Mitsubishi Electric 55624R(S)-MF Service Manual

54-l

CHASSIS

ELECTRICAL

CONTENTS

M54AA”

AUDIO SYSTEM

.......................................................

112

Antenna Assembly

.................................................

153

Feeder Cable

.........................................................

155

Power Amplifier

.....................................................

151

Radio and Tape

Player

.............................................

. 49

Service Adjustment Procedures

...............................

148

Speaker

................................................................

151

Specifications

........................................................

1 12

Torque Specifications

.........................................

1 12

Troubleshooting

.....................................................

1 12

BATTERY

.................................................................

2

Service Adjustment Procedures

...............................

4

Specifications

........................................................

2

General Specifications

........................................

2

Troubleshooting

.....................................................

3

CIGARETTE LIGHTER

...............................................

106

Cigarette Lighter

....................................................

108

Specifications

........................................................

106

General Specifications

........................................

106

Troubleshooting

.....................................................

106

CLOCK

_......._.....,

......................................................

109

Specifications

........................................................

109

General Specifications

........................................

109

Troubleshooting

.....................................................

109

COLUMN SWITCH...._._...___

.......................................

100

Column Switch

......................................................

101

Specifications

........................................................

100

General Specifications

........................................

100

Torque Specifications

.........................................

100

HORN

...................................

.._

................................

103

Horn

.....................................................................

105

Relay

....................................................................

105

Specifications

........................................................

103

General Specifications

........................................

103

Troubleshooting

.....................................................

104

IGNITION SWITCH

.........................

.._

.......................

6

Ignition Switch

...............................................

___._

...

6

LIGHTING SYSTEM...._....._...........................__..._.__

...

36

Fog

Light

..............................................................

94

Fog Light Switch

...................................................

99

Hazard Switch

.......................................................

98

Headlights

.............................................................

92

High Mounted Stop Light

.......................................

96

Rear Combination Light

..........................................

95

Relay

....................................................................

Rheostat

...............................................................

Service

Adjustment

Procedures

...............................

Special Tools

.........................................................

Specifications

........................................................

General Specifications

........................................

Sealants

and

Adhesives

.....................................

Service Specifications

.........................................

Troubleshooting

.....................................................

METERS AND GAUGES

............................................

Meters and Gauges

...............................................

Service Adjustment Procedures

...............................

Inspection

.........................................................

Specifications

........................................................

General Specifications

........................................

Sealants and Adhesives

.....................................

Service Specifications

.........................................

Torque

Specifications

.........................................

Troubleshooting

.....................................................

97

99

89

40

38

38

40

40

41

8

33

29

29

8

8

10

9

10

12

REAR

WINDOW

DEFOGGER

.....................................

156

-

Defogger Relay

.....................................................

163

Defogger Timer

.....................................................

164

Rear Window Defogger Switch

...............................

163

Service

Adjustment

Procedures

...............................

162

Troubleshooting

.....................................................

156

THEFT-ALARM SYSTEM

...........................................

165

Special Tools

.........................................................

165

Troubleshooting

.....................................................

165

ACTIVE-ELECTRONIC CONTROL

SUSPENSION

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

REFER

TO

GROUP

338

AIR CONDITIONING

. . . . . . . . . . . . . . . . . . . . .

REFER TO GROUP 55

ANTI-LOCK BRAKING SYSTEM . . . . REFER TO GROUP 35

&JT&RUISE

CONTROL

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

REFER TO GROUP 13

CENTRAL DOOR LOCKING

SYSTEM

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

REFER

TO GROUP 42

ELECTRONIC CONTROL

DOOR

MIRROR

............................

REFER

TO GROUP

51

HEATER

.......................................

REFER

TO GROUP

55

POWER

WINDOW ........................

REFER

TO GROUP 42

RADIATOR FAN MOTOR

..............

REFER TO GROUP 14

gE& e,Etr,

(AUTOMATIC

..................................

REFER TO GROUP 52

SUNROOF

....................................

REFER

TO GROUP 42

;V~D&;lELD

WIPER AND

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

REFER TO GROUP 51

54-2

BATTERY -

Smxifications

BATTERY

SPECIFICATIONS

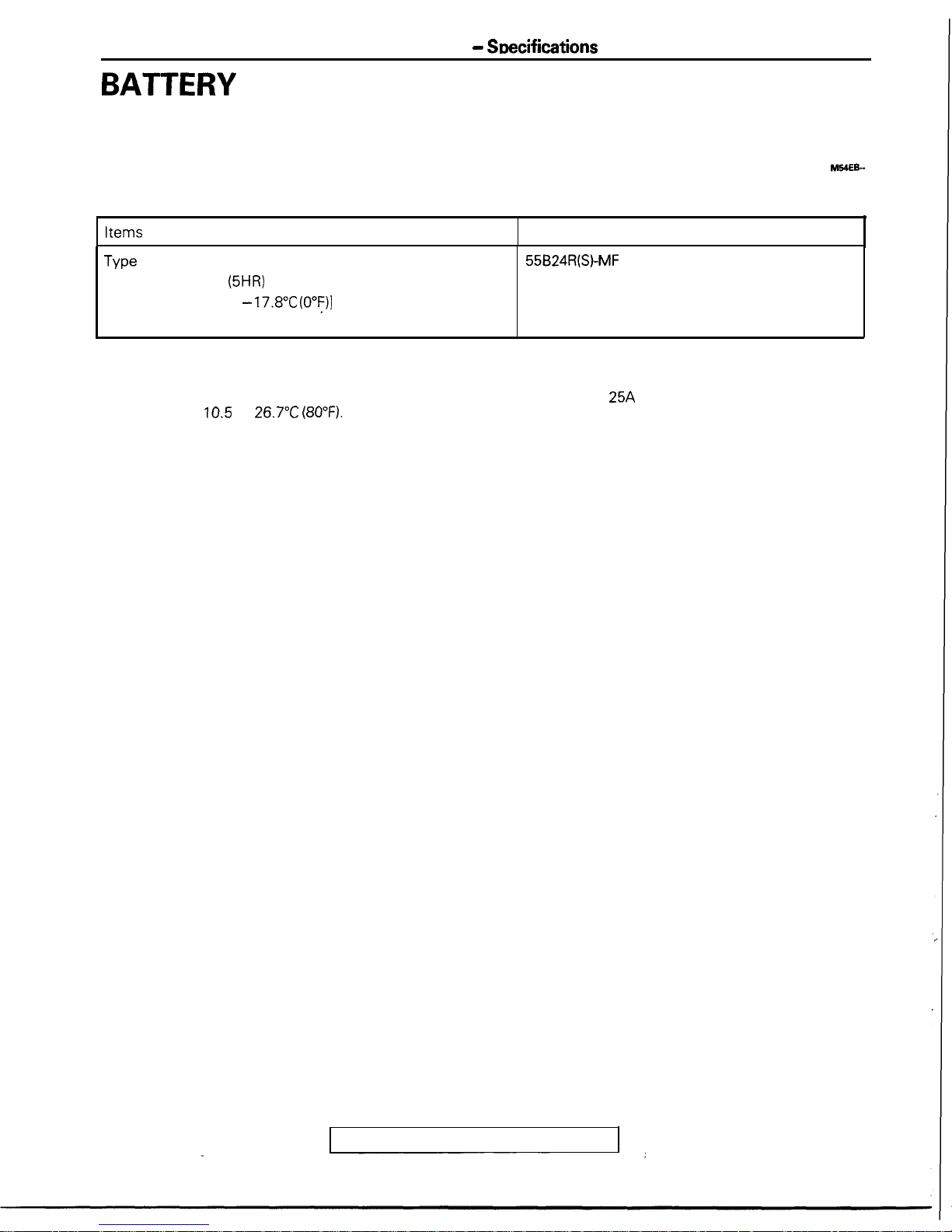

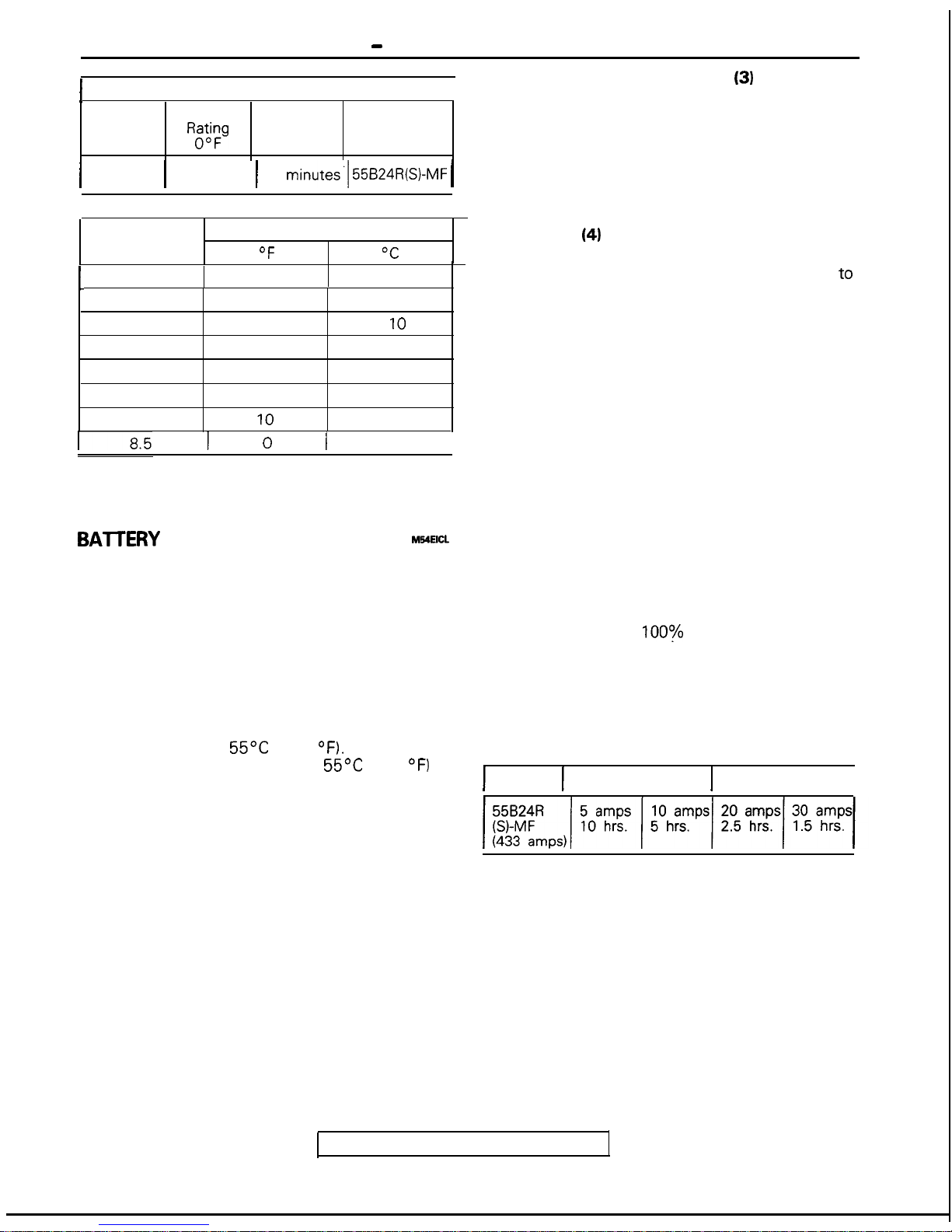

GENERAL SPECIFICATIONS

BATTERY

Items

Specifications

Type

Ampere hours

(5HR)

Ah

Cranking rating [at -

17.8”C (O”F)I

Reserve capacity

min.

A

55624R(S)-MF

40

433

79

NOTES

1. CRANKING RATING is the current a

greater at a specified temperature.

2. RESERVE CAPACITY RATING is the

voltage of

10.5

at

26.7”C (80°F).

battery can deliver for 30 seconds and maintain a terminal voltage of 7.2 or

amount of time a battery can deliver

25A

and maintain a minimum terminal

TSB Revision

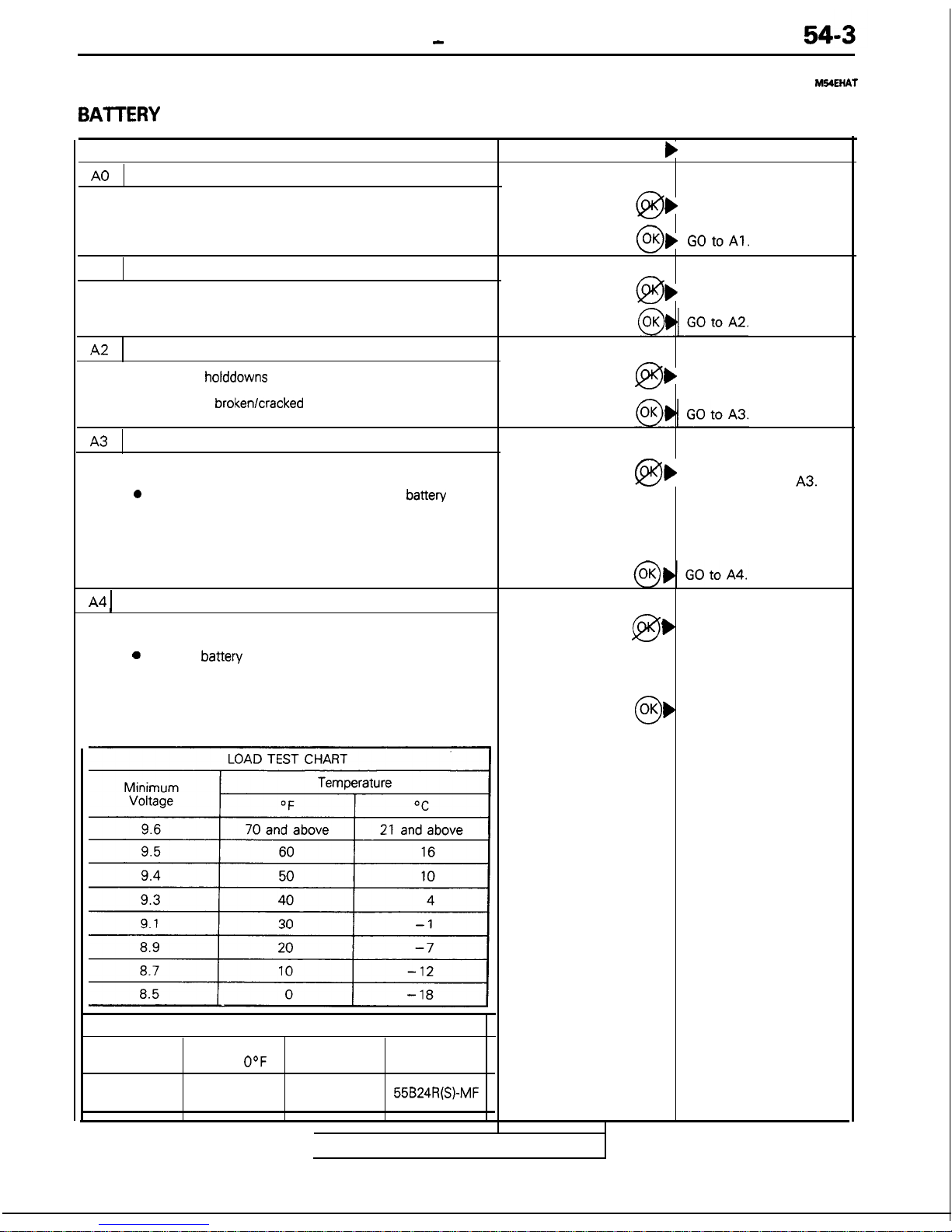

BATTERY - Troubleshooting

TROUBLESHOOTING

BAlTERY

TESTING PROCEDURE

TEST STEP

RESULT

b

ACTION TO TAKE

A0

VISUAL INSPECTION

l

Remove negative cable, then positive cable.

)

CLEAN terminals and

clamps. GO to Al.

l

Check for dirty or corroded connections.

0

OK) GOtoAl.

Al

LOOSE BATTERY POST

l

Check for loose battery post.

@

)

REPLACE battery.

A2

CRACKED BATTERY ‘COVER

l

Remove

holddowns

and shields.

@

)

REPLACE battery.

l

Check for

broken/cracked

case or cover.

A3

TEST INDICATOR/OPEN CIRCUIT VOLTAGE TEST

l

Turn headlights on for 15 seconds

0

Turn headlights off for 2 minutes to allow

battery

voltage to stabilize.

l

Disconnect cables.

l

Read open circuit voltage.

A4 1

LOAD TEST

@b

CHARGE battery at 5

Blue dot invisible and’

amps then GO to

A3.

open circuit voltage under

12.4 volts

l

Connect a load tester to the battery.

0

Load the

battery

at the recommended discharge rate

(see LOAD TEST RATE CHART) for 15 seconds.

l

Read voltage after 15 seconds, then remove load.

@

)

REPLACE battery.

Voltage is less than

minimum listed (white

indicator).

0,

OK

Battery OK.

Voltage is more than

minimum listed.

Load Test

(Amps)

210 amps

LOAD TEST RATE CHART

Cranking

Reserve

Rating

O°F

Capacity

433 amps

79 minutes

Application

55B24R(S)-MF

TSB Revision

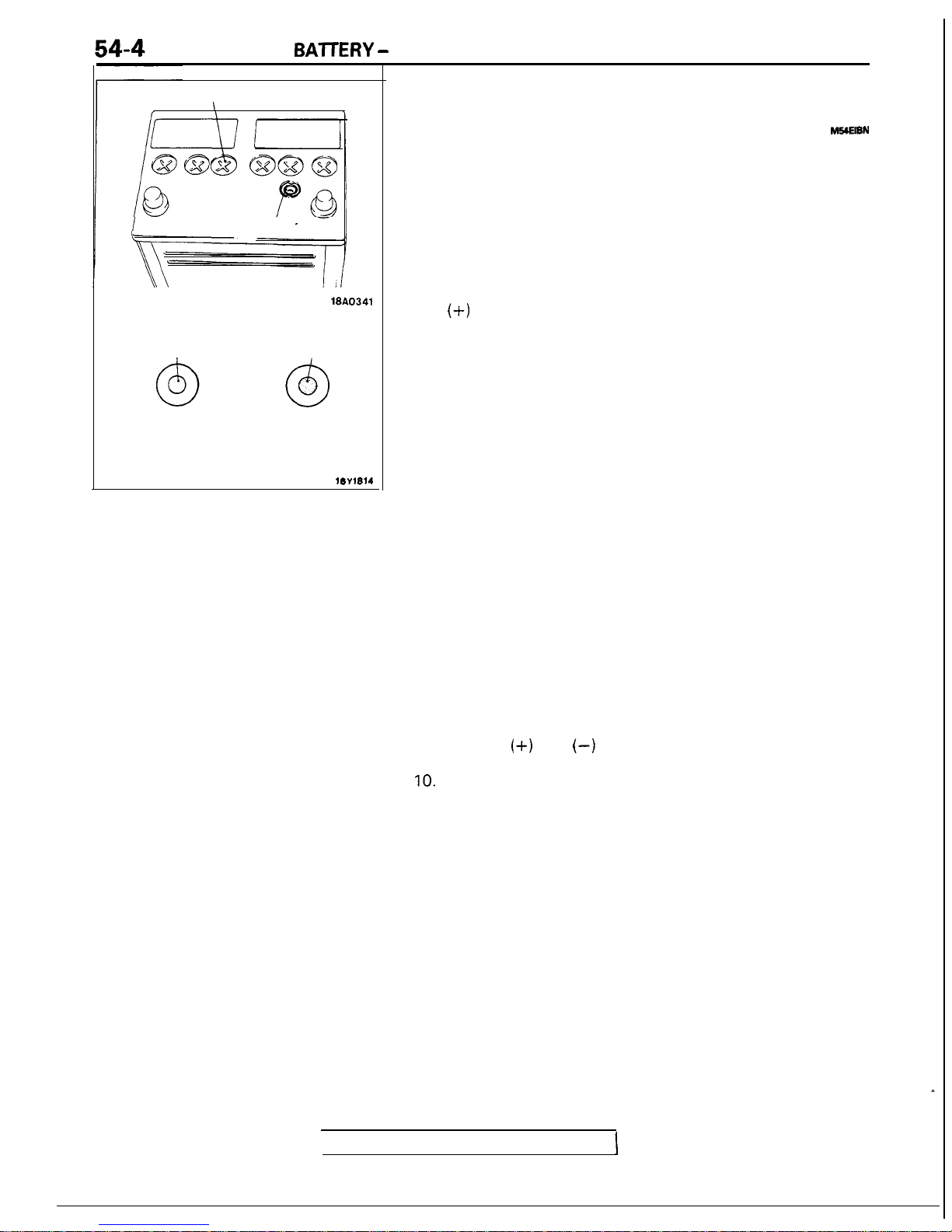

Vent plug

\

BATT’ERY -

Service Adjustment Procedures

SERVICE ADJUSTMENT PROCEDURES

Indicator

18A0341

White

Blue

Charging

necessary

Good

condition

18Y1814

BATTERY INSPECTION

M!XEl8N

BATTERY VISUAL INSPECTION (1)

The battery contains a visual test indicator which gives blue

signal when an adequate charge level exists, and white signal

when charging is required.

BATTERY VISUAL INSPECTION (2)

Make sure ignition switch is in Off position and all battery feed

accessories are Off.

1.

Disconnect ground cable from battery before disconnecting

(+)

cable.

2. Remove battery from vehicle.

Caution

Care should be taken in the event battery case is

cracked or leaking to protect hands from the electrolyte. A suitable pair of rubber gloves

(not

the household type) should be worn when removing battery by

hand.

3.

Inspect battery carrier for damage caused by loss of acid

from battery. If acid damage is present, it will be necessary

to clean area with a solution of clean warm water and

baking soda. Scrub area with a stiff bristle brush and wipe

off with a cloth moistened with ammonia or baking soda in

water.

4. Clean top of battery with same solutions as described in

Step (3).

5. Inspect battery case and cover for cracks. If cracks are

present, battery must be replaced.

6.

Clean the battery post with a suitable battery post cleaning

tool.

7. Clean the inside surfaces of the terminal clamps with a

suitable battery terminal cleaning tool. Replace damaged or

frayed cables and broken terminals clamps.

8. Install the battery in vehicle.

9. Connect (+) and

(-)

cables to battery in the order of

mention.

IO.

Tighten the clamp nut securely.

TSB Revision

BATTERY - Service Adjustment Procedures

54-5

I

LOAD TEST RATE CHART

I

Load

Test

(Amps)

Cranking

REg

Reserve

Capacity

Application

I

210 amps

1

433 amps 1 79

minutes.1 55B24R(S)-MF (

I

LOAD TEST CHART

I

Minimum

Voltage

Temperature

OF

OC

L

9.6

70 and above

21 and above

9.5

60

16

9.4

50

10

9.3

40

4

9.1

30

-1

8.9

20

-7

8.7

10

-12

1

I 0

I

-18

I

Note

The temperature is an ambient temperature of the battery

that has been exposed to for the preceding few hours.

BA-ITERY

CHARGING

MYEICL

Caution

When batteries are being charged, an explosive

gas forms beneath the cover of each cell. Do not

smoke near batteries on charge or which have

recently been charged.

Do not break live circuits at the terminals of the

batteries on charge. A spark will occur where the

live circuit is broken.

Keep all open flames away from the battery.

Battery electrolyte temperature may temporarily be

allowed to rise to

55OC

(131

OF).

Increase of

electrolyte temperature above

55OC

(131 “F) is

harmful to the battery, causing deformation of battery

cell, decrease in life of battery, etc.

CHARGE RATE

If the test indicator is white, the battery should be

charged as outlined below.

OPEN CIRCUIT VOLTAGE TEST

(3)

1. Turn headlights on for 15 seconds.

2.

Turn headlights off for 2 minutes to allow battery

voltage to stabilize.

3. Disconnect cables.

4. Read open circuit voltage.

5. If the open circuit voltage is under 12.4 volts,

charge the battery. (See BATTERY CHARGING)

LOAD TEST

(4)

1. Connect a load tester to the battery.

2. Load the battery at 15 amps for 15 seconds to

remove surface charge.

3. Load the battery at the recommended discharge

rate. (See LOAD TEST RATE CHART)

4. Read voltage after 15 seconds and then remove

the load.

5. If the voltage is not maintained at the minimum

voltage in the LOAD TEST CHART throughout the

test, the battery should be replaced.

TSB Revision

When the dot appears or when maximum charge

shown below is reached, charging should be

stopped.

NOTE

When the charging is performed at 5 amps,

charging is virtually

loo:!

three hours after the

indicator’s indication changes from white to blue.

Use fast charging only in an emergency.

If the indicator does not turn to blue even after the

battery is charged, the battery should be replaced;

do not overcharge.

Charge Rate Chart

1

Battery 1 Slow Charging

1

Fast Charging

I

54-6

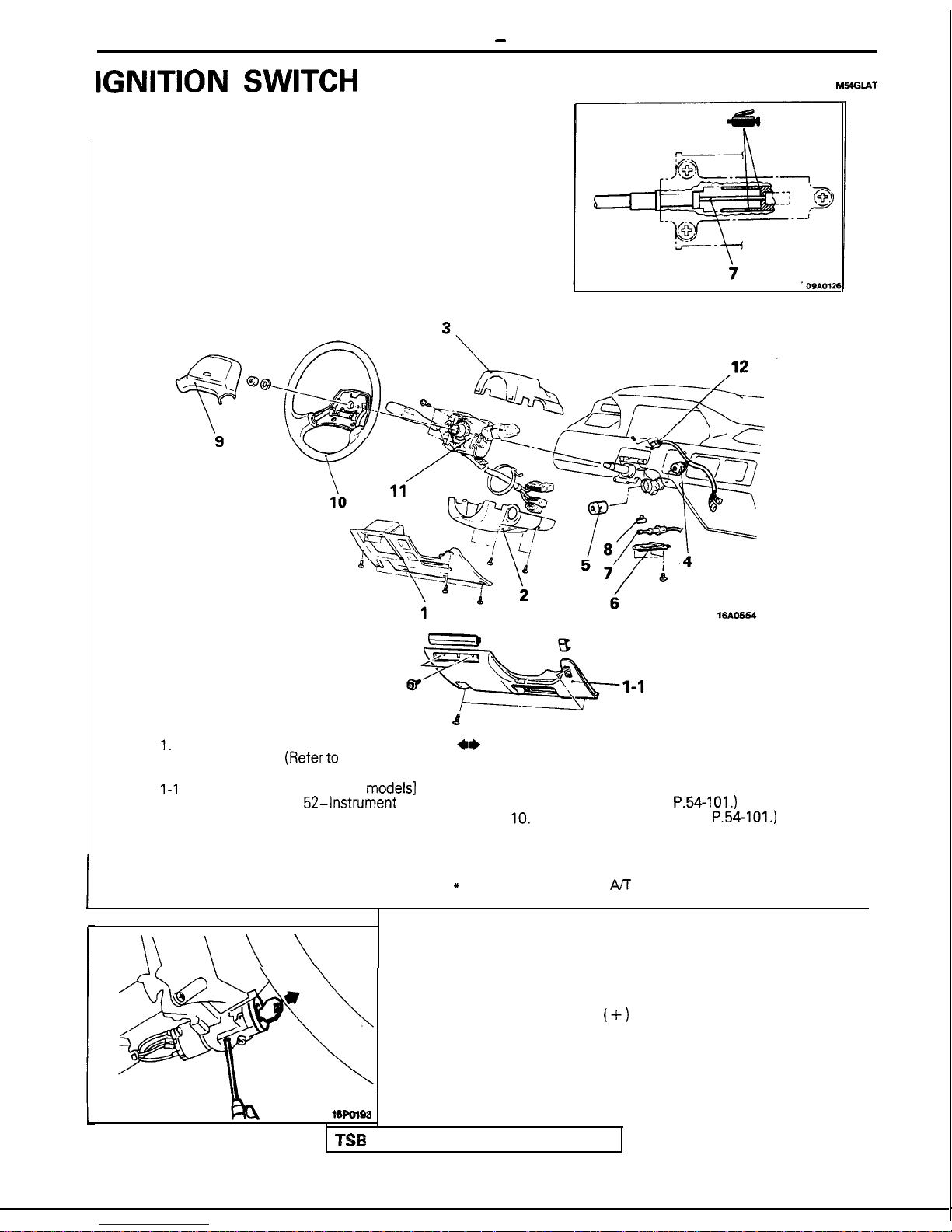

IGNITION SWITCH - Ignition Switch

IGNITION SWITCH

REMOVAL AND INSTALLATION

Removal steps

d

I.

Instrument panel under cover

4*

(1989 models]

(Referto

GROUP 52-

::

Instrument Panel.)

l 4

7.

I-1 Knee protector [From 1990

models]

l 4

8.

(Refer to GROUP

52-Instrument

Panel.)

9.

2.

Column cover lower

10.

3.

Column cover upper

11.

4.

ignition switch segment

12.

Steering lock cylinder

Cover*

Key interlock cable*

Slide lever*

Horn pad (Refer to

P.54-101.)

Steering wheel (Refer to

P.54-101.)

Column switch

Key reminder switch segment

NOTE

*

indicates vehicles with M safety-lock system.

\\

\

\

\

SERVICE POINTS OF REMOVAL

5. REMOVAL OF THE STEERING LOCK CYLINDER

(1) Insert the key in the steering lock cylinder and turn it to

the “ACC” position.

(2) Using a cross-tip

(+)

screwdriver (small) or a similar

tool, push the lock pin of the steering lock cylinder

inward and then pull the steering lock cylinder toward

you.

16POl63

TSB

Revision

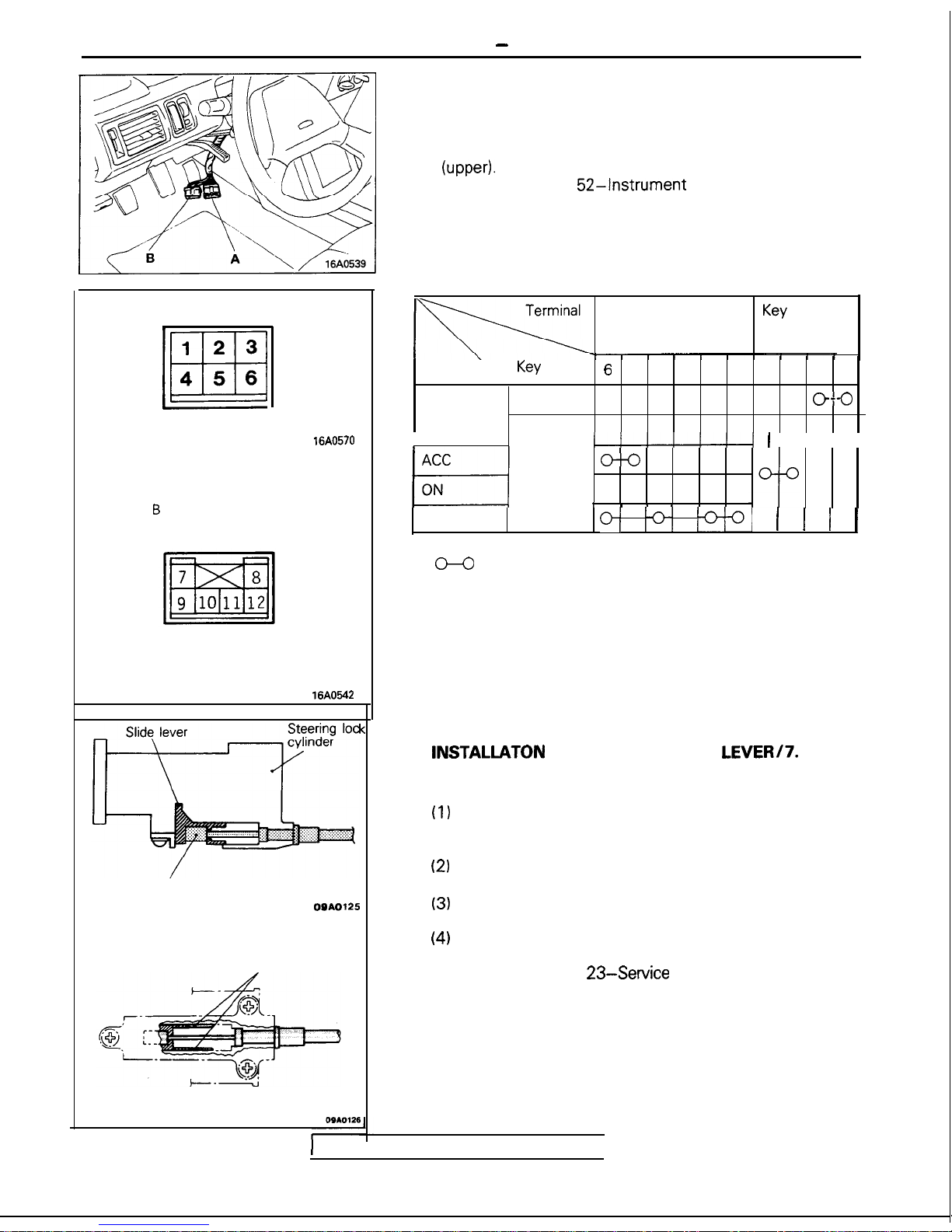

IGNITION SWITCH

-

ignition Switch

54-7

Connector A

16A0570

Connector

B

16A0642

Key interlock cable

OQAO12.5

Apply grease

k

INSPECTION

IGNITION SWITCH INSPECTION

(1) Remove the instrument panel under cover (or knee

protector), the column cover (lower), and the column cover

(upped.

(Refer to GROUP

52-Instrument

Panel).

(2) Disconnect the wiring connector from the ignition switch

and key reminder switch, and connect an ohmmeter to the

switch side connector.

(3) Operate the switch, and check the continuity between the

terminals.

Ignition switch

Key

reminder

switch

Position

Key

6 3

4

2 5

17

8

912

Removed

o--o

LOCK

I

I

I I I I

o--o

Inserted

o-u-o--o

r I 1 I

START

o( ;3;

;qq

(1 1

1

NOTE

(1)

O-O

indicates that there is continuity between the terminals.

(2) O---O indicates vehicles with ETACS.

SERVICE POINTS OF INSTALLATION

8.

INSTALLATON

OF THE SLIDE LEVERi7. KEY

INTERLOCK CABLE (STEERING LOCK ASSEMBLY

SIDE)

(1)

With the ignition key either at the “LOCK” position or

removed, install the slide lever to the steering lock

cylinder.

(2)

Connect, as shown in the figure, the key interlock cable

to the slide lever and the steering lock cylinder.

(3)

Apply a light coating of multi-purpose grease where

shown in the figure.

(4)

Check whether or not the key interlock system is

functioning normally.

(Refer to GROUP

23-Service

Adjustment Procedures.)

1

TSB Revision

I

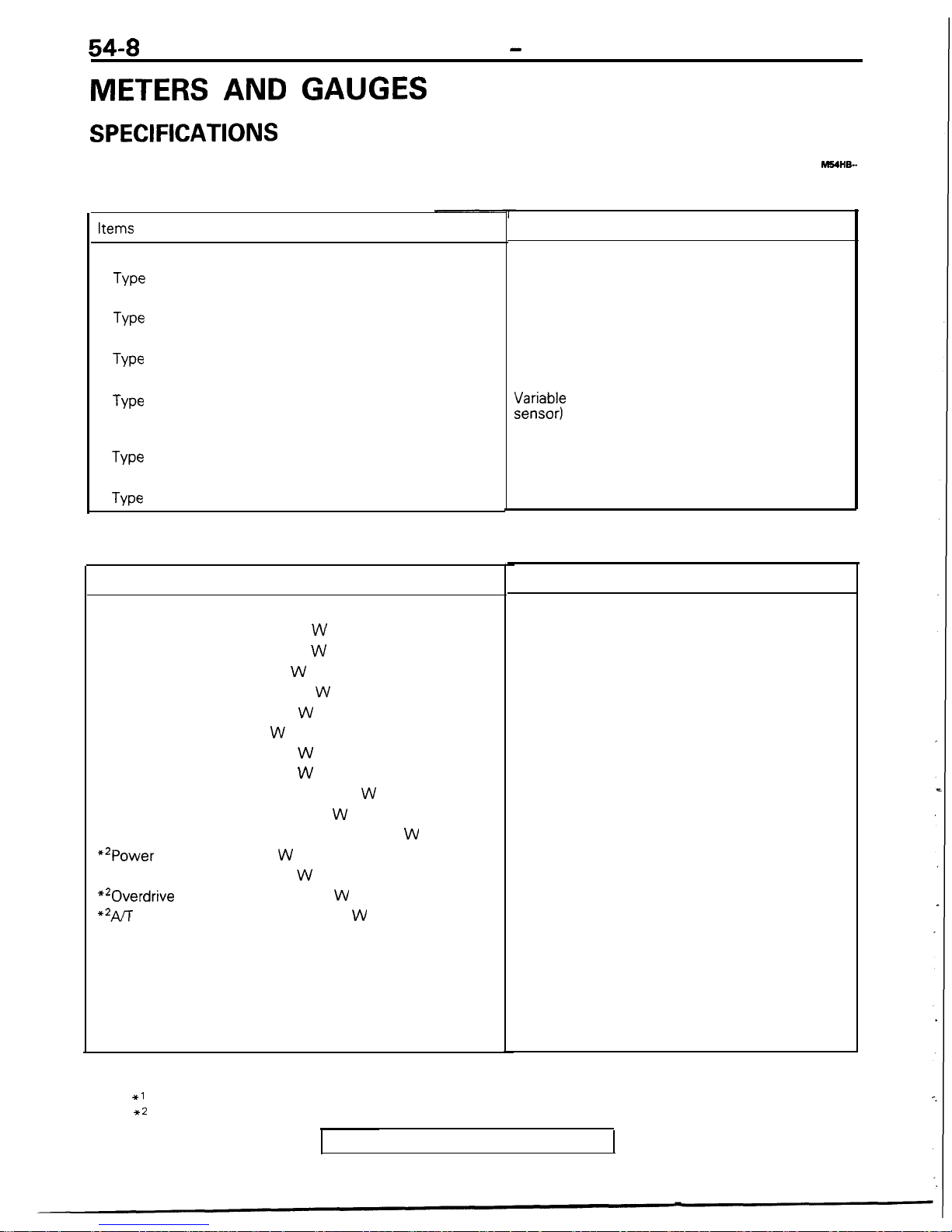

54-8

METERS AND GAUGES - Specifications

METERS AND GAUGES

SPECIFICATIONS

GENERAL SPECIFICATIONS

Meters and Gauges

Items

Speedometer

Type

Tachometer

Type

Fuel gauge

Type

Fuel gauge unit

Type

Engine coolant temperature gauge

Type

Engine coolant temperature gauge unit

Type

Indicators and Warning Lights

Items

Indicator lights

Turn signal indicator light

W

High beam indicator light

W

Charging warning light

W

Oil pressure warning light

W

Door ajar indicator light

W

Brake warning light

W

Fuel level warning light

W

Seat belt indicator light

W

Auto-cruise control indicator light

W

*‘Anti-lock brake warning light

W

Check engine/malfunction indicator lamp

*‘Power indicator light

W

**Economy indicator light

W

*20verdrive

OFF indicator light

W

**AA

shift position indicator light

W

Park

Reverse

Neutral

Drive

Second

Low

W

NOTE

1. The values in parentheses denote SAE trade numbers.

2. The *l symbol indicates vehicles with anti-lock braking system.

3. The ** symbol indicates vehicles with AA.

hl54HQ-

Specifications

Rotary magnet type

Pulse type

Cross coil type fixed needle gauge

;;;:&I;)

resistance type (with fuel level warning

Cross coil type

Thermistor type

Specifications

3.4

(158)

3.4

(158)

1.4

(74)

1.4

(74)

1.4 (74)

1.4

(74)

3.4

(158)

1.4 (74)

1.4

(74)

1.4

(74)

1.4

(74)

1.4

(74)

1.4

(74)

1.4 (74)

1.4

(74)

1.4

(74)

1.4 (74)

1.4

(74)

1.4

(74)

1.4 (74)

TSB Revision

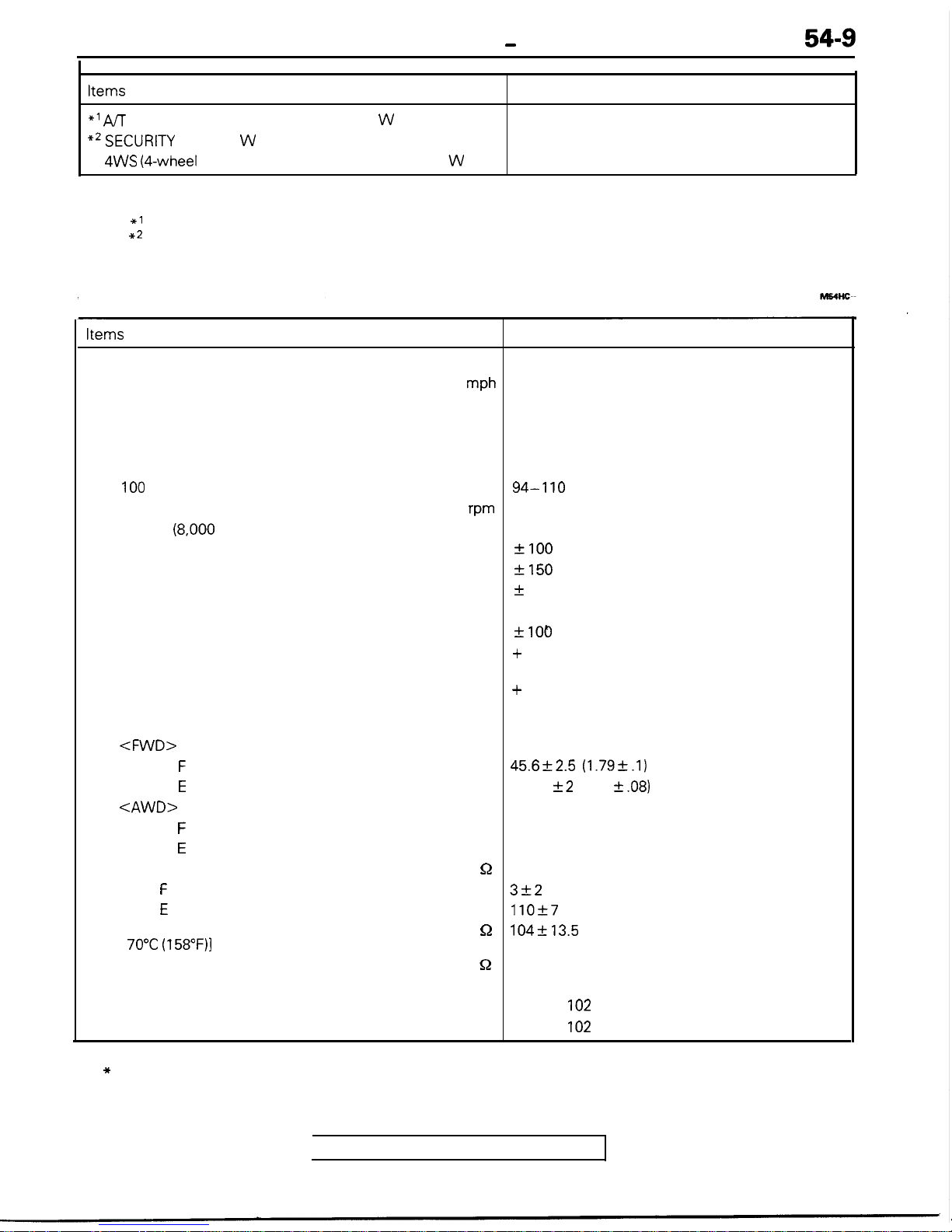

METERS AND GAUGES - Specifications

Items

Specifications

*’ A/T

fluid temperature warning light

W

1.4 (74)

**SECURITY

light

W

1.4 (74)

4WS (4-wheel

steering system) warning light

W

1.4 (74)

54-9

NOTE

1. The value in parentheses denote SAE trade numbers

2. The *1 symbol indicates AWD-AK.

3. The ** symbol indicates vehicles with theft-alarm system.

SERVICE SPECIFICATIONS

Items

Specifications

Standard value

Speedometer indication error

mph

20

19-22

40

38-44

60

57-66

80

76-88

100

94-l 10

Tachometer indication error

wm

Type 1

(8,000

rpm indication)

700

?I00

3,000

+150

6,000

+

300

Type 2 (9,000 rpm indication)*

700

+100

3,000 + 225

-100

7,000 + 400

-100

Operation range of fuel gauge unit

mm (in.)

<FWD>

Point

F

45.6k2.5 (1.79k.l)

Point

E

177.5 +2 (6.98 2.08)

<AWD>

Point

F

43 (1.69)

Point

E

174 (6.85)

Fuel gauge unit resistance

52

Point

F

3f2

Point

E

110+7

Engine coolant temperature gauge unit resistance

n

104+13.5

[at

70°C (158”F)l

Fuel gauge resistance

52

Between A-B

Approx. 203

Between A-C

Approx.

102

Between B-C

Approx.

102

NOTE

The * symbol indicates DOHC models.

TSB Revision

METERS AND GAUGES -

Suecifications

Items

Engine coolant temperature gauge resistance

<Vehicles built up to Dec.

1988>

Between A-B

Between A-C

Between B-C

<Vehicles built from Jan.

1989>

Between

A-0

Between A-C

Between B-C

Specifications

Q

Approx.

130

Approx. 53

Approx. 162

Approx. 146

Approx. 60

Approx. 206

TORQUE SPECIFICATIONS

Items

Engine coolant temperature gauge unit

Nm

10-12

ft.lbs.

7-8

SEALANTS AND ADHESIVES

M54HF-

Items Specified sealant and Adhesive

Engine coolant temperature gauge unit 3M ATD Part

No.8660

or equivalent

I TSB

Revision

54-P 1

NOTES

54-12

METERS AND GAUGES - Troubleshooting

TROUBLESHOOTING

M54HHAQb

<Up to 1990 models>

J/B

z8

c-37

1

:

t

METER AND GAUGES CIRCUIT

CIRCUIT DIAGRAM

TAILLIGHT RELAY

31

__--__-____---___---~~---~~-----~-~---~~

---__--___---_-_----~~--~~~--~~~~-~~~~~-

WITH

WITHOUT

METER COLOR

METER COLOR

CHANGER SWITCH

CHANGER SWITCH

r

I

METER COLOR

CHANGER SWITCH

\I

\/

_--_-_--___--___--~~~--

__--________________________

10

Ti6 C-50

ii2

>

3515

,AWD

,

FWD,

J/C

(TAIL)

RHEOSTAT

E-01

m

J/C

(RHEO)

J/C

(GROUND)

P

m

F-21-1 i

pmq

;

4

------

1

I

>

I

I

,3

I

,C

I

I

I

I

I

I

I

I

I

I

I

I

FUEL

r'$2 G-03 j

8KE

m3 m

j

I

------e-J

D-26

35-AC-Hl014-NY

TSB Revision

r

@

IOA

IGNITION

SWITCH(IG1)

METERS AND GAUGES - Troubleshooting

54-13

COIL

)ELS>

IN

;;;.;>STOR MFI

CONTROL UNIT

RHEOSTAT

I--

2

POWER

T

Cl990 M

1234

Ell

7

c-43 56'8

1

J/B

3

0

-------------_-_-------------.

3

c-00

$C

1234

m

5678

z

13

t

3

-------------

a.

1C

TEMPERATURE

GAUGE UNIT

u B-01

=

p=J

m

cl

1

TSB

Revision

1

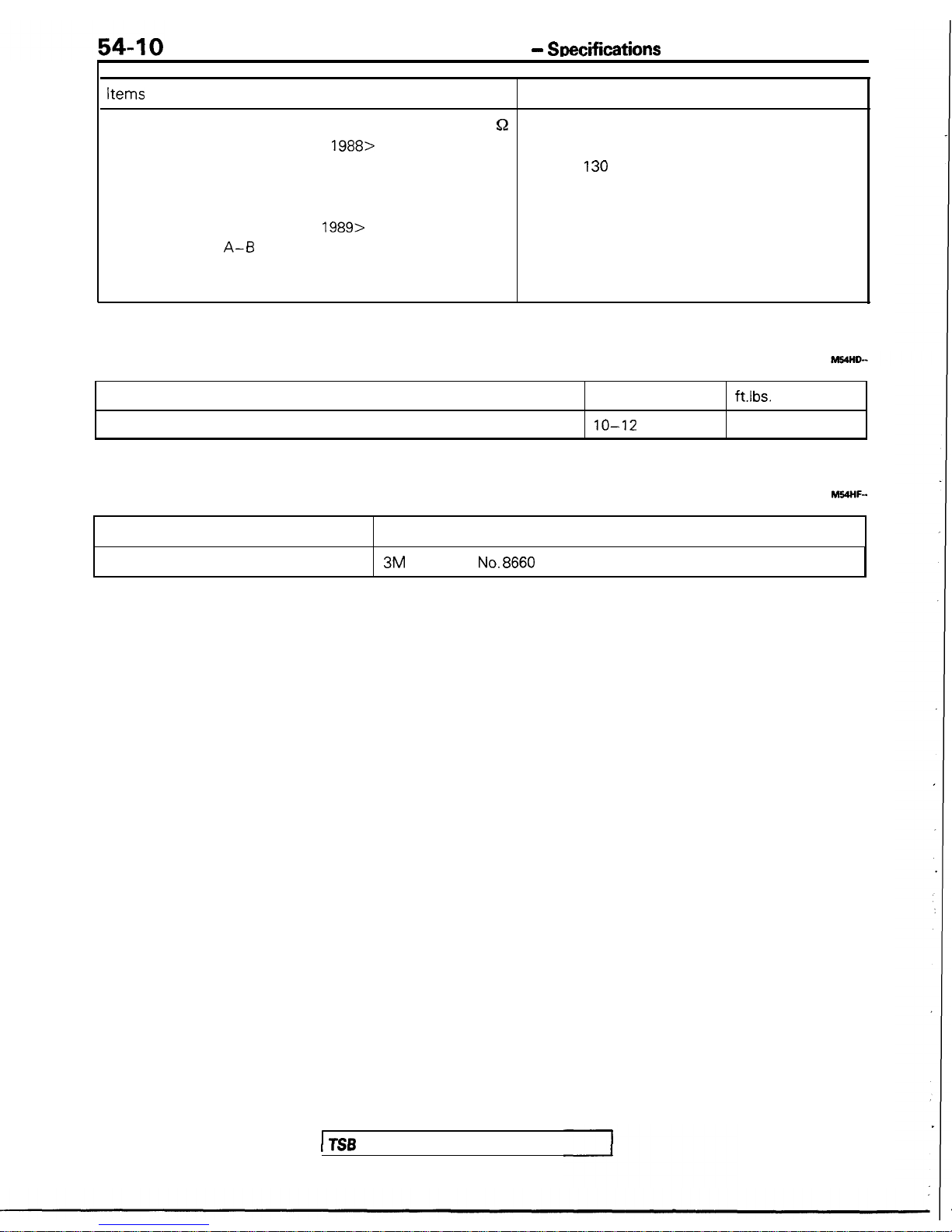

METER AND GAUGES CIRCUIT

CIRCUIT DIAGRAM

<from 1991 models>

TAILLIGHT RELAY

J/B

%6

\

c-37

,\

I

54-14

METERS AND GAUGES - Troubleshooting

L

3

"5

c-44

c-32

3

COMBINATION

11

c-52

METER

I;-

-----------_-___-----------------------,

-___-----------_-----------------

-------

m

WITH

0

METER CO

k

OR

WITHOUT METER COLOR

@

CHANGER

WITCH

*

CHANGER SWITCH

I

1

I

I

METER COLOR

I

CHANGER SWITCH

I

I

I

I

I

I

I

I

I

!

I

\

I

I

I

I

@

I

I

I

@

I

\I

“16

C-50

>

F-----z

AWD

F-25

J/C

J/C

(TAIL)

(RHEO)

s

RHEOSTAT

E-01

@=T&

r-1

D-26

TSB Revision

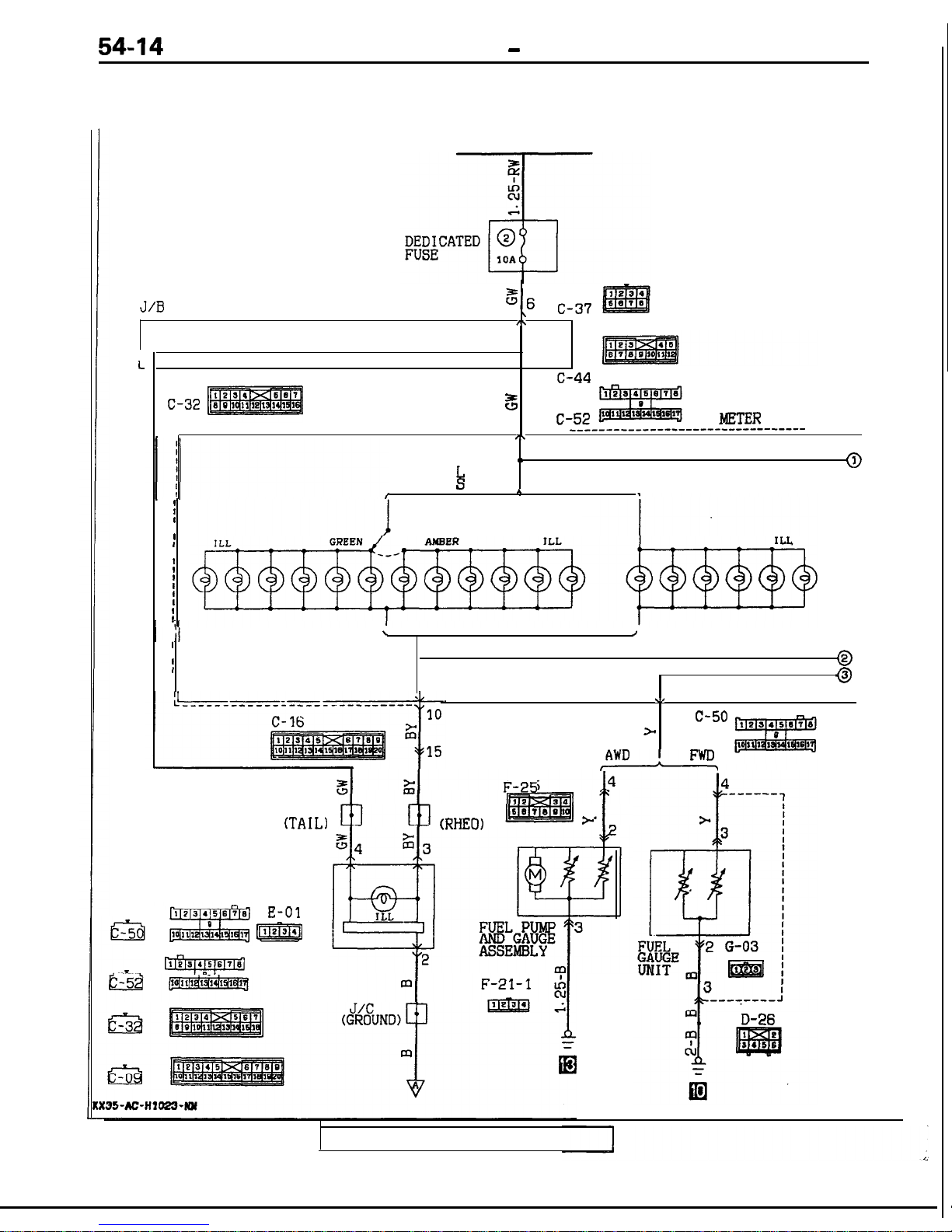

METERS AND GAUGES - Troubleshooting

IGNITION SWITCH(IG1)

@

L

10A

8

IGNITIJ

POWER

m

,c

!%TROL

UNIT

.NSISTOR

%lJ

.b

\I

j 17m

“14 m

m

J/B

ENGINE

COOLANT

TEMPERATURE

GAUGE UNIT

B-01

4

cl

El

Remarks

tA: (UP

to 1992

models)

%B:

XC:

ii

From 1993 m d

Is)

OHCWP

to

1898

models)

UNIT

3

C-08

RHEOSTAT

C-38

TSB Revision

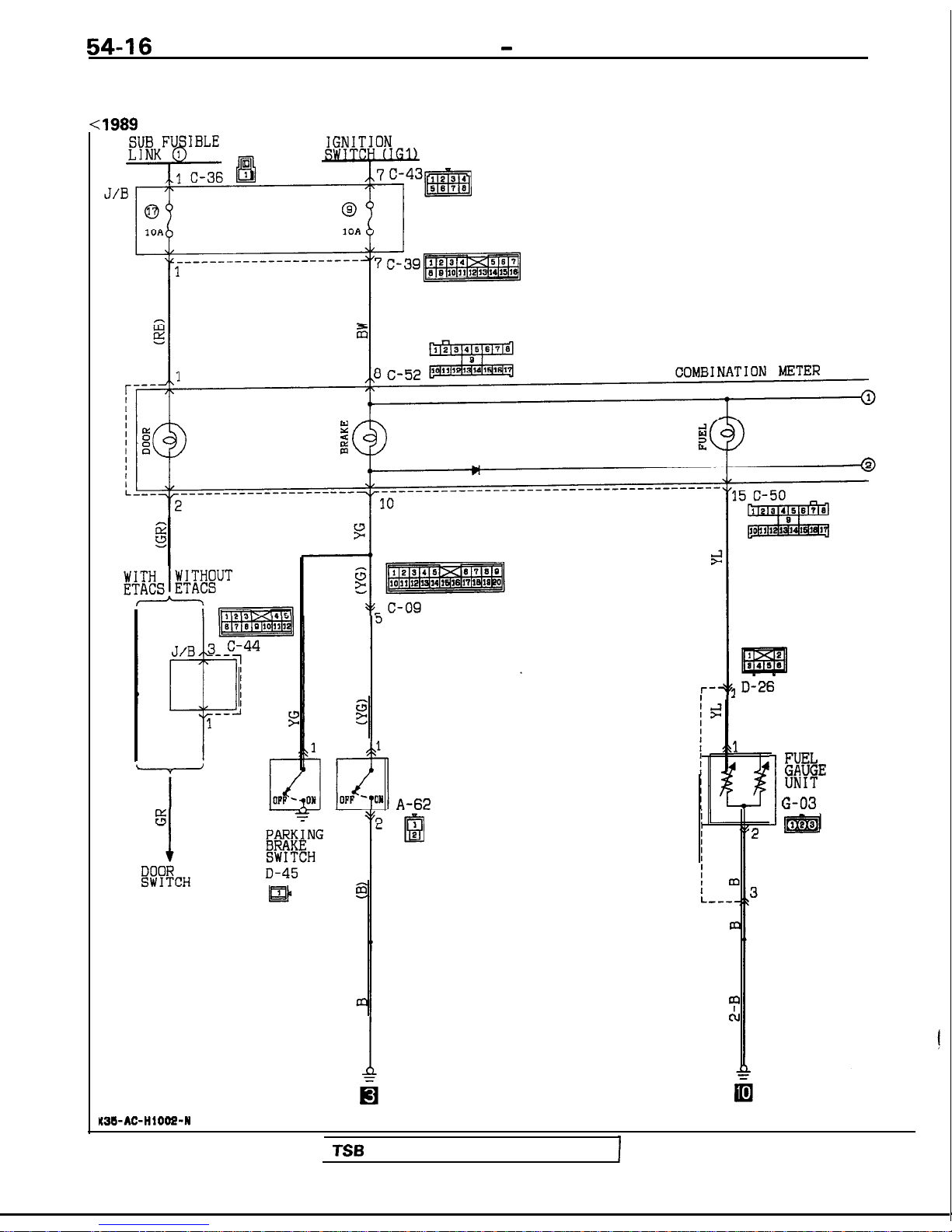

54-16

METERS AND GAUGES - Troubleshooting

WARNING LIGHT CIRCUIT

CIRCUIT DIAGRAM

<

:1989

models>

KM-AC-HlOOZ-N

BRAKE

FLUID

LEVEL

SENSOR

A-62

1

G-03

@Jg

TSB

Revision

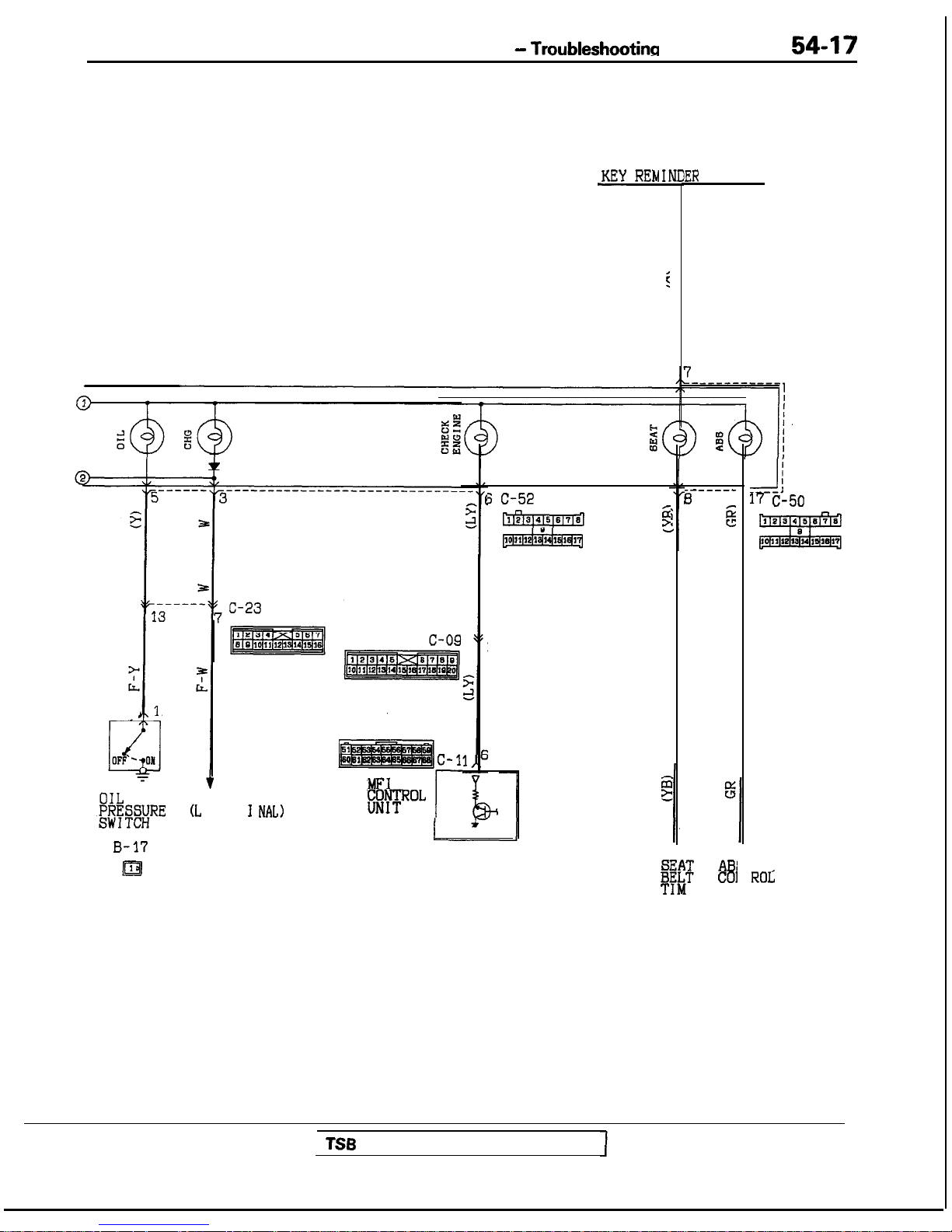

METERS AND GAUGES -

Troubleshootinn

54-17

-KEY REMI.

i

B-17

Es

GENERATOR

(L

TERM I

NAL

J

C-l

MFI

tEFoL

r

; C-52

5

TSB

Revision

13

4

B

T

1ER

SWITCH

------s

g

T ABI

co1

ER UN

17 c-50

ROS,

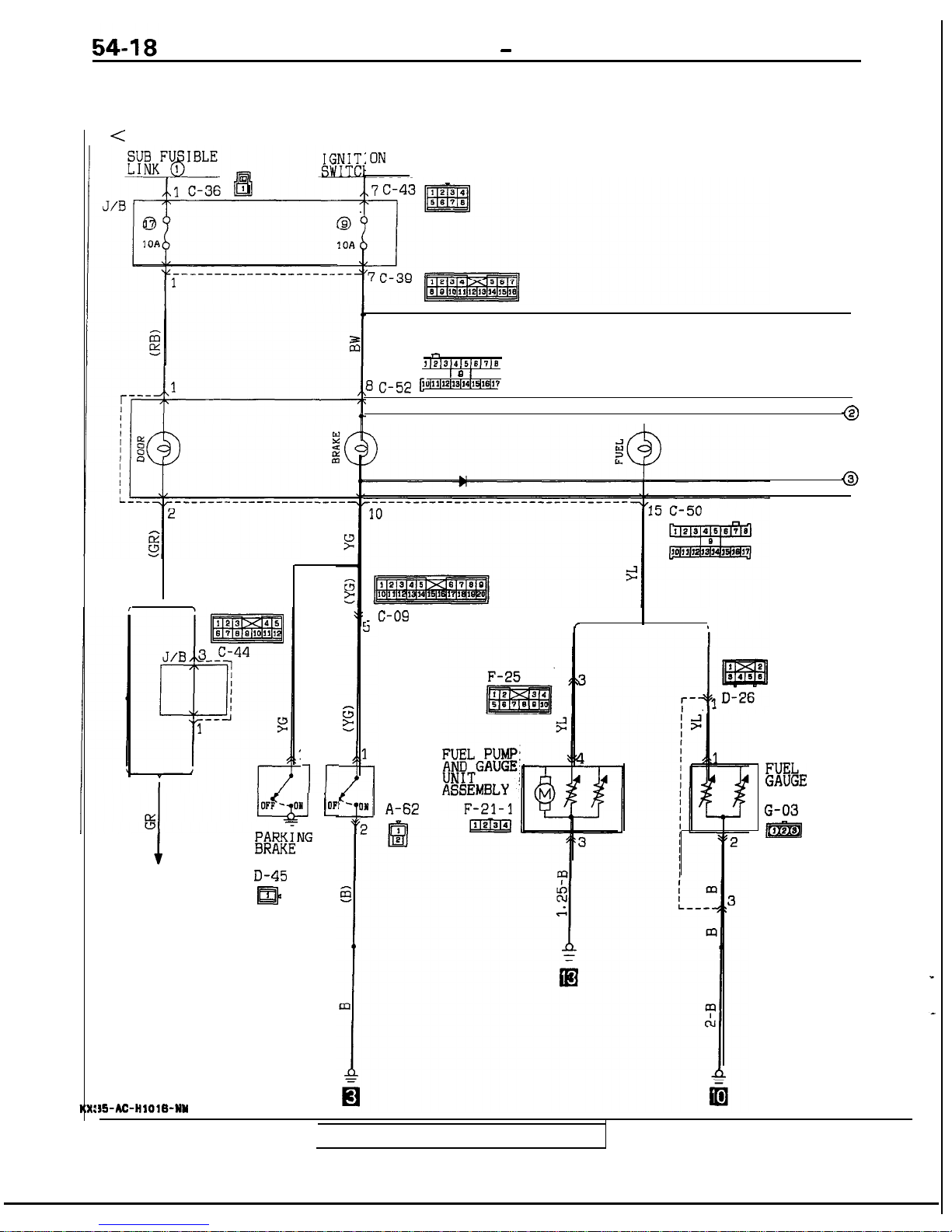

METERS AND GAUGES - Troubleshootina

WARNING LIGHT CIRCUIT

CIRCUIT DIAGRAM

<

1990 models>

WITH WITHOUT

ETACS ETACS

L

OFI

I

I

lr

ixifi””

SWITCH

DOOR

SWITCH

D-45

m

:ON

1

n

~IP~314~5~6J7~2

SC-52 G

I 2 1

1ul13~12~12~14~1~1~17

COMBINATION METER

~

c-09

AWD

.

FWD

r

,

BRAKE

FLUID

LEVEL

SENSOR

A-62

XkE

UNIT

G-03

@Q

3%AC-HlOlB-NY

TSB Revision

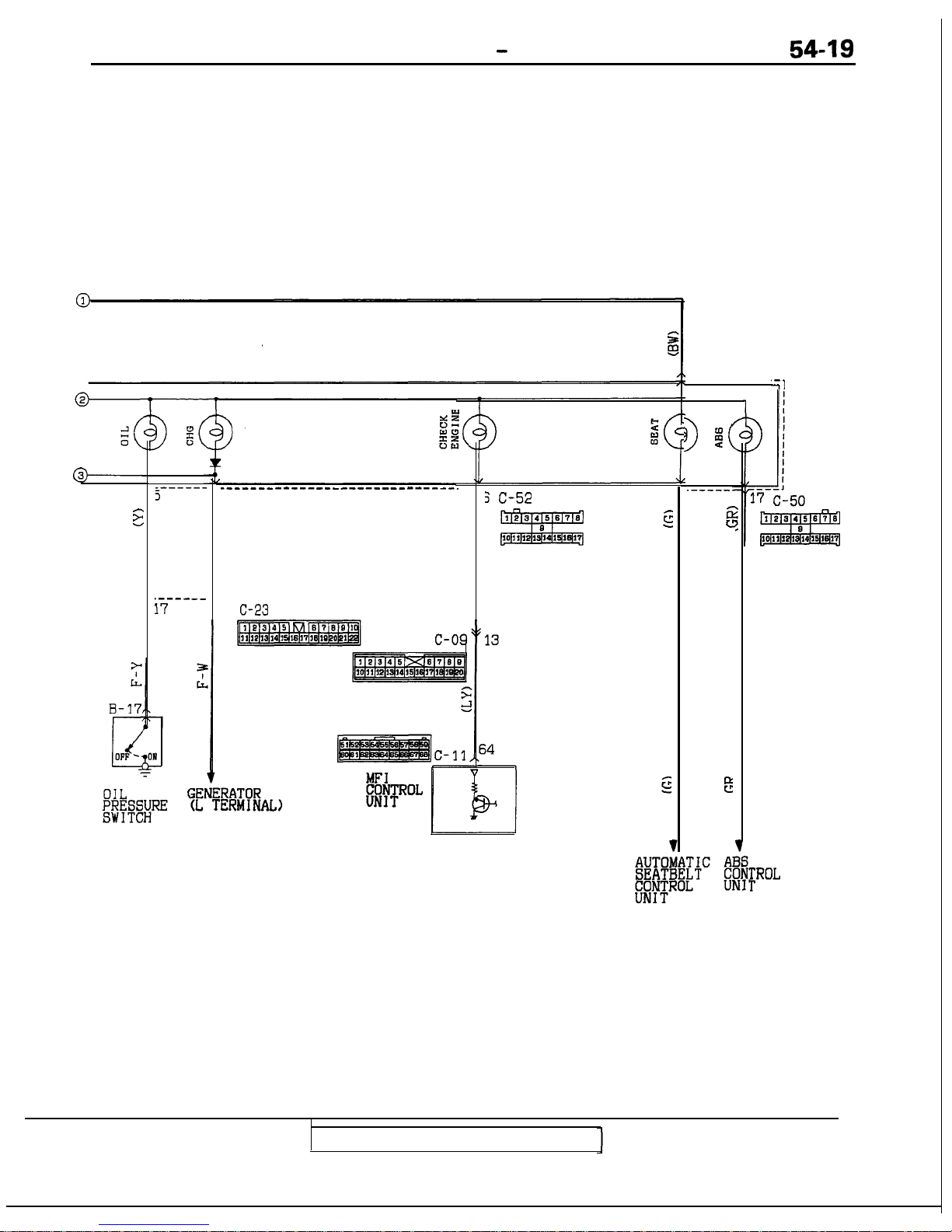

METERS AND GAUGES - Troubleshootina

54-19

@------

E

=-----3

3

3

.-----,T)

II

-----------------------------.

3

0

C-23

3 C-52

g

7

-----------

i-1

(I big

.------

3

g

%

[ROL

TSB Revision

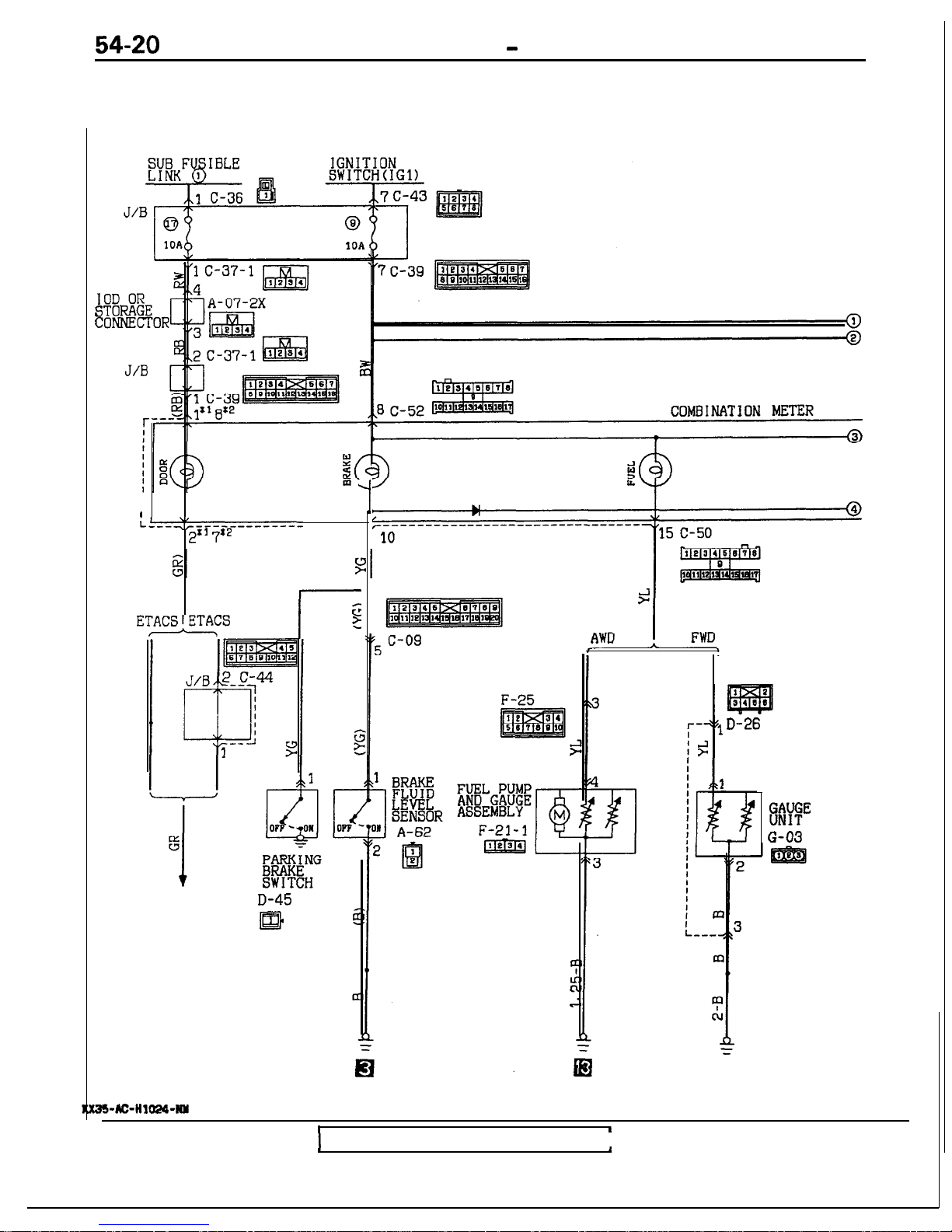

54-20

METERS AND GAUGES - Troubleshooting

WARNING LIGHT CIRCUIT

CIRCUIT DIAGRAM

I

E

C

<From 1991 models>

‘1

1

I

I

I

L---$-------------

-------

tp¶pZ

WITH WITHOUT

I-

z

ETACS*ETAFS

t

DOOR

SWITCH

D-45

ml

D-26

I

1

1

TSB Revision

I

,

4

FUEL

mwE

G-03

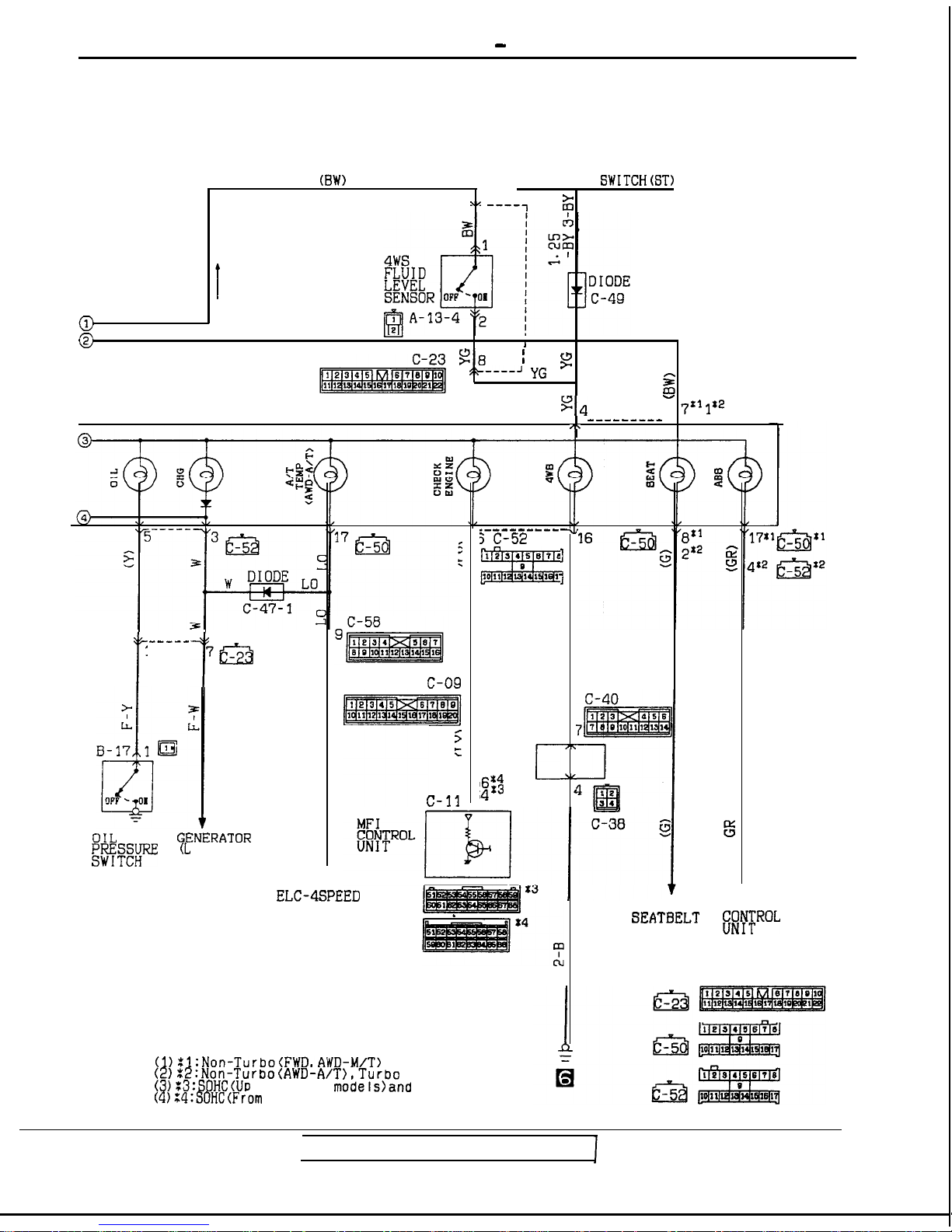

METERS AND GAUGES - Troubleshooting

54-21

(BW)

IGNITION

SWITCH(ST)

,,

19

-----I

ii

@

@

I

b

%6

I

9

5+----J .fG

i.2

g4

- 7’1

1’2

---------

I\

-----

35

f

1

7553

OIL

GENERATOR

EREfRE

(L

TERMINAL)

C-OS

13

5

c

J/B

7c

,6’4

c

AL

,

d

c-11

,4:3

_---------

3 C-52

7,

I

1

ELC-4SPEED

AUTOMATIC

TRANSAXLE

CONTROL MODULE

AUTOMATIC ABS

SEATBELT

CONTROL

##FROL

UNIT

Remarks

(l)%l:Non-Turbo(FWD,AWD-M/T)

(2)%2:Non-Turbo(AWD-A/T),Turbo

(~)Z~:SOHC(UP

to 1992

models)and

DOHC

(4):4:SOHC(From

1993 models)

TSB

Revision

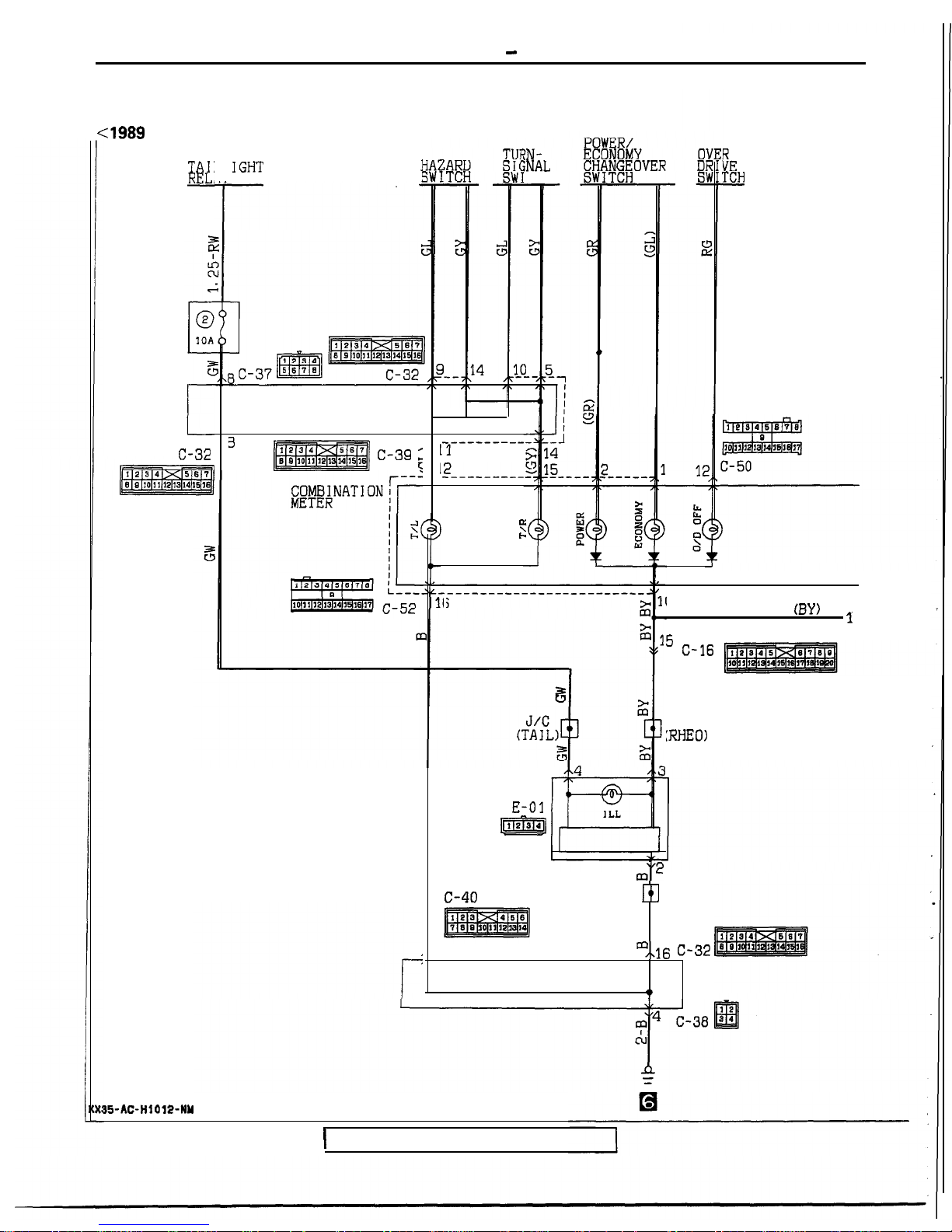

54-22

METERS AND GAUGES - Troubleshooting

INDICATOR LIGHT CIRCUIT

CIRCUIT DIAGRAM

cl989

models>

FE

TCH

-

ZN;NAL

TCH

TAI:

REL,

IGHT

1

DEDICATED

FUSE

J/B

r

I

C-32

3

p!$Tzaq c-39 ;

_------_--

I1

‘2--------

I

e

L-

6

3

(BY) l

5 C-16

J/C

:RHEO)

m’2

c-40

J/C

~3

(GROUND)

,

m/,16 C-32

J/B

t

RHEOSTAT

E-01

m

15-AC-H1012-NY

1

TSB Revision

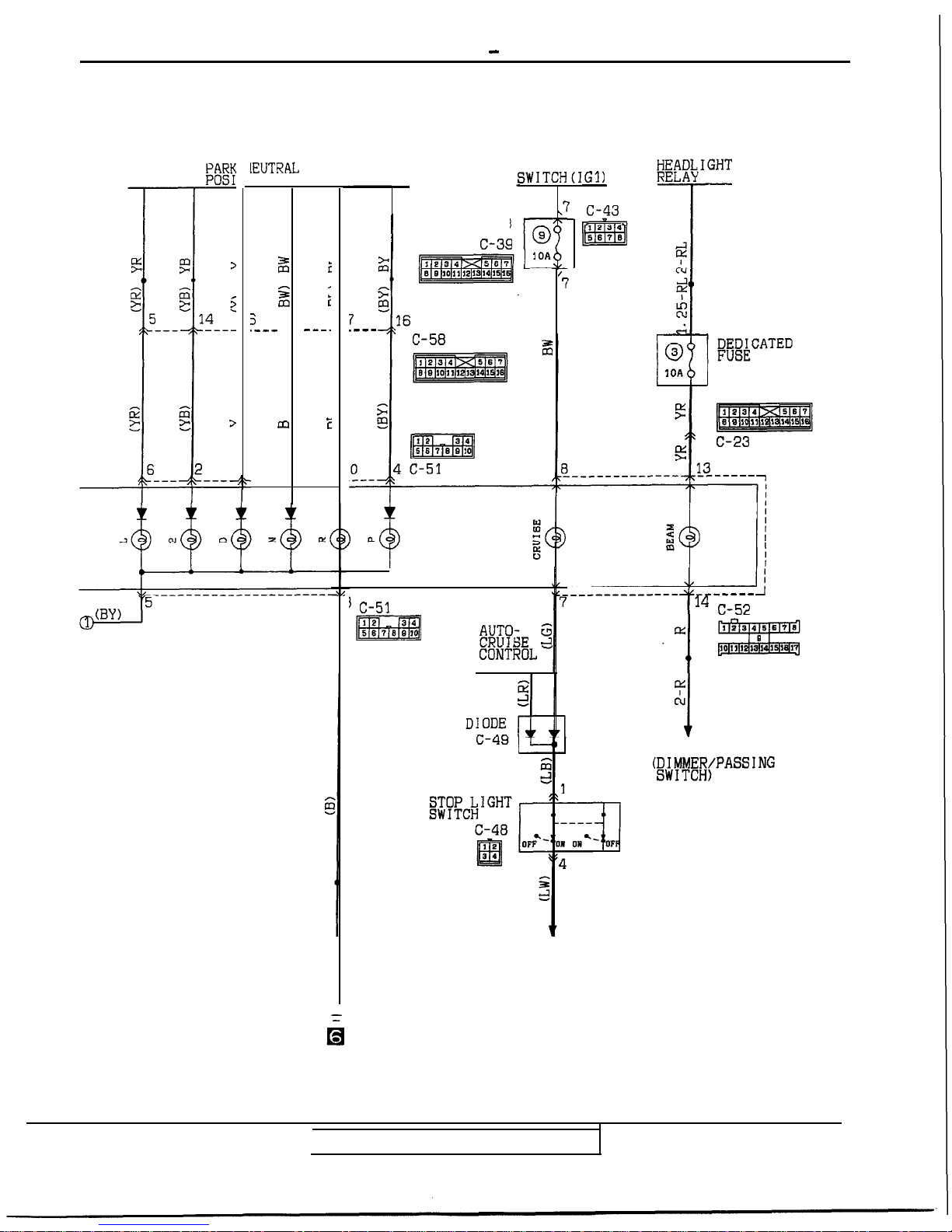

METERS AND GAUGES - Troubleshooting

54-23

lEUTRAL

ON SWITCH

z

i

2

;

5

-15 .

.___ ---.

3

al

E

I

9

--- ----

a

I

J/B

c-39

IGNITION

SWITCH(IG1)

,i

77

1

>

I

'i

7

.---

C-58

1 c-51

pil%Iq

&&E

3

CONTROL-

ACTUATOR

?

I

6

55

C-23

.___----------

_------

-I

l4 C-52

COLUMN SWITCH

(#t#$PASSING

AUTO-CRUISE

CONTROL UNIT

TSB Revision

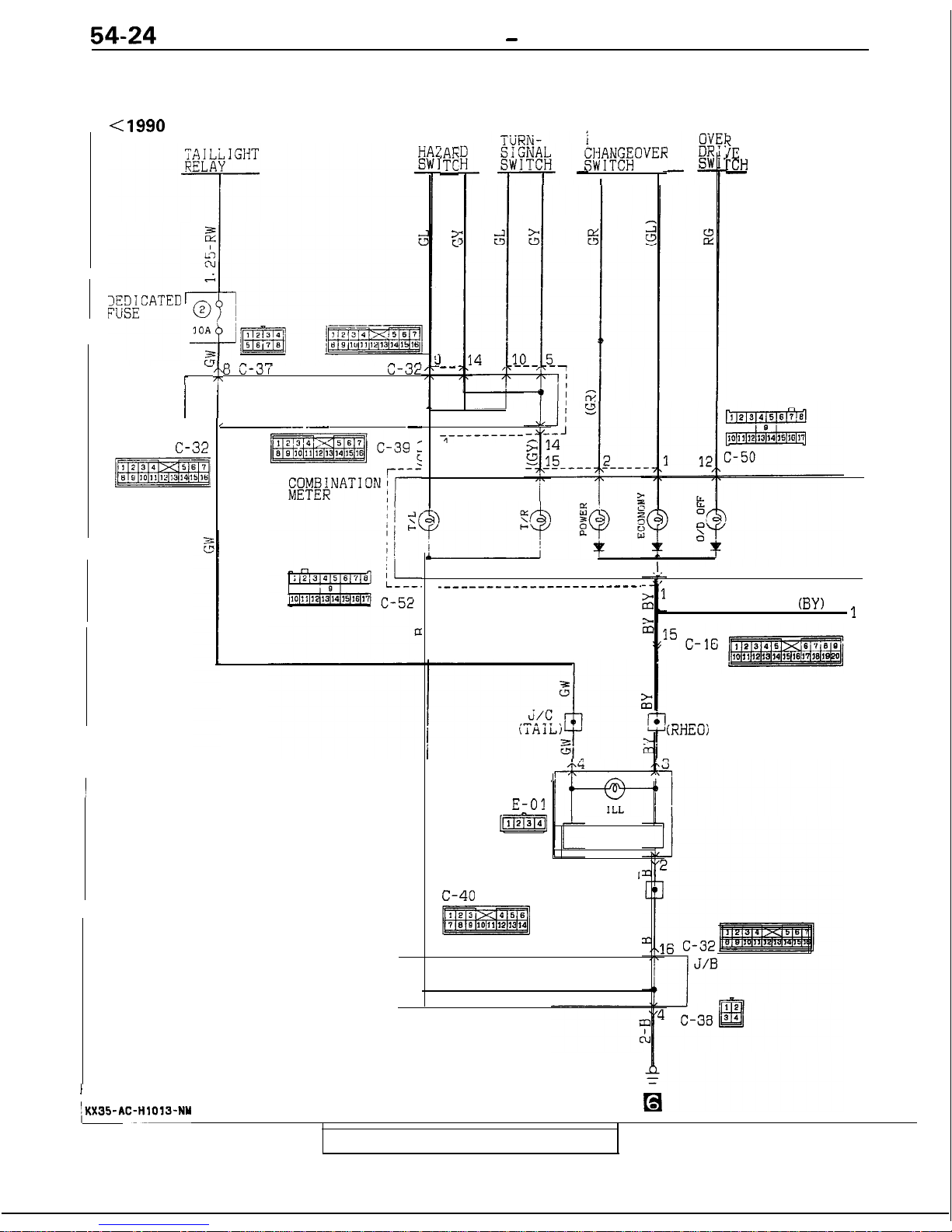

54-24

METERS AND GAUGES - Troubleshooting

INDICATOR LIGHT CIRCUIT

CIRCUIT DIAGRAM

< 1990

models>

POWER/

ECONOMY

iZ(jf'E;OVER

I

3c

TCH

-

YE

-

5

I

--

r

u

r ?:

0 C-37

C-32

J/B

I

I

,

-- .-

-

I---------

*

0

C-32

p7zmsJq

2

----------

____---_-_-_--_____-----.

6

0

(BY) 1

J/C

(RHEOj

RHEOSTAT

E-01

pF5i-q

J/C

'

(GROUND)

c-40

pRiz$mq

I

\KX35-AC-HlOY3-NY

TSB Revision

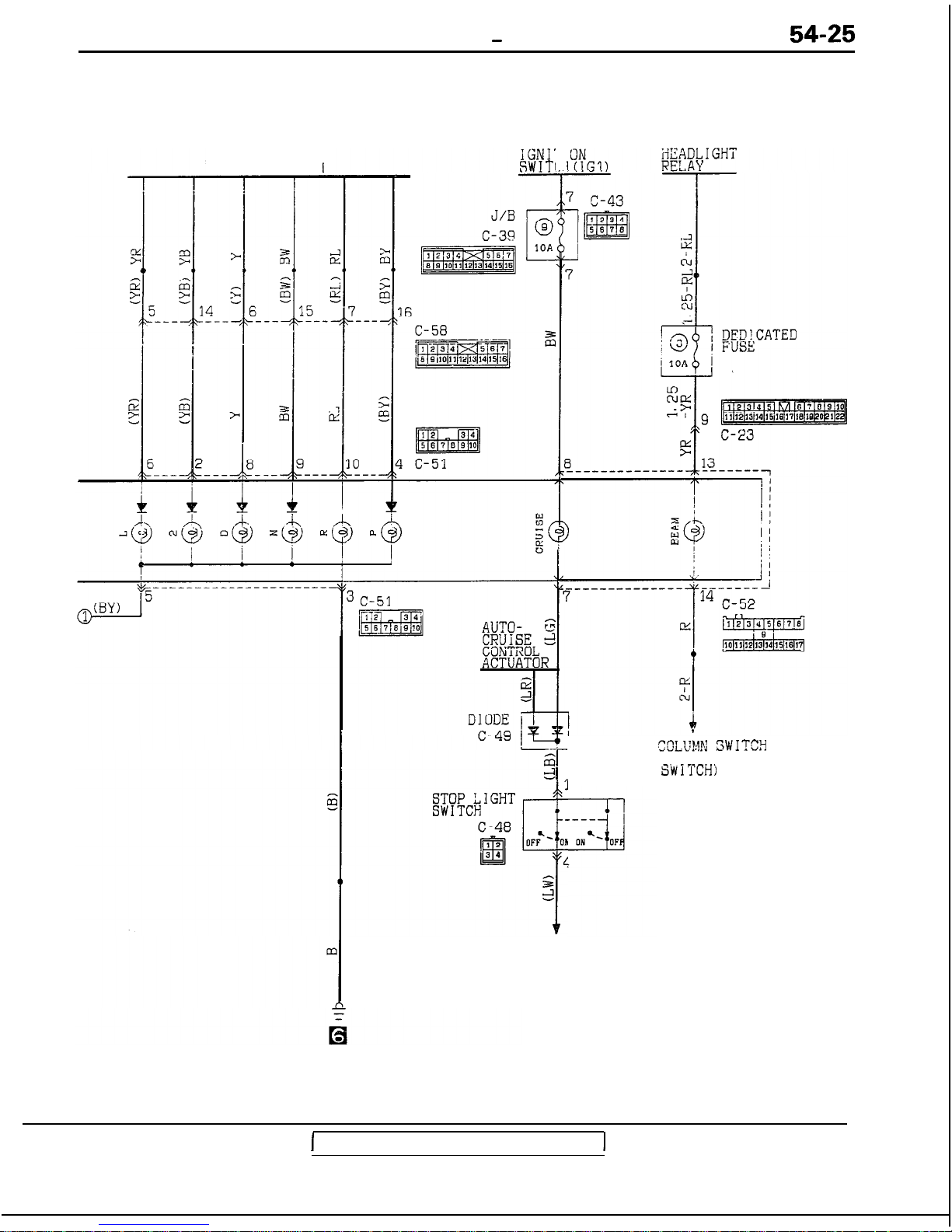

METERS AND GAUGES - Troubleshooting

54-25

PARK/NEUTRAL

POSITION SWITCH

IGNI'

SWITl

I

3

e

Oh

4

i

AUTO-CRUISE

CONTROL UNIT

COLU?J.h:

3WITCH

(DIMMER/PASSING

SWiTCHj

1

TSB Revision

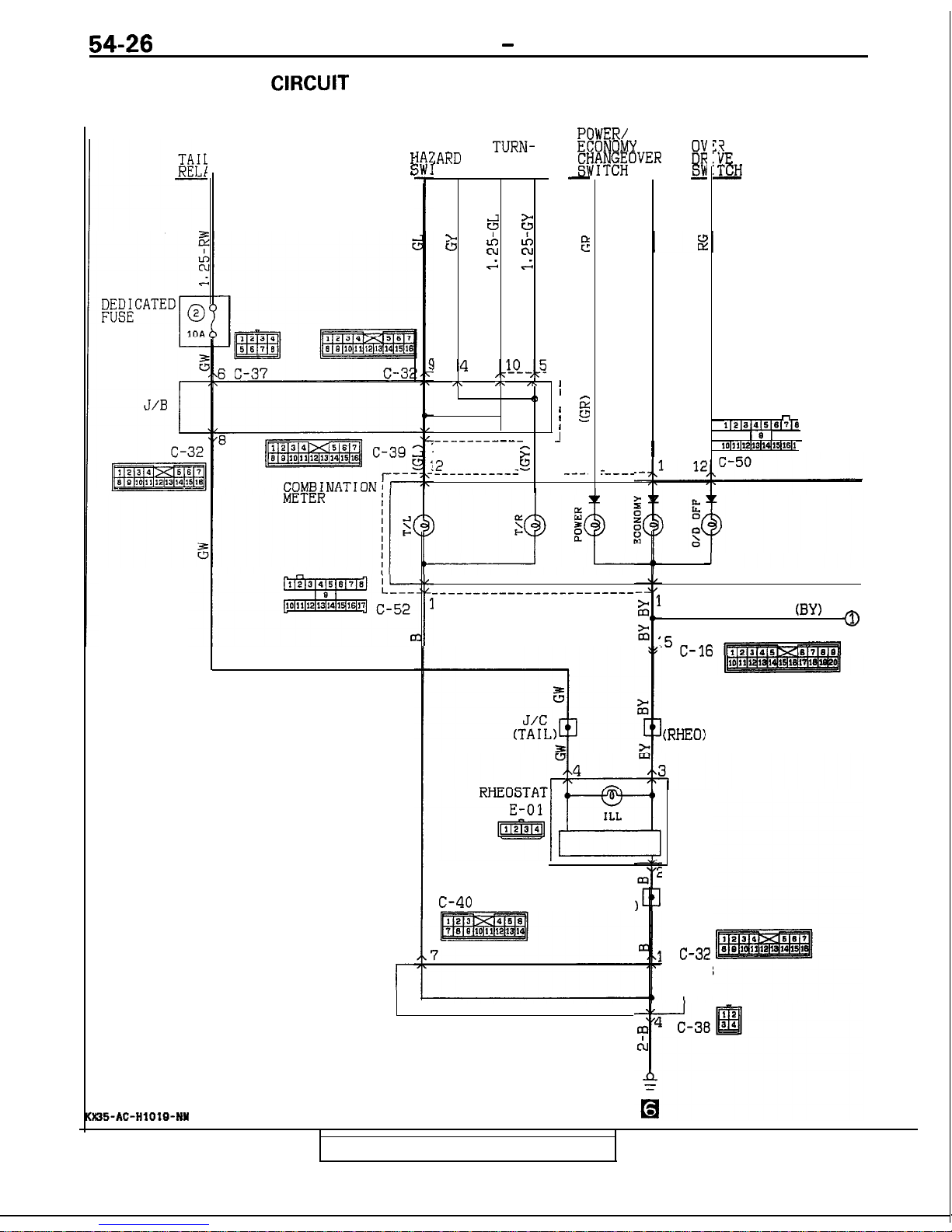

54-26

METERS AND GAUGES - Troubleshooting

INDICATOR LIGHT

CIRCUIT

CIRCUIT DIAGRAM

<From 1991 models>

35-AC-HIOYO-NY

IGHT

f

E

r

TURN-

3

:ARD

TCH

SIGNAL

Ei

SWITCH

_

>

+ +

(3

z

kc

E

.G .s

14

--

,,u?.-,c5

-1

,\ I\ ,\ I

I

<I

,

'

3

f -

::

J

---_-------

--

11

g

14

82

52

15

'__---------

---

---.

3WER/

:ONOMY

jIK!OVER

84;

T-T-

a

)

:----

_----_---------_-~_~~~~~

6

c-40

J/C

(GROUND

I

I

1

'1

:*

k

ZE

I'CH

-

n

1~2~2~4~5~8(7~8

161

l3~llll2ll3ll4llsk6ll

0

(BY) a

.5

C-16

J/C

(RHEO)

6

C-32

1

J/B

TSB Revision

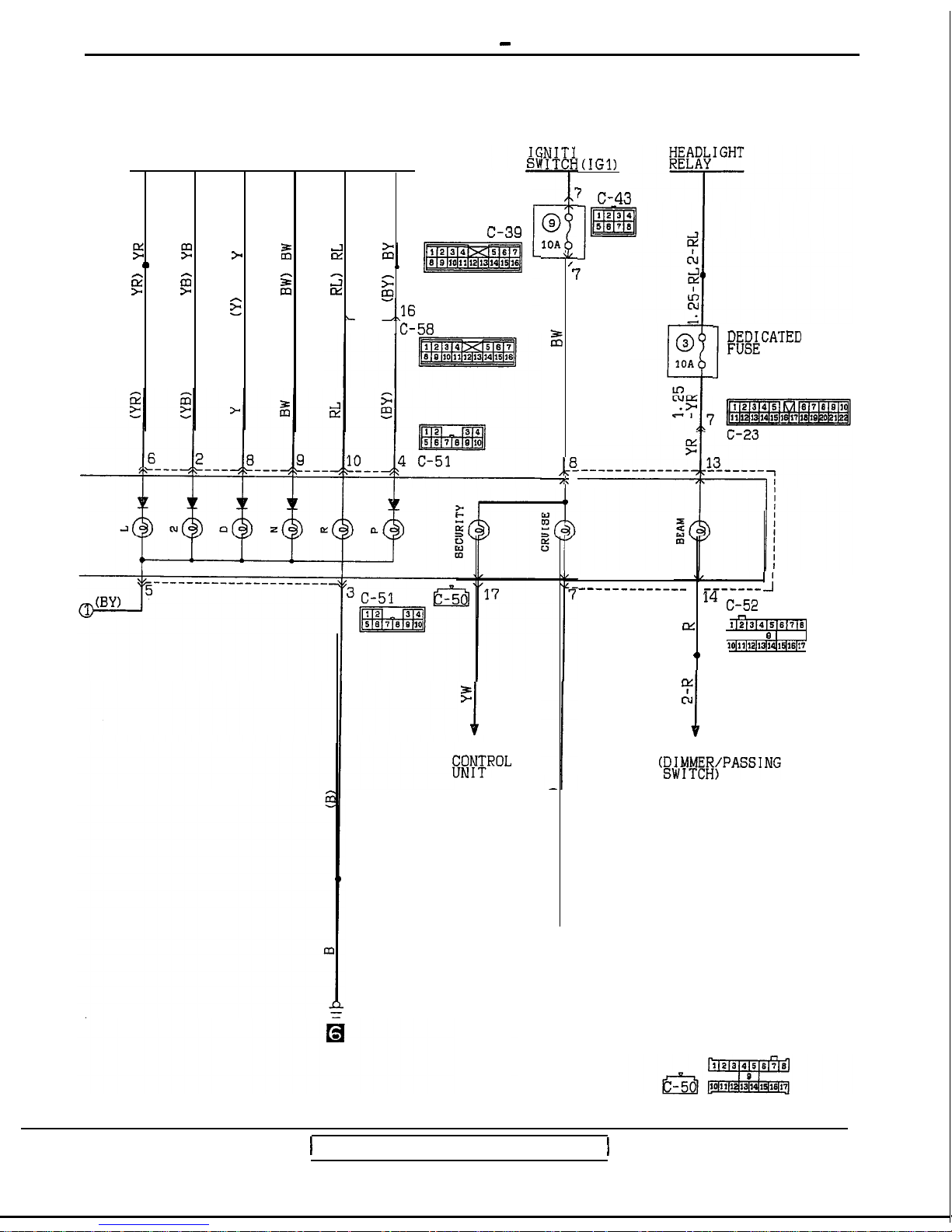

METERS AND GAUGES - Troubleshooting

54-27

PARK/NEUTRAL

POSITION SWITCH

J/B

c-39

5 5 >

z

2

0

p3TzRq

E E

-5 -14

2

2

2

6

-152-7

---

--- --- ___~___

-,l6

c-58

F

I

ETACS

iC#TROL

;NITI

IITCH

\L

I

i

z

,,8_

1.

ON

(IGl)

7 c-43

I

1

I

F&BACATED

~~-----_-_---

-----__

_;

l4 C-52

n

L1?

ll2(3l4~5f6~7~2

I 0

1

16~~1~12~13)1~15(16~17

0

II:

Al

I

COLUMN SWITCH

(&##{PASSING

AUTO-CRUISE

CONTROL UNIT

1

TSB Revision

l When the engine coolant temperature is high,

the

unit’s

resistance is low and there is a great

flow of current in the circuit, so the gauge’s

indicator indicates in the “H” area.

l When the engine coolant temperature is low,

the unit’s resistance is high and there is a small

flow of current in the circuit, so the gauge’s

indicator indicates in the “C” area.

<Reed switch>

l Pulses are produced in accordance with the

vehicle speed, and vehicle-speed signals are

input to systems (the transaxle-control system,

etc.) that regulate according to the vehicle

speed.

NOTE

For operation of warning light and indicator light,

refer to

P.54-36.

3. Systems dependent upon control according to

the vehicle speed do not function correctly.

l Check the reed switch (located within the

speedometer).

4. The meter illumination light does not illuminate.

(1)

The tail lights illuminate.

l Check the rheostat.

.

i

TSB Revision

54-28

METERS AND GAUGES

-

Troubleshooting

OPERATION

<Fuel gauge>

l When the ignition key is at the “ON” position,

the fuel gauge is activated.

l

When there is much fuel, the unit’s resistance is

small and the current flowing in the circuit is

great, so the gauge’s indicator indicates in the

“F” area.

l

When there is little fuel, the unit’s resistance is

high and the current flowing in the circuit is

small, so the gauge’s indicator indicates in the

“E” area.

<Engine coolant temperature gauge>

l When the ignition key is at the “ON” position,

the engine coolant temperature gauge is activated.

TROUBLESHOOTING HINTS

1. The fuel gauge doesn’t function, or shows the

incorrect indication.

(1) Disconnect the connector of the fuel gauge

unit; the “F” side is indicated when terminal

3 (FWD) or 2 (AWD) is then grounded.

l Check the fuel gauge.

2. The engine coolant temperature gauge doesn’t

function, or shows the incorrect indication.

(1) The “H” side is indicated when the connec-

tor of the engine coolant temperature gauge

unit is disconnected and then grounded.

l Check the engine coolant temperature

gauge unit.

METERS AND GAUGES - Service Adjustment Procedures

54-29

Drum

stopper

16LO294

Reference value

Il.150 mm (45.3 in.)]

Front

trac

hook

Front

-L

:tion

\

-7

SERVICE ADJUSTMENT PROCEDURES

INSPECTION

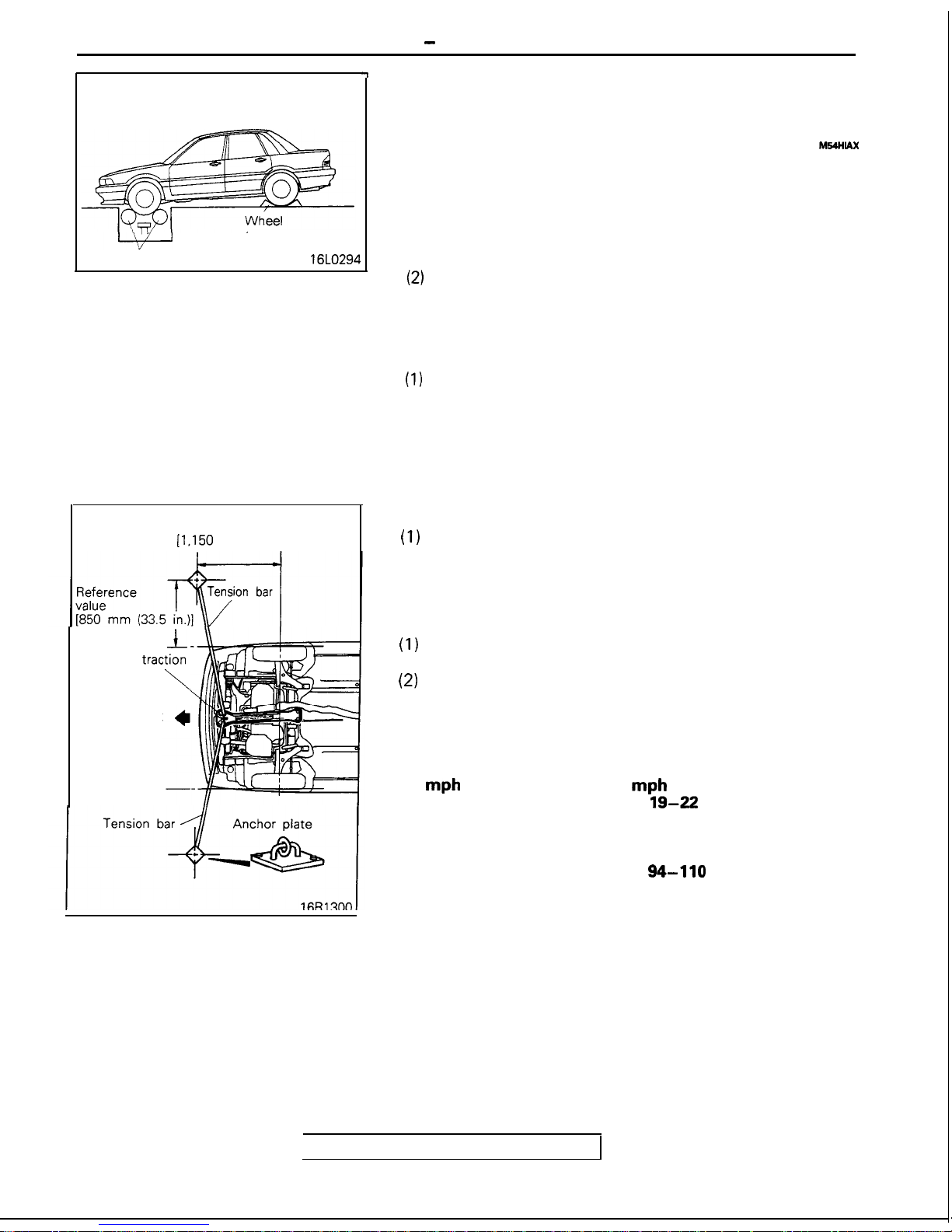

SPEEDOMETER INSPECTION

MWIAX

NOTE

For AWD models, refer to the section concerning special

handling instructions for AWD models in GROUP 00.

Take note of the following before inspection:

(1) Assure tire pressure at standard value.

(Refer to GROUP 31 -Specifications.)

(2)

When placing the vehicle on a speedometer tester drum,

make sure the center line of the vehicle is at right angles to

the center line of the drum. Also, make sure the drum is

positioned so as to center between the front tires.

Rear wheel safety procedures

(1)

Be sure to chock both rear wheels to prevent the vehicle

from moving. Secure the stoppers to the floor, or take

measures to prevent the stoppers from slipping.

(2) Make sure the parking brake has been set.

Front wheel away prevention procedure

(1)

Attach tension bars to the front traction hook. Secure the

ends of both bars to anchor plates.

(2) Make sure the tension on the right and left bars is the

same. Also be sure there is enough tension on each bar.

Accident prevention procedures

(1)

Attach a chain or wire to the rear traction hook. Make sure

the end of the wire or chain is secured firmly.

(2)

Take all other necessary precautions.

Use a speedometer tester to measure the speedometer’s

indication error.

Standard value:

Standard indication Allowable range

mph

mph

20

19-22

40

38-44

60

57-66

80

76-88

100

94-110

TSB Revision

METERS AND GAUGES - Service Adjustment Procedures

For female

Din

(insert clip in

side awav from

lock link)

’

For male pin

(insert clip in

lock link

side)0,Lo246

<Other models>

i”

II

Intake manifold

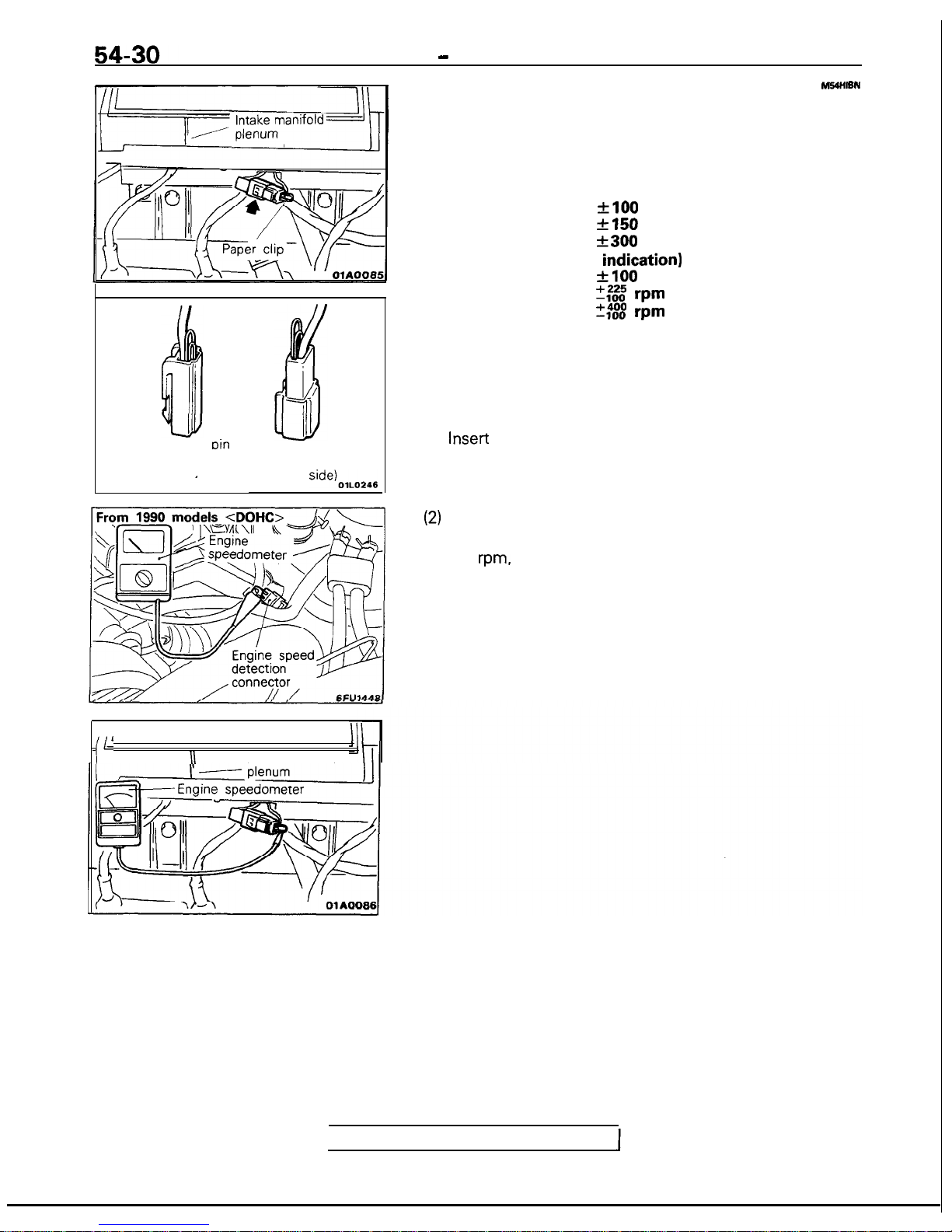

TACHOMETER

INSPECTION

MSUWSN

Connect engine speedometer and compare the engine speedometer and tachometer readings. Replace tachometer if differ-

ence is excessive.

Standard value:

Type 1 (8,000 rpm indication)

700 rpm

flO0

rpm

3,000 rpm

f150

rpm

6,000 rpm

f300

rpm

Type 2 (9,000 rpm

indication)

700 rpm

flO0

rpm

3,000 rpm

7,000 rpm

2; vm

-100

vm

Caution

As the tachometer is negative grounded, do not connect

battery conversely to prevent damaging transistor and

diode.

Connect the engine speedometer.

(1) Insert the paper clip from behind the connector.

Caution

Insert the paper clip parallel to the terminal surface as

shown in the figure at left.

(2)

Connect the engine speedometer to the inserted clip.

NOTE (From 1990 models <DOHC>)

For

rpm.

one-half of the actual engine rpm is indicated, so

the actual engine rpm is two times the indicated value

shown by the tachometer.

TSB Revision

Loading...

Loading...