Page 1

Pub.No.TWDE0911, NOVEMBER 2009

Shop Manual

diesel engine

Page 2

diesel engine

Pub.No.TWDE0911

NOVEMBER 2009

Shop Manual

Page 3

Pub.No.TWDE0911, NOVEMBER 2009

Page 4

GROUP INDEX

FOREWORD

This Shop Manual is published for the information and

guidance of personnel responsible for maintenance of

Mitsubishi Fuso 4M4 series diesel engine, and includes

procedures for adjustment and maintenance services.

We earnestly look forward to seeing that this manual is

made full use of in order to perform correct services with

no wastage.

GENERAL..........................................

ENGINE .............................................

LUBRICATION...................................

FUEL AND ENGINE CONTROL .......

COOLING ..........................................

INTAKE AND EXHAUST ...................

EMISSION CONTROL.......................

HYBRID ELECTRIC VEHICLE

SYSTEM ............................................

00

11

12

13

14

15

17

18

For more details, please consult your nearest authorized

Mitsubishi dealer or distributors.

Kindly note that the specifications and maintenance service figures are subject to change without prior notice in

line with improvement which will be effected from time to

time in the future.

NOVEMBER 2009

Applicable models

4M42T3

©2009 Mitsubishi Fuso Truck & Bus Corporation

Page 5

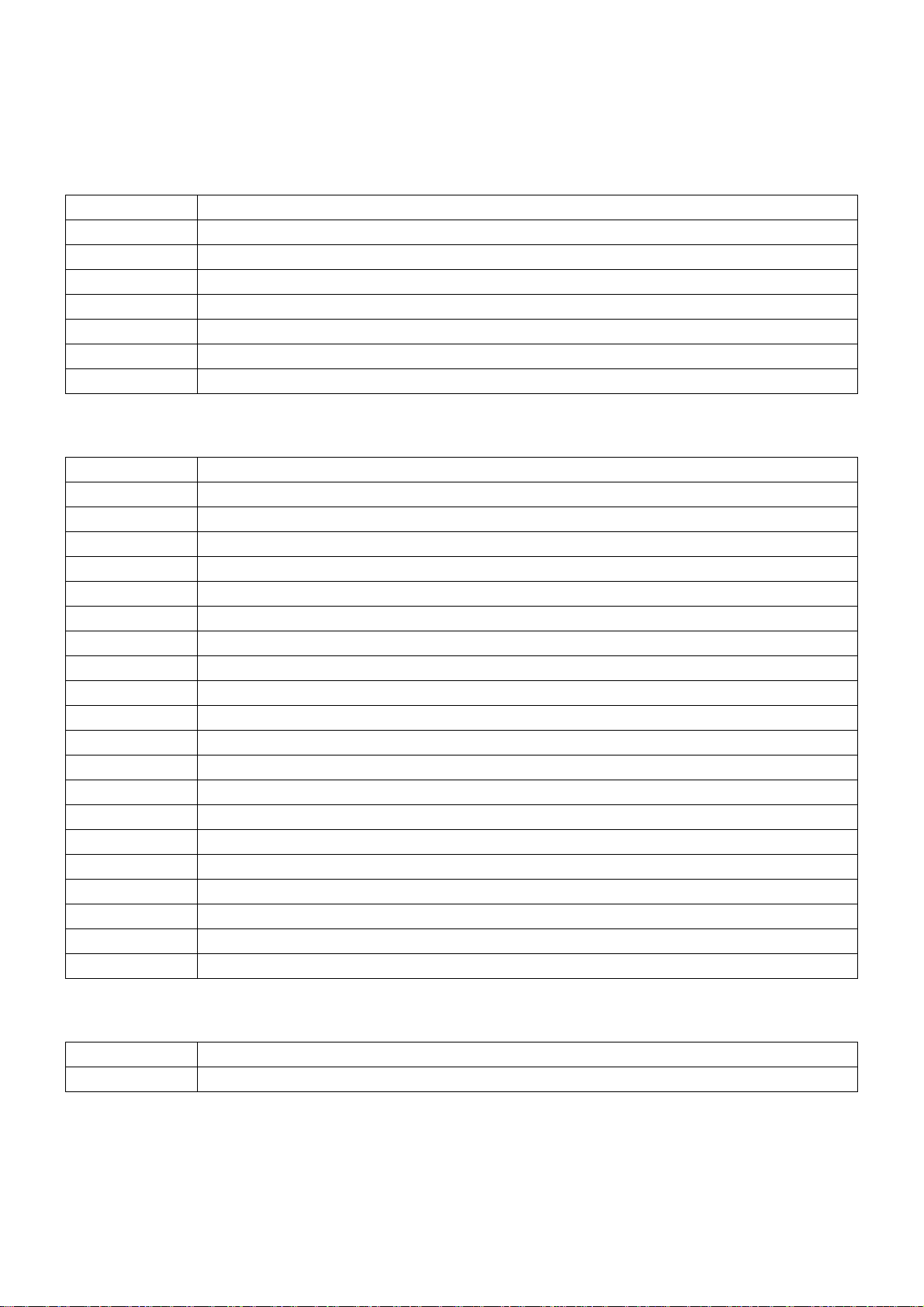

This Shop Manual contains the information classified into the following groups.

If any system or equipment has two or more variations with significantly different construction, the variations are

handled as different groups. These groups are identified by different alphabets preceded by the same number.

1. ENGINE volume

Group No. Group subject

11 ENGINE

12 LUBRICATION

13 FUEL AND ENGINE CONTROL

14 COOLING

15 INTAKE AND EXHAUST

17 EMISSION CONTROL

18 HYBRID ELECTRIC VEHICLE SYSTEM

2. CHASSIS volume

Group No. Group subject

21 CLUTCH

22 MANUAL TRANSMISSION

22E INOMAT-II

25 PROPELLER SHAFT

26 FRONT AXLE

27 REAR AXLE

31 WHEEL, TIRE

33 FRONT SUSPENSION

34 REAR SUSPENSION

35 BRAKE

35EA POWER ANTI-LOCK BRAKE SYSTEM

35EB HILL START ASSIST SYSTEM

36 PARKING BRAKE

37 STEERING

41 BUMPER, FRAME

42 CAB MOUNTING, TILT

43 DOOR

51 EXTERIOR

52 INTERIOR

55 HEATER, AIR-CONDITIONER

3. ELECTRICAL volume

Group No. Group subject

54 ELECTRICAL

Page 6

GROUP 00 GENERAL

MODIFICATION SUMMARY ............................................................. 00-2

VEHICLE MODEL CODING SYSTEM .............................................. 00-4

EQUIPMENT TYPE CODING SYSTEM ............................................ 00-6

POWER TRAIN TABLE .................................................................... 00-7

HOW TO READ THIS MANUAL ....................................................... 00-8

CHASSIS NUMBER, ENGINE NUMBER, MOTOR NUMBER

AND NAME PLATE ......................................................................... 00-16

PRECAUTIONS FOR MAINTENANCE OPERATION .................... 00-18

JACKING UP THE VEHICLE .......................................................... 00-28

DIAGNOSIS CODES

1. Diagnosis Codes ...................................................................... 00-30

2. Reading and Erasing the Diagnosis Code ................................. 00-31

TABLE OF STANDARD TIGHTENING TORQUES ........................ 00-36

13A

13E

00-1

Page 7

MODIFICATION SUMMARY

1. Characteristics of and Precautions for the ECO HYBRID Model

• The following are added to the characteristics of the CANTER ECO HYBRID.

• The CANTER ECO HYBRID is equipped with a dedicated high voltage battery (350 V) for the hybrid electric ve-

hicle system aside from the 24 V battery.

• High voltage is cut off when the starter switch is OFF and the vehicle is stationary.

• High voltage is generated in the high voltage circuit when the starter switch is ON or when the gear is engaged

and the wheels are rotating.

• High voltage in the high voltage circuit may be generated irrespective of the vehicle condition during the hybrid

electric vehicle system abnormalities (the hybrid electric vehicle warning lamp illuminates).

• Be sure to observe the regulations of your country or region regarding the qualifications or trainings required for

servicing the high-voltage equipment.

• The following are added to the precautions concerning high voltage cable and high voltage devices.

DANGER

• High voltage (350 V) may be generated in the high voltage circuit that consists of various high voltage devices (motor generator, motor electronic control unit and high voltage battery box) and cable (orange). Utmost care is required in handling these parts. When servicing, see Gr18 HYBRID ELECTRIC VEHICLE

SYSTEM.

• Improper use of the high voltage battery may cause electric shock, overheating or fire though it is safe

when properly handled. It may explode in the worst case.

• The following are added to the remedies against vehicle damage by collision or the like.

WARNING

• When the vehicle is on fire, use the ABC fire extinguisher to put out the fire. Since it is dangerous to fight

a fire with a small quantity of water, spray a large amount of water from a fire hydrant or wait for the arrival of the fire brigade.

• When the vehicle is soaked in water, do not touch the high voltage devices and high voltage cable including the safety plug of the high voltage battery box to prevent electric shock. Work on the vehicle after

pulling it out of water.

• Insulate any high voltage terminal that is exposed by damage with vinyl tape or the like to prevent electric

shock.

CAUTION

• The electrolyte in the high voltage battery is as flammable as kerosene. If there is any fluid leakage near

the high voltage box, wipe up the fluid while keeping fire away from it.

• Turn the starter switch to OFF to cut off the high voltage system. If it cannot be confirmed that the starter

switch is OFF, disconnect the negative side battery cable from the 24 V battery. Then, remove the safety

plug of the high voltage battery box with insulated gloves on while referring to Gr18 HYBRID ELECTRIC

VEHICLE SYSTEM.

• In the case of the abnormality described above, replace the defective part referring to Gr18 HYBRID

ELECTRIC VEHICLE SYSTEM.

00-2

Page 8

M E M O

00

00-3

Page 9

VEHICLE MODEL CODING SYSTEM

<For Hong Kong and Singapore>

1 743 52 986

FE84BE

1 Basic vehicle type F Cab-over engine truck

2 Load capacity, drive system E 2 ton class and over, 4 × 2

3 Cab type 8 Wide cab

4 Suspension 4 Independent axle

5 Engine B 4M42T

6 Wheelbase E 3350 mm

7 Chassis arrangement for use V Van use

8 Rear tire arrangement, payload 3

9 Vehicle specification H Hybrid

10 Engine output variation 6 4M42T3 (96 kW {130 PS})

11 Export specification EX

V3H6

11

10

EX

Low deck/rear double

Payload 3000 to 4000 kg

00-4

Page 10

<For Australia and New Zealand>

00

1 743 52 986

FE84BE

1 Basic vehicle type F Cab-over engine truck

2 Load capacity, drive system E 2 ton class and over, 4 × 2

3 Cab type 8 Wide cab

4 Suspension 4 Independent axle

5 Engine B 4M42T

6 Wheelbase E 3350 mm

7 Chassis arrangement for use V Van use

8 Rear tire arrangement, payload 7

9 Steering position R Right-hand drive vehicle

10 Export specification FA

11 Vehicle specification H Hybrid

V7RFA

11

10

H

Rear double

Payload 3000 to 4000 kg

00-5

Page 11

EQUIPMENT TYPE CODING SYSTEM

Component Name plate marking Code description

Engine

4M42T3 4 M 4 2 T 3

Classification of turbocharger

Turbocharged

Order of development within same series

Order of development among different series

Diesel engine

No. of cylinders (4)

Clutch

C3W28 C 3 W 28

Disc outside diameter

Facing material (W: Woven)

Load carrying capacity of truck class (ton nage) on which the clutch is primarily used

Initial letter of the clutch

Transmission

M036S5 M 036 S 5

Forward speeds

Type of mesh (S: Synchromesh)

Load carrying capacity of truck class (ton nage) on which the clutch is primarily used

Initial letter of the transmission

Propeller shaft

P3 P 3

Front axle

F200T F 200 T

Rear axle

R033T R 03 3 T

Reduction and differentioal

D033H D 03 3 H

Load carrying capacity of truck class (ton nage) on which the clutch is primarily used

Initial letter of the propeller shaft

Vehicle type (T: Truck)

Load carrying capacity of truck class (ton nage) on which the clutch is primarily used

Initial letter of the front axle

Vehicle type (T: Truck)

Order of development within same series

Load carrying capacity of truck class (ton nage) on which the clutch is primarily used

Initial letter of the rear axle

Tooth profile (H: Hypoid gear)

Order of development within same series

Load carrying capacity of truck class (ton nage) on which the clutch is primarily used

Initial letter of the reduction & differentioal

00-6

Page 12

POWER TRAIN TABLE

00

Vehicle model Engine Clutch Transmission Propeller shaft Rear axle

FE84BEV3H6EX 4M42T3 C3W28 M036S5 P3 R033T D033H

FE84BEV7RFAH 4M42T3 C3W28 M036S5 P3 R033T D033H

Reduction and

differential

00-7

Page 13

HOW TO READ THIS MANUAL

This manual consists of the following parts:

• Specifications

• Structure and Operation

• Troubleshooting

• On-vehicle Inspection and Adjustment

• Service procedures

On-vehicle Inspection and Adjustment

• Procedures for inspection and adjustment of individual parts and assemblies as mounted on the vehicle are de-

scribed including specific items to check and adjust. Specified or otherwise, inspection should be performed for

looseness, play, backlash, crack, damage, etc.

Service procedures

• Procedures for servicing components and parts off the vehicle are described centering on key points in their re-

moval, installation, disassembly, reassembly, inspection, etc.

Inspection

• Check items subject to “acceptable/unacceptable” judgement on the basis of service standards are all given.

• Some routine visual checks and cleaning of some reused parts are not described but must always be included in

actual service work.

Caution

• This service manual contains important cautionary instructions and supplementary information under the following

four headings which identify the nature of the instructions and information:

DANGER

WARNING

CAUTION

NOTE

Terms and Units

• Front and rear

The forward running direction of the vehicle is referred to as the front and the reverse running direction is referred

to as the rear.

• Left and right

Left hand side and right hand side, when facing the forward running direction of the vehicle, are respectively left

and right.

Precautions that should be taken in handling potentially dangerous substances

such as battery fluid and coolant additives.

Precautionary instructions, which, if not observed, could result in serious injury or

death.

Precautionary instructions, which, if not observed, could result in damage to or destruction of equipment or parts.

Suggestions or supplementary information for more efficient use of equipment or

better understandings.

Standard value

• Standard value dimensions in designs indicating: the design dimensions of individual parts, the standard clear-

ance between two parts when assembled, and the standard value for an assembly part, as the case may be.

Limit

• When the value of a part exceeds this, it is no longer serviceable in respect of performance and strength and must

be replaced or repaired.

00-8

Page 14

00

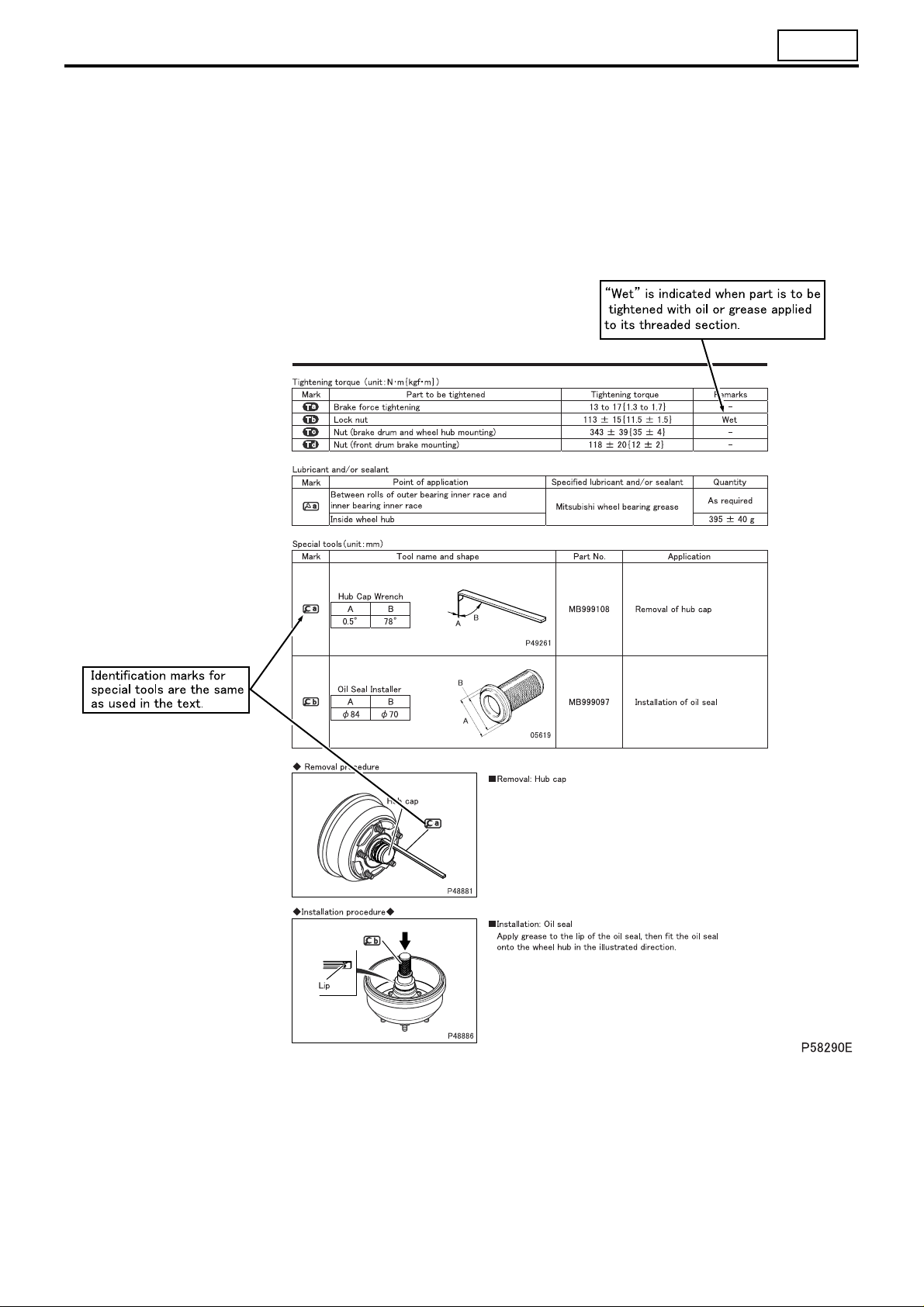

Tightening torque

• Values are directly specified for out-of-standard tightening torques for bolts and nuts.

• Where there is no specified figure for tightening torque, follow the table covering standard tightening torques.

(Values for standard tightening torques are based on thread size and material.)

• When the item is to be tightened in a wet state, “wet” is indicated. Where there is no indication, read it as dry.

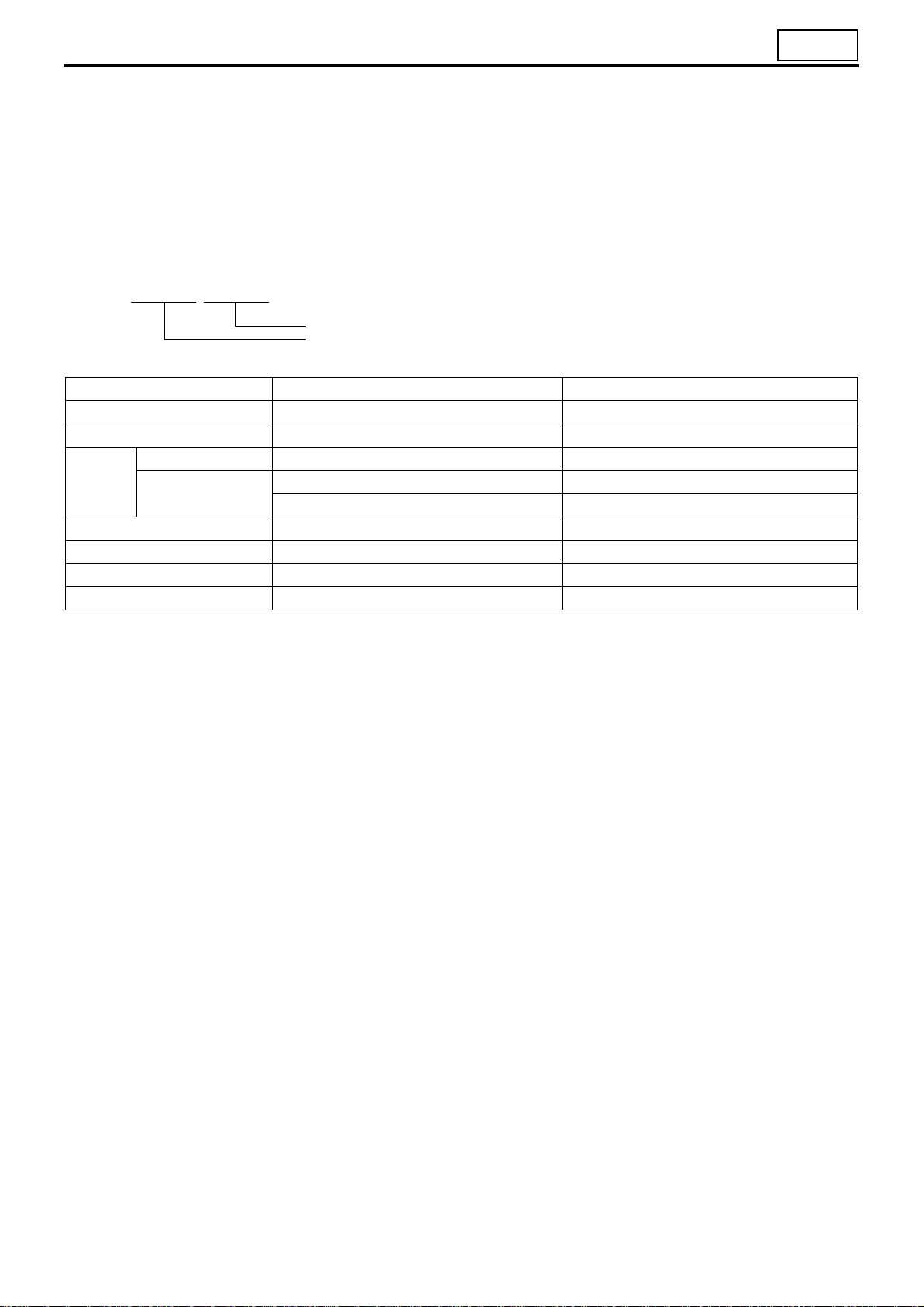

Units

• Tightening torques and other parameters are given in SI* units with metric units added in brackets { }.

*SI: Le Système International d’Unités

Example: 390 N·m {40 kgf·m}

Metric unit

SI unit

Item SI unit {metric unit} Conversion factor

Force N {kgf} 9.80665 N {1 kgf}

Moment of force N·m {kgf·m} 9.80665 N·m {1 kgf·m}

Positive pressure kPa {kgf/cm2} 98.0665 kPa {1 kgf/cm2}

Pressure

Volume dm

Heat quantity J {kcal} 4186.05 J {1 kcal}

Heat flow W {kcal/h} 1.16279 W {1 kcal/h}

Power kW {PS} 0.7355 kW {1 PS}

Vacuum pressure

kPa {mmHg} 0.133322 kPa {1 mmHg}

Pa {mmH

O} 9.80665 Pa {1 mmH2O}

2

3

{L} 1 dm3 {1 L}

00-9

Page 15

HOW TO READ THIS MANUAL

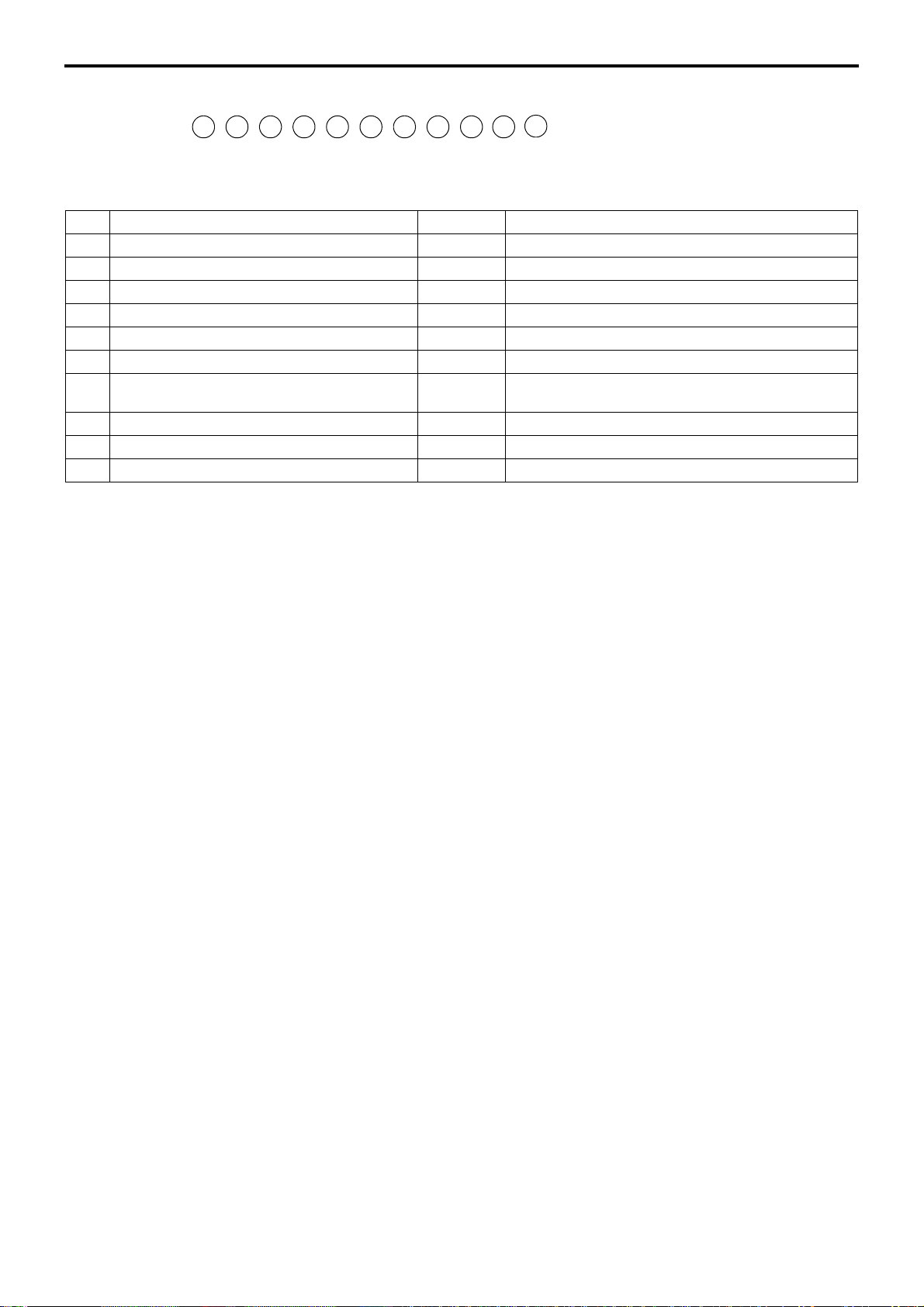

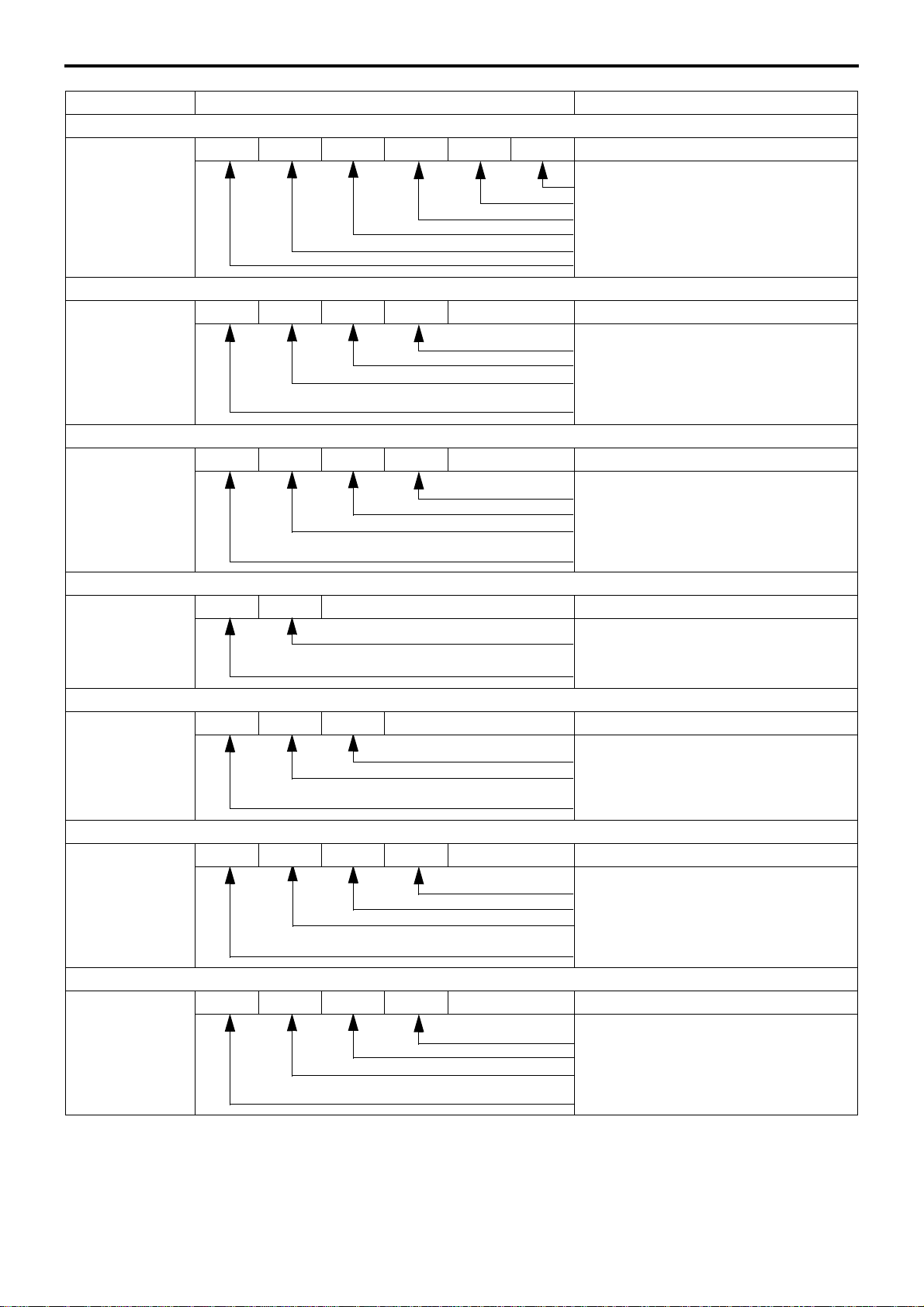

1. Illustrated Parts Breakdown and Service Procedures

Symbol Denotation Application Remarks

Tightening torque

Locating pin Parts to be positioned for installation

Non-reusable parts Parts not to be reused

Lubricant and/or

sealant

Special tool

*a Associated part

Parts not tightened to standard torques

(standard torques specified where necessary for servicing)

Parts to be coated with lubricant or sealant

for assembly or installation

Parts for which special tools are required for

service operation

Parts associated with those removed/disassembled for servicing

Specified values shown in table

See Table of Standard Tightening Torques for

parts for which no tightening torques are specified.

Necessary lubricant and/or sealant, quantity required, etc. are specified in table.

Tool name/shape and part number are shown in

table.

00-10

Page 16

00

00-11

Page 17

HOW TO READ THIS MANUAL

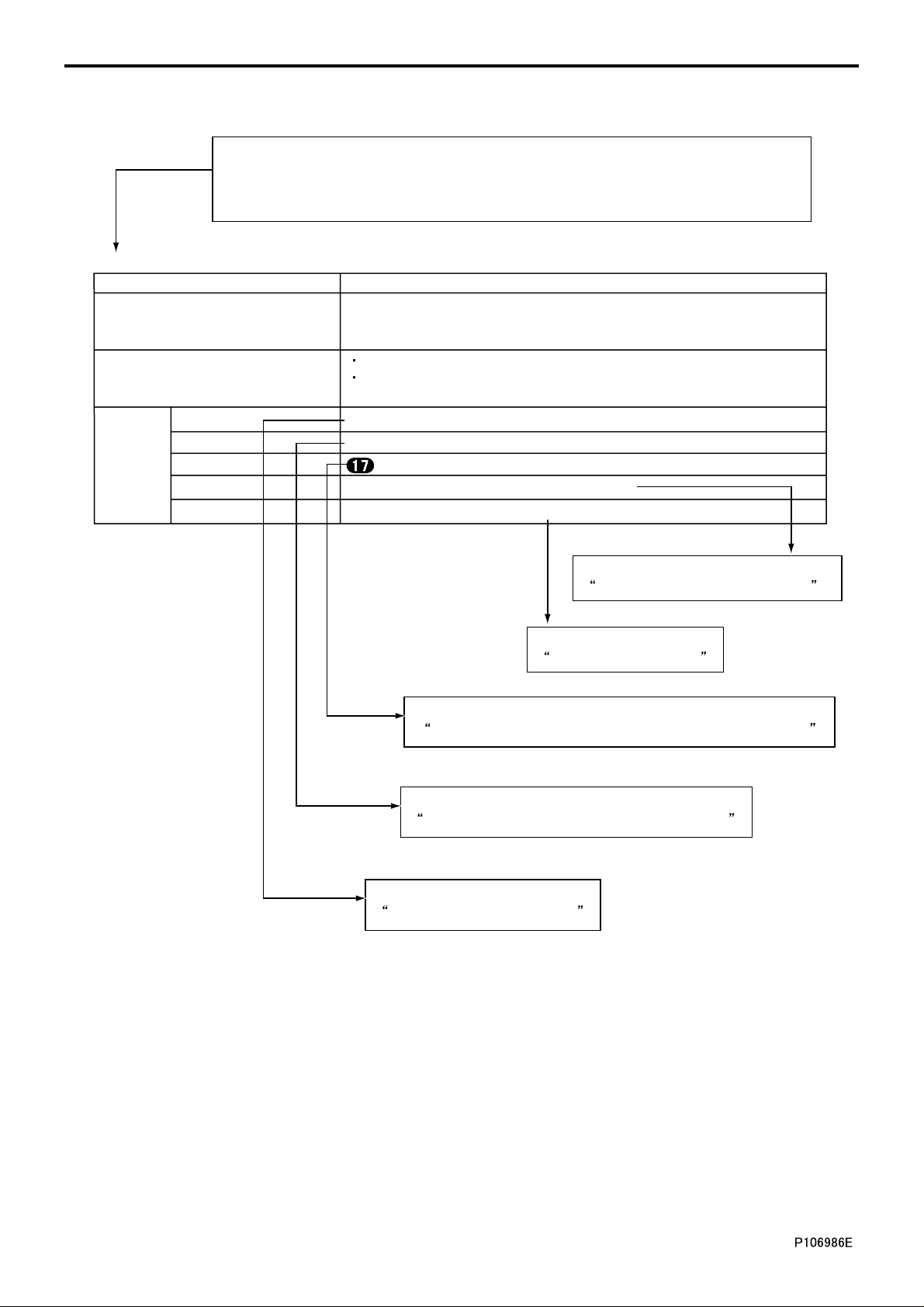

2. How to Use Diagnosis Codes <Electronic Control System>

There are the diagnosis code and message displayed on Multi-Use Tester.

Numerical values in parenthesis are added only when a diagnostic code indicated in

the Multi-Use Tester display differs from the code indicated by the number of warning

lamp flashes.

P0475: Exhaust Brake PWR (Open) (warning lamp flashes: 93)

Generation condition Exhaust shutter 3-Way magnetic valve circuit is open

System recovers if any valid signal is input when starter switch is turned

Recoverability

Control effected by electronic control

unit

Service data C2: Auxiliary brake M/V1

Actuator test AA: Auxiliary brake M/V1

Inspection

Electronic control unit : Exhaust shutter 3-Way magnetic valve

Electrical equipment #565: Exhaust shutter 3-Way magnetic valve

Electric circuit diagram Exhaust shutter 3-Way magnetic valve circuit

from OFF to ON (the warning lamp does not extinguish unless 3 consecutive

valid signals are input).

Control of auxiliary brake function is deactivated.

White smoke reduction control is deactivated if idling condition is held

for an extended period of time.

Refer to

Refer to

Inspections Performed At Electronic Control Unit Connectors.

Refer to

Actuator Tests Performed Using Multi-Use Tester.

Refer to

Multi-Use Tester Service Data.

Refer to

Inspection of Electrical Equipment.

Electric Circuit Diagram.

00-12

Page 18

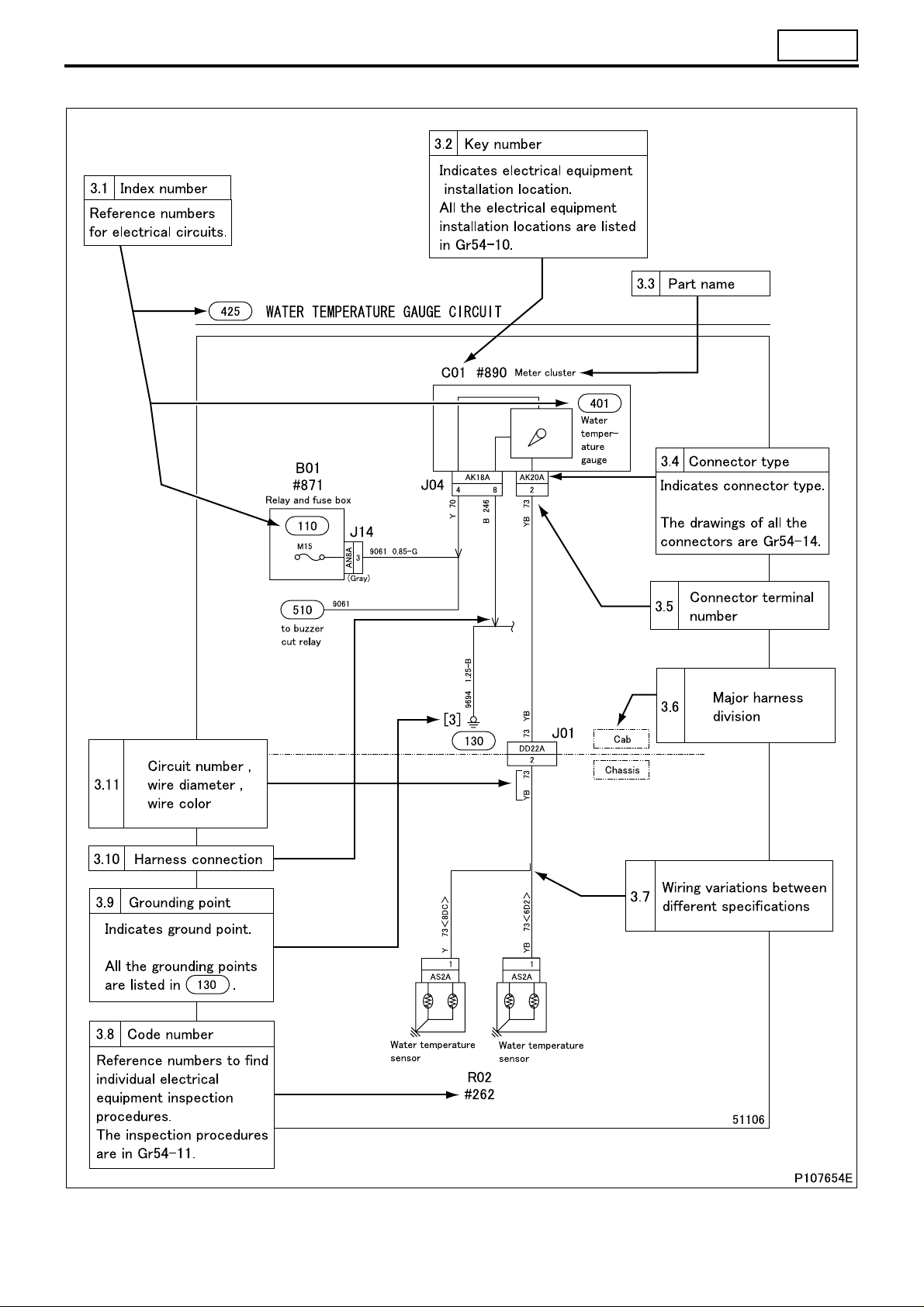

3. How to Read Circuits

00

00-13

Page 19

HOW TO READ THIS MANUAL

3.1 Index number: to

• Index numbers are used as reference numbers for electrical circuits. Each electrical circuit has been assigned its

own index number.

100 999

3.2 Key number: A01 to Z99

• Key numbers indicate electrical equipment installation locations. The installation location of a part can be easily

found using its key number shown in a circuit diagram.

All of the electrical equipment installation locations are listed in Gr54-10.

3.3 Part name

3.4 Connector type (type indication)

• A list of the connectors used is included in Gr54-14.

3.5 Connector terminal number

3.6 Major harness division

• Major harness divisions are shown.

3.7 Wiring variations between different specifications

• Variations in wiring/circuit between different vehicle specifications are clearly indicated as shown.

3.8 Code number: #001 to #999

• Code numbers are reference numbers to find individual electrical equipment inspection procedures. The inspec-

tion procedure for a electrical equipment can be found using its code number shown in a circuit diagram.

3.9 Grounding point: [1] to [99]

• Locations where wires are grounded to the vehicle. All of the grounding points are listed in .

130

3.10 Harness connection

• The arrow in the wiring diagram indicates where harnesses are connected, and NOT the flow of electricity.

3.11 Circuit number, wire diameter, wire color

00-14

Page 20

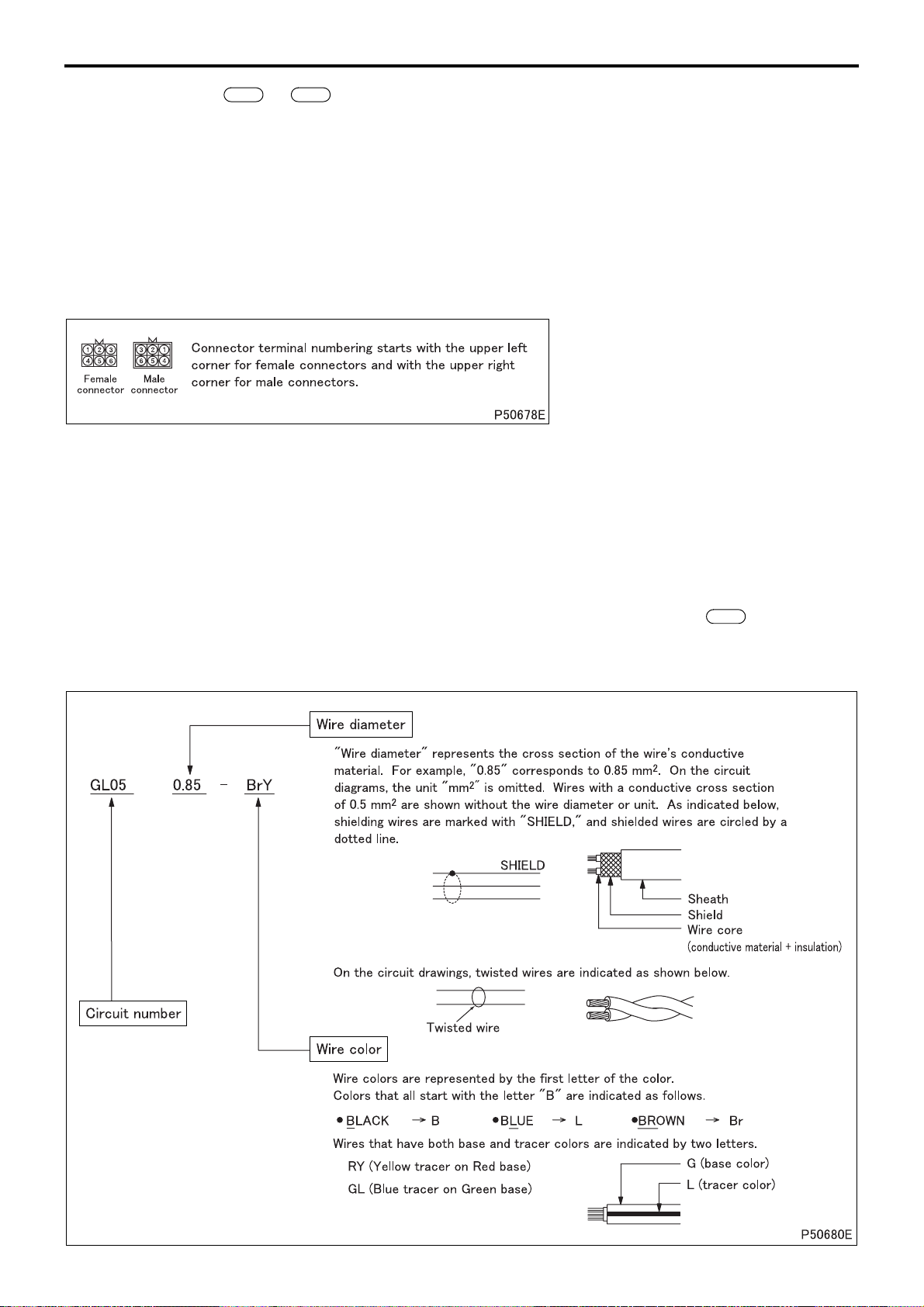

(1) Wire color

Wire color Base color + tracer

BBlackBW

Br Brown BrW

GGreenGW

Gr,

Gy

LBlueLW

Lg

O Orange OL

PPinkPB

Pu Purple

RRedRW

Sb Sky blue

VVioletVY

WWhiteWR

YYellow

green

Gray

Light

GrL,

GyL

LgR

YR

YP

Black/

white

Brown/

white

Green/

white

Gray/

blue

Blue/

white

Light

green/

Orange/

blue

Pink/

black

Red/

white

Violet/

yellow

White/

Yell ow /

Yell ow /

pink

BY

BrB

GR

GrR,

GyR

LR Blue/red LY

LgY

red

OB

PG

RB

VW

WB

red

YB

red

YV

Black/

yellow

Brown/

black

Green/

red

Gray/

red

Light

green/

yellow

Orange/

black

Pink/

green

Red/

black

Violet/

white

White/

black

Yell ow /

black

Yell ow /

violet

BR Black/red BG

BrY

GY

LgB

OG

PL

RY

VR Violet/red VG

WL

YG

Brown/

yellow

Green/

yellow

Blue/

yellow

Light

green/

black

Orange/

green

Pink/

blue

Red/

yellow

White/

blue

Yell ow /

green

BrR

GB

LB

LgW

PW

RG

WG

YL

Black/

green

Brown/

red

Green/

black

Blue/

black

Light

green/

white

Pink/

white

Red/

green

Violet/

green

White/

green

Yell ow /

blue

BL

BrG

GL

LO

RL Red/blue RO

WO

YW

Black/

blue

Brown/

green

Green/

blue

Blue/

orange

White/

orange

Yellow/

white

GO

LG

YO

00

Green/

orange

Blue/

green

Red/

orange

Yellow/

orange

00-15

Page 21

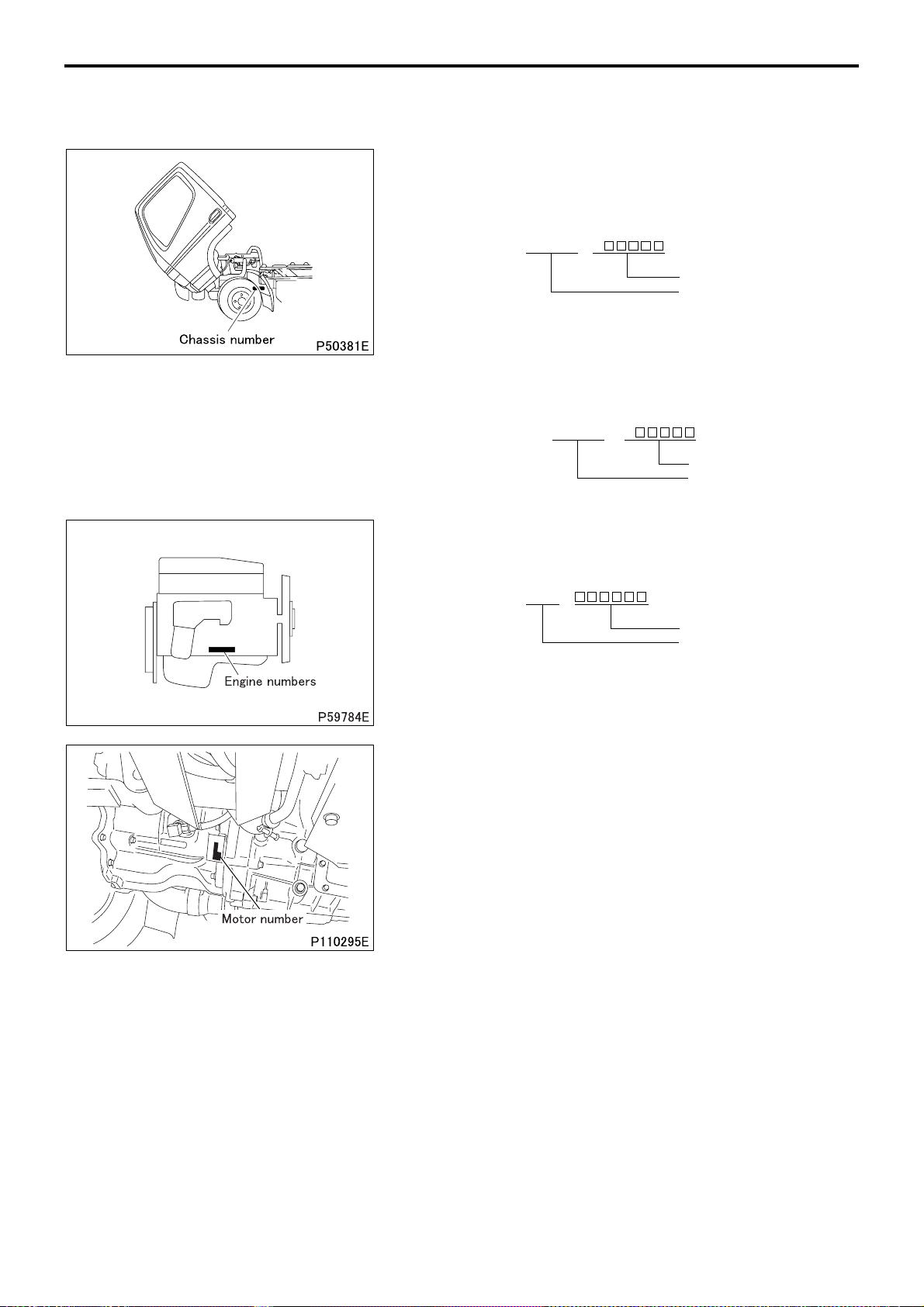

CHASSIS NUMBER, ENGINE NUMBER, MOTOR NUMBER AND NAME PLATE

• Serial chassis and engine numbers are assigned to the vehicles and engines in manufacturing sequence. Every

vehicle and engine has its own number. These numbers are required for registration and related inspection of the

vehicle.

Chassis number

<Type 1>

• The chassis number is indicated on the left frame, near the left

front wheel.

Example: FE84BE – A

Chassis number

Vehicle number

<Type 2>

• The chassis number is included in the vehicle identification number (V.I.N), which is stamped on the left-hand frame near the left

front wheel.

Example: JLF FE84BE0K J

Chassis number

Vehicle number

Engine number

• The engine number is indicated on the right side of the crank-

case.

Example: 4M42 –

Engine number

Engine model

Motor number

• The motor number is indicated on the left below part of the

clutch housing.

Example: S10B12345

00-16

Page 22

00

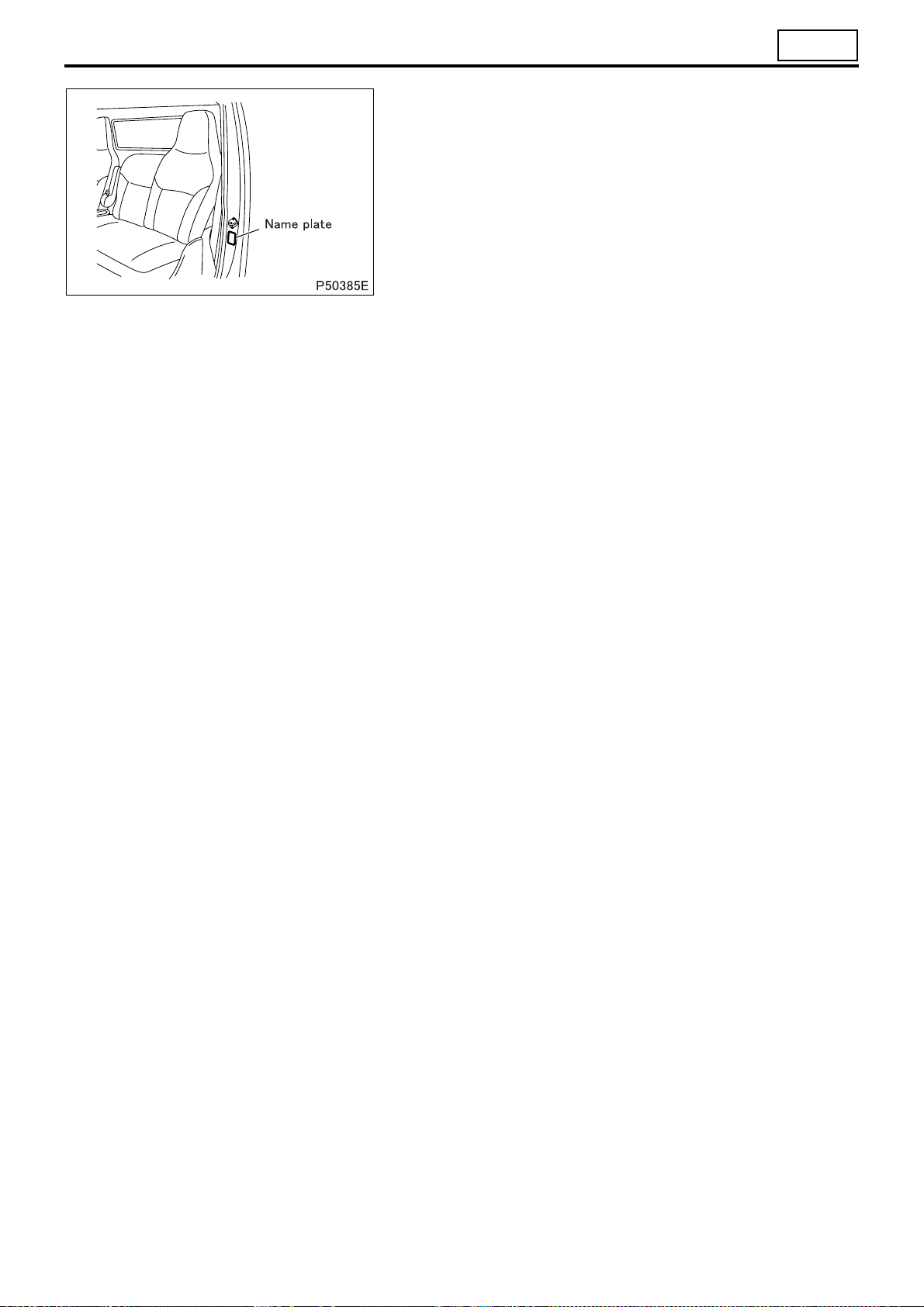

Name plate

<Type 1>

• Name plate contains the following information.

• MODEL

• Chassis number

• Engine number

• Wheel base

<Type 2>

• Vehicle compliance and date plate are attached to the assistant

driver’s side door opening. The compliance plate certifies that

your vehicle complied with Australian Design Rules at the time

of manufacture. In all correspondence related to your vehicle the

following information should be quoted.

• The engine number.

• The vehicle identification number (V.I.N.) – shown on compli-

ance plate.

• The S.O.A. No. (where applicable), option code, paint and

trim codes located on date plate.

00-17

Page 23

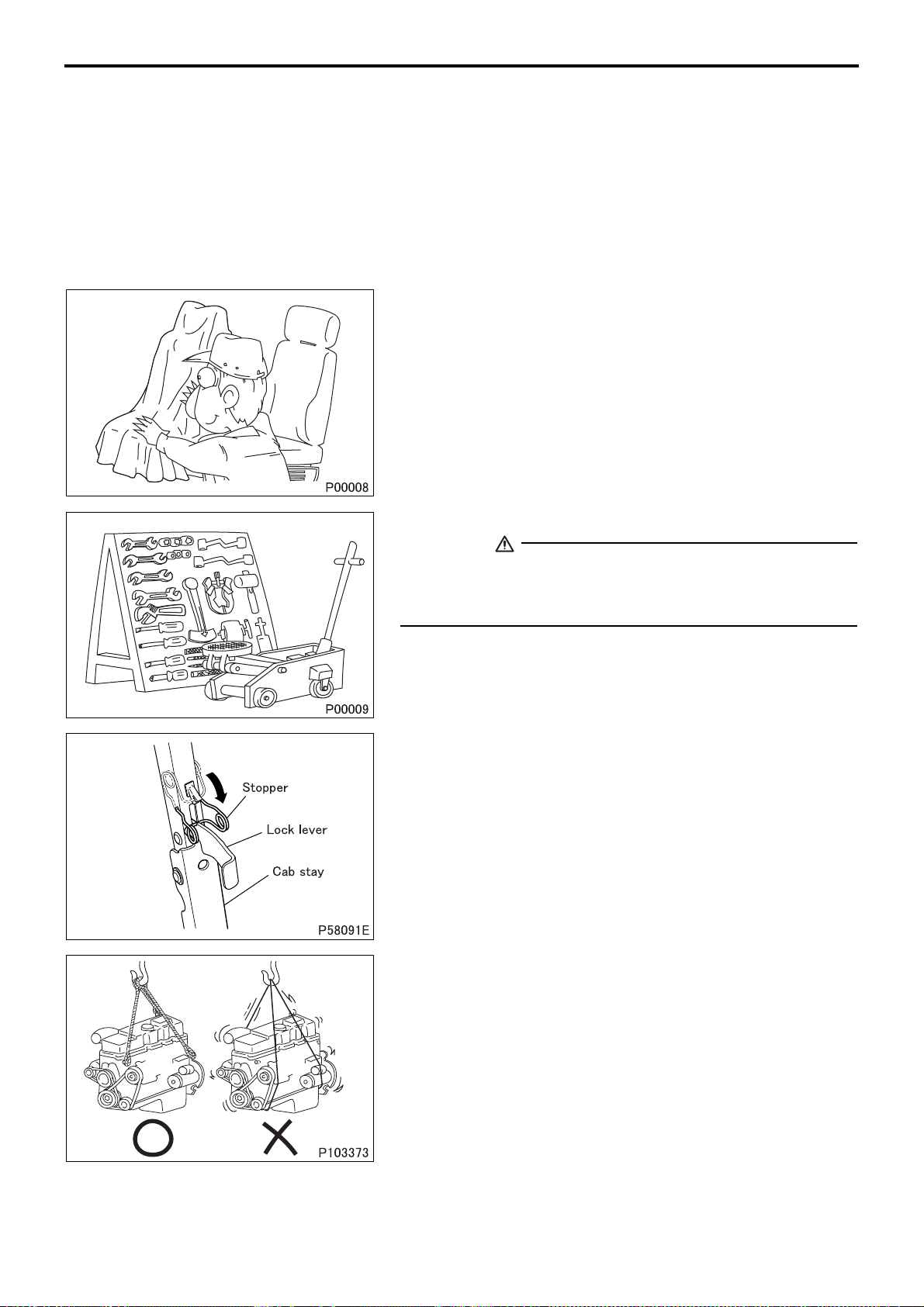

PRECAUTIONS FOR MAINTENANCE OPERATION

• Before performing service operations, inquire into the customer’s complaints and ascertain the conditions by

checking the total distance traveled, the conditions under which the vehicle is operated, and other relevant factors

about the vehicle. And note the necessary information. This information will help you to service the vehicle efficiently.

• Check the location of the fault, and identify its cause. Based on

your findings, determine whether parts must be removed or disassembled. Then, follow the service procedure given in this

manual.

• Perform service operations on a level surface. Before starting,

take the following preparatory steps:

• To prevent soiling and damage, place covers over the seats,

trim and floor in the cab and over the paintwork of the body.

• Prepare all the general and special tools necessary for the job.

WARNING

• Special tools must be used wherever specified in this manual. Do not attempt to use other tools since they could

cause injuries and/or vehicle damage.

• After manually tilting the cab, be sure to engage the stopper with

the lock lever to secure the cab stay in a rigid state.

• Take extreme care when removing/installing heavy items such

as engine, transmission and axle. When lifting heavy items using

a cable etc., observe the following precautions.

00-18

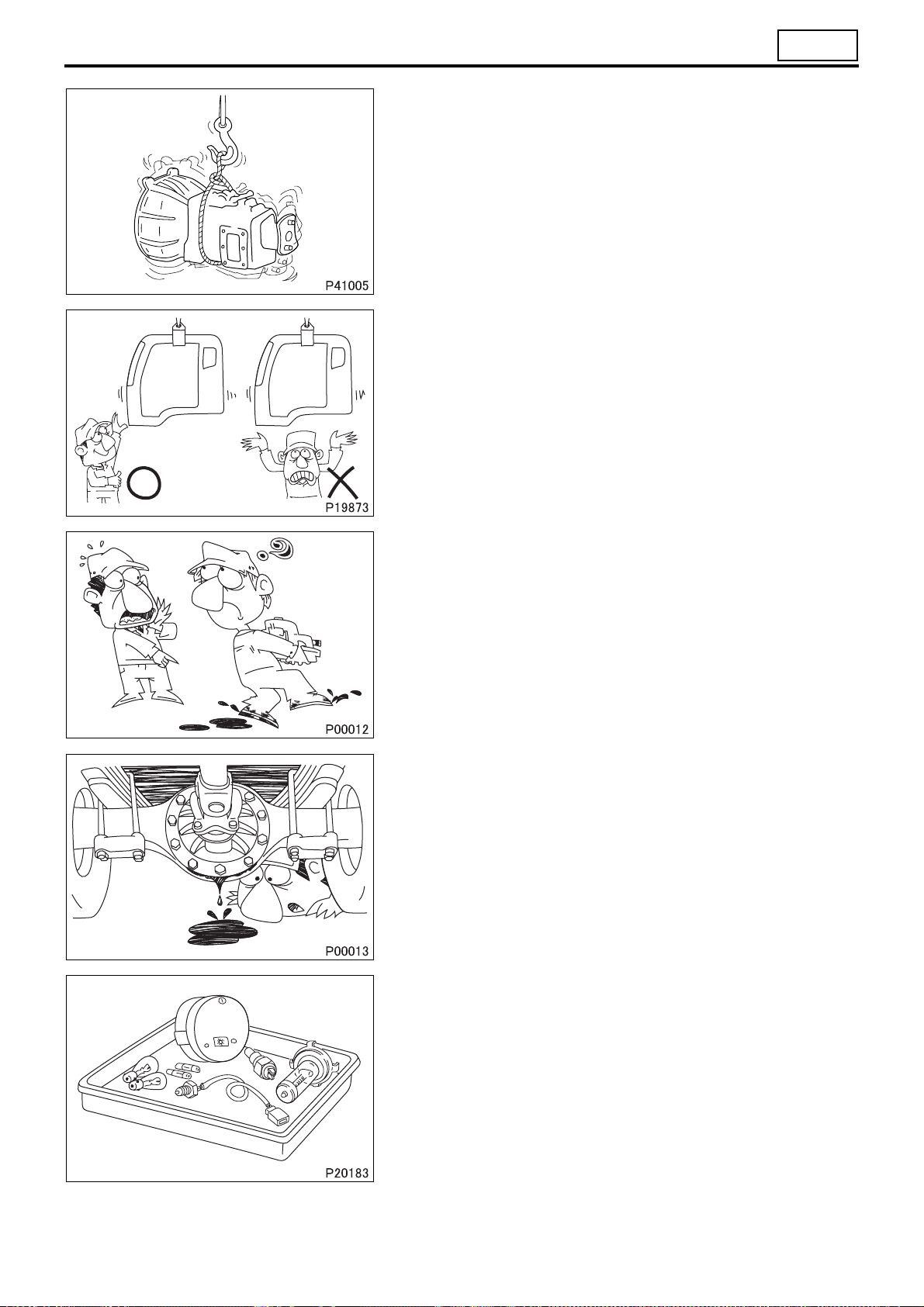

• Identify the mass of the item being lifted. Use a cable that is

strong enough to support the mass.

• When lifting the engine, always use the engine hanger.

Page 24

00

• If lifting eyes are not provided on the item being lifted, tie a ca-

ble around the item taking into account the item’s center of

gravity.

• Do not allow anyone to pass or stay under a lifted item that

may fall.

• Never work in shoes that have oily soles.

When working with a partner or in a group, use pre-arranged signals and pay constant attention to safety. Be careful not to touch

switches and levers unintentionally.

• Inspect for oil leakage etc. before washing the vehicle. If the order is reversed, any oil leakage or fault that may exist could go

unnoticed during inspection.

• Prepare replacement parts ready for installation.

00-19

Page 25

PRECAUTIONS FOR MAINTENANCE OPERATION

• Oil seals, packings, O-rings and other rubber parts, gaskets, and

split pins must be replaced with new ones after removal. Use

only genuine MITSUBISHI replacement parts.

• When disassembling parts, visually check them for wear, cracks,

damage, deformation, deterioration, rust, corrosion, defective rotation, fatigue, clogging and any other possible defect.

• To facilitate correct reassembly of parts, make alignment marks

on them before disassembly and arrange disassembled parts

neatly. Make punch marks and other alignment marks where

they will not detract from parts’ functionality and appearance.

• After removing parts from the vehicle, cover the area to keep it

free of dust.

CAUTION

• Be careful not to mix up identical parts, similar parts and

parts that have left/right alignments.

• Keep new replacement parts and original (removed) parts

separately.

• Apply the specified oil or grease to U-seals, oil seals, dust seals

and bearings before reassembly.

• Always use the specified oils and greases when performing inspection or replacement. Immediately wipe away any excess oil

or grease with a rag.

00-20

• Wear safety goggles when using a grinder or welder. Wear

gloves when necessary, and watch out for sharp edges and other items that might wound your hands.

Page 26

00

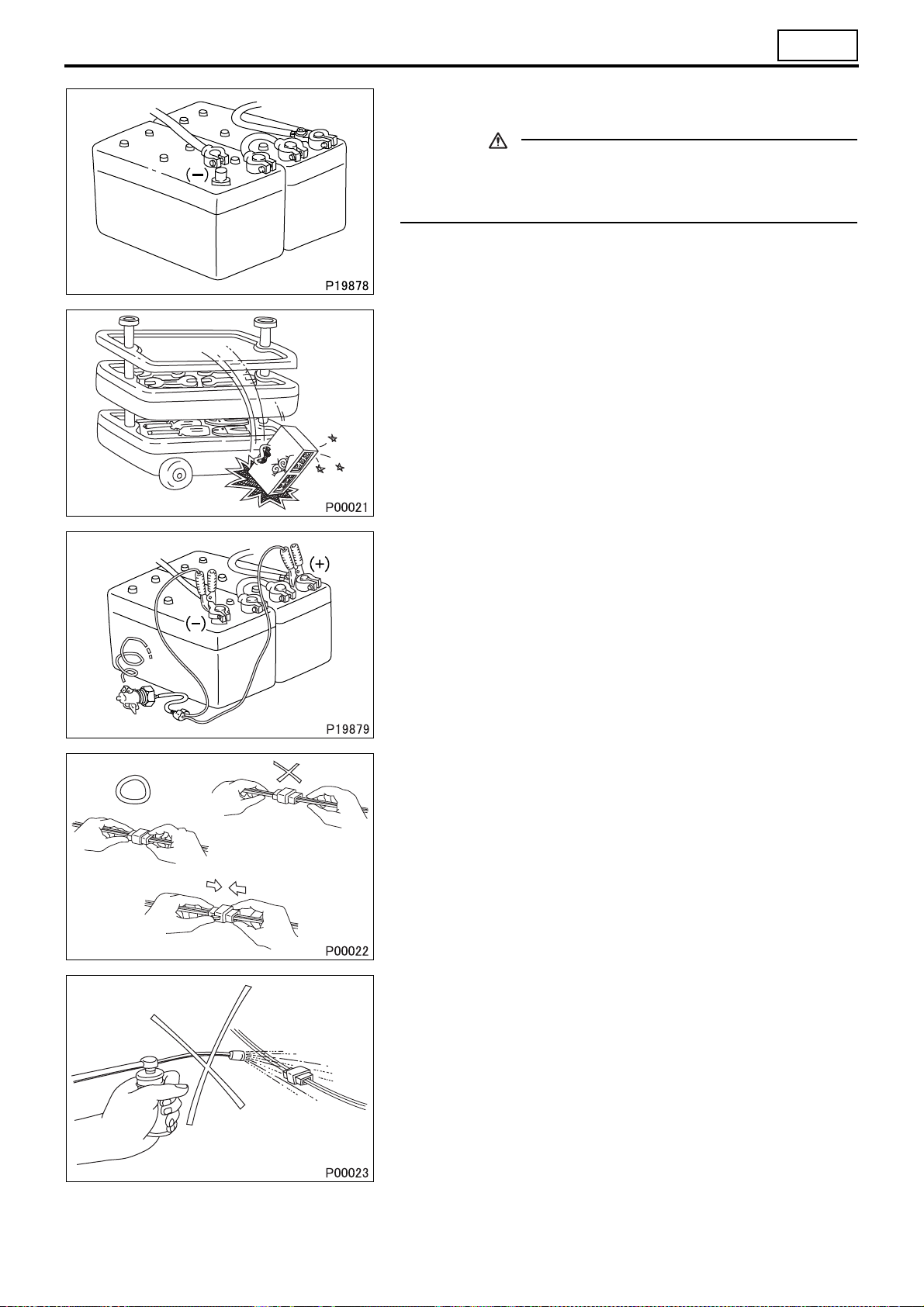

• Before working on the electrical system, disconnect the (–) bat-

tery cable to prevent short circuits.

CAUTION

• Make sure the starter switch and lighting switches are OFF

before disconnecting or connecting battery cable.

Semiconductor components may otherwise be damaged.

• Carefully handle sensors relays, and other items that are sensi-

tive to shock and heat. Do not remove or paint the cover of any

control unit.

• When applying a voltage to a part for inspection purposes,

check that the (+) and (–) cables are connected properly then

gradually increase the voltage from zero. Do not exceed the

specified voltage.

Remember that control units and sensors do not necessarily operate on the battery voltage.

• When separating connectors, grasp the connectors themselves

rather than the harnesses.

• To separate locking connectors, first push them in the direction

of the arrows. To reconnect locking connectors, push them together until they click.

• Before washing the vehicle, cover electrical parts to keep them

dry. (Use plastic sheets or the like.) Keep water away from harness connectors and sensors and immediately wipe off any water that gets on them.

00-21

Page 27

PRECAUTIONS FOR MAINTENANCE OPERATION

1. Handling Precautions for Electric Circuits

CAUTION

• Do not pierce wire insulation with test probes or alligator

clips when performing electrical inspections. Doing so can,

particularly with the chassis harness, hasten corrosion.

1.1 Inspection of harnesses

(2) Inspections with connectors fitted together

(2.1) Waterproof connectors

• Connect an inspection harness and connector A between the

connectors B of the circuit to be inspected. Perform the inspection by applying a test probe C to the connectors of the inspection harness. Do not insert the test probe C into the wire-entry

sides of the waterproof connectors since this would damage

their waterproof seals and lead to rust.

(2.2) Non-waterproof connectors

• Perform the inspection by inserting a test probe C into the wire-

entry sides of the connectors. An extra-narrow probe is required

for control unit connectors, which are smaller than other types of

connector. Do not force a regular-size probe into control unit

connectors since this would cause damage.

(3) Inspections with connectors separated

(3.1) Inspections on female terminals

• Perform the inspection by carefully inserting a test probe into the

terminals. Do not force the test probe into the terminals since

this could deform them and cause poor connections.

00-22

(3.2) Inspections on male terminals

• Perform the inspection by applying test probes directly to the

pins.

.

CAUTION

• Be careful not to short-circuit pins together with the test

probes. With control unit connectors, short-circuiting of

pins can cause damage to the control unit’s internal circuitry.

Page 28

00

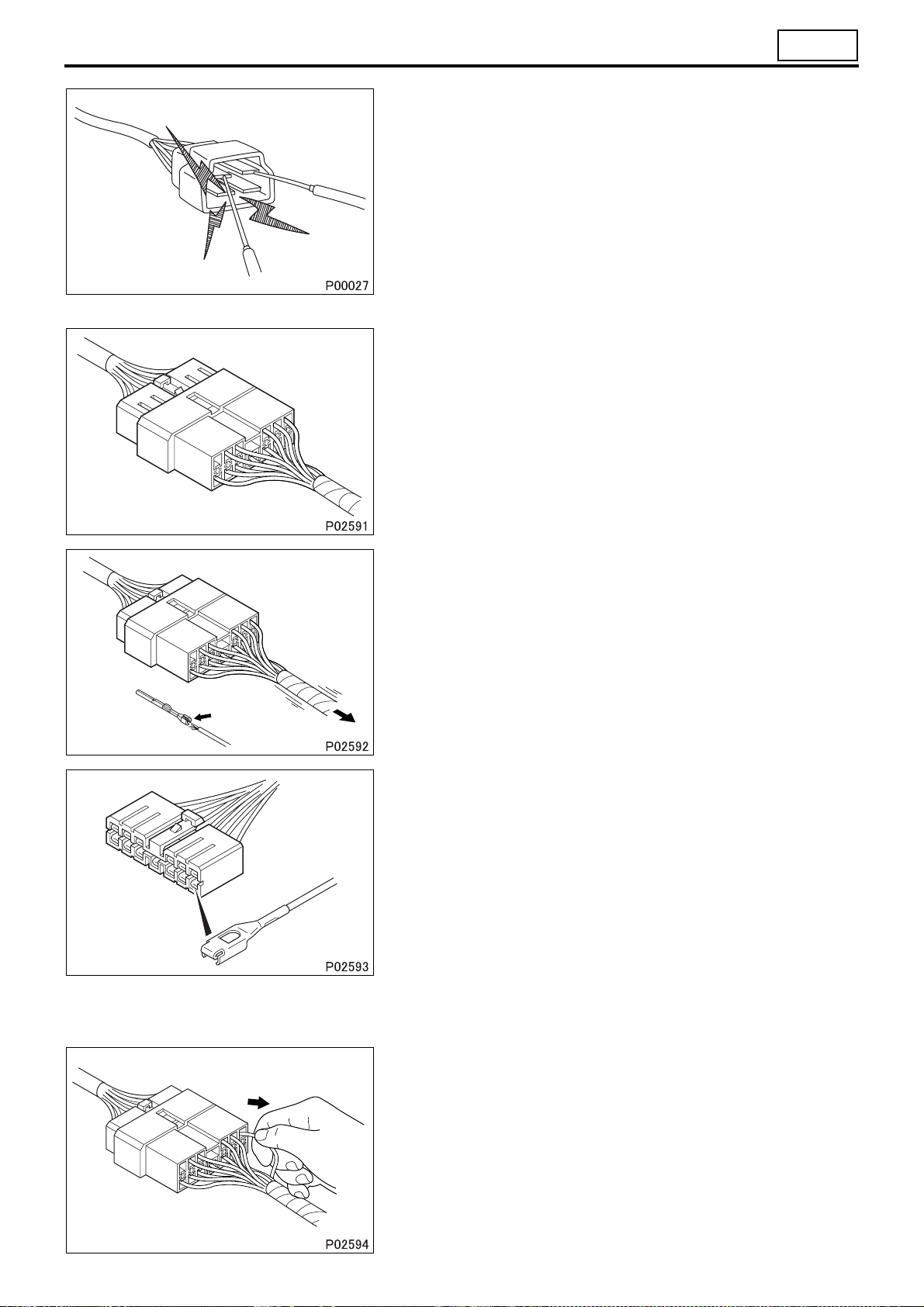

• When using a multimeter to check continuity, do not allow the

test probes to touch the wrong terminals.

1.2 Inspection of connectors

(1) Visual inspection

• Check that the connectors are fitted together securely.

• Check whether wires have been separated from their terminals

due to pulling of the harness.

• Check that male and female terminals fit together tightly.

• Check for defective connections caused by loose terminals, by

rust on terminals, or by contamination of terminals by foreign

substances.

(2) Checking for loose terminals

• If connector terminal retainers become damaged, male and fe-

male terminals may not mate with each other when the connector bodies are fitted together. To check for such terminals, gently

pull each wire and see whether any terminals slip out of their

connector housings.

00-23

Page 29

PRECAUTIONS FOR MAINTENANCE OPERATION

1.3 Inspections when a fuse blows

• Remove the fuse, then measure the resistance between ground

and the fuse’s load side.

Next, close the switch of each circuit connected to the fuse. If

the resistance measurement between any switch and ground is

zero, there is a short circuit between the switch and the load. If

the resistance measurement is not zero, the circuit is not currently short-circuited; the fuse probably blew due to a momentary short circuit.

• The main causes of short circuits are as follows:

• Harnesses trapped between chassis parts

• Harness insulation damage due to friction or heat

• Moisture in connectors or circuitry

• Human error (accidental short-circuiting of components)

1.4 Inspection of chassis ground

• A special ground bolt is used to tighten a ground terminal. When

servicing the ground point, be sure to follow the procedures described below:

• When reinstalling the ground bolt

• When relocating the ground point

2. Service Precautions for Alternators

• When servicing alternators, observe the following precautions:

• Never reverse the polarity of battery connections.

Tighten the ground bolt to the specified torque.

A special ground bolt must be used. Spot-weld a nut to a

frame and tighten the ground bolt to the specified torque. Be

sure to apply touch-up paint to the welded point.

If the polarity of the battery connections were to be reversed,

a large current would flow from the battery to the alternator,

damaging the diodes and regulator.

00-24

• Never disconnect the battery cables with the engine running.

Disconnection of the battery cables during engine operation

would cause a surge voltage, leading to deterioration of the diodes and regulator.

Page 30

00

• Never perform inspections using a high-voltage multimeter.

The use of a high-voltage multimeter could damage the diodes

and regulator.

• Keep alternators dry.

Water on alternators can cause internal short circuits and damage.

• Never operate an alternator with the B and L terminals short-circuited. Operation with the B and L terminals connected together

would damage the diode trio.

• Disconnect the battery cables before quick-charging the battery

with a quick charger.

Unless the battery cables are disconnected, quick-charging can

damage the diodes and regulator.

00-25

Page 31

PRECAUTIONS FOR MAINTENANCE OPERATION

3. Intermittent Faults

• An intermittent fault typically occurs only under certain operating

conditions. Once these conditions have been identified, the

cause of the intermittent fault can be ascertained easily. First,

ask the customer about the vehicle operating conditions and

weather conditions under which the fault occurs. Also ask about

the frequency with which the fault occurs and about the fault

symptoms. Then, reproduce the fault based on this information.

In accordance with the conditions under which the fault occurs,

determine whether the fault is caused by vibration, heat or other

factors. if vibration is a possible factor, see if the fault can be reproduced by performing the following checks on individual connectors and other parts:

• Gently move connectors up and down and to left and right.

• Gently move wiring harnesses up and down and to left and

right.

• Gently wiggle sensors and other devices by hand.

• Gently wiggle wiring harnesses on suspension systems and

other moving parts.

• Connectors and other parts to be checked are those included or

given as likely fault locations in inspection procedures corresponding to diagnosis codes and/or fault symptoms.

00-26

Page 32

00

4. Precautions for Arc Welding

• When arc welding is performed, current from the welder flows to ground via the vehicle’s metal parts. Unless ap-

propriate steps are taken, this current can damage control units, other electrical devices and wiring harnesses.

And any electrical device near the point on the vehicle to which the (–) cable of the welder is connected, might be

largely damaged.

• Current flows backward as shown below.

4.1 From battery (–) cable

To prevent damage to the battery and to electrical devices that are

connected directly to the battery, it is essential to disconnect the

battery’s (–) cable.

4.2 Procedure

• Turn the starter switch to the LOCK position.

• Disconnect the battery’s (–) cable.

• Remove the safety plug of the high voltage battery box referring

to Gr18 HYBRID ELECTRIC VEHICLE SYSTEM.

• Cover all parts of the vehicle that may be damaged by welding

sparks.

• Connect the welder’s (–) cable to the vehicle as close as possible to the area being welded. Do not connect the welder’s (–) cable to the cab if the frame is being welded, and vice versa.

• Set the welding current in accordance with the part being welded.

5. Maintenance for Trucks with Airbags

• For maintenance of SRS airbags and seat belts with pretensioners, work should be conducted safely by following

the work procedure and precautions.

6. Precautions When Starting the Engine

• The engine warning lamp may illuminate if the starter switch is kept turned to the START position for a while with

the gear engaged. (Diagnosis code P0016 “No SNSR Offset/Backup Mode” of the engine electronic control unit

occurs.)

• If the engine warning lamp illuminated, place the transmission in neutral and turn the starter switch from OFF to

ON four times to turn off the warning lamp.

00-27

Page 33

JACKING UP THE VEHICLE

<Front of Vehicle>

Jacking up procedure

1 Apply chocks to the rear wheels.

2 Raise the front of the vehicle using a bottle jack or garage jack.

3 Place rigid racks to support the frame on the front side of the vehicle.

WARNING

• Apply chocks to the rear wheels to hold the vehicle in place.

• Do not remove the chocks until service operations are finished.

• It is extremely dangerous to support the vehicle with a bottle jack or garage jack alone. Use rigid racks

additionally to support the frame on the front side of the vehicle.

• Leave the bottle jack or garage jack and rigid racks in place until all service operations are completed. Be

sure not to remove them during work.

00-28

Page 34

<Rear of Vehicle>

00

Jacking up procedure

1 Apply chocks to the front wheels.

2 Raise the rear of the vehicle using a bottle jack or garage jack.

3 Place rigid racks to support the frame on both sides of the vehicle.

WARNING

• Apply chocks to the front wheels to hold the vehicle in place.

• Do not remove the chocks until service operations are finished.

• It is extremely dangerous to support the vehicle with a bottle jack or garage jack alone. Use rigid racks

additionally to support the frame on both sides of the vehicle.

• Leave the bottle jack or garage jack and rigid racks in place until all service operations are completed. Be

sure not to remove them during work.

00-29

Page 35

DIAGNOSIS CODES

1. Diagnosis Codes

• Diagnosis codes indicate the faulty sections of the vehicle.

• A fault can be repaired by reading out the diagnosis code(s) stored in the control unit and performing the remedy

for that code(s).

• Diagnosis codes can be displayed in the following two methods. Select either of them according to the system to

be diagnosed.

• Using a Multi-Use Tester

• Using flashing of a warning lamp on meter cluster

• The table below indicates the systems for which diagnosis codes can be displayed and the methods usable for in-

dividual systems.

1.1 Systems and diagnosis code displaying methods

Diagnosis codes

Warning

lamp

System

Common rail

Turbo charger

Diesel particulate filter

Exhaust gas recirculation 17

Starter continuous energizing preventing function

Pre-heat control

displaying methods

Multi-Use

Te st e r

OO

Flashing of

warning lamp

Reference

Gr

13

15

54

Hybrid electric vehicle system O O 18

O

(ORANGE)

INOMAT-II

Power anti-lock brake system O O 35EA

Hill start assist system O O 35EB

SRS airbag O – 52

(Gear shift

indicator indi-

cation)

O 22E

1.2 Types of diagnosis codes

(1) Present diagnosis code

• Fault developed in the vehicle after the starter switch is set to ON is indicated by corresponding diagnosis code.

• The fault warning lamp is lit at the same time.

(2) Past diagnosis code

• Past fault developed in the vehicle is indicated by corresponding diagnosis code stored in the memory of the elec-

tronic control unit.

• With the vehicle restored to its normal condition or the starter switch turned from OFF to ON after inspection or repair against present diagnosis codes, the present diagnosis code is stored as past diagnosis codes in the memory

of the electronic control unit.

• When reading out the past diagnosis codes, the warning lamp does not illuminate as such codes do not indicate

the current fault.

00-30

Page 36

2. Reading and Erasing the Diagnosis Code

2.1 Using a Multi-Use Tester

(1) Connecting a Multi-Use Tester

Special tools

Mark Tool name and shape Part No. Application

00

SOFTWARE DISC

Multi-Use Tester-III

SOFTWARE DISC

V.C.I. MH062927

Multi-Use Tester test

Harness E

A: Harness for inspection and drive recorder

B: Harness for drive recorder

C: Drive recorder harness

D: Cigarette lighter

plug harness

FMS-E09-2*

(Multi-Use

Tester-III version)

MH063659

A: MH063661

B: MH063663

C: MH063665

D: MH063666

*Installation of the Multi-Use Tester-III

or version-up of the current version

into Multi-Use Tester-III SOFTWARE

DISC (Pub. No. SG0901A)

Data transmission between electronic

control unit and PC

Power supply to V.C.I. and communication with electronic control unit

Multi-Use Tester test

harness D

(used for extension)

USB cable MH063668

MH062951

Multi-Use Tester test harness B extension

Communication between V.C.I. and

PC

00-31

Page 37

DIAGNOSIS CODES

(1.1) To perform system inspection

• Move the starter switch to the LOCK position.

• Connect PC installed , , -A and as shown.

• Connect -A connector to the Multi-Use Tester connector on

the vehicle.

(1.2) To use drive recorder function

• Move the starter switch to the LOCK position.

• Connect PC installed , , -A, -C, -D and

as shown.

• Connect -C connector to the Multi-Use Tester connector on

the vehicle.

• Connect the cigarette lighter plug of -D to the cigarette light-

er socket on the vehicle.

(1.3) To extend the Multi-Use Tester test harness

• Connect to -A to extend the test harness to use the

Multi-Use Tester outside the vehicle.

00-32

Page 38

00

(2) Access of diagnosis code

• Set the starter switch to ON.

• Operate the Multi-Use Tester for a display of necessary diagnosis code stored in the memory of the electronic

control unit and identify the location of the fault.

(3) Clearing of diagnosis code

• Set the starter switch to ON (the engine not to be started).

• Operate the Multi-Use Tester to delete all the diagnosis codes stored in the memory of the electronic control unit.

2.2 Using flashing of a warning lamp on meter cluster

(1) Engine control, Power anti-lock brake system, Hill start assist system, Hybrid electric vehicle system

• Using the diagnosis and memory clear

switches, display diagnosis codes.

• Diagnosis codes of the battery electronic control unit are sent to the motor

electronic control unit and are displayed along with those of the motor

electronic control unit by the diagnosis

switch operation.

However, some diagnosis codes (minor faults) can be checked only with

the Multi-Use Tester.

CAUTION

• Opening the memory clear switch

followed by its reconnection will

erase the stored diagnosis codes

from the memory. To avoid inadvertently erasing necessary codes,

be sure to read well the procedure

described below before handling diagnosis codes.

00-33

Page 39

DIAGNOSIS CODES

(1.1) Reading diagnosis codes

• To read a diagnosis code, observe how may times the warning

lamp flashes and how long each illumination lasts.

• The duration of illumination differs between the first and second

digits.

• Second digit: 1.2 sec.

• First digit: 0.4 sec.

• A diagnosis code consists of the flashing of second digit and the

flashing of first digit in that order. If a diagnosis code has “0” in

the second digit, only the first digit will be displayed.

• The diagnosis code 01 will be displayed if the system is normal.

• The same diagnosis code will be displayed 3 times in a row be-

fore moving to the display of the next code.

• After the last diagnosis code is displayed, the first code will be

displayed again 3 times in a row and then the subsequent

codes. This will be repeated.

(1.2) Present diagnosis codes

• Turn the starter switch ON.

• Remove the diagnosis switch.

• Present diagnosis codes will be displayed by flashing of the

warning lamp.

• When the diagnosis switch is connected, electronic control unit

will stop (terminate) displaying diagnosis codes.

(1.3) Present and past diagnosis codes

• Turn the starter switch to the ON position.

• Open the diagnosis switch.

• Present diagnosis codes will be displayed by flashing of the

warning lamp.

• Open the memory clear switch.

• Present and past diagnosis codes will be displayed by flashing

of the warning lamp.

• Turn the starter switch to the OFF position and connect the

memory clear switch and diagnosis switch to terminate the diagnosis code displaying mode.

00-34

(1.4) Erasing diagnosis codes

• Turn the starter switch to the ON position (do not start the en-

gine).

• Open the memory clear switch and reconnect it; all diagnosis

codes stored in electronic control unit memory will be erased.

To cancel diagnosis code erasure after opening the memory

clear switch, turn the starter switch to the OFF position and then

reconnect the memory clear switch.

• Erase the diagnosis codes stored in the battery electronic control unit using the Multi-Use Tester.

Page 40

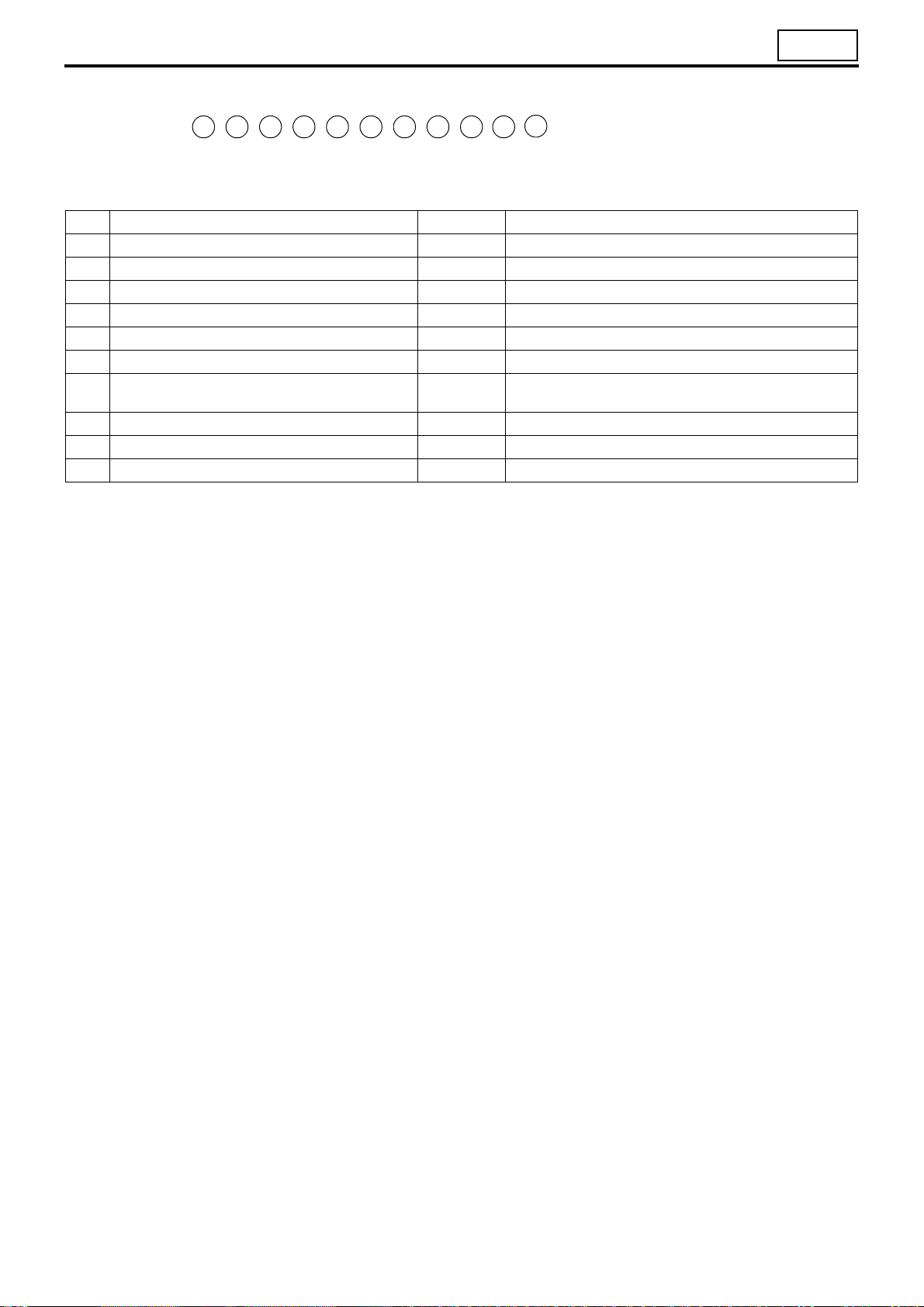

(2) INOMAT-II

00

• Display diagnosis codes using the di-

agnosis switch and memory clear

switch.

NOTE

• Diagnosis codes are erased by disconnecting and connecting operation of the memory clear switch.

Fully understand the procedures

before working.

(2.1) Reading diagnosis codes

• To read a diagnosis code, check the indication of the gear shift

indicator.

Example:If the codes are 12 and 34, they will be displayed as

shown in the drawing.

• If the system is normal, the diagnosis code 01 will be displayed.

• Diagnosis codes will be displayed each code once in the reverse

chronological order.

• After the last diagnosis code is displayed, the first code will be

displayed again and then the subsequent codes. This will be repeated.

(2.2) Present diagnosis codes

• Turn the starter switch to ON.

• Disconnect the diagnosis switch.

• The present diagnosis codes will be displayed on the gear shift

indicator.

• When the diagnosis switch is connected, ECU will stop (terminate) displaying diagnosis codes.

(2.3) Present and past diagnosis codes

• Turn the starter switch to ON.

• Disconnect the diagnosis switch.

• The present diagnosis codes will be displayed on the gear shift

indicator.

• Disconnect the memory clear switch.

• The present and past diagnosis codes will be displayed on the

gear shift indicator.

• After the starter switch is turned to OFF, connect the memory

clear switch and diagnosis switch to terminate the operation.

(2.4) Erasing diagnosis codes

• Turn the starter switch to ON. (Do not start the engine.)

• All diagnosis codes stored in the electronic control unit can be

erased by disconnecting the memory clear switch and then connecting it again. If you discontinue the operation after the memory clear switch is disconnected, turn the starter switch to OFF

and then connect the memory clear switch.

00-35

Page 41

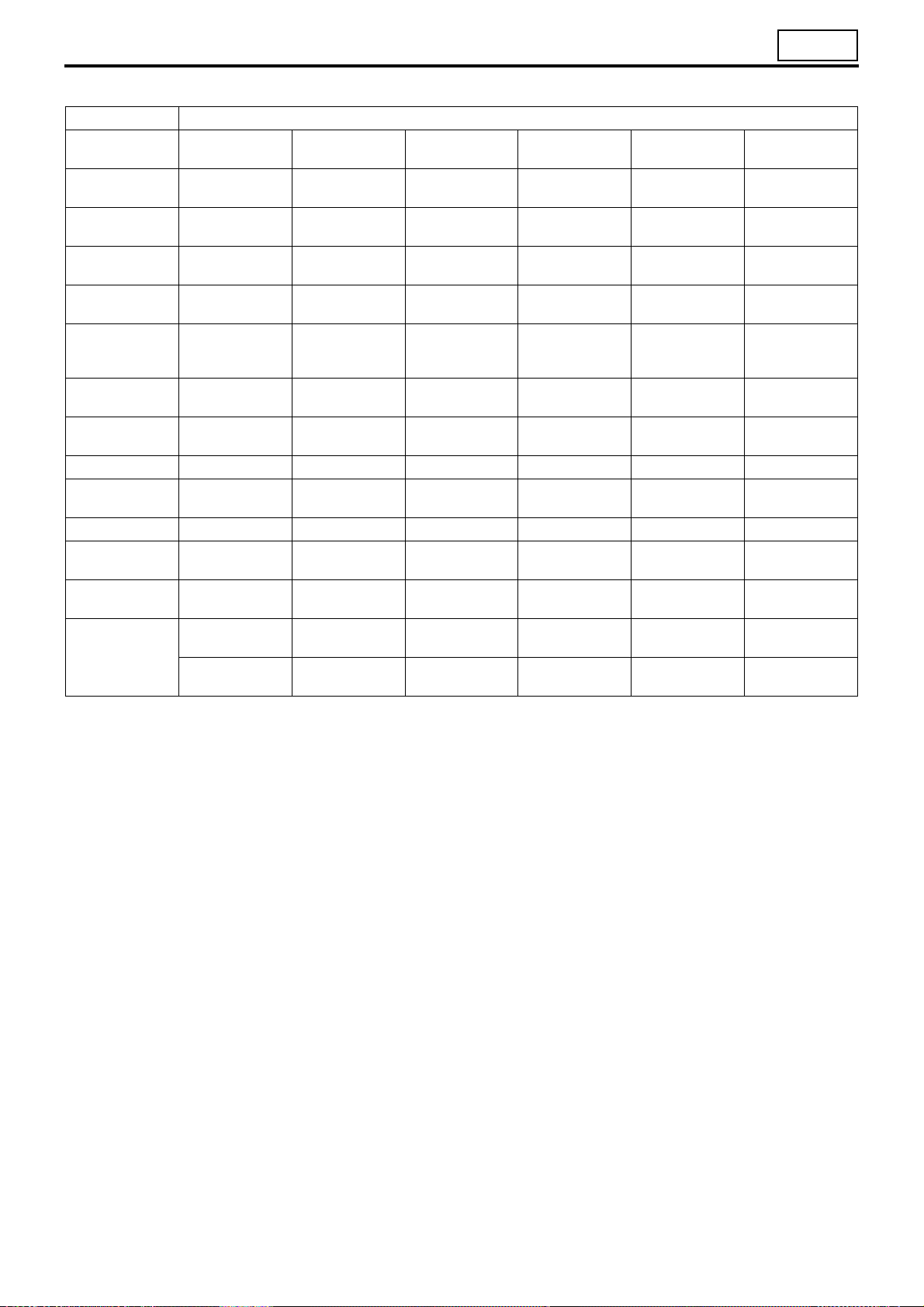

TABLE OF STANDARD TIGHTENING TORQUES

• Use specified bolts and nuts. Tighten them to the torques shown below as appropriate, unless otherwise speci-

fied.

• Threads and bearing surfaces shall be dry.

• If the mating nut and bolt (or stud bolt) are different in level of strength, tighten them to the torque specified for the

bolt.

Hexagon Head Bolts and Stud Bolts (Unit: N·m {kgf·m})

Strength

Identification

symbol

Nominal

diameter (stud) (stud) (stud)

M5

M6

M8

M10

M12

M14

M16

M18

M20

M22

M24

2 to 3

{0.2 to 0.3}

4 to 6

{0.4 to 0.6}

9 to 13

{0.9 to 1.3}

18 to 27

{1.8 to 2.7}

34 to 50

{3.4 to 5.1}

60 to 80

{6.0 to 8.0}

90 to 120

{9 to 12}

130 to 170

{14 to 18}

180 to 240

{19 to 25}

250 to 330

{25 to 33}

320 to 430

{33 to 44}

4T 7T 8T

–

–

–

17 to 25

{1.8 to 2.6}

31 to 45

{3.1 to 4.6}

55 to 75

{5.5 to 7.5}

90 to 110

{9 to 11}

120 to 150

{12 to 16}

170 to 220

{17 to 22}

230 to 300

{23 to 30}

290 to 380

{29 to 39}

4 to 6

{0.4 to 0.6}

7 to 10

{0.7 to 1.0}

16 to 24

{1.7 to 2.5}

34 to 50

{3.5 to 5.1}

70 to 90

{7.0 to 9.5}

110 to 150

{11 to 15}

170 to 220

{17 to 23}

250 to 330

{25 to 33}

340 to 460

{35 to 47}

460 to 620

{47 to 63}

600 to 810

{62 to 83}

–

–

–

32 to 48

{3.3 to 4.9}

65 to 85

{6.5 to 8.5}

100 to 140

{11 to 14}

160 to 210

{16 to 21}

220 to 290

{23 to 30}

310 to 410

{32 to 42}

420 to 560

{43 to 57}

540 to 720

{55 to 73}

5 to 7

{0.5 to 0.7}

8 to 12

{0.8 to 1.2}

19 to 28

{2.0 to 2.9}

45 to 60

{4.5 to 6.0}

80 to 105

{8.5 to 11}

130 to 170

{13 to 17}

200 to 260

{20 to 27}

290 to 380

{30 to 39}

400 to 530

{41 to 55}

540 to 720

{55 to 73}

700 to 940

{72 to 96}

–

–

–

37 to 55

{3.8 to 5.7}

75 to 95

{7.5 to 10}

120 to 160

{12 to 16}

190 to 240

{19 to 25}

250 to 340

{26 to 35}

360 to 480

{37 to 49}

490 to 650

{50 to 67}

620 to 830

{63 to 85}

Hexagon Head Flange Bolts (Unit: N·m {kgf·m})

Strength

Identification

Nominal

diameter

M6

M8

M10

M12

symbol

4 to 6

{0.4 to 0.6}

10 to 15

{1.0 to 1.5}

21 to 31

{2.1 to 3.1}

38 to 56

{3.8 to 5.5}

4T 7T 8T

–

–

20 to 29

{2.0 to 3.0}

35 to 51

{3.5 to 5.2}

8 to 12

{0.8 to 1.2}

19 to 28

{2.0 to 2.9}

45 to 55

{4.5 to 5.5}

80 to 105

{8.0 to 10.5}

–

–

37 to 54

{3.8 to 5.6}

70 to 95

{7.5 to 9.5}

10 to 14

{1.0 to 1.4}

22 to 33

{2.3 to 3.3}

50 to 65

{5.0 to 6.5}

90 to 120

{9 to 12}

–

–

50 to 60

{5.0 to 6.0}

85 to 110

{8.5 to 11}

00-36

Page 42

Hexagon Nuts (Unit: N·m {kgf·m})

00

Strength

Identification

Nominal

diameter

M5

M6

M8

M10

M12

M14

M16

M18

M20

M22

M24

symbol

Standard screw

thread

2 to 3

{0.2 to 0.3}

4 to 6

{0.4 to 0.6}

9 to 13

{0.9 to 1.3}

18 to 27

{1.8 to 2.7}

34 to 50

{3.4 to 5.1}

60 to 80

{6.0 to 8.0}

90 to 120

{9 to 12}

130 to 170

{14 to 18}

180 to 240

{19 to 25}

250 to 330

{25 to 33}

320 to 430

{33 to 44}

4T 6T

Coarse screw

thread

–

–

–

17 to 25

{1.8 to 2.6}

31 to 45

{3.1 to 4.6}

55 to 75

{5.5 to 7.5}

90 to 110

{9 to 11}

120 to 150

{12 to 16}

170 to 220

{17 to 22}

230 to 300

{23 to 30}

290 to 380

{29 to 39}

Standard screw thread Coarse screw thread

4 to 6

{0.4 to 0.6}

7 to 10

{0.7 to 1.0}

16 to 24

{1.7 to 2.5}

34 to 50

{3.5 to 5.1}

70 to 90

{7.0 to 9.5}

110 to 150

{11 to 15}

170 to 220

{17 to 23}

250 to 330

{25 to 33}

340 to 460

{35 to 47}

460 to 620

{47 to 63}

600 to 810

{62 to 83}

–

–

–

32 to 48

{3.3 to 4.9}

65 to 85

{6.5 to 8.5}

100 to 140

{11 to 14}

160 to 210

{16 to 21}

220 to 290

{23 to 30}

310 to 410

{32 to 42}

420 to 560

{43 to 57}

540 to 720

{55 to 73}

Hexagon Flange Nuts (Unit: N·m {kgf·m})

Strength

Identification

Nominal

diameter

M6

M8

M10

M12

symbol

Standard screw

thread

4 to 6

{0.4 to 0.6}

10 to 15

{1.0 to 1.5}

21 to 31

{2.1 to 3.1}

38 to 56

{3.8 to 5.6}

4T

Coarse screw

thread

–

–

20 to 29

{2.0 to 3.0}

35 to 51

{3.5 to 5.2}

00-37

Page 43

TABLE OF STANDARD TIGHTENING TORQUES

Tightening Torque for General-Purpose Flare Nut (Unit: N·m {kgf·m})

Pipe diameter φ4.76 mm φ6.35 mm φ8 mm φ10 mm φ12 mm φ15 mm

Tightening torque 17 {1.7} 25 {2.6} 39 {4.0} 59 {6.0} 88 {9.0} 98 {10}

Tightening Torque for General-Purpose Air Piping Nylon Tube (DIN Type) (Unit: N·m

{kgf·m})

Nominal diameter

× wall thickness

Tightening torque 20 {2.0 } 34 {3.5 } 49 {5.0 } 54 {5.5 }

Tightening Torque for General-Purpose Air Piping Nylon Tube (SAE Type) (Unit: N·m

{kgf·m})

Nominal diameter 1/4 in. 3/8 in. 1/2 in. 5/8 in.

Tightening torque 13 {1.3 } 29 {3.0 } 49 {5.0 } 64 {6.5 }

6 × 1 mm 10 × 1.25 mm 12 × 1.5 mm 15 × 1.5 mm

+60+0.6

+40+0.4

0

0

+10

+5

+1.0

0

0

+0.5

0

0

+100+1.0

+50+0.5

0

0

+50+0.5

+50+0.5

0

0

00-38

Page 44

GROUP 11 ENGINE

SPECIFICATIONS .............................................................................. 11-2

STRUCTURE AND OPERATION

1. Exploded View ............................................................................. 11-3

2. Cylinder Head and Cylinder Head Gasket .................................... 11-4

3. Valve Mechanism ......................................................................... 11-5

4. Timing Chain ............................................................................... 11-6

5. Timing Gears ............................................................................... 11-7

6. Connecting Rod ........................................................................... 11-8

7. Piston .......................................................................................... 11-8

8. Flywheel .............................................................................................. 11-9

9. Crankcase, Crankshaft and Main Bearing ..................................... 11-10

10.Oil Seal ............................................................................................. 11-13

TROUBLESHOOTING ..................................................................... 11-14

ON-VEHICLE INSPECTION AND ADJUSTMENT

1. Measuring Compression Pressure ............................................. 11-16

2. Inspection and Adjustment of Valve Clearance .......................... 11-18

3. Inspection and Replacement of Timing Chain ............................ 11-19

4. Protrusion of Timing Chain Tensioner’s Plunger ........................ 11-25

5. Damage to the Starter Pinion Contact Surface of Ring Gear ....... 11-26

ENGINE REMOVAL AND INSTALLATION........................................11-28

ROCKER COVER ............................................................................ 11-30

CAMSHAFT HOLDER AND CAMSHAFT

....................................... 11-32

CYLINDER HEAD AND VALVE MECHANISM..................................11-38

PISTON AND CONNECTING ROD ...................................................11-54

FLYWHEEL ........................................................................................11-66

TIMING GEAR CASE.........................................................................11-70

TIMING GEAR....................................................................................11-74

CRANKSHAFT AND CRANKCASE ..................................................11-80

11-1

Page 45

SPECIFICATIONS

Item Specifications

Engine model 4M42T3

Type 4-cylinder, in-line, water-cooled, 4-cycle diesel engine

Combustion chamber Direction injection type

Valve mechanism Double overhead camshaft (DOHC)

Maximum output kW {PS} /rpm 96 {130} /3200

Maximum torque N·m {kgf·m} /rpm 294 {30} /1700

Bore × stroke mm φ95 × 105

3

Total displacement cm

Compression ratio 17.0

{L} 2977 {2.977}

11-2

Page 46

STRUCTURE AND OPERATION

1. Exploded View

11

11-3

Page 47

STRUCTURE AND OPERATION

2. Cylinder Head and Cylinder Head Gasket

2.1 Cylinder head

• The arrangement of the intake ports

and exhaust ports is of a cross-flow

type. The exhaust ports are provided

on the right side and the intake ports

are provided on the left side of the cylinder head.

• Cylinder head bolt (M12) is fastened to

the upper crankcase and cylinder

head bolt (M10) is fastened to the timing gear case.

• The cylinder head bolts must be tightened according to the specified procedure.

11-4

2.2 Cylinder head gasket

• Select and use a cylinder head gasket

of a thickness that can accommodate

the piston projection.

• The size (thickness) class of the gasket can be identified by the shape of

the notches cut on the edge of each

gasket.

Page 48

3. Valve Mechanism

11

• The camshaft is driven by the timing chain. The exhaust camshaft and the intake camshaft are supported by cam-

shaft holders at the journals and are retained by camshaft caps from above.

• There are two types of rocker arms: long rocker arm and short rocker arm. They are alternately provided by the

valve position.

11-5

Page 49

STRUCTURE AND OPERATION

4. Timing Chain

• The timing chain is an endless chain with 110 links that connects the exhaust cam sprocket, intake cam sprocket

and the idler sprocket.

• The timing chain has mark link plates at three locations that indicate the position at which the crankshaft and the

camshaft should take when the chain is installed. There are two plates at the first location and one plate at the

second location. The first location (two-mark-link location) must be aligned with the mating mark “ ” on the exhaust cam sprocket and the intake cam sprocket, and the second location (one-mark-link location) must be

aligned with the mating mark “ ” on the idler sprocket.

• The chain tensioner gives tension to the timing chain. The chain tensioner has a plunger with a built-in spring.

• When the chain tensioner is installed in position, the plunger directly pushes the tension lever, and the timing

chain is tensioned automatically by a force determined by the tension of the plunger spring.

• After the plunger is installed, it is locked in place by a cam provided in the chain tensioner, which prevents accidental deflection of the timing chain while it is driven. Do not crank the engine in the reverse direction after installing the chain tensioner, as this will apply undue forces to the plunger and may cause such undesirable

consequences as cam being over ridden by the plunger.

11-6

Page 50

5. Timing Gears

11

• Each timing gear has mating mark(s) “1” or “5” to ensure that it is engaged correctly with another gear during in-

stallation.

5.1 Idler gear

• The idler gear is press fitted into the

idler sprocket, which drives the timing

chain, and rotates on the idler shaft.

• The idler shaft is anchored to the

crankcase using the idler washer and

bolt.

The idler sprocket is fitted with the

idler bushing, which is lubricated by

engine oil supplied through the oil

holes drilled in the idler shaft.

11-7

Page 51

STRUCTURE AND OPERATION

6. Connecting Rod

• The “F” mark indicates the assembly direction onto the piston and engine front side.

• The color mark indicates the diameter class of the large end.

7. Piston

• For selective fit of the pistons with the

upper crankcase, match corresponding size marks on the pistons and upper crankcase. The size marks of the

pistons are “A” through “C” and the “C”

marked piston has the largest outside

diameter.

• Install the pistons with the front marks

facing forward of the engine.

11-8

Page 52

8. Flywheel

11

• The bearing is fitted into the flywheel and held in place by the washers.

• The peripheral edge on one side of the ring gear is chamfered for easy engagement of the gear with the starter

pinion.

11-9

Page 53

STRUCTURE AND OPERATION

9. Crankcase, Crankshaft and Main Bearing

9.1 Crankcase

• The crankcase is a bi-block type con-

sisting of an upper crankcase and a

lower crankcase that are assembled to

grip the crankshaft in between.

• The upper crankcase has cylinders

whose surfaces are machined for direct contact with sliding pistons.

The walls of the cylinders have water

jackets for cooling the cylinders.

• The main cap bolts that hold the upper

crankcase and the lower crankcase together must be tightened according to

the specified procedure.

11-10

Page 54

11

• The upper crankcase is provided with

piston size marks “A”, “B” and “C”

stamped to help to select appropriate

pistons.

9.2 Crankshaft

• The crankshaft has two sets of color

marks. Color mark A indicates the outside diameter of the journals (at five

locations), and color mark B indicates

the outside diameter of the pins (at

four locations).

9.3 Main bearing

• Each upper main bearing has an oil

hole, which provides a passage for engine oil to the corresponding crankshaft journal.

• Main bearings of different thickness

are available so that the most appropriate ones can be selected to ensure

proper clearance between them and

journals.

Bearing thickness classes are identified by color marks (red, blue and yellow) painted on the sides of the

bearings.

• All the upper and lower main bearings

are identical except for the No. 3 upper bearing and the No. 3 lower bearing.

11-11

Page 55

STRUCTURE AND OPERATION

9.4 Thrust plates

• Two upper and lower thrust plate pairs

are installed on both sides of the upper and lower main bearings at the

rear most journal of the crankshaft.

• The thrust plates must be of a thickness that corresponds to the end play

of the crankshaft.

Each thrust plate has two oil grooves

to ensure its minimum friction against

the crankshaft journal.

11-12

Page 56

10.Oil Seal

11

10.1 Front oil seal

• The front oil seal is fitted in the timing

gear case, and prevents oil from leaking by contact of its lip with the crankshaft pulley.

10.2 Rear oil seal

• The rear oil seal is fitted in the rear oil

seal case, and prevents oil from leaking by contact of its lip with the crankshaft.

11-1 3

Page 57

TROUBLESHOOTING

Symptoms

Reference Gr

Possible causes

Incorrect valve clearance O O

Cylinder head and valve

mechanism

Defective timing chain-related parts O

Timing gears

Camshaft

Pistons and connecting

rods

Crankshaft

Fuel system

Cooling system

Intake and exhaust system

Incorrect oil viscosity O

Incorrectly fitted piping and hoses O

Defective/incorrectly fitted alternator and other auxiliaries O

Defective cylinder head gasket O O

Worn valve and valve seat; carbon deposits O O

Weakened valve spring O O

Worn lifter shim O

Incorrect backlash in timing gears O

Poor lubrication of timing gears and idler shaft O

Excessive end play in camshaft O

Worn camshaft O

Worn/damaged piston ring groove(s) O O

Worn/damaged piston ring(s) O O

Worn piston pin and connecting rod small end O

Excessive end play in crankshaft O

Incorrectly fitted crankshaft O

Worn/damaged crankshaft pins and connecting rod bearings

Worn/damaged crankshaft journals and main bearings O

Defective supply pump O O

Faulty fuel spray from injector O O

Air or water trapped in fuel system components O

Irregular fuel (kerosene, heavy oil, bio-fuel, etc.) is used O

Malfunctioning cooling system O

Loose/damaged belts O

Clogged air cleaner O

Clogged muffler O

Low power output

Abnormal engine noise

O

Gr13

Gr14

Gr15Malfunctioning turbocharger O O

11-14

Page 58

M E M O

11

11-1 5

Page 59

ON-VEHICLE INSPECTION AND ADJUSTMENT

1. Measuring Compression Pressure

Service standards

Location Maintenance item Standard value Limit Remedy

Each cylinder

(at 220 rpm)

– Compression pressure

Cylinder-to-cylinder pressure difference

Special tools (Unit: mm)

Mark Tool name and shape Part No. Application

Compression gauge

adaptor

2840 kPa

{29 kgf/cm2}

–

2260 kPa

{23 kgf/cm2}

295 kPa

{3 kgf/cm

2

or less

Inspect

}

Inspect

AB

M16 × 1.5 M10 × 1.25

MH063494 Measuring compression pressure

• For the hybrid electric vehicle system, there are two methods of cranking the engine, a conventional method using

the starter and a method using the motor of the hybrid electric vehicle system.

• If the engine is cranked with the motor of the hybrid electric vehicle system, measurement of compression pressure may become inaccurate since the engine speed is slightly higher than when the starter is used for cranking.

For this reason, engine cranking should be performed using the starter following the procedure below.

• Turn the starter switch quickly up to the START position before the READY indicator lamp in the meter cluster

illuminates. Though the indicator lamp illuminates in several seconds, the starter will keep running.

• If the starter switch is turned to the START position after the READY indicator lamp in the meter cluster illumi-

nates, the starter will not run and the engine is cranked with the motor of the hybrid electric vehicle system. In

this case, turn the starter switch to OFF and try again.

• A drop in compression pressure can be used as a guide to determine when the engine should be overhauled.

• Measure the compression pressure at regular intervals. Keeping track of its transmission can provide a useful tool

for troubleshooting. On new vehicles and vehicles with newly replaced parts, the compression pressure will be

somewhat higher depending on the break-in condition of piston rings, valve seats, etc., but this will return to normal as the parts wear down.

• Before the compression measurement, check that the engine oil, starter, and battery are in normal condition.

• Place the vehicle in the following conditions.

• Warm up the engine until the coolant temperature reaches approximately 80 to 90°C.

• Turn off the lights and auxiliaries.

• Place the transmission shift lever into the N position.

• Place the steering wheel in the straight-ahead position.

11-16

• Remove the fuse (M9) to prevent fuel from being injected when

the engine is cranked by the starter.

CAUTION

• When cranking the engine, never shut off the power to the

engine electronic control unit by disconnecting the engine

electronic control unit connector or the like.

If the engine is cranked while shutting off the power to the

engine electronic control unit, the electronic control unit

cannot control the supply pump and this may cause failure

to the pump.

Page 60

11

• Remove all glow plugs.

• Cover the glow plug mounting holes with shop towels. After

cranking the engine with the starter, check that no foreign substances are deposited on the shop towels.

• If there are deposits (such as engine oil or coolant) on the shop

towels, the following may be the cause:

• Deposits of engine oil alone can mean a defective piston ring

seal; the piston rings must be inspected.

• Deposits of both engine oil and coolant can mean cracks in

the cylinders or cylinder head; the crankcase or cylinder head

must be replaced.

WARNING

• When coolant and engine oil deposits are evident, crank-

ing the engine could be dangerous as these substances,

heated to high temperatures, will blow out from the glow

plug mounting holes. Make sure to stay away from the

glow plug mounting holes when the engine is being

cranked.

• Attach to one of the glow plug mounting holes and then at-

tach a compression gauge.

• Crank the engine and measure the compression pressure for all

the cylinders one after another. Determine the compression

pressure difference between the cylinders.

• If the compression pressure and the cylinder-to-cylinder pressure difference are not within the limit, pour a small amount of

engine oil into the corresponding glow plug mounting hole and

remeasure the compression pressure.

• If the compression pressure increases, the piston rings and

cylinder surfaces may be badly worn or otherwise damaged.

• If the compression pressure remains unchanged, there may

be seizure in the valves, the valves may be incorrectly seated

or the cylinder head gasket may be defective.

• Install the glow plugs. (See later sections.)

11-1 7

Page 61

ON-VEHICLE INSPECTION AND ADJUSTMENT

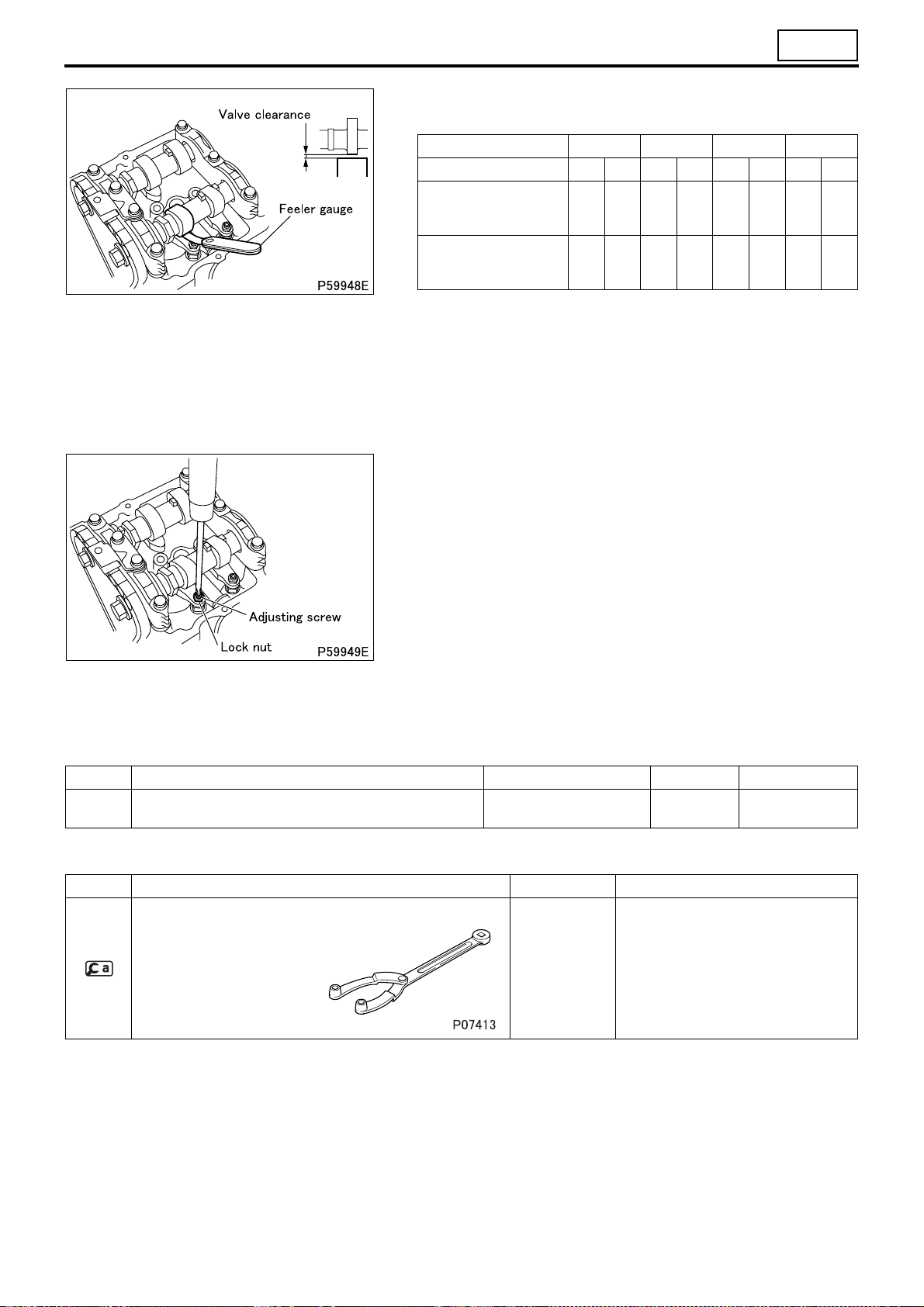

2. Inspection and Adjustment of Valve Clearance

Service standards (Unit: mm)

Location Maintenance item Standard value Limit Remedy

Valve clearance (when en-

–

gine is cold)

Tightening torque (Unit: N·m {kgf·m})

Mark Parts to be tightened Tightening torque Remarks

– Lock nut (adjusting screw mounting) 9 to 10 {0.9 to 1.1} –

Special tools

Mark Tool name and shape Part No. Application

Intake valve 0.1 – Adjust

Exhaust valve 0.15 – Adjust

Front hub and flange

yoke holder

MB990767 For cranking the engine

• Valve clearance should be checked and adjusted as follows

while the engine is still cold.

[Inspection]

• Remove the rocker cover.

• Bring the No. 1 or No. 4 cylinder piston to the top dead center

(TDC) on the compression stroke according to the following procedure:

• Rotate the crankshaft pulley in the illustrated direction so that

the notch on the crankshaft pulley is aligned with the “0” mark

on the timing gear case.

CAUTION

• Do not turn the crankshaft pulley in the opposite direction

to the illustrated one (counterclockwise), as this may cause

damage to the tensioner that is adjusting the tension of the

timing chain on the timing gear. If you turn the crankshaft

pulley in the wrong direction by mistake, remove and reinstall the chain tensioner.

11-18

• This will place either the No. 1 or No. 4 cylinder piston at TDC

on the compression stroke. When the protrusion on the camshaft is facing upward the No.1 piston is at TDC. Rotate the

engine by one full turn to switch the TDCs of the No. 1 and

No. 4 cylinder pistons.

Page 62

11

• With the No. 1 or No. 4 cylinder piston at TDC, measure the

clearance of the valves marked with a circle in the table below.

Cylinder No. 1 2 3 4

Valve INEXINEXINEXINEX

No. 1 cylinder piston at

TDC on compression

stroke

No. 4 cylinder piston at

TDC on compression

stroke

• The feeler gauge must have a slight drag when taking measurements.

• If the feeler gauge can be moved without any resistance, the

measurement will be incorrect.

• If the measurements are not within the standard value range,

adjust the valve clearance via the following procedures.

[Adjustment]

• For valve clearance adjustment, loosen the lock nut and turn the

adjusting screw so that the feeler gauge moves with some resistance.

• After the adjustment, hold the adjusting screw in place with a

screwdriver and tighten the lock nut to the specified torque. Inspect the valve clearance again with the feeler gauge.

• After the inspection, install the rocker cover and the gasket. (See

later sections.)

OOO – –O – –

–––OO–OO

3. Inspection and Replacement of Timing Chain

Service standards (Unit: mm)

Location Maintenance item Standard value Limit Remedy

– Protrusion of chain tensioner’s plunger – 20

Special tools (Unit: mm)

Mark Tool name and shape Part No. Application

Front hub and flange

yoke holder

MB990767 Cranking the engine

Replace timing

chain

11-1 9

Page 63

ON-VEHICLE INSPECTION AND ADJUSTMENT

Mark Tool name and shape Part No. Application

Fixture tool *MH063678

Dummy tensioner *MH063554

Chain disassembly tool

A: Body

B: Slider

C

13.5

Riveting tool

A: Set bolt

B: Punch

C: Die

D: Holder

EF

18 9.6

*MH063555

A: MH063556

B: MH063558

*MH063559

A: MH063563

B: MH063565

C: MH063564

D: MH063560

Tools marked with * are components of the timing chain tool set (MH063679).

[Inspection]

• Perform the following inspections. If there is any abnormality, re-

place the timing chain.

(1) Noise

• Run the engine and check for any abnormal noise caused by in-

terference between piston and valve.

• If abnormal noise is heard, check the pistons and valves for possible interference. (See “CYLINDER HEAD AND MECHANISM”

and “PISTON AND CONNECTING ROD”.)

(2) Protrusion of chain tensioner’s plunger

• Measure the protrusion of the chain tensioner’s plunger to deter-

mine the elongation of the timing chain.

• Remove the chain tensioner from the cylinder head. The plunger

is bounced a little out of the chain tensioner by the spring inside.

Prevent the plunger from falling.

• Measure the distance from the forward end of the plunger to the

farthest wear mark. If the measured value exceeds the specified

limit, replace the timing chain.

Replacement of timing chain

11-20

Page 64

11

[Replacement]

• Remove the fan coupling, front engine hanger and rocker cover.

• To check the timing position, rotate the crankshaft pulley clock-

wise with and align the timing mark “0” on the timing gear

case with the notch on the crankshaft pulley to bring the No. 1

cylinder piston to the top dead center (TDC) on the compression

stroke. The No. 1 cylinder piston is at TDC if the protrusion on

the camshaft is facing upward.

• With the No. 1 cylinder piston at TDC, check that the two mating

marks “ ” on the cam sprocket are at the illustrated positions.

• Install on the cylinder head and tighten the bolts (M8 × 20

mm) firmly.

• Crank the engine by hand and bring the mark link plate (one

plate) of the timing chain to the illustrated position of the cam

sprocket.

11-2 1

Page 65

ON-VEHICLE INSPECTION AND ADJUSTMENT

• Remove the chain tensioner and its gasket from the cylinder

head.

• Install on the cylinder head.

CAUTION

• Fill the space around the timing chain with shop towels to

prevent parts from falling into the timing gear case.

• Using , remove the pins of the mark link plate (one plate)

from the timing chain. Then, remove the mark link plate and the

plate from the timing chain.

• If the pins are difficult to remove, press them out by inserting the

temporary link of the timing chain kit into the pin holes from the

front side of the engine.

CAUTION

• Do not mix up the mark link plate, pins and plates of the timing gear with those of the timing chain kit.

11-22

Page 66

11

• With the mark link plate (two plates) of the new timing chain fac-

ing the front of the engine, connect the new timing chain with the

unlinked end of the old timing chain using a temporary link and

clip.

• Remove the shop towels from the timing chain.

• Slowly crank the engine by hand in the normal direction to rotate

the timing chain so that the new timing chain takes the place of

the old one.

• Stop cranking when the old timing chain is completely delivered

and the temporary link comes to the illustrated position of the

cam sprocket.

• Fill the space around the timing chain with shop towels again.

Remove the temporary link and the timing chain.

CAUTION