Page 1

Operating Instructions

Washer-disinfector

G 7899

To prevent accidents

and machine damage

read these instructions

before

installation or use.

en-US

M.-Nr. 09 461 360

Page 2

2

Page 3

Contents

IMPORTANT SAFETY INSTRUCTIONS

Intended use

Guide to the machine

Opening and closing the door

To open the door using the emergency release ..........................13

Water softener

Setting the water softener ...........................................14

Filling the salt reservoir .............................................16

Add salt indicator..................................................17

Applications

Loading the machine ...............................................19

Water connector spring adapter ......................................20

Height adjustable top basket.........................................20

Surgical instruments ...............................................21

ENT ............................................................22

GYN............................................................23

Rigid Endoscopy ..................................................25

Ophthalmology ...................................................26

Possible effects of using non-recommended Cleaning Agents

Dispensing cleaning agents

Add rinse aid indicator .............................................31

Adding rinse aid ..................................................31

Setting the dosage.................................................32

Adding neutralizing agent ...........................................33

Add neutralizing agent indicator .....................................34

Adding cleaning agent .............................................35

Using powder cleaning agents .......................................35

Operation

Turning on .......................................................37

Starting a program.................................................37

Selecting “Drying” 0............................................37

Program sequence indicators ........................................38

At the end of the program ...........................................38

Additional drying................................................38

Canceling a program...............................................39

Turning off .......................................................39

3

Page 4

Contents

Program chart

Programmable functions

To activate the programming mode .................................42

Saving values in programming mode................................42

Exiting the programming mode without saving ........................42

Resetting the operating hours counter for the filter in the drying unit ..........43

DOS 1 (liquid detergent) ............................................44

Setting the dosage concentration...................................44

Priming the dispensing system.....................................45

DOS 3 (neutralizer) ................................................46

Setting the neutralizer dosage .....................................46

Priming the dispensing system.....................................47

Buzzer ..........................................................48

Changing program parameters .......................................49

Changing wash and rinse parameters ...............................49

Changing the drying parameters ...................................49

Changing the temperature ........................................50

Changing the temperature holding time..............................50

Restoring to factory default settings ...................................51

Setting the time and date............................................52

Process documentation

Cleaning and care

Cleaning the filters in the wash cabinet.................................56

Cleaning the spray arms ............................................58

Baskets and inserts ................................................60

Drying unit (TA) - Maintenance .......................................61

Cleaning the drain pump and non-return valve...........................62

Cleaning the water intake filters.......................................63

Frequently asked questions

After sales service

Caring for the environment

Installation

Electrical connection

Plumbing

Technical data

4

Page 5

IMPORTANT SAFETY INSTRUCTIONS

This washer-disinfector complies

with all applicable safety

regulations. However, improper use

may cause material damage and/or

personal injury.

Read the operating instructions

carefully before using this

appliance. This will help keep you

safe and avoid damage to the

appliance.

Keep these instructions in a safe,

accessible location.

Intended use

This washer-disinfector is not

~

intended for any purpose that is not

specified in the operating instructions.

Conversions, modifications, and other

unintended uses are considered to be

dangerous. The cleaning and

disinfection processes described

herein apply only to those medical

products that are specifically designed

by the manufacturer to be re-used and

thermally disinfected. Always follow the

instrument manufacturer’s instructions.

This washer-disinfector is intended

~

for stationary indoor use only.

Please pay attention to the following

to maintain safe procedures.

Installation and repair work should

~

only be performed by a Miele

authorized service technician. Work by

unqualified persons could be

dangerous and may void the warranty.

The installation and the work flow of

~

the instruments must be in such a way,

that a recontamination of disinfected

instruments and a mixed up of clean

and dirty instruments is not possible.

AMMI ST79 shows an example of

proper layout and work-flow.

Do NOT install the appliance in an

~

area where there is a risk of explosion

or freezing.

The electrical safety of this

~

appliance is only ensured if it is

connected to a properly grounded

electrical system. It is very important to

verify this fundamental safety feature. If

in doubt have the wiring checked by an

electrician.

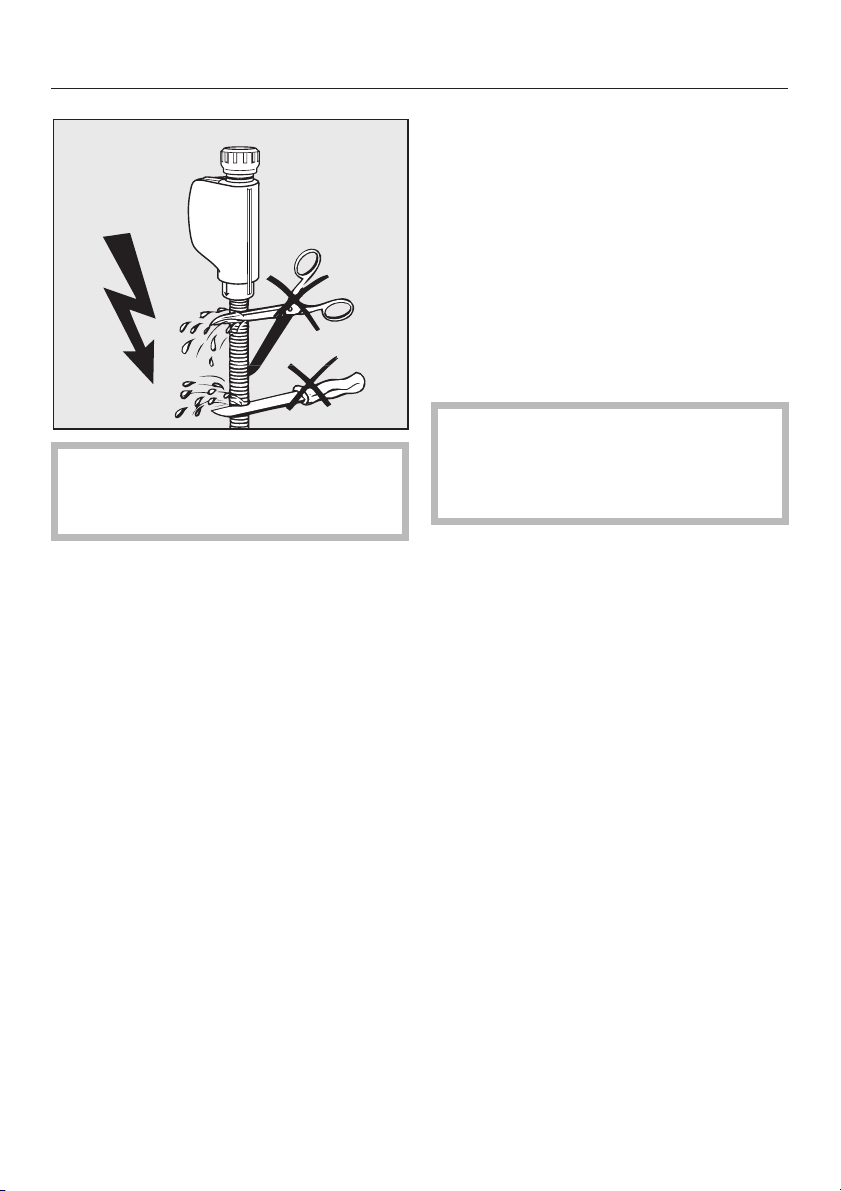

A damaged or leaking

~

washer-disinfector may be dangerous

and pose a safety hazard. If you

suspect a leak, shut down the

washer-disinfector and immediately

contact Miele.

As standard, the washer-disinfectors

~

drain water will reach temperatures

greater than 160°F. These temperature

can damage the drain system. In order

to reduce the drainage temperature

Miele offers an optional drain

temperature reduction Kit.

5

Page 6

IMPORTANT SAFETY INSTRUCTIONS

Operators must be trained on a

~

regular basis. Untrained personnel

should not be allowed access to the

appliance or its controls.

Please do not use the

~

washer-disinfector, before it has been

set up by a Miele Service Technician.

The Technician will perform the initial

set-up and verification of the machine.

Always exercise caution when

~

handling cleaning agents. Some are

corrosive and irritants. Wear safety

glasses and gloves! Always follow the

manufacturer’s safety

recommendations when using cleaning

agents.

The washer-disinfector is designed

~

to operate with water and the

recommended cleaning agents only!

The appliance MUST NOT be used with

organic solvents or flammable liquids.

These may cause an explosion or

damage rubber and plastic

components, which in turn could cause

leaks.

Avoid inhaling powdered products.

~

Never swallow cleaning agents as this

can result in chemical burns to the

mouth and throat, or suffocation.

The water in the wash cabinet is

~

NOT safe to drink!

When operating the

~

washer-disinfector, beware of the high

temperatures involved. Bypassing the

electronic door lock to open the door

carries the risk of burns or scalding.

Allow mobile units, baskets, inserts,

~

and loads to cool before removing

them. Empty any water from hollow

items into the wash cabinet before

removing.

Do not touch the heating elements.

~

They may still be hot enough to cause

burns several minutes after the

program has ended.

NEVER hose down the

~

washer-disinfector or the immediate

vicinity with a water hose, steam

cleaner, or power washer.

Before servicing the

~

washer-disinfector, disconnect it from

the power supply.

To assist in maintaining quality

standards when processing medical

devices (such as surgical

instruments), to protect patients, and

to avoid damage to property, the

following items should be observed!

Only authorized persons should

~

interrupt a program, and only in

exceptional cases.

Do not lean or sit on the open door.

~

This could damage the

washer-disinfector or cause it to tip

over.

Take care when loading items with

~

sharp, pointed ends. Position them in

the wash cabinet so that they do not

pose a risk of injury.

6

It is the responsibility of the operator

~

to check that the required cleaning and

disinfection standards are met. Process

results need to be regularly checked

and documented through inspection.

Page 7

IMPORTANT SAFETY INSTRUCTIONS

Under certain circumstances, some

~

cleaning agents can cause damage to

the appliance. Consult the cleaning agent

manufacturer for recommendations. For

concerns involving possible damage to

the appliance or materials, please

contact Miele.

Pre-treating (e.g. with cleaners or

~

disinfectants) as well as some types of

soiling and the interaction of cleaning

agents can cause foaming. Foam can

have an adverse effect on cleaning and

disinfection.

Some disinfectant can denaturate

~

proteins which has an adverse effect on

cleaning. Please only use non foaming

and non denaturation cleaners or

disinfectants for manual prewash.

To prevent damage to the

~

washer-disinfector and accessories

from the effects of cleaning agents only

use chemical agents which have been

approved by their manufacturer for use

in the application you are using. Miele

can recommend suitable products.

Even when a cleaning agent is

~

recommended, the appliance

manufacturer takes no responsibility for

the effect of such chemicals on the

items being washed.

Note that formulation changes, storage

conditions, etc. that are not disclosed

by the manufacturer may adversely

affect the cleaning results.

Always follow the manufacturer’s

~

instructions when using cleaning

agents. To avoid possible chemical

reactions, only use cleaning agents for

the applications and purposes intended

by their manufacturer.

For critical applications where very

~

high processing quality requirements

must be met, it is strongly

recommended that all process-related

factors (cleaning agents, water quality,

etc.) be discussed in advance with

Miele.

Use mobile units, baskets and

~

inserts only as instructed by the

manufacturer.

Hollow items must be positioned so

they receive full exposure to wash

water.

Empty all containers and hollow

~

items before loading them in the

washer.

Ensure that no acid or solvent

~

residues, especially hydrochloric acid

or chloride solutions, get inside the

wash cabinet. Any items that can rust

should also be avoided.

Any solvents used should not be

present in more than trace amounts.

To avoid corrosion, ensure that the

~

stainless steel exterior does not come

into contact with solvents containing

hydrochloric acid / vapors.

Whenever work is conducted on the

~

water supply, the supply lines to the

washer must be bled.

Failure to do so can result in damage to

the appliance.

Follow the instructions in this manual

~

and in the Installation manual.

7

Page 8

IMPORTANT SAFETY INSTRUCTIONS

Accessories

Whatever the application, only Miele

~

accessories should be connected to, or

used in, this machine. Consult Miele on

the type and application of such

equipment.

Use only Miele mobile units, baskets

~

and inserts. If Miele accessories are

altered in any way, or equipment from

another manufacturer is used, cleaning

and disinfection results cannot be

ensured. Damage caused in these

cases may be excluded from the

warranty.

Only use Miele approved cleaning

~

agents. Use of other cleaning agents

may void the warranty and may result is

poor cleaning results.

Please consult Miele Applications

(medical@mieleusa.com) for any

questions regarding detergents and

effects on the items being cleaned.

Symbols on the appliance

Warning:

Observe the operating

instructions!

Warning:

Risk of electric shock!

Disposing your old appliance

Please note that the appliance may

~

be contaminated by blood or other

bodily fluids and must be

decontaminated before disposal.

For safety and environmental

protection, be sure to remove all

chemical residue, in compliance with

safety regulations (wear protective

eyewear and gloves!).

Remove or destroy the door latch, to

prevent children from locking

themselves inside. The appliance can

now be sent for disposal through the

proper resource recovery facilities.

SAVE THESE

INSTRUCTIONS

8

Page 9

Intended use

This washer-disinfector can be used to

clean, rinse, intermediate-level

thermally disinfect, and dry a wide

range of reusable medical devices in

hospitals, surgery centers, and clinics.

Always follow the surgical instrument

manufacturer’s instructions for

machine-based cleaning. This

washer-disinfector provides an

automated process for the initial steps

of cleaning and intermediate-level

disinfection of re-useable surgical

instruments prior to sterilization

G 7899 is designed for applications

such as:

General Surgical Instruments

^ Reusable, hard-surfaced surgical

instruments such as scissors,

forceps, etc.

^ Stainless steel lumened instruments.

These can be processed but must be

connected to Miele injection ports

according to loading instructions

provided with the specific Miele

accessory.

Minimally Invasive Surgical (MIS)

Instruments

. The

Microsurgical Instruments

Such as instruments used in eye

^

surgery

When processing instruments in the

Miele washer-disinfector you must:

Follow the instrument manufacturer’s

^

instructions for cleaning and

disinfection. Instruments must be

disassembled according to the

manufacturer’s instructions

Follow Miele instructions for proper

^

loading (included with specific

accessories and in the “applications”

section of this manual). Proper

instrument loading and connection of

lumened instruments to injection

ports is required

^ This washer-disinfector is intended to

provide the initial step in

reprocessing of soiled, re-usable

medical devices. Any devices that

contact blood or compromised

tissues must be sterilized prior to

re-use following industry best

practices such as AAMI ST79.

^

Rigid endoscopes

^

Note: The G 7899 is NOT intended

for reprocessing of flexible

endoscopes of any kind.

Containers and utensils

^

Such as kidney dishes, sterilization

containers, trays, etc.

9

Page 10

Intended use

Processing instruments by machine

achieves reproducible results with less

opportunity for human error when

compared with to manual cleaning.

Thermal disinfection can be carried out

using the Vario TD program which

meets the parameters to achieve

intermediate-level disinfection.

The cleaning program as well as

chemical agents must be chosen

according to the type of soil and load

being processed.

Medical devices are best processed

using the Vario TD program. The final

result will be instruments that are clean,

free of residue, and ready for

subsequent sterilization. Only then can

the instruments be safely used.

The use of a suitable load carrier

(basket, module, insert, etc.) is

important to ensure the adequate

cleaning of the load. Examples are

given in the “Applications” section.

The washer-disinfector can be

programmed to perform the final rinse

with tap water, or with purified water of

a quality to suit the application

(de-ionized, de-mineralized, reverse

osmosis (RO), distilled). We

recommend the use of purified water.

All instruments and accessories

cleaned in the washer-disinfector

(with the exception of non-critical

items) must be sterilized before use.

10

Page 11

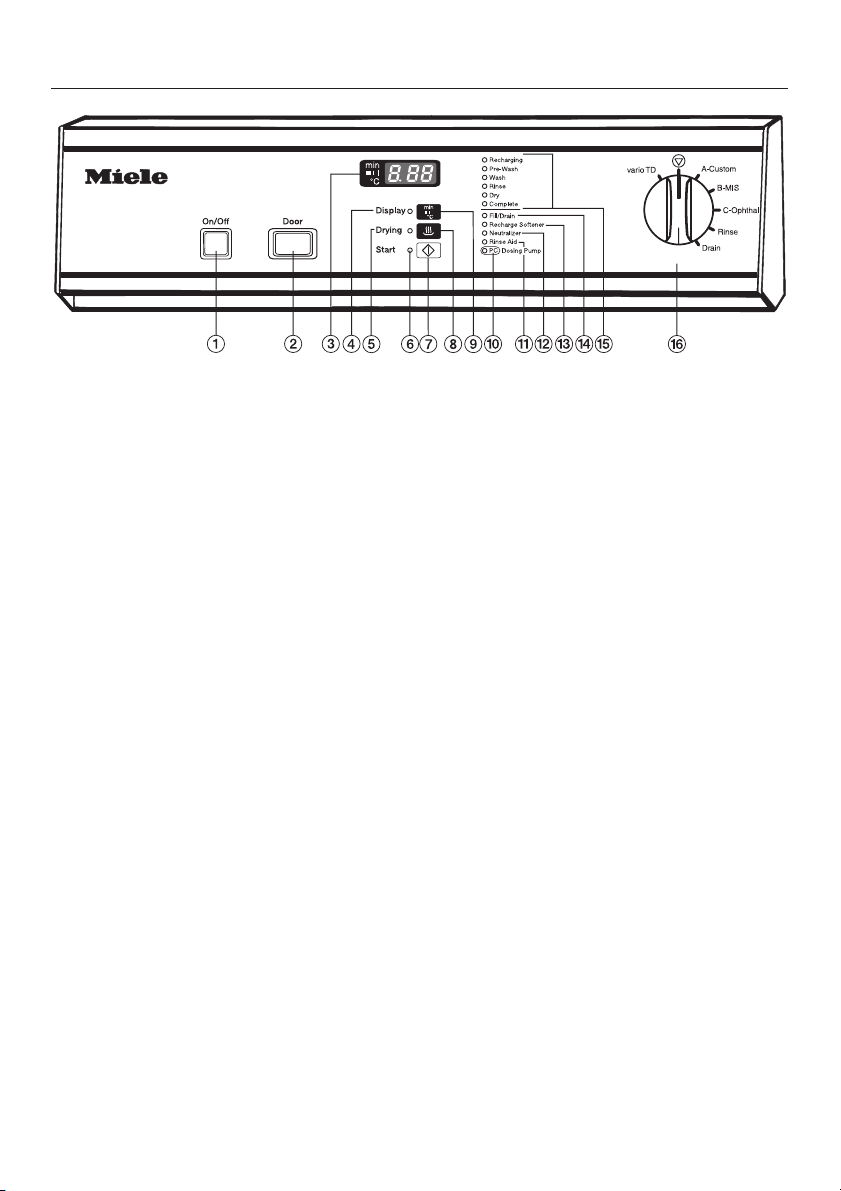

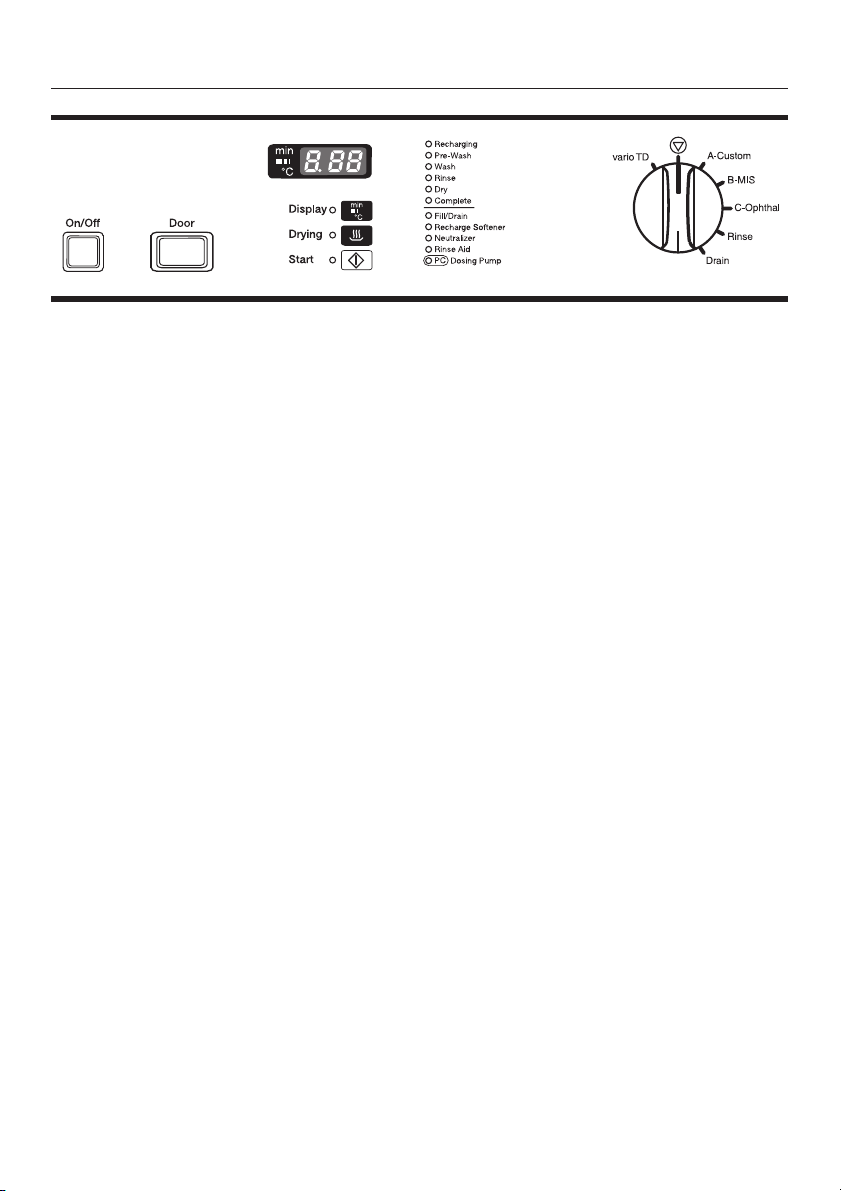

Guide to the machine

a “On/Off” button

b “Door” button

c Display

d “Display” indicator

e “Drying” indicator

f “Start” indicator

g “Start” 6 button

h “Drying” 0 button

i “Display” ß button

to toggle between the:

- actual Temperature in °C

- elapsed time

- active wash blocks

j “8 Dosing Pump” indicator and

optical interface for

service technician.

Also used as an

“add liquid cleaning agent”

indicator when connected

toaK60DOSmodule for

liquid cleaning agent

k Refill “Rinse Aid” indicator

l Refill “Neutralizer” indicator

m “Recharge Softener” indicator

n “Fill/Drain” indicator

o Program sequence display

p Program selector

11

Page 12

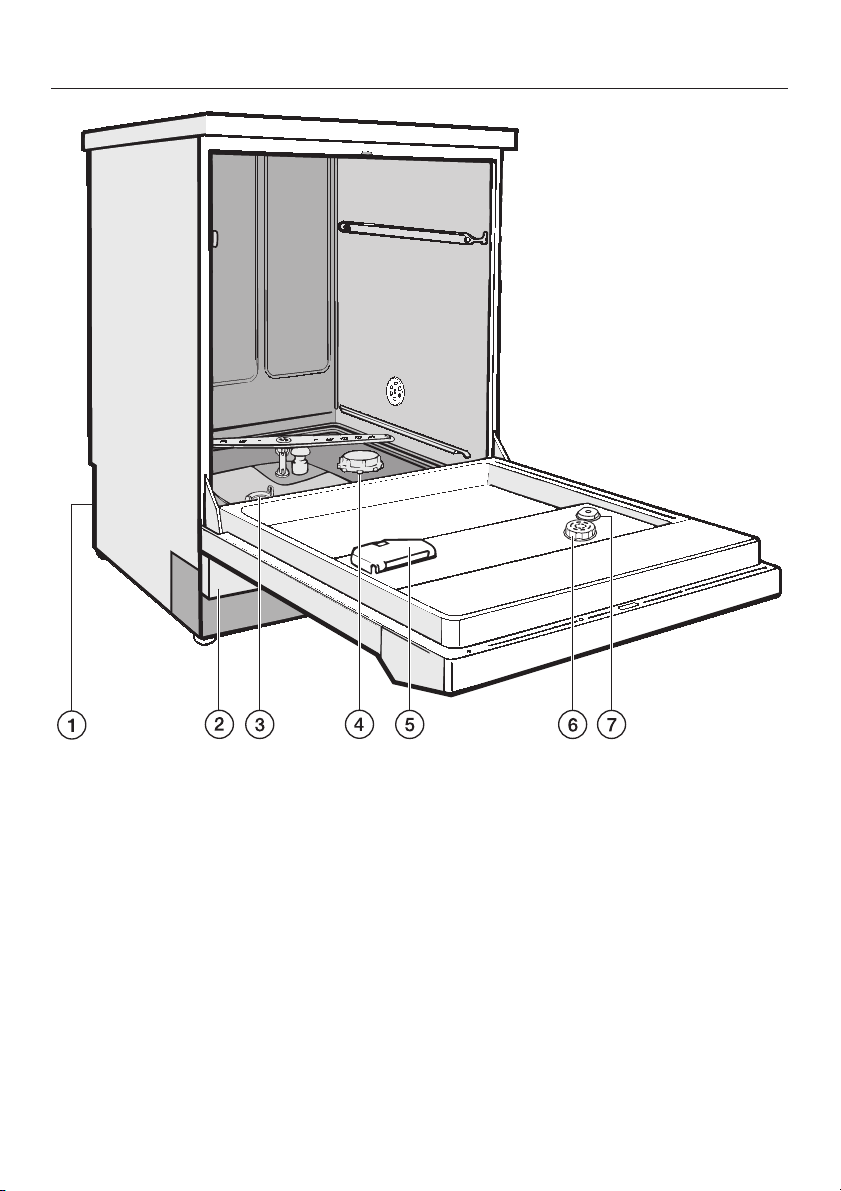

Guide to the machine

a Connection for the optional K 60

DOS module for liquid cleaning

agents

b Service panel

c Combination filter

d Salt reservoir

e Dispenser for powder cleaning agent

12

f Rinse aid reservoir (with dosage

selector)

g Rinse aid level indicator

At the rear of the machine:

–

RS 232 Interface connection

(used for optional process

documentation via a printer or

software)

–

Suction tube for external neutralizing

agent container

Page 13

Opening and closing the door

Electric door lock

This machine is equipped with an

electric door lock.

The door can only be opened when:

the electrical supply to the machine

^

is on and

the “On/Off” button is pressed.

^

To open the “Door”

Press the door release switch in as

^

far as it will go, and at the same time

grip the handle and and pull the door

open.

Do not touch the heating

,

elements, you could burn yourself.

They remain hot for some time after

the end of the program.

The door cannot be opened after a

wash program has been started, and it

will remain locked until the end of the

program. It is possible however to open

the door during the “Rinse” and “Drain”

programs.

The machine can also be programmed

(by a Miele service technician) to open

during “Drying”.

To close the door

Lift the door and push it until it clicks

shut. Do not press the door release

button while shutting the door.

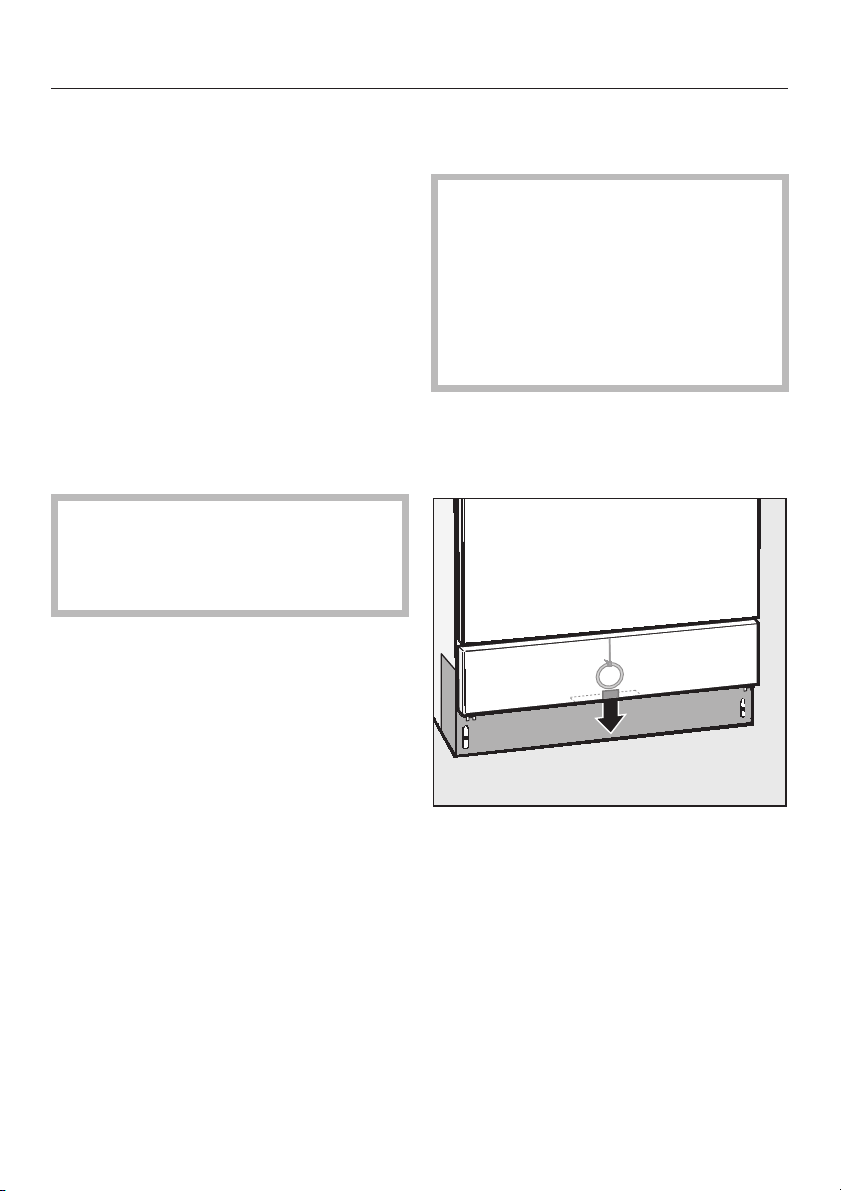

To open the door using the

emergency release

The emergency release should only

be used when the door cannot be

opened normally, such as in the

event of a power failure.

If the door is opened using the

emergency release cord, there is a

danger or burning or scalding!

Turn the program selector to f.

^

Turn the machine off with the

^

“On/Off” button.

^

The emergency release cord is

located at the bottom of the machine

behind the service panel. Pull it

downwards to open the door.

13

Page 14

Water softener

Before using the washer-disinfector for

the first time, the water softener should

be programmed. The water should be

softened to avoid calcium deposits on

instruments and in the washer

chamber.

If the water supply is harder or softer

than the default factory setting of

19 gr/gal (340 ppm CaCO

), the setting

3

should be changed. See “Setting the

water softener”.

In order to function properly, the

–

water softener requires a supply of

reactivation salt.

– The washer must be programmed to

match the hardness of the water

supply.

– Your local water authority can

provide information about the

hardness of the tap water in your

area.

If the water hardness is known to

fluctuate, always program the softener

for the highest value.

Setting the water softener

Close the door.

^

Use the On/Off button to turn off the

^

machine.

Turn the program selector to f.

^

Simultaneously press and hold the

^

“Display” ß and “Start” 6 buttons,

while pressing the On/Off button.

The current program version P....

will appear in the display, and the

“Fill/Drain” indicator will light.

Press the “Drying” 0 button once.

^

E01 will appear in the display.

^ Turn the program selector switch to

the one o’clock position.

The number 19 will appear in the

display (this indicates the factory

setting in gr/gal).

Please refer to the “Water softener Settings” table on the following page to

determine the setting you will need.

The built-in water softener can be

programmed between1-60gr/gal

(20 - 1080 ppm).

Please note the water hardness in the

space provided here:

gr/gal or ppm CaCO

This may be needed for any

troubleshooting should problems occur

in the future.

14

^

Press and hold the “Display” ß

button until the required value

appears in the display.

(Once the 60 setting has been

reached, the counter will begin again at

0.)

^

Press “Start” 6.

SP will appear in the display.

3

^

Press “Start” 6 again.

The setting you selected is now stored

in memory. The display light(s) will turn

off.

The machine is now ready for use.

Page 15

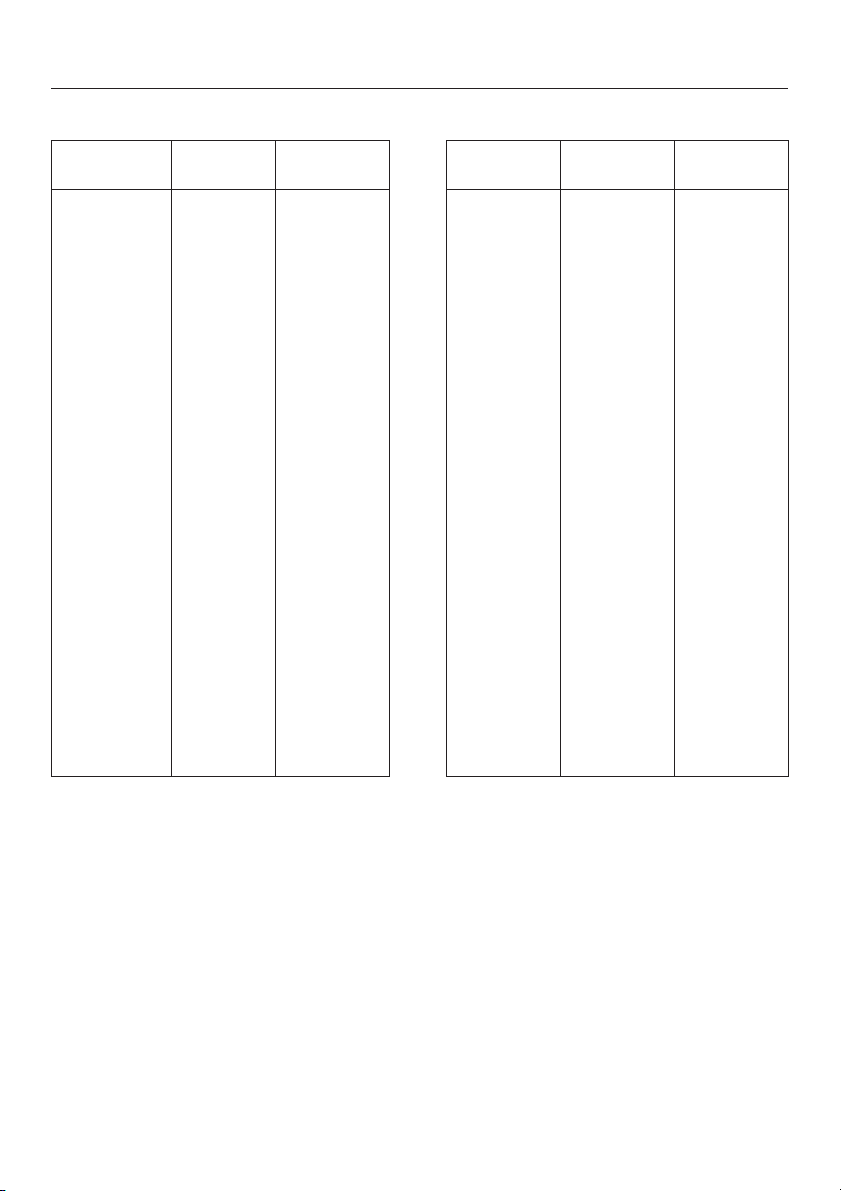

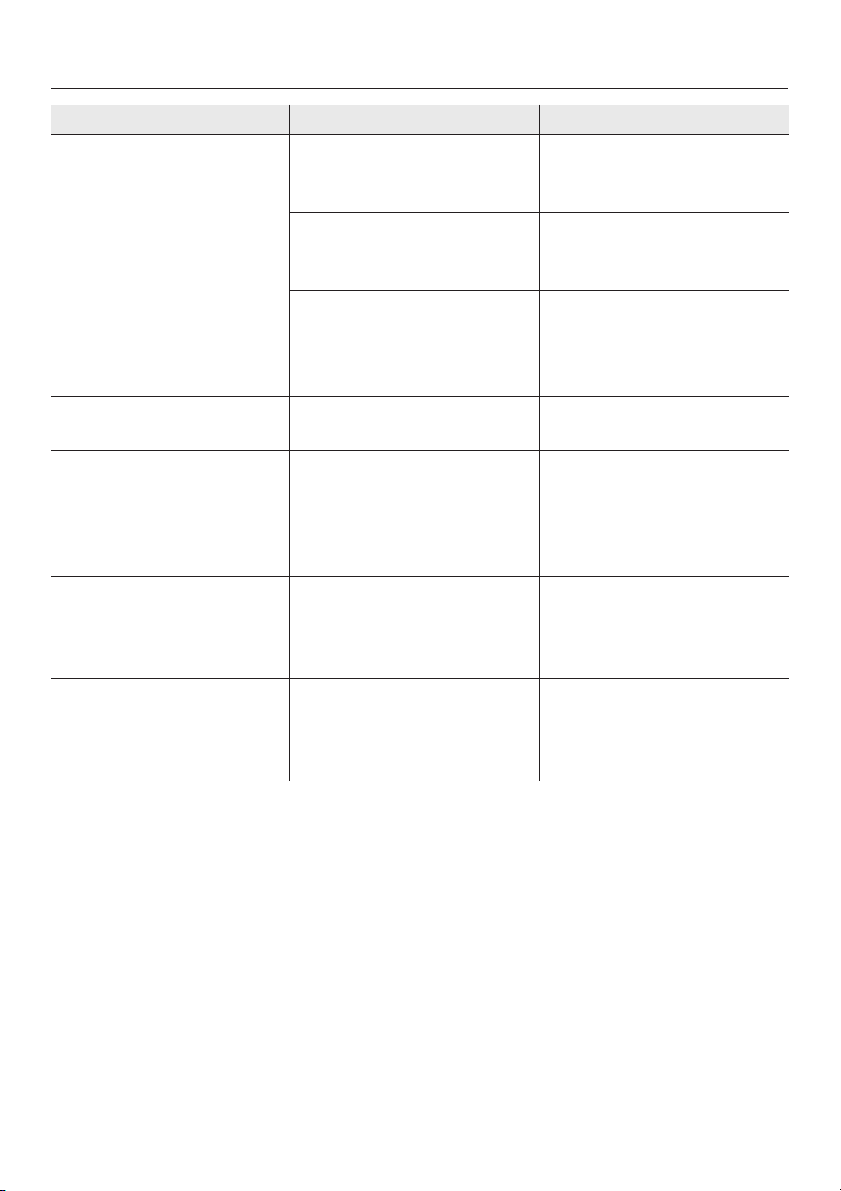

Settings

Water softener

Settings

1-30

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

gr/gal

1-30

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19 *)

20

21

22

23

24

25

26

27

28

29

30

ppm

CaCO

20

40

50

70

90

110

130

140

160

180

200

220

230

250

270

290

310

320

340

360

380

400

410

430

450

470

490

500

520

540

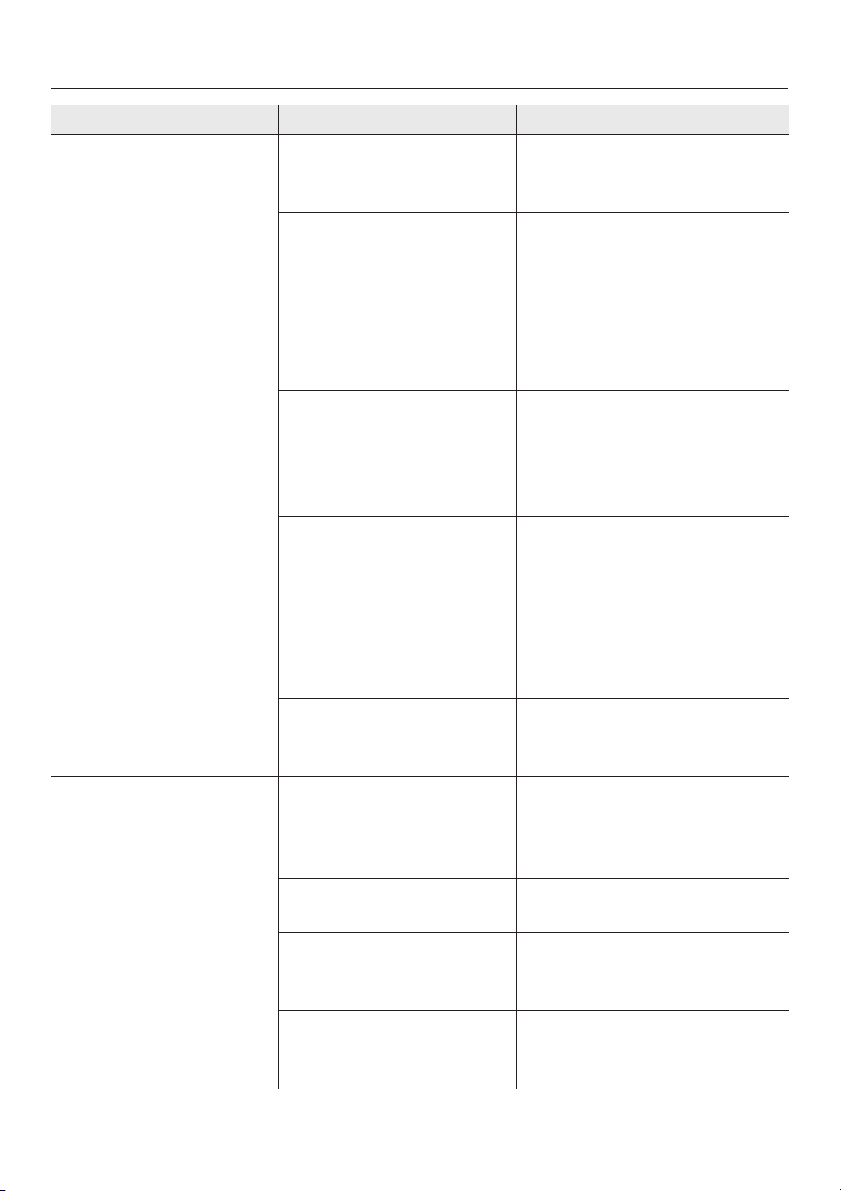

Settings

3

31 -60

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

gr/gal

31 -60

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

ppm

CaCO

560

580

590

610

630

650

670

680

700

720

740

760

770

790

810

830

850

860

880

900

920

940

950

970

990

1010

1030

1040

1060

1080

3

*) factory setting

15

Page 16

Water softener

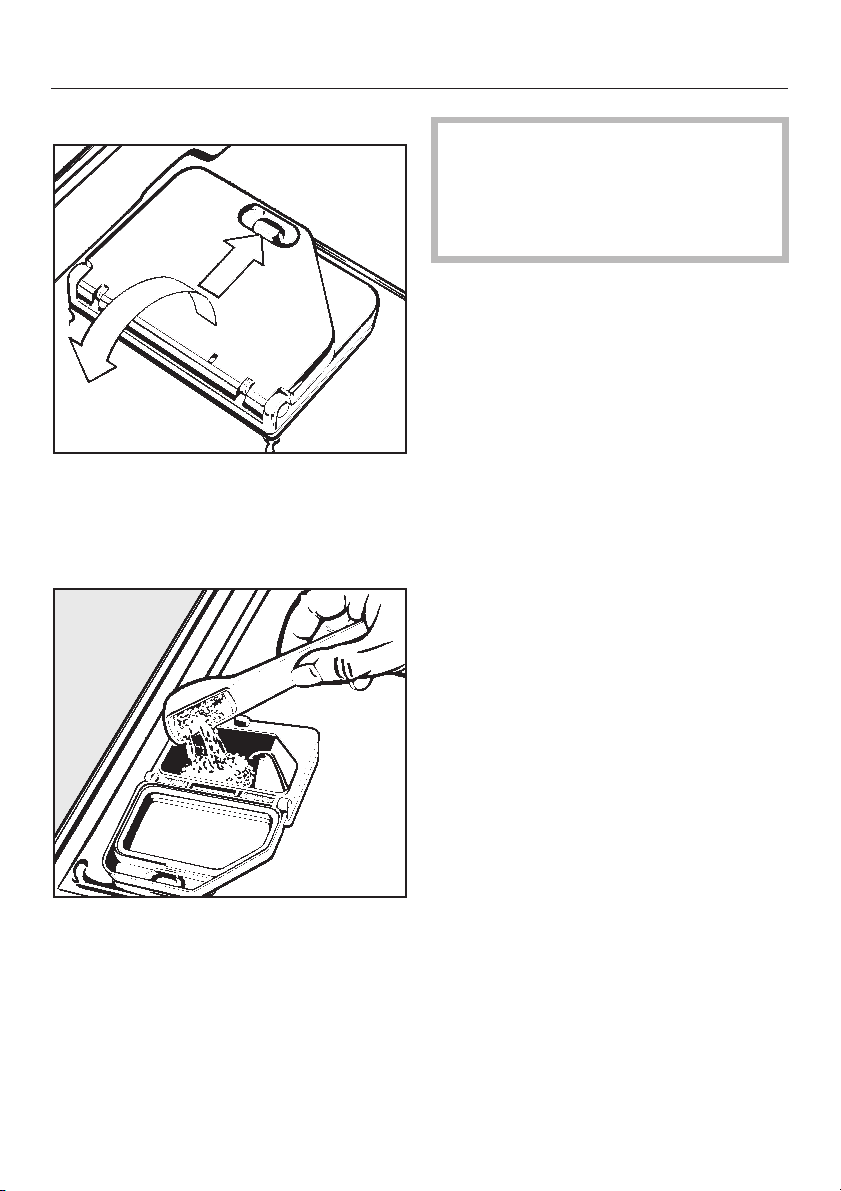

Filling the salt reservoir

Only use reactivation salt with granules

of approx.1-4mm.Donotuseother

types of salt such as cooking salt,

agricultural grade or road salt. These

may contain insoluble additives which

can impair the functioning of the water

softener. If in doubt please contact

Miele.

Reactivation salt can be ordered

directly from Miele.

The salt reservoir holds approx.

2.5 kg of salt.

Inadvertently filling the salt

,

reservoir with cleaning agent will

damage the water softener.

Before filling the salt reservoir

make sure that there is no fluid

covering the salt reservoir cap.

Remove the bottom basket from the

^

machine.

Unscrew the salt reservoir cap.

^

Before filling the salt reservoir with

reactivation salt for the first time, you

will have to fill the reservoir with

approx. 2/3 gal (2.5 liters) of clean

water to enable the salt to dissolve.

Once the machine has been used,

this will no longer be necessary.

16

^

Place the provided funnel in position.

^

Fill carefully with salt.

As it is poured in, displaced water will

run out.

Page 17

Remove the funnel and wipe any

^

residual salt off the seal and the

screw threads.

^ Screw the cap back on firmly.

^ Run the “Rinse” program to remove

any traces of salt from the cabinet.

The program sequence may be

delayed for a few minutes after the

start of the “Rinse” program. This is

normal as the water softener is

being reactivated.

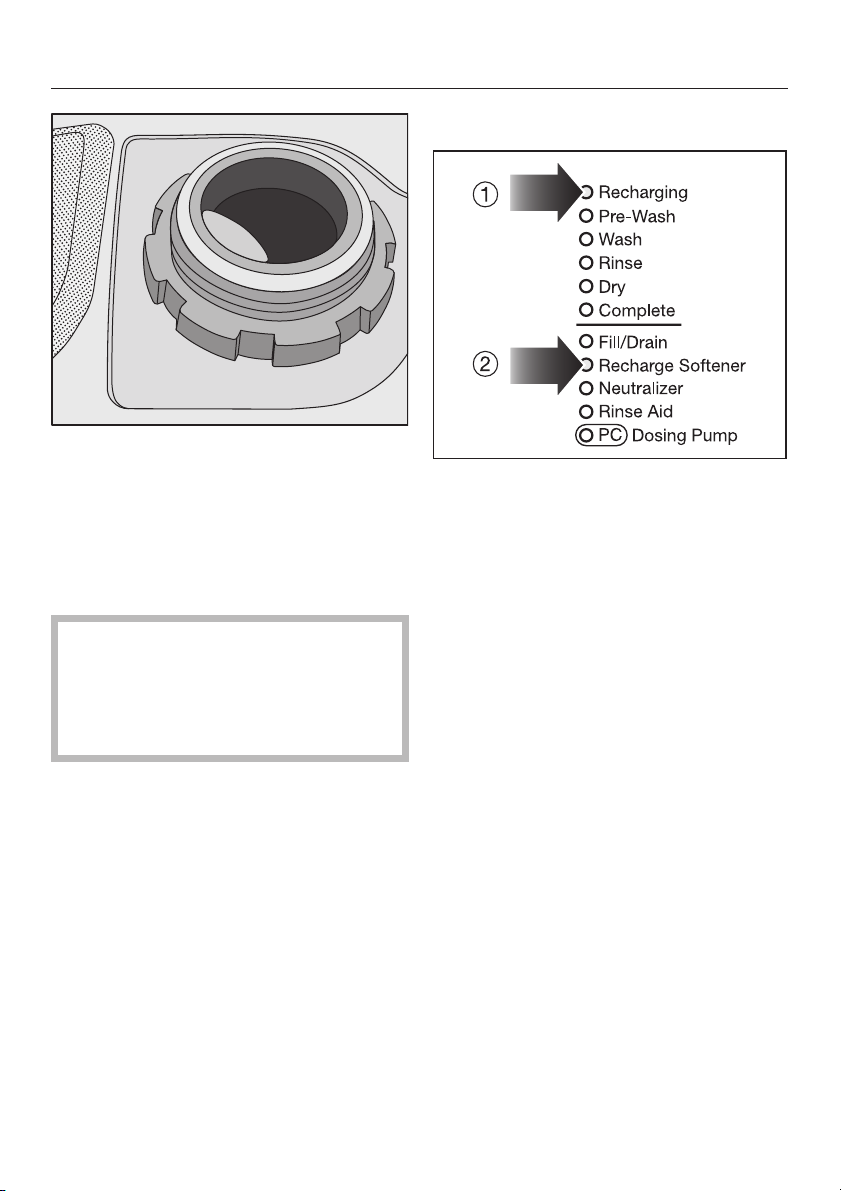

Water softener

Add salt indicator

Reactivation will take place

automatically when needed prior to the

start of your selected program. The

“Recharging” indicator lamp a will be

lit during this process.

^ Add salt when the “Recharge

Softener” indicator b lights up.

17

Page 18

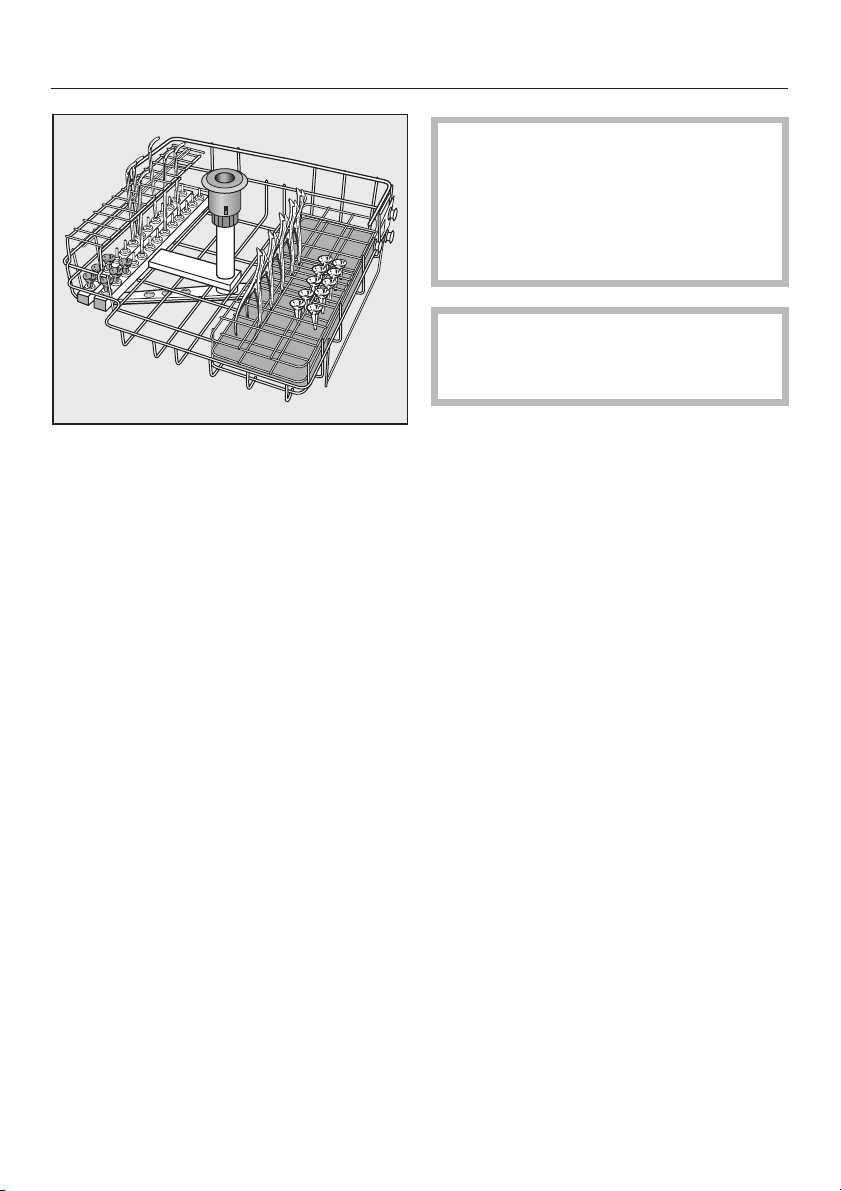

Applications

This washer-disinfector normally

requires a top and bottom basket.

Various inserts and special baskets are

available for a wide variety of

instruments and utensils.

Select baskets and inserts which are

appropriate for the application.

Applications and loading examples are

given on the following pages.

Before starting a program, visually

check the following:

– Is everything correctly

loaded/connected?

– Are the lumen or necks of hollow

instruments positioned so that water

can access them unhindered?

– Are the spray arms clean and do

they freely rotate?

– Are the filters clean? Remove any

coarse soils and clean them if

necessary.

–

Is the adapter connecting the water

supply to the spray arms/jets

connected correctly?

–

Are all chemical containers

sufficiently filled?

At the end of each program:

Visually check the load for

–

cleanliness.

Check that all hollow shafted

–

instruments are still securely

positioned on their jets.

Any hollow instruments that have

,

become disconnected from their

adapters during processing must be

processed again.

Check that the lumen of hollow

–

instruments are free of obstruction.

– Check that jets and connectors are

securely in position in the baskets or

inserts.

Verification testing

For verification of the cleaning process,

periodic testing as outlined in current

best practices documents such as

AAMI ST79 is highly recommended.

While Miele washers automatically

monitor critical parameters such as

time, temperature and dispensing,

periodic verification to ensure proper

soil removal should be part of your

quality and safety program.

Miele also offers process

documentation to support your periodic

verification.

18

Page 19

Loading the machine

For proper cleaning, arrange the

–

load so that water can access all

surfaces.

Do not place items inside other

–

pieces where they may be

concealed.

Hollow instruments must be

–

throughly cleaned, internally and

externally.

Ensure that instruments with long

–

narrow hollow sections can be

flushed through properly before

placing them in inserts or connecting

them to jets.

Applications

Only process instruments made of

–

surgical steel, as these are less

susceptible to corrosion.

Nickel plated instruments, colored

–

anodized aluminum instruments, or

disposable instruments are not

suitable for machine reprocessing.

Preparing the load

Empty all containers before loading

^

them into the machine.

Ensure that acids and residual

,

solvents, especially those containing

hydrochloric acid or chlorides, do

not get into the wash cabinet.

– Hollow vessels should be inverted

and placed in the correct baskets or

inserts to ensure that water can flow

into and out of them unrestricted.

– Large or concave items should be

placed at an angle to make sure

water runs off them freely.

–

Tall, narrow, hollow items should be

placed in the center of the baskets to

ensure better water coverage.

–

Lightweight items should be secured

with a cover net (e.g. an A 6) and

small items placed in a mesh tray to

prevent them from bouncing around

or blocking the spray arms.

–

The spring adapter of the mobile

units or baskets must be correctly

engaged.

–

The spray arms must not be blocked

by items which are too tall or which

hang down in their path.

Loading instruments

Contaminated instruments can be

placed directly in the machine without

pre-treatment (no soaking required).

Always refer to the surgical instrument

manufacturer’s instructions for

cleaning.

,

Chemically pre-treated

instruments must be thoroughly

rinsed before placing them in the

machine.

19

Page 20

Applications

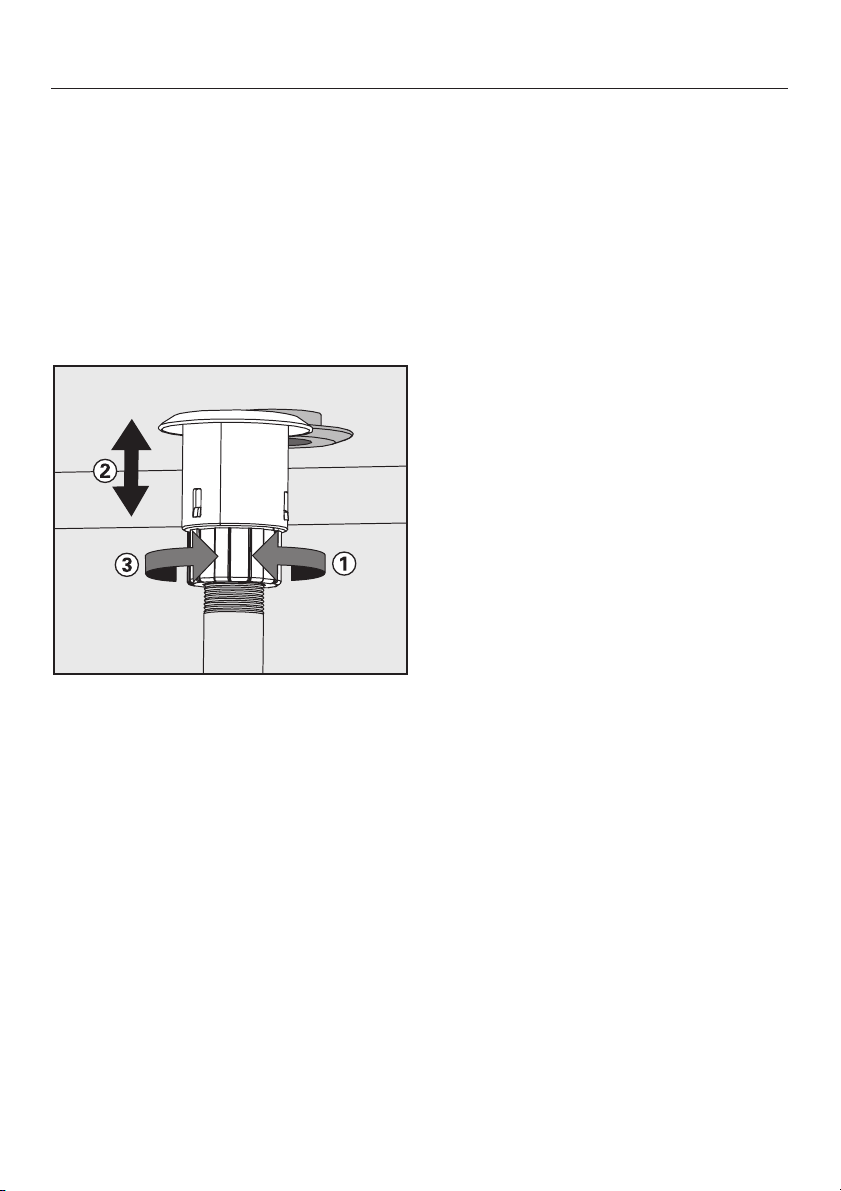

Water connector spring

adapter

Make sure that the spring adapter to

the water connector engages correctly

when a basket or injector unit is

inserted in the machine. It must be

4-5 mm higher than the water

connection inlet in the machine.

If it is not, adjust the adapter as follows.

^ Loosen the lock ring a.

Height adjustable top basket

The top basket can be adjusted above

and below its middle position by 2 cm.

Items of different heights can be

cleaned in this machine by changing

the position of the upper basket.

To adjust the top basket:

Pull out the basket until a resistance

^

is felt; lift it from the runners and

remove.

Loosen the roller bearings on both

^

sides of the basket witha7mm

wrench and reposition it to the height

desired.

^ Re-tighten the roller bearings.

^

Push the adaptor b up.

^

Tighten the lock ring c.

20

Page 21

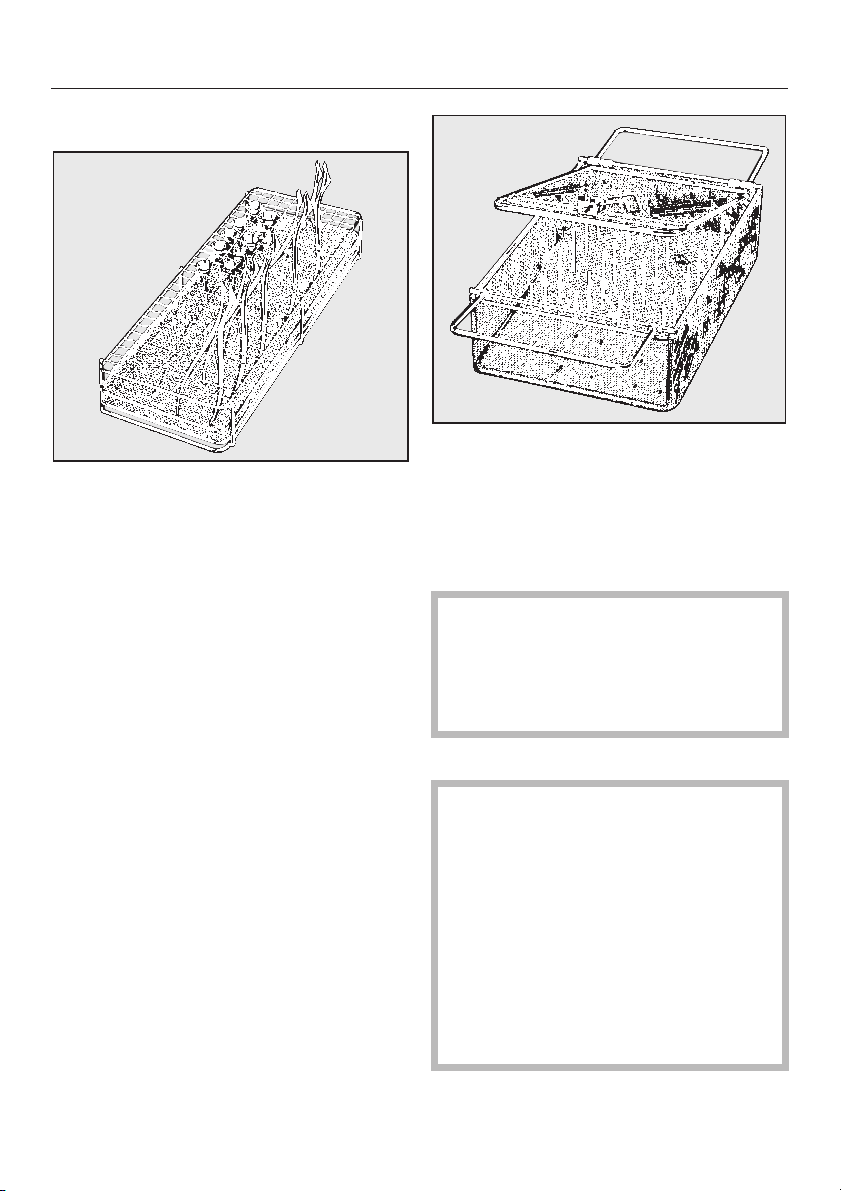

Surgical instruments

Surgical instruments should be stored

for as short a time as possible before

cleaning them.

Disinfection of surgical and minimally

invasive instruments is performed

thermally, after they have been

cleaned. Deionized water should be

used for the final rinse to help prevent

spotting and corrosion.

More information regarding the water

quality you can find in the AAMI

publication TIR34:2007

Open up any hinged instruments and

place them in mesh trays so that they

are not touching each other.

Instruments with very narrow lumen

must be manually pre-rinsed where

necessary. Follow the

manufacturer’s instructions on how

to process them.

Applications

21

Page 22

Applications

ENT

E 373 Insert

E 417 Insert

For ear funnels and ear and nasal

specula. This insert can be placed in

the top or bottom basket.

^ Open the specula before loading so

the water can access all surfaces.

For ENT instruments, such as ear

funnels. The insert can be placed in the

top basket.

The thin chrome plating on ear

funnels can be very sensitive to

neutralizing agents. Make sure your

neutralizer is compatible with your

funnels before washing.

Please note:

The Miele washer-disinfector is

intended for cleaning and

intermediate-level disinfection only.

This cleaning and disinfection

process is intended as a preliminary

step prior to sterilization.

Semi-critical instruments such as

those used for this type of

application should be sterilized

before use.

22

Page 23

Applications

GYN

E 416 Insert

Insert for gynecology specula.

^ Load as shown in the illustration.

One part specula:

Place opened one part specula

^

between the holders.

Two part specula:

Place the lower parts in the narrow

^

section of the insert (on the left in the

illustration).

Place the upper parts in the wide

^

sections of the insert (on the right in

the illustration).

Specula should always be arranged

so that they do not come into

contact or cover each other.

Please note:

The Miele washer-disinfector is

intended for cleaning and

intermediate-level disinfection only.

This cleaning and disinfection

process is intended as a preliminary

step. Semi-critical instruments such

as those used for this type of

application should be sterilized

before use.

23

Page 24

Applications

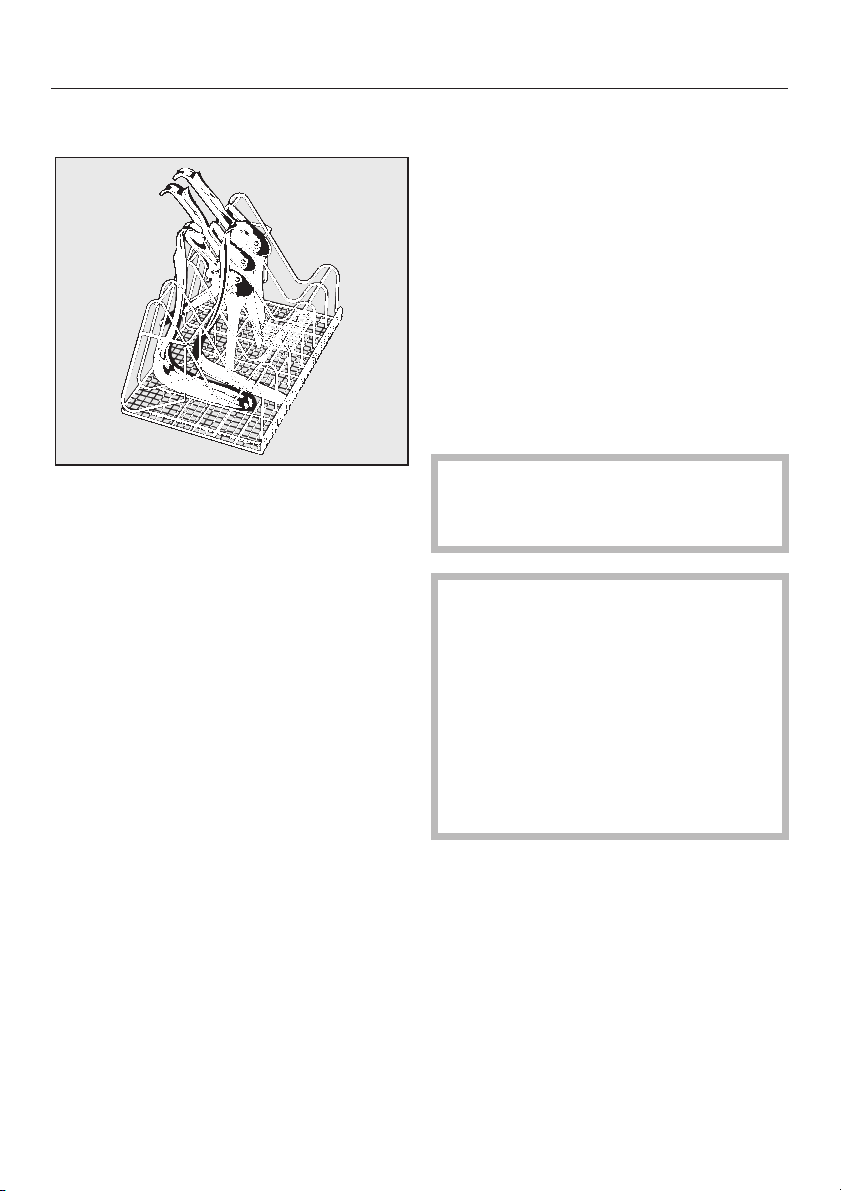

O 177/1 Top injector basket

The left side of the O 177/1, has a

retaining grid with 28 jets in silicone

receptacles for hollow-bodied

instruments. The jets spray the wash

water directly into the instrument so that

the recesses can be thoroughly

flushed, cleaned, and disinfected.

To avoid injury from instruments

,

that are pointed at both ends or

standing instruments with

upward-facing probes, the washer

should be loaded from back to front,

and unloaded from front to back.

The O 177/1 Top basket and E 337/1

insert come with their own

instructions for use.

Depending on the items to be cleaned,

special nozzles, bushings or adapters

are required. Further information can be

obtained from the Miele Professional

Sales Department.

The right side of the O 177/1 is left free

to hold various inserts, such as the

E 337/1 (shown) for standing

instruments.

24

Page 25

Rigid Endoscopy

O 176/1 Top Injector Basket

Please note that the washer

disinfector is designed for RIGID

Endoscope cleaning and

disinfection only. The endoscopes

must first be disassembled for the

best cleaning results. Always

consult the manufacturer’s

instuctions before processing any

instrument in the washer-disinfector.

To ensure that water can flow in and out

of the hollow parts of instruments,

remove any caps and/or seals. Open

valves and arrange according to the

manufacturer’s instructions.

The left hand side of the basket is left

free for inserts, such as the E 379.

Applications

To minimize the risk of injury

,

from instruments that have a probe

at the end, the washer should be

loaded from back to front and

unloaded from front to back.

This basket should be loaded only with

slightly contaminated items.

25

Page 26

Applications

Ophthalmology

The “C - Ophtha” program is

especially designed for ophthalmic

applications. This program has an

additional rinse which uses

deionized water.

This program is locked at the factory.

To unlock this program please contact

Miele Technical Service.

To prevent cross contamination

,

of lumen or hollow items, the

treatment of ophthalmic instruments

should only be performed in a

washer-disinfector designed for this

application. Also, do not use plastic

fiber cover nets (Miele nets A2 or

A3) at any time in a washer

disinfector that is also used for

ophthalmic instrument processing.

,

Do not use Rinse Aid or any

other rinsing agents when

processing ophthalmic items.

The E 429 mobile injector can be used

to clean and disinfect surgical,

ophthalmic instruments used in the OR.

The top of the injector unit has

connections for hollow instruments

such as rinsing or suction hand pieces

and cannulae, as well as silicone

holders that are used to secure the

instruments to their hose connections.

The lower level of the E 429 mobile

injector can accommodate E 441/1

inserts or E 142 mesh trays that can be

used for holding solid bodied

instruments.

The E 429 mobile injector unit for

surgical ophthalmic instruments

comes with its own operating

instructions.

,

Use of the E 429 requires a

modification to the water intake path

inside the wash chamber. This

means that the E 429 cannot be

used interchangeably with other

mobile units or baskets.

26

Page 27

Possible effects of using non-recommended Cleaning Agents

Cleaning Agents

Effect Remedy

Damage to elastomer (seals and hoses)

or plastic components of the

washer-disinfector may cause the

materials to swell, shrink, harden or

become brittle and develop cracks.

This will impair their function or

generally lead to leaks.

Strong foaming during the program will

prevent proper cleaning and rinsing of

the load. Foam escaping from the wash

cabinet can also result in damage to

the washer-disinfector.

If foaming occurs, the cleaning process

cannot be standardized and validated.

Corrosion on the stainless steel of the

wash cabinet and accessories can

have various appearances:

– rust formation (red spots / stains),

– black spots / stains,

– white spots / stains (smooth surface

is slightly pitted).

Corrosion that forms holes can result in

leaks in the washer-disinfector.

Depending on the application, the

corrosion may also impair the cleaning

and/or rinsing results or cause the

instruments or other items to corrode.

Find and correct the cause of the

–

damage.

Find and correct the cause of the

–

foaming.

Checking the process regularly in

–

order to eliminate foaming.

– Find and correct the cause of the

corrosion.

27

Page 28

Possible effects of using non-recommended Cleaning Agents

Cleaning Agents

Effect Remedy

The ingredients of the cleaning agents

can have a considerable effect on the

durability of the dispensing systems.

The dispensing hoses and pumps are

generally designed for a specific type

of cleaning agent.

General categories are:

alkaline to pH-neutral products,

–

acidic to pH-neutral products,

–

hydrogen peroxide.

–

The cleaning agents can damage the

elastomer and plastic components of

the washer-disinfector and its

accessories.

The instructions and

–

recommendations of the

manufacturer of the cleaning agents

must be observed.

Perform regular visual inspections of

–

the dispensing system.

Regularly check the flow rate of the

–

dispensing system.

– The instructions and

recommendations of the

manufacturer of the cleaning agents

must be observed.

– Perform regular visual inspections of

all accessible elastomer and plastic

components.

28

Page 29

Possible effects of using non-recommended Cleaning Agents

Cleaning Agents

Effect Remedy

Cleaning agents and rinse aids

containing tensides can cause

excessive foaming.

The foaming can occur:

in the program section in which the

–

cleaning agent is added, or

in the subsequent program section

–

due to carry-over.

Anti-foaming agents, particularly

silicone-based ones, can cause the

following:

– deposits in the wash cabinet,

– deposits on the items,

– damage to the elastomer and plastic

components of the

washer-disinfector,

– degradation of certain plastics (e.g.

polycarbonates, plexiglass, etc.) in

the load.

The process parameters of the wash

–

program (e.g. dispensing

temperature, dosage concentration,

etc.) must be set so that the overall

process creates little or no foam.

Follow the instructions of the

–

cleaning agent manufacturers.

Use anti-foaming agents only in

–

exceptional cases or when they are

absolutely necessary for the process.

– Consult Miele Professional Sales

29

Page 30

Possible effects of using non-recommended Cleaning Agents

Soiling

Effect Remedy

The following substances can cause

excessive foaming during washing and

rinsing:

disinfection agents or detergents

–

foaming substances in general, such

–

as tensides.

The following substances can cause

corrosion of the stainless steel in the

wash cabinet and the accessories:

– hydrochloric acid,

– other substances that contain

chlorides (e.g. sodium chloride)

– concentrated sulphuric acid,

– chromic acid,

– iron particles and shavings.

Reactions between cleaning agents and soils

Effects Remedy

In combination with alkaline cleaning

agents, items with soil that contain

proteins, such as blood, can cause

excessive foaming.

Rinse the items with a sufficient

–

quantity of water before placing them

in the washer-disinfector.

Select a wash program with one or

–

more short pre-rinses with cold or hot

water.

Rinse the items with a sufficient

–

quantity of water before placing them

in the washer-disinfector.

– Let the items drip dry on the counter

or in the sink before putting them in

the baskets or inserts or placing

them in the wash cabinet.

–

Select a wash program with one or

more short pre-rinses with cold

water.

In combination with very acidic or

alkaline cleaning agents, metals such

as aluminum, magnesium and zinc may

release hydrogen (explosive gas).

30

–

Follow the instructions of the

cleaning agents manufacturer.

Page 31

Use only chemicals specifically

,

made for thermal

washer-disinfectors and observe the

manufacturer’s recommendations for

use. In particular, always observe

the manufacturer’s instructions

regarding allowed residual amounts

that do not pose any toxicological

risk. Suitable cleaning agents can

be obtained from Miele.

Add rinse aid indicator

Dispensing cleaning agents

Adding rinse aid

To dispense rinse aid in the final

rinse, the DOS 2 program block has

to be activated by a Miele service

technician.

Liquid rinse aid can be used to prevent

water spots on items and to help them

dry faster.

The dispensing of rinse aid should only

be activated if deionized water is not

used in the final rinse program.

Rinse aid residue will remain on the

surface of the clean items after

drying. Rinse aid should only be

used if it is appropriate for the

application and the items intended

use.

^

Add liquid rinse aid to the rinse aid

reservoir when the “Rinse Aid”

indicator lights up.

,

Do not use rinse aids on

ophthalmic items!

Rinse aid is poured into its reservoir

and the set amount is then dispensed

automatically.

The rinse aid reservoir holds approx.

180 ml.

,

Only fill the rinse aid reservoir

with liquid rinse aid formulated for

washer-disinfectors.

Never fill with cleaning agent as this

will damage the reservoir!

31

Page 32

Dispensing cleaning agents

Open the door all the way.

^

^ Unscrew the cap.

^ Add liquid rinse aid until the level

indicator is dark (see arrow in the

illustration). Use a funnel if

necessary.

Setting the dosage

The dosage adjuster is under the

reservoir fill cap and has settings

adjustable from 1 to 6 (1-6 ml). It is set

to 3 (3 ml) at the factory.

If spots appear on items:

^ Use a higher setting.

If clouding or smearing appears on

items:

^

Screw the cap back on.

^

Wipe up any spilled rinse aid. This

help prevent over-foaming during the

next program.

32

^

Use a lower setting.

Page 33

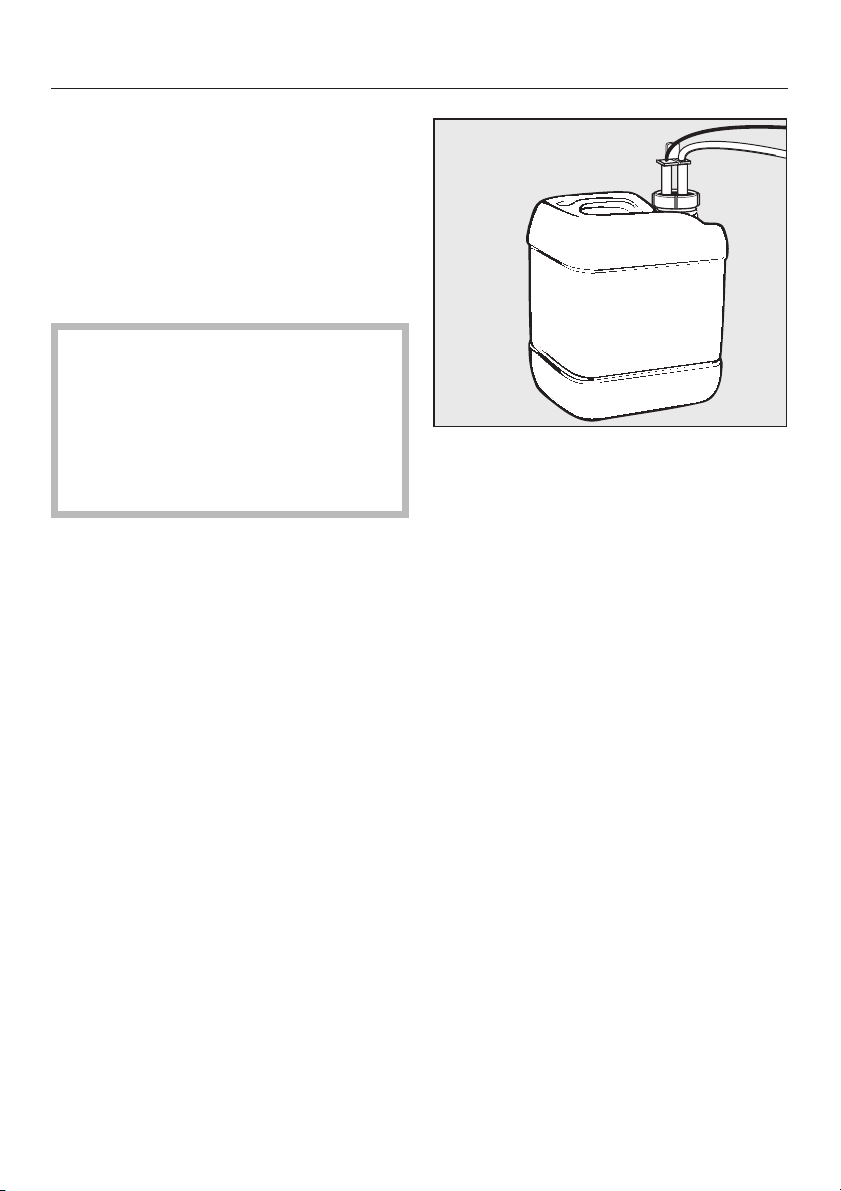

Adding neutralizing agent

Neutralizing agent is used in the interim

rinse stage to help prevent

discoloration and rust spots appearing

on the items, especially at the joints.

Acidic neutralizing agents neutralize

residues of alkaline cleaning agents on

the surface of instruments and utensils.

If the cleaning agent being used is

mildly alkalinic, use a phosphoric

acid based neutralizing agent.

If using a neutral, enzyme based

liquid cleaning agent, you will need

to use a citric acid based

neutralizing agent.

Dispensing cleaning agents

Insert the siphon tube into the

^

container and screw the cap on

securely (observe the color code).

The neutralizing agent is automatically

dispensed in the rinse cycle of the

wash program. The dispensing system

container should be filled with

neutralizing agent and primed prior to

starting the machine.

Match the red capped container to the

red siphon connection and blue

container to the blue siphon hose.

The red is the acid neutralizing agent

and the blue is the cleaning agent,

which may be alkaline.

Do not mix the connections as this may

cause the cleaning agents to react with

each other, clogging the tubing.

^

Place the container on the floor next

to the washer-disinfector or in an

adjoining cabinet.

See the “Programmable functions”

section for details on how to prime the

dispensing system and set the dosage.

33

Page 34

Dispensing cleaning agents

Add neutralizing agent

indicator

^ Replace the neutralizing agent with a

full container when the “Neutralizer”

indicator lights up.

Please remember to exchange the

container before it runs empty. If

allowed to empty completely, you

will have to prime the pump again.

34

Page 35

Dispensing cleaning agents

Adding cleaning agent

Only use cleaning agents

,

suitable for thermal

washer-disinfectors. Do not use

cleaning agents designed for

domestic dishwashers.

Using a liquid cleaning agent

A liquid cleaning agent can be

dispensed via the K 60 DOS module

(dispensing pump for liquid cleaning

agent). The machine must be set up for

this by a Miele service technician. The

DOS module is connected externally.

See “Programmable functions” for

details on how to prime the dispensing

system and set the dosage.

In general, Miele recommends the

optional K 60 DOS Module for

dispensing liquid cleaning agents.

Using powder cleaning agents

Avoid inhaling powdered

,

products.

Never swallow cleaning agents as

this can result in chemical burns to

the mouth and throat, or suffocation.

Before starting a wash program, fill the

dispenser with powder cleaning agent.

Follow the agent manufacturer’s

instructions for dosing if they differ.

Dosage example:

Approx. 10.5 liters of water are in the

“Main wash” program.

30 g of cleaning agent will be required

for a concentration of approx. 3 g/l .

Dosages need not be exact. If in doubt,

adding a little more detergent will not

harm the items or the machine.

When using the following top

baskets, liquid cleaning agents

must be dispensed using the K 60

DOS module:

– O 176

– O 176/1

– O 183

– O 190/2

It is only necessary to use one type

of cleaning agent. Do not use both

powder and liquid agents

simultaneously!

35

Page 36

Dispensing cleaning agents

To add powder agent

^ Press the button on the dispenser

cover. The cover will pop open.

The cover will already be open after a

completed wash program.

Certain types of soil may require

special combinations of cleaning

agents and additives to achieve an

acceptable result. In such cases,

please contact Miele.

^

Add the correct amount of cleaning

agent to the compartment.

^

Snap the cover closed.

36

Page 37

Operation

Turning on

Close the door.

^

Make sure the water valves are open.

^

Press the “On/Off” button.

^

When the program selector is at f,a

dot will light up in the display.

Starting a program

Choose your program according to the

type of items to be cleaned.

The different programs and their uses

are described in the “Program chart”.

^

Turn the program selector clockwise

or counterclockwise to the desired

program.

The temperature of the first stage of the

selected program will appear in the

display (except with the “Rinse” and

“Drain” programs).

The indicator light next to the start

button 6 will flash.

Selecting “Drying” 0

“Drying” may be chosen immediately

after the program has been selected

(except with the program “Rinse”).

To do this:

^ Press 0.

The program will be extended by

Drying block 1 and 2, (see the times in

the Program chart).

The display shows the time that has

been selected for Drying block 2. This

can be altered in 5 minute increments

by pressing the 0 button.

The total running time for the program

will increase accordingly.

The drying program activates the

heater coils in the bottom of the wash

chamber. Narrow lumen instruments

will not dry thoroughly as there is not

active airflow in the chamber.

^

Press the Start button 6.

The current temperature will appear in

the display.

The indicator light next to the Start

button 6 will light up.

37

Page 38

Operation

Once the program has started, all other

programs are locked out.

If the program selector is turned to

another program, the display will go out

but the program will continue running.

The values can be seen again by

turning the program selector back to

the position of the currently running

program.

During a program, you can switch

between the following displays:

the current temperature,

–

the elapsed program time and

–

– the current program block:

1 = Pre-Wash 1

2 = Pre-Wash 2

3 = Main Wash 1

4 = Main Wash 2

6 = Rinse 1

7 = Rinse 2

8 = Rinse 3

9 = Rinse 4

10 = Final Rinse 1

11 = Final Rinse 2

12 = Drying 1

13 = Drying 2

^

Press the ß button to switch

between the displays.

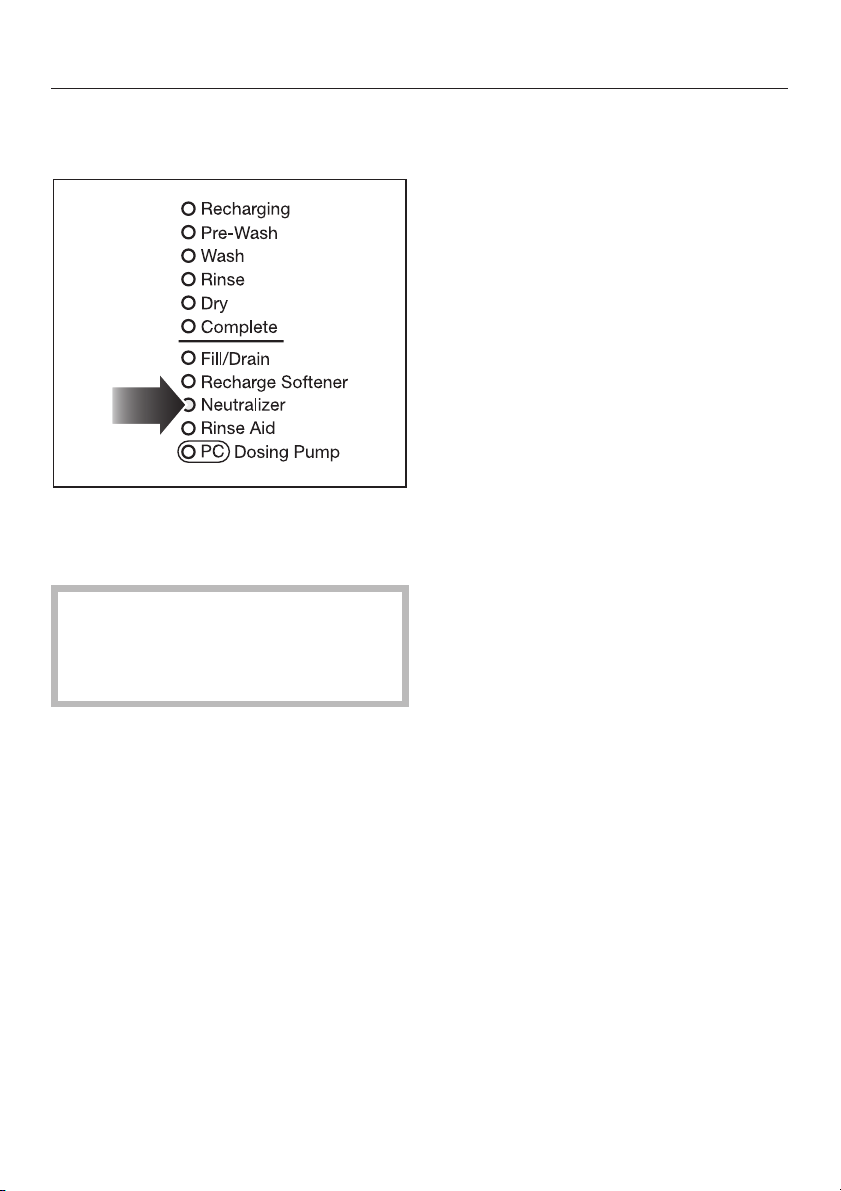

Program sequence indicators

The indicator light for the current

program step will light up during the

program:

Recharging

Pre-Wash (Pre-Wash1+2)

Wash (Main Wash1+2)

Rinse (Rinse1-4/

Final Rinse1+2)

Drying (Drying1+2)

Complete Program parameters

achieved

At the end of the program

The program has ended when the

“Complete” indicator in the program

sequence display is on and the 6

indicator has gone out. A 0 will appear

in the middle of the display. All the

other indicators light in sequence.

A buzzer will also sound for a maximum

of 30 seconds.

The buzzer time can be changed (see

“Programmable functions”).

Use the ß button to view the total

running time of a program or the

current temperature.

Additional drying

38

If additional drying is required after the

end of a program, the “Drain” program

can be used with the additional

“Drying” function. The running time for

this will be 1 minute more than the

drying time displayed.

Page 39

Operation

Canceling a program

If a program is canceled, the

,

items in the washer-disinfector must

be reprocessed!

Program cancellation due to a fault

If the program is canceled before

completion, a fault message “F..” will be

displayed.

Depending on the cause, appropriate

measures may need to be taken to

resolve the problem. See the

“Frequently asked questions” section.

Canceling the program manually

Avoid canceling a running program

unless absolutely necessary, for

instance if items in the wash cabinet

are moving around excessively or the

wrong program was selected.

Turn the program selector to f.

^

The washer-disinfector will stop running

after approx. 2 seconds.

Press the “Door” button and open the

^

door.

Caution! The items may be hot.

,

There is a risk of burns or scalding.

^ Rearrange the items. Wear protective

gloves where necessary, and

observe appropriate health and

safety regulations relating to

infectious diseases.

^ If required, add detergent.

^ Close the door.

^

Start the “Drain” program.

The water is pumped out.

^

Re-select and re-start the program.

Turning off

^

Press and release the “On/Off”

button.

Because of the electric door lock,

the door can only be opened if the

“On/Off” button is pushed in (see

Opening and closing the door).

39

Page 40

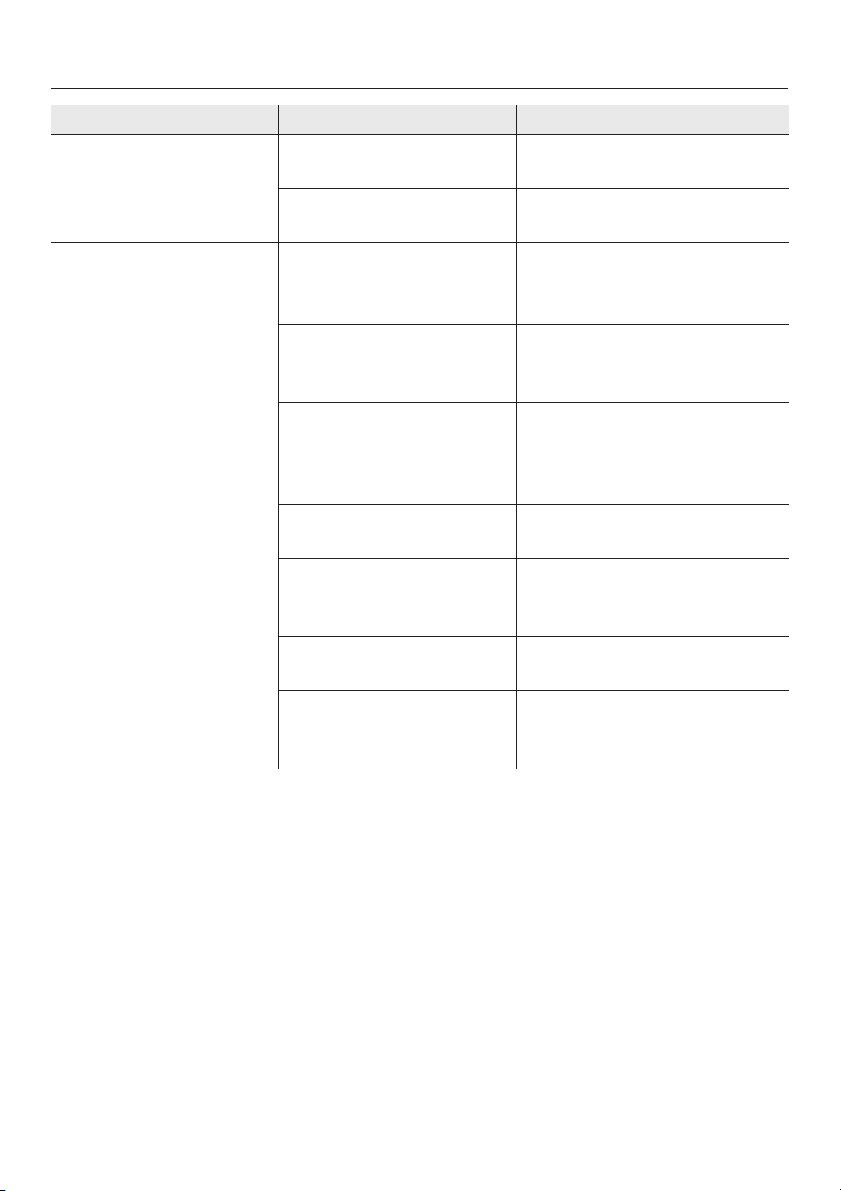

Program chart

Program When to use

A-Custom

B-MIS

C-Ophthal

RINSE

DRAIN

varioTD

Custom program for special applications. Contact Miele Service to arrange for

special programming.

For treating instruments used in minimally invasive surgery.

Contains 5 minute final rinse plus two intermediate rinses.

Use when processing ophthalmic instruments.

* This program is locked at the factory. To unlock this program please contact

Miele Technical Service.

For rinsing off chemical residues, e.g. after soaking them in disinfecting agent, to

avoid a build-up of foam in the washer-disinfector.

For draining water out of the washer-disinfector, such as when a program has

been canceled.

Program that meets general hygiene requirements for intermediate level

disinfection.

40

Page 41

Program chart

Program sequence

Pre-wash

12

CW CW

CW CW

CW CW

CW = cold water

DW = distilled water

°C = temperature

min = holding time

DOS 1 = dispensing of cleaning agent when 40°C is reached

DOS 3 = dispensing of neutralizing agent when water intake is finished

Main wash

12

DOS 1

55°C

10 min

DOS 1

55°C

5 min

DOS 1

55°C

5 min

Rinse

12

DOS 3

DOS 3

DOS 3

34

CW

CW

CW

CW DW

Rinse

Final rinses *

CW DW

93°C

5 min

DW DW DW

CW

12

93°C

5 min

93°C

5 min

x

Drying

12

99°C

35 min

99°C

35 min

65°C

30 min

99°C

35 min

* The DOS 2 rinse aid dosage must be activated by Miele Technical Service. Do not use any rinsing

agents on ophthalmic items!

x = Additional function

41

Page 42

Programmable functions

For future service work, please document any alterations to the factory default

settings in the appropriate box.

General notes:

Switch positions that have not been allocated a function are indicated in the

–

middle part of the display by a bar ( - ).

The programming level is called up via the f position.

–

It is shown as E.. in the display.

When processing medical devices, any changes made to programs or

–

dispensing systems should be documented and the machine’s cleaning and

disinfecting ability should be verified.

The following applies to all programmable functions:

To activate the programming mode

^ Turn the program selector to f.

^ Turn off the machine.

^ Press ß and 6 at the same time,

hold them in and, while doing so,

press the On/Off switch.

Saving values in programming mode

^

Press 6.

^

Press 6 again.

Exiting the programming mode without saving

^

Press the On/Off button to turn off

the machine.

42

The current program version P.. will

appear in the display. The Fill/Drain

indicator light will come on.

SP appears in the display.

The change is saved.

Any change is canceled.

Page 43

Programmable functions

Resetting the operating hours counter for the filter in the drying

unit

After the filter in the drying unit has been changed, the operating hours counter

needs to be reset.

Step Display / Result

Activate the programming mode (see

^

“Programmable functions - To activate

programming mode”.

Press the “Drying” 0 button as often as

^

necessary or hold it pressed in until E04 appears

in the display.

Turn the program selector to the 7 o’clock position. The current value will appear

^ Press the “Display” ß button once.

^ Save the changes (see “Programmable functions

- Saving values in programming mode”).

Once the setting has been saved and you leave the programming mode, the

operating hours counter will go out.

E04

in the display, e.g. 105

000

43

Page 44

Programmable functions

DOS 1 (liquid detergent)

Setting the dosage concentration

The dosage concentration only needs to be set for liquid detergents. Set

the concentration according to the detergent manufacturer’s

recommendations. Do not change the setting if you are using powdered

detergent in the door dispenser.

The volume of water used is 10.5 l in the main wash cycle.

Step Display / Result

Activate the programming mode (see

^

“Programmable functions - To activate

programming mode”.

^ Press the “Drying” 0 button until E02

appears in the display.

^ Turn the program selector to B - MIS

(2-o’clock-position).

without DOS Module connected:

with DOS Module connected:

^ Press or hold down the “Display” ß button

until the required time or dosage

concentration appears in the display,

(e.g. 0.50).

^

Save the changes (see “Programmable

functions - Saving values in programming

mode”).

Dosage concentration setting :

E02

10 = 10 sec dosage length

1.00 = 1.0 % dosage concentration

0.50

The dosage time / dosage

concentration is now set.

44

Page 45

Programmable functions

Priming the dispensing system

The dispensing system must be primed:

– when the dosage concentration is set for the first time,

– if the liquid cleaning agent container runs out and is not replaced in time.

Step Display / Result

Activate the programming mode (see

^

“Programmable functions - To activate

programming mode”.

Press 0 until E02 appears.

^

Turn the program selector to A-

^

Custom (1-o’clock-position).

Press ß.

^

^ Exit the programming mode.

Start the “Rinse” program.

E02

d§1

The dispensing system will be primed

automatically. 0 will appear in the

display when the priming process has

finished.

Any agents which are in the wash

cabinet after the priming process will

be diluted before being drained away.

45

Page 46

Programmable functions

DOS 3 (neutralizer)

Setting the neutralizer dosage

Set dosage concentration according to the neutralizer manufacturer’s

recommendations.

Step Display / Result

Activate the programming mode (see

^

“Programmable functions - To activate

programming mode”.

Press 0 until E02 appears.

^

E02

Turn the program selector to the

^

6-o’clock-position.

^ Press ß as many times as necessary or

hold pressed in until the required value

appears in the display, e.g. 0.20.

^ Save the changes (see “Programmable

functions - Saving values in programming

mode”).

Dosage concentration setting :

The dosage concentration which is

programmed will appear in the

display,

e.g. 0.10 = 0.1 %

0.20

The dosage concentration level has

now been set.

46

Page 47

Programmable functions

Priming the dispensing system

The dispensing system must be primed:

– when the dispensing system is used for the first time,

– if the neutralizing agent container runs out and is not replaced in time.

Step Display / Result

Activate the programming mode (see

^

“Programmable functions - To activate

programming mode”.

Press 0 until E02 appears

^

Turn the program selector to the

^

5-o’clock-position.

E02

d§3

^ Press ß

^ Exit the programming mode.

Start the “Rinse” program.

The dispensing system will be

primed automatically. 0 will appear

in the display when the priming

process has finished.

Any agents which are in the wash

cabinet after the priming process

will be diluted before being drained

away.

47

Page 48

Programmable functions

Buzzer

A buzzer can be programmed to sound for the following:

– a constant tone will sound at the end of a program,

– at one second intervals as a fault warning, and

– 3 short beeps followed by a 2 second pause, then 3 short beeps

as a reminder to remove an item for testing.

The buzzer settings are displayed as numbers:

20 Switched off

21 At the end of a program (factory default setting)

22 Fault indication

23 At end of a program + fault indication

24 Reminder to remove an item

25 At the end of a program + reminder to remove an item

26 Fault indication + reminder to remove an item

27 At the end of program + fault indication + reminder to remove an item.

Step Display / Result

^ Activate the programming mode (see

“Programmable functions - To activate

programming mode”.

^ Press 0 until E04 appears

^ Turn the program selector to B - MIS

(2-o’clock-position).

^

Press ß repeatedly or hold pressed in until

the required number appears in the display,

e.g. 26.

^

Save the changes (see “Programmable

functions - Saving values in programming

mode”).

Value set :

The buzzer will sound at the selected time for 30 seconds.

To switch the buzzer off early:

- turn the program selector to f,or

- press ß,or

- open the door.

48

E04

21

26

Page 49

Programmable functions

Changing program parameters

The factory-default temperature and holding time settings for the individual

program blocks are listed in the program chart.

Be sure to document any changes made to a program, by making a note in the

corresponding column in the program chart.

Changing wash and rinse parameters

The temperatures and holding times for the program blocks “Main Wash” 2 (in

program “B - MIS”) and “Final Rinse” can be changed.

Adjustable temperature range:

86°F - 199°F (30°C - 93°C)

–

Temperatures above 131°F (55°C) can cause blood to denature and set.

Appropriate infection-control measures must be observed for all programs.

Adjustable temperature holding time range:

1 - 15 min.

Changing the drying parameters

The drying temperature and drying time can both be changed in program blocks

“Drying” 1 (if available) and “Drying” 2.

The temperature range is: 131°F - 199°F (50 °C -99 °C)

Values which can be set for the drying times:

Drying 1: 1-99 minutes in 1-minute increments

Drying 2: 5-95 minutes in 5-minute increments

The drying time for program block “Drying” 2 can also be altered using the 0

button (see “Operation - Selecting Drying”).

49

Page 50

Programmable functions

Changing the temperature

Step Display / Result

Activate the programming mode (see

^

“Programmable functions - To activate programming

mode”.

Press or hold down the 0 button until the desired

^

program block level appears in the display.

Turn the program selector to the program you wish to

^

change, e.g. B-MIS.

E09 for Main wash 1

E12 for Main wash 2

E25 for Final rinse 2

E28 for Drying 1

E31 for Drying 2

°C ~55

^ Press or hold down the ß button until the desired

value appears in the display, e.g. 158°F (70°C).

^ Save the changes (see “Programmable functions -

Saving values in programming mode”).

Changing the temperature holding time

Step Display / Result

^

Activate the programming mode (see

“Programmable functions - To activate

programming mode”.

^

Press or hold down the 0 button until the

desired program block level appears in the

display.

^

Turn the program selector to the program you

wish to change, e.g. B-MIS.

^

Press or hold down the ß button until the

desired value appears in the display, e.g. 10.

°C ~70

E10 for Main wash 1

E13 for Main wash 2

E26 for Final rinse 2

E29 for Drying 1

E32 for Drying 2

min _ 5

min _ 10

^

Save the changes (see “Programmable functions

- Saving values in programming mode”).

50

Page 51

Programmable functions

Restoring to factory default settings

Step Display / Result

Activate the programming mode (see “Programmable

^

functions - To activate programming mode”.

Press or hold down the 0 button until E33 appears

^

in the display.

Turn the program selector to a program.

^

E33

Factory default setting:

The program was changed:

When PP is displayed, press the ß button.

^

^ Save the changes (see “Programmable functions -

Saving values in programming mode”).

Please note: The factory default setting for the water softener is also restored

during this process. Reprogramming is required (see “Setting the water

softener”).

Changes that were made to the customized programs “A - Custom”, “B-MIS”

and “C-Ophthal” are maintained.

00

PP

00, the factory default

settings have been

restored.

51

Page 52

Programmable functions

Setting the time and date

If your washer-disinfector is connected to a printer through the RS 232 serial

interface, you can set the time and date that will be displayed in the printout.

The individual values of date and time are stored according to the position of the

program selector:

“1 o’clock” position: Calendar day 01 - 31

“2 o’clock” position: Month 01 - 12

“3 o’clock” position: Year 00 - 99 = 2000 - 2099

“4 o’clock” position: Hours 00 - 23 (24 hour time)

“5 o’clock” position: Minutes 00 - 59

If the serial interface is not being used, a “-” will appear in the display each time

E34 is selected.

Step Display / Result

^ Activate the programming mode (see

“Programmable functions - To activate

programming mode”.

^ Press 0 repeatedly or hold it pressed in until

E34 appears in the display.

Wait 30 seconds before continuing. The control unit is reading

^

Turn the program selector to the position of the

parameter you wish to change, e.g. the “4 o’clock”

position to change the hours.

^

Press ß repeatedly until the desired value

appears in the display.

^

Save the changes (see “Programmable functions Saving values in programming mode”).

The new values will be transmitted to the serial interface and printer once you

have saved them and left the programming mode. Wait 30 seconds before turning

off the machine.

52

E34

the current values.

current value

new value

Page 53

Process documentation

The washer-disinfector provides the

option of documenting the treatment

process (process documentation).

Process documentation can be

generated by using special software or

via a printer.

For this purpose, the washer-disinfector

is equipped with a serial interface at the

rear.

The interface must be configured by

Miele.

Process documentation using

documentation software

The process parameters are sent to

external documentation software for

digital archiving.

Process documentation using a

printer

The process parameters are printed

and are archived in hard copy format.

No digital storage is possible.

As a program is running, the following

data are recorded:

Date and machine number:

–

Program start and program name

–

Blocks used in the program

–

Dispensing system number with

–

dosage amount, temperature and, if

applicable, dosage target quantity

Target values for temperatures and

–

holding times

Minimum temperature during holding

–

time

– Any faults detected (e.g. Water inlet

fault)

– Program end time

– Messages (e.g. insufficient salt)

The reports can be generated in

German, English, French, Italian and

Spanish.

Please contact Miele if you require

further information about suitable

printers and software.

53

Page 54

Cleaning and care

Periodic checks

After every 1000 hours of operation

or at least once a year, Miele

recommends that routine maintenance

and process verification is performed

on your washer-disinfector.

Maintenance covers inspections/repairs

to the following:

Electrical safety check

–

Door mechanism and door seal

–

Any screw connections and

–

connectors in the wash cabinet

– Water inlet and drainage

– Internal and external dispensing

systems

– Spray arms

– Combination filter

– Sump including drain pump and

non-return valve

The following operational tests will also

be performed as part of the

maintenance visit:

A program test run

–

Temperature measurements of the

–

wash cabinet

Seals will be tested for water

–

tightness

All relevant measuring systems will

–

be safety tested, including fault

displays.

To schedule a regular

maintenance/verification check,

please contact the Miele Service

Department.

– All baskets, inserts and modules

–

Drying unit

and where applicable:

–

Steam condenser

–

Printer

54

Page 55

Cleaning and care

Process verification

The cleaning and disinfection process

of an automated washer should be

verified annually. In addition,

verification should take place when the

unit is first installed, after any major ser

vice repair to the washer, and after

repair or replacement of utilities

connected to the washer.

Routine checks

The frequency of routine checks should

be determined by the end users, based

on use. High use means checking the

operation more often.

The following items must be checked:

All filters in the wash cabinet

–

The spray arms in the

–

washer-disinfector and in the baskets

The wash cabinet and the door seal

–

The dispensing systems

–

– Baskets and inserts.

When using a powder cleaning agent,

the temperature at the time of

dispensing should be checked every

14 days.

Check the temperature during the

program sequence. When the sound of

the dispenser cover flipping open is

heard, read the temperature in the

display, document it and compare it

with the temperature in the past

verification record.

,

Notify Miele Technical Service if

the displayed temperature deviates

from the temperature in the

verification record by more than

+/- 2°C.

55

Page 56

Cleaning and care

Cleaning the filters in the wash

cabinet

The filters in the base of the wash

cabinet are designed to prevent coarse

soils from getting into the circulation

system.

A build-up of these soils can cause the

filters to clog. They should be checked

routinely and cleaned if necessary.

DO NOT use the machine

,

without all filters in place.

Watch out for glass splinters,

,

needles etc. which could cause

injury.

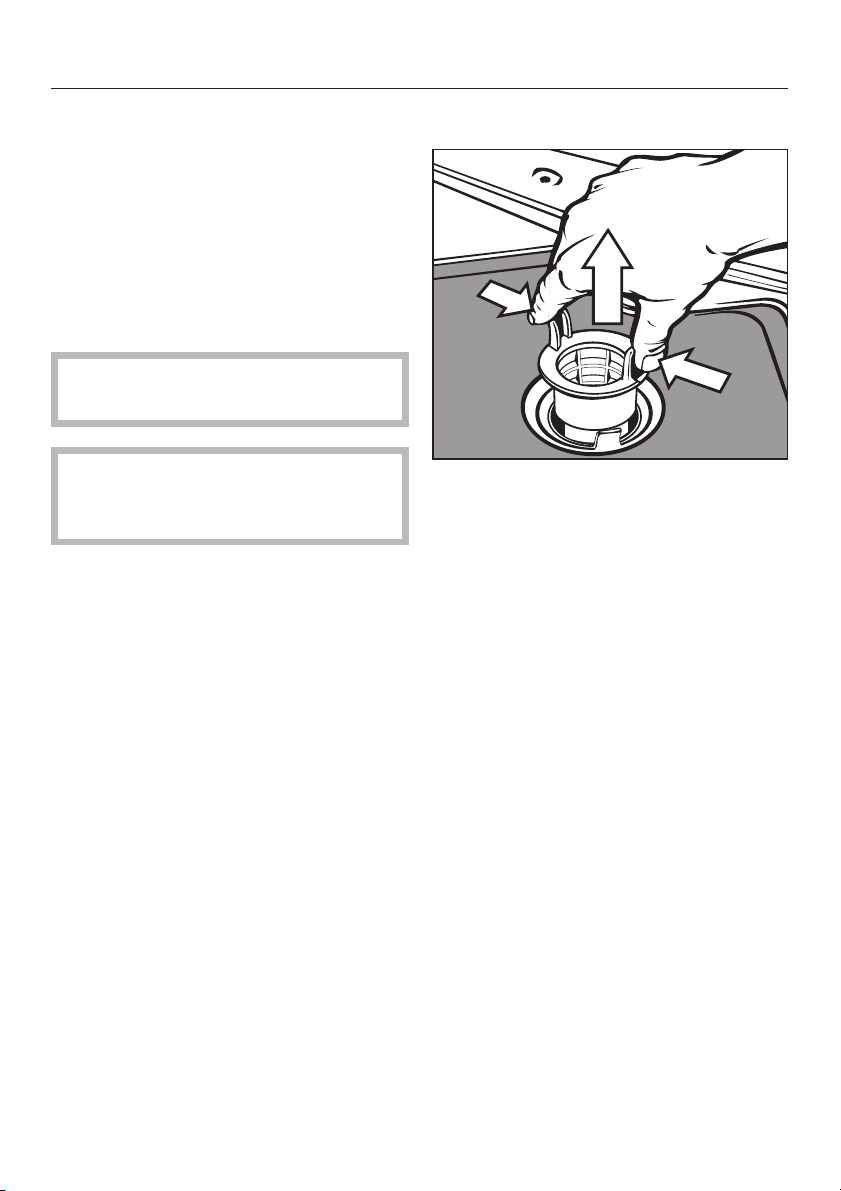

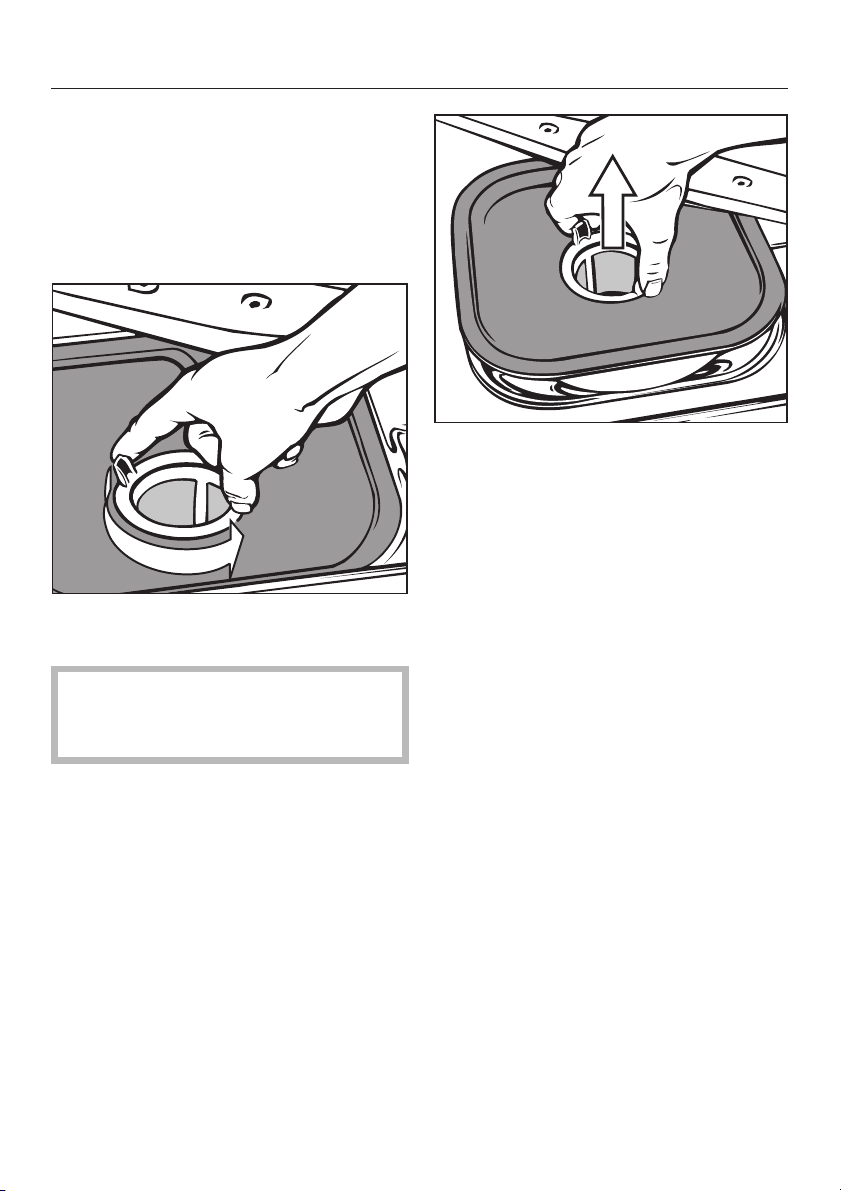

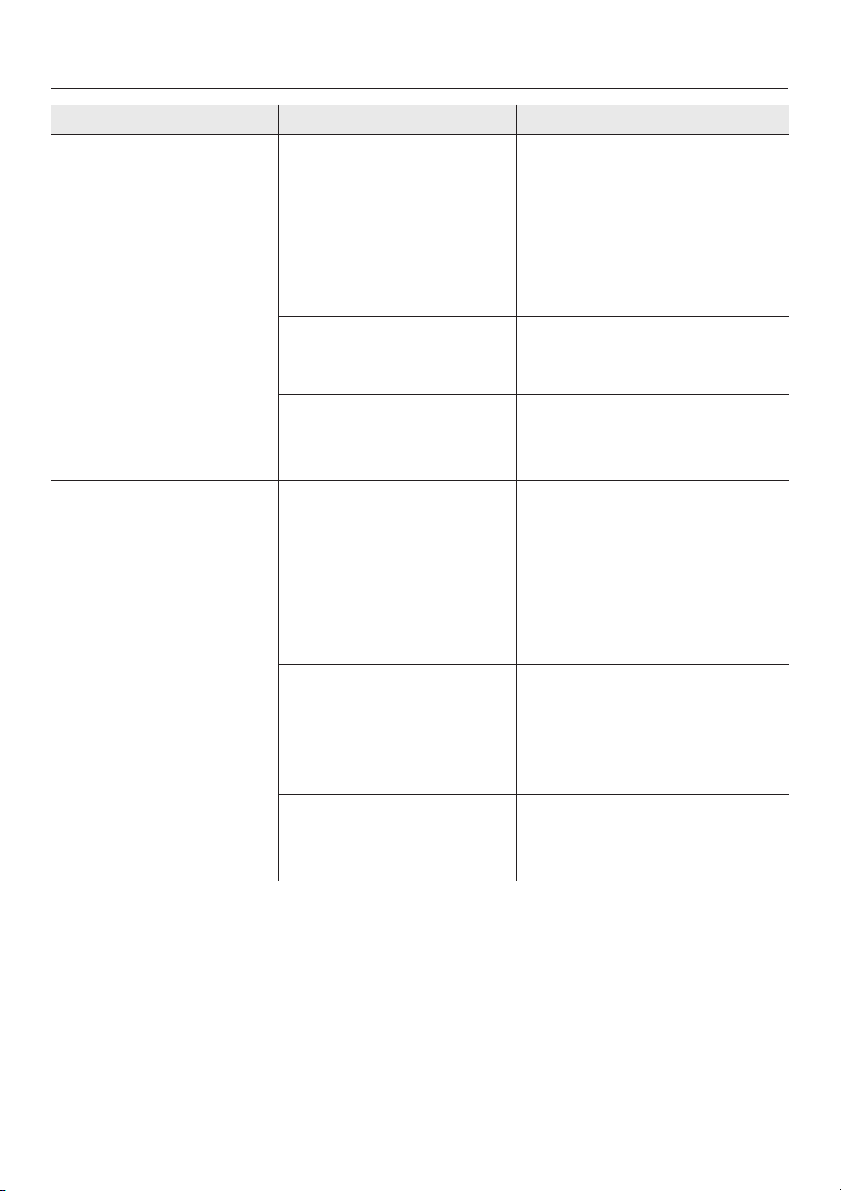

Cleaning the coarse filter

^ Press the two lugs together, remove,

and clean the coarse filter.