (both sides)

B Top vi ew

C Service space (front side)

A

B

C

F

D

E

A

B

153

86

58181

55

50 72 104

121

A Refrigerant piping (gas) B Refrigerant piping (liquid)

C Drain outlet D Front view

E Left side view F Right side view

(Unit: mm)

A

A

E

C

F

B

D

[Fig. 7.1.1]

[Fig. 7.1.2]

A Thermal insulation

B Pull out insulation

C Wrap with damp cloth

D Return to original position

E Ensure that there is no gap here

F Wrap with insulating tape

A Cut here

B Remove brazed cap

Page 3

3

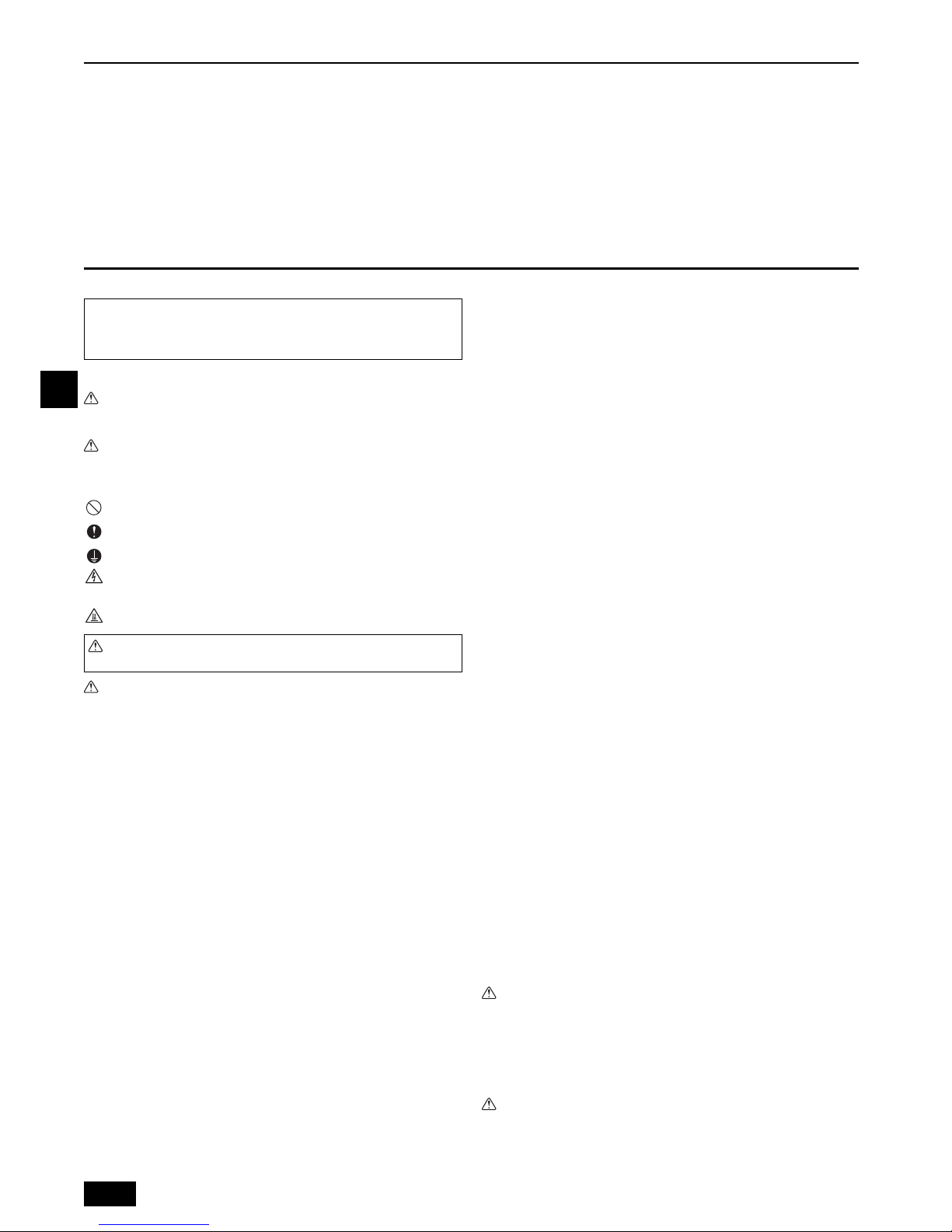

7.3

[Fig. 7.3.1]

7.4

[Fig. 7.4.1] [Fig. 7.4.2]

88.1

[Fig. 8.1.1]

8.2

C C C

D 2

E

A

B

1

A Downward slope 1/100 or more

B Drain hose

C Unit

D Collective piping

E Maximize this length to ap prox. 10 cm

A

B

A

A

C

A Screws

B Front panel

C Control box

C

A

A

B

D

E

A To prevent external tensile force from applying to the wiring connection sec-

tion of power source terminal block use buffer bushing like PG connection

or the like.

B External signal input cable

C Power source wiring

D Tensile force

E Back view

TB2 TB2

L

N

L

N

A

B

A PWFY-P•VM-E-AU

B PAC -SV 01P W-E

OUT4OUT3OUT2

TB141A

OUT1

TB141A

OUT2OUT1 OUT3 OUT4

TB1

123

A

B

[Fig. 8.2.1] [Fig. 8.2.2]

A PWFY-P•VM-E-AU

B PAC-SV01PW-E

Page 4

4

GB

Contents

1. Safety precautions .............................................................................................4

1.1. Before installation and electric work .................................................4

1.2. Precautions for devices that use R410A refrigerant.........................4

1.3. Before getting installed .....................................................................5

1.4. Before getting installed (moved) -electrical work..............................5

1.5. Before starting the test run ...............................................................5

2. About the product ..............................................................................................5

3. Parts list .............................................................................................................6

4. Lifting method ....................................................................................................6

5. Installation of unit and service space .................................................................6

5.1. Installation ........................................................................................6

5.2. Service space...................................................................................6

6. Refrigerant pipe and drain pipe specifications ................................................... 6

6.1. Refrigerant pipd, drain pipe and filling port.......................................6

7. Connecting refrigerant pipes and drain pipes .................................................... 7

7.1. Refrigerant piping work ....................................................................7

7.2. Refrigerant piping limitation..............................................................7

7.3. Drain piping work.............................................................................. 7

7.4. Connecting electrical connections....................................................7

8. Electrical wiring ..................................................................................................8

8.1. Power supply wiring .........................................................................8

8.2. Connecting solenoid coil transmission cables..................................8

1. Safety precautions

1.1. Before installation and electric work

Symbols used in the text

Warning:

Describes precautions that should be observed to prevent danger of injury or

death to the user.

Caution:

Describes precautions that should be observed to prevent damage to the unit.

Symbols used in the illustrations

Warning:

• If the supply cord is damaged, it must be replaced by the manufacturer, its

service agent or similarly qualified persons in order to avoid a hazard.

• This appliance is not intended for use by persons (including children) with

reduced physical, sensory or mental capabilities, or lack of experience and

knowledge, unless they have been given supervision or instruction cocerning use of the appliance by a person responsible for their safety.

• Do not use refrigerant other than the type indicated in the manuals provided

with the unit and on the nameplate.

- Doing so may cause the unit or pipes to burst, or result in explosion or fire during

use, during repair, or at the time of disposal of the unit.

- It may also be in violation of applicable laws.

- MITSUBISHI ELECTRIC CORPORATION cannot be held responsible for mal-

functions or accidents resulting from the use of the wrong type of refrigerant.

• Do not use steel pipes as water pipes.

- Copper pipes are recommended.

• The water circuit should be a closed circuit.

• Ask the dealer or an authorized technician to install the air conditioner.

- Improper installation by the user may result in water leakage, electric shock, or

fire.

• Install the unit in a place that can withstand its weight.

- Inadequate strength may cause the unit to fall down, resulting in injuries.

• Do not touch the unit. The unit surface can be hot.

• Do not install the unit where corrosive gas is generated.

• Use the specified cables for wiring. Make the connections securely so that

the outside force of the cable is not applied to the terminals.

- Inadequate connection and fastening may generate heat and cause a fire.

• Prepare for rain and other moisture and earthquakes and install the unit at

the specified place.

- Improper installation may cause the unit to topple and result in injury.

• Always use an strainer and other accessories specified by Mitsubishi Electric.

- Ask an authorized technician to install the accessories. Improper installation by

the user may result in water leakage, electric shock, or fire.

• Never repair the unit. If the air conditioner must be repaired, consult the

dealer.

- If the unit is repaired improperly, water leakage, electric shock, or fire may result.

• Do not touch the refrigerant pipes and Water pipes.

- Improper handling may result in injury.

• When handling this product, always wear protective equipment.

EG: Gloves, full arm protection namely boiler suit, and safety glasses.

- Improper handling may result in injury.

• If refrigerant gas leaks during installation work, ventilate the room.

- If the refrigerant gas comes into contact with a flame, poisonous gases will be

released.

• Install the unit according to this Installation Manual.

- If the unit is installed improperly, water leakage, electric shock, or fire may result.

• Have all electric work done by a licensed electrician according to “Electric

Facility Engineering Standard” and “Interior Wire Regulations” and the

instructions given in this manual and always use a special circuit.

- If the power source capacity is inadequate or electric work is performed improp-

erly, electric shock and fire may result.

• Keep the electric parts away from water (washing water etc.).

- It might result in electric shock, catching fire or smoke.

• Securely install the heat source unit terminal cover (panel).

- If the terminal cover (panel) is not installed properly, dust or water may enter the

heat source unit and fire or electric shock may result.

• When installing and moving the air conditioner to another site, do not

charge it with a refrigerant different from the refrigerant (R410A) specified

on the unit.

- If a different refrigerant or air is mixed with the original refrigerant, the refrigerant

cycle may malfunction and the unit may be damaged.

• If the air conditioner is installed in a small room, measures must be taken to

prevent the refrigerant concentration from exceeding the safety limit even if

the refrigerant should leak.

- Consult the dealer regarding the appropriate measures to prevent the safety

limit from being exceeded. Should the refrigerant leak and cause the safety limit

to be exceeded, hazards due to lack of oxygen in the room could result.

• When moving and reinstalling the air conditioner, consult the dealer or an

authorized technician.

- If the air conditioner is installed improperly, water leakage, electric shock, or fire

may result.

• After completing installation work, make sure that refrigerant gas is not

leaking.

- If the refrigerant gas leaks and is exposed to a fan heater, stove, oven, or other

heat source, it may generate noxious gases.

• Do not reconstruct or change the settings of the protection devices.

- If the pressure switch, thermal switch, or other protection device is shorted and

operated forcibly, or parts other than those specified by Mitsubishi Electric are

used, fire or explosion may result.

• To dispose of this product, consult your dealer.

• The installer and system specialist shall secure safety against leakage

according to local regulation or standards.

- Following standards may be applicable if local regulation are not available.

• Pay a special attention to the place, such as a basement, etc. where refrigeration gas can stay, since refrigeration is heavier than the air.

• Children should be supervised to ensure that they do not play with the

appliance.

1.2. Precautions for devices that use R410A

refrigerant

Warning:

• Do not use refrigerant other than the type indicated in the manuals provided

with the unit and on the nameplate.

- Doing so may cause the unit or pipes to burst, or result in explosion or fire during

use, during repair, or at the time of disposal of the unit.

- It may also be in violation of applicable laws.

- MITSUBISHI ELECTRIC CORPORATION cannot be held responsible for mal-

functions or accidents resulting from the use of the wrong type of refrigerant.

Caution:

• Do not use the existing refrigerant piping.

- The old refrigerant and refrigerant oil in the existing piping contains a large

amount of chlorine which may cause the refrigerant oil of the new unit to deteriorate.

- R410A is a high-pressure refrigerant and can cause the existing piping to burst.

Before installing the unit, make sure you read all the “Safety pre-

cautions”.

The “Safety precautions” provide very important points regard-

ing safety. Make sure you follow them.

: Indicates an action that must be avoided.

: Indicates that important instructions must be followed.

: Indicates a part which must be grounded.

: Beware of electric shock. (This symbol is displayed on the main unit label.)

<Color: yellow>

: Beware of hot surface.

Warning:

Carefully read the labels affixed to the main unit.

Page 5

5

GB

• Use refrigerant piping made of C1220 (CU-DHP) phosphorus deoxidized

copper as specified in the JIS H3300 “Copper and copper alloy seamless

pipes and tubes”. In addition, be sure that the inner and outer surfaces of

the pipes are clean and free of hazardous sulphur, oxides, dust/dirt, shaving

particles, oils, moisture, or any other contaminant.

- Contaminants on the inside of the refrigerant piping may cause the refrigerant

residual oil to deteriorate.

• Store the piping to be used during installation indoors and keep both ends

of the piping sealed until just before brazing. (Store elbows and other joints

in a plastic bag.)

- If dust, dirt, or water enters the refrigerant cycle, deterioration of the oil and com-

pressor trouble may result.

• Use ester oil, ether oil or alkylbenzene (small amount) as the refrigerant oil

to coat flares and flange connections.

- The refrigerant oil will degrade if it is mixed with a large amount of mineral oil.

• Use liquid refrigerant to fill the system.

- If gas refrigerant is used to seal the system, the composition of the refrigerant in

the cylinder will change and performance may drop.

• Do not use a refrigerant other than R410A.

- If another refrigerant (R22, etc.) is mixed with R410A, the chlorine in the refrig-

erant may cause the refrigerant oil to deteriorate.

• Use a vacuum pump with a reverse flow check valve.

- The vacuum pump oil may flow back into the refrigerant cycle and cause the

refrigerant oil to deteriorate.

• Do not use the following tools that are used with conventional refrigerants.

(Gauge manifold, charge hose, gas leak detector, reverse flow check valve,

refrigerant charge base, refrigerant recovery equipment)

- If the conventional refrigerant and refrigerant oil are mixed in the R410A, the

refrigerant may deteriorated.

- If water is mixed in the R410A, the refrigerant oil may deteriorate.

- Since R410A does not contain any chlorine, gas leak detectors for conventional

refrigerants will not react to it.

• Do not use a charging cylinder.

- Using a charging cylinder may cause the refrigerant to deteriorate.

• Be especially careful when managing the tools.

- If dust, dirt, or water gets in the refrigerant cycle, the refrigerant may deteriorate.

1.3. Before getting installed

Caution:

• Do not install the unit where combustible gas may leak.

- If the gas leaks and accumulates around the unit, an explosion may result.

• Do not use the air conditioner where food, pets, plants, precision instruments, or artwork are kept.

- The quality of the food, etc. may deteriorate.

• Do not use the air conditioner in special environments.

- Oil, steam, sulfuric smoke, etc. can significantly reduce the performance of the

air conditioner or damage its parts.

• When installing the unit in a hospital, communication station, or similar

place, provide sufficient protection against noise.

- The inverter equipment, private power generator, high-frequency medical equip-

ment, or radio communication equipment may cause the air conditioner to operate erroneously, or fail to operate. On the other hand, the air conditioner may

affect such equipment by creating noise that disturbs medical treatment or

image broadcasting.

• Do not install the unit on a structure that may cause leakage.

- When the room humidity exceeds 80 % or when the drain pipe is clogged, con-

densation may drip from the indoor unit. Perform collective drainage work

together with the unit, as required.

1.4. Before getting installed (moved) - electri-

cal work

Caution:

• Ground the unit.

- Do not connect the ground wire to gas or water pipes, lightning rods, or telephone ground lines. Improper grounding may result in electric shock.

• Install the power cable so that tension is not applied to the cable.

- Tension may cause the cable to break and generate heat and cause a fire.

• Use power line cables of sufficient current carrying capacity and rating.

- Cables that are too small may leak, generate heat, and cause a fire.

• Do not wash the air conditioner units.

- Washing them may cause an electric shock.

• Be careful that the installation base is not damaged by long use.

- If the damage is left uncorrected, the unit may fall and cause personal injury or

property damage.

• Install the drain piping according to this Installation Manual to ensure

proper drainage. Wrap thermal insulation around the pipes to prevent condensation.

- Improper drain piping may cause water leakage and damage to furniture and

other possessions.

• Be very careful about product transportation.

- Only one person should not carry the product if it weighs more than 20 kg.

- Some products use PP bands for packaging. Do not use any PP bands for a

means of transportation. It is dangerous.

- When transporting the unit, support it at the specified positions on the unit base.

Also support the unit at four points so that it cannot slip side ways.

• Safely dispose of the packing materials.

- Packing materials, such as nails and other metal or wooden parts, may cause

stabs or other injuries.

- Tear apart and throw away plastic packaging bags so that children will not play

with them. If children play with a plastic bag which was not torn apart, they face

the risk of suffocation.

1.5. Before starting the test run

Caution:

• Error code "7130" appears when both of the following conditions are met.

- The PWFY unit is connected to the outdoor unit of Y series.

- The version of the software is the one listed below.

PWFY series: earlier than Ver. 1.13

Y(YHM) series: earlier than Ver. 12.27

Y(YJM) series: earlier than Ver. 1.31

Replace Y(YJM) series: earlier than Ver. 11.31

HP(ZUBADAN) series: earlier than Ver. 22.27

WY series: earlier than Ver. 12.29

• Do not touch the switches with wet fingers.

- Touching a switch with wet fingers can cause electric shock.

• Do not touch the refrigerant pipes during and immediately after operation.

- During and immediately after operation, the refrigerant pipes are may be hot

and may be cold, depending on the condition of the refrigerant flowing through

the refrigerant piping, compressor, and other refrigerant cycle parts. Your hands

may suffer burns or frostbite if you touch the refrigerant pipes.

• Do not operate the air conditioner with the panels and guards removed.

- Rotating, hot, or high-voltage parts can cause injuries.

• Do not turn off the power immediately after stopping operation.

- Always wait at least five minutes before turning off the power. Otherwise, water

leakage and trouble may occur.

• Do not touch the panels with bare hands: they can get hot while the unit is in

operation (even if it is stopped) or immediately after operation and poses a

risk of burns. Wear gloves to protect your hands when it is necessary to

touch the panels.

• Be sure to provide a pathway for the exhaust air from the fan.

• Water pipes can get very hot, depending on the preset temperature. Wrap

the water pipes with insulating materials to prevent burns.

• Update the software version on the PWFY to 1.20 or later to which the solenoid valve kit will be connected.

• Set Dip SW 3-6 on the PWFY to ON.

2. About the product

Warning:

• Do not use refrigerant other than the type indicated in the manuals provided

with the unit and on the nameplate.

- Doing so may cause the unit or pipes to burst, or result in explosion or fire during

use, during repair, or at the time of disposal of the unit.

- It may also be in violation of applicable laws.

- MITSUBISHI ELECTRIC CORPORATION cannot be held responsible for mal-

functions or accidents resulting from the use of the wrong type of refrigerant.

• This unit uses R410A-type refrigerant.

• Piping for systems using R410A may be different from that for systems using conventional refrigerant because the design pressure in systems using R410A is

higher. Refer to Data Book for more information.

• Some of the tools and equipment used for installation with systems that use other

types of refrigerant cannot be used with the systems using R410A. Refer to Data

Book for more information.

• Do not use the existing piping, as it contains chlorine, which is found in conventional refrigerating machine oil and refrigerant. This chlorine will deteriorate the

refrigerant machine oil in the new equipment. The existing piping must not be

used as the design pressure in systems using R410A is higher than that in the

systems using other types of refrigerant and the existing pipes may burst.

Page 6

6

GB

3. Parts list

Package contents

This kit contains the following parts.

Attach the supplied specification label below the specification label on the PWFY unit to which the Solenoid valve kit will be connected.

Before attaching the specification label, wipe the surface clean with alcohol.

Use the supplied Liquid pipe and Gas pipe to adjust the piping height when installing the Solenoid valve kit on the same level with the PWFY unit.

List of field-supplied parts

• Refrigerant pipes other than the ones provided in the kit

• Heat-resistant insulation material (for field-supplied refrigerant pipes)

• Insulation cover tape

4. Lifting method

Caution:

Be very careful when carrying the product.

- Do not have only one person to carry product if it is more than 20 kg.

- PP bands are used to pack some products. Do not use them as a mean for transportation because they are dangerous.

- Tear plastic packaging bag and scrap it so that children cannot play with it. Otherwise plastic packaging bag may suffocate children to death.

5. Installation of unit and service space

5.1. Installation

• Using the anchoring holes shown below, firmly bolt the unit to the base.

[Fig. 5.1.1] (P.2)

Bases

• Be sure to install unit in a place strong enough to withstand its weight. If the base

is unstable, reinforce with a concrete base.

• The unit must be anchored on a level surface. Use a level to check after installation.

• If the unit is installed near a room where noise is a problem, using an anti-vibration

stand on the base of the unit is recommended.

Warning:

• Be sure to install unit in a place strong enough to withstand its weight.

Any lack of strength may cause unit to fall down, resulting in a personal

injury.

• Have installation work in order to protect against earthquake.

Any installation deficiency may cause unit to fall down, resulting in a personal injury.

5.2. Service space

• Please allow for the following service spaces after installation.

(All servicing can be performed from the front of the unit)

[Fig. 5.2.1] (P.2)

(Unit: mm)

6. Refrigerant pipe and drain pipe specifications

To avoid dew drops, provide sufficient antisweating and insulating work to the refrigerant and drain pipes.

When using commercially available refrigerant pipes, be sure to wind commercially

available insulating material (with a heat-resisting temperature of more than 100 ˚C

and thickness given below) onto both liquid and gas pipes.

Be also sure to wind commercially available insulating material (with a form polyethylene’s specific gravity of 0.03 and thickness given below) onto all pipes which pass

through rooms.

1 Select the thickness of insulating material by pipe size.

2 If the unit is used on the highest story of a building and under conditions of high

temperature and humidity, it is necessary to use pipe size and insulating material’s thickness more than those given in the table above.

3 If there are customer’s specifications, simply follow them.

6.1. Refrigerant pipe, drain pipe and filling port

[Fig. 6.1.1] (P.2)

Parts name Installation manual Specification label Liquid pipe Gas pipe

O.D. ø15.88 mm-

I.D. ø19.05 mm

O.D. ø19.05 mm-

I.D. ø15.88 mm

Shape

Qty.111111

A 4-ø14 (Anchoring hole) B (Top view)

Model a b c d

PAC-SV01PW-E 150 210 600 400

A Piping space (both sides) B Top view

C Service space (front side)

Applicable models PWFY-P100VM-E1-AU PWFY-P200VM-E1-AU

Gas

ø

15.88

ø

19.05

Liquid

ø

9.52

ø

9.52

Drain

ø

32

Insulating material's thickness More than 10 mm

A Refrigerant piping (gas) B Refrigerant piping (liquid)

C Drain outlet D Front view

E Left side view F Right side view

Page 7

7

GB

7. Connecting refrigerant pipes and drain pipes

7.1. Refrigerant piping work

This piping work must be done in accordance with the installation manuals for both

outdoor unit and BC controller (simultaneous cooling and heating series R2).

• Series R2 is designed to operate in a system that the refrigerant pipe from an outdoor unit is received by BC controller and branches at the BC controller to connect

between indoor units.

• For constraints on pipe length and allowable difference of elevation, refer to the

outdoor unit manual.

• The method of pipe connection is brazing connection.

Caution:

• Install the refrigerant piping for the indoor unit in accordance with the following.

1. Cut the tip of the indoor unit piping, remove the gas, and then remove the brazed

cap.

[Fig. 7.1.1] (P.2)

2. Pull out the thermal insulation on the site refrigerant piping, braze the unit piping,

and replace the insulation in its original position.

Wrap the piping with insulating tape.

Note:

• Pay strict attention when wrapping the copper piping since wrapping the

piping may cause condensation instead of preventing it.

* Before brazing the refrigerant piping, always wrap the piping on the main body,

and the thermal insulation piping, with damp cloths to prevent heat shrinkage and burning the thermal insulation tubing. Take care to ensure that the

flame does not come into contact with the main body itself.

[Fig. 7.1.2] (P.2)

Cautions On Refrigerant Piping

Be sure to use non-oxidative brazing for brazing to ensure that no foreign

matter or moisture enter into the pipe.

Be sure to apply refrigerating machine oil over the flare connection seating

surface and tighten the connection using a double spanner.

Provide a metal brace to support the refrigerant pipe so that no load is

imparted to the indoor unit end pipe. This metal brace should be provided

50 cm away from the indoor unit’s flare connection.

Warning:

• Do not use refrigerant other than the type indicated in the manuals provided

with the unit and on the nameplate.

- Doing so may cause the unit or pipes to burst, or result in explosion or fire during

use, during repair, or at the time of disposal of the unit.

- It may also be in violation of applicable laws.

- MITSUBISHI ELECTRIC CORPORATION cannot be held responsible for mal-

functions or accidents resulting from the use of the wrong type of refrigerant.

• When installing and moving the unit, do not charge it with refrigerant other

than the refrigerant (R407C or R22) specified on the unit.

- Mixing of a different refrigerant, air, etc. may cause the refrigerant cycle to mal-

function and result in severe damage.

Caution:

• Use refrigerant piping made of C1220 (CU-DHP) phosphorus deoxidized

copper as specified in the JIS H3300 “Copper and copper alloy seamless

pipes and tubes”. In addition, be sure that the inner and outer surfaces of

the pipes are clean and free of hazardous sulphur, oxides, dust/dirt, shaving

particles, oils, moisture, or any other contaminant.

• Never use existing refrigerant piping.

- The large amount of chlorine in conventional refrigerant and refrigerator oil in

the existing piping will cause the new refrigerant to deteriorate.

• Store the piping to be used during installation indoors and keep both ends

of the piping sealed until just before brazing.

- If dust, dirt, or water gets into the refrigerant cycle, the oil will deteriorate and the

compressor may fail.

7.2. Refrigerant piping limitation

*Do not install the Solenoid valve kit on the square-arch-shaped piping as shown in

the figure above.

Piping length limitation

7.3. Drain piping work

1. Ensure that the drain piping is downward (pitch of more than 1/100) to the outdoor

(discharge) side. Do not provide any trap or irregularity on the way. (1)

2. Ensure that any cross-wise drain piping is less than 20 m (excluding the difference

of elevation). If the drain piping is long, provide metal braces to prevent it from

waving. Never provide any air vent pipe. Otherwise drain may be ejected.

3. Use a hard vinyl chloride pipe VP-25 (with an external diameter of 32 mm) for

drain piping.

4. Ensure that collected pipes are 10 cm lower than the unit body’s drain port as

shown in 2.

5. Do not provide any odor trap at the drain discharge port.

6. Put the end of the drain piping in a position where no odor is generated.

7. Do not put the end of the drain piping in any drain where ionic gases are generated.

[Fig. 7.3.1] (P. 3)

7.4. Connecting electrical connections

Verify that the model name on the operating instructions on the cover of the control

box is the same as the model name on the nameplate.

Step 1

Remove the screws holding the terminal box cover in place.

[Fig. 7.4.1] (P. 3)

Note:

Ensure that the wiring is not pinched when fitting the terminal box cover.

Pinching the wiring may cut it.

Caution:

Install wiring so that it is not tight and under tension. Wiring under tension

may break, or overheat and burn.

• Fix power source external input line wiring to control box by using buffer bushing

for tensile force to prevent electric shock. (PG connection or the like.) Connect

transmission wiring to transmission terminal block through the knockout hole of

control box using ordinary bushing.

• After wiring is complete, make sure again that there is no slack on the connections, and attach the cover onto the control box in the reverse order removal.

[Fig. 7.4.2] (P. 3)

Caution:

Wire the power supply so that no tension is imparted. Otherwise disconnection, heating or fire result.

A Cut here

B Remove brazed cap

A Thermal insulation B Pull out insulation

C Wrap with damp cloth D Return to original position

E Ensure that there is no gap here F Wrap with insulating tape

Item Piping in the figure Max. length

Farthest AU from first joint

A+B 40

Length between AU and SV kit B

5

Height between AU and IC (AU)

h

15

A Downward slope 1/100 or more

B Drain hose

C Unit

D Collective piping

E Maximize this length to approx. 10 cm

A Screws B Front panel

C Control box

A To prevent external tensile force from applying to the wiring connection section of

power source terminal block use buffer bushing like PG connection or the like.

B External signal input cable

C Power source wiring

D Tensile force

E Back view

AU AU

SV kit

SV kit

SV kit

AU

A

B

h

AU

SV kit

㪁㪁

IC

Page 8

8

GB

8. Electrical wiring

Precautions on electrical wiring

Warning:

Electrical work should be done by qualified electrical engineers in accordance

with “Engineering Standards For Electrical Installation” and supplied installation manuals. Special circuits should also be used. If the power circuit lacks

capacity or has an installation failure, it may cause a risk of electric shock or

fire.

1. Be sure to take power from the special branch circuit.

2. Ensure that there is no slack on all wire connections.

3. Some cables (power cable or external input/output line) above the ceiling may be

bitten by mouses. Use as many metal pipes as possible to insert the cables into

them for protection.

4. Never connect the power cable to leads for the transmission cables. Otherwise

the cables would be broken.

5. Be sure to ground the unit.

Caution:

Be sure to put the unit to the ground on the outdoor unit side. Do not connect

the earth cable to any gas pipe, water pipe, lightening rod, or telephone earth

cable. Incomplete grounding may cause a risk of electric shock.

8.1. Power supply wiring

• Power supply cords of appliances shall not be lighter than design 60245 IEC 57 or

60227 IEC 57.

• A switch with at least 3 mm contact separation in each pole shall be provided by

the Air conditioner installation.

• Connect the SV kit TB2 and PWFY TB2.

• Run the power supply wire through the access hole for power supply wire on the

PWFY unit. If the hole is already used to run other wires from the existing PWFY

units, use any other wire access holes except the control wire access hole.

• Tighten terminal block screws to a torque of 1.73 N•m ± 10%.

[Fig. 8.1.1] (P. 3)

ELECTRICAL WORK

1. Electrical characteristics

2. Power cable specifications

8.2. Connecting solenoid coil transmission

cables

• Connect the "1" and "2" on SV kit TB1 to the OUT1 on PWFY external output ter-

minal.

• Run the external signal input cable through the access hole for external wiring out-

put wire on the PWFY unit. If the hole is already used to run other wires from the

existing PWFY units, use any other wire access holes except the control wire

access hole.

• Tighten terminal block screws to a torque of 0.80 N•m ± 10%.

[Fig. 8.2.1] (P. 3)

PWFY External output terminal

External output terminal (refer to Fig. 8.2.2) is ineffective when the circuit is open.

Refer to Table 8.2.2 for information about each contact.

The current and voltage in the circuit to be connected to external output terminal

(TB141A OUT1) must meet the following conditions.

Table 8.2.2

A PWFY-P•VM-E-AU

B PAC -SV 01P W-E

Model

Power supply RLA (A)

Hz Volts Voltage range

0.070-0.074-0.077

PAC-SV01PW-E 50/60 220-230-240 V

Max. 264 V

Min. 198 V

Model

Minimum wire thickness (mm

2

)

Main cable branch Ground

PAC-SV01PW-E 1.5 1.5 1.5

A PWFY-P•VM-E-AU

B PAC-SV01PW-E

Contact rating

current

AC250V 1A or less

AC125V 3A or less

DC30V 3A or less

OUT1 Operation ON/OFF

OUT2 Defrost

OUT3 Compressor

OUT4 Error signal

Contact rating

voltage

Page 9

49

RU

Содержание

1. Меры предосторожности...............................................................................49

1.1. Перед установкой прибора и выполнением

электроработ.................................................................................49

1.2. Меры предосторожности для приборов, в которых

используется хладагент R410A ...................................................50

1.3. Перед выполнением установки...................................................50

1.4. Выполнение электроработ до установки

(перемещения)..............................................................................50

1.5. Перед началом пробной эксплуатации......................................50

2. Информация об изделии...............................................................................51

3. Список компонентов.......................................................................................51

4. Перемещение прибора..................................................................................51

5. Установка прибора и пространство для обслуживания прибора...............51

5.1. Установка......................................................................................51

5.2. Пространство

для обслуживания прибора .................................51

6. Техничиеские условия трубы хладагента и дренажной трубы ..................52

6.1. Трубопровод хладагента, дренажная труба и

заливное отверстие......................................................................52

7. Соединение труб хладагента и дренажных труб ........................................52

7.1. Прокладка труб хладагента.........................................................52

7.2. Ограничение на трубы для хладагента ......................................53

7.3. Прокладка дренажных труб.........................................................53

7.4. Выполнение электросоединений................................................53

8. Электрическая проводка ...............................................................................53

8.1. Проводка подачи электропитания...............................................53

8.2. Подключение кабелей передачи соленоида..............................54

1. Меры предосторожности

1.1. Перед установкой прибора и выпол-

нением электроработ

Символика, используемая в тексте

Предупреждение:

Описывает меры предосторожности, необходимые для предотвращения

получения травмы или гибели пользователя.

Осторожно:

Описывает меры предосторожности, необходимые для предотвращения

повреждения прибора.

Символика, используемая в иллюстрациях

Предупреждение:

• Если провод питания поврежден, производитель, обслуживающий

персонал произво ителя или квалифицированный персонал должен

его заменить, чтобы исключить опасность для пользователей.

• Данное устройство не предназначено для использования лицами

(включая детей) со сниженными физическими, сенсорными и умствен-

ными способностями, а также лицами, без достаточных знаний и

опыта, за исключением случаев, когда устройство используется

под

присмотром или руководством человека, ответственного за безопасность таких лиц.

• Не используйте хладагент другого типа, кроме указанного в руководствах из комплекта поставки блока и на паспортной табличке.

- Это может повлечь за собой прорыв трубопроводов или блока либо стать

причиной взрыва или возгорания в процессе эксплуатации, ремонта или

утилизации блока.

- Та кж е это может нарушать действующее законодательство.

- MITSUBISHI ELECTRIC CORPORATION не несет ответственности за неис-

правности или несчастные случаи, причиной которых стало использование

хладагента неподходящего типа.

• Не используйте в качестве водяных труб стальные трубы.

- Реко мендуется использовать медные трубы.

• Водяной контур должен быть замкнутым.

• Обратитесь к дилеру или квалифицированному технику для выполне

ния установки

кондиционера воздуха.

- Неправильная установка, выполненная пользователем, может вызвать

утечку воды, электрошок или пожар.

• Устанавливайте прибор в месте, способном выдержать его вес.

- Недостаточно прочное основание может вызвать падение прибора и при-

вести к т равме.

• Не прикасайтесь к устройству. Поверхность устройства может быть

горячей.

• Не устанавливайте устройство в местах, где

образуется коррозионный

газ.

• Используйте указанные кабели для электропроводки. Выполняйте

соединения с соблюдением требований безопасности, чтобы кабели

не приводили к повреждению клемм.

- Недостаточно надежные соединения могут вызвать перегрев и стать причиной пожара.

• Подготовьтесь к дождям, атмосферным осадкам и землетрясениям и

установите прибор в соответствующем месте.

- Неправильная установка может вызвать падение

прибора и причинить

травму.

• Всегда используйте сетчатый фильтр и другие принадлежности,

соответствующие техническим требованиям компании Mitsubishi

Electric.

- Обратитесь к услугам квалифицированногоу техника для установки допол-

нительных приспоосблений. Неправильная установка, выполненная пользователем, может вызвать утечку воды, электрошок или пожар.

• Никогда не ремонтируйте прибор самостоятельно. Если требуется

ремонт кондиционера воздуха, обратитесь к дилеру.

- Если прибор неправильно отремонтирован, это может вызвать утечку

воды, электрошок или пожар.

• Не прикасайтесь к трубам хладагента и водяным трубам.

- Неправильное обращение с прибором может привести к травме.

• При работе с этим продуктом, всегда надевайте защитную спецодежду,

НAПP. перчатки, полную защиту рук, т.е. комбинезон, и защитные очки.

- Неправильное обращение с прибором может привести к травме.

• При утечке газа охлаждения во время установки проветрите помеще

ние.

- При контакте газа охлаждения с огнем будут выделяться ядовитые газы.

• Устанавливайте устройство согласно инструкциям, приведенным в

данном Руководстве по установке.

- Неправильная установка может вызвать утечку воды, электрошок или

пожар.

• Все электроработы

должны выполняться квалифицированным лицен

зированным электриком согласно“Электротехническим Станадартам”и“Нормам проведения внутренней проводки”и инструкциям, приведенным в данном руководстве; всегда используйте отдельную

схему.

- При недостаточной мощности источника питания или неправильном

выполнении электроработ может возникнуть электрошок или пожар.

• Не допускайте попадания на электрические детали воды (используемой для мытья

и т.д.).

- Это может привести к электрошоку, пожару или задымлению.

• Надежно установите крышку (панель) коробки терминала выводов

наружного прибора.

- Если крышка (панель) коробки терминала выводов не установлена надле-

жащим образом, то в наружный прибор может попасть пыль или вода, что,

в свою очередь, может привести к пожару или электрошоку

.

• При установке кондиционера в новом месте или его перемещении не

заполняйте его хладагентом, отличным от специально предназначенного для него хладагента (R410A).

- При смешении другого хладагента или воздуха с первоначальным хлада-

гентом может произойти сбой цикла охлаждения и прибор может быть поврежден.

• Если кондиционер установлен в небольшом помещении, необходимо

принять

меры для предотвращения концентрации хладагента свыше

безопасных пределов в случае утечки хладагента.

- Проконсультируйтесь с дилером относительно соответствующих мер по

предотвращению превышения допустимой концетрации. В случае утечки

хладагента и превышения допустимых лимитов концентрации может возникнуть опасносная ситуация в связи с недостатком кислорода в помеще

нии.

• При перемещении и повторной установке кондиционера

проконсульти

руйтесь с дилером или квалифицированным техником.

- Неправильная установка, выполненная пользователем, может вызвать

утечку воды, электрошок или пожар.

• По завершении установки убедитесь в отсутствии утечки газа охлажде

ния.

До установки прибора убедитесь, что Вы прочли все “Меры

предосторожности”.

“Меры предосторожности” содержат важные указания по

технике безопасности. Убедитесь, что Вы им следуете.

: Указывает действие, которое следует избегать.

: Указывает на важную инструкцию.

: Указывает, что данная часть должна быть заземлена.

: Опасайтесь электрошока (Этот символ указан на этикетке основного

прибора.) <Цвет: желтый>

: Будьте осторожны, чтобы не прикоснуться к горячей поверхности

Предупреждение:

Внимательно прочтите текст на этикетках главного прибора.

Page 10

50

RU

- При утечке газа охлаждения и попадании его под воздействие обогрева-

теля, печи, духовки или другого источника тепла могут образоваться ядовитые газы.

• Не переделывайте и не изменяйте предохранительных установок на

защитных устройствах.

- При коротком замыкании и насильственном включении выключателей дав-

ления, термовыключателей или других элементов, кроме тех, которые указаны

фирмой Mitsubishi Electric, может возникнуть пожар или взрыв.

• Если Вы хотите избавиться от этого изделия, проконсультируйтесь с

Вашим дилером.

• Монтажник и специалист по системам должны будут обеспечить меры

по предупреждению протеканий в соответствии с местными прави

лами или стандартами.

- Следующие стандарты могут применяться в случае, если местные пра-

вила отсутствуют.

• Обратите особое

внимание на место, например подвал (или цокольный

этаж), где могут скапливаться пары хладагента, так как хладагент тяжелее воздуха.

• Необходимо наблюдать за детьми, чтобы они не играли с устройством.

1.2. Меры предосторожности для прибо-

ров, в которых используется хладагент R410A

Предупреждение:

• Не используйте хладагент другого типа, кроме указанного в руководствах из комплекта поставки блока и на паспортной табличке.

- Это может повлечь за собой прорыв трубопроводов или блока либо стать

причиной взрыва или возгорания в процессе эксплуатации, ремонта или

утилизации блока.

- Та кж е это может нарушать действующее законодательство.

- MITSUBISHI ELECTRIC CORPORATION не несет ответственности за

неис-

правности или несчастные случаи, причиной которых стало использование

хладагента неподходящего типа.

Осторожно:

• Не используйте имеющиеся трубы хладагента.

- Использование старых труб хладагента и старого масла охлажднения,

содержащих большие количества хлорина, может привести к порче

масла охлаждения нового прибора.

- Хладагент R410A находится под высоким давлением, что может привести к

прорыву трубы.

• Используйте трубы хладагента, изготовленные из раскисленной фосфором меди типа С1220 (Cu-DHP), как указано в

JIS H3300 “Бесшовные

трубы из меди и медных сплавов”. Кроме этого убедитесь, что внутренняя и внешняя поверхность труб чистая, без частиц серы, окисей,

пыли/грязи, частиц стружки, масел, влаги или других загрязнений.

- Загрязнение внутренней поверхности труб хладагента может вызвать

ухудшение остаточного масла охлаждения.

• Храните предназначенные для установки трубы в помещении, герметически закрытыми с обоих концов до припайки. (Углы и другие соединнеия храните в пластмассовом пакете).

- Попадание в цикл охлаждения пыли, грязи или воды, может ухудшить

масло и вызвать проблемы с компрессором.

• Используйте в качестве масла охлаждения масло сложного или про

стого эфира или алкилбензол (небольшое количество) для покрытия

раструбов и

фланцевых соединений.

- Масло охлаждения испортится при смешивании с большим количеством

минерального масла.

• Используйте для заполнения системы жидкий хладагент.

- При использовании газового хладагента для герметизации системы,

состав хладагента в баллоне изменится, а рабочие показатели прибора

могут ухудшиться.

• Не пользуйтесь другими хладагентами, кроме R410A.

- При использовании другого хладагента (например, R22) в смеси с R410A,

наличие в нем хлора может привести к ухудшению эксплуатационных

качеств холодильного масла.

• Используйте вакуумный насос с контрольным клапаном обратного

хода.

- Масло вакуумного насоса может проникнуть обратно в цикл охлаждения и

привести к ухудшению масла охлаждения.

• Не используйте указанные ниже инструменты с обычным хладагентом.

(Трубопровод манометра, зарядный шланг, детектор обнаружения

утечки газа

, контрольный клапан, основу заряда хладагентом, обору-

дование для сбора хладагента)

- Если в R410A примешан обычный хладагент и холодильное масло, хлада-

гент может разрушиться.

- Если в R410A примешана вода, холодильное масло может разрушиться.

- Поскольку R410A не содержит хлорина, детекторы утечки газа для обыч-

ных хладагентов на него не отреагируют.

• Не используйте зарядный

баллон.

- Использовние зарядного баллона может вызвать ухудшение хладагента.

• Обращайтесь с инструментами особенно внимательно.

- Попадание в цикл охлаждения пыли, грязи или воды может вызвать ухуд-

шение масла охлаждения.

1.3. Перед выполнением установки

Осторожно:

• Не устанавливайте прибор там, где возможна утечка горючего газа.

- При утечке газа и его скоплении около прибора может произойти взрыв.

• Не используйте кондиционер воздуха в местах содержания продуктов,

домашних животных, растений, точных приборов или предметов

искусства.

- Качество продуктов и т.д. может ухудшиться.

• Не используйте кондиционер воздуха в особых

условиях.

- Наличие масел, пара, сульфурных испарений и т.д. может вызвать значи-

тельное ухудшение рабочих показателей кондиционера или повредить его

элементы.

• При установке прибора в больнице, на станции связи или в аналогичном помещении обеспечьте достаточную защиту от шума.

- Преобразовательное оборудование, частный электрогенератор, высоко-

вольтное медицинское оборудование или оборудование

для радиосвязи

могут вызвать сбой в работе кондиционера или его отключение. С другой

стороны, кондиционер может мешать работе такого оборудования создаваемым шумом, который нарушает ход медицинских процедур или радиовещания.

• Не устанавливайте прибор на конструкции, которая может стать причиной утечки.

- При влажности в помещении свыше 80 % или при засорении дренажной

трубы, с внутреннего прибора может капать конденсирующаяся влага.

Выполняйте дренаж одновременно с устройством, когда это требуется.

1.4. Выполнение электроработ до уста-

новки (перемещения)

Осторожно:

• Заземлите прибор.

- Не подсоединяйте провод заземления к газовой трубе, водяной трубе, гро-

моотводу или линии заземления телефонной проводки. При неправильном

заземлении может возникнуть электрошок.

• Проложите сетевой кабель так, чтобы он не был натянут.

- Натяжение может привести к разрыву кабеля и стать источником пере-

грева и пожара.

• Используйте сетевой кабель

достаточной мощности напряжения.

- Кабели слишком малой мощности могут прогореть, вызвать перегрев и

пожар.

• Не мойте детали кондиционера.

- Мытье деталей кондиционера может вызвать электрошок.

• Проявляйте осторожность, следите, чтобы установочное основание не

было повреждено после длительного использования.

- При неустранении повреждения основания прибор может упасть и причи-

нить травму или повреждение имущества

.

• Проложите дренажные трубы в соответствии с инструкциями в данном

Руководстве по установке для обеспечения надлежащего дренирова

ния. Оберните трубы термоизоляционным материалом для предотвращения конденсации.

- Неправильная прокладка дренажных труб может вызвать утечку воды и

повредить мебель и другое имущество.

• Будьте очень внимательным при транспортировке прибора.

- Нельзя, чтобы перемещение прибора выполнял

один человек, если вес

прибора превышает 20 kg.

- Для упаковки некоторых изделий используются PP (пластиковые) ленты.

Не применяйте PP (пластиковые) ленты для транспортировки. Это опасно.

- При перемещении устройства обеспечьте его опору в указанных точках

основания. Также поддерживайте его в четырех точках, чтобы не допустить

соскальзывания.

• Утилизируйте упаковочные материалы с соблюдением правил безо

пасности

- Такие упаковочные

материалы, как гвозди и другие металлические или

деревянные части, могут причинить порез и другую травму.

- Уд а лит е пластиковый упаковочный пакет и устраните его так, чтобы он был

недоступен детям. Дети могут задохнуться и умереть, если будут играть с

пластиковым упаковочным пакетом.

1.5. Перед началом пробной эксплуатации

Осторожно:

• При следующих условиях отображается код ошибки "7130".

- Блок PWFY подключен к внешнему блоку серии Y.

- Используется версия программного обеспечения из приведенного ниже

списка.

Серия PWFY: ниже версии. 1.13

Серия Y(YHM): ниже версии. 12.27

Серия Y(YJM): ниже версии. 1.31

Серия Replace Y(YJM): ниже версии. 11.31

Серия HP(ZUBADAN): ниже версии. 22.27

Серия WY: ниже версии. 12.29

• Не прикасайтесь к выключателям мокрыми руками.

- Прикосновение к выключателю мокрыми руками может вызвать электрошок.

• Не прикасайтесь к трубам хладагента во время работы и сразу после

выключения прибора.

Page 11

51

RU

- В течение и сразу после эксплуатации прибора трубы хладагента могут быть

горячими или холодными, в зависимости от условий протекающего в трубах,

компрессоре и других элементах цикла охлаждения хладагента. Вы можете

обжечь или обморозить руки при прикосновении к трубам хладагента.

• Не используйте кондиционер воздуха, если его панели и крышки

сняты.

- Вращающиеся, горячие части или части под напряжением могут причинить

травму.

• Не отключайте питание немедленно после выключения прибора.

- Всегда подождите не менее пяти минут до отключения питания. Иначе

может возникнуть утечка воды и другие проблемы.

• Не прикасайтесь голыми руками к панелям

возле выходного отверстия

вентилятора: они могут стать горячими во время работы устройства

(даже если оно остановлено) или непосредственно после завершения

его работы, что несет в себе риск получения ожогов. Если необходимо

прикасаться к панелям, наденьте перчатки для защиты рук.

• Обязательно обеспечьте путь для воздуха, выходящего от вентилятора.

• В зависимости от

установленной температуры водяные трубы могут

нагреться очень сильно. Оберните водяные трубы изоляционным

материалом, чтобы предотвратить ожоги.

• Обновите программное обеспечение PWFY, к которому будет подключаться комплект электромагнитных клапанов, до версии 1.20 или

выше.

• Установите переключатель Dip SW 3-6 на PWFY в положение ON (Вкл.).

2. Информация об изделии

Предупреждение:

• Не используйте хладагент другого типа, кроме указанного в руководствах из комплекта поставки блока и на паспортной табличке.

- Это может повлечь за собой прорыв трубопроводов или блока либо стать

причиной взрыва или возгорания в процессе эксплуатации, ремонта или

утилизации блока.

- Та кж е это может нарушать действующее законодательство.

- MITSUBISHI ELECTRIC CORPORATION не несет ответственности за

неис-

правности или несчастные случаи, причиной которых стало использование

хладагента неподходящего типа.

• В данном изделии применяется хладагент R410A.

• Схема трубных соединений систем, использующих хладагент R410A, может

отличаться от систем, использующих хладагенты обычного типа, поскольку

рабочее давление систем, использующих R410A, выше. Для получения

дополнительной информации см. технические характеристики.

• Некоторые инструменты и устройства, применяемые для монтажа

систем с

другими типами хладагента, не могут использоваться с системами, в которых используется R410A. Для получения дополнительной информации см.

технические характеристики.

• Использование старых труб с остатками хлора, который содержится в обычном холодильном масле и хладагенте, может привести к порче холодильного

масла хладагента нового прибора. Наличие хлора вызовет ухудшение

свойств холодильного

масла новой установки. Также существующие трубы

не могут быть использованы по причине более высокого рабочего давления

в системах, использующих R410A, что может привести к разрыву труб.

3. Список компонентов

Комплект поставки

Данный комплект содержит следующие компоненты.

Приклейте табличку с характеристиками из комплекта поставки под табличкой с характеристиками на блоке PWFY, к которому будет подключаться комплект

электромагнитных клапанов.

Перед прикреплением таблички начисто протрите поверхность спиртом.

С помощью жидкостной и газовой трубки из комплекта поставки отрегулируйте высоту трубопровода при установке комплекта электромагнитных клапанов на

одном уровне с блоком PWFY.

Список компонентов, поставляемых в полевых условиях

• Трубы для хладагента, отличные от включенных в комплект

• Жаропрочный изоляционный материал (для труб для хладагента)

• Верхняя изоляционная лента

4. Перемещение прибора

Внимание:

Будьте очень внимательны при транспортировке прибора.

- Нельзя, чтобы перемещение прибора выполнял один человек, если вес прибора превышает 20 kg.

- Для упаковки некоторых изделий используются пластиковые ленты. Не применяйте их для транспортировки, это опасно.

- Разорвите пластиковую упаковку и утилизируйте ее. Не разрешайте детям играть с пластиковой упаковкой. Играя с пластиковым пакетом, ребенок может задохнуться.

5. Установка прибора и пространство для обслуживания прибора

5.1. Установка

• Используя анкерные отверстия, изображенные ниже, плотно привинтите

прибор к основанию болтами.

[Fig. 5.1.1] (P.2)

Основания

• Убедитесь в том, что место установки прибора достаточно прочно, чтобы

выдержать его вес. Если фундамент неустойчив, усильте его бетонным основанием.

• Анкеровку прибора необходимо производить на ровной поверхности. После

установки проверьте с помощью уровня.

• Если прибор устанавливается в

месте, где шум нежелателен, на основание

для крепления прибора рекомендуется устанавливать виброзащитный

стенд.

Предупреждение:

• Обязатнельно устанавливайте прибор на достаточно прочном основа

нии, которое выдержит вес прибора.

Недостаточно прочное основание может вызвать падение прибора,

что причинит личную травму.

• Устанавливайте прибор так, чтобы он был защищен от землетрясения.

Любой дефект установки может вызвать падение прибора, что приведет к личной травме.

5.2. Пространство для обслуживания при-

бора

• При установке пожалуйста обеспечьте следующее простанство для обслуживания.

(Все работы по обслуживанию можно проводить с лицевой стороны прибора)

Наименова

ние

Руководство по

установке

Наклейка с

характеристиками

Жидкостная трубка Газовая трубка

Н.Д. ø15,88 mm-

В.Д. ø19,05 mm

Н.Д. ø19,05 mm-

В.Д. ø15,88 mm

Вид

Кол-во 111111

A 4-ø14 (Анкерное отверстие) B (Вид сверху)

Page 12

52

RU

[Fig. 5.2.1] (P.2)

(Блок: mm)

6. Техничиеские условия трубы хладагента и дренажной трубы

Обеспечьте достаточную защиту от конденсации и изоляцию трубы хладагента

и дренажной трубы, чтобы предотвратить образование влаги.

Если используются имеющиеся в массовой продаже трубы хладагента, обязательно оберните изоляционный материал (имеющийся в широкой продаже,

обладающий устойчивостью к температуре свыше 100 °С и толщиной, указан-

ной в таблице ниже) вокруг труб с жидкостью и с газом.

Также обязательно оберните имеющимся в широкой продаже изоляционным

материалом (с удельным весом полиэтилена

0,03 и толщиной, указанной в таблице ниже) все трубы, проходящие в помещении.

1 Толщин у изоляционного материала выбирайте в соответствии с размером труб.

2 Если прибор используется на самом верхнем этаже здания, в условиях

высокой температуры и влажности, необходимо

использовать трубы боль-

шего размера и изоляционный материал большей толщины по сравнению с

теми параметрами, которые указаны в таблице выше.

3 Если имеются технические условия заказчика, следуйте им.

6.1. Трубопровод хладагента, дренажная труба и заливное отверстие

[Fig. 6.1.1] (P.2)

7. Соединение труб хладагента и дренажных труб

7.1. Прокладка труб хладагента

Это соединение труб должно быть выполнено в соответствии с руководствами

по установке внешнего прибора и регулятора ВС (серия приборов R2, обеспечивающих охлаждение и обогрев).

• Серия приборов R2 сконструирована так, чтобы работать в системе, в которой труба хладагента от внешнего прибора принимается регулятором ВС и

разветвляется по регулятору ВС для соединения между

внутренними прибо-

рами.

• Ограничения параметров длины трубы и допустимые перепады возвышения

указаны в руководстве к прибору, предназначенному для установки снаружи.

• Методом трубного соединения является метод пайки.

Осторожно:

• Установите трубы хладагента для внутреннего прибора в соответствии

со следующими инструкциями.

1. Обрежьте конец трубы внутреннего прибора, удалите газ, затем удалите

припаянный колпачок.

[Fig. 7.1.1] (P.2)

2. Вытяните термоизоляцию труб хладагента на площадке, пропаяйте трубу на

приборе и установите изоляцию в исходное положение.

Оберните трубы изолирующей лентой.

Примечание:

• Будьте очень внимательны, оборачивая медные трубы, так

как обора-

чивание труб может привести к образованию конденсации вместо предотвращения от нее.

* Перед пайкой трубопровода хладагента, во избежание термоусадки и воз-

горания термоизоляции, всегда оборачивайте трубопровод корпуса

блока, а также термоизоляцию трубопровода влажной тканью. Следите,

чтобы пламя не контактировало с корпусом блока.

[Fig. 7.1.2] (P.2)

Меры предосторожности при прокладке труб хладагента

Используйте только неокисляющийся припой для пайки с тем, чтобы

предотвратить попадание в трубу посторонних веществ или влаги.

Необходимо нанести на поверхность седла колокообразного соедине-

ния охлаждающее машинное масло и затянуть соединение двусторонним гаечным ключем.

Установите металлическую скобу для поддержки трубы хладагента

таким образом, чтобы на конечную трубу прибора, устанавливаемого

внутри

, не было нагрузки. Металлическая скоба должна быть установ-

лена на расстоянии 50 cm от колокообразного соединения прибора,

устанавливаемого внутри.

Предупреждение:

• Не используйте хладагент другого типа, кроме указанного в руководствах из комплекта поставки блока и на паспортной табличке.

- Это может повлечь за собой прорыв трубопроводов или блока либо стать

причиной взрыва или возгорания в процессе эксплуатации, ремонта или

утилизации блок а.

- Также это может нарушать действующее законодательство.

- MITSUBISHI ELECTRIC CORPORATION не несет ответственности за

неис-

правности или несчастные случаи, причиной которых стало использование

хладагента неподходящего типа.

• При установке и монтаже устройства заправляйте его только хладагентом (R407C или R22), указанным на устройстве.

- Подмешивание другого хладагента, воздуха и т.д. может нарушить цикл

охлаждения и стать причиной серъезного повреждения.

Осторожно:

• Используйте трубы хладагента, изготовленные из раскисленной фос-

фором меди типа С1220 (Cu-DHP), как указано в JIS H3300 “Бесшовные

трубы из меди и медных сплавов”. Кроме этого убедитесь, что внутренняя и внешняя поверхность труб чистая, без частиц серы, окисей,

пыли/грязи, частиц стружки, масел, влаги или других загрязнений.

• Никогда не пользуйтесь имеющимися трубами

хладагента.

- Большое количество хлорина в обычном хладагенте и масле охлаждения в

имеющихся трубах вызовет ухудшение нового хладагента.

• Храните трубы, предназначенные для установки, в помещении; оба

конца труб должны быть герметически закрыты до непосредственного

момента спайки.

- При попадании пыли, грязи или воды в цикл охлаждения масло ухудшится

и может выйти из строя

компрессор.

Модель abcd

PAC-SV01PW-E 150 210 600 400

A Пространство для прокладки труб (по обеим сторонам)B Вид сверху

C Пространство для обслуживания (лицевая сторона)

Соответствующие модели PWFY-P100VM-E1-AU PWFY-P200VM-E1-AU

Газ

ø

15,88

ø

19,05

Жидкость

ø

9,52

ø

9,52

Дренаж

ø

32

Толщин а изоляционного материала Свыше 10 mm

A Труба хладагента (газ) B Труба хладагента (жидкость)

C Дренажное отверстие D Вид спереди

E Вид слева F Вид справа

A Обрезать здесь

B Удалить припаянный колпачок

A Термоизол яц ия B Потянуть

C Обернуть влажной тряпкой D Установить в исходное положение

E Убедитесь в отсутствии здесь зазора

F Оберните изолирующей лентой

Page 13

53

RU

7.2. Ограничение на трубы для хладагента

*Не устанавливайте комплект электромагнитных клапанов на трубу в виде

квадратной арки, как показано на рисунке выше.

Ограничение на длину трубопровода

7.3. Прокладка дренажных труб

1. Убедитесь, что дренажные трубы наклонены вниз (наклон свыше 1/100) к

наружной (выпускной) стороне. На этом пути не должно быть никакой

ловушки или помехи. (1)

2. Убедитесь, что любые поперечные дренажные трубы менее 20 m (не считая

разницы в высоте). Если дренажные трубы длинные, укрепите металлические скобы, чтобы трубы были устойчивы. Никогда не устанавливайте здесь

трубы

воздушной вентиляции. В противном случае сток может выталк-

тваться обратно.

3. Используйте в качестве дренажной трубы трубу из твердого винилхлорида

VP-25 (с внешним диаметром 32 mm).

4. Убедитесь в том, что собранные трубы на 10 cm ниже дренажного отверстия

корпуса установки, как показано на 2.

5. На выпускном дренажном канале не должно быть никаких ловушек запаха.

6. Ус тан ови те

дренажные трубы в такое место, где не вырабатывается запах.

7. Не устанавливайте конец дренажных труб в такой сток, где образуются ионные газы.

[Fig. 7.3.1] (P.3)

7.4. Выполнение электросоединений

Убедитесь в том, что название модели на инструкции по эксплуатации на

крышке коробки управления и название модели на именной плате совпадают.

Шаг 1

Снимите винты, удерживающие на месте крышку коробки терминалов.

[Fig. 7.4.1] (P.3)

Примечание:

Убедитесь в том, что при закрытии крышки коробки терминалов не была

сдавлена электропроводка. Сдавливание электропроводки может привести к ее

обрыву.

Осторожно:

Проводите электропроводку без натяжения и растяжения проводов. Натянутые провода могут оборваться или перегреться и сгореть.

• Прикрепите провод внешней входной линии источника питания к блоку

управления с помощью буферной втулки, обеспечивающей прочность на

растяжение, чтобы предотвратить поражение электрическим током. (Соединение PG или подобное.) Проведите кабели передачи к блоку терминалов

передачи сквозь пробивное

отверстие на коробке управления, используя

обычный ввод.

• После завершения проведения электропроводки убедитесь в отсутствии

ослабленных соединений, затем закрепите крышку коробки управления в

порядке, обратном ее снятию.

[Fig. 7.4.2] (P.3)

Осторожно:

Проводите провода электропитания без натяжения. В противном случае

может произойти их отсоединение, перегрев или возгорание.

8. Электрическая проводка

Меры предосторожности при проводке электричес

тва

Предупреждение:

Электрическая проводка должна выполняться квалифицированными

электриками в соответствии со “Стандартами электротехнических работ

при установке электрооборудования” и инструкциями, указанными в поставляемых руководствах. Также следует использовать специальные линии. Если мощность электролинии недостаточна, или если имеется

неполадка в проводке, это может вызвать электрошок или пожар.

1. Убедитесь, что питание подается от специальной ветви цепи

или специаль-

ной линии.

2. Убедитесь в отсутствии провисания или слабины в соединениях проводов.

3. Некоторые кабели над потолком (кабели электропитания или внешней вход-

ной/выходной линии) могут прокусить мыши. По возможности максимально

используйте защитные металлические кожухи, в которые вставляются

кабели.

4. Никогда не подсоединяйте силовой кабель питания к проводам для кабелей

передачи.

В противном случае кабели могут быть порваны.

5. Обязательно выполните заземление устройства.

Осторожно:

Обязательно заземлите прибор со стороны прибора, установленного

снаружи. Не соединяйте кабель заземления с каком-либо кабелем заземления газовой трубы, трубы для воды, громоотвода или телефонной линии. Недостаточное заземление может вызвать электрошок или пожар.

8.1. Проводка подачи электропитания

• Шнуры электропитания для приборов не должны быть легче промышленных

образцов 60245 IEC 57 или 60227 IEC 57.

• При установке кондиционера необходимо использовать выключатель с зазо

ром между контактами на каждом полюсе не менее 3 mm.

• Соедините разъемы TB2 комплекта электромагнитных клапанов и PWFY

TB2.

• Проложите провод питания через отверстие для кабеля питания на блоке

PWFY. Если отверстие уже занято другими проводами

существующих блоков PWFY, используйте любые другие отверстия для проводов, кроме отверстия для контрольного провода.

• Затяните винты на блоке выводов с моментом 1,73 N•m ± 10%.

[Fig. 8.1.1] (P. 3)

Электротехнические работы

1. Электрические характеристики

Элемент

Трубопровод на

рисунке

Макс. длина

Самый дальний блок вода-воздух

(AU) от первого соединения

A+B 40

Расстояние между блоком вода-

воздух (AU) и блоком ЭК

B

5

Высота между блоком вода-воздух

(AU) и IC (вода-воздух (AU))

h

15

AU AU

Блок ЭК

Блок ЭК

Блок ЭК

AU

A

B

h

AU

Блок ЭК

㪁㪁

IC

A Угол наклона вниз 1/100 или более

B Отводящий шланг

C Устрой ст во

D Общий трубопровод

E Увеличьте расстояние приблизительно до 10 cm

A Винты B Передняя панель

C Коробка управления

A Для предотвращения действия внешней растягивающей силы на отрезок под-

соединения электропроводки блок а терминала источника электропитания

используйте буферный проходной изолятор наподобие соединения PG или

ему подобного.

B Входной кабель внешнего сигнала

C Провод источника электропитания

D Растягивающая сила

E Вид сзади

A PWFY-P•VM-E-AU

B PAC-SV01PW-E

Модель

Электропитание RLA (A)

Hz Напряжение

Диапазон напряжения

0,070-0,074-0,077

PAC-SV01PW-E 50/60 220-230-240 V

Макс. 264 V

Мин. 198 V

Page 14

54

RU

2. Технические характеристики силового кабеля

8.2. Подключение кабелей передачи соле-

ноида

• Подключите "1" и "2" на блоке электромагнитных клапанов TB1 к OUT1 на

внешнем выходном выводе PWFY.

• Проведите внешний входной сигнальный кабель через отверстие для внешних проводов на бл оке PWFY. Если отверстие уже занято другими проводами существующих блоков PWFY, используйте любые другие отверстия

для проводов, кроме отверстия для контрольного провода.

• Затяните винты на блоке выводов с

моментом 0,80 N•m ± 10%.

[Fig. 8.2.1] (P. 3)

PWFY Разъем внешнего выходного сигнала

В случае размыкания цепи, разъем внешнего выходного сигнала (см. Fig. 8.2.2)

не будет функционировать.

Обратитесь к Таблице 8.2.2 для получения информации и каждом контакте.

Сила тока и напряжение цепи, подключаемой к внешней выходной клемме

(TB141A OUT1), должны соответствовать следующим условиям.

Таблица 8.2.2

Модель

Минимальная толщина провода (mm2)

Магистральный кабель

ответвление

Заземление

PAC-SV01PW-E 1,5 1,5 1,5

A PWFY-P•VM-E-AU

B PAC -SV 01P W-E

Номинальный ток контакта

AC250V 1 A или меньше

AC125V 3 A или меньше

DC30V 3 A или меньше

OUT1 Работа ON/OFF

OUT2 Размораживание

OUT3 Компрессор

OUT4 Сигнал ошибки

Номинальное

напряжение

контакта

Page 15

WT06721X01 Printed in Japan

This product is designed and intended for use in the residential,

commercial and light-industrial environment.

The product at hand is

based on the following

EU regulations:

• Low Voltage Directive 2006/95/EC

• Electromagnetic Compatibility Directive

2004/108/EC

Please be sure to put the contact address/telephone number on

this manual before handing it to the customer.

HEAD OFFICE: TOKYO BLDG., 2-7-3, MARUNOUCHI, CHIYODA-KU, TOKYO 100-8310, JAPAN

Authorized representative in EU:MITSUBISHI ELECTRIC EUROPE B.V.

HARMAN HOUSE, 1 GEORGE STREET, UXBRIDGE, MIDDLESEX UB8 1QQ, U.K.

Loading...

Loading...