Page 1

BeneVision N17/BeneVision N15/

BeneVision N12

Patient Monitor

Service Manual

Page 2

Page 3

Copyright 2018-2019 Shenzhen Mindray Bio-Medical Electronics Co., Ltd. All rights reserved.

Release time: January 2019

Revision 5.0

BeneVision N17/BeneVision N15/BeneVision N12 Patient Monitor Service Manual I

Page 4

Intellectual Property Statement

SHENZHEN MINDRAY BIO-MEDICAL ELECTRONICS CO., LTD. (hereinafter called Mindray) owns the

intellectual property rights to this product and this manual. This manual may refer to information

protected by copyrights or patents and does not convey any license under the patent rights of Mindray,

nor the rights of others. Mindray does not assume any liability arising out of any infringements of patents

or other rights of third parties.

Mindray intends to maintain the contents of this manual as confidential information. Disclosure of the

information in this manual in any manner whatsoever without the written permission of Mindray is strictly

forbidden. Release, amendment, reproduction, distribution, rent, adaption and translation of this manual

in any manner whatsoever without the written permission of Mindray is strictly forbidden.

, is the trademark, registered or otherwise, of Mindray in China and other countries. All

other trademarks that appear in this manual are used only for editorial purposes without the intention of

improperly using them. They are the property of their respective owners.

This posting serves as notice under 35 U.S.C.§287(a) for Mindray patents:

http://www.mindrayna.com/patents.

WARNING

Federal Law (USA) restricts this device to sale by or on the order of a physician or other

practitioner

licensed by U.S. state law to use or order the use of this device.

NOTE

This manual describes all features and options. The equipment may not have all of them. Contact

Mindray Technical Support department for any questions.

II BeneVision N17/BeneVision N15/BeneVision N12 Patient Monitor Service Manual

Page 5

Manufacturer’s Responsibility

Contents of this manual are subject to changes without prior notice.

Mindray is responsible for safety, reliability and performance of this product only on the condition that:

All installation operations, expansions, changes, modifications and repairs of this product are

conducted by Mindray authorized personnel;

The electrical installation of the relevant room complies with the applicable national and local

requirements;

This product is operated under strict observance of the operator’s manual.

Return Policy

In the event that it becomes necessary to return a unit to Mindray, follow the instructions below.

1. Obtain a return authorization.

Contact the Mindray Service Department and obtain a Mindray Customer Service Authorization

Number. The Mindray Customer Service Authorization Number must appear on the outside of the

shipping container. Return shipments will not be accepted if the Mindray Customer Service

Authorization Number is not clearly visible. Please provide the model number, serial number, and a

brief description of the reason for return.

2. Freight policy

The customer is responsible for freight charges when this product is shipped to Mindray for service

(including any relevant customs fees or other freight related charges).

3. Return address

Please send the part(s) or equipment to the address offered by Customer Service Department.

BeneVision N17/BeneVision N15/BeneVision N12 Patient Monitor Service Manual III

Page 6

Service

Mindray maintains a network of service representatives and factory-trained distributors. Prior to

requesting service, perform a complete operational check of the instrument to verify proper control

settings. If operational problems continue to exist, contact Mindray service.

In North America contact the Service Department at (800) 288-2121, ext: 8116 for Technical Support or

(201) 995-8000 for assistance in determining the nearest field service location.

Please include the instrument model number, the serial number, and a description of the problem with all

requests for service.

Any questions regarding the warranty should be directed to your local sales or service representative.

NOTE

Upon request, Mindray provides circuit diagrams, component part lists, descriptions, calibration

instructions, or other information which assist the user’s appropriately qualified technical

personnel to repair those parts of the equipment which are designated by Mindray DS USA, Inc. as

repairable.

Contact Information

Manufacturer:

Address:

Tel:

Fax:

Website:

Distributor:

Address:

Tel:

Website:

Shenzhen Mindray Bio-Medical Electronics Co., Ltd.

Mindray Building, Keji 12th Road South, High-tech Industrial Park, Nanshan, Shenzhen

518057 P.R. China

+86 755 81888998

+86 755 26582680

www.mindray.com

Mindray DS USA, Inc.

800 MacArthur Boulevard, Mahwah, New Jersey 07430 USA

1.800.288.2121, 1.201.995.8000

www.mindray.com

IV BeneVision N17/BeneVision N15/BeneVision N12 Patient Monitor Service Manual

Page 7

Preface

Manual Purpose

This manual provides detailed information about the assembly, disassembly, testing and troubleshooting

of the equipment to support effective troubleshooting and repair. It is not intended to be a

comprehensive, in-depth explanation of the product architecture or technical implementation. Use of the

manual is necessary for proper equipment maintenance and will help to eliminate equipment damage

and personal injury.

This manual is based on the maximum configuration; therefore, some contents may not apply to your

monitor. If you have any question, please contact our Customer Service Department.

Intended Audience

This manual is for biomedical engineers, authorized technicians or service representatives responsible for

troubleshooting, repairing and maintaining the patient monitors.

Contact your local Mindray Service Organization for information on product courses which address service

and support for this product.

Passwords

A password may be required to access different modes within the monitor. The passwords are listed below:

User maintenance: MIN888 (User adjustable)

Configuration mode: MIN315 (User adjustable)

It is recommended that the user should change the passwords for user maintenance and configuration

mode once they take ownership of the equipment.

BeneVision N17/BeneVision N15/BeneVision N12 Patient Monitor Service Manual V

Page 8

FOR YOUR NOTES

VI BeneVision N17/BeneVision N15/BeneVision N12 Patient Monitor Service Manual

Page 9

Contents

1 Safety ................................................................................................................................................................................. 1-1

1.1 Safety Information .......................................................................................................................................................................................... 1-1

1.1.1 DANGER ................................................................................................................................................................................................ 1-1

1.1.2 Warnings .............................................................................................................................................................................................. 1-2

1.1.3 Cautions ............................................................................................................................................................................................... 1-2

1.1.4 Notes ..................................................................................................................................................................................................... 1-2

1.2 Equipment Symbols ....................................................................................................................................................................................... 1-2

2 Operation Theory .............................................................................................................................................................. 2-1

2.1 Overview ............................................................................................................................................................................................................ 2-1

2.2 Product System Architecture ...................................................................................................................................................................... 2-1

2.2.1 Main Control Board .......................................................................................................................................................................... 2-2

2.2.2 Internal Module Rack COM Board ............................................................................................................................................... 2-3

2.2.3 Power Architecture ........................................................................................................................................................................... 2-3

2.2.4 Independent Display Board (for the N17 Only) ..................................................................................................................... 2-4

2.2.5 iView Module (for the N17 Only) ................................................................................................................................................. 2-4

2.2.6 Alarm LAMP Board ........................................................................................................................................................................... 2-4

2.2.7 Power Switch Board ......................................................................................................................................................................... 2-4

2.3 Data Logic Flow ............................................................................................................................................................................................... 2-4

3 Testing and Maintenance .................................................................................................................................................. 3-1

3.1 Introduction ...................................................................................................................................................................................................... 3-1

3.1.1 Test Equipment .................................................................................................................................................................................. 3-1

3.1.2 Preventative Maintenance ............................................................................................................................................................. 3-1

3.1.3 Recommended Frequency ............................................................................................................................................................ 3-2

3.1.4 Visual Inspection ............................................................................................................................................................................... 3-3

3.1.5 NIBP Tests ............................................................................................................................................................................................. 3-4

3.1.6 Sidestream and Microstream CO2 Tests .................................................................................................................................... 3-6

3.1.7 AG Tests ................................................................................................................................................................................................ 3-8

3.2 Power On Test ................................................................................................................................................................................................ 3-11

3.3 Module Performance Tests ....................................................................................................................................................................... 3-11

3.3.1 ECG Tests ........................................................................................................................................................................................... 3-11

3.3.2 Resp Performance Test ................................................................................................................................................................. 3-12

3.3.3 SpO2 Test ........................................................................................................................................................................................... 3-12

3.3.4 NIBP Tests .......................................................................................................................................................................................... 3-13

3.3.5 Temp Test .......................................................................................................................................................................................... 3-13

3.3.6 IBP Tests ............................................................................................................................................................................................. 3-13

3.3.7 C.O. Test ............................................................................................................................................................................................. 3-15

3.3.8 Sidestream and Microstream CO2 Tests .................................................................................................................................. 3-15

3.3.9 AG Tests ............................................................................................................................................................................................. 3-15

3.3.10 EEG Test ........................................................................................................................................................................................... 3-16

3.3.11 BIS Test ............................................................................................................................................................................................. 3-17

BeneVision N17/BeneVision N15/BeneVision N12 Patient Monitor Service Manual 1

Page 10

3.3.12 CCO/SvO2 Tests .............................................................................................................................................................................. 3-18

3.3.13 NMT Tests ........................................................................................................................................................................................ 3-18

3.4 Nurse Call Relay Performance Test ......................................................................................................................................................... 3-20

3.5 Analog Output Performance Test ........................................................................................................................................................... 3-20

3.6 Electrical Safety Tests .................................................................................................................................................................................. 3-20

3.7 Recorder Check ............................................................................................................................................................................................. 3-21

3.8 Network Print Test ........................................................................................................................................................................................ 3-21

3.8.1 Device Connection and Setup ................................................................................................................................................... 3-21

3.9 Battery Check ................................................................................................................................................................................................. 3-22

3.10 Mounting Check ......................................................................................................................................................................................... 3-22

3.10.1 Safety check ................................................................................................................................................................................... 3-22

3.10.2 Overall Test and Check of Installed System ........................................................................................................................ 3-22

4 Troubleshooting ................................................................................................................................................................ 4-1

4.1 Introduction ..................................................................................................................................................................................................... 4-1

4.2 Part Replacement ........................................................................................................................................................................................... 4-1

4.3 Check before Powering on the Monitor ................................................................................................................................................. 4-1

4.4 Software Version Check ................................................................................................................................................................................ 4-1

4.5 Technical Alarm Check .................................................................................................................................................................................. 4-2

4.6 Troubleshooting Guide ................................................................................................................................................................................ 4-2

4.6.1 Power On/Off Failures ..................................................................................................................................................................... 4-2

4.6.2 Display Failures .................................................................................................................................................................................. 4-3

4.6.3 Module Rack Failures ...................................................................................................................................................................... 4-4

4.6.4 Alarm Failures .................................................................................................................................................................................... 4-5

4.6.5 Output Interface Failures ............................................................................................................................................................... 4-6

4.6.6 Power Supply Failures ..................................................................................................................................................................... 4-7

4.6.7 Network Related Problems ........................................................................................................................................................... 4-7

4.6.8 Device Integration Failures ........................................................................................................................................................... 4-8

4.6.9 Recorder Failures .............................................................................................................................................................................. 4-9

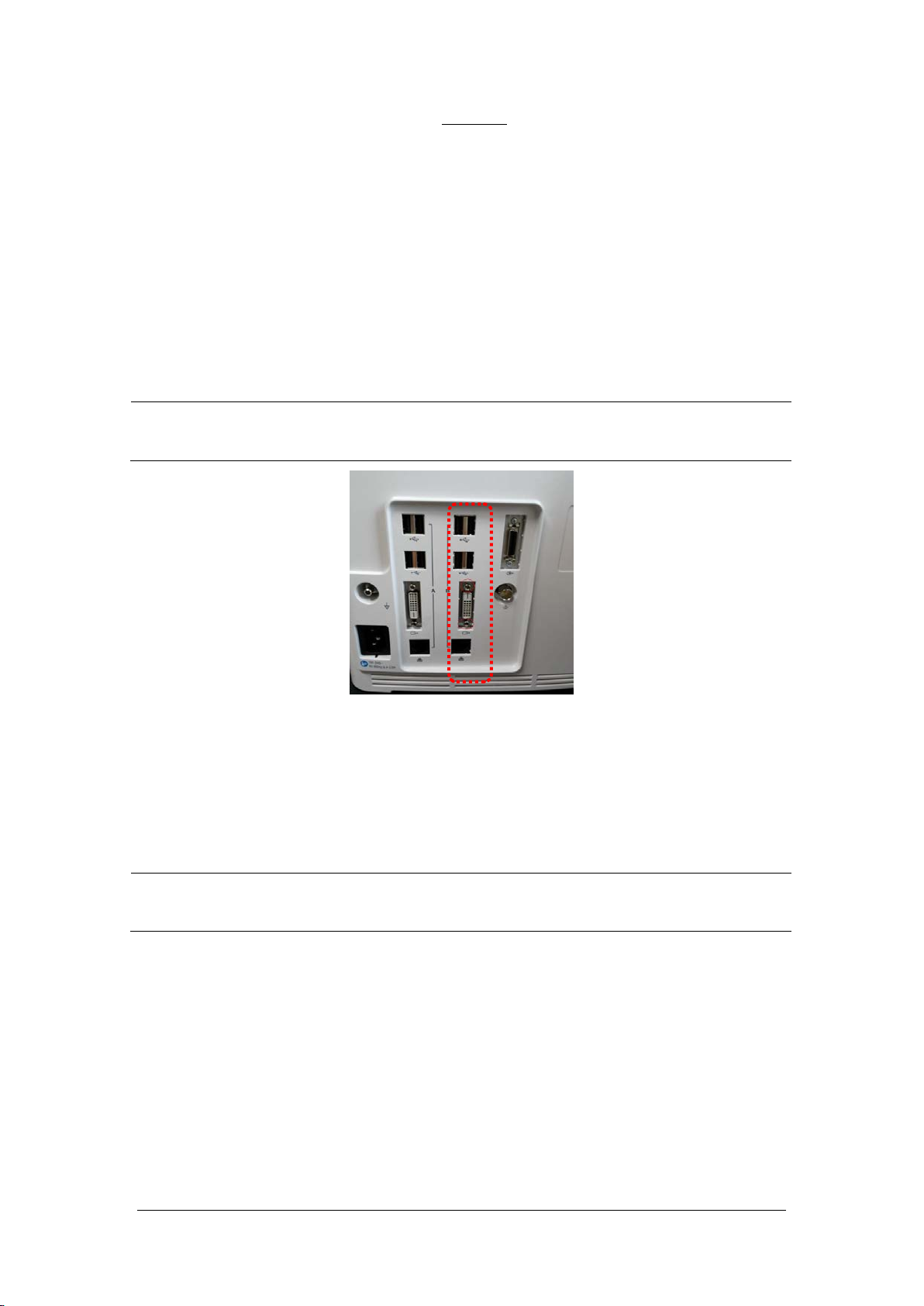

5 Hardware Configuration Options .................................................................................................................................... 5-1

5.1 Overview ........................................................................................................................................................................................................... 5-1

5.2 Optional Parameter Function Modules .................................................................................................................................................. 5-2

5.3 Optional Functional Assemblies ............................................................................................................................................................... 5-3

5.3.1 Installing an SMR .............................................................................................................................................................................. 5-3

5.3.2 Setting up Wireless Network Functions ................................................................................................................................... 5-3

5.3.3 Upgrading Recorder ........................................................................................................................................................................ 5-4

5.3.4 Upgrading iView System ................................................................................................................................................................ 5-4

5.3.5 Upgrading Independent Display Function ............................................................................................................................. 5-4

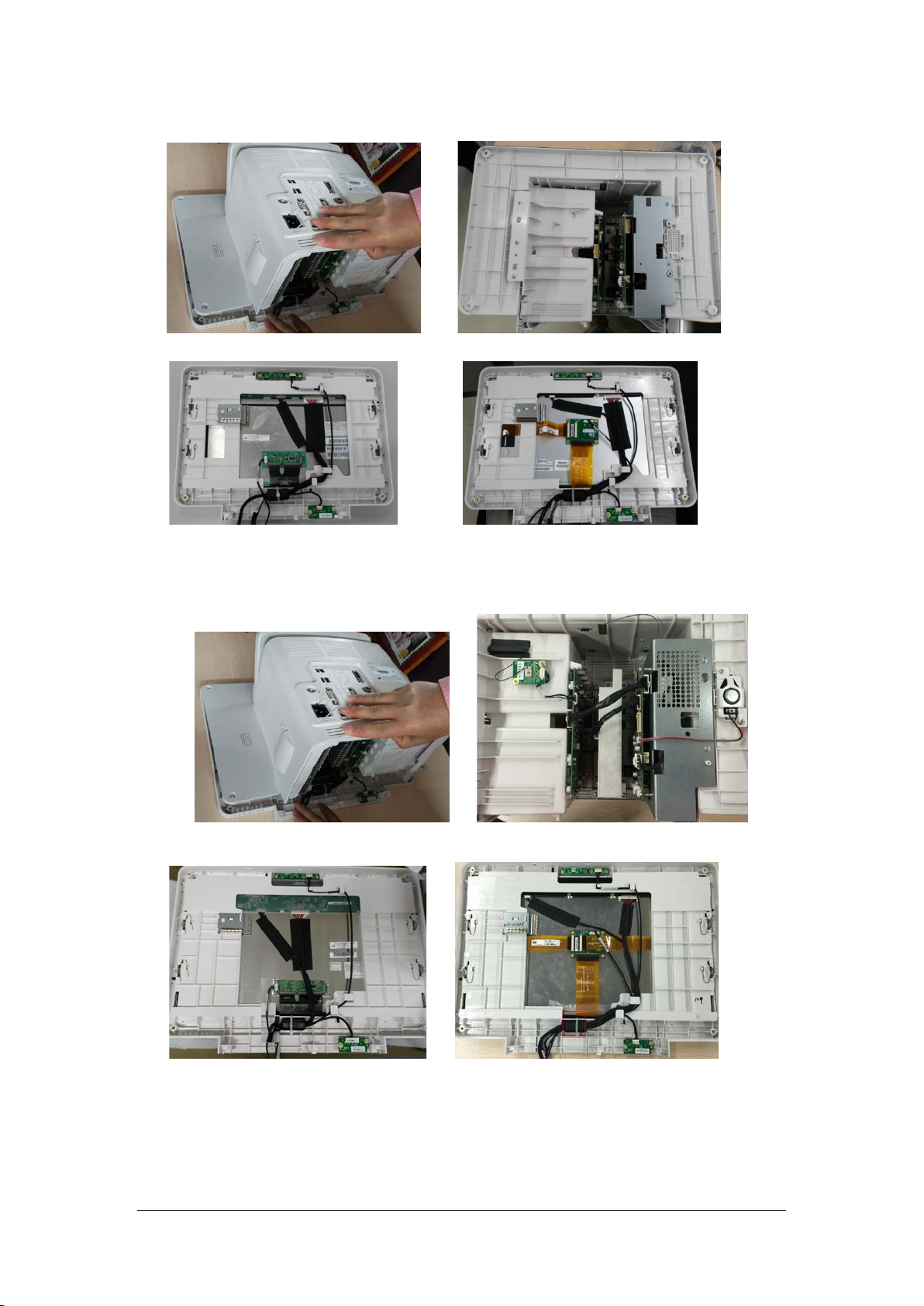

6 Repair and Disassembly .................................................................................................................................................... 6-1

6.1 Tools..................................................................................................................................................................................................................... 6-1

6.2 Preparations for Disassembly ..................................................................................................................................................................... 6-1

6.3 Main Unit Disassembly ................................................................................................................................................................................. 6-2

6.3.1 Basic Disassembly............................................................................................................................................................................. 6-2

6.3.2 Disconnecting the Base ................................................................................................................................................................. 6-3

2 BeneVision N17/BeneVision N15/BeneVision N12 Patient Monitor Service Manual

Page 11

6.3.3 Separating the Front and Rear Half of the Monitor .............................................................................................................. 6-4

6.4 Further Disassembly of the Front Case Assembly ............................................................................................................................... 6-7

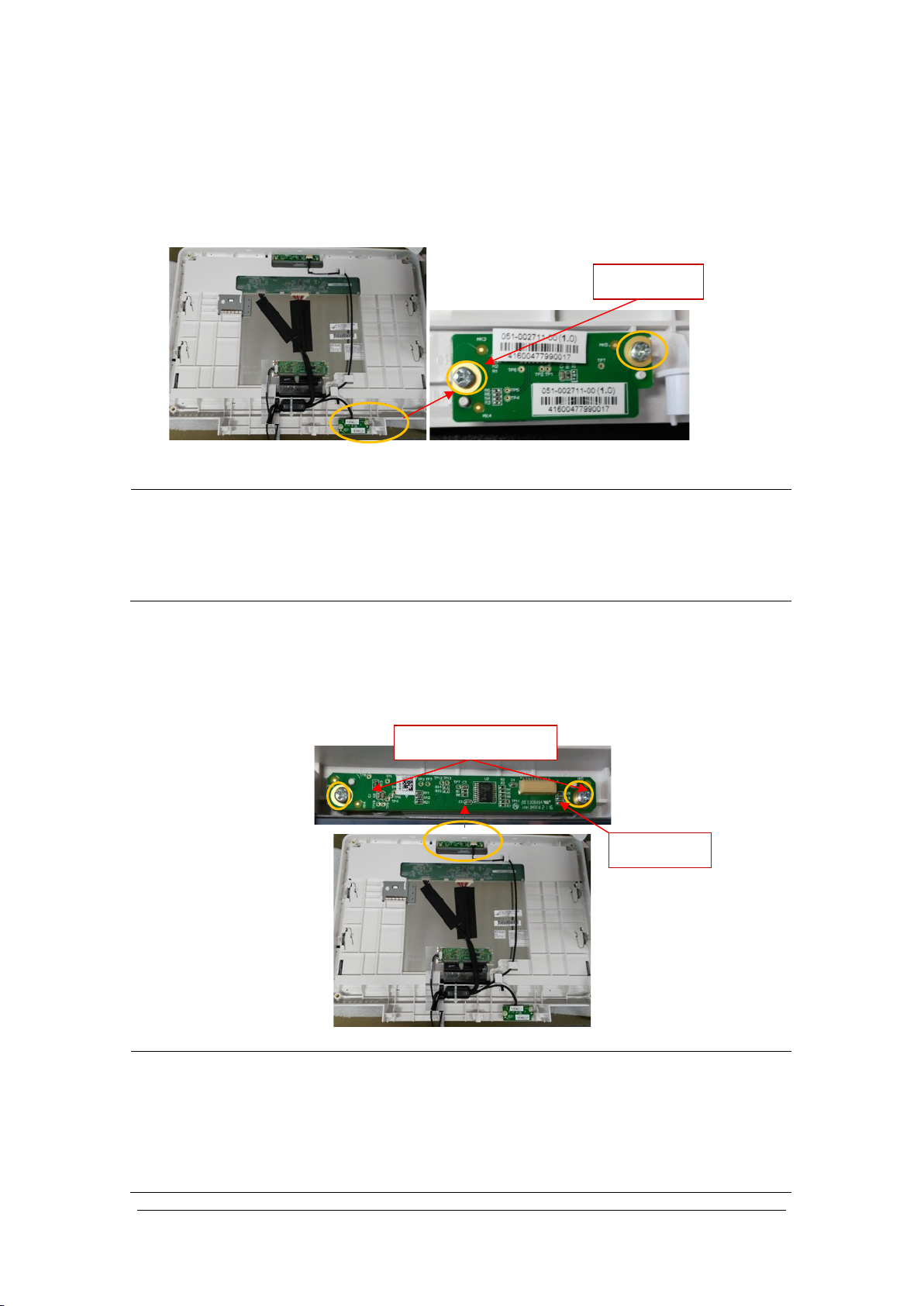

6.4.1 Removing the Power Switch Board ............................................................................................................................................ 6-7

6.4.2 Removing the Alarm Lamp and Light Sensor Board............................................................................................................ 6-7

6.4.3 Removing the Screen Assembly Cables ................................................................................................................................... 6-8

6.5 Further Disassembly of the Rear Case Assembly ................................................................................................................................ 6-9

6.5.1 Removing the Recorder .................................................................................................................................................................. 6-9

6.5.2 Further Disassembly of the Recorder ........................................................................................................................................ 6-9

6.5.3 Removing the Bluetooth Board ................................................................................................................................................ 6-11

6.5.4 Removing the Wi-Fi Module ...................................................................................................................................................... 6-12

6.5.5 Removing the Internal Module Rack Assembly .................................................................................................................. 6-13

6.5.6 Removing the Main Support Assembly (N12& N15) ......................................................................................................... 6-16

6.5.7 Removing the iView Board Assembly (N17) ......................................................................................................................... 6-20

6.5.8 Removing the Independent Display Board Assembly (N17 Series)............................................................................. 6-22

6.5.9 Removing the Handle .................................................................................................................................................................. 6-23

6.6 Further Disassembly of the Base Assembly ........................................................................................................................................ 6-24

6.7 Disassembling the Module Rack ............................................................................................................................................................ 6-25

6.8 Disassembling the MPM Module ........................................................................................................................................................... 6-28

7 Parts ................................................................................................................................................................................... 7-1

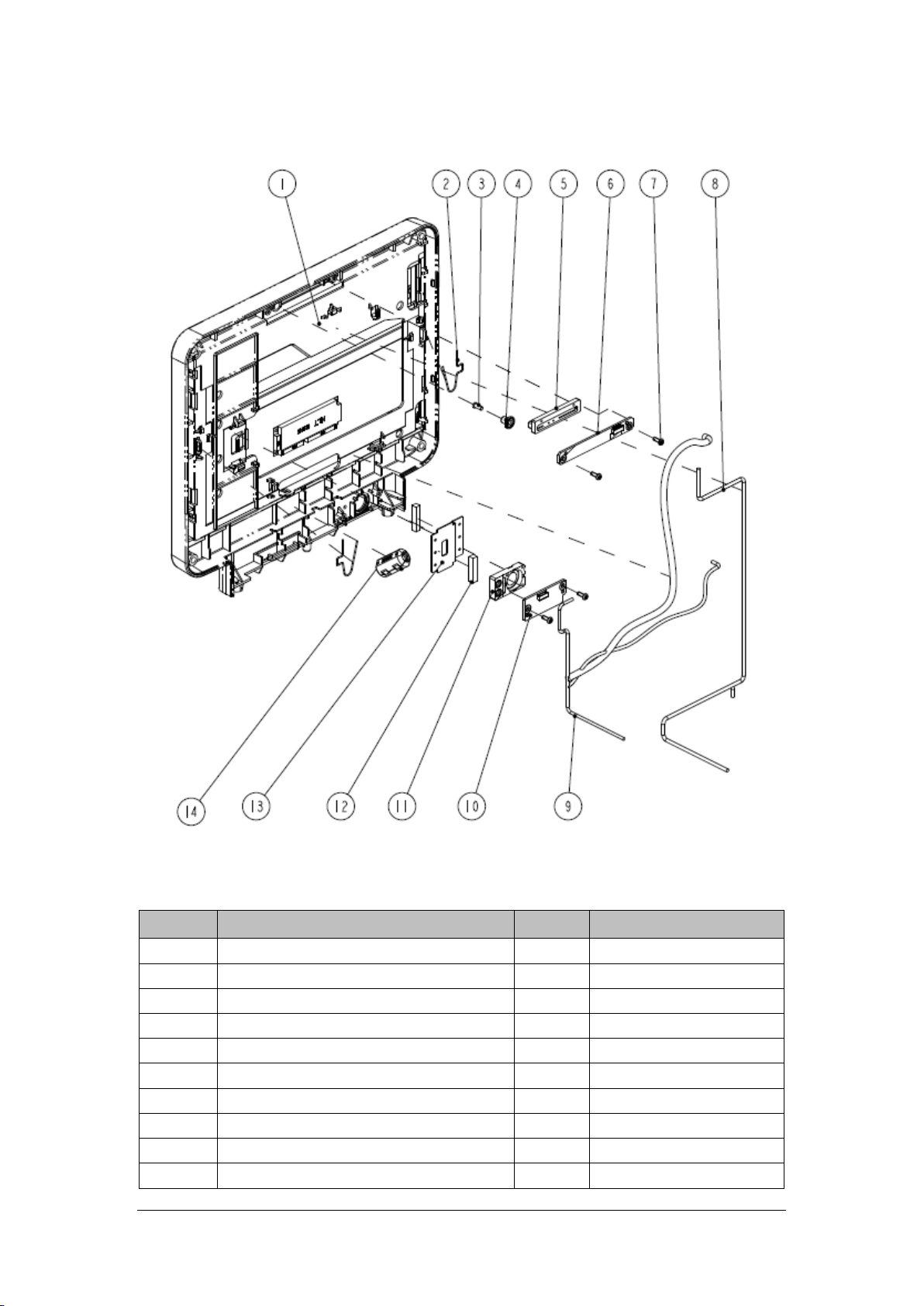

7.1 N12 Parts ............................................................................................................................................................................................................ 7-1

7.1.1 N12 Whole Unit .................................................................................................................................................................................. 7-1

7.1.2 N12-NLT Front Housing Assembly .............................................................................................................................................. 7-2

7.1.3 N12-Sharp Front Housing Assembly .......................................................................................................................................... 7-3

7.1.4 N12 Rear Housing ............................................................................................................................................................................. 7-4

7.1.5 N12 Rear Housing Assembly (FRU)(115-044499-00) ............................................................................................................ 7-6

7.1.6 N12 Battery Cavity Assembly (FRU)(115-044504-00) ........................................................................................................... 7-7

7.1.7 N12 Module Rack Body Assembly (FRU) (115-044507-00) ................................................................................................ 7-8

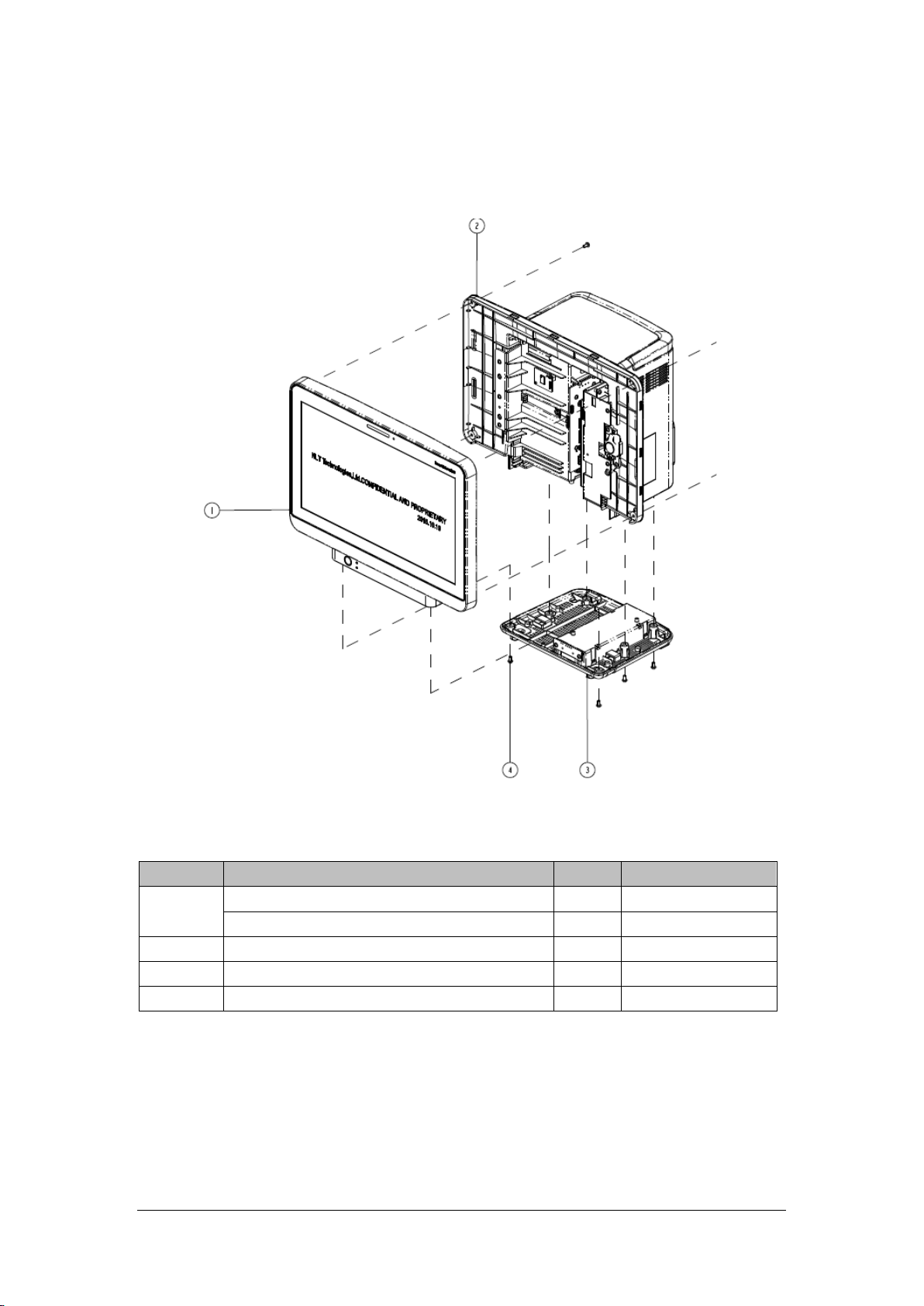

7.2 N 15 Parts ........................................................................................................................................................................................................... 7-9

7.2.1 N15 Whole Unit .................................................................................................................................................................................. 7-9

7.2.2 N15-NLT Front Housing Assembly ........................................................................................................................................... 7-10

7.2.3 N15-Sharp Front Housing ........................................................................................................................................................... 7-11

7.2.4 N15 Rear Housing .......................................................................................................................................................................... 7-12

7.2.5 N15 Rear Housing Assembly (FRU) (115-044541-00) ..................................................................................................... 7-14

7.2.6 N15 Base Assembly (FRU)(115-044543-00) .......................................................................................................................... 7-15

7.2.7 N15N17 Module Rack Body Assembly (FRU) (115-044546-00) ..................................................................................... 7-16

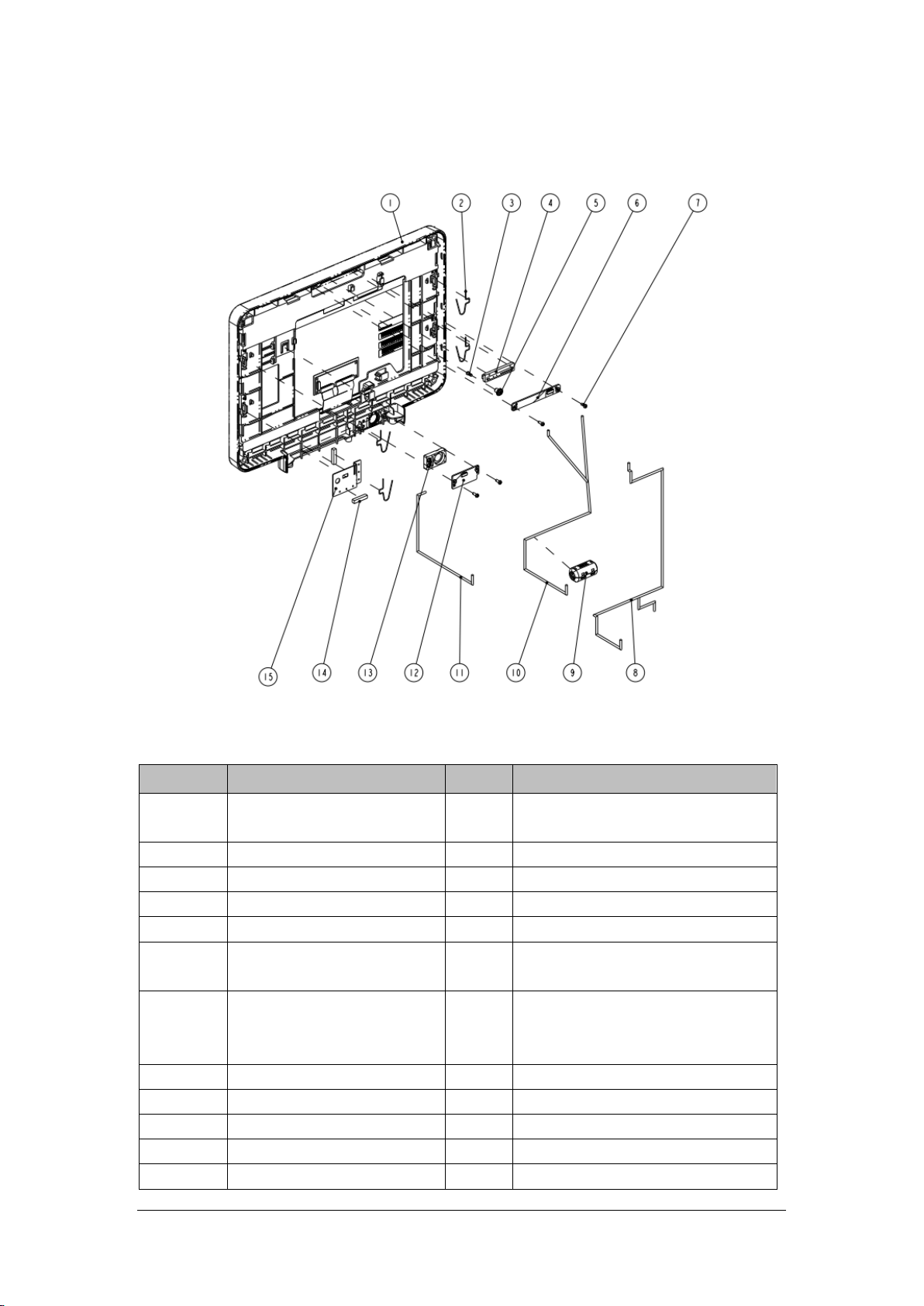

7.3 N17 Parts ......................................................................................................................................................................................................... 7-17

7.3.1 N17 Whole Unit ............................................................................................................................................................................... 7-17

7.3.2 N17-NLT Front Housing Assembly ........................................................................................................................................... 7-18

7.3.3 N17-Sharp Front Housing ........................................................................................................................................................... 7-19

7.3.4 N17 Rear Housing .......................................................................................................................................................................... 7-20

7.3.5 N17 Rear Housing Assembly (FRU)( 115-044548-00) ........................................................................................................ 7-22

7.3.6 N17 Base Assembly (FRU) (115-044550-00) ......................................................................................................................... 7-23

7.3.7 Independent Display Upgrade Package (115-044554-00) .............................................................................................. 7-24

7.3.8 Independent Display Assembly ................................................................................................................................................ 7-25

7.3.9 iView Module Assembly (115-050002-00) ............................................................................................................................ 7-26

BeneVision N17/BeneVision N15/BeneVision N12 Patient Monitor Service Manual 3

Page 12

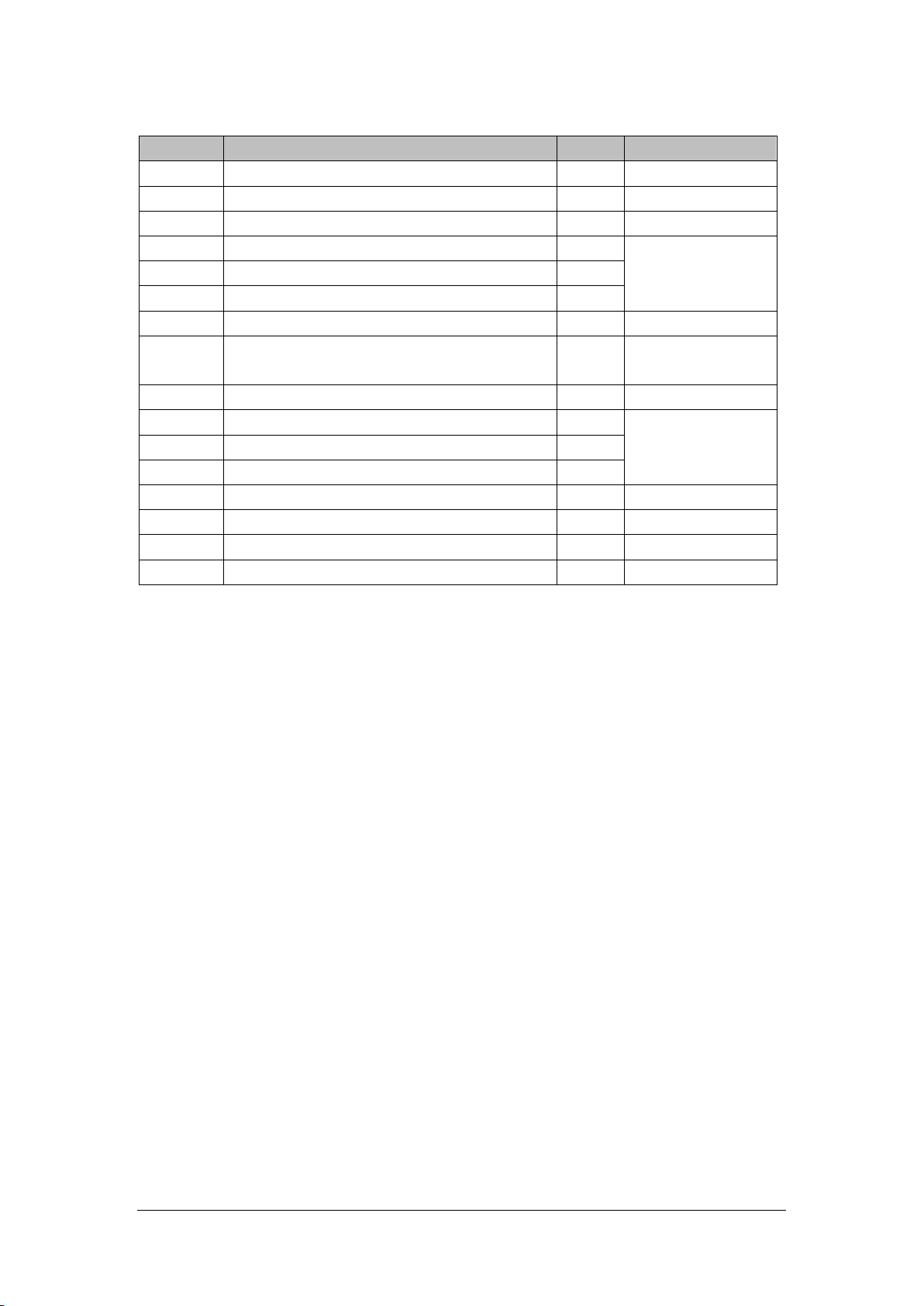

7.4 External Satellite Module Rack (SMR) ................................................................................................................................................... 7-27

7.4.1 Exploded View ................................................................................................................................................................................. 7-27

7.4.2 Parts List ............................................................................................................................................................................................. 7-27

7.5 M51C Module ................................................................................................................................................................................................. 7-28

7.5.1 Exploded View ................................................................................................................................................................................. 7-28

7.5.2 Parts List ............................................................................................................................................................................................. 7-28

A Electrical Safety Inspection .............................................................................................................................................. A-1

A.1 Power Cord Plug ............................................................................................................................................................................................. A-1

A.2 Device Enclosure and Accessories ........................................................................................................................................................... A-1

A.3 Device Labelling ............................................................................................................................................................................................. A-2

A.4 Scheduled Electrical Safety Inspection .................................................................................................................................................. A-2

A.5 Electrical Safety Inspection after Repair ................................................................................................................................................ A-2

A.6 Electrical Safety Inspection Tes t ................................................................................................................................................................ A-3

4 BeneVision N17/BeneVision N15/BeneVision N12 Patient Monitor Service Manual

Page 13

DANGER

1 Safety

1.1 Safety Information

Indicates an imminent hazard that, if not avoided, will result in death or serious injury.

WARNING

Indicates a potential hazard or unsafe practice that, if not avoided, could result in death or

serious injury.

CAUTION

Indicates a potential hazard or unsafe practice that, if not avoided, could result in minor

personal injury or product/property damage.

NOTE

Provides application tips or other useful information.

1.1.1 DANGER

There are no dangers that refer to the product in general. Specific “Danger” statements may be given in the

respective sections of this manual.

BeneVision N17/BeneVision N15/BeneVision N12 Patient Monitor Service Manual 1-1

Page 14

1.1.2 Warnings

WARNING

All installation operations, expansions, changes, modifications and repairs of this product

should be conducted by Mindray authorized personnel.

There is high voltage inside the equipment. Never disassemble the equipment before it is

disconnected from the AC power source.

When you disassemble/reassemble a parameter module, a patient leakage current test must

be performed before it is used again for monitoring.

The equipment must be connected to a properly installed power outlet with protective earth

contacts only. If the installation does not provide for a protective earth conductor, disconnect

it from the power line and operate it on battery power, if possible.

Dispose of the package material, observing the applicable waste control regulations and

keeping it out of children’s reach.

1.1.3 Cautions

CAUTION

Make sure that no electromagnetic radiation interferes with the performance of the

equipment when preparing to carry out performance tests. Mobile phone, X-ray equipment

or MRI devices are a possible source of interference as they may emit higher levels of

electromagnetic radiation.

Before connecting the equipment to the power line, verify the voltage and frequency ratings

of the power line are the same as those indicated on the equipment’s label or in this manual.

Protect the equipment from damage caused by drop, impact, strong vibration or other

mechanical force during servicing.

1.1.4 Notes

NOTE

Refer to Operation Manual for detailed operation and other information.

1.2 Equipment Symbols

See the N series Operator’s Manual (P/N: 046-011259-00) for information about the symbols used on this

product and its packaging.

1-2 BeneVision N17/BeneVision N15/BeneVision N12 Patient Monitor Service Manual

Page 15

2 Operation Theory

2.1 Overview

As a bedside workstation for multi-parameter monitoring, the N series can provide the complete patient

management, abundant physiological parameter monitoring and physiological alarm functions, as well

the powerful data review function and the flexible wired and wireless network configuration and

application capabilities. The third-party application can be accessed easily through the iView application,

meeting the increasingly common information requirements of hospitals. The provided series of CAA

applications can help doctors to make auxiliary diagnosis for patients. Meanwhile, the N series provide the

hospital management personnel with more excellent monitor management applications, rendering

assistance in fixing the efficiency and quality problems during monitor equipment management of

hospitals.

The N series provide the product models with display screens of different sizes according to the demand

of clinical application. In addition to touch screen operations, the user can use the mouse and keyboard to

operate the monitor. The N series can connect to multiple display screens to function as mirror screens or

extension screens.

The series of products are compatible with the BeneView T series plug-in modules and related accessory

products. They can work together with the TDS to implement the intra-hospital transfer application of

patients.

In comparison with the BeneView T series products, the N series boast better human-computer

interaction design and clinical applicability, more complete IT solution capability of hospitals, and more

abundant CDS applications.

2.2 Product System Architecture

All the N17/N15/N12 monitors have only one main unit:

The N12 main unit uses the 12.1” TFT WXGA display screen.

The N15 main unit uses the 15.6” TFT FHD display screen.

The N17 main unit uses the 18.5”TFT FHD display screen.

All of them use the touch screen as an input device and can extend the mouse, keyboard and

remote control.

An internal module rack is integrated, with 4 slots (N12) or 6 slots (N15/N17).

The MPAN and WiFi modules are optional.

The built-in recorder is optional.

The N15/N17 can connect to the external module rack and TDS; the N12 can connect to the

TDS.

BeneVision N17/BeneVision N15/BeneVision N12 Patient Monitor Service Manual 2-1

Page 16

Main control board

LCD

iView assembly

(N17 Optional)

DVI

RJ45

2*USB

2*USB

Power switch

board

Alarm lamp

board

MPAN module

(Optional)

TP control

board

AC/DC

module

Battery interface

board

(N15/N17)

Recorder

(Optional)

Speaker

Battery

Front

shell

Back

shell

AC/DC

interface

2*USB 2*USB DVI RJ45

WiFi module

(Optional)

Independent display board

(N17 Optional)

DVI

Internal module com board(4slots/6slots)

4/6*Module

communication

interface

Nurse call

interface

SMR

interface

Bottom

shell

Battery interface

board

(N12/N12C)

Battery

Main Processor

DDR3

Program

Memory

Data Memory

E2ROM

USB hub

Touch-

controller

SPI

USB

Audio

codec/AMP

Speaker

Touch panel

Power M0

PHY

WiFi

(optional)

Internal Module

Rack communication

board

RTC

Photo

senseor

Power key board

RJ-45

DVI

interface

USB 4*port

MMC

MMC

RMII1

PHY

Independent

display

board/iView

MPAN Module

E2ROM(funnct

ion cfg)

Nursecall

interface

Alarm light

controller

SMR

Interface

FPGA

(N15/N17)

LCD

Back light

driver

DVI

transfer

SPI

UART

LCDC

I2C

I2C

Main

Control

board

Figure 2-1 System block diagram of the N17/N15/N12/N12C

2.2.1 Main Control Board

There are the main control CPU, program memory, data memory, system configuration memory, system

FPGA, WiFi module (optional), power management MCU, battery charging circuit, and DC-DC circuit on

the main control board. The internal interface and external interfaces are also provided on the board. The

internal interface is an interface between the recorder, internal module rack COM board, AC-DC, and the

battery. The external interfaces refer to the DVI display interface, USB interface, and Ethernet interface.

2-2 BeneVision N17/BeneVision N15/BeneVision N12 Patient Monitor Service Manual

Figure 2-2 Diagram of the main control board

Page 17

AC

/

DC

module

100

~

240

V AC

AC-DC in

Battery

BAT

charger

switch

M0

DC/DC

+12

V

DC/

DC

LDO

+3.3V_1

VBUS:

9.6~11.1V,

+15

V

ON/OFF

ON/

OFF

+5V

Power switch

board

+5V/+3.3V

+3.3V

Alarm lamp

board

Photo

senseor

Led driver

Recorder

+

12V

LCD&TP

+12V

Internal module rock COM

board

iView module

+12V

Independent display

board

+

5V

+

5V

ON/OFF

+3

.3V

DC/

DC

DC

/

DC

+

3.

3V

_

2

MPAN module

2.2.2 Internal Module Rack COM Board

Two models of internal module rack COM boards are available. The N12 uses the 4-slot COM board, and

the N15/N17 uses the 6-slot COM board. The internal module rack COM board is used to provide the

interface for communication with the parameter module, the SMR interface and nurse call interface, and

the MPAN module interface. Besides, the data forwarding FPGA and corresponding power circuit are also

provided on the internal module rack COM board.

2.2.3 Power Architecture

Figure 2-3 Diagram of power architecture

The AC/DC power module outputs 15V to the main control board, and 3.3V, 5V and 12V can be generated

through the internal DC-DC conversion circuit in the main control board to provide a power supply to

other modules or boards in the main unit. The battery charging circuit is powered by 15V, and the AC

power supply and battery power supply can be switched according to AC on-line detection.

The +12V power supply is provided to the power supply, including the external module rack, and the

DC-DC isolation design is implemented at the module end.

The iVIew assembly uses the power rail Vbus, which is the switching output between the AC-DC output

and battery and aims to avoid abnormal power failure of the iView module and running exception of the

Windows OS running on other modules due to an unexpected power failure of the AC power supply. The

battery supports the main unit to stop the iView module in the normal power-off mode. In the case of

battery power supply, the iView module cannot start.

BeneVision N17/BeneVision N15/BeneVision N12 Patient Monitor Service Manual 2-3

Page 18

Data

collection

Data

forwarding

System

application

Display and

user interface

Data

output

Data storage

2.2.4 Independent Display Board (for the N17 Only)

It is used to connect the main unit to a display and extend the main screen display. It adopts the DVI

interface. Moreover, the external display with a touch screen can be supported through the USB interface

of the main unit. At present, the supported display with a touch screen is Elo 1919LM.

2.2.5 iView Module (for the N17 Only)

As an embedded computer module, it provides the following external interfaces: the network interface,

DVI interface, and the USB interface. It can connect to the keyboard, mouse, network cable, and display

independently. The configuration of the iView module is mutually exclusive with that of the independent

display module.

2.2.6 Alarm LAMP Board

The LED alarm lamp and light sensor are provided on the board. The light sensor implements the ambient

light detection and is used to adjust brightness of the LCD background light.

2.2.7 Power Switch Board

There are the power switch and three indicators on the power switch board, which are the AC on-line

indicator, battery indicator, and the power-on indicator.

2.3 Data Logic Flow

Figure 2-4 Data flow diagram

The monitoring parameters are collected and analyzed through the module, and then forwarded to the

system software through the internal or external module rack. The system software displays the waveform,

numerical value and alarm information, and the data, alarm information and numerical value are also

stored in the internal data memory at the same time. Meanwhile, they can also be sent to the central

station or other monitors through the wired or wireless network.

2-4 BeneVision N17/BeneVision N15/BeneVision N12 Patient Monitor Service Manual

Page 19

3 Testing and Maintenance

3.1 Introduction

To ensure the patient monitor always functions properly, qualified service personnel should perform

regular inspection, maintenance and test. This chapter provides a checklist of the testing procedures for

the patient monitor with recommended test equipment and frequency. The service personnel should

perform the testing and maintenance procedures as required and use appropriate test equipment.

The testing procedures provided in this chapter are intended to verify that the patient monitor meets the

performance specifications. If the patient monitor or a module fails to perform as specified in any test,

repairs or replacement must be done to correct the problem. If the problem persists, contact our

Customer Service Department.

CAUTION

All tests should be performed by qualified service personnel only.

Care should be taken when changing the settings in Maintenance and Configuration menus to

avoid loss of data.

Service personnel should possess a working knowledge of the test tools and make sure that

test equipment and cables are applicable.

3.1.1 Test Equipment

Required Test Equipment is listed in the specific test procedure.

3.1.2 Preventative Maintenance

The following sections provide a list of recommended preventative maintenance procedures. It is

recommended to verify accuracy and calibrate the patient monitor as needed at least once every two

years (and once a year for CO

and contents.

and AG modules). See the following sections for detailed test procedures

2

BeneVision N17/BeneVision N15/BeneVision N12 Patient Monitor Service Manual 3-1

Page 20

3.1.3 Recommended Frequency

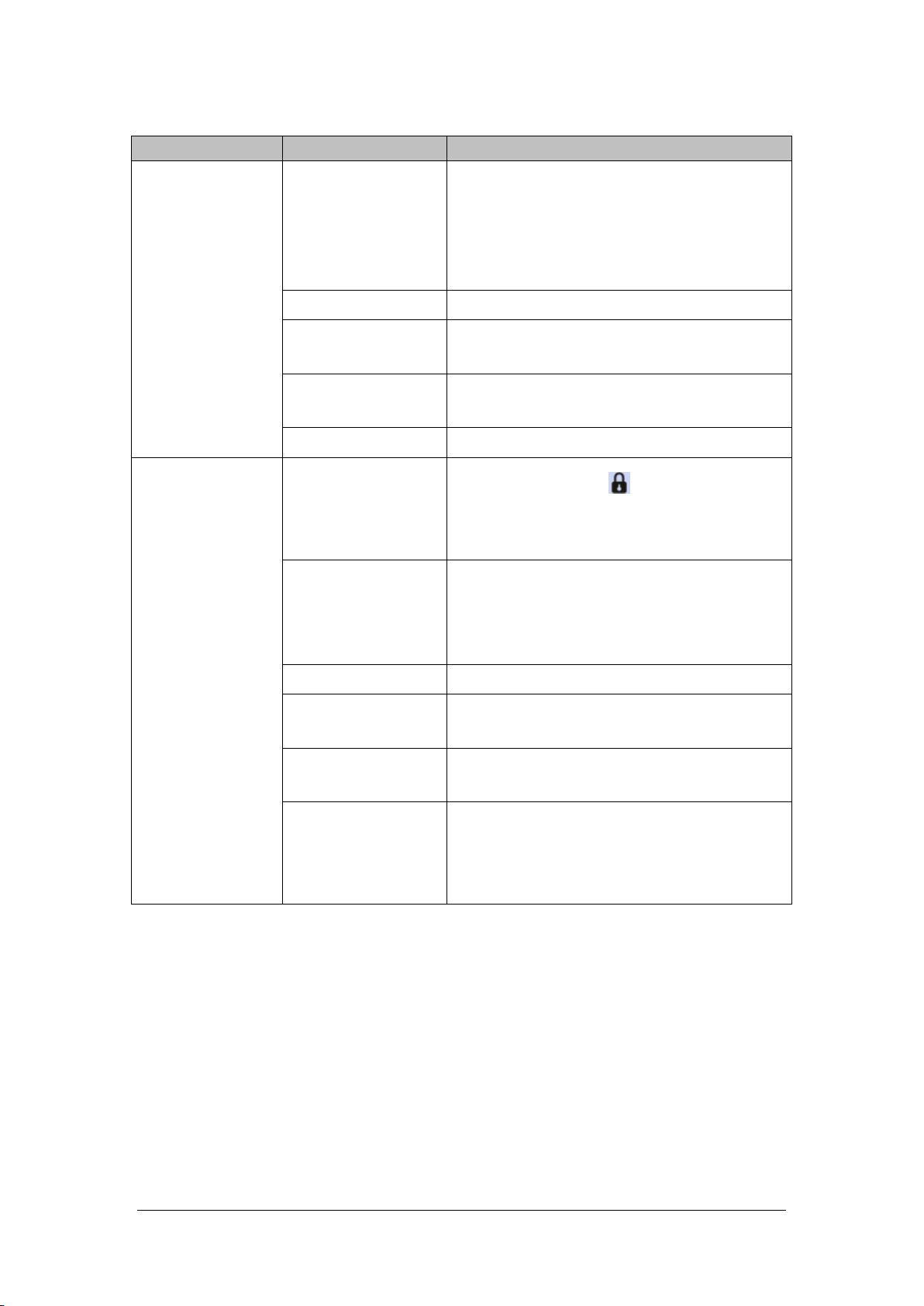

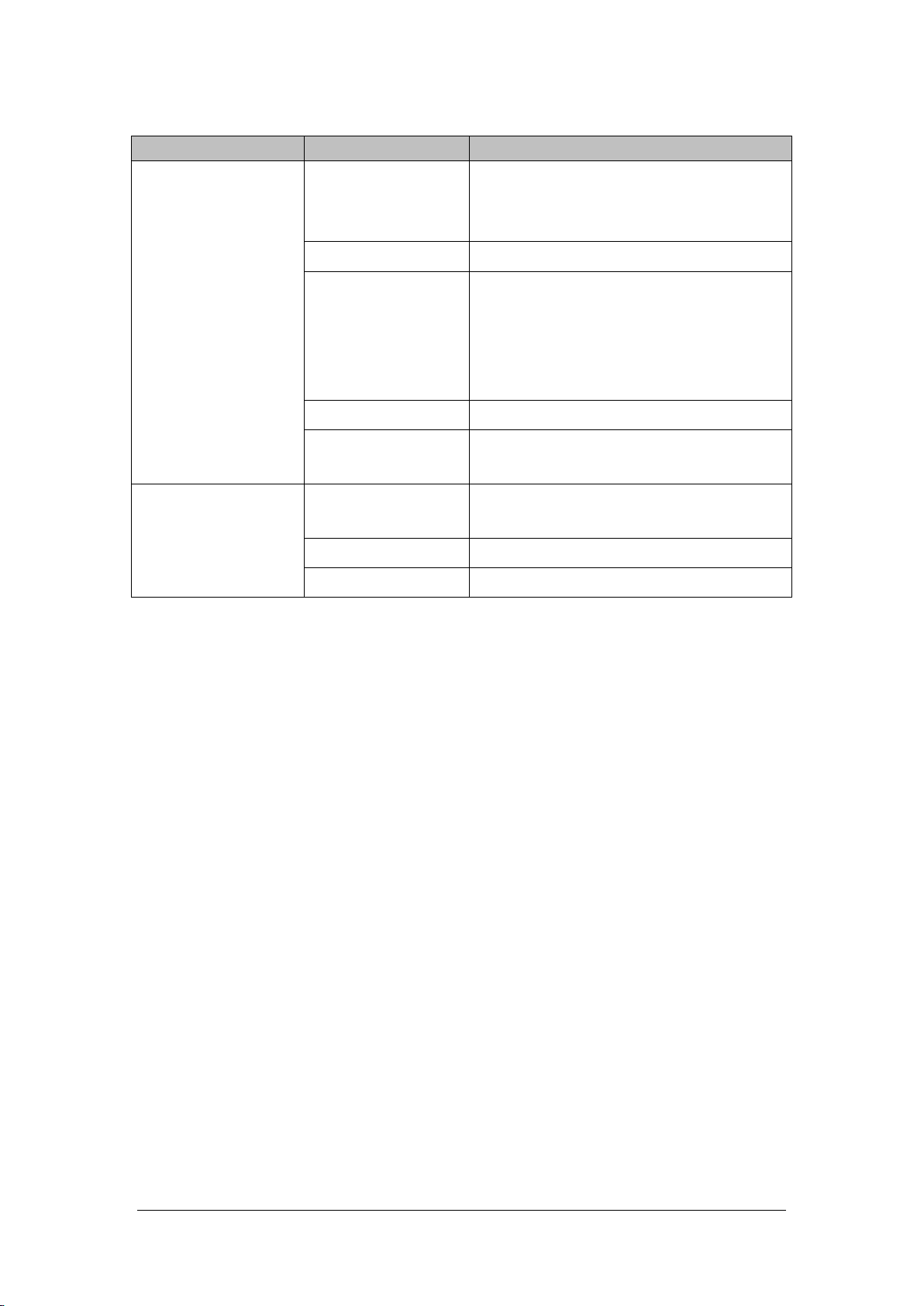

Check/Maintenance Item Frequency

Preventative Maintenance Tests

Visual inspection When first installed or reinstalled.

NIBP tests

Sidestream and

Microstream CO

2

tests

AG tests

Performance Tests

ECG tests

Resp test

SpO2 test

NIBP test

Temp test

IBP tests

C.O. test

Sidestream and

Microstream CO

2

tests

AG tests

Pressure check

Leakage test

Leakage test

Performance test

Calibration

Performance test

Calibration

Performance test

Calibration

Pressure check

Leakage test

Performance test

Pressure calibration

Leakage test

Performance test

Calibration

Leakage test

Performance test

1. If the user suspects that the measurement is incorrect.

2. Following any repair or replacement of relevant module.

3. For NIBP module, at least once every two years; for CO

and

2

AG modules, once a year.

4. AG leakage test should be performed before AG

measurement.

1. If the user suspects that the measurement is incorrect.

2. Following any repair or replacement of relevant module.

3. At least once every two years. For CO

AG and NMT

2,

modules, at least once a year.

4. AG leakage test should be performed before AG

measurement.

Calibration

EEG test

BIS test

Interconnecting

CCO/SvO2 tests

function

Output calibration

Performance test

NMT tests

Sensor check

3-2 BeneVision N17/BeneVision N15/BeneVision N12 Patient Monitor Service Manual

Page 21

Nurse call relay performance test

Analog output performance test

If the user suspects that the nurse call or analog output does

not function properly.

Electrical Safety Tests

Earth impedance

Electrical safety

tests

Earth leakage test

Patient leakage current

1. Following any repair or replacement of the power module.

2. When the patient monitor is dropped.

3. At least every two years or as required.

Patient auxiliary current

Other Tests

1. When first installed or reinstalled.

Power on test

2. Following any maintenance or the replacement of any

main unit parts.

Recorder check Following any repair or replacement of the recorder.

Network print test

1. When first installed.

2. Whenever the printer is serviced or replaced.

1. When first installed.

Device integration check

2. Following any repair or replacement of the external device.

1. When first installed.

Function test

2. Whenever a battery is replaced.

Battery check

Performance test

Once every two months or when the battery run time is

reduced significantly.

1. When first installed.

Mounting check

2. At least every two years or as required.

Note: Performance test is not required for the rSO

perform self tests, and the ScvO

needs to be calibrated prior to use.

2

, and ScvO2 modules, because the rSO2, modules

2

3.1.3.1 Preventative Maintenance Procedures

3.1.4 Visual Inspection

Inspect the equipment for obvious signs of damage. The test is passed if the equipment has no obvious

signs of damage. Follow these guidelines when inspecting the equipment:

Carefully inspect the case, display screen, buttons, knobs, and handle for obvious signs of damage.

Inspect the SMR and parameter modules for obvious signs of damage.

Inspect the power cord, bracket and module accessories for obvious signs of damage.

Inspect all external connections for loose connectors, bent pins or frayed cables.

Inspect all connectors on the equipment for loose connectors or bent pins.

Make sure that safety labels and data plates on the equipment are clearly legible.

BeneVision N17/BeneVision N15/BeneVision N12 Patient Monitor Service Manual 3-3

Page 22

3.1.5 NIBP Tests

3.1.5.1 Leakage Test

Tools required:

NIBP cuff for adult patient

NIBP hose

Cylinder

Follow this procedure to perform the test:

1. Set Patient Category to Adult.

2. Connect the NIBP cuff to the NIBP connector on the patient monitor.

3. Wrap the cuff around the rigid cylinder as shown below.

Monit

Hose

NIBP connector

4. Select Main Menu → Maintenance → enter the required password → Module → NIBP → NIBP

Leakage Test. The message NIBP Leakage Test is displayed in the NIBP parameter area.

5. The cuff automatically deflates after 20s, which means NIBP leakage test is completed.

6. If no message is displayed in the NIBP parameter area, it indicates that the system has no leak. If the

message NIBP Airway Leak is displayed, it indicates that the system may have a leak. In this case,

verify the connections and make sure that the NIBP cuff, hose, and connectors are not leaking. Then,

perform the test again.

You can also perform a manual leakage test:

1. Perform steps 1-4 in the1.1.5.2 NIBP Accuracy Test section.

2. Raise the pressure in the rigid vessel to 250 mmHg with the squeeze bulb. Then, wait for 5 seconds

until the measured values become stable.

Cylinder

Cuff

3. Record the current pressure value and meanwhile count time with a timer. Then, record the pressure

value after counting to 60 seconds.

4. Compare the two values and make sure the difference is not greater than 6 mmHg.

3-4 BeneVision N17/BeneVision N15/BeneVision N12 Patient Monitor Service Manual

Page 23

3.1.5.2 NIBP Accuracy Test

Squeeze bulb

Tools required:

T-shape connector

Tubing

Squeeze bulb

Rigid vessel with 500 ± 25 ml internal volume

Reference manometer (calibrated with accuracy equal to or greater than 1 mmHg)

Follow this procedure to perform the test:

1. Connect the equipment as shown below.

Monitor

Tubing

NIBP connector

2. Before inflation, the reading on the manometer should be zero. If not, open the valve of the squeeze

bulb to let the whole airway open to the atmosphere. Close the valve after the reading turns to zero.

3. Select Main Menu → Maintenance → enter the required password → Module → NIBP → NIBP

Accuracy Test.

4. Check the reading of the manometer and the reading of the patient monitor. Both should be 0

mmHg.

5. Raise the pressure in the rigid vessel to 50 mmHg with the squeeze bulb. Then, wait for 10 seconds

until the measured values become stable.

6. Compare the reading of the manometer with the reading of the patient monitor. The difference

should be 3 mmHg or less. If it is greater than 3 mmHg, contact your service personnel.

Manometer

Rigid vessel

7. Raise the pressure in the rigid vessel to 200 mmHg with the squeeze bulb. Then, wait for 10 seconds

until the measured values become stable. Repeat step 6.

NOTE

You can use an NIBP simulator to replace the squeeze bulb and the reference manometer to

perform the test.

You can use an appropriate cylinder and a cuff instead of the rigid vessel.

BeneVision N17/BeneVision N15/BeneVision N12 Patient Monitor Service Manual 3-5

Page 24

3.1.6 Sidestream and Microstream CO

Leakage Test

1. Plug the module into the module rack.

Tests

2

2. Wait until CO

trap (by using your finger or a pinched sample line). The sidestream and microstream CO

will behave as follows:

Sidestream: Plug the sidestream CO

Microstream: After 3 seconds, the alarm message "CO

Accuracy Test

Tools required:

2 warmup is finished and then completely block the gas inlet of the module or water

2 modules

module into the module rack of the main unit. Wait one

2

minute until the module warmup is finished and then completely block the gas inlet of the

module (you may use a pneumatic plug or your finger to manually occlude the port). An alarm

message CO2 Airway Occluded will appear on the screen. Block the gas inlet for another 60

seconds. Select Main Menu → Maintenance → enter the required password → Module →

CO2 → Calibration. If the flow rate is less than 10 ml/min and the alarm message continues, it

indicates that the module does not leak. If the alarm message CO2 Airway Occluded disappears,

or the flow rate is greater than or equal to 10 ml/min, it indicates that the module leaks.

Purging" is displayed on the screen.

2

Block the gas inlet for another 30 seconds. If the alarm message "CO

Airway Occluded" is

2

displayed, it indicates that the module does not leak.

For microstream CO

module and sidestream CO2 module without O2 module, a gas cylinder with

2

5±0.03% CO2, 21.0% O2 and balance gas N2 (P/N 0075-00-0033-01) o r a st e e l g a s cylin d e r wit h :

CO2 concentration 3% - 7%

a/c ≤ 0 .01 (wh e r e a = a b so lu t e ga s co nc e nt rat io n ac c u racy, c = g a s co n c e nt rat io n )

balance gas N2

For sidestream CO

module with O2 module equipped, a steel gas cylinder (P/N 0075-00-0048-01)

2

with 6% CO2, 4% Desflurane, 45% N2O, and 45% O2,

T-shape connector

Tubing

Flowmeter

1. Plug the module into the module rack.

2. Wait until the CO2 module warmup is finished. Check the airway for leak and perform a leakage test

as well to make sure that the airway has no leak.

3. Select Main Menu → Maintenance → enter the required password → Module → CO2.

4. Connect the test system as follows:

3-6 BeneVision N17/BeneVision N15/BeneVision N12 Patient Monitor Service Manual

Page 25

Flowmeter

Tubing

Relief valve

T-shape connector

Monitor

Gas cylinder

5. Open the relief valve, and adjust it until the flowmeter has a stable reading between

10 ml/min and 50 ml/min.

6. Verify that the real-time CO

CO

, the value is 45±2 mmHg).

2

value is within 6±0.2% in the CO2 Maintenance menu (for microstream

2

7. Replace the cylinder to the steel gas cylinder with >40% O2 and balance gas N2(applicable to

sidestream CO

within ±2% (when O

module with O2 module equipped) and verify that the real-time O2 value error is

2

≤80%) or ±3% (80%≤O2≤100%).

2

Calibration

Tools required:

For microstream CO

module and sidestream CO2 module without O2 module, a gas cylinder with

2

5±0.03% CO2, 21.0% O2 and balance gas N2 (P/N 0075-00-0033-01) o r a st e e l g a s cylin d e r wit h :

CO2 concentration 3% - 7%

a/c ≤ 0 .01 (wh e r e a = a b so lu t e ga s co nc e nt rat io n ac c u racy, c = g a s co n c e nt rat io n )

balance gas N2

For sidestream CO

module with O2 module equipped, a steel gas cylinder (P/N 0075-00-0048-01)

2

with 6% CO2, 4% Desflurane, 45% N2O, and 45% O2,

T-shape connector

Tubing

Flowmeter

1. Make sure that the sidestream or microstream CO

module has been warmed up or started up.

2

2. Check the airway for leaks and perform a leakage test as well to make sure that the airway has no

leakage.

3. Select Main Menu → Maintenance → enter the required password → Module → CO2.

4. In the CO2 Maintenance menu, select Zero.

BeneVision N17/BeneVision N15/BeneVision N12 Patient Monitor Service Manual 3-7

Page 26

5. After the zero calibration is finished successfully, connect the equipment as follows:

Flowmeter

Tubing

Relief valve

Monitor

T-shape connector

Gas cylinder

6. Open the relief valve, and adjust it until the flowmeter has a stable reading between

10 ml/min and 50 ml/min.

7. In the Calibrate CO2 menu, select 6% (the CO

concentration) for CO2 calibration. The measured CO2

2

concentration is displayed.

8. After the measured CO

concentration becomes stable, select Calibrate CO2 to calibrate the CO

2

module.

9. Replace the cylinder to the steel gas cylinder with >40% O2 and balance gas N2(applicable to

sidestream CO2 module with O2 module equipped) and calibrate O2.

If the calibration is finished successfully, the message Calibration Completed! is displayed in the Calibrate

CO2 menu. If the calibration failed, the message Calibration Failed! is displayed. In this case, check

whether the operations are correct and perform another calibration. If the calibration fails several times,

return the module to Mindray for repair.

3.1.7 AG Tests

Leakage Test

1. Plug the AG module into the module rack.

2. Wait until the AG module warmup is finished and then completely block the gas inlet of the AG

module (you may use a pneumatic plug or your finger to manually occlude the port). An alarm

message AG Airway Occluded will appear on the screen.

2

3. Block the gas inlet for another 60 seconds. Select Main Menu → Maintenance → enter the

required password → Module → AG → Calibration. Check that the flow rate is less than 10

ml/min. If the alarm message continues, it indicates that the module does not leak.

If the alarm message disappears, or the flow rate is greater than or equal to 10 ml/min, it indicates that the

module leaks.

3-8 BeneVision N17/BeneVision N15/BeneVision N12 Patient Monitor Service Manual

Page 27

Accuracy Test

Tools required:

Gas cylinder with a certain standard gas (such as 6±0.05% CO2, Bal N

) or standard gas mixture. Gas

2

concentration should meet the following requirements: AA > 1.5%, CO2 > 1.5%, N2O > 40%, O2 > 40%,

of which AA represents an anesthetic agent. Precision requirement: a/c ≤ 0.01 (a is the gas absolute

concentration accuracy; c is the gas concentration)

T-shape connector

Tubing

Flowmeter

1. Plug the AG module into the module rack.

2. Wait at least 10 min and then perform a leakage test to make sure that the airway has no leakage.

3. Connect the test system as follows:

Flowmeter

Tubing

Relief valve

T-shape connector

Monitor

Gas cylinder

4. Open the relief valve, and adjust it until the flowmeter has a stable reading between 10 ml/min and

50 ml/min.

5. Verify that the concentration of each composition meets the specification stated in the Operator's

Manual.

Calibration

Tools required:

A supply of medical grade 100% O2 and an anesthetic calibration gas (4% Desflurane, 6% CO2, 45%

N2O, Bal O2, P/N: 0075-00-0048-01 and flow regulator P/N: 0119-00-0235). Gas concentration should

meet the following requirements:

AA ≥ 1.5%, CO2 ≥ 1.5%, N2O ≥ 40%, O2 ≥ 40%, of which AA represents an anesthetic

agent.

BeneVision N17/BeneVision N15/BeneVision N12 Patient Monitor Service Manual 3-9

Page 28

a/c ≤ 0.01 (a is the gas absolute concentration accuracy; c is the gas concentration)

T-shape connector

Tubing

Follow this procedure to perform a calibration:

1. Select Main Menu → Maintenance → enter the required password → Module → AG.

2. Check the airway and make sure that there are no occlusions or leaks.

Vent the sampling tubing to the air and check if the Current Flow Rate and Set Flow Rate are

approximately the same. If the deviation is great, it indicates that there is an occlusion in the

tubing. Check the tubing for an occlusion.

Perform a leakage test to make sure that the airway has no leakage.

3. Connect the test system as follows:

4. Open the relief valve and vent a certain standard gas or gas mixture. Adjust the relief valve until the

flowmeter has a stable reading between 10 ml/min and 50 ml/min.

Flowmeter

Tubing

Relief valve

T shape connector

Monitor

Gas cylinder

5. In the Calibrate AG menu, the concentration and flowrate of each measured gas are displayed.

If the difference between the measured gas concentration and the actual one is within tolerance,

a calibration is not needed.

If the difference is not within tolerance, a calibration should be performed. Select Calibrate.

6. Enter the vented gas concentration. If you use only one gas for calibration, set other gases'

concentration to 0. If the calibration is performed for all gases, the gas with an entered

calibration value of 0 is not calibrated.

7. Select Calibrate to start a calibration.

8. If the calibration is finished successfully, the message Calibration Completed! is displayed. If the

calibration failed, the message Calibration Failed! is displayed. In this case, perform another

calibration. If the calibration fails several times, return the module to Mindray for repair.

3-10 BeneVision N17/BeneVision N15/BeneVision N12 Patient Monitor Service Manual

Page 29

CAUTION

Calibrate the O

module, if it has been transported for long distance.

2

3.2 Power On Test

This test is to verify that the patient monitor can power up correctly. The test is passed if the patient

monitor starts up by following this procedure:

1. Connect the patient monitor to the AC mains. The AC mains LED and battery LED light up.

2. Press the power on/off switch to switch on the patient monitor. The system sounds a beep indicating

the self test on alarm sounds is passed. The alarm lamps light red, yellow and cyan respectively, and

then go off, indicating the self test on alarm sound is passed.

3. The patient monitor enters the main screen and start-up is finished.

3.3 Module Performance Tests

3.3.1 ECG Tests

ECG Performance Test

Tools required:

Medsim300B patient simulator or other equivalent simulator

1. Connect the patient simulator with the ECG module using an ECG cable.

2. Set the patient simulator as follows: ECG sinus rhythm, HR = 60 bpm with the amplitude as 1 mV.

3. Verify that the ECG waves are displayed correctly without noise and the displayed HR value is within

60±1 bpm.

4. Disconnect each of the leads in turn and observe the corresponding lead off message displayed on

the screen.

5. Set the output of the simulator to deliver a paced signal and set Paced to Yes on the monitor. Check

the pace pulse marks on the monitor screen.

ECG Verification

Tools required: vernier caliper

1. Select the ECG parameter window or waveform area →Filter→Diagnostic.

2. Select

3. Select Calibration. A square wave appears on the screen and the message "ECG Calibrating" is

Main Menu →Maintenance → enter the required password → Module..

displayed.

4. Compare the amplitude of the square wave with that of the scale. The difference should be with 5%.

5. After completing the calibration, select Stop Calibration.

BeneVision N17/BeneVision N15/BeneVision N12 Patient Monitor Service Manual 3-11

Page 30

If necessary, you can print out the square wave and wave scale through the recorder and then measure

the difference.

3.3.2 Resp Performance Test

Tools required:

Medsim300B patient simulator or other equivalent simulator

1. Connect the patient simulator to the module using a non ESU-proof cable and set lead II as the

respiration lead.

2. Configure the simulator as follows: lead II as the respiration lead, base impedance line as 500 Ω; delta

impedance as 1 Ω, respiration rate as 20 rpm.

3. Verify that the Resp wave is displayed without any distortion and the displayed Resp value is within

20±1 rpm.

3.3.3 SpO

Tools required:

Test

2

None.

1. Connect SpO2 sensor to the SpO2 connector of the monitor. Set Patient Category to Adult and PR

Source to SpO2 on the monitor.

2. Apply the SpO

sensor to the ring finger of a healthy person.

2

3. Check the Pleth wave and PR reading on the screen and make sure that the displayed SpO2 is within

95% and100%.

4. Remove the SpO

sensor from your finger and make sure that an alarm of SpO2 Sensor Off is

2

triggered.

Measurement accuracy verification:

The SpO

accuracy of the MPM module has been verified in human experiments by comparing with

2

arterial blood sample reference measured with a CO-oximeter. Pulse oximeter measurements are

statistically distributed and about two-thirds of the measurements are expected to come within the

specified accuracy range compared to CO-oximeter measurements.

NOTE

A simulator cannot be used to assess the accuracy of a pulse oximeter monitor or a SpO

2

sensor. Instead, it can only verify that whether the monitor is functional. The accuracy of a

pulse oximeter monitor or a SpO2 sensor needs to be verified by clinical data.

3-12 BeneVision N17/BeneVision N15/BeneVision N12 Patient Monitor Service Manual

Page 31

3.3.4 NIBP Tests

See section 3.1.5NIBP Tests.

3.3.5 Temp Test

Tools required:

Resistance box (with accuracy above 0.1 Ω)

1. Connect the two pins of any Temp connector of a module to the two ends of the resistance box using

two wires.

2. Set the resistance box to 1354.9 Ω (corresponding temperature is 37ºC).

3. Verify each Temp channel of the monitor and make sure that the displayed value is within 37±0.1ºC.

4. Repeat steps 1 to 3 to verify each Temp channel of the monitor.

3.3.6 IBP Tests

Performance Test

Tools required:

Patient simulator Medsim300B, MPS450, or other equivalent equipment

Dedicated IBP adapter cable (P/N 00-002199-00 for 300B, P/N 00-002198-00 for MPS450)

1. Connect the patient simulator to the monitor's IBP connector.

2. Set the patient simulator output to the IBP channel to 0 mmHg.

3. Press the Zero key on the module to make a zero calibration.

4. Set static pressure to 200 mmHg on the patient simulator.

5. The displayed value should be within 200±2 mmHg.

6. If the error is beyond ±2 mmHg, calibrate the IBP module. If the IBP module was calibrated with a

dedicated reusable IBP sensor, check the calibration together with this IBP sensor.

7. Make the patient simulator outputs 120/80 mmHg ART signals and 120/0 mmHg LV signals

respectively to each IBP channel and check that the IBP wave is displayed correctly.

8. Repeat the preceding steps to test all IBP channels.

Pressure Calibration

Method 1:

Tools required:

Medsim300B patient simulator, MPS450, or other equivalent equipment

Dedicated IBP adapter cable (300B, P/N 00-002199-00) (use P/N 00-002198-00, if the simulator is

MPS450)

BeneVision N17/BeneVision N15/BeneVision N12 Patient Monitor Service Manual 3-13

Page 32

1. Connect the patient simulator to the monitor's IBP connector.

2. Set the patient simulator to 0 pressure for the desired IBP channel.

3. Press the Zero key from the IBP menu.

4. Set static pressure to 200 mmHg on the patient simulator.

5. Select Main Menu → Maintenance → enter the required password → Module → IBP.

6. Set the calibration value to 200 mmHg.

7. Select the Calibrate button next to the desired IBP channel to start a calibration.

8. If the calibration is completed successfully, the message Calibration Completed! will be displayed.

Otherwise, a corresponding message will be displayed.

Method 2:

Tools required:

Standard sphygmomanometer

Squeeze bulb

Tubing

T-shape connector

1. Connect the 3-way stopcock, the sphygmomanometer and the squeeze bulb through a T-shape

connector, as shown below.

2. Zero the transducer, and then open the stopcock to the sphygmomanometer.

Pressure transducer

3-way stopcock

Pressure adapter cable

T-shape connector

Sphygmomanometer

3. Select Main Menu→ Maintenance → enter the required password → Module → IBP. In the

displayed interface, set the target calibration value of the target channel. Value range: 80 to 300

mmHg.

IBP

module

4. Inflate using the squeeze bulb until the reading of sphygmomanometer approximates the preset

calibration value.

5. Adjust the calibration value in the IBP Maintenance menu until it is equal to the reading of

sphygmomanometer

3-14 BeneVision N17/BeneVision N15/BeneVision N12 Patient Monitor Service Manual

Page 33

6. Select the Calibrate button next to the desired IBP channel to start a calibration.

If the calibration is completed successfully, the message Calibration Completed! will be displayed.

Otherwise, a corresponding message will be displayed.

3.3.7 C.O. Test

Tools required:

Medsim300B patient simulator or other equivalent simulator

C.O. adapter box (for 300B)

1. Connect the patient simulator to the C.O. module using a C.O. main cable.

2. Set the blood temperature (BT) to 37ºC on the patient simulator and check the temperature value is

37±0.1ºC.

3. Switch off Auto TI and adjust TI (IT) to 24ºC. Select C.O. Measure to enter the C.O. measurement

window and set Comp. Const. to 0.595.

4. Set the injectate temperature to 24ºC and the C.O. to 5 L/min on the C.O. simulator. Select Start in

the C.O. measurement window to start C.O. measurements, and press the run key on the simulator

after 3-10 seconds.

6. Verify that the C.O. value is 5±0.25 L/min.

3.3.8 Sidestream and Microstream CO

See section 3.1.6Sidestream and Microstream CO2 Tests.

3.3.9 AG Tests

See section 3.1.7AG Tests.

Tests

2

BeneVision N17/BeneVision N15/BeneVision N12 Patient Monitor Service Manual 3-15

Page 34

3.3.10 EEG Test

You can choose either of the following methods to perform the test:

Method 1:

Tools required:

ECG simulator with Sine wave output function.

1. Connect pins of EEG lead wires to an ECG simulator.

Set the ECG simulator to output Sine wave and frequency to between 0.5 and 30Hz. The range is 2mV. The

GND pin of EEG module connects to RL of ECG simulator. The A+ pin of EEG module connects to LA of ECG

simulator. The other pins of EEG lead wires connect to any ECG lead as you wish.

2. Open the EEG setting menu on monitor, Set the Scale of EEG to be 2000uV. Then you can find a Sine

wave on screen of Patient Monitor.

Method 2:

Tools required:

None.

Connect all the pins of EEG lead wire together, for example, you can connect them to some metal

materials. Then check the EEG module resistance test, if all the leads are green then pass.

Method 3:

Tools required:

Resistance box

Multimeter

Connect the EEG module/cable to the EEG simulator and the monitor.

1. Set Montage Type: Bipolar Mode.

2. Adjust the resistance box to 1 kΩ, verify the resistance value displayed on the monitor is 1kΩ.

3. Test the lead type of the monitor to B+, C+ and D+ respectively instead of lead A+.

4. Set Montage Type: Monopolar Mode , then repeat the step 3~4.

3-16 BeneVision N17/BeneVision N15/BeneVision N12 Patient Monitor Service Manual

Page 35

3.3.11 BIS Test

You can choose either of the following methods to perform the test:

Method 1:

Tools required:

None.

1. Connect the BIS sensor to a healthy, wide-awake adult as directed in the Operator's Manual.

2. Check the EEG wave and BIS numerics displayed on the screen and make sure the BIS value is within

80 and 100.

Method 2:

Tools required:

BIS simulator (Covidien PN: 186-0137)

1. Connect the BIS sensor with the BIS simulator. Select BIS area parameter or waveform to access BIS

Setup. Then, select Sensor Check to perform a cyclic impedance check.

2. After the cyclic impedance check is finished, check that the result for each electrode is passed.

Method 3:

Tools:

Signal generator, (Maker: NF, Model:WF1946B)

Covidien Signal simulator (Covidien PN:189-0137)

1. Insert the BIS module to the monitor, connect the BIS module/cable to the Covidien Signal

simulator, signal generator.

2. Adjust the signal generator to produce a 90Hz, 35.4mV(RMS) sine signal to the Convidien Signal

simulator.

3. Set the time length of the review window to the shortest.

4. Verify the EMG value range from 65 to 75, and SQI value should be 100 displayed on Graphic

Trends.

BeneVision N17/BeneVision N15/BeneVision N12 Patient Monitor Service Manual 3-17

Page 36

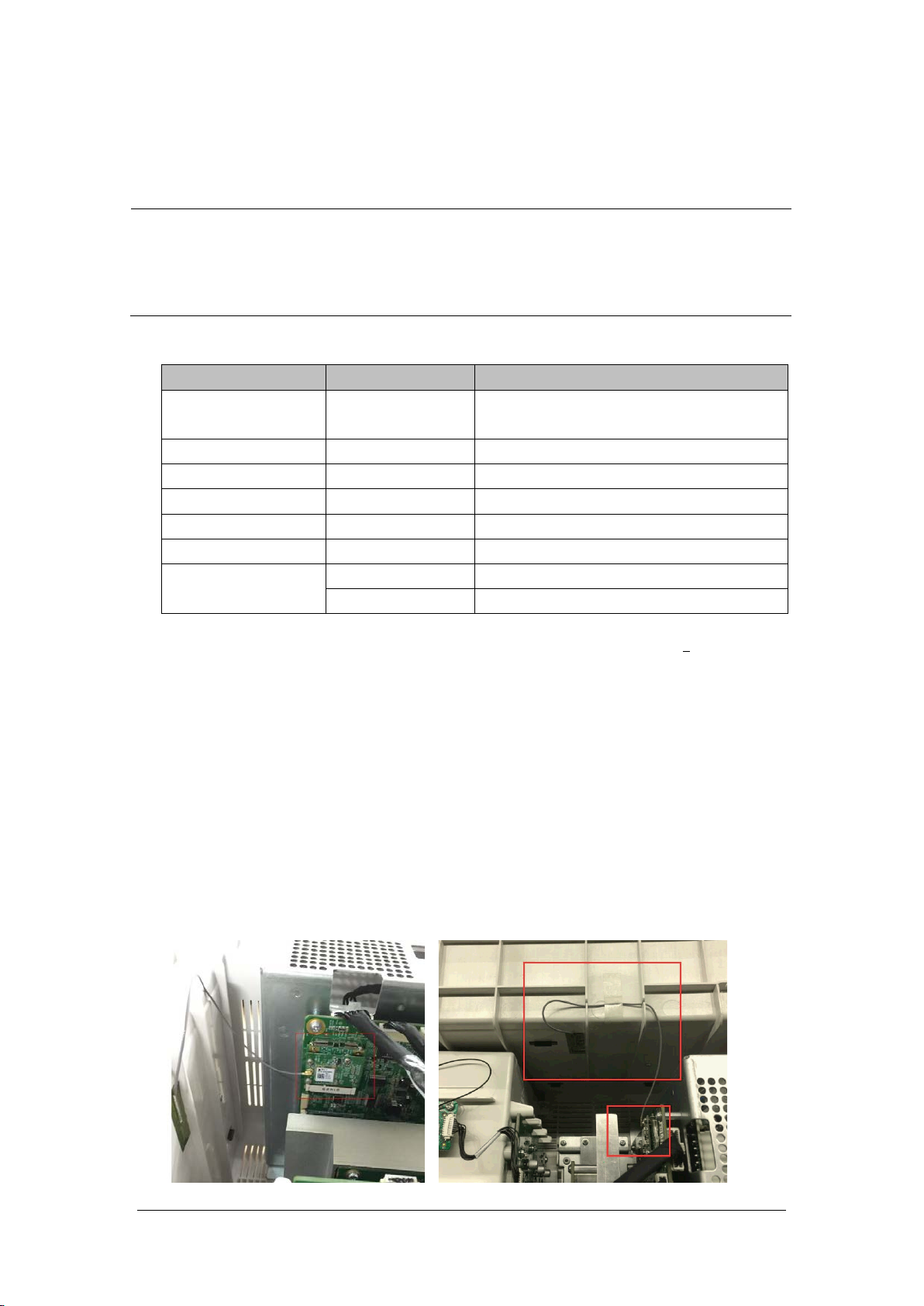

3.3.12 CCO/SvO

Tests

2

Interconnecting Function

Tools required:

None.