Page 1

Page 2

Page 3

Intellectual Property Statement

Mindray DS USA, Inc. (hereinafter called Mindray DS) owns the intellectual property rights

to this product and this manual. This manual may refer to information protected by

copyrights or patents and does not convey any license under the copyright and the patent

rights of Mindray DS, nor the rights of others.

Mindray DS intends to maintain the contents of this manual as confidential information.

Disclosure of the information in this manual in any manner whatsoever without the written

permission of Mindray DS is strictly forbidden. Release, amendment, reproduction,

distribution, rental, adaption and translation of this manual in any manner whatsoever without

the written permission of Mindray DS is strictly forbidden.

is a trademark or a registered trademark of Shenzhen Mindray Bio-Medical

Electronics Co., Ltd. All third-party trademarks that appear in this manual are used solely for

editorial purposes and are the property of their respective owners.

Contents of this manual are subject to changes without prior notice.

© 2008-2010 Mindray DS USA, Inc. All rights reserved.

WARNING

z Federal Law (USA) restricts this device to sale by or on the order of a physician.

I

Page 4

FOR YOUR NOTES

II

Page 5

Preface

Manual Purpose

This manual provides detailed information about the assembling, dissembling, testing and

troubleshooting of the equipment to support effective troubleshooting and repair. It is not

intended to be a comprehensive, in-depth explanation of the product architecture or technical

implementation. Observance of the manual is a prerequisite for proper equipment

maintenance and prevents equipment damage and personnel injury.

This manual is based on the maximum configuration; Therefore, some contents may not

apply to your monitor. If you have any question, please contact our Customer Service

Department.

Intended Audience

This manual is for biomedical engineers, authorized technicians or service representatives

responsible for troubleshooting, repairing and maintaining the monitors.

Revision History

This manual has a revision number. This revision number changes whenever the manual is

updated due to software or technical specification change. Contents of this manual are subject

to change without prior notice

Revision number: 2.0

Release time: 2010-04

Password

A password is required to access the service mode. The service password is 321.

1

Page 6

FOR YOUR NOTES

2

Page 7

Contents

1 Safety................................................................................................................................. 1-1

1.1 Safety Information ..........................................................................................................1-1

1.1.1 Warnings............................................................................................................. 1-2

1.1.2 Cautions ............................................................................................................. 1-2

1.1.3 Notes .................................................................................................................. 1-2

1.2 Equipment Symbols ........................................................................................................ 1-3

2 Theory of Operation ........................................................................................................ 2-1

2.1 Introduction..................................................................................................................... 2-1

2.2 System Structure ............................................................................................................. 2-1

2.3 Hardware Structure ......................................................................................................... 2-3

2.3.1 Main Board......................................................................................................... 2-4

2.3.2 Power Board....................................................................................................... 2-5

2.3.3 Key&displays Board .......................................................................................... 2-6

2.3.4 Parameter Boards ............................................................................................... 2-7

2.3.5 Recorder ............................................................................................................. 2-9

2.3.6 Bar Code Scanner............................................................................................... 2-9

3 Testing and Maintenance................................................................................................. 3-1

3.1 Introduction..................................................................................................................... 3-1

3.1.1 Recommended Frequency .................................................................................. 3-2

3.2 Visual test........................................................................................................................ 3-2

3.3 Power-On Test................................................................................................................. 3-3

3.3.1 NIBP Tests.......................................................................................................... 3-3

3.3.2 SpO

3.3.3 Temp Test ........................................................................................................... 3-6

3.4 Nurse Call Performance Test........................................................................................... 3-7

3.5 Bar Code Scanner Test.................................................................................................... 3-7

3.6 Electrical Safety Tests .....................................................................................................3-8

3.6.1 Enclosure Leakage Current Test......................................................................... 3-9

3.6.2 Earth Leakage Current Test.............................................................................. 3-10

3.6.3 Patient Leakage Current Test ........................................................................... 3-10

3.6.4 Patient Auxiliary Leakage Current Test ........................................................... 3-10

3.7 Recorder Check..............................................................................................................3-11

3.8 Program upgrade ............................................................................................................3-11

4 T ro ubleshooting................................................................................................................ 4-1

4.1 Introduction..................................................................................................................... 4-1

4.2 Part Replacement ............................................................................................................4-1

4.3 Monitor Status Check...................................................................................................... 4-1

4.4 Technical Alarm Check ................................................................................................... 4-2

Test............................................................................................................ 3-5

2

1

Page 8

4.5 Troubleshooting Guide.................................................................................................... 4-2

4.5.1 Power On/Off Failures ....................................................................................... 4-2

4.5.2 Display Failure ................................................................................................... 4-3

4.5.3 LED Digital Display & Indication Lamp Failure............................................... 4-3

4.5.4 Alarm Problems.................................................................................................. 4-3

4.5.5 Button Failure..................................................................................................... 4-4

4.5.6 Recorder Failures ............................................................................................... 4-4

4.5.7 Interface Failures................................................................................................ 4-5

4.5.8 Power Supply Failures ....................................................................................... 4-5

4.5.9 Network related problems .................................................................................. 4-7

4.5.10 Software Upgrade Problems............................................................................. 4-7

4.5.11 Bar Code Scanner Failures ............................................................................... 4-8

4.5.12 NIBP Measurement Failures ............................................................................ 4-8

4.5.13 SpO2 Measurement Failure.............................................................................. 4-9

4.5.14 Temp Measurement Failures ............................................................................ 4-9

5 Repair and Disassembly ............................... .. ... .. ... ......................................................... 5-1

5.1 Tools................................................................................................................................ 5-1

5.2 Preparation for Disassembly ........................................................................................... 5-1

5.3 Disassembly .................................................................................................................... 5-2

5.3.1 Separating the Front and Rear Half of the Monitor............................................ 5-2

5.3.2 Disassembling the Front Housing Assembly...................................................... 5-4

5.3.3 Removing the Main Rack Assembly.................................................................. 5-6

5.3.4 Disassembling NIBP Module............................................................................. 5-7

5.3.5 Removing the Main Board ................................................................................. 5-8

5.3.6 Removing the Power Board ............................................................................... 5-8

5.3.7 Removing the Battery Assembly........................................................................ 5-9

5.3.8 Removing the Fan and Speaker.......................................................................... 5-9

5.3.9 Removing the Power Socket ............................................................................ 5-10

5.3.10 Removing the Temp Module .......................................................................... 5-10

5.3.11 Removing the SpO

Module........................................................................... 5-12

2

6 Parts .................................................................................................................................. 6-1

6.1 Main Unit ........................................................................................................................ 6-1

6.2 Main Rack Assembly (For Lead-acid Batteries)............................................................. 6-2

6.3 Main Rack Assembly (For Lithium Battery)................................................................... 6-4

6.4 Front housing Assembly.................................................................................................. 6-6

6.5 Rear Housing Assembly.................................................................................................. 6-7

6.6 Lithium Battery Charger Assembly................................................................................. 6-8

6.7 Lead-acid Battery Assembly ........................................................................................... 6-9

6.8 MASIMO SpO

Board Assembly ................................................................................. 6-10

2

6.9 Temp Assembly..............................................................................................................6-11

2

Page 9

1 Safety

1.1 Safety Information

WARNING

z Indicates a potential hazard or unsafe practice that, if not avoided, could result in

death or serious injury.

CAUTION

z Indicates a potential hazard or unsafe practice that, if not avoided, could result in

minor personal injury or product/property damage.

NOTE

z Provides application tips or other useful information to ensure better maintenance

operation.

1-1

Page 10

1.1.1 Warnings

WARNING

z Disassembly and repair of this product should be conducted by Mindray DS

authorized personnel only.

z To avoid explosion hazard, do not use the equipment in the presence of

flammable anesthetics, vapors or liquids.

z Follo w the applicable wa ste contro l re gulations to dispose of the package

material and keep it out of children’s reach.

z The equipment must be connected to a properly installed power outlet with

protective earth contacts only. If the installation does not provide a protective

earth conductor, disconnect the equipment from the power line and opera te it

on battery power, if possible.

1.1.2 Cautions

CAUTION

z Magnetic and electrical fields are capable of interfering with the proper

performance of the equipment. For this reason, make sure that all external

devices operated in the vicinity of the equipment comply with the relevant EMC

requirements. Mobile phones, X-ray equipment or MRI devices are possible

sources of interference as they may emit higher levels of electromagnetic

radiation.

z Before connecting the equipment to the power line, check that the voltage and

frequency ratings of the power line are the same as those indicated on the

equipment’s label or in this manual.

z Protect the equipment from damage caused by drop, impact, strong vibration or

other mechanical force during servicing.

1.1.3 Notes

NOTE

z Refer to Operation Manual for detailed operation and other information.

1-2

Page 11

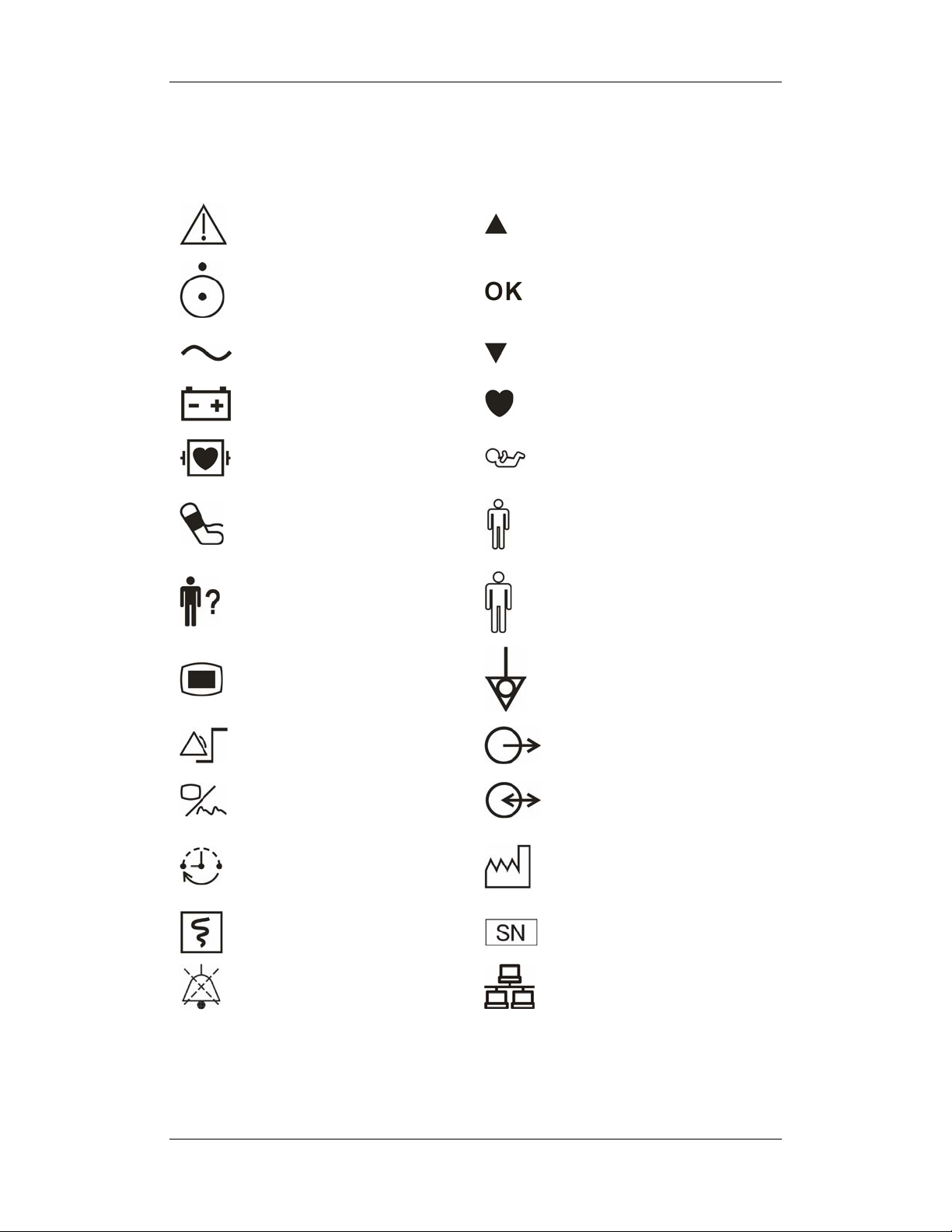

1.2 Equipment Symbols

Attention (Consulting this

manual).

Power On/Off

Alternating current (AC)

Battery indicator

Type CF applied part.

Defibrillator-proof

NIBP start/stop button

Patient Information

Up button

Confirm button

Down button

Pulse Rate (PR)

Neonate

Pediatric

Adult

Main menu

Set alarms

Display Tabular Trends/Pleth

Wave

NIBP interval

Record

Alarm Silence

Equipotential grounding

Nurse Call connector

RS-232 connector

Date of manufacture

Serial number

Network connector

1-3

Page 12

FOR YOUR NOTES

1-4

Page 13

2 Theory of Operation

2.1 Introduction

The monitor is intended for monitoring the patient’s vital signs including non-invasive blood

pressure (NIBP), pulse oxygen saturation (SpO

paediatric and neonatal patient. It is also designed to monitor the temperature Temp) for

single adult and paediatric patient.

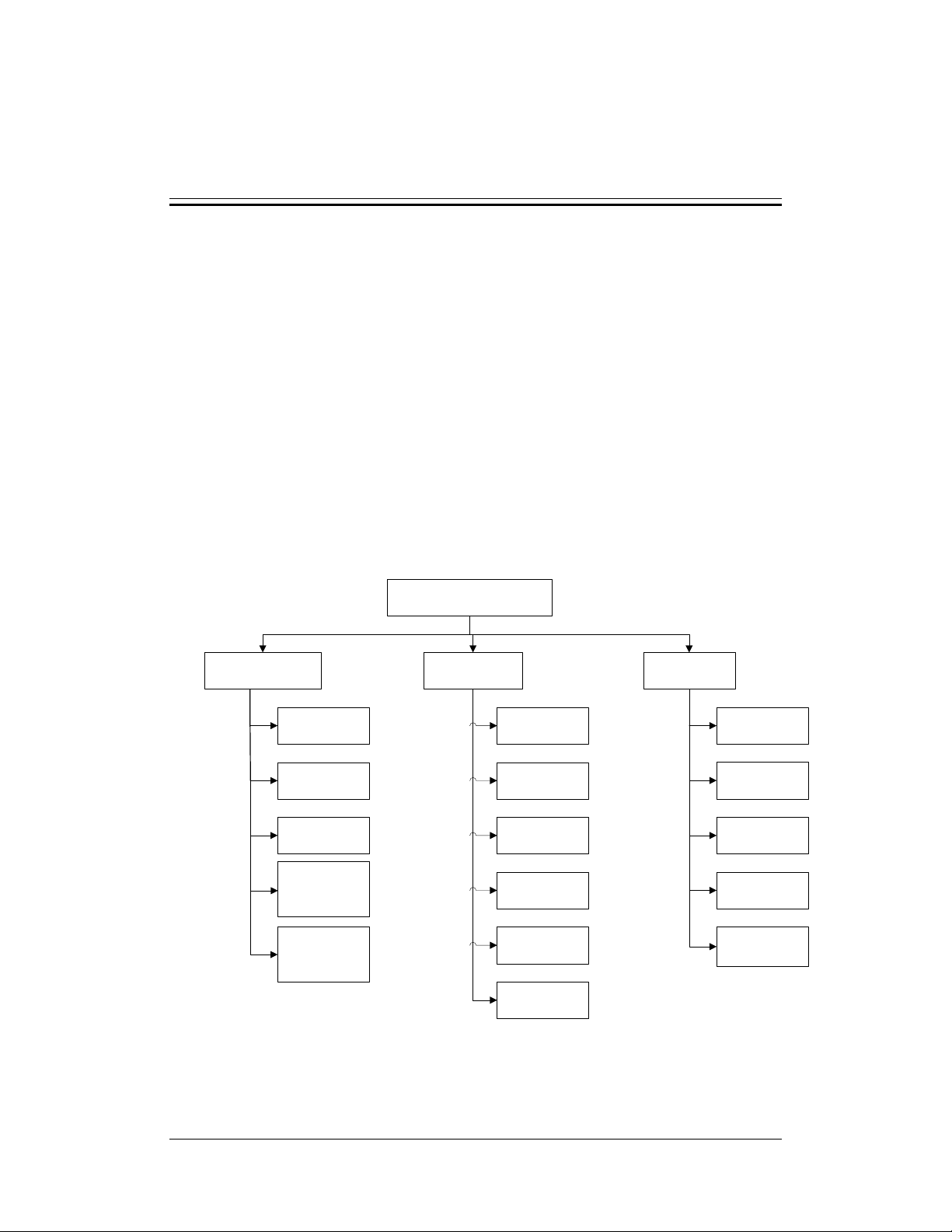

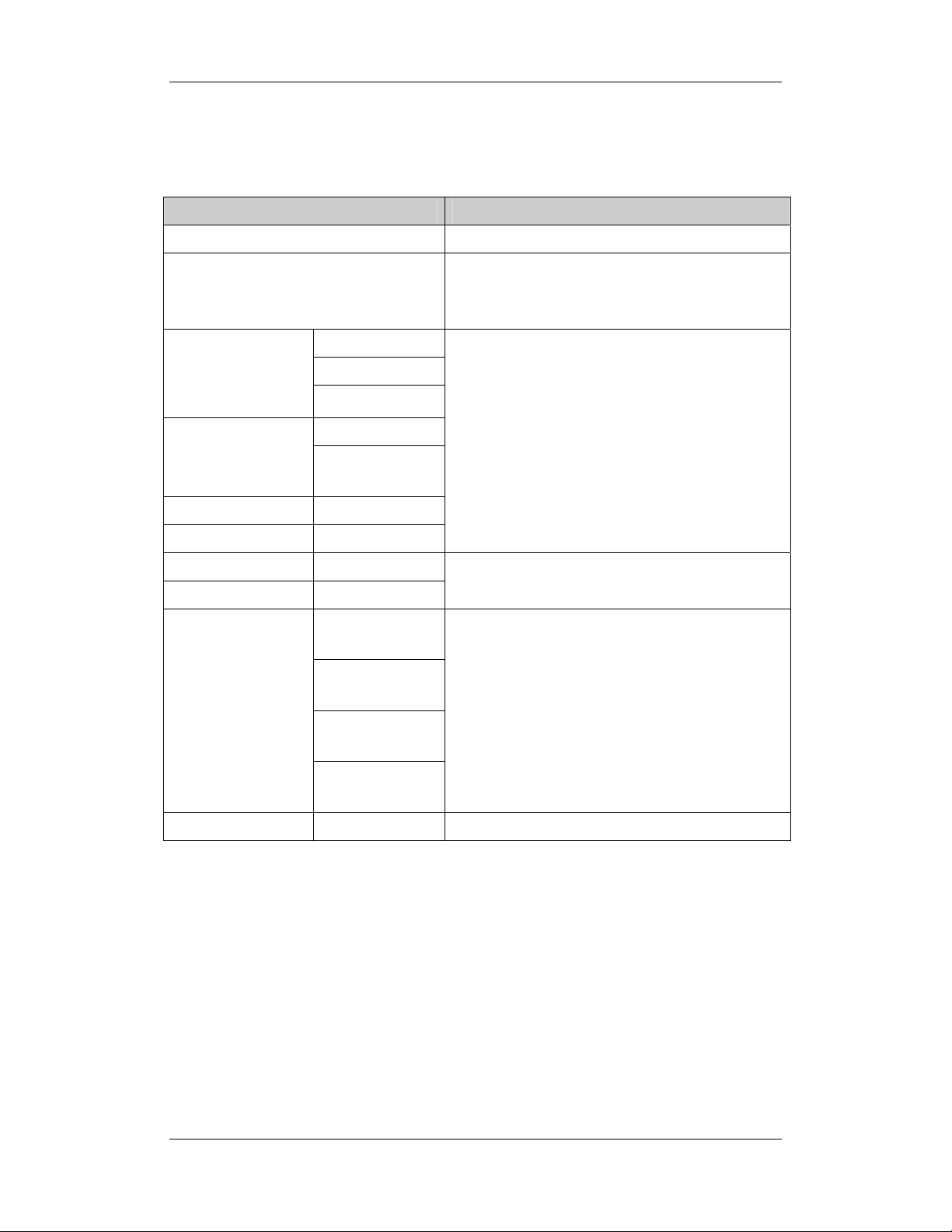

2.2 System Structure

The whole system consists of mechanical parts, hardware and software, as follows:

) and pulse rate (PR) for single adult,

2

System

Mechanical Hardware Software

Main unit

Recorder

Battery

chamber

Temp

module

charmber

Barcode

scanner

support

Main board

Power board

Key&display

Parameter

boards

Recorder

board

Barcode

scanner

System

software

Parameter

software

Upgrade

software

Print

software

Gateway

software

2-1

Page 14

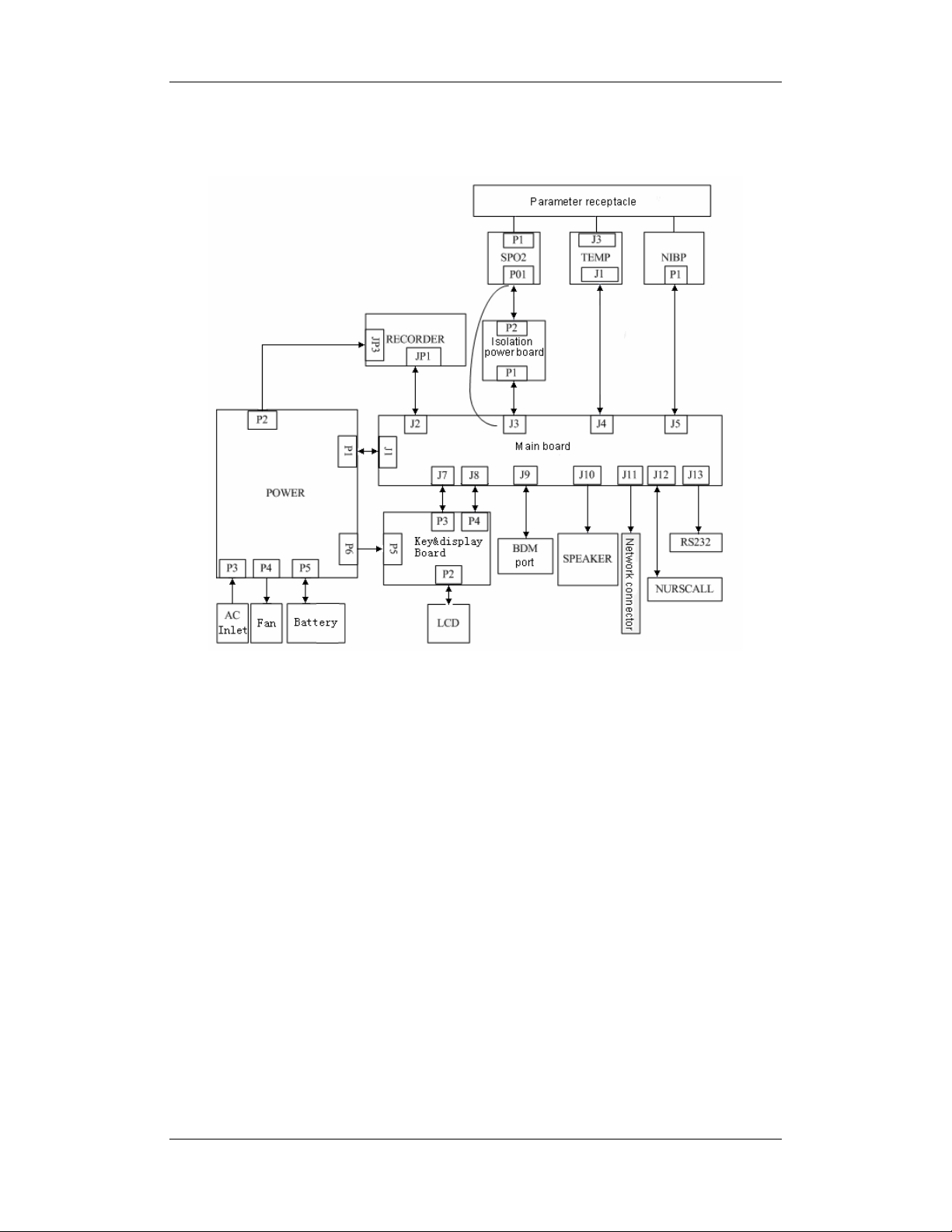

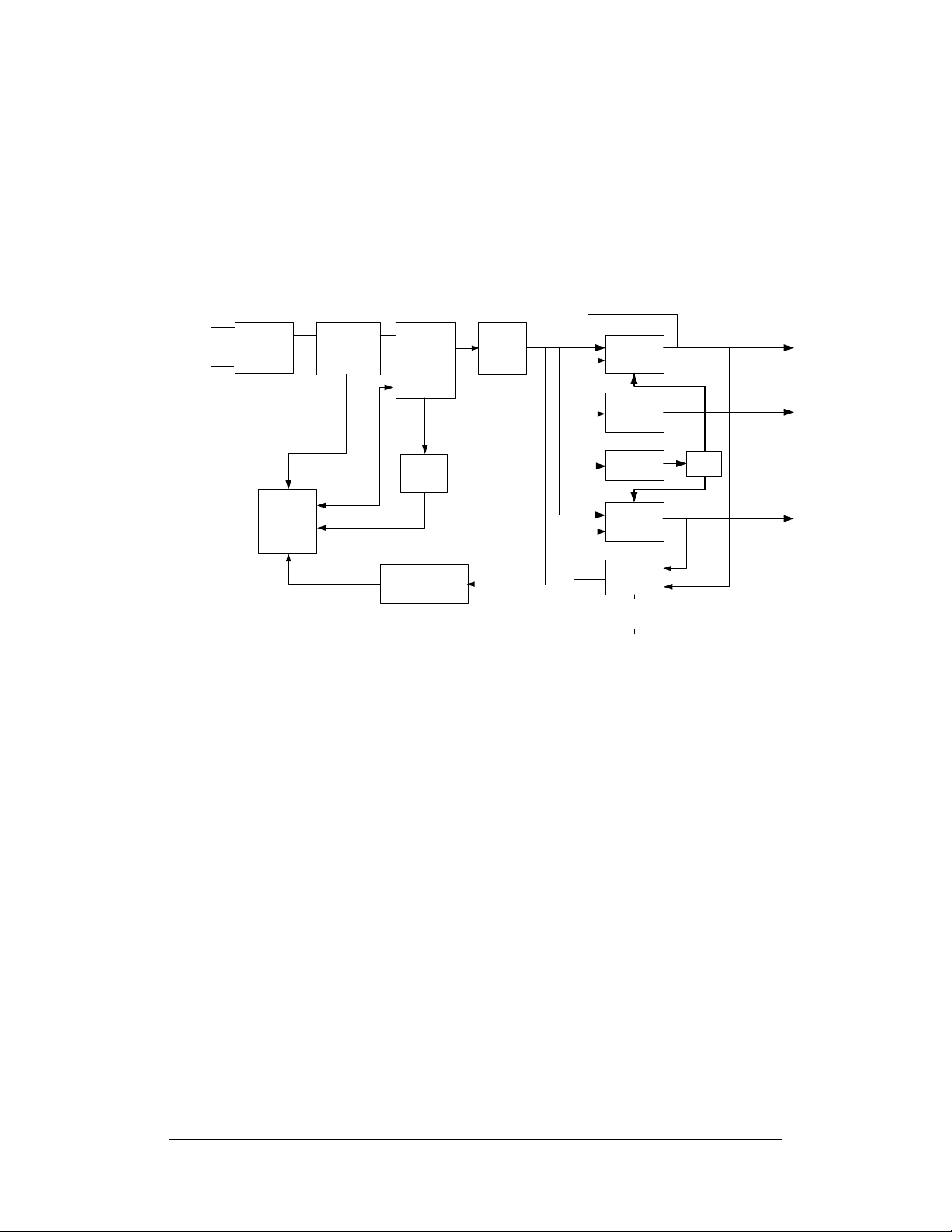

The system’s PCBAs are connected as shown below:

2-2

Page 15

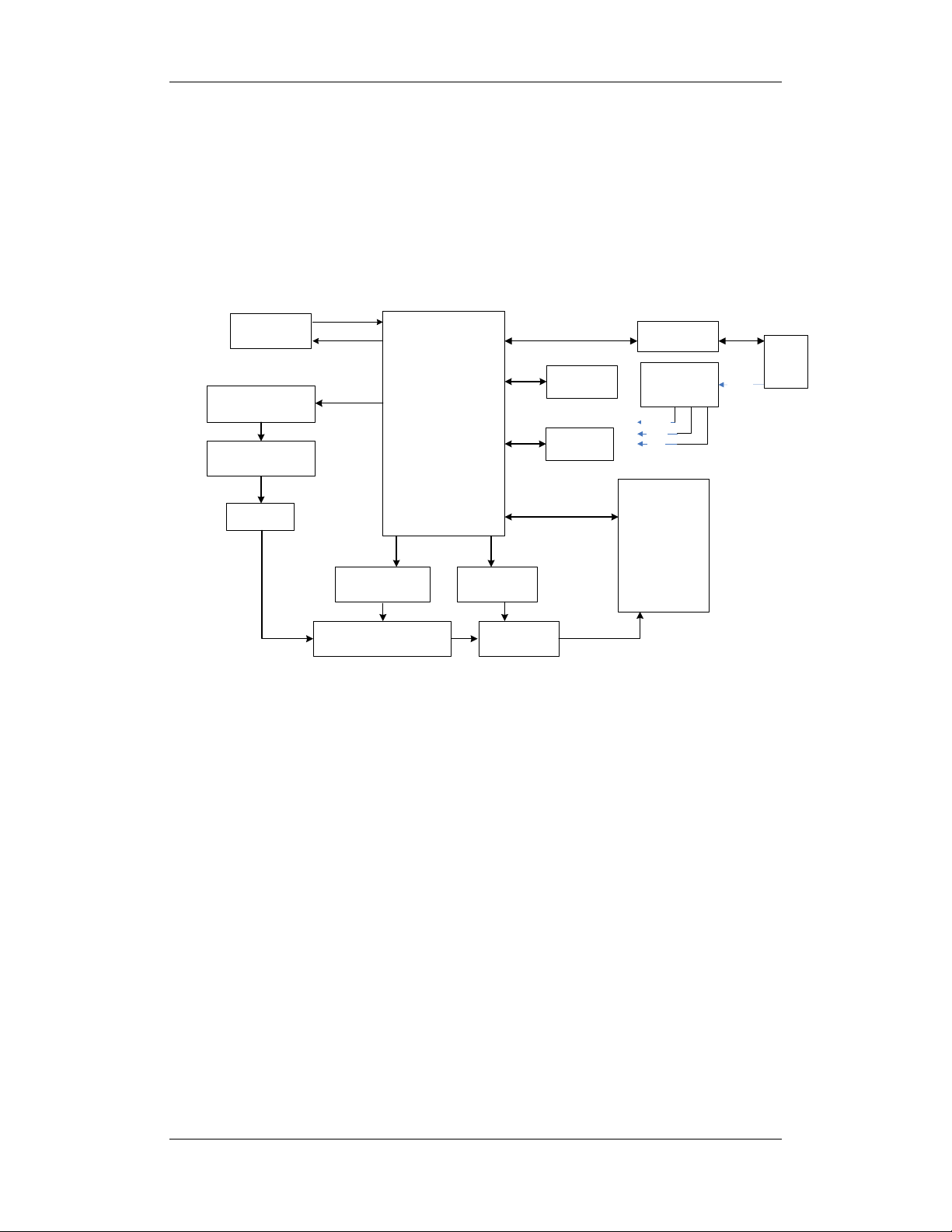

2.3 Hardware Structure

The monitor’s hardware structure is shown in the figure below.

Key&display

board

LED &

KEY

LCD

Power

supply

NIBP module

Speaker

SpO2 module

Isolation power

board *

Communication/p

ower supply

Recorder

TEMP module

Main board

Fan

Communication/p

ower supply

Ethernet

RS232

NurseCall

Battery

Power board

VS-800

* Mindray SpO2 module does not require the isolation power board.

The core of the system is the main board which provides power supply for all parameter

modules. The parameter modules directly communicate with the main board, and the

measurements and status of all modules are processed by the main board and then displayed

on the key&display board. The main board also controls communication with the speaker, the

recorder and all the external connectors.

AC

2-3

Page 16

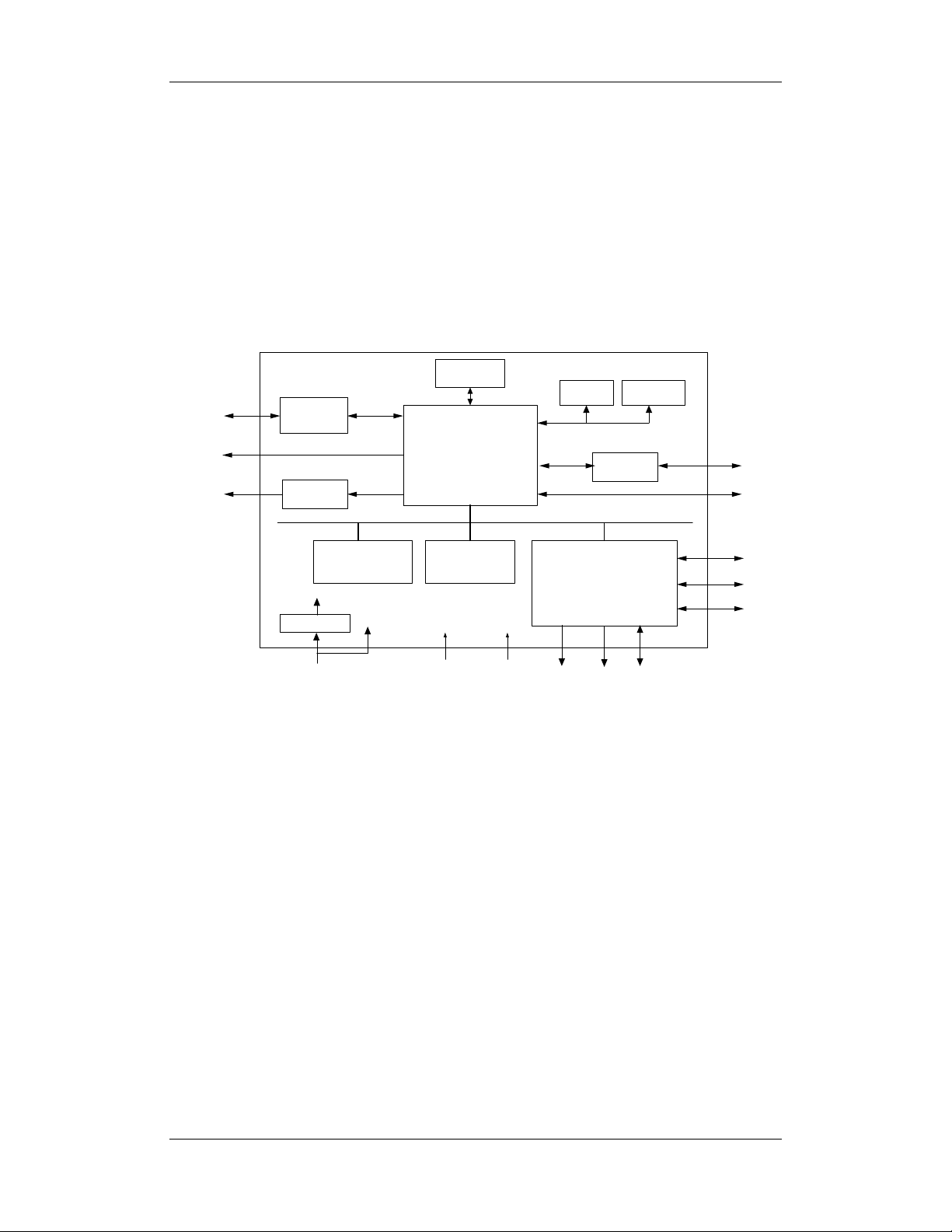

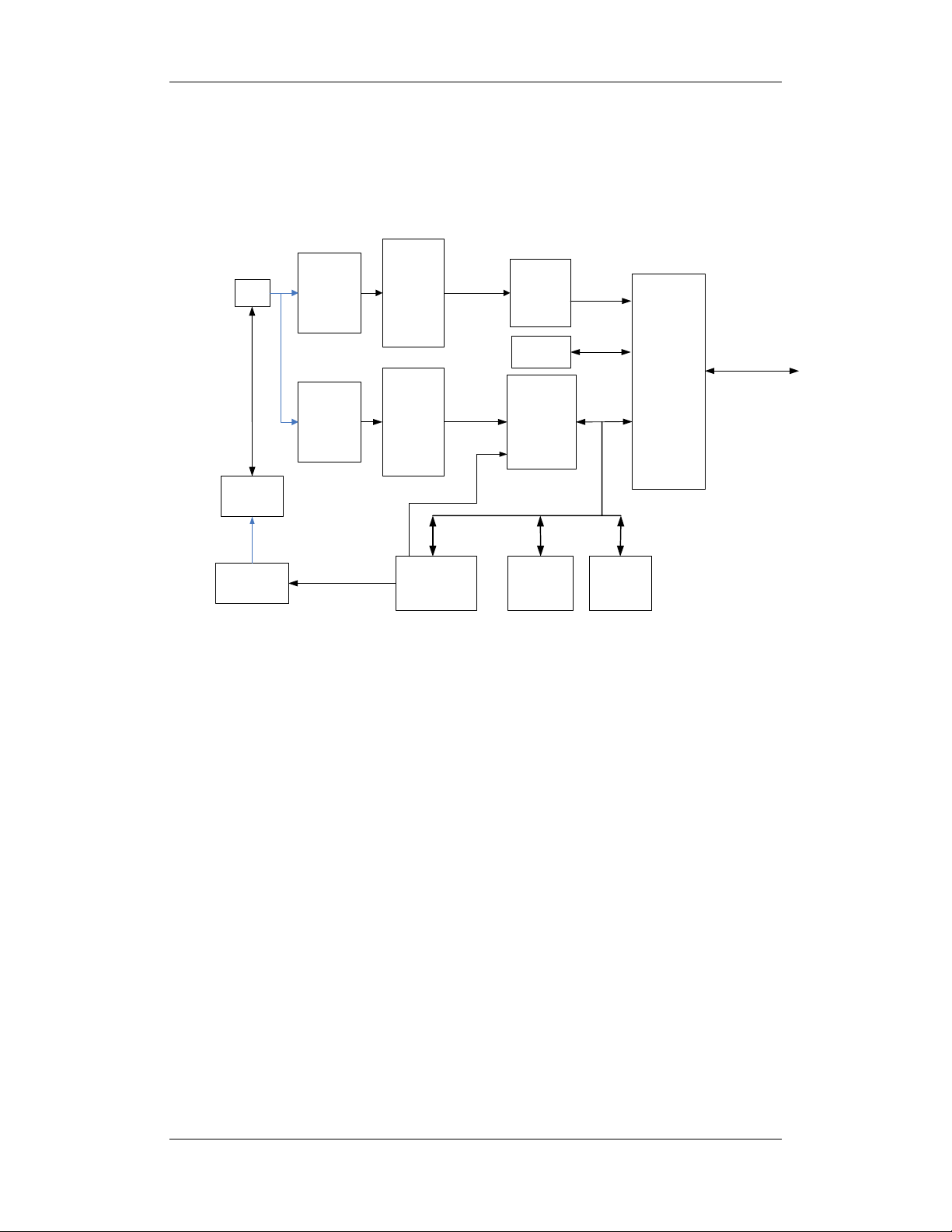

2.3.1 Main Board

The main board provides resources and supports for the overall system. It controls LCD,

LED, keyboard, speaker and recorder. It also enables to communicate with parameter

modules and connectors.

2.3.1.1 Principle Diagram

Watchdog

Ethernet

Nurse Call

Speaker

PHY

RTL8201

CPU

Audio process

circuit

RTC E2PROM

SPI

Serial port 0

RS232 IC

RS232

Serial port 1: NIBP

FlashSDRAM

FPGA

1.5V

Linear power

3.3V

5.0V

12V

LCD

LED

KEY

2.3.1.2 Function Description

The main board communicates with all the parameter modules and the recorder through

FPGA extended serial port.

The main board supplies information through FPGA for the key&display board to display; it

detects the keys and implements user interface.

The main board controls the alarm indicator via FPGA and the signal wire is adapted from

key&display board.

The main board controls the speaker to give audible alarm, key tones and Pitch Tone.

The main board provides nurse call connector, network connector and R232 connector.

The real-time clock is implemented by the RTC chip. The RT clock is powered according to

the priority of AC mains, battery, and button cell on the main board. This ensures the normal

working status of the clock in the event that AC mains and batteries are not available.

SDRAM is responsible for storing data temporarily and running programs. Flash serves as

the system memory and trend data memory whereas EEPROM services as the device

configuration memory.

Serial port 2: SpO2

Serial port 3: Temp

Serial port 4: Recorder

2-4

Page 17

2.3.2 Power Board

The power board converts the input power (AC mains or battery) to different working

voltages for other boards; it also has the function of charging battery.

2.3.2.1 Principle Diagram

AC

input

EMI

filter

controller

PWM

Rectifer &

filter

Flyback

converter

Current

detection

Coupler feedback

& isolation circuit

Rectifier

& filter

OVP&OPP

16.8V

DC/DC

converter

DC/DC

converter

Charging

circuit

DC/DC

converter

Switch

circuit

PCON

OVP&OCP

Battery

OVP&OCP

2.3.2.2 Functions

After the AC input reaches the power board, it flows through the EMI filter circuit and

rectifier and filter circuit. Then it is converted to a DC voltage, which is further converted to

the 16.8V DC voltage by the Flyback converter. The 16.8V DC voltage is the main input of

DC/AC converter and charging circuit; it is used to charge the lithium battery or lead-acid

battery, and also converted to 12V, 5V and 3.3V DC voltage by corresponding circuit

conversion. In case the AC input is unavailable, the battery can supply power for the DC/DC

converters to get 12V, 5V and 3.3V DC voltages, which are under the control of device

poweron/poweroff signal.

The 16.8V DC output is protected against over-voltage and over-power, the 12V and 3.3V

DC outputs are protected against over-voltage, short-circuit and over –current, the 5V DC

output is protected against over-voltage and short-circuit.

Two power boards are developed for the lead-acid battery and lithium battery. Each board

demonstrates the battery types it supports via the main board connector, facilitating the main

unit to process information such as battery capacities. The power board charges the battery

merely under AC input. The monitor runs on AC mains if both AC mains and battery are

available.

12V

output

5V

output

3.3V

output

2-5

Page 18

2.3.3 Key&displays Board

The key&displays board provides the user’s interface. The LCD module, 7-segment digital

display, LED indication lamp and keys are integrated on the board.

2.3.3.1 Principle Diagram

LCD signal

ADV

3.3V

VSB

FSTN LCD

module

Key

matrix

3.3V

disable

Switch

LED

CPLD

Start-up

circuit

2.3.3.2 Functions

The LCD module has the function of adjusting the contrast and brightness in 10 levels,

displaying menus, trend data and Pleth waveform.

The 7-segment digit displays are used to display systolic pressure, diastolic pressure, mean

pressure/cuff pressure, SpO

The AC indicator is driven by the ADV output from the power board whilst the working

status indicator (built in the Power On/Off key) is driven by 3.3V voltage. The battery

indicator is jointly controlled by the flash control signal, ADV signal and /BC signal.

The keypad consists of the power ON/OFF key and the other 11 functional keys.

, PR, Temp and so forth.

2

LED&KEY

detection

2-6

Page 19

2.3.4 Parameter Boards

2.3.4.1 SpO2 Module

The principle diagram of SpO2 module is shown below:

/RST

WATCHDOG

WDI

DRIVE DAC

LED DRIVE

CIRCUITRY

CPU

DRAM

FLASH

Isolated Serial

In/Output Port

4KV Isolated

Power

Supply

+3.3V

+5V

-5V

HOST

+12V

SENSOR

GAIN CONTROL

CIRCUITRY

PROGRAMMABLE GAIN

CIRCUITRY

OFFSET DAC

OFFSET

AMPLIFIER

A/D

CONVERTER

The SpO2 sensor collects the red and infrared light signal transmitting through the finger or

toe which is pulsing and process the collected signal to get the measured result. The drive

circuit of the LED and the gain of the amplifying circuit should be controlled according to the

perfusions and transmittances of the tested objects.

2-7

Page 20

2.3.4.2 NIBP Module

The principle diagram of NIBP module is shown below:

CUFF

PRESSURE

SENSOR

FOR

PROTECT

PRESSURE

SIGNAL

AMPLIFIED

CIRCUITS

FOR

PROTECT

OVER

PRESSURE

PROTECT

CIRCUIT

WATCHDO

G

ASYNCHRONOUS

SERIAL

COMMUNICATION

CPU

PRESSURE

SIGNAL

AMPLIFIED

CIRCUITS

MOTOR CONTROL

FEEDBACK SIGNAL

Windpipe

Valve and Air

Pump

PRESSURE

SENSOR

The NIBP is measured based on the pulse vibration principle. Inflate the cuff which is on the

forearm till the cuff pressure blocks the arterial blood, and then deflate the cuff according to a

specified algorithm. While the cuff pressure is decreasing, the arterial blood has pulses,

which are sensed by the pressure transducer in the cuff. Consequently, the pressure transducer

connected with the windpipe of the cuff, generates a pulsation signal, which is then processed

by the NIBP module to get the NIBP value.

NIBP values are based on the oscillometric method of noninvasive blood pressure

measurement and correspond to comparisons with auscultative values (applied to adults and

pediatrics elder than 3 years) and intra-arterial values (applied to neonates and pediatrics

younger than 3 years) within ANSI/AAMI SP10 Standards for accuracy (a mean difference of

± 5 mmHg, and a standard deviation of < 8 mmHg).

PRESSURE

SIGNAL

PUMP AND

VALVES

CONTROLED

CIRCUITS

A/D

CONVERTER

FLASH

DRAM

2-8

Page 21

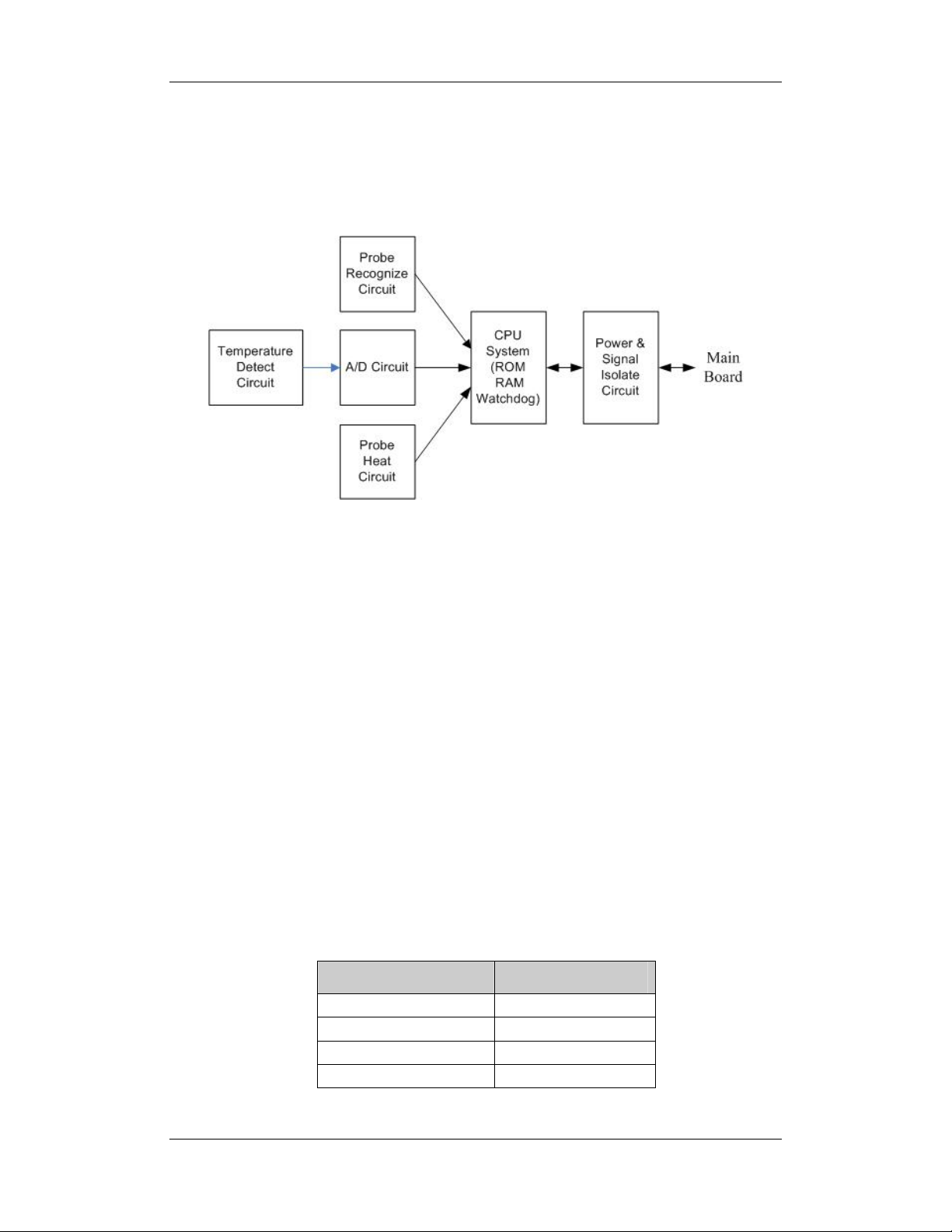

2.3.4.3 Temp Module

The principle diagram of Temp module is shown below:

Normally, the sensor used for measuring temperature is a thermistor. The resistance of a

given thermistor is nonlinearly relative to the temperature. Thus, the resistance of a

thermistor can be conversed into temperature. By applying given field current to the

thermistor, its resistance can be easily obtained by measuring the voltage on the thermistor.

2.3.5 Recorder

The recorder receives data from the main board and then sends them to the thermal printhead

for printing. The recorder has a hardkey(starting/stopping recordings) and a green LED on its

front.

2.3.6 Bar Code Scanner

The bar code scanner enables to read the one-dimensional and two-dimensional bar codes,

simplifying patient admit. The bar code scanner communicates with the monitor and gets

power supply to the power source via the serial ports. The scanner’s serial port is defined as

follows:

PIN Definition

2 Barcode_RX

3 Barcode_TX

5 GND

9

VCC(5VDC)

2-9

Page 22

The monitor’s serial port is defined as follows:

PIN Definition

2 DPM 3_TX

3 DPM 3_RX

5 GND

9

VCC(5VDC)

Basic settings of the bar code scanner are listed in the table below:

Bar code scanner Factory default

Host Parameters

Baud Rate 9600 9600

Data Bits 8 8

Stop Bits 1 1

Calibration bit 0 0

Handshaking None None

User Parameters

Beeper Tone Medium Medium

Beeper Volume Medium High

Trigger Mode Level Auto Aim

Parameter Scanning Disable Enable

Data Format

Prefix Value 7013 <CR><LF> 7013 <CR><LF>

Suffix 1 Value

7013 <CR><LF> 7013 <CR><LF>

Suffix 2 Value

Scan Data Transmission

Format

<PREFIX><DATA><SUFFIX

1><SUFFIX 2>

Data only

You shall program the bar code scanner to perform various functions.

To change parameter settings, scan the following bar codes in sequence.

1. Set Default Parameter

2-10

Page 23

2. Beeper Volume

3. Trigger Mode

4. Scan Data Transmission Format

5. Disable Parameter Scanning

2-11

Page 24

FOR YOUR NOTES

2-12

Page 25

3 Testing and Maintenance

3.1 Introduction

To ensure the monitor always functions normally, qualified service personnel should perform

regular inspection, maintenance and test. This chapter provides a checklist of the testing

procedures for the monitor with recommended test equipment and frequency. The service

personnel should perform the testing and maintenance procedures as required and use

appropriate test equipment.

The testing procedures provided in this chapter are intended to verify that the monitor meets

the performance specifications. If the monitor or a module fails to perform as specified in any

test, repairs or replacement must be done to correct the problem. If the problem persists,

contact our Customer Service Department.

CAUTION

z All tests should be performed by qualified service personnel only.

z Care should be taken to change the settings in the [MAINTAIN] menu to avoid loss

of data.

z Service personnel should acquaint themselves with the test tools and make sure

that test tools and cables are applicable.

3-1

Page 26

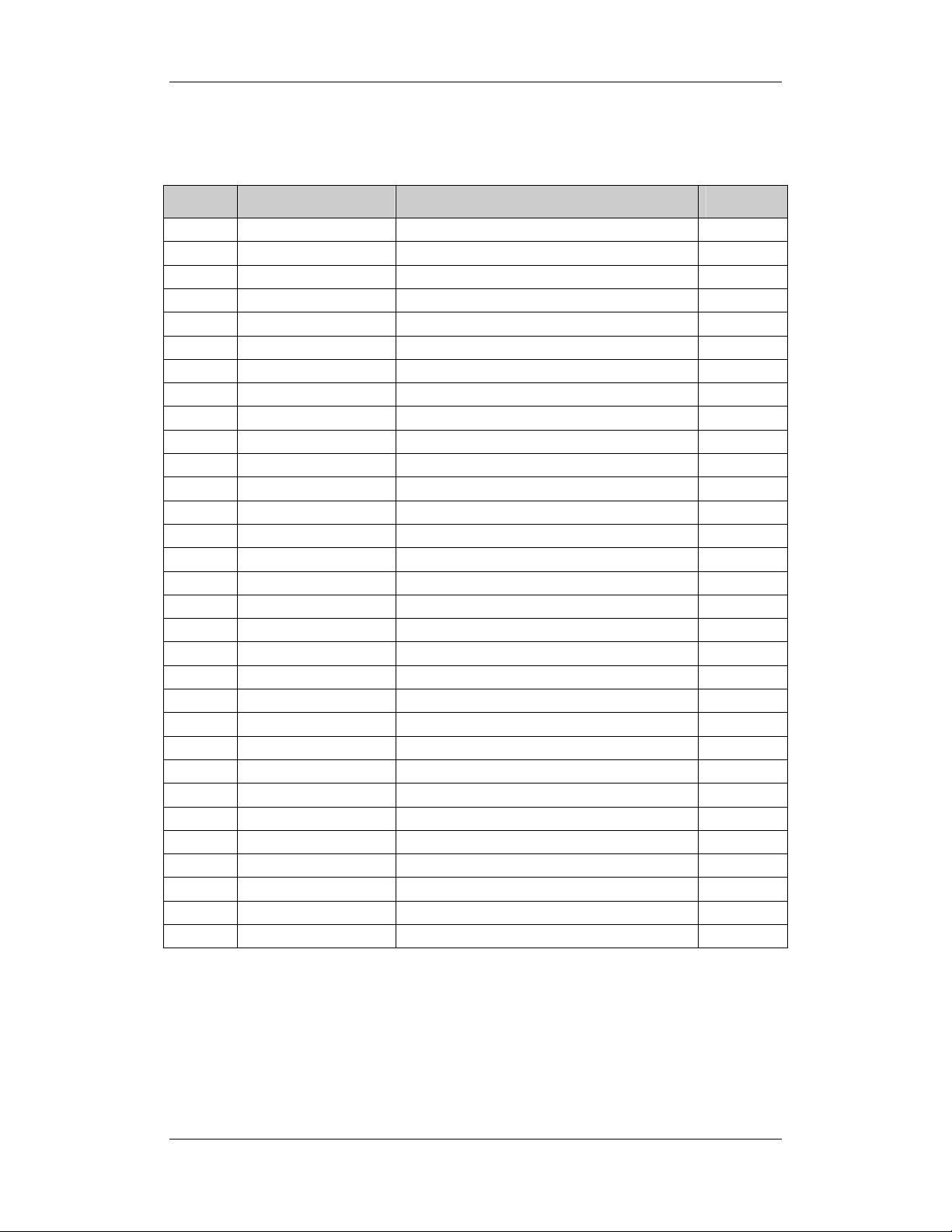

3.1.1 Recommended Frequency

Check/Maintenance Item Frequency

Visual test When first installed or after reinstalled.

Power on test 1. When first installed or after reinstalled.

2. Following any maintenance or the replacement of

any main unit parts.

NIBP tests

SpO2 test /

Temp test /

Analog output test /

Bar code scanner test /

Electrical safety tests

Accuracy test

Leakage test

Calibration

Performance test IBP tests

Pressure

calibration

Enclosure leakage

current test

Earth leakage

current test

Patient leakage

current test

Patient auxiliary

current test

1. If the user suspects that the measurement is

incorrect.

2. Following any repairs or replacement of respective

module.

3. At least once every two years.

If the user suspects that analog output or bar code

scanner is abnormal.

1. Following any repair or replacement of the power

module.

2. At least once every two years.

Recorder check / Following any repair or replacement of the recorder.

3.2 Visual test

Inspect the equipment for obvious signs of damage. The test is passed if the equipment has no

obvious signs of damage. Follow these guidelines when inspecting the equipment:

Carefully inspect the case, the display screen and the buttons for physical damage.

Inspect all external connections for loose connectors, bent pins or frayed cables.

Inspect all connectors on the equipment for loose connectors or bent pins.

Make sure that the labels on the equipment are clearly legible.

3-2

Page 27

3.3 Power-On Test

This test is to verify that the monitor can power up correctly. The test is passed if the monitor

starts up by following this procedure:

1. Insert the lead-acid batteries or lithium battery in the battery compartment and connect

the monitor to the AC mains; the AC mains LED and battery LED light.

2. Press the Power On/Off button to turn on the monitor. The operating status LED which

is built in the Power On/Off button lights up.

3. The system gives a beep indicating the self test related to alarm sounds is passed and all

the LEDs on the front panel light up. At the same time, the technical alarm lamp turns

yellow, and then turns off, indicating that the self test related to alarm lamps is passed.

4. The start-up screen disappears; the monitor enters the main screen and start-up is

finished.

3.3.1 NIBP Tests

NIBP Accuracy test

Tools required:

T-shape connector

Appropriating tubing

Balloon pump

Metal Vessel with volume 500 ± 25 ml

Reference manometer with accuracy 1 mmHg

Follow this procedure to perform the test:

1. Connect the equipment as shown above.

Monitor

NIBP cuff connector

Manometer

Tubing

Balloon pump

Metal vessel

3-3

Page 28

r

2. Before inflating the metal vessel, the reading of the manometer should be 0. If not,

disconnect the airway and reconnect it until the readings is 0.

3. Press the MENU key; select [MAINTAIN >>]→[NIBP CALIBRATE] to start NIBP

calibration. Compare the manometer values with the displayed values. The difference

should be no greater than ±3mmHg (±0.4kPa).

4. Raise the pressure in the metal vessel to 50 mmHg with the balloon pump. Repeat step3.

5. Raise the pressure in the metal vessel to 200 mmHg with the balloon pump. Repeat

step 3.

Contact our service personnel if the difference between any manometer value and the

displayed value is greater than ±3 mmHg.

NOTE

z You can use an NIBP simulator to replace the balloon pump and the reference

manometer to perform the test.

NIBP Leakage Test

Tools required:

NIBP cuff for adult patient

Approprating tubing

Cylinder

Follow this procedure to perform the test:

1. Set [PATIENT TYPE] to [ADU].

2. Connect the NIBP cuff with the NIBP connector on the monitor.

3. Apply the cuff to the cylinder as shown below.

Monitor

NIBP cuff connecto

4. Press the MENU key; select [MAINTAIN >>]→ [NIBP LEAK TEST].

5. The cuff automatically deflates in 20s, which means NIBP leakage test is completed.

Air tubing

Cylinder

Cuff

6. If the system does not leak, no message will be displayed in the technical alarm

area/prompt area. If it leaks, the message [PNEUMATIC LEAK] will be displayed. In

this case, check for loose connection and perform the test again.

Please contact our service personnel if the NIBP test fails.

3-4

Page 29

3.3.2 SpO2 Test

Tool Required: SpO2 simulator.

For the monitor equipped with Mindray DS SpO2 module, BIO-TEK Index-2

SpO2 simulator is recommended.

For the monitor equipped with Nellcor SpO2 module, SRC-MAX SpO2 simulator

is recommended.

For the monitor equipped with Masimo SpO2 module, BIO-TEK Index-2 SpO2

simulator is recommended.

3.3.2.1 SpO2 Test under Normal Condition

1. Connect the SpO2 simulator to the SpO2 sensor.

2. Select the model and the manufacturer of the SpO2 module under test, and then

configure the SpO2 simulator as follows: SpO2 96%; PR 80 bpm.

3. The displayed SpO2 and PR values should be within the ranges listed below.

3.3.2.2 SpO2 Test in Motion Mode

1. Connect the SpO2 simulator to the SpO2 sensor.

2. Select the model and the manufacturer of the SpO2 module under test; take

measurement in the motion mode preset by the SpO

3. The displayed SpO2 and PR values should be within the ranges listed below.

Manufacturer SpO2 sensor SpO2 PR (bpm)

512B, 512 D, 512E, 512G, 512F, 512H,

518B, ES-3212-9/envitec, MAX-A,

MAX-P,

MAX-I, DS-100A, OXI-P/I, 520A,

Mindray DS

520P,

520I, 2211-1 Envite, 2211-2 Envite,

2211-5 Envite

520N, MAX-N, OXI-A/N, 2211-6

Envite

simulator.

2

96%±2%

96%±3%

80±3

3-5

Page 30

Manufacturer SpO2 sensor SpO2 PR (bpm)

96%±3%

(without motion)

LNCS-NeoPt-L, LNCS Neo-L

Masimo

LNCS Inf-L , LNCS-Pdt,

LNCS-Adtx ,LNCS DC-I,LNCS DC-I

Pt

96%±3%

(with motion)

96%±2%

(without motion)

96%±3%

80±3 bpm

(without motion)

80±5 bpm

(with motion)

(with motion)

MAX-A, MAX-P, MAX-I, 96%±2%

Nellcor

DS-100A, OXI-A/N (Adult), OXI-P/I,

MAX-N

96%±3%

80±3 bpm

OXI-A/N (Neonate) 96%±4%

NOTE

z The SpO

properly. It cannot be used to verify the accuracy of the pulse oximeter or the SpO

sensor. To verify the accuracy, clinical tests are required.

Please contact our service personnel if the SpO

simulator can only be used to verify that the pulse oximeter operates

2

test fails.

2

3.3.3 Temp Test

Tool required: thermostatic oil tank, HART 7102 recommended.

1. Set the temperature of the oil tank to 37℃ and conduct the test after the temperature

stabilizes.

2

2. Set the [TEMP TYPE] to [MONITOR]. Remove the Temp probe from the probe

sheath and then put it into the oil tank.

3. Wait till the Temp value displayed on the monitor stabilizes. Verify that the displayed

value is 37±0.2 .℃

Please contact our service personnel if the Temp test fails.

3-6

Page 31

3.4 Nurse Call Performance Test

Tools required: Multimeter

1. Connect the nurse call cable to the analog output connector.

2. Trigger a psychological alarm or a technical alarm.

3. Select [NURSE CALL>>] in the [MAINTAIN] menu. In the [NURSE CALL] menu,

select [ALM LEV] and [ALM TYPE]; set [CONTACT TYPE] to [NORMAL

OPEN].

4. In the [NURSE CALL >>] menu, set [SIGNAL TYPE] to [PULSE]. Trigger an alarm

and measure the contact output with the multimeter. The output should be square waves

with an interval of 1s,

5. In the [NURSE CALL >>] menu, set [SIGNAL TYPE] to [CONTINUUM]. Trigger

an alarm and measure the contact output with the multimeter. The output should be

continuous high level.

Please contact our service personnel if the nurse call test fails.

3.5 Bar Code Scanner Test

Tools required: None

1. Aim the bar code scanner at the target bar code. Adjust the field of view to capture the

bar code.

2. Hold the trigger until the bar code scanner gives a beep, indicating the bar code is

successfully decoded. Meanwhile, the indication lamp turns to green and scanned

characters are displayed on the monitor.

Please contact our service personnel if the bar code scanner fails to work normally.

3-7

Page 32

3.6 Electrical Safety Tests

WARNING

z Electrical safety tests are a proven means of verifying the electrical safety of the

monitor. They are intended for determining potential electrical hazards. Failure to

find out these hazar ds timely may cause p e r so n nel injury.

z Commercialy available test equipment such as safety analyzer can be used for

electrical safety tests. Be sure that the test equipment can be safely and reliably

used with the monitor before use. The service personnel should acquaint

themselves with the use of the test eqipment.

z Electrical safety tests should meet the requiremnets of the latest editions of EN

60601-1 and UL60601.

z These electrical safety tests do not supercede local requiremnets.

z All devices using the AC mains and connected to medical equipment within patient

environments must meet the requiremnets of the IEC 60601-1 medical electrical

systems standard and should be put under electrical safety tests at the frequency

recommended fo r the monitor.

Electrical safety tests are intended to timely check the potential electrical hazards to the

patient, operator or service personnel arising from the equipment. Electrical safety test should

be performed under normal ambient conditions of temperature, humidity and atmospheric

pressure.

The electrical safety test plan described hereunder takes 601 safety analyzer as an example.

Different safety analyzers may be used in different areas. Be sure to choose applicable test

plan.

3-8

Page 33

Connection of the equipments is shown below:

Tools required:

Safety analyzer

Isolation transformer

3.6.1 Enclosure Leakage Current Test

1. Connect the 601 safety analyzer to an AC power supply (264V, 60 Hz).

2. Connect SUM terminal of the applied part connection apparatus to RA input terminal of

601 safety analyzer, another terminal to the applied part of EUT.

3. Connect the EUT to the 601 analyzer’s auxiliary output connector by using a power

cord.

4. Attach on end of the red lead to the red input terminal of the analyzer, and the other end

to tinsel over the enclosure of the EUT.

5. Power on the 601 safety analyzer and then press the “5-Enclosure leakage” button on the

analyzer’s panel to enter the enclosure leakage test screen.

6. Under normal condition, the enclosure leakage current should be no greater than 100µA.

Under single fault condition, it should be no greater than 300µA.

3-9

Page 34

3.6.2 Earth Leakage Current Test

1. Connect the 601 safety analyzer to an AC power supply (264V, 60 Hz).

2. Connect the SUM terminal of the applied part connection apparatus to RA input

terminal of 601 safety analyzer, another terminal to the applied part of EUT.

3. Connect the EUT to the 601 analyzer’s auxiliary output connector by using a power

cord.

4. Power on the 601 safety analyzer and then press the “4-Earth leakage” button on the

analyzer’s panel to enter the earth leakage test screen.

5. Under normal condition, the earth leakage current should be no greater than 300µA.

Under single fault condition, it should be no greater than 1000 µA.

3.6.3 Patient Leakage Current Test

1. Connect the 60 safety analyzer to an AC source (264V, 60Hz).

2. Connect the SUM terminal of the applied part connection apparatus to RA input

terminal of 601 safety analyzer, another terminal to the applied part of EUT.

3. Connect the EUT to the 601 analyzer’s auxiliary output connector by using a power

cord.

4. Power on the 601 safety analyzer and then press the “6-Patient leakage” on the 601

analyzer’s panel.

5. Repeatedly press the “APPLIED PART” button to measure AC and DC leakage

alternatively. DC leakage reading is followed by “DC”.

6. Under normal status, the patient leakage current should be no greater than 10 µA. Under

single fault condition, it should be no greater than 50µA.

3.6.4 Patient Auxiliary Leakage Current Test

1. Connect the 601 safety analyzer to an AC source (264V, 60Hz).

2. Connect the equipment under test (EUT) to the analyzer’s auxiliary output connector by

using a power cord.

3. Connect the sensors of the applied part to the applied part connection apparatus, whose

RA-P terminal is connected to 601 safety analyzer’s RA terminal and SUM terminal to

601 safety analyzer’s LA terminal. RA terminal is switched on.

3-10

Page 35

4. Power on the 601 safety analyzer and then press the “8-Patient Auxiliary Current Test”

button on the analyzer’s panel to enter the patient auxiliary current test screen.

5. Repeatedly press the “APPLIED PART” button to measure AC and DC leakage

alternatively. DC leakage reading is followed by “DC”.

6. Under normal status, the patient auxiliary leakage current should be no greater than 10

µA. Under single fault condition, it should be no greater than 50µA.

Please contact our service personnel if the electrical safety test fails.

3.7 Recorder Check

1. Print SpO

clear.

2. Set the recorder to some problems such as out of paper, paper jam and etc, the monitor

should give corresponding prompt messages. After the problem is removed, the recorder

should be able to work correctly.

3. Set the recorder to print trend data. Check that the recorder can give printouts

accordingly.

Please contact our service personnel if the recorder test fails.

Pleth waveforms. The recorder should print correctly and printout should be

2

3.8 Program upgrade

You can upgrade the monitor by downloading the upgrade software through network. At the

same tine, you can view the upgrade status log. The upgrade software can directly run on a

portable PC or desktop PC. Through the network or by connecting the monitor to a PC via a

network cable, you can upgrade the following programs:

Bootstrap program

System program

Bar code recognition configuration

Multiligual library

General configurations (including passwords, company logo)

System functional configuration

FPGA program

Parameter module programs: SpO2 module (Mindray DS), NIBP module and Temp

module.

Please refer to help and instructions for program upgrade for details.

3-11

Page 36

CAUTION

z Disconnect the monitor from the patient and make sure the important date are

saved before upgrade.

z Do not shut down or power off the equipment when upgrading the bootstrap

program. Otherwsie, it may cause the equipemnt to break down.

z Programs upgrade should be performed by qualified service personnel only.

NOTE

z After upgrading the boot program, re-upgrade the system program and other

programs to ensure compatibility.

z Make sure the version of the upgrade package is your desired one. If yo u want to

obtain the latest upgrade package, contact our Customer Service Department.

3-12

Page 37

4 Troubleshooting

4.1 Introduction

In this chapter, monitor problems are listed along with possible causes and recommended

corrective actions. Refer to the tables to check the monitor, identify and eliminate the

troubles.

The troubles we list here are frequently arisen difficulties and the actions were recommended

can correct most problems, but not all of them. For more information on troubleshooting,

please contact our Customer Service Department.

4.2 Part Replacement

Printed circuit boards (PCBs), major parts and components in the monitor are replaceable.

Once you isolate a PCB you suspect defective, follow the instruction in 5 Repair and

Disassembly to replace the PCB with a known good one and check that the trouble disappear

or the monitor passes all performance tests. If the trouble remains, exchange the replacement

PCB with the original suspicious PCB and continue troubleshooting as directed in this

chapter. Defective PCB can be sent to us for repair.

To obtain information on replacement parts or order them, please refer to 6 Parts.

4.3 Monitor Status Check

Some troubleshooting tasks may require you to identify the hardware version and status of

your monitor.

1. To view system software version and FPGA version, select [MENU] →

[MAINTAIN>>] → [VERSION].

2. To view the monitor’s total runtime, select [MENU] → [MAINTAIN>>] →

[VERSION]→[TOTAL RUN TIME>>].

3. To view modules’ software version, select [MENU] → [MAINTAIN>>]→

[VERSION] →[MODULE VERSION>>].

4-1

Page 38

4.4 Technical Alarm Check

Check whether technical alarm message is displayed on the monitor before troubleshooting.

If an alarm message is presented, eliminate the technical alarm first and troubleshoot in

accordance with the following instructions. For further information on technical alarm

message, possible cause and corrective action, please refer to the monitor’s Operation

Manual.

4.5 Troubleshooting Guide

4.5.1 Power On/Off Failures

Symptoms Possible Cause Corrective Actions

The monitor fails

to start. AC LED

or battery LED

does not light

AC mains not connected

or battery too low.

Power supply protection

Cables defective or

poorly connected

Power switch & LED

board defective

Power module defective Replace the power module

Main board Defective Replace the main board

Check whether AC mains is properly connected

or battery capacity is sufficient

Refer to 4.5.8Power Supply Failures.

1. Check whether the cables from power switch

& LED board to button board, button board to

main board, and power module to main board are

correctly connected.

2. Check whether cables and connectors are

damaged.

Replace the power switch & LED board

4-2

Page 39

4.5.2 Display Failure

Symptoms Possible Cause Corrective Actions

The display is

black or blank, but

the monitor still

works correctly.

overlapped or

distorted

Cables defective or

poorly connected

Backlight defective Replace LCD.

LCD defective Replace LCD.

FPGA error Update or upgrade FPGA. Images

Cables defective or

poorly connected

1. Check whether cables from the display to the

main board are correctly connected.

2. Check whether cables and connectors are

damaged.

1. Check whether the cable from the display to

the main board is correctly connected.

2. Check whether the cables and connectors are

damaged.

4.5.3 LED Digital Display & Indication Lamp Failure

Symptoms Possible Cause Corrective Actions

LED digital

display or

indication lamp

display

abnormally.

Signal wires damaged 1. Check whether LED signal wires are correctly

connected

2. Check whether cables and connectors are

damaged

LED digital display or

indication lamp damaged

Replace LED digital display or indication lamp

4.5.4 Alarm Problems

Symptoms Possible Cause Corrective Actions

The alarm lamp is

not light or

extinguished but

alarm sound is

issued

Cables defective or

poorly connected

Alarm LED board

failure

Button board failure Replace the button board.

Main board failure Replace the main board.

1. Check whether cables from alarm LED board to

button board and button board to main board are

properly connected.

2. Check that connecting cables and connectors are

not damaged.

Replace the alarm LED board.

4-3

Page 40

Symptoms Possible Cause Corrective Actions

No alarm sound is

issued but alarm

lamp lights

properly

Audio alarm

disabled

Cable defective or

poorly connected

Audio program error

identified in the

system program

Speaker failure Replace the speaker

Main board failure Replace the main board

Select [MENU] → [MAINTAIN>>] → [USER

MAINTAIN >>] → enter the required password. In

the pop-up menu, set the [MIN ALARM VOL] to a

value other than zero.

1. Check whether the cable between speaker and

main board is properly connected.

2. Check whether the connecting cables and

connectors are damaged.

Upgrade system programs

4.5.5 Button Failure

Symptoms Possible Cause Corrective Actions

Buttons do not

work

Cables defective or

poorly connected

Button board failure Replace button board

1. Check whether the cable between button board

and main board is properly connected

2. Check whether connecting cables and connectors

are damaged

4.5.6 Recorder Failures

Symptoms Possible Cause Corrective Action

No printout

Recorder module

disabled

Paper reversely

installed

Cable defective or

poorly connected

Recorder power

supply failure

Recorder failure Replace the recorder

1. Check whether the recorder status LED is on

2. If yes, please reset the recorder. Otherwise, check

for other possible causes.

Re-install the paper roll

1. Check whether the cable between recorder and

main board is appropriately connected

2. Check whether connecting cables and connectors

are damaged

Check if the power module outputs 5V DC and 12V

DC correctly.

4-4

Page 41

Symptoms Possible Cause Corrective Action

Poor print quality

or paper not

feeding properly

Paper roll not

properly installed

Dirty thermal print

head

Recorder failure Replace the recorder

Stop the recorder and re-install the paper roll

1. Check the thermal print head and the paper roller

for foreign matter.

2. Clean the thermal print head with an appropriate

detergent

4.5.7 Interface Failures

Symptoms Possible Cause Corrective Action

No nurse call signals are

issued

Bar code scanner unable

to be used

Incorrect function

settings

Main board failure Replace the main board

Bar code scanner failure Please refer to 4.5.11Bar Code Scanner

Serial port failure Replace the main board

Select [MENU] → [MAINTAIN>>] →

[NURSE CALL >>] → select desired

nurse call output.

Failures.

4.5.8 Power Supply Failures

Symptoms Possible Cause Corrective Action

Fluctuating battery

voltage

Battery fails to be

fully charged

Battery failure Replace battery

Cable defective or

poorly connected

Power board failure Replace the power board

Battery failure Replace battery

Cable defective or

poorly connected

Power board failure Replace the power board

1. Check whether the cable between battery

interface board and power module is

correctly connected.

2. Check whether cables and connectors are

damaged

1. Check whether the cable between battery

interface board and the power module is

properly connected

2. Check whether the connecting cables and

connectors are damaged

4-5

Page 42

Symptoms Possible Cause Corrective Action

Battery unable to be

recharged

No +3.3 V output

No +5.0 V output

No +12 V output

Battery damaged Replace battery and recharge the replacement

battery. If the replacement battery can be

recharged, the original one fails.

Cable defective or

poorly connected

Power board failure Replace the power board

1. Power supply

protection

2. Power board failure

1. Check whether the cable between battery

interface board and the power module is

properly connected

2. Check whether the connecting cables and

connectors are damaged

1. Turn off the monitor then restart it.

2. If the problem remains, disconnect the AC

mains for 5 s and reconnect it, then restart the

monitor.

3. If the problem still remains, replace power

board.

NOTE

z When the power module has a failure, it may cause problems to other components,

e.g. the monitor suddenly shuts downs during the start-up, as the power module

may have a power supply protection. In this case, troubleshoot the power module

as per the procedure described in the table above.

z Parameter module, recorder and bar code scanner are powered by the power

module. In the event that a componet malfunctions, check if the operating voltage

is correct. Refer to 2 Theory of Operation for the operating voltage and

measurement point of each component.

4-6

Page 43

4.5.9 Network related problems

Symptoms Possible Cause Corrective Actions

The monitor cannot be

connected to the CMS.

Frequent dropouts and

network

disconnections

No connection to LAN 1. Confirm whether the cables and

connectors are in good condition and whether

the network is correctly connected.

2. Check whether the hub or switch facilities

is correctly configured

Improper LAN cable

connection

Incorrect IP address

configuration

Check LAN cable connection. LAN cable

shall not be longer than 50 m.

Check for IP address conflict. Reconfigure IP

address.

4.5.10 Software Upgrade Problems

Symptoms Possible Cause Corrective Actions

Bootstrap upgrade

fails

Program upgrade fails

Power failure or

unintended power off

during bootstrap upgrade

Incorrect network

connection

Wrong upgrade package

has been downloaded

Incorrect IP address

configuration

Return the main board to the factory for

repair

1. Check that network connector on the

monitor is used.

2. Make sure that the hub or the switcher runs

normally. Check whether net cables are of

the right type and have been connected

correctly.

Upgrade package shall be .mup files. Select

desired package according to the program

you want to upgrade.

Configure a fixed IP address in range C as

specified for the monitor. We recommend not

to upgrade a program when the monitor is

connected to a network with multiples PCs.

4-7

Page 44

4.5.11 Bar Code Scanner Failures

Symptoms Possible Cause Corrective Actions

Bar code scanner does

not work

Bar code scanner

cannot decode the

target bar codes

Scanned characters

incorrectly displayed

on the monitor

Bar code scanner not

powered on

Incorrect interface cables

used

Loose Interface cables Make sure that interface cables are fixed

Bar code scanner not

programmed based on

bar code categories

Unreadable bar code Make sure the bar code is flawless and check

Scanner and bar code at

improper distance and

angle

The monitor’s bar code

recognition

configuration does not

meet the format of the

target bar code.

Scanner serial port

output incorrectly set

Select [MAINTAIN >>] → [USER

MAINTAIN >>] → enter required user

password; set [BARCODE POWER] to

[ON] in the pop-up menu to switch on the

bar code scanner.

Replace interface cables

Make sure to program the bar code scanner

so that it can decode the bar codes of

specified types.

if bar codes of the same type can be decoded.

Aim the scanner at the bar code and adjust

the distance between the scanner and the bar

code.

Download correct bar code recognition

configuration for the monitor.

Configure the scanner’s serial port output

according to the host serial port settings.

4.5.12 NIBP Measurement Failures

Symptoms Possible Cause Corrective Actions

Unable to start NIBP

measurement

inflation/deflation

failure

Cables detective Check whether cables between NIBP module

and the main board are in good condition.

Main board failure Replace the main board.

Pump or valve damaged Replace NIBP module. Cuff

Air tubing occluded Replace the air tubing.

4-8

Page 45

4.5.13 SpO2 Measurement Failure

Symptoms Possible Cause Corrective Actions

Unable to measure

SpO2

SpO2 sensor failure Replace the SpO2 sensor.

Cables defective Check whether the cable between SpO2

module and the main board is in good

condition.

SpO2 module failure Replace SpO2 module.

Main board failure Replace the main board.

4.5.14 Temp Measurement Failures

Symptoms Possible Cause Corrective Actions

Unable to measure

patient temperature.

Temp probe damaged Replace the Temp probe.

Cables detective Check whether the cable between Temp

module and the main board is in good

condition.

Main board failure Replace the main board

4-9

Page 46

FOR YOUR NOTES

4-10

Page 47

5 Repair and Disassembly

5.1 Tools

During disassembly and replacement, the following tools may be required:

Philips screwdrivers

Wire cutters

Sharp nose pliers

M6 spanner

5.2 Preparation for Disassembly

Before disassembling the monitor, stop monitoring the patients, turn off the monitor and

disconnect all the accessories and peripheral devices.

Caution

z Before disassembling the monitor, be sure to eliminate the static charges first.

When disassembling the parts labeled with static-sensitive symbols, make sure you

are wearing electrostatic discharge protection such as antistatic wristband or

gloves to avoid damaging the equipment.

z Properly connect the cables or wires when reassembling the monitor to avoid short

circuit.

z When assembling the monitor, be sure to select proper screws. If an unfit screw is

tightened by force, the monitor may be damaged and the screw or the part may fall

off during use to cause unpredictable damage or human injury.

z Be sure to follow the correct sequence to disassemle the monitor. Otherwise, the

monitor may be damaged permanently.

z Be sure to disconnect all the cables before disassembling any parts. Be sure not to

damage any cables or connectors.

z Place the screws and parts removed from the monitor properly, avoiding avoid

falling off, tarnishing or losing the parts.

5-1

Page 48

5.3 Disassembly

5.3.1 Separating the Front and Rear Half of the Monitor

1. If the monitor is configured with Temp module,

Unscrew the two M3×6 crosshead screws with a screwdriver as shown in the figure

below.

Disconnect the wires from the PCBA as shown in the figure below.

Unscrew the four M3×20 crosshead screws with a screwdriver(102) as shown in

the figure below.

5-2

Page 49

2. If the device is not equipped with a Temp module,

Unscrew the four M3×20 crosshead screws directly with a screwdriver(102) as

shown in the figure below.

NOTE

z When separating the front and the rear part, use screwdriver(102) instead of

screwdriver (107) to unscrew the four M3×20 crosshead screws.

3. Release the clips on the front and rear housings; cut the cable tie of the LCD signal wire

with a wire cutter; disconnect the cables and air tubing connecting the front and the rear

housings; and then separate the front and the rear housings.

Clip

5-3

Page 50

NOTE

z Exercise care when separating the front and the rear housings. Be sure not to

damage the cables and connectors.

5.3.2 Disassembling the Front Housing Assembly

1. Unscrew the six M3×6 crosshead screws with a screwdriver and remove the button

board.

2. Unscrew the four M3×8 crosshead screws with a screwdriver; disconnect the flexible

cables on the button board; and then remove the LCD.

5-4

Page 51

3. Unscrew the three M3×6 crosshead screws with a screwdriver and take out the SpO

rack.

4. Unscrew the M3×6 screw with a screwdriver and take out the SpO

module.

2

Mindray DS SpO2

module

Masimo SpO

module Nellcor SpO2 module

2

2

5. Unscrew the plastic nut and take out the SpO

signal cable.

2

5-5

Page 52

5.3.3 Removing the Main Rack Assembly

1. Unscrew the two M3×6 crosshead screws with a screwdriver and take out the recorder

by unclenching the clips.

2. Remove the cables from the recorder and unscrew the M3×6 crosshead screw with a

screw driver.

3. Unscrew the five M3×6 crosshead screws with a screwdriver and take out the main rack

assembly.

5-6

Page 53

4. Provided that the device is configured with a Temp module, unscrew the three PT3×8

tapping screws with a screwdriver and then remove the Temp module.

5.3.4 Disassembling NIBP Module

1. Cut the cable tie with a wire cutter

2. Unscrew the three M3×6 crosshead screws with a screwdriver and take out the NIBP

rack.

5-7

Page 54

3. Unscrew the four M3×6 crosshead screws with a screwdriver and take out the NIBP

module.

5.3.5 Removing the Main Board

Disconnect all the cables connecting the main board and then take out the main board by

unscrewing the four M3×6 crosshead screws with a screwdriver.

5.3.6 Removing the Power Board

Pull out the cables that connect the power board and remove the power board by unscrewing

the three M3×6 crosshead screws with a screwdriver.

5-8

Page 55

5.3.7 Removing the Battery Assembly

1. If the monitor is equipped with the lead-acid battery assembly, unscrew the four M3×8

crosshead screws with a screwdriver.

2. If the monitor is equipped with the lithium battery assembly, unscrew the three M3×6

crosshead screws with a screwdriver.

5.3.8 Removing the Fan and Speaker

Cut the cable ties on the fan, speaker and the main rack; remove the fan cushion; unscrew the

three M3×15 crosshead screws with a screwdriver and remove the fan. The speaker can be

removed from the main rack directly.

5-9

Page 56

5.3.9 Removing the Power Socket

1. Remove the nut securing the grounding post with a spanner and take out the grounding

terminal of the power socket.

2. Unscrew the two M3×8 crosshead screws with a screwdriver and remove the power

socket.

5.3.10 Removing the Temp Module

1. Remove the Temp probe assembly first.

5-10

Page 57

2. Unscrew the two M3×6 cross head screws with a screwdriver and take out the cover

plate.

3. Unscrew the four M3×6 crosshead screws with a screwdriver and remove the Temp

module main board.

5-11

Page 58

5.3.11 Removing the SpO2 Module

1. Mindray DS SpO

2. For Masimo SpO

module needs not be removed.

2

module, remove the isolation power board by unscrewing the three

2

M3 nuts with sharp nose pliers; unscrew the three M3×6 crosshead screws with a

screwdriver; and then remove the SpO

board.

2

3. For Nellcor SpO

remove the isolation power board and the SpO

module, unscrew the M3×18 crosshead screw with a screwdriver; then

2

board.

2

5-12

Page 59

6 Parts

6.1 Main Unit

Exploded View

Parts List

SN P/N Description Qty

1 6006-30-39446 Front housing assembly 1

2

3 6006-30-39586 Rear housing assembly (with Temp module) 1

4 M04-000505--- Screw M3×20 4

5 M04-004012--- Crosshead screw M3×6 5

6006-30-39405

Main rack assembly (for lead-acid batteries) 1

6-1

Page 60

6.2 Main Rack Assembly (For Lead-acid Batteries)

Exploded View

6-2

Page 61

Parts List

SN P/N Description Qty

1 6006-20-39367 Main rack (for lead-acid batteries) 1

2 6006-30-39448 Lead-acid battery assembly 1

3 M04-004015--- Crosshead screw M3×8 4

4 6006-20-39385 Speaker and cables 1

5 6006-20-39379 Speaker spacer 1

6 6006-20-39464 Power board insulating plate 1

7 M04-004012--- Crosshead screw M3×6 16

8 6006-30-39478 Power board for lead-acid battery 1

9 M04-000106--- Bolt M3×7+8-6 2

10 M04-011002--- M3 nut with spring washer 2

11 0000-10-10996 Spring strip 2

12 6006-20-39387 Fan and cables 1

13 6006-20-39373 Fan rack 1

14 M04-051016-00 Crosshead screw M3×15 3

15 6006-20-39434 Fan spacer 1

16 0509-20-00098 Grounding terminal 1

17 M04-000405--- Crosshead screw M3×8 2

18 6006-20-39386 Power board AC input cable 1

19 6006-20-39421 External connector overlay 1

20 6006-20-39486 Battery bar setscrew 1

21 7000-20-24365 Battery baffle 1

22 6006-20-39485 Torsion spring 1

23 6006-20-39368 NIBP rack 1

24 630D-30-09121 630D NIBP unit 1

25 M04-021024--- Flat washer 4

26 6006-30-39352 Main board 1

27 6006-20-39451 Main board insulating plate 1

28 6006-20-39450 Key pad insulating plate 1

29 6006-20-39509 NIBP rack overlay 1

30 M04-021003--- Flat washer 1

31 M04-004504--- Spring washer 1

32 M04-004401 Stainless steel nut 1

6-3

Page 62

6.3 Main Rack Assembly (For Lithium Battery)

Exploded View

6-4

Page 63

Parts List

SN P/N Description Qty

1 6006-20-39416 Main rack (for lithium battery) 1

2 6006-30-39449 Lithium battery assembly 1

3 M04-004012 Crosshead screw M3×6 17

4 6006-20-39385 Speaker and cables 1

5 6006-20-39379 Speaker spacer 1

6 6006-20-39464 Power board insulating sheet 1

7 M04-011002--- M3 nut with spring washer 2

8 6006-30-39393 Power board for lithium battery 1

9 M04-000106--- Bolt M3×7+8-6 2

10 0000-10-10996 Spring strip 2

11 6006-30-39393 Power board 1

12 6006-20-39373 Fan rack 1

13 M04-051016-00 Crosshead screw M3×15 3

14 6006-20-39434 Fan spacer 1

15 0509-20-00098 Grounding terminal 1

16 M04-000405--- Crosshead screw M3×8 2

17 6006-20-39386 Power board AC input cable 1

18 6006-20-39421 External connector overlay 1

19 6006-20-39485 Battery baffle setscrew 1

20 6006-20-39486 Battery baffle 1

21 7000-20-24365 Torsion spring 1

22 6006-20-39368 NIBP rack 1

23 630D-30-09121 630D NIBP unit 1

24 M04-021024--- Flat washer 4

25 6006-30-39352 Main board 1

26 6006-20-39451 Main board insulating plate 1

27 6006-20-39512 Key pad insulating plate 1

28 6006-20-39509 NIBP rack overlay 1

29 M04-021003--- Flat washer 1

30 M04-004504--- Spring washer 1

31 M04-004401 Stainless steel nut 1

6-5

Page 64

6.4 Front housing Assembly

Exploded View

Parts List

SN P/N Description Qty

1 6006-20-39358 Front housing 1

2 6006-20-39520 Waterproof seal 1

3 6006-20-39372 Key pad 1

4 6006-20-39431 Key pad fixer 1

5 M04-021000--- Flat washer 5

6 6006-20-39488 Dust proof strip 2 2

7 6006-20-39482 LED shade 4

8 6006-30-39584 Key pad 1

9 6006-30-39471 SpO2 module kit (Masimo) 1

10 M04-004012--- Crosshead screw 13

11 M04-011002--- M3 nut with spring washer 4

12 6006-20-39508 Grounding washer 1

13 6006-20-39502 LCD spacer 2

14 0000-10-10997 LCD screen 1

15 6006-20-39487 Dust proof strip 1 2

16 M04-051003--- Tapping screw PT2×6 5

17 6006-20-39415 Power button 1

6-6

Page 65

SN P/N Description Qty

18 6006-20-39376 Battery door link 1

19 6006-20-39359 Battery door 1

20 M04-003905--- Tapping screw PT3×6 1

21 M04-021024--- Flat washer 1

22 0010-20-12194 NIBP connector for main unit 1

23 047-000214-00 Front housing overlay (with Temp module) 1

24 6006-20-39361 Alarm LED cover 1

6.5 Rear Housing Assembly

Exploded View

Parts List

SN P/N Description Qty

1 6006-20-39351 Rear housing 1

2 047-000196-00 Label 1

3 M04-002505--- Screw M3×6 2

4 6006-30-39572 Temp module 1

5 6006-20-39375 Foot cushion 2

6 6006-20-39418 Speaker spacer 1

7 6006-20-39369 Recorder support 1

8 M04-003905--- Tapping screw PT3×6 3

9 M04-000603--- Washer 1

6-7

Page 66

SN P/N Description Qty

10 M04-003105--- Tapping screw PT3×8 2

11 M04-021024--- Flat washer 2

12 6006-20-39350 Handle cover 2

13 M04-004012--- Crosshead screw M3×6 3

14 TR6C-30-16670 TR60-C recorder 1

6.6 Lithium Battery Charger Assembly

Exploded View

Parts List

SN P/N Description Qty

1 6006-20-39417 Lithium battery mounting rack 1

2 6006-30-39427 Lithium battery receptacle board 1

3 M04-030030--- Bolt M3×12 1

4 9201-20-36038 Spring 1

5 M04-000605--- Screw M3×8 2

6 M04-051096--- Stainless steel screw M3×8 1

7 M90-000002-03 Insulating spacer ф3×0.5 1

6-8

Page 67

6.7 Lead-acid Battery Assembly

Exploded View

Parts List

SN P/N Description Qty

1 6006-20-39419 Lead-acid battery mounting rack 1

2 8002-20-36151 Spring 2

3 8002-20-36152 Battery charging flexible support 1

4 8002-20-36154 Battery contact 2

5 M07-00043S--- Switch 1

6 M04-004015--- Screw M3×8 1

7 9000-20-07286 Spring 1

8 M04-011002--- M3 nut with spring washer 1

9 M04-051060--- Tapping screw M2.0×8 2

10 M04-021000--- Flat washer 2

6-9

Page 68

6.8 MASIMO SpO2 Board Assembly

Exploded View

Parts List

SN P/N Description Qty

1 DA8K-20-14524 insulating plate for SpO2 isolation power board 1

2 M90-000002--- Insulation washer 3

3 M04-000301--- Stainless steel nut, GB6170-M3 3

4 0010-30-12095 Masimo M7 isolation power board 1

5 0010-10-12275

6 M04-000104--- Spring washer 3

7 M04-000106--- Bolt M3×7 3

8 6006-20-39366 SpO2 mounting rack 1

9 M04-002505--- Screw M3×6 4

Masimo M7 board(Masimo kit)

1

6-10

Page 69

6.9 Temp Assembly

Exploded View

Parts List

SN P/N Description Qty

1 6006-20-39363-51 Temp module housing 1 1

2 M04-003905--- Tapping screw PT3×6 3

3 6006-20-39364 Temp module housing 2 1

4 M04-002505--- Screw M3×6 2

5 6006-20-39569 Temp module waterproof pad 1

6 M04-002505--- Crosshead screw M3×6 4

7 M09A-30-62103 Temp main board assembly 1

8 6006-20-39365 Temp probe cover pack support 1

9 6006-20-39377 Temp probe well 1

6-11

Page 70

Page 71

Page 72

P/N: 046-000179-00 (2.0)

Loading...

Loading...