Mitsubishi MSC-GE20VB-E1, MSC-GE25VB-E1, MSC-GE35VB-E1, MS-GE50VB-E1, MSH-GE50VB-E1 Service Manual

SPLIT-TYPE AIR CONDITIONERS

INDOOR UNIT

SERVICE MANUAL

Models

No. OBH529

MSC-GE20VB MSC-GE25VB MSC-GE35VB MS-GE50VB MSH-GE50VB -

E1

E1

E1

E1

E1

Outdoor unit service manual

MU-GA•VB Series (OB386)

MUH-GA•VB Series (OB387)

MUX-A•VB Series (OB384)

MXZ-A•WV Series (OB319)

MU/MUH-GE•VB Series (OBH530)

CONTENTS

1. TECHNICAL CHANGES ··································· 2

2. PART NAMES AND FUNCTIONS ····················· 2

3. SPECIFICATION ················································ 4

4. NOISE CRITERIA CURVES ······························ 5

5. OUTLINES AND DIMENSIONS ························ 7

6. WIRING DIAGRAM ············································ 9

7. REFRIGERANT SYSTEM DIAGRAM ············· 10

8. SERVICE FUNCTIONS ····································11

9. MICROPROCESSOR CONTROL ··················· 14

10. TROUBLESHOOTING ····································· 22

11. DISASSEMBLY INSTRUCTIONS ···················· 32

PARTS CATALOG (OBB529)

NOTE:

RoHS compliant products have <G> mark on the spec name plate.

1

TECHNICAL CHANGES

E1

-

-

E1

-

E1

-

E1

E1

-

→

→

→

→

→

MSC-GE20VB

MSC-GE25VB

MSC-GE35VB

MS-GE50VB

MSH-GE50VB

MSC-GA20VB

MSC-GA25VB

MSC-GA35VB

1. Front panel has been changed.

MS-GA50VB

1. Indoor fan motor has been changed.

MSH-GA50VB

1. Indoor fan motor has been changed.

2

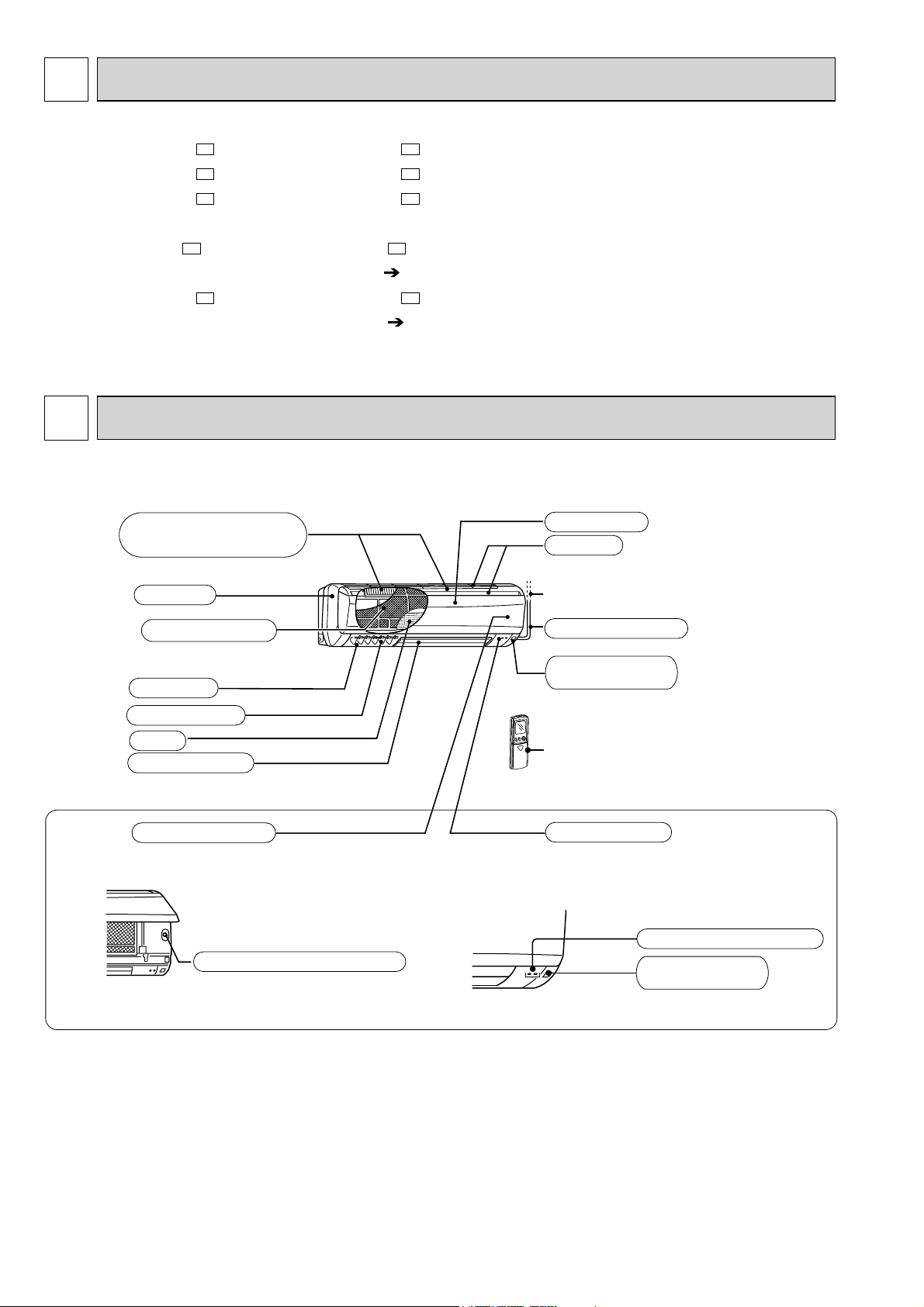

PART NAMES AND FUNCTIONS

(RC4V32-AA RC4V32-BA)

(RC4V32-AA RC4V32-BA)

E1

-

E1

-

E1

-

E1

-

E1

-

MSC-GE20VB MSC-GE25VB MSC-GE35VB

Air cleaning filter(option)

(White bellows type)

Panel

Front panel

Air inlet

to Breaker

Catechin air filter

Air outlet

Vertical vanes

Fan

Horizontal vane

Operation section

(When the front panel is opened)

Emergency operation switch

Power supply cord

Remote control

receiving section

Remote controller

Display section

Operation indicator lamp

Remote control

receiving section

2

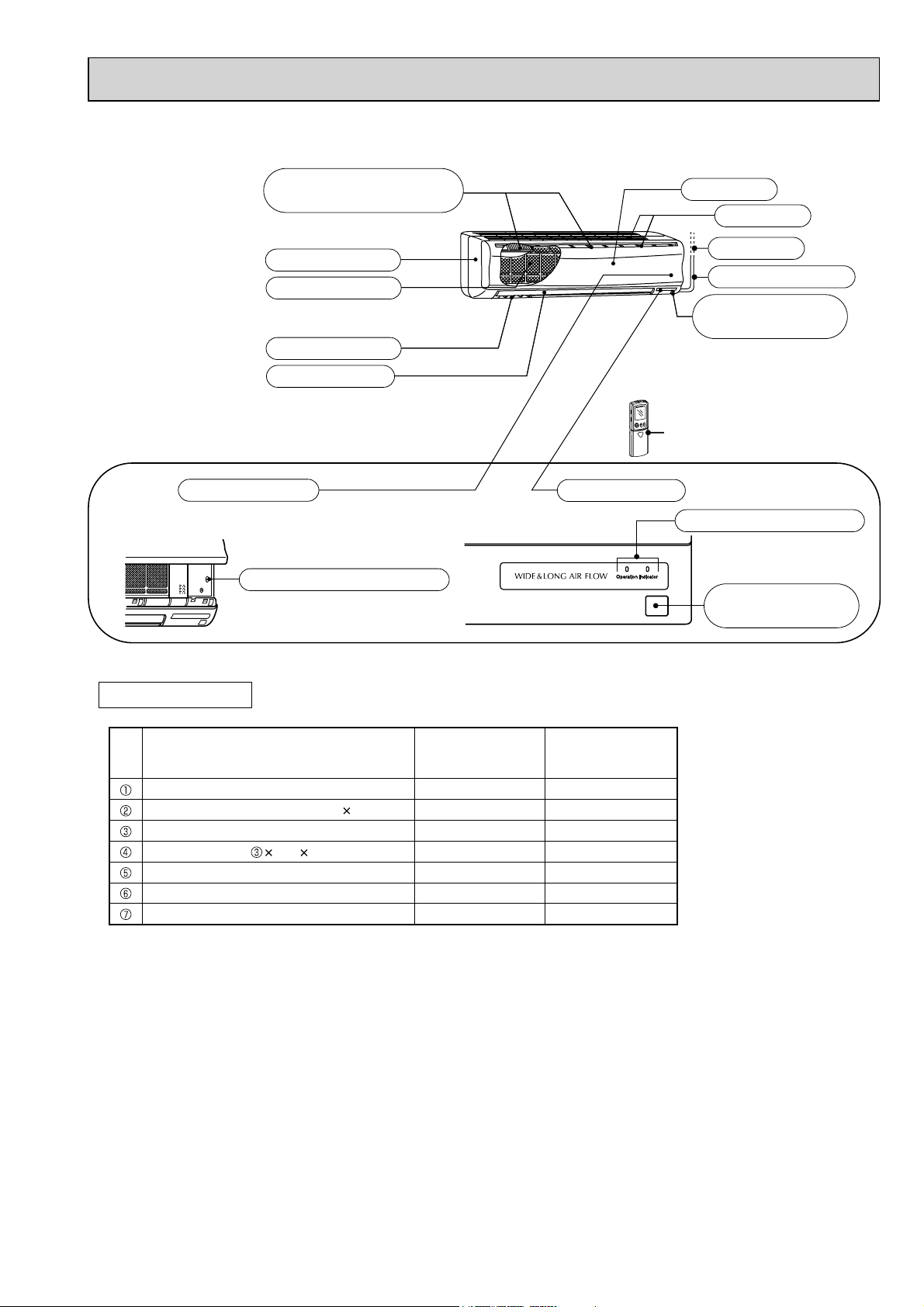

MS-GE50VB MSH-GE50VB

Air cleaning filter (option)

(White bellows type)

Catechin air filter

Vertical vanes

Horizontal vane

Operation section

(When the grille is opened)

Emergency operation switch

Panel

Front panel

Air inlet

To breaker

Power supply cord

Remote control

receiving section

Remote controller

Display section

Operation indicator lamp

Remote control

receiving section

ACCESSORIES

Installation plate

Installation plate fixing screw 4 25 mm

Remote controller holder

Fixing screw for 3.5 1.6 mm (Black)

Battery (AAA) for remote controller

Wireless remote controller

Felt tape (Used for left or left-rear piping)

MSC-GE20VB

MSC-GE25VB

MSC-GE35VB

1

5

1

2

2

1

1

MS-GE50VB

MSH-GE50VB

1

7

1

2

2

1

1

3

3

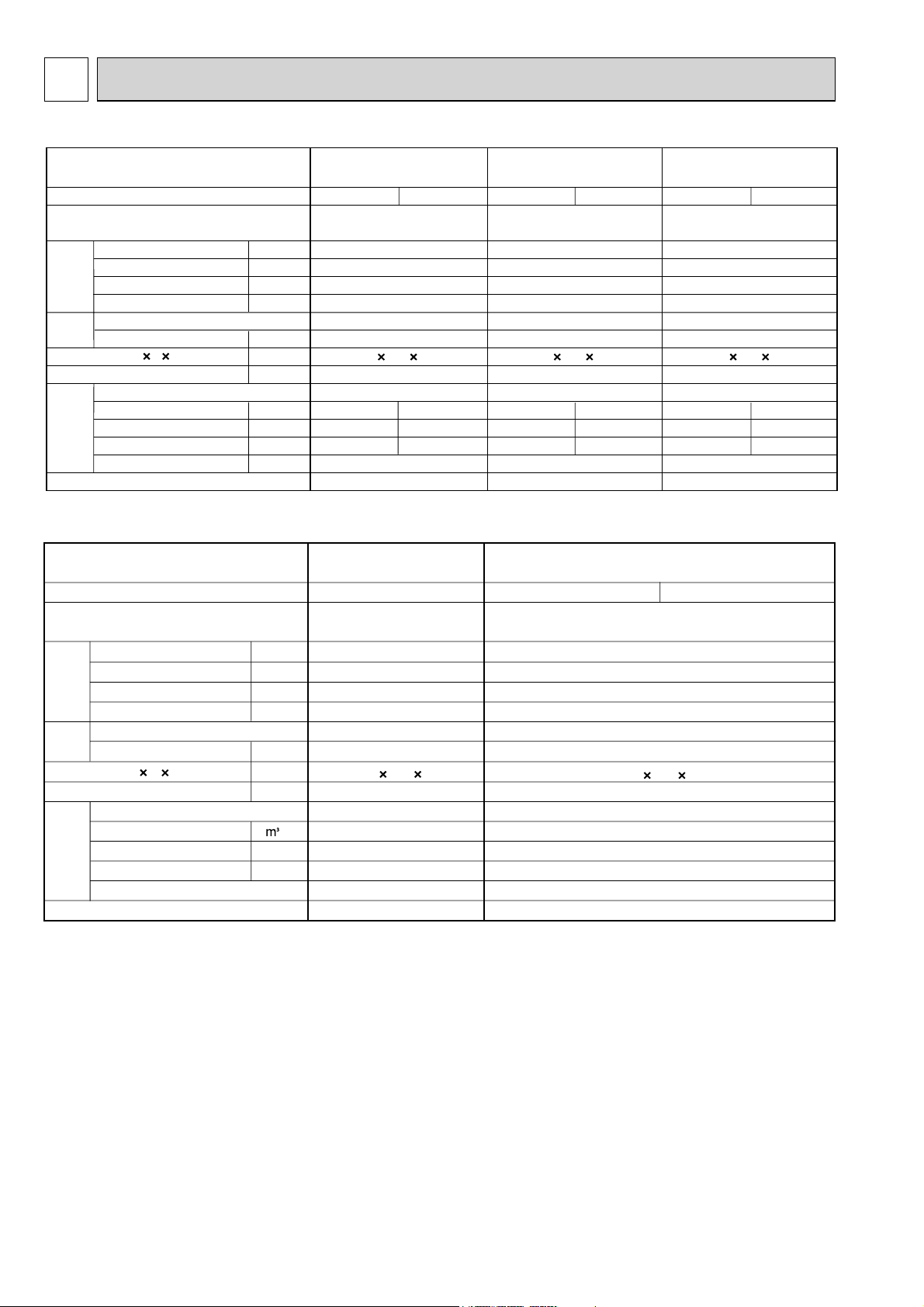

SPECIFICATION

Indoor model

Function

Power supply

Breaker capacity

Running current

Power input

Electrical

data

Power factor

Model

Fan motor current

Fan

motor

Dimensions W

Weight

Air direction

Air flow (High/Med./Low)

Sound level (High/Med./Low)

Fan speed (High/Med./Low)

Special

remarks

Fan speed regulator

Remote controller model

Indoor model

Function

Power supply

Breaker capacity

Running current

Power input

Power factor

Electrical data

Model

Fan motor current

Fan

motor

Dimensions W H D

Weight

Air direction

Air flow

Sound level

Special

remarks

Fan speed

Fan speed regulator

Remote controller model

NOTE: Test conditions are based on ISO 5151.

Cooling: Indoor Dry-bulb temperature 27°C Wet-bulb temperature 19 °C

Outdoor Dry-bulb temperature 35°C Wet-bulb temperature 24 °C

Heating: Indoor Dry-bulb temperature 20°C Wet-bulb temperature - °C

Outdoor Dry-bulb temperature 7°C Wet-bulb temperature 6°C

Indoor-Outdoor piping length: 5 m

H D

(High/Med./Low)

(High/Med./Low)

(High/Med./Low)

A

A

W

%

A

mm

kg

3

/h

m

dB

rpm

900/750/600

A

A

W

%

A

mm

kg

/h

dB

rpm

MSC-GE20VB

Cooling

Single phase

230 V, 50 Hz

RC4V19-JA

815

474/372/276

36/31/25

KM04F

MS-GE50VB

Cooling

Single phase

230 V, 50 Hz

RC4V32-BA

1,100 325 258

768/642/516

42/38/34

1,070/920/780

KM04B

Heating

10

0.17

35

90

0.17

278 244

9

5

510/420/342

36/31/25

950/820/700

3

0.3

60

87

0.3

16

5

3

MSC-GE25VB

Cooling

Single phase

230 V, 50 Hz

RC4V19-JA

815

474/384/306

36/31/25

900/770/650

MSC-GE35VB

Heating

10

0.17

35

90

0.17

278 244

9

5

588/456/342

39/32/25

1,050/870/700

3

KM04F

MSH-GE50VB

Cooling Heating

Single phase

230 V, 50 Hz

RC4V32-BA

1,100 325 258

768/642/516

42/38/34

1,070/920/780

582/444/324

1010

0.3

60

87

0.3

16

5

3

KM04A

Cooling

Single phase

230 V, 50 Hz

0.19

RC4V19-HA

0.19

815

278 244

40/33/26

930/760/600

KM04F

10

40

92

10

5

606/498/396

960/830/700

3

Heating

39/33/26

4

4

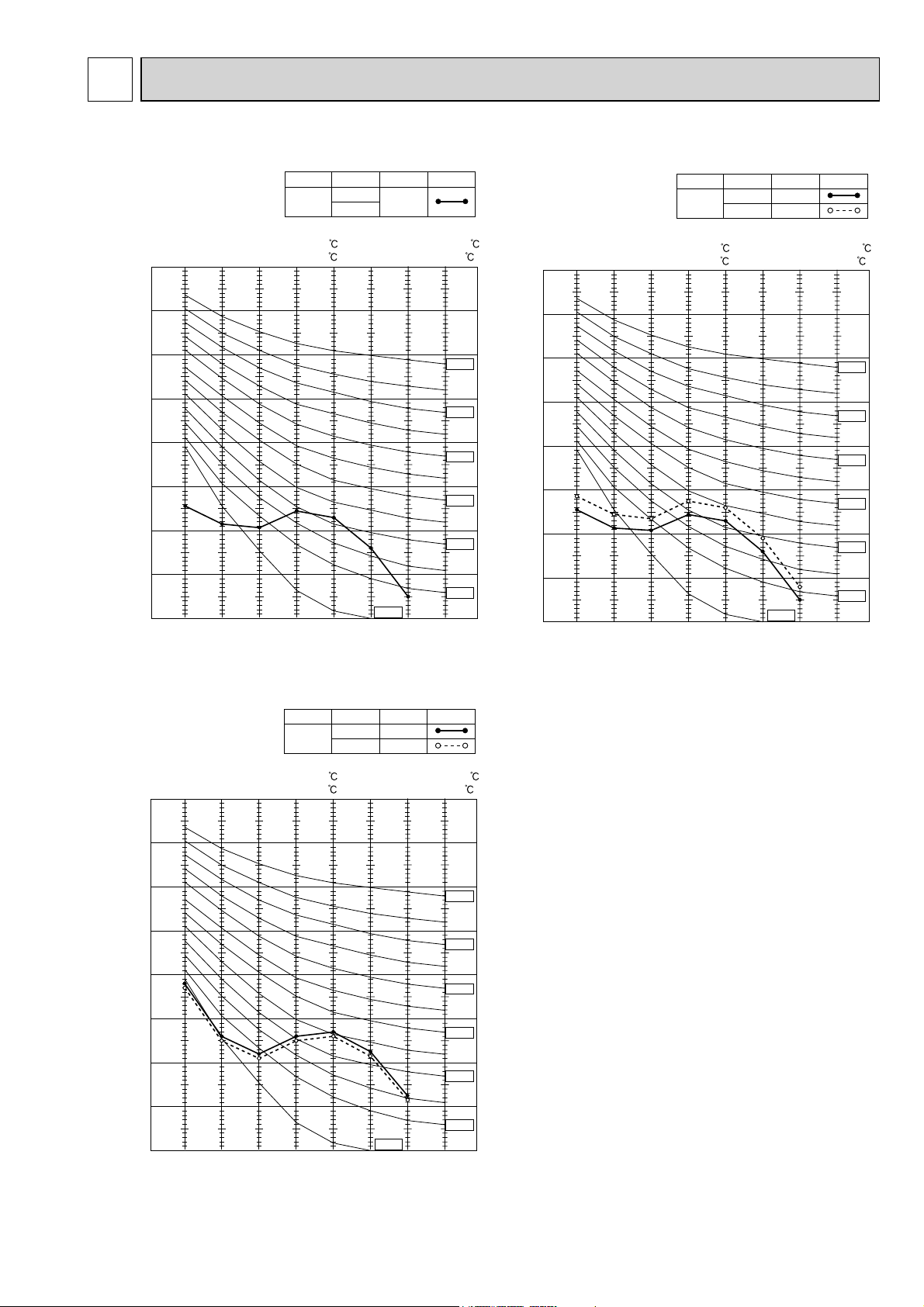

NOISE CRITERIA CURVES

MSC-GE20VB

High

FUNCTIONFAN SPEED

COOLING

HEATING

SPL(dB(A))LINE

36

Test conditions,

Cooling : Dry-bulb temperature 27 Wet-bulb temperature19

Heating : Dry-bulb temperature 20 Wet-bulb temperature -

90

80

70

60

50

40

30

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.0002 MICRO BAR

20

10

63 125 250 500 1000 2000 4000 8000

BAND CENTER FREQUENCIES, Hz

NC-10

NC-70

NC-60

NC-50

NC-40

NC-30

NC-20

MSC-GE25VB

High

FUNCTIONFAN SPEED

COOLING

HEATING 39

SPL(dB(A))LINE

36

Test conditions,

Cooling : Dry-bulb temperature 27 Wet-bulb temperature 19

Heating : Dry-bulb temperature 20 Wet-bulb temperature -

90

80

70

60

50

40

30

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.0002 MICRO BAR

20

10

63 125 250 500 1000 2000 4000 8000

BAND CENTER FREQUENCIES, Hz

NC-10

NC-70

NC-60

NC-50

NC-40

NC-30

NC-20

MSC-GE35VB

High

FUNCTIONFAN SPEED

COOLING

HEATING

SPL(dB(A))LINE

40

39

Test conditions.

Cooling : Dry-bulb temperature 27 Wet-bulb temperature 19

Heating : Dry-bulb temperature 20 Wet-bulb temperature -

90

80

70

60

50

40

30

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.0002 MICRO BAR

20

10

63 125 250 500 1000 2000 4000 8000

BAND CENTER FREQUENCIES, Hz

NC-10

NC-70

NC-60

NC-50

NC-40

NC-30

NC-20

5

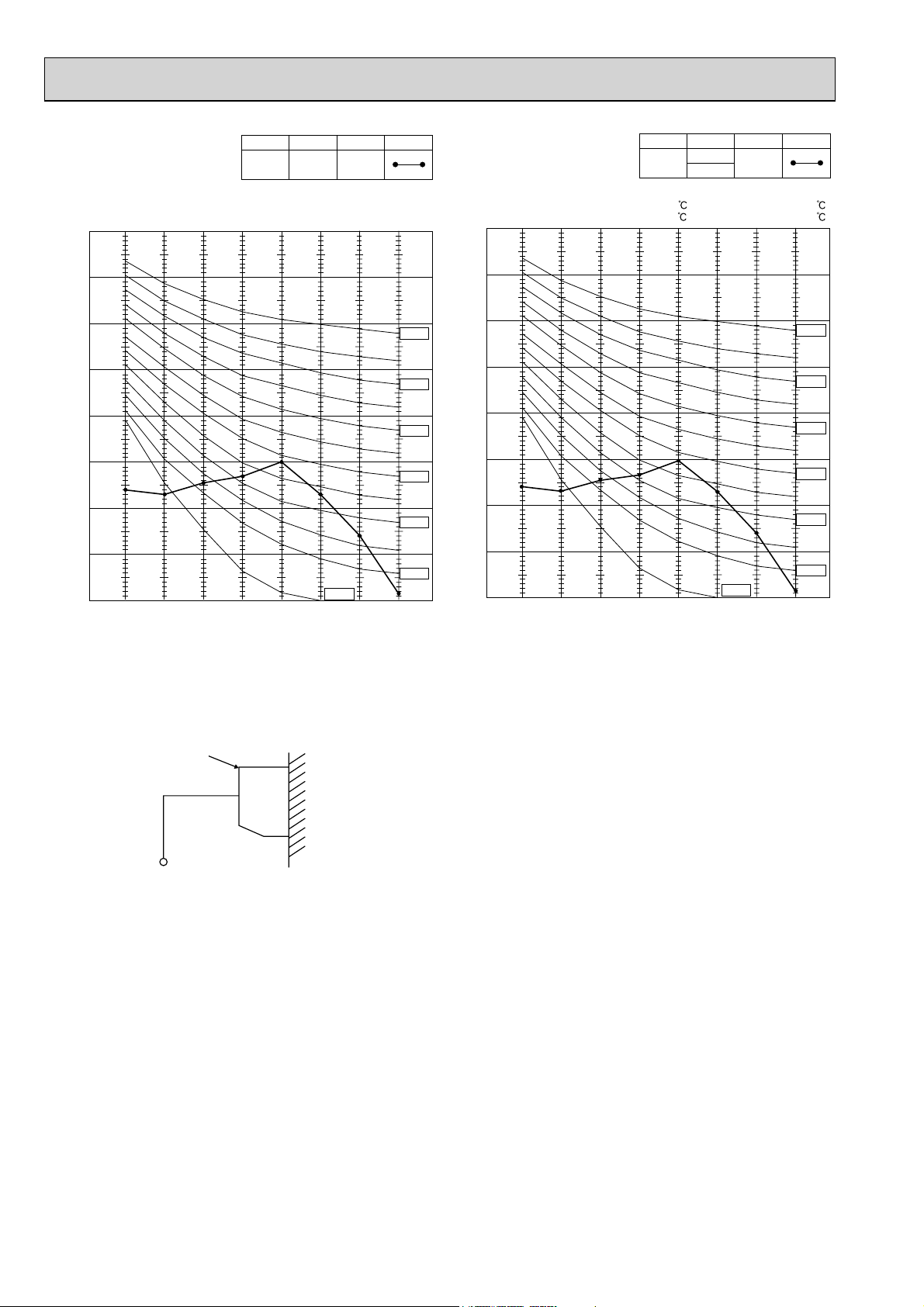

MS-GE50VB

FUNCTIONFAN SPEED

COOLING

SPL(dB(A))LINE

42High

Test conditions,

Cooling : Dry-bulb temperature 27°C Wet-bulb temperature 19°C

90

(A))LINE

MSH-GE50VB

High

FUNCTIONFAN SPEED

COOLING

HEATING

SPL(dB

42

Test conditions,

Cooling : Dry-bulb temperature 27 Wet-bulb temperature 19

Heating : Dry-bulb temperature 20 Wet-bulb temperature -

80

70

60

50

40

30

20

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.0002 MICRO BAR

10

63 125 250 500 1000 2000 4000 8000

NC-10

BAND CENTER FREQUENCIES, Hz

NC-70

NC-60

NC-50

NC-40

NC-30

NC-20

80

70

60

50

40

30

20

OCTAVE BAND SOUND PRESSURE LEVEL, dB re 0.0002 MICRO BAR

10

63 125 250 500 1000 2000 4000 8000

NC-10

BAND CENTER FREQUENCIES, Hz

NC-70

NC-60

NC-50

NC-40

NC-30

NC-20

INDOOR UNIT

1m

0.8m

MICROPHONE

WALL

6

5

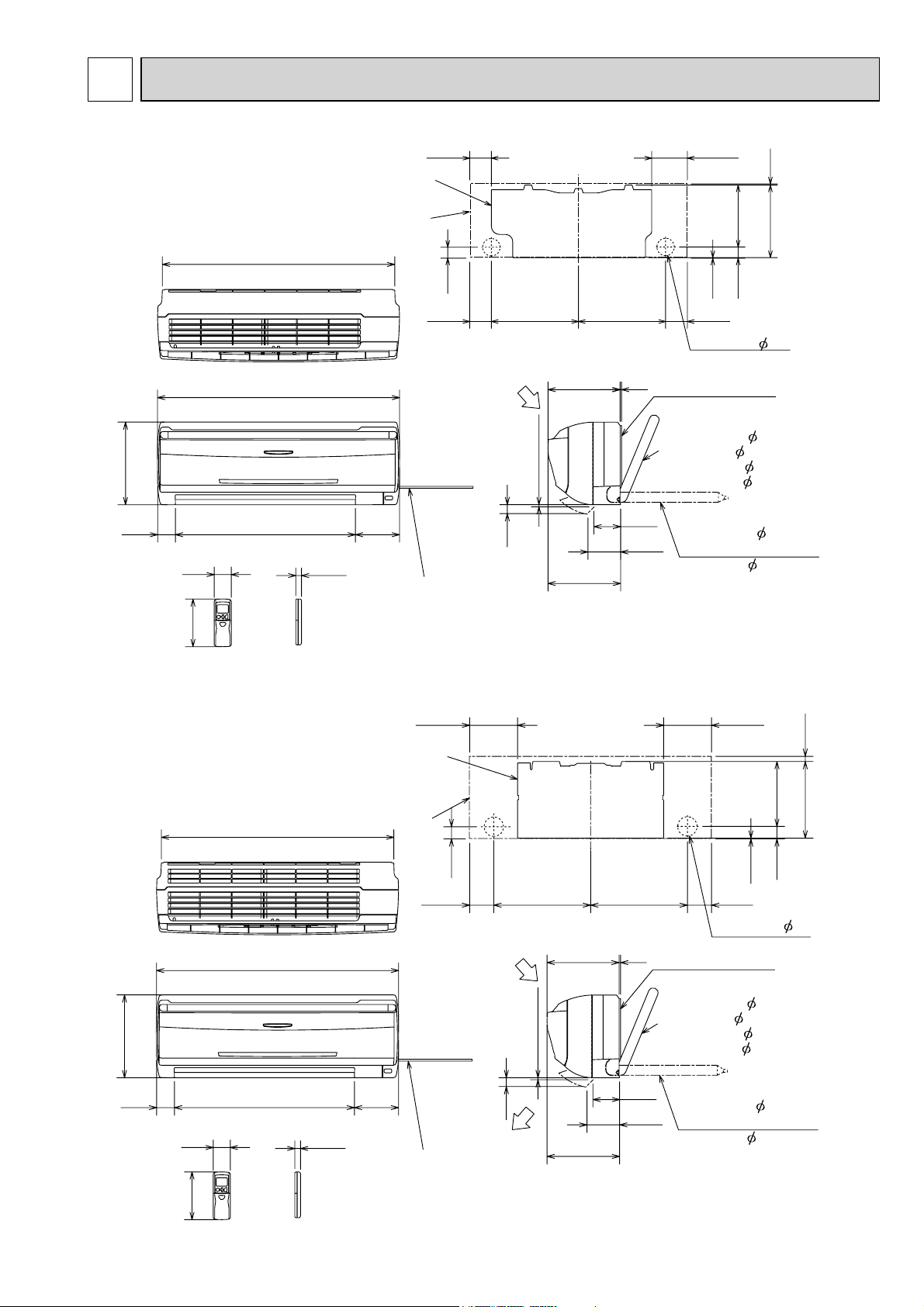

OUTLINES AND DIMENSIONS

MSC-GE20VB

MSC-GE25VB

278

60

58

162

606

783

815

Installation plate

Indoor unit

149

19

Power supply cord

Lead to right 1.0m

Lead to left 0.3m

81.5

41

81.5

Air in

30

Air out

242 5

7 or more

244

326326

Installation plate

{

90

110

133.5

4.5

271

231.5

42

2.5

81.5

Wall hole 65

Liquid line 6.35-0.5m

Gas line 9.52-0.43m

Insulation 37 O.D

21 I.D

Drain hose 16

(Connected part O,D)

Insulation 28

Unit: mm

Wireless remote controller

MSC-GE35VB

278

60

58

162

606

783

815

Installation plate

Indoor unit

149

19

Power supply cord

Lead to right 1.0m

Lead to left 0.3m

41

Air in

30

Air out

242

7 or more

244

161.5161.5

326326

5

Installation plate

{

90

110

81.581.5

Wall hole 65

Liquid line 6.35-0.5m

Gas line 9.52-0.43m

Insulation 37 O.D

21 I.D

Drain hose 16

(Connected part O,D)

Insulation 28

2.5

218.5

42

Unit: mm

17.5

258

Wireless remote controller

7

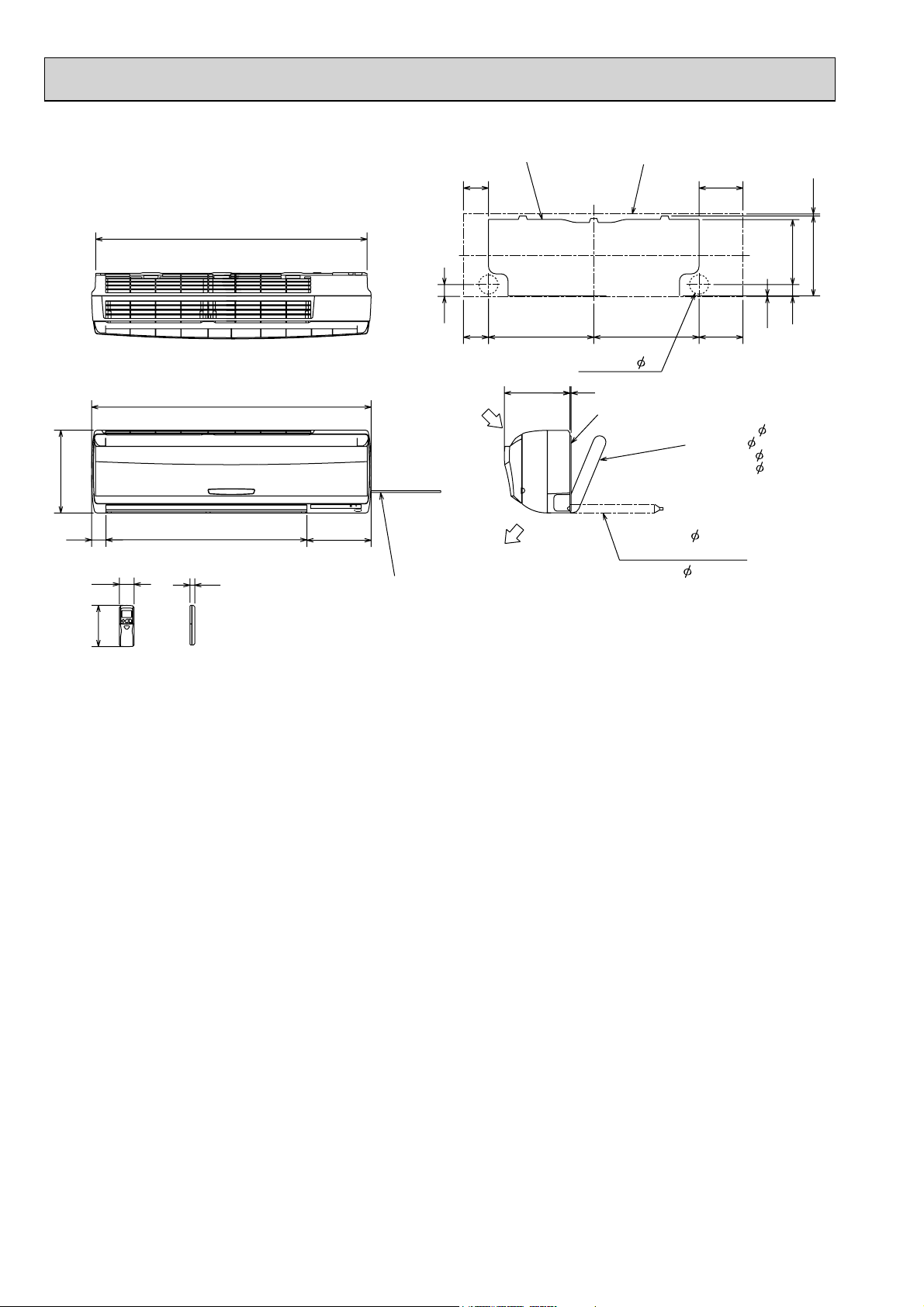

MS-GE50VB

MSH-GE50VB

1068

Installation plate

98

Indoor unit

173

Unit: mm

7.5

255.547

315

325

56

58

162

Wireless remote controller

110 0

791

19

253

Power supply cord

Lead to right 2.0 m

Lead to left 1.0 m

47

98 173414.5 414.5

Wall hole 75

258

Air in

Air out

5

Installation plate

Liquid line 6.35- 0.5 m

Gas line

{

Insulation

Drain hose 16

(Connected part O.D)

Insulation 28

2.5

12-0.43 m

50 O.D

32 I.D

8

6

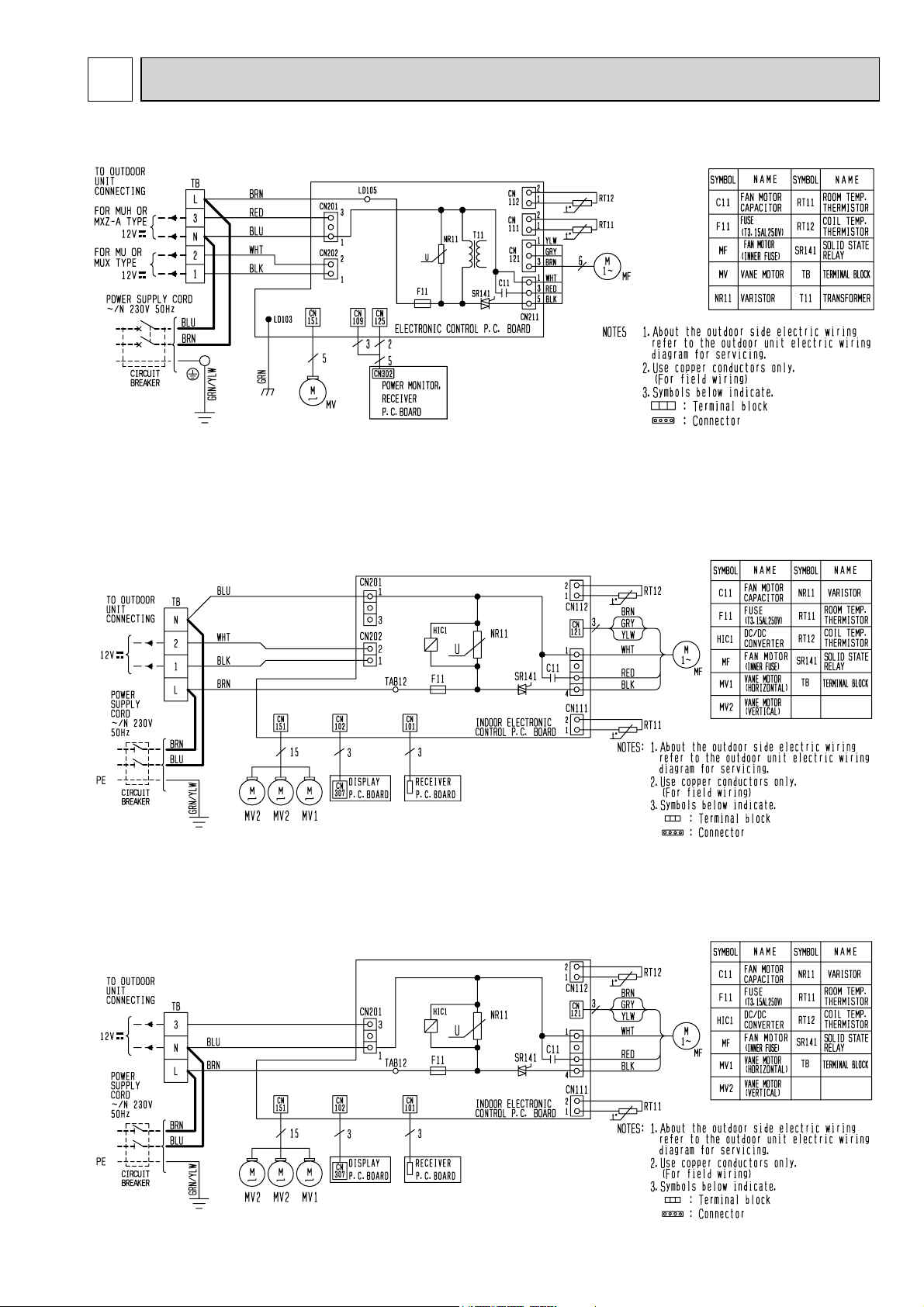

MSC-GE20VB MSC-GE25VB MSC-GE35VB

WIRING DIAGRAM

MS-GE50VB

MSH-GE50VB

9

7

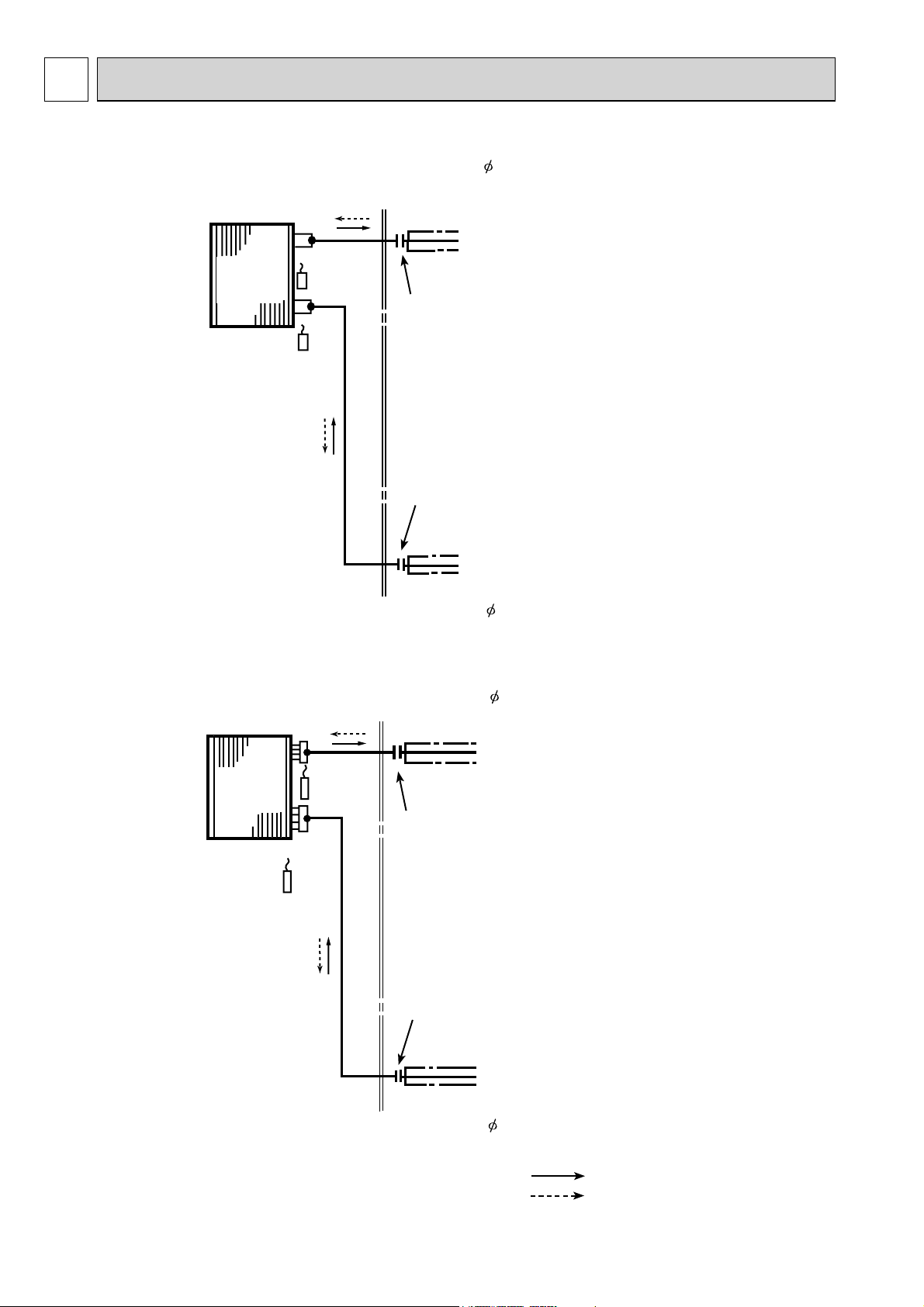

REFRIGERANT SYSTEM DIAGRAM

MSC-GE20VB MSC-GE25VB MSC-GE35VB

Refrigerant pipe 9.52

(with heat insulator)

Unit:mm

Indoor

heat

exchanger

Room temperature

thermistor

RT11

MS-GE50VB MSH-GE50VB

Indoor coil

thermistor

RT12

Flared connection

Flared connection

Refrigerant pipe 6.35

(with heat insulator)

Refrigerant pipe

(with heat insulator)

12.7

Indoor

heat

exchanger

Room temperature

thermistor

RT11

Indoor coil

thermistor

RT12

Distributor

Flared connection

Flared connection

Refrigerant pipe

(with heat insulator)

6.35

Refrigerant flow in cooling

Refrigerant flow in heating (MSC,MSH)

10

8

SERVICE FUNCTIONS

MSC-GE20VB MS-GE50VB

MSC-GE25VB MSH-GE50VB

MSC-GE35VB

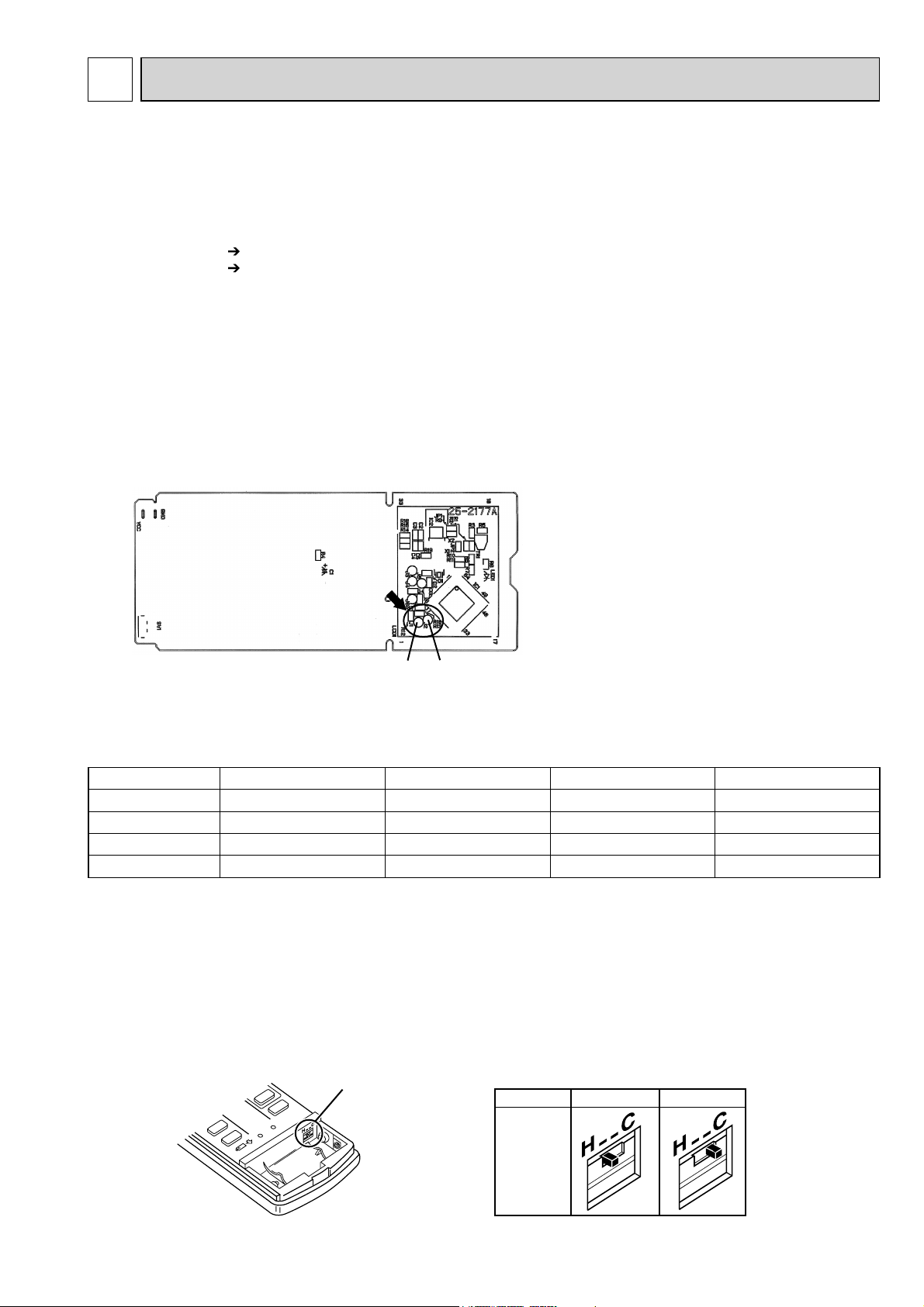

8-1. TIMER SHORT MODE

For service, set time can be shortened by short circuit of JPG and JPS on the electronic control P.C. board.

The time will be shortened as follows.

Set time: 1 minute 1-second

Set time: 3 minute 3-second (It takes 3 minutes for the compressor to start operation. However, the starting time is short-

ened by short circuit of JPG and JPS.)

8-2. P.C. BOARD MODIFICATION FOR INDIVIDUAL OPERATION

A maximum of 4 indoor units with wireless remote controllers can be used in a room.

In this case, to operate each indoor unit individually by each remote controller, P.C. boards of remote controller must be

modified according to the number of the indoor unit.

How to modify the remote controller P.C. board

Remove batteries before modification.

The board has a print as shown below:

NOTE: For modification, take out the batteries and press the OPERATE/STOP (ON/OFF) button 2 or 3 times at first.

After modification, put back the batteries then press the RESET button.

J2

J1

The P.C. board has the print “J1” and “J2”. Solder “J1” and “J2” according to the number of indoor unit as shown in Table 1.

After modification, press the RESET button.

Table 1

1 unit operation

No. 1 unit

No. 2 unit

No. 3 unit

No. 4 unit

How to set the remote controller exclusively for particular indoor unit

After you turn the breaker ON, the first remote controller that sends the signal to the indoor unit will be regarded as the

remote controller for the indoor unit.

The indoor unit only accepts the signal from the remote controller that has been assigned to the indoor unit once they are

set. The setting will be cancelled if the breaker has turned off, or the power supply has shut down.

Please conduct the above setting once again after the power has restored.

No modification

–

–

–

2 units operation

Same as at left

Solder J1

–

–

3 units operation

Same as at left

Same as at left

Solder J2

–

4 units operation

Same as at left

Same as at left

Same as at left

Solder both J1 and J2

8-3. REMOTE CONTROLLER (How to set the type) MSC-GE

This remote controller setting needs to be switched according to the type of air conditioner (COOL & HEAT or COOL

ONLY).

If the setting is incorrect, the air conditioner does not operate normally. Therefore, check if the setting corresponds to the

type of-air conditioner. If not, correct the setting as shown below.

Slide switch

Type

COOL ONLYCOOL & HEAT

The position

of the slide

switch

11

Loading...

Loading...