Mindray H-046-011618-00-BP10-Service-Manual-FDA-2.0 S70 Basic Service Manual Software version v203 Direction Number: BC291740-1EN Revision: Rev. 1

Page 1

BP10 NIBP Module

Service Manual

Page 2

Page 3

Intellectual Property Statement

SHENZHEN MINDRAY BIO-MEDICAL ELECTRONICS CO., LTD. (hereinafter called

Mindray) owns the intellectual property rights to this product and this manual. This manual

may refer to information protected by copyrights or patents and does not convey any license

under the patent rights of Mindray, nor the rights of others. Mindray does not assume any

liability arising out of any infringements of patents or other rights of third parties.

Mindray intends to maintain the contents of this manual as confidential information.

Disclosure of the information in this manual in any manner whatsoever without the written

permission of Mindray is strictly forbidden.

Release, amendment, reproduction, distribution, rent, adaptation and translation of this

manual in any manner whatsoever without the written permission of Mindray is strictly

forbidden.

, and are the registered trademarks or trademarks owned by

Mindray in China and other countries. All other trademarks that appear in this manual are

used only for editorial purposes without the intention of improperly using them. They are the

property of their respective owners.

This posting serves as notice under 35 U.S.C.§287(a) for Mindray patents: http://

www.mindrayna.com/patents.

For this manual, the issued Date is January 2019 (Version: 2.0).

© 2017-2019 Shenzhen Mindray Bio-Medical Electronics Co., Ltd. All rights reserved

WARNING

Federal Law (USA) restricts this device to sale by or on the order of a

physician or other practitioner licensed by U.S. state law to use or order the

use of this device.

NOTE

This manual describes all features and options. The equipment may not have all of

them. Contact Mindray service department for any questions.

I

Page 4

Manufacturer’s Responsibility

Contents of this manual are subject to changes without prior notice.

All information contained in this manual is believed to be correct. Mindray shall not be liable

for errors contained herein nor for incidental or consequential damages in connection with the

furnishing, performance, or use of this manual.

Mindray is responsible for the effects on safety, reliability and performance of this product,

only if:

All installation operations, expansions, changes, modifications and repairs of this

product are conducted by Mindray authorized personnel;

The electrical installation of the relevant room complies with the applicable national and

local requirements;

The product is used in accordance with the instructions for use.

WARNING

This manual is for biomedical engineers or technicians responsible for

troubleshooting, repairing, and maintaining the telemetry monitoring system.

II

Page 5

Return Policy

In the event that it becomes necessary to return a unit to Mindray, follow the instructions

below.

1. Obtain a return authorization.

Contact the Mindray Service Department and obtain a Mindray Customer Service

Authorization Number. The Mindray Customer Service Authorization Number must appear

on the outside of the shipping container. Return shipments will not be accepted if the

Mindray Customer Service Authorization Number is not clearly visible. Please provide the

model number, serial number, and a brief description of the reason for return.

2. Freight policy

The customer is responsible for freight charges when this product is shipped to Mindray for

service (including any relevant customs fees or other freight related charges).

3. Return address

Please send the part(s) or equipment to the address offered by Customer Service Department.

Contact Information

Manufacturer:

Address:

s ww.mindray.com

Website:

E-mail Address: service@mindray.com

Tel: +86 755 81888998

Fax: +86 755 26582680

Distributor:

Address:

Tel:

Website:

Shenzhen Mindray Bio-Medical Electronics Co., Ltd.

Mindray Building,Keji 12th Road South, High-tech Industrial

park,Nanshan,Shenzhen 518057,P.R.China

Mindray DS USA, Inc.

80 M0 acArthur Boulevard, Mahwah, New Jersey 07430, USA

1.800.288.212 1.2011, .995.8000

http://www.mindraynorthamerica.com/

IV

Page 6

Preface

Manual Purpose

This manual provides detailed information about the assembling, dissembling, testing and

troubleshooting of the equipment to support effective troubleshooting and repair. It is not

intended to be a comprehensive, in-depth explanation of the product architecture or technical

implementation. Observance of the manual is a prerequisite for proper equipment

maintenance and prevents equipment damage and personnel injury.

This manual is based on the maximum configuration. Therefore, some contents may not

apply to your device. If you have any question, please contact our Customer Service

Department.

Intended Audience

This manual is for biomed

representatives responsible for troubleshooting, repairing and maintaining the BP10

NIBP modules.

ical engineers, authorized technicians or service

V

Page 7

Contents

1 Safety ......................................................................................................................................... 1-1

1.1 Safety Information .............................................................................................................. 1-1

1.1.1 Warnings .................................................................................................................... 1-1

1.1.2 Cautions ..................................................................................................................... 1-2

1.1.3 Notes .......................................................................................................................... 1-3

1.2 Equipment Symbols ............................................................................................................ 1-3

2 Design Principles ...................................................................................................................... 2-1

2.1 Intended Use ....................................................................................................................... 2-1

2.2 System Connections ............................................................................................................ 2-1

2.3 Peripheral Interfaces............................................................................................................ 2-2

2.4 Compositions of the Main Unit ........................................................................................... 2-3

3 Equipment Installation ............................................................................................................ 3-1

3.1 Unpacking ........................................................................................................................... 3-1

3.2 Preparations for Installation ................................................................................................ 3-1

3.2.1 Environmental Requirements ..................................................................................... 3-1

3.2.2 Electricity Requirements ............................................................................................ 3-2

3.3 Installing the BP10 NIBP module ....................................................................................... 3-2

3.4 Startup ................................................................................................................................. 3-2

4 T est and Maintenance .............................................................................................................. 4-1

4.1 Introduction ......................................................................................................................... 4-1

4.2 Startup Check ...................................................................................................................... 4-1

4.2.1 Battery Check ............................................................................................................. 4-2

4.3 Maintenance Mode .............................................................................................................. 4-2

4.4 NIBP Module Maintenance ................................................................................................. 4-6

4.4.1 NIBP Accuracy Test ................................................................................................... 4-6

4.4.2 NIBP Overpressure Calibration .................................................................................. 4-7

4.4.3 Leakage Test ............................................................................................................... 4-8

4.4.4 Hardware Test ............................................................................................................ 4-8

4.4.5 Watchdog Test ............................................................................................................ 4-9

4.5 Upgrading the System ......................................................................................................... 4-9

5 Tr ou bleshoot ing ........................................................................................................................ 5-1

5.1 Overview ............................................................................................................................. 5-1

5.2 Replacing a Component ...................................................................................................... 5-1

5.3 Viewing Software Version ................................................................................................... 5-1

5.4 Viewing System Logs ......................................................................................................... 5-1

5.5 Error Codes and Corresponding Solutions .......................................................................... 5-2

1

Page 8

6 Maintenance and Disassembly ................................................................................................ 6-1

6.1 Tools .................................................................................................................................... 6-1

6.2 Preparations for Disassembly .............................................................................................. 6-1

6.3 Main Unit Disassembly ....................................................................................................... 6-2

6.3.1 Separating the Front and Rear Half of the Monitor .................................................... 6-3

6.3.2 Disassembling the Rear Housing ............................................................................... 6-4

6.3.3 Disassembling Pump, Valve and Integrated Airway .................................................. 6-5

6.3.4 Disassembling Front Housing Assembly ................................................................... 6-6

7 Components .................................................................. ............................................................ 7-1

7.1 Introduction ......................................................................................................................... 7-1

7.2 Components of the Main Unit ............................................................................................. 7-1

7.2.1 Exploded View ........................................................................................................... 7-1

7.2.2 Parts List .................................................................................................................... 7-2

7.3 Front Housing Assembly ..................................................................................................... 7-2

7.3.1 Exploded View ........................................................................................................... 7-2

7.3.2 Parts List .................................................................................................................... 7-3

7.4 Rear Housing Assembly ...................................................................................................... 7-3

7.4.1 Exploded View ........................................................................................................... 7-3

7.4.2 Parts List .................................................................................................................... 7-4

2

Page 9

1 Safety

1.1 Safety Information

WARNING

Indicates a potential hazard or unsafe practice that, if not avoided, will result in

death, serious injury, or property damage.

CAUTION

Indicates a potential hazard or unsafe practice that, if not avoided, could result in

minor personal injury, product fault, or product/property damage.

NOTE

Provides application tips or other useful information to ensure that you get the

most from your product.

1.1.1 Warnings

WARNING

BP10 is intended to be used for a single patient at a time.

BP10 must be operated by medical personnel in hospitals or medical institutions.

To avoid explosion hazard, do not use the equipment in the presence of oxygen-rich

atmospheres, flammable anesthetics, or other flammable agents.

Do not use this equipment in conjunction with Electro Surgical Unit (ESU).

Before putting the system into operation, the operator must verify that the

equipment and accessories are in correct working order and operating condition.

Do not come into contact with the patient during defibrillation. Otherwise serious

injury or death could result.

Do not touch the patient and live parts simultaneously.

1-1

Page 10

Do not open the equipment housing s. All servicing and future upgrades must be

carried out by trained and authorized personnel.

The physiological data displayed on the system are for reference only and cannot

be directly used for diagnostic interpretation.

Only use parts and accessories specified in this manual.

Route, wrap and secure the hose to avoid inadvertent disconnection, stumbling and

entanglement.

1.1.2 Cautions

CAUTION

Do not let BP10 directly touch the patient’s skin when the device is on. The device

temperature rises when the device is on. If the device contacts the patient’s skin for

a long time, skin burns may occur.

When disposing of the packaging material, be sure to observe the applicable waste

control regulations and keep it out of children’s reach.

Magnetic and electrical fields are capable of interfering with the proper

performance of the equipment. For this reason make sure that all external

equipment operated in the vicinity of the equipment comply with the relevant EMC

requirements. Mobile phone, X-ray equipment or MRI equipment are a possible

source of interference as they may emit higher levels of electromagnetic radiation.

Always install or carry the equipment properly to avoid damage caused by drop,

impact, strong vibration or other mechanical force.

Dry the equipment immediately in case of rain or water spray.

The system generates and uses the Radio Frequency (RF) energy. If it is not

installed correctly or not used as per the manual, RF interference to other

equipment could result.

At the end of its service life, the equipment, and its accessories, must be disposed of

in compliance with the guidelines regulating the disposal of such products to

prevent bringing potential negative consequences to the environment and human

health. If you have any questions concerning disposal of the equipment, please

contact Mindray.

1-2

Page 11

1.1.3 Notes

NOTE

Place the equipment in a location where you can easily see the screen, and access

the operating controls.

Keep this manual in the vicinity of the equipment so that it can be obtained

conveniently when needed.

1.2 Equipment Symbols

See the BP10 Operator’s Manual (P/N: 046-011008-00) for information about the symbols

used on this product and its packaging.

1-3

Page 12

FOR YOUR NOTES

1-4

Page 13

2 Design Principles

2.1 Intended Use

BP10 NIBP module (hereinafter referred as BP10) can measure, display, review, store the

NIBP parameter for ambulating Adult and Pediatric patients over three years old, and transfer

the information to TMS60/TM80 in BeneVision Central Monitoring System.

2.2 System Connections

The figure below shows the connection system of the BP10 and its peripherals. The BP10 can

communicate with the TD60/TM80 through Bluetooth and upload the NIBP measurement

result to the telemetry box.

2-1

Page 14

2.3 Peripheral Interfaces

The interfaces included in the BP10 are shown as follows:

USB interface: used to upgrade software.

Battery interface: used for power supply of BP10 and supporting the rechargeable

battery and the 2-AA battery holder.

Battery interface

USB connector

2-2

Page 15

2.4 Compositions of the Main Unit

The BP10 host hardware consists of the parameter board and button board. Figure 5 shows

division of the functional block diagram of the two boards. Main functions of each board are

as follows:

M0+ parameter board: Side button detection, main pressure measurement, power

management, on/off control, pump valve control, communication with M4, and system

status monitoring.

M4 main control board: Overpressure protection, front button detection, buzzer driver,

real-time clock, bluetooth communication, USB communication, EEPROM data storage

and LCD driver.

UART

GPIO

2-3

Page 16

FOR YOUR NOTES

2-4

Page 17

3 Equipment Installation

3.1 Unpacking

Before unpacking, examine the packing case carefully for signs of damage. If any damage is

detected, contact the carrier. If the packing case is intact, open the packing case in a right way,

take out the BP10 NIBP Module and other components from the packing case, and check

according to the Packing List.

Check whether there is any mechanical damage on the BP10 NIBP Module and whether all

items in the Packing List have been received. Contact us in case of any problem.

When the equipment is moved from one place to another, condensation may occur because of

temperature or humidity difference. In this case, never start the equipment before the

condensation disappears.

3.2 Preparations for Installation

3.2.1 Environmental Requirements

To avoid explosion hazard, do not use the equipment in the presence of flammable

anesthetics, vapors or liquids. The monitor shall be placed in an environment free from

vibration, dust, and corrosive. Otherwise, proper operation of the monitor cannot be

guaranteed.

Environmental Conditions Operating Conditions Storage Conditions

Temperature 0°C to 40°C -20°C to 60°C

Relative humidity

(non-condensation)

Atmospheric pressure 427.5 mmHg to 805.5 mmHg,

15% to 95% 10% to 95%

120 mmHg to 805.5 mmHg, or

or 57.0 kPa to 107.4 kPa

16.0 kPa to 107.4 kPa

3-1

Page 18

3.2.2 Electricity Requirements

This BP10 NIBP Module is powered by two AA (LR6) alkaline batteries or Li-ion

rechargeable batteries (022-000198-00).

The rechargeable battery needs to be charged using the central charging station, as shown

below.

3.3 Installing the BP10 NIBP module

To install the NIBP module, do as follows:

1. Check the equipment and accessories according to the Packing List.

2. Check whether the equipment and accessories are damaged.

3. Install batteries. For operation details, see the BP10 Operator’s Manual (P/N:

046-011008-00).

4. Connect all accessories.

3.4 Startup

When the rechargeable lithium-ion or AA battery is properly installed into the compartment

door, BP10 will be powered on automatically.

When BP10 is powered off, press the

displays and a beep sounds.

Upon powering up, there are two situations:

If BP10 is turned on for the first time, the device will request you to set up language,

maintenance passcode, service passcode for the first time startup.

If BP10 is turned on next time, the device will directly go to the main screen.

key to turn on BP10. The startup logo screen

3-2

Page 19

4 Test and Maintenance

4.1 Introduction

To ensure that the BP10 NIBP module will operate optimally, maintenance personnel must

conduct regular inspection, preventive maintenance, and test on the BP10 NIBP module. This

section describes the basic method of testing the BP10 NIBP module and recommends

appropriate test frequency and test tools for you. Maintenance personnel shall select proper

tools to conduct maintenance and test on the BP10 NIBP module as required.

The test method described in this section is mainly used to verify that the performance of the

BP10 NIBP module meets specifications. If the monitor fails to pass the test, the BP10 NIBP

module or a certain functional module of the BP10 NIBP module is faulty. In this case,

maintenance personnel shall repair or replace the faulty BP10 NIBP module. Contact the

Service Department of Mindray in case of any problem.

When necessary, maintenance personnel can ask for the circuit diagram, component list,

operating manual, calibration description, and other necessary materials that can facilitate

maintenance of the components allowed to be maintained from the manufacturer.

CAUTION

All test tasks must be executed by qualified professional maintenance personnel.

Configure and change the co ntents in the device maintenance menu with caution

because misoperation may cause data loss.

Before a test, maintenance personnel should ensure the applicability of the test

tools and connection cables. In addition, the maintenance personnel shall be

familiar with the test tools.

4.2 Startup Check

BP10 power-on detection is used to determine whether the device can be started for operation

normally. Each time when the device is powered on, the BP10 will perform detection

automatically. If no error message is displayed on the screen after powering on, the power-on

self test will pass.

4-1

Page 20

4.2.1 Battery Check

The BP10 uses the 2-AA battery or rechargeable battery. Battery is detected after being

connected. For the AA battery, the device will check the battery voltage; for the rechargeable

battery, the device will check the power level, voltage and battery status.

CAUTION

Do not use batteries of different types or batteries with different amounts of

electricity at the same time.

WARNING

Use only batteries specified by the manufacturer.

Remove the batteries prior to transport or if the BP10 NIBP Module is not likely to

be used for a long time, avoiding monitor faults caused by liquid leakage of the

batteries.

Replace damaged batteries immediately when you find the damage or leakage. Do

not use faulty batteries to power the BP10 NIBP Module.

4.3 Maintenance Mode

The BP10 supports Maintenance and Service. To access these modes, press the key,

and choose [System] [Maintenance]. Password is required. Two modes support the

following functions:

Maintenance Functions: NIBP Settings, Restore Factory Defaults, Display Auto Off,

Device Name, Edit Passcodes, NIBP Accuracy Test, NIBP Leakage Test, Language,

Service.

Service Functions: Software Version, Service Log, Device Information, Overpressure

Calibration, Hardware Test, Watchdog Test, NIBP Calibration Info, Debug Information.

4-2

Page 21

Maintenance Menu

NIBP Settings:

Parameter Timeout

OFF, 5 min , 10 min, 15 min, 30 min, 45 min,

60 min

NIBP End tone

Measure on Clock

Units

ON, OFF

ON, OFF

mmHg, KPA

Restore Factory Defaults:

All history data will be cleared (yes & No)

Display Auto Off:

Off, 1 min, 2 min, 5 min, 15 min, 30 min

Device Name:

NIPB-

(Field Range 0-9)

Edit Passcodes:

Maintenance Passcode

Service Passcode

(Field Range 0-9)

(Field Range 0-9)

NIBP Accuracy Test:

Start

Actual

---

mmHg

NIBP Leakage Test:

Start

Actual

The NIBP leakage tests checks the integrity of

the system and of the valve

.

---

mmHg

Language:

English, Portuguese, Czech, Turkish, Danish, Finnish, Hungarian, Norwegian,

4-3

Page 22

Note: Default language gets configured at initial setup.

Service:

Enter passcode to access Service:

(Field Range 0-9) Service Password gets configured at initial

setup.

Service Menu

Software Version:

Software Version xx.xx.xx.xx/ xx.xx.xx.xx

Boot Version xx.xx.xx.xx

Language Library Version xx.xx.xx

Icon Libraray Version xx.xx.xx

Logo Library Version xx.xx.xx

Nibp Algorithm Version xx.xx.xx

MPAN xx.xx(xx.xx)

Service Log:

Error Code Time List the error code

Device Information:

System Startup Time

Accumulated Runtime

Battery Capatity

Battery Voltage

Screen Resolution/Size

Overpressure Calibrate:

Start

Actual

---

mmHg

The overpressure protection

calibration of Adu/Ped is

320-330mmHg

4-4

Page 23

Hardware Test:

Start

NIBP Calibrage Info:

150mmHg Set Value

Press value*10

150mmHg Measured value

Press value*10

300mmHg Set Value

Press value*10

300mmHg Measured value

Press value*10

Debug Information:

Debug Switch

ON, OFF

Watchdog Test:

Start

4-5

Page 24

4.4 NIBP Module Maintenance

4.4.1 NIBP Accuracy Test

The NIBP accuracy test is required at least once every two years or whenever you doubt the

NIBP reading.

Inspection tools: T-connector, airway tube, squeeze bulb, rigid vessel (500 ml), standard

manometer (with the precision not lower than 1 mmHg).

The inspection steps are as follows:

1. Connect the BP10, standard manometer, squeeze bulb and rigid vessel as shown in the

following figure.

Monitor

Connector for NIBP

cuff

Squeeze Bulb Rigid Vessel

2. Before inflation, the reading on the manometer should be 0. If the reading is not 0,

disconnect the airway to make the reading return to 0.

3. Press the BP10

select [NIBP Accuracy Test]. Press Start.

4. Compare the reading of the manometer with the reading of the BP10. The difference

should not be greater than 3 mmHg.

5. Raise the pressure in the rigid vessel to 50 mmHg with the squeeze bulb, and repeat step

4.

6. Raise the pressure in the rigid vessel to 200 mmHg with the squeeze bulb, and repeat step

4.

7. After the pressure test is completed, click [Stop] to exit the pressure test mode.

Main menu key and select [Maintenance], select [Service] and

Appropriate tubing

Standard

sphygmomanometer

NOTE

You can replace the standard manometer/squeeze with a blood pressure simulator

to form a test system.

4-6

Page 25

q

4.4.2 NIBP Overpressure Calibration

The NIBP overpressure calibration is required at least once every two years or whenever you

doubt the NIBP reading.

Calibration tools:

T-shaped connector

Airway tube

Balloon pump

Rigid vessel (volume 500±25 ml)

Reference manometer (calibrated with accuracy not lower than 1 mmHg)

Calibration procedure:

1. Connect the equipment as shown in the following figure.

BP-10

Connector for NIBP

cuff

ueeze Bulb

S

2. Before inflation, the reading on the manometer should be 0. If the reading is not 0,

disconnect the airway to make the reading return to 0.

3. Press the BP10

select [Overpressure Calibrate]. Press Start.

4. Raise the pressure in the rigid vessel to 320 to 330 mmHg with the squeeze bulb, and

press the [Confirm] button. The interface exits after prompting "Calibration

Completed!"

Main menu key and select [Maintenance], select [Service] and

Appropriate tubing

Standard

sphygmomanometer

Rigid Vessel

4-7

Page 26

4.4.3 Leakage Test

The NIBP leakage test checks the integrity of the system and of the valve. It is required at

least once every two years or whenever you doubt the NIBP reading.

Test tools:

Adult cuff

Inflation tube

Cylinder

Test procedure:

1. Connect the cuff and inflation tube to the NIBP cuff connector of the BP10.

2. Wrap the cuff around the cylinder, as shown in the following figure.

Cylinder

Connector for NIBP

cuff

3. Press the BP10

select [NIBP Leakage Test]. Press Start.

4. The BP10 will automatically deflate in about 20 seconds. This means that the test is

completed. The test result is displayed on the screen. If "Airway is normal" is displayed

on the screen, the system does not have a leakage problem. If the message "NIBP

Pneumatic Leak" is displayed, it indicates that the system may have a leak. Check the

tubing and connections for leakages. If you ensure that the tubing and connections are all

correct, perform a leakage test again.

5. If fault prompt still appears, contact Mindray for maintenance.

Main menu key and select [Maintenance], select [Service] and

Air tubing

Cuff

4.4.4 Hardware Test

Press the BP10 Main menu key and select [Maintenance], select [Service] and select

[Hardware Test]. Press Start.

If “Test Successed!” is displayed continuously for three times on the screen, the system does

not have a hardware problem. If the message “Test Failed!” is displayed, contact Mindray

for maintenance.

4-8

Page 27

4.4.5 Watchdog Test

Press the BP10 Main menu key and select [Maintenance], select [Service] and select

[Watchdog Test]. Press Start.

If the BP10 restarts in three seconds, the system does not have a watchdog problem. If the

BP10 does not restart or no fault prompt appears, contact Mindray for maintenance.

4.5 Upgrading the System

CAUTION

Before upgrade, disconnect the BP10 from patients and save important data in the

monitor.

During upgrade, do not remove the USB connection. Otherwise, the equipment

may malfunction

The upgrade operation can only be performed by professional maintenance

personnel.

NOTE

Before upgrade, make sure that the upgrade package is the one you desire. To

obtain the latest upgrade package, please contact the After-sales Service

Department of Mindray.

System upgrade procedure:

1. Run the network upgrade tool G-110-003608-00 on the tooling computer, select the

corresponding .tool file of G-110-003613-00, click [OK], and then select the model NIBP

PtxOD.

2. Click [Select Package] on the interface of the upgrade tool, click [Browse] on the

displayed interface, select the combined upgrade package .mpkg file prepared in section

2.3, and click [OK] after confirming that the checksum and version are correct.

4-9

Page 28

1 Click to select the

upgrade package.

2 Select the combined

upgrade package .mpkg

file prepared in section 2.3

3 Confirm that the checksum

and version are correct

3. Click the [Start] button on the interface of the upgrade tool, and use a Micro USB cable

to connect the BP10 main unit (not installed with the battery) to the tooling computer. Use

two hands to press the [Return] key and [Menu] key of the BP10 main unit at the same

time, and install the battery. The BP10 main unit starts upgrade. After upgrade, the

interface of the BP10 main unit displays "Upgrade Completed!"

4. Remove the battery and then install it again. The machine starts automatically.

4-10

Page 29

5 Troubleshooting

5.1 Overview

This section classifies faults based on the components where faults occur and fault symptoms.

During troubleshooting, please refer to relevant fault list and check, locate, and rectify faults

in sequence.

The solutions recommended in this section can help to rectify most of the equipment faults

you may encounter. In case of a fault not included in this section, please contact the Mindary

Service Department.

5.2 Replacing a Component

You can replace some main components or parts of this monitor, including the circuit board

of the monitor. After determining that the circuit board of the monitor is faulty, you can

replace the faulty circuit board with a new one according to 6 Maintenance and Disassembly,

and then check whether the fault is rectified. If the fault is rectified, it indicates that the

original circuit board is damaged. In this case, deliver it back to Mindray for maintenance. If

the fault persists, install the original circuit board and continue to perform troubleshooting

based on other possible causes.

5.3 Viewing Software Version

To view the software version, press the BP10 Main menu key and select [Maintenance],

select [Service] and select [Software Version].

5.4 Viewing System Logs

To view the log record, press the BP10 Main menu key and select [Maintenance],

select [Service] and select [Service Log].

5-1

Page 30

5.5 Error Codes and Corresponding Solutions

See Chapter 12 Troubleshooting in the BP10 Operator’s Manual (P/N: 046-011008-00) for

information about the error codes and corresponding solutions.

NOTE

In case of fault, you must send the faulty BP10 NIBP Module to an authorized

service center for maintenance. Otherwise, the warranty card will become invalid.

5-2

Page 31

6 Maintenance and Disassembly

6.1 Tools

When disassembly or replacing components, you may need to use the following tools:

Ph2 screwdriver

Needle nose pliers

Tweezers

Philips screwdriver

Cutting pliers

6.2 Preparations for Disassembly

Before disassembly the monitor, make the following preparations:

Take ESD protection measures before disassembly. Do not directly touch any boards

during disassembly.

Stop monitoring patients, remove the two batteries from the monitor, and disconnect all

accessories and external devices from the monitor.

CAUTION

Maintenance personnel must take ESD protection measures before disassembling

the monitor. When disassembling some ESD-sensitive components, maintenance

personnel must wear a protection device like ESD wrist strap or ESD glove to

avoid damage on these components.

When reinstalling the monitor, install and place the connection lines properly to

protect them from being damaged, thereby avoiding short circuit.

When reinstalling the monitor, connect the airway components properly to prevent

them from being extruded, thereby avoiding airway blocking.

When reinstalling the monitor, select and use screws of appropriate models. If you

forcibly drive in a screw of inappropriate model, the monitor may be damaged. In

addition, during use after the reinstallation, the component fastened by using this

inappropriate screw may fall off, causing unpredictable product damage or

personal injury.

When disassembling the monitor, dismount various components in proper

sequence. Forcible disassembly in wrong sequence may cause an irreversible

6-1

Page 32

equipment damage.

Before disassembly components, make sure that all connection lines are removed.

Do not snap the connection lines or damage the connectors during disassembly.

Separately place the disassembled screws and other parts and components based

on their types to facilitate future reinstallation and avoid drop, pollution, or loss.

The monitor has waterproof requirement. When reinstalling the monitor, ensure

that the waterproof accessories like the waterproof strip are properly installed.

6.3 Main Unit Disassembly

NOTE

When disassembling the monitor, ensure that the site for placing the monitor is

smooth and no foreign material that may scratch the anti-dazzling screen or touch

screen or damage the knob exists at the site. In addition, you have to protect the

two button stands at the front of the rear housing during disassembly.

All operations shall be performed by professional maintenance personnel.

Maintenance personnel must wear insulating gloves during the maintenance.

If an optional function is configured, relevant operations may be involved. If this

optional function is not configured, no operation is involved.

6-2

Page 33

6.3.1 Separating the Front and Rear Half of the Monitor

1. After tearing off the label on the device back, remove the four M1.6×3.5 screws and two

M1.6×13.3 screws, as shown below.

Two M1.6×13.3 screws

Four M1.6×3.5 screws

2. Separate the front housing and rear housing along the device top, and then remove the

FPC between the front housing and rear housing.

6-3

Insert the shorter end of

FPC into the main control

board socket

Insert the longer end of

FPC into the parameter

board socket

Page 34

pump

NOTE

During re-installation, check whether the flexible cable is installed in place.

6.3.2 Disassembling the Rear Housing

Todisassemble the ABPM peripheral board, do as follows:

1. Place the rear housing of the device flat on a table and remove the connection line on the

parameter board.

2. Remove the five M1.6×3.5 screws and the pump support sheet metal.

3. Pull up to remove the parameter board.

Buzzer line wiring direction

Two M1.6×3.5 screws to fix

support sheet metal

the

Valve line socket

Buzzer line socket

Pump line socket

Bluetooth

antenna wiring

direction

Three M1.6×3.5 screws to

fix the parameter board

6-4

Page 35

6.3.3 Disassembling Pump, Valve and Integrated Airway

The following figure shows the effect after the parameter board is removed. Next, dismount

the inflation pump:

1. Remove the two M1.6×3.5 screws.

2. Pull up to remove the pump, valve and integrated airway.

The pump line passes

through the gap between

the large valve and the

plastic column, with the

red wire below the black

wire. They cannot pass

through the battery

terminal limiting column.

Two M1.6×3.5 screws

NOTE

During pump assembly, connect the pump connection line according to the

instruction in the figure.

6-5

Page 36

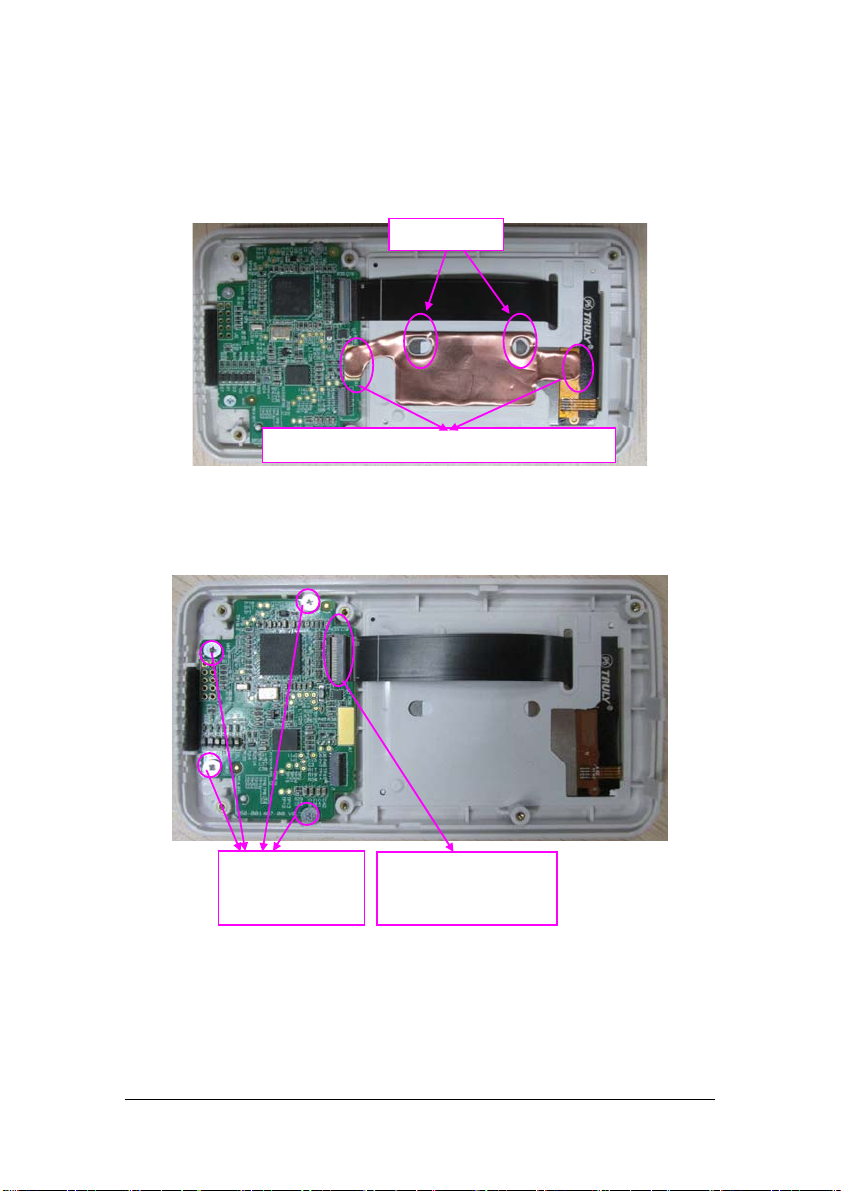

6.3.4 Disassembling Front Housing Assembly

Remove the grounding copper foil from the figure, as shown below:

Hole alignment

Connect the grounding copper foil to the ground point

Remove the screen FPC and four M1.6×2.4 screws from the main control board

Four M1.6×3.4

cross recessed

cheese head screws

Insert the FPC of LCD

screen into the socket on

the main control board

6-6

Page 37

7 Components

7.1 Introduction

This section provides theexploded view and part numbers of the monitor to illustrate the

assembling relationships between various components and parts, thereby facilitating

disassembly and replacing components and parts by maintenance personnel.

7.2 Components of the Main Unit

7.2.1 Exploded View

7-1

Page 38

7.2.2 Parts List

No. P/N Description Remark

1 115 -035519-00 BP10 Front Housing Assembly /

6 115-035520-00 BP10 Rear Housing Assembly /

2 115-035521-00 M1.6×13.3 screws /

5 115-035521-00

BP-10 Maintenance Kit

7 NIBP POD internal signal FPC

(FRU)

3 0156 main unit label (CE) /

4 045-001700-00 BP10 two AA battery tray assembly /

M1.6×3.5 screws

7.3 Front Housing Assembly

7.3.1 Exploded View

7-2

Page 39

7.3.2 Parts List

No. P/N Description Remark

1 115-035519-00

BP10 Front Housing

2 BP POD dust-proof mat 1

Assembly Kit (FRU)

3 BP POD dust-proof mat 2

4 LCD screen TFT 2.4" 240*320 3.3V

5 BP POD front housing (silk screen)

6 BP POD grounding copper foil

7 BP POD air inlet dustproof sponge

11 BP POD plastic button 2

12 BP POD plastic button 4

13 BP POD plastic button 1

14 BP POD plastic button 3

8 030-000661-00 Screw M1.6 x 3.4 mm /

9 115-035518-00

BP10 Main Control

Board Kit (FRU)

10 BP POD ESD shielding sheet

BP POD lens /

NIBP POD main control board

PCBA

/

7.4 Rear Housing Assembly

7.4.1 Exploded View

7-3

Page 40

7.4.2 Parts List

No. P/N Description Remark

3

5

7 NIBP connector

115-035520-00

8 BP POD rear housing (silk screen)

BP10 Rear Housing

9 BP POD USB silica gel cap

Assembly Kit (FRU)

10 TP battery fastener spring piece

11 BP POD battery fixing slide fastener

12

1 082-002009-00 Air Pump DC 4.2V 300 mmHg /

2

115-035522-00

BP10 Integrated Gas

13

circuit and valve

assembly Kit (FRU)

14 Solenoid valve (1501)

4

3 BP POD connector fixing rack

115-035521-00

6 BP POD buzzer shock pad

BP10 Maintenance Kit

(FRU)

7 NIBP connector

16 M1.6×3.5 screws

15 051-001707-00 NIBP POD parameter board PCBA /

17 042-012035-00 BP POD pump support sheet metal /

BP POD connector fixing rack

Bluetooth antenna (BP) L=112mm

BP_ANT(BT)

BP POD battery buckle fixing cover

plate

BP POD integrated airway assembly

Air valve, double valve normally

open, DC3.3V 300mmHg

Buzzer Φ13*2.5 80DB terminal

/

/

/

7-4

Page 41

Page 42

P/N: 046-011618-00(2.0)

Loading...

Loading...