Page 1

CS-323C

CP-323C

Vibratory Soil

Compactors

Cat®3054C Diesel Engine

oss Power

Gr

Dr

um Width 1270 mm 50"

Centrifugal Force 66.8 kN 15,000 lb

Vibratory Frequency 35 Hz 2100 vpm

62 kW 83 hp

Operating Weight

CS-323C 4390 kg 9,680 lb

CP-323C

4620 kg

10,190 lb

Page 2

CS-323C and CP-323C Soil Compactors

Ideally-sized for small compaction jobs or working in tight areas such as trenches

or job sites with limited space.

ibratory System

V

An industry-proven eccentric weight

design combined with high amplitude

and frequency delivers superior

compaction in the fewest number of

passes.

Page 4

Engine

Caterpillar®3054C diesel engine

delivers 62 kW (83 hp) and is built for

performance and reliability without

sacrificing fuel economy.

Page 4

Propel System

The single pump propel system with

flow divider provides balanced

hydraulic flow to both the rear drive

axle and the front drum drive motor to

minimize drum and wheel spin-out in

low traction conditions. (Flow divider is

optional on CS-323C without a blade.)

This system enables the operator to

achieve good gradeability and machine

control while compacting on a grade or

using the optional leveling blade.

Page 5

2

Page 3

Operator’

The 300C-Series Soil Compactors

feature exceptional operator comfort

and visibility. A propel lever, grouped

control gauges and conveniently located

control switches enhance operator

productivity and reduce operator

fatigue. Four heavy-duty isolation

mounts provide a smooth ride. A new

steering wheel with integrated center

horn function and steering knob helps

reduce operator fatigue. The operator’s

platform is enclosed by handrails and

features angled foot rests for sure

footing when working on a grade. A

ROPS/FOPS canopy with a rear view

mirror is standard.

Page 5

Versatility

Narrow machine width of 1.39 m

(4' 6") is ideal for working in trench

applications or job sites with limited

space. The machine weight is good for

light compaction of uniform layers over

sewer and water pipes.

Page 6

s Station

The optional leveling blade increases

machine utilization to tackle

backfilling, material knockdown and

light dozing applications.

Page 6

Serviceability

Daily check points are accessible from

ground level. The optional hinged side

access doors open wide for easy access

to engine components. The operator’s

station tilts forward to provide access to

the hydraulic pumps. The engine

lubrication change interval is 500 hours.

Page 7

Performance and reliability you can depend on.

Durable field-proven powertrain and vibratory systems, production

enhancing options and the world’s largest and most dedicated dealer

support system ensure the CS-323C and CP-323C Soil Compactors

will provide maximum compaction performance and value.

3

Page 4

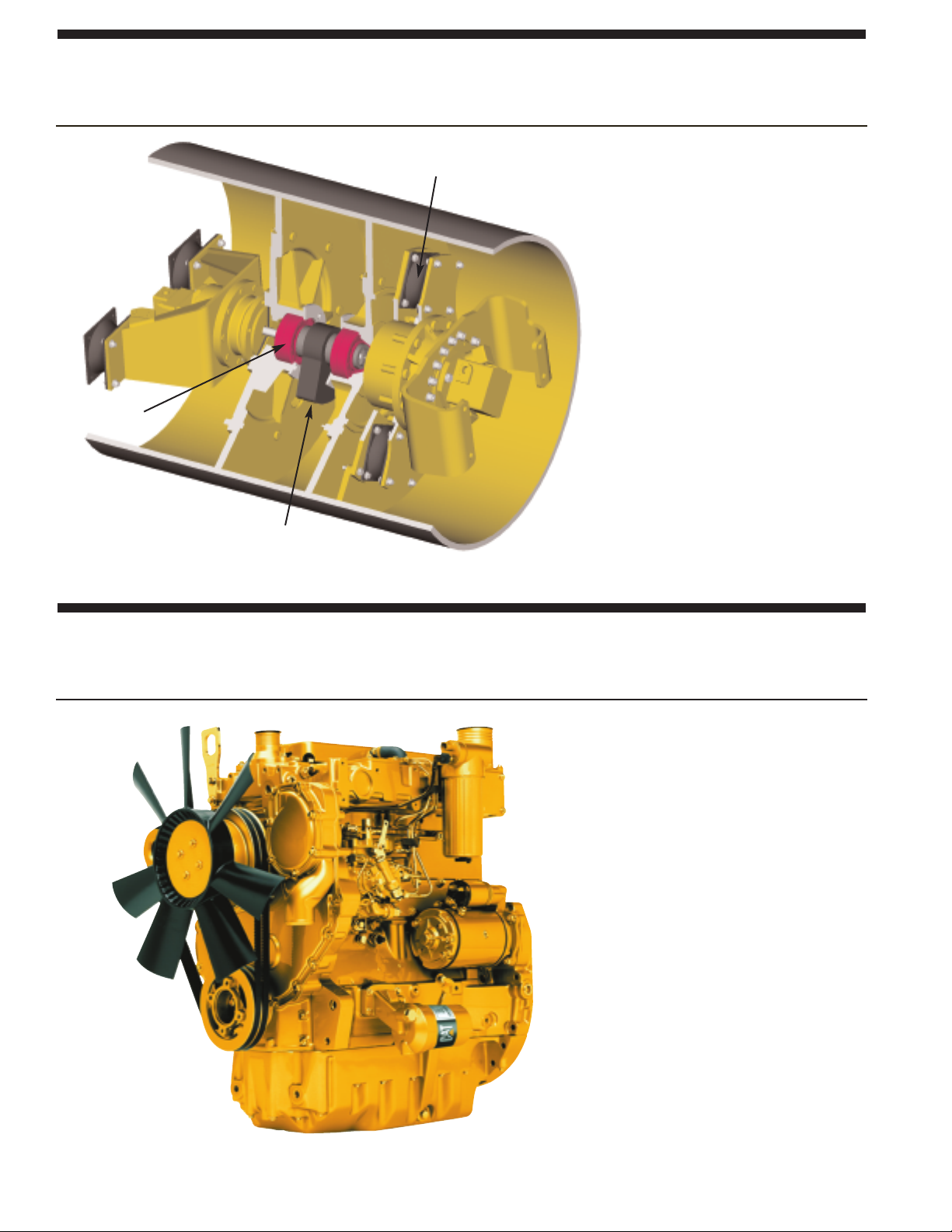

Vibratory System

Industry-proven drum design delivers superior compactive force and high reliability.

High centrifugal force and amplitude

provides superior compactive ef

exceptional productivity.

ibratory frequency

V

vpm) combined with optimal drum

weight, enables the operator to achieve

density in fewer passes.

Large heavy-duty bearings for the

eccentric weight shaft designed for high

compactive forces.

1 year/1000 hour vibratory bearing lube

service interval reduces maintenance.

Heavy-duty isolation mounts allow

more force to be transmitted to the

ground and less vibration to the drum

yoke.

of 35 Hz (2100

w

1 Swinging Eccentric Weight

2 Heavy-duty Bearings

3 Isolation Mounts

e

q

fort and

Caterpillar 3054C Series Diesel Engine

High-tech four cylinder engine provides outstanding durability, performance, reliability and

operating economy.

Adjustment-free direct injection fuel

system provides individually metered

high-pressure, direct injection of fuel

for maximum efficiency.

Large engine oil cooler reduces oil

deterioration and varnishing of internal

components. Allows for 500 hour

engine oil change intervals.

Low-mounted oil pump for quicker

start-up lubrication.

Combination fuel filter and water

separator offers superior protection for

the fuel injection system.

ier 2 and

T

Engine meets U.S. EP

European EU Stage II emissions control

standards worldwide.

A

4

Page 5

Efficient Propel System

High tractive effort and gradeability for outstanding productivity, machine control and

utilization.

Single propel pump with flow divider

provides separate, balanced hydraulic

flow to the rear wheel axle and the

drum drive motors. Provides high

r

e

q

gradeability and increases tractive effort

in loose or poor underfoot conditions.

(Flow divider is optional on CS-323C

without a leveling blade.)

Limited slip differential provides

balanced tractive effort and smooth

torque transfer to both rear wheels.

y

t

w

1 Propel Pump

2 Caterpillar 3054C Diesel Engine

3 Limited Slip Differential

4 Rear Wheel Drive Motor

5 Drum Drive Motor

6 Flow Divider

Infinitely variable speed range for

maximum torque when using the

leveling blade or grade climbing, plus

the ability to move quickly over longer

distances.

Flushing valves in each propel circuit

help keep hydraulic oil cool and clean

for maximum system efficiency.

High travel speed up to 8.9 km/h

(5.5 mph).

Operator’s Station with ROPS/FOPS Canopy

Designed for simple control, comfort and productivity. The platform is equipped with a

ROPS/FOPS canopy and is enclosed by handrails and features foot rests for sure footing.

Single lever control for propel and

vibratory On/Off provides simple and

low effort operation.

Easy to reach propel lever located to

the right of the operator’s seat for

convenient and accurate machine

control.

Operational gauges are located on the

steering console for easy reference

when operating.

estricted visibility

Unr

tire edge and to the side and rear of the

machine.

table and durable adjustable

Comfor

seat with flip-up arm rests and 76 mm

(3") wide retractable seat belt.

Isolated operator’

duty rubber mounts reduce machine

vibration transmitted to the operator

to the drum and

s station

with heavy-

.

5

Page 6

Compact Size for Specific Applications

Features and benefits designed specifically for utility construction with narrow working

widths like trench compaction or job sites with limited space.

row machine width

Nar

(4' 6") is ideal for working in trench

applications or job sites with limited

space.

Machine weight is good for light

compaction of uniform layers over

sewer and water pipes.

Propel system allows the operator to

stop, maintain machine position and

change directions while on a grade.

Short turning radius for good

maneuverability in confined work areas.

Padfoot drum features involuted pads in

shape to walk out of the lift without

fluffing or “kicking up” the soil around

the pads. Pads are tapered to help clean

themselves. Heavy-duty scrapers

mounted on the front of the drum are

individually adjustable and replaceable.

Helps to reduce excessive material

build up between the pads.

of 1.39 m

Leveling Blade

Leveling blade option increases machine versatility and utilization, plus greatly enhances

productivity.

Expands machine versatility and

utilization for use in material

knockdown, site leveling, trench

backfilling and light dozing

applications.

Single lever blade contr

the right of the operator’s seat for

simple and convenient operation.

Efficient propel system combined with

ample engine horsepower

plenty of power and tractive effort for

effective blade use without drum spin.

Two-piece reversible and replaceable

cutting edges increase edge service life

and reduce replacement costs.

High mounting point provides superior

curb and obstruction clearance.

ol

located to

provides

6

Page 7

Reliability and Serviceability

Reliability and serviceability are integrated into every Caterpillar Soil Compactor. These

important features keep your machine investment profitable.

Visual indicators allow easy check of

radiator coolant, hydraulic oil tank level

and air restriction indicator.

Operator’s station tilts forward to allow

convenient access to the hydraulic

pumps.

Rear mounted cooling system provides

easy access for cleaning. Hydraulic oil

cooler tilts rearward for additional

access to the radiator.

500 hour engine oil change inter

1 year/1000 hour vibratory bearing lube

service interval for reduced

maintenance.

Quick-connect hydraulic test por

simplify system diagnostics.

Ecology drains provide an

environmental method to drain fluids.

They are included on the radiator,

engine oil pan, hydraulic and fuel tank.

S•O•SSMports allow for simple fluid

collection of engine oil, engine coolant

and hydraulic oil.

val.

ts

Secure hose routing with polyethylene

routing blocks to reduce rubbing and

increase service life.

Nylon braided wrap and all-weather

connectors ensure electrical system

integrity. Electrical wiring is colorcoded, numbered and labeled with

component identifiers to simplify

troubleshooting.

Maintenance-free Caterpillar batteries

are mounted in the rear of the machine

and are accessible through the swing

out rear grill. Cat batteries are

specifically designed for maximum

cranking power and protection against

vibration.

Machine is Product Link wire-ready.

The Caterpillar Product Link System

(CPLS) ensures maximum uptime and

minimum repair costs by simplifying

tracking of equipment fleets. Provides

automatic machine location and hour

updates. Can be obtained through your

local Caterpillar dealer.

Daily ser

ground level and are grouped on one

side of the engine. The optional hinged

side access doors open wide for easy

access to engine components.

vice points ar

e accessible fr

om

7

Page 8

Drum and Vibratory System Specifications

Drum width

Drum shell thickness 20 mm 0.78"

Drum diameter 1016 mm 40"

Drum diameter (over pads) CP-323C 1016 mm 40"

Pads (CP-323C only)

Number of pads 88

Pad height 88 mm 3.5"

Pad face area 79.3 cm

Number of chevrons

Eccentric weight drive Hydrostatic

Weight at Drum (with ROPS/FOPS canopy)

CS-323C 2040 kg 4,500 lb

CP-323C 2210 kg 4,870 lb

Static Linear Load*

CS-323C 16 kg/cm 90 lb/in

*Meets NFP

Frequency

Standard 35 Hz 2100 vpm

Nominal Amplitude

High 1.3 mm 0.05"

Centrifugal Force @ 35 Hz (2100 vpm)

Maximum 66.8 kN 15,000 lb

98736 class: VM2

1270 mm 50"

2

11

12.3 in

2

Transmission

A variable displacement piston pump

supplies pressurized flow to singlespeed piston motor driving the rear axle

and a single-speed piston motor driving

the drum.

flow divider (optional on the smooth

A

drum model without a blade) splits the

hydraulic flow between the wheel drive

motor and the drum drive motor. If

either the drum or wheels begin to slip,

the flow divider restricts flow to the

spinning drive motor and routes the

additional oil flow to the other motor to

keep the machine moving.

A single propel lever located on the

control console provides smooth

hydrostatic control of the machine’s

infinitely variable speeds in both

forward and reverse.

Max. speeds (forward and reverse):

8.9 km/h - 5.5 mph

Engine

Four-stroke, four cylinder Caterpillar

3054C naturally aspirated diesel engine.

Meets U.S. EPA Tier 2 and European

EU Stage II emissions control standards

worldwide.

Ratings at RPM kW hp

Gross power 2200 62 83

Ratings of Caterpillar machine engines

are based on standard air conditions of

°F) and 100 kPa (29.61" Hg)

C (77

°

25

dry barometer. Power is based on using

API gravity of 35 at 15°C (60°F), fuel

having a LHV of 42 780 kJ/kg (18,390

Btu/lb) used at 30°C (86°F) [ref. a fuel

density of 838.9 g/L (7.001 lb/U.S.

gal)]. Net power advertised is the power

available at the flywheel when the

engine is equipped with fan, air cleaner,

muffler and alternator.

The following ratings apply at 2200

RPM when tested under the specified

standard conditions:

Net Power kW hp

EEC 80/1269 59 80

ISO 9249 59 80

SAE J1349 59 80

Dimensions

Bore 105 mm 4.13"

Stroke 127 mm 5"

Displacement

Dual-element, dry-type air cleaner with

visual restriction indicator, glug plug

starting aid and fuel/water separator are

standard.

4.4 liters

269 cu. in.

Final Drives and Axle

Final drive is hydrostatic with gear

reducer to the drum and hydrostatic

with differential and planetary gear

reduction to each wheel.

Axle:

Heavy-duty fixed rear axle with a

limited slip differential for smooth and

quiet torque transfer.

Axle width 1.27 m (4' 2")

Tires:

CS-323C: 11.2" x 24" 6-ply flotation

CP-323C: 1

1.2" x 24" 8-ply traction

8

CS-323C and CP-323C specifications

Page 9

Operator and Machine Protective Equipment

Roll Over Pr

Object Protective Structure (ROPS/FOPS)

canopy is a two-post structure that bolts

directly onto flanges welded to the

operator platform. The structure meets

SAE J1040 and SAE J231, ISO 3449

and ISO 3471.

Backup Alarm— 107 dB(A) alarm

sounds whenever the machine is in

reverse.

Forward Warning Horn— located on

the front of machine to alert ground

personnel.

Seat Belt— 76 mm (3") wide seat belt

is standard.

otective Structure/Falling

Steering

A priority-demand hydraulic powerassist steering system provides smooth

low-effort steering. The steering system

has priority over other other hydraulic

functions.

Minimum turning radius:

Inside

Outside 3.89 m (12' 2")

Steering angle:

(each direction) ± 38°

Oscillation angle:

(each direction) ± 15°

Hydraulic system:

One 64 mm (2.5") bore, double-acting

cylinder powered by a gear-type pump.

2.62 m (8' 7")

Electrical

The 24-volt electrical system consists

of two maintenance-free Caterpillar

batteries, color-coded and numbered

wiring wrapped in nylon braid. The

starting system provides 750 cold

cranking amps (cca). The system

includes a 55-amp alternator.

Service Refill Capacities

Liters Gallons

Fuel tank 144 38

Cooling system 18 4.8

Engine oil w/filter 6.8 1.8

Vibratory bearing lube

CS-323C 50.8 13.4

CP-323C 25.4 6.7

Axle & final drives 9.5 2.5

Hydraulic tank 49.2 13

Filtration system (pressure type)

Instrumentation

The instrument panel is located in front

of the operator and features a warning

system that constantly monitors various

machine systems; alerts the operator if

a problem does occur with a light and

an audible warning horn. Warning

system includes: Low Engine Oil

Pressure, High Engine Coolant

Temperature, High Hydraulic Oil

Temperature and Low Charge System

Pressure. Instrumentation also includes

an Alternator Malfunction Light, Start

Aid Switch, Service Hour Meter and

Fuel Gauge.

Frame

Fabricated from structural steel plate

and joined at the articulation pivot. The

articulation area is structurally

reinforced and joined by hardened steel

pins. Two vertical pins provide a

steering angle of ± 38° and a horizontal

pin allows frame oscillation of ± 15°.

The articulation lock prevents machine

articulation when placed in the locked

position. Frame also includes tie-down

points for transport.

Operating Weights

Weights shown are approximate and include lubricants, coolant, full fuel and

hydraulic tanks and a 80 kg (175 lb) operator.

Machine Weights CS-323C CP-323C

with ROPS/FOPS canopy 4390 kg 9,680 lb 4620 kg 10,190 lb

equipped with leveling blade 4710 kg 10,380 lb 4940 kg 10,890 lb

Brakes

Service brake features

• Closed-loop hydrostatic drive system

provides dynamic braking during

operation.

Secondary brake features*

• Spring-applied/hydraulically-released

multiple disc type brake mounted on

the drum drive gear reducer.

Secondary brakes are activated by a

button on the operator’s console, loss

of hydraulic pressure in the brake

circuit or when the engine is shut

down. A brake interlock system

prevents driving through the

secondary brake.

*Braking system meets SAE J1472.

Weight at Drum

with ROPS/FOPS canopy 2040 kg 4,500 lb 2210 kg 4,870 lb

equipped with leveling blade 2470 kg 5,450 lb 2640 kg 5,820 lb

CS-323C and CP-323C specifications

9

Page 10

CP-323CCP-323C

Dimensions

CS-323C CP-323C

A Overall length 4.12 m (13' 6") 4.12 m (13' 6")

Length with blade 4.5 m (14' 9") 4.5 m (14' 9")

B

C Overall width 1.39 m (4' 6") 1.39 m (4' 6")

D Drum width 1270 mm (50") 1270 mm (50")

E Width with blade 1.57 m (5' 2") 1.57 m (5' 2")

F Blade height 558 mm (22") 558 mm (22")

Blade cutting depth 76 mm (3") 76 mm (3")

G

H Drum shell thickness 20 mm (0.78") 20 mm (0.78")

I Drum diameter 1016 mm (40") 840 mm (35")

Drum diameter over pads — — 1016 mm (40")

J Height at ROPS/FOPS canopy 2.51 m (8' 2") 2.51 m (8' 2")

K Wheelbase 2.24 m (7' 4") 2.24 m (7' 4")

L Ground clearance 347 mm (13.6") 347 mm (13.6")

M Curb clearance 335 mm (13.2") 335 mm (13.2")

Inside turning radius 2.62 m (8' 7") 2.62 m (8' 7")

Outside turning radius 3.89 m (12' 9") 3.89 m (12' 9")

J

H

F

L M

I

K

A

B

G

10

CS-323C and CP-323C specifications

D

C

E

Page 11

Optional Equipment

Leveling Bladebolts onto the drum

yoke and is available for both the

-323C and CP-323C. The complete

CS

assembly includes blade, push arms,

reversible/replaceable cutting edges,

replaceable skid plates, center-mounted

hydraulic lift cylinder, control valve and

flow divider

constructed of heat-treated structural

sections. Blade raise and lower is

controlled by a lever to the right of the

propel lever.

Flow Divider is standard on the

CP-323C and CS-323C machines

ordered with a leveling blade. The

CS-323C ordered without a blade, can

be ordered with this option to provide

increased tractive ef

grades or working in thick lifts of soft

material.

. The moldboard is

fort in climbing

orking Light Package

W

front-facing and two rear-facing working

lights for working under dim or low

light conditions. This system is intended

for use under working conditions and

not for highway transport purposes.

Engine Compartment Enclosures

features lockable swing open side

engine covers to protect the engine from

vandals and harsh environmental

conditions.

Spark Arrester Muffler meets the

specifications for those applications that

require a spark arresting muffler.

Vinyl Suspension Seat is fully

adjustable to include fore and aft

positions, bottom cushion height and

suspension stif

armrests.

Total Customer Support System

includes two

fness and flip-up

Drum Guard Systemhelps protect the

drum hydraulic components. Especially

useful when working in trenches.

Flexible Urethane Scrapers for the

CS-323C mounted at the front and rear

of the drum are made of polyurethane

and are designed to contact the drum

and completely clean debris from the

drum surface.

Rear Scraper Teeth for the CP-323C

mounted at the rear of the drum and work

in conjunction with the standard front

scraper teeth.

8-Ply Tires with traction tread are

available for the CS-323C.

Service capability — most dedicated dealer support system to

ensure fast service whether at the dealer’s shop or in the field by

trained technicians using the latest tools and technology.

Parts availability — most parts on dealer’s shelf when you need

them. Computer-controlled, emergency search system backup.

Parts stock lists — dealer helps you plan on-site parts stock to

minimize your parts investment while maximizing machine

availability.

Literature support — easy-to-use parts books, operation and

maintenance manuals and service manuals to help you get

maximum value from your Caterpillar equipment.

Remanufactured parts — pumps and motors, pod-style weight

housings, engines, fuel system and charging system components

available from dealer at a fraction of new part cost.

Machine management services — effective preventive

maintenance programs, cost-effective repair options, customer

meetings, operator and mechanic training.

Flexible financing — your dealer can arrange attractive financing

on the entire line of Caterpillar equipment. Terms structured to

meet cash flow requirements. See how easy it is to own, lease or

rent Cat equipment.

CS-323C and CP-323C specifications

11

Page 12

Caterpillar offers a comprehensive line of vibratory soil compactors.

Contact your local Caterpillar dealer to learn more about the complete line of Caterpillar Paving Products.

The 600E-Series Soil Compactors

Operating Weight (with ROPS/FOPS)

CS-663E 16 700 kg 36,820 lb

CP-663E 16 500 kg 36,375 lb

CS-683E 18 500 kg 40,785 lb

Drum Width 2.13 m 7'

Gross Power 129 kW 173 hp

The 500E-Series Soil Compactors

Operating Weight (with ROPS/FOPS)

CS-533E 10 485 kg 23,120 lb

CP-533E 11 320 kg 24,960 lb

CS-563E 11 120 kg 24,520 lb

CP-563E 11 555 kg 25,479 lb

CS-573E 13 570 kg 29,922 lb

CP-573E 13 750 kg 30,319 lb

CS-583E 15 100 kg 33,296 lb

CP-583E 15 235 kg 33,593 lb

Drum Width 2.13 m 7'

Gross Power (CS/CP-533E only) 97 kW 130 hp

Gross Power 112 kW 150 hp

QEHQ9778-01 (3/04)

Replaces QEHQ9778

The 400E-Series Soil Compactors

Operating weight (with ROPS/FOPS)

CS-423E

CS-433E 6745 kg 14,875 lb

CP-433E 7145 kg 15,750 lb

Drum Width 1.67 m 5' 6"

Gross Power

CS-423E 62 kW 83 hp

CS/CP-433E

6745 kg

75 kW

Featured machines in photography may include optional equipment.

14,875 lb

100 hp

Materials and specifications are subject to change without notice.

© 2004 Caterpillar

www.CAT.com

Loading...

Loading...