Mitsubishi 4G1 User Manual

11A-0-1

ENGINE

4G1 SERIES

CONTENTS

GENERAL INFORMATION |

11A-0-3 |

|

|

||

|

||

1. SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 11A-1-1 |

|

SERVICE SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

11A-1-1 |

|

REWORK DIMENSIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

11A-1-3 |

|

TORQUE SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

11A-1-4 |

|

NEW TIGHTENING METHOD - BY USE OF BOLTS TO BE |

|

|

TIGHTENED IN PLASTIC AREA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

11A-1-6 |

|

SEALANT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

11A-1-6 |

|

FORM-IN-PLACE GASKET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

11A-1-7 |

|

2. SPECIAL TOOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

11A-2-1 |

|

3. ALTERNATOR AND IGNITION SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . |

11A-3-1 |

|

4. TIMING BELT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

11A-4-1 |

|

5. FUEL AND EMISSION CONTROL SYSTEM . . . . . . . . . . . . . . . . . . . . |

11A-5-1 |

|

6. WATER PUMP AND WATER HOSE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

11A-6-1 |

|

7. INTAKE AND EXHAUST MANIFOLD . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

11A-7-1 |

|

8. ROCKER ARMS AND CAMSHAFT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

11A-8-1 |

|

9. CYLINDER HEAD AND VALVES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

11A-9-1 |

|

10. OIL PUMP AND OIL PAN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

11A-10-1 |

|

11. PISTON AND CONNECTING ROD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

11A-11-1 |

|

12. CRANKSHAFT, CYLINDER BLOCK . . . . . . . . . . . . . . . . . . . . . . . . . . . |

11A-12-1 |

|

|

|

|

|

|

|

E Mitsubishi Motors Corporation |

Nov. 1995 |

PWEE9520 |

11A-0-2

NOTES

E Mitsubishi Motors Corporation |

Nov. 1995 |

PWEE9520 |

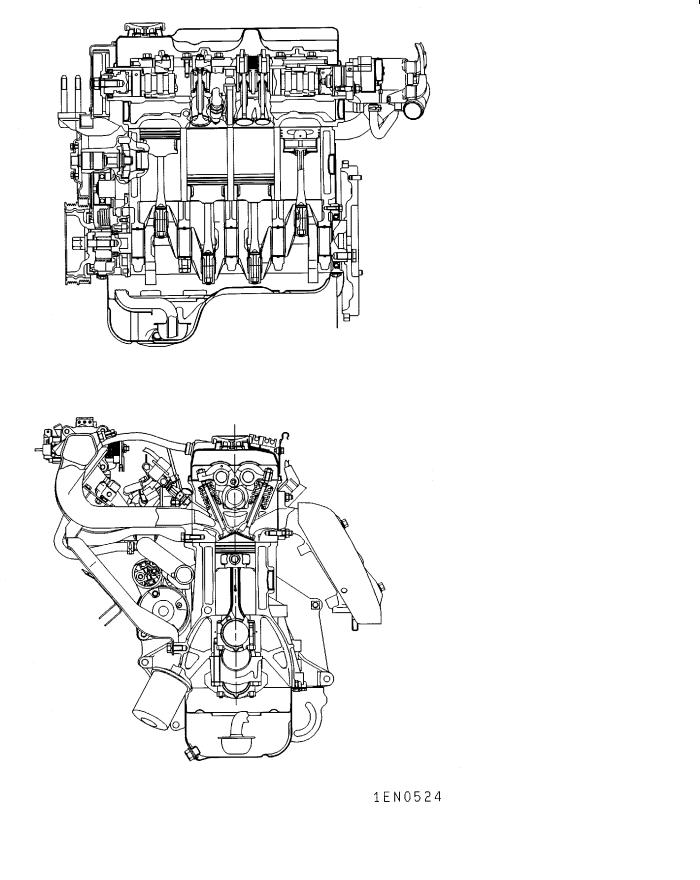

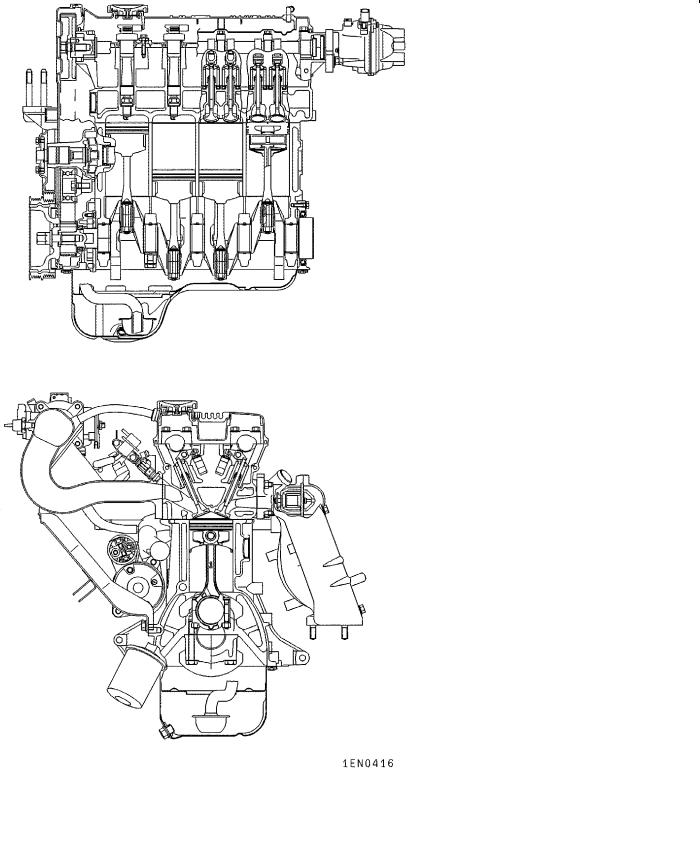

4G1 ENGINE (E - W) - General Information |

11A-0-3 |

GENERAL INFORMATION

E Mitsubishi Motors Corporation |

Nov. 1995 |

PWEE9520 |

11A-0-4 |

4G1 ENGINE (E - W) - General Information |

E Mitsubishi Motors Corporation |

Nov. 1995 |

PWEE9520 |

|

|

4G1 ENGINE (E - W) - General Information |

11A-0-5 |

||

|

|

|

|

|

|

Descriptions |

|

4G13 12-VALVE-CARBURETOR |

4G13 12-VALVE-MPI |

|

|

|

|

|

|

|

|

Type |

|

In-line OHV, SOHC |

In-line OHV, SOHC |

|

|

|

|

|

|

|

|

Number of cylinders |

4 |

4 |

|

||

|

|

|

|

|

|

Combustion chamber |

Pentroof type |

Pentroof type |

|

||

|

|

|

|

|

|

Total displacement dm3 |

1,299 |

1,299 |

|

||

Cylinder bore mm |

71.0 |

71.0 |

|

||

|

|

|

|

|

|

Piston stroke mm |

82.0 |

82.0 |

|

||

|

|

|

|

|

|

Compression ratio |

9.5 |

9.5 |

|

||

|

|

|

|

|

|

Number of |

|

Intake |

8 |

8 |

|

valves |

|

|

|

|

|

|

Exhaust |

4 |

4 |

|

|

|

|

|

|||

|

|

|

|

|

|

Valve timing |

|

Intake opens |

BTDC 14_ |

BTDC 19_ |

|

|

|

|

|

|

|

|

|

Intake closes |

ABDC 48_ |

ABDC 43_ |

|

|

|

|

|

|

|

|

|

Exhaust opens |

BBDC 55_ |

BBDC 60_ |

|

|

|

|

|

|

|

|

|

Exhaust closes |

ATDC 13_ |

ATDC 8_ |

|

|

|

|

|

||

Lubrication system |

Pressure feed, full-flow filtration |

Pressure feed, full-flow filtration |

|||

|

|

|

|

|

|

Oil pump type |

|

Trochoid type |

Trochoid type |

|

|

|

|

|

|

||

Cooling system |

|

Water-cooled, forced circulation |

Water-cooled, forced circulation |

||

|

|

|

|

||

Water pump type |

Centrifugal impeller type |

Centrifugal impeller type |

|

||

|

|

|

|

|

|

E Mitsubishi Motors Corporation |

DecNov. 19985 |

PWEE9520-A |

Revised |

11A-0-6 |

4G1 ENGINE (E - W) - General Information |

|||

|

|

|

|

|

Descriptions |

|

4G13 16-VALVE-MPI |

4G18 16-VALVE-MPI |

|

|

|

|

|

|

Type |

|

In-line OHV, SOHC |

In-line OHV, SOHC |

|

|

|

|

|

|

Number of cylinders |

4 |

4 |

||

|

|

|

|

|

Combustion chamber |

Pentroof type |

Pentroof type |

||

|

|

|

|

|

Total displacement dm3 |

1,299 |

1,584 |

||

Cylinder bore mm |

71.0 |

76.0 |

||

|

|

|

|

|

Piston stroke mm |

82.0 |

87.3 |

||

|

|

|

|

|

Compression ratio |

10 |

9.5 |

||

|

|

|

|

|

Number of |

|

Intake |

8 |

8 |

valves |

|

|

|

|

|

Exhaust |

8 |

8 |

|

|

|

|||

|

|

|

|

|

Valve timing |

|

Intake opens |

BTDC 17_ |

BTDC 17_ |

|

|

|

|

|

|

|

Intake closes |

ABDC 39_ |

ABDC 39_ |

|

|

|

|

|

|

|

Exhaust opens |

BBDC 49_ |

BBDC 49_ |

|

|

|

|

|

|

|

Exhaust closes |

ATDC 7_ |

ATDC 7_ |

|

|

|

|

|

Lubrication system |

Pressure feed, full-flow filtration |

Pressure feed, full-flow filtration |

||

|

|

|

|

|

Oil pump type |

|

Trochoid type |

Trochoid type |

|

|

|

|

|

|

Cooling system |

|

Water-cooled, forced circulation |

Water-cooled, forced circulation |

|

|

|

|

||

Water pump type |

Centrifugal impeller type |

Centrifugal impeller type |

||

|

|

|

|

|

E Mitsubishi Motors Corporation |

DecNov. 19985 |

PWEE9520-A |

Revised |

|

|

4G1 ENGINE (E - W) - General Information |

11A-0-7 |

||

|

|

|

|

|

|

Descriptions |

|

4G15-CARBURETTOR |

4G15-MPI |

|

|

|

|

|

|

|

|

Type |

|

In-line OHV, SOHC |

In-line OHV, DOHC |

|

|

|

|

|

|

|

|

Number of cylinders |

4 |

4 |

|

||

|

|

|

|

|

|

Combustion chamber |

Semi spherical type |

Pentroof type |

|

||

|

|

|

|

|

|

Total displacement dm3 |

1,468 |

1,468 |

|

||

Cylinder bore mm |

75.5 |

75.5 |

|

||

|

|

|

|

|

|

Piston stroke mm |

82.0 |

82.0 |

|

||

|

|

|

|

|

|

Compression ratio |

9.0 |

9.5 |

|

||

|

|

|

|

|

|

Number of |

|

Intake |

8 |

8 |

|

valve |

|

|

|

|

|

|

Exhaust |

4 |

8 |

|

|

|

|

|

|||

|

|

|

|

|

|

Valve timing |

|

Intake opens |

BTDC 14_ |

BTDC 16_ |

|

|

|

|

|

|

|

|

|

Intake closes |

ABDC 48_ |

ABDC 40_ |

|

|

|

|

|

|

|

|

|

Exhaust opens |

BBDC 55_ |

BBDC 45_ |

|

|

|

|

|

|

|

|

|

Exhaust closes |

ATDC 13_ |

ATDC 15 _ |

|

|

|

|

|

||

Lubrication system |

Pressure feed, full-flow filtration |

Pressure feed, full-flow filtration |

|||

|

|

|

|

|

|

Oil pump type |

|

Trochoid type |

Trochoid type |

|

|

|

|

|

|

||

Cooling system |

|

Water-cooled, forced circulation |

Water-cooled, forced circulation |

||

|

|

|

|

||

Water pump type |

Centrifugal impeller type |

Centrifugal impeller type |

|

||

|

|

|

|

|

|

E Mitsubishi Motors Corporation |

DecNov. 19985 |

PWEE9520-A |

Added |

NOTES

|

4G1 ENGINE (E - W) - Specifications |

11A-1-1 |

|||

1. SPECIFICATIONS |

|

|

|

|

|

SERVICE SPECIFICATIONS |

|

|

|

|

|

|

|

|

|

|

|

Item |

|

|

Standard |

Limit |

|

|

|

|

|

|

|

Rocker arms, rocker shafts, and camshaft |

|

|

|

|

|

|

|

|

|

|

|

Camshaft cam |

SOHC 12-VALVE |

Intake (primary) |

38.78 |

|

38.28 |

height mm |

|

|

|

|

|

|

Intake (secondary) |

38.78 |

|

38.28 |

|

|

|

|

|||

|

|

|

|

|

|

|

|

Exhaust |

39.10 |

|

38.60 |

|

|

|

|

|

|

|

SOHC 16-VALVE |

Intake |

36.99 |

|

36.49 |

|

|

|

|

|

|

|

|

Exhaust |

36.85 |

|

36.35 |

|

|

|

|

|

|

|

DOHC |

Intake |

34.67 |

|

38.28 |

|

|

|

|

|

|

|

|

Exhaust |

34.26 |

|

38.60 |

|

|

|

|

|

|

Camshaft journal diameter mm |

SOHC |

45.9345.94 |

- |

||

|

|

|

|

|

|

|

|

DOHC |

25.9525.97 |

- |

|

|

|

|

|

|

|

Cylinder head and valves |

|

|

|

|

|

|

|

|

|

||

Flatness of cylinder head gasket surface mm |

|

0.05 or less |

- |

||

|

|

|

|

||

Cylinder head gasket surface grinding limit (including grinding of |

- |

|

0.2 |

||

cylinder block gasket surface) mm |

|

|

|

|

|

|

|

|

|

||

Cylinder head overall height mm |

SOHC 12-VALVE |

106.9- 107.1 |

- |

||

|

|

|

|

|

|

|

|

SOHC 16-VALVE |

119.9- 120.1 |

- |

|

|

|

|

|

|

|

|

|

DOHC |

131.9- 132.1 |

- |

|

|

|

|

|

|

|

Cylinder head bolt nominal length mm |

|

- |

|

103.2 |

|

|

|

|

|

|

|

Valve margin mm |

|

Intake |

1.0 |

|

0.5 |

|

|

|

|

|

|

|

|

Exhaust |

1.5 |

|

1.0 |

|

|

|

|

|

|

Valve stem diameter mm |

SOHC 12-VALVE |

6.6 |

|

- |

|

|

|

|

|

|

|

|

|

SOHC 16-VALVE |

5.5 |

|

- |

|

|

|

|

|

|

|

|

DOHC |

5.5 |

|

- |

|

|

|

|

|

|

Valve stem-to-guide |

SOHC 12-VALVE |

Intake |

0.020- 0.050 |

0.10 |

|

clearance mm |

|

|

|

|

|

|

Exhaust |

0.050- 0.085 |

0.15 |

||

|

|

||||

|

|

|

|

|

|

|

SOHC 16-VALVE |

Intake |

0.020 - 0.047 |

0.10 |

|

|

|

|

|

|

|

|

|

Exhaust |

0.030 |

- 0.062 |

0.15 |

|

|

|

|

|

|

|

DOHC |

Intake |

0.020- 0.047 |

0.10 |

|

|

|

|

|

|

|

|

|

Exhaust |

0.030- 0.062 |

0.15 |

|

|

|

|

|

|

|

Valve face angle |

|

|

45_45.5_ |

- |

|

|

|

|

|

|

|

Valve stem projec- |

SOHC 12-VALVE |

Intake |

43.70 |

|

44.20 |

tion mm |

|

|

|

|

|

|

Exhaust |

43.30 |

|

43.80 |

|

|

|

|

|||

|

|

|

|

|

|

|

SOHC 16-VALVE |

Intake |

53.21 |

|

53.71 |

|

|

|

|

|

|

|

|

Exhaust |

54.10 |

|

54.60 |

|

|

|

|

|

|

|

DOHC |

Intake |

48.80 |

|

49.30 |

|

|

|

|

|

|

|

|

Exhaust |

48.70 |

|

49.20 |

|

|

|

|

|

|

E Mitsubishi Motors Corporation |

DecNov. 19985 |

PWEE9520-A |

Revised |

11A-1-2 |

|

|

4G1 ENGINE (E - W) - Specifications |

|

|||

|

|

|

|

|

|

|

|

Item |

|

|

|

|

|

Standard |

Limit |

|

|

|

|

|

|

||

Overall valve length |

|

SOHC 12-VALVE |

Intake |

100.75 |

100.25 |

||

mm |

|

|

|

|

|

|

|

|

|

|

|

Exhaust |

101.05 |

105.55 |

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

SOHC 16-VALVE |

Intake |

111.56 |

111.06 |

|

|

|

|

|

|

|

|

|

|

|

|

|

Exhaust |

114.71 |

114.21 |

|

|

|

|

|

|

|

|

|

|

|

|

DOHC |

Intake |

106.35 |

105.85 |

|

|

|

|

|

|

|

|

|

|

|

|

|

Exhaust |

106.85 |

106.35 |

|

|

|

|

|

|

|

|

Valve |

spring |

free |

|

SOHC 12-VALVE |

Intake |

46.1 |

45.6 |

height mm |

|

|

|

|

|

|

|

|

|

|

Exhaust |

46.8 |

46.3 |

||

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

SOHC 16-VALVE |

|

50.9 |

50.4 |

|

|

|

|

|

|

|

|

|

|

|

|

DOHC |

|

49.1 |

48.6 |

|

|

|

|

|

|

|

|

Valve |

spring |

load/ |

|

SOHC 12-VALVE |

Intake |

226/40.0 |

- |

installed height N/ |

|

|

|

|

|

||

|

|

Exhaust |

284/39.6 |

- |

|||

mm |

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

SOHC 16-VALVE |

|

216/44.2 |

- |

|

|

|

|

|

|

|

|

|

|

|

|

DOHC |

|

177/40.0 |

- |

|

|

|

|

|

|||

Valve spring squareness |

|

2_ |

4_ |

||||

|

|

|

|

||||

Valve seat contact width mm |

|

0.9- 1.3 |

- |

||||

|

|

|

|

||||

Valve guide internal diameter mm |

SOHC 12-VALVE |

6.6 |

- |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

SOHC 16-VALVE |

5.5 |

- |

|

|

|

|

|

|

|

|

|

|

|

|

|

DOHC |

5.5 |

- |

|

|

|

|

||||

Valve guide projection mm |

SOHC 12-VALVE |

17.0 |

- |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

SOHC 16-VALVE |

23.0 |

- |

|

|

|

|

|

|

|

|

|

|

|

|

|

DOHC |

23.0 |

- |

|

|

|

|

|

|||

Oil pump and oil pan |

|

|

|

|

|||

|

|

|

|

||||

Oil pump tip clearance mm |

|

0.06- 0.18 |

- |

||||

|

|

|

|

||||

Oil pump side clearance mm |

|

0.04- 0.10 |

- |

||||

|

|

|

|

||||

Oil pump body clearance mm |

|

0.10- 0.18 |

0.35 |

||||

|

|

|

|

||||

Pistons and connecting rods |

|

|

|

||||

|

|

|

|

||||

Piston outside diameter mm |

4G13 |

71.0 |

- |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

4G15 |

75.5 |

- |

|

|

|

|

|

|

|

|

|

|

|

|

|

4G18 |

76.0 |

- |

|

|

|

|

||||

Piston ring side clearance mm |

No. 1 ring |

0.02- 0.06 |

- |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

No. 2 ring |

0.02- 0.06 |

- |

|

|

|

|

||||

Piston ring end gap clearance |

No. 1 ring |

0.20- 0.35 |

0.8 |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

No. 2 ring |

0.35- 0.50 |

0.8 |

|

|

|

|

|

|

|

|

|

|

|

|

|

Oil ring |

0.20- 0.50 |

1.0 |

|

|

|

|

|

|||

Piston pin O. D. mm |

|

|

18.0 |

- |

|||

|

|

|

|||||

Piston pin press-in load (at room temperature) N |

4,90014,700 |

- |

|||||

|

|

|

|

||||

Crankshaft pin oil clearance mm |

|

0.02- 0.04 |

0.1 |

||||

|

|

|

|

||||

Connecting rod big end side clearance mm |

|

0.10- 0.25 |

0.4 |

||||

|

|

|

|

|

|

|

|

E Mitsubishi Motors Corporation |

DecNov. 19985 |

PWEE9520-A |

Revised |

4G1 ENGINE (E - W) - Specifications |

11A-1-2a |

||

|

|

|

|

Item |

|

Standard |

Limit |

|

|

|

|

Crankshaft and cylinder block |

|

|

|

|

|

|

|

Crankshaft end play mm |

|

0.05- 0.18 |

0.25 |

|

|

|

|

Crankshaft journal diameter mm |

|

48.0 |

- |

|

|

|

|

Crankshaft pin diameter mm |

|

42.0 |

- |

|

|

|

|

Crankshaft journal oil clearance mm |

|

0.02- 0.04 |

0.1 |

|

|

|

|

Cylinder block gasket surface flatness mm |

|

0.05 or less |

- |

|

|

|

|

Cylinder block gasket surface grinding limit (including grinding of |

- |

0.2 |

|

cylinder head gasket surface) mm |

|

|

|

|

|

|

|

Cylinder block overall height mm |

|

256 |

- |

|

|

|

|

Cylinder block cylindricity mm |

|

0.01 |

- |

|

|

|

|

Cylinder block I. D. mm |

4G13 |

71.0 |

- |

|

|

|

|

|

4G15 |

75.5 |

- |

|

|

|

|

|

4G18 |

76.0 |

- |

|

|

|

|

Piston-to-cylinder clearance mm |

|

0.02- 0.04 |

- |

|

|

|

|

E Mitsubishi Motors Corporation |

DecNov. 19985 |

PWEE9520-A |

Added |

11A-1-2b |

4G1 ENGINE (E - W) - Specifications |

Intentionally blank

E Mitsubishi Motors Corporation |

Dec.Nov 19985 |

PWEE9520-A |

Added |

|

4G1 ENGINE (E - W) - Specifications |

11A-1-3 |

|||

REWORK DIMENSIONS |

|

|

|

|

|

|

|

|

|

|

|

Item |

|

|

|

Standard |

Limit |

|

|

|

|

|

|

Cylinder head and valves |

|

|

|

|

|

|

|

|

|

|

|

Cylinder head oversize valve guide |

SOHC 12-VALVE |

0.05 O. S. |

12.05012.068 |

- |

|

hole diameter mm |

|

|

|

|

|

|

|

0.25 O. S. |

12.25012.268 |

- |

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

0.50 O. S. |

12.50012.518 |

- |

|

|

|

|

|

|

|

|

SOHC 16-VALVE |

0.05 O. S. |

10.55010.568 |

- |

|

|

|

|

|

|

|

|

|

0.25 O. S. |

10.75010.768 |

- |

|

|

|

|

|

|

|

|

|

0.50 O. S. |

11.00011.018 |

- |

|

|

|

|

|

|

|

|

DOHC |

0.05 O. S. |

10.55010.568 |

- |

|

|

|

|

|

|

|

|

|

0.25 O. S. |

10.75010.768 |

- |

|

|

|

|

|

|

|

|

|

0.50 O. S. |

11.00011.018 |

- |

|

|

|

|

|

|

Oversize valve seat |

SOHC |

Intake (primary) |

0.3 O. S. |

27.30027.325 |

- |

ring hole diameter |

12-VALVE |

|

|

|

|

|

0.6 O. S. |

27.60027.625 |

- |

||

mm |

|

|

|||

|

|

|

|

|

|

|

|

Intake (secondary) |

0.3 O. S. |

32.30032.325 |

- |

|

|

|

|

|

|

|

|

|

0.6 O. S. |

32.60032.625 |

- |

|

|

|

|

|

|

|

|

Exhaust |

0.3 O. S. |

35.30035.325 |

- |

|

|

|

|

|

|

|

|

|

0.6 O. S. |

35.60035.625 |

- |

|

|

|

|

|

|

|

SOHC |

Intake |

0.3 O. S. |

28.30028.321 |

- |

|

16-VALVE |

|

|

|

|

|

|

0.6 O. S. |

28.60028.621 |

- |

|

|

<4G13> |

|

|||

|

|

|

|

|

|

|

|

Exhaust |

0.3 O. S. |

26.30026.321 |

- |

|

|

|

|

|

|

|

|

|

0.6 O. S. |

26.60026.621 |

- |

|

|

|

|

|

|

|

SOHC |

Intake |

0.3 O. S. |

30.30030.321 |

- |

|

16-VALVE |

|

|

|

|

|

|

0.6 O. S. |

30.60030.621 |

- |

|

|

<4G18> |

|

|||

|

|

|

|

|

|

|

|

Exhaust |

0.3 O. S. |

28.30028.321 |

- |

|

|

|

|

|

|

|

|

|

0.6 O. S. |

28.60028.621 |

- |

|

|

|

|

|

|

|

DOHC |

Intake |

0.3 O. S. |

31.30031.325 |

- |

|

|

|

|

|

|

|

|

|

0.6 O. S. |

31.60031.625 |

- |

|

|

|

|

|

|

|

|

Exhaust |

0.3 O. S. |

27.80027.825 |

- |

|

|

|

|

|

|

|

|

|

0.6 O. S. |

28.10028.125 |

- |

|

|

|

|

|

|

E Mitsubishi Motors Corporation |

DecNov. 19985 |

PWEE9520-A |

Revised |

11A-1-4 |

4G1 ENGINE (E - W) - Specifications |

||

TORQUE SPECIFICATIONS |

|

||

|

|

|

|

Item |

|

|

Nm |

|

|

|

|

Alternator and ignition system |

|

||

|

|

|

|

Water pump pulley bolt |

|

|

9 |

|

|

|

|

Alternator brace (alternator side) |

|

|

22 |

|

|

|

|

Alternator brace (tightened with water pump) |

23 |

||

|

|

|

|

Alternator pivot bolt |

|

|

44 |

|

|

|

|

Oil level gauge guide |

|

|

23 |

|

|

|

|

Crankshaft bolt |

|

|

125 |

|

|

|

|

Spark plug |

|

|

25 |

|

|

|

|

Distributor |

|

|

11 |

|

|

|

|

Ignition coil |

|

|

10 |

|

|

|

|

Camshaft position sensor |

|

|

9 |

|

|

|

|

Camshaft position sensor support |

13 |

||

|

|

|

|

Camshaft position sensing cylinder |

21 |

||

|

|

|

|

Timing belt |

|

|

|

|

|

|

|

Timing belt cover |

|

|

11 |

|

|

|

|

Timing belt tensioner |

|

|

23 |

|

|

|

|

Crankshaft angle sensor (Rear wheel drive) |

9 |

||

|

|

|

|

Engine support bracket (left) |

|

|

35 |

|

|

|

|

Idler pulley |

|

|

35 |

|

|

|

|

Camshaft sprocket bolt |

|

|

88 |

|

|

|

|

Fuel system |

|

|

|

|

|

|

|

Delivery pipe |

|

|

11 |

|

|

|

|

Fuel pressure regulator |

|

|

9 |

|

|

|

|

Throttle body |

|

|

18 |

|

|

|

|

Fuel pump |

|

|

11 |

|

|

|

|

Breather tube |

|

|

22 |

|

|

|

|

Carburetor |

|

|

17 |

|

|

|

|

Air temperature sensor |

|

|

13 |

|

|

|

|

EGR valve |

|

|

21 |

|

|

|

|

Water pump |

|

|

|

|

|

|

|

Water inlet fitting |

|

|

22 |

|

|

|

|

Water inlet pipe assembly |

|

|

12 |

|

|

|

|

Water inlet pipe |

|

M6 |

12 |

|

|

|

|

|

|

M8 |

25 |

|

|

|

|

Fitting (Rear wheel drive) |

|

|

23 |

|

|

||

Water outlet fitting (Rear wheel drive) |

23 |

||

|

|

|

|

Thermostat case |

|

|

23 |

|

|

|

|

E Mitsubishi Motors Corporation |

DecNov. 19985 |

PWEE9520-A |

Revised |

|

4G1 ENGINE (E - W) - Specifications |

11A-1-5 |

|||

|

|

|

|

|

|

Item |

|

|

Nm |

|

|

|

|

|

|

|

|

Thermo valve |

|

|

27 |

|

|

|

|

|

|

|

|

Water temperature gauge unit |

|

|

11 |

|

|

|

|

|

|

|

|

Water temperature sensor |

|

|

29 |

|

|

|

|

|

|

|

|

Water pump |

|

|

13 |

|

|

|

|

|

|

|

|

Exhaust manifold and intake manifold |

|

|

|

||

|

|

|

|

|

|

Boost sensor |

|

|

5 |

|

|

|

|

|

|

|

|

Solenoid valve assembly |

|

|

9 |

|

|

|

|

|

|

|

|

Intake manifold |

|

|

17 |

|

|

|

|

|

|

|

|

Intake manifold stay (MPI) |

|

M8 |

17 |

|

|

|

|

|

|

|

|

|

|

M10 |

21 |

|

|

|

|

|

|

|

|

Intake manifold stay (carburetor) |

|

|

29 |

|

|

|

|

|

|

|

|

Exhaust manifold cover |

|

|

29 |

|

|

|

|

|

|

|

|

Exhaust manifold |

|

M8 |

17 |

|

|

|

|

|

|

|

|

|

|

M10 |

29 |

|

|

|

|

|

|

|

|

Oxygen sensor |

|

|

44 |

|

|

|

|

|

|

||

Rocker arms, rocker shafts, and camshaft |

|

|

|

||

|

|

|

|

|

|

Fuel pump cover |

|

|

12 |

|

|

|

|

|

|

|

|

Rocker cover |

|

|

4 |

|

|

|

|

|

|

|

|

Rocker shaft assembly |

|

|

31 |

|

|

|

|

|

|

|

|

Adjusting screw |

|

|

15 |

|

|

|

|

|

|

|

|

Bearing cap |

|

|

24 |

|

|

|

|

|

|

|

|

|

|

|

11 |

|

|

|

|

|

|

|

|

Cylinder head and valves |

|

|

|

|

|

|

|

|

|

|

|

Cylinder head bolt |

|

|

20 |

+ 90_ + 90_ |

|

Tighten to 49 Nm, then completely loosen and retighten as described. |

|

|

|

||

|

|

|

|||

|

|

|

|

|

|

Oil pump and oil pan |

|

|

|

|

|

|

|

|

|

|

|

Transmission stay |

|

|

23 |

|

|

|

|

|

|

|

|

Oil pan |

|

|

7 |

|

|

|

|

|

|

|

|

Drain plug |

|

|

39 |

|

|

|

|

|

|

|

|

Oil screen |

|

|

18 |

|

|

|

|

|

|

|

|

Front case |

|

|

13 |

|

|

|

|

|

|

|

|

Relief plug |

|

|

44 |

|

|

|

|

|

|

|

|

Oil pump cover |

|

|

10 |

|

|

|

|

|

|

|

|

Pistons and connecting rods |

|

|

|

|

|

|

|

|

|

|

|

Connecting rod nut |

|

|

17 |

+ 90_ to 100_ |

|

|

|

|

|

|

|

E Mitsubishi Motors Corporation |

DecNov. 19985 |

PWEE9520-A |

Revised |

11A-1-5a |

4G1 ENGINE (E - W) - Specifications |

|

|

|

|

Item |

|

Nm |

|

|

|

Crankshaft and cylinder block |

|

|

|

|

|

Flywheel |

|

132 |

|

|

|

Drive plate |

|

132 |

|

|

|

Rear plate |

|

10 |

|

|

|

Bell housing cover |

|

10 |

|

|

|

Rear oil seal case |

|

11 |

|

|

|

Bearing cap bolt |

|

51 |

|

|

|

Oil pressure switch |

|

18 |

|

|

|

Knock sensor |

|

23 |

|

|

|

E Mitsubishi Motors Corporation |

DecNov. 19985 |

PWEE9520-A |

Added |

4G1 ENGINE (E - W) - Specifications |

11A-1-5b |

Intentionally blank

E Mitsubishi Motors Corporation |

Dec.Nov 19985 |

PWEE9520-A |

Added |

11A-1-6 |

4G1 ENGINE (E - W) - Specifications |

NEW TIGHTENING METHOD USING PLASTIC REGION TIGHTENING BOLTS

Parts of the engine use plastic region tightening bolts. The tightening procedure for these is different from that of conventional bolts and is described in relevant parts of this manual. Note that plastic region tightening bolts have fixed service limits. These limits are indicated in relevant parts of this manual and must be strictly observed.

DPlastic region tightening bolts are used for the following applications:

(1)Cylinder head bolts

(2)Connecting rod cap bolts

DThe tightening procedure is basically as follows:

After tightening a bolt to the specified torque, tighten it by a further 90 _ + 90_ or by a further 90–100°. The exact tightening procedure differs depending on the bolt and is described in relevant parts of this manual.

SEALANTS

Item |

Specified sealant |

Quantity |

|

|

|

|

|

Water pump |

Mitsubishi Genuine Part No. MD970389 or equivalent |

As required |

|

|

|

|

|

Thermo valve |

Mitsubishi Genuine Part No. MD970389 or equivalent |

As required |

|

|

|

|

|

Engine coolant temperature sensor |

3M |

Nut Locking Part No. 4171 or equivalent |

As required |

|

|

|

|

Engine coolant temperature gauge unit |

3M |

ATD Part No. 8660 or equivalent |

As required |

|

|

|

|

Camshaft bearing cap |

3M |

ATD Part No. 8660 or equivalent |

As required |

|

|

|

|

Semi-circular packing |

3M |

ATD Part No. 8660 or equivalent |

As required |

|

|

|

|

Rocker cover |

3M |

ATD Part No. 8660 or equivalent |

As required |

|

|

|

|

Front oil seal case |

Mitsubishi Genuine Part No. MD970389 or equivalent |

As required |

|

|

|

|

|

Oil pump |

Mitsubishi Genuine Part No. MD970389 or equivalent |

As required |

|

|

|

|

|

Oil pressure switch |

3M |

ATD Part No. 8660 or equivalent |

As required |

|

|

|

|

E Mitsubishi Motors Corporation |

Nov. 1995 |

PWEE9520 |

4G1 ENGINE (E - W) - Specifications |

11A-1-7 |

FORM-IN-PLACE GASKET

The engine has several areas where the form-in-place gasket (FIPG) is in use. To ensure that the gasket fully serves its purpose, it is necessary to observe some precautions when applying the gasket. Bead size, continuity and location are of paramount importance. Too thin a bead could cause leaks. Too thick a bead, on the other hand, could be squeezed out of location, causing blocking or narrowing of the fluid feed line. To eliminate the possibility of leaks from a joint, therefore, it is absolutely necessary to apply the gasket evenly without a break, while observing the correct bead size.

The FIPG used in the engine is a room temperature vulcanization (RTV) type and is supplied in a 100-gram tube (Part No. MD970389 or MD997110). Since the RTV hardens as it reacts with the moisture in the atomospheric air, it is normally used in the metallic flange areas. The FIPG, Part No. MD970389, can be used for sealing both engine oil and coolant, while Part No. 997110 can only be used for engine oil sealing.

Disassembly

The parts assembled with the FIPG can be easily disassembled without use of a special method. In some cases, however, the sealant between the joined surfaces may have to be broken by lightly striking with a mallet or similar tool. A flat and thin gasket scraper may be lightly hammered in between the joined surfaces. In this case, however, care must be taken to prevent damage to the joined surfaces. For removal of the oil pan, the special tool “Oil Pan Remover” (MD998727) is available. Be sure to use the special tool to remove the oil pan. <Except aluminium die-cast oil pans>

Surface Preparation

Thoroughly remove all substances deposited on the gasket application surfaces, using a gasket scraper or wire brush. Check to ensure that the surfaces to which the FIPG is to be applied is flat. Make sure that there are no oils, greases and foreign substances deposited on the application surfaces. Do not forget to remove the old sealant remained in the bolt holes.

Form-In-Place Gasket Application

When assembling parts with the FIPG, you must observe some precautions, but the procedures is very simple as in the case of a conventional precut gasket.

Applied FIPG bead should be of the specified size and without breaks. Also be sure to encircle the bolt hole circumference with a completely continuous bead. The FIPG can be wiped away unless it is hardened. While the FIPG is still moist (in less than 15 minutes), mount the parts in position. When the parts are mounted, make sure that the gasket is applied to the required area only. In addition, do not apply any oil or water to the sealing locations or start the engine until a sufficient amount of time (about one hour) has passed after installation is completed.

The FIPG application procedure may vary on different areas. Observe the procedure described in the text when applying the FIPG.

E Mitsubishi Motors Corporation |

Nov. 1995 |

PWEE9520 |

NOTES

|

|

|

4G1 ENGINE (E - W) - Special Tools |

11A-2-1 |

||

2. SPECIAL TOOLS |

|

|

|

|||

|

|

|

|

|

|

|

Tool |

Number |

Name |

Use |

|

||

|

|

|

|

|

|

|

|

|

|

MB990767 |

End yoke holder |

Holding camshaft sprocket when loosening or |

|

|

|

|

|

|

tightening bolt (used with MD998715) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MD998011 |

Crankshaft rear oil |

Installation of crankshaft rear oil seal |

|

|

|

seal installer |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MD998054 |

Oil pressure switch |

Removal and installation of oil pressure switch |

|

|

|

wrench |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MD998304 |

Crankshaft front oil |

Installation of crankshaft front oil seal |

|

|

|

seal installer |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MD998305 |

Crankshaft front oil |

Guide for installation of crankshaft front oil seal |

|

|

|

seal guide |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MD998713 |

Camshaft oil seal |

Installation of camshaft oil seal |

|

|

|

installer |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MD998715 |

Pin (2-off) |

Holding camshaft sprocket when loosening or |

|

|

|

|

tightening bolt (used with MB990767) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MD998727 |

Oil pan remover |

Removal of oil pan |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

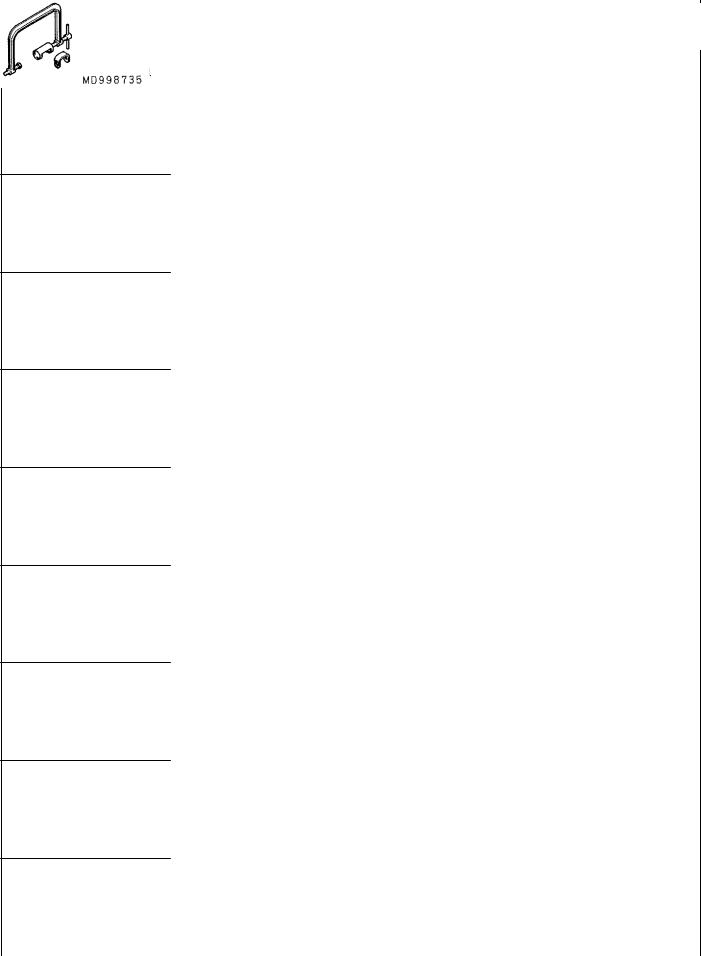

MD998735 |

Valve spring com- |

Compression of valve springs |

|

|

|

|

pressor |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

E Mitsubishi Motors Corporation |

Nov. 1995 |

PWEE9520 |

11A-2-2 |

4G1 ENGINE (E - W) - Special Tools |

||||

|

|

|

|

|

|

Tool |

Number |

Name |

Use |

||

|

|

|

|

|

|

|

|

|

MD998760 |

Valve stem seal |

Installation of valve stem seals |

|

|

|

|

installer |

(SOHC 12-VALVE) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MD998780 |

Piston pin setting |

Removal and press-fitting of piston pins |

|

|

|

tool |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MB991659 |

Guide-D |

Guide for removal and press-fitting of piston |

|

|

|

|

pins |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MD998772 |

Valve spring com- |

Compression of valve springs |

|

|

|

pressor |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MD998440 |

Leak-down tester |

Testing of automatic lash adjusters |

|

|

|

|

(DOHC) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MD998442 |

Air bleed wire |

Testing of automatic lash adjusters |

|

|

|

|

(DOHC) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MD998781 |

Flywheel stopper |

Locking flywheel in fixed position |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MB991671 |

Valve stem |

Press-fitting of valve stem seals |

|

|

|

installer |

(SOHC 16-VALVE, DOHC) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

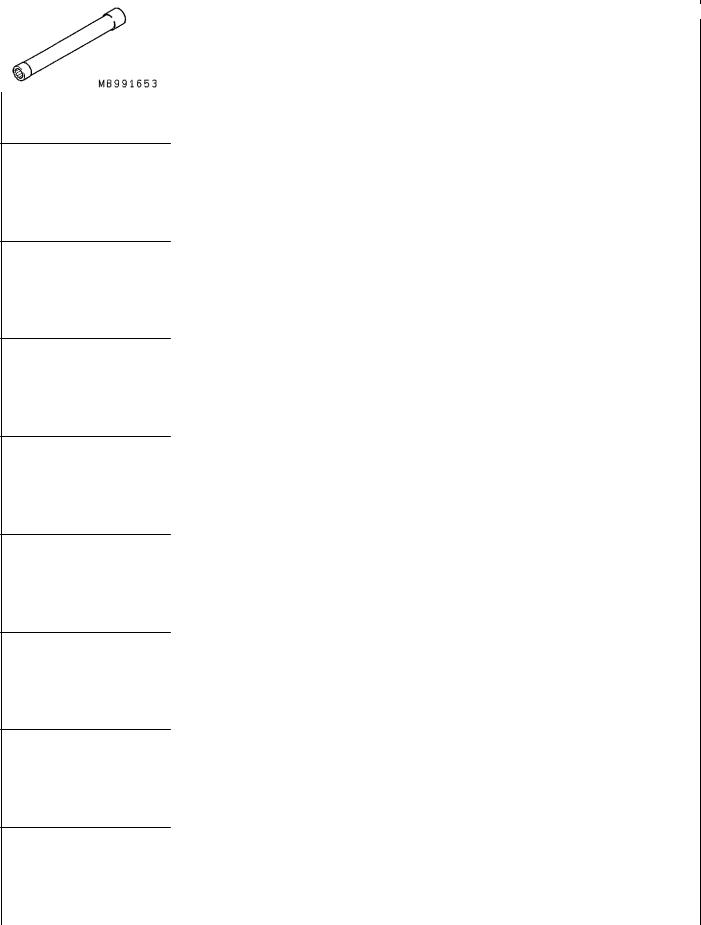

MB991653 |

Cylinder head bolt |

Removal and installation of cylinder head bolt |

|

|

|

|

wrench (10) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

E Mitsubishi Motors Corporation |

DecNov. 19985 |

PWEE9520-A |

Revised |

4G1 ENGINE (E - W) - Alternator and Ignition System |

11A-3-1 |

3. ALTERNATOR AND IGNITION SYSTEM

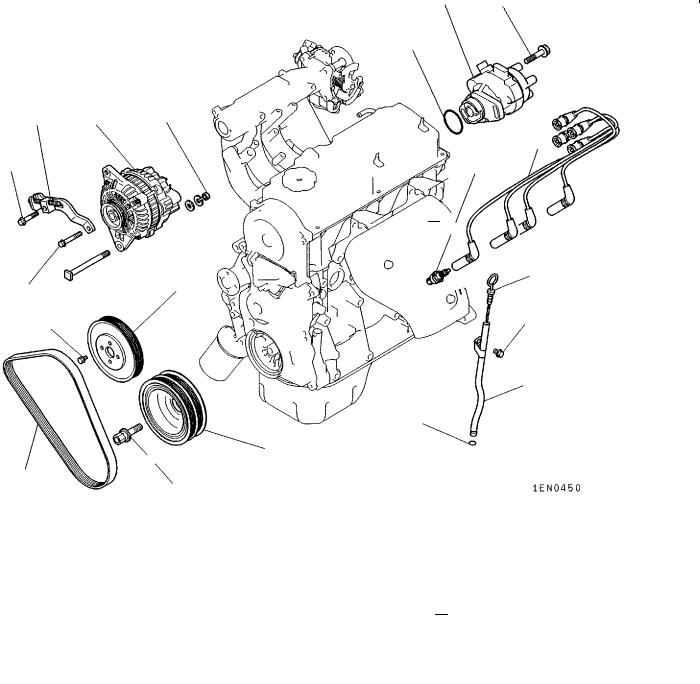

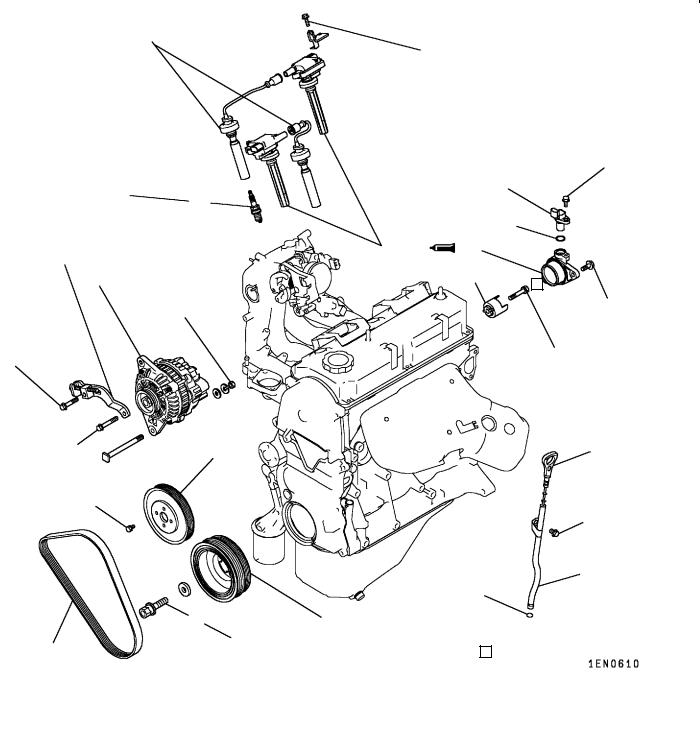

REMOVAL AND INSTALLATION <SOHC 12-VALVE>

12 |

|

12 Nm |

13

13

6 |

7 |

44 Nm |

|||

|

|

|

10 |

||

|

|

|

|

|

|

22 Nm |

|

25 Nm |

|||

|

|

|

|

|

|

|

11 |

|

1 |

23 Nm |

5 |

|

|

9 Nm |

23 Nm |

|

2

3

3

8 |

9 |

|

|

|

|

4 |

|

|

|

123 Nm |

|

|

|

|

Removal steps |

|

|

|

1. |

Oil level gauge |

10. |

Spark plug cable |

2. |

Oil level gauge guide |

11. |

Spark plug |

3. |

O-ring |

"AA 12. |

Distributor |

4. |

Drive belt* |

13. |

O-ring |

5. |

Water pump pulley |

NOTE |

|

6. |

Alternator brace |

*: For details of adjustment, refer to the relevant model’s |

|

7. |

Alternator |

chassis workshop manual. |

|

AA" "BA 8. Crankshaft bolt |

|

|

|

9. |

Crankshaft pulley |

|

|

E Mitsubishi Motors Corporation |

DecNov. 19985 |

PWEE9520-A |

Revised |

11A-3-1a 4G1 ENGINE (E - W) - Alternator and Ignition System

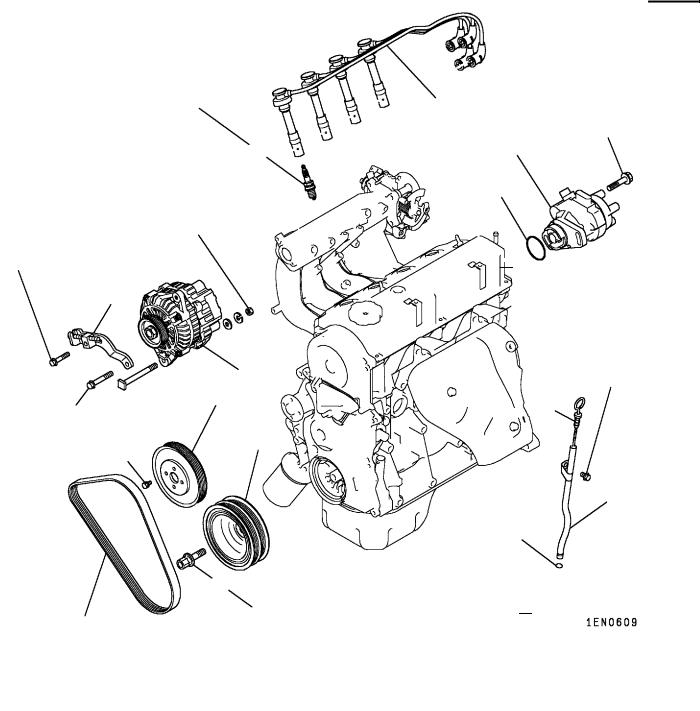

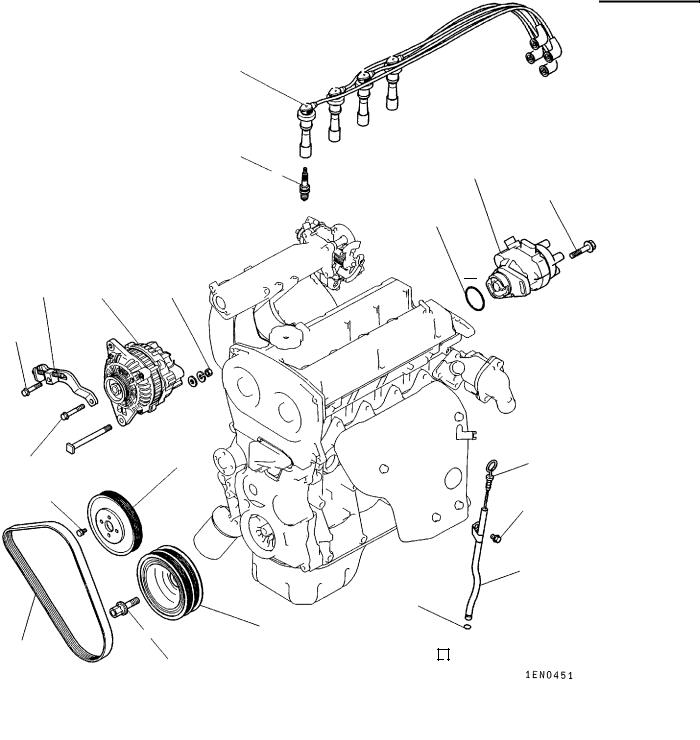

REMOVAL AND INSTALLATION <SOHC 16-VALVE - FRONT WHEEL DRIVE>

25 Nm

11

44 Nm

22 Nm

6

7

5

23 Nm

9

9 Nm

8

125 Nm

4

10

12 Nm

12

13

13

23 Nm

1

2

3

3

Removal steps |

|

|

|

1. |

Oil level gauge |

10. |

Spark plug cable |

2. |

Oil level gauge guide |

11. |

Spark plug |

3. |

O-ring |

"AA 12. |

Distributor |

4. |

Drive belt* |

13. |

O-ring |

5. |

Water pump pulley |

NOTE |

|

6. |

Alternator brace |

*: For details of adjustment, refer to the relevant model’s |

|

7. |

Alternator |

chassis workshop manual. |

|

AA" "BA 8. Crankshaft bolt |

|

|

|

9. |

Crankshaft pulley |

|

|

E Mitsubishi Motors Corporation |

DecNov. 19985 |

PWEE9520-A |

Added |

4G1 ENGINE (E - W) - Alternator and Ignition System |

11A-3-1b |

REMOVAL AND INSTALLATION <SOHC 16-VALVE - REAR WHEEL DRIVE>

10

10 Nm

9 Nm

|

25 Nm |

|

|

13 |

|

|

||

|

12 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

6 |

|

|

11 |

14 |

|

|

||

|

|

|

|

|||||

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

7 |

|

|

15 |

|

|

||

|

44 Nm |

|

|

|

|

|

13 Nm |

|

22 Nm |

|

|

|

|

|

|

|

21 Nm |

23 Nm |

|

5 |

|

1 |

||||

9 Nm |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

23 Nm |

|

|

|

|

2 |

||||

|

|

8 |

9 |

|

|

3 |

|

|

|

|

|

||||||

|

|

|

|

|

|

|

||

4 |

|

|

125 Nm |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Removal steps |

|

|

|

|

|

|

|

|

1. |

Oil level gauge |

|

10. |

Spark plug cable |

||||

2. |

Oil level gauge guide |

11. |

Ignition coil |

|||||

3. |

O-ring |

|

12. |

Spark plug |

||||

4. |

Drive belt* |

|

13. |

Cam position sensor |

||||

5. |

Water pump pulley |

"CA 14. |

Cam position sensor support |

|||||

6. |

Alternator brace |

|

15. |

Cam position sensing cylinder |

||||

7. |

Alternator |

|

NOTE |

|

|

|

|

|

AA" "BA 8. Crankshaft bolt |

|

*: For details of adjustment, refer to the relevant model’s |

||||||

9. |

Crankshaft pulley |

|

chassis workshop manual. |

|||||

E Mitsubishi Motors Corporation |

DecNov. 19985 |

PWEE9520-A |

Added |

11A-3-2 4G1 ENGINE (E - W) - Alternator and Ignition System

REMOVAL AND INSTALLATION <DOHC>

10

25 Nm

11 |

12 |

11 Nm

13

13

6 |

7 |

44 Nm |

22 Nm

23 Nm |

5 |

1 |

|

|

9 Nm

23 Nm

|

|

|

|

|

2 |

|

8 |

9 |

|

3 |

|

|

|

|

|||

|

|

|

|||

|

|

|

|

||

4 |

103 Nm |

|

|

|

|

|

|

|

|

|

|

Removal steps |

|

|

|

|

|

1. |

Oil level gauge |

10. |

Spark plug cable |

||

2. |

Oil level gauge guide |

11. |

Spark plug |

||

3. |

O-ring |

"AA 12. |

Distributor |

||

4. |

Drive belt* |

13. |

O-ring |

||

5. |

Water pump pulley |

NOTE |

|

||

6. |

Alternator brace |

*: For details of adjustment, refer to the relevant model’s |

|||

7. |

Alternator |

chassis workshop manual. |

|||

AA" "BA 8. Crankshaft bolt |

|

|

|

|

|

9. |

Crankshaft pulley |

|

|

|

|

E Mitsubishi Motors Corporation |

Nov. 1995 |

PWEE9520 |

4G1 ENGINE (E - W) - Alternator and Ignition System |

11A-3-3 |

MD998781

Alignment mark

Alignment mark

MD998781

REMOVAL SERVICE POINT

AA"CRANKSHAFT BOLT REMOVAL

(1)Lock the flywheel or drive plate in position using the special tool shown in the illustration, then loosen the crankshaft bolts.

INSTALLATION SERVICE POINTS

"AADISTRIBUTOR INSTALLATION

(1)Turn the crankshaft clockwise until cylinder No. 1 is at top dead center on its compression stroke.

(2)Align the alignment marks on the distributor housing and coupling.

(3)Fit the distributor onto the engine, aligning the stud bolts with the slots in the distributor mounting flange.

"BACRANKSHAFT BOLT INSTALLATION

(1)Lock the flywheel or drive plate in position using the special tool shown in the illustration, then tighten the crankshaft bolts.

E Mitsubishi Motors Corporation |

Nov. 1995 |

PWEE9520 |

NOTES

4G1 ENGINE (E - W) - Timing Belt |

11A-4-1 |

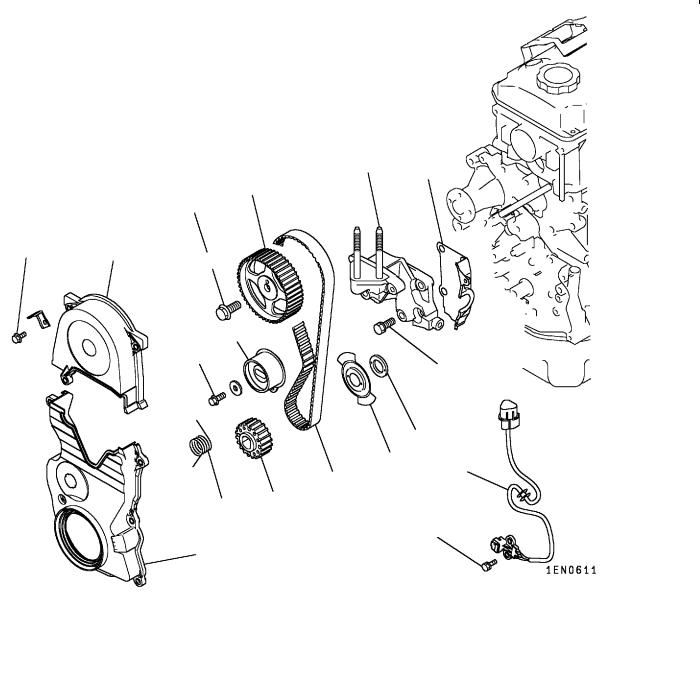

4. TIMING BELT

REMOVAL AND INSTALLATION <SOHC>

12 13

11

|

|

88 Nm |

11 Nm |

1 |

10 |

|

|

5

23 Nm

35 Nm

8

9 6

3

4 7

9 Nm

2

Removal steps |

|

|

||

1. |

Timing |

belt upper cover |

7. |

Crankshaft sprocket |

2. |

Timing |

belt lower cover |

8. |

Spacer <Rear wheel drive> |

AA" "CA 3. Timing belt |

9. |

Sensing blade <Rear wheel drive> |

||

"BA 4. Tensioner spring |

AB" "AA 10. |

Camshaft sprocket bolt |

||

"BA 5. |

Timing belt tensioner |

11. |

Camshaft sprocket |

|

6. |

Crankshaft angle sensor |

12. |

Engine support bracket |

|

|

<Rear wheel drive> |

13. |

Timing belt rear cover |

|

E Mitsubishi Motors Corporation |

Dec.Nov 19985 |

PWEE9520-A |

Revised |

11A-4-2 |

4G1 ENGINE (E - W) - Timing Belt |

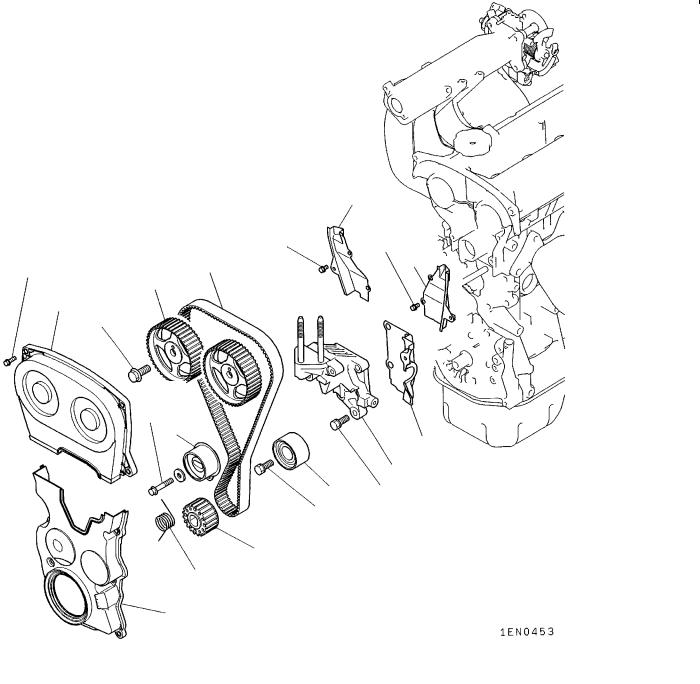

REMOVAL AND INSTALLATION <DOHC>

|

|

|

12 |

|

|

11 Nm |

11 Nm |

|

|

|

|

11 Nm |

3 |

|

13 |

|

|

||

|

|

|

9

1

88 Nm

8

23 Nm

5

11

|

10 |

6 |

35 Nm |

35 Nm

7

4

2

Removal steps

1.Timing belt upper cover

2.Timing belt lower cover AA" "DA 3. Timing belt

AA" "BA 4. Tensioner spring

AA" "BA 5. Timing belt tensioner

6.Idler pulley

7.Crankshaft pulley

AB" "AA 8. Camshaft sprocket bolt

9.Camshaft sprocket

10.Engine support bracket

11.Timing belt rear cover (lower)

12.Timing belt rear cover (right)

13.Timing belt rear cover (left)

E Mitsubishi Motors Corporation |

Nov. 1995 |

PWEE9520 |

Loading...

Loading...