mitsubishi 500 Maintenance Manual

-

--

’

BNP-B3744+9

‘=I

MITSUBISHI CNC

BIELDB

MAINTENANCE MANUAL (HARDWARE)

500 SERIES

ADVANCED AND

EVER

ADVANCING

MITSUBISHI ELECTRIC

Preface

(1) The contents of this manual include the items required to maintenance the entire

MELDAS

the target model and specified configuration.

Use this manual with the Instruction Manual, instruction Manual issued by the

machine maker, and other Instruction Manuals.

(2) This Manual is targeted for the general user and machine maker engineers. If there

are any unclear points, please contact Mitsubishi.

(3) An effort has been made to match the contents of this manual with the NC unit. We

ask for your understanding if there are any differences in the contents.

(4) Related material

MELDAS

500 Series CNC unit, so the system configuration may differ according to

500 Series Connection Manual

Contents

1. Outline

1 .l System Configuration

1 .l .l System configuration

.....................

.................................

...............................

1.1.2 Internal system diagram

1.2 Control Unit Configuration

1.2.1

Control unit configuration

.............................

1.2.2 Control section PCB configuration

1.3 Operation Board Configuration

1.4 Table of Configuration Units

i

......................

............................

...........................

.....................

..........................

............................

2. Daily Maintenance and Periodic Inspection and Maintenance

2.1 Maintenance Instruments

2.2 Maintenance Items

...................................

2.3 Cleaning the Operation Board Escutcheon and CRT

2.4 Maintenance and Handling of the Floppy Disk Unit

2.4.1 Maintenance of the floppy disk unit

2.4.2 Handling of the floppy disk

2.4.3.

Other precautions for handling

2.4.4 Troubleshooting

2.5 Battery Replacement

..............................

..........

...........

....................

..........................

.......................

..................................

.................................

...

10

10

10

11

12

12

.12

13

14

15

3. Troubie Diagnosis and Measures

........................

3.1 Confirmation of State of Trouble Occurrence

3.2 Examples of Troubles and Troubleshooting

3.2.1

Examples of troubles

3.2.2 Examples of troubleshooting

3.3 LED List of Each PCB (unit)

3.4 Presumed Causes for Alarms

3.5 Procedure for Inspection of Each Trouble

...............................

.........................

............................

...........................

..................

3.6 Replacement of Various Units in Control Unit

3.6.1

Replacement of power unit

3.6.2 Replacement of cooling fan

3.6.3 Replacement of the QX card

3.6.4 Replacement of memory cassette card

3.6.5 Precautions during replacement

..........................

..........................

.........................

.................

......................

...............

................

...............

16

16

17

17

18

23

25

37

39

40

40

40

42

43

_i_

4. Installation Adjustment Procedure

4.1 Working Conditions

4.2 Input Power

........................................

4.3 External Connections

..................................

.................................

4.3.1 Connection of input power

4.3.2 Connection of motor

4.3.3 External connections

4.4 Installation Check List

4.5 Turning on the Power

...............................

...............................

................................

................................

.......................

..........................

4.5.1 Power on, ready on, emergency stop, ready off flow chart

4.6 Setting Capacity (hardware setting)

......................

...

44

44

44

45

45

45

45

47

48

48

49

5. Explanation of Hardware

5.1 Outline

5.2 Flow of Signals

...........................................

.....................................

5.3 Control Unit Functions and Handling

5.3.1 Power supply

5.3.2

PC6

functions and handling

...............................

.....................

....................................

..........................

5.4 Functions and Handling of the Operation Board

5.4.1 CRT

5.4.2 EL display

5.4.3 Color LCD

5.4.4 Floppy disk unit

...........................................

.......................................

......................................

..................................

5.4.5 Replacement of each module in operation board

5.4.6

PC6

functions and handling

.........................

5.5 Functions and Handling of Manual Handle (HD60)

5.5.1 Functions

5.5.2 Replacement and handling

.......................................

..........................

.............

..........

...........

51

51

54

57

57

58

67

67

67

68

68

69

72

74

74

75

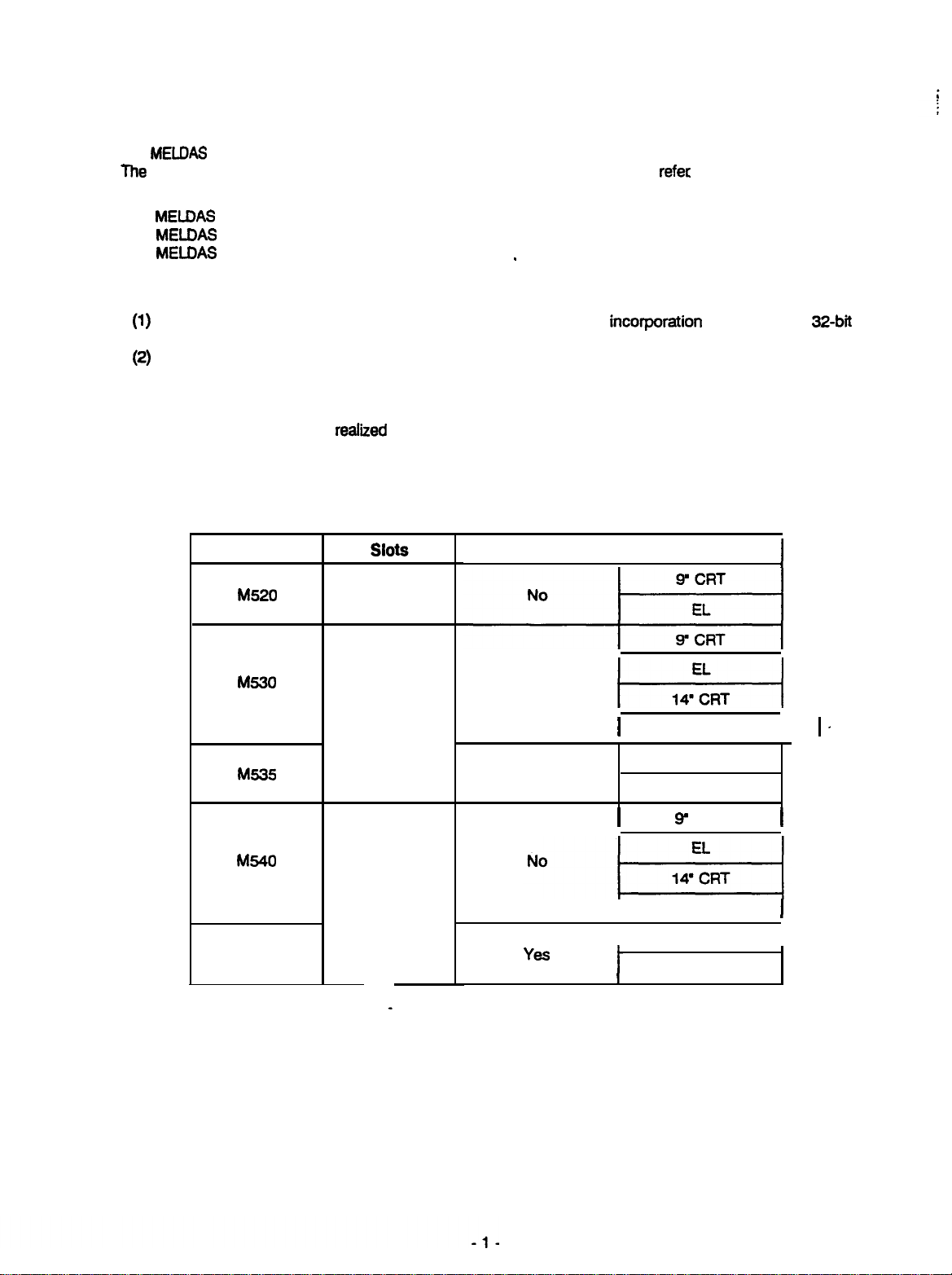

1. Outline

The

MELDAS

The

following material has been prepared in addition to this Manual. Please

this manual.

(1)

MELDAS

(2)

MELDAS

(3)

MELDAS

n

Features

(1)

(2)

(3)

(4)

This manual commonly explains the maintenance, troubleshooting, installation adjustment and hardware

for the following CNC units. However, the model name is listed for those units having limits in each

section.

500 Series CNC unit is a product that has thoroughly pursed high productivity and reliability.

refec

to these together with

500 Series Instruction Manual (per model)

500 Series Connection Manual

500 Series PLC Interface Manual

A high speed and high precision has been realized with the

microprocessor.

A high reliabiiii has been realiied with the incorporation of high integrated parts such as the

custom LSI.

By fully digitaliiing the servo amplifier, a high maintainabilii, reliability and precision has been

achieved.

Systemization has been

realized

with the modulation and unitization of the product.

,

incorporation

of a complete

32-bit

Model

M520

M530

M535

M540

(M545)

name

Automatic program

4

No

Display

I

t-GE-i

4

Yes

6

YW

Color LCD 1

I

14’ CRT

Color LCD

9

I

I

I

t

CRT

Color LCD

14’ CRT

Color LCD

.

I

I

I

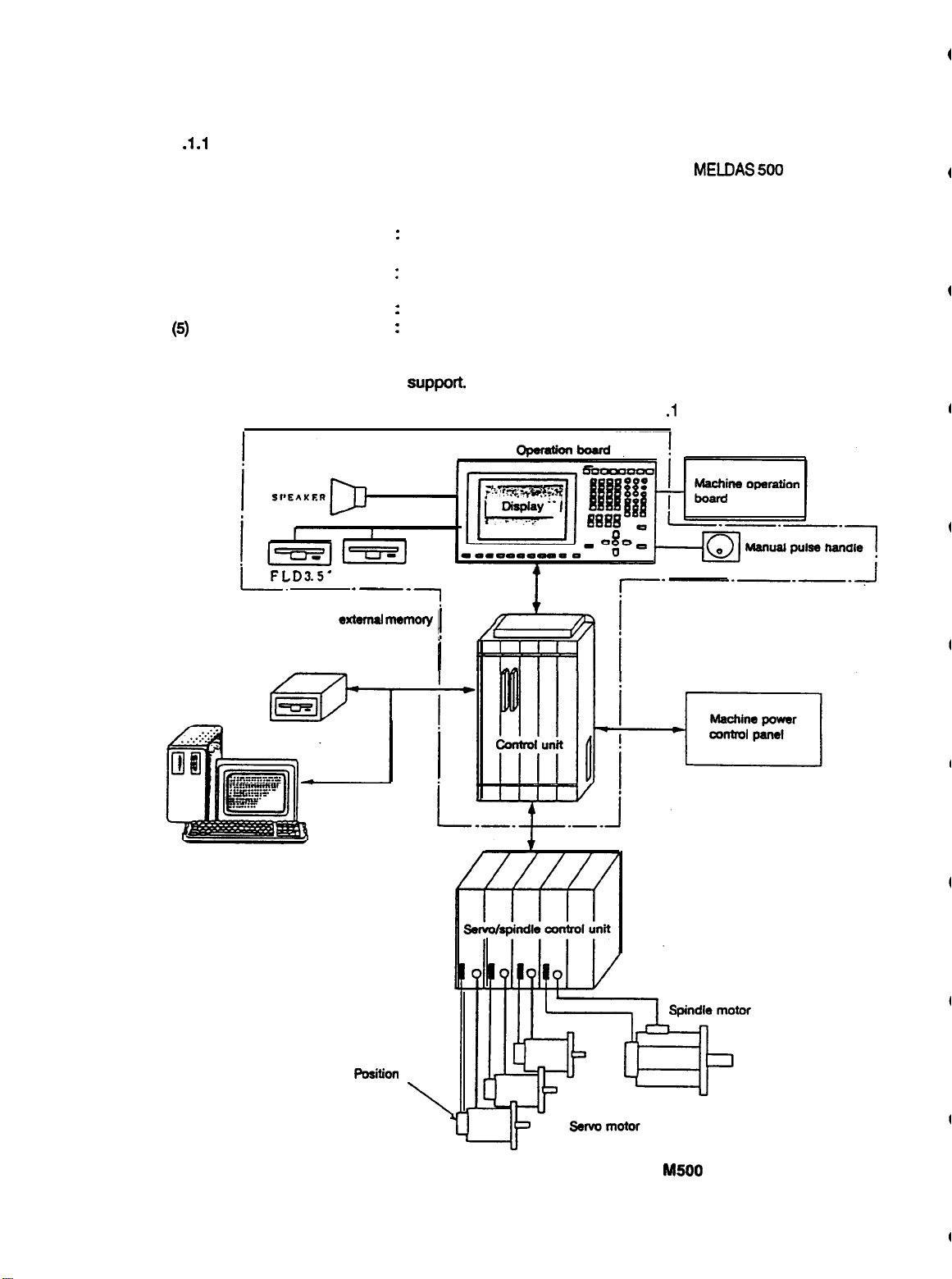

1.1 System Configuration

1

.l .l

System configuration

The following units are generally

(1) Control unit

(2) Operation board

(display operation section)-

(3) Servo/spindle control unit

(4) Servo/spindle motor

(5)

Position/speed detector

(6) Other peripheral equipment:

This manual explains the sections enclosed with a dotted line in Fig. 1

FLD3.5’

L-.

Peripheral equipment such as

and programming support

---7

extemal

used to compose the system using the

This unit has the computation processing functions for numerical

control. (This is also called the NC unit.)

:

This unit has the setting and display functions.

This is a servo/spindle amplifier composed of a conductor for obtaining

:

DC from AC and an inverter for obtaining AC from DC.

:

Thii drive motor moves the machine.

:

This sensor outputs a pulse that corresponds to the machine

movement amount

Peripheral equipment such as external memory and programming

support-

.l

.

memow

!

MELDAS 566

Series.

Position

I

detector

\

Fig. 1.1 General configuration of system using

MS00

-2-

Series

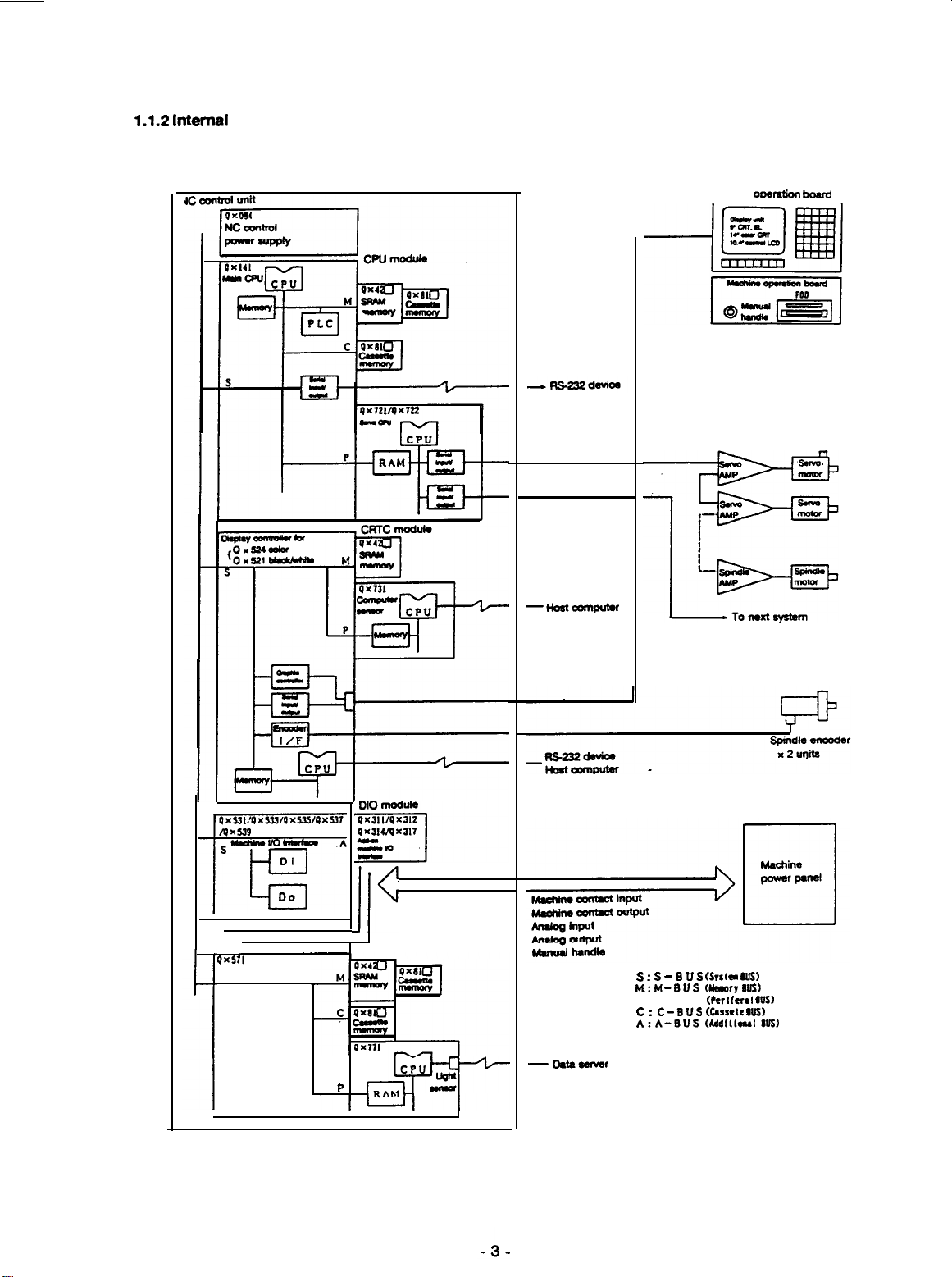

1.1.2

lntemal system diagram

NC

owmtion

bard

qxs3I:oxs33/oax5/Pxsl7

AXM

S-

I==

Di

Do

Ei

.A

JC

PXS7l

S

P

-Hoatamputer

-Data-r

s : s - 8

us (STSIU

M:M-BUS

P : P-BUS

c :

c-eus

A:A-BUS Mddlllodws)

Ills)

wmw

Ius)

ckrlfcnl aus)

(CUSPID

aus)

(Note) The above diagram shows the most general configuration, and the actually mounted hardware

configuration may differ according to hardware flexibility and specifications.

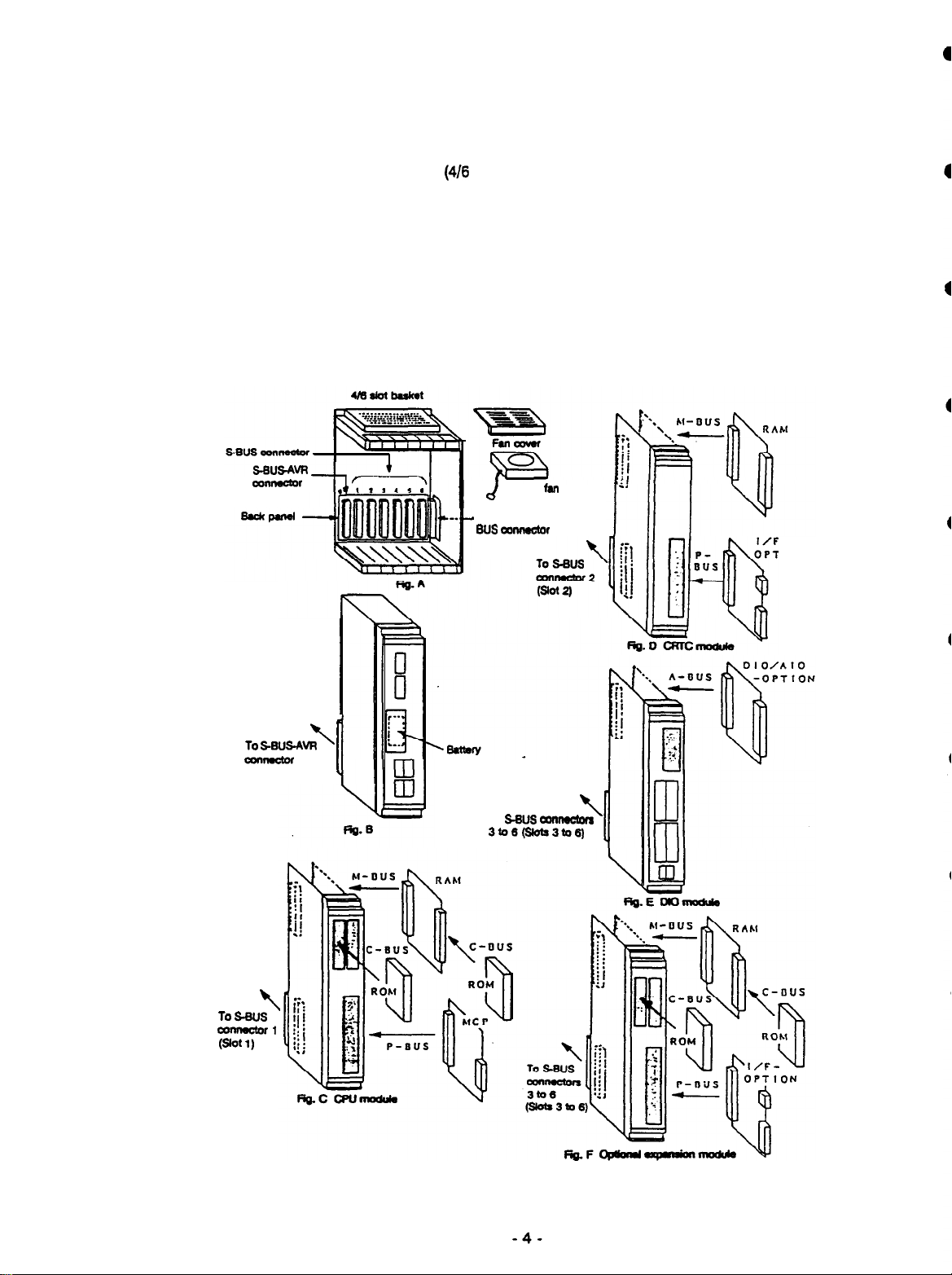

1.2 Control Unit Configuration

1.2.1 Control unit configuration

The control unit is composed of baskets

control section PCB) that are assembled into the baskets. The back panel into which the control power

and control modules are mounted is on the back of the basket, and the cooling fan is mounted on the

top. The cooling fan is mounted inside the fan cover as shown in Fig. A, and can be replaced easily be

removing the fan cover from the basket unit. The control power is mounted on the far left slot of the

basket, the CPU module’in slot 1, the CRTC model in slot 2. and the number of DIO modules required

from the system are mounted from the far right slot. Optional expansion modules are mounted from the

left into the empty slots.

(416

slots) and the control power and control modules (integrated

conneotor

To

ssusAvR

oonn9ctor

z

Cooling

I J

.

Expansion

SIJS

ii

To

3ros(sk#xstae)

fan

oonmotor

SBUS

anmocwa

‘ION

z

To S-SIJS

m-1

t*t

1)

2

Fig. 1.2.1 Control unit configuration diagram

1.22

Control section PCB configuration

The control section PCB uses a control module to which various

300 x 140mm standard size PCB as shown in Figs. C to E shown in Fig. 1.2.1 Control unit configuration

diagram.

A system BUS connector that is connected to the back panel is mounted on the lower back of the control

module and an interface connector and LED indicator are mounted on the front. A plastic front panel is

mounted over this.

Fig. 1.22 shows the state from the front and side when the control module’s front panel is removed. Fig.

1.22 shows the CPU module, and the M-BUS PCB, P-BUS PCB are mounted on the 300 x

standard PCB (S-BUS PCB) so that the part mounting face faces the S-BUS PCB. Cassette memory can

be mounted freely onto the front surface of the S-BUS PCB and M-BUS PCB.

This is possible with other control modules lf the various add-on

PCBs,

this is not possible due to limits in the configuration, however, the ideology is the same.

S-BUS PCB

PCBs

Caaadte

PCBs

are mounted horizontally onto a

140mm

listed above are mounted. In some

memory

S-BUS PCB

Caswtta

memory

\

/

:

!

!

I

; :

2

:

F

1

~

Fig. 1.22 Example of control module (integrated PCB)

M-BUS

Fixing

Spacer

P-BUS

Fixing screw

‘Spaoar

PCB

2zrehv

PCB

Yl

El,

M-BUS PCB

I

P-BUS PCB

/

-.

System

oonnector

/

BUS

1.3 Operation Board Configuration

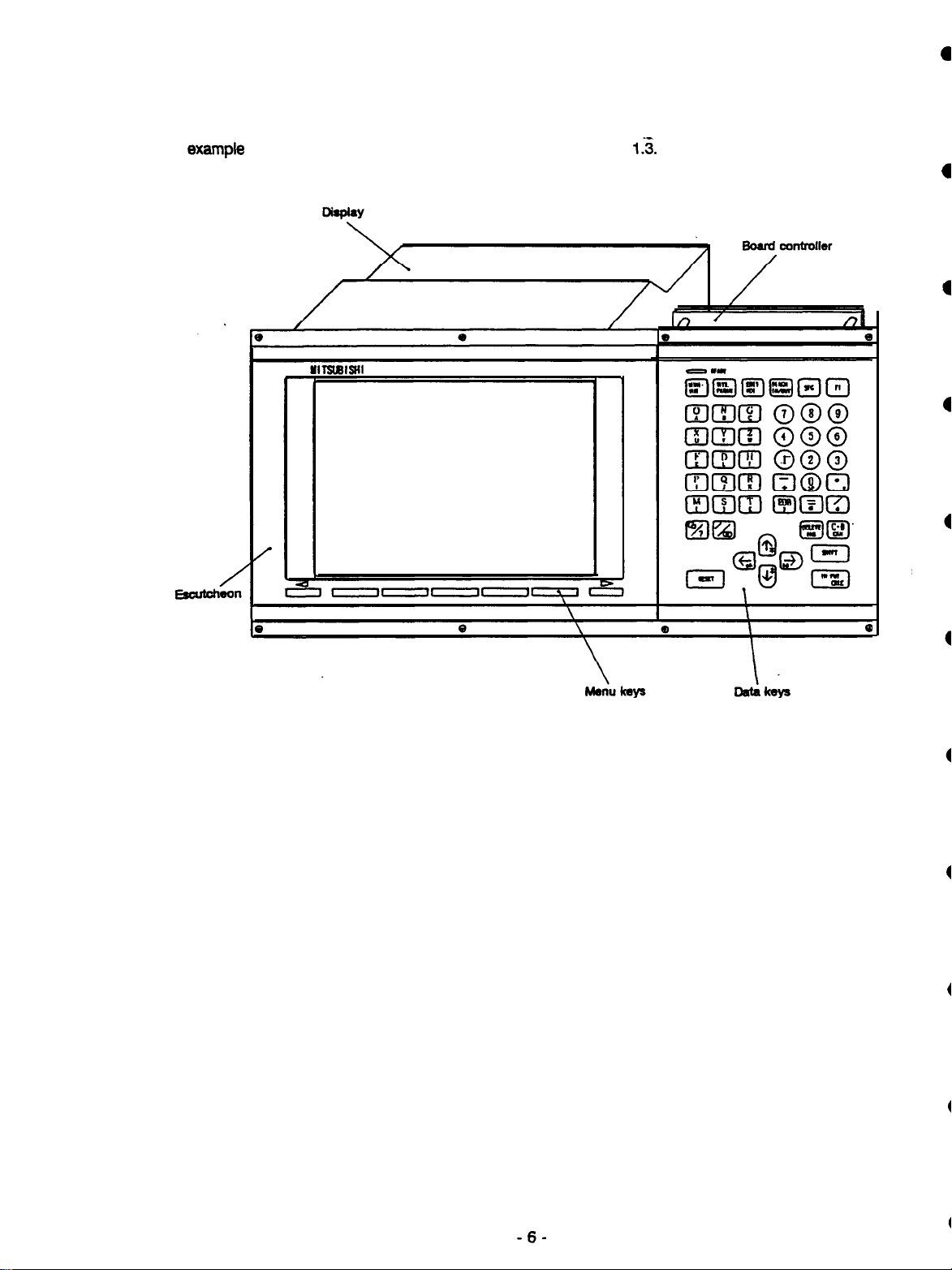

An

exampie

of the operation board configuration is shown in Fig.

1.3.

Fig. 1.3 Operation board configuration

-6-

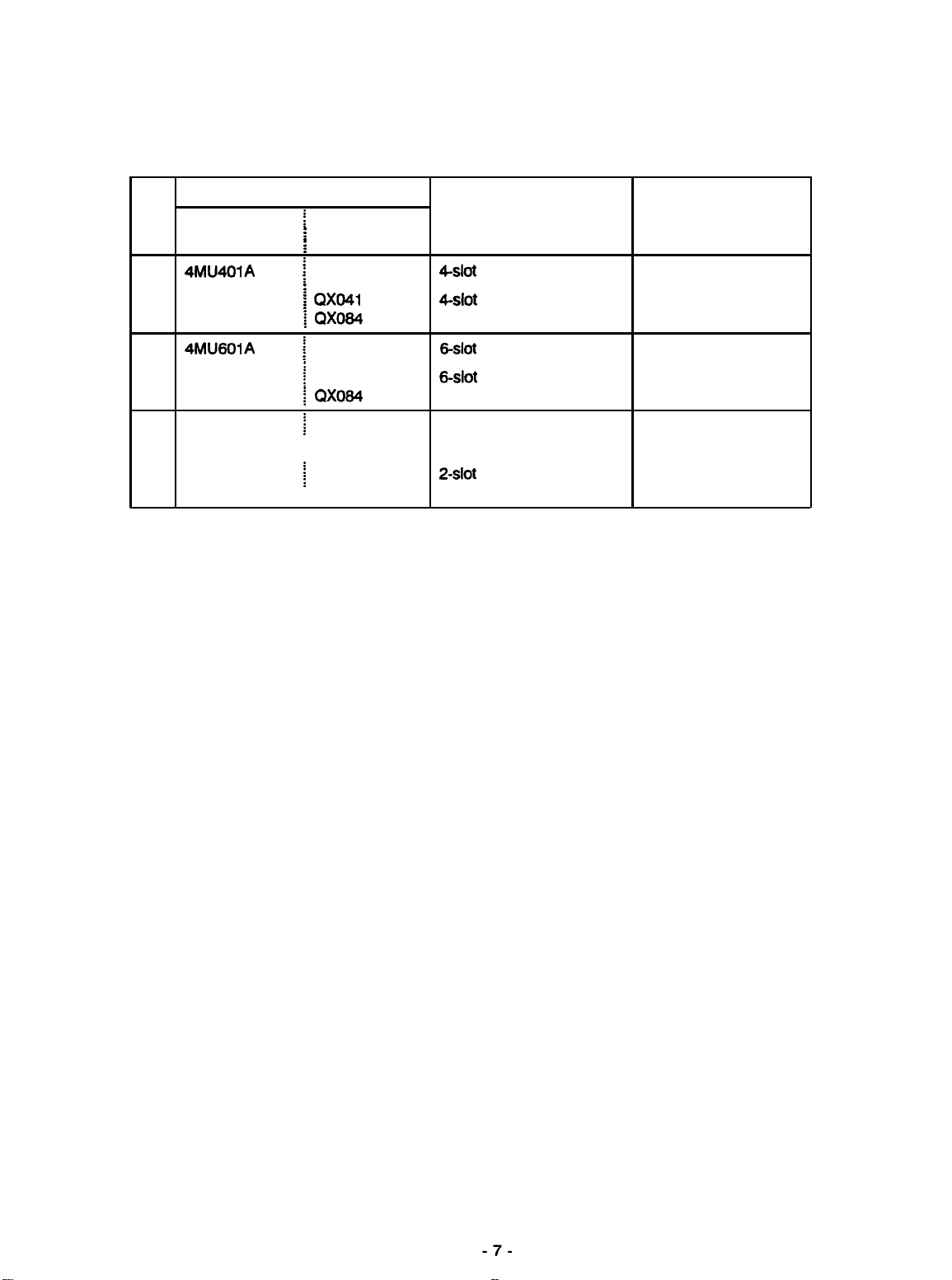

1.4 Table of Configuration Units

(1) Control unit

Model name

No.

1

2

Model name

4MU401A

4MU601A

i

Configuration

i

i

element name

f

i ax041

f 0x084

i

i

QX061

t QX084

Function Remarks

4-slot

control unit

4-slot

back panel

Control power supply

6-slot

control

Sslot

back panel

Control power supply

unit

Expansion unit

3

f

i

QX025

2-slot expansion control

unit

2-slot

expansion back

panel

-7-

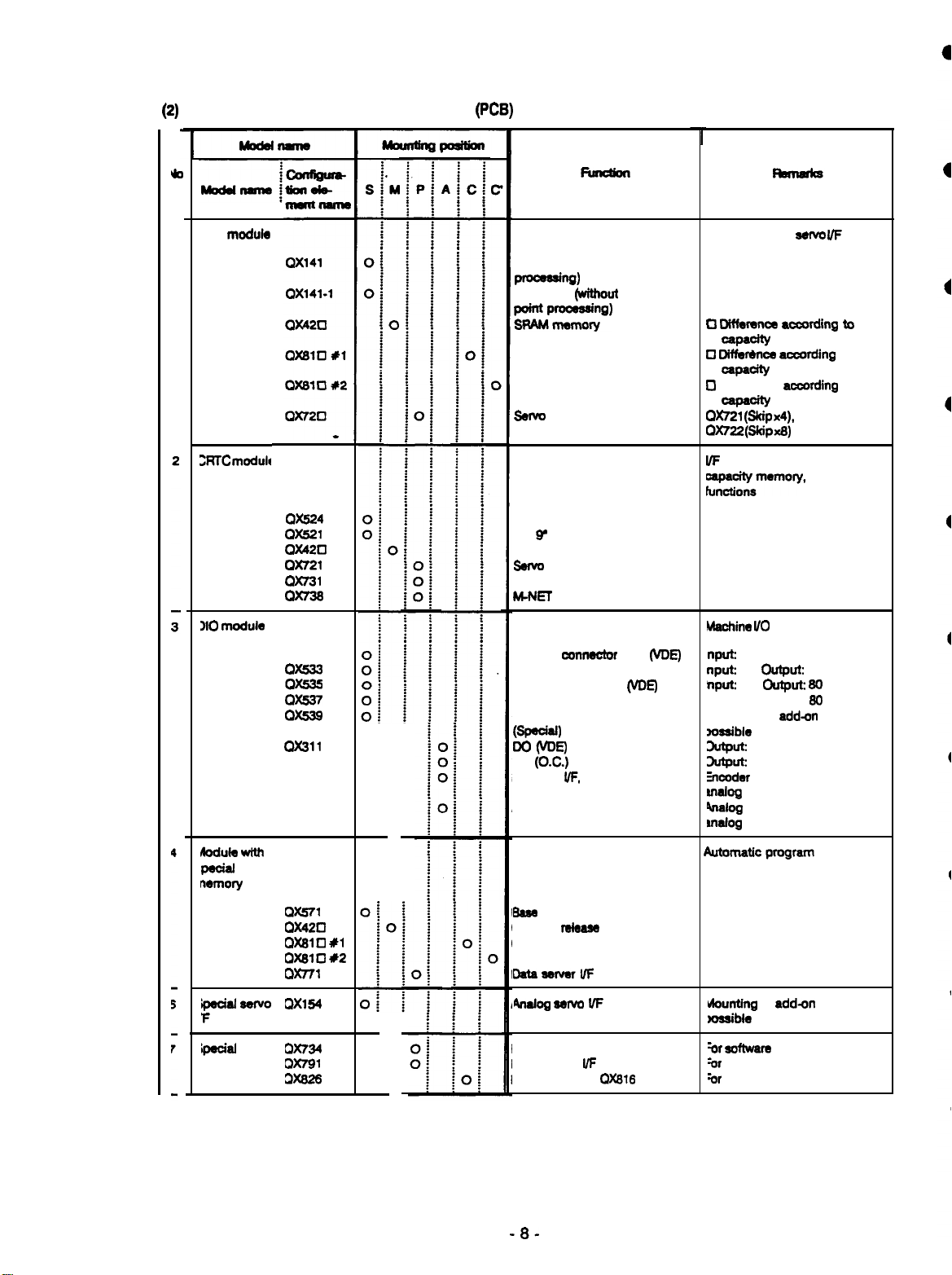

(2)

Control section printed circuit boards

b

CPU

1

moduk

(PCS)

Main CPU (with floating point

Vng)

Main CPU

==zg)

Main memory

User PLC memory

sewo CPU

@Shout

floating

CPU, memory,

Cl

Dlffemnoe acoordlng

m=w

0 Differ&we according

-@acity

0

Difference

capacity

0x721

(skipx4),

QX722(Skipx6)

servo l/F

aocording

to

to

to

XTC mod&

30

module

todule

wlth

wa

nemoty

QW24

QXZ.21

OX420

QX721

OX731

QX736

QX631

OX533

:z

QX63!3

Qx311

QX312

QX314

QX317

Qx571

QX420

Qx610

#l

0x610 +2

QxT71

For color CRT, color LCD

For Q CRT, EL

Large capacity memory

Sawo

CPU for additional axes

Computer link

M-NET

HONDA

oonnector

HONDA connector type (O.C.)

Rat connector type

flat connector type (O.C.)

HONDA connector type

(sped~)

DOwE)

DO

(O.C.)

Encoder

Analog input, analog output

Base

Custom

Custom release memory

l/F,

(no functions)

release

type

(ME)

(VDE)

analog output

RAM

DataseweruF

IIF

with display unit, large

zsmemory.

Mechine l/O

nput:

64. Output: 46

nput:

64.

rlpti

60,

nput: 60, Output:

Mounting of addon PCB not

mssible

3utpu-t:

16

%I$&

16

%xder

input: 2,

malog

output: 2

bnalog

input: 4,

mdog output: 2

other

intetfaos

output:

46

Qutputz 60

60

ipeoial

F

@ecial

servo

PCB

QX164

ax734

QX791

3)(826

4rmklIg

selvo

l/F

Ethernet

Floppy disk

RAM board for

i/F

-8-

QX616

hmting

of

addon

&ble

%or softwam

*or

software development

*or

software development

PCB not

development

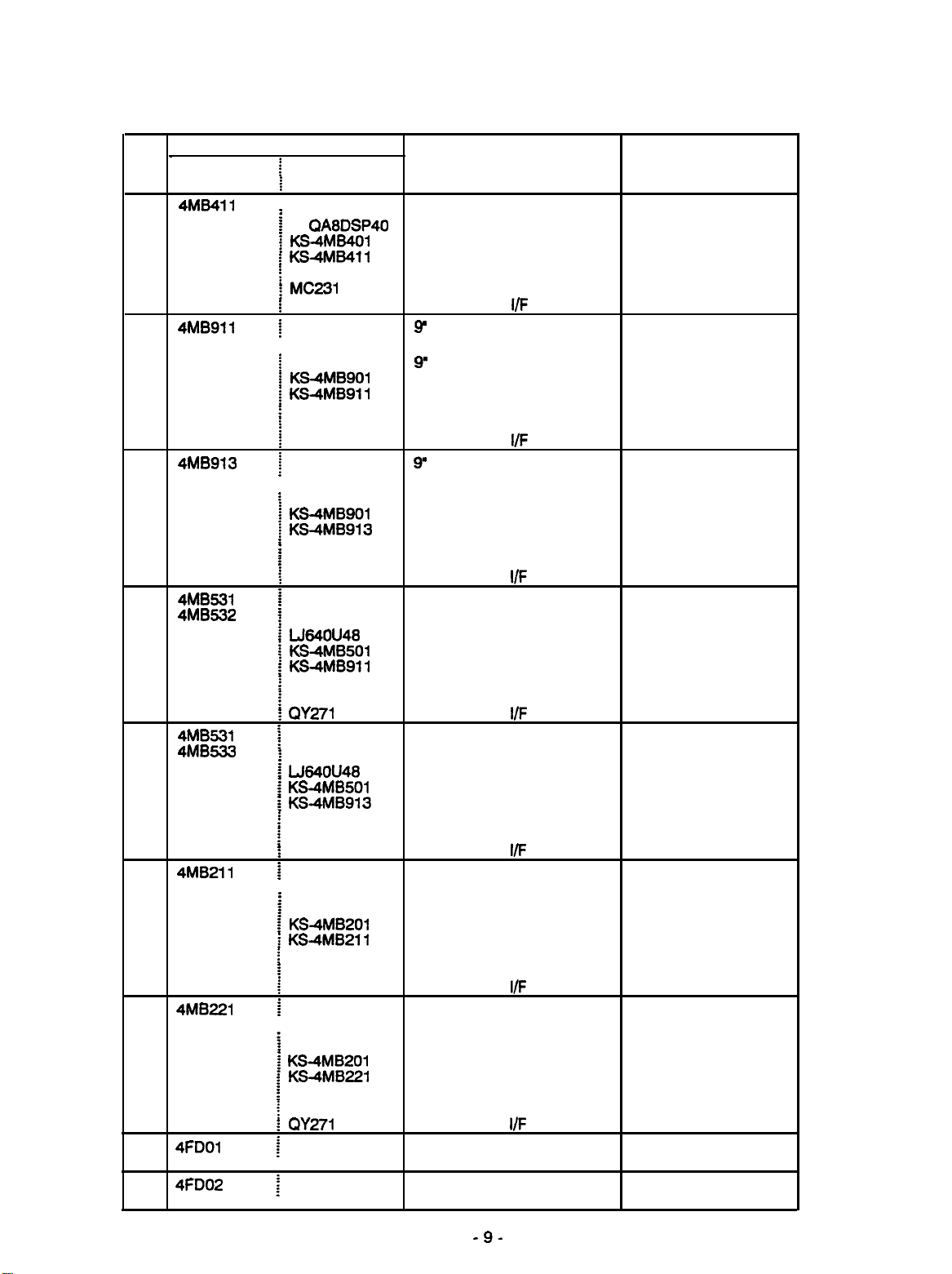

(3) Operation board

No.

.

Model name

4MB411

1

4MB911

2

3

4MB913

4

4MB631

4MB632

5 4MB831

4MB633

6 4MB211

7

4MB221

8

4FDOl

9

4FD02

Model name

I

f

[

f KS4MB401

i KS4MB411

;

f MC231

i

;

i

i KS4MB901 Menu keys

i KS4MB911

i

i

i

I

i

f KS4MB901

i KS4MB913

i

i

i:

i

i

t W64OU48

i KS4MB501

i KS4MB911

f

f

i QY271

!

i

! LJ64OU48

i KS4MB501

; KS4MB913

f

QY201

!

MC231

i

QY271

:

i

f KS4MB201

j KS4MB211

i

QY201

:

MC231

i

QY271

i

i

10.5’ LCD

i KS4MB201

; KS4MB221

t

QY201

f

MC231

i QY271

;

i

Configuration

element name

Al

QA8DSP40

QY201

QY271

MDT-962B-1 A

QY201

MC231

QY271

MDT-9628-l A

QY201

MC231

QY271

QY201

MC231

10.5’ LCD

Function Remarks

14'

CRT standard

14’ CRT unit

Menu keys

Data keys

Board controller

Board contact input/output

Audio output

9

CRT standard

I/F

(machining center system)

9’

CRT

Data keys

Board controller

Board contact input/output

Audio output

9’

CRT standard (lathe

I/F

system)

9’ CRT

Menu keys

Data keys

Board controller

Board contact input/output

Audio output

I/F

EL standard, separated

(machining center system)

9.4’ EL

Menu keys

Data keys

Board controller

Board contact input/output

Audio output

I/F

EL standard, separated

(lathe system)

9.4’ EL

Menu keys

Data keys

Board controller

Board contact input/output

Audio output

I/F

10.4’ LCD standard

(horizontal)

10.4’ LCD

Menu keys

Data keys

Board controller

Board contact input/output

Audio output

I/F

10.4’ LCD standard

(vertical)

10.4’ LCD

Menu keys

Data keys

Board controller

Board contact input/output

Audio output

I/F

Floppy disk unit

Floppy disk unit

Floppy disk unit

w/one buiit-in drive

Floppy disk unit

w/two built-in drives

-9-

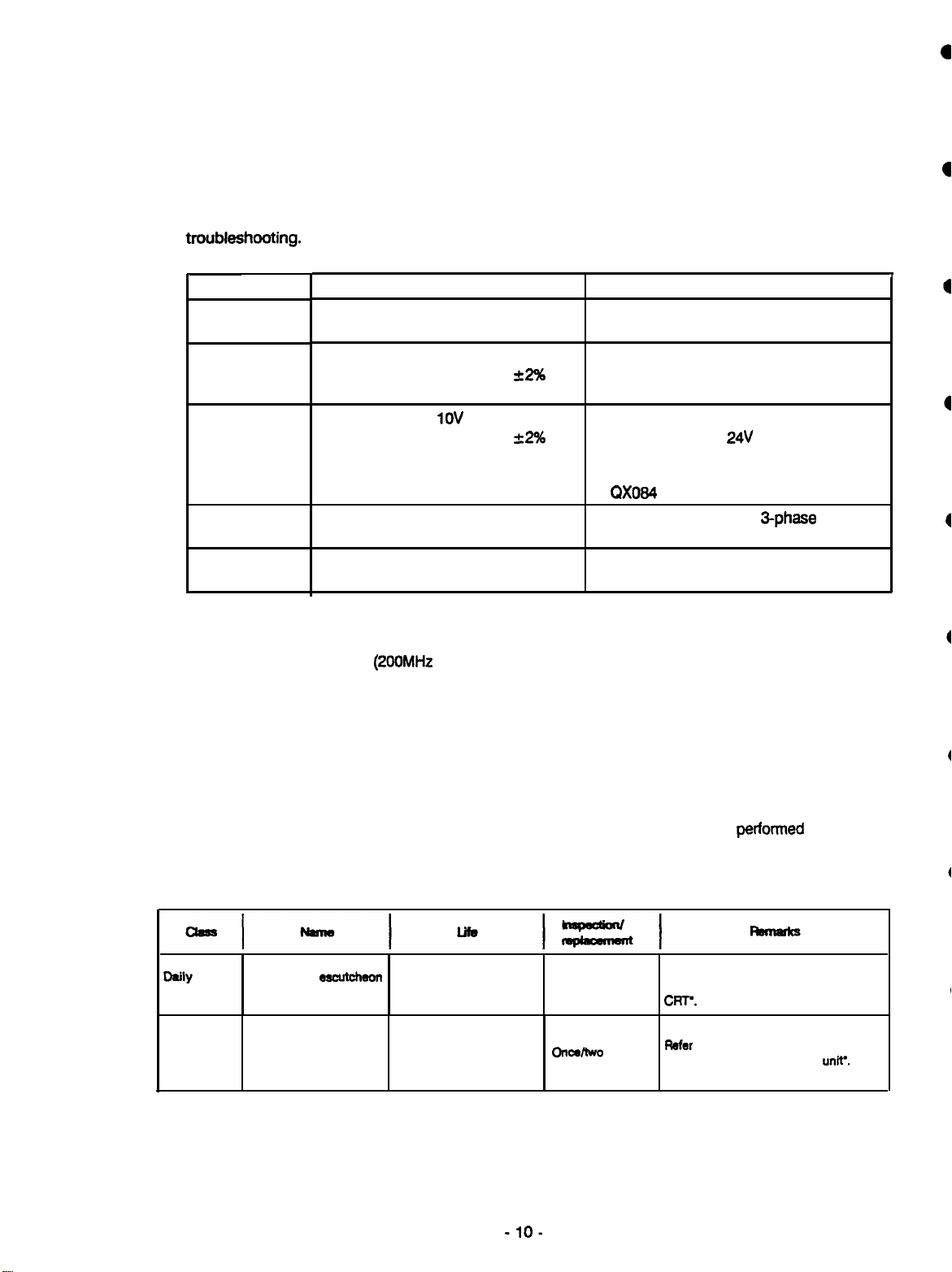

2. Daily Maintenance and Periodic Inspection and Maintenance

2.1 Maintenance Instruments

(1)

Measurement instruments

The following instruments are used for measurement to confirm that the power is being properly

supplied to the NC unit and that the wiring to the NC unit is correct, and during simple

Table 2.1 Maintenance instruments

Instrument

Tester

Conditions

Check that the wiring to the NC unit is

Application

correct before turning on the power.

AC voltmeter

The AC power voltage is measured.

The tolerable difference is

f2%

or

The AC power votage supplied to the

NC unit is measured.

less.

DC voltmeter

Maximum scale

30V tolerable difference is

less.

1OV

22%

or

The DC power voltage is measured.

External supply

24V

(I/O interface

DIO-A)

Battery voltage

QX034

DC output

Phase rotation

meter

Oscilloscope

Check the order of AC

power connection

For general measurement and simple

3-phase

input

troubleshooting

(Note 1) Currently, a high precision digital muitimeter has been generally diffused as a tester,

and is most commonly used. This digital multimeter can also be used for the AC

voltmeter and DC voltmeter.

(Note 2) A logic analyzer

(200MHz

or higher) is required for complicated troubleshooting.

(2) Tools

Screwdriver (large, medium, small)

I

2.2 Maintenance Items

Maintenance is divided into daily, periodic inspection and maintenance (items not

designated), and periodic maintenance replacement (replacement of parts whose life is

Table 2.2 List of maintenance items

Daily

maintenance and CRT

Periodic

inspection

and

maintenance

Cleaning of

Cleaning of floppy disk

unit (operation board

built-in type)

ewutcheon

-lO-

Daily

Once/two

months

Refer to the section ‘Cleaning the

operation board escutcheon and

CFIT-.

Mar

handling of the floppy disk

perfom-red

to the section ‘Maintenance and

daily but as

up).

unn’.

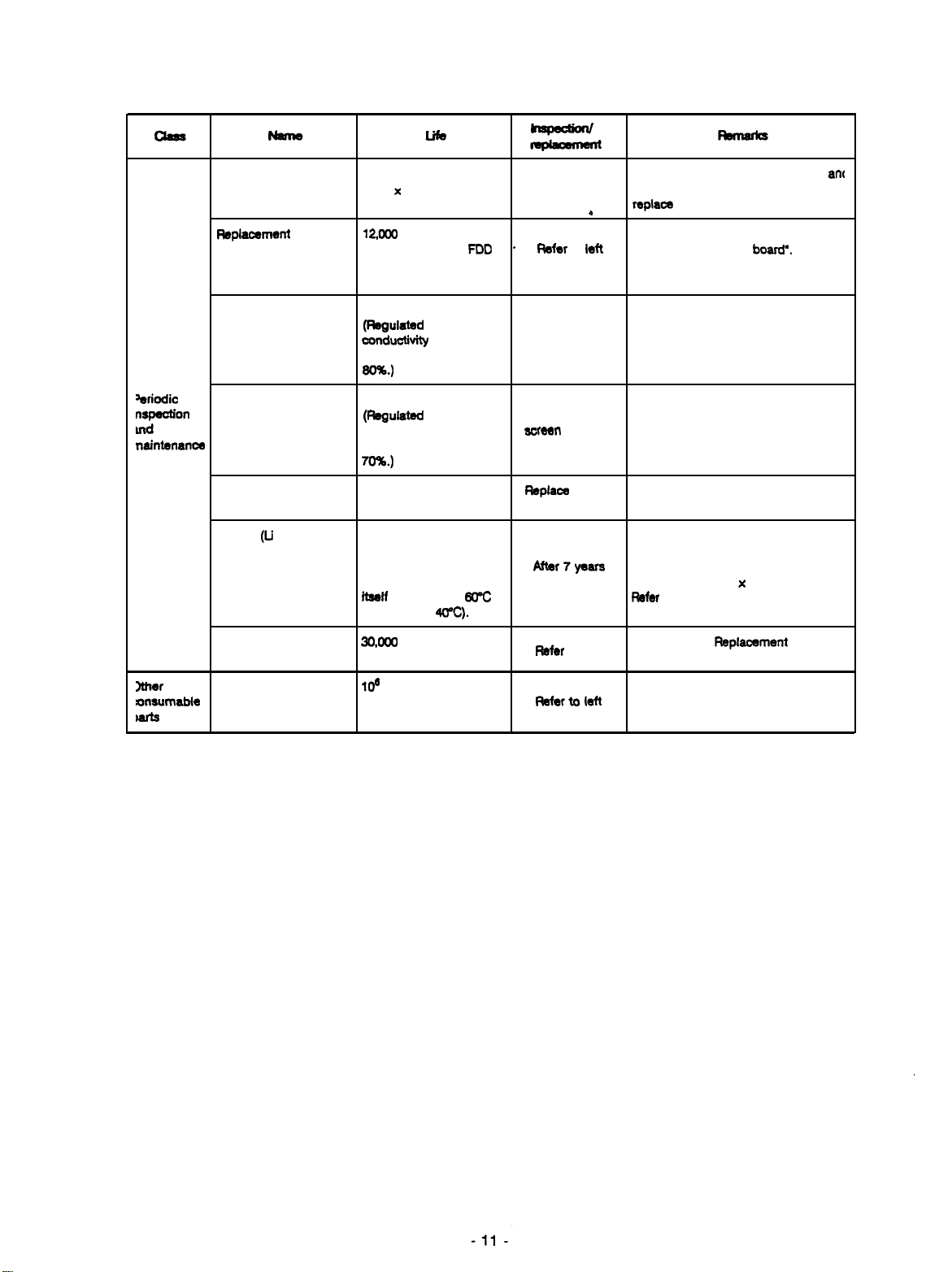

Life

Jeriodic

nspection

uId

naintenanoe

Replacement of floppy

disk sheet (operation

board built-in type)

Replaoement

disk drive (operation

board built-in type)

of floppy

CRT

EL display unit 30,000 hours

Color LCD display unit 10.000 hours

Battery

(Li

battery)

Cooling fan 30,OW

(control unit)

3 x 10s path/track

12,WO

hours of aooess

or after 5 years of R30

motor rotation. Which

ever is first.

7,000 hours

(Fbgulated

conductivity

brightness to drop below

=.)

FWulated by

oonduotivity time for

brightness to drop below

m%.)

(backlight life) screen darkens.

Data saving time: 7 years

(discharge time 2,000

days)

The life of the battery

itself

(8.5 years at

by

time for

is 7 years at

hours

4WC).

6WC

Refer to the section ‘Maintenance

handling of me floppy disk unit’ and

replaoa

*

.

FIefer

to

left

Fbplace when adjusted by the user.

screen darkens.

Replace when the user.

soreen

darkens.

Fleplace

when

After7years

Flefer

to left

the floppy disk sheet.

Refer to ‘Replacement of each

module in operation

Note, that the brightness can be

The brightness can be adjusted by

The data hold time is calculated by

the discharge time/year Max. 6,840

hours (average 240 days x 16 +

holidays 125 days x 24)

Ftefer

to ‘Battery replacement” for the

replacement method.

Refer to 3.6.2

cooling fan’.

Fleplacement

ark

boa&.

of

ld

Xher

onsumable

rafts

Keyboard

punches

Aefertolatt

2.3 Cleaning the Operation Board Escutcheon and CRT

(1)

Remove the escutcheon with the same method as for replacing each operation board module

explained in section 54.5.

(2)

Using a neutral detergent, etc. and soft cloth, wipe the escutcheon and CRT clean.

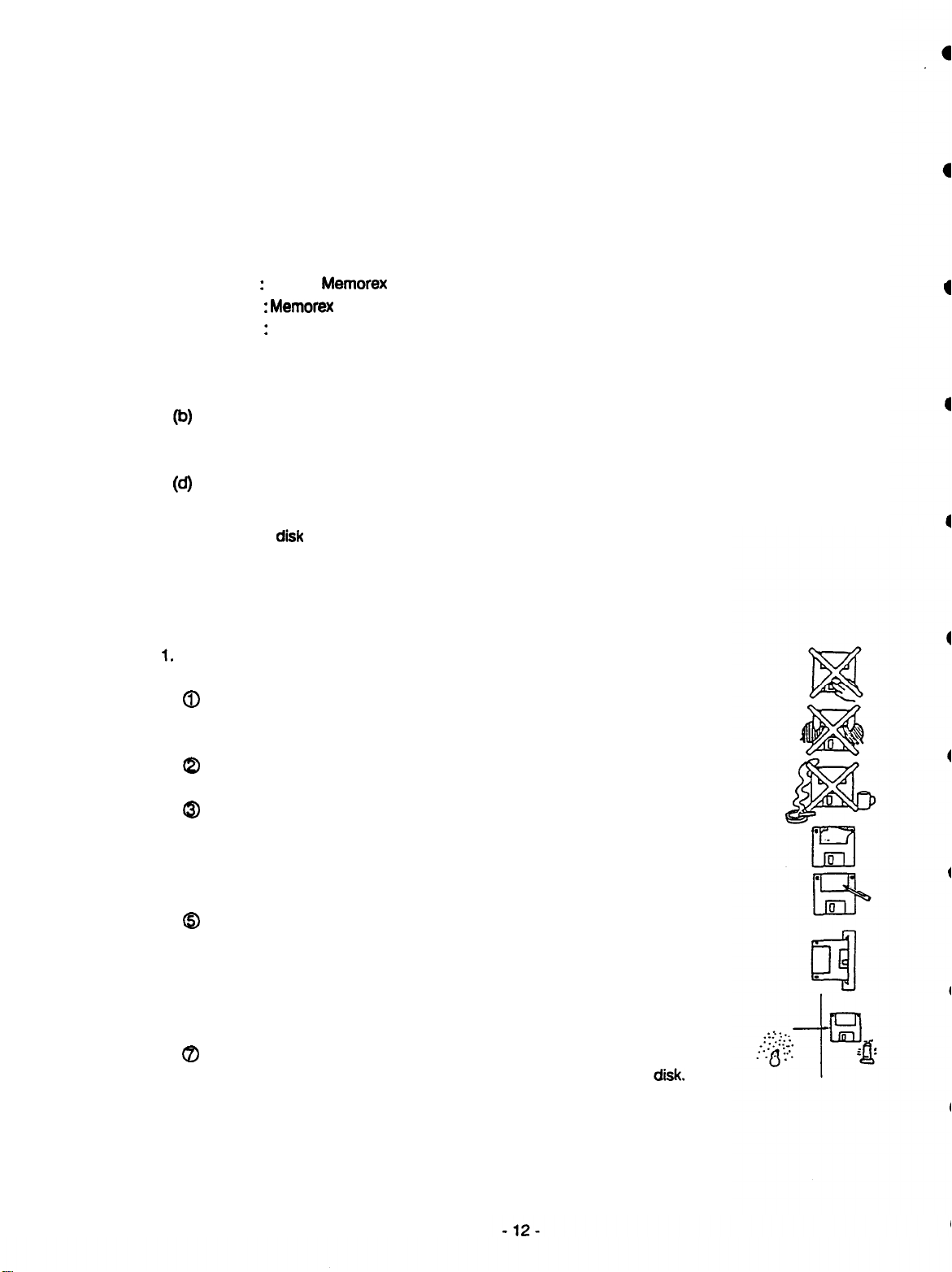

2.4 Maintenance and Handling of the Floppy Disk Unit

2.4.1 Maintenance of the floppy disk unit

Magnetic powder and dust will adhere onto the surface of the floppy disk drive head over a long time,

and may not allow read out to be performed properly.

Clean the head about once every two months with the following procedure.

(1) Recommended cleaning disk

Maker : Japan

Model

Method : Dry

(2) Cleaning method

(a)

insert the cleaning disk into the floppy disk drive in the floppy disk unit to be cleaned.

(b)

Select the disk input/output screen from the ‘Data Input/Output’ function on the display screen and

display the directory.

(c)

Cleaning is completed when the message ‘DISK ERROR’ appears on the display screen.

(d)

Eject the cleaning disk.

(Note) 1. The cleaning disk can be used 60 times. Replace the cleaning disk with a new one when

2.4.2 Handling of the floppy disk

: Memorex

the

Memorex

Cleaning Floppy 3.5 inch double sided

disk

has been used 60 times.

Observe the following points to use the floppy disk for a long time.

1,

Precautions for handling

@

Never touch the magnetic surface.

Read out will not be possible if fingerprints get on the magnetic surface.

a

Do not touch the floppy disk with oily or powder coated hands.

@

Do not place the floppy disk near tobacco smoke or solvents.

@When sticking on an index label, make sure that it is in the correct direction

and that it will not peel off. Do not overlay labels.

@

Fill in the index label before sticking it on. Use a soft-tipped pen, such as a

felt pen when writing on a label that has already been stuck on the disk.

@Gradually insert the disk in the correct direction into the drive. Rough

insertion and ejection will damage the disk.

@

When moving the disk between rooms with great differences in temperature

and humidity, always wait at least 30 minutes before using the

disk.

2 Precautions for storage

@

When not using the floppy disk or when storing back up disks, always place

them in a plastic case.

@

Do not store the disks where they

will

be subject to direct sunlight or near

heating appliances.

@

Do not place the disks near magnets or magnetic fields. Magnetic rings and

necklaces may also erase the data on the disk, so avoid handling the disks

near these types of items.

@

Do not place objects on the disks.

24.3 Other precautions for handling

1.

floppy

disk life

The life of the floppy disk is either

fwe

years of the FDD motor rotation or 12000 hours. The

durability is ensured for the shorter of these two times. However, when using the unit in a dirty

environment, reading out of the data may not be possible if dirt or other matters adhere onto the

head.

Always perform the periodic head cleaning (refer to section 23.1) to prevent this type of trouble.

2 Recommendation for backups

Copy the floppy disks to store important data so that data will not be lost due to unforeseen

accidents such as scratches or destroyed data

3. Working conditions

The floppy disk unit and floppy disks are very sensitive to changes in temperature and humidii.

In regard to temperature, the data track and head’s relative position will deviate and proper readout

of the data may not be possible if the conditions are not satisfied (start up in below freezing

conditions).

Always wait for the internal temperature to rise before starting.

4. Writing to floppy disks

Data must be written into the floppy disks at a temperature between

10°C

and

40%.

Always

observe the temperature conditions when writing data into the disk.

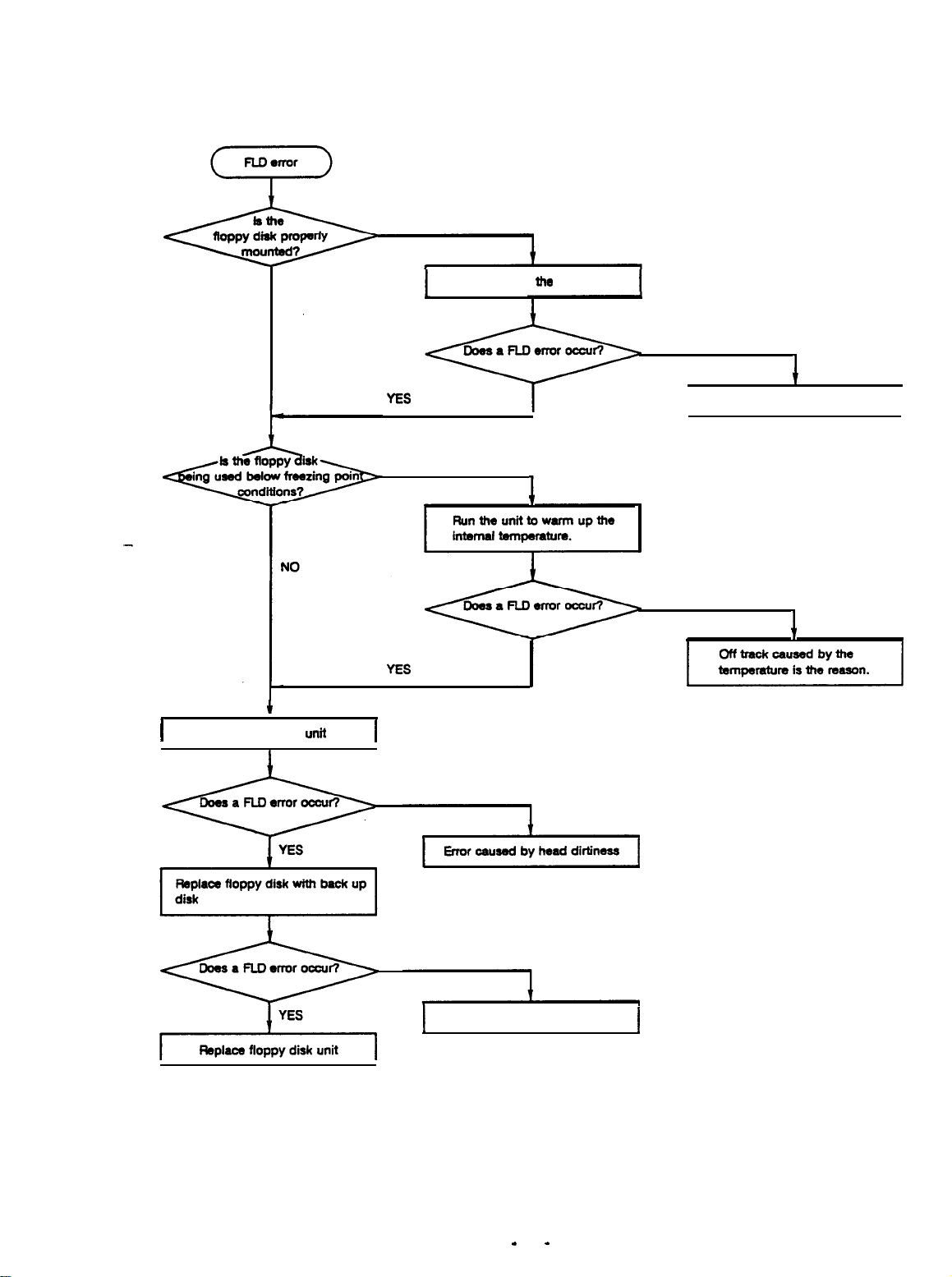

24.4 Troubleshooting

NO

Clean the floppy disk

I

YES

unif

head

I

YES

Properly mount

I

fhe

floppy disk.

NO

I

Floppy disk mounting defect

NO

I

NO

NO

Floppy disk is defective

-

14

-

I

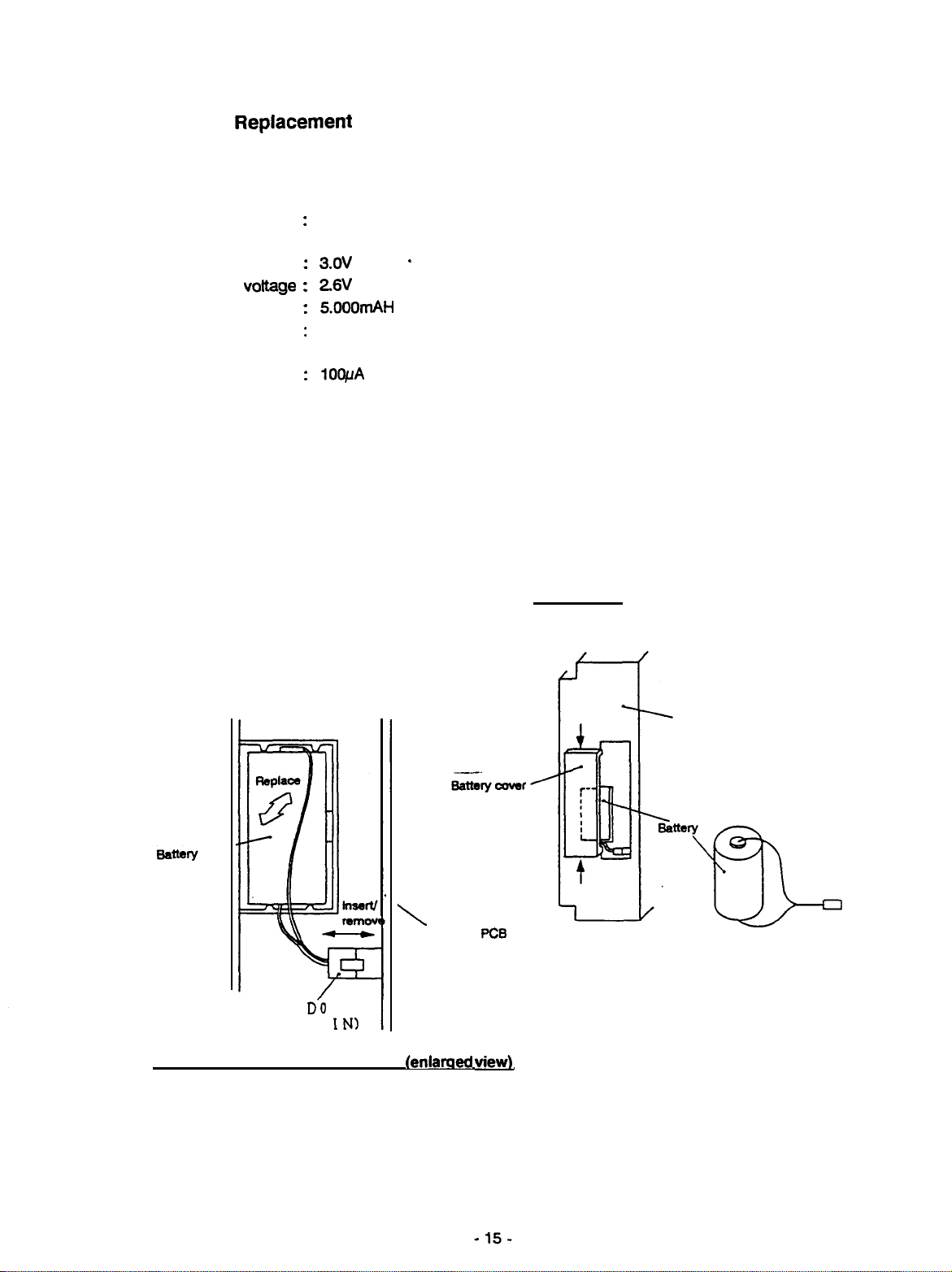

2.5 Battery

Data that must be backed up such as the parameters and machining programs, etc., are saved by the

lithium battery mounted in the front panel on the front of the control power supply when the power is

turned OFF.

Battery used

Battery voltage

Alarm

Battery capacity

Battery back up time

Battery life

Discharge current

The battery must be replaced before the life is up to ensure proper operation of the system.

(If the battery alarm is displayed, the internal data may be destroyed.)

Replacement procedure

The machine (NC) power may be ON or OFF.

(1) Remove the battery cover on the front panel of

the control power supply.

(2) Disconnect the connector on the battery.

(3) Replace the battery and connect the connector.

(4) Replace the battery cover

Replacemeflt

BR-CC7P with connector

:

(Matsushita Denchi Kogyo with Mitsubishi specifications)

3.ov

:

voftage :

26V

5000mAH

:

7 years

:

7 years

10wA

:

or less

*

1

If

complete this procedure within

30 minutes.

the power is turned OFF,

\

Power supply

C

P

D-0

7

(BAT

State with batterv cover removed

IN)

Power supply front panel

(left edge of control unit)

PC6

(enlamed view1

3. Trouble Diagnosis and Measures

If any

trouble occurs during operation, it is necessary to accurately find the cause so that appropriate

measures can be taken. Perform the following check to find the cause.

3.1 Confirmation of State of Trouble Occurrence

Confirm ‘when’, ‘what was done’ and what

(1) When did the trouble

occufl

The time that the trouble occurred.

(2) What was done?

What mode was the NC operating in?

During automatic operation: Program No., sequence No., and program details of when the trouble

occurred.

:

During manual operation

What was the manual operation mode?

What was the procedure?

What were the last and next steps?

What is on the setting and

display unit screen?

Was data being input or output?

What was the machine side state?

Were tools being exchanged?

Has hunting occurred in the control axis?

kind.of

trouble’ has occurred.

(3) What kind of trouble occurred?

l

What alarm is being displayed on the alarm diagnosis screen in the setting and display unit?

Display the alarm diagnosis screen and confirm the displayed details.

l

What is displayed on the drive amplifier’s status display?

Look at the display of the drive amplifier’s status and confirm the alarm details.

l

What is displayed for the machine sequence alarm?

l

Is the CRT screen normal?

(4) How frequently does the trouble occur?

When did the trouble occur? How frequently? (During operation of other machines?) If the trouble

occurs infrequently, the power voltage may be incorrect, or noise may be the cause. Check that

the power voltage is correct (does the power voltage drop instantaneously when other machines

are operated), and confirm that measures against noise have been taken.

Did the trouble occur in a specific mode?

Did the trouble occur when the ceiling crane was operated?

What is the frequency of occurrence in the same workpiece.

Repeat the operation to see if the same trouble occurs during the same step.

Confirm whether the same trouble occurs when the conditions are changed.

(Try changing the override, program contents, and operation steps, etc.)

What is the ambient temperature?

(Was there a sudden change in temperature? Is the fan on the top of the control unit rotating?)

Are there any defective cable contacts or defective insulation?

(Has oil or cutting fluids splattered on the cables?)

-

16

-

3.2 Examples of Troubles and Troubleshooting

3.2.1 Examples of trouble

(1) The NC power does not turn on.

l

Is the power being supplied to the NC unit?

l

Is the power supply section fuse blown?

(2) The unit does not operate even when started up.

l

Is the correct mode selected?

l

Is the tape correctly mounted during tape operation?

. Are the starting conditions correct?

(In some machines, the start up will be locked unless specific

conditions

l

Is the override or manual speed setting O?

l

Is the reset signal input?

’

Is the feed hold signal input?

l

Is the machine lock on?

wfth

the ‘Instruction Manual’ issued by the machine maker.)

condllions

are satisfied. Confirm the

-

17

-

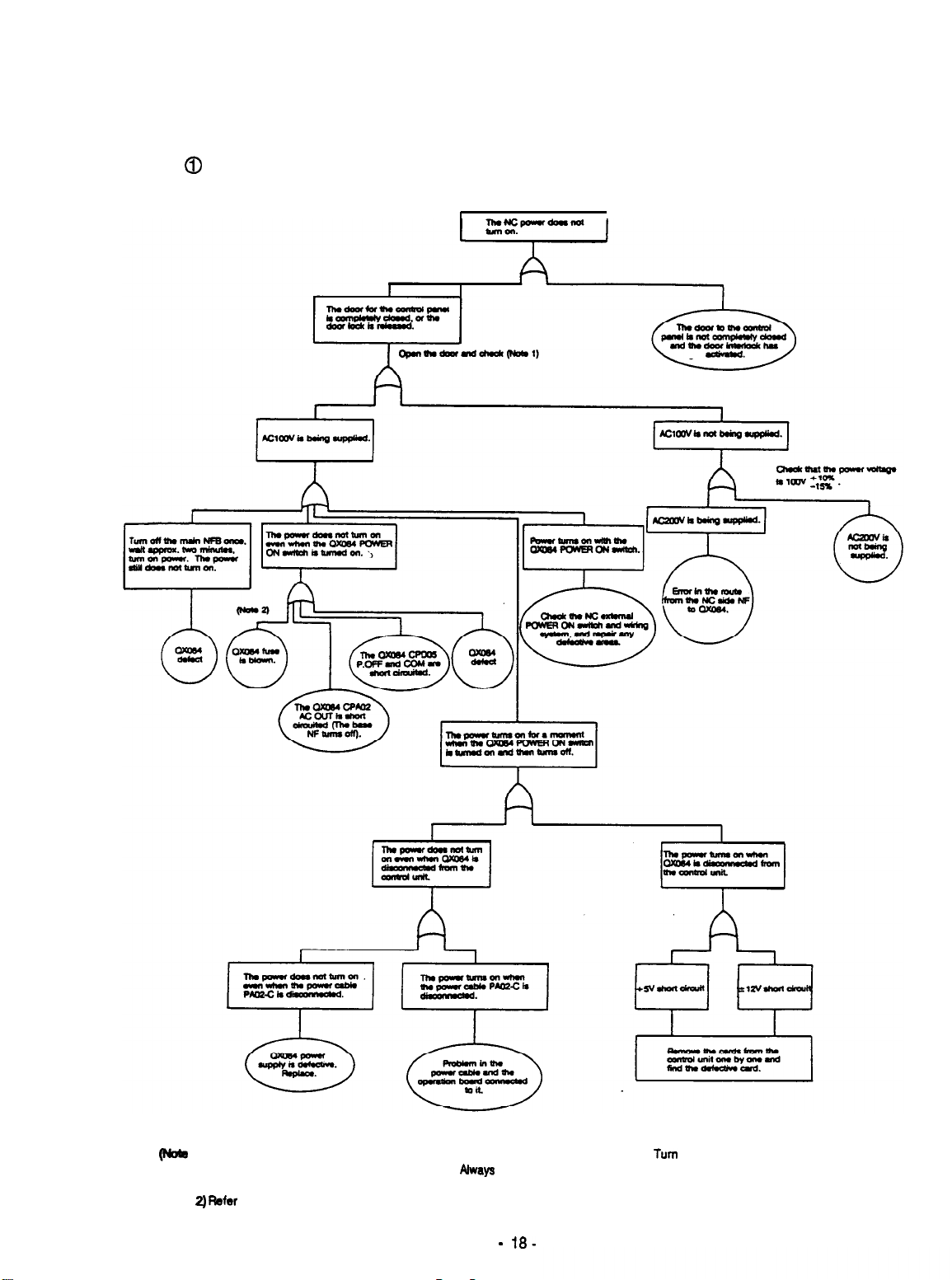

3.22 Examples of troubleshooting

Power supply related troubleshooting

@

The NC power does not turn on.

(Nob 1) When the NC body door is opened, the door interlock limit switch will turn off. Turn the door interlock switch off with the

(Note 2)

door interlock key and then open the door.

then close the door.

FIefor

to section 5.3.1 for details on blown fuses.

Always

return the door interlock switch to ON after removing the trouble, and

-

ia-

a

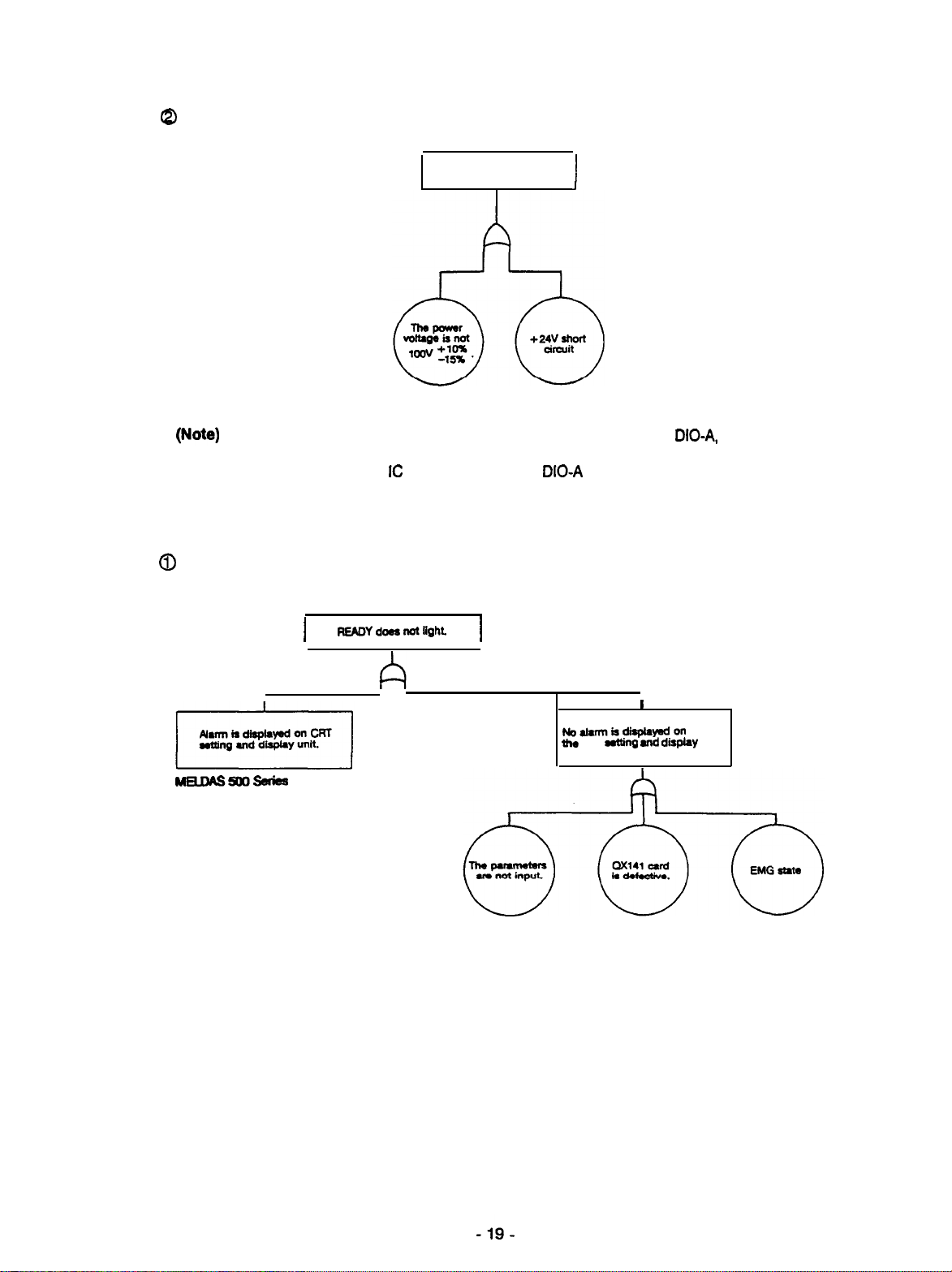

AC FAIL (red) on QX084 lights.

AC FAIL lights.

When the QXO84 24V output is being used for the I/O interface

signal may be short circuited due to mis-wiring, etc.

in the above case, the IC in the I/O interface

Troubleshooting in operation preparation stage

0

Operation preparation (READY) cannot be entered.

1

READYdoes~~i9hi

I

I

DIO-A

card may be destroyed.

DIOA,

the machine output

MElDAs5aJ~

Fbfer to the Alarm Lists provided

for each model, confirm the alarm

details, and inspect accordingly.

I

Noahtmisdisplayedon

the

CRT

niting and display

unit.

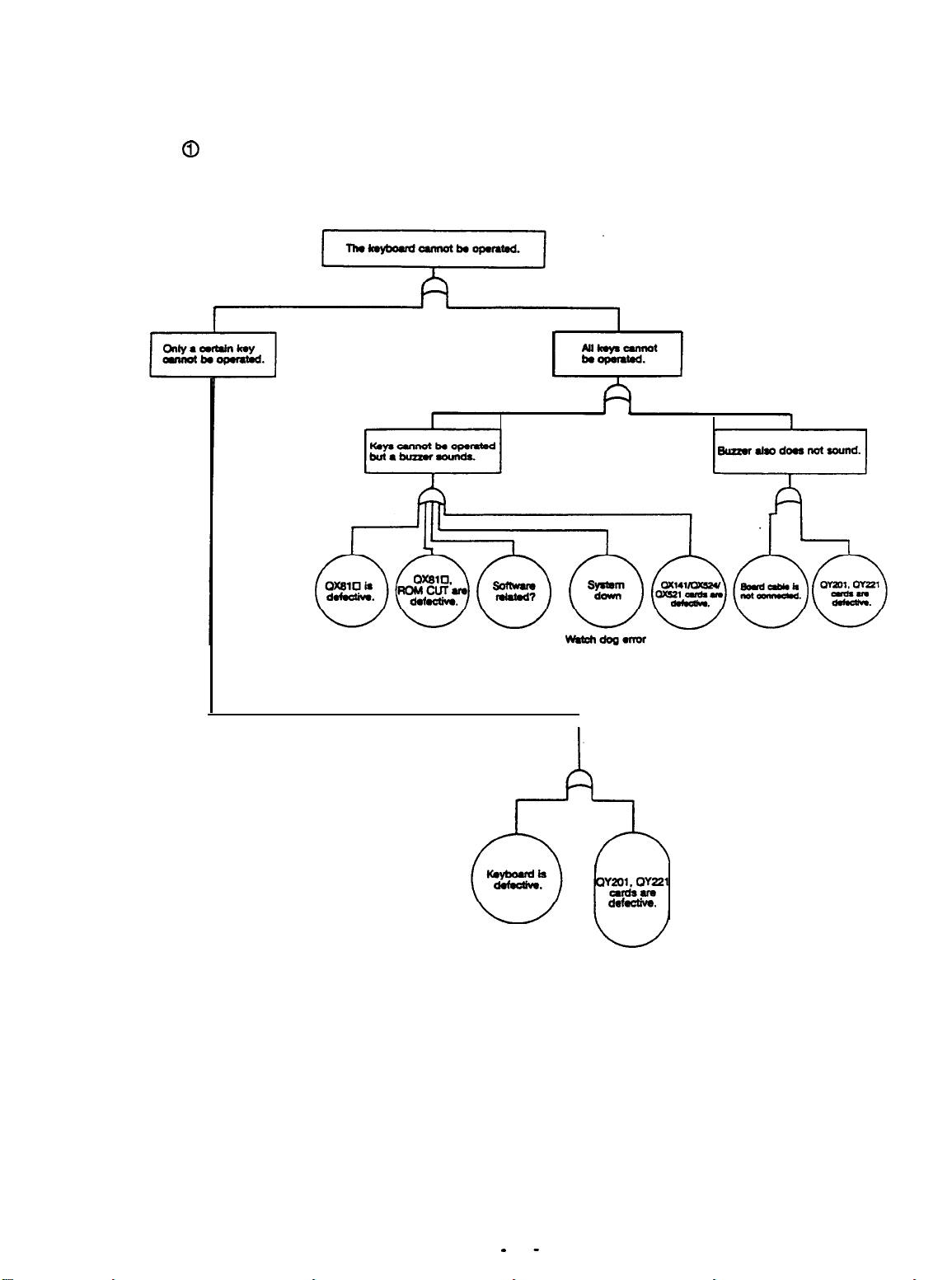

Operation board redated troubleshooting

@

The operation keyboard cannot be operated.

-

20

defatfve.

-

Loading...

Loading...