Page 1

Installation plan

Washer-extractor

PW 5134 MF

To avoid the risk of accidents or damage to the machine, it is essential to read

operating and installation instructions before installation and commissioning

This prevents you from harm and the machine from damage.

en - GB

09 748 180 / 02

Page 2

Legend:

Connection required

Connection optional or required,

depending on model

AV

Dump valve

KWH

Cold water (raw water)

B

Machine anchors

OS

Offshore version

BS

Installation on concrete plinth

PA

Equipotential bonding

DOS

Dispenser connection

SLA

Peak-load/energy management

EL

Electrical connection

UG

Box plinth

F

Machine feet, adjustable

UO

Open plinth

KW

Cold water

WW

Hot water

KWF

Cold water liquid dispensing

XKM

Communication module

All rights reserved. 04/14/431

2 09 748 180 / 02

Page 3

PW 5134 en - GB

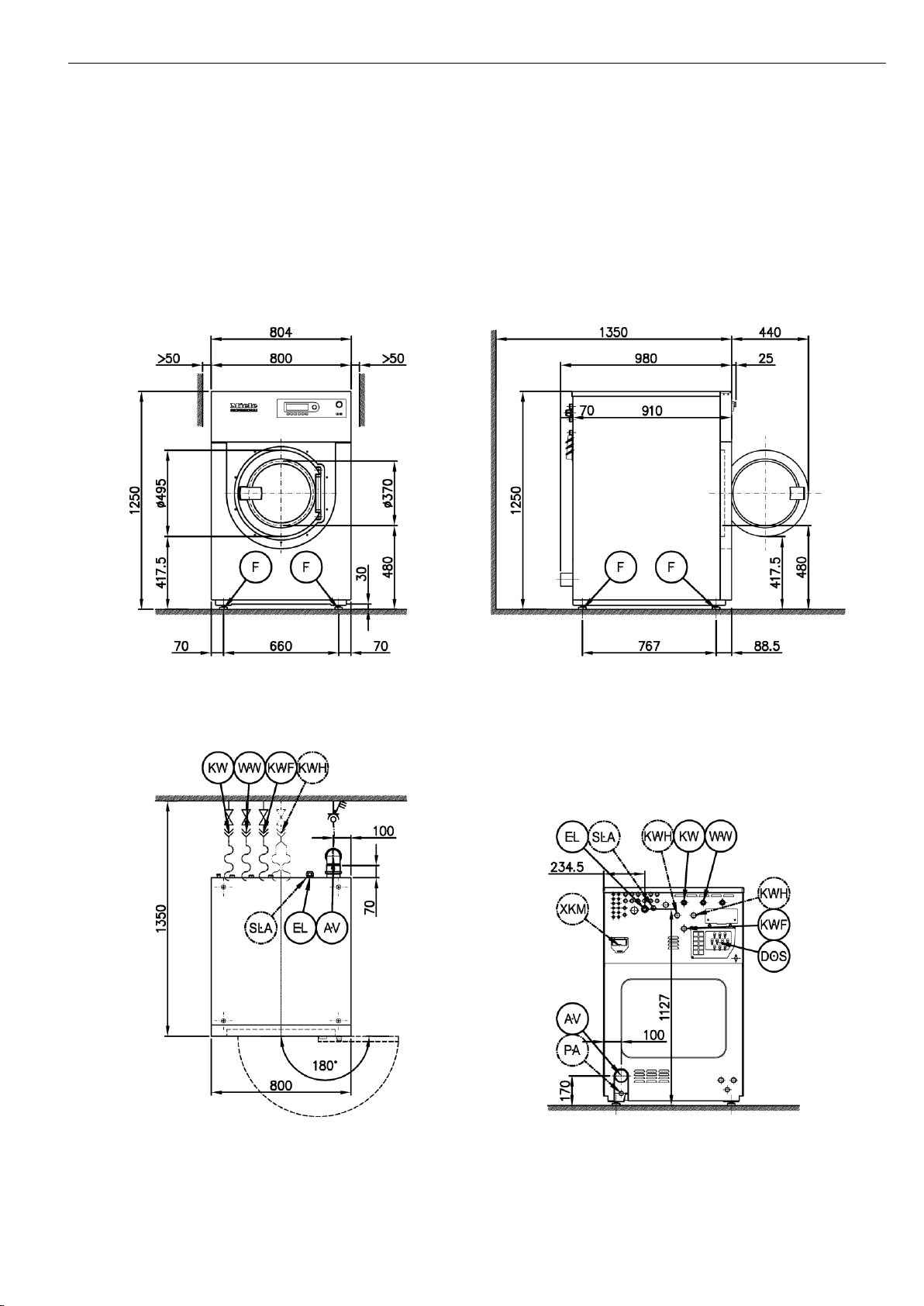

Machine dimensions PW 5134

09 748 180 / 02 3

Page 4

en - GB PW 5134

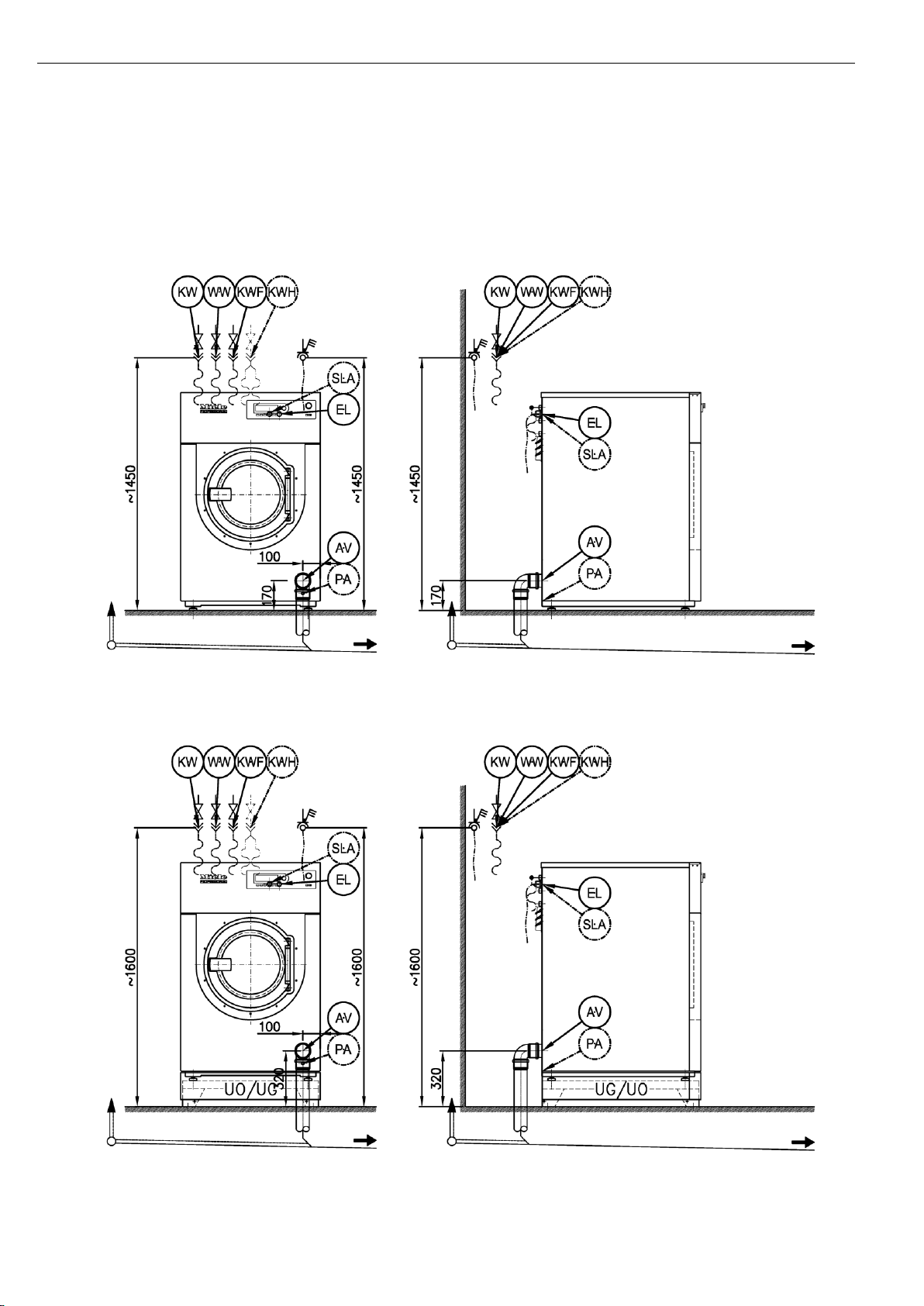

Installation PW 5134

4 09 748 180 / 02

Page 5

PW 5134 en - GB

Installation PW 5134

09 748 180 / 02 5

Page 6

en - GB PW 5134

Installation PW 5134

6 09 748 180 / 02

Page 7

PW 5134 en - GB

Technical data

PW 5134 MF

Detergent dispenser (WEK)

-

Load capacity (load ratio 1:25)

kg

13 Drum volume

l

130 Spin speed, max.

rpm

1050 g factor

360

Connection data

Heater rating / Nominal heat load

kW

15 Motor rating - Drive motor

W

2200

Electrical connection (EL)

Standard voltage

3N AC 380-415 V

Frequency

Hz

50 - 60

Total rated load, max.

kW

17 Fuse rating (B trip rating according to EN 60898)

A

3 x 25

Supply lead min. cross-section

mm²

5 x 4

Variations in the following countries:

Standard voltage (N only)

3 AC 220-240 V

Frequency

Hz

50 - 60

Total rated load, max.

kW

17 Fuse rating (B trip rating according to EN 60898)

A

3 x 50

Supply lead min. cross-section

mm²

4 x 10

Cold water, (KW)

Machine connection

Water pressure (flow rate)

kPa

100 - 1000

Recommended flow pressure (for short water intake times)

kPa

300 Flow rate, max.

l/min

16 Flow rate, max. (in absence of on-site water heating)

l/min

32 Average water consumption (60°C in standard mop programme)

l/h

Approx. 205

Connection to be provided on site, external thread according to DIN 44 991

Inch

3/4“

Connection hose 1/2" with 3/4" threaded union

No. 1

Connection hose length

mm

1500

Hot water (WW)

Machine connection

Max. permissible water temperature

°C

70 Water pressure (flow rate)

kPa

100 - 1000

Recommended flow pressure (for short water intake times)

kPa

300 Flow rate, max.

l/min

16 Average water consumption (60°C in standard mop programme)

l/h

Approx. 40

Connection to be provided on site, external thread according to DIN 44 991

Inch

3/4“ Connection hose 1/2" with 3/4" threaded union

No. 1

Connection hose length

mm

1500

Cold raw water (KHW)

Machine connection (separate kit required)

Water pressure (flow rate)

kPa

100 - 1000

Recommended flow pressure (for short water intake times)

kPa

300 Flow rate, max.

l/min

32 Connection to be provided on site, external thread according to DIN 44 991

Inch

1“ Y-piece connector 3/4" to 1"

No. 1

Connection hose 1/2" with 3/4" threaded union

No. 2

Connection hose length

mm

1500

= standard, = optional, + = only on request, - not available

09 748 180 / 02 7

Page 8

en - GB PW 5134

Technical data

PW 5134 MF

Cold water liquid dispensing (KWF)

Machine connection

Water pressure (flow rate)

kPa

100 - 1000

Recommended flow pressure (for short water intake times)

kPa

300 Flow rate, max.

l/min

5.5 Connection to be provided on site, external thread according to DIN 44 991

Inch

3/4“ Connection hose 1/2" with 3/4" threaded union

No. 1

Connection hose length

mm

1500

Dump valve (AV)

Machine connection

Max. drainage temperature

°C

95 Connection (ext. diameter)

mm

75 (DN 70)

Sleeve connection to be provided on site (int. diameter)

mm

75 (DN 70)

Max. transient flow rate

l/min

200

Equipotential bonding (PA)

Machine connection

Bolt hole (diameter)

mm

10

Peak load/energy management (SLA)

Machine connection

Control signal voltage

AC 230 V

Recommended supply lead cross-section

mm²

5 x 1.5

Communication module (XKM)

Communication module slot

Communication module for serial connection (XKM RS 232)

Dispenser connection (DOS)

Connection for 1 - 10 liquid products

Connection for 2 paste-type products

Hose connection for liquid dispensing, cross-section

mm

6 / 8 / 12

Hose connection for dispensing of paste-type products, cross-section

mm

12

Dispenser pumps

Connections of 1 - 6 dispenser pumps

Connection of electrical dispenser pumps 7 - 12 (optional kit)

Dispenser pump connection voltage

Connections for 'Container empty' and dispensing signals

Alternative flowmeter connection for monitoring dispensing

Installation on machine feet (F)

No. of machine feet

No. 4

Machine foot, height-adjustable with thread

mm

±10 Machine foot diameter

mm

25

Anchoring (B)

Standard anchoring

Anchor kit using angled brackets (from transport lock)

Required anchor points

No. 2

Wood screws according to DIN 571

mm

8 x 80

Rawl plugs (diameter x length)

mm

12 x 60

Anchoring of Miele plinths

Accessory: Miele plinth (fasteners included)

Required anchor points

No. 4

Wood screws according to DIN 571

mm

8 x 80

Rawl plugs (diameter x length)

mm

12 x 60

= standard, = optional, + = only on request, - not available

8 09 748 180 / 02

Page 9

PW 5134 en - GB

Technical data

PW 5134 MF

Plinth floor anchoring (to be provided on site)

Machine installation on on-site plinth (concrete or masonry)

Plinth installation footprint (W/D)

mm

950/1000

Required anchor points

No. 2

Wood screws according to DIN 571

mm

8 x 80

Rawl plugs (diameter x length)

mm

12 x 60

Machine data

Sound emissions and floor load

Transport weight (incl. packaging)

kg

360 Machine weight (net weight)

kg

340 Max. static floor load

N

3778 Max dynamic floor load

N

503 Max. floor load in operation

N

4290 Drum frequency

Hz

18.3

Site-access dimensions

Min. site-access (H/W)

mm

1300/820

Unit dimensions

Overall machine dimensions (H/W/D):

mm

1250/804/1005

Stripped-down machine dimensions(H/W/D)

mm

1250/800/910

Installation dimensions

Min. side gap

mm

50

Recommended distance to opposite wall from front of machine

mm

1350 Min. wall gap to machine lid

mm

400

Emissions

Sound pressure level: in accordance with EN ISO 11204, workplace-related

dB(A)

69 Sound power level (A) according to EN ISO 9614 Part 2

dB(A)

< 80 Heat dissipation rate to installation site

W

1470

Options / Accessories

Features

Box plinth (UG)

Box plinth, H 150 mm (UG 6013)

Galvanised plinth, stainless-steel front, octoblue side panels

Box plinth, H 300 mm (UG 6013-30)

Galvanised plinth, stainless-steel front, octoblue side panels

Open plinth (UO)

Open plinth, H 150 mm (UO 6013)

Galvanised plinth, octoblue stove finish

Open plinth, H 300 mm (UO 6013-30)

Galvanised plinth, octoblue stove finish

Communication module (XKM)

Communication module for serial connection (XKM RS 232)

Plug-in module with cable and Sub-D plug, 9-pole

Fluff filter box (FFK)

Fluff filter box, standalone (FFK01)

Stainless-steel fluff filter box, perforated stainless-steel filter, DN70 connection

Accessories

Water recycling (WRG02)

Water recovery module

Vapour and foam venting kit (BWS01)

Kit to discharge steam and foam from machine

Kit: Raw water (BSH)

Kit containing additional inlet valves for raw (untreated) water

Flowmeter (FRZ01)

Operating data acquisition kit for recording water volumes

Connection for payment system (BSK)

Connection of single-machine coin mechanisms

Connection of peak-load/energy management (BSS)

Connection for peak-load and energy management functionalities

= standard, = optional, + = only on request, - not available

09 748 180 / 02 9

Page 10

en - GB PW 5134

Installation and planning notes

Installation requirements:

The electrical connection may only be made to a power network

provided in accordance with all appropriate local and national

legislation and regulations.

In addition, all regulations issued by the appropriate utilities as well as

standards relating to occupational safety, and all applicable valid

regulations and technical standards must be observed!

The machine should only be commissioned, serviced and

maintained by a Miele authorised and trained service technician

only.

Transportation and site access

The machine must not be moved without the transit bars in place.

Keep the strut in a safe place. They must be re-fitted if the machine is

to be moved again (e.g. when moving house).

General operating conditions

Ambient temperature in installation room: 15°C - 40°C

Relative humidity: 10% - 85%

Depending on the nature of the installation site, sound emissions and

vibration may occur.

Miele recommends consulting a specialist if particular requirements

apply at the installation site with respect to sound emissions.

Electrical connection

Electrical connection is the responsibility of a qualified electrician.

Take note of the rated loads on the machine and in the enclosed

wiring diagram.

The machine can be hard-wired or connected using a switched

connection in accordance with IEC 60309-1. The wall socket or switch

must be accessible after installation.

It is always recommended to make electrical connection via a plug

and socket so that electrical safety checks, e.g. during repair or

service work, can be carried out easily.

If the machine is disconnected from the electricity supply ensure

adequate measures are taken to ensure that the machine cannot be

reconnected to the electricity supply until all work has been carried

out.

If an earth leakage circuit breaker (ELCB) is required by local

regulations, a Type B earth leakage circuit breaker (AC/DCsensitive) should be used.

A supply lead is not supplied with the machine and must be provided

on site.

References to cable cross-sections in the technical data refer only to

the required supply lead. Please consult relevant local and national

regulations when calculating any other wire gauges.

Cold water connection

Connection to the water supply should be carried out by a qualified

plumber and should incorporate a tap with a threaded union. If not

available, a qualified plumber should connect the machine to the

water supply.

The machine can be connected to a potable water supply without a

non-return valve as the machine is designed according to the latest

standards to protect drinking water.

The machine must be connected to the water supply using the inlet

hoses provided.

Connection using 2 inlet hoses

A Y-piece is supplied with the machine.

Hot water connection

The same connection requirements as for cold water also apply to hot

water (max. 70°C).

The hot water supply must not exceed the maximum temperature.

In the event that hot water is not available on site, connection of the

second hose must be made to a cold water supply.

The required amount of hot water should be added to the cold water

volume.

Cold water (raw water)

The connection of an optional type of water is optional and requires

the use of an additional kit.

The same requirements apply as for the cold water connection.

Cold water liquid dispensing

The connection for an additional inlet hose is either provided on the

machine or can be retrofitted using an additional kit when connecting

a liquid dispensing system.

The additional cold water intake flushes the contents of the dispenser

into the drum and prevents any carryover of detergent.

The same requirements apply as for the cold water connection.

Equipotential bonding

If necessary, equipotential bonding with good galvanic contact must

be guaranteed in compliance with all applicable local and national

installation specifications.

Equipotential bonding must have an earth current rating >10 mA.

Connection material for equipotential bonding must be provided on

site.

10 09 748 180 / 02

Page 11

PW 5134 en - GB

Peak load/energy management

The machine can be connected to a peak-load or energy

management system using an optional kit.

Three signals are issued by the machine via a terminal strip. The

terminal strip is labelled a, b, c, and d.

a - Output signal, Start of machine operation

b - Output signal, Machine heating request

c - Peak-load input signal, Machine heating deactivated

d - Neutral conductor

When a peak-load signal is received, the heating is deactivated and

the programme stopped. An appropriate message appears in the

display.

The programme is resumed automatically when the peak-load system

reactivates the heating.

Dispenser connection

Depending on the model, up to 12 products can be dispensed.

It is particularly important to observe manufacturer's instructions

when using a combination of detergents, additives and specialpurpose products.

Connection of dispenser to mixer box

Dump valve

Machine drainage is effected by a pinch valve which is operated by

the pressure of the water supply.

The machine can be connected directly to the on-site drainage system

(without an odour trap) or via a floor drain (with odour trap).

A vented drainage system is vital for unimpeded drainage. If on-site

venting is insufficient, a vent kit (Mat. no. 05239540) is available from

Miele Spares or authorised dealers.

If several machines are connected to a single drain pipe, this should

be sufficiently large to allow all machines to drain simultaneously.

Slow or obstructed drainage or a backlog of water in the drum as a

result of undersized pipework can result in faults occurring during

programmes which will result in error messages appearing in the

display.

Installation and anchoring

The machine must be installed on a perfectly smooth, level and firm

surface which is able to withstand the quoted loads.

The machine should be levelled in both directions with the aid of the

adjustable feet.

The floor load created by the machine is concentrated and transferred

to the installation footprint via the machine feet.

It is absolutely necessary to bolt the machine to the floor.

The angled brackets provided can be used to anchor the machine.

The material provided is intended to bolt the machine to a concrete

floor.

Bolts and fasteners for all other floor types must be provided on site.

The gaps between the machine and adjacent walls are to be

construed as minimum requirements. Side gaps must be observed to

allow for the dynamic movement of machines.

Connections 1 and 2 are provided for viscous agents. These

connections are sealed and need to be drilled open using a drill bit.

Water connections for liquid dispensing connections 3 to 12 are for

liquid dispensing. These connections are sealed and must be cut to

suit the diameter of the hose with a suitable hacksaw.

If opened connections are no longer required, they must be resealed.

Feed pumps can be connected directly inside the machine for

dispensing. The machine's electronic controls monitor dispensing and

the calibration of the dispenser pumps.

Alternatively, flowmeters can be connected to provide greater

dispensing accuracy.

'Container empty' signals are provided to ensure that sufficient

volumes of dispensed products are available during external

dispensing. A message appears in the display when a container is

empty.

Plinth installation

The machine can be installed on a machine plinth (open or box plinth,

available as an optional Miele accessory) or on a concrete plinth to be

provided on site.

The quality of the concrete and its strength must be assessed

according to the machine load. Ensure that any raised concrete plinth

is adequately bonded to the concrete floor below!

09 748 180 / 02 11

Loading...

Loading...