Miele PW 5134 MOPSTAR 130 Operating instructions

Operating instructions

Washer-extractor

PW 5134 MOPSTAR 130

To avoid the risk of accidents or damage to the machine,

it is essential to read these instructions before it is installed,

commissioned and used for the first time.

en-GB

M.-Nr. 09 295 411

2

Contents

Warning and Safety instructions...............................................................4

Caring for the environment ...................................................................9

Description of the machine (with detergent compartment) ........................................10

Description of the machine (without detergent compartment)......................................11

Description of the machine ..................................................................12

Control panel ..............................................................................12

Language selection .........................................................................13

Washing ..................................................................................14

Laundry preparation .........................................................................14

Max. load .................................................................................14

Adding detergent using the detergent dispenser compartment........................................15

Detergent dispensing ........................................................................16

Selecting a programme ......................................................................16

Washing (without detergent compartment) .....................................................17

Liquid dispensing ...........................................................................17

Washing ..................................................................................19

Open the drum door after the programme has finished. .............................................20

Programme chart ..........................................................................21

Additional functions ........................................................................24

Start time..................................................................................24

Programme stop ............................................................................25

Programme cancellation......................................................................25

Communication module ......................................................................26

Problem solving guide ......................................................................27

The drum door cannot be opened ..............................................................27

Power cut during a wash process, opening the door in an emergency..................................27

Fault messages.............................................................................29

Service ...................................................................................30

Cleaning and care ..........................................................................31

Installation and connection ..................................................................32

Transport safety devices .....................................................................33

On-site connection (with detergent compartment)..................................................34

On-site connections (without detergent compartment) ..............................................34

Dispensing agent connection to the liquid dispensing mixing compartment .............................36

Electrical connection ........................................................................37

Connecting the dispensing pumps .............................................................37

Technical data .............................................................................38

General information ........................................................................39

Overview of function levels ....................................................................39

Access to Supervisor level / changing the password .............................................40

Language / Time, Date ......................................................................41

Dispensing................................................................................42

Settings ..................................................................................43

3

Warning and Safety instructions

To avoid the risk of accidents or damage to the machine, it is essential to read these

instructions before it is used for the first time.

Correct application

This washer-extractor is only intended for items of laundry which have not been

~

impregnated with dangerous or inflammable substances.

Only machine wash articles which have a care label stating that they are suitable for

~

machine washing or for wet cleaning.

Do not use chemical cleaning agents such as those use for dry cleaning in this machine.

~

Danger of fire or explosion.

Do not store or use benzine, petrol, paraffin, or other easily flammable liquids near the

~

machine. Do not use the machine lid as a resting place.

Danger of fire or explosion.

Do not store chemicals (liquid detergent etc.) on the machine lid. They can damage

~

lacquered surfaces and cause discolouration. Accidental chemical spillages must be

thoroughly removed using a wet cloth.

If the machine is operated in a publically accessible place, it is the supervisor's

~

responsibility to ensure suitable measures are in place to protect users from any source of risk

or danger.

The machine is not intended for outdoor use.

~

Explanation of safety instructions and warnings on the machine

Read the operating instructions

Read all the instructions, e.g. the installation instructions.

Warning, hot surfaces

Warning, voltage up to 1000 volts

Earthing

4

Warning and Safety instructions

Technical and electrical safety

The electrical safety of this machine can only be guaranteed when continuity is complete

~

between it and an effective earthing system which complies with local and national safety

regulations. It is most important that this basic safety requirement is present and regularly

tested, and where there is any doubt, the installation should be inspected by a qualified

electrician. The manufacturer cannot be held liable for the consequences of an inadequate or

non-existent earthing system.

Do not damage, remove or bypass the safety components or control elements of this

~

washer-extractor.

Machines with a damaged control panel, wires or cables must not be used until they have

~

been repaired.

Only operate the machine when all removable outer panels are in place so that it is

~

impossible to touch an electrical component or moving part.

If the machine is hard wired, a multiple-pole separator must be installed.

~

The machine is only completely isolated from the electricity supply when switched off at the

~

mains isolator, or the mains fuse is disconnected.

Repairs to electrical, gas and steam heated machines should only be undertaken by a

~

suitably qualified service technician to ensure safety. Unauthorised repairs could be

dangerous.

Do not use force to open the door. To ensure the door lock operates correctly the handle

~

has a safety device incorporated in it.

Faulty components must only be replaced by genuine Miele original spare parts. The

~

manufacturer can only guarantee the safety of the machine when Miele replacement parts are

used.

The very best materials are used in the manufacture of this machine, and every care is

~

taken in its manufacture. However, with time, parts such as hoses can deteriorate. Check them

regularly for signs of deterioration such as cracks and kinks, and replace in good time to avoid

leaks and subsequent damage.

If this machine is being used in a commercial environment please ensure that all relevant

~

health and safety regulations are obeyed.

5

Warning and Safety instructions

Use of the machine

This washer-extractor can only be used by people with reduced physical, sensory or mental

~

capabilities, or lack of experience or knowledge, if they are supervised whilst using it or have

been shown how to use it in a safe way and understand and recognise the consequences of

incorrect operation.

If the machine is operated in a publically accessible place, it is the supervisor's

~

responsibility to ensure suitable measures are in place to protect users from any source of risk

or danger.

Never allow children to play in, on or near the washer-extractor or to operate it themselves.

~

When washing with high temperatures please be aware that the porthole glass can get hot.

~

Do not let children touch it during a wash programme.

Always close the door after use. This way you will avoid the danger of:

~

Children climbing into the machine or hiding things in it.

–

Pets or other small animals climbing into it.

–

Always make sure that the drum is stationary before reaching in to remove laundry.

~

Reaching into a moving drum is extremely dangerous.

Danger of entrapment and loss of fingers in the area around the door hinges.

~

The area necessary to open the drum door completely must not be obstructed by doors or

~

other structures.

Water used for washing in this machine is not drinking water.

~

It must be discharged into a proper drainage system.

This washer-extractor should only be operated unsupervised if there is a floor drain (gully) in

~

the immediate vicinity of the machine.

If the machine is switched off and the door is shut you have to switch the machine on before

~

you can open the door.

If there is water in the suds container when the door is open: close the door and then switch

the machine on.

It is the supervisor's responsibility to ensure that the standard of disinfection in thermal as

~

well as chemo thermal procedures is maintained (in accordance with § 18 IFSG) by carrying

out suitable validation tests. These procedures should be checked on a regular basis, either

thermo-electrically using loggers, or bacteriologically with bio indicators. The supervisor must

pay particular attention to maintaining the correct parameters in the procedure, including

temperature and with chemo thermal programmes the chemical concentration used.

Disinfection programmes must not be interrupted, as this can have a limiting effect on the

disinfection result.

Always follow the chemical manufacturer's instructions when using a combination of

~

cleaning agents and special application chemicals. Only use such chemicals for the purpose

and in the situation specified by the manufacturer in order to avoid the danger of adverse

chemical reactions and material damage.

If in doubt check the suitability of the product for use in this machine with the manufacturer

before using it.

6

Warning and Safety instructions

Proprietary dyes, dye removers and descaling agents may only be used in this machine if

~

the manufacturer expressly states that they are suitable for use in a washing machine.

Instructions on the packaging must be observed.

Laundry soiled with biological oils or fats must be inspected after washing. If oils or fats are

~

not washed out properly they can cause the laundry to self ignite during machine drying. Use a

suitable detergent and wash programme for such items.

Do not use a pressure washer or hose to clean the machine.

~

Further notes

Disinfecting and cleaning agents often have compounds containing chlorides in them. If

~

these agents dry on to stainless steel surfaces, the residual chlorides will attack the steel and

can cause rusting. To protect your machine from rust damage, we recommend only using

chloride free disinfecting and cleaning agents for washing and disinfecting programmes and

for cleaning stainless steel surfaces of the machine itself.

If you are unsure about a particular agent, contact the manufacturer of that agent for advice.

Accidental spillages of agents containing chlorides should be rinsed off affected surfaces with

with water and then dried with a soft cloth.

Recommending a chemical cleaning agent on technical application grounds does not imply

~

that the manufacturer of the machine takes responsibility for the effect of the chemical on the

material of the items being cleaned or on the machine.

Please be aware that changes in formulation, storage conditions etc., which may not be

publicised by the chemical producer, can have a negative effect on the cleaning result.

Using accessories

Accessory parts may only be fitted when expressly approved by Miele. If other parts are

~

used, guarantee, performance and product liability claims will be invalidated.

Any external equipment used, e.g. lances, electronic water meters, detergent dispensing

~

meters, and sensors must be classified as Class II equipment.

Any connected external PC must conform to the requirements of EN 60950-1:2001 (IEC

60950-1:2001).

Disposing of your old machine

Before disposing of an old washer-extractor (scrapping it), render the door lock inoperable

~

so that children cannot lock themselves in the machine by mistake and endanger their lives.

If other persons are being shown how to operate the machine, they must be given or made

aware of these important safety instructions.

Keep these instructions in a safe place

7

Warning and Safety instructions

Chlorine and component damage

Notes on using chlorine bleach and perchloroethylene (PCE)

Frequent use of chlorine products increases the risk of damage to components.

~

The use of agents containing chlorine, such as sodium hypochlorite and chlorine bleach in

powder form, can damage the protective upper surface of stainless steel and cause corrosion

to components. Factors affecting this are chlorine concentration levels, contact time, and

temperature. It is therefore advisable to avoid the use of such agents. Oxygen based

bleaching agents should be used instead.

If you still need to use chlorine-based bleach for specific soiling, you will need to perform a

neutralising step each time. If this is not done machine components and laundry can suffer

irreparable damage.

Anti-chlorine treatment

Anti-chlorine treatment has to be carried out immediately after chlorine bleach has been used.

The use of hydrogen peroxide or an oxygen based cleaning or bleaching agent is

recommended and the laundry should not be drained in between.

With thiosulfate, especially when used with hard water, gypsum can form, which can lead to

incrustations on laundry or deposits in the machine, on the laundered items or a build-up of

deposits in the machine. The use of hydrogen peroxide is preferable as it aids the chlorine

neutralising process.

The exact quantity of additives and the treatment temperatures required must be set and

tested on site in accordance with the dosage recommendations of the detergent and additive

manufacturers. The laundry must also be tested to check whether it contains any active

chlorine residues.

8

Caring for the environment

Disposing of the packing material

The packaging is designed to protect the machine

from damage during transportation. The packaging

materials used are selected from materials which are

environmentally friendly for disposal and should be

recycled. Recycling the packaging reduces the use

of raw materials in the manufacturing process and

also reduces the amount of waste in landfill sites.

Packaging materials such as plastic film and

,

bags must be kept out of the reach of babies and

children. Danger of suffocation.

Disposing of your old machine

Electrical and electronic machines often contain

valuable materials. They also contain materials which,

if handled or disposed of incorrectly could be

potentially hazardous to human health and to the

environment. They are, however, essential for the

correct functioning of your machine. Please do not

dispose of it with your general waste.

Tips on saving energy

To save energy and water, try to load the maximum

for the programme selected. Underloading is

uneconomical. Overloading gives a poorer quality of

wash result and may cause unnecessary creasing.

Make sure that your laundry is thoroughly spun

before drying. This saves time and energy.

Carrying out the final rinse with hot water helps to

reduce the residual moisture level, and the residual

heat in the laundry will help keep processing time

down in dryer and for ironing, thus saving energy.

Follow detergent manufacturer's advice regarding the

right amount of detergent to use.

This will depend on the size of the load, the water

hardness level and the amount of soiling in the

laundry.

Chose the correct programme (with pre-wash or

intensive options selected) and the correct

temperature.

Please dispose of it at your local community waste

collection/recycling centre.

Please contact your dealer, your local waste

collection centre or scrap merchant about recycling

schemes.

Please store it out of the reach of children whilst

awaiting disposal.

9

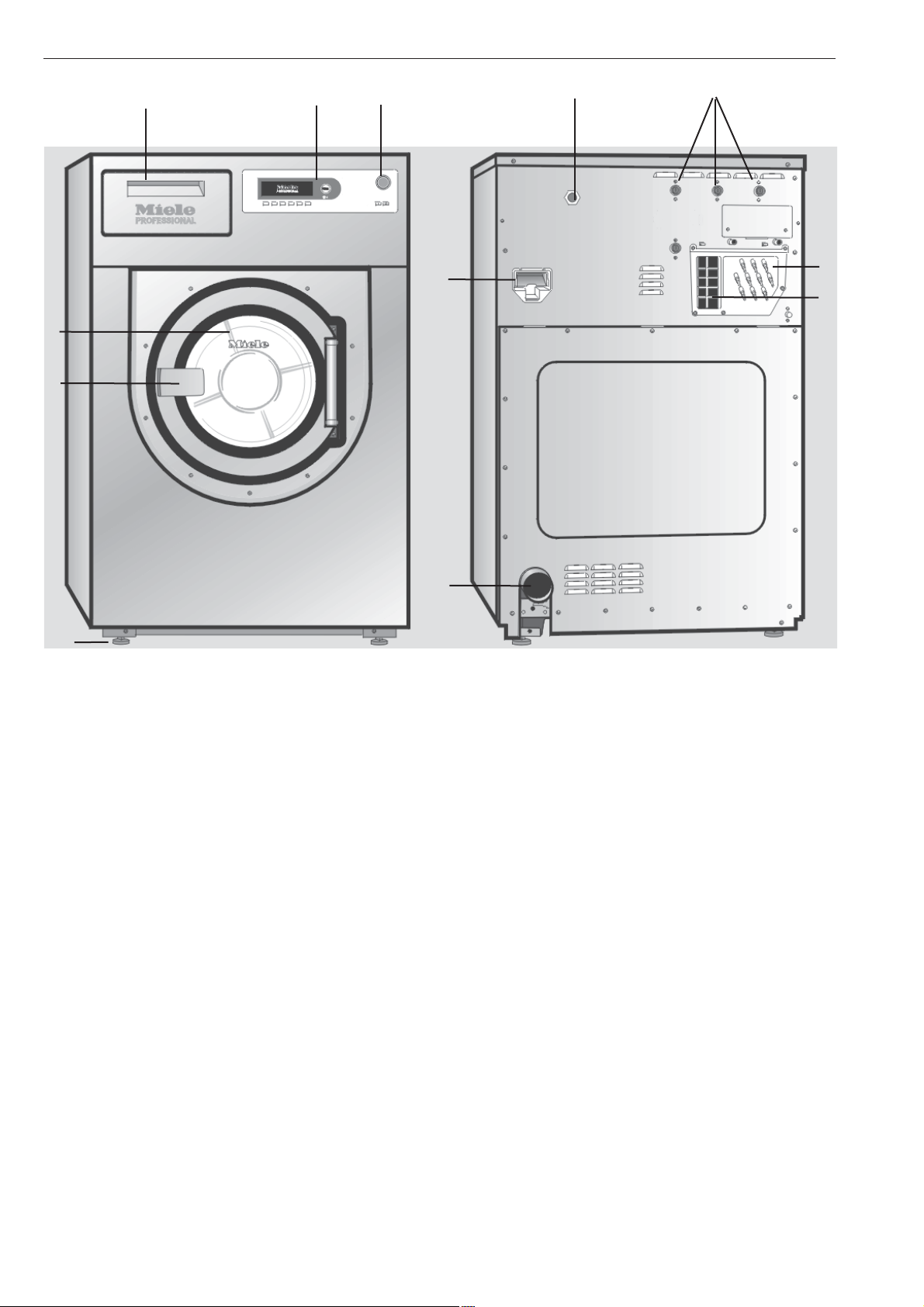

Description of the machine (with detergent compartment)

d

e

c

b

a

i

g

h

k

l

f

a Emergency off switch

Pressing the red button switches the machine off.

b Control panel

c Detergent dispenser compartment

Pull the handle to open the flap.

d Drum door

Pull the door handle to open the drum door. Never

use force to open the door.

e Door handle

To ensure the door lock operates correctly the handle

has a safety device incorporated in it.

f 4 adjustable feet

j

g Electrical connection

h Plumbing connections

i Communication slot

j Water drainage

k Water connection for liquid dispensing

connections

l Vapour outlet

See "Installation and connection"

10

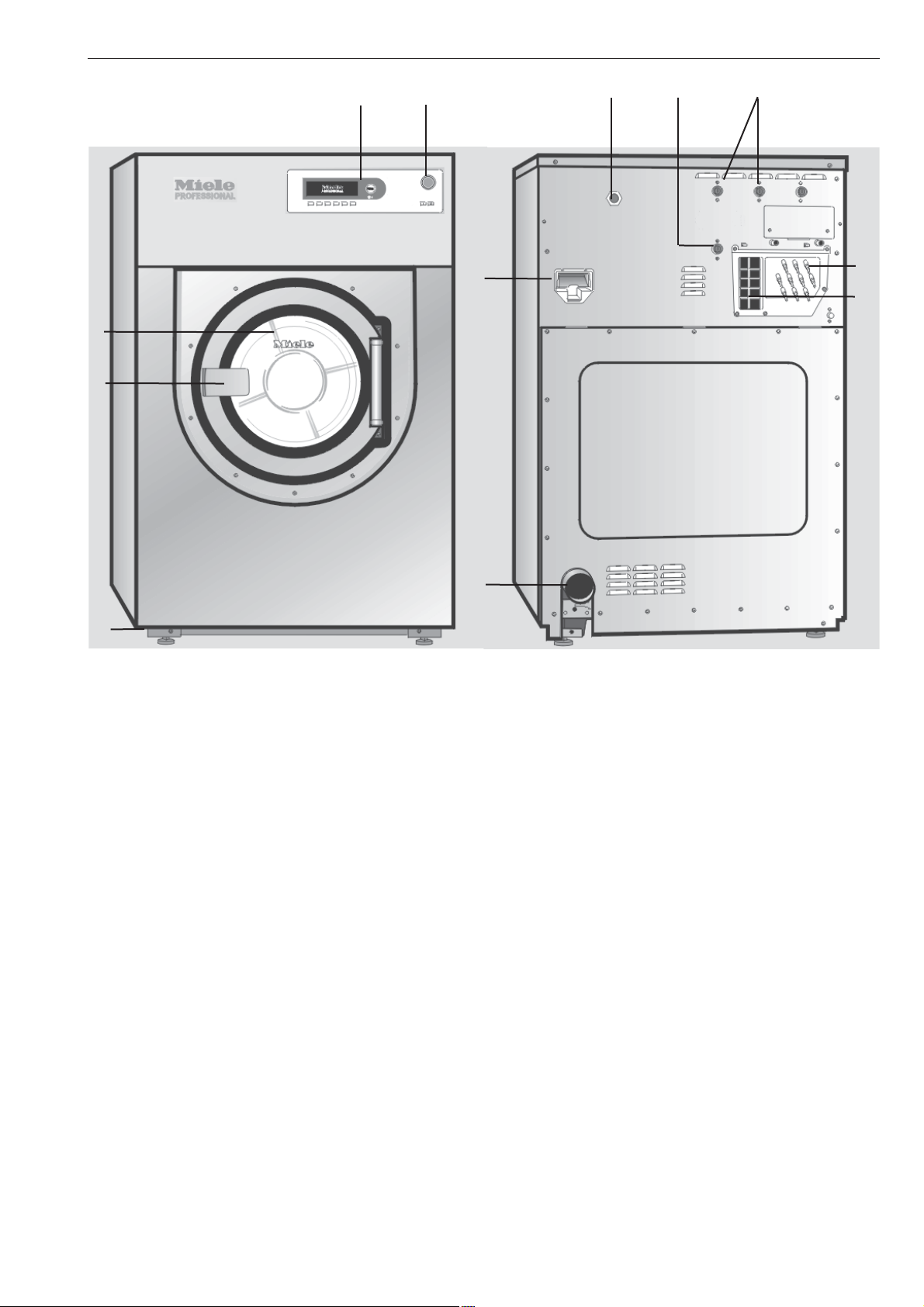

Description of the machine (without detergent compartment)

c

d

b

a

i

f

g

h

k

l

e

a Emergency off switch

Pressing the red button switches the machine off.

b Control panel

c Drum door

Pull the door handle to open the drum door. Never

use force to open the door.

d Door handle

To ensure the door lock operates correctly the handle

has a safety device incorporated in it.

e 4 adjustable feet

j

f Electrical connection

g Plumbing connections for liquid dispensing

h Plumbing connections

i Communication slot

j Water drainage

k Water connection for liquid dispensing

connections

l Vapour outlet

See "Installation and connection"

11

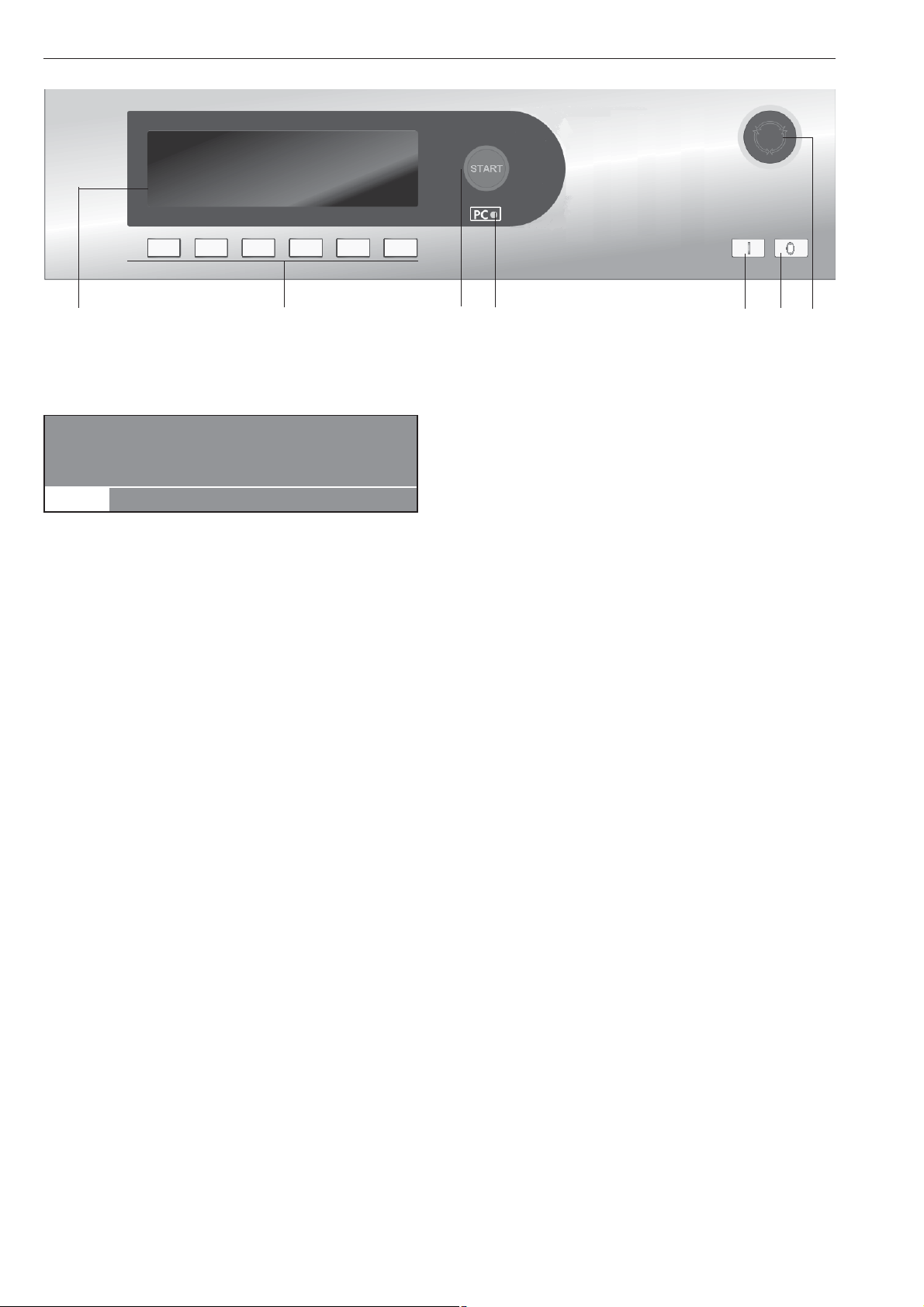

Description of the machine

a b c d e f g

Control panel

a Display

1 Mops standard 13,0/13,0 kg

Pre-wash

60°C Main wash

1

When the machine is switched on the welcome

screen will appear briefly, followed by the first

programme or the last programme started.

b Function buttons

These buttons can be allocated specific functions

depending on the status of the machine.

These appear in the display above the buttons and

are highlighted when selected.

The first 6 programmes in the programme list can be

selected directly using buttons1-6.

Further programmes can be selected by pressing

and holding button 6 ~.

234F 56~

e I Power On button

For switching the machine on

f 0 Power Off button

For switching the machine off

~

g Emergency off switch

Use only in case of an emergency.

The machine is switched off by pressing the red

button. When the hazard has been removed, the

switch is released by turning it clockwise.

When the "START" button is pressed again, the

interrupted programme continues.

c Start button

The light ring flashes if a selected programme can be

started. When it is pressed, the selected programme

will start. After a programme has been started, the

display content can be shown again by pressing this

button.

d Optical interface PC

Using PC software, data can be transmitted to and

from the controls to a PC.

The optical interface on the control panel provides

the connection point.

12

Description of the machine

Function buttons

A function is activated by pressing the relevant button

and deactivated by pressing a second time.

f Stop/Finish

When a programme has started, the right-hand

function button acts as a stop button.

When it is pressed the selected programme is

stopped or a stopped programme is finished.

+i Block plus

The corresponding programme block (e.g. Pre-wash)

is added to the programme.

m Starch stop

Press this button if the laundry is to be starched.

k Without spin

Press this button if a final spin is not required after the

final rinse.

- b + Settings

For setting programme parameters.

FC Language settings

Another language can be temporarily selected using

this button.

m Start time

When this button is pressed before starting the

programme, information about selecting a start time

will appear in the display.

K Information

Any information which was input during

commissioning (e.g. Service Dept. telephone

number) will appear in the display when this button is

pressed.

Language selection

The language can be changed temporarily via the

flag symbol before starting the programme.

5 minutes after the programme has finished and

when the door is opened, the language reverts to its

original setting.

1 Mops standard 13,0/13,0 kg

60°C Main wash

Rinses 1050 rpm

1

If the FC function button is pressed and held for

more than 3 seconds, the following display will

appear:

Settings

Main menu

+

Confirm with the "OK" button.

^

Settings

Language F english (GB)

-

^ Select the language you want with the "+" button

and confirm your selection with the OK button.

234F 56~

Back <-

Language F

Supervisor level

OK

OK

~

+

FC

Back <- -

english (US) e

FC A

A

q Water drainage

A Back

Return to previous display page.

e/- Next / last line

~ Next page

S Save

See access to Supervisor level

$ Programme locked

Once a locked programme has been started, after 1

minute has elapsed it can no longer be stopped and

cancelled with the Finish button.

) Programme unlocked

Tone (buzzer) off

The display changes to the selected language.

Use the "A"button to return to the programme.

13

Washing

The machine should be commissioned by a Miele

service technician or an authorised Miele Service

dealer only.

Open the water supply valve.

^

Switch on the power supply main switch.

^

Switch the machine on with the I "Power On" button.

^

M

PROFESSIONAL

PW 5134

Welcome

The welcome screen will appear in the display.

1 Mops standard 13,0/13,0 kg

Pre-wash

60°C Main wash

1

234F 56~

Max. load

(dry laundry)

PW 5134

max. 13 kg

Maximum load weights are given in the programme

chart

Load the laundry.

^

Close the drum door using the handle. Do not slam

^

it.

Make sure that no items of washing are caught

between the door and the drum.

~

The first 6 programmes in the programme list can be

selected using buttons1-6.

Further programmes can be selected by pressing

and holding button 6 ~.

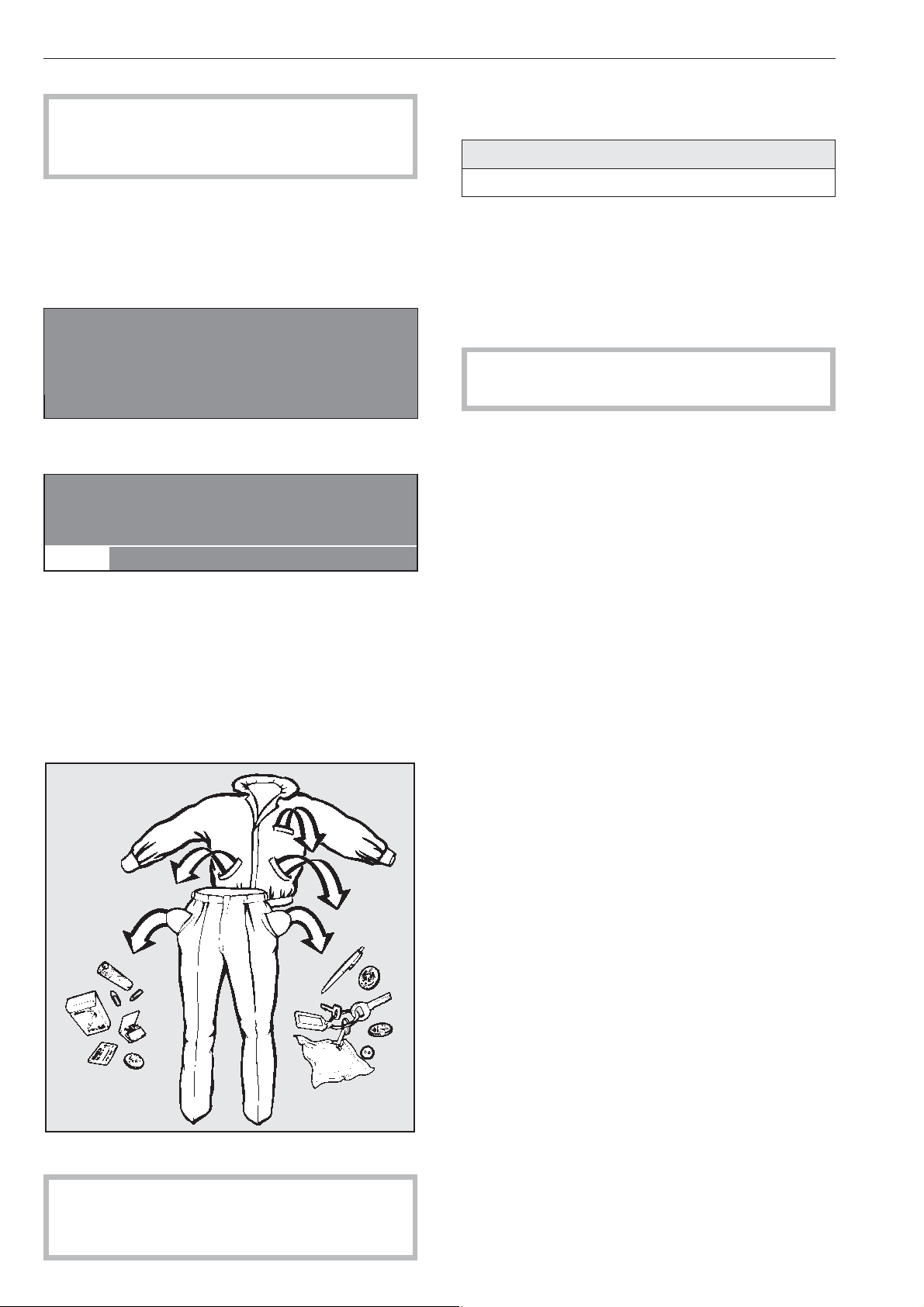

Laundry preparation

^

Empty all pockets

Foreign objects (e.g. nails, coins, paper clips, etc.)

can cause damage to textiles and to components

in the machine.

14

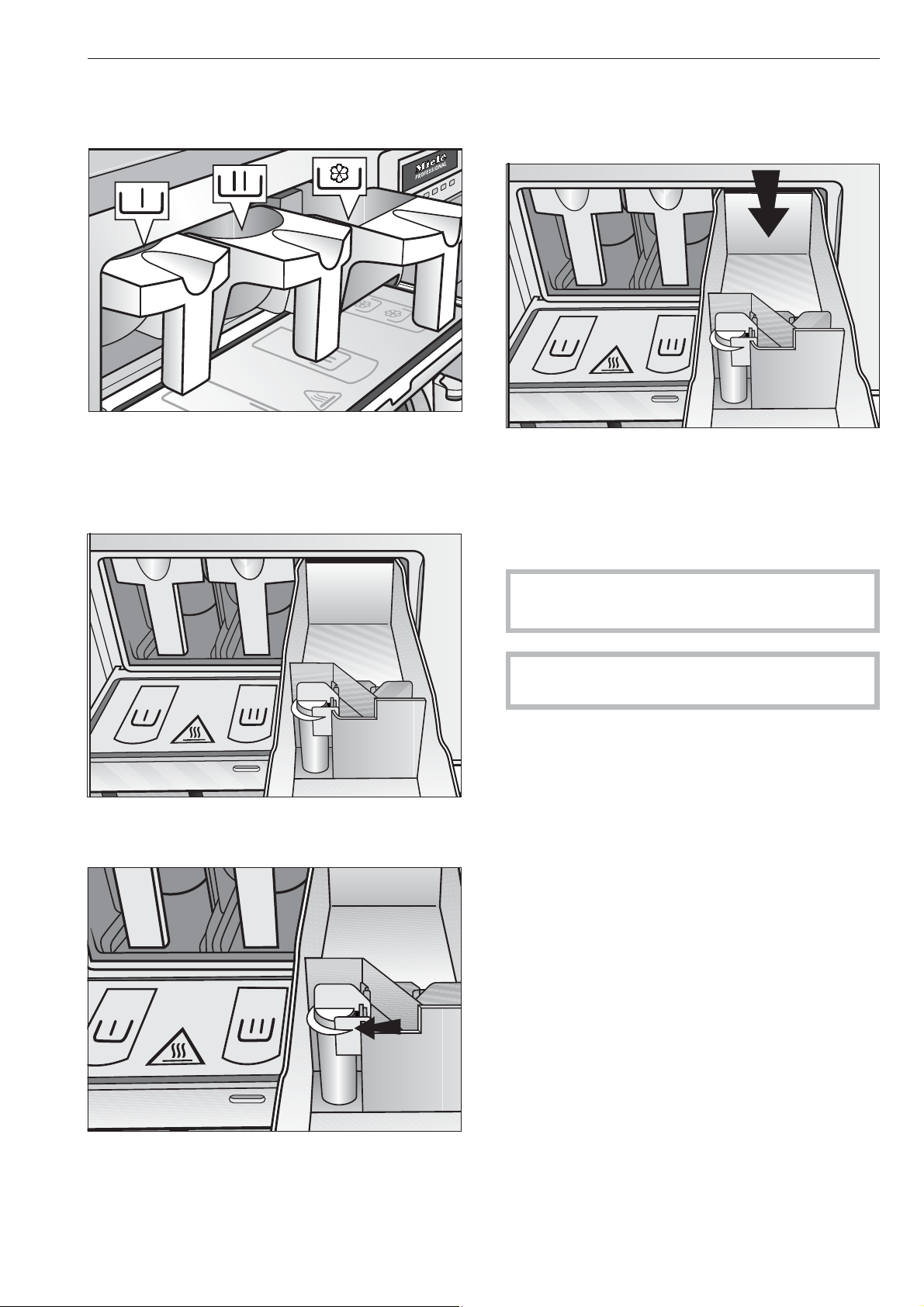

Washing

Adding detergent using the detergent

dispenser compartment.

For standard wash programmes add the detergent

^

for the main wash to the j compartment and if

desired, add detergent for a pre-wash to the i

compartment.

Add fabric conditioner to the front of the p

compartment.

Bleaching agent

Only use bleach on textiles marked with the x

symbol on the wash care label.

Liquid bleaching agents must only be dispensed

through designated dispenser compartments. The

agent will then be dispensed automatically during the

2nd rinse. Liquid bleaching agents should only be

used on coloured textiles which have a wash care

label stating that they are colour fast and suitable for

bleaching.

^

Add any other liquid agents to the back of the p

compartment (if this has been programmed).

For bleaching a 3rd rinse must also be

programmed into the machine.

,

Frequent use of chlorine products increases

the risk of damage to components.

Dyes, Colour-run/ dye removers and descaling

agents must be suitable for use in washing

machines. Please follow the manufacturer's

instructions.

^

Do not fill compartment p above the level marker

with liquid agents, as they will get through the

siphon and into the suds container before needed.

15

Loading...

Loading...